Page 1

Positive Pressure Storage System

50/60 Hz

Installation, Operating, and Maintenance

Instructions

For Use With Positive Pressure Chillers

SAFETY CONSIDERATIONS

Positive pressure storage systems are designed to provide safe and reliable service when operated within design specifications. When operating this equipment, use

good judgment and safety precautions to avoid damage

to equipment and property or injury to personnel.

Be sure you understand and follow the procedures and

safety precautions contained in this guide.

DO NOT VENT refrigerant relief valves within a building. Outlet

from rupture disc or relief valve must be vented outdoors in accordance with the latest edition ofASHRAE 15 (American Society

of Heating, Refrigeration, and Air Conditioning Engineers). The

accumulation of refrigerant in an enclosed space can displace oxygen and cause asphyxiation.

PROVIDE adequate ventilation in accordance with ASHRAE 15,

especially forenclosed and low overheadspaces. Inhalation of high

concentrations of vapor is harmful and may cause heart irregularities, unconsciousness,or death. Misusecan be fatal.Vaporis heavier

than air and reduces the amount of oxygen available for breathing.

Product causes eye and skin irritation. Decomposition products are

hazardous.

DO NOT USE OXYGEN to purge lines or to pressurize a machine

for any purpose. Oxygen gas reacts violently with oil, grease, and

other common substances.

NEVER EXCEED specified test pressures, VERIFY the allowable

test pressure by checking the instruction literature and the design

pressures on the equipment nameplate.

DO NOT USE air for leak testing. Use only tracer gases and dry

nitrogen.

DO NOT VALVE OFF any safety device.

BE SURE that all pressure relief devices are properly installed and

functioning before operating any machine.

with soapand water.If any entersthe eyes, IMMEDIATELYFLUSH

EYES with water and consult a physician.

NEVER APPLY an open flame or live steam to a refrigerant cylinder. Dangerous overpressure can result. When necessary to heat

refrigerant, use only warm (110 F [43 C]) water.

DO NOT REUSE disposable (nonreturnable) cylinders or

attempt to refill them. It is DANGEROUSAND ILLEGAL. When

cylinder is emptied, evacuate remaining gas pressure, loosen

the collar and unscrew and discard the valve stem. DO NOT

INCINERATE.

CHECK THE REFRIGERANT TYPE before transferring refrigerant to the machine. Theintroduction of the wrong refrigerant can

cause damage or malfunction to this machine.

Operation of this equipment with refrigerants other than those

cited herein shouldcomply with ASHRAE 15 (latest edition). Contact Carrierfor further information on use of thismachine with other

refrigerants.

DO NOTATTEMPT TO REMOVE fittings, covers, etc., while machine is under pressure or while machine is running. Be sure pressure is at 0 psig (0 kPa) before breaking any refrigerant

connection.

CAREFULLY INSPECT all relief devices, rupture discs, and other

relief devices AT LEAST ONCE A YEAR. If machine operates in

a corrosive atmosphere, inspect the devices at more frequent

intervals.

DO NOT ATTEMPT TO REPAIR OR RECONDITION any relief

device when corrosion or build-up of foreign material (rust, dirt,

scale, etc.) is found within the valve body or mechanism. Replace

the device.

DO NOT install relief devices in series or backwards.

USE CAREwhen working near orin line witha compressed spring.

Sudden release of the spring can cause it and objects in its path to

act as projectiles.

19XB

DO NOT WELD OR FLAMECUT any refrigerant line or vessel

until allrefrigerant (liquid andvapor) has beenremoved from chiller.

Traces of vapor should be displaced with dry air or nitrogen and

the work area should be well ventilated. Refrigerant in contact with

an open flame produces toxic gases.

DO NOT USE eyebolts or eyebolt holes to rig machine sections or

the entire assembly.

DO NOT work on high-voltage equipment unless you are a qualified electrician.

DO NOTWORK ON electricalcomponents, including control panels, switches, starters, or oil heater until you are sureALL POWER

IS OFF and no residual voltage can leak from capacitors or solidstate components.

LOCK OPEN ANDTAGelectrical circuits during servicing.IF WORK

IS INTERRUPTED, confirm that all circuits are deenergized before resuming work.

DO NOT syphon refrigerant by mouth.

AVOID SPILLING liquid refrigerant on skin or getting it into the

eyes. USE SAFETY GOGGLES. Wash any spills from the skin

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Tab 5a

PC 211 Catalog No. 531-927 Printed in U.S.A. Form 19XB-1SI Pg 1 6-96 Replaces: New

DO NOT STEP on refrigerant lines. Broken lines can whip about

and cause personal injury and damage to the machine.

DO NOT climb over a machine. Use platform, catwalk, or staging.

Follow safe practices when using ladders.

USE MECHANICAL EQUIPMENT (crane, hoist, etc.) to lift or

move inspection covers or other heavy components. Even if components are light, use such equipment when there is a risk of slipping or losing your balance.

BE AWARE that certain automatic start arrangements CAN ENGAGE THE STARTER. Open the disconnect ahead of the starter

in addition to shutting off the machine or pump.

USE only repair or replacement parts that meet the code requirements of the original equipment.

DOUBLE-CHECK that coupling nut wrenches, dial indicators, or

other items have been removed before rotating any shafts.

DO NOT LOOSEN a packing gland nut before checking that the

nut has a positive thread engagement.

PERIODICALLY INSPECT all valves, fittings, and piping for corrosion, rust, leaks, or damage.

DO NOTMIX REFRIGERANTfrom chillers thatuse differentcompressor oils. Compressor damage can result.

Page 2

CONTENTS

Page

SAFETY CONSIDERATIONS ...................1

INTRODUCTION ..............................2

INSTALLATION .............................2-10

Complete Pre-Installation Checks .............2

• IDENTIFY UNIT

• INSPECT SHIPMENT

Mount the Pumpout Unit .....................3

• MOUNTING ON THE CHILLER

• FLOOR MOUNTING

Rig the Storage Tank .........................3

Make Piping Connections ....................7

• INSTALL VENT PIPING TO RELIEF DEVICES

Make Electrical Connections ..................7

CONTROLS AND COMPONENTS ..............11

Pumpout Unit ................................11

• CONTROLS

• SAFETY CONTROL SETTINGS

• COMPRESSOR

• CONDENSER

• OIL SEPARATOR

• SUCTION AND DISCHARGE VALVES

Storage Tank ................................11

• DRAIN VALVE

• DUAL RELIEF VALVES

• PRESSURE GAGE

• LEVEL GAGE

OPERATION ...............................11-15

Overview ...................................11

• REFRIGERANT TRANSFER

• TRANSFERRING LIQUID REFRIGERANT FROM

THE CHILLER COOLER TO THE CHILLER

CONDENSER OR PUMPOUT STORAGE TANK

• TRANSFERRING LIQUID REFRIGERANT FROM

THE CHILLER CONDENSER OR PUMPOUT

STORAGE TANK TO THE CHILLER COOLER

• DISTILLING THE REFRIGERANT

Pumpout and Refrigerant Transfer

Procedures ...............................12

• OPERATING THE PUMPOUT UNIT

• TO READ REFRIGERANT PRESSURES

• POSITIVE PRESSURE CHILLERS WITH STORAGE

TANKS

• CHILLERS WITH ISOLATION VALVES

• DISTILLING THE REFRIGERANT

MAINTENANCE ............................15,16

Pumpout Unit ...............................15

• PUMPOUT COMPRESSOR OIL CHARGE

Storage Tank ...............................16

Ordering Replacement Parts .................16

TROUBLESHOOTING ........................16

INTRODUCTION

The 19XB Positive Pressure Storage (PPS) System has

been designed to help owners and operators of positive pressure chillers store refrigerants HCFC-22 and HFC-134a during service and repair work. The 19XB system conserves

these refrigerantsand prevents the releaseofexcessive amounts

of refrigerant into the atmosphere. The proper use of this

equipment minimizes the loss of HFCs and HCFCs.

