Carrier 38VH User Manual

Number One

AirCorditbninq

Maker

Division of

Carrier Corporation

Carrier Parkway • Syracus

N Y 13221

Air-Cooled Condensing Units

INDEX

SAFETY CONSIDERATIONS........................... 1

INSTALLATION

Step 1 — Check Equipment and Jobsite.... 2,3

• UNPACKAGE UNIT

• INSPECT EQUIPMENT

• COMPLETE OR CONSIDER SYSTEM

REQUIREMENTS

Step 2 — Make Tubing Connections

• REPLACE THE ACCURATER™

REFRIGERANT CONTRQL PISTON IN

THE INDOOR COIL

• CONNECT REFRIGERANT LINES

Step 3 — Make Electrical Connections........... 5,6

• INSTALL A BRANCH CIRCUIT

DISCONNECT PER N.E.C.

• ROUTE LINE POWER LEADS INTO UNIT

• CONNECT GROUND LEAD AND

POWER WIRING

• CONNECT CONTROL POWER

WIRING (24 v)

START-UP

................................................................

SERVICE.................................................................. 9-II

MAINTENANCE

..................................................

...............

Page

3-5

6

II-I2

SAFETY CONSIDERATIONS

Installation and servicing of air conditioning

equipment can be hazardous due to system pres

sure and electrical components. Only trained

and qualified service personnel should install,

repair or service air conditioning equipment.

Untrained personnel can perform basic main

tenance functions of cleaning coils and cleaning

and replacing filters. All other operations should bci

performed by trained service personnel. When

working on air conditioning equipment, observe

precautions in the literature, tags and labels

attached to the unit and other safety precautions

that may apply.

Follow all safety codes. Wear safety glasses and

work gloves. Use quenching cloth for brazing

operations. Have fire extinguisher available for all

brazing operations.

WARNING; Before performing service or

maioienance oj^erairon^ on system, turn off

m^n power switch to iadoor mut and out

door UJI&. Tui» off accessory heater power

switch if applicable. Eleetrical shock could

cause persoii^ injury.

ik -If MTG

SLOTS(USE ANY

2)

C=3 SPACE REQUIRED FOR SERVICE

^ CONDENSER AIRFLOW

CONCRETE MOUNTING PAD^ISQUARE OR CIRCULAR)

