CARRIER BRD52 Service Manual

SERVICE &

INSTALLATION

MANUAL

Modular

Merchandiser

51-0195-01

1/2003

CARRIER COMMERCIAL REFRIGERATION, INC.

Providing BEVERAGE-AIR • FRIGIDAIRE • KELVINATOR • UNIVERSAL NOLIN Products/Services

If additional information is necessary, call the factory.

Our toll free number is 1-800-684-1199.Technical assis-

tance engineers are willing to assist you in any way possible. Office hours are from 8:00 a.m. to 5:30 p.m., Eastern

Standard Time.

Important information is contained in this manual which should

be retained in a convenient location for future reference.

Information in this manual is subject to change without notice.

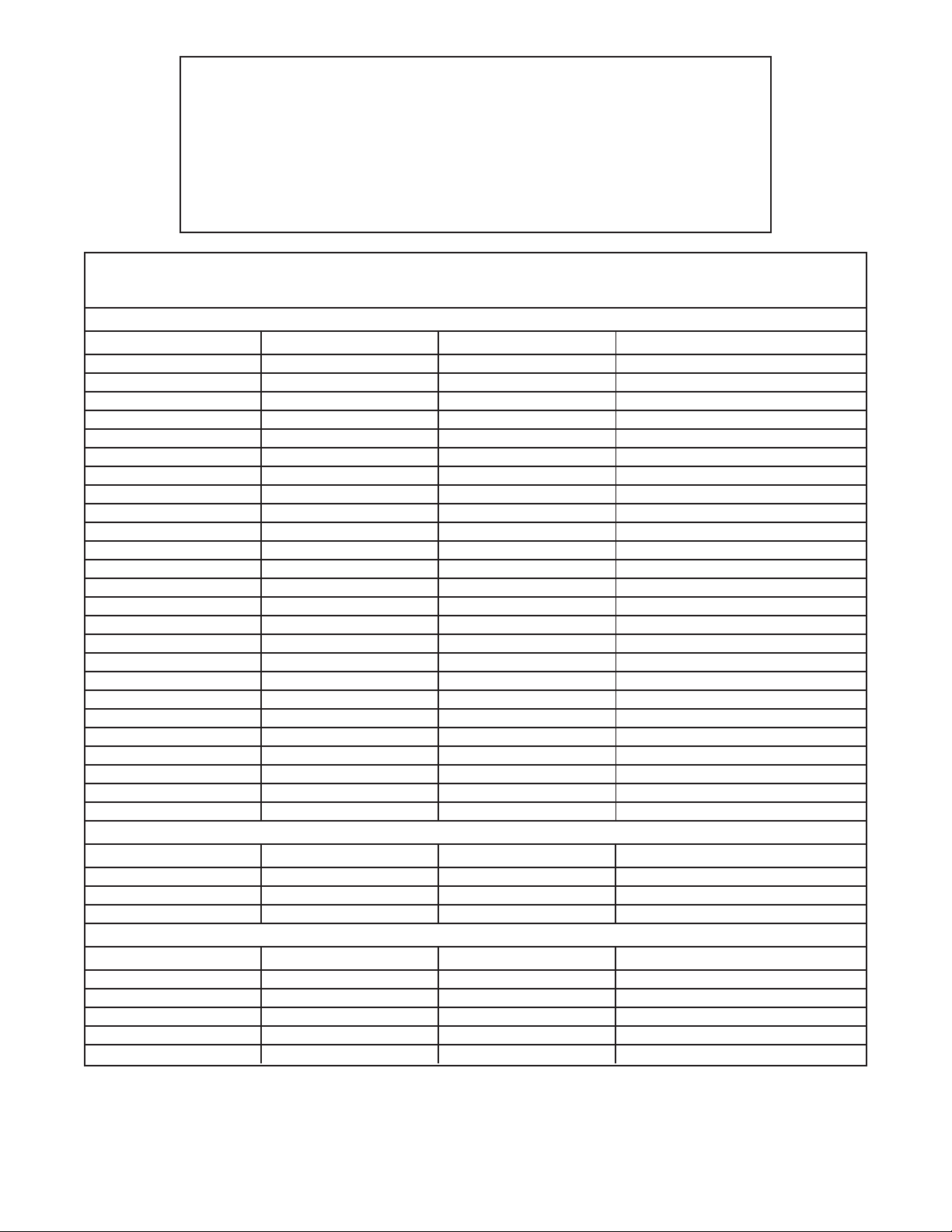

MODEL DESIGNATION INFORMATION

115V, 60HZ

PART # MODEL # DATA PLATE STYLE

52-1029-01 CRPD3 CRPD3 MEDIUM TEMP, CURVED

52-1029-02 CRPD4 CRPD4 MEDIUM TEMP, CURVED

52-1029-05 CRPD6 CRPD6 MEDIUM TEMP, CURVED

52-1030-01 RPD3 RPD3 MEDIUM TEM, STRAIGHT

52-1030-02 RPD4 RPD4 MEDIUM TEMP, STRAIGHT

52-1030-04 RPD4PT RPD4 MEDIUM TEMP, STRAIGHT

52-1030-05 RPD6 RPD6 MEDIUM TEMP, STRAIGHT

52-1031-01 CDPD3 CDPD3 DRY, NON REF, CURVED

52-1031-02 CDPD4 CDPD4 DRY, NON REF, CURVED

52-1031-05 CDPD6 CDPD6 DRY, NON REF, CURVED

52-1032-01 DPD3 DPD3 DRY, NON REF, STRAIGHT

52-1032-02 DPD4 DPD4 DRY, NON REF, STRAIGHT

52-1032-05 DPD6 DPD6 DRY, NON REF, STRAIGHT

52-1033-01 CFPD3 CFPD3 LOW TEMP, CUR VED

52-1033-02 CFPD4 CFPD4 LOW TEMP, CUR VED

52-1034-01 FPD3 FPD3 LOW TEMP, STRAIGHT

52-1034-02 FPD4 FPD4 LOW TEMP, STRAIGHT

52-1035-01 COHM3 COHM3 MEDIUM, OPEN, CURVED

52-1035-02 COHM4 COHM4 MEDIUM, OPEN, CURVED

52-1035-03 COHM6 COHM6 MEDIUM, OPEN, CURVED

52-1036-01 OHM3 OHM3 MEDIUM, OPEN, STRAIGHT

52-1036-02 OHM4 OHM4 MEDIUM, OPEN, STRAIGHT

52-1036-03 OHM6 OHM6 MEDIUM, OPEN, STRAIGHT

52-1036-04 OHM3 BLACK OHM3 MEDIUM, OPEN, STRAIGHT

52-1047-02 BRD52 BRD52 LOW TEMP, STRAIGHT

EXPORT 220V, 50HZ

PART # MODEL # DATA PLATE STYLE

52-1033-05 ECFPD4 ECFPD4 LOW TEMP, CUR VED

52-1034-05 EFPD4 EFPD4 LOW TEMP, STRAIGHT

52-1047-06 EBRD52 EBRD52 LOW TEMP, SRAIGHT

EXPORT 220V, 60HZ

PART # MODEL # DATA PLATE STYLE

52-1033-03 KCFPD4 KCFPD4 LOW TEMP, CUR VED

52-1033-04 KCFPD4C KCFPD4 LOW TEMP, CUR VED

52-1034-03 KFPD4 KFPD4 LOW TEMP, STRAIGHT

52-1034-04 KFPD4C KFPD4 LOW TEMP, STRAIGHT

52-1047-04 KBRD52 KBRD52 LOW TEMP, STRAIGHT

Manual effective for models produced January,2003.

Starting serial number 6701822.

