Page 1

Infant Flow® LP SiPAP and SiPAP Model M675

Service manual

Page 2

ii Infant Flow

®

LP SiPAP Model M675

This document is protected by United States and International Copyright laws.

This document may not be copied, reproduced, translated, stored in a retrieval system, transmitted in any

form, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

written permission of CareFusion. Information in this document is subject to change without notice.

This document is for informational purposes only and should not be considered as replacing or

supplementing the terms and conditions of the License Agreement.

© 2008 – 2011 CareFusion Corporation or one of its subsidiaries. All rights reserved Infant Flow is a

registered trademark of CareFusion Corporation or one of its subsidiaries. All other trademarks are

property of their respective owners.

USA

CareFusion

22745 Savi Ranch Parkway

Yorba Linda, California 92887-4668

Authorized European Representative

CareFusion Germany 234 GmbH

Leibnizstrasse 7

97204 Hoechberg, Germany

800.231.2466 tel

+1.714.283.2228 tel

+1.714.283.8493 fax

carefusion.com

Literature number: 675–120 Revision G

+49.931.4972.0 tel

+49.931.4972.423 fax

675–120 Rev. G

Page 3

Service Manual iii

September 2003

675-120(1)

Release

page 88.

Update list of service parts

Updated Table 6 starting on page 43

Revision History

Date Revision Changes

November 2004 B

December 2004 C

May 2005 D

Release manual in VIASYS Healthcare template using

VIASYS Healthcare Respir ator y Care nomenclature.

Revised per EO 27980. Removed the picture

from the title page.

Deleted the ESD warning from page 19.

Removed “O2 Sensor” and added the word “measured”

on page 30.

Changed “O2 sensor” to “fuel cell” on pages 39, 45, 62,

68, 69, 73, 86, and 87.

Replaced the O2 senor row on page 50.

Updated the error codes on pages 56 and 57.

Replaced the warning on page 61.

Changed the Fitting procedure on pages

64, 68, and 75.

Changed step 6 on page 65.

Added Addendum A – Oxygen Leak Test

Changed Transducer Assy. To Transducer Interface on

Revised per ECO 60329

Update address/contact info

Update battery remove/install procedure

Added note for fuel cell disposal

Update check valve assembly remove/install procedure

Update water trap & restrictor remove/install procedure

Delete redundant leak test

August 2008 E

675-120 Rev. G

Updated company information

Updated company information

Corrected Table 2 and updated Table 3

Updated Figure 6

Updated Figure 10

Updated the section “Diagnostics.”

Page 4

iv Infant Flow

FRONT”

Model M675

Date Revision Changes

April 2010 F Changed Ti to T-High throughout

Figure 5 - Diagnostic screen updated

Spelling correction from “GRD” to “GND”

Added “Note: transducer must be attached.”

Changed “10 V” to “11.10 V”

Updated Table 6 - Error Codes (E50 - E54) and added

E55

Removed “Blender (Check Valves and Filter) Annually”

from table 7.

Added “, and two screws on the case-bottom”.

Added “and document L2879”

Replaced Ti symbol with T-High symbol

Changed “PL5” to “PL2”

Replaced Figure 3

Replaced Figure 4 and 5. Changed “value doesn’t” to

“value on the external oxygen analyzer doesn’t”.

Changed “467352” to “68289”; changed “777245” to

“52700A”; removed items 677-005A, 675-311, S117635,

467461, 467460.

Removed item S117641; changed “675-310” to “M675A-

®

LP SiPAP Model M675

May 2011 G

Added instructions and specifications for LP SiPAP

675-120 Rev. G

Page 5

Service Manual v

Warranty

The Infant Flow® LP SiPAP and SiPAP systems are warranted to be free from

defects in material and workmanship and to meet the published specifications for

One (1) year from date of shipment.

The liability of CareFusion, (referred to as the Company) under this warranty is

limited to replacing, repairing or issuing credit, at the discretion of the Company, for

parts that become defective or fail to meet published specifications during the

warranty period; the Company will not be liable under this warranty unless (A) the

Company is promptly notified in writing by Buyer upon discovery of defects or failure

to meet published specifications; (B) the defective unit or part is returned to the

Company, transportation charges prepaid by Buyer; (C) the defective unit or part is

received by the Company for adjustment no later than four weeks followin g t he last

day of the warranty period; and (D) the Company’s examination of such unit or part

shall disclose, to its satisfaction, that such defects or failures have not been caused

by misuse, neglect, improper installation, unauthorized repair, alteration or accident.

Any authorization of the Company for repair or alteration by the Buyer must be in

writing to prevent voiding the warranty. In no event shall the Company be liable to

the Buyer for loss of profits, loss of use, consequential damage or damages of any

kind based upon a claim for breach of warranty, other than the purchase price of any

defective product covered hereunder.

The Company warranties as herein and above set forth shall not be enlarged,

diminished or affected by, and no obligation or liability shall arise or grow out of the

rendering of technical advice or service by the Company or its agents in connect ion

with the Buyer's order of the products furnished hereunder.

Limitation of Liabilities

This warranty does not cover normal maintenance such as cleaning, adjustment or

lubrication and updating of equipment parts. This warranty shall be void and shall not

apply if the equipment is used with accessories or parts not manufactured by the

Company or authorized for use in writing by the Company or if the equipment is not

maintained in accordance with the prescribed schedule of maintenance.