^CONCRETE PAD SHOULD WEIGH |-f TO 2 TIMES WEIGHT OF UNIT

Certified dimension drawings available on request

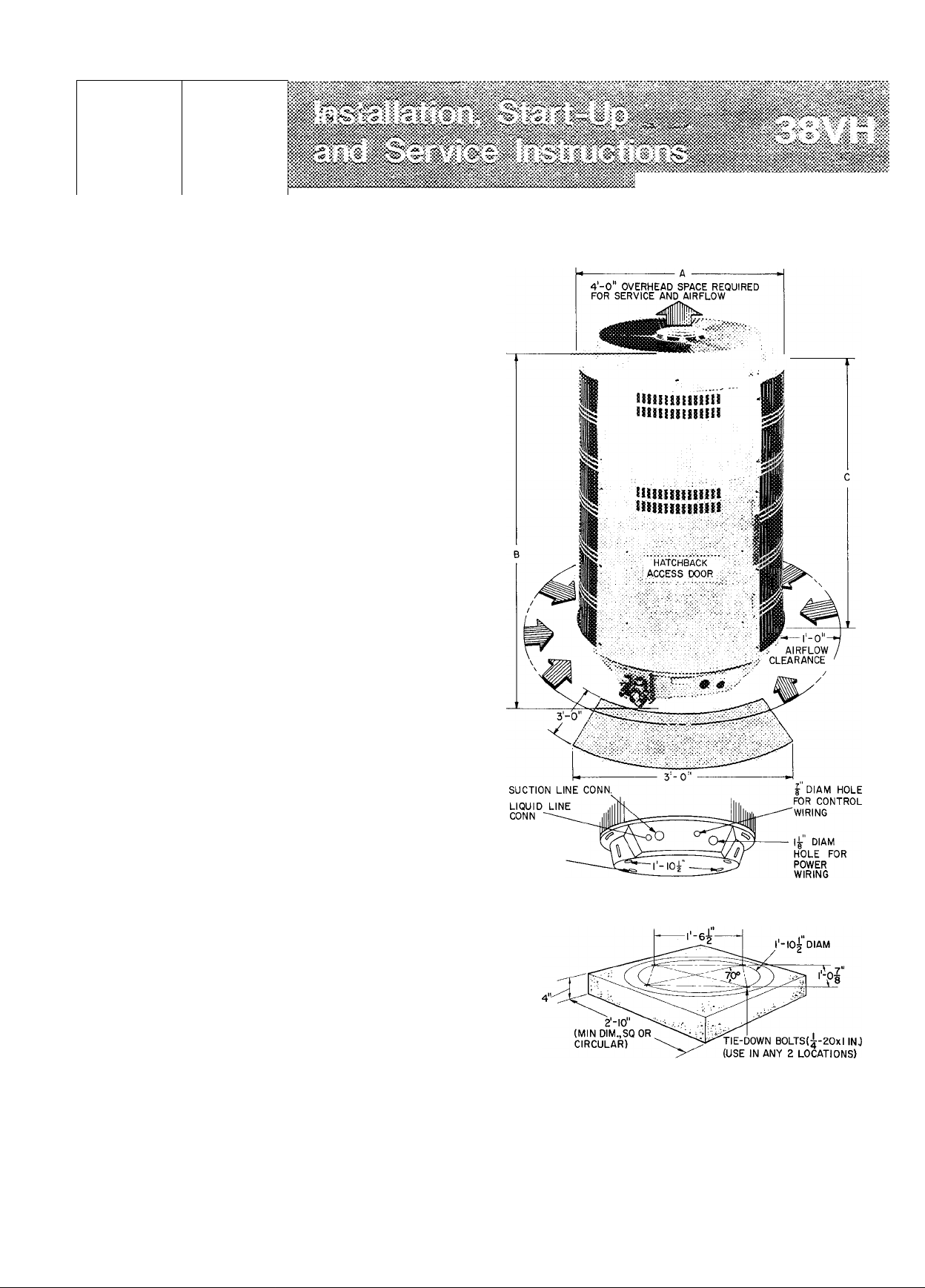

Fig. 1 — Dimensions, Connections and

Mounting Pad

© Carrier Corporation 1980

Form 38VH-2SI

Table 1 — Physical Data

MODEL 38VH

OPER WT (lb)

DIMEN. (ft-in.)

Diameter A

Unit Height B

Coil Height C

REFRIG CONN*

Suction (in. ODF)

Liquid (in. ODF)

*AII models except 38VH001 are supplied with a 3/4-in to

1-1/8 in suction valve connection adapter (field installed)

for 1-1/8 in suction line (field supplied)

001

0021003

165

20q 205

2- 8

3-2 3-2

1-11

2-5 2-5

5/8 1 3/41 3/41 3/4 I 3/4 | 3/4

-5-1/4

2

004

225

3- 8

2-11

3/8

045 005

250

240

3- 8

3- 8

2-11

2-11

INSTALLATION

Step 1 — Check Equipment and Jobsite

UNPACKAGE UNIT — Move to final location.

Slide from carton taking special care not to damage

service valves or grilles.

INSPECT EQUIPMENT — File claim with ship

ping company if damaged or incomplete.

COMPLETE OR CONSIDER SYSTEM RE

QUIREMENTS before installation:

Consult local building codes and National

Electrical Code (NEC) for special installation

requirements.

When installing, allow sufficient space for airflow

clearance, wiring, refrigerant piping and service.

Recommended space minimum requirements are:

overhead — 4 ft, perimeter — 3 ft (Fig. 1). Position

so water from roof or eaves does not pour directly

on unit.

Install on a solid, level mounting pad. Position

tie-down bolts in pad. Any 2 holes in unit base may

be used to fasten unit to pad.

