Carrier 58DP User Manual

58DP,DR

HEATING A COOLING

Downflow Gas-Fired Natural-Draft Furnaces

Installation, Start-Up and Service

Instructions

NOTE: Read the entire instructions before starting the

installation.

NOTE: The Energy Guide tag can be removed from the fur

nace when the installation is complete.

INTRODUCTION

Before installing the furnace, refer to “Procedures for

Natural-Draft Gas-Fired Furnaces” (packaged with the

equipment) for information concerning combustion, venting,

piping, and other standard installation practices. Further

reference is made to the current edition of the National Fuel

Gas Code NFPA No. 54, T1A-54-1984-1/ANSI Z223.1-1984,

Z223.1a-1987.

Each furnace is shipped from the factory completely assem

bled with multispeed direct-drive blower and wired ready for

downflow indoor heating installation only. AU sizes feature

a printed-circuit board control center with easy-to-read, lowvoltage terminal strip to ensure proper connections.

A CAUTION

Do not install furnace in a damp, corrosive, or contami

nated atmosphere. Make sure all combustion and circu

lating air requirements listed in “Procedures for

Natural-Draft Gas-Fired Furnaces” are adhered to, in

addition to all local codes and ordinances.

Do not use this furnace during construction when adhe

sives, sealers and/or new carpets are being installèd. If

the furnace is required during construction, use clean

outside air for combustion and ventilation. Compoxmds

of chlorine and fluorine when burned with combustion

air form acids which will cause corrosion of the heat

exchangers and metal vent system. Some of these com

pounds are paneling and dry wall adhesives, paints,

thinners, masonry cleaning materials, and many other

solvents commonly used in the construction process.

The design of the downflow gas-flred furnace is A.G.A. cer

tified for installation on noncombustible flooring. The fur

nace may be installed on combustible flooring when

installed with the accessory floor base. This furnace is for

installation in alcoves, basements, closets, or utility rooms.

This furnace line is not A.G.A. design certified for installa

tion in a mobile home, recreation vehicle, or outdoors.

Installation comprises the following:

*1. Inspection

*11. Location, Ventilation, and Air for Combustion

*III. Gas Piping

*IV. Venting

V. Supply-Air Plenum Installation

VI. Electrical

EFFICIENCY

RATING

CERTIFIED

a

Sizes 050 075 thru 150

Sides—Single-Wall Vent 1 1

Back 0 0

Top of Plenum

Vent Connector—Single-Wall 6 6

Front-Combustion Air* * 6 6

*The 6-inch front clearance is needed for combustion-air entry and

drafthood reiief.

