Carrier 38TMA User Manual

HEATING & COOLING

instaiiation and Start-Up instructions

NOTE: Read this entire instruction before beginning installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock or other condi

tions which may cause personal injury or property damage.

Consult a qualified installer, service agency, or your distributor or

branch for information or assistance. The qualified installer or

agency must use factory-authorized kits or accessories when

modifying this product. Refer to the individual instructions pack

aged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth for brazing operations. Have fire extinguisher

available. Read these instmctions thoroughly and follow all

warning or cautions attached to the unit. Consult local building

codes and National Electrical Code (NEC) for special require

ments.

It is important to recognize safety information. This is the

safety-alert symbol ^ . When you see this symbol on the unit and

in instructions or manuals, be alert to the potential for personal

injury.

Understand the signal word— DANGER, WARNING, or CAU

TION. These words are used with the safety-alert symbol. DAN

GER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards that could

result in personal injury or death. CAUTION is used to identify

unsafe practices, which would result in minor personal injury or

product and property damage.

A WARNING

Before installing or servicing system, always turn off main

power to system. There may be more than one disconnect

switch. Turn off accessory heater power if applicable. Elec

trical shock can cause personal injury or death.

INSTALLATION

Step 1—Check Equipment and Jobsite

UNPACK UNIT

Move to final location. Remove carton taking care not to damage

unit.

INSPECT EQUIPMENT

File claim with shipping company prior to installation if shipment

is damaged or incomplete. Locate unit rating plate on unit service

panel. (See Fig. 2.) It contains information needed to properly

install unit. Check rating plate to be sure unit matches job

specifications.

