Carrier 50DQ User Manual

Carrier

installation, Start-Up

and Service Instructiôns*

Single-Package Heat Pump Units

50DQ

Ô16

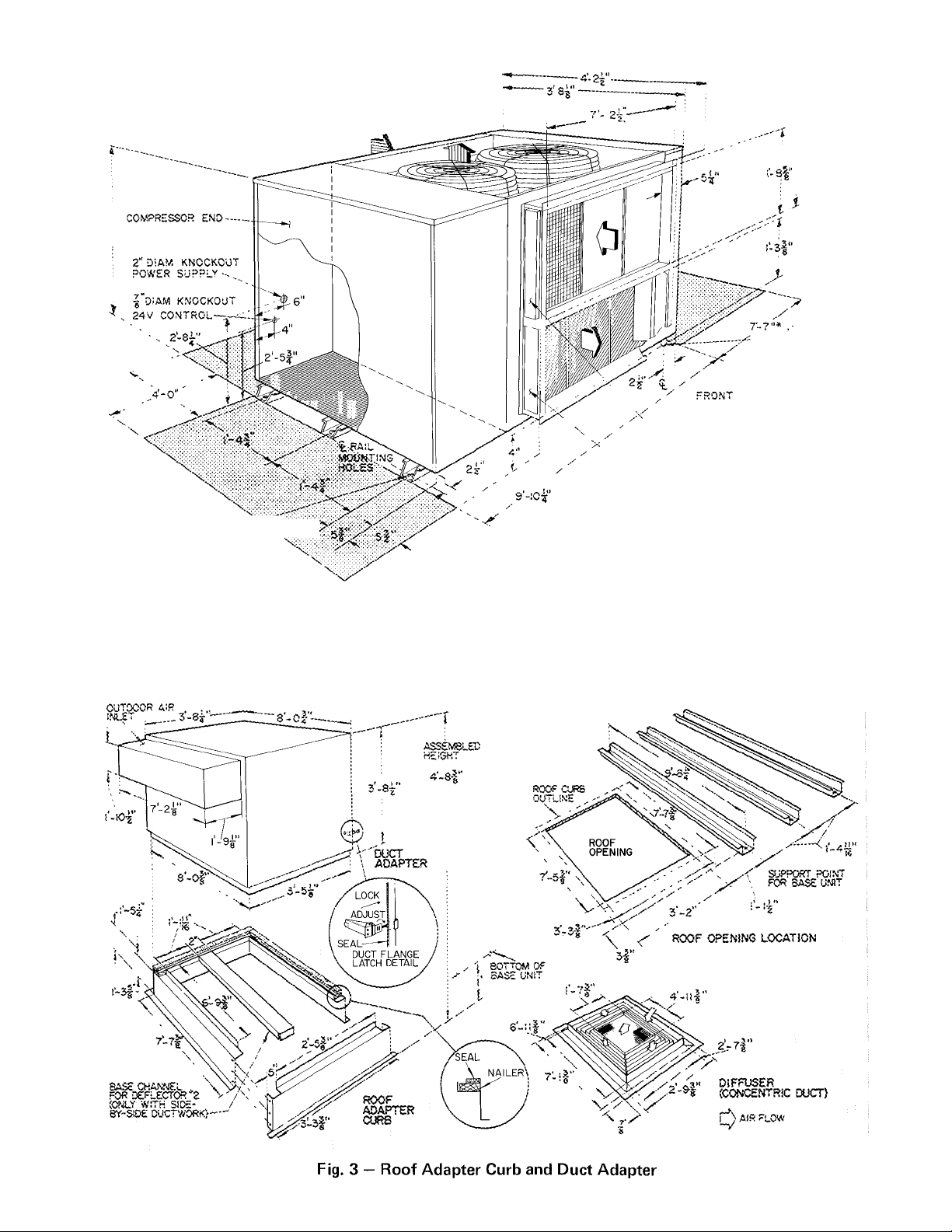

INSTALLATION

General — Unit components are mounted to

eliminate vibration. Isolators are not required for

slab mounting. In some rooftop installations,

rubber pad-type isolators may be required due to

type of roof construction. For proper support of

unit, refer to Table 1 for weights. Pads, blocks, or

beams must be in contact with at least 4 in. of the

surface area at the ends and center of each rail

located at bottom of the unit. Regardless of the

type of mounting configuration, allow a minimum

of 12 in. under the outdoor coil for condensate

drainage. Increase to 18 in. where prolonged sub-

freezing temperatures exist. Refer to paragraph on

Roof Adapter Curb and Duct Adapter Fabrication.

