Carnes EK Installation Manual

Installation and Maintenance Manual IM 902

McQuay Direct Expansion (DX) Cooling

Coils

Types EN, EF, ER, EJ, EK

Group: Applied Air

Part Number: IM 902

Date: February 2008

© 2008 McQuay International

Contents

Introduction .............................................................. 3

General Information................................................ 3

Hazard Identification Information............................ 3

Receiving Instructions ............................................ 3

Coil Types............................................................... 3

Model EN............................................................ 3

Model EF ............................................................ 3

Model ER............................................................ 3

Model EJ............................................................. 3

Model EK ............................................................ 3

Nomenclature......................................................... 4

Installation ................................................................ 5

Mounting ................................................................ 5

Installation.............................................................. 5

Operation and Maintenance.................................... 7

Operation ............................................................... 7

General .............................................................. 7

Maintenance .......................................................... 7

General .............................................................. 7

Introduction

Introduction

General Information

Guidelines for the installation, operation and maintenance of

McQuay direct expansion (DX) cooling coils have been

provided to help insure proper performance of the coils and

their longevity. These are general guidelines that may have to

be tailored to meet the specific requirements of any one job.

As always, an experienced installation company or fully

trained individual should perform the installation and

maintenance of any coil. Protective equipment such as safety

glasses, steel toe boots and gloves are recommended during

the installation and routine maintenance of the coil.

Hazard Identification Information

DANGER

Dangers indicate a hazardous situation which will result in

death or serious injury if not avoided.

WARNING

Warnings indicate potentially hazardous situations, which can

result in property damage, severe personal injury, or death if

not avoided.

3 Damaged and/or missing items should be noted on the

carrier's freight bill and signed by the driver.

4 For additional assistance, contact your local McQuay sales

representative.

Coil Types

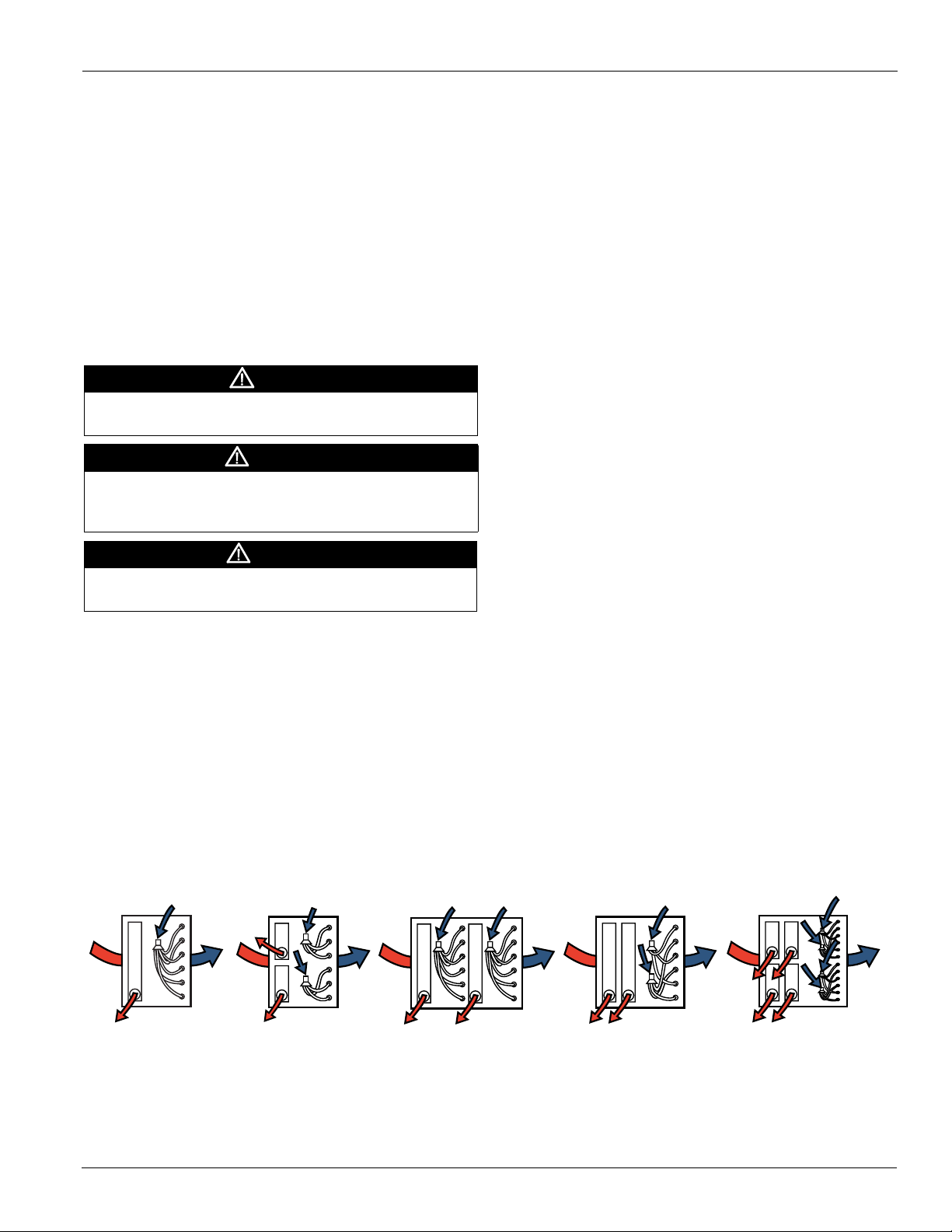

Model EN

This evaporator coil is used for applications where capacity

control is not required. Single or multiple distributors are

available depending on the number of circuits required. Model

EN (Figure 1) evaporators utilize dual suction connections

when multiple distributors are used.

Model EF

Face control (model EF - Figure 1) is another evaporator coil

option offered. Face control is the simplest form of capacity

control. These coils are normally furnished with two

distributors and two suction connections offering 50% capacity

reduction capabilities.

Model ER

CAUTION

Cautions indicate potentially hazardous situations, which can

result in personal injury or equipment damage if not avoided.

Receiving Instructions

1 All McQuay coils are factory tested at 315 psig minimum

air pressure while submersed in water, inspected, and

carefully packaged.

2 Damage to the coils can occur after they have left the

factory. Therefore, the coils should be inspected for

shipping damage upon receipt. The freight bill should also

be checked against items received for complete delivery.

Figure 1: Evaporator Coil Types

McQuay offers a row control option (model ER - Figure 1) for

six row evaporator coils. These coils are split into two rows

and four rows that offer approximately a 50% capacity

reduction.

Model EJ

These evaporator coils (model EJ - Figure 1) come with

interlaced circuiting. This form of capacity control utilizes two

distributors with each feeding every other tube in the first row

of the coil. Each distributor has a separate suction connection.

Model EK

For applications that require face control and interlaced

circuits, we offer evaporator model EK (Figure 1). Interlaced

face control utilizes four distributors and four suction

connections.

EN

Normal

Rows 2, 3, 4, 5

6, 8, 10, 12

McQuay IM 902 3

EF

Face Control

Rows 2, 3, 4, 5

6, 8, 10, 12

ER

Row Control

Rows 6

2 Distributors

EJ

Interlaced

Rows 3, 4, 6, 8

2 Distributors

EK

Interlaced

Face Control

Rows 4, 8

4 Distributors

Loading...

Loading...