Humidifiers | Steam Humidifiers

COMMERCIAL, INDUSTRIAL

Humidifiers

AND INSTITUTIONAL

STEAM HUMIDIFIERS

HCHH Shown

www.carnes.com G-1

Humidifiers | Steam Humidifiers

Humidifiers

CARNES MICROPROCESSOR CONTROLLED STEAM HUMIDIFIERS use ordinary

untreated tap water and convert it to mineral free steam for humidity control in commercial,

industrial, institutional and residential applications.

ECONOMICAL

Disposable Cylinders Eliminate Periodic Maintenance for Reduced Maintenance Costs

Fast and Easy Installation

Reliable Electronic Components for Long Life

EFFICIENT

Circuit Board Utilizes Microprocessor to Maximize Energy Conservation

Exclusive Circuit Board Design with Attached True Touchscreen Control Display

VERSATILE

Digital Output on a True Touchscreen Control Display Providing Status and Help Buttons For

Operational Details and Troubleshooting

Capacities up to 200 Pounds of Steam Per Hour Per Single Unit

Utilize any On-Off Humidistat, Carnes Proportional Humidistat or External Signal from DDC Controls

Flexible steam hose

distribution pipe.

Hinged and removable

door provides easy

access for service.

Door lock

prevents

unauthorized

adjustments.

connects to

HBGH Shown

Easy access

“On-Off-Drain”

Switch.

True Touchscreen

control display.

20 gauge metal partition

covers line voltage wiring

for added safety.

Optional internal circuit

breaker available. Please

note: certain units require

circuit breakers per NEC

48 amp guidelines.

Disposable plastic cylinder eliminates

periodic maintenance.

Cut-away used steam cylinder

The simplicity and unique advantages of humidity from

showing mineral deposits.

directly boiling water in disposable cylinders has been

well known since Carnes pioneered the concept in North

America in 1969. Pan type humidifiers require messy, time

consuming cleaning that may require the use of acids.

Electric heating elements in pan type units may also require

replacement. Easily changeable steam cylinders containing

electrodes can be replaced in less than five minutes.

G-2 www.carnes.com

Humidifiers | Displays & Internal Controls

FRONT PANEL DISPLAYS & CONTROLS

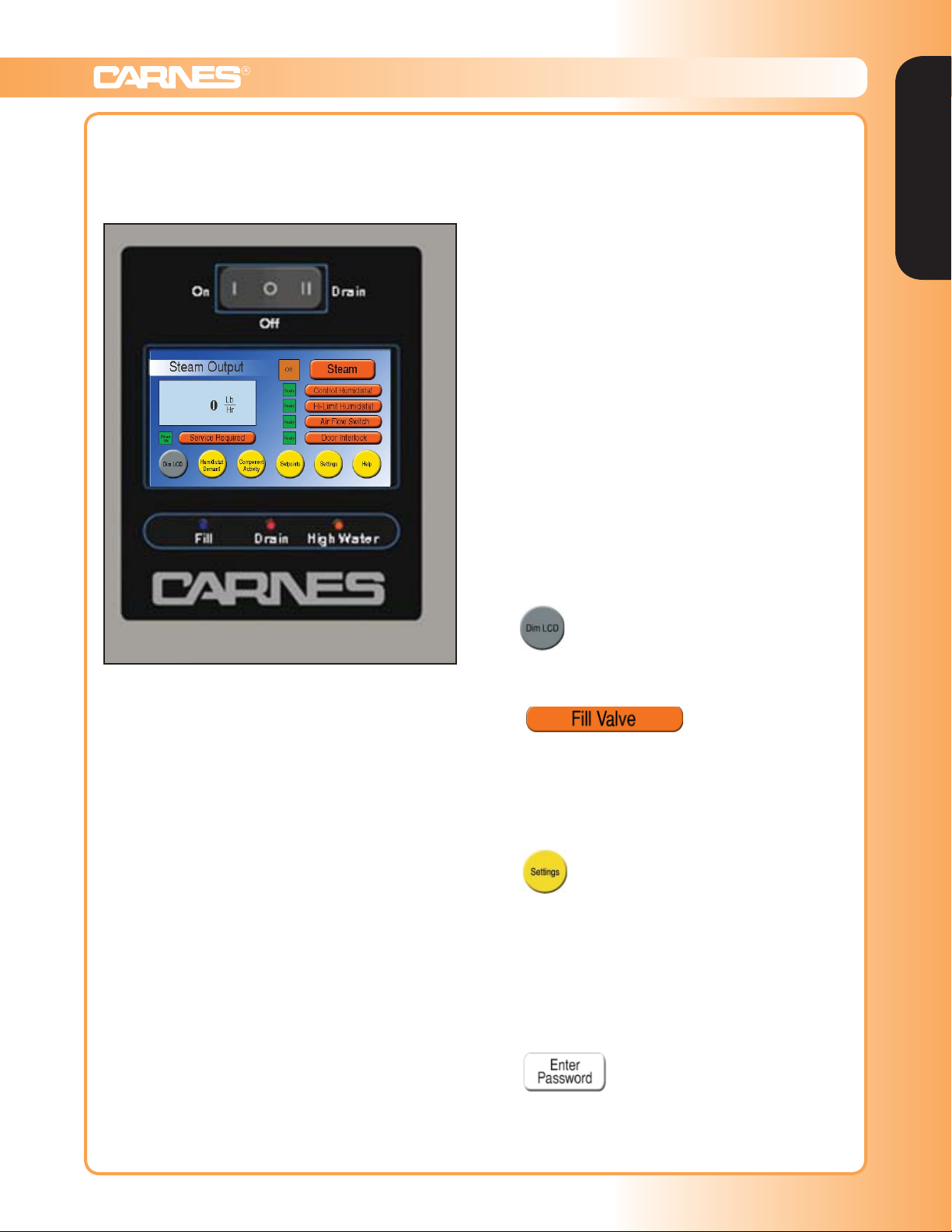

The display on the front panel of the humidifier cabinet contains the “On-Off-Drain” switch, the LCD True

Touchscreen display and the “Fill”, “Drain” and “High

Water” LED’s.