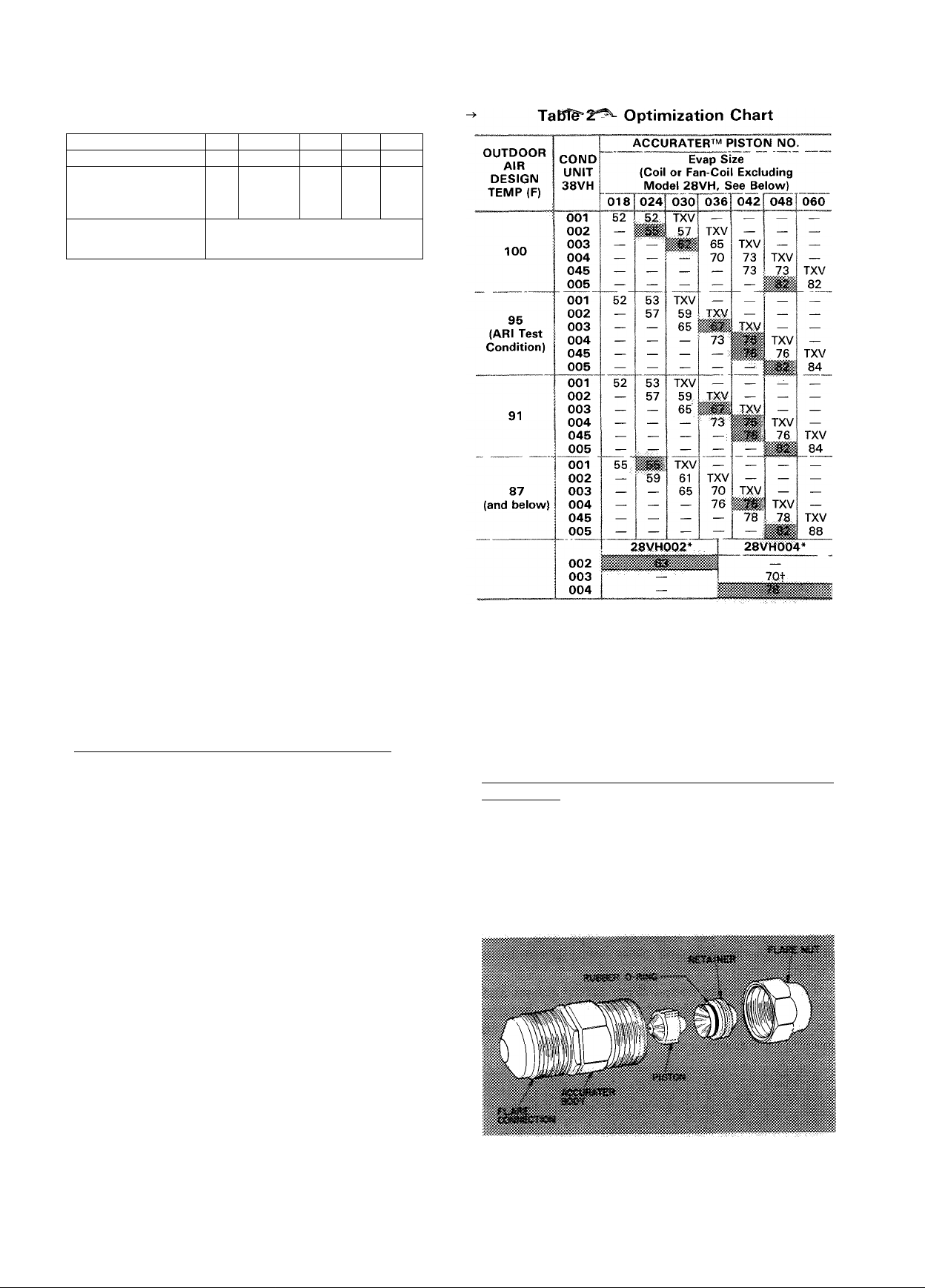

Carrier Cooling System Capacity Optimization may

require field replacement of piston in AccuRater™

(bypass type) refrigerant control supplied on evap

orator. See Table 2. Enter table at cooling system

Outdoor Air Design Temperature closest to that of

locality. Find AccuRater Piston number required

for condenser/evaporator system being installed.

Piston change is not necessary if table indicates that

required piston is factory installed in evaporator coil.

When evaporator is more than one size larger

than condensing unit (i.e. 38VH002I28AR036), re

move AccuRater and use a bleed-type thermal

expansion valve (TXV) for refrigerant control. Size

TXV to nominal capacity of condensing unit.

A replacement AccuRater piston is factory sup

plied on Models 38VHOO 1,002,003 and 004. This

piston is correctly sized for an evaporator of the

same capacity as the condensing unit at an outdoor

air design temperature of 95 F. Mix-matching and

outdoor air design temperatures other than 95 F

may require another piston number or thermal ex

pansion valve. (Refer to Table 2.)

