Page 1

Refrigerant Management System

Installation, Operating and Maintenance

Instructions

For Use With Low-Pressure Centrifugal Liquid Chillers

SAFETY CONSIDERATIONS

Refrigerant recovery devices are designed to provide safe

and reliable service when operated within design spec

ifications. When operating this equipment, use good judg

ment and safety precautions to avoid damage to equip

ment and property or injury to personnel.

Be sure you understand and follow the procedures and

safety precautions contained in this guide.

A DANGER

DO NOT VENT refrigerant relief valves within a building. Outlet

from rupture disc or relief valve must be vented outdoors in ac

cordance with the latest edition of ASHRAE 15 (Safety Code for

Mechanical Refrigeration). The accumulation of refrigerant in an

enclosed space can displace oxygen and cause asphyxiation.

PROVIDE adequate ventilation in accordance with ASHRAE 15,

especially for enclosed and low overhead spaces. Inhalation of

high concentrations of vapor is harmful and may cause heart ir

regularities, unconsciousness, or death. Misuse can be fatal. Va

por is heavier than air and reduces the amount of oxygen available

for breathing. Product causes eye and skin irritation. Decomposi

tion products are hazardous.

DO NOT USE OXYGEN to purge lines or to pressurize a ma

chine for any purpose. Oxygen gas reacts violently with oil, grease,

and other common substances.

NEVER EXCEED specified test pressures, VERIFY the allow

able test pressure by checking the instruction literature and the de

sign pressures on the equipment nameplate.

DO NOT USE air for leak testing. Use only tracer gases and dry

nitrogen.

DO NOT VALVE OFF any safety device.

BE SURE that all pressure relief devices are properly installed

and functioning before operating any machine.

A WARNING

DO NOT WELD OR FLAMECUT any refrigerant line or vessel

until all refrigerant (liquid and vapor) has been removed from chiller.

Traces of vapor should be displaced with dry air or nitrogen and

the work area should be well ventilated.

with an open flame produces toxic gases.

DO NOT USE eyebolts or eyebolt holes to rig machine sections

or the entire assembly.

DO NOT work on high-voltage equipment unless you are a qual

ified electrician.

DO NOT WORK ON electrical components, including control pan

els, switches, starters, or oil heater until you are sure ALL POWER

IS OFF and no residual voltage can leak from capacitors or solidstate components.

LOCK OPEN AND TAG electrical circuits during servicing. IF

WORK IS INTERRUPTED, confirm that all circuits are de

energized before resuming work.

DO NOT siphon refrigerant by mouth.

AVOID SPILLING liquid refrigerant on skin or getting it into the

eyes. USE SAFETY GOGGLES. Wash any spills from the skin

Refrigerant in contact

with soap and water. If any enters the eyes, IMMEDIATELY FLUSH

EYES with water and consult a physician.

NEVER APPLY an open flame or live steam to a refrigerant cyl

inder. Dangerous overpressure can result. When necessary to heat

refrigerant, use only warm (110 F [43 C]) water,

DO NOT REUSE disposable (nonreturnable) cylinders or

attempt to refill them. It is DANGEROUS AND ILLEGAL. When

cylinder is emptied, evacuate remaining gas pressure, loosen

the collar and unscrew and discard the valve stem. DO NOT

INCINERATE.

CHECK THE REFRIGERANT TYPE before adding refrigerant

to the machine. The introduction of the wrong refrigerant can cause

damage or malfunction to this machine.

Operation of this equipment with refrigerants other than those

cited herein should comply with ASHRAE-15 (latest edition). Con

tact Carrier for further information on use of this machine with

other refrigerants.

DO NOT ATTEMPT TO REMOVE fittings, covers, etc., while

machine is under pressure or while machine is running. Be sure

pressure is at 0 psig (0 kPa) before breaking any refrigerant

connection.

CAREFULLY INSPECT all relief devices, rupture discs, and other

relief devices AT LEAST ONCE A YEAR. If machine operates

in a corrosive atmosphere, inspect the devices at more frequent

intervals.

DO NOT ATTEMPT TO REPAIR OR RECONDITION any re

lief device when corrosion or build-up of foreign material (rust,

dirt, scale, etc.) is found within the valve body or mechanism.

Replace the device.

DO NOT install relief devices in series or backwards.

USE CARE when working near or in line with a compressed spring.

Sudden release of the spring can cause it and objects in its path to

act as projectiles.

A CAUTION

DO NOT STEP on refrigerant lines. Broken lines can whip about

and cause personal injury.

DO NOT climb over a machine. Use platform, catwalk, or stag

ing. Follow safe practices when using ladders.

USE MECHANICAL EQUIPMENT (crane, hoist, etc.) to lift or

move inspection covers or other heavy components. Even if com

ponents are light, use such equipment when there is a risk of slip

ping or losing your balance.

BE AWARE that certain automatic start arrangements CAN EN

GAGE THE STARTER. Open the disconnect ahead of the starter

in addition to shutting off the machine or pump.

USE only repair or replacement parts that meet the code require

ments of the original equipment.

DOUBLE-CHECK that coupling nut wrenches, dial indicators, or

other items have been removed before rotating any shafts.

DO NOT LOOSEN a packing gland nut before checking that the

nut has a positive thread engagement.

PERIODICALLY INSPECT all valves, fittings, and piping for

corrosion, rust, leaks, or damage.

19QA

50/60 Hz

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book|2 |2 PC 221 Catalog No 531-963 Printed in U S A Form 19QA-2SI Pg 1 9-94 Replaces: 19QA-1 SI

Tab |5a|5d

Page 2

CONTENTS

Page

SAFETY CONSIDERATIONS

INTRODUCTION

.........................................................

.....................................

INSTALLATION ..........................................................2-7

Complete Pre-Installation Checks............................2

• IDENTIFY UNIT

• INSPECT SHIPMENT

Make Piping Connections

Make Electrical Connections

Optional Caster Installation

CONTROLS AND COMPONENTS

.........................................

....................................

......................................

.............................

7,8

Pump and Motor .........................................................7

Oil Separator...............................................................7

Heater ..........................................................................7

Tube-in-Tube Condenser...........................................7

Level Gage ..................................................................7

Water Separation Sight Glass

Purge Separator Assembly

..................................

.......................................

7

Refrigerant Hoses ......................................................8

Liquid Indicator

..........................................................

8

Filter Drier ...................................................................8

OPERATION .............................................................9-14

Evacuation ..................................................................9

Liquid Refrigerant Transfer.......................................9

• BEFORE TRANSFERRING LIQUID

REFRIGERANT

• TO TRANSFER LIQUID REFRIGERANT

Refrigerant Vapor Transfer

• BEFORE TRANSFERRING REFRIGERANT

VAPOR

• TRANSFER REFRIGERANT

......................................

10

Purge Separator Assembly ......................................12

Oil Separation ............................................................12

Water Separation .......................................................13

MAINTENANCE

Maintaining the Pump

Pump Coupling

High-Pressure Cutout Switches

.........................................................