“DRAIN” LED

The DRAIN LED is a red light illuminated when the

Drain Valve is activated. An activated Drain Valve

allows water to drain from the humidifier. An analogous

indicator, and a description of its operation, is offered in

the “Component Activity” menu.

“HIGH WATER” LED

The HIGH WATER LED is an orange light illuminated

when the High Water Sensor is activated. An activated

High Water Sensor indicates that the water has risen to

the maximum allowable level in the cylinder. This can

be a normal situation, particularly if the cylinder is being

filled with mostly unconditioned water. An activated High

Water Sensor can also be a sign that the cylinder is close

to end-of-life and needs replacing, or, in rarer cases, the

cylinder is not conductive enough for the fresh water

entering the humidifier. An analogous indicator, and a

description of its operation, is offered in the “Component

Activity” menu. More information on troubleshooting High

Water situations can also be found through the “Help”

menu on the home screen.

HUMIDIFIER TRUE TOUCHSCREEN MENU PAGES

The humidifier True Touchscreen user interface uses

color conventions to help the user navigate the controls.

The colors of different buttons indicate the following.

1. Gray —

Humidifiers

Figure P

“ON-OFF-DRAIN” SWITCH

In the “On” position the humidifier will operate if all controls are calling for humidity. The “Off” position is used

for seasonal shut down if desired. The “Drain” position

is used to drain water from the steam cylinder for maintenance. The fill solenoid valve will be on whenever the

drain is activated to reduce the drain water temperature.

LCD TRUE TOUCHSCREEN DISPLAY

This LCD True Touchscreen display offers the necessary interface to control and monitor many aspects of

the humidifier. On the home screen is the current steam

output in Lbs./Hr. (or Kg/Hr). To select either is available

in the settings menu. A “Service Required” indicator

and button outlining current service issues, indicators

for the four basic controls necessary for operation

(control humidistat, high limit humidistat, air flow switch and

door interlock), and various buttons which navigate to

other menu pages when pressed are also available

on the home page screen. The menu pages and their

capabilities are detailed further in “True Touchscreen

Menu Pages” section of this document.

“FILL” LED

The FILL LED is a blue light illuminated when the Fill

Valve is activated. An activated Fill Valve allows water

to flow into the cylinder of the humidifier. An analogous

indicator, and a description of its operation, is offered in

the “Component Activity” menu.

Dim LCD is the only gray button. More information is

available in the “home” page description.

2. Orange —

Orange buttons represent the object or subject

described across the button. Most orange buttons

have an indicator next to them, which can change

in color, e.g. green, yellow or gray. Pressing orange

buttons will bring you to a page which describes the

object or subject in question.

3. Yellow —

Yellow buttons navigate a user to a new page

dedicated to a set of functions. For example, the

“Humidistat Demand” button brings the user to a

page that shows what percentage demands both

the Control and High Limit Humidistats are currently

requesting, and details their functions. The bottom

of each page, other than the home screen, has

a square “Back” or “Home” button dedicated to

directing the user back to their previous page.

4. White —

White buttons are used for confirming or entering

data into the touchscreen. For example, they are

used to confirm a change to the “Max Output”

parameter, or entering a password to access the

“Settings” menu.

www.carnes.com G-3

Humidifiers | Displays & Internal Controls

Humidifiers

5. Maize —

Help buttons are used exclusively in the “Help”

page. These help buttons answer frequently asked

questions about the operation, maintenance

and troubleshooting of the humidifier. It is also a

convenient place to look at humidifier electrical data

when an IOM is not available.

“HOME” PAGE

The home page is the main screen through which most

other pages can be accessed. The large blue square to

the left shows the steam output. The orange and yellow

buttons on the home page are considered “Operational

& Status” indicators. Touching any of these displays will

show dialog explaining the subject or status of that button.

The orange buttons also have indicator boxes to the left

showing actual status. Green shows ready to operate.

1. Dim LCD (gray) - As a power saving feature, press-

2. Humidistat Demand (yellow) - Brings the user to

3. Component Activity (yellow) - Button lists the

4. Setpoints (yellow) - The three setpoints of the unit

5. Settings (yellow) - Any settings of the humidifier,

6. Help (yellow) - Frequently asked questions about

7. Service Required (orange) - Invokes a page that

ing the Dim LCD button will shut the backlight of the

LCD off. Once off, pressing anywhere on the True

Touchscreen will turn the backlight on. The humidifier can also automatically turn off the backlight after

15 minutes. See the “Settings” page for more information on enabling/disabling the Auto-Dim feature.

a page that shows what percentage demands both

the Control and High Limit Humidistats are currently requesting, and further details their functions.

internal components used in the humidifier.

Their respective indicators showing whether the

components are activated or not. From this

page, the user can view more information on the

components and their functions.

are listed on this page. The setpoint is the target

Lb./Hr. output of the humidifier.

e.g. Max Output, Timers or Fan Speed, can be

accessed through this page. This page is password protected. For more information, refer to the

“Settings” page section.

the humidifier can be answered through the Help

page. It is a convenient resource to resolve many

issues quickly and effectively.

describes what service is needed by the humidifier,

if any. Indicator light to the left of the button turns

red when service is needed, and will otherwise

remain green. Refer to the separate “Service

Required” page for more information.

8. Steam (orange) - Explains the status of the “Steam”

indicator light. The humidifier will only produce

steam if the “Steam” indicator light is green. The

indicator will be brown when the On/Off/Drain

switch is in the “Off” position. It will turn yellow if

the switch is in the “On” position, but one or more

of the four basic controls are not satisfied (Control

Humidistat, High Limit, Air Flow, Door Interlock).

