Page 1

Combination Heating/Cooling Units

MODEL

48DL,DM006300

48DL,DM006310

48DL,DM006400

48DL,DM006410

48DL,DM0Ò65Ò0

48DL,DM006510

48DL,DM006600

48DL,DM006610

o

O

□

INDEX

VOLTS/PH

230/1

208/3

230/3

460/3

LABEL DIAGRAM

F

48DL504344

48DL504334

48DL504364

LEGEND

Contactoi

Cooling Compensator

Com|)i essoi

Gas Valve

Heal ArUicipalor

Ignition Commi

Indooi Fan Moloi

Indoor Fari Motor Capaoiloi

Indooi Fan Relay

Limit Switch

Outdoor Fan Motor

Outdoor Fan Motot Capacitor

Ouad Ter minai

Run Capacitor

Roll-Out Swilcii

Star t Capacitor

Start Relay

Thermostat Cooling

Time Delay Relay

Thermostat Healing

r I atisiormcr

To indicate common potential only,

not to represent wire

Field F-^ower Wires

Fiiild Control Wires

Field Ground Wites

Field Splice

Junction

Component Conriections (marked)

Comporront Connections (uninai ked)

Tliermostat Conriectiotis

Dwg No.

NOTES

1. Fan motors are thermally protected.

2 Terminations in low-voltage connection box

suitable for connection of NFC Class 2 control

circuit wiring at 24 volts.

3. Wire units in accordance with local codes

4 When original factory wiring must be replaced,

use the same type of wire or equivalent

5 Use copper or copper-clad conductors only

CONTROL CENTERS

No. 1 No. 2 No. 3

HH07AT074 HH01AD042

Thermostat 1 hermostnt Thermostat

and and and

HH93AZ076t

S u b b a s e

*Contml Centers shown on Label Diagrams

¡Automatic Changeover Subbase

HH93AZ080 is suitable for use if manual changcovei is

desired

HH93AZ042

Subbase Subbase

INITIAL START-UP SEQUENCE

Start-Up Sequence, Natural and LP Gas Units With

Intermittent Spark Ignition of Pilot, indoor (evap

*

HH01AD040

1IH93AZ040

orator) fan motor time delay relay and Essex

SX242 gas valve. (See Caution above )

MANUAL SEQUENCE

1 With power off turn manual gas valve knob to

ON position

2 Set thermostat selector switch at HEAT posi

tion and set thermostat dial a few degrees above

room temperature.

3 Turn power on.

AUTOMATIC SEQUENCE

1 Pilot valve opens, spark ignition and indoor fan

time delay relay energize.

2 Gas flows to pilot and ignites Pilot flame

sensing probe permits energizing of the main

gas valve Gas flows to main burner and ignites

3 Time delay relay starts indoor fan motor in 30

— 45 seconds.

4. When thermostat setting is satisfied, main gas

valve and pilot gas valve close and flames are

extinguished

5 Indoor fan motor stops in 1- to 1-1/2 minutes

© Cairiei Corporation 1977

Forni 48DL 1W

Page 2

CaBXIO??-. Do iiot »so màfcii»s to'

piìot oa ioimriiiient pOotumit^aS' fó'pos&ifcìe

elect ncsJ sitot.^ ha/:,arii.

GENERAL OPERATING SEQUENCES

These sequences apply to both natural and LP

gas units in normal operation after initial start-up

Operating Sequence-Heating

NATURAL GAS AND LP UNITS WITH INTER

MITTENT PILOT

1 Thermostat selector switch at HEAT or AUTO.

Thermostat dial set above room temperature,

2. Pilot gas valve opens Gas flows to pilot and

ignites Pilot flame setting probe causes main

gas valve to open Gas flows to main burner and

ignites.

3. TDR starts indoor fan motor in 30 — 45

seconds

4 When thermostat is satisfied both pilot gas and

main gas valves close. Pilot and main burner

flames arc extinguished.

5 TDR stops indoor fan motor in 1- to 1-1/2

minutes.

6 Pilot is on only when thermostat calls for

heating

Operating Sequence — Cooling

1 Unit energized. Thermostat selector switch at

COOL or AUTO Thermostat dial set below

room temperature

2 Indoor and outdoor fans and compressor start

3. When thermostat setting is satisfied, fans and

compressor stop.

Automatic Operation — Power and gas on. Room

thermostat (control center) set at AUTO. Fan

switch (on control center) set at AUTO.

Unit performs as described in the operating

sequences above on call for heating or cooling.

Automatic changeover type thermostat is required

Continuous Fan Operation — With power supplied

to unit and fan switch at ON position, indoor fan

remains on at all times.