The warranty stated above shall extend for a period of One (1) year fr om date of

shipment, with the following exceptions:

1. Components for monitoring of physical variables such as temperature, pressure,

or flow are warranted for ninety (90) days from date of receipt.

2. Elastomeric components and other parts or components subject to deterioration,

over which the Company has no control, are warranted for sixty (60) days from

date of receipt.

3. Internal batteries are warranted for ninety (90) days from the date of receipt.

The foregoing is in lieu of any warranty, expressed or implied, including, without

limitation, any warranty of merchantability, except as to title, and can be amended

only in writing by a duly authorized representative of the Company.

675-120 Rev. G

Page 6

vi Infant Flow

®

LP SiPAP Model M675

Contents

Revision History ................................................................................ iii

Warranty ............................................................................................ v

Limitation of Liabilities ........................................................................ v

Notices ............................................................................................ viii

EMC Notice ............................................................................................................... viii

MRI Notice ................................................................................................................. viii

Intended Use Notice ................................................................................................... ix

Regulatory Notice ....................................................................................................... ix

Classification .............................................................................................................. ix

Declaration of Conformity Notice ................................................................................. x

Chapter 1 – Product Description ................................................................................ 1

Chapter 2 – Product Specifications ............................................................................ 3

Modes .......................................................................................................................... 3

Controls ....................................................................................................................... 3

Monitors ....................................................................................................................... 3

Alarms ......................................................................................................................... 4

Pneumatic Supply ........................................................................................................ 4

Electrical Supply .......................................................................................................... 4

Atmospheric & Environmental ...................................................................................... 5

Physical ....................................................................................................................... 5

Chapter 3 – Warnings and Cautions .......................................................................... 7

Terms .......................................................................................................................... 7

Warnings ..................................................................................................................... 7

Cautions ...................................................................................................................... 9

Chapter 4 – System Construction ............................................................................ 11

Touch Screen ............................................................................................................ 15

Alarm Conditions ....................................................................................................... 17

Diagnostic Screen ...................................................................................................... 17

Chapter 5 – Theory of Operation .............................................................................. 19

Gas Flow ................................................................................................................... 19

Electronic Functions .................................................................................................. 22

E

lectrical Layout ........................................................................................................ 23

Fault Management ..................................................................................................... 24

675-120 Rev. G

Page 7

Service Manual vii

Chapter 6 – Operational Setup ................................................................................ 25

Preparing and Connecting the Equipment ....................................... 25

Switching On the IFSD .................................................................... 29

User Verification Test ...................................................................... 30

Power-on Check ........................................................................................................ 30

Two Point O

Leak Test ................................................................................................................... 32

Alarms Test ................................................................................................................ 33

Infant Flow

Setting up the Equipment ........................................................................................... 36

Setting the NCPAP Parameters ................................................................................. 37

Setting the BiPhasic Parameters ................................................................................ 38

Setting the Triggered BiPhasic Parameters ................................................................ 39

Calibration .................................................................................................................. 41

Giving a Manual Timed Sigh ...................................................................................... 41

Operation Without Electrical Power ............................................................................ 41

Fault Indications ......................................................................................................... 42

Diagnostics ................................................................................................................ 48

Sensor Calibration ................................................................................ 31

2

®

LP SiPAP/SiPAP User Verification Test Checklist .................................. 35

Chapter 7 – Maintenance ......................................................................................... 55

Maintenance Frequencies ................................................................ 55

PM Procedure ............................................................................................................ 55

Tools Required........................................................................................................... 55

Cleaning .......................................................................................... 56

General ...................................................................................................................... 56

Removal and Fitting of Case ...................................................................................... 59

Removal and Fitting of Battery ................................................................................... 60

Removal and Fitting of Oxygen Filter ......................................................................... 61

Removal and Fitting of Fuel Cell Filter/Restrictor ....................................................... 62

Removal and Fitting of the Oxygen Sensor ................................................................ 63

Removal and Fitting of Blender and Components ...................................................... 64

Removal and Fitting of Water Trap Filter .................................................................... 68

Removal of the Pilot Drive Check Valves ................................................................... 68

R

emoval and Fitting of Case Bleed Filtered Restrictor ............................................... 69

Removal and Fitting of Valve/Sensor PCB ................................................................. 70

Removal and Fitting of the Muffler/Filter ..................................................................... 70

Chapter 8 – Explanation of Symbols ........................................................................ 71

Appendix A – Oxy g en Leak Test.............................................................................. 75

Appendix B – Produc t C on fig ur ati ons ...................................................................... 79

Non-US Configuration Parameters ............................................................................. 79

US Configuration Parameters .................................................................................... 79

Appendix C – Spare Parts ....................................................................................... 81

Appendix D – Pneumatics Assembly ....................................................................... 83

Glossary ................................................................................................................... 85

675-120 Rev. G

Page 8

viii Infant Flow

Notices

EMC Notice

This equipment radiates and is susceptible to radio frequency energy. If not installed

and used in accordance with the instructions in this manual, electromagnetic

interference may result. The equipment has been tested and found to comply with

the limits set forth in BS EN60601-1-2 for Medical Electrical Equipment Part 1-2:

General requirements for safety-collateral standard. Electromagnetic compatibility –

requirements and tests. These limits provide reasonable protection against

electromagnetic interference when operated in the intended use environments (e.g.

hospitals) described in this manual.