ama

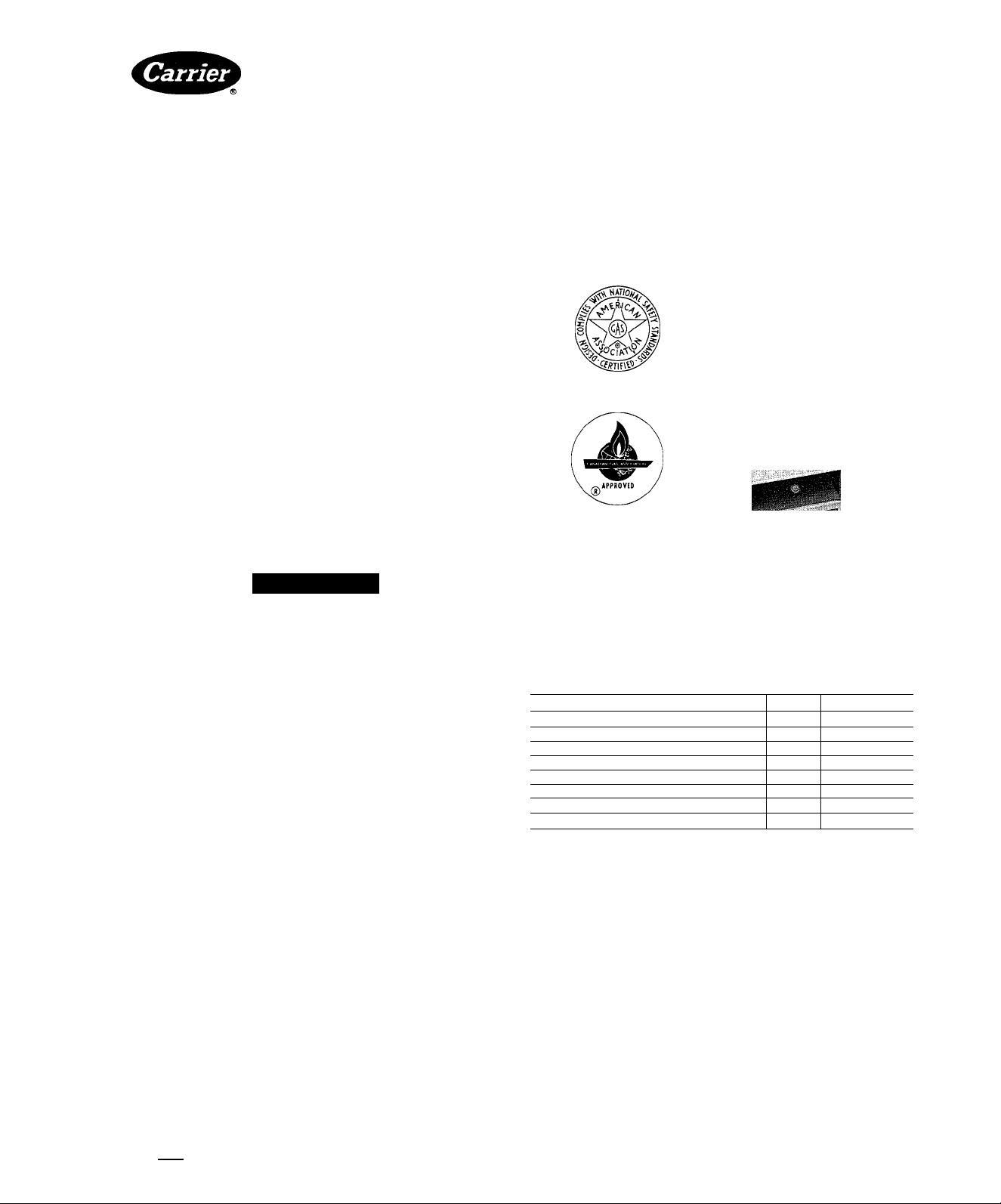

Fig. 1—Model 58DP

Table 1—Clearances (In Inches)

Type-BI Double-Wall Vent 0 1

1 1

Type-B1 Double-Wall 1 1

Service 30 30

A78593

VII. Sequence of Operation

VIII. Filter

IX. Startup and Adjustment

X. Care and Maintenance

*To perform these sections (or installation steps), refer to

the appropriate sections of “Procedures for Natural-Draft

Gas-Fired Furnaces” booklet packaged with this unit.

For accessory installation details, refer to the applicable

installation literature.