..............................................

.........................................................

..............................

15

15

15

15

Refrigerant Storage Tank.........................................15

Refrigerant Hoses

.....................................................

15

TROUBLESHOOTING................................................16

Table 1 — Interconnecting Refrigerant Hoses,

Valves, and Fittings

NUMBER

1

2

2

2

2

1

2

1 KA73PS012

1 19QA020-152 Liquid Indicator

8

1 19QA015-142

NOTE: Refer to Fig. 1 for model number description and accessory

caster package part numbers.

PART NUMBER PART

KA73PS003 3 ft (.91 m) Hose

KA73PS006 6 ft (1.88 m) Hose

12 ft (3.66 m) hose

19QA020-132 Valve and Coupler

Chiller Vapor Valve

INSTALLATION

Complete Pre-Installation Checks

IDENTIFY UNIT — Identify the model number and serial

number printed on the nameplate. Check this information

against the job requirements.

7

INSPECT SHIPMENT — Inspect unit for damage before

removing unit from shipping conveyance. If unit appears

damaged, it should be inspected by a shipping inspector be

fore removal. File claim with shipping company if ship

ment is damaged or incomplete. The manufacturer is not

responsible for damage incurred during transit.

Check all components. Notify the supplier immediately

if any item is missing. To prevent loss or damage, leave all

parts in their original package until they are needed.

Make Piping Connections — All connections be

tween the pump, tube-in-tube condenser, storage tank, and

chiller can be made using the factory supplied refrigerant

hoses. A hand valve with coupler is factory supplied, but

must be field installed at each end of the 4 hoses. See

Fig. 5. Field supplied copper tubing and valve manifolds

must be used if a permanent installation is required.

The 19QA is factory equipped with a dual relief valve

assembly. See Fig. 4. The outlet of the valves is 1-1/2 in.

MPT. Vent the dual relief assembly outdoors in accordance

with ASHRAE 15 (Safety Code for Mechanical Refrigera

tion), latest edition, and all applicable local codes. Use a

minimum 1-1/2 in. pipe for the relief valve outlet. Provide

fittings so vent piping can be disconnected periodically for

inspection and testing of valves.

Cover the outdoor vent with a rain cap and place a field

supplied condensate drain at the low point in vent piping to

prevent water build up on the atmospheric side of the valve.

INTRODUCTION

The 19QA Refrigerant Management System (RMS) has

been designed to help owners and operators of centrifugal

chillers conserve low pressure refrigerants and prevent the

release of excessive amounts of refrigerant into the atmo

sphere. The proper use of this equipment will minimize the

loss of CFCs and HCFCs. The 19QA will also recycle re

frigerant contaminated with water, oil, or acid. See Fig. 1

and Table 1 for component information.

The 19QA is ARI (Air Conditioning & Refrigeration In

stitute) certified as a refrigerant recovery/recycling device

and is registered with ETL (Electrical Testing Laboratory)

for safety. The Refrigerant Management System’s storage

tanks are rated for 20, 30, or 40 cu ft (.57, .85, 1.13 cu

meters). See Table 2. Casters are available as an option on

all storage tanks. See Fig. 1-3. See Fig. 4 and 5 for addi

tional RMS component descriptions and dimensions.

Make Electrical Connections — The 19QA has 2

electrical cords. See Table 3 and Fig. 6. One electrical cord

is attached to the pump and the other is attached to the stor

age tank heater. If both electrical cords are used at the same

time, separate outlets are required. Connect electrical power

in accordance with minimum circuit amps (MCA) and max

imum overcurrent protection amps (MOCP) as specified on

the unit nameplate. Be sure that the unit is connected and

grounded in accordance with all applicable electrical codes.

Optional Caster Installation — if optional casters

have been provided, bolt the 4 caster assemblies to the stor

age tank. See Fig. 1-3. Size 020 and 030 storage tanks have

2 rigid casters mounted on one end of the tank and 2 swivel

casters with brakes mounted on the other end of the storage

tank. The size 040 storage tanks have 2 swivel casters with

brakes mounted on one end of the storage tank and 2 swivel

casters with locks mounted on the other end of the storage

tank.