The 19XB PPS systemshownin Fig. 1 consists of a pumpout unit mounted on a storage tank. The pumpout unit is offered as a free-standing unit that can be used with chillers

that have an existing storage tank or with chillers that have

isolation valves that permit built-in refrigerant storage.

The 19XB PPS systems are factory tested and certified to

theAmerican Society of Mechanical Engineers(ASME)pressure vessel code. The tanks are constructed of certified steel

and are pressure rated at 300 psig (2068 kPa). The PPS storage tank is equipped with dual relief valves for proper venting per ASHRAE 15 (American Society of Heating Refrigeration, and Air Conditioning Engineers) guidelines. An

automatic level switch is prewired to the control circuit to

ensure proper storage levels.

The 19EA pumpout unit is a complete, hermetic, compact

unit that consists of:

• a spring-mounted reciprocating compressor with a direct-

drive motor

• a water-cooled refrigerant condenser

• an oil separator

• suction and discharge valves to control refrigerant flow

• prewired safety and control devices.

When referencing refrigerant charges in this manual, the

HCFC-22 charge will be listed first and the HFC-134a value

will follow in brackets.

INSTALLATION

Complete Pre-Installation Checks

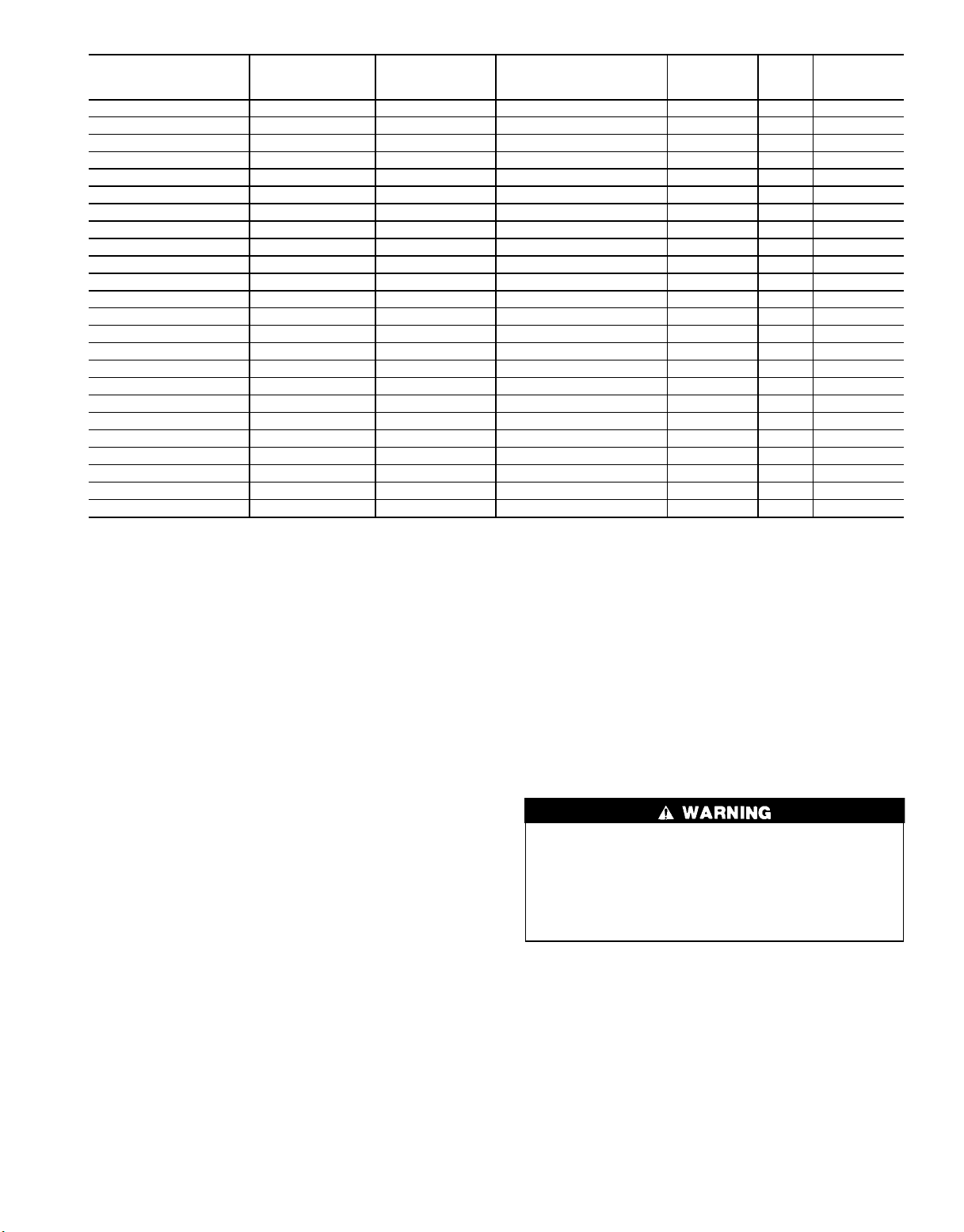

IDENTIFY UNIT — Identify the assembly number

(T able1) printed on the pumpout unit andstoragetank nameplates. Check this information against the job requirements.

Fig. 1 shows the PPS system and its major components.

Refer to Tables 2 and 3 for physical data.

INSPECT SHIPMENT — Inspect unit for damage before

removing unitfromshipping conveyance. If unit appearsdamaged, it should be inspected by a shipping inspector before

removal. File a claim with the shipping company if shipment is damaged or incomplete. The manufacturer is not responsible for damage incurred during transit.

Check all components. Notify the supplier immediately if

any item is missing. To prevent loss or damage, leave all

parts in their original package until they are needed.