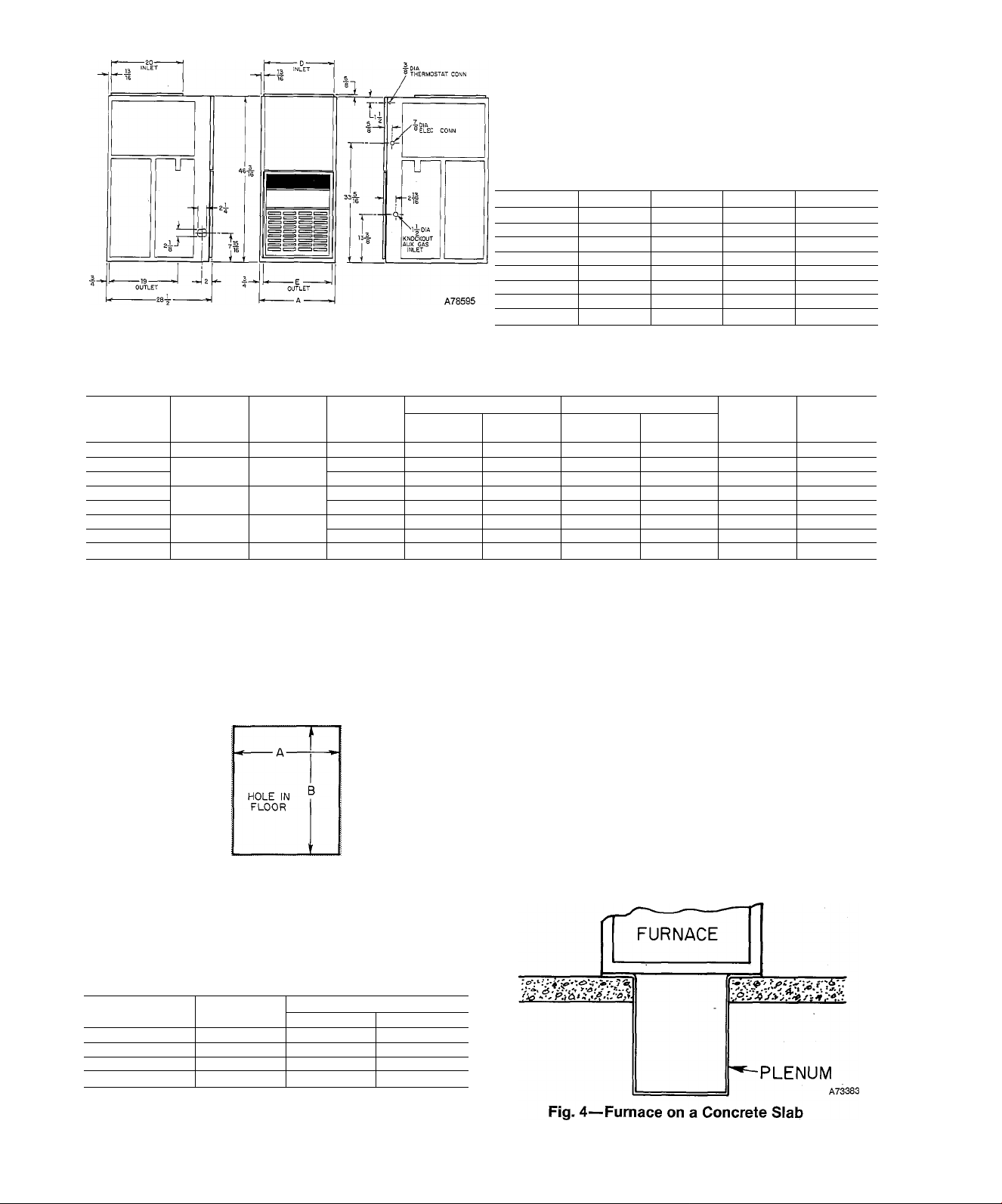

V. SUPPLY-AIR PLENUM INSTALLATION

A. Installation on a concrete slab

1. See Fig. 2 for dimensions and location of supply-air

opening in furnace bottom.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

'' I ^ PC 101 Cataiog No. 535-871 Printed in U.S.A. Form 58DP,DR-2SI 11/87

Tab I6al8a

Pgl

Repiaces: 58DP,DR-1Si

Table 2—Dimensions (in Inches)

Size Vent

050-BA

075-AA

075-BA

100-AA 17’¿

100-BA

125-AA 21

125-BA

150-BA

14^16 12^,6

M'h

M'k

177^

21

24’¿

15%

157s

15%

15%

19%

19%

22'%s

12-’-’/i6

16 4

16 4

16 5

16

19% 5

19%

23

Fig. 2—Dimensionai Drawing

Table 3—Ratings and Performance*

Size

050-BA

075-AA

075-BA

100-AA

100-BA

125-AA

125-AA

150-BA

*The above ratings are certified for aititudes to 2000 ft. For elevators above 2000 ft, reduce ratings 4% for each 1000 ft above sea level. Refer to'

National Fuel Gas Code Table F4.

fDetermined by U.S. Government tests.

ijrDeduct 1000 Btuh for Model 58DR.