The light will turn green if all of the above switches

and controls are satisfied.

9. Control Humidistat (orange) - Explains the

status of the Control Humidistat indicator light,

and also shows the current demand of the Control

Humidistat.

10. High Limit Humidistat (orange) - Explains the

status of the High Limit Humidistat indicator light,

and also shows the current demand of the High

Limit Humidistat.

11. Air Flow (orange) - Explains the status of the Air

Flow switch.

12. Door Interlock (orange) - Explains the status of the

Door Interlock switch.

“SERVICE REQUIRED” PAGE

“SERVICE REQUIRED” PAGE

The “Service Required” page outlines any service issues

that are in need of being resolved. Many issues can be

traced back to variability in water parameters, and often

the solution can be dealt with through the changing of

cylinders or modifying timer values within the “Settings”

page. This page is used to alert the user and direct them

on the right path towards resolution.

“HUMIDISTAT DEMAND” PAGE

The Humidistat Demand page lists both the Control

Demand and the High Limit Demand of the humidifier.

Each demand signal is represented by an orange button,

and next to each button is a numerical box specifying

the percentage of demand each humidistat is currently

calling for.

G-4 www.carnes.com

Humidifiers | Displays & Internal Controls

The Control humidistat, which provides the Control

Demand, is normally the humidistat in the room being

humidified. It is either installed in the room itself or the

return air duct. The High-Limit humidistat, which provides

the Hi-Limit Demand, is a safe-guard humidistat installed

in the supply duct roughly 10-15 feet past the distribution

tube. This humidistat is usually set to a high level (8090%), and will shut down the humidifier if the humidity

gets too high in the supply duct. Without a High-Limit

humidistat properly installed, the supply duct could reach

a humidity level where any steam entering the duct would

readily condense.

Both Control humidistats and High-Limit humidistats

are wired in the same way, only Control humidistats

are wired to port J16 of the circuit board and High-Limit

humidistats are wired to port J17. Both ports have the

same number of pins and connection layout.

When using an on/off humidistat, the percentage

should be either 100% or below 20%. In this case the

control is either calling for full output or no output. On-Off

humidistats are dry-contact switches. They will have two

wires; each connected to pins 2 and 4 (in no particular

order/polarity).

For a proportional humidistat, any percentage value is

possible between 0% and 100%. In this case the humidifier can be modified to output any fraction of its max

output. If the proportional control falls to 20% or below,

the humidifier is shut off. The input signal of a proportional

humidistat must be of the 0-10V DC variety. Proportional

humidistats will have three wires, with ‘power’ going to

pin 1, ‘signal’ to pin 3, and ‘ground’ to pin 4.

In lieu of a humidistat, a DDC signal from a building

management system may also be used. Here, the ‘signal’

should be connected to pin 3, and ‘ground’ to pin 4. In

this case, ‘power’ can be ignored. A DDC signal must be

of a 0-10V DC variety, though a 4-20 mA control signal

can be converted to a 0-10V signal by adding a 470 Ohm

resistor between the ‘signal’ (pin 3) and ‘ground’ (pin 4).

