Carnes EDDA Installation Manual

FORM 40009

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

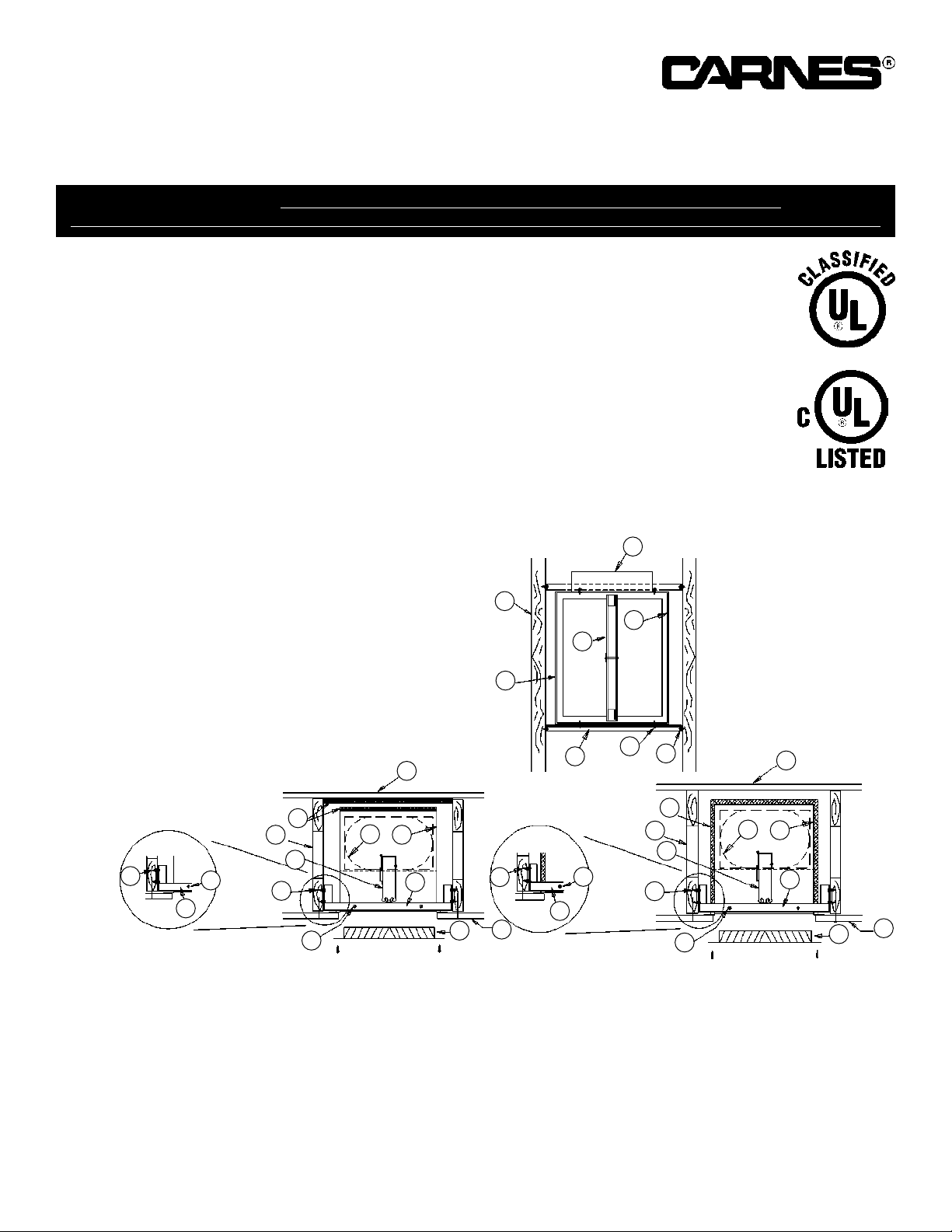

Model EDDA - Ceiling Dampers for

Wood Framed Joist With Gypsum Ceilings

CAUTION! DO NOT INSTALL, USE OR OPERATE THIS EQUIPMENT UNTIL THIS

MANUAL HAS BEEN READ AND UNDERSTOOD. READ AND SAVE THESE INSTRUCTIONS FOR FUTURE USE.

