Carnes ABBD Installation Manual

COPYRIGHT © 2010

SUPERSEDES 18647-L 18647- M, Page 1

All Rights Reserved

Models AVCD, AVWE, AVED, ABBD, ABWD,

ADCC and ADCD

READ AND SAVE THESE INSTRUCTIONS

INSTALLATION and OPERATION MANUAL

FOR

VAV

THROTTLING UNITS

CARNES COMPANY, 448 S. Main St., P.O.Box 930040, Verona, WI 53593-0040 Phone: 608/845-6411 Fax: 608/845-6470 carnes@carnes.com www.carnes.com

FORM 18647-M, Page 2

INSPECT UNIT

UNPACKING AND INSPECTION

1. Open shipping carton or crate and check for concealed

shipping damage. Report damage immediately to the carrier

that delivered the unit.

2. Inspect the unit for loose or missing components.

3. Optional accessories may be packed within the unit or in the

same shipping carton.

GENERAL

1. Each VAV unit and accessory is shipped with an

identification label showing the Carnes order number,

unit item number from the order, unit model number,

maximum and minimum CFM settings on terminal

units with pressure independent control options, and

unit tagging (or mark).

INSTALLATION

MOUNTING

1. Units are to be supported in a horizontal and level

position. For convenience, it is suggested that the

units be installed prior to installation of the ceiling tile

grid system.

2. Avoid abrupt transitions or duct turns at the inlet of the

unit that would alter the cross-section area.

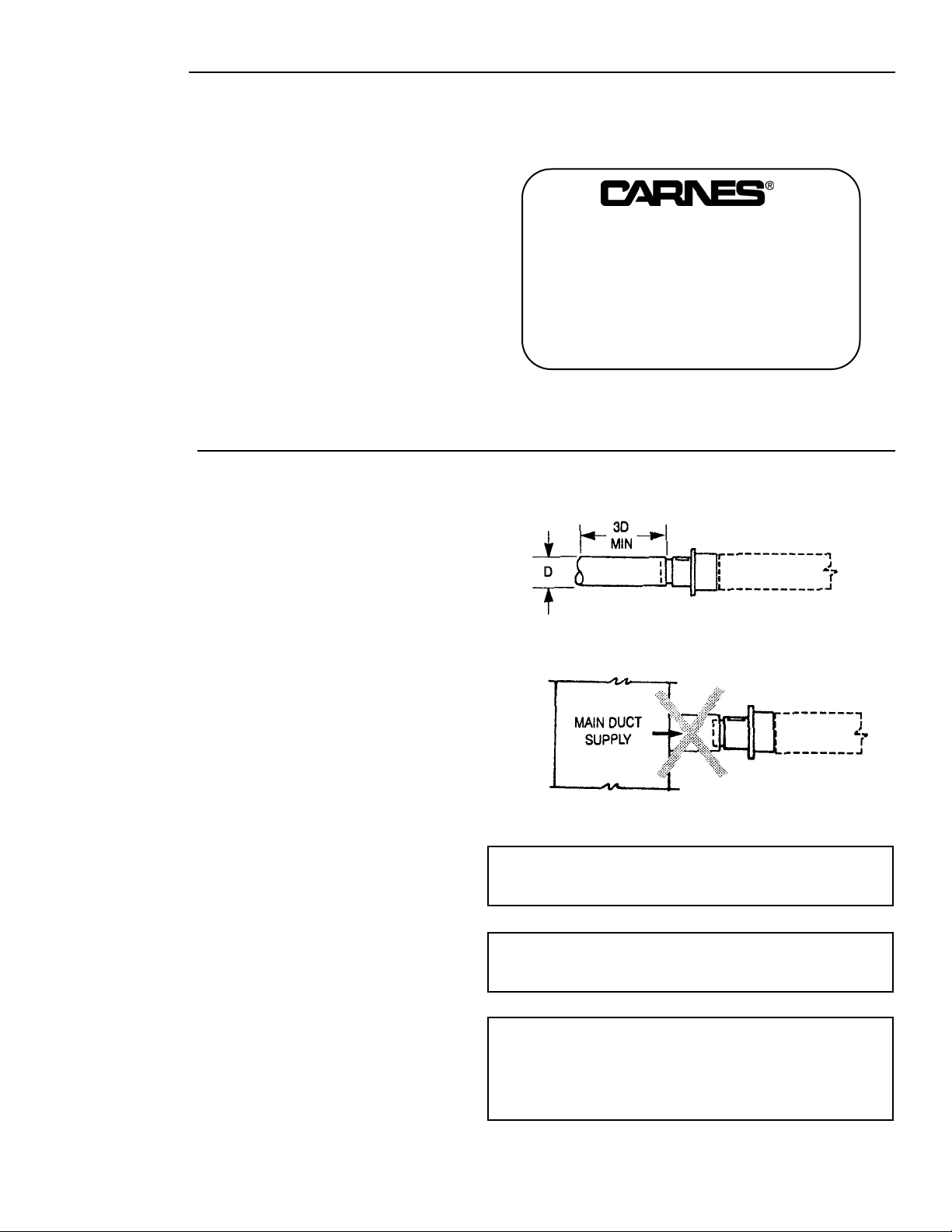

3. A minimum of three duct diameters of straight duct

upstream of inlet sensor is recommended. (i.e., 6” inlet

dia. = 18” or more straight upstream duct.) Figure 1

4. Close coupling the terminal unit inlet to the side of the

main duct is NOT recommended. Figure 2

5. The control unit must be mounted such that the

velocity sensor is at the inlet of the terminal unit,

upstream of the damper blade.

6. Dual duct units may have a velocity sensor mounted

downstream at the discharge opening. The dual duct

unit should be mounted with the two inlets upstream of

the damper blades.

7. The diameter of the inlet duct in inches must be equal

to the listed inlet collar diameter of the terminal unit.

8. A minimum clearance of six inches (6”) is required at

the top discharge opening (by-pass) on Models ABB

and ABW.

9. All control enclosures require adequate clearance to

allow for field adjustments and service.

10. Terminal units may be provided with optional hanger

brackets which are suitable for supporting the terminal

unit by wire hangers or threaded rods.

11. Strap hangers may be used for supporting the units

when hanger brackets are not provided.

CAUTION: Do not install hangers so as to impair the

movement or performance of control

components.

CAUTION: Do not install hangers with screws into

the uninsulated coil casing. Permanent

coil damage may result.

CAUTION: Do not install hangers so as to impair or

restrict the movement of the slide

balancing damper on By-Pass terminal

units. (Models ABB & ABW).

Figure 1

Figure 2

CARNES COMPANY, VERONA, WI

ORDER ITEM

MODEL

MAX. CFM/MIN. CFM

MARK

STRAIGHT DUCT UPSTREAM

CLOSE COUPLING NOT RECOMMENDED

Loading...

Loading...