READ AND SAVE THESE INSTRUCTIONS

INSTALLATION, OPERATION & MAINTENANCE MANUAL

FOR

Balance and Calibration of

Pneumatic Controls

Models ADCC and ADCD

DUAL DUCT

CARNES COMPANY 448 S. Main St., P. O. Box 930040, Verona, WI 53593-0040 Phone: (608)845-6411 Fax: (608)845-6470 www.carnes.com

COPYRIGHT © 2010 CARNES COMPANY

ALL RIGHTS RESERVED

SUPERSEDES 20225-C 20225-D, Page 1

FORM 20225-D, Page 2

Model ADCC - With or Without Airflow Mixing

Model ADCD - Constant Volume Airflow

BALANCE AND CALIBRATION OF MODEL ADCC DUAL DUCT UNITS WITH NO AIRFLOW

MIXING CONTROL.

1. For units that require no HOT or COLD airflow mixing, refer to Installation and Operation Manual for Pressure

Independent Controls - Form 18675.

2. Calibration of these units is the same as setting two Single Duct Throttling Units.

1. Determine the following system parameters:

a. Satisfied set point pressure of the pneumatic thermo

stat (P).

b. Set point temperature of the thermostat (T).

c. Sensitivity output of the thermostat (S).

d. Desired temperature mixing range (M).

2. Calculate the reset start point and reset span for both the

hot and cold deck controllers based on system

parameters.

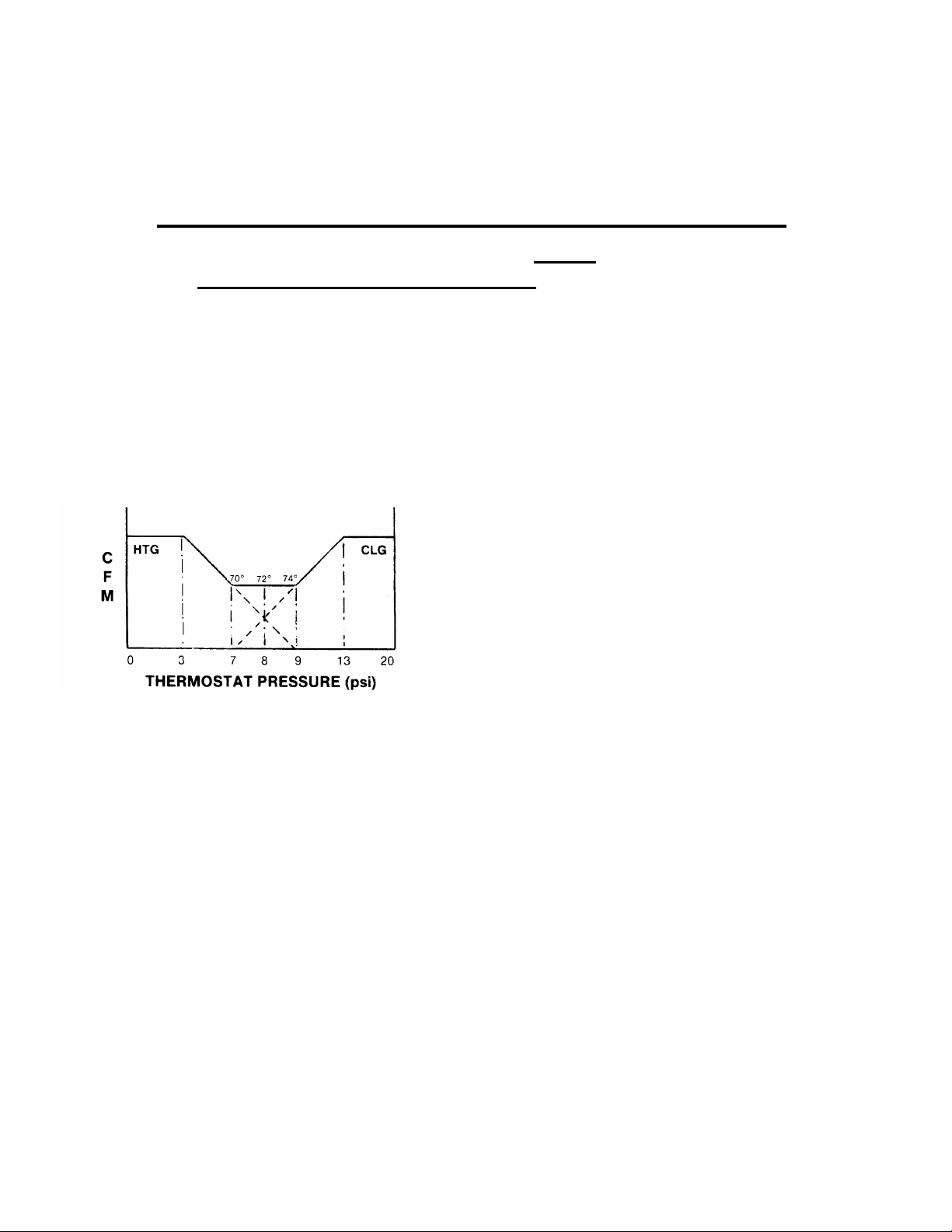

EXAMPLE:

P = 8 psi

T = 72oF

S = 2oF/psi

M = 4oF: (70-74oF)

Based on the desired system parameters the control diagram

can be drawn (see above). Calibration of the reset start point

and reset span can be initiated based on information taken

from the control diagram:

Cold Deck: Reset Start Point = 7 psi

Reset Span = 6 psi

Hot Deck: Reset Start Point = 3 psi

Reset Span = 6 psi

3. Setting the reset start point (if other than 8 psi):

a. Remove the cap on the “G” port of the controller and

connect an accurate 0-30 psi (max.) gauge.

b. Regulate the thermostat pressure to the “T” port of the roller

to the desired start point pressure.

c. Adjust the “Reset Start” on the controller to indicate 0 psi on

the “G” port gauge. Then adjust the “RESET Start” to indicate a pressure slightly higher than 0 psi (i.e. 0.1 psi) to

ensure that this setting is not over-adjusted.

d. Remove the auxiliary gauge from the “G” port and replace

the cap over the “G” port tap.

4. Adjusting the reset span (if other than 5 psi).

a. Remove the cap on the “G” port of the controller and

connect an accurate 0-30 (max.) gauge.

b. Regulate the thermostat pressure to the “T” port of the

controller to 20 psi.

c. Adjust the “Reset Span” on the controller to indicate the

desired span on the “G” port gauge.

d. Remove the auxiliary gauge from the “G” port and replace

the cap over the “G” port tap.

5. Calibration Procedures: Setting maximum and minimum

CFM.

a. Direct Acting Thermostat -- Cold Deck

1. Set zone thermostat call for full heating (0 psi) at the “T”

port of controller.

2. Connect a differential pressure gauge across the

Cold Deck inlet sensor tubes. The green tube is the

total pressure (“HI” signal) and the yellow tube is the

static pressure (“LO” signal).

3. Adjust the “LO stat DP” to the desired minimum cooling

airflow limit. REFER TO CALIBRATION CHART ON

INLET.

4. Set zone thermostat to call for full cooling (20 psi) at the

“T” port of controller.

5. Adjust the “HI stat DP” to the desired maximum cooling

airflow limit. REFER TO CALIBRATION CHART ON

INLET.

b. Direct Acting Thermostat -- Hot Deck

1. Set zone thermostat to call for full heating (0 psi) at the

“T” port of controller.

2. Connect a differential pressure gauge across the Hot

Deck inlet sensor tubes. The green tube is the total

pressure (“HI” signal) and the yellow tube is the static

pressure (“LO” signal).

3. Adjust the “LO stat DP” to the desired maximum cool-

ing airflow limit. REFER TO CALIBRATION CHART ON

INLET.

4. Set zone thermostat to call for full cooling (20 psi) at the

“T” port of controller.

5. Adjust the “HI stat DP” to the desired minimum cooling

airflow limit. REFER TO CALIBRATION CHART ON

INLET.

c. Reverse Acting Thermostat -- Cold Deck

1. Set zone thermostat to call for full cooling (0 psi) at the

“T” port of controller.

2. Connect a differential pressure gauge across the Cold

Deck inlet sensor tubes. The green tube is the total

pressure (“HI” signal) and the yellow tube is the static

pressure (“LO” signal).

3. Adjust the “LO stat DP” to the desired maximum cool-

ing airflow limit. REFER TO CALIBRATION CHART ON

INLET.

4. Set zone thermostat to call for full heating (20 psi) at the

“T” port of controller.

5. Adjust the “HI stat DP” to the desired minimum cooling

airflow limit. REFER TO CALIBRATION CHART ON

INLET.

d. Reverse Acting Thermostat -- Hot Deck

1. Set zone thermostat to call for full cooling (0 psi) at the

“T” port of controller.

2. Connect a differential pressure gauge across the Hot

Deck inlet sensor tubes. The green tube is the total

pressure (“HI” signal) and the yellow tube is the static

pressure (“LO” signal).

3. Adjust the “LO stat DP” to the desired minimum heating

airflow limit. REFER TO CALIBRATION CHART ON

INLET.

4. Set zone thermostat to call for full cooling (20 psi) at the

“T” port of controller.

5. Adjust the “HI stat DP” to the desired maximum heating

airflow limit. REFER TO CALIBRATION CHART ON

INLET.

BALANCE AND CALIBRATION OF MODEL ADCC DUAL DUCT UNITS WITH

ADJUSTABLE AIRFLOW MIXING

CONTROL OPTIONS

Loading...

Loading...