Carrier 58MVC080-F-10114, 58MVC080-F-10120, 58MVC060-F-10114 Installation Guide

Visit www.Carrier.com

®

Turn to the Expertg

Installation Instructions

NOTE: Read the entire instruction manual before starting

the installation.

Please retain these instructions with the furnace after installation

for future reference.

NOTE: This furnace can be installed as a (2-pipe) direct vent

or (1-pipe) non-direct vent condensing gas furnace.

Special Venting Requirements for Installations in Canada

Installation in Canada must conform to the requirements of CSA

B149 code. Vent systems must be composed of pipe, fittings,

cements, and primers listed to ULC $636. The special vent

fittings and accessory concentric vent termination kits and

accessory external drain trap have been certified to ULC $636 for

use with those IPEX PVC vent components which have been

certified to this standard. In Canada, the primer and cement must

be of the same manufacturer as the vent system - IPEX System

636, PVC/CPVC Primer, Purple Violet for Flue Gas Venting and

IPEX System 636(1) TM , PVC Cement for Flue Gas Venting, rated

Class IIA, 65 deg C. must be used with this venting system - do

not mix primers and cements from one manufacturer with a vent

system from a different manufacturer. Follow the manufacturer's

instructions in the use of primer and cement and never use primer

or cement beyond its expiration date.

The safe operation, as defined by ULC $636, of the vent system

is based on following these installation instructions, the vent

system manufacturer's installation instructions, and proper use of

primer and cement. All fire stop and roof flashing used with this

system must be UL listed material. Acceptability under Canadian

standard CSA B149 is dependent upon full compliance with all

installation instructions. Under this standard, it is recommended

that the vent system be checked once a year by qualified service

personnel.

The authority having jurisdiction (gas inspection authority,

municipal building department, fire department, etc) should be

consulted before installation to determine the need to obtain a

permit.

11

ISO 9001:2000

Consignes sp_ciales pour l'installation de ventillation au Canada

L'installation faite au Canada doit se conformer aux exigences du

code CSA B149. Ce syst_me de ventillation doit se composer de

tuyaux, raccords, ciments et appr_ts conformes au ULC $636. La

tuyauterie de ventillation des gaz, ses accessoires, le terminal

concentrique mural ainsi que l'ensemble du drain de condensat

ext_rieur ont _t_ certifies ULCS 636 pour l'application des

composantes IPEX PVC qui sont certifi_es 5. ce standard. Au

Canada l'appr_t et le ciment doivent _tre du m_me manufacturier

que le syst_me de ventillation - IPEX Syst_me 636, Appr_t

PVC/CPVC. Mauve Violette pour conduit en _vacuation des gaz

et IPEX Syst_me 636(1) TM, ciment pour PVC pour conduit en

_vacuation des gaz, _valu_ CLASSE IIA, 65 deg. C. doit _tre

utilis_ avec ce syst_eme d'_vacuation - ne pas m_langer l'appr_t

et le ciment d'un manufacturier avec le syst_me de ventillation

d'un autre manufacturier. Bien suivre les indications du

manufacturier lors de l'utilisation de l'appr_t et du ciment et ne

pas utiliser ceux-ci si la date d'expiration est atteinte.

L'op_ration s_curitaire, tel que d_finit par ULC $636, du syst_me

de ventilation est bass sur les instructions d'installation suivantes,

ainsi que l'usage appropri_ de l'appr_t et ciment. Tout arr_t feu et

solin de toit utilis_s avec ce syst_me doivent _tre des mat_riaux

list,s UL L'acceptation du standard Canadien CSA B419 est

directement reli_ 5. l'installation conforme aux instructions ci-

haut mentionn_es. Le standard Canadien recommande 1'

inspection par un personel qualifi_ et ce, une fois par annie.

Les autorit_es ayant juridiction (inspecteurs de gas, inspecteurs en

bfitiments, d@artement des incendies, etc) devraient _tre

consult_es avant l'installation afin de d_terminer si un permis est

requis.

(1) System 636 is a trademark of IPEX Inc.

Required Notice for Massachusetts Installations

IMPORTANT

The Commonwealth of Massachusetts requires compliance with regulation 248 CMR as follows:

5.08: Modifications to NFPA-54, Chapter 10

2) Revise 10.8.3 by adding the following additional requirements:

(a.)For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in

whole or in part for residential purposes, including those owned or operated by the Commonwealth and where the

side wall exhaust vent termination is less than seven (7) feet above finished grade in the area of the venting,

including but not limited to decks and porches, the following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the side wall horizontal vented

gas fueled equipment, the installing plumber or gasfitter shall observe that a hard wired carbon monoxide detector with an

alarm and battery back-up is installed on the floor level where the gas equipment is to be installed. In addition, the installing

plumber or gasfitter shall observe that a battery operated or hard wired carbon monoxide detector with an alarm is installed on

each additional level of the dwelling, building or structure served by the side wall horizontal vented gas fueled equipment. It

shall be the responsibility of the property owner to secure the services of qualified licensed professionals for the installation of

hard wired carbon monoxide detectors

a. In the event that the side wall horizontally vented gas fueled equipment is installed in acrawl space or an attic, the hard wired

carbon monoxide detector with alarm and battery back-up may be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision can not be met at the time of completion of installation, the owner shall

have a period of thirty (30) days to comply with the above requirements; provided, however, that during said thirty (30) day

period, a battery operated carbon monoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as required in accordance with the

above provisions shall comply with NFPA 720 and be ANSI/UL 2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently mounted to the exterior of the building at a minimum

height of eight (8) feet above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled

heating appliance or equipment. The sign shall read, in print size no less than one-half (1/2) inch in size, "GAS VENT

DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS".

4. INSPECTION. The state or local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve the

installation unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed in accordance

with the provisions of 248 CMR 5.08(2)(a)1 through 4.

5. EXEMPTIONS: The following equipment is exempt from 248 CMR 5.08(2)(a)1 through 4:

(1.) The equipment listed in Chapter 10 entitled "Equipment Not Required To Be Vented" in the most current edition of NFPA

54 as adopted by the Board; and

(2.) Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure separate from the

dwelling, building or structure used in whole or in part for residential purposes.

(c.) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM PROVIDED. When the

manufacturer of Product Approved side wall horizontally vented gas equipment provides a venting system design or

venting system components with the equipment, the instructions provided by the manufacturer for installation of the

equipment and the venting system shall include:

1. Detailed instructions for the installation of the venting system design or the venting system components; and

2. A complete parts list for the venting system design or venting system.

(d.)MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED. When the

manufacturer of a Product Approved side wall horizontally vented gas fueled equipment does not provide the parts

for venting the flue gases, but identifies "special venting systems", the following requirements shall be satisfied by

the manufacturer:

1. The referenced "special venting system" instructions shall be included with the appliance or equipment installation

instructions; and

2. The "special venting systems" shall be Product Approved by the Board, and the instructions for that system shall include a

parts list and detailed installation instructions.

(e.)A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled equipment,

all venting instructions, all parts lists for venting instructions, and/or all venting design instructions shall remain with

the appliance or equipment at the completion of the installation.

For questions regarding these requirements, please contact the Commonwealth of Massachusetts Board of State Examiners of Plumbers and

Gas Fitters, 239 Causeway Street, Boston, MA 02114. 617-727-9952.

TABLE OF CONTENTS

PAGE

IMPORTANT INFORMATION ........................ 2

SAFETY CONSIDERATIONS ........................ 3

CODES AND STANDARDS .......................... 7

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS .. 7

INTRODUCTION .................................. 7

APPLICATIONS ................................... 8

Upflow ........................................ 8

Downflow ..................................... 11

Horizontal Left .................................. 12

Horizontal Right ................................ 15

LOCATION ...................................... 16

INSTALLATION .................................. 18

Air Ducts ....................................... 21

Air for Combustion and Ventilation .................. 28

Combustion Air Pipe .............................. 34

Vent Pipe ...................................... 36

Vent Termination ................................ 39

Condensate Drain ................................ 43

START-UP, ADJUSTMENTS, AND SAFETY CHECK ... 44

CHECKLIST ..................................... 60

AIRFLOW

d>

"i

SAFETY CONSIDERATIONS

FURNACE RELIABILITY HAZARD

Failure to follow this caution may result in unit damage.

Improper installation or misapplication of furnace may

require excessive servicing or cause premature component

failure. This furnace can be vented as either a direct vent

(2-pipe) furnace or as an optional ventilated combustion air

application.

A direct vent system shall be installed in accordance with

the direct vent (2-pipe) procedures in the Combustion Air

and Vent Pipe Systems section within this instruction. For

optional ventilated combustion air applications, refer to the

ventilated combustion air option procedures in the same

section.

Application of this furnace should be indoors with special

attention given to vent sizing and material, gas input rate,

air temperature rise, unit leveling, and unit sizing.

FIRE, EXPLOSION, ELECTRICAL SHOCK AND

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

iniury, death, or property damage.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause carbon monoxide poisoning,

explosion, fire, electrical shock, or other conditions which

may cause personal iniury or property damage. Consult a

qualified installer, service agency, local gas supplier, or your

distributor or branch for information or assistance. The

qualified installer or agency must use only

factory-authorized and listed kits or accessories when

modifying this product.

©

AIRFLOW

Fig. l - Furnace Orientation

A93041

CUT HAZARD

Failure to follow this caution may result in personal iniury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing and gloves when

handling parts.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical shock, or

other conditions which may cause death, personal iniury, or

property damage. Consult a qualified installer, service agency, or

your distributor or branch for information or assistance. The

qualified installer or agency must use factory-authorized kits or

accessories when modifying this product. Refer to the individual

instructions packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Have a fire extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions

include in literature and attached to the unit. Consult local

building codes, the current editions of the National Fuel Gas

Code (NFGC) NFPA 54/ANSI Z223.1 and the National

Electrical Code (NEC) NFPA 70.

g

2 IN (51 mm) COMBUSTION

!_lN(13mm)

GAS CONN

2IN

VENTCONN

]_INDIA(13mm)

1

(684 ram)

664 ram)

©

AIRFLOW

A_ (14 ram)

TYP

(829 ram)

(21 ram)

TRAP LOCATION

(DOWNFLOW &

HORIZONTAL LEFT)

;a IN D]A (22ram)

--POWER CONN

ACCESSORY

POWER ENTRY

LOCATION

(ALTERNATE

UPFLOW)

DRAIN TRAP ]

9_s" 17 _16"

TYP (439

(240 ram)

DRAIN LOCATION 11'!6"_ _ 1'16"

(UPFLOW) (17 ram) (17 ram)

NOTES: 1. Minimum return-air openings at furnace, based on metal duct. If flex duct is used,

see flex duct manufactureris recommendations for equivalent diameters.

2. Minimum return-air opening at furnace:

a. For 800 OFM 16-in. (408mm) round or 141A (388 mm)x 12-in. (305 mm) rectangle

b. For !200 CFM 20-in. (508mm) round or 141# (368mm)x 197Mn. (495mm).rectangle

c. For !600 CFM 22-in. (558mm) round or 141# (368mm)x 231/4-in,(591mm) [ectangle

d. For aidlow requirements above 1800 CFM, see Air Delivery table in Product Data

literature for specific use of single side inlets. The use of both side inlets, a

combination of 1 side and the bottom, or the bottom only will ensure adequate

return air openings for airflow requirements above 1800 CFM.

D-- 'l:,r,, "{POUTLET

_NLET

_E_

CONDENSATE DRAIN

(DOWNFLOW &

HORIZONTAL RIGHT) "_

OR ALTERNATE

!_z IN D]A GAS CONN

26 i¢,, (724 mm)

_26 %6" (664 mm)

2614" (667 mm)

22 5i_" (567 mm)_

_19"(463 ram) _ _!3fl6" (21 ram)

I / COMBUSTION AIR OONN b6"|

GAS OONN

......../

1

3O 1< /+-. 2 N _/T,r,l_5 39 7S"

(......... ) f_ _'_"- _/ENTSONN (......... )

1

17......

T_4 E R M O S+_,]r_'T Ry /

SIDE INLET ,

b <1

..........

DRAIN LOCATION / _ 22 11"TYP ------'_'_1 _g_6" (11 ram)

(UPFLOW) (a65 ram)

.............. J --------_OT_;_1r'47----II...... "1 ........ )

FOR HORIZONTAL

HANGING (614 ram)

A05124

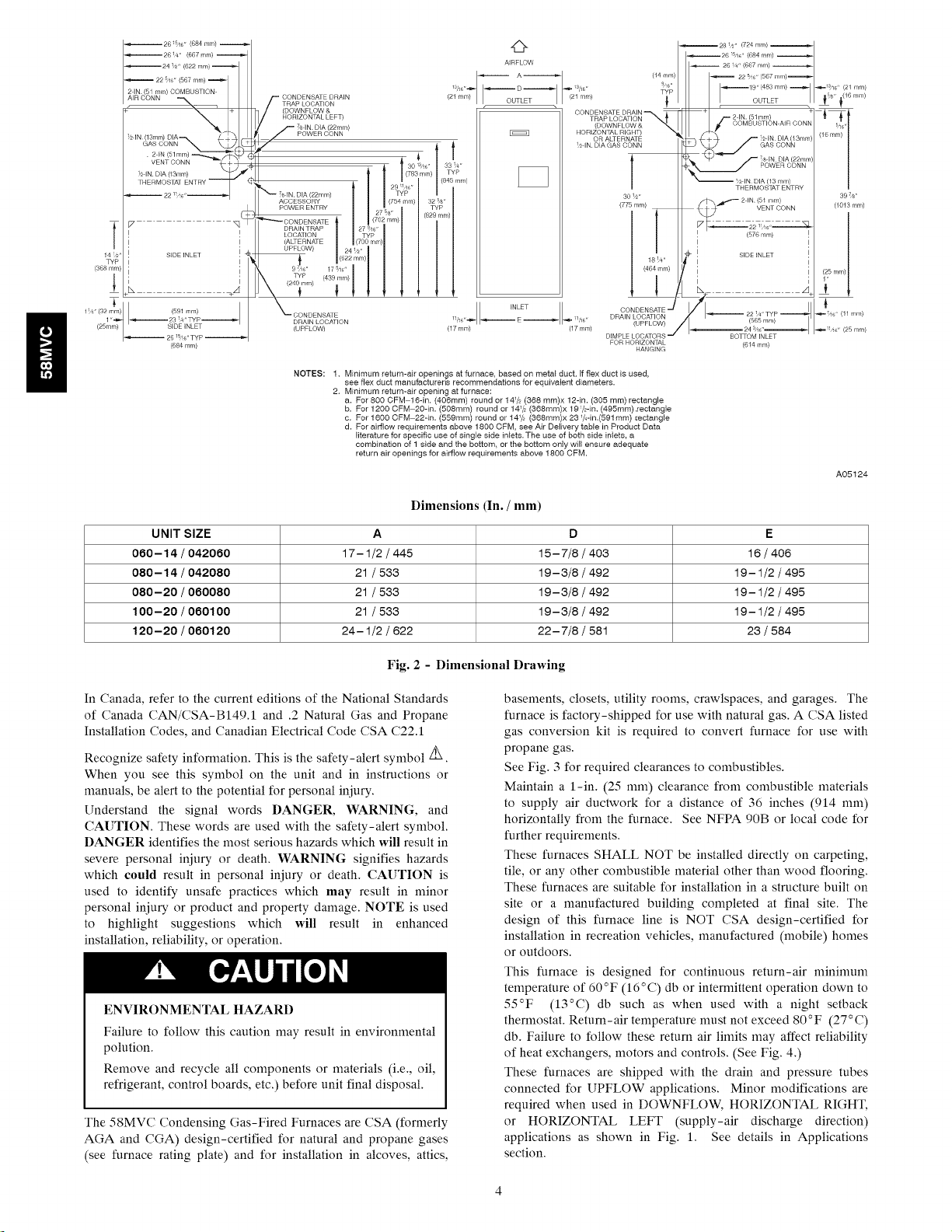

Dimensions (In. / mm)

UNIT SIZE A D E

080-14 / 042080 17-1/2 / 445 15-7/8 / 403 16 / 406

080-14 / 042080 21 / 533 19-3/8 / 492 19-1/2 / 495

080-20 / 080080 21 / 533 19-3/8 / 492 19-1/2 / 495

100-20 / 080100 21 / 533 19-3/8 / 492 19-1/2 / 495

120-20 / 080120 24-1/2 / 822 22-7/8 / 581 23 / 584

Fig. 2 - Dimensional Drawing

In Canada, refer to the current editions of the National Standards

of Canada CAN/CSA-BI49.1 and .2 Natural Gas and Propane

Installation Codes, and Canadian Electrical Code CSA C22.1

Recognize safety information. This is the safety-alert symbol/_.

