Page 1

Carrier

Combination Heating/

/У

— 'y

Cooling Units

48DD

Gas Heating 275,000 Btuh

Electric Cooling 124,000 Btuh

48DD012

DESCRIPTION

The 48DD012 is a one-piece combination gas heating/

electric cooling unit designed primarily for outdoor rooftop

installation on a factory-supplied curb accessory but can be

installed on grade or conventional steel framework. This

unif combines superior performance with compactness,

versatility of application and ease of installation to supply

year-round air conditioning for commercial and industrial

FEATURES

• Two-Stage Heating and Cooling — Both heating and

cooling stages have 50 percent or 100 percent capacity

ranges of operation This reduces operating costs

• Multiple Choice of Air Flow — Air can be delivered to

the building either thru the bottom of the unit with

separate inlet and outlet air ducts or concentric ducting, or

it can be delivered thru the side of the unit with separate

inlet and outlet air ducts

• Gas Safety Control will shut off the main gas valve in

case of pilot or combustion air failure, or overheating of the

heat exchangers

• Induced Draft Combustion — Unaffected by winds and

drafts Equipped with safety shut-off devices in case of

combustion air failure or blockage

buildings The unit is completely factory assembled,

charged and tested Requires only natural gas, and suitable

electrical and duct connections for hookup. Air can be

supplied to the building either thru bottom of the unit or

thru the side A manually-adjustable outdoor air intake is

provided Condensers are air cooled Low silhouette design

allows units to be easily hidden from street level view

• Automatic Electric Ignition — Pilot flame is auto

matically relighted in case of interruption of power or gas

• Aluminized Heat Exchangers — Resist corrosion and

provide long, quiet, safe, and efficient operation These

heat exchangers have a full ten-year warranty

• Time Guard Circuit* prevents rapid cycling, extends

compressor life When power to unit is interrupted,

compressor cannot restart for five minutes

• Head Pressure Control automatically cycles one of two

condenser fans, permitting cooling operation down to 35 F

ambient temperature

• Other Quality Components — Crankcase heaters and

accumulators to protect the compressor against flooded

starts, filter-driers and sight glasses for moisture control and

visual inspection of refrigerant charge