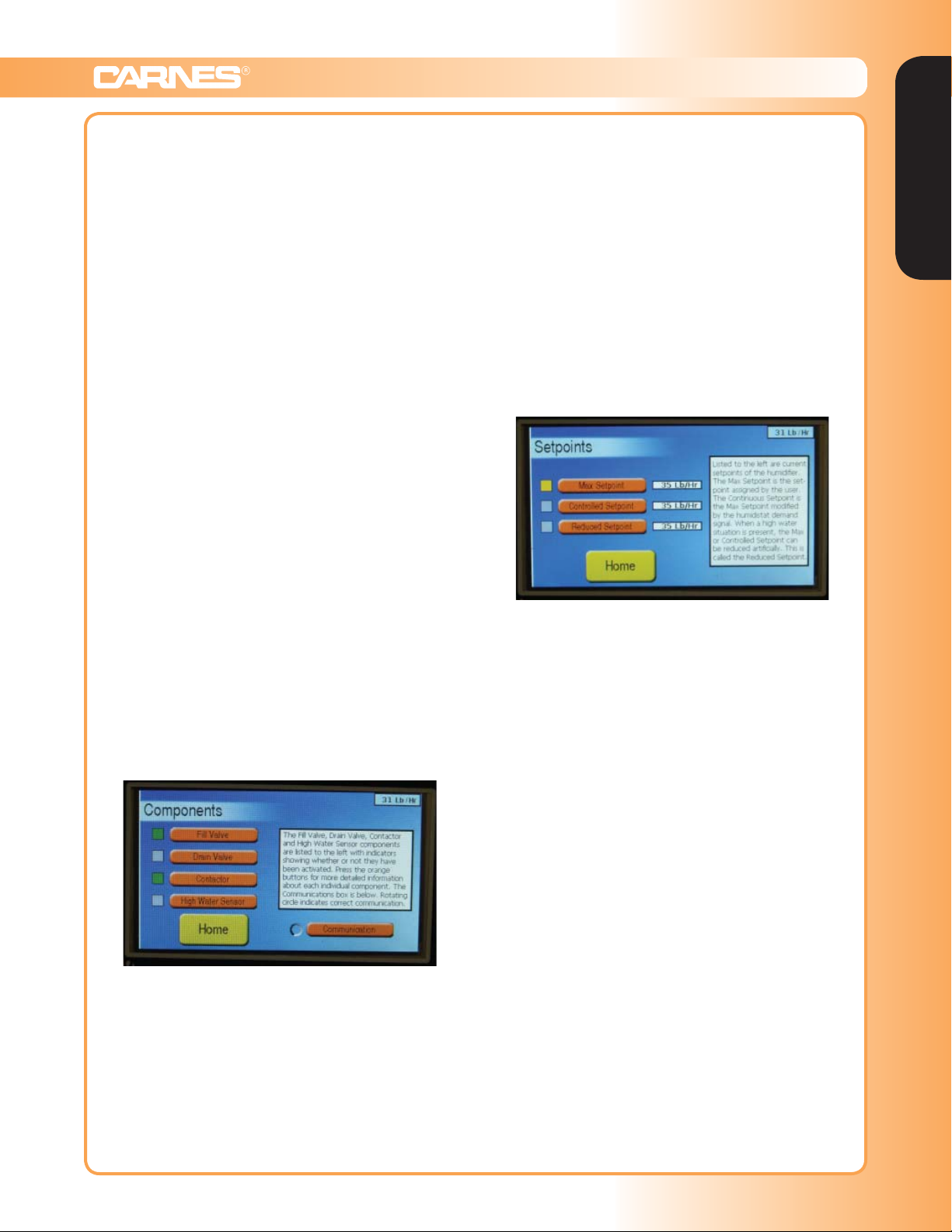

“COMPONENT ACTIVITY” PAGE

The Component Activity page lists all internal components that can switch on and off during operation. This

includes the Fill Valve, Drain Valve, Contactor, and High

Water Sensor. Each orange button in the component

list is accompanied by a colored indicator representing

whether or not the component is currently ‘on’. Green

indicates that the component is ‘on’, whereas gray

indicates the component is ‘off’. The Fill Valve is on

when the unit is either filling or draining the cylinder.

The Drain Valve is on when the humidifier is draining

the cylinder. The Contactor is on when the humidifier is

producing steam. The High Water Sensor is on when

the humidifier has identified a high water situation. When

in a high water situation, the fill valve is disabled for 5

minutes. At the end of 5 minutes the high water sensor

light will go out, the fill valve will open, if there is a call for

more humidity, and unit will continue normal operation.

High water sensors can be cumulative depending on the

condition of the water.

The other item present on this screen is the

Communication button. The Communication button has

a rotating indicator that represents whether the True

Touchscreen controller on the circuit board is properly

communicating with the microcontroller. If this icon is not

rotating and has a red ‘X’ through it, the information on

the screen is invalid and you should contact the factory.

“SETPOINTS” PAGE

The Setpoints page displays the setpoints (the target

steam output of the humidifier) associated with the unit.

There are three different setpoints, but only one setpoint

is active at any given time. Each setpoint is accompanied

by the current value of the setpoint to the right, and an

indicator that represents its status. For all setpoints, the

following colors represent the status of the setpoints:

Gray – The setpoint is inactive because it is not

currently necessary.

Green – The setpoint is active, and the humidifier is

producing steam at or above the setpoint value.

Yellow – The setpoint is active, but the humidifier is

producing steam below the setpoint value.

Yellow/Black X – The setpoint is inactive because it is

being overridden by a setpoint with a higher priority.

The three different types of setpoint are as follows: The

Max Setpoint is the user-specified setpoint active when

no external controls or internal reduction is taking place.

The Max Setpoint is always modifiable via the “Max

Output Adjust” within the settings menu. The Controlled

Setpoint is the setpoint when a humidistat (Control or

High Limit), reduces the target output of the humidifier

due to changing room requirements. The Reduced

Setpoint is active when the unit requires a reduction in

output due to a high water situation.

The setpoints have the following priorities: The Reduced

Setpoint has the highest priority and always overrides the

Controlled Setpoint and the Max Setpoint when active.

The Controlled Setpoint has the next highest priority, and

always overrides the Max Setpoint. It should be noted

that the Reduced Setpoint is always lower than or equal

to the Max Setpoint (or Controlled Setpoint, if active),

and the Controlled Setpoint is always lower or equal to

the Max Setpoint.