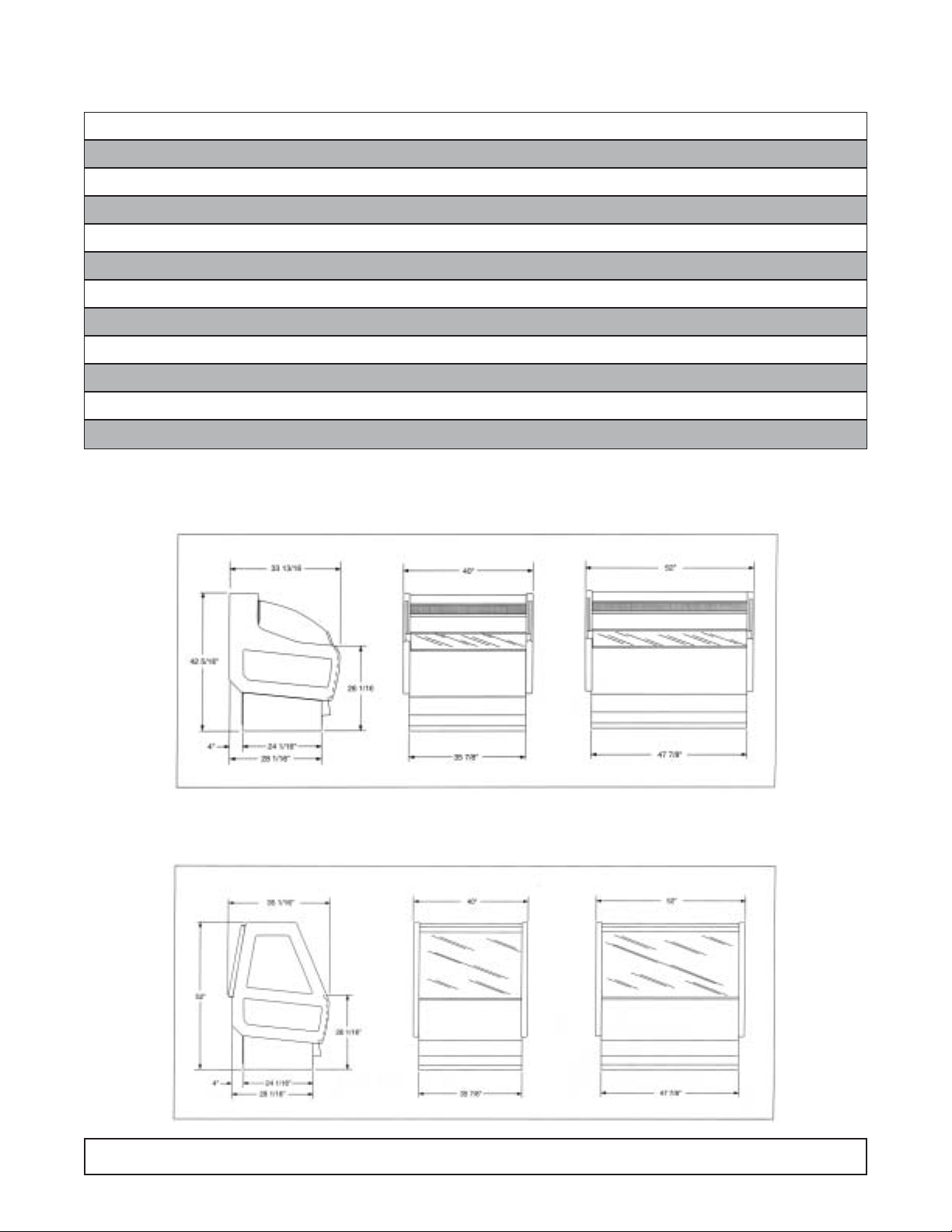

MED TEMP LOW TEMP

Temperature Range 32°F to 60°F 0°F to -15°F

Insulation 23⁄16" Foam in Place 2 5⁄16" Foam in Place

Compressor Size 1/2 H.P. 1 H.P.

Condenser Type Fin & Tube Fin & Tube

Evaporator T ype Fin & Tube Slow Moving Air Fin & Tube Slow Moving Air

Refrigerant Type 404A 404A

Defrost System On Demand On Demand

Electrical Specs. 115/60/1 115/60/1

NSF NSF 1 NSF 1

Shelves

Shelves, Epoxy Coated, Bracket Supported Shelves, Epoxy Coated, Bracket Supported

UL & CSA Listing Yes Yes

MODULAR MERCHANDISER 1

SPECIFICATIONS - DISPLAY CABINETS

DIMENSION DRAWINGS - COHM & OHM

DIMENSION DRAWINGS - FPD, CFPD, RPD & CRPD

An Important Message for Installers

and Operators

These instructions include information which is intended to assure the operator of correct installation, operation and service. Before attempting installation, adjustment or maintenance be certain of the following:

1.That you have read and fully understand

the instructions.

2. That you have all tools required and are trained to

use them.

3.That you have met all installation and usage restric-

tions and are familiar with the functions and operation of the unit.

4.That you follow all instructions exactly as given.

All fittings, measurements, procedures and recommendations are significant. Substitutions and approximations must be avoided.Improper handling, maintenance,

installation and adjustment, or service attempted by

anyone other than a qualified technician, may void the

future warranty claims and cause damage to the unit

and/or result in injury to the operator and/or bystanders.

Important Information Is contained In these

instructions which should be retained in a

convenient location for future reference .

Record for Service

Model No.

Serial No.

Invoice Date

Start-up Date

Telephone for Service

BE SURE TO INSPECT CABINET FOR SHIPPING

DAMAGE BEFORE AND AFTER UNCRATING IT.

HANDLING & INSTALLATION

Inspecting for Damage

NOTE: The transportation company or other parties

involv ed in the shipment are responsible f or loss and/or

damage.When direct delivery was made by the trans-

portation company, follow the procedure as outlined in

the following steps:Always make an Inspection before

and after uncrating.Inspect the uncrated unit(s) before

locating (preferably at the point of unloading by the

transportation company.) You may leave the skid on

the unit for ease of locating it later.

a. Damaged cartons or containers - If these are damaged in any way, open them and inspect the contents

in the driver’s presence.

b. Have the driver note the nature and extent of the

damage on the freight bill.

c. Notify the transportation company’s office to request

an inspection. Carrier claim policies usually require

inspections to be made within 15 days of delivery.

d. Always use care when removing shipping tape,

blocks, pads, hardware, or other materials. Retain all

crate and packaging material until you are satisfied

that the unit is completely operational.

e. Contact factory if technical assistance is required.

f. If damage is noticed (whether before or after uncrat-

ing the unit) the following claim procedure must be

completed.

Inspecting for Shortages

NOTE: Refer to the “Inspecting for Damage” instructions and follow the procedure described.

a. Check the number of cartons and/or containers

delivered with the quantity shown on your receipt.

b. If the quantities are not the same, have the driver

note the shortage and file your claim accordingly.

Filing Claims

a. File a claim for loss or damage at once with the

transportation company for:

1) A cash adjustment

2) Repairs

3) Replacement

b.When filing y our claim, retain all pac kaging materials

and receipts.

Handling the Cabinet

The refrigeration system of the cabinet is designed to

operate with the cabinet located on a flat surface.

Avoid tilting the cabinet more than 30° to any side. If

the cabinet must be tilted on an angle for handling or

moving purposes, allow it to sit in an upright position

20 to 30 minutes prior to plugging it in and starting the

cooling of the storage compartment.

GENERAL INFORMATION

2 MODULAR MERCHANDISER

Removing the Skid

Remove the four (4) bolts securing the cabinet to four

(4) angle brackets attached to the skid. Remove the

skid bolts and angle brackets.Carefully slide the cabinet off the skid onto the floor.

Locating the Cabinet

This model is a display cabinet and should be positioned to expose the illuminated displays to customers

in the store and provide a clear space behind for the

person serving.

Select a location where you are sure that the cabinet

won’t be exposed to heat sources such as sun through

a window, store heating or cooling ducts, exhausts

from other cabinets, etc. Make sure there is adequate

space on the serving side for loading cabinet and serving efficiently.

DO NOT DRILL HOLES IN THE CABINET WALLS.

THIS WILL VOID THE W ARRANTY

a.The cabinet must be installed on a sturdy and solid,

level floor.

b. The cabinet should be installed in a protected, dr y,

and well-ventilated area, away from any heat source.

Leveling the Cabinet

Level the cabinet using a spirit level on top. Level front

to back and side to side to assure a quiet operation

and satisfactory door and drain operation. Doors are

self-closing (sliding door models only) when cabinet is

level. Shim under the cabinet base as necessary to

assure a level cabinet. To meet NSF requirements,

these cabinets must be sealed to the floor with an NSF

listed or FDA approved sealant.

Setting up the Cabinet

Cabinets are shipped with the adjustable shelf mounting brackets in place. Shelving is also supplied with

the cabinet.

Shipping material (cardboard, paper, plastic, ties,

etc.) should be removed from shelving and the

product area.

CAUTION: Make sure that the shelf light plugs or

receptacle covers are completely inserted into the light

socket receptacles.This prev ents electrical arcing and/

or possible equipment damage.