Input

Btuh

50,000 39,000f

75,000 58,000

100,000 78,000t

125,000 97,000f

150,000

Capacity

Btuht

116,000f

Temp

Rise

Range

45—75 0.50

70—100 0.12

45—75 0.50 895

70—100 0.20 850

60—90 0.50

70—100 0.20

60—90

55—85 0.50 1535

Ext Static

Pressure

0.50

Heating

CFM

Ext Static

600 0.5 800 %-SP

630

960 0.5 1630 %-PSC

1050

1195 0.5 1620 'k-PSC 187

Cooling Motor

Pressure

— —

0.5 1255 %-SP 157

— —

0.5 2075 %-PSC

CFM

—

HP&

Type

7io-SP

%-SP

'h-SP

2. Construct hole in floor per dimensions in Fig. 3 and

Table 4.

3. Place plenum and furnace as shown in Fig. 4.

B. Installation on a combustible floor

1. Read Installation Instructions packaged with acces

sory combustible floor base.

2. Cut and frame hole in floor per dimensions hsted in

Installation Instructions packaged with combustible

floor base. If this requires cutting of a floor joist, tie

ends of cut joist into adjacent joists so that proper

floor support win be maintained.

3. Assemble and install combustible floor base per

instructions packaged with base.

4. When completed, combustible floor base, plenum, and

furnace (or coü casing when used) should be installed as

shown in Fig. 6.

A73382

4

5

5

6

Approx

Shipping

Weight

129

148

163

170

187

227

Fig. 3—Floor Opening for

Concrete Slab

Table 4—Opening Dimensions

Furnace Casing

Width

14%6

17%

21

24%

♦These dimensions apply when a Model 28RC or RD Evaporator Coil

casing is to be installed.

A B

13% 19%

16%6

19% 19%

23%6

Heat-Only Heat/Cool*

19%

19%

19%6

19%s

19%6

19%6

—2—

Fig. 5—Combustible Floor Base

A WARNING

The cabinet must have an uninterrupted or unbroken

ground according to National Electrical Code, ANSI/

NFPA 70-1987, or local codes to minimize personal

injury if an electrical fault should occur. This may con

sist of electrical wire or conduit approved for electrical

ground when installed in accordance with existing elec

trical codes. Do not use gas piping as an electrical

ground. A failure to adhere to this warning can result in

an electrical shock, fire, or death.

If line-voltage wiring to the unit is encased in a nonmetallic

sheath, connect the incoming ground wire to the grounding

wire inside the furnace J-box. If metallic conduit is used, it

will serve as the ground.