Humidifiers

www.carnes.com G-5

Humidifiers | Displays & Internal Controls

Humidifiers

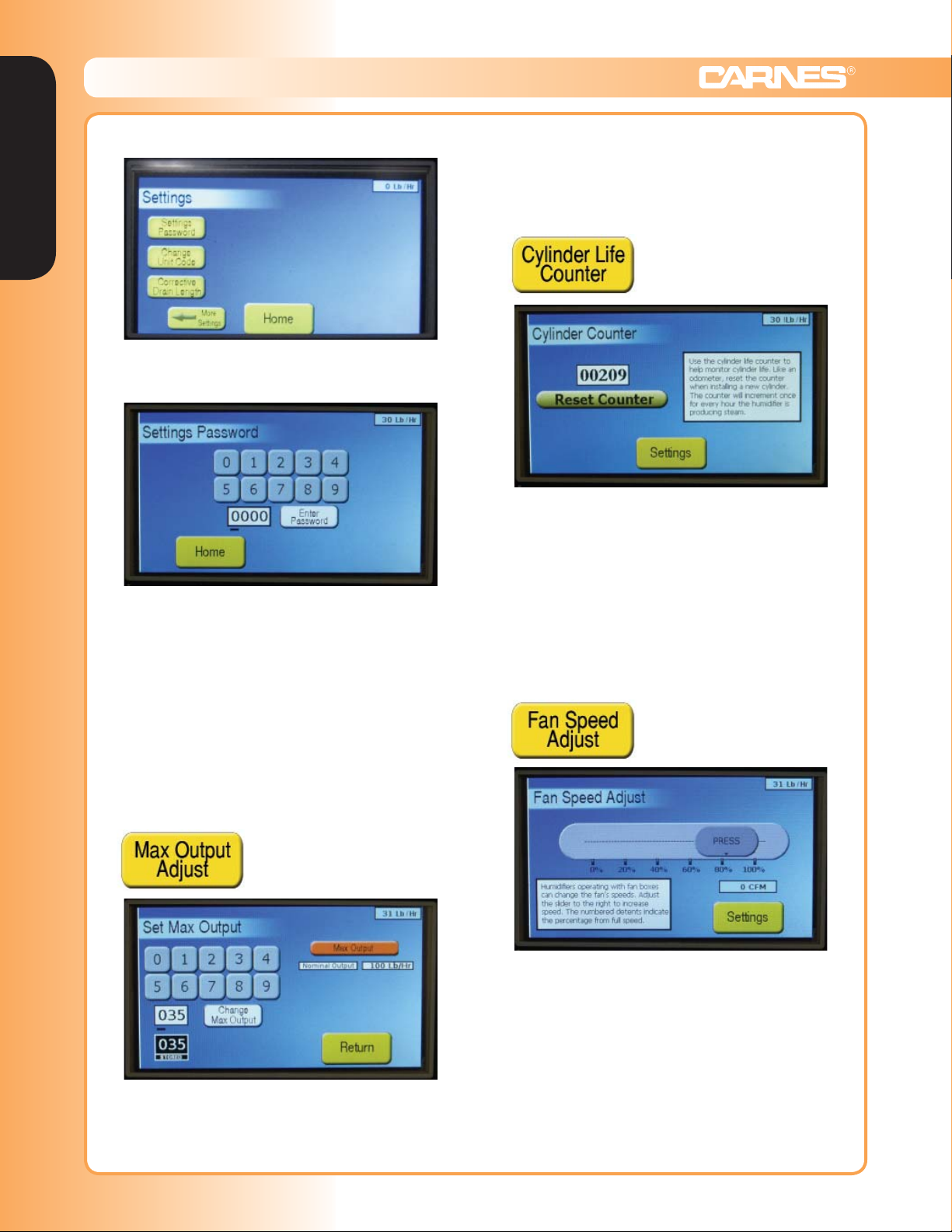

“SETTINGS”

The Settings menu is the page where all operational

values can be set. It is password protected by default,

with a default password of ‘1212’.

The password can be disabled under the ‘Settings

Password’ on the second Settings page. See ‘Settings

Password’ section for more details.

of the humidifier. The Maximum Output value, when

changed, also changes the Max Setpoint value on the

Setpoints page.

Cylinder Life Counter –

This page consists of a counter where the user can

monitor the life, in hours, of the cylinder. When changing

a cylinder, press the ‘Reset’ button on this page to reset

the timer. The Cylinder Life Counter only counts the

amount of actual runtime of the cylinder (the time when

the contactor is pulled in). The counter value is saved

even when the humidifier is powered down. The national

average cylinder life is about 1150 hours, but this can

vary greatly depending on individual water conditions.

Any adjustment made to any setting can be done ‘on-thefly’. Which means when a change occurs, the humidifier

will react accordingly without the need of shutting off the

unit or even stopping steam output. In general, any page

within the True Touchscreen system can be accessed,

monitored, or changed ‘on-the-fly’.

Max Output Adjust –

This page adjusts the Maximum Output of the humidifier.

The Maximum Output can be adjusted lower from the

nominal output value of the unit (set at the factory). The

unit cannot be set lower than 20% of the nominal value

Fan Speed Adjust –

This page consists of a slider bar that can change the

speed of the fans when the humidifier is connected to

an optional blower box. This slider bar will not affect the

operation of the humidifier if no blower box is attached.

The bar can change the speeds of the fans from 0 to

100% of the max fan speed. Also displayed on this page

is an estimate of the current fan air output, in Cubic Feet

per Minute (CFM). This adjustment is particularly useful

if the humidifier is of a smaller capacity, and less noise

from the fans is appreciated.