MODULAR MERCHANDISER 3

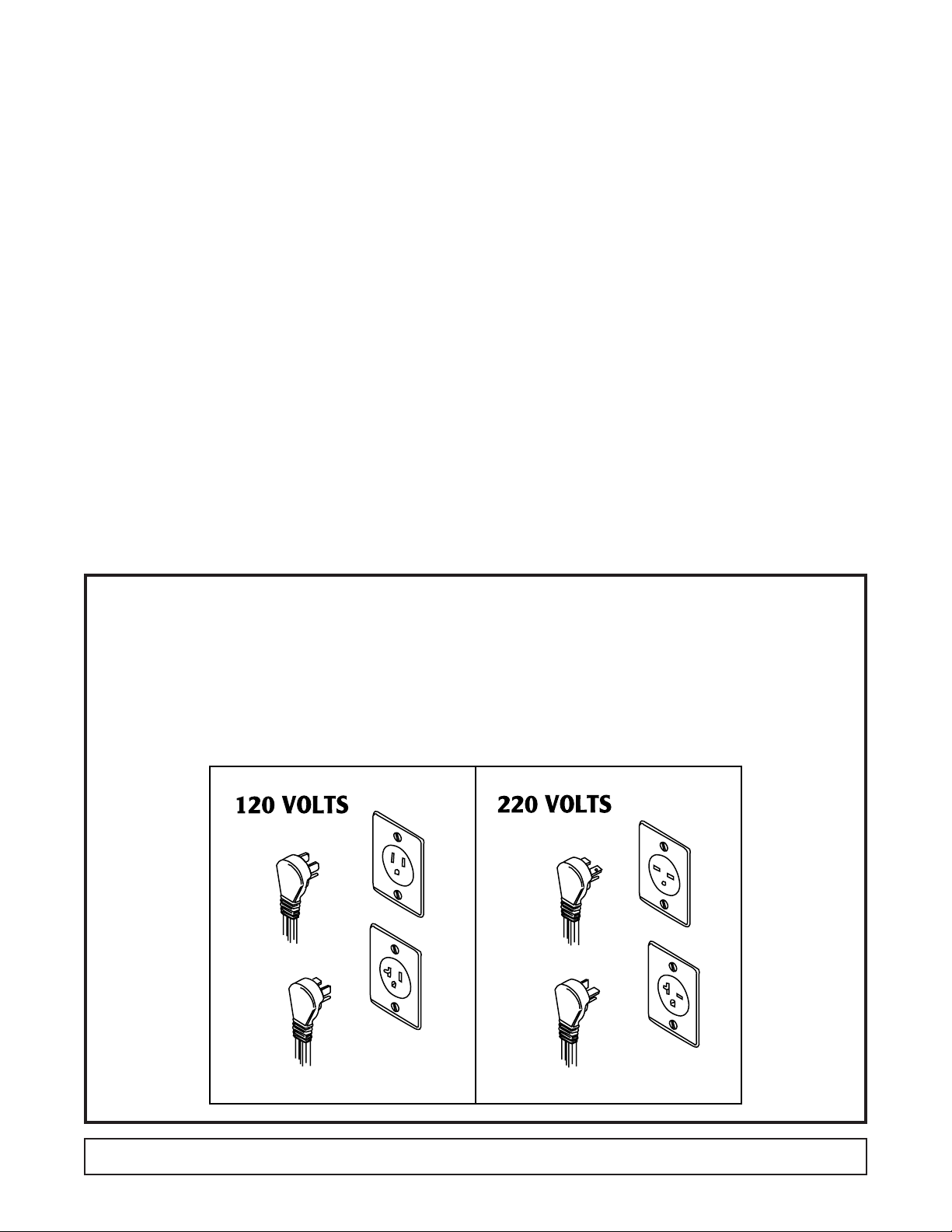

Grounding Instructions

This appliance is equipped with a three-prong (grounding) plug for your protection against shock hazards.The appliance should be plugged directly into a proper ly grounded three prong receptacle.

Where a two-prong wall receptacle is encountered, it must be replaced with a properly grounded threeprong receptacle in accordance with the National Electrical Code and local codes and ordinances.The

work must be done by a licensed electrician (cabinet should be on a dedicated circuit unto itself.Refer

to serial data for correct circuit ampacity).

20 Amp

15 Amp

15 Amp

20 Amp

GENERAL INFORMATION-cont.

Power Supply Switch

NOTE:When ser vicing or cleaning supply power must

be turned off.The power supply switch is located at the

rear of each cabinet behind the lower rear grill. The

switch is incorporated into the electrical box assembly.

Light Switch-Auxiliary Outlet

The light switch is located at the rear of each cabinet

(when applicable) just above the unit compartment

opening on the right hand side.

The auxiliary outlet is provided to power an external

sign scale (when applicable).

These cabinets utilize a microprocessor control to

manage both cavity temperature and defrost functions.

Cabinet OperationRefrigeration Mode

Upon setting the cabinet in it’s final location, turn

power supply on. The cabinet display should be indicating the cabinet temperature.There is a three minute

time delay sequence built in each time the supply

power is lost (compressor circuit). Evaporator fan

starts and lights come on (medium temp models).

Three minutes later the compressor starts. On low

temp models the evaporator fan delays until the evaporator coil reaches 28°F.

The display located on the lower front panel has several functions,

Display cabinet temperature

Change cavity set point temperature

NOTE: ON MED TEMP CABINETS DO

NOT SET BELOW 33°F.

Display service interface. Only qualified service personnel should activate this function.

Defrost Mode

This is on a demand basis as needed on both medium

and low temperature models.Defrost can be manually

activated through the display if needed.See below.

High Temp Thermodisc Open 140°F

Close 90°F

Notable points

1. This system utilizes a 3 minute off cycle timer to pre-

vent short cycles.

2. When the system initiates a defrost, the setpoint will

flash on and off until the defrost is terminated and the

cavity reaches the setpoint. At this time the cavity tem-

perature will be displayed as normal.

Changing Setpoint

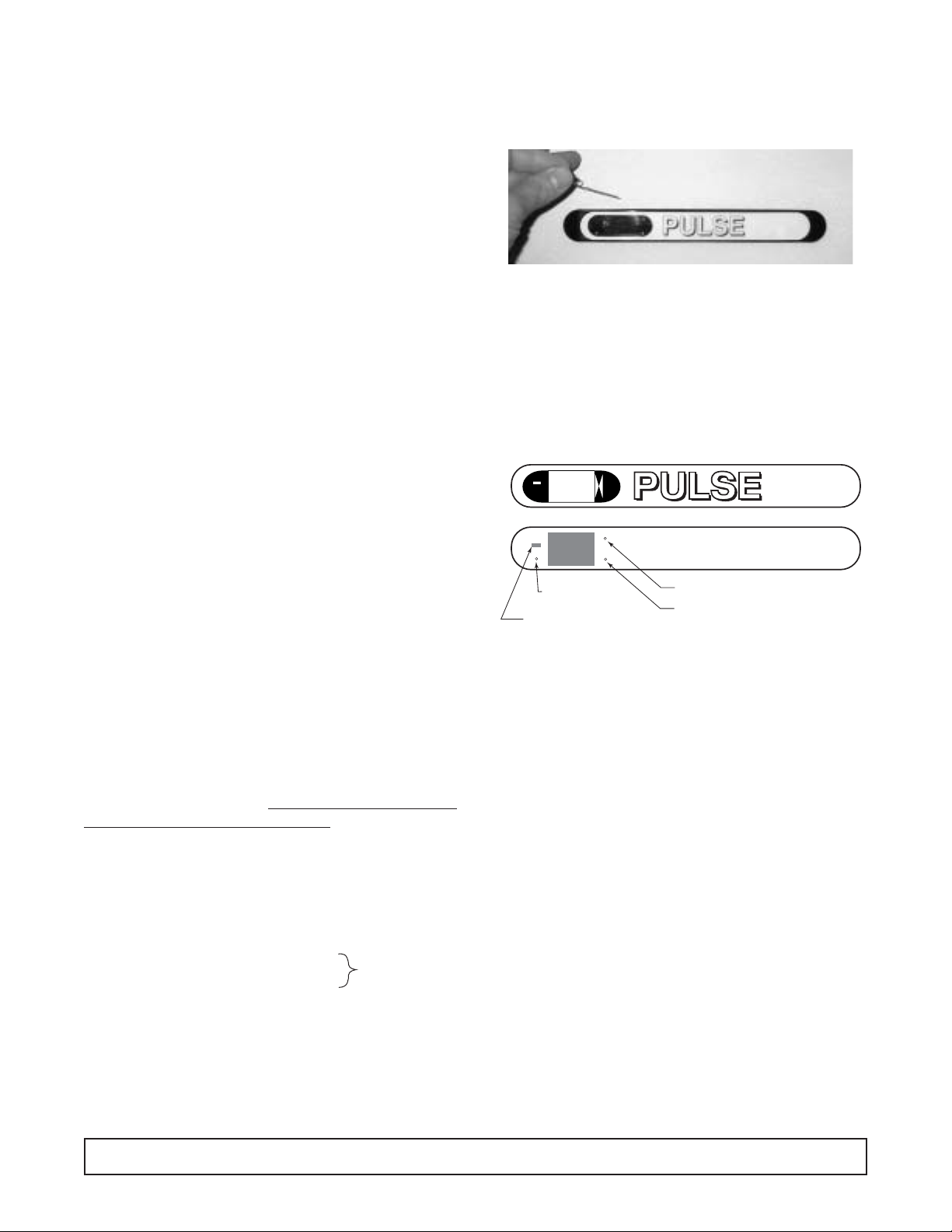

Note: Use a paper clip to access the

function keys.