APPLICATION:

Carnes Ceiling Radiation Dampers have been tested, approved, and classified by Underwriters Laboratories for use

in UL Fire Resistance Floor-Ceiling and Roof-Ceiling Designs as listed in the UL Fire Resistance Directory. These

dampers have been approved for, but not limited to, wood joist systems incorporating gypsum wallboard ceilings.

Designs specifically tested pertain to UL Designs L501, L502, L503, L506, L507, L508, L512, L513, L514, L515, L516,

L517, L519, L522, L523, L533, L537, and L545 and ULC Designs M500, but are not limited to. New UL Ceiling

designs are constantly being added. Refer to the UL Fire Resistance Directory for current approved listings. Carnes

ceiling dampers may be substituted into any UL design which incorporates a hinge door type damper as outlined in

the Fire Resistance Directory.

GENERAL NOTES:

A. Fasteners must be placed, so not to interfere with the operation of the damper.

B. Classified flex duct must be attached with steel clamps, plastic straps, or 18 SWG minimum steel wires.

C. The mounting angles (#8 below) are to be placed such that 1/2” leg rest on the ceiling materials.

D. The maximum size damper approved for the this installation is 16” x 12” or 15” diameter.

E. The insulating material mentioned in #3 below can optionally be gypsum secured by 4 sheet metal screws to the top of the metal box

(#10) and another secured to the floor (#9) the width of the joist by damper length plus 4 inches when the damper size is not greater

than 110 sq. in. If the damper size is greater than 110 sq. in. or previous option not used, then an insulating material must be

supplied by Carnes to fully wrap the metal box (#10).

COMPONENTS:

1. Wood Frame Member or Joist

2. Ceiling Damper

3. Insulating Material (See Note E Above)

4. Grille

5. Gypsum Wallboard per UL Design Number

6. #8 Screw (min.) or 6 Penny Nail

7. #8 Screw (min.) or 3/16” Steel Rivet

8. 1” x 1/2” x 20 ga. Steel Mounting Angle

9. Floor/Roof

10. Metal Box (22 ga. min., can be supplied by contractor/installer)

11. Cut Opening/Transition In Box

INSTALLATION OF CEILING DAMPERS:

A. Measure spacing between framing members. Cut angle to distance between members plus 6”. Two full lengths of

1” x 1/2” x 20 ga. steel mounting angles will be required for each damper.

B. Cut a slit in the 1” length, 3” from each end. Bend each end of the mounting angle 90°.

C. Attach the bent section of one of the mounting angles to the wood framing member using #8 screws or 6 penny nails. Use a

minimum of two fasteners per bent section. The mounting angles are to be placed such that 1/2” leg rest on the ceiling materials.

D. Attach the ceiling damper to the 1” x 1/2” mounting angle using #8 screws or 3/16” rivets. A minimum of two fasteners per angle on

the square/rectangular damper and one fastener per angle on the round damper required.

E. Position the remaining mounting angle on the opposite side of the damper between the joists. Attach one of the 3” bent angle to the

wood joist with two #8 screws or 6 penny nails. The mounting angles are to be placed such that 1/2” leg rest on the ceiling materials.

F. Attach the ceiling damper to the 1” x 1/2” mounting angle using #8 screws or 3/16” rivets. A minimum of two fasteners per angle on

the square/rectangular damper and one fastener per angle on the round damper required.

G. Attach the remaining end of the 3” bent angle to the wood joist with two #8 screws or 6 penny nails.

FORM 40009

CARNES COMPANY 448 S. Main St., P. O. Box 930040, Verona, WI 53593-0040 Phone: (608)845-6411 Fax: (608)845-6470 www.carnes.com

Less Than and Equal to

110 Sq. In.

Greater Than

110 Sq. In.

5

1

4

6

8

2

3

9

11

10

6

7

8

7

8

7

6

3

2

1

11

10

11

10

6

8

7

1

4

6

8

2

3

9

7

5

Loading...

Loading...