Page 3

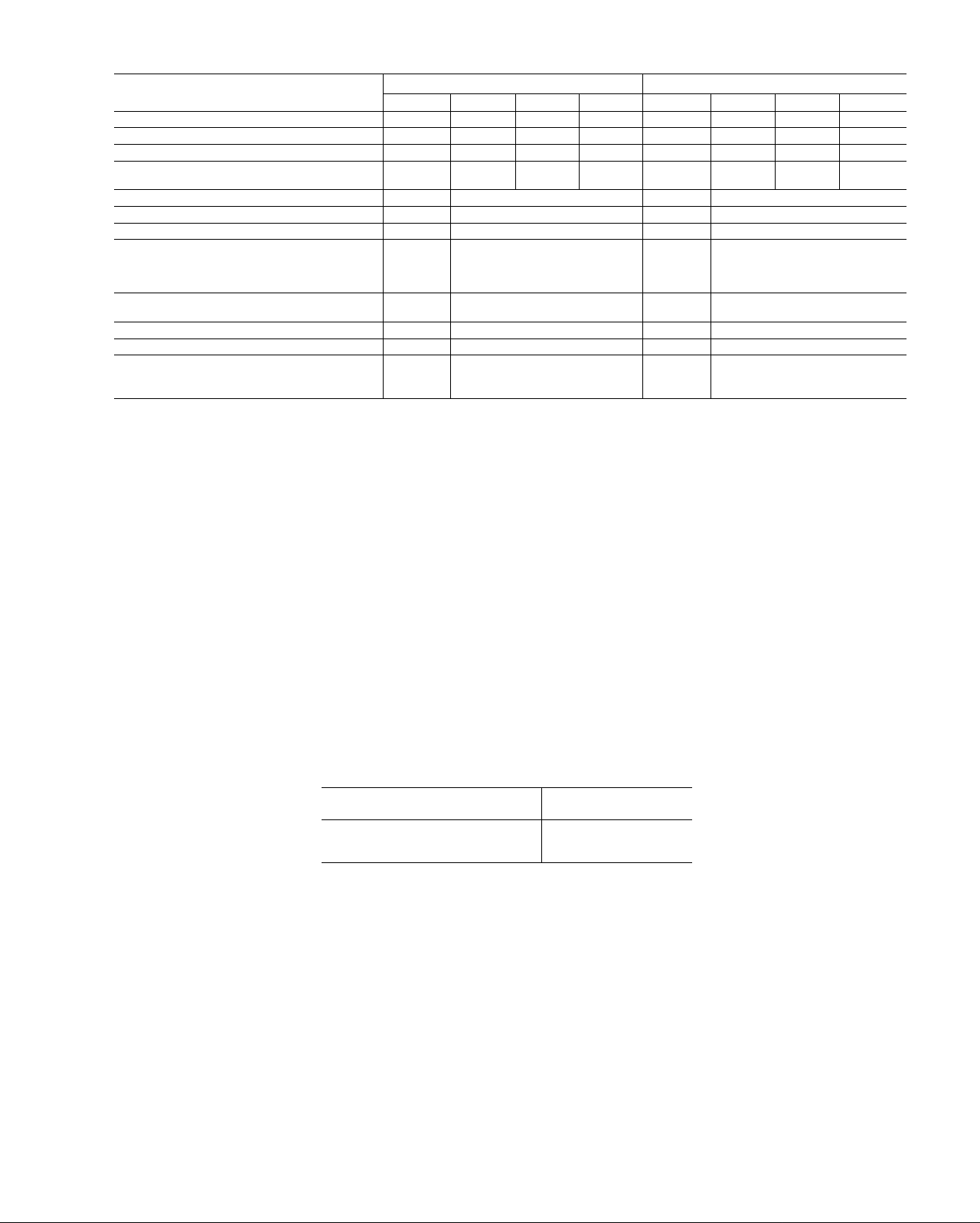

Table 2 — Physical Data

19QA

DRY WEIGHT OF RMS

DRY WEIGHT OF RST

TANK SIZE

TANK STORAGE CAPACITY

CFC-11 Liquid

DESIGN PRESSURE

MAX. OPERATING PRESSURE

CONNECTION SIZES

HIGH-PRESSURE SWITCHES

Tank Heater and Pump

Cutout

Manual Reset

PUMP

Motor Hp

Max. Discharge Pressure

Min. Vacuum (Gage)

Flow Rate

60 Hz

50 Hz

RMS — Refrigerant Management System

RST — Refrigerant Storage Tank

ENGLISH

Size

lb 740

lb

cu ft 20 30 40

lb 1600 2450 3300

psig 15 kPa 103

psig 10 kPa 69

in. Va Flare in.

psig

psig

psig

in. Hg 29 kPa -98

cfm

020 030

841 942

495 546 586

10

<4

%

10 kPa

10.5

8.8

040

Size

kg

kg

CU m .57

kg

kPa

kPa

L/s

SI

020 030

336

225 248 266

727 1114

382

.85 1.13

У2 Flare

69

<28

%

69

4.96

4.16

040

428

1500

19QA - 020 - 2 74

19QA

Size

020 — 20 cu ft (.57 cu meters)

030 — 30 cu ft (.85 cu meters)

040 — 40 cu ft (1.13 cu meters)

- Refrigerant

Management

System

NOTE: Accessory caster packages are avaiiabie for use with the

19QA. Refer to the following table for specific part numbers.

ACCESSORY CASTER

PACKAGE PART NUMBER

19QA 020 213 020

19QA 030 213

19QA 040 213

RMS — Refrigerant Management System

RST — Refrigerant Storage Tank

Fig. 1 — Model Number Description

74 — Refrigerant Management

System

84 — Refrigerant Storage Tank

V-Ph-Hz

2 — 115-1-50/60

3 — 230-1-50/60

RMS/RST SIZE

030

040

Page 4

UNIT

SIZE

19QA020

19QA030

19QA040

A B

4'-9"

[1448]

7'-3"

[2209]

Q'-Q"

[2972]

5'-4%''

[1648]

7'-10%"

[2410]

10'-4%"

[3172]

NOTE: Dimensions in [ ] are in mm.

Fig. 2 — 19QA Refrigerant Management System Dimensions

WEIGHT

EMPTY

MAXIMUM REFRIGERANT

lbs kg lbs

740 336 1600

841 382 2450

942 428 3300

CHARGE

ACCESSORY

CASTERS

kg

727 34 15

1114 48

1500

lbs kg

62 28

22

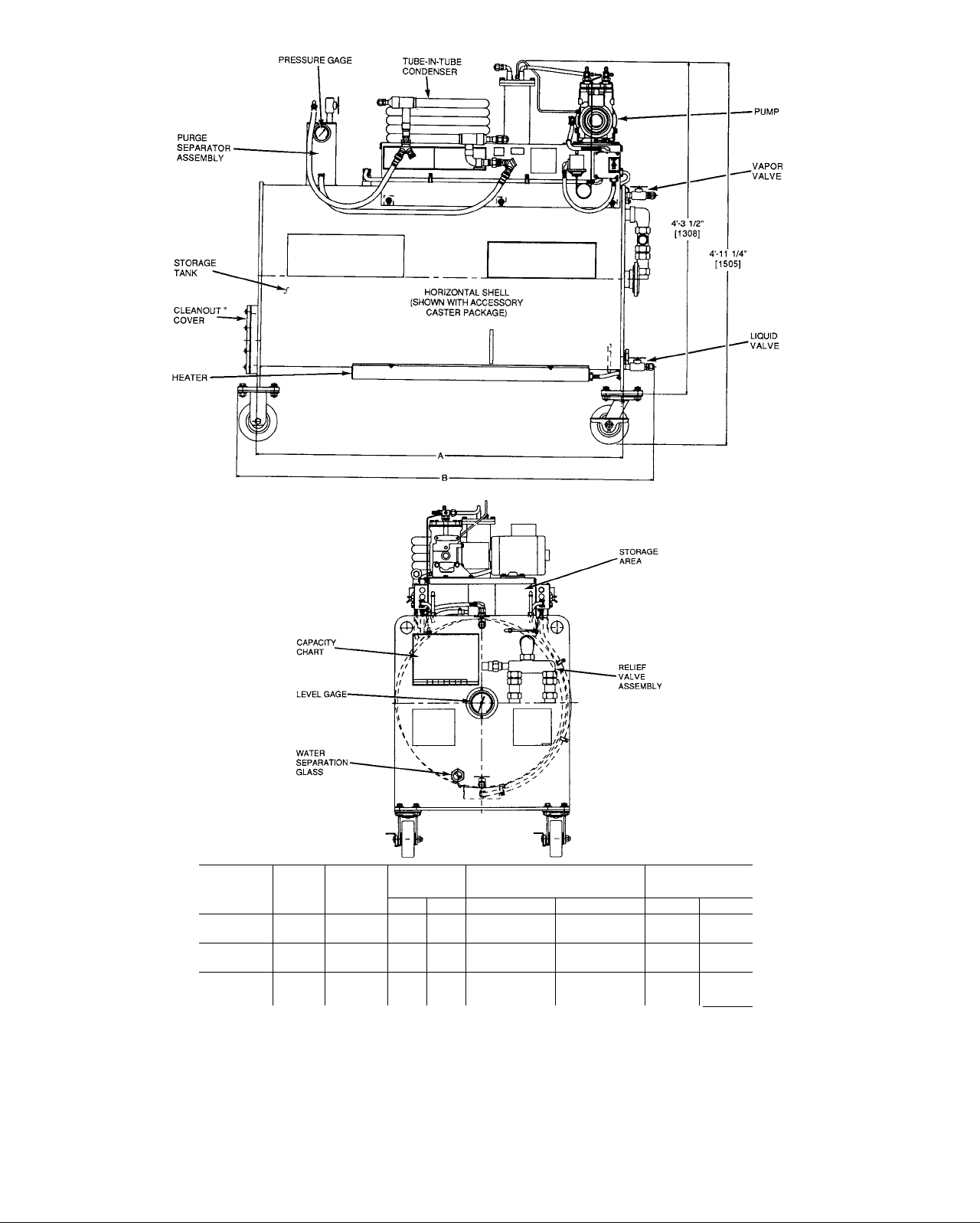

Page 5

PRESSURE GAGE

VAPOR

VALVE

UNIT

SIZE

19QA020

19QA030

19QA040

A

4'-9"

[1448]

7'-3"

[2209]

Q'.Q"

[2972]

B

5'-4%"

[1648]

7'-10%”

[2410]

10'-4%"

[3172]

NOTE: Dimensions in [ ] are in mm.