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal iniury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety-alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal iniury or death. WARNING signifies hazards

which could result in personal iniury or death. CAUTION is

used to identify unsafe practices which may result in nfinor

personal iniury or product and property damage. NOTE is used

to highlight suggestions which will result in enhanced

installation, reliability, or operation.

ENVIRONMENTAL HAZARD

Failure to follow this caution may result in environmental

polution.

Remove and recycle all components or materials (i.e., oil,

refrigerant, control boards, etc.) before unit final disposal.

The 58MVC Condensing Gas-Fired Furnaces are CSA (formerly

AGA and CGA) design-certified for natural and propane gases

(see furnace rating plate) and for installation in alcoves, attics,

basements, closets, utility rooms, crawlspaces, and garages. The

furnace is factory-shipped for use with natural gas. A CSA listed

gas conversion kit is required to convert furnace for use with

propane gas.

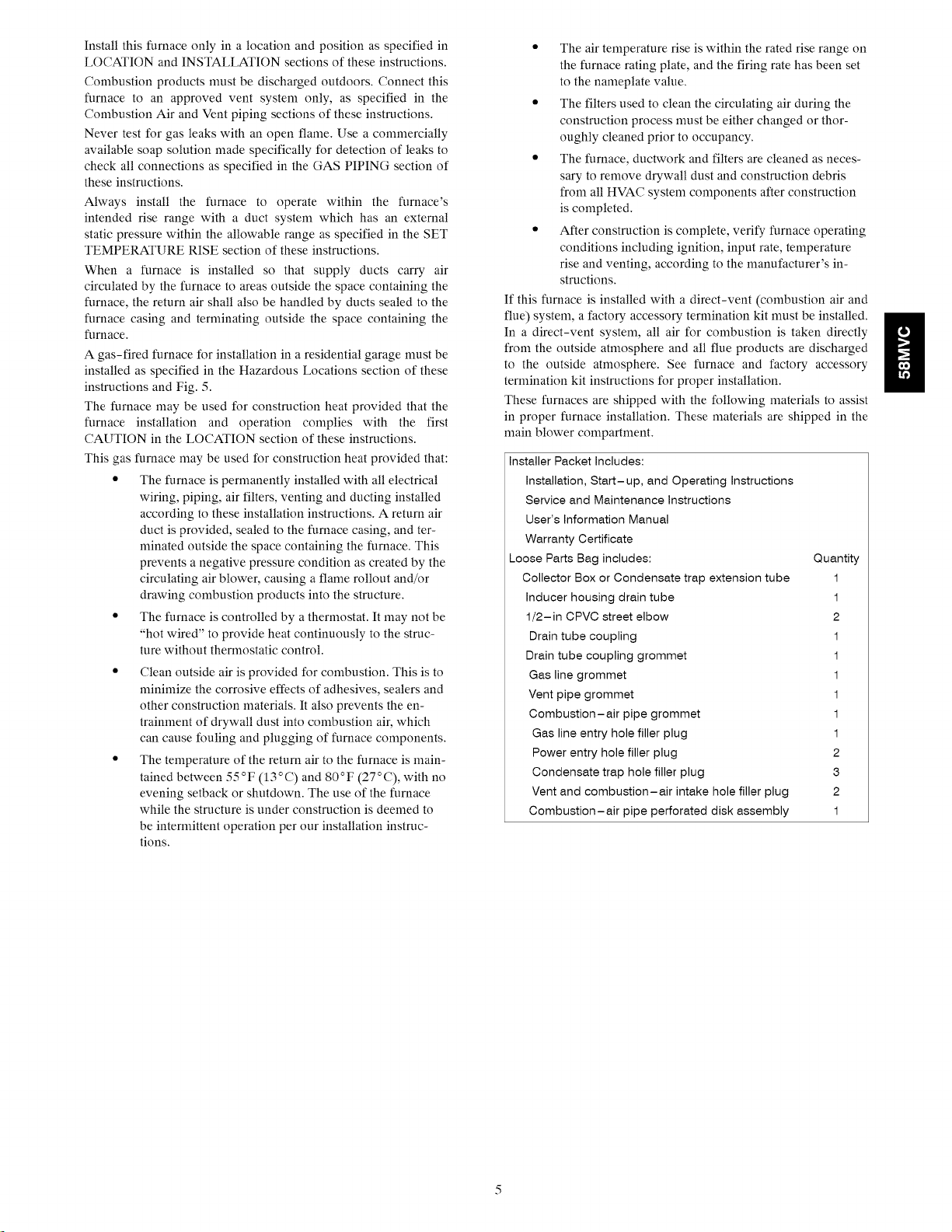

See Fig. 3 for required clearances to combustibles.

Maintain a 1-in. (25 ram) clearance from combustible materials

to supply air ductwork for a distance of 36 inches (914 ram)

horizontally from the furnace. See NFPA 90B or local code for

further requirements.

These furnaces SHALL NOT be installed directly on carpeting,

tile, or any other combustible material other than wood flooring.

These furnaces are suitable for installation in a structure built on

site or a manufactured building completed at final site. The

design of this furnace line is NOT CSA design-certified for

installation in recreation vehicles, manufactured (mobile) homes

or outdoors.

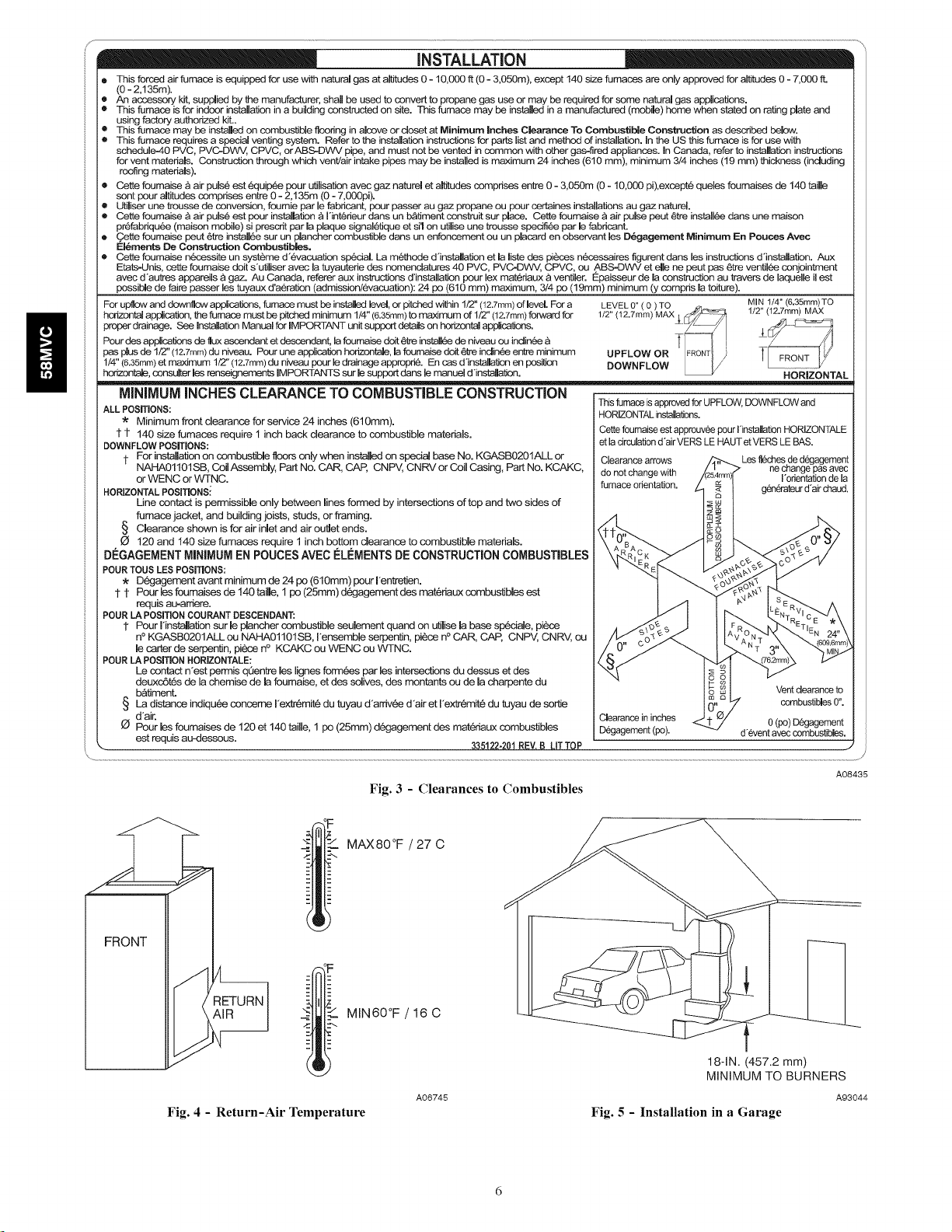

This furnace is designed for continuous return-air minimum

temperature of 60 °F (16 °C) db or internfittent operation down to

55°F (13°C) db such as when used with a night setback

thermostat. Return-air temperature nmst not exceed 80°F (27 °C)

db. Failure to follow these return air linfits may affect reliability

of heat exchangers, motors and controls. (See Fig. 4.)

These furnaces are shipped with the drain and pressure tubes

connected for UPFLOW applications. Minor modifications are

required when used in DOWNFLOW, HORIZONTAL RIGHT,

or HORIZONTAL LEFT (supply-air discharge direction)

applications as shown in Fig. 1. See details in Applications

section.

Install this furnace only in a location and position as specified in

LOCATION and INSTALLATION sections of these instructions.

Combustion products must be discharged outdoors. Connect this

furnace to an approved vent system only, as specified in the

Combustion Air and Vent piping sections of these instructions.

Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for detection of leaks to

check all connections as specified in the GAS PIPING section of

these instructions.

Always install the furnace to operate within the furnace's

intended rise range with a duct system which has an external

static pressure within the allowable range as specified in the SET

TEMPERATURE RISE section of these instructions.

When a furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space containing the

furnace, the return air shall also be handled by ducts sealed to the

furnace casing and terminating outside the space containing the

furnace.

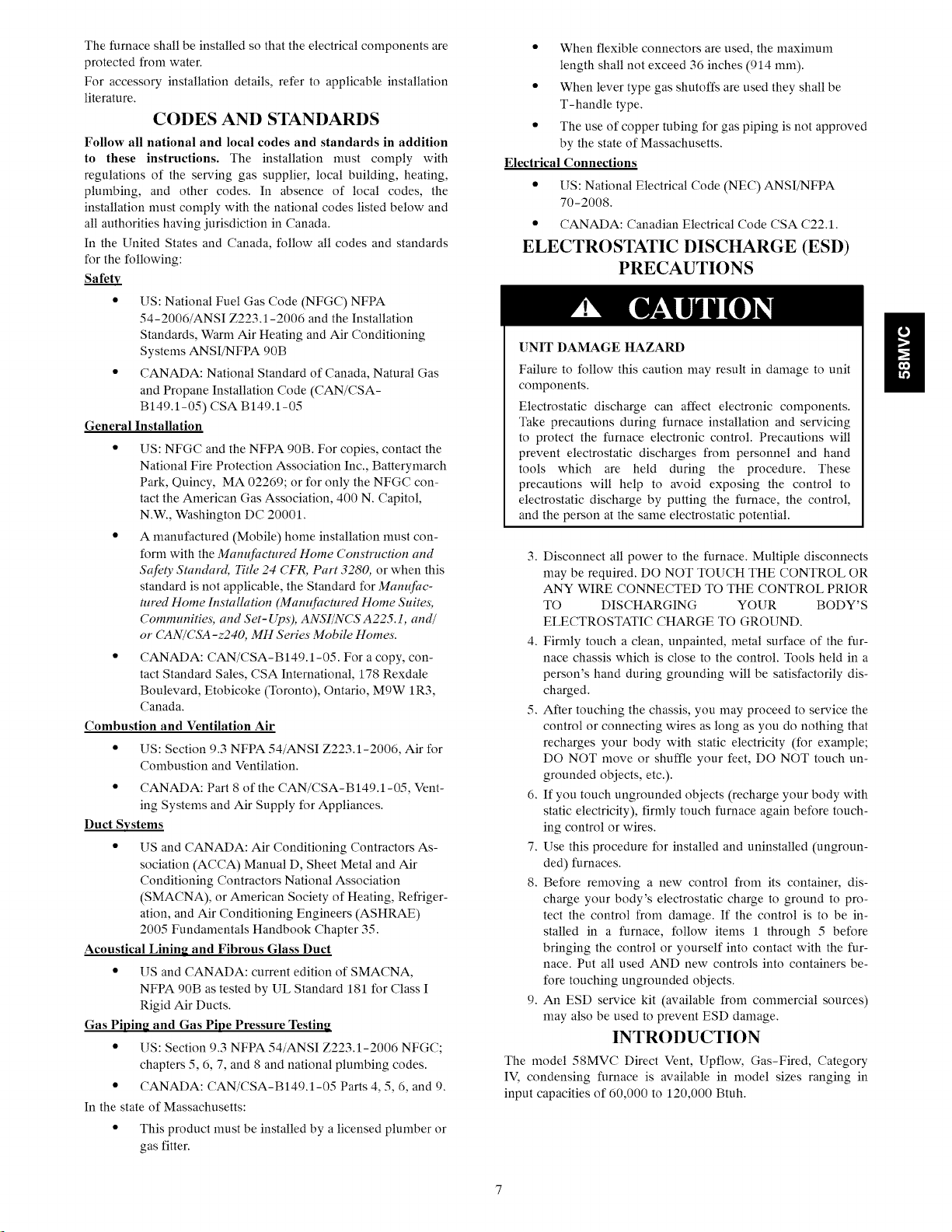

A gas-fired furnace for installation in a residential garage must be

installed as specified in the Hazardous Locations section of these

instructions and Fig. 5.

The furnace may be used for construction heat provided that the

furnace installation and operation complies with the first

CAUTION in the LOCATION section of these instructions.