Replace piston as required before connecting

refrigerant lines. Bypass type AccuRater com

ponents are shown in Fig. 2. Piston replacement

i Standard factory-installed AccuRater piston

*The 28VH piston designations are applicable to full temperature

range

fSize 70 piston factory supplied with 28VH004 .

NOTE: Piston numbers effective December 1, 1979

instructions are included in evaporator Installation

book. After system installation is complete, use

Chargemaster charging device or charging chart to

check and/or adjust refrigerant charge.

Condensing Units Connected to Carrier-Approved

Evaporators — Condensing units contain correct

system refrigerant charge for operation with evap

orator of same size when they are connected by 50 ft

of field-supplied tubing of recommended size (see

Piping Connections) or 50 ft or less of Carrier acces

sory tubing. Check refrigerant charge for maximum

system efficiency. See Refrigerant Charging for

details.

Fig. 2 — AccuRater (Bypass Type)

Components

Condensing Units Connected to Non-Carrier Evap

orators — Check refrigerant charge when the con

densing unit is added to a system in which other than

a Carrier-approved evaporator is to be used or

where the evaporator has been previously installed.

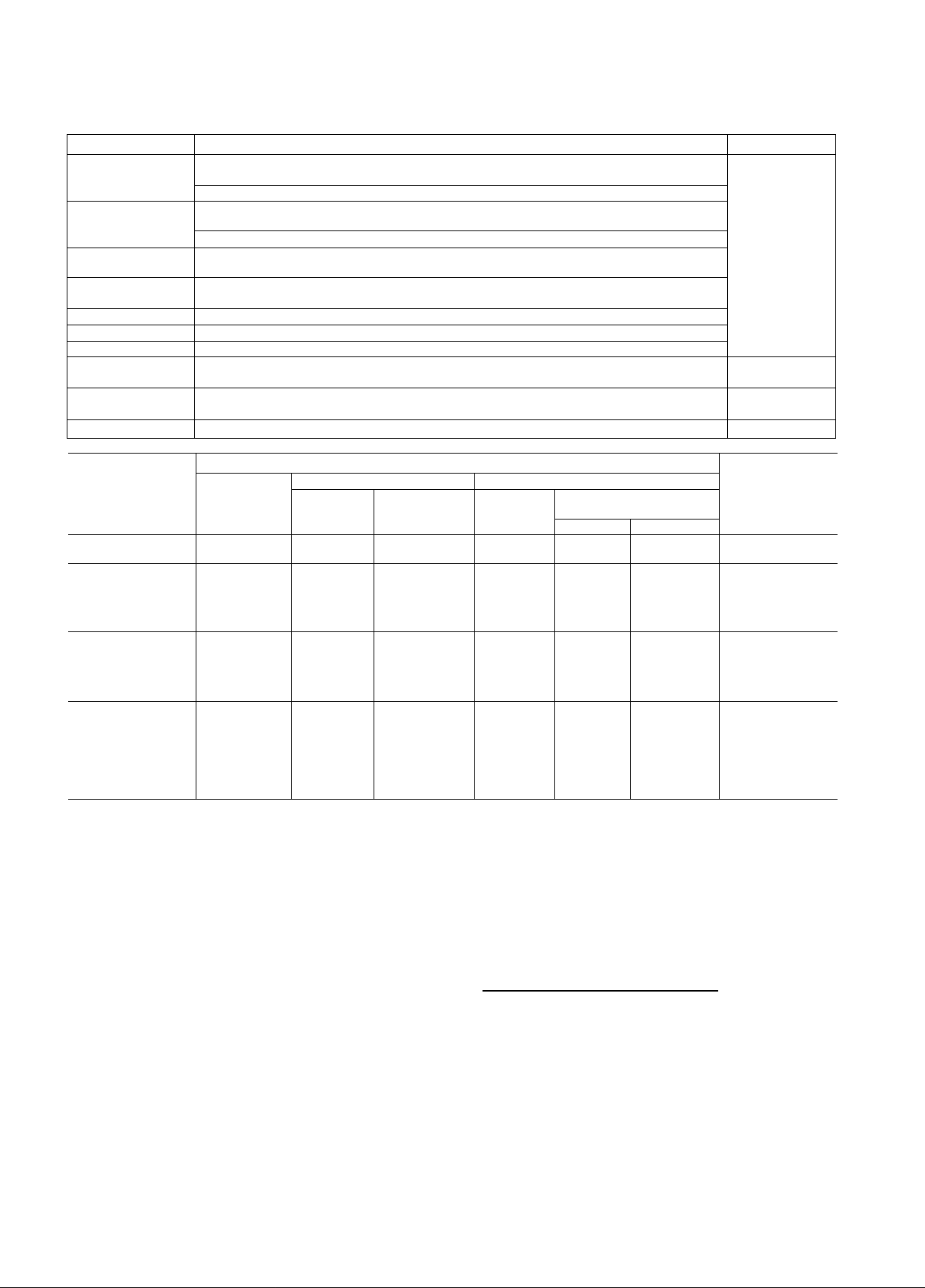

Check that field-supplied refrigerant piping is in

accordance with refrigerant piping data (Table 3).

Step 2 — Make Tubing Connections — Con

densing units may be connected to evaporator sec

tions using Carrier accessory tubing package or

field-supplied tubing of refrigerant grade. See Table

4 for accessory tubing sizes. Table 3 for recom

mended field-supplied tubing sizes.