This device is also designed and manufactured to comply with the following

standards;

Safety: UL 60601-1: 2003 Medical Electrical Equipment, Part 1: General

Requirements for Safety.

CAN/CSA C22.2 No 601.1-M90, Medical Electrical Equipment - Part

1: General Requirements for Safety including C22.2 No. 601.1S1-94

(IEC601-1, Amendment 1:1991) Supplement No. 1-94 to CAN/CSA

22.2 No. 601.1-M90

®

LP SiPAP Model M675

With regards to Electrical Safety:

Class 1 equipment

Contains type BF patient applied parts

Continuous Operation

MRI Notice

This equipment contains electromagnetic components whose operation can be

affected by intense electromagnetic fields.

Do not operate this device in a MRI environment or in the vicinity of high-frequency

surgical diathermy equipment, defibrillators, or short-wave therapy equipment.

Electromagnetic interference could disrupt the operation of the device.

675-120 Rev. G

Page 9

Service Manual ix

Intended Use Not ice

The Infant Flow® LP SiPAP system, consisting of a Driver and Generator plus

NCPAP Prongs and Masks, is a medical device intended for the provision of Bi-Level

CPAP to produce a sigh. This system is for use in Hospital, Hospital Type facilities

and intra-Hospital transport environments and is indicated for the treatment of

Newborn and Infant patients.

Operators of this equipment and Se rvice En gineers are required to read and thoroughly

understand the contents of this manual before using or maintaining the equipment.

This manual is intended for use by a competent, fully qualified Service

Engineer. It includes a description of the unit and how it w or ks. It also contains

operating and diagnostic procedures and maintenance instructions. For usage

of associated equipment, refer to the Manufacturer’s literature.

Regulatory No t ice

Federal law restricts the sale of this device except by or on order of a physician.

Classification

Type of Equipment: Medical Equipment, Class 1 and internally powered, IPX1

Protected, and uses type BF applied parts. Equipment is not suitable for use in

presence of flammable anesthetics.

675-120 Rev. G

Page 10

x Infant Flow

Declaration of Conformity Notice

This medical equipment complies with the Medical Device Directive, 93/42/EEC, and

the following Technical Standards, to which Conformity is declared:

Council Directive(s): MDD 93/42/EEC Annex II (excluding section 4)

Safety: EN 60601-1, EN 794-1

EMC: EN 60601-1-2:2001

Conformity Assessment: MDD Annex II

Quality System: ISO 13485

EU Notified Body: BSI (Reg. No. 0086)

Device Classification: IIb

®

LP SiPAP Model M675

EU Notified Body:

BSI (Reg. No. 0086)

Trade names:

Infant Flow LP SiPAP

Manufactured by:

CareFusion

22745 Savi Ranch Parkway

Yorba Linda, CA 92887, USA

If you have a question regarding the Declaration of Conformity for this product,

please contact CareFusion.

675-120 Rev. G

Page 11

Service Manual 1

Chapter 1 – Product Description

The Infant Flow® LP SiPAP and SiPAP systems are non-invasive forms of respiratory

support designed for use in hospital environments such as Neonatal and Pediatric

Intensive Care Units. They can also be used when transporting patients within the

hospital environment.

The Infant Flow

Comprehensive configuration. The Plus configuration provides NCPAP and time

triggered, BiPhasic modes with and without breath-rate monitoring. The

Comprehensive configuration offers these features plus patient BiPhasic mode with

apnea backup breaths. The Infant Flow

standard in all configurations with an LCD touch screen display, pressure time

waveform graphics, integrated patient monitoring, alarms for high and low pressure

and FiO

and up to 2 hours of backup battery power.

2

As a result of the unique, patented design, the Infant Flow

systems have been proven to provide the most stable CPAP at the lowest work-ofbreathing for patients compared to other devices. The outstanding performance of

the Infant Flow

expiratory flows. This system has been designed and tested to perform optimally

when used only with accessories available from CareFusion. These accessories

include circuits and generators, prong and mask patient interfaces and bonnets.

®

LP SiPAP and SiPAP systems are currently available in the Plus or

®

LP SiPAP and SiPAP systems come

®

LP SiPAP and SiPAP

®

LP SiPAP and SiPAP systems is irrespective of patient demand or

Infant Flow® LP SiPAP and SiPAP Features

The expanded capabilities of the Infant Flow® LP SiPAP and SiPAP, Plus and

Comprehensive configurations, allow for applications to a broader range of patients

who may otherwise not be candidates for non-invasive respiratory support.

NCPAP. Allows for continuous positive airway pressure based on clinician set

pressure. Breath rate monitoring/alarm can be activated in this mode.

BiPhasic. Allows for time triggered pressure assists to be delivered based on

clinician set inspiratory time, rate, and pressure criteria. Breath rate monitoring/alarm

can be activated in this mode.

BiPhasic tr*. Allows for patient triggered pressure assists to be delivered based on

clinician set inspiratory time and pressure criteria. Breath rate monitoring/alarm, and

Apnea backup breaths are automatically active in the mode.

Patented Infant Flow

device for the generation of consistent infant nasal CPAP with a low work of

breathing. The Infant Flow LP system has a lower driving pressure than other

variable-flow devices.