WEIGHT

EMPTY

lbs

495 225 1600 727

546 248 2450 1114

586 266

MAXIMUM REFRIGERANT

kg

lbs kg

3300 1500 62

CHARGE

RELIEF

-VALVE

ASSEMBLY

■ LEVEL GAGE

ACCESSORY

CASTERS

lbs

34 15

48 22

kg

28

Fig. 3 — 19QA Refrigerant Storage Tank Dimensions

Page 6

NO. ITEM NO.

1 — Pressure Gage 12 —

2 — Purge Separator Assembly

3 — Refrigerant (Vapor) In 13 —

4 — Tube-in-Tube Condenser 14 —

5 — Filter Drier Vi SAE Flare (Hidden)

6 — Refrigerant (Liquid) Out

7 — Oil Separator

8 — Pump

9 — Pump Motor

10 — Heater High-Pressure

11 — Heater ON/OFF Switch (Hidden) 15 —

Cutout Switch (Hidden)

Fig. 4 — 19QA Refrigerant Management System Components

ITEM

Pump High-Pressure

Cutout Switch

Pump ON/OFF Switch

Storage Area

Components Included:

Refrigerant Hose, 3 ft

Refrigerant Hose, 6 ft (2)

Refrigerant Hose, 12 ft

Valve With Coupler (8)

Chiller Vapor Valve

Liquid Indicator With Coupler

Vapor Valve

NO. ITEM

16 — Refrigerant Capacity Chart

17 — Relief Valve Assembly

18 — Level Gage

19 — Liquid Valve

20 — Accessory Casters

21 — Water Separation Sight Glass

22 — Heater With Cover

23 — Storage Tank

24 — Water In

25 — Water Out

(Available On All Tank Sizes)

Table 3 — Electrical Data

Fig. 5 — Interconnecting Refrigerant Hoses,

Valves, and Fittings

VOLTS-PH-HZ 115-1-50

PUMP MOTOR

Hp 3/4

Amps 9.6 8.6 4.8 4.3

MCA

HEATER

Amps

MCA 12 12 11 11

MOCP 15* 15*

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection (Amps)

*Two circuits required for simultaneous operation.

NOTE: Use time-delay fuses.

10

12 12 6

LEGEND

115-1-60 230-1-50

3/4

10

3/4 3/4

5 5

15

230-1-60

6

15

Page 7

HUiH LEVEL

SWITCH

L2

MOTOR WIRING SCHEMATIC

Ll

TOGGLE

SWITCH

NOTE; The 115 and 230 v control wiring are identicai.

PRESSURE

SWITCH

HEATER WIRING SCHEMATIC

Fig. 6 — Typical Control Wiring Schematic

CONTROLS AND COMPONENTS

Pump and Motor — The pump is designed for vac

uum and pressure duty. The pump is splash lubricated and

operates in conjunction with an oil separator. It is directly

coupled to and driven by a 3/4-hp motor. The coupling be

tween the pump and motor has a rubber insert to compen

sate for slight misalignment. Start and stop the pump by

using the toggle switch located next to the pump. A tank

pressure switch set at 10 psig (69 kPa) and a tank level

switch set 90% full will shut off the pump if either limit is

reached. See Table 1 for additional information on the pump

and motor.

Oil Separator — The oil separator removes the oil that

is mixed with the discharge gas leaving the pump. The dif

ferential pressure between the oil separator and the pump

crankcase returns the oil to the pump through the float valve

in the oil separator when the specified oil level is achieved

in the oil separator.

Heater — A 1500 watt, etched-foil, electric heater is at

tached to the bottom of the storage tank. See Fig. 2. The

heater is encased in an insulated protective cover and is con

trolled by a toggle switch.

Use the heater when refrigerant recycling by distillation

is necessary. When the heater toggle switch is in the ON

position, the indicating light, located next to the toggle switch,

will be lit. A pressure switch will shut off the heater if the

tank pressure reaches 10 psig (69 kPa) when heating

refrigerant.

L2

-ORN-

-WHT

---^-------

HEATER

——

LAMP

WHT-

Tube-in-Tube Condenser — A tube-in-tube con

denser allows refrigerant vapor to be condensed when re

moving vapor from a chiller or when distilling refrigerant.

Garden hose connections (3/4 in.) are provided for condens

ing water. Condensing water temperature should be as low

as possible to minimize the time required to complete an

operation. A water flow rate of 2 gpm (.012 L/s) at 70 F

(21 C) is normally adequate.

Level Gage — A geared, float level gage displays the

storage tank’s percentage of full capacity of liquid refrig

erant. The actual level of refrigerant will vary based upon

temperature and the type of refrigerant used. See Fig. 4

and 7.

Water Separation Sight Glass — A water separa

tion sight glass is located above the liquid valve. Use the

water separation sight glass to view the refrigerant/water

interface when separating water from the refrigerant. See

Fig. 4.

Purge Separator Assembly — Use the manual hand

valve on the purge separator assembly to remove noncon

densable gases that may accumulate in the storage tank dur

ing vapor recovery. The purge separator assembly contains

a water coil, 1/16-in. orifice, and 1/2-in. ball valve. The

bottom of the purge separator assembly opens into the stor

age tank. See Fig. 8.

Page 8

CFC-11 or HCFC-123

CFC-113

Ib(Kg)

This graph is based on 70 F The following multipliers may be used to more accurately determine weights at temperatures

other than 70 F

TEMPERATURE F (C)

MULTIPLIER

40 (4.4)

1 026

50 (10) 60 (15 5)

1 018

1 009 1 000

70 (21,1)

80 (26.6) 90 (32 2) 100 (37 7)

991 982

973

Fig. 7 — Storage Tank Capacity

Refrigerant Hoses — Four, l/2-in. refrigerant hoses

and 8 ball valves with couplers are factory supplied with

the RMS unit. See Table 1. The refrigerant hoses are used

to transfer liquid and vapor through the Refrigerant Man

agement System. They are designed to withstand high vac

uum pressure without collapsing.