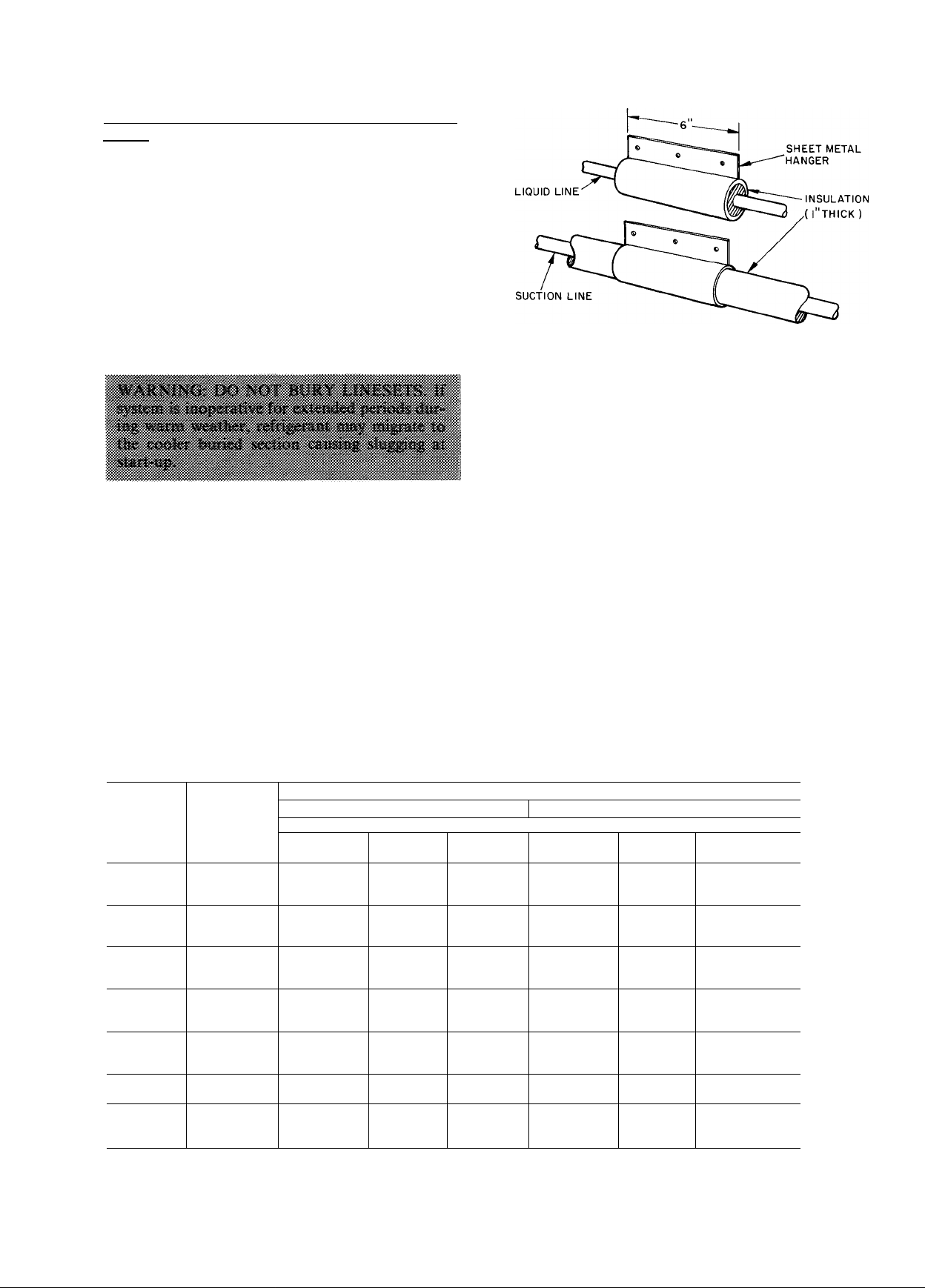

Isolate interconnecting tubing from framing and

ductwork or where tubing runs thru stud spaces,

enclosed ceilings or pipe chases. Use isolation type

hanger (Fig. 3) since rigid fastening transmits pulsa

tions to structure creating objectionable sound.

A capacity and efficiency reduction results if

undersized Carrier accessory tubing is used in 38VH

systems. (Example: When a 25-ft accessory tubing

Fig. 3 — Refrigerant Line Hangers

package is used on a 38VH004 system, the smaller

suction line will result in a capacity reduction of 3%.)

For maximum capacity and efficiency from this sys

tem, use suction line recommended in Table 3.

Length of interconnecting tubing may necessitate

refrigerant charge adjustment. Follow special re

quirements described in Initial Start-Up, Refrig

erant Charging. Do not use less than 10 ft of inter

connecting tubing. On Carrier accessory tubing

packages, do not cut 5/16-in. or 1 / 4-in. liquid line or

7/8-in. suction line. These tubing packages have

swaged ends. If swage at end of tubing is cut off, the

tubing will not fit into unit refrigerant line fittings.

Bend or coil excess tubing to fit.

Table 3 — Field-Supplied Tubing Data

NOTES

1 Maximum allowable vertical separation for evaporator over the

condensing unit is 50 feet

2 Over 50-ft vertical separation, the condensing unit must be

located above evaporator