1. Pressing the top right button(i.e. up key) on the display unit will raise the set point one degree

Fahrenheit. Holding the button down will scroll the

adjustment.

2. Pressing the lower right button(i.e.down key) on the

display unit will lower the set point one degree

Fahrenheit.

The Service Interface and

the Service Menu

(Refer to Pulse Service Manual 51-2484-00 for complete

service information.)

The service menu offers the service technician direct

control of the components of the system. This allows the

technician to force the system into a defrost state or the

refrigeration state. This feature also allows the technician to toggle the state in order to analyze separate components of the system (e.g., start kit, compressor,

heaters, etc.).

1. To access the service menu, press and hold the

service key for 2 seconds. The system will enter the

service menu and c0 will alternately flash with evaporator temperature. Code versions 1.5 and earlier do not

display evaporator temperature. This is the top of the

service menu. To exit the service menu, press the service key again at any time.

2. The service menu offers five functions:

Refrigeration state, Defrost state, code revision level

indication, the option to blank the display (code version

1.6 and later), and Celsius or Fahrenheit operation

(code version 1.6 and later).While in the service menu,

4 MODULAR MERCHANDISER

GENERAL INFORMATION-cont.

Low temp

models only

Service

Interface

Indicates T emp .

below 0°F

Setpoint up

Setpoint down

the down key serves to scroll the menu and the up key

serves as a toggle to activate and deactivate the function state.

A. To access the functions simply press the down key

to scroll through the menu until the desired function

is reached.The Refr igeration state is the first function and is denoted by an alternating display of c0

and the evaporator temperature. The Defrost state

is the second function and is denoted by a display

of d0.The third function is a passive state and only

indicates which version of code is running. This

function alternately flashes cc and the code version

01 - 99. The fourth function allows the user the

option to blank the display and is denoted by S0.

The fifth and last option allows the user to select

between Fahrenheit and Celsius operation and is

denoted by a C or a F. Continuing to scroll will bring

the user to the top of the menu again where c0 will

be displayed.

B.To activate a function state, simply press the down

key to scroll the menu until the desired function is

reached. Now press the up key. At this point the

chosen function state is toggled from inactive to

active.

C. To force a defrost: First press and hold the

service button to enter the service menu. Then

press the down key until d0 is displayed. Next

press the up key. The heater is now energized

and d1 is displayed.

D. To activate the refrigeration state: (i.e., this turns on

the compressor, condenser fans, and evaporator

fans) First enter the service menu. Press the top

right button.c0 will change to c1.Use this function to

check refrigerant charge and pressures, evaporator

fans, compressor and start components and etc.

E. To deactivate the function state, press the up key

again (i.e., this button toggles the state from active

to inactive and vice versa).

NOTES:a. When an attempt is made to scroll the

menu while a function state is active, the

active function state will automatically

deactivate.This is to prevent the service

technician from simultaneously activating

the Refrigeration state and the Defrost

state. Only one function may be active at

any given time.

b. If no operation is performed within 45

minutes while in the service menu, the

system will automatically exit the service

menu and return to normal refrigeration.

c. If the Defrost state is activated and left

unattended, the service menu will terminate the defrost as normal on evaporator

temperature; otherwise, the defrost will

terminate in 45 minutes. Upon defrost

termination the system will automatically

exit the service menu.

d. When the system exits the service menu,

the compressor will not start for

3 minutes.

e. The off cycle timer is not incorporated in

the service menu so the service technician has direct control of components.

MODULAR MERCHANDISER 5

GENERAL INFORMATION-cont.

AMBIENT 70°F 80°F 90°F

Display setting 41° 36° 31° 41° 36° 31° 41° 36° 31°

Cavity Temp.(F) 39° 35° 30° 39° 35° 30° 39° 34° 30°

Suction Pressure (PSIG) 47 41 36 47 42 37 48 43 39

Discharge Pressure (PSIG) 255 245 233 286 276 262 320 309 297

Compressor Amps 5.9 5.6 5.3 6.0 5.7 5.5 6.2 5.9 5.7

Total Refrigeration Amps 7.9 7.5 7.3 8.0 7.7 7.5 8.2 7.8 7.6

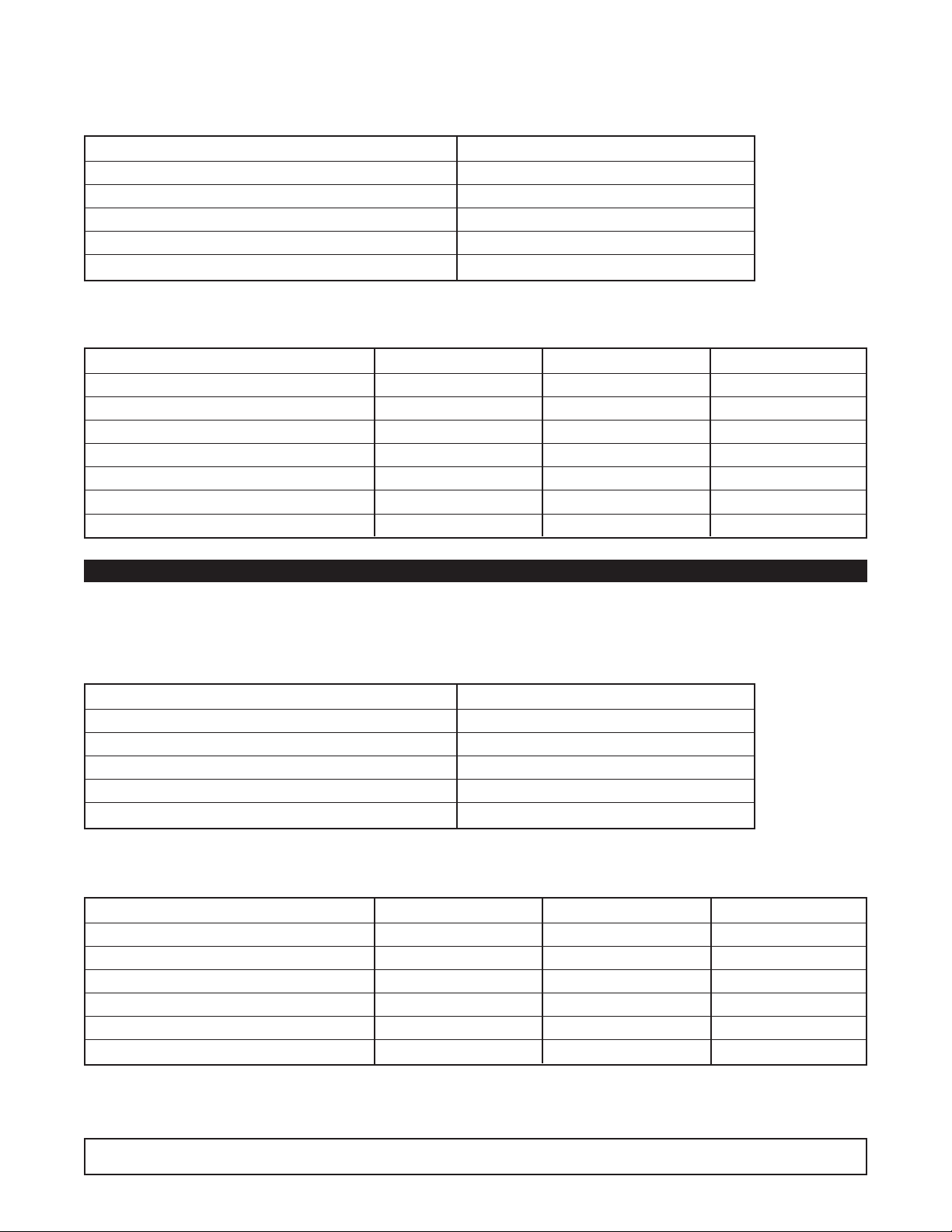

ELECTRICAL/REFRIGERATION SPECIFICATIONS

SYSTEM COMPONENTS - RPD4 & CRPD4

SYSTEM PERFORMANCE -

(READINGS AT CUT-OUT)