When used with the refrigerant hoses, the ball valve and

coupler assembly prevent refrigerant loss. Connect the ball

valve and coupler assembly to each end of the 4 refrigerant

hoses. Hand tighten the ball valve and coupler assembly to

the refrigerant hose. The ball valve and coupler assembly

connect to the RMS unit or chiller, depending upon the type

of operation. The coupler should be hand tightened to the

RMS unit or chiller. Excessive tightening will damage the

rubber gaskets.

Liquid Indicator — The 1/2 in. liquid indicator (in line

sight glass) is factory supplied. Use the liquid indicator dur

ing either the liquid refrigerant transfer or the vapor con

densing process to determine the end point of the process.

When liquid is no longer visible in the glass, the process is

almost complete.

Filter Drier — The filter drier should be used to recycle

refrigerant. Use the factory supplied filter drier when re

moving moisture and small particles from the refrigerant.

The filter drier is most effective when used with liquid re

frigerant. The filter drier holds approximately .39 oz

(11 g) of water. See Table 4.

When cleaning large quantities of saturated refrigerant,

use a field supplied, replaceable core filter drier assembly.

The assembly should have four, 100 in.^ cores. It will re

move approximately 4.2 oz (118 g) of water.

WATER OUT

WATER IN

NOTE: [ ] indicates millimeters

Fig. 8 — Purge Separator Assembly

Table 4 — Water Solubility In Refrigerant

SOLUBILITY

REFRIGERANT

TYPE

CFC-11,

CFC-113,

[HCFC-123]

LEGEND

ppm — Parts Per Million

TEMPERATURE

60 F 70 32

(16 C) [660]

70 F

(21 C) [770]

80 F

(27 C) [900]

90 F 140 64

(32 C) [1000]

OF WATER IN

REFRIGERANT

(ppm)

90

113 51 1 80

NOTE: [ ] indicates HCFC-123 refrigerant

GRAMS OF

WATER

PER

1000 LB

[303] [10.7]

41

[349] [12.3]

[408]

[453] [16 0]

OZ

1.13

1.15

[14.4]

2.26

Page 9

OPERATION

Evacuation — To minimize refrigerant loss, air must

not be allowed to mix with the refrigerant vapor. All spaces

that could contain refrigerant (such as chillers, storage tanks,

and refrigerant hoses) must be completely evacuated before

charging the RMS with refrigerant.

To evacuate air from the storage tank or chiller, connect

the suction service valve of the pump to a vapor valve on

the storage tank or chiller using the shortest possible 1/2-in.

diameter refrigerant hose. Use of hoses or fittings smaller

than 1/2 in. diameter will greatly increase the time required

to pull a complete vacuum of 29 in. Hg (25 mm Hg abso

lute). Refer to Table 5 for additional information. See

Fig. 9.

Once the connections are made, turn on the pump and

discharge the air into the atmosphere.

■ — Tank Size — 20 cu ft (.57 cu meters)

NOTE: A 29 in. Hg vacuum (25 mm Hg absolute) may be obtained

at a rate of approximateiy 1 minute per cu ft of volume.

Typical 400 Ton Chiller

Fig. 9 — Evacuation of Chiller and Storage Tank

Liquid Refrigerant Transfer

A CAUTION

To prevent release of refrigerant from the dual relief

valve assembly due to expansion, the storage tank must

not be filled above 90% full at 90 F (32 C).

The storage tank is 90% full when the level gage is read

ing 100%. See Fig. 7.

BEFORE TRANSFERRING LIQUID REFRIGERANT Before using the pump for liquid or vapor transfer, run the

pump using air only for approximately 15 minutes. Run

ning the pump on air will allow it to achieve a normal op

erating temperature of 120 F (49 C). If refrigerant is used

when the pump is cold, excessive amounts of refrigerant

will be absorbed into the oil, causing dilution of the oil.

This condition may cause oil loss and shorten the life of the

pump.

A WARNING

Do not connect the pump suction service valve directly

to a liquid refrigerant source. Liquid refrigerant will

cause damage to the pump.

Use the same process when transferring liquid refrigerant

from the chiller to the storage tank or from the storage tank

to the chiller. Completely evacuate any vessel that will have

refrigerant transferred to it.

A WARNING

Do not transfer liquid refrigerant into an evacuated chiller

that contains water in the cooler tubes. Freezing water

will cause the cooler tubes to rupture.

NOTE: Make sure the ball valve and coupler assembly are

connected to all refrigerant hoses.

Prior to transferring liquid refrigerant from the storage

vessel to the chiller, make sure all water is completely drained

from the cooler tubes or raise the chiller pressure by using

refrigerant gas (24 in. Hg [ — 81 kPa] for CFC-113,

18 in. Hg [-61 kPa] for HCFC-123, and 15 in. Hg

[-51 kPa] for CFC-11).

TO TRANSFER LIQUID REFRIGERANT

Storage Tank to Chiller — To transfer liquid refrigerant from

the storage tank to the chiller, connect a 6-ft refrigerant hose

from the liquid valve on the storage tank to the chiller charg

ing valve. Install the liquid indicator on the refrigerant hose.

See Fig. 10. Connect a 12-ft refrigerant hose to the vapor

service valve on the chiller and the suction service valve on

the pump. Copper tubing is factory installed from the pump

to the oil separator. Connect another 6-ft refrigerant hose

from the discharge connection on the oil separator to the

vapor valve on the storage tank. Open the liquid valve on

the storage tank, the charging valve on the chiller, and the

two interconnecting hose valves.

Once liquid refrigerant enters the chiller, open the chiller

vapor valve, the storage tank vapor valve, all valves be

tween the chiller vapor valve and the storage tank vapor

valve. Turn on the pump. The pump will remove refriger

ant gas from the chiller and discharge it into the storage

tank. This will create a pressure differential between the

chiller and the storage tank and provide the specified flow

rate.

The end of the liquid refrigerant transfer can be deter

mined by observing the liquid indicator. When liquid is no

longer visible, the transfer is complete. Close the liquid valve

on the chiller and turn off the pump.

Chiller to Storage Tank — To transfer liquid refrigerant from

the chiller to the storage tank, connect a 6-ft refrigerant hose

from the storage tank liquid valve to the chiller charging

valve. Install the liquid indicator to determine when liquid

transfer is complete. Connect a 12-ft refrigerant hose to the

vapor service valve on the chiller and the suction service

valve on the pump. Copper tubing is factory installed from

the pump to the oil separator. Connect another 6-ft refrig

erant hose from the discharge connection on the oil sepa

rator to the vapor valve on the chiller. Open the charging

valve on the chiller, the liquid valve on the storage tank,

and the two interconnecting hose valves.

Once liquid refrigerant enters the storage tank, open the

storage tank vapor valve, chiller vapor valve, and all valves

between the storage tank vapor valve and chiller vapor valve.

Turn on the pump. The pump will remove refrigerant gas

from the storage tank and discharge it into the chiller. This

will create a pressure differential between the storage tank

and provide the specified flow rate.