G-6 www.carnes.com

Humidifiers | Displays & Internal Controls

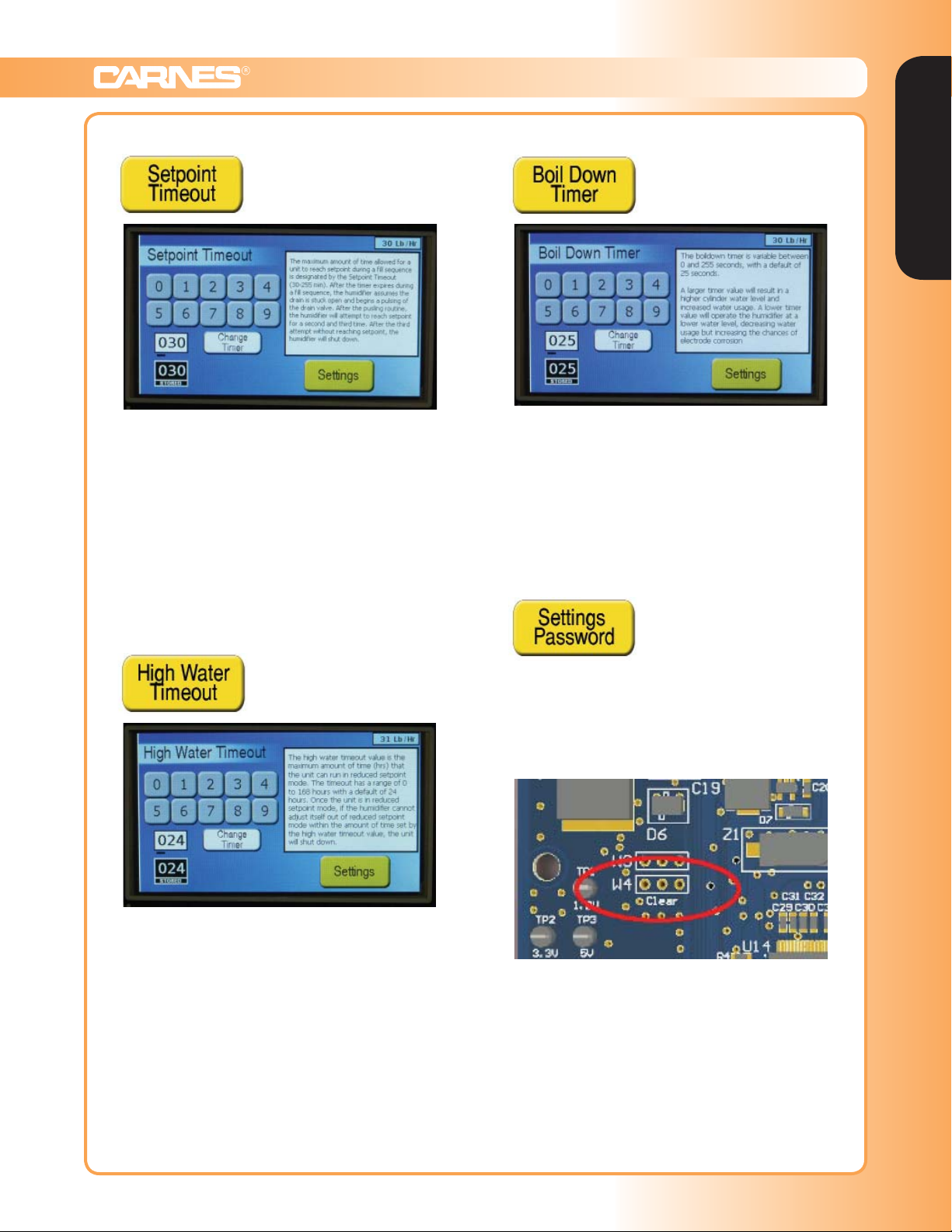

Setpoint Timeout –

This page is where the Setpoint Timeout value is set. The

maximum amount of time allowed for the unit to reach

setpoint during a fill sequence is designated by the

Setpoint Timeout. Its default value is 30 minutes, but

can be set as high as 255 minutes. After the timer

expires during a fill sequence, the humidifier assumes

the drain valve is stuck open (due to sediment buildup),

and begins pulsing the drain valve to attempt to unclog

it. After the pulsing routine, the humidifier will attempt to

reach setpoint for a second and third time. After the third

attempt without reaching setpoint, the unit will shut down.

Boil Down Timer –

Humidifiers

This page is where the Boil Down Timer is set. The Boil

Down Timer is variable between 0 and 255 seconds,

with a default value of 25 seconds. Setting the Boil Down

Timer higher will result in an increased water level, and

less-conditioned water. This may be helpful in reducing

low water level induced arcing and corrosion of cylinders.

More water is consumed by the humidifier when the Boil

Down Timer value is increased.

Settings Password –

High Water Timeout –

This page is where the High Water Timeout value is

set. This is the maximum amount of time allowed for

the unit to run in a ‘Reduced Setpoint’ mode (See

Setpoints page). The timeout has a range from 0 to 168

hours, with the default being 24 hours. If the humidifier

setpoint is artificially reduced due to a high water situation, the humidifier will continue to run. If the humidifier

cannot work it’s way back up the normal max/controlled

setpoint, the humidifier will shut down after the High

Water Timeout value elapses.

This page is where the password for the settings menu

can be changed or disabled.

If the password for the Settings menu is forgotten, it can

be reset. To do this, remove power to the humidifier,

move the jumper on W4 from pins ‘1 and 2’ to ‘2 and 3’,

and power the unit back on.

Return the jumper to pins ‘1 and 2’ afterward. Pins ‘1 and

2’ are to the left, and pins ‘2 and 3’ are to the right.

The different yellow buttons on both setting pages allow

for the changing of different values. Below is a brief

summary of each, and more information can be accessed

within the page itself.