38TMA

Air Conditioning Unit

A88160

Fig. 1—Model 38TMA

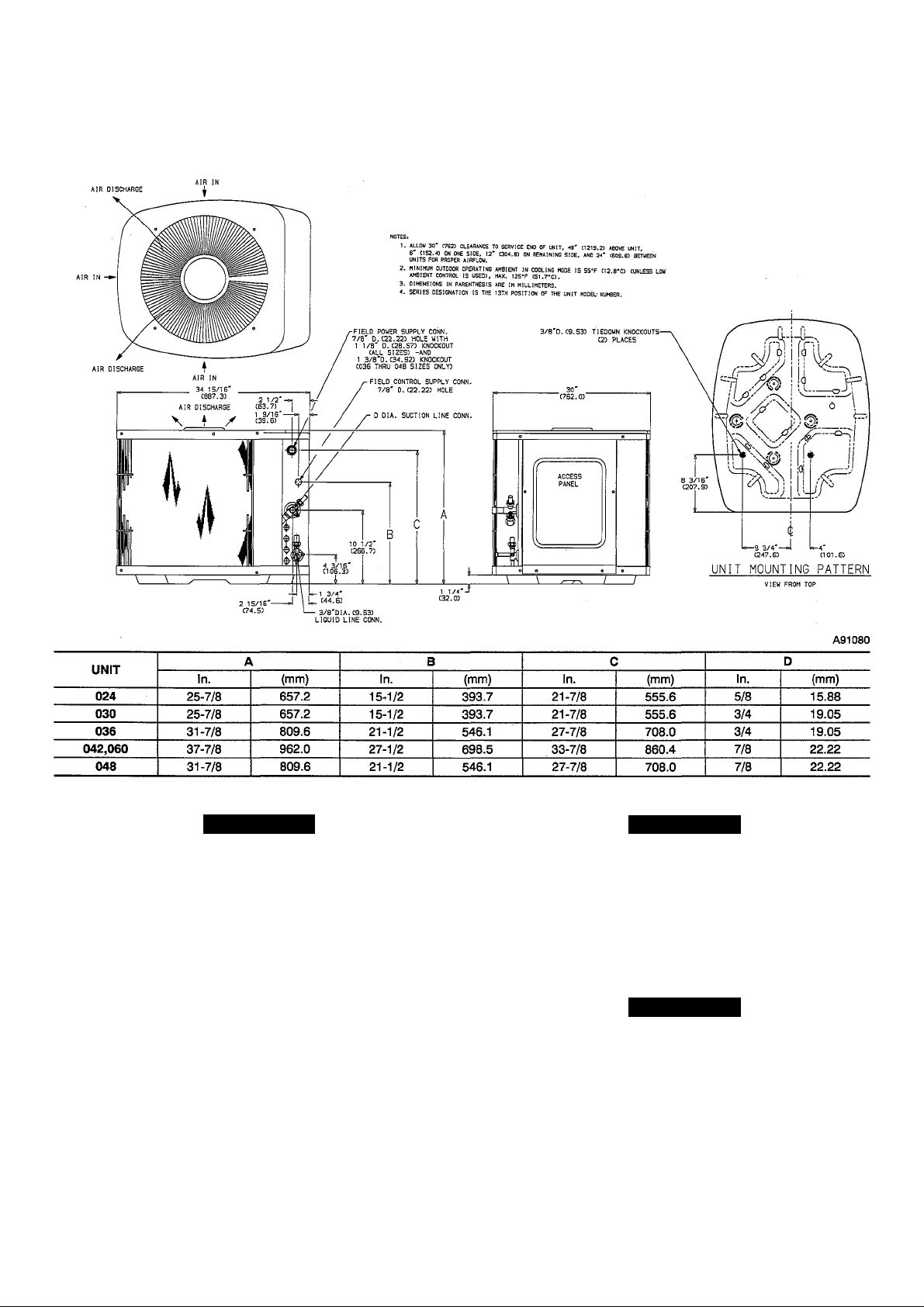

Step 2—Install on a Solid, Level Mounting Pad

The minimum mounting pad dimensions are 26 in. x 32 in.

(660.4mm X 812.8mm). If conditions or local codes require the

unit be attached to pad, tiedown bolts should be used and fastened

through knockouts provided in unit base pan. Refer to unit

mounting pattern in Fig. 2 to determine base pan size and knockout

hole location.

When installing, allow sufficient space for airflow clearance,

wiring, refrigerant piping and service. Allow 30-in. (762mm)

clearance to service end of unit and 48 in. (1219mm) above unit.

For proper airflow, a 6-in. (152mm) clearance on one side of unit

and 12 in. (305mm) on all remaining sides must be maintained.

Maintain a distance of 24 in. (610mm) between air conditioners.

Position so snow or ice from roof or eaves cannot fall directly on

unit.

On rooftop applications, locate unit 6 in. (152mm) above roof

surface. Where possible, place unit above a loadbearing wall.

Arrange supporting members to adequately support unit and

minimize transmission of vibration to building. Consult local

codes governing rooftop applications.

Step 3—Replace Indoor AccuRater® Piston, if Required

Check indoor coil piston to see if it matches the required piston

shown on unit rating plate. If it does not match, replace indoor coil

piston with piston shipped with this unit. The piston shipped with

outdoor unit is correct for any approved indoor coil combination.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book 1 4

Tab 3a 2a

PC 101 Catalog No. 563-812 Printed in U.S.A. Form 38TMA-1SI

pgi

12-91 Replaces: New

Fig. 2—Unit Reference Drawing

A CAUTION A CAUTION

If unit is to be installed on system with a thermostatic

expansion valve (TXV), removal of the indoor coU piston is

required.

Step 4—Make Piping Connections

Outdoor units may be connected to indoor sections using accessory

tubing package or field-supplied tubing of refrigerant grade,

correct size, and condition. The liquid- and vapor-tube diameters

can be determined by using Table 1. For tubing requirements

beyond 50 ft (15.24m), obtain information from your local

distributor.

If required, install solenoid valve in liquid line to achieve desired

rating. (See Fig. 3.)

DO NOT BURY MORE THAN 36 IN. (914mm) OF RE

FRIGERANT TUBING IN GROUND. If any section of

tubing is buried, there must be a 6- in.(152mm) vertical rise

to the valve connections on the outdoor unit. K more than the

recommended length is buried, refrigerant may migrate to

cooler buried section during extended periods of unit shut

down, causing refrigerant slugging and possible compressor

damage at start-up.

A CAUTION

For systems installed with a liquid-hue solenoid valve,

solenoid valve must be energized during evacuation and

purging for effective evacuation.

If either refrigerant tubing or indoor coil is exposed to atmospheric

conditions for longer than 5 minutes, it must be evacuated to 1000

microns to eliminate contamination and moisture in the system.

Loading...

Loading...