This gas furnace may be used for construction heat provided that:

• The furnace is permanently installed with all electrical

wiring, piping, air filters, venting and ducting installed

according to these installation instructions. A return air

duct is provided, sealed to the furnace casing, and ter-

minated outside the space containing the furnace. This

prevents a negative pressure condition as created by the

circulating air blower, causing a flame rollout and/or

drawing combustion products into the structure.

• The furnace is controlled by a thermostat. It may not be

"hot wired" to provide heat continuously to the struc-

ture without thermostatic control.

• Clean outside air is provided for combustion. This is to

minimize the corrosive effects of adhesives, sealers and

other construction materials. It also prevents the en-

trainment of drywall dust into combustion air, which

can cause fouling and plugging of furnace components.

• The temperature of the return air to the furnace is main-

tained between 55°F (13°C) and 80°F (27°C), with no

evening setback or shutdown. The use of the furnace

while the structure is under construction is deemed to

be intermittent operation per our installation instruc-

tions.

• The air temperature rise is within the rated rise range on

the furnace rating plate, and the firing rate has been set

to the nameplate value.

• The filters used to clean the circulating air during the

construction process must be either changed or thor-

oughly cleaned prior to occupancy.

• The furnace, ductwork and filters are cleaned as neces-

sary to remove drywall dust and construction debris

from all HVAC system components after construction

is completed.

• After construction is complete, verify furnace operating

conditions including ignition, input rate, temperature

rise and venting, according to the manufacturer's in-

structions.

If this furnace is installed with a direct-vent (combustion air and

flue) system, a factory accessory termination kit must be installed.

In a direct-vent system, all air for combustion is taken directly

from the outside atmosphere and all flue products are discharged

to the outside atmosphere. See furnace and factory accessory

termination kit instructions for proper installation.

These furnaces are shipped with the following materials to assist

in proper furnace installation. These materials are shipped in the

main blower compartment.

Installer Packet Includes:

Installation, Start-up, and Operating Instructions

Service and Maintenance Instructions

User's Information Manual

Warranty Certificate

Loose Parts Bag includes: Quantity

Collector Box or Condensate trap extension tube 1

Inducer housing drain tube 1

1/2-in CPVC street elbow 2

Drain tube coupling 1

Drain tube coupling grommet 1

Gas line grommet 1

Vent pipe grommet 1

Combustion-air pipe grommet 1

Gas line entry hole filler plug 1

Power entry hole filler plug 2

Condensate trap hole filler plug 3

Vent and combustion-air intake hole filler plug 2

Combustion-air pipe perforated disk assembly 1

g

INSTALLATION

e This forced air fumace is equipped for use with natural gas at altitudes 0 - 10,000 ft (0 - 3,050m), except 140 size furnaces are only approved for altitudes 0 - 7,000 fL

(0 - 2,135m).

• An accessory kit, supplied by the manufacturer, shah be used to convert to propane gas use or may be Pequired for some natural gas applicetions.

• This famace is for indoor installation in a building constructed on site. This furnace may be instated in a manufactured (mobile) home when stated on rating plate and

using factory authorized kit..

• This furnace may be instated on combustible floodng in alsove or closet at Minimum Inches Clearance To Combustible Construction as described below.

e This _mace requires a special venting system. Refer to the installation instructions for parts list and method of installation. In the US this furnace is for use with

schedule=40 PVC, PVC-DWV, CPVC, or AB,S-DWV pipe, and must not be vented in common with other gas-fired appliances. In Canada, refer to installation instructions

for vent materials. Construction through which vent/air intake pipes may be installed is maximum 24 inches (610 ram), minimum 3/4 inches (19 mm) thickness (including

roofing materials).

e Cette foumaise _ air puis6 est 6quip6e pour utilisation avec gaz naturem et altitudes comprises entre 0 - 3,050m (0 - 10,000 pi),except6 queles foumaises de 140 taifle

sont pour altitudes comprises entre 0 - 2,135m (0 - 7,000pi).

® Utiiiser une trousse de conversion, foumie par le fabdcant, pour passer au gaz propane ou pour certaines installations au gaz natureL

e Cette foumaise & air pulse est pour installation a I'intedeur dans un b_timent construit sur place. Cette foumaise a air pulse peut 6tre install6e dans une maison

prCfabdqu6e (maison mobile) si prescrit par la plaque signal6tique et si'l on utilise une trousse specifi6e par le fabrleant.

• C.ette foumaise pout 6tre install6e sur un plancher combustible dans un enfoncement ou un placerd en observant les D6gagernent Minimum En Pouces Avec

EI6ments De Construction Combustibles.

• Cette foumaise n6cessite un syst_me d'6vacuation sp6cial. La m6thode d'instaliation et la iiste des pi_ces n6cessaires figurent dana les instructions d"installation. Aux

Etats-Unis, cette foumaise dolt s'utiliser avec la tuyautede des nomenclatures 40 PVC, PVC-DWV, CPVC, ou ,ABS-DWV et elle ne peut pas _tre ventil6e conjointment

avec d'autres appareils & gaz. Au Canada, referer aux instructions d'installation pour lax matedaux a ventiler. Epaisseur de la construction au travers de laquene il est

possible de faire passer les tuyaux d'aeration (admission/evacuation): 24 po (610 mm) maximum, 3/4 pc (19mm) minimum (y compds la toiture).

For up&3w and downflow applications, furnace must be installed level, or pitched within 1/2" (12.7ram) of level. For a LEVEL 0" ( 0 ) TO _,. MINI 14" (6.35mm) TO

horizonfal application, the furnace must be pitched minimum 1/4" (6.35mm) to maximum of 1/Z' (12.7mm) forward for 1/2" (12.7mm) MAXj ¢_L-_-_ 1/2" (12.7mm)MAX

proper drainage. See Installation Manual for IMPORTANT unit support details on horizontal applications.

Pour des applications de flux ascendant et descendant, la foumaise doit ¢¢e install6e de niveau ou indin6e _ T ............. !

pas plus de 1/2" (12.7mm) du niveau. Pour une application hodzontale, la fOumaise dOlt &'Ire inclle_-_eenli'e minimum UPFLOW OR F_ORON_ )

1/4" (6.35mm) et maximum 1/2" (12.7ram) du niveau pour le drainage appropn& En cas d'installation en position DOWN FLOW

hodzootale, consulter les renseignements mMPORTANTS sur le support dans le manuel d'instaHation. HORIZONTAL

MINIMUMINCHESCLEARANCE TO COMBUSTIBLE CONSTRUCTION

ALL POSiTiONS:

* Minimum front clearance for service 24 inches (610mm).

t 1 140 size furnaces require I inch back clearance to combustible materials.

DOWNFLOW POSITIONS:

t For installation on combustible 11oors only when instated on special base No. KGASB0201ALL or

NAHA01101SB, CoilAssembly, Part No. CAR, CAP, CNPV, CNRV or Coil Casing, Part No. KCAKC,

or WENC or WTNC.

HORIZONTAL POSITIONSi

Line contact is permissible only between lines formed by intersections of top and two sides of

furnace jacket, and building joists, studs, or framing.

§ Clearance shown is for air inlet and air ou_et ends.

O 120 and 140 size furnaces require 1 inch bottom clearance to combustible materials.

DEGAGEMENT MINfl_UIVIEN POUCESAVEC I_LleMENTSDECONSTRUCTION COMBUSTIBLES

POUR TOUS LES POSITIONS:

D@jagement avant minimum de 24 po (610mm ) pour l'entretien.

1- t Pour les foumaises de 140 taifle, 1 pc (25mm) d6gagement des mat6riaux combustibles est

requis au-arriere.

POUR LA POSITION COURANT DESCENDANT:

1 Pour Ilnstaflation sur le plancher combustible seulement quand on utilise la base sp_ciale, piece

n° KGASB0201ALL ou NAHA01101SB, I'ensemble serpentin, pi_:e n ° CAR, CAP, CNPV, CNRV, ou

le carter de serpentin, piece n ° KCAKC ou WENC ou WTNC.

POUR LA POSmON HORIZONTALE:

Le contact n'est permis qQentre les lignes form6es par les intersec_ons du dessus et des

deuxottes de la chemise de la foumaise, et des solives, des montants ou de la charpente du

batiment.

§ La distance indiqu_e conceme I'extr_mit6 du tuyau d'ardv_e d'air et I'extr_mit_ du tuyau de sortie

d'aic

Pour les foumaises de 120 et 140 taifie, 1 pc (25mm) d6gagement des materiaux combustibles

est requis au-dessous.

This furnace is approved for UPFLOW, DOWNFLOW and

HORIZONTAL installations.

Cette foumaise est approuv_e pour I'installation HORIZONTALE

et la circulation d'air VERS LE HAUT et VERS LE BAS.

Clearance arrows Les _hes de degagement

do not change with ne change pas avec

furnace orientation, gen#rateur d'air chaud.

Clearanceininches 0 (pc) D_Jagement

D6gagement(pc). d'_ventaveccombustibles.

I'orientation de la

Vent dearance to

combustibles 0".

FRONT

! MAX80°F/27C

o

_ MIN60°F / 16 C

Fig. 4 - Return-Air Temperature

Fig. 3 - Clearances to Combustibles

A06745

A08435

18-IN. (457.2 mm)

MINIMUM TO BURNERS

A93044

Fig. 5 - Installation in a Garage

Thefurnaceshallbeinstalledsothat the electrical components are

protected from water.

For accessory installation details, refer to applicable installation

literature.

CODES AND STANDARDS

Follow all national and local codes and standards in addition

to these instructions. The installation must comply with

regulations of the serving gas supplier, local building, heating,

plumbing, and other codes. In absence of local codes, the

installation must comply with the national codes listed below and

all authorities having jurisdiction in Canada.

In the United States and Canada, follow all codes and standards

for the following:

US: National Fuel Gas Code (NFGC) NFPA

54-2006/ANSI Z223.1-2006 and the Installation

Standards, Warm Air Heating and Air Conditioning

Systems ANSI/NFPA 90B

CANADA: National Standard of Canada, Natural Gas

and Propane Installation Code (CAN/CSA-

B149.1-05) CSA B149.1-05

General

Combustion and Ventilation Air

Duct Systems

Acoustical Lining and Fibrous Glass Duct

Gas Piping and Gas Pipe Pressure Testing

In the state of Massachusetts:

Installation

• US: NFGC and the NFPA 90B. For copies, contact the

National Fire Protection Association Inc., Batterymarch

Park, Quincy, MA 02269; or for only the NFGC con-

tact the American Gas Association, 400 N. Capitol,

N.W, Washington DC 20001.

• A manufactured (Mobile) home installation nmst con-

form with the Manufactured Home Construction and

Safi, ty Standard, Title 24 CFR, Part 3280, or when this

standard is not applicable, the Standard for Manufac-

tured Home Installation (Manufactured Home Suites,

Communities, and Set-Ups), ANSI/NCS A225.1, and/

or CAN/CSA-z240, MH Series Mobile Homes.

• CANADA: CAN/CSA-B149.1-05. For a copy, con-

tact Standard Sales, CSA International, 178 Rexdale

Boulevard, Etobicoke (Toronto), Ontario, M9W 1R3,

Canada.

• US: Section 9.3 NFPA 54/ANSI Z223.1-2006, Air for

Combustion and Ventilation.

• CANADA: Part 8 of the CAN/CSA-B149.1-05, Vent-

ing Systems and Air Supply for Appliances.

• US and CANADA: Air Conditioning Contractors As-

sociation (ACCA) Manual D, Sheet Metal and Air

Conditioning Contractors National Association

(SMACNA), or American Society of Heating, Refriger-

ation, and Air Conditioning Engineers (ASHRAE)

2005 Fundamentals Handbook Chapter 35.

• US and CANADA: current edition of SMACNA,

NFPA 90B as tested by UL Standard 181 for Class I

Rigid Air Ducts.

• US: Section 9.3 NFPA 54/ANSI Z223A-2006 NFGC;

chapters 5, 6, 7, and 8 and national plumbing codes.

• CANADA: CAN/CSA-BI49.1-05 Parts 4, 5, 6, and 9.

• This product must be installed by a licensed plumber or

gas fitter.

• When flexible connectors are used, the maximum

length shall not exceed 36 inches (914 ram).

• When lever type gas shutoffs are used they shall be

T-handle type.

• The use of copper tubing for gas piping is not approved

by the state of Massachusetts.

Electrical Connections

• US: National Electrical Code (NEC) ANSI/NFPA

70-2008.

• CANADA: Canadian Electrical Code CSA C22.1.

ELECTROSTATIC DISCHARGE (ESD)

PRECAUTIONS

[]NIT DAMAGE HAZARD

Failure to follow this caution may result in damage to unit

components.

Electrostatic discharge can affect electronic components.

Take precautions during furnace installation and servicing

to protect the furnace electronic control. Precautions will

prevent electrostatic discharges from personnel and hand

tools which are held during the procedure. These

precautions will help to avoid exposing the control to

electrostatic discharge by putting the furnace, the control,

and the person at the same electrostatic potential.

3. Disconnect all power to the furnace. Multiple disconnects

may be required. DO NOT TOUCH THE CONTROL OR

ANY WIRE CONNECTED TO THE CONTROL PRIOR

TO DISCHARGING YOUR BODY'S

ELECTROSTATIC CHARGE TO GROUND.

4. Firmly touch a clean, unpainted, metal surface of the fur-

nace chassis which is close to the control. Tools held in a

person's hand during grounding will be satisfactorily dis-

charged.

5. After touching the chassis, you may proceed to service the

control or connecting wires as long as you do nothing that

recharges your body with static electricity (for example;

DO NOT move or shuffle your feet, DO NOT touch un-

grounded objects, etc.).

6. If you touch ungrounded objects (recharge your body with

static electricity), firmly touch furnace again before touch-

ing control or wires.

7. Use this procedure for installed and uninstalled (ungroun-

ded) furnaces.

8. Before removing a new control from its container, dis-

charge your body's electrostatic charge to ground to pro-

tect the control from damage. If the control is to be in-

stalled in a furnace, follow items 1 through 5 before

bringing the control or yourself into contact with the fur-

nace. Put all used AND new controls into containers be-

fore touching ungrounded objects.

9. An ESD service kit (available from commercial sources)

may also be used to prevent ESD damage.

INTRODUCTION

The model 58MVC Direct Vent, Upflow, Gas-Fired, Category

IV, condensing furnace is available in model sizes ranging in

input capacities of 60,000 to 120,000 Btuh.

g

APPLICATIONS

General

Some assembly and modifications are required for furnaces

installed in any of the four applications shown in Fig. 1. All

drain and pressure tubes are connected as shown in Fig. 7. See

appropriate application instructions for these procedures.

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property

damage.

Local codes may require a drain pan under entire furnace

and condensate trap when a condensing furnace is used in

an attic application or over a finished ceiling.

current CAN/CSA-B149.1-05 and/or local codes.

NOTE: In Canada, installations shall be in accordance with

UPFLOW APPLICATION

An upflow furnace application is where furnace blower is located

below combustion and controls section of furnace, and

conditioned air is discharged upwards.