Roof Mount — Check building codes for weight

distribution requirements. Mount unit on a level

platform or frame adequate to support unit weight

and size.

Slab Mount — Provide a level concrete slab that

extends beyond unit cabinet at least 6 in. Make

slab 8 in. thick and 4 in. above grade. Refer to

Table 1 for proper clearance under outdoor coils.

Provide a gravel apron in front of outdoor air

openings to prevent grass and foliage from ob

structing air flow.

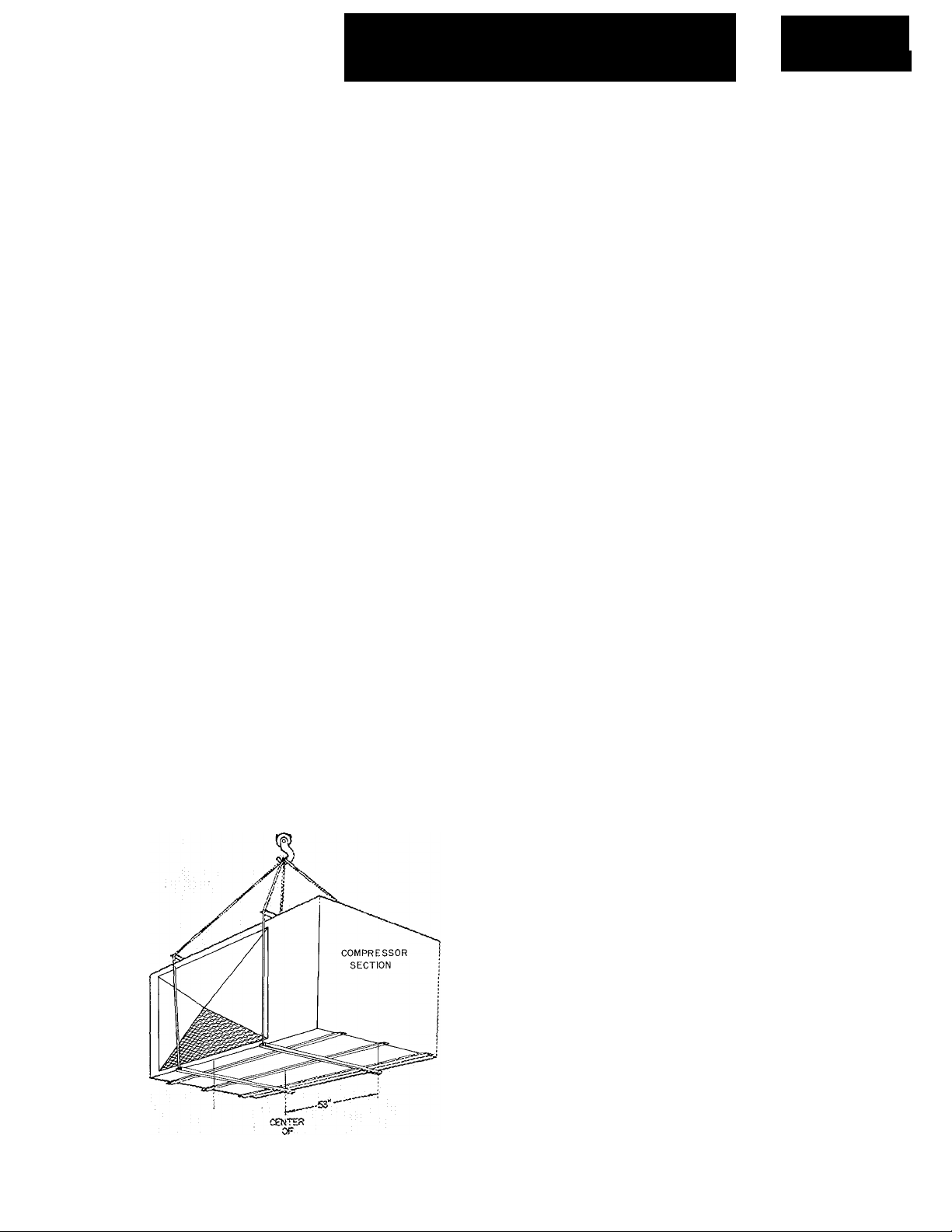

Rigging and Unit Placement — Inspect unit for

transportation damage. File claim with trans

portation agency. Do not remove shipping skid

until unit is ready to be placed. Do not drop unit.

GRAVirv

Fig. 1 - Rigging

Keep unit upright. Use spreader bars to prevent

sling or cable damage to unit (Fig. 1). Level unit

using unit frame as reference.

Locate unit as close as possible to duct open

ings. Outdoor air inlet is not affected by wind. Do

not locate unit air inlets near exhaust vents or

other sources of contaminated air. Provide clear

ance around and above unit for air flow, safety and

service access area as shown in Fig. 2.

Although unit is weatherproof, guard against

water from higher grade runoff and overhangs. •

Table 1 — Physical Data

UNIT 50DQ

OPERATING WEIGHT (lb)

REFRIGERANT; R-22 (lb)

COMPRESSOR

Oil PP 33-2 (pf)

OUTDOOR AIR FANS

Motor Hp ... Rpm

1-ph

3-ph

Motor Frame (NEMA)

INDOOR AIR FAN SECTION

Motor Hp ... Rpm

Motor Frame (NEMA)

Motor Pulley Range (in.)

Fan Pulley (in.)

Belt; No. ... Type ... Length (in.)

Fan Speed Range

Fan Factory Setting (Rpm)