The end of the liquid refrigerant transfer can be deter

mined by observing the liquid indicator. When liquid is no

longer visible, the transfer is complete. Close the bottom

valve on the chiller and turn off the pump.

Page 10

Refrigerant Vapor Transfer

A WARNING

If the required vacuum level cannot be reached due to

the presence of a large leak in the chiller, the vapor

recovery process should be stopped. The constant in

filtration of air into the chiller may contaminate the

refrigerant.

Refrigerant vapor recovery is required after the liquid re

frigerant has been removed. Most refrigerant vapor can be

recovered by evacuating the chiller or storage tank and con

densing the vapor. The United States EPA requires the evac

uation level for low pressure chillers to be 29 in. Hg

(25 mm Hg absolute). Refer to Table 5 for additional

information.

Before using the pump for vapor recovery, make sure it

is at the correct operating temperature of 120 F (49 C). This

can be achieved by running the pump on air only for ap

proximately 15 minutes. If the pump is operating below op

erating temperature with refrigerant, excessive amounts of

refrigerant will be absorbed into the oil, causing dilution of

the oil. This condition may cause reduced vacuum capabil

ity and may shorten the life of the pump.

NOTE: If oil dilution is affecting the pump’s ability to achieve

29 in. Hg (25 mm Hg absolute), an oil change may be re

quired. See the Maintenance section on page 15.

BEFORE TRANSFERRING REFRIGERANT VAPOR When transferring refrigerant vapor from a chiller to a stor

age tank, connect the 12-ft refrigerant hose from the vapor

valve on the chiller to the suction service valve on the pump.

See Fig. 11. Copper tubing is factory installed from the

pump to the oil separator. Connect a 6-ft refrigerant hose

from the discharge connection of the oil separator to the in

let of the tube-in-tube condenser. See Fig. 4 for location.

Connect another 6-ft refrigerant hose from the refrigerant

outlet of the tube-in-tube condenser to the vapor valve on

the storage tank. See Fig. 4. Close the bottom valve on the

chiller and turn off the pump. The tube-ln-tube condenser

must be evacuated before starting this process.

The tube-in-tube condenser must be evacuated. Make sure

all refrigerant hose valves are closed. Remove the refriger

ant hose end connected to the pump suction service valve.

Remove the refrigerant hose end connected to the top valve

on the storage tank and connect it to the pump suction serv

ice valve. Close the pump discharge service valve and re

move the 1/4-in. cap on top of the pump discharge service

valve. Open all valves between the suction and discharge

service valves of the pump. Turn on the pump for about

5 seconds to evacuate the tube-in-tube condenser. The air

will be discharged through the 1/4 in. discharge port on the

pump discharge service valve. Once the evacuation is com

plete, reconnect the refrigerant hoses to their original con

nections. Replace the 1/4-in. cap on the pump discharge

service valve. Open the pump discharge service valve.

Connect a water hose to the water inlet connection (lo

cated on the bottom of the tube-in-tube condenser) and the

other water hose to the water outlet connection (located on

top of the tube-in-tube condenser). A water flow rate of ap

proximately 2 gpm (.012 L/s) is required at 70 F (21 C).

Refrigerant Hose

Direct Coupled Connection

Factory-Installed Copper Tubing

Fig. 10 — Liquid Refrigerant Transfer

(From Storage Tank to Chiller)

10

Page 11

WATER

CONNECTIONS

DISCHARGE

Refrigerant Hose

Water Hose

Direct Coupled Connection

Factory-Installed Copper Tubing

Fig. 11 — Refrigerant Vapor Transfer/Evacuation Connections

TO TRANSFER REFRIGERANT - Open all valves be

tween the chiller and storage tank. Turn on the water to the

tube-in-tube condenser. Turn on the pump. After a few min

utes, the condensed vapor will be seen in its liquid form

flowing through the liquid indicator to the storage tank. The

end of the vapor transfer can be determined by observing

the liquid indicator. When liquid is no longer visible, the

transfer is complete.

A CAUTION

Be sure to run the chiller water pumps when removing

refrigerant vapor. Trapped liquid may boil and can cause

tube freeze-up.

The vapor recovery process is complete when the vac

uum in the chiller has reached 29 in. Hg (25 mm Hg). Be

fore turning off the pump, shut off the water to the tubein-tube condenser and then drain the water from the condenser.

As the condenser warms up, it will help drain any liquid

remaining in the condenser and refrigerant hose into the stor

age tank. Turn off the pump. Close the valves to the stor

age tank and chiller. Disconnect the refrigerant hoses. Any

refrigerant vapor remaining in the refrigerant hoses and the

tube-in-tube condenser are considered to be de minimis. See

Fig. 12.

Use the same process when transferring vapor refrigerant

from the storage tank to the chiller.

10

20 30

WEIGHT (Kg OF CFC-11)

Fig. 12 — Refrigerant Vapor Remaining

in Chiller After Removal

of Liquid Refrigerant (400 Ton Unit)

40

11

Page 12

Purge Separator Assembly — A purge separator

assembly is used to remove noncondensable gases that may

be mixed with the refrigerant being recovered. See Fig. 4.

If vapor is being recovered from a leaking chiller, air will

enter the machine. The air will mix with the refrigerant gas

and collect in the storage tank. The air will raise the pres

sure of the storage tank until the pressure reaches 10 psig

(69 kPa). At this point, the high pressure cutout switch will

turn off the pump. To avoid this situation, a purge separa

tor assembly is factory installed. See Fig. 8.

During the vapor recovery process, the pressure in the

storage tank should not be higher than the corresponding

pressure/temperature relationship for a given refrigerant, based

on ambient conditions. If the room temperature is approx

imately 75 F (24 C) and CFC-11 is being recovered, the

pressure in the storage tank should be approximately 0 psig

(0 kPag). If the pressure is higher than 0 psig (0 kPag), a

noncondensable gas is present in the storage tank. See

Table 5.

A pressure gage is mounted on top of the purge separator

assembly. When the pressure reaches 8 psig (55 kPag) and

the pressure/temperature relationship shows this as exces

sive, the purge valve on top of the purge separator assem

bly should be opened to remove the noncondensable gas.

See Fig. 4. Based on the ambient temperature, the purge

separator assembly should be operated until the saturated

pressure is achieved. If the ambient temperature is 75 F

(24 C), the purge valve should be opened until the storage

tank pressure reaches 0 psig (0 kPa).

Oil Separation — The refrigerant management system

separates oil from refrigerant through distillation. The re

frigerant can be transferred from the chiller to the storage

tank and then distilled back to the chiller or another storage

tank.

Connect the 3-ft refrigerant hose from the storage tank

vapor valve to the pump suction service valve. See Fig. 13.

Copper tubing is factory installed from the pump to the oil

separator. Connect the 6-ft refrigerant hose from the oil sep

arator discharge connection to the top connection on the

tube-in-tube condenser. Connect the 12-ft refrigerant hose

with the liquid indicator to the refrigerant outlet connection

on the condenser and to the chiller charging valve or an

other storage tank. Provide water at approximately 2 gpm

(.012 L/s) and a maximum temperature of 70 F (21 C) to

the tube-in-tube condenser using suitable water hoses. Turn

on the pump and heater using the toggle switches provided.