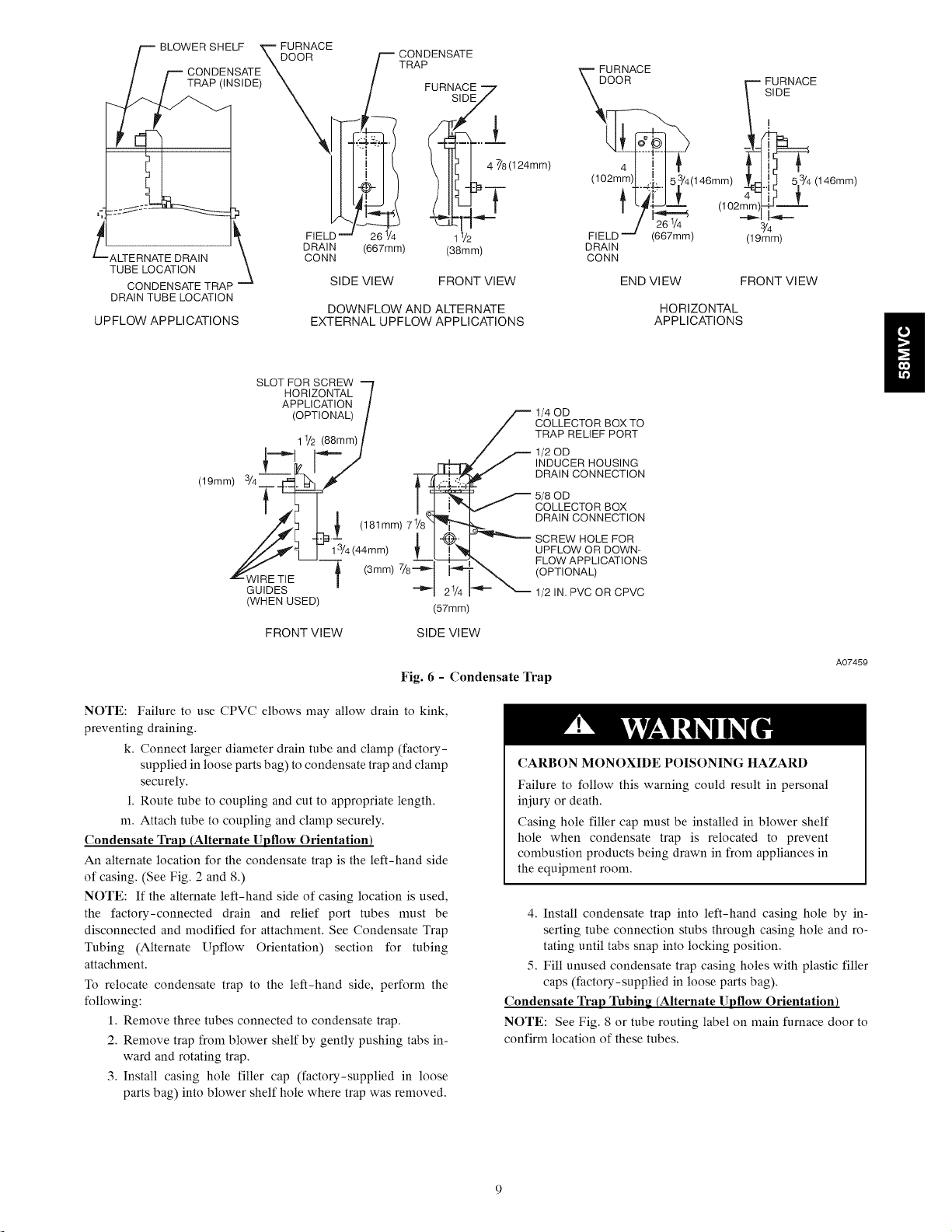

Condensate Trap (Factory-Shipped Orientation)

The condensate trap is factory installed in the blower shelf and

factory connected for UPFLOW applications, A factory-supplied

tube is used to extend the condensate trap drain connection to the

desired furnace side for field drain attachment. See Condensate

Trap Tubing section for drain tube extension details, (See Fig. 6.)

Condensate Trap Tubing (Factory-Shipped Orientation)

NOTE: See Fig. 7 or tube routing label on main furnace door to

confirm location of these tubes.

1. Collector Box Drain, Inducer Housing Drain, Relief Port,

and Pressure Switch Tubes.

These tubes should be factory attached to condensate trap

and pressure switch ready for use in UPFLOW applica-

tions. These tubes can be identified by their connection

location and also by a color label on each tube. These

tubes are identified as follows: collector box drain tube

(blue label), inducer housing drain tube (violet label or

molded), relief port tube (green label), and pressure switch

tube (pink label).

2, Condensate Trap Drain Tube

The condensate trap drain connection must be extended

for field attachment by doing the following:

f. Determine location of field drain connection, (See Fig.

2 or 7.)

NOTE: If internal filter or side filter/media cabinet is used, drain

tube should be located to opposite side of casing from return duct

attachment to assist in filter removal.

g. Remove and discard casing drain hole plug button from

desired side.

h. Install drain tube coupling grommet (factory-supplied in

loose parts bag) in selected casing hole.

i. Slide drain tube coupling (factory-supplied in loose parts

bag) through grommet so long end of coupling faces

blower.

j. Cement 2 factory-supplied 1/2-in. (13 mm) street CPVC

elbows to rigid drain tube connection on condensate trap.

(See Fig. 7.) These elbows must be cemented together

and cemented to condensate trap drain connection.

m BLOWER SHELF &-- FURNACE

/_ _TERNATE DRAIN

TUBE LOCATION

CONDENSATE TRAP --

DRAIN TUBE LOCATION

UPFLOW APPLICATIONS

DOOR

\

f_ CONDENSATE

/ TRA;uRNACE -7

j SIDe,,,"

,:_3 ......

_'/ /I 47/8(124mm)

21 J l iie

FIELD,..._

DRAIN

CONN

EXTERNAL UPFLOW APPLICATIONS

SLOT FORSCREW --j

HORIZONTAL /

APPLICATION

(OPTIONAL) /

11/2(88mm)]

261/4 /2

(667mm) (38mm)

SIDE VIEW FRONT VIEW

DOWNFLOW AND ALTERNATE

Uq --- ;

GUIDES -- _1 ,!

(WHEN USED)

FRONT VIEW SIDE VIEW

(57mm)

FURNACE

DOOR

4

(102mm)

FIELD (667mm)

DRAIN

CONN

END VIEW

1/40D

COLLECTOR BOX TO

TRAP RELIEF PORT

1/20D

INDUCER HOUSING

DRAIN CONNECTION

5/80D

COLLECTOR BOX

DRAIN CONNECTION

SCREW HOLE FOR

UPFLOW OR DOWN-

FLOW APPLICATIONS

(OPTIONAL)

1/2 IN. PVC OR CPVC

%2972 /4

(102ram'

HORIZONTAL

APPLICATIONS

FURNACE

SIDE

!

3/4

(19ram)

FRONT Vl EW

4(146mm)

Fig. 6 - Condensate Trap

NOTE: Failure to use CPVC elbows may allow drain to kink,

preventing draining.

k. Connect larger diameter drain tube and clamp (factory-

supplied in loose parts bag) to condensate trap and clamp

securely.

1. Route tube to coupling and cut to appropriate length.

m. Attach tube to coupling and clamp securely.

Condensate Trap (Alternate Upflow Orientation)

An alternate location for the condensate trap is the left-hand side

of casing. (See Fig. 2 and 8.)

NOTE: If the alternate left-hand side of casing location is used,

the factory-connected drain and relief port tubes must be

disconnected and modified for attachment. See Condensate Trap

Tubing (Alternate Upflow Orientation) section for tubing

attachment.

To relocate condensate trap to the left-hand side, perform the

following:

1. Remove three tubes connected to condensate trap.

2. Remove trap from blower shelf by gently pushing tabs in-

ward and rotating trap.

3. Install casing hole filler cap (factory-supplied in loose

parts bag) into blower shelf hole where trap was removed.

A07459

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

iniury or death.

Casing hole filler cap must be installed in blower shelf

hole when condensate trap is relocated to prevent

combustion products being drawn in from appliances in

the equipment room.

4. Install condensate trap into left-hand casing hole by in-

serting tube connection stubs through casing hole and ro-

tating until tabs snap into locking position.

5. Fill unused condensate trap casing holes with plastic filler

caps (factory-supplied in loose parts bag).

Condensate Trap 3klbing (Alternate Uptlow Orientation)

NOTE: See Fig. 8 or tube routing label on main furnace door to

confirm location of these tubes.

PLUG

COLLECTOR BOX

DRAIN TUBE (BLUE &

WHITE STRIPED)

CAP

COLLECTOR BOX

TUBE (PINK)

INDUCER HOUSING

(MOLDED) DRAIN

TUBE (BEHIND

COLLECTOR BOX

DRAIN TUBE)

COLLECTOR BOX

DRAIN TUBE (BLUE)

COLLECTOR BOX

TUBE (GREEN

ROUTES BEHIND

INDUCER)

CONDENSATE

TRAP

FIELD-INSTALLED

FACTORY-SUPPLIED

DRAIN TUBE

COUPLING (LEFT

DRAIN OPTION)

FIELD-INSTALLED

FACTORY-SUPPLIED

DRAIN TUBE

FIELD-INSTALLED

FIELD-INSTALLED FACTORY-SUPPLIED

FACTORY-SUPPLIED DRAIN TUBE

1/2- IN. CPVC STREET COUPLING (LEFT

ELBOWS (2) FOR DRAIN OPTION)

LEFT DRAIN OPTION

A07274

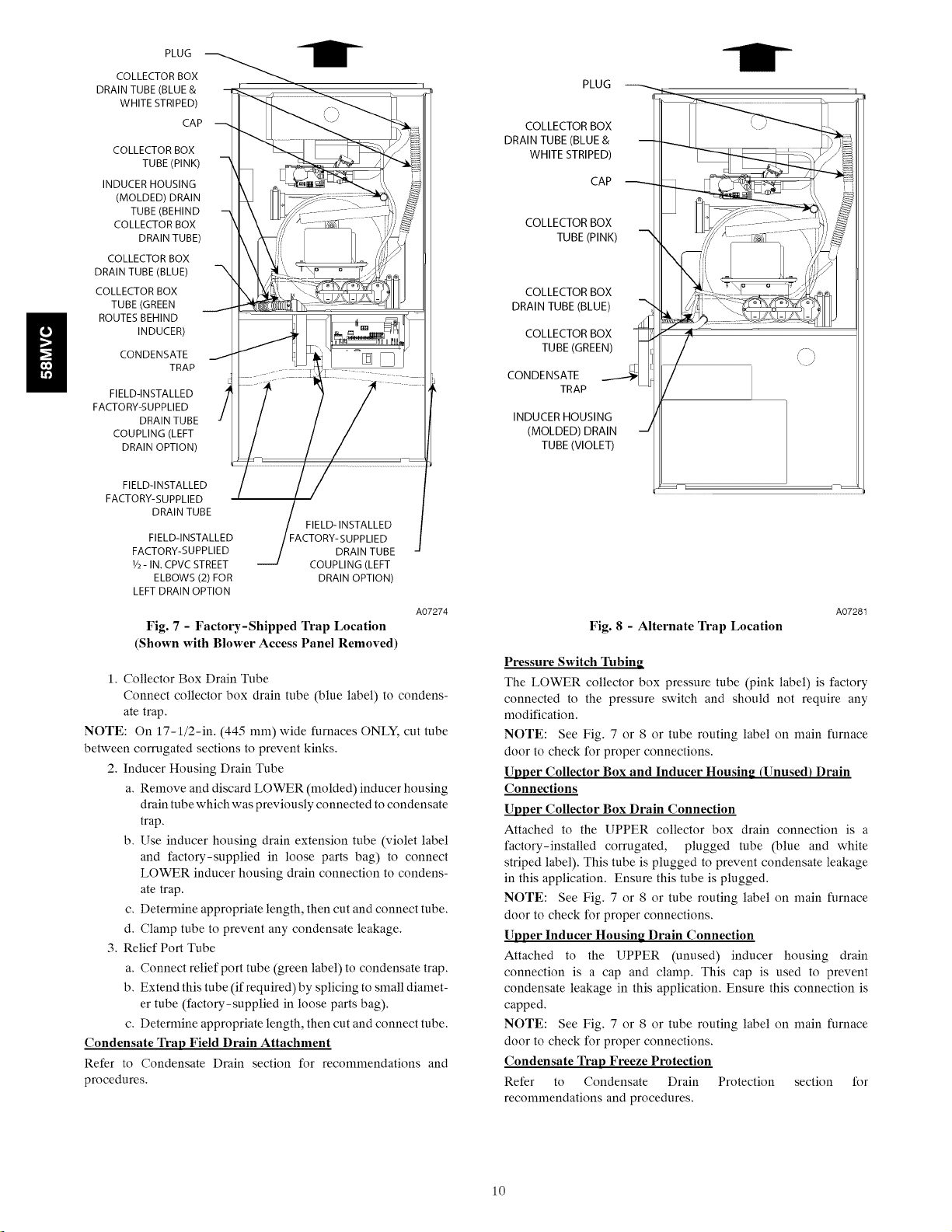

Fig. 7 - Factory-Shipped Trap Location

(Shown with Blower Access Panel Removed)

1. Collector Box Drain Tube

Connect collector box drain tube (blue label) to condens-

ate trap.

NOTE: On 17-1/2-in. (445 ram) wide furnaces ONLY, cut tube

between corrugated sections to prevent kinks.

2. Inducer Housing Drain Tube

a. Remove and discard LOWER (molded) inducer housing

drain tube which was previously connected to condensate

trap.

b. Use inducer housing drain extension tube (violet label

and factory-supplied in loose parts bag) to connect

LOWER inducer housing drain connection to condens-

ate trap.

c. Deternfine appropriate length, then cut and connect tube.

d. Clamp tube to prevent any condensate leakage.

3. Relief Port Tube

a. Connect relief port tube (green label) to condensate trap.

b. Extend this tube (if required) by splicing to small diamet-

er tube (factory-supplied in loose parts bag).

c. Deternfine appropriate length, then cut and connect tube.

Condensate Trap Field Drain Attachment

Refer to Condensate Drain section for recommendations and

procedures.