ACCESSORIES

• 32LM MotormasterTM Head Pressure Control mod

ulates speed of condenser fan motor to maintain saturated

condensing temperature at low outdoor temperatures

• Thermostat Assembly is a two-step heating/two-step

cooling thermostat and a matching switch base Either

automatic or manual changeover is available

• Remote Control Center allows manual control of the

unit from a location remote from the thermostat The

thermostat furnished with the remote control center has no

knobs or switches for manual control

© Carrier Corporation 1970

•Single Feature Sheet Available Form 48DD-1 P

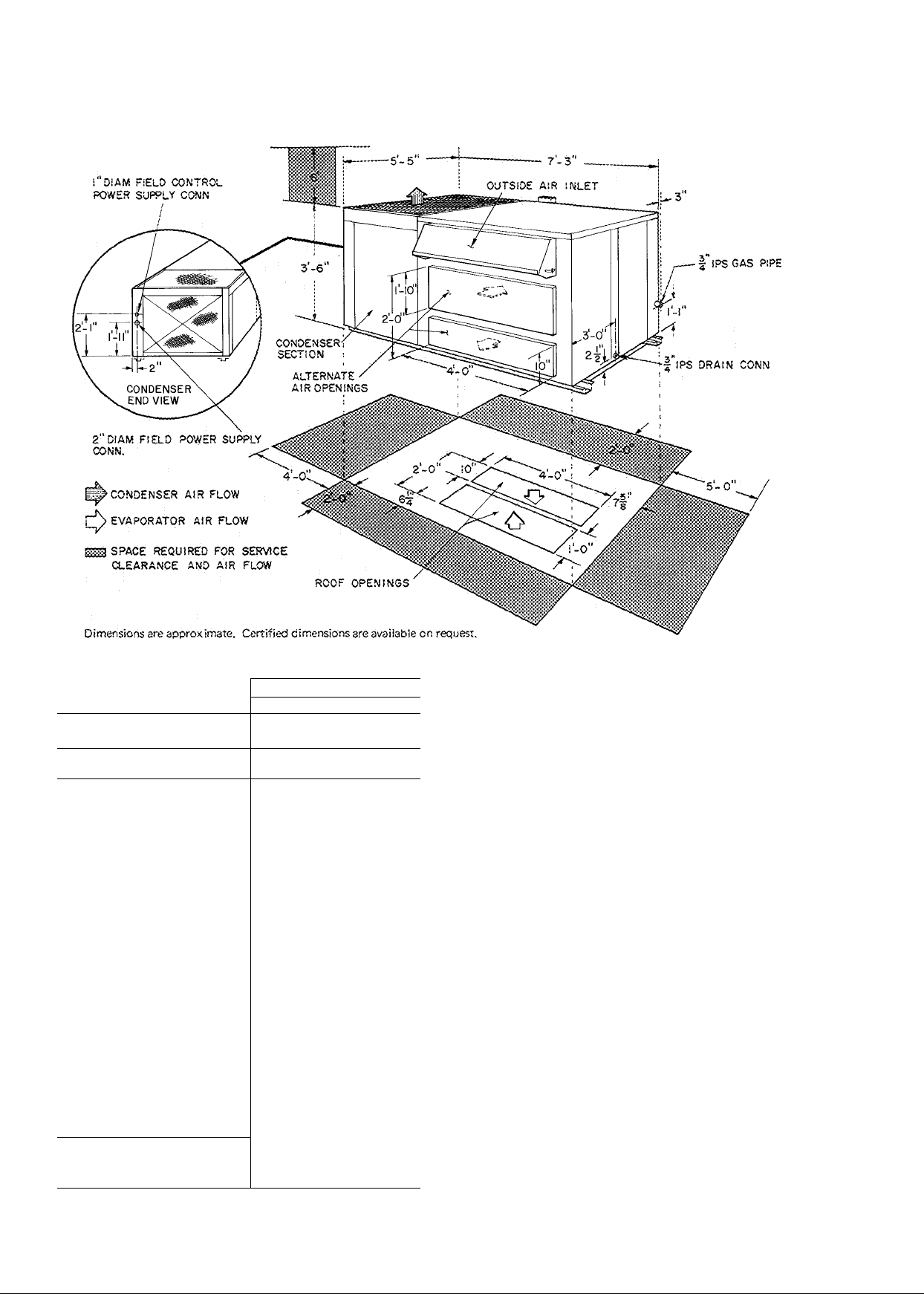

• Roof Curb frames roof opening, is watertight connec

tion between unit and roof Designed so ductwork and roof

flashing may be installed prior to placing the unit

• Modulating Outside Air Control Package (economizer)

can furnish outside air for cooling when outside air

temperature is below 60 F. It can replace operation of the

refrigerant system under these conditions

• LP Conversion Kit used to convert the unit from natural

gas to LP gas usage

• Relief Damper used to relieve positive building pressure

Page 2

DIMENSIONS

PHYSICAL DATA

UN IT 48 D D

OP ER A TI NG W E IG H T (lb )

RE FR IG E RA N T

Op era ti ng C h arg e (Ib )

CO MP R E SS O R

Cyl in de rs ... Rp m (6 0- H z)

OU TD O O R AI R FA N S

No . .. .D iam (in .)

No m Cf m ea c h. ..to ta l

Mo to r H p ...R p m

CO ND E N SE R C OI L

Ro ws ... F ins /i n.

Tot al Fa c e A re a (s q ft)

IND O OR A IR F A N S

No . .. .S ize (i n. )

No m Cf m

Rp m Ra n ge (S ta n da rd D riv e )

Ma x A ll ow a ble R p m

Bel t T yp e ...L e ng th (i n. )

Mo to r

No . .. .H p. ..R pm

Ma x B ra k e H p

Fra m e

Sha ft D ia m (in .)

Pul le y P it ch D ia m (in .)

EVA P O RA T OR C O IL

Tot al Fa c e A re a (s q ft)

Ro ws ... F ins /i n.

HE AT E XC H A NG E R S

A.G .A . C e rti fie d R ise

No . .. .E lem e nt s (ea c h)

012

169 0

22

9 ea c h S y ste m

(2) Re ci pr oc ati ng H er m eti c

4 ea c h 3 5 00

Pro pe lle r; Di re ct Dr ive

2 2 2

320 0 .6 40 0

1/ 1 1 40 (3 -p ha se )

107 5 (1 -i^ ha s e)

Pla te Fi n

4 1 3

14 0

Cen tr ifu ga l; Be lt Dr ive

2 10x10

400 0

123 0 to 15 40

170 0

A. 4 4

1 3 17 4 5

3 4 5

182 T

iVs

5 6

Pla te Fi n

10 02

3 1 4

Alu mi niz e cd S tee l

45 to 75 F

2 .5

SELECTION PROCEDURE (With Example)

I Determine cooling and heating requirements at design

conditions.