Compressor Americold

Compressor Model HP 127

Recommended Operating Temp. Range 36° TO 42°

Cabinet V olts 115

Expansion Device 7' x .054 Capillary Tube

Charge Refrig.Type / Oz./ Grams R-404 /24 / 680.4 grams

6 ELECTRICAL/REFRIGERATION SPECIFICATIONS

ELECTRICAL/REFRIGERATION SPECIFICATIONS

SYSTEM COMPONENTS - RPD3,CRPD3,RPD6,CRPD6

SYSTEM PERFORMANCE -

(READINGS AT CUT-OUT)

Compressor Americold

Compressor Model HP 127

Recommended Operating Temp. Range 36°F to 42°F

Cabinet V olts 115

Expansion Device 7' x .054 Capillary Tube

Charge Refrig.Type / Oz./ Grams R-404 / 16 / 453.6 grams

AMBIENT 70°F 80°F 90°F

Display setting 41° 36° 31° 41° 36° 31° 41° 36° 31°

Cavity Temp.(F) 42° 37° 3° 42° 37° 32° 43° 38° 32°

Suction Pressure (PSIG) 47 39 34 47 41 36 51 43 39

Discharge Pressure (PSIG) 249 231 223 281 268 256 317 303 242

Compressor Amps (Each Compressor) 6.1 5.7 5.6 6.3 6.0 5.7 6.5 6.2 6.0

TotalRefrigerationAmps (RPD3, CRPD3) 8.3 7 7 8.5 8.2 7.8 8.6 8.4 8.1

Total Refrigeration Amps (RPD6, CRPD6) 17.0 16.3 15.6 16.6 15.9 15.2 17.5 16.2 15.5

AMBIENT 70°F 80°F 90°F

Display setting 41° 36° 31° 41° 36° 31° 41° 36° 31°

Cavity Temp.(F) 43° 37° 34° 43° 40° 35° 44° 41° 39°

Suction Pressure (PSIG) 50 45 41 49 46 43 49 47 40

Discharge Pressure (PSIG) 269 254 247 295 283 283 326 323 304

Compressor Amps 6.2 6.0 5.7 6.3 6.2 6.1 6.5 6.5 5.9

Total Refrigeration Amps 9.0 8.5 8.3 9.1 8.7 8.6 9.3 9.0 8.7

ELECTRICAL/REFRIGERATION SPECIFICATIONS

SYSTEM COMPONENTS - OHM4 & COHM4

SYSTEM PERFORMANCE -

(READINGS AT CUT-OUT)

Compressor Americold

Compressor Model HP 127

Recommended Operating Temp. Range 36° TO 42°

Cabinet V olts 115

Expansion Device 7' x .054 Capillary Tube

Charge Refrig.Type / Oz./ Grams R-404 /25 / 708.7 grams

ELECTRICAL/REFRIGERATION SPECIFICATIONS 7

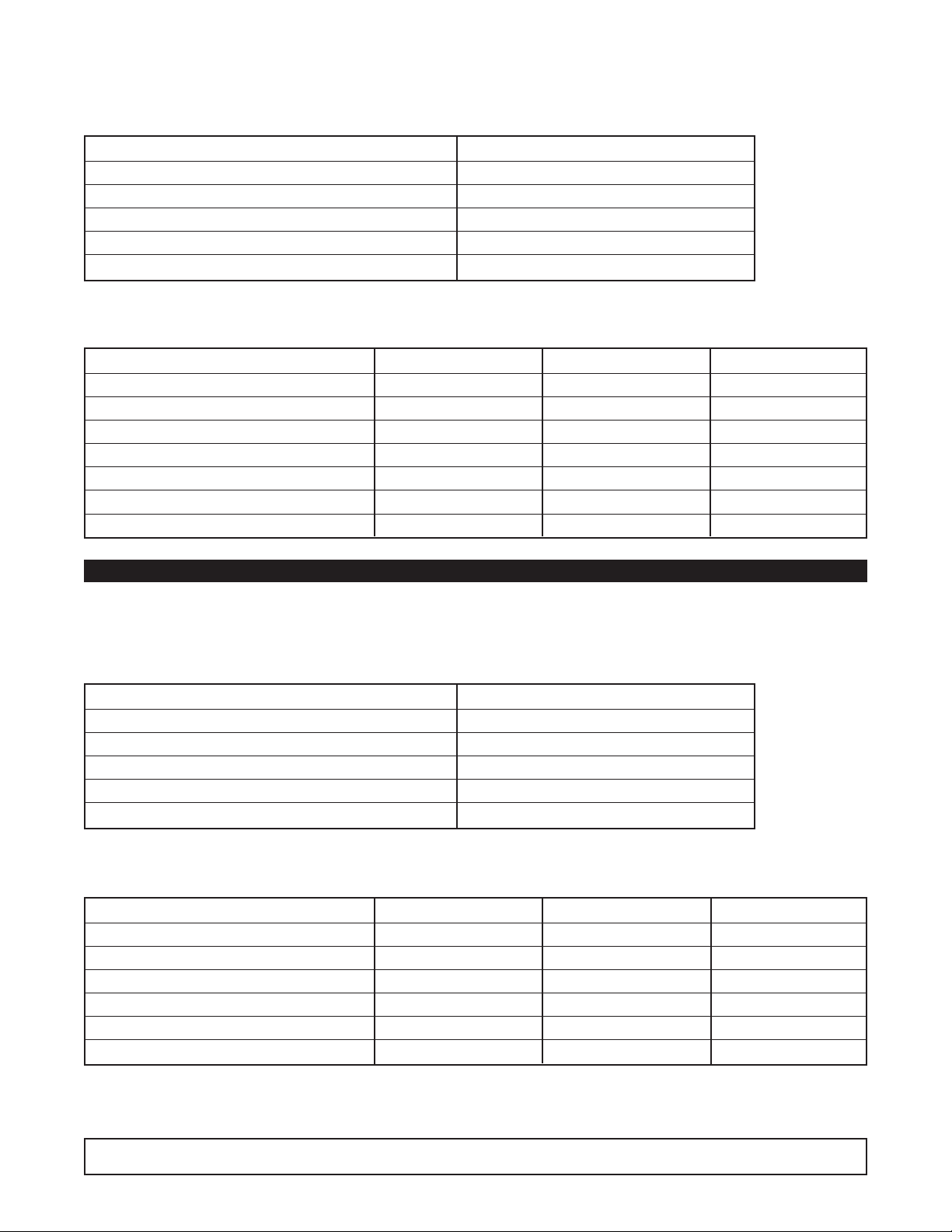

ELECTRICAL/REFRIGERATION SPECIFICATIONS

SYSTEM COMPONENTS - OHM3,COHM3,OHM6,COHM6

SYSTEM PERFORMANCE -

(READINGS AT CUT-OUT)

Compressor Americold

Compressor Model HP 127

Recommended Operating Temp. Range 36°F to 42°F

Cabinet V olts 115

Expansion Device 7' x .054 Capillary Tube

Charge Refrig.Type / Oz./ Grams R-404 / 18 / 510.3 grams

AMBIENT 70°F 80°F 90°F

Display setting 41° 36° 31° 41° 36° 31° 41° 36° 31°

Cavity Temp.(F) 41° 37° 33° 42° 38° 34° 44° 41° 37°

Suction Pressure (PSIG) 45 43 37 46 44 40 47 46 40

Discharge Pressure (PSIG) 251 245 233 280 271 267 310 307 293

Compressor Amps (Each Compressor) 7.0 6.8 6.5 7.1 7.0 6.8 7.3 7.2 6.9

TotalRefrigerationAmps (OHM3, COHM3) 7.9 7.8 7.4 8.1 7.9 7.7 8.2 8.2 7.8

Total Refrigeration Amps (OHM6, COHM6) 11.6 11.4 11.2 11.7 11.1 11.4 11.6 11.2 11.3

ELECTRICAL/REFRIGERATION SPECIFICATIONS

SYSTEM COMPONENTS

SYSTEM PERFORMANCE -

(READINGS AT CUT-OUT)