www.carnes.com G-7

Humidifiers | Displays & Internal Controls

Humidifiers

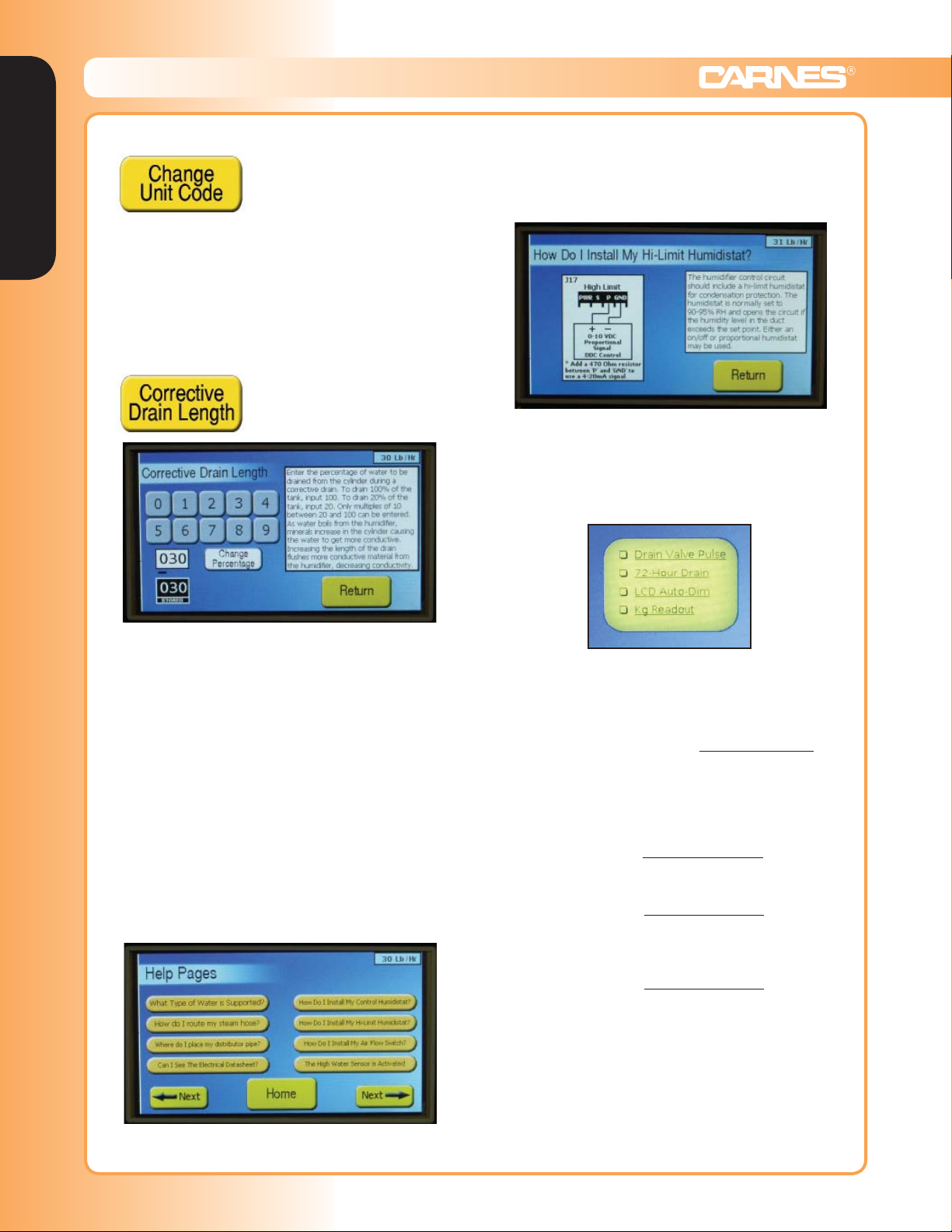

Calibration Password –

This page is where the Humidifier Unit Code, the four

digit number identifying the humidifier, is programmed

into the unit. This page is password protected, and

number should not be modified by the end user. Contact

the factory if further information is needed.

Corrective Drain Length –

The help pages consist of maize color buttons labeled

with questions. When a button is pressed, information

will be given answering and/or giving information about

the subject in question. A basic help page consists of text

and/or diagrams to help the user through basic problems.

For example, in the picture above the question of how to

install a high limit humidistat is answered with a diagram

and corresponding text. Some pages consist of more

buttons to help guide a user through different processes.

These buttons can be used and referenced as needed.

Checkboxes –

This page is where the Corrective Drain Length is set.

This value represents how much water should be drained

from the cylinder when the humidifier senses a corrective drain is needed. As water boils from the humidifier,

minerals increase in the cylinder causing the water to

get more conductive. Increasing the length of the drain

flushes more conductive material from the humidifier,

decreasing the water conductivity.

The input here is a percentage value. To set the

Corrective Drain Length to drain 20% of the cylinder

during a corrective drain, input 020. To drain all of the

tank, input 100. 30 is the default value, and only multiples

of 10 between 20 and 100 can be entered.

“HELP”

There are a few operational options that do not need

separate pages, and therefore are only enabled/disabled via checkboxes on the main Settings Page. Their

functionality is described as follows:

The Drain Valve Pulse option is enabled by default. This

option allows the drain valve to pulse when the humidifier executes a corrective drain. This actuates the water

within the drain piping, allowing for minerals buildup to

be discharged more easily. Enabling this option will make

the unit noisier whenever a corrective drain is executed.

The 72-Hour Drain is disabled by default. This option,

when enabled, allows the humidifier to drain the cylinder

completely after 72 hours of idle operation.

The LCD Auto-Dim is disabled by default. This option,

when enabled, will automatically turn off the backlight of

the LCD after 15 minutes of idleness. This feature can

save on energy consumed.

The Kg./Hr Readout is disabled by default. This option,

when enabled, will turn the steam readout on home page,

and in the upper right hand corner of other pages, into

Kg/Hr instead of Lb/Hr.

G-8 www.carnes.com

Humidifiers | Steam Humidifiers

APPLICATIONS

COMFORT

Temperature and relative humidity affect the comfort and

well being of all living things. High temperatures require

low humidity to maintain comfort conditions, while low

temperatures can more easily be tolerated at high

relative humidity. Humidification occurs when air is

moisturized by a humidification unit or when hygroscopic

materials (materials containing moisture) lose moisture

to drier air. Proper humidification is widely accepted as

healthy, minimizing employee illness and lost work time.

MATERIALS STORAGE

Paper, fabrics, wood, plastic, chemicals and most other

materials are hygroscopic. Their water content depends

on the humidity of the air around them. If air is too dry,

these substances lose moisture until an equilibrium is

reached between hygroscopic materials and the air.

PROCESS

Process operations, such as data processing areas, are

affected by two major humidity factors: hygroscopic

material and generation of static electricity.

Hygroscopic material used in the process influences

material weights, dimensions and workability.

Static Electricity can totally disrupt high speed process

operations as found in a data processing center, paper or

film handling business. Created by friction between two

substances, static electricity can be prevented by proper

humidification of the process environment.

RECOMMENDED TEMPERATURE AND HUMIDITY

RANGE - Table 1

APPLICATION TEMP F° RH %

Computer Rooms 72+2 50+5

Office Buildings 70-74 20-30

Libraries & Museums 68-72 40-55

Archival Libraries & Museums 55-65 35

Art Storage 60-72 50+2

Stuffed Animals 40-50 50

Bowling Centers 70-74 20-30

Health Facilities

Full Term Nursery 75 30min.-60max.

Special Care Nursery 75-80 30min.-60max.

Patient Rooms 75 30

Intensive Care 75-80 30min.-60max.

Operating Rooms 68-76 50min.-60max.

Recovery Rooms 75 50min.-60max.

Lasik Eye Centers

Electrical Instrument Mfg. 70 50-55

Fur Storage 40-50 55-65

Photo Film Darkroom 70-72 45-55

Photo Print Darkroom 70-72 45-55

Photo Drying Room 90-100 35-45

Photo Finishing Room 72-75 40-55

Cellophane Wrapping 75-80 45-65

Animal Laboratories

Mouse, Rat 64-79 40-70

Cat 65-85 30-70

Dog 65-85 30-70

Primate 65-84 30-70

Clean Rooms 67-77 40-55

Printing Plants

Lithography 76-80 43-47+2

Rotogravure 45-50+2

Collotype 80+2 85+2

Platemaking 75-80+2 45+2

Telephone Terminal Rooms 72-78 30-40

Radio and TV Studios 74-78 30-40

Reprinted with permission of the American Society of Heating, Refrigerating

and Air Conditioning Engineers, Inc., Atlanta, GA 30329.