GIVEN;

Required Cooling Capacity (TO

Sensible Heat Capacity (SHC)

Required Heating Capacity

Condenser Entering Air Temp

Indoor Air Temp

Evaporator Air Quantity

Electrical Characteristics

External Static Pressure

II Select unit based on required cooling capacity.

Enter Cooling Capacities table at condenser entering air tempera

ture of 95 F. The 48DD012 at 4000 cfm and 67 F Ewb will

provide a total capacity of 132,000 Btuh and a sensible heat of

96,000 Btuh Calculate SHC correction if required

III Compare the heating capacity of the unit selected with the

design conditions.

Unit 48DD012 provides an input of 275,000 Btuh with a bonnet

capacity of 206,000 Btuh

IV Determine fan speed and brake hp requirements at design

conditions.

Enter Fan Performance table. At 4000 cfm and 8 in wg, the fan

speed is 1 405 rpm and brake hp is 2.34 The table indicates that

standard drive is adequate.

V Select unit that corresponds to available power source.

Refer to Electrical Data table and choose unit as required A

48DD012 230-3-60 is available.

128.000 Btuh

90,000 Btuh

198.000 Btuh

80 F Edb, 67 Ewb

. 95 F

4000 Cfm

230-3-60

8 in. wg

Page 3

48D D 01 2 AR I* - 12 4, 00 0 BT U H

T e mp ( F)

Air En t

Co nd

85

95

100 SHC

105

115

72 *62

TC 147 1

SH C

KW 14.4

TC

SH C

KW 15.6 14.9

TC

KW

TC

SH C 65 3 81 6

KW 16.7 15,8 15.0 16.9 16. 1

TC 121 0 112 1 104 1 123 6

SH C

KW 17.6

134 8 122 5

73 0 87 5 103 5

14.C

128 i

138 9

84.9 101 4

68 7

134 0 124 S 114 8 137 6

84 0 99 6 73 7

67 3

15,3 14.6 16,3 15,7

16.1

130 4 120 7

61 .6

78 4

16.6 15 6

*Rated in accordance with latest ARI Standard 210

Capacities shown (except ARI) are gross capacities

which do not include a deduction for indoor fan

motor heat.

Eva p A

300 0/ .08 ” I ’ 4" c

lyg p A

149 4 139.4

13.4

117 4 141 6

14.2

ms 133

98 2

96 8

BF — Bypass Factor

Ewb — Entering Wet-Bulb

KW — Compressor Motor Power Input

SHC — Sensible Heat Capacity (1000 Btuh)

TC — Total Capacity (1000 Btuh)

ir — C fm / B F

00/ .10 1 5 C

ir - E

12

wkiF

ei

62

129 5

78 8 99 6 120 2

14.2 13.9 14,7 14.6

14.7

132 2 123 8

76 3

96 4 117 6

15.9 15.2 14.6

117 3

128 2

114 8

94 9

15.5 16.5 16,0

114 8 147 2 128 9

123 8

71 8 92 9 89 7

16.9

109 1 126 9

114 8

89 7

109 1 75.9

16 2

68 3

17.7 16.9

PERFORMANCE DATA

COOLING CAPACITIES (60-Hz)

NOTES:

)6o /. 1 2

67 62

144 1

153 0

131 0

87 7 1115 131 0

14.2

146 2 136 8

83 4

16.3 15.6 15,0

142 6 133 4 125 1

82 2 107 0 125 1

108 2

128 6

128 6

15.4

"l21 7

105 0 121 3

79 9

17.1 16.6

18 3

15.9

117 0 114.0

1 14 0

101 5

16 8

17 3

1. Direct interpolation is permissible Do not extrapolate

2 The following formulas may be used:

Mdb fedb ■

f|wb ^ Wet-bulb temperature corresponding to enthalpy of air

h|wb - ■

Where

hewb^ Enthalpy of air entering evaporator coil

SHC is based on 80 F edb temp of air entering evaporator coil

Below 80 F edb, subtract (corr factor x cfm) from SHC

BF

10

20

.30 76

Interpolation is permissible

Correction Factor = 1.08 x (1 - BF) X (edb - 80)

sensible capacity (Btuh)

1 08 X cfm

leaving evaporator coil (h|y^,[з)

total capacity (Btuh)