PLUG

COLLECTOR BOX

DRAIN TUBE (BLUE &

WHITE STRIPED)

CAP

COLLECTOR BOX

TUBE (PINK)

COLLECTOR BOX

DRAIN TUBE (BLUE)

COLLECTOR BOX

TUBE (GREEN) _

CONDENSATE

TRAP

INDUCER HOUSING

(MOLDED) DRAIN

TUBE (VIOLET)

A07281

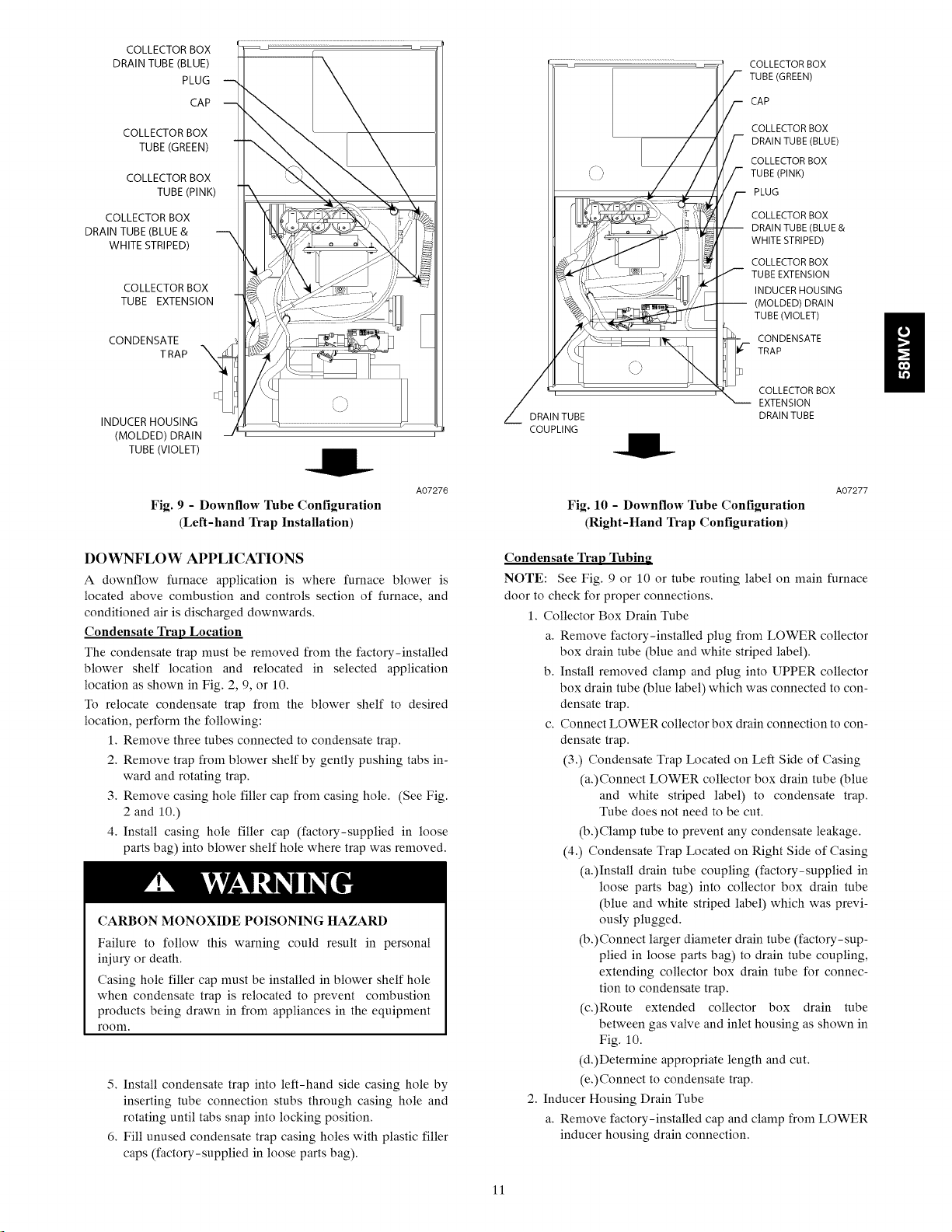

Fig. 8 - Alternate Trap Location

Pressure Switch Tubing

The LOWER collector box pressure tube (pink label) is factory

connected to the pressure switch and should not require any

modification.

NOTE: See Fig. 7 or 8 or tube routing label on main furnace

door to check for proper connections.

Upper Collector Box and Inducer Housing (Unused) Drain

Connections

Upper Collector Box Drain Connection

Attached to the UPPER collector box drain connection is a

factory-installed corrugated, plugged tube (blue and white

striped label). This tube is plugged to prevent condensate leakage

in this application. Ensure this tube is plugged.

NOTE: See Fig. 7 or 8 or tube routing label on main furnace

door to check for proper connections.

Upper Inducer Housing Drain Connection

Attached to the UPPER (unused) inducer housing drain

connection is a cap and clamp. This cap is used to prevent

condensate leakage in this application. Ensure this connection is

capped.

NOTE: See Fig. 7 or 8 or tube routing label on main furnace

door to check for proper connections.

Condensate Trap Freeze Protection

Refer to Condensate Drain Protection section for

recommendations and procedures.

10

COLLECTORBOX =

DRAINTUBE(BLUE)

PLUG

CAP

COLLECTORBOX

TUBE(GREEN)

COLLECTORBOX

TUBE(PINK)

DRAINTUBE(BLUE&

WHITESTRIPED)

COLLECTORBOX _

COLLECTORBOX

TUBE EXTENS,ON _i i_ _

COLLECTOR BOX

TUBE (GREEN)

CAP

COLLECTOR BOX

DRAIN TUBE (BLUE)

COLLECTOR BOX

S TUBE (PINK)

PLUG

F COLLECTOR BOX

DRAIN TUBE (BLUE &

WHITE STRIPED)

COLLECTOR BOX

TUBE EXTENSION

INDUCER HOUSING

-- (MOLDED) DRAIN

TUBE (VIOLET)

CONDENSATE

TRAP

CONDENSATETRAP __q •

INDUCERHOUSING . _ •

(MOLDED)DRAIN

TUBE(VIOLET)

A07276

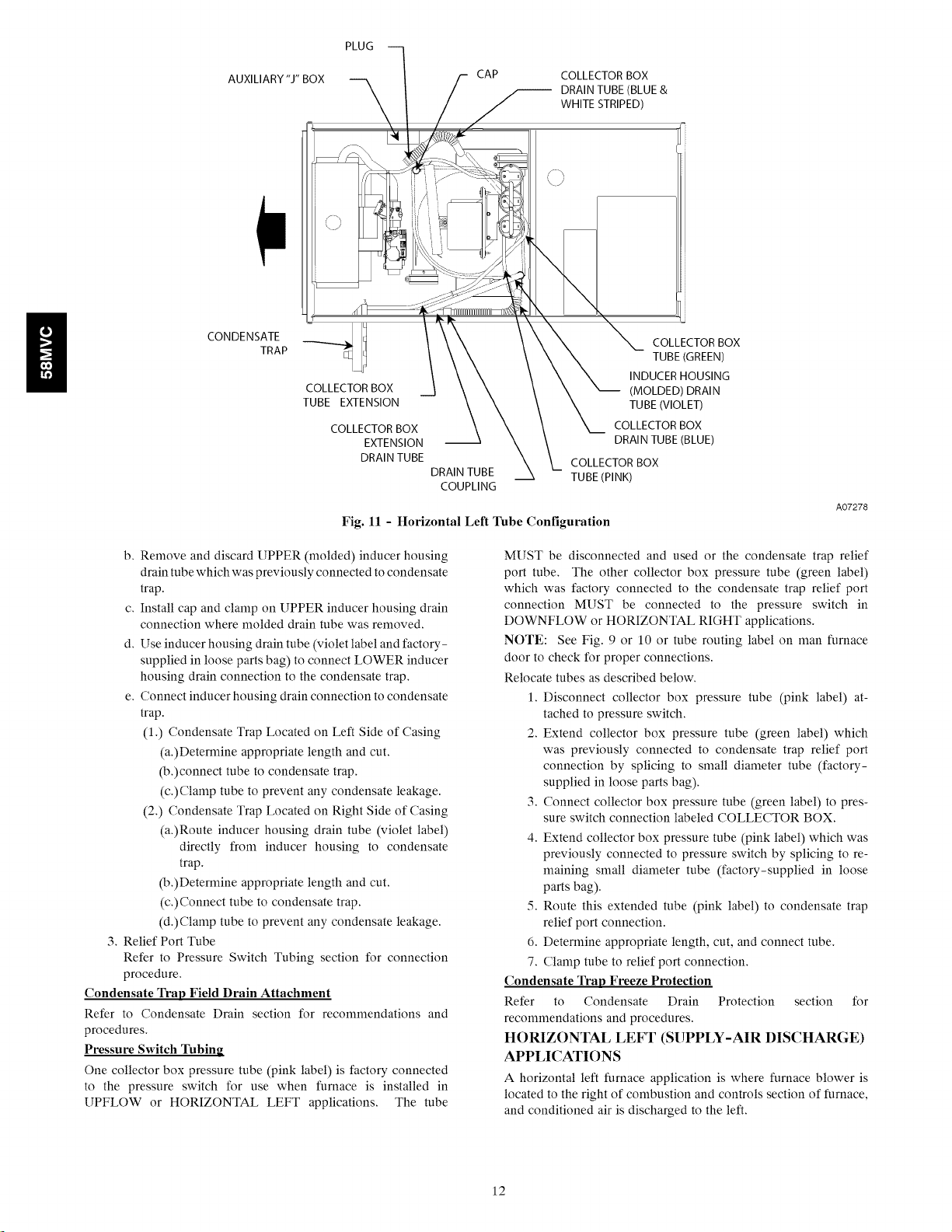

Fig. 9 - Downflow Tube Configuration

(Left-hand Trap Installation)

DOWNFLOW APPLICATIONS

A downflow furnace application is where furnace blower is

located above combustion and controls section of furnace, and

conditioned air is discharged downwards.

Condensate Trap Location

The condensate trap must be removed from the factory-installed

blower shelf location and relocated in selected application

location as shown in Fig. 2, 9, or 10.

To relocate condensate trap from the blower shelf to desired

location, perform the following:

1. Remove three tubes connected to condensate trap.

2. Remove trap from blower shelf by gently pushing tabs in-

ward and rotating trap.

3. Remove casing hole filler cap from casing hole. (See Fig.

2 and 10.)

4. Install casing hole filler cap (factory-supplied in loose

parts bag) into blower shelf hole where trap was removed.

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

iniury or death.

Casing hole filler cap must be installed in blower shelf hole

when condensate trap is relocated to prevent combustion

products being drawn in from appliances in the equipment

room.

5. Install condensate trap into left-hand side casing hole by

inserting tube connection stubs through casing hole and

rotating until tabs snap into locking position.

6. Fill unused condensate trap casing holes with plastic filler

caps (factory-supplied in loose parts bag).

/

Z DRAIN TUBE

COUPLING

COLLECTOR BOX

EXTENSION

DRAIN TUBE

A07277

Fig. 10 - Downflow Tube Configuration

(Right-Hand Trap Configuration)

Condensate Trap Tubing

NOTE: See Fig. 9 or 10 or tube routing label on main furnace

door to check for proper connections.

1. Collector Box Drain Tube

a. Remove factory-installed plug from LOWER collector

box drain tube (blue and white striped label).

b. Install removed clamp and plug into UPPER collector

box drain tube (blue label) which was connected to con-

densate trap.

c. Connect LOWER collector box drain connection to con-

densate trap.

(3.) Condensate Trap Located on Left Side of Casing

(a.)Connect LOWER collector box drain tube (blue

and white striped label) to condensate trap.

Tube does not need to be cut.

(b.)Clamp tube to prevent any condensate leakage.

(4.) Condensate Trap Located on Right Side of Casing

(a.)Install drain tube coupling (factory-supplied in

loose parts bag) into collector box drain tube

(blue and white striped label) which was previ-

ously plugged.

(b.) Connect larger diameter drain tube (factory-sup-

plied in loose parts bag) to drain tube coupling,

extending collector box drain tube for connec-

tion to condensate trap.

(c.)Route extended collector box drain tube

between gas valve and inlet housing as shown in

Fig. 10.

(d.)Determine appropriate length and cut.

(e.)Connect to condensate trap.

2. Inducer Housing Drain Tube

a. Remove factory-installed cap and clamp from LOWER

inducer housing drain connection.

11

PLUG

AUXILIARY "J" BOX

CONDENSATE

TRAP

CAP

COLLECTOR BOX

TUBE EXTENSION

COLLECTOR BOX

EXTENSION

DRAIN TUBE

DRAIN TUBE

COUPLING

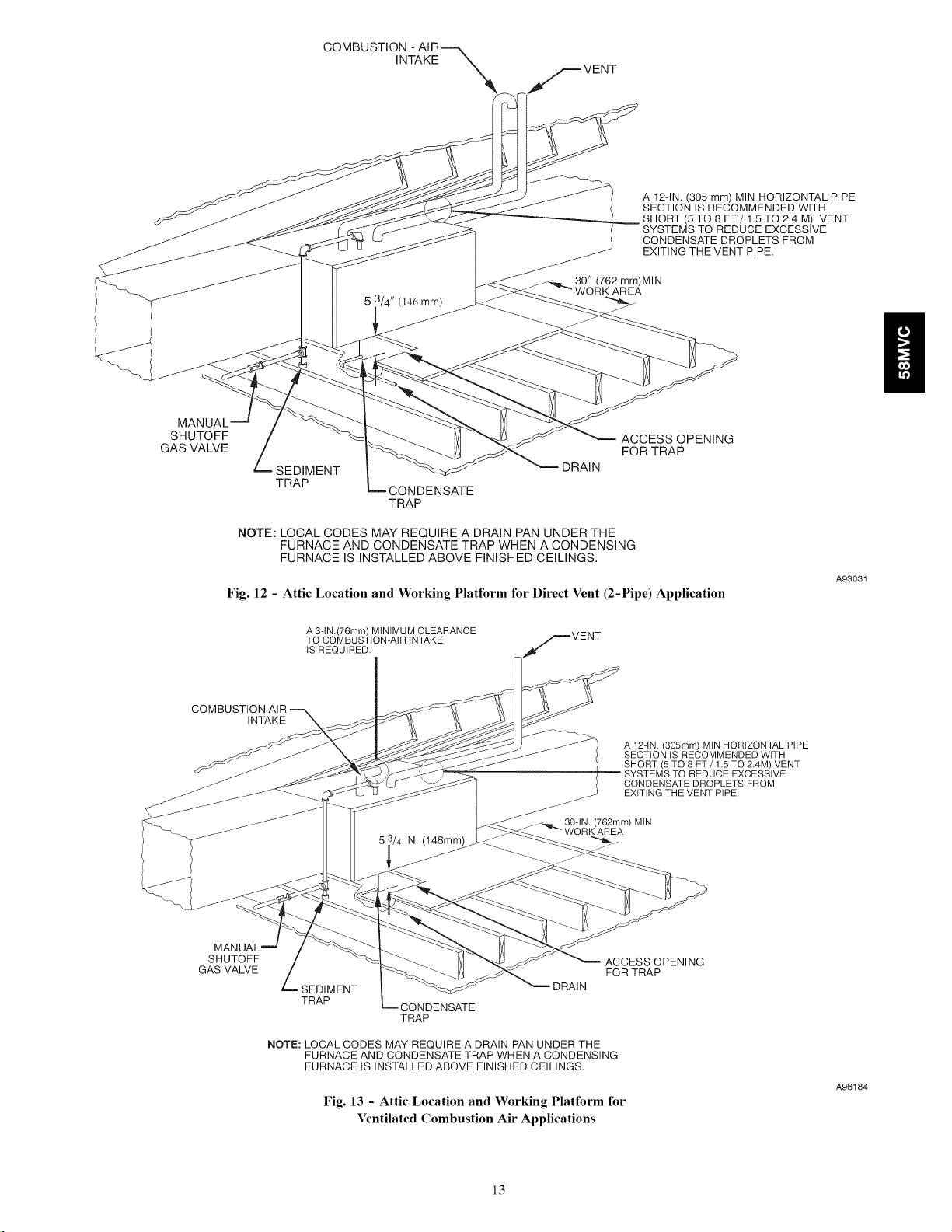

Fig. 11 - Horizontal Left Tube Configuration

COLLECTOR BOX

DRAIN TUBE (BLUE &

WHITE STRIPED)

COLLECTOR BOX

TUBE (GREEN)

INDUCER HOUSING

(MOLDED) DRAIN

TUBE (VIOLET)

COLLECTOR BOX

DRAIN TUBE (BLUE)

COLLECTOR BOX

TUBE (PINK)

A07278

b. Remove and discard UPPER (molded) inducer housing

drain tube which was previously connected to condensate

trap.

c. Install cap and clamp on UPPER inducer housing drain

connection where molded drain tube was removed.

d. Use inducer housing drain tube (violet label and factory-

supplied in loose parts bag) to connect LOWER inducer

housing drain connection to the condensate trap,

e. Connect inducer housing drain connection to condensate

trap.