2

Page 3

Table 1 — Positive Pressure System Assembly Numbers

POSITIVE PRESSURE

SYSTEM ASSEMBLY

NUMBER

19XB04280205 19EA42-748 R-22 208-3-60 13.2 63.5 28 cu ft

19XB04280206 19EA44-748 R-22 230-3-60 11.5 57.5 28 cu ft

19XB04280207 19EA46-748 R-22 400/460-3-50/60 5.8 28.8 28 cu ft

19XB04280208 19EA47-748 R-22 575-3-60 4.6 23.0 28 cu ft

19XB04280213 19EA48-748 R-134a 208-3-60 13.2 63.5 28 cu ft

19XB04280214 19EA49-748 R-134a 230-3-60 11.5 57.5 28 cu ft

19XB04280215 19EA51-748 R-134a 400/460-3-50/60 5.8 28.8 28 cu ft

19XB04280216 19EA52-748 R-134a 575-3-60 4.6 23.0 28 cu ft

19XB04280601 19EA42-748 R-22 208-3-60 13.2 63.5 None

19XB04280602 19EA44-748 R-22 230-3-60 11.5 57.5 None

19XB04280603 19EA46-748 R-22 400/460-3-50/60 5.8 28.8 None

19XB04280604 19EA47-748 R-22 575-3-60 4.6 23.0 None

19XB04280605 19EA48-658 R-134a 208-3-60 13.2 63.5 None

19XB04280606 19EA49-658 R-134a 230-3-60 11.5 57.5 None

19XB04280607 19EA51-658 R-134a 400/460-3-50/60 5.8 28.8 None

19XB04280608 19EA52-658 R-134a 575-3-60 4.6 23.0 None

19XB04520205 19EA42-748 R-22 208-3-60 13.2 63.5 52 cu ft

19XB04520206 19EA44-748 R-22 230-3-60 11.5 57.5 52 cu ft

19XB04520207 19EA46-748 R-22 400/460-3-50/60 5.8 28.8 52 cu ft

19XB04520208 19EA47-748 R-22 575-3-60 4.6 23.0 52 cu ft

19XB04520213 19EA48-748 R-134a 208-3-60 13.2 63.5 52 cu ft

19XB04520214 19EA49-748 R-134a 230-3-60 11.5 57.5 52 cu ft

19XB04520215 19EA51-748 R-134a 400/460-3-50/60 5.8 28.8 52 cu ft

19XB04520216 19EA52-748 R-134a 575-3-60 4.6 23.0 52 cu ft

LEGEND

LRA — Locked RotorAmps

RLA — Rated LoadAmps

PUMPOUT UNIT

ASSEMBLY NO.

REFRIGERANT

COMPRESSOR MOTOR

(V-Ph-Hz)

NOTES:

1. Allstorage vesselsare 300 psig (2068 kPa)designs perthe ASME

(American Society of Mechanical Engineers) Boiler Pressure

Vessel Code, Section VIII Division 1.

2. Allunits aboveare shippedwitha 15psig (103kPa) nitrogencharge.

3. Nominal horsepower for all pumpout units is 3.0.

MAXIMUM

RLA

LRA

STORAGE

TANK

MountthePumpoutUnit— The pumpout unit, if pur-

chased separately, may be mounted directly on the chiller or

it may be floor mounted.