3 The maximum total tubing length between units is 150 feet

REFRIGERANT LINE LENGTH (ft)

CONO

UNIT

38VH

001 024

002

003 036 7/8

004

045

nriR

002

003

004 28VH004

EVAP

SIZE

018

030 5/8

024

030 7/8

036 7/8

030 7/8

042

036 1-1/8

042 1-1/8

048

042

048 1-1/8

060 1-1/8

048 1-1/8

060 1-1/8

28VH002 1-1/8

28VH004 1-1/8

Suction

(in.)

5/8

5/8

7/8

7/8

1-1/8

1-1/8

1-1/8

10 to 50 ft

Liquid

(in.)

3/8

3/8 52

3/8 TXV

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8 TXV

3/8 82

3/8 84

3/8

3/8

3/8

4 All suction tubing must be insulated with 3/8-in thick, flexible

foam tubing (Armaflex 22 or equivalent)

5 Piston numbers effective December 1, 1979

Vertical separation from 51 to 100 feet (Condensing unit

iabove evaporator)

51 to 150 ft

Line Diameter

Indoor

Piston*

52 3/4

57

59

TXV

63

65

TXV

76

78

TXV

76

78

63

70

78 1-1/8 5/16

Suction

(in.)

3/4

3/4

7/8 5/16 57 ■

7/8

7/8

1-1/8

1-1/8 5/16 65 ■

1-1/8 5/16 TXV ■

1-1/8 5/16 76 U.

1-1/8

1-1/8 5/16 TXV ■

1-1/8

1-1/8

1-1/8

1-1/8

1-1/8

1-1/8 5/16 63 W

1-1/8 5/16 70 W

Liquid

(in.)

5/16

5/16 52 ■

5/16

5/16 59 ■

5/16

5/16 63 ■

5/16 78 ■

3/8 76 ■

3/8

3/8

3/8

3/8 84 fm

Indoor

Piston*

TXV ■

TXV ■

78 m .

TXV »

52 ^

82 ■

78 B

*At 95 F outdoor air design temperature At other design temperatures, piston sizes may vary See Table 2

Table 4 — Accessories

PART NO.