If the distilled refrigerant is being returned to the chiller,

run cool water through the evaporator heat exchanger. Ap

proximately 1.2 lb per minute (.54 kg per minute) of CFC-11

can be distilled per hour. When liquid refrigerant is no longer

seen in the liquid indicator, the distillation process is

complete.

After the distillation process is complete, the oil remain

ing in the bottom of the storage tank should be drained us

ing the liquid valve on the storage tank. After the oil is

drained, the tank can be wiped clean by opening the access

cover located on the opposite end of the level gage.

WATER

CONNECTIONS

Refrigerant Hose

Water Hose

Direct Coupled Connection

Factory-lnstailed Copper Tubing

Fig. 13 — Oil Separation Connections

12

Page 13

Water Separation — Water is only slightly soluble in

refrigerant. See Table 4. If additional water is present, it

will float on top of the refrigerant and can be easily re

moved by the RMS unit.

Transfer the water contaminated refrigerant to the stor

age tank using the procedures described in the Liquid Re

frigerant Transfer section. If the refrigerant contamination

was caused by a chiller failure, the chiller must be repaired,

dehydrated, and vacuum broken with refrigerant. Use

24 in. Hg (-81 kPa) for CFC-113, 18 in. Hg (-61 kPa)

for HCFC-123, and 15 in. Hg (-51 kPa) for CFC-H to

avoid freezing the tubes in chiller before the cleaned liquid

refrigerant can be returned to the chiller. If the chiller is not

repaired, the clean refrigerant should be transferred to an

other clean tank.

Connect the 12-ft refrigerant hose from the chiller or clean

storage tank vapor valve to the suction service valve on the

pump. See Fig. 14. Copper tubing is factory installed from

the pump to the oil separator. Connect a 6-ft refrigerant

hose from the discharge connection of the oil separator to

the vapor valve on the storage tank. Connect the 3-ft refrig

erant hose and liquid level indicator from the liquid valve

of the storage tank to the filter drier canister. See Fig. 5.

Connect the remaining 6-ft refrigerant hose from the filter

drier canister to the chiller charging valve or the liquid valve,

if using a storage tank. Open all valves between the storage

tank and the chiller. Turn on the pump.

While the liquid refrigerant is being transferred into the

chiller or another storage tank, use the water separation glass

at the bottom of the tank to determine when the water/

refrigerant level is close to the liquid valve. See Fig. 4. Re

duce the liquid flow rate as the water level approaches the

liquid valve. Close the liquid valve when the water/

refrigerant level is at the bottom of the water separation

glass to prevent water from entering the other storage tank.

To prevent the loss of remaining refrigerant, transfer the

water/refrigerant mixture into an open container. Skim the

water off the top of the refrigerant. Transfer the remaining

refrigerant into the storage tank.

Refrigerant Hose

Direct Coupled Connection

Factory-Installed Copper Tubing

FILTER DRIER

Fig. 14 — Water Separation

13

Page 14

Table 5 — Vapor Pressure

TEMPERATURE

°F

-20

-15

-10

-5

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

110

115

120

125

130

135

140

145

150

NOTE: Italics indicates in. Hg vacuum.