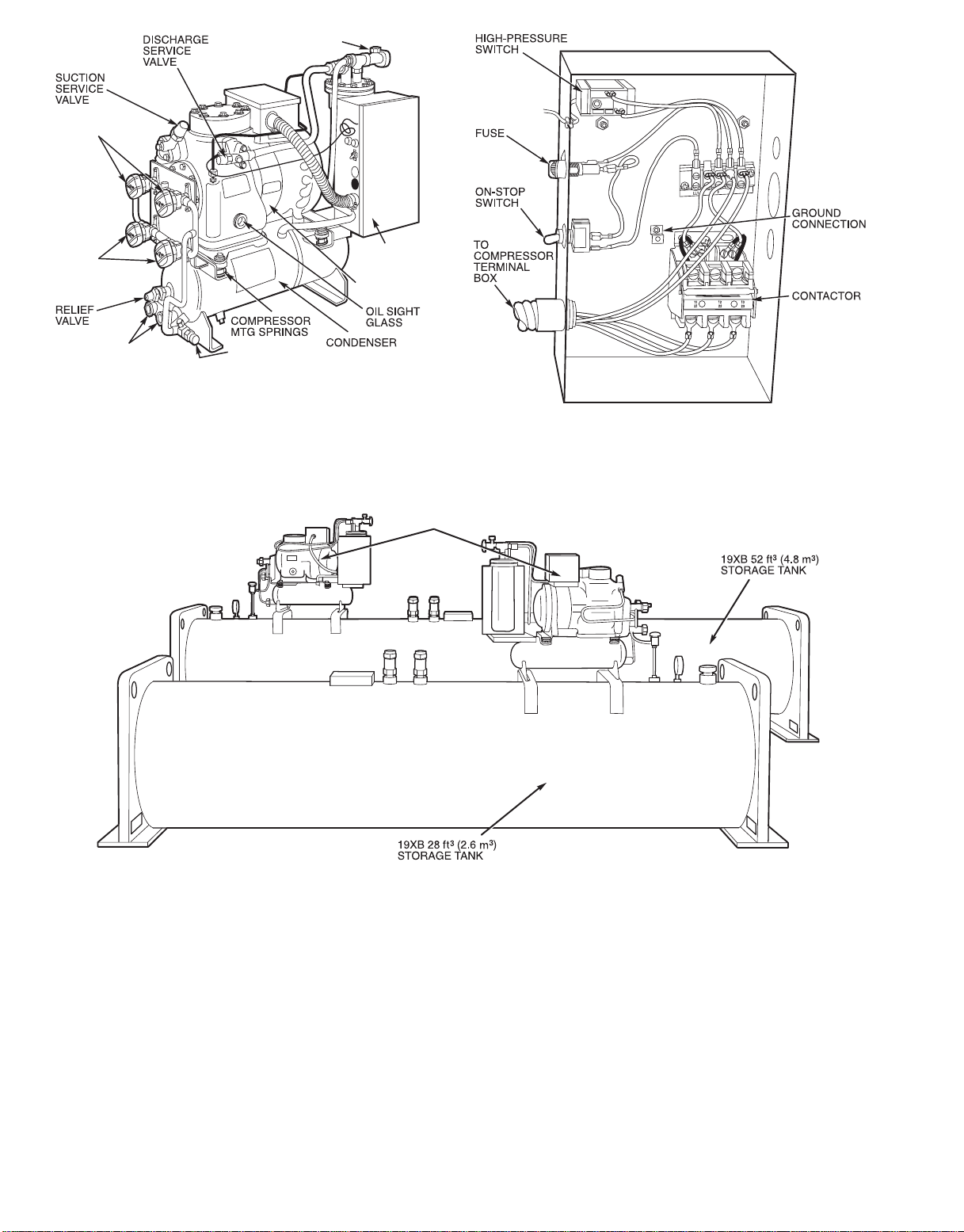

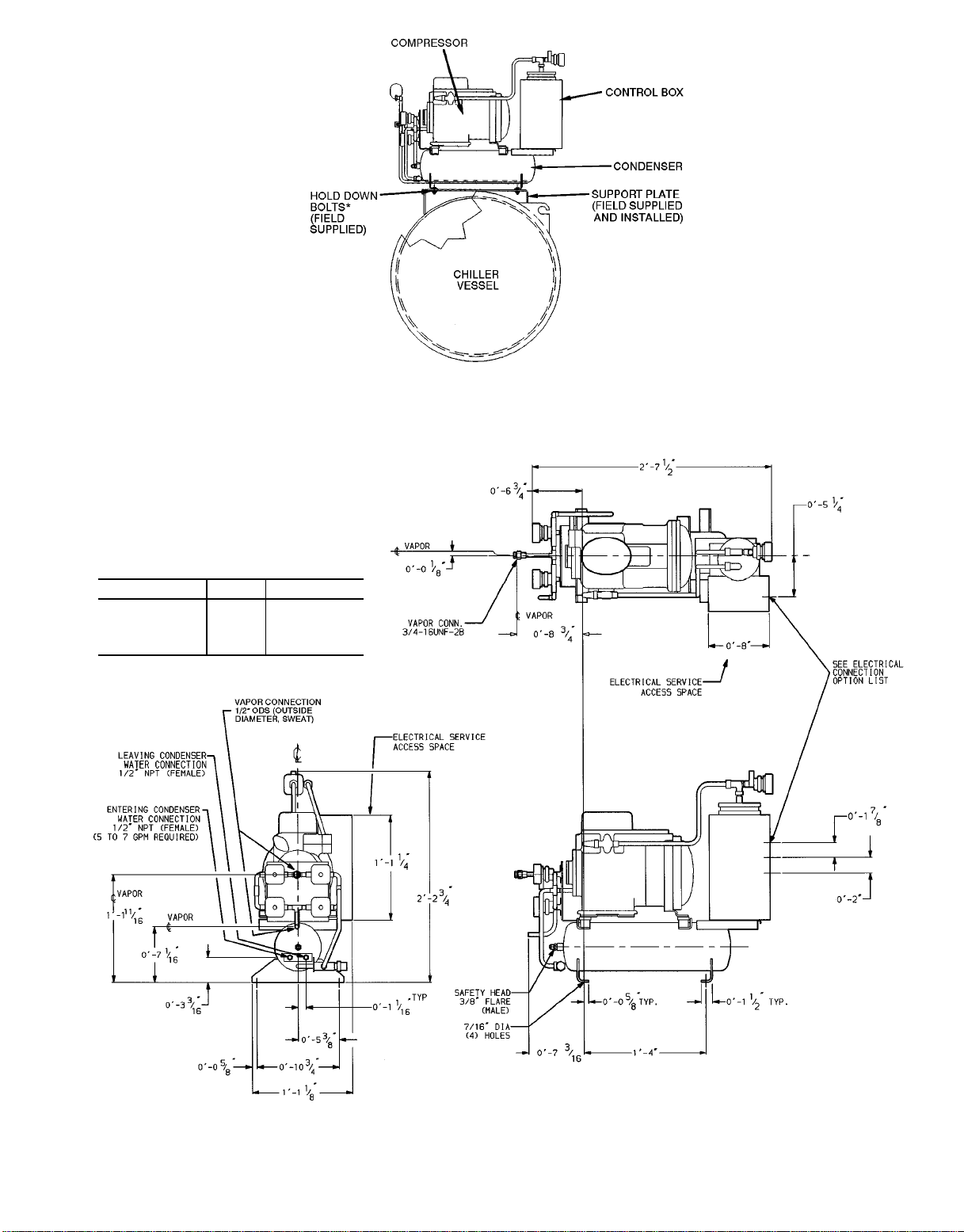

MOUNTING ON THE CHILLER — See instructions provided with the chiller for mountingthepumpout unit. Atypical chiller mount is shown in Fig. 2.

FLOOR MOUNTING — Select a ventilated and accessible

area, free of traffic or other hazards. Removeand discard the

4 angle supports at the base of the pumpout unit and bolt the

unit to the floor through the 4

pumpout unit. Special isolation is unnecessary. Contact surface and dimensions for the pumpout unit are given in

Fig. 3.

7

⁄16in. holes at the base of the

Rig the Storage Tank — The complete 19XB system

can be rigged as a single assembly. See the rigging instructions on the label attached to the assembly. Also refer to the

rigging guide (Fig. 4), physical data in Tables 2 and 3, and

contact surface and dimensions for the complete system in

Fig. 5. Lift the assembly only from the 4 points indicated in

the rigging guide. Each rigging cable must be capable of

supporting the entire weight of the assembly.

Lifting the assembly from points other than those specified may result in serious damage to the assembly and

personal injury. Riggingequipmentand procedures must

be adequate forassembly. See Tables 2 and 3for weights.

NOTE: These weights are broken down into pumpout

unit and storage tank weights. For the complete assembly weight, add all components together.

3

Page 4

VALVES

VENT VALVE

VALVES

CONDENSER

WATER

CONNECTIONS

(FIELD PIPING)

REFRIGERANT

INLET VALVE

19EA PUMPOUT UNIT

CONTROL BOX

(WIRING BY

CONTRACTOR)

COMPRESSOR

19EA PUMPOUT UNITS

19EA CONTROL BOX (INTERIOR)

Fig. 1 — 19XB Positive Pressure Storage System

4

Page 5

*3⁄8-16 bolts × 1-in. lg; 4 required.

Fig. 2 — 19EA Pumpout Unit: Typical Chiller Mount

ELECTRICAL CONNECTION

OPTION LIST

TRADE SIZE QTY LOCATION

1

⁄2( 1TOP

3

⁄

4

( 1 BOTTOM

1( 1 MIDDLE

1

1

⁄4( 1 MIDDLE

Fig. 3 — Pumpout Unit Contact Surfaces and Dimensions

5

Page 6

NOTES:

1. Each chainmust be capable of supporting the entireweight of the

machine.

2. Minimum chain length:

3

tank — 108-09

28 ft

3

52 ft

tank — 158-69

3. Total weight equals empty weight from chart and charge weight

given on label.

STORAGE

TANK SIZE

3

28 Ft

3

52 Ft

CENTER OF GRAVITY

APPROX. DIM. — ft-in. (mm)

AB

4- 51⁄

(1353)

6-101⁄

(2086)

4

8

1-77⁄

(505)

1-83⁄

(527)

8

4

EMPTY WEIGHT

LB (Kg)

(1080)

(1569)

Fig. 4 — Rigging Guide

Table 2 — Physical Data

19EA Pumpout Unit

ENGLISH (SI)

Pumpout Unit Weight* lb (kg) 210 (95)

Pumpout Condenser Water Flow Rate gpm (L/s) 5 to 7 (.32 to .44)

Pumpout Condenser Water Pressure Drop psig (kPa) 6 to 10.7 (41.4 to 73.8)

Maximum Entering Condenser Water Temperature F (C) 85 (29)

Maximum Leaving Condenser Water Temperature F (C) 100 (37)

Condenser Relief Valve (Fusible Plug) psig (kPa) 385 (2655)

Condenser Pressure Rating

Refrigerant Side psig (kPa) 385 (2655)

Waterside psig (kPa) 150 (1034)

Compressor Rating 1750 rpm (29 r/s) Reciprocating cfm (L/s) 8.7 (.25)

Valves (4-Valve Manifold, Copper with

Brass Turn Knob Valves)

in. OD

*The pumpout unit weight includes the compressor/condenser, control box, and the oil separator.

NOTES:

1. The motor is hermetic with thermal protection.

2. The control box is mounted and wired with a fuse on/off switch according to NEMA 1 (National

Electrical Manufacturing Association).

3. The starter contactor is located in the control box. The overloads on the motor are wired and the

disconnect switch is supplied by the customer.

4. The condenser tube is copper.

1

⁄

2

2380

3460

1

⁄

2

6

Page 7

Table 3 — 19XB Storage Tank Rated Dry Weight and Refrigerant Capacity

English

SIZE CODE

0428 24.00 2380 1842 1860 1704 1716

0452 27.25 3460 3527 3563 3264 3286

SIZE CODE

0428 610 1080 836 844 773 778

0452 592 1569 1600 1616 1481 1491

ANSI — American National Standards Institute

ASHRAE — American Society of Heating, Refrigeration,

UL — Underwriters’ Laboratories

*The above dry weight includes the pumpout unit weight of 210 lbs (95 kg).

and Air Conditioning Engineers

TANK OD

(in.)

TANK OD

(mm)

LEGEND

DRY WEIGHT*

(lb)

DRY WEIGHT*

(kg)

SI

MakePipingConnections— Figure 6representstypi-

cal pumpout unit/chiller piping connections. Standard connections for1⁄2-in. OD copper tubing are provided. Install

the field-supplied FPT tee with pipe plug in the piping as

shown in Fig. 6. This tee is used for refrigerant charging.