HH01AD040

HH93AZ040

HH51AR001

HH07AT070

HH07AT074

HH93AZ076

HH01AD042

HH93AZ042

HH01YA092

HH93YZ094

38GS900102

38GS900212

38HQ900011

38UE900001

32LT900301 Motormaster® Head Pressure Control Special field-installed fan motor HC42VE233 required

38GS900321 Liquid Line Filter-Drier (Six 38GS900332)

TUBING

PACKAGES

38LS958151

38LS958201

38LS958251

38LS958301

38LS958351

38LS958401 40 5/16 3/8 5/8 3/4i

38LS958501 50

38LS934251

38LS934301

38LS934351

38LS934401 40 3/8 3/8

38LS934501

38LS978151

38LS978201

38LS978251

38LS978301

38LS978351

38LS978401

38LS978501

Low-Voltage Control — Floneywell Deluxe Thermostat

Thermostat Subbase

Comfort Control Center (Use with FIFI01AD040)

Low-Voltage Control — Honeywell Thermostat

Thermostat Subbase (with Automatic Changeover)

Low-Voltage Control — Honeywell Thermostat

Thermostat Subbase

Low-Voltage Control — Grayson Thermostat

Thermostat Subbase

Indoor Fan Relay (Six HN61KJ210)

Low-Voltage Transformer (Six 38GS900091)

Hot Shot — domestic water pre-heater

Chillermate refrigerant-to-water heat exchanger

Liquid

Length

(ft)

15 3/8 3/8

20 3/8 3/8

25 3/8 3/8

30

35

25

30 3/8 3/8

35 3/8 3/8

50

15 3/8 3/8

20

25

30 3/8 3/8

35 3/8 3/8

40 3/8 3/8

50

OD

(in )

5/16

5/16

1/4

3/8

3/8 3/8

3/8 3/8 7/8

3/8

3/8 3/8

DESCRIPTION

TUBING*

Tube End

OD (in.)

3/8

3/8

3/8

3/8

3/8

Suctionf

OD

(in.)

5/8 3/4t

5/8 3/4t

5/8 3/4t

5/8 3/4J

5/8

5/8

3/4

3/4 3/4

3/4

3/4

3/4

7/8

7/8

7/8

7/8

7/8

7/8

Evap Cond

3/4i

3/4i

3/4 3/4

3/4 3/4

3/4 3/4

3/4 3/4

3/4

3/4

3/4

3/4 3/4 38VH005

3/4 3/4

3/4 3/4

3/4 3/4

Tube End,

OD (in.)

5/8 38VH001

5/8

5/8

5/8

5/8 38VH001

5/8

5/8

3/4

3/4 38VH003

3/4 38VH004

3/4 38VH045

UNIT

C

All

38VH003,004,

045,005

38VH002,003,004,

045,005

All

UNIT

38VH002

38VH002

(See Note 2)

*For maximum capacities, use suction line sizes recommended in

Table 3 If accessory tubing package is used on 38VH004,045,

005 units, a reduction in capacity can result Field-supplied

1-1/8 in suction line is recommended with all 28VFI coil

installations

Do not use damaged or contaminated tubing.

Always evacuate or purge evaporator coil and

tubing system. When purging, use field-supplied

refrigerant, not unit holding charge refrigerant.

When making tubing connections, be sure to pro

vide clearance at unit for electrical connections.

REPLACE THE ACCURATER™ REFRIGER

ANT CONTROL PISTON IN THE INDOOR

COIL, if required, before connecting refrigerant

lines. See Carrier Cooling System Optimization,

page 2.

CONNECT REFRIGERANT LINES to fittings on

condensing unit suction and liquid service valves

fSuction line is insulated and has a 90 degree bend at one end

JFor 5/8-in evaporator connection, cut off 3/4-in end

NOTE Do not cut 3/8-in OD liquid lines to a length shorter than

10 feet Do not cut 5/16-or 1/4-in liquid line Do not cut 7/8-in

OD suction lines

(Fig. 1). Unit Compatible Fittings permit mechani

cal (quick connect) or sweat connections.

Models 38VH002,003,004,045,005 — When using

1-1/8 in. field-supplied suction line, remove suction

line adapter taped to compressor suction line. Sweat

connect refrigerant suction line to 1-1/8 in. end of

adapter. Be sure to provide a heat sink at the service

valve to prevent damage during sweating operation.

Connect 3/4-in. end of adapter to unit suction line

Compatible Fitting. Connect liquid refrigerant line

to unit. When a 7/8-in. field-supplied suction line

is used, provide a field-supplied 3/4-in. to 7/8-in.

suction line adapter. (Not necessary if 38LS acces

sory tubing is used.)

Loading...

Loading...