Fully integrated alarms packages. Supply gases failure, High Patient Pressure,

Low patient pressure, high and low delivered Oxygen concentration, change from AC

to DC power source, low and flat battery charge status and Low breath rate/apnea

alarm.

®

LP Generator. The Infant Flow® LP Generator is a fluidic

Battery Backup. Up to 2 hours of battery backup allows for intra-hospital transport.

Clear indicators are provided for power supply in use (AC or DC), and battery charge

level.

675-120 Rev. G

Page 12

2 Infant Flow

NCPAP

•

•

NCPAP with breath rate monitoring

and alarm

• •

BiPhasic

•

•

and alarm

• •

BiPhasic tr*

•

Internal Battery

•

•

Manual Breath

•

•

Apnea Back up rate

•

Screen lock

•

•

Prioritization of alarms

•

•

LP. Refers to the low driving pressure of the Infant Flow LP Generator. The Infant

Flow LP SiPAP system is compatible only with the Infant Flow LP Generator. T he

prescribed nCPAP level will not be obtained if other variable flow generators are

used.

Screen Lock. After 120 seconds of no screen inputs, the screen changes to the

Locked Screen to prevent inadvertent changes. Upon activation of a high priority

alarm the screen changes to an unlocked state to allow for immediate interventions

as required.

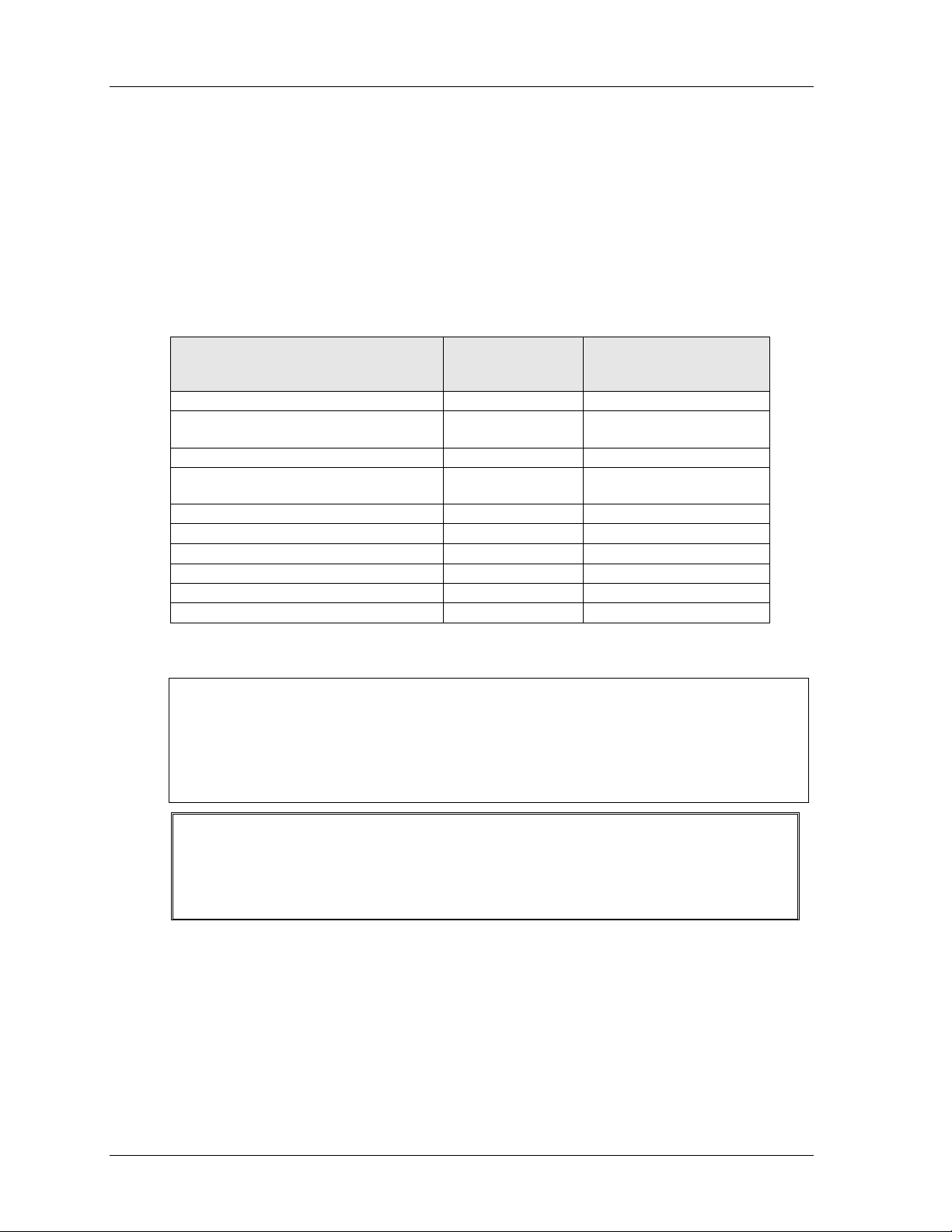

Table 1 - Functions and Accessories

Functions & Accessories Plus Comprehensive*

®

LP SiPAP Model M675

BiPhasic with breath rate monitoring

*Comprehensive configuration not available for sale in the United States

CAUTION!