NOTE: If any field piping runs exceed 50 ft in length, use

7

⁄8-in. OD copper tubing to minimize pressure drop.

Pumpout unit water piping connections are shown in

Fig. 6. Both connections are

valve should be installed in the water line. Provide a means

for blowing water from the condenser coil at winter shutdown to prevent freeze-up damage. Refer to the Job Data for

water piping particulars.

INSTALL VENT PIPING TO RELIEF DEVICES — The

pumpout storage tank is factory-equipped with relief devices. Refer to Fig. 5 and Table 2 for size and location of the

relief devices. Vent the relief devices to the outdoors in accordance with ANSI/ASHRAE 15 Safety Code (latest edition) for Mechanical Refrigeration and all other applicable

codes. Relief devices are set to relieve at 300 psig

(2068 kPa).

Refrigerant discharged into confined spaces can displace oxygen and cause asphyxiation.

1

⁄2-in. NPT (female). A shutoff

MAXIMUM REFRIGERANT CAPACITY (lb)

ASHRAE/ANSI 15 UL 1963

R-22 R-134a R-22 R-134a

MAXIMUM REFRIGERANT CAPACITY (kg)

ASHRAE/ANSI 15 UL 1963

R-22 R-134a R-22 R-134a

1. If relief devices are manifolded, the cross-sectional area

of the relief pipe must at least equal the sum of the areas

required for individual relief pipes.

2. Provide a pipe plug near outlet side of each relief device

for leak testing. Provide pipe fittings that allow vent piping to be disconnectedperiodicallyfor inspection of valve

mechanism.

3. Piping to relief devices must not apply stress to the device. Adequately support piping.Alength of flexible tubing or piping near the device is essential on springisolated machines.

4. Cover the outdoor vent with a rain cap and place a condensation drain at the low point in the vent piping to prevent water build-up on the atmospheric side of the relief

device.

Make Electrical Connections — See nameplate on

compressor of pumpout unit and Table 1 for motor electrical

data. Wire unit according to the diagram inside the control

box.

Fig. 7 is the wiring schematic for a complete system that

includes the 19XB storage tank and the pumpout unit.

Fig. 8 is the wiring schematic for the pumpout unit. Use this

schematic for installations that do not include an auxiliary

pumpout storage tank.

NOTE: Use copper conductors only.

7

Page 8

DIMENSIONS

ENGLISH (ft-in.)

TANK

SIZE

0428 10- 5 9-10 4-9 2-4

0452 14-111⁄414- 41⁄25-07⁄82-81⁄21-41⁄43-47⁄167- 21⁄44-0 3-117⁄83-15⁄163-57⁄80-33⁄87-11⁄21-83⁄41-79⁄163-8 5-01⁄

TANK

SIZE

0428 3175 2997 1448 730 365 945 1499 1121 1118 849 965 89 1442 505 491 1111 1530

0452 4553 4382 1546 826 413 1027 2191 1219 1216 948 1064 86 2172 528 497 1118 1537

NOTES:

1. Denotes center of gravity.

2. Dimensions in ( ) are in millimeters.

3. The weights and centerof gravity values given are for an empty storage

4. For additional information on the pumpout unit, see certified drawings.

5. The available conduit knockout sizes are:

A B CDE F G H J K LMNPR ST

3

⁄41-23⁄83-13⁄164-11 3-81⁄83- 8 2-97⁄163-2 0-31⁄24-83⁄41-77⁄81-75⁄163-73⁄45-01⁄

SI (mm)

ABCDEFGHJKLMNPRST

tank.

4

2

TRADE

SIZE

1

⁄2( 1 top

3

⁄4( 1 bottom

1( 1 middle

11⁄4( 1 middle

QTY LOCATION

Fig. 5 — PPS Contact Surface and Dimensions

8

Page 9

CHILLERS WITHOUT ISOLATION VALVES CHILLERS WITH ISOLATION VALVES

(WITH OR WITHOUT PUMPOUT STORAGE TANKS)

GENERAL PIPING CONNECTION SIZES

CONNECTION SIZE (in.)

Refrigerant Transfer Connections

Condenser Water Cooling Connectors

Safety Relief Head Pumpdown Condenser

ODS — Outside Diameter, Sweat

NOTES:

1. The field-suppliedtubing is to be

be arranged and supported to avoid stresses on the equipment,

transmission of vibrations, and interference with routine access

during the reading, adjusting, and servicing of the equipment. If

the distance from the chiller to thepumpout unit is over 50ft, then

7

⁄8-in. OD tubing (min.)must be used. Provisions should be made

for adjustment in each plane of the tubing and for both periodic

and majorservicing of the equipment.Special care mustbe taken

so that the safety head does not experience tubing strain. Vent

the safety head per ASHRAE 15 (American Society of Heating,

Refrigeration, and Air Conditioning Engineers), latest revision.

2. The tubing and valve from the storage tank to the pumpout compressor is factory supplied when the unit is factory mounted.

1

⁄2-in. ODtubing (min.) and must

1

⁄2ODS (female)

1

⁄2NPT (female)

3

⁄8Flare (male)

Fig.6—Typical Pumpout Unit/Chiller Connection Schematic

LEGEND

Factory-Supplied Tubing

Field-Supplied Tubing

Field-Supplied Tubing (Multiple Chillers)

Service Valve (Factory Supplied)

Service Valve (Field Supplied)

9

Page 10

Table 4 — Relief Devices

STORAGE

TANK SIZE

28

52

RELIEF VALVE

OUTLET SIZE

1 in. NPT

Female Connector

1 in. NPT

Female Connector

QUANTITY

lb air

min

2 31.4 14.2

2 52.3 23.7

REQUIRED FACTOR

Kg air

min

LEGEND

Ground

Field Wiring

Factory Wiring

Contactor Term.

Overload Term.

Pumpdown Term.

Pumpdown Comp’r.

Term.

Fig. 7 — 19XB Pumpout System Wiring Schematic

LEGEND

C—Contactor

Fu — Fuse, 3 Amps

HP — High-Pressure Cutout

L—Compressor Motor Voltage Line (3-phase)

LL — Low-Line Control Voltage (single-phase)

OL — Compressor Overload

T’stat — Internal Thermostat

*Bimetal thermal protector imbedded in motor winding.

Compressor Terminal

Contactor Terminal

Overload Terminal

Pumpout Unit Terminal

Fig. 8 — Pumpout Unit Wiring Schematic

10

Page 11

CONTROLS AND COMPONENTS

Figure 1 shows the major components of the PPS system.

PumpoutUnit— The pumpout unit consists of a spring-

mounted directmotor-driven reciprocating compressor,a watercooled refrigerant condenser, an oil separator, suction and

dischargevalvesto control refrigerant flow, and prewired safety

and control devices. The pumpout unit comes equipped with

a 4-way transfer valve manifold to interconnect both liquid

and vapor transfer and to pressurize the chiller during transfer of refrigerant from chiller to storage tank.

CONTROLS — The pumpout unit has the following controls: an on/off switch, a 3-amp fuse, compressor overloads,

an internal thermostat, a compressor contactor, and a refrigerant high pressure cutout.

SAFETYCONTROL SETTINGS — Thepumpoutunit highpressure switch (Fig. 1) is set to open at the settings listed

in Table 5. The switch setting is checked by operating the

pumpout condenser and slowly throttling the pumpout condenser water.