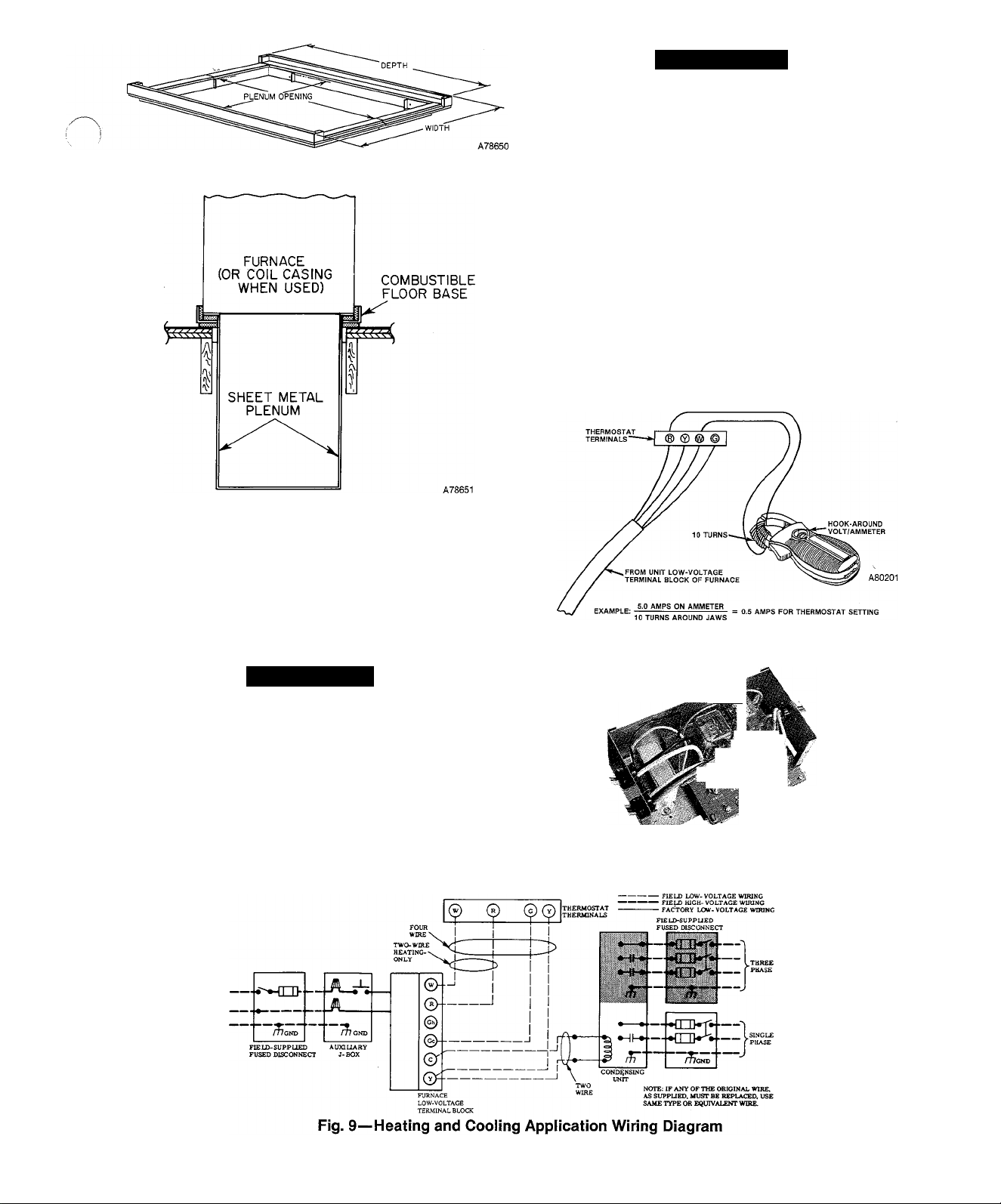

B. Low-Voltage Wiring

Make field low-voltage connections at the low-voltage termi

nal strip. See Fig. 9.

NOTE: Use AWG No. 18 “color-coded” copper thermostat

wire for lengths up to 100 ft. Above 100 ft, use AWG No. 16

wire.

Fig. 6—Furnace, Plenum, and

Base Installed on a Combustible Floor

VI. ELECTRICAL CONNECTIONS

A. Line-Voltage Wiring

NOTE: Refer to “Procedures for Natural-Draft Gas Fur

naces” (packaged with the equipment) for additional

information.

A CAUTION

Do not connect aluminum wire between disconnect

switch and furnace.

See Fig. 9 for wiring diagram showing the proper field high-

and low-voltage wiring.

Use a separate fused branch electrical circuit containing a

properly sized fuse or HACR-type circuit breaker for this

furnace. A disconnecting means must be located within

sight from, and readily accessible to, the furnace. In some

areas, the unit door switch may qualify as the disconnecting

means.

Fig. 7—Amp Draw Check With Ammeter

mSm

A79077

Fig, 8—Printed-Circuit Control Center

—3—

A78461.

Loading...

Loading...