FPD4 EFPD4 KFPD4

CFPD4 ECFPD4 KCFPD4

BRD52 EBRD52 KBRD52

Compressor Copeland Copeland Copeland

Compressor Model RS80C1ECAA RS80C2ECAZ-250 RS80C2ECAV

Cabinet Volts 115V 60Hz 220V 50Hz 220V 60Hz

Recommended Operating Temp. Range 36° TO 42°

Expansion Device 7' x .049 Capillary Tube

Charge Refrig.Type / Oz./ Grams R-404 /16/ 453.6 grams

AMBIENT 70°F 80°F 90°F

Display setting +5° -5° -15° +5° -5° -15° +5° -5° -15°

Cavity Temp.(F) 6.0° -2° -11° 6.0° -2° -11° 1.0° -2° -12°

Suction Pressure (PSIG) (115V) 10 8 6 12 10 7 14 12 9

Discharge Pressure (PSIG) (115V) 230 228 213 270 263 245 303 291 280

Compressor Amps (115V) 8.4 8.7 8.5 8.8 8.9 8.2 9.1 9.1 8.8

Total Refrigeration Amps (115V) 12.9 13.1 12.8 13.3 13.3 12.5 13.6 13.6 13.1

Suction Pressure (PSIG) (220V) 7.7 7.2 5.7 10.2 9.2 7.1 12.7 11.1 8.7

Discharge Pressure (PSIG) (220V) 211.1 209.0 203.5 245.3 239.6 232.3 281.2 272.5 263.6

Compressor Amps (220V) 5.0 5.0 4.7 5.0 5.2 4.8 5.6 5.4 4.9

Total Refrigeration Amps (220V) 6.1 6.0 5.9 6.3 6.2 5.9 6.5 6.3 6.1

8 ELECTRICAL/REFRIGERATION SPECIFICATIONS

ELECTRICAL/REFRIGERATION SPECIFICATIONS

SYSTEM COMPONENTS - FPD3 & CFPD3

SYSTEM PERFORMANCE -(READINGS AT CUT-OUT)