Table 5 — High Condition Pressure Switch Settings

English

REFRIGERANT

R-134a 161 ± 5 psig

R-22 220 ± 5 psig

REFRIGERANT

R-134a 1110±34kPa

R-22 1517 ± 34 kPa

NOTES:

1. R-22 units use high-pressure cutout switch HK01UA181.

2. R-134a units use high-pressure cutout switch HK01UA187.

HIGH-PRESSURE SWITCH

Cutout CutIn

+0

130 − 5 psig

+0

185 − 5 psig

SI

HIGH-PRESSURE SWITCH

Cutout Cut-In

+0

896 − 34 kPa

+0

1276 − 34 kPa

COMPRESSOR — The pumpout compressor assembly has

a positive displacement of 1750 rpm (29 r/s) and 8.7 cfm

(0.004 m3/s). It comes equipped with thermal protection on

the motor and an in-line oil separator.

CONDENSER —The water-cooled condenser is fullyASME

constructed. During transfer, it condenses refrigerant vapor

to liquid.The condenser transfer tank safety reliefvalves comply with ASHRAE 15 standards.

OIL SEPARATOR — The pumpout unit includes an in-line

oil separator to remove oil that becomes mixed with refrigerant and returns the oil to the compressor.

SUCTION AND DISCHARGE VALVES — The pumpout

unit comes with a 4-way transfer valve manifold to interconnect both liquid and vapor transfer and to pressurize the

chiller during transfer of refrigerant from chiller to storage

tank or from one chiller vessel to another.

Storage Tank — The storage tank is rated for positive

pressure refrigerants underASME Section VIII pressure vessel codes with a minimum of 300 psig (2068 kPa) rating.

The tank components include:

DRAIN VALVE — Located at its lowest point of drain with

a minimum of 1 in. NPT.

DUAL RELIEF VALVES — Two relief valves and a 3-way

shut-off valve.

PRESSURE GAGE —A 30in.-0-400psig (101-0-2760 kPa)

compound pressure gage.

LEVEL GAGE — Liquid level gage (magnetically coupled

dial type) with electronic shut-off at 90% liquid capacity.

During transfer of refrigerant into and out of the pumpout storage tank, carefullymonitorthe storage tank level

gage. Do not fill the tank more than 90% of capacity to

allow for refrigerant expansion. Overfilling may result

in damage to the tank and personal injury. For maximum refrigerant capacity, refer to Table 2.

OPERATION

Overview —

another is accomplished by using either gravity or pressure

differential. A difference in elevation between 2 vessels results in agravityflow of liquid; a dif ferencein pressure forces

the liquid from one vessel to the other. The latter method

requires lowering the pressure in one vessel. If there is liquid in that vessel, its temperature must be lowered, and the

pressure in the other vessel must be simultaneously

increased.

Under most circumstances, creating the pressure differential is not a difficult process. Some applications, such as

ice storage, outdoor installations, or installations with high

temperature differentials between the storage tank and the

chiller may require additional consideration. In some instances, it may be necessary to add auxiliary heat to one of

the vessels or to insulate the storage tank at job sites where

high ambient temperature or sun load make it difficult to reduce the temperature and pressure in the tank. Outdoor installations must have a roof or cover over thestorage tank to

ensure that thepressurein the tank does not exceed the chiller

relief pressure setting.

REFRIGERANT TRANSFER — When refrigerant is being

evacuated from the chiller cooler or condenser vessels, any

liquid refrigerant left in a vessel will flash off, lowering the

temperature in that vessel enough to freeze the fluid (usually

water) flowing through the cooler or condenser tubes. This

event, called tube freeze-up, can cause extensive damage to

the chiller; therefore, all liquid refrigerant must be removed

from a vesselbeforeevacuation of refrigerant vapor is started.

If all the liquid cannot be removed, then the cooler water

and condenser water pumps mustbeoperated throughout the

process of evacuating refrigerant vapor to keep fluid moving

through the cooler and condenser tubes.

TRANSFERRING LIQUID REFRIGERANT FROM THE

CHILLER COOLERT OTHE CHILLER CONDENSER OR

PUMPOUT STORAGE TANK — Chiller and pumpout unit

valves are set to permit the pumpout compressor to discharge refrigerantvaporinto the cooler vessel, lowering pressure in the condenser vessel/storage tank. The pressure differential forcesliquidfrom the cooler vesselintothe condenser

vessel/storage tank. After all the liquid is transferred, the refrigerant vapor remaining in the cooler vessel can be drawn

off by reducing pressure in the chiller and discharging the

vapor through the pumpout unit condenser into the condenser vessel/storage tank.

TRANSFERRING LIQUID REFRIGERANT FROM THE

CHILLER CONDENSERORPUMPOUT STORAGETANK

TO THE CHILLER COOLER — Chiller and pumpout unit

valves are set to increase pressure in the chiller condenser

vessel/storage tank and to reduce pressure in the cooler vessel. Pressure in the cooler vessel is lowered to correspond to

a saturated refrigerant liquid temperature 2 F (1.1 C) above

the freezing temperature of the liquidcirculatingthrough the

chiller cooler/condenser tubes (34 F [1.1 C] for water). The

valves are set sothatthe pressure in the cooler vessel is lower

than that of the condenser vessel/storage tank, forcing the

liquid into the cooler vessel.

Transferring refrigerant from one vessel to

11

Page 12

NOTE: During this operation, maintain water circulation

through the chiller cooler and condenser vessels to prevent

tube freeze-up.

DISTILLING THE REFRIGERANT — Refrigerant vapor

is transferred from the chiller cooler vessel or pumpout storage tank through the pumpout condenser, condensed to a liquid, and pumped to the chiller condenser vessel. During this

operation, water circulation mustbemaintained in the pumpout condenser.Refrigerant impurities left in the chiller cooler

vessel or storage tank are then drained off. This operation

can takefrom4 to 14 hours, dependingon the type and amount

of refrigerant being distilled.

The Pumpout and Refrigerant Transfer Procedures section gives step-by-step instructions on performing these

operations.

Pumpout and Refrigerant Transfer Procedures

Three possibilities are available:

—

1. If there are no isolation valves on the chiller, a complete

pumpout system with a pumpout storage tank and pumpout unit is needed.

2. Whether or not isolation valvesare available on the chiller,

the refrigerant can be pumped to and isolated in a pumpout storage tank by using the pumpout unit.

3. If isolation valves are available on the chiller, the refrig-

erant can be pumped to either the cooler vessel or the

condenser vessel using the pumpout unit.

The following procedures describe how to transfer refrigerant from one vessel to another and how to evacuate the

chiller.

OIL RETURN

LINE

CONNECTION

CONDENSER

WATER

CONNECTIONS

VENT VALVE 8

REFRIGERANT

INLET VALVE

PUMPOUT

CONTROL BOX

(WIRING BY

CONTRACTOR)

Fig. 9 — Pumpout Unit

2. Attach a 30 in.-0-400 psi (101-0-2760 kPa) gage to the

storage tank to determine its pressure.

POSITIVE PRESSURE CHILLERS WITH STORAGE

TANKS — In the Valve/Condition tables that accompany

these instructions, the letter 9C9 indicates a closed valve.

Figures 9 and 10 show the locations of the valves.

Do not mix refrigerants from chillers that use different

compressor oils. Compressor damage canresult.For example, the compressor oil in a 23XL chiller that uses

HCFC-22 refrigerant can cause severe lubrication problems in a 19XL chiller that uses HCFC-22 refrigerant.