The Infant Flow® LP SiPAP and SiPAP systems have been designed and tested

as complete systems using Infant Flow® accessories. Only accessories approved

for use should be used. If in doubt, please contact your local CareFusion

representative.

WARNING!

The Infant Flow® LP SiPAP system is compatible only with the Infant Flow

LP Generator. The prescribed nCPAP level will not be obtained if other

variable flow generators are used.

675-120 Rev. G

Page 13

Service Manual 3

Chapter 2 – Product Specifications

Modes

• NCPAP

• NCPAP with breath rate monitoring and low rate alarm

• BiPhasic (t im e triggered)

• BiPhasic (t im e triggered) with breath rate monitoring and low rate alarm

• BiPhasic tr (patient triggered ) with breath rate monitoring, low breath rate

alarm, and apnea back up

Controls

• Inspiratory Time (T-High): 0.1-3.0 seconds

• Rate (R): 1-120 (Comprehensive only. The comprehensive configuration is

not available for sale in the United States.)

• Rate (R): 1-54 (Plus only)

• Apnea Inter val (T

• Apnea Inter val (T

• NCPAP/Pres Low flowmeter: 0-15LPM, accuracy +/- 15% of selected output

• NCPAP/Pres High flowmeter: 0-5LPM, accuracy +/- 15% of selected output

• Manual Breath: X 1

• Rate monitoring on/off: NCPAP

• %O

Monitors

• CPAP

• PEEP

• MAP

• PIP

• %O

• I:E r a ti o

apnea): 10-30 seconds, 5 second intervals (Comp* only)

LBR): 10-30 seconds, 5 second intervals (Plus only)

: 21 - 100% - accuracy +/-3%

2

2

• Spontaneous rate (Rs)

• Battery charg e level

675-120 Rev. G

Page 14

4 Infant Flow

Alarms

• High airway pressure – 3 cmH20 above measured airway pressure

• Hig h cir cuit pressure – maximum 11 cmH20 in time triggered Biphasic mode

• Hig h cir cuit pressure – maximum 15 cmH20 in patient triggered Biphasic tr

mode (Comprehensive only. The comprehensive configuration is not

available for sale in the United States.)

• Low airway pressure – 2 cmH20 below measured airway pressure or 1

cmH20 if otherwise would be zero

• Hig h and Low delivered Oxygen concentration +5% of setting

• Low breath r ate alarm

• Low or Flat battery charge level

• Alarm volume (electronic alarms) 70 dBa at 1 meter

Pneumatic Supply

• Patient Gas Outlet: 15 mm standard taper fitting

®

LP SiPAP Model M675

• Patient Pressure Input: 4.5 mm Luer taper fitting

• Gas Supply: Nominal 4 bar or 60 psi, clean, dry medical air and oxygen

• Range: 2.8 to 6 bar (40 to 90 psi); maximum differential pressure 2 bar

(30 psi)

• Manometer: Range 0 to + 20 cmH

• Gas Connecti ons: Standard DISS or NIST connectors

Electrical Supply

• Input Voltage:100-230 VAC

• Input Frequency: 50/60 Hz

• Power Consumption: 50 VA maximum

• Fuse Rating For 220 V nominal operation: “T” Type 2.5 A at 250 V

• Device Housing Prot ection rating level: IPX1

• Battery Worki ng Time: 2 hours (from fully charged state)

• Battery Charging Time: max. 16 hours

O, accuracy, ± 2% of span

2

675-120 Rev. G

Page 15

Service Manual 5

Atmospheric & Environmental

• Temperatur e Range-Operating: 5 – 40° C

• Storage: 0 - 50° C

• Relative Humidit y -Operating: 0 – 90% non-condensing

• Storage: 0 – 90% non-condensing

Physical

• Dimensions (driver only) -(W x H x D) 26 x38 x 23.5 cm /

10.25 x15 x 9.25 in

• Weight (driver only)-8.8 kg / 19.5 lb

675-120 Rev. G

Page 16

6 Infant Flow

®

Infant Flow

LP SiPAP an d SiPAP

Model M675

®

LP SiPAP Model M675

675-120 Rev. G

Page 17

Service Manual 7

Chapter 3 – Warnings and Cautions

Please review the following safety information before operating the Infant Flow® LP

SiPAP or SiPAP system. Attempting to operate this equipment without fully

understanding its features and functions may result in unsafe operating conditions.

Warnings and Cautions, which are general to the use of the device under all

circumstances, are included in this section. Some Warnings and Cautions are also

inserted within the manual where they are most meaningful.

Notes are also located throughout the manual to provide additional information

related to specific features.

If you have a question regarding the installation, set up, operation, or maintenance of

the device, contact technical support at CareFusion.

Terms

WARNINGS identify conditions or practices that could result in serious adverse

reactions or potential safety hazards.

CAUTIONS identify conditions or practices that could result in damage to the

ventilator or other equipment.

NOTES identify supplemental information to help you better understand how

Warnings

• Whenever a patient is attached to respiratory care equipment, constant

attendance is required by qualified personnel. The use of an alarm or

monitoring system does not give absolute assurance of warning for every

malfunction that may occur in the system. In addition, some problems may

require immediate attention.