4.5 X cfm

Entering Air Dry-Bulb Temp (F)

78 I 77 1 76 I 75 [ under 75^"

Correction Factor

97 1 95

86 1 73

2 92 3 89

2 59

1 51 2 27 3 03 3 78

4 86

3 46 4 32

use formula

shown below

HEATING CAPACITIES

UN IT 48 D D0 1 2

Firs t St ag e

Ful l

NOTES

1 Ratings are approved for altitudes to 2,000 ft At altitudes over

2,000 ft, ratings are 4 percent less for each 1,000 ft above sea

level

2 At altitudes up to 2,000 ft, the following formula may be used

to calculate air temp rise:

bonnet capacity

At =

1.08 X air quantity

INP U T

(Bt uh )

37,000

275,000

BO NN E T

(Bt uh )

103.000

206.000

3 At altitudes above 2,000 ft, the following formula may be used:

At

----

--------------------

4 Maximum allowable gas pressure is 14 0 in wg Minimum

allowable gas pressure for full rated input is 5 0 in wg

5 Unit may be field converted for 100 percent LP gas, using

Carrier factory parts Units will maintain A.G A, certification if

conversion is performed as directed and conversion nameplate is

attached to unit adjacent to existing unit nameplate

FAN PERFORMANCE, 48DD012

EXT E RN A L ST A TI C PR E SS U R E ( in . w g )

CF M

300 0

340 0

380 0

400 0

420 0

460 0

- I

J

970 <1030 <1095 \ 1155 1(215 I 1270 I 1320 ! 1380 ! 1425 I 1470 ¡1515 I (560 I (605 i (6.50 i (695

! 1010 i 1075 i 1135 < 1195 i 1245 I 1300 ¡1355 1 1405 I 1450 I 1495 ¡1540 I 1590 i (655 1 1680 I

( 1055 < 1115 ! ((75 I 1230 : 1275 i 1330 i 1385 : 1430 i 1480 i 1520 5 (565 i (6(0 , 1655 \ 1700

1145 ! (200 I 1245 I 1290 I 1345 ! 1400 i 1445 I 1485 I 1530 ! 1575 \ 1620 \ 1665 I

! 1020 I 1080 I 1140 I 1210 \ 1265 1 1325 I 1380 I 1430 I 1475 i 1520 T (560 I 160? I 1650 1 1695 I

.4 r .5 [ .6 [ . 7 1 .8 ] .9 j 1 .0 ^ 1 .1 1 1 .2

Fan R p m

“i 1230 j 1270 I 1315 I 1370 1 1420 i 146.5 > 1510 ' (5.50 i 1595 <1640 <1685 \

bonnet capacity

( 24 X specific weight of air x 60) (air quantity)

1 I

1.5 1 1.6

I

Motor brake horsepower

NOTES:

1 Fan performance has deductions for unit casing losses, wet coil,

heat exchanger, and clean filters

2. Fan motor bhp is based on minimum voltage and 80 F air

across the standard motor

3. All table values printed in italics indicate non standard conditions

Page 4

OPERATING SEQUENCE

ELECTRICAL DATA

Cooling — Power on and thermostat assembly set at "Cool,” "Fan

Auto" and desired temperature.

Step 1 of cooling thermostat energizes outdoor and indoor fans

and Time Guard Circuit Time Guard Circuit delays the start of the

compressor for fifteen seconds.

Step 2 of cooling thermostat operates a second Time Guard

Circuit which delays the start of the second compressor for fifteen

seconds. On compressor shutdown for any reason, Time Guard

Circuit prevents compressor restart for at least five minutes.

Capacity Control — Two-step thermostat operates the compressors

as the cooling load changes.

Heating — Turn power and gas on, and set thermostat assembly at

"Heat," "Fan Auto" and desired temperature.

The induced draft motor is energized whenever unit field power

is on with thermostat set for "Heat" or "Auto." No. 1 glow coil

ignites the no. 1 pilot (a thirty-second delay occurs before glow coil

lights the pilot) Electric pilot shifts to no. 2 glow coil and no. 2

pilot ignites.

After all pilots ignite, unit is ready to heat When step 1 of

heating thermostat closes: the gas valve relay energizes, the main gas

valve opens, the indoor fan relay (IFR 2) closes, the indoor fan

contactor energizes, and the indoor fan motor starts. Burners are

now at 50 percent capacity.

When step 2 of heating thermostat closes and energizes the

second stage of gas valve, the unit operates at full capacity.