OPERATING THE PUMPOUT UNIT

1. Be sure that the suction and the discharge service valves

on the pumpout compressor (Fig. 9) are open (backseated) during operation.Rotatethe valve stem fully counterclockwise to open. Frontseating the valve closes the

refrigerant line and opens the gage port to compressor

pressure.

2. Make sure that the pumpout compressor holddown bolts

(Fig. 2) have been loosened to allow free spring travel.

Transfer, addition, or removal of refrigerant in springisolated chillers may place severe stressonexternal piping if springs on the chiller have not been blocked in

both up and down directions.

3. Open the refrigerant inlet valve (Fig. 9) on the pumpout

compressor.

4. Oil should be visible in the pumpout compressor sight

glass under all operating conditions and during shutdown. If oil is low, add oil as described in the Maintenance section.

TO READREFRIGERANTPRESSURES — During pumpout or leak testing:

1. Refer to the display on the chiller control center to determine refrigerant-side pressures and low (soft)vacuum.

Use a quality vacuum indicator or manometer to measure

evacuation and dehydrationand to ensure the desired range

and accuracy.

Always run chiller cooler and condenser water pumps

and always charge or transfer refrigerant as a gas when

chiller vessel pressure is less than 60 psig (414 kPa)

[30 psig (207 kPa)]. Below these pressures, liquid refrigerant flashes intogas,resulting in extremely low temperatures inthe cooler/condenser tubesand possibly causing

tube freeze-up.

Transfer Refrigerant from Pumpout Storage Tank to Chiller:

During transfer of refrigerant into and out of the 19XB

storage tank,carefullymonitor the storage tanklevel gage.

Do not fill the tank more than 90% of capacity to allow

for refrigerant expansion. Overfillingmayresult in damage to the tank and personal injury.

1. Equalize refrigerant pressure.

a. Turn on chiller water pumps and monitor chiller

pressures.

b. Close pumpout and storage tank valves 2, 4, 5, 8, and

10, and close refrigerant chargingvalve 7; open chiller

isolation valve 1 1and any other chiller isolationvalves,

if present.

c. Open pumpout and storage tank valves 3 and 6; open

chiller valves 1a and 1b.

VALVE 1a1b23456781011

CONDITION C C C C C C

d. Gradually crack open valve 5 to increase chiller pres-

sure to 60 psig (414 kPa),[30psig (207 kPa)]. Slowly

feed refrigerant to prevent freeze-up.

12

Page 13

Fig. 10 — Valve Locations for 19XB Pumpout Unit With 19XB Storage Tank

e. Open valve 5 fully after thechillerpressure rises above

the freezing point of the refrigerant. Let the storage

tank andchiller pressure equalize.Openrefrigerant charging valve 7 and storage tank charging valve 10 to let

liquid refrigerant drain into the chiller.

VALVE 1a1b23456781011

CONDITION C C C

2. Transfer remaining refrigerant.

a. Close valve 5 and open valve 4.

VALVE 1a1b23456781011

CONDITION C C C

b. Turn off the pumpout condenser water,and turn on the

pumpout compressor to push liquid refrigerant out of

the storage tank. Monitor the storage tank level until

the tank is empty.

c. Close refrigerant charging valves 7 and 10.

d. Turn off the pumpout compressor.

e. Turn off the chiller water pumps.

f. Close valves 3 and 4.

g. Open valves 2 and 5.

VALVE 1a1b23456781011

CONDITION C C C C C

h. Turn on pumpout condenser water.

i. Run the pumpout compressoruntil the storage tank pres-

sure reaches 5 psig (34 kPa), 18 in. Hg (41 kPa

absolute).

j. Turn off the pumpout compressor.

k. Close valves 1a, 1b, 2, 5, and 6.

VALVE 1a1b23456781011

CONDITION C C CCCCCCC C

l. Turn off pumpout condenser water.

Transfer the Refrigerant from Chiller to Pumpout Storage

Tank.

1. Equalize refrigerant pressure.

a. Valve positions:

VALVE 1a1b23456781011

CONDITION C C C C C C

b. Slowly open valve 5 and refrigerant chargingvalves7

and 10 to allow liquid refrigerant to drain by gravity

into the storage tank.

VALVE 1a1b23456781011

CONDITION C C C

2. Transfer the remaining liquid.

a. Turn offpumpout condenser water. Place valves in the

following positions:

VALVE 1a1b23 456781011

CONDITION C C C

b. Run the pumpoutcompressor for approximately 30 min-

utes, then close valve 7 and 10.

VALVE 1a1b23456781011

CONDITION C C C C C

13

c. Turn off the pumpout compressor.

Page 14

3. Remove any remaining refrigerant.

a. Turn on chiller water pumps.

b. Turn on pumpout condenser water.

c. Place valves in the following positions:

VALVE 1a1b23456781011

CONDITION C C C C C

d. Run the pumpout compressor until the chiller pres-

sure reaches 60 psig (414 kPa), [30 psig (207 kPa)];

then, shut off the pumpout compressor. Warm chiller

condenser water will boil off any entrapped liquid refrigerant and chiller pressure will rise.

e. When chiller pressure rises to 70 psig (483 kPa),

[40 psig (276 kPa)]; turn on the pumpout compressor

until the pressure again reaches 60 psig (414 kPa)

[30 psig (207 kPa)]; then, turn off the pumpout compressor. Repeat this process until the chiller pressure

no longer rises; then, turn on the pumpout compressor

and pump out until the chiller pressure reaches

18 in. Hg (41 kPa absolute).

f. Close valves 1a, 1b, 3, 4, and 6.

VALVE 1a1b23456781011

CONDITION C C CCCCCCC C

g. Turn off the pumpout condenser water.

4. Establish vacuum for service. To conserve refrigerant, operate the pumpout compressor as describedinStep 3e until the chiller pressure is reduced to 18 in. Hg (41 kPa

absolute).

CHILLERS WITH ISOLATION VALVES — Thevalvesreferred to in the following instructions are shown in Fig. 9

and 11. Valve 7 remains closed.

Transfer All Refrigerant to Chiller Condenser Vessel:

1. Push refrigerant into chiller condenser vessel.

a. Turn on thechillerwater pumps and monitor the chiller

pressure.

b. Valve positions:

VALVE 1a1b2345811

CONDITION C C C

c. Equalize the refrigerant in the chiller cooler and

condenser.

d. Turn off chiller water pumps and pumpout condenser

water supply.

e. Turn on pumpout compressor to push liquid out of the

chiller cooler vessel.

f. When all liquid has been pushed into the chiller con-

denser vessel, closethe cooler refrigerant isolation valve

(11).

g. Turn on the chiller water pumps.

h. Turn off the pumpout compressor.

2. Evacuate gas from chiller cooler vessel.

a. Close pumpout valves 2 and 5; open valves 3 and 4.

VALVE 1a1b2345811

CONDITION C C C C

b. Turn on pumpout condenser water.

c. Run pumpout compressor until the chiller cooler ves-

sel pressure reaches 18 in. Hg vac (41 kPa absolute).

Monitor pressures on the chiller control panel and on

refrigerant gages.

Fig. 11 — Valve Locations for 19XB Pumpout Unit Without Storage Tank

14

Page 15

d. Close valve 1a.

e. Turn off pumpout compressor.

f. Close valves 1b, 3, and 4.

VALVE 1a1b2345811

CONDITION C C CCCCCC

g. Turn off pumpout condenser water.

h. Turn off chiller water pumps and lock out chiller

compressor.