• The gas blender incorporated in this product is designed to mix medical

grade air and oxygen only. Do not modify the inlets to accommodate other

source gases such as anesthetic gases.

• Check that the water trap is empty before use and empty it frequently during

use.

• Liquid water or other contaminants in either gas supply, particularly the air

supply, may cause malfunction of this equipment and equipment connected

to it.

• When f illing a humidifier, do not move the stand. Moving or transporting the

stand while refilling may cause the stand and equipment to over balance.

the ventilator works.

• The Infant Flow LP SiPAP system is compatible only with the Infant Flow LP

675-120 Rev. G

Generator. The prescribed nCPAP level will not be obtained if other variable

flow g ener ators are used.

Page 18

8 Infant Flow

• Do not use conductive patient circuits with the Infant Flow® LP SiPAP Driver.

• Nasal CPAP can cause nasal irritation, septal distortion, skin irritation and

pressure necrosis. Observe the usage guidelines to minimize these

complications.

®

LP SiPAP Model M675

• This device exhausts O

during normal operation. Oxygen vigorously

2

accelerates combustion. To avoid fire hazard, do not place flammable

materials or sources of heat close to the exhaust.

• Do not use the equipment without the exhaust tube fitted (refer to Figure 2).

• To reduce trip hazard, always ensure cable and tubes are restrained away

from walking areas.

• The Abdominal Respiratory Sensor will not detect all forms of apnea.

Independent monitoring should always be used with this device.

• If the unit is shelf mounted, ensure that the unit is stable and that hoses and

cables are restrained to avoid hazard of toppling.

• This equipment is not suitable for use in the presence of a flammable

anesthetic mixture.

• The NCPAP Pres High flowmeter must be adjusted to zero when not required

for the patient.

• Under extr eme conditions (minimum supply pressure and maximum gas

demand, including auxiliary output) output flow rates and delivered pressure

may be reduced.

• Only use the supplied AC cable to connect to the power supply.

• Do not attach the Generator to the patient until the initial set up is complete.

• The

indicates a connection between the transducer interface and the

unit. It does not indicate correct positioning of the Abdominal Respiratory

Sensor.

• Calibration m ust only be done when the unit is not connected to the patient.

• Verif y that the displayed value for delivered FiO

corresponds to the value set

2

on the blender. Refer to Faults and Indications.

• Oxygen vigor ously accelerates combustion. To avoid explosion hazard, do

not use any instrument or other equipment that may have been exposed to oil

or grease contamination.

675-120 Rev. G

Page 19

Service Manual 9

Cautions

• Federal Law (USA) restricts this device to sale by or on the order of a

physician.

• The precision gas blender in this product may become non-functional or

damaged if used without the protective water trap and filters provided.

• The power switch on this unit does not isolate the external power supply.

Disconnect the power supply cable to ensure complete isolation.

• Before use, verif y that this equipment has been authorized for use by a

qualified person.

• The Infant Flow

tested as complete systems using Infant Flow

accessories approved for use should be used. If in doubt, please contact your

local CareFusion representative.

• Where the integrit y of the external protective earth conductor is in doubt, the

equipment shall be powered by its internal power source (battery).

• Do not immerse any part of the IFSD in water or sterilize it with gas or steam.

®

LP SiPAP and SiPAP systems have been designed and

®

SiPAP accessories. Only

• Ensure patient breathing circuit is replaced at regular intervals.

675-120 Rev. G

Page 20

10 Infant Flow

®

Infant Flow

LP SiPAP and SiPAP

Model M675

®

LP SiPAP Model M675

675-120 Rev. G

Page 21

Service Manual 11

Chapter 4 – System Construction

CAUTION!

Where the integrity of the external protective earth conductor is in doubt the

equipment shall be powered by its internal power source (battery).

The IFSD is AC powered with an integral rechargeable DC battery that provides

power for up to two hours without any interruption of performance or function. If the

AC power supply fails or is disconnected, the IFSD automatically switches to battery

power and gives an audio and visual alarm.