Max Allowable Fan Speed (Rpm)

Speed change per ^2 turn of motor

movable pulley flange (Rpm)

Movable pulley factory setting

turns open

Max Allowab le full turns from

closed position

PRESSUrIsTAT SETTINGS (psig)

High cutout

cut-in

Low cutout

cut-in _

DEFROST THERMO CONTACTS -

EMERGENCY HEAT THERMO

CONJACTS_ _ _

FILTERS (factory-supplied)

No. ... Size

ANTICIPATOR SETTINGS

First Stage Heating Thermostat

Second Stage Heating Thermostat

1 relay

2 relays

3 relays

C L E A R ^ Q li IR E D U N D E R

OUTDOOR COILS

____

_____

Open

Close

. Open

. Close

016

1853

34

06DB537

10

2

% .. 1075

% 1140

48

3 .. 1725

56

4.0 - 5.0

8.2

A48 ... 49.3

860-1060

980

1200

20

2

5

390 ± 5

290 + 15

29 i 5

64 + 5

43 F

105 F

______

6 5 ± 6 F ^

80 ± 6 F

C leanable

2 .. 20 X 20 X 1

2 ... 20 X 25 X 1

4

.8

1.2

12 to 18 in.

(S) © Carrier Corporation 1971

275

Form 50DQ-1SI

5 DIAM MOUNTING

HOLES (6)

© Outdoor coil air flow

indoor coil a;r flow

SPACE FOR SERVICE AND AIR FLOW'

\FiLTER ACCESS PANEL

(SOTH ENOS)

\ ACCESSORY ELECTRIC

HEATER ACCESS

'For eiectric heater and indoor air fan section

rerriovai.

NOTES:

1 Provide 6 ft above unit for fan deck service

clearance and outdoor coii air flow.

2. Provide 3 ft in front of unit to accorrs.-nodate

rooftop adapter (if used).

3 fi/iain power connections for accessory eiectric

¡'.eaters (if used) must be at compressor end

of unit

Certified dimension drawings are available on recuest.

Fig. 2 — Physical Data and Dimensions; 50DQ016 Unit

■-}

.-'i?

5 MPT

CONDENSATE

DRAIN

4

Loading...

Loading...