(1.) Condensate Trap Located on Left Side of Casing

(a.)Determine appropriate length and cut.

(b.)connect tube to condensate trap.

(c.)Clamp tube to prevent any condensate leakage.

(2.) Condensate Trap Located on Right Side of Casing

(a.)Route inducer housing drain tube (violet label)

directly from inducer housing to condensate

trap.

(b.)Determine appropriate length and cut.

(c.)Connect tube to condensate trap.

(d.)Clamp tube to prevent any condensate leakage,

3. Relief Port Tube

Refer to Pressure Switch Tubing section for connection

procedure,

Condensate Trap Field Drain Attachment

Refer to Condensate Drain section for recommendations and

procedures.

Pressure Switch Tubing

One collector box pressure tube (pink label) is factory connected

to the pressure switch for use when furnace is installed in

UPFLOW or HORIZONTAL LEFT applications. The tube

MUST be disconnected and used or the condensate trap relief

port tube, The other collector box pressure tube (green label)

which was factory connected to the condensate trap relief port

connection MUST be connected to the pressure switch in

DOWNFLOW or HORIZONTAL RIGHT applications.

NOTE: See Fig. 9 or 10 or tube routing label on man furnace

door to check for proper connections.

Relocate tubes as described below.

1. Disconnect collector box pressure tube (pink label) at-

tached to pressure switch.

2. Extend collector box pressure tube (green label) which

was previously connected to condensate trap relief port

connection by splicing to small diameter tube (factory-

supplied in loose parts bag).

3. Connect collector box pressure tube (green label) to pres-

sure switch connection labeled COLLECTOR BOX.

4. Extend collector box pressure tube (pink label) which was

previously connected to pressure switch by splicing to re-

maining small diameter tube (factory-supplied in loose

parts bag).

5. Route this extended tube (pink label) to condensate trap

relief port connection.

6. Determine appropriate length, cut, and connect tube.

7. Clamp tube to relief port connection.

Condensate Trap Freeze Protection

Refer to Condensate Drain Protection section for

recommendations and procedures.

HORIZONTAL LEFT (SUPPLY-AIR DISCHARGE)

APPLICATIONS

A horizontal left furnace application is where furnace blower is

located to the right of combustion and controls section of furnace,

and conditioned air is discharged to the left,

12

MAN1

SHUTOFF

GAS VALVE

SEDIMENT

TRAP

COMBUSTION -

INTAKE

(I46 mm)

CONDENSATE

TRAP

30" (762 mm)MIN

)RK AREA

DRAIN

A 12qN. (305 mm) MIN HORIZONTAL PIPE

SECTION IS RECOMMENDED WITH

(5 TO 8 FT/1.5 TO 2.4 M) VENT

SYSTEMS TO REDUCE EXCESSIVE

CONDENSATE DROPLETS FROM

EXITING THE VENT PIPE.

ACCESS OPENING

FOR TRAP

g

NOTE: LOCAL CODES MAY REQUIRE A DRAIN PAN UNDER THE

FURNACE AND CONDENSATE TRAP WHEN A CONDENSING

FURNACE IS INSTALLED ABOVE FINISHED CEILINGS.

Fig. 12 - Attic Location and Working Platform for Direct Vent (2-Pipe) Application

A 3-IN (76mm) MINIMUM CLEARANCE

TO COMBUSTION-AIR INTAKE

IS REQUIRED.

COMBUSTI{

GAS VALVE

MAN[

SHUTOFF

INTAKE

(146mm)

SEDIMENT

TRAP

NOTE: LOCAL CODES MAY REQUIRE A DRAIN PAN UNDER THE

FURNACE AND CONDENSATE TRAP WHEN A CONDENSING

FURNACE IS INSTALLED ABOVE FINISHED CEILINGS.

Fig. 13 - Attic Location and Working Platform for

CONDENSATE

TRAP

Ventilated Combustion Air Applications

30qN. (762mm) MIN

WORK AREA

ACCESS OPENING

DRAIN

FOR TRAP

A 12-IN. (305mm) MIN HORIZONTAL PIPE

SECTION IS RECOMMENDED WITH

SHORT (5 TO 8 FT / 1.5 TQ 2AM) VENT

SYSTEMS TO REDUCE EXCESSIVE

CONDENSATE DROPLETS FROM

EXITING THE VENT PIPE.

A93031

A96184

13

g

PROPERTY DAMAGE

Failure to follow this caution may result in property

damage.

Local codes may require a drain pan under entire furnace

and condensate trap when a condensing furnace is used in

an attic application or over a finished ceiling.

NOTE: In Canada, installations shall be in accordance with

current NSCNGPIC and/or local codes.

Condensate Trap Location

The condensate trapnmst be removed from the factory-installed

blower shelf location and relocated in selected application

location as shown in Fig. 2 or 11.

To relocate condensate trap from the blower shelf to desired

location, perform the following:

1. Remove three tubes connected to condensate trap.

2. Remove trap from blower shelf by gently pushing tabs in-

ward and rotating trap.

3. Remove casing hole filler cap from casing hole. (See Fig.

2 or 11.)

4. Install casing hole filler cap (factory-supplied in loose

parts bag) into blower shelf hole where trap was removed.

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

injury or death.

Casing hole filler cap must be installed in blower shelf hole

when condensate trap is relocated to prevent combustion

products being drawn in from appliances in the equipment

room.

5, Install condensate trap into left-hand side casing hole by

inserting tube connection stubs through casing hole and

rotating until tabs snap into locking position.

6. Fill unused condensate trap casing holes with plastic filler

caps (factory-supplied in loose parts bag).

Condensate Trap _bing

NOTE: See Fig. 11 or tube routing label on main furnace door

to check for proper connections.

1. Collector Box Drain Tube

a. Install drain tube coupling (factory-supplied in loose

parts bag) into collector box drain tube (blue label) which

was previously connected to condensate trap.

b. Connect large diameter drain tube and clamp (factory-

supplied in loose parts bag) to drain tube coupling, ex-

tending collector box drain tube.

c. Route extended tube (blue label) to condensate trap and

cut to appropriate length.

d. Clamp tube to prevent any condensate leakage.

2. Inducer Housing Drain Tube

(a.)Remove and discard LOWER (molded) inducer

housing drain tube which was previously con-

nected to condensate trap.

(b.)Use inducer housing drain extension tube (violet

label and factory-supplied in loose parts bag) to

connect LOWER inducer housing drain connec-

tion to condensate trap.

(c.)Deternfine appropriate length, cut and connect

tube.

(d.)Clamp tube to prevent any condensate leakage.

3. Relief Port Tube

a. Extend collector box tube (green label) which was previ-

ously connected to condensate trap by splicing to small

diameter tube (factory-supplied in loose parts bag).

b. Route extended collector box pressure tube to relief port

connection on condensate trap.

c. Deternfine appropriate length, cut, and connect tube.

d. Clamp tube to prevent any condensate leakage.

Condensate Trap Field Drain Attachment

Refer to Condensate Drain section for recommendations and

procedures.

Pressure Switch Tubing

The LOWER collector box pressure tube (pink label) is factory

connected to the High Pressure Switch for use when furnace is

installed in UPFLOW applications. This tube MUST be

disconnected, extended rerouted, and then reconnected to the

pressure switch in HORIZONTAL LEFT applications for 060

and 080 heating input furnaces.

NOTE: See Fig. 11 or tube routing label on main furnace door

to check for proper connections.

Modify tube as described below.

1. Disconnect collector box pressure tube (pink label) at-

tached to High Pressure Switch.

2. Use smaller diameter tube (factory-supplied in loose parts

bag) to extend tube disconnected in Item 1.

3. Route extended tube:

a. Behind inducer housing.

b. Between blower shelf and inducer housing.

4. Deternfine appropriate length, cut, and reconnect tube to

High Pressure Switch connections labeled COLLECTOR

BOX.

Condensate Trap Freeze Protection

Refer to Condensate Drain Protection section for

recommendations and procedures.

Construct a Working Platform

Construct working platform where all required furnace clearances

are met, (See Fig. 3 and 12 or 13 0

[]NIT OPERATION HAZARD

Failure to follow this caution may result in internfittent unit

operation.

The condensate trap MUST be installed below furnace. See

Fig. 6 for dimensions. The drain connection to condensate

trap must also be properly sloped to an open drain.

NOTE: A 12-in. (305 ram) nfininmm offset pipe section is

recommended with short (5 to 8 ft. or 1.5M to 2.4M) vent

systems. This recommendation is to reduce excessive condensate

droplets from exiting the vent pipe. (See Fig. 12, 13, or 44.)

14

HORIZONTALRIGHT

(SUPPLY-AIR DISCHARGE) APPLICATIONS

A horizontal right furnace application is where furnace blower is

located to the left of combustion and controls section of furnace,

and conditioned air is discharged to the right.

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property

damage.

Local codes may require a drain pan under entire furnace

and condensate trap when a condensing furnace is used in

an attic application or over a finished ceiling.

NOTE: In Canada, installations shall be in accordance with

current NSCNGPIC and/or local codes.

NOTE: The auxiliary junction box (J-box) MUST be relocated

to opposite side of furnace casing. (See Fig. 14.) See Electrical

Connection section for J-box relocation.

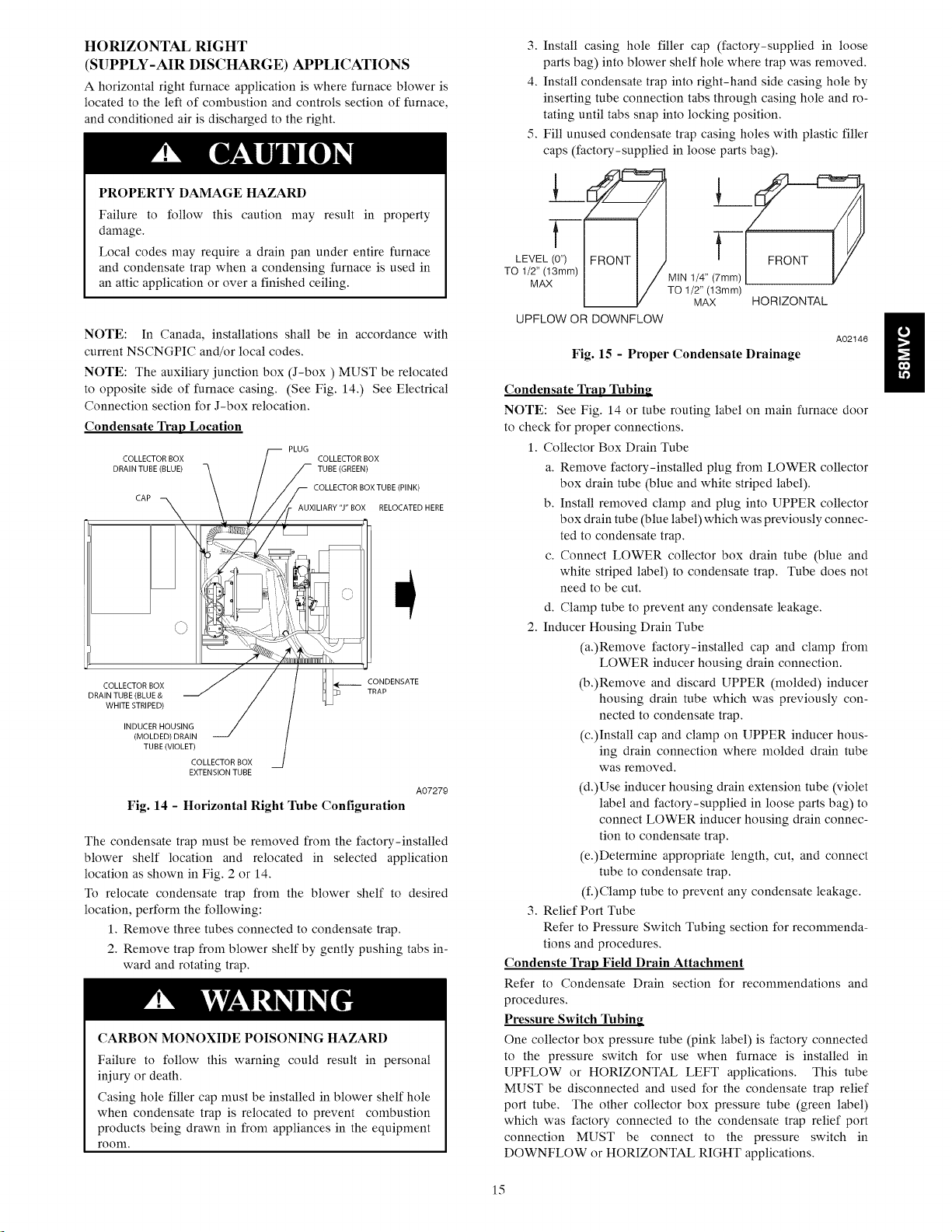

Condensate Trap Location

COLLECTOR BOX COLLECTOR BOX

DRAIN TUBE (BLUE) TUBE (GREEN)

CAP

COLLECTOR BOX [J _ CONDENSATE

DRAIN TUBE (BLUE & t]_]3 TRAP

WHITE STRIPED)

INDUCER HOUSING

(MOLDED) DRAIN

TUBE (VIOLET)

COLLECTOR BOX

EXTENSION TUBE

Fig. 14 - Horizontal Right 1hbe Configuration

The condensate trapmust be removed from the factory-installed

blower shelf location and relocated in selected application

location as shown in Fig. 2 or 14.

To relocate condensate trap from the blower shelf to desired

location, perform the following:

1. Remove three tubes connected to condensate trap.

2. Remove trap from blower shelf by gently pushing tabs in-

ward and rotating trap.

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

injury or death.

Casing hole filler cap must be installed in blower shelf hole

when condensate trap is relocated to prevent combustion

products being drawn in from appliances in the equipment

room.

PLUG

COLLECTOR BOX TUBE (PINK)

AUXILIARY "J" BOX RELOCATED HERE

A07279

3. Install casing hole filler cap (factory-supplied in loose

parts bag) into blower shelf hole where trap was removed.

4. Install condensate trap into right-hand side casing hole by

inserting tube connection tabs through casing hole and ro-

tating until tabs snap into locking position.

5. Fill unused condensate trap casing holes with plastic filler

caps (factory-supplied in loose parts bag).