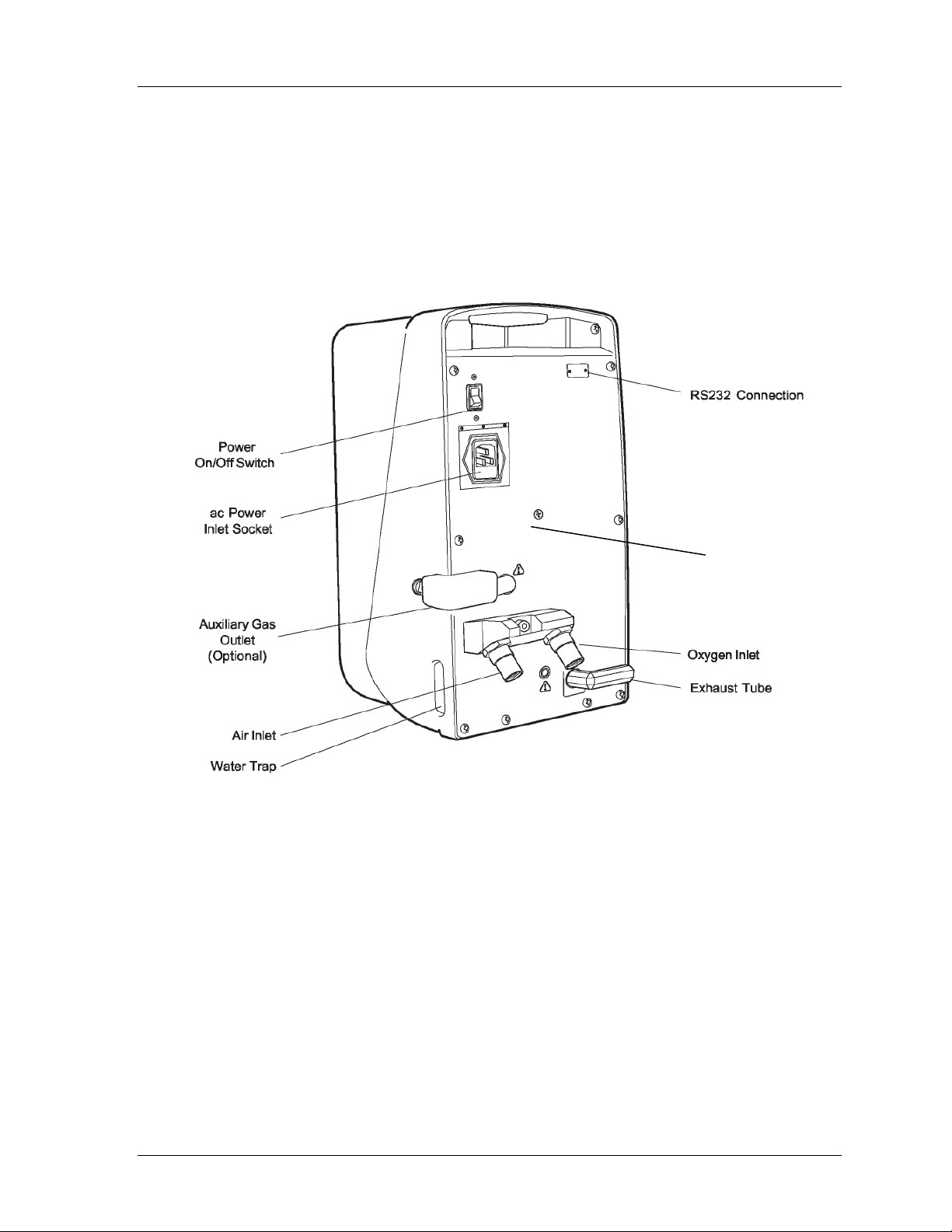

The IFSD is enclosed in a case with Operator controls and input connectors on the

front and rear panel. The front panel is shown in Figure 1. The back panel is shown

in Figure 2. The case incorporates non slip feet for table top use or must be fitted to

a dedicated stand. The major components within the casing are:

• a gas module

• an electronics module

• a front panel module

• a patient trigger module

• a firmware module

675-120 Rev. G

Page 22

12 Infant Flow

®

LP SiPAP Model M675

Figure 1: IFSD Front Panel

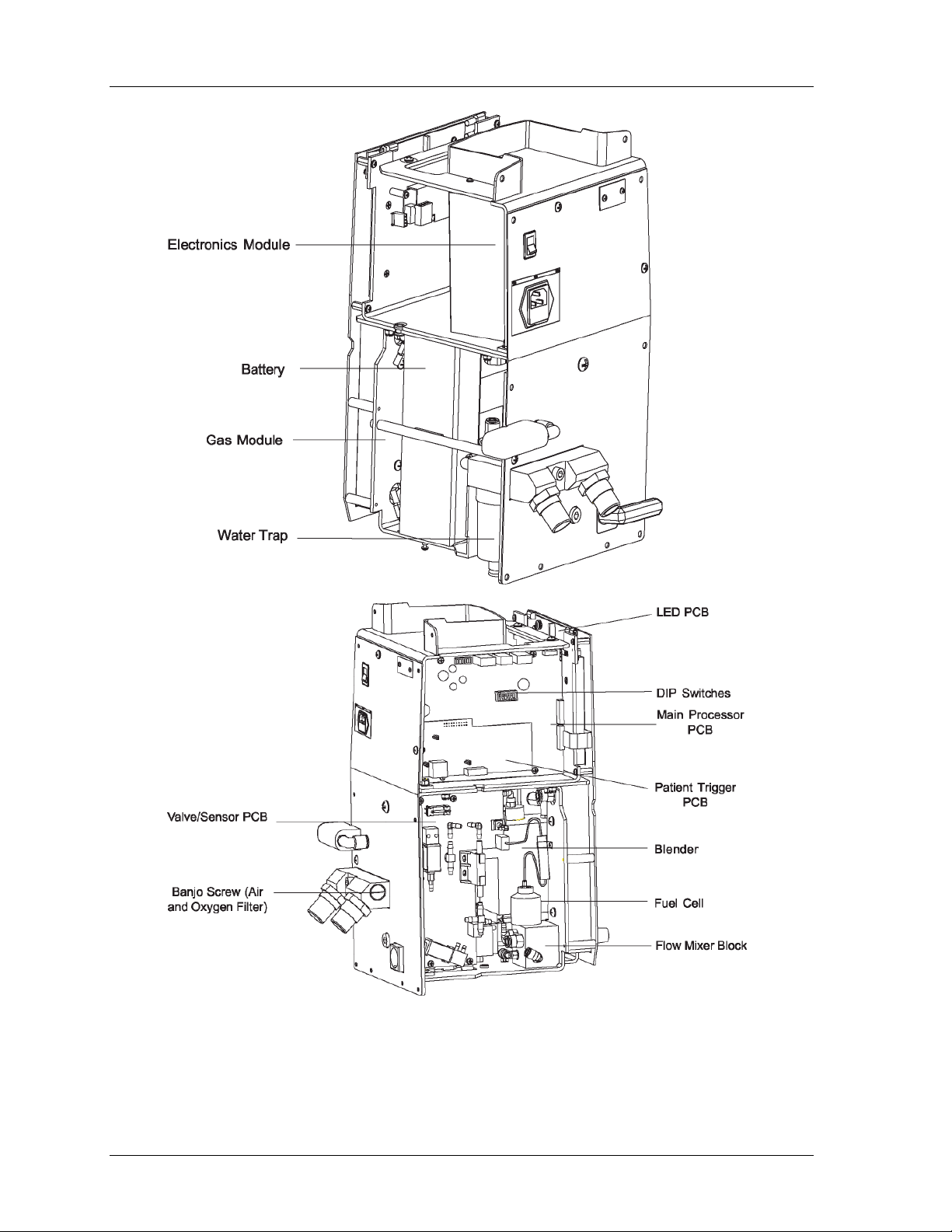

Gas Module

The function of the gas module is to take air and oxygen, blend them into the

required mixture and deliver this mixture to the patient at the prescribed flow rat e.

The gas module also measures the oxygen concentration, measures the patient

pressure, provides an auxiliary gas outlet (optional) and provides switched Biphasic flow.

The main components are an air/oxygen blender, a flow manifold, a vent valve, an

exhaust manifold with alarm whistle, NCPAP Pres low and NCPAP Pres high flowmeters,

and a valve/sensor PCB. The inlet gas connections are on an interc han geable i nlet bl ock

to allow for different gas fittings. The exhaust manifold discharges gas to the outside of

the case and is positioned away from the electrical connectors and switch to reduce any

potential explosive hazard.

675-120 Rev. G

Page 23

Service Manual 13

Leak Test

Electronics Module

The function of the electronics module is to power the unit either by AC mains supply

or DC emergency battery supply, to control the gas module and read the gas module

sensors. The main components are a power supply unit, a rechargeable batt ery, a

main processor PCB, LED PCB, Valve/Sensor PCB and a LCD screen (touch

screen). The LCD screen includes a back-light which is always on when the IFSD is

powered. The touch screen displays information and receives inputs from the Operator

via the touch screen keyboard.

Figure 2: IFSD Back Panel

Port

675-120 Rev. G

Page 24

14 Infant Flow

®

LP SiPAP Model M675

Figure 3: IFSD Internal Components

675-120 Rev. G

Page 25

Service Manual 15

Front Panel Module

The function of the front panel module is to house the gas and electrical connections

to the patient, Operator controls and indicators. The module consists of a front panel

plate, the touch screen with key pad, flowmeters and FiO

and indicators and an ambient light sensor. The backlight on the touch screen is

decreased if the ambient light sensor detects a low ambient light level and increased

if it detects a high ambient light level.

The green Power light is always on when AC power is connected to the unit.

control, patient connectors

2

The Alarm Warning Bar

Patient Trigger Module (P lus and Comprehensive Models)

The patient trigger module consists of a PCB which plugs into the main processor

PCB. Its function is to detect patient breaths and apnea and give this information to the

main processor in the electronics module. The main processor uses the signals from the

patient trigger module to instruct the biphasic pressure control to provide a timed sigh

to the patient.

Firmware Module

The firmware module is the unit’s embedded software. Its function is to instruct the

microprocessor how to control the unit and to interact with the Operator.

Touch Screen

The touch screen provides the Operator with a series of screens with icons to enable

settings, calibration and fault diagnosis. The Start Up Screen is shown in Figure 4.

The display includes a status bar which incorporates a battery status, mode

indicator, alarm button and patient trigger indicator. The center part of the display

shows icons which relate to the function being selected or performed. The display also

includes a key pad with six keys. The icon in each key changes depending on the

function being performed.

flashes red to indicate an alarm.

Battery Status and Chargi ng Indicator

If the battery status shows three bars or less, the display flashes alternately between

red bars on a white background and a pink background.

Alarm Button

The alarm button alerts the Operator to fault conditions. An audible alarm is activated

at the same time. In the unalarmed condition the button is green

high-priority alarm condition, the button flashes

heard. If the alarm button is pressed (to silence the audible alarm), the button

changes to

flashes

condition, the button is solid

675-120 Rev. G

. In the

red and an audible alarm is

and flashes red. In a medium-priority alarm condition, the button

yellow and an audible alarm is heard. In a low-priority alarm

yellow with an audible alarm. If any alarm

Page 26

16 Infant Flow

condition resets itself, the yellow alarm bar remains to alert the clinician of a previous

problem.

Caution/Information

The Caution/Information icon alerts the Operator to read this manual. It flashes

during an alarm condition.

Mode Indicator

The Mode Indicator shows four question marks when in Start up or Adjust and

changes to show the applicable mode in use (e.g. NCPAP).

®

LP SiPAP Model M675

Figure 4: Touch Screen Display – Start Up