Transfer All Refrigerant to Chiller Cooler Vessel:

1. Push refrigerant into the chiller cooler vessel.

a. Turn on thechillerwater pumps and monitor the chiller

pressure.

b. Valve positions:

VALVE 1a1b2345811

CONDITION C C C

c. Equalize the refrigerant in the chiller cooler and

condenser.

d. Turn off chiller water pumps and pumpout condenser

water.

e. Turn on pumpout compressor to push refrigerant out

of the chiller condenser.

f. When all liquid is out of the chiller condenser, close

valve 11 and any other liquid isolation valves on the

chiller.

g. Turn off the pumpout compressor.

2. Evacuate gas from chiller condenser vessel.

a. Turn on chiller water pumps.

b. Make sure that pumpout valves 3 and 4 are closedand

valves 2 and 5 are open.

VALVE 1a1b2345811

CONDITION C C C C

c. Turn on pumpout condenser water.

d. Run the pumpout compressor until the chiller con-

denser reaches 18 in. Hg (41 kPa absolute). Monitor

pressure atthe chiller control paneland refrigerant gages.

e. Close valve 1b.

f. Turn off pumpout compressor.

g. Close valves 1a, 2, and 5.

VALVE 1a1b2345811

CONDITION C C CCCCCC

h. Turn off pumpout condenser water.

i. Turn off chiller water pumps and lock out chiller com-

pressor.

Return Refrigerant to Normal Operating Conditions

1. Be sure that the chiller vessel that was opened has been

evacuated.

2. Turn on chiller water pumps.

3. Open valves 1a, 1b, and 3.

VALVE 1a 1b 2 3 4 5 8 11

CONDITION C C C C C

4. Crack open valve 5, gradually increasing pressure in the

evacuated chiller vessel to 60 psig (414 kPa), [30 psig

(207 kPa)]. Feed refrigerant slowly to prevent tube

freeze-up.

5. Leak test to ensure chiller vessel integrity.

6. Open valve 5 fully.

VALVE 1a1b2345811

CONDITION C C C C

7. Close valves 1a, 1b, 3, and 5.

8. Open chiller isolation valve 11 and any other isolation

valves, if present.

VALVE 1a1b2345811

CONDITION C C CCCCC

9. Turn off chiller water pumps.

DISTILLING THE REFRIGERANT

1. Transfer the refrigerant from the chiller to the pumpout

storage tank as described in the Transfer the Refrigerant

from Chiller to Pumpout Storage Tank section.

2. Equalize the refrigerant pressure.

a. Turn on chiller water pumps and monitor chiller

pressures.

b. Close pumpout and storage tank valves 2, 4, 5, 8, and

10, and close chillerchargingvalve 7; open chiller isolation valve 11 and any other chiller isolation valves,

if present.

c. Open pumpout and storage tank valves 3 and 6; open

chiller valves 1a and 1b.

VALVE 1a1b23456781011

CONDITION C C C C C C

d. Gradually crack open valve 5 to increase chiller pres-

sure to 60 psig (414 kPa), [30 psig (207 kPa)]. Slowly

feed refrigerant to prevent freeze-up.

e. Open valve 5 fully after thechillerpressure rises above

the freezing point of the refrigerant. Let the storage

tank and chiller pressure equalize.

3. Transfer remaining refrigerant.

a. Close valve 3.

b. Open valve 2.

VALVE 1a1b23456781011

CONDITION C C C C C

c. Turn on pumpout condenser water.

d. Run the pumpout compressor until the storage tank

pressure reaches 5 psig (34 kPa), 18 in. Hg (41 kPa

absolute).

e. Turn off the pumpout compressor.

f. Close valves 1a, 1b, 2, 5, and 6.

g. Turn off pumpout condenser water.

VALVE 1a1b23456781011

CONDITION C C CCCCCCC C

4. Drain the contaminants from the bottom of the storage

tank into a container. Dispose of contaminants safely.

MAINTENANCE

Periodic maintenance is necessary to keep all components

functioning as designed. A maintenance log is recommended to ensure a proper maintenance schedule is

followed.

Pumpout Unit — For maintenance details, refer to the

06D, 07D Installation, Start-Up, and Service Instructions.

15

Page 16

PUMPOUT COMPRESSOR OILCHARGE — Use oil conforming to Carrier specifications for reciprocating compressor use. Oil requirements are listed in Table 6.

Table 6 — Pumpout Compressor Oil Requirements

REFRIGERANT

R-22 86 PP49-7 PP23BZ101

R-134a 68 PP47-31 PP23BZ103

ISO

VISCOSITY

CARRIER

SPECIFICATION

NO.

CARRIER

PART NO.

The total oil charge, 4.5 pints (2.6 L), consists of 3.5 pints

(2.0 L) for the compressor and one additional pint (0.6 L)

for the oil separator.

Oil should be visible in one of the pumpout compressor

sight glasses both during operation and at shutdown.Always

check the oil level before operating the pumpout compressor. Before adding or changing oil, relieve the refrigerant

pressure as follows:

1. Attach a pressure gage to the gage port of either pumpout

compressor service valve (Fig. 10).

2. Close the suction service valve and open the discharge

line to the pumpout storage tank or the chiller.

3. Operate the compressor until the crankcasepressuredrops

to 2 psig (13 kPa).

4. Stop the pumpout compressor and isolate the pumpout

system by closing the discharge service valve.

5. Slowly remove the oil return lineconnection(Fig. 9). Add

oil as required.

6. Replace the connections and reopen the pumpout compressor service valves.

Storage Tank — To prevent moisture and contami-

nants from entering the storage tank, maintain positive pressure in the tank when not transferring refrigerant. Leak test

the storage tank according to your normal vessel leak test

procedures and schedule.

Ordering Replacement Parts — The following in-

formation mustaccompanyan order for Carrier-specifiedparts:

• machine model number and serial number

• name, quantity, and part number of the part required

• delivery address and method of shipment

TROUBLESHOOTING

Information on troubleshooting for the PPS is included in

Table 7.

Table7—Troubleshooting

SYMPTOM PROBABLE CAUSE REMEDY

Compressor does not run Main power line open Replace fuse or reset circuit breaker.

Loose terminal connection Check connections.

Improperly wired controls Check wiring and rewire.

Low line voltage Check line voltage; determine location of voltage drop.

Compressor motor defective Check motor winding for open or short. Replace compressor if

Seized compressor Replace compressor.

High level gage alarm Check refrigerant level and remove excess.

Compressor cycles on

high-pressure control

Unit operates too long Isolation valves partially open Close valves.

System Noises Piping vibrations Support piping as required. Check for loose pipe connectors.

Compressor Loses Oil Leak in system Locate and repair leak.

High-pressure control erratic in action Check capillary tube for pinches. Set control as required..

Discharge valve partially closed. Open valve.

Air in system Purge system.

Condenser scaled. Clean condenser.

Condenser water pump or fans not operat-

ing.

Compressor noisy Check valve plates for valve noise. Replace compressor (worn

Insufficient compressor oil Add oil.

Plugged or stuck compressor oil return

check valve

Dirty accumulator Clean accumulator.

necessary.

Start pump or fans.

bearings). Check for loose compressor holddown bolts.

Repair or replace valve.

Copyright 1996 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Tab 5a

PC 211 Catalog No. 531-927 Printed in U.S.A. Form 19XB-1SI Pg 16 6-96 Replaces: New

Loading...

Loading...