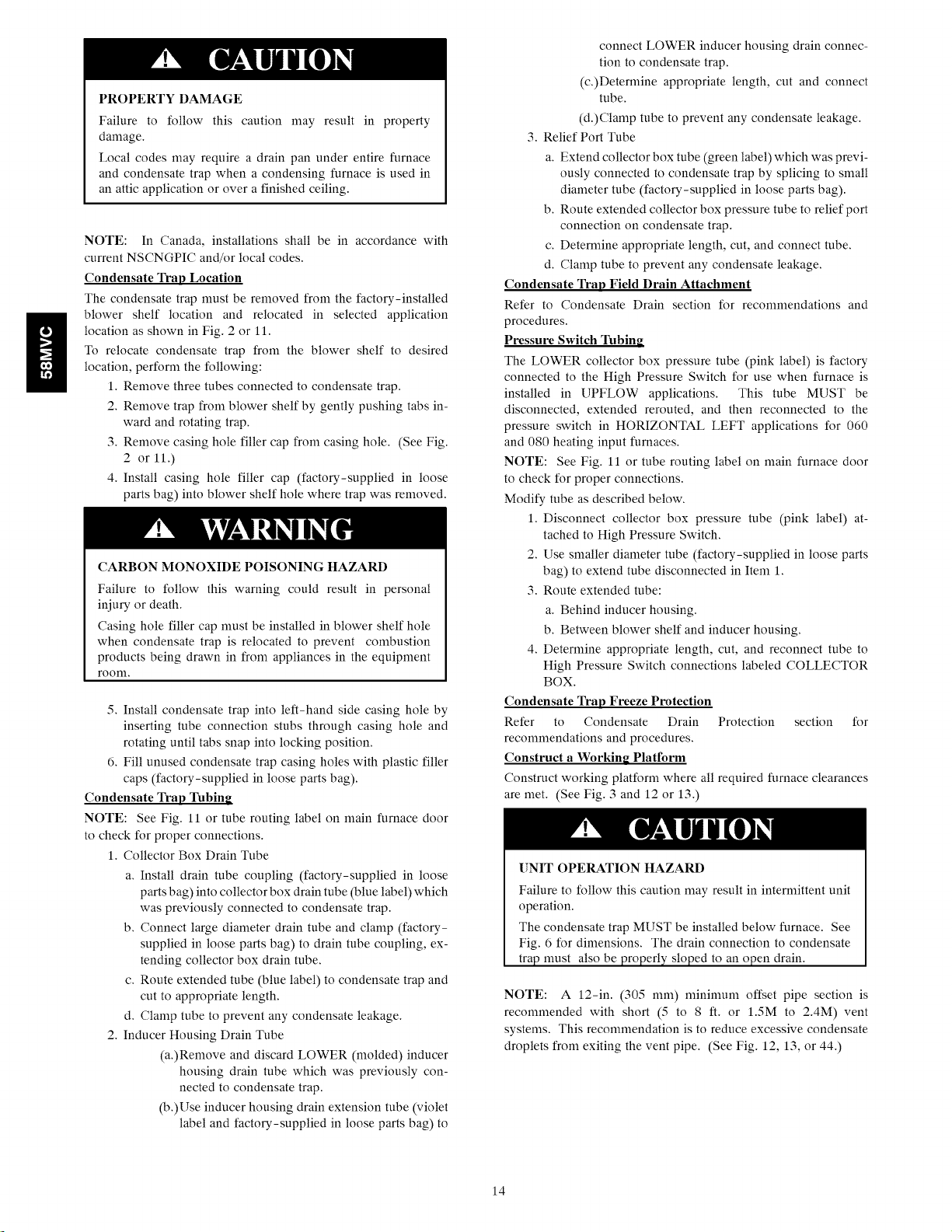

MIN I/4" (7[l_Lm _

TO 1/2" (13mm)

MAX HORIZONTAL

UPFLOW OR DOWNFLOW

A02146

Fig. 15 - Proper Condensate Drainage

Condensate Trap Tubing

NOTE: See Fig. 14 or tube routing label on main furnace door

to check for proper connections.

1. Collector Box Drain Tube

a. Remove factory-installed plug from LOWER collector

box drain tube (blue and white striped label).

b. Install removed clamp and plug into UPPER collector

box drain tube (blue label) which was previously connec-

ted to condensate trap.

c. Connect LOWER collector box drain tube (blue and

white striped label) to condensate trap. Tube does not

need to be cut.

d. Clamp tube to prevent any condensate leakage.

2. Inducer Housing Drain Tube

(a.)Remove factory-installed cap and clamp from

LOWER inducer housing drain connection.

(b.)Remove and discard UPPER (molded) inducer

housing drain tube which was previously con-

nected to condensate trap.

(c.)Install cap and clamp on UPPER inducer hous-

ing drain connection where molded drain tube

was removed.

(d.)Use inducer housing drain extension tube (violet

label and factory-supplied in loose parts bag) to

connect LOWER inducer housing drain connec-

tion to condensate trap.

(e.)Deternfine appropriate length, cut, and connect

tube to condensate trap.

(f.)Clamp tube to prevent any condensate leakage.

3. Relief Port Tube

Refer to Pressure Switch Tubing section for recommenda-

tions and procedures.

Condenste Trap Field Drain Attachment

Refer to Condensate Drain section for recommendations and

procedures.

Pressure Switch 1hbing

One collector box pressure tube (pink label) is factory connected

to the pressure switch for use when furnace is installed in

UPFLOW or HORIZONTAL LEFT applications. This tube

MUST be disconnected and used for the condensate trap relief

port tube, The other collector box pressure tube (green label)

which was factory connected to the condensate trap relief port

connection MUST be connect to the pressure switch in

DOWNFLOW or HORIZONTAL RIGHT applications,

15

NOTE:SeeFig.14ortuberoutinglabelonmainfurnacedoor

tocheckforproperconnections.

Relocatetubesasdescribedbelow.

1.Disconnectcollectorboxpressuretube(pinklabel)at-

tachedtopressureswitch.

2.Extendcollectorboxpressuretube(greenlabel)which

waspreviouslyconnectedtocondensatetrapreliefport

connectionbysplicingtosmalldiametertube(factory-

suppliedinloosepartsbag.)

3.Connectcollectorboxpressuretube(greenlabel)topres-

sureswitchconnectionlabeledCOLLECTORBOX.

4.Useremainingsmalldiametertube(factory-suppliedin

loosepartsbag)toextendcollectorboxpressuretube

(pinklabel)whichwaspreviouslyconnectedtopressure

switch.

5.Routethisextendedtube(pinklabel)tocondensatetrap

reliefportconnection.

6.DetermineappropriateLength,cut,andconnecttube.

7.Clamptubetoreliefportconnection.

Condensate Trap Freeze Protection

Refer to condensate Drain Protection section for

recommendations and procedures.

Construct a Working Platform

Construct working platform where all required furnace clearances

are met. (See Fig. 3 and 12 or 13.)

UNIT OPERATION HAZARD

Failure to follow this caution may result in intermittent unit

operation.

The condensate trap MUST be installed below furnace. See

Fig. 6 for dimensions. The drain connection to condensate

trap must also be properly sloped to an open drain.

• not be installed directly on any combustible material

other than wood flooring (refer to SAFETY

CONSIDERATIONS).

• be located so combustion-air and vent pipe maximum

lengths are not exceeded. Refer to Table 7.

• be located where available electric power and gas sup-

plies meet specifications on the furnace rating plate.

• be attached to an air distribution system and be located

as close to the center of the distribution system as pos-

sible. Refer to Air Ducts section.

• be provided with ample space for servicing and clean-

ing. Always comply with minimum fire protection

clearances shown on the furnace clearance-to-com-

bustibles label. (See Fig. 3.)

This furnace may be located in a confined space without special

provisions for dilution or ventilation air.

NOTE: For upflow/downflow applications install furnace so that

it is level or pitched and forward within 1/2-in. (13 ram) for

proper furnace operation. For horizontal applications pitch

1/4-in. (6 mm) n_ininmm to 1/2-in. (13 mm) n_axinmm forward

to ensure proper condensate drainage from secondary heat

exchangers. (See Fig. 15.)

When a furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space containing the

furnace, the return air shall also be handled by ducts sealed to

furnace casing. The ducts terminate outside the space containing

the furnace to ensure there will not be a negative pressure

condition within equipment room or space.

NOTE: A 12-in. (305 ram) n_ininmm offset pipe section is

recommended with short (5 to 8 ft. or 1.5M to 2.4M) vent

systems. This recommendation is to reduce excessive condensate

droplets from exiting the vent pipe. (See Fig. 12, 13, or 44.)

LOCATION

General

This furnace nmst

• be installed so the electrical components are protected

from water.

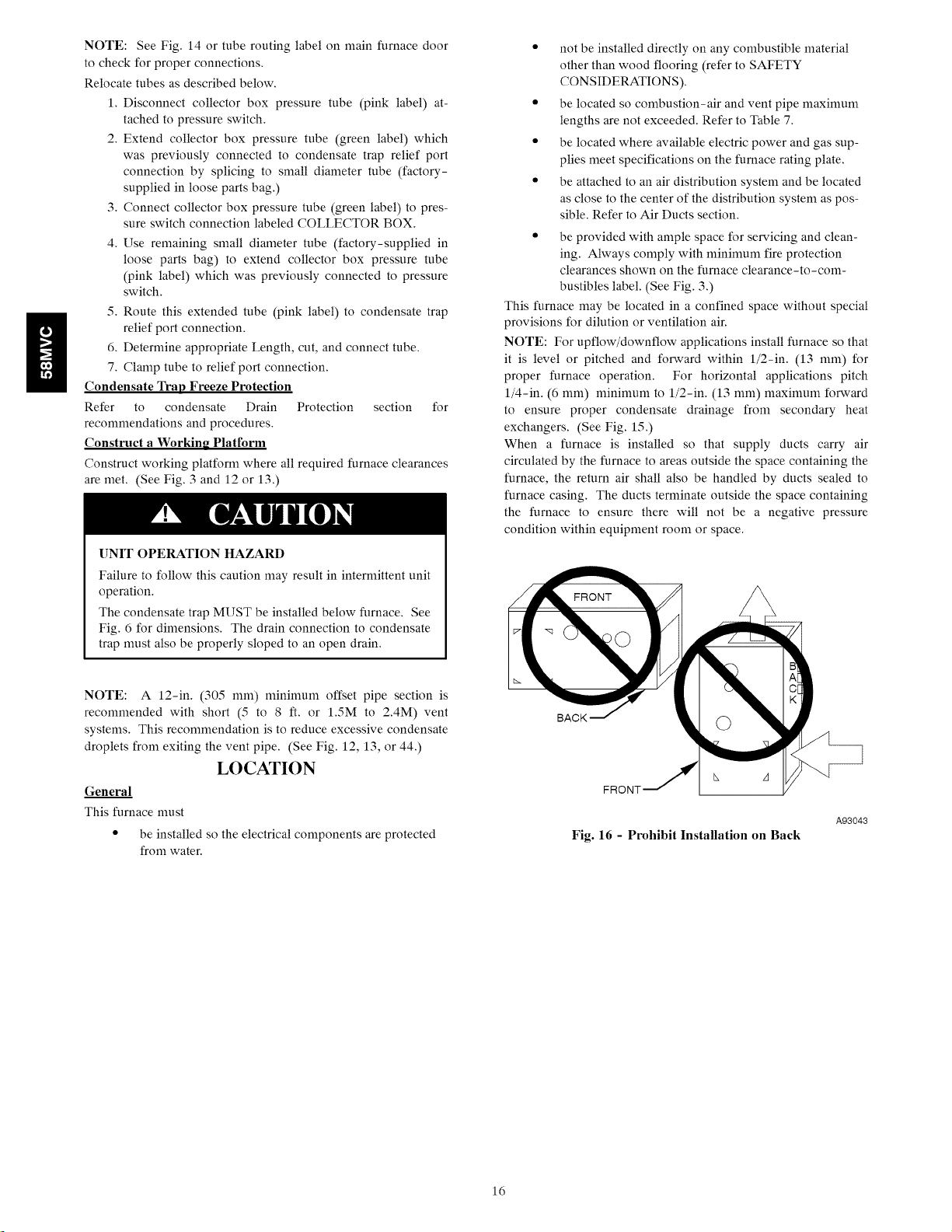

BACK

A93043

Fig. 16 - Prohibit Installation on Back

16

[]NIT DAMAGE HAZARD

This gas furnace may be used for construction heat

provided that:

-The furnace is permanently installed with all electrical

wiring, piping, air filters, venting and ducting installed

according to these installation instructions. A return air duct

is provided, sealed to the furnace casing, and ternfinated

outside the space containing the furnace. This prevents a

negative pressure condition as created by the circulating air

blower, causing a flame rollout and/or drawing combustion

products into the structure.

-The furnace is controlled by a thermostat. It may not be

"hot wired" to provide heat continuously to the structure

without thermostatic control.

-Clean outside air is provided for combustion. This is to

nfininfize the corrosive effects of adhesives, sealers and

other construction materials. It also prevents the

entrainment of drywall dust into combustion air, which can

cause fouling and plugging of furnace components.

-The temperature of the return air to the furnace is

maintained between 55°F (13°C) and 80°F (27°C), with

no evening setback or shutdown. The use of the furnace

while the structure is under construction is deemed to be

internfittent operation per our installation instructions.

-The air temperature rise is within the rated rise range on

the furnace rating plate, and the firing rate has been set to

the nameplate value.

-The filters used to clean the circulating air during the

construction process nmst be either changed or thoroughly

cleaned prior to occupancy.

-The furnace, ductwork and filters are cleaned as necessary

to remove drywall dust and construction debris from all

HVAC system components after construction is completed.

-After construction is complete, verify furnace operating

conditions including ignition, input rate, temperature rise

and venting, according to the manufacturer's instructions.

FIRE OR DEATH HAZARD

Failure to follow this warning could result in property

damage, personal injury, or death.

Do not install furnace on its back. (See Fig. 16.) Safety

control operation will be adversely affected. Never connect

return-air ducts to back of furnace.

The furnace and its return air system shall be designed and

installed so that negative pressure created by the air circulating

fan cannot affect another appliance's combustion air supply or act

to nfix products of combustion with circulating air, and that the

air circulating fan of the furnace, if installed in an enclosure

communicating with another fuel-burning appliance not of the

direct-vent type, shall be operable only when any door or panel

covering an opening in the furnace fan compartment or in a return

air plenum on ducts is in the closed position.