°c

-28.9

-26.1

-23.3

-20.6

-17.8

-15.0

-12.2 23.0

-9.4

-6.7 21.0

-3.9

-1.1

-1.7

10.0

12.8

15.6

18.3

21.1

23.9

26.7

29.4

32.2

35.0

37.8

40.6

43.3

46.1

48.9

51.7

54.4

57.2

60.0

62.8

65.6

Psi

Gage

26.9

26.5

25.9

25.3

24.6

23.9

22.1 3.8

19.8

18.5

17.1

15.6

4.4

13.8 7.9

7.2

12.0

9.9

7.7 10.9

5.3

2.7

0.1

1.6

3.2

4.9

6.8

8.8

10.9

13.2 27.9 91.0

15.7 30.3 108.3

18.3

21.1

24.0

27.1

30.5 45.1 210.3

34.0

37.7

Psi kPa

Absolute Gage

1.4

1.7 -89.7 11.7

1.9

2.2 -85.7 15.2

2.6

2.9 -80.9^ 19.9

3.4 -77.9

4.3

4.9

5.6 -62.6 38.6

6.3 -57.9

7.0 -52.8 48.3

8.8

9.8 -33.5 67.6

12.0 -17.9

13.4 -9.1

14.7

16.2

17.9

19.6 33.8

21.5

23.5 60.7 162.0

25.6 75.2

32.9 126.2

35.7

38.7 165.5

41.8

48.6

52.7

CFC-11

145.5

186.9

234.4 335.1

259.9

kPa

Absolute Gage

-91.1

-87.7 13.1

-83.3 17.9

-74.8 26.2

-71.1 29.6

-67.0 33.8

-46.7 54.5

-40.6

-26.1

.6

11.0

22.1 123.4

46.9

9.7

23.4 27.5

43.4

60.7 22.9

75.2 20.9

82.7 19.8

92.4 18.6

101.4

111.7

135.1

148.2 10.5

176.5

192.4 3.8

208.9

226.8

246.2 2.2

266.8 3.8

288.2 5.5

310.9

363.4

CFC-113

Psi

29.0

28.8

28.6

28.4

28.1 08 -95.1

27.9

27.1

26.7

26.3 1.8 -89.1

25.7 2.0

25.1 2.4

24.4 2.7

23.7

21.9

17.2 6.2 -58.2

15.8 6.9

14.2

12.2 8.5

8.5

6.3

1.2

0.8

7.3

9.2 23.9

11.2 25.9

Psi

Absolute Gage

0.4

0.5

0.6

07 -96.2

0.9

1.1

1.3

1.5

3.1 -80.2

3.4

3.9

4.4

5.0

5.5

7.7

9.5

10.5

12.2 -21.3

13.8 -12.9

14.6

15.4 5.5

16.6

18.5 26.2

20.2

21.9 50.3

kPa

-98.2 2.8

-97.5

-96.8 4.1

-94.5

-93.1

-91.8 8.9

-90.4 10.3

-87.0 13.8

-85.0 16.5

-82.6 18.6

-77.6 23.4

-74.2 26.9

-70.8 30.3

-67.0 34.5

-62.9 37.9

-53.5

-48.1

-41.9

-35.6

-28.8

-4.1

15.2 114.5

37.9

63.4 164.8

77.2

kPa

Absolute

3.4 27.3

4.8

5.5

6.2

7.6

12.4

21.4 16.5

42.7 4.0

47.6

53.1

58.6

65.5

72.4

84.1 8.1

95.2 10.3

100.7

106.2 15.1

127.6

139.3

151.0

178.6

HCFC-123

Psi Psi kPa

Absolute Gage Absolute

Gage

27.6

26.8

26.3

25.8

25.1 2.3

24.4

23.3

22.7 3.5

21.7

20.6 4.5

19.4

18.0 5.8

14.9

13.0

11.0

8.9

6.6

1.2

0.9

2.5

4.2

6.1

12.6

17.7

20.6

23.4

26.8

30.2 45.0 208.2

33.8

1.1 -93.5 7.6

1.3

1.5

1.8

2.0

2.6 -82.6 17.9

3.1

4.0

5.2 -65.7 35.9

6.6

7.3

8.3

9.2 -37.2

10.3

11.4

12.8

14.1 -4.1

15.7 6.2 108.3

17.2 17.2

19.0 28.9

20.8 42.1

23.0

25.0

27.4

29.8

32.6 122.2

35.3 142.0

38.4

41.5 184.8

48.5 233.1

-92.4 9.0

-90.7 10.3

-89.1

-87.4 13.8

-84.9 15.9

-80.0 21.4

-76.8

-73.4 27.6

-69.8 31.0

-60.9 39.9

-55.9 45.5

-50.5 50.3

-44.0 57.2

-30.1

-22.3 78.6

-13.5 88.3

55.8

71.0

86.9

104.1

161.3

kPa

12.4

24.1

63.4

71.0

97.2

118.6

131.0

143.4

158.6

172.4

188.9

205.5

224.8

243.4

264.8

286.2

310.3

334.4

14

Page 15

MAINTENANCE

Periodic maintenance is necessary to keep all compo

nents functioning as designed. A maintenance log is rec

ommended to ensure a proper maintenance schedule is

followed.

Maintaining the Pump — Clean lubricating oil is es

sential to maintaining the required vacuum capabilities. If

the oil is diluted with refrigerant, it will not be able to ob

tain a 29 in. Hg (25 mm Hg absolute) rating. Refer to

Table 5 for additional information.

Change the oil in the pump and separator before each

use. Both the pump and the oil separator use 16 oz. of

300 SSU oil at 100 F (38 C). The pump and oil separator

have drain ports for oil removal. The drain port for the oil

separator is located on top of the separator. The drain port

for the pump is located on the bottom of the pump. Drain

the oil from the separator by using the pump to pressurize

the oil separator with air.

Install a 3-ft refrigerant hose on the discharge connection

of the oil separator and close the refrigerant hose valves.

Open the pump’s suction and discharge service valves. Turn

the pump on and let it run until it shuts down due to the

high pressure cutout at 10 psig (69 kPa). Use this pressure

to drain the oil from the separator. When this is complete,

drain the oil from the pump. Use the oil drain fittings and a

hand pump to add new oil to the pump and separator.

Check pump’s vacuum capability once per year. Place a

test gage capable of reading 29 in. Hg (25 mm Hg) on the

suction service valve. Open the pump suction and dis

charge service valves. Start the pump and measure the vac

uum. If the pump does not achieve the proper vacuum, a

new valve plate assembly should be installed. Installation

instructions are provided with the new valve plate assembly

from the manufacturer.

secured on a tapered shaft with a key and lock nut. The mo

tor half of the coupling is secured on a straight shaft with a

key and set screw. The rubber insert, found between each

coupling half, should be inspected for damage and replaced

as needed. Remove the coupling guard and pump to access

the pump coupling. Leave the base brackets in place.

High-Pressure Cutout Switches — Check the pres

sure cutout setting for the pump and heater pressure switches

once per year. Each switch should shut the pump off at

10 psig (69 kPa). To check the pump and heater switches,

disconnect the capillary tube and use a regulated pressure

source. Verify with an ohmmeter that the switch opened at

10 psig (69 kPa).

Refrigerant Storage Tank — The refrigerant stor

age tank contains a cleanout cover. Remove the cover to

clean the tank when required. Use a clean cloth to wipe the

inside of the tank. Reinstall cleanout cover.

Refrigerant Hoses — Each refrigerant hose has a fac

tory supplied, field installed ball valve and coupler assem

bly at each end. These couplers contain a rubber seat that

must be replaced periodically. Inspect the rubber seats be

fore each use. Replace the seats if they appear to be dam

aged. See Fig. 15.

Periodically check refrigerant hoses for cuts or abrasions

that may allow refrigerant to leak into the atmosphere.

Pump Coupling — The aluminum, self-aligning cou

pling should be inspected for wear at least once a year or as

required based on usage. The pump half of the coupling is

SIDE VIEW END VIEW

Fig. 15 — Refrigerant Hose Seats

15

Page 16

TROUBLESHOOTING

SYMPTOM

Unit hums and vibrates

excessiveiy.

Pump does not puli a 29 in.

Hg vacuum (25 mm Hg

absolute).

Unit is plugged into electri

cal outlet but does not

start.

Unit shuts off on the high

pressure switch.

Motor draws high amps at

start-up.

Compressor is damaged at

start-up.

Storage tank relief valve is

relieving refrigerant gas.

Liquid and vapor recovery

rates are slower than

specified.

Purge unit is constantly

open to remove noncon

densable gas from the stor

age tank.

PROBABLE CAUSE

Motor/pump assembly out of alignment.

Motor/pump assembly holddown bolts are

loose.

Pump and oil separator oil is diluted with

refrigerant.

Valves and valve plates are worn.

The ON/OFF switch, high-pressure switch,

motor thermal overload and/or motor wind

ing are faulty.

Unit is plugged into a nonoperational

outlet.

All valves on the discharge side of the

pump are not open.

Cutout setting on the switches is incorrect.

Inadequate water flow through the

condenser.

Noncondensable gas has accumulated in

the storage tank.

Pump oil is very cold. Warm up pump by running it with the suction and discharge

Liquid refrigerant entered the suction valve. Check pump for internal damage.

Storage tank contains excessive noncon

densable gas.

Storage tank is placed in a hot room

(above 115 F [46 C]).

Vapor valve connection on the chiller is

smaller than V2 inches in diameter.

There is a restriction in the refrigerant hose

system.

Chiller probably has a severe leak.

Check alignment and adjust if necessary.

Check hoiddown bolts and tighten as necessary.

Change oil in pump and oil separator as specified in mainte

nance section on page 15.

Replace valves and valve plates in pump.

Test all components for proper operation and replace as

needed.

Try another outlet and test for presence of voltage.

Open ail valves on the discharge side of the pump.

Adjust switch as necessary.

Increase water flow or use a colder water source.

Purge noncondensable gases from storage tank.

service valves open to the atmosphere.

Bleed noncondensable gases from storage tank.

Move storage tank to a cooler room.

Install a V2 in. vapor valve on the chiller.

Check all refrigerant hose valves and verify that they are open.

Stop the recovery process.

REMEDY

Copyright 1994 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

Book|2 |2 PC 221 Cataiog No 531-963 Printed in U S A. Form 19QA-2SI Pg 16 9-94 Replaces: 19QA-1 SI

Tab 5a 5d

Loading...

Loading...