When call for heat is satisfied, step 2 of thermostat opens,

de-energizing the second stage of the gas valve.

Unit may cycle between 50 percent and full capacity as step 2

dictates. When step 1 of the thermostat opens, the gas valve relay

shuts off the main gas valve and indoor fan motor.

Automatic Changeover — When system selector switch is set at

"Auto," unit will automatically change from heating to cooling

when the temperature of the conditioned space rises to the cooling

lever setting. When the temperature of the conditioned space falls to

the heating lever setting, the unit will automatically change from

cooling to heating

The thermostat and unit are so connected that the cooling and

heating systems will not operate simultaneously.

Air Circulation — With power on and unit controls set at "Off" and

"Fan," indoor air fan operates' continuously for air circulation.

When controls are set at "Heat" or "Cool" and "Fan," heating or

cooling is provided as required, while indoor fan motor operates

continuously.

TYPICAL WIRING

OPERATING SEQUENCE - ACCESSORY MODULATING

OUTSIDE AIR CONTROL

Cooling Season — Thermostat assembly set at "Cool" and "Fan

Auto." Damper goes to "Vent" when step 1 of cooling thermostat

closes, energizing outdoor and indoor fan motors and the

compressors.

When step 1 is satisfied, outdoor and indoor fan motors and the

compressor shut off, and the outside air damper closes. (Damper

always stays at "Vent" during cooling sequence if fan switch is at

"Fan," and night switch is closed.)

Intermediate Season — Same as for cooling season, except that as

step 1 of thermostat closes and indoor fan motor starts, compressor

and outdoor fan motor remain off if outside air temperature is

below outdoor air thermostat setting. If outside and return air

temperature rises above or drops below mixed air thermostat

setting, the outside air damper will reposition to maintain the

thermostat setting. Damper will move to closed position when

cooling step 1 is satisified Damper will move to "Vent" position

when fan switch is at "Fan."

The outside air damper will close when the night switch is

opened (night position), or whenever the indoor fan shuts down.

Heating Season — Damper always stays at "Vent" while fan motor is

operating. Outside air damper closes when night switch opens.

C

■ Compressor Contactor LP

■ Cooling Compensators LS

cc

Ccw '

•Counterclockwise MAT.

CH

■ Crankcase Heater NS

CR

■ Control Relay

CS

■ Centrifugal Switch OAT.

Cw

■ Clockwise OFC

DM

■ Damper Motor OI

FDM

■ Forced Draft Motor Pii

FDR

■ Forced Draft Relay R

GC

■Glow Coil RES

GV

■ Gas Valve TB

GVR

■ Gas Valve Relay TC

HA

■ Heating Anticipator TDR

HPCT

■ Head Pressure TH

• Control Thermostat TM

HR

■ Holding Relay TRANS

■ Indoor Fan Contactor

IFC

IFR

■ Indoor Fan Relay

IP

■ Internal Protector

LEGEND

_______

_______

- Low Pressure Switch

- Limit Switch

- Mixed Air Thermostat

- Night Switch

(Field supplied)

- Outside Air Thermostat

- Outdoor Fan Contactor

- Overload

■ Pilot

- Relay

- Resistance Wire

- Terminal Block

- Thermostat, Cooling

- Time Delay Relay

- Thermostat, Heating

• Timer Motor

- Transformer

Factory Wiring

Field Wiring

Page 5

ELECTRICAL DATA (Cont)

ELECTRICAL DATA (60-Hz)

VOLTAGE

V/PH

208/3 220-180

230/3

460/3

RANGE

254-198 70 0

506-414

WSA ICF

79.6

33 9 69

FLA — Full Load Amps

FU — Fuse (max allowable amps)

ICF —Max Instantaneous Current Flow during start-up is the sum of

compressor LRA plus the FLA of all other motors in the unit

UNIT

152

137

COMPR* IFM OFM

FU FLA LRA FLA (ea)

10.6

100 27.60

90

23.80

45 11 85 50

1 10

100

9.2 3 2

4.6

3.2

1 2

IFM — Indoor Fan Motor

LRA — Locked Rotor Amps

OFM — Outdoor Fan Motor

WSA — Wire Sizing Amps per NEC equals 1 25 X FLA of the largest

motor plus the sum of the FLA of all other motors in

the unit.

*Unit has two compressor motors; values are for each.