Compressor Copeland

Compressor Model RS80CIECAA

Recommended Operating Temp. Range 36°F to 42°F

Cabinet V olts 115

Expansion Device 7' x .049 Capillary Tube

Charge Refrig.Type / Oz./ Grams R-404 / 14 / 396.9 grams

AMBIENT 70°F 80°F 90°F

Display setting +5° -5° -15° +5° -5° -15° +5° -5° -15°

Cavity Temp.(F) +5° -3° -13° +5° -3° -13° 6.1° -3° -12°

Suction Pressure (PSIG) 11.2 8.1 5.2 13 10 7.2 15 12 10

Discharge Pressure (PSIG) 262 244 216 296 272 246 334 311 289

Compressor Amps 9.0 8.3 7.7 9.2 8.6 7.8 9.3 8.7 8.3

Total Refrigeration Amps 12.0 11.3 10.7 12.3 11.6 10.9 12.3 11.8 11.3

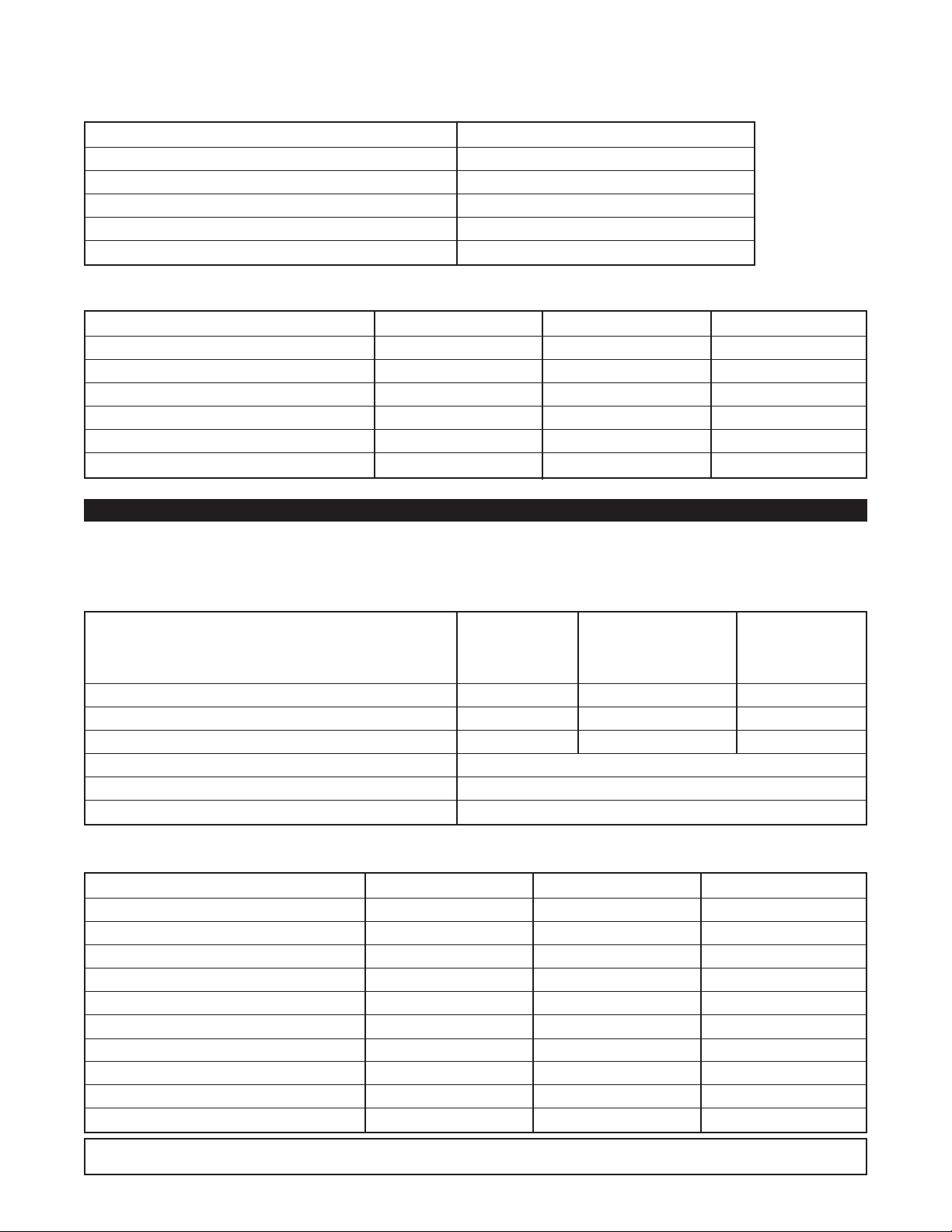

WIRING DIAGRAM 9

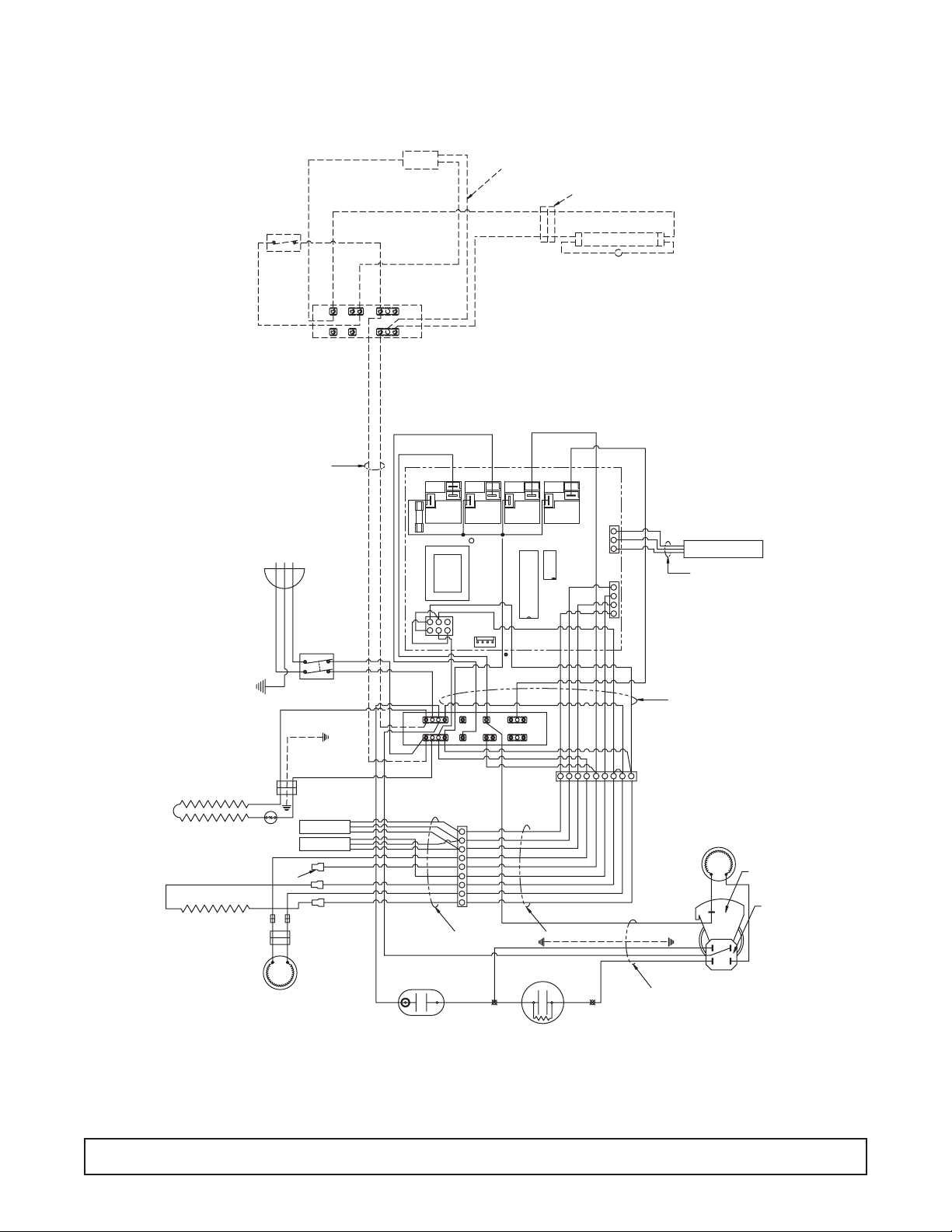

WIRING DIAGRAM – COHM3, COHM 4, OHM3, OHM4

HEATER, WATER DISSIPATION

LIGHT

SWITCH

BLACK

BALLAST BOX HARNESS

115 VAC. 60 Hz.-1Ø

15-AMP POWER SUPPLY

N

(L2)

L1

(BLUE)

(BROWN)

WHITE

BLACK

SUPPLY

SWITCH

GREEN

BLACK

BLACK

BLUE (BLACK ON 20W)

BLACK

3

5

4

6

BLACK

BLACK

WHITE

WHITE

WHITE

BLUE

WHITE

BLACK

1

2

BLACK

BLACK

BALLAST

BLACK

WHITE

BLACK

WHITE

WHITE

ORANGE

FUSE

WH

BLACK

PURPLE

RELAY #1

654

123

YELLOW

WHITE WIRES NOT PRESENT

ON 20W BALLAST.

(FOR MODELS WITH LAMP)

BLUE

YELLOW

RELAY #2

BLACK

LED

BLACK

WHITE

PURPLE

ORANGE

BLACK

ORANGE

BLUE

BROWN

RELAY #4RELAY #3

1 2 3 4 5 6 7 8

O

BROWN

WHITE

RED

BLACK

BROWN

BLUE

UPPER LAMP HARNESS

WHITE

BROWN

N

1

2

3

BLUE

MAIN LAMP

S

3

2

1

4

3

2

1

5

4

98

6

7

DISPLAY

DISPLAY HARNESS

PROCESSOR HARNESS

GREEN

BLUE

GRAY

RED

BLACK

GREEN

RED

BLACK

BLACK

WHITE

RUN CAP.

12

3

4

5

6

7

8

9

EVAPORATOR HARNESS

BLACK

BLACK

YELLOW

RED

BLACK

START CAP.

ORANGE

BROWN

BLUE

RED

GRAY

WHITE

EVAPORATOR HARNESS

GREEN

BLACK

BLACK

CONDENSER

FAN MOTOR

YELLOW

COMPRESSOR

HARNESS

BLUE

2

3

1

4

COMPRESSOR

TERMINAL BOX

MOTOR

PROTECTOR

(PTCR)

BLACK

HEATER, ANTI-SWEAT

THERMOSTAT

BLACK

EVAPORATOR

FAN MOTOR

BROWN

DUMMY

PLUG

1

TEMP. SENSOR

EVAPORATOR

2

TEMP. SENSOR

WHITE

RETURN AIR

WIRING DIAGRAM-OPEN, MED-TEMP.

00-0219-00

10 WIRING DIAGRAM

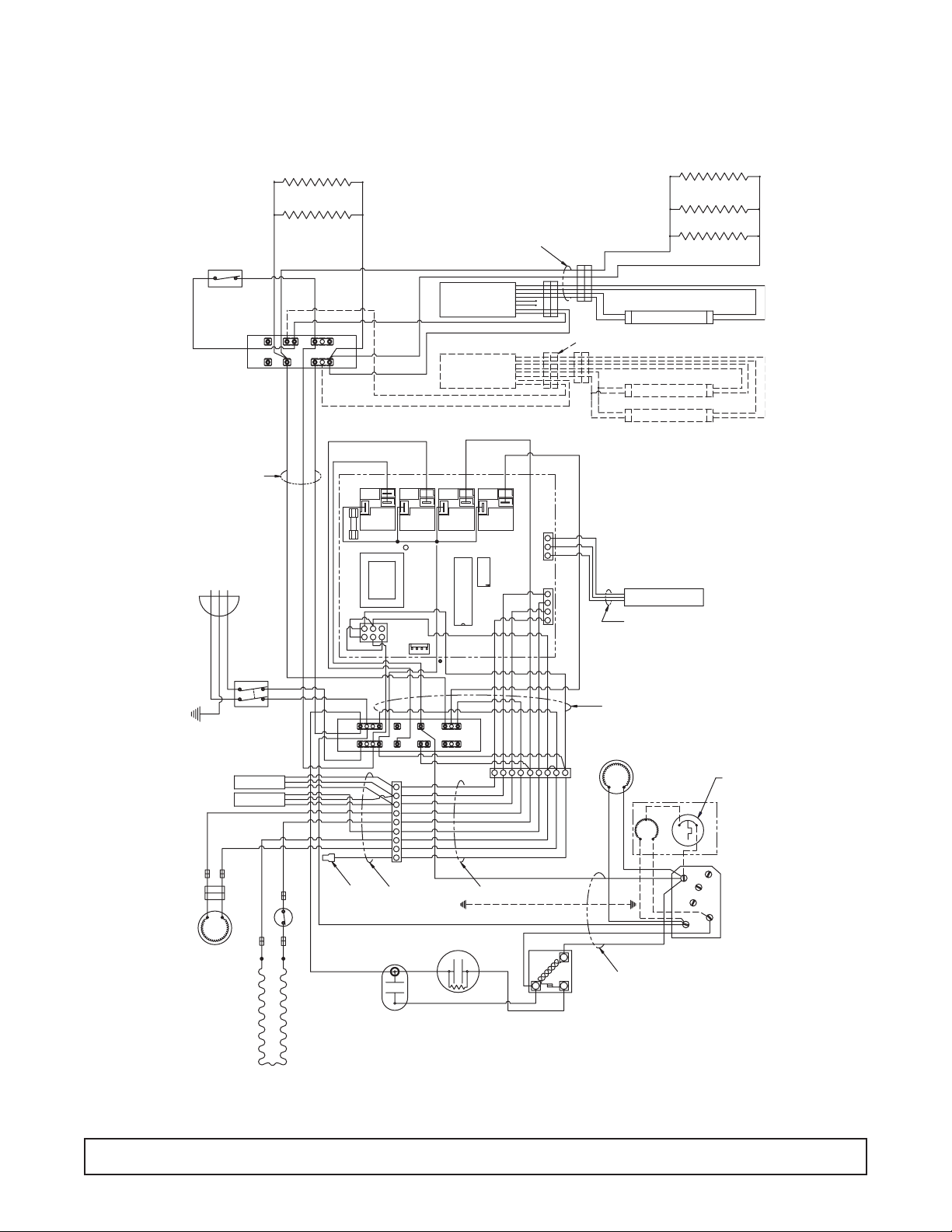

WIRING DIAGRAM – CFPD3, CFPD4, FPD3, FPD4, BRD52

LIGHT

SWITCH

BLACK

BALLAST BOX HARNESS

115 VAC. 60 Hz.-1Ø

20-AMP POWER SUPPLY

N

(L2)

L1

(BLUE)

(BROWN)

WHITE

BLACK

SUPPLY

SWITCH

RETURN AIR

1

TEMP. SENSOR

EVAPORATOR

2

TEMP. SENSOR

BROWN

WHITE

EVAPORATOR

FAN MOTOR

BLACK

BLUE

DISPLAY

S

LAMP

LAMP

LAMP

HEATER-GLASS

HEATER-GLASS

PERIMETER

HEATER-LAMP

CHANNEL

C

2

3

R

BLUE

PROTECTOR

COMPRESSOR

TERMINAL BOX

1

S

BLUE

RED

RED

MOTOR

BLUE

HEATER-DOOR

OPENNING

HEATER-DOOR

OPENNING

BLACK

UPPER LAMP HARNESS

BLACK

BLACK

BALLAST

BLACK

3

5

6

1

WHITE

4

2

WHITE

WHITE

BALLAST

WHITE

WHITE

BLACK

BLACK

WHITE

BROWN

GREEN

RED

BLACK

GREEN

RED

BLACK

BLUE

GRAY

BROWN

WHITE

WHITE

BLACK

BLACK

WHITE

WHITE

BLACK

ORANGE

FUSE

WH

BLACK

DUMMY

PLUG

PURPLE

RELAY #1

654

WHITE

RELAY #2

BLACK

LED

BLACK

WHITE

123

YELLOW

ORANGE

PURPLE

ORANGE

YELLOW BROWN

BLUE

12

3

4

5

6

7

8

9

EVAPORATOR HARNESS

WHITE

BLACK

RED

START CAP.