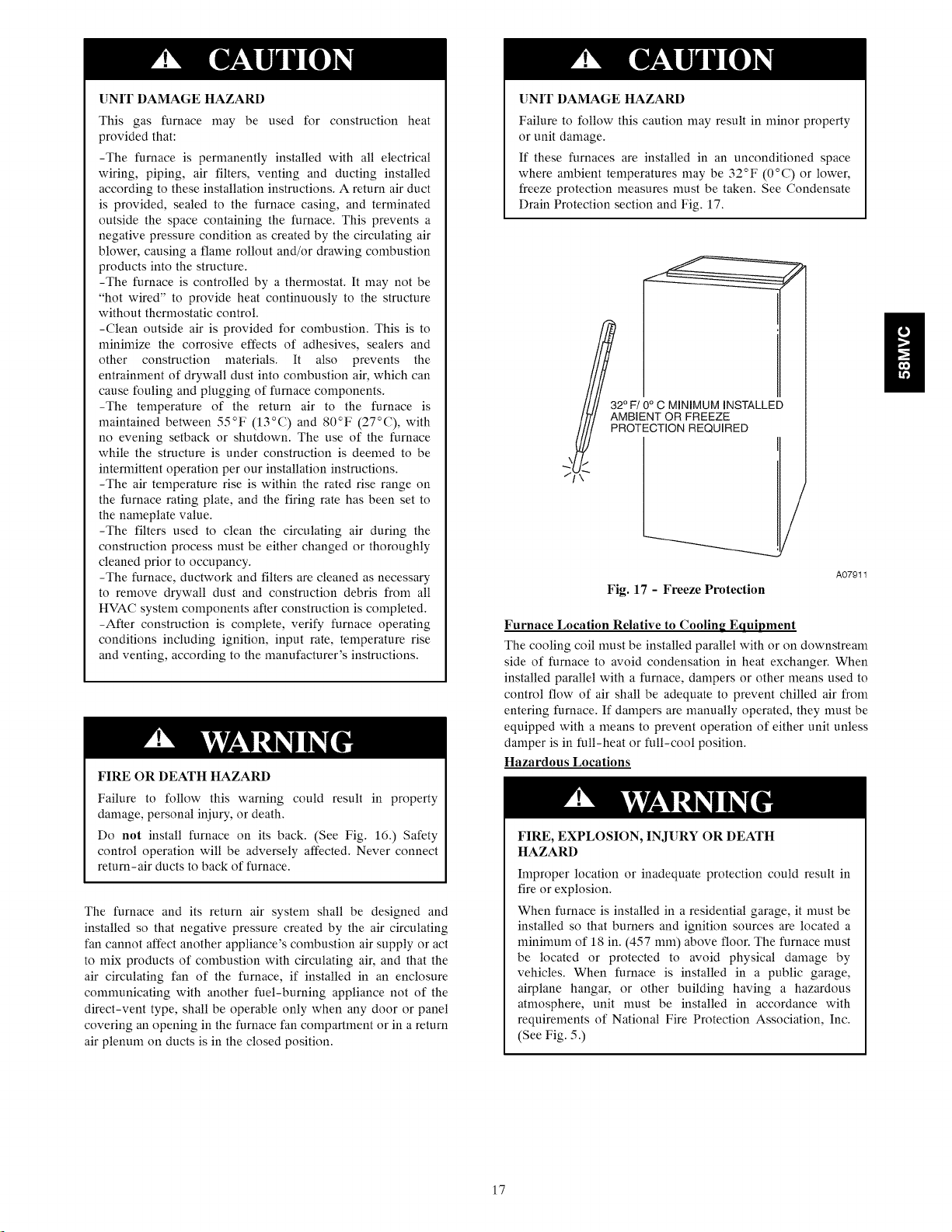

UNIT DAMAGE HAZARD

Failure to follow this caution may result in nfinor property

or unit damage.

If these furnaces are installed in an unconditioned space

where ambient temperatures may be 32°F (0°C) or lower,

freeze protection measures must be taken. See Condensate

Drain Protection section and Fig. 17.

g

_3/ff/ 2MFfONCg4NFIMgMZI#STALLED

_ PROTECTION REQUIRED

/

A07911

Fig. 17 - Freeze Protection

Furnace Location Relative to Cooling Equipment

The cooling coil must be installed parallel with or on downstream

side of furnace to avoid condensation in heat exchanger. When

installed parallel with a furnace, dampers or other means used to

control flow of air shall be adequate to prevent chilled air from

entering furnace. If dampers are manually operated, they nmst be

equipped with a means to prevent operation of either unit unless

damper is in full-heat or full-cool position.

Hazardous Locations

FIRE, EXPLOSION, INJURY OR DEATH

HAZARD

Improper location or inadequate protection could result in

fire or explosion,

When furnace is installed in a residential garage, it nmst be

installed so that burners and ignition sources are located a

nfininmm of 18 in. (457 ram) above floor. The furnace nmst

be located or protected to avoid physical damage by

vehicles. When furnace is installed in a public garage,

airplane hangar, or other building having a hazardous

atmosphere, unit must be installed in accordance with

requirements of National Fire Protection Association, Inc.

(See Fig. 5.)

17

(8ram)

and forth until it breaks off. Be careful of sharp edges. (See Fig.

22.)

g

1 3/4

(44ram)

1 3/4"

(44ram)

(8ram)

5/16"

(8mm)

(44mm) 1 3/4"

(44mm) 1

A89014

Fig. 18 - Leveling Legs

INSTALLATION

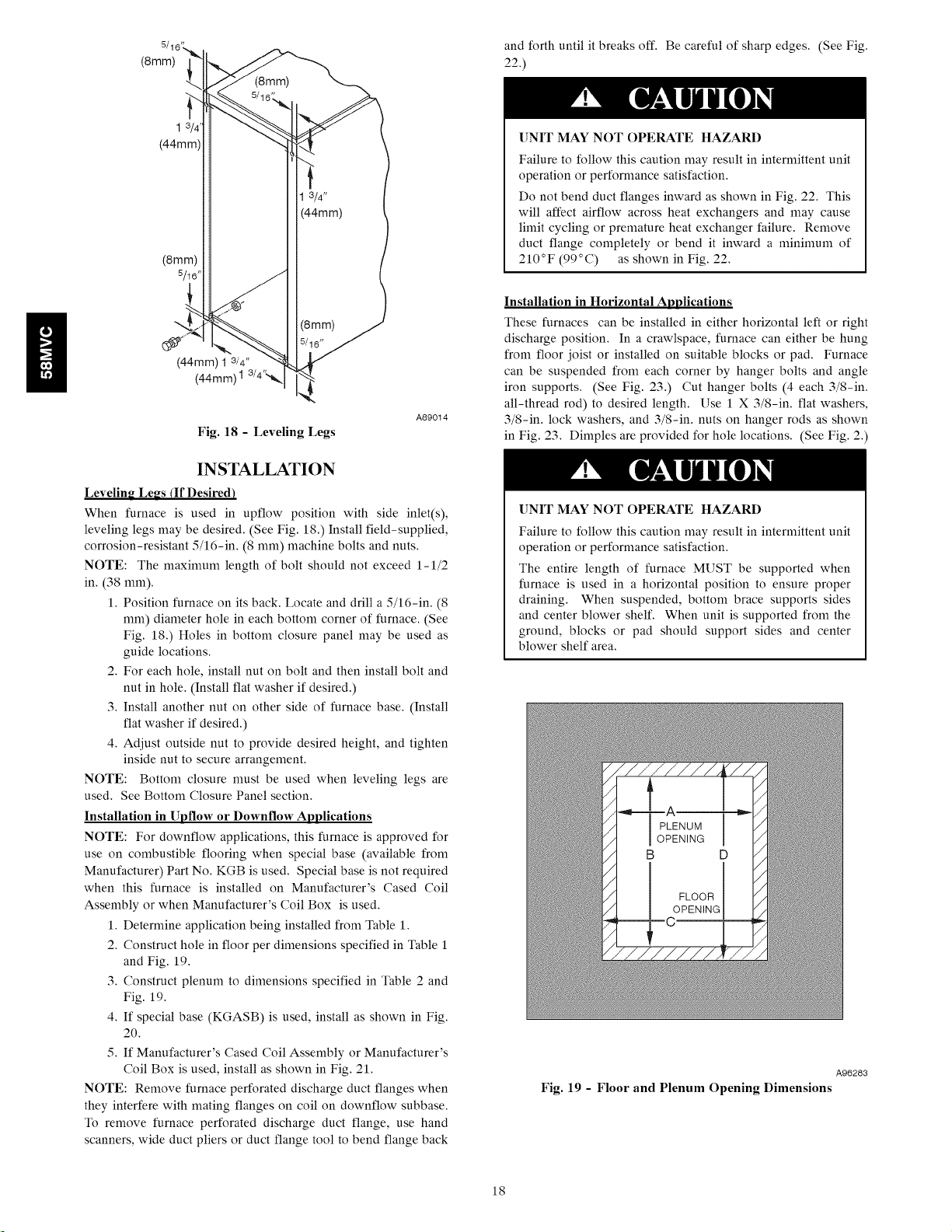

Levelin_ Le_s (If Desired)

When furnace is used in upflow position with side inlet(s),

leveling legs may be desired. (See Fig. 18.) Install field-supplied,

corrosion-resistant 5/16-in. (8 ram) machine bolts and nuts.

NOTE: The maximum length of bolt should not exceed 1-1/2

in. (38 mm).

1. Position furnace on its back. Locate and drill a 5/16-in. (8

ram) diameter hole in each bottom corner of furnace. (See

Fig. 18.) Holes in bottom closure panel may be used as

guide locations.

2. For each hole, install nut on bolt and then install bolt and

nut in hole. (Install flat washer if desired.)

3. Install another nut on other side of furnace base. (Install

flat washer if desired.)

4. Adjust outside nut to provide desired height, and tighten

inside nut to secure arrangement.

NOTE: Bottom closure nmst be used when leveling legs are

used. See Bottom Closure Panel section.

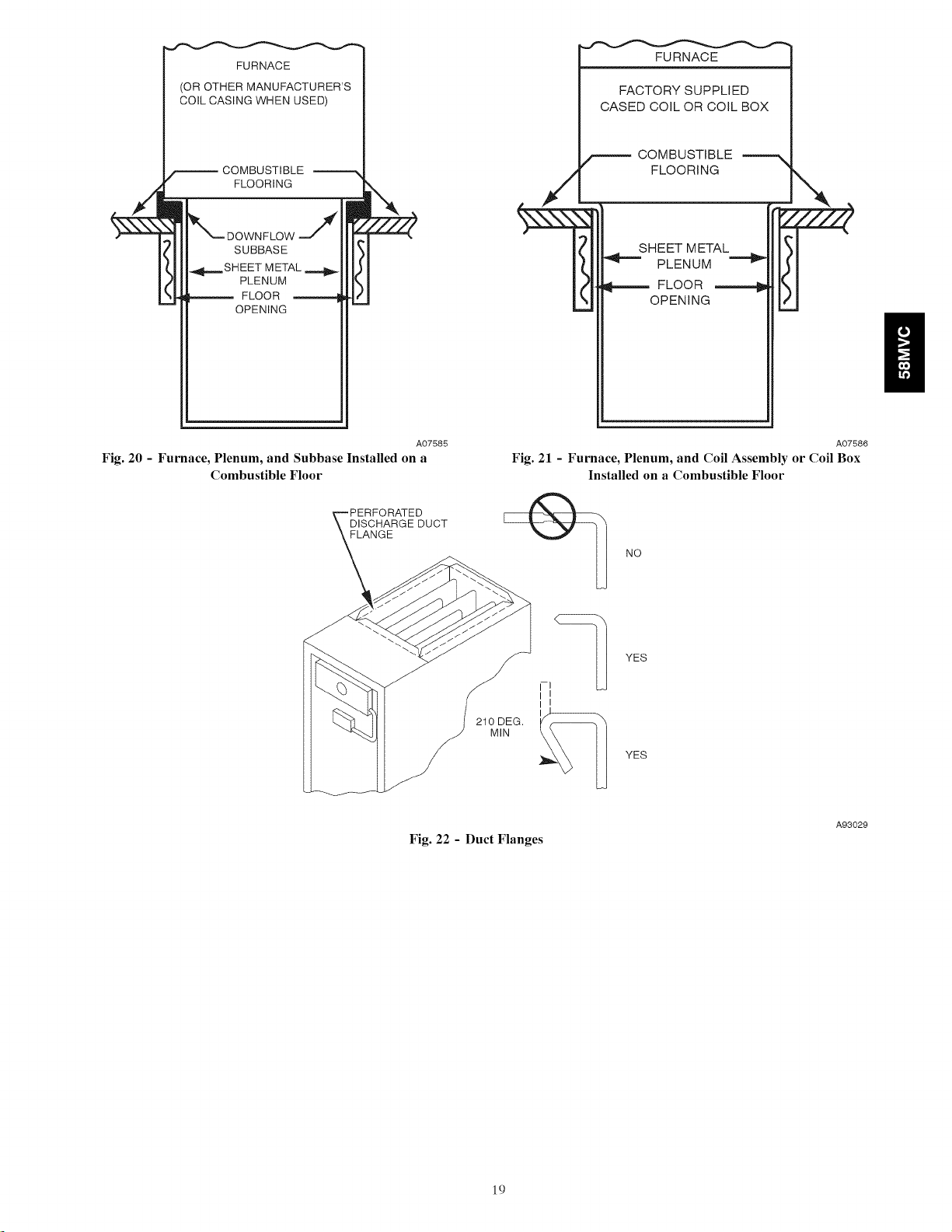

Installation in Upflow or Downflow Applications

NOTE: For downflow applications, this furnace is approved for

use on combustible flooring when special base (available from

Manufacturer) Part No. KGB is used. Special base is not required

when this furnace is installed on Manufacturer's Cased Coil

Assembly or when Manufacturer's Coil Box is used.

1. Determine application being installed from Table 1.

2. Construct hole in floor per dimensions specified in Table 1

and Fig. 19.

3. Construct plenum to dimensions specified in Table 2 and

Fig. 19.

4. If special base (KGASB) is used, install as shown in Fig.

20.

5. If Manufacturer's Cased Coil Assembly or Manufacturer's

Coil Box is used, install as shown in Fig. 21.

NOTE: Remove furnace perforated discharge duct flanges when

they interfere with mating flanges on coil on downflow subbase.

To remove furnace perforated discharge duct flange, use hand

scanners, wide duct pliers or duct flange tool to bend flange back

[]NIT MAY NOT OPERATE HAZARD

Failure to follow this caution may result in intermittent unit

operation or performance satisfaction.

Do not bend duct flanges inward as shown in Fig. 22. This

will affect airflow across heat exchangers and may cause

limit cycling or premature heat exchanger failure. Remove

duct flange completely or bend it inward a minimum of

210°F (99°C) as shown in Fig. 22.

Installation in Horizontal Applications

These furnaces can be installed in either horizontal left or right

discharge position. In a crawlspace, furnace can either be hung

from floor joist or installed on suitable blocks or pad. Furnace

can be suspended from each corner by hanger bolts and angle

iron supports. (See Fig. 23.) Cut hanger bolts (4 each 3/8-in.

all-thread rod) to desired length. Use 1 X 3/8-in. flat washers,

3/8-in. lock washers, and 3/8-in. nuts on hanger rods as shown

in Fig. 23. Dimples are provided for hole locations. (See Fig. 2.)

[]NIT MAY NOT OPERATE HAZARD

Failure to follow this caution may result in intermittent unit

operation or performance satisfaction.

The entire length of furnace MUST be supported when

furnace is used in a horizontal position to ensure proper

draining. When suspended, bottom brace supports sides

and center blower shelf. When unit is supported from the

ground, blocks or pad should support sides and center

blower shelf area.

A96283

Fig. 19 - Floor and Plenum Opening Dimensions

18

FURNACE

(OR OTHER MANUFACTURER'S

COIL CASING WHEN USED)

FURNACE

FACTORY SUPPLIED

CASED COIL OR COIL BOX

COMBUSTIBLE

FLOORING

SUBBASE

SHEET METAL

PLENUM

FLOOR

OPENING

Fig. 20 - Furnace, Plenum, and Subbase Installed on a

Combustible Floor

DISCHARGE DUCT

FLANGE

A07585

/_ COMBUSTIBLE

FLOORING

SHEET METAL

PLENUM

FLOOR -_

OPENING

A07586

Fig. 21 - Furnace, Plenum, and Coil Assembly or Coil Box

Installed on a Combustible Floor

NO

210 DEG.

MIN

Fig. 22 - Duct Flanges

YES

YES

A93029

19

Loading...

Loading...