Fig. 1 — Label Diagram, 48DL,DM006; 230-1-60

2

Page 3

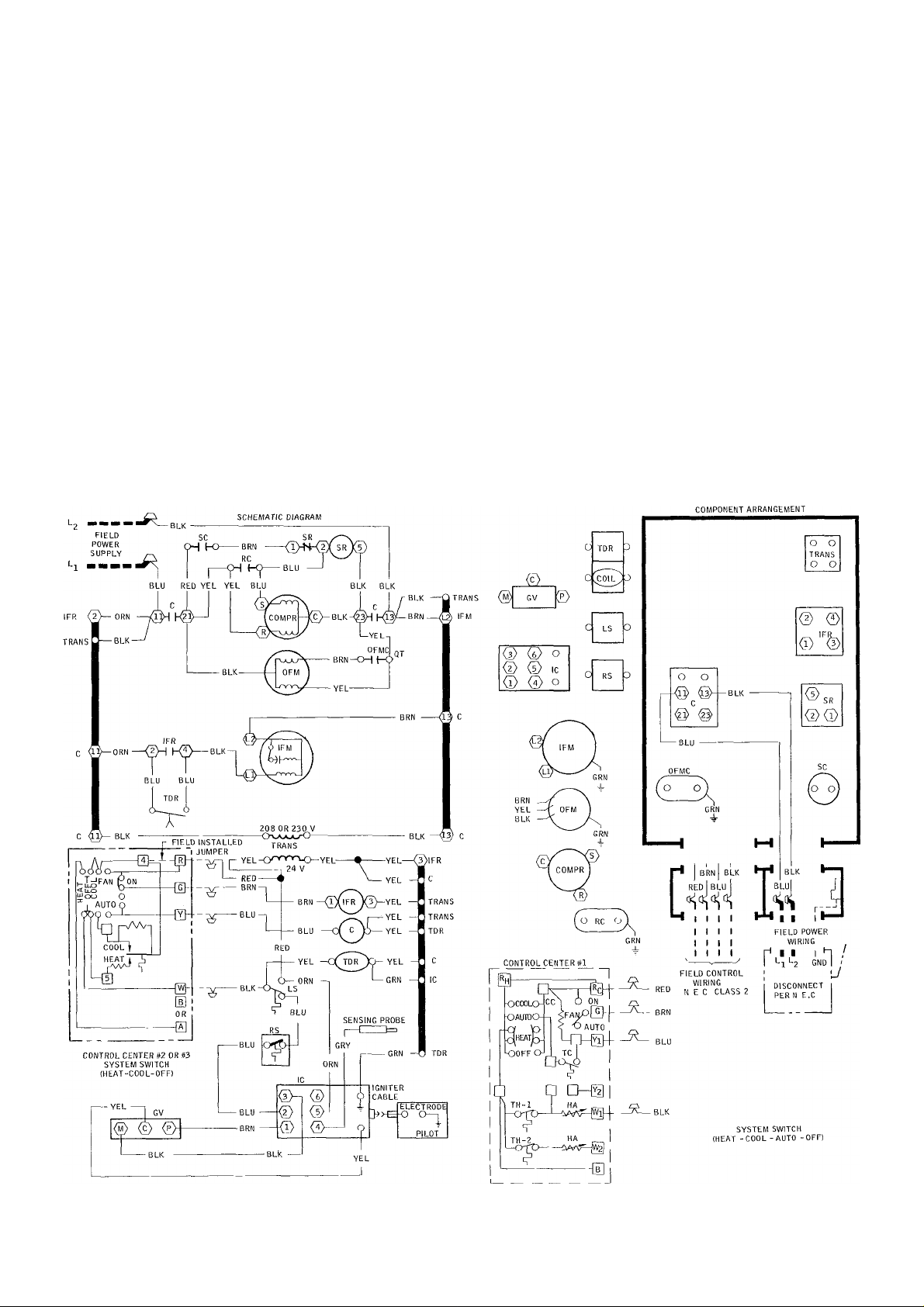

SCHEMATIC DIAGRAM

COMPONENT ARRANGEMENT

Fig. 2 - Label Diagram, 48DL,DM006; 208/230-3-60

Page 4

i)

(3> <6) 0

(D 0 'C

0 0 0

<g> '© <g) ©

<s> €> ®

BRN \

YEL ^ OFM J

BLK “\3A

l'^3

C COIL

lEf

C

TRANS

#1

4.

GRN

COMPONENT ARRANGEMENT

BLK

0 0 1

0

0 0

0

(w

C

0

o o

TRANS

0#2 0

0 0

Q 0

IFR

CONTROL CENTER #1

Fig. 3 — Label Diagram, 48DL,DM006; 460-3-60

FIELD CONTROL

WIRING

RED NEC CLASS 2

I BLU

I

YEL BLK GNDJ

FIELD POWER

WIRING .

I I I I I

M I ■ I I h

I L2 Lj L3 GND| /

I u

' DISCONNECT

PER NEC

SYSTEM SWITCH

(HEAT-COOL-AUTO-OFF)

I I EQUtPr

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Tab 6 Foim 48DL-1W New Piinled in USA 8-77 PC 1 H Catnloci No 534-844

1 4

Book

Tab

6a

la

Loading...

Loading...