+ = plus or minus

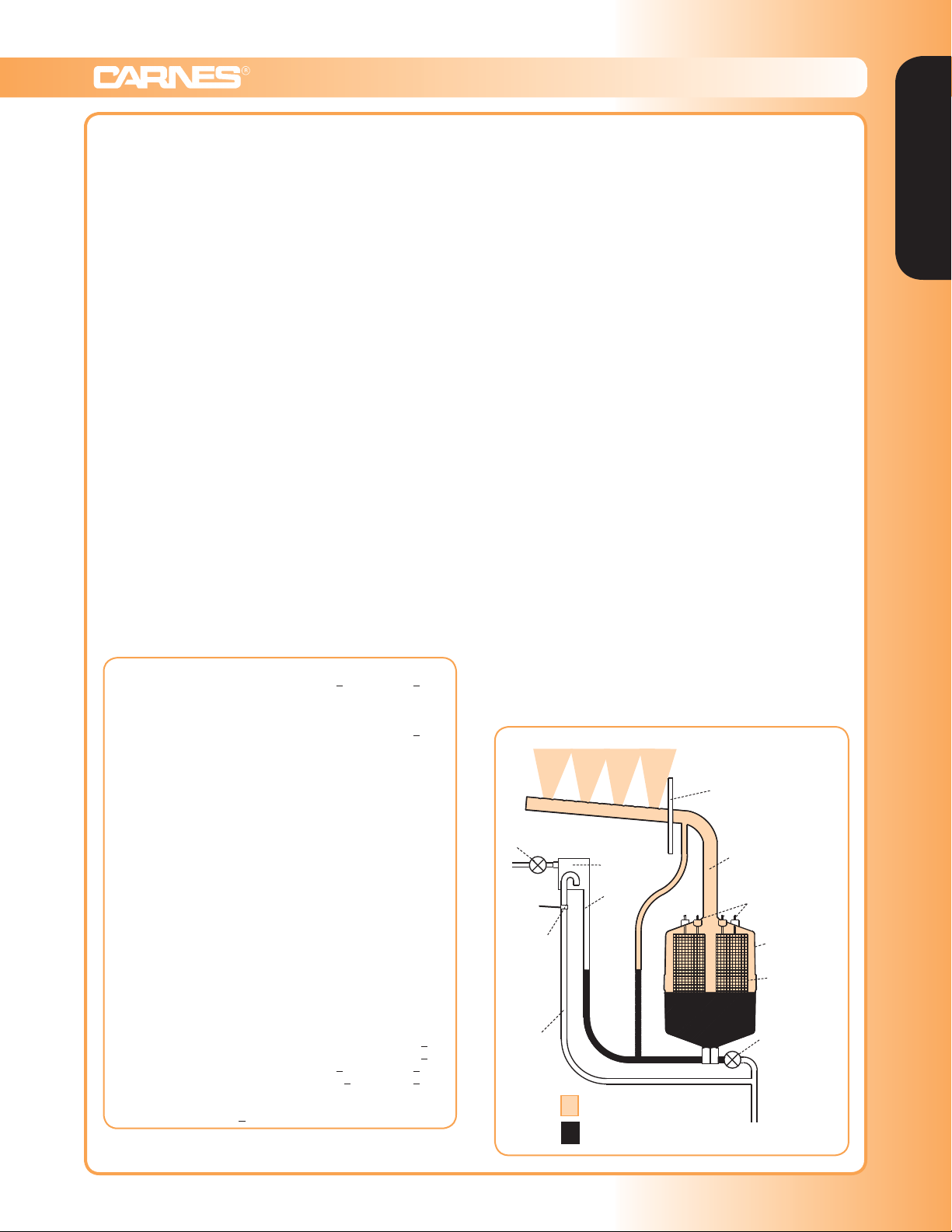

OPERATION

Upon a signal from external controls the circuit board

opens a fill solenoid valve, allowing water to flow across

an air gap into a standpipe. The standpipe provides a

column of water to be fed into the cylinder using gravity.

The air gap prevents back flow into the water supply

and prevents the cylinder from becoming a pressure

vessel. The steam cylinder operates at a pressure of

approximately 1/2 psi.

The circuit board also closes a power contactor allowing

current to flow to vertical electrodes sealed inside the

cylinder. Current flows between the electrodes using

minerals in the water as a conductor. The water is

heated to boiling and converted to steam which leaves

the cylinder through the flexible steam hose which is

connected to the steam distributor pipe.

The circuit board reacts to current flow between the

electrodes and automatically opens the fill solenoid valve

when more water is required to maintain the desired

output rate, and closes when the desired rate is

reached. The operation of the drain solenoid valve

is automatically controlled by the circuit board which

responds to any changes in water conditions and drains

the required quantity of water to provide stable operation

and long cylinder life.

As mineral deposits build up within the cylinder the water

level will slowly rise to contact clean electrode surfaces

to maintain the desired steam output rate. When mineral

deposits have covered all available electrode surface

areas, current flow will be reduced to a level where the

desired steam output cannot be reached and the service

light will signal the need for maintenance. When the

cylinder is filled with minerals it is easily changed in less

than five minutes.

Figure A

Steam

Distributor

Pipe

Fill

Solenoid Valve

Air Gap

Stand

Pipe

Non Contact

High Water

Sensor

Overflow

Tube

STEAM

WATER

Steam

Hose

From Power

Contactor

Cylinder

Vertical

Electrodes

Drain

Solenoid

Valve

To Drain

Humidifiers

www.carnes.com G-9

Loading...

Loading...