TYPICAL PIPING AND WIRING

ROOFTOP INSTALLATION WITH SEPARATE SUPPLY AND RETURN DUCTWORK

ADDITIONAL UNIT AI R FLOW ARRANGEMENTS

CONCENTRIC DUCTING THRU THE BOTTOM

APPLICATION

THRU The side

[^AIRFLOW

note ; Accessory economizer cannot be used with this air flow arrangement.

Page 6

APPLICATION (Coni)

LOW OUTDOOR TEMPERATURE COOLING OPERATION

It is not necessary to use the refrigeration system for cooling

when the outdoor air temperature is below 60 F. The use of

outdoor air will handle the cooling load. This is a more economical

method of cooling in cold weather

One condenser fan motor is cycled off when the outdoor air

temp drops to 55 F. This allows operation down to 35 F outdoor

CONTROLS (Protective Devices)

temperature The other condenser fan motor is suitable for use with

the 32LM MotormasterTM Head Pressure Control at outdoor

temperatures below 35 F (see Accessories). Operation with this

control requires winter start provisions (low pressure switch

recalibration): and may require field-fabricated condenser air

baffles.

• Limit Switches shut off gas supply if excessive air temperatures

should develop; limit discharge air temperature to 175 F when unit

is used for heating.

• Current Overloads with Automatic Reset are current sensitive

and temperature compensated; will open the control circuit if

compressor current is excessive.

• Internal Thermostat with Automatic Reset Is embedded in

compressor windings; de-energizes the control circuit if extreme

temperatures should develop due to excessive suction gas tempera

ture or motor overloading

• High Pressure Relief Device protects unit from excessive com

pressor discharge pressures and prevents overheating.

GUIDE SPECIFICATIONS

Unit shall be of the single-package type, combination air-to-air

cooling and gas-fired heating.

Total Net Cooling Capacity of the system shall be 124,000 Btuh

or greater, and sensible capacity shall be 94,900 Btuh or greater, at

conditions of: 4500 cfm evaporator air entering unit at 67 F

wet-bulb, 80 F dry-bulb and condenser entering air temperature of

95 F dry-bulb Compressor power input shall not exceed 15.5 kw.

Heating Capacity of the system shall be 206,000 Btuh or greater,

with gas input of 275,000 Btuh

Casing shall be constructed of galvanneal steel, bonderized and

coated with baked enamel

Compressor — The unit shall contain two hermetic compressors

with suitable vibration isolators. Crankcase heaters shall be supplied

with the unit

Coils shall be constructed with aluminum plate fins mechanically

bonded to copper tubes

Fans and Motors - The indoor fan shall be of the forward-

curved centrifugal type, belt driven by a 3 hp motor The condenser

• Circuit Breaker provides short circuit protection for controls.

• Low Pressurestat with Automatic Reset de-energizes the control

circuit if refrigerant pressure drops below setting; provides pro

tection from loss of refrigerant charge.

• Inherent Fan Motor Protection with Automatic Reset opens

power circuit if temperatures or current become excessive on

3-phase motors (single-phase motors are temperature sensitive only).

• Fusible Plug located on the accumulator, protects against

excessive pressures or temperatures in the refrigerant system.

• Centrifugal Switch located in the induced air fan motor will

de-energize the gas valve in case of combustion air failure.

section shall have two propeller fans, each directly driven by a 1/2

hp motor.

Heat Exchanger shall be constructed of corrosion resistant

aluminized steel. Burners shall be of the Bunsen (aerated) slotted

port type: readily accessible, and covered by a 10-year warranty.

Safety Controls — Cooling section shall be protected by: fusible

plug, low pressurestat, compressor motor overloads, and a timing

device which will prohibit the compressor motor from being

subjected to starting current more than once every five minutes.

Heating Controls shall consist of an automatic gas valve, pilot,

automatic ignition system, limit switches and a centrifugal switch.

Dimensions — The unit casing shall have width of not more than

65 in., length of not more than 87 in , and height of not more than

42 inches

Accessories — Roof Curb, Modulating Outdoor Air Control,

Remote Control Center, Two-Stage Heat-Cool Automatic Change

over Thermostat, Relief Damper, LP Conversion Kit, and 32LM

MotormasterTM Head Pressure Control.

Manufacturer reserves the right to change any product specifications without notice.

CARRIER AIR CONDITIONING COMPANY • SYRACUSE, NEW YORK

Tab 6

Form48DD-1P New

Printed in U.S.A.

2-70

Codes B and MS

Catalog No. 524-811

Loading...

Loading...