BLUE

RELAY #4RELAY #3

1 2 3 4 5 6 7 8

N

O

BROWN

BROWN

WHITE

BLACK

BLUE

YELLOW

RED

ORANGE

BROWN

BLACK

EVAPORATOR HARNESS

GREEN

BLACK

1

BROWN

2

3

BLUE

3

2

1

4

3

2

1

5

4

6

7

RED

GRAY

WHITE

BLACK

YELLOW

21

98

5

POTENTIAL RELAY

BLACK

RED

RED

SHELF LAMP HARNESS

YELLOW

YELLOW

YELLOW

YELLOW

DISPLAY HARNESS

PROCESSOR HARNESS

BLACK

BLUE

COMPRESSOR

HARNESS

WHITE

CONDENSER

FAN MOTOR

C

R

RUN CAP.

HEATER-DEFROST

WIRING DIAGRAM-DISPLAY, LOW TEMP.

00-0216-00

WIRING DIAGRAM 11

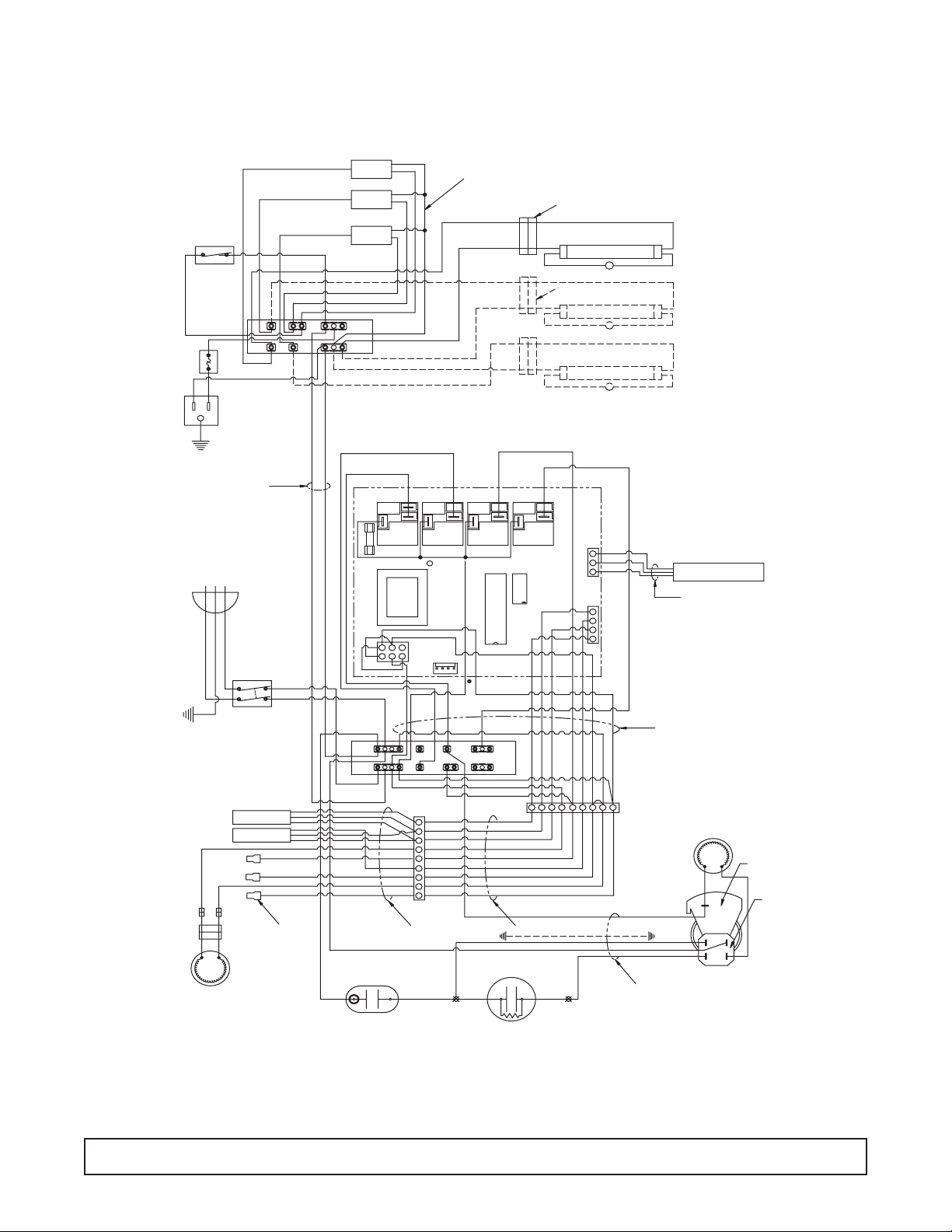

WIRING DIAGRAM – CRPD3, CRPD4, RPD3, RPD4

BLACK

2-AMP.

CIRCUIT

BREAKER

BALLAST BOX HARNESS

115 VAC. 60 Hz.-1Ø

15-AMP POWER SUPPLY

EVAPORATOR

FAN MOTOR

LIGHT

SWITCH

N

(L2)

(BLUE)

WHITE

BLACK

1

2

BROWN

WHITE

WHITE

2-AMPS

MAXIMUM

L1

(BROWN)

SUPPLY

SWITCH

RETURN AIR

TEMP. SENSOR

EVAPORATOR

TEMP. SENSOR

BLUE (BLACK ON 20W)

BLUE (BLACK ON 20W)

BLUE (BLACK ON 20W)

BLACK

5

4

6

BLACK

WHITE

GREEN

RED

BLACK

GREEN

RED

BLACK

BLUE

GRAY

DUMMY

PLUG

3

BLACK

WHITE

WHITE

BLACK

BLUE

BLUE

BLUE

WHITE

BLACK

BLACK

BALLAST

BALLAST

BALLAST

BLACK

BLACK

BLACK

1

2

BLACK

WHITE

BLACK

RUN CAP.

WHITE

WHITE

WHITE

WHITE

ORANGE

FUSE

WH

BLACK

PURPLE

RELAY #1

321

456

RELAY #2

BLACK

LED

BLACK

WHITE

YELLOW

PURPLE

ORANGE

YELLOW

ORANGE

BLUE

1

2

3

4

5

6

7

8

9

EVAPORATOR HARNESS

BLACK

WHITE WIRES NOT PRESENT

ON 20W BALLAST.

BLUE

BROWN

RELAY #3

RELAY #4

1 2 3 4 5 6 7 8

N

O

BLACK

BROWN

WHITE

BROWN

RED

BLACK

BROWN

BLUE

1

2

RED

ORANGE

BROWN

BLUE

BLACK

EVAPORATOR HARNESS

GREEN

BLACK

3

YELLOW

BLACK

START CAP.

UPPER LAMP HARNESS

MAIN LAMP

WHITE

SHELF LAMP HARNESS

WHITE

WHITE

4

S

SHELF LAMP

S

SHELF LAMP

S

3

2

1

4

3

2

1

5

9

8

6

7

RED

GRAY

WHITE

BLACK

BLUE

BLUE

BLUE

CONDENSER

FAN MOTOR

YELLOW

COMPRESSOR

HARNESS

DISPLAY

DISPLAY HARNESS

PROCESSOR HARNESS

BLUE

3

4

COMPRESSOR

TERMINAL BOX

MOTOR

PROTECTOR

(PTCR)

2

1

WIRING DIAGRAM-DISPLAY, MED-TEMP.

00-0217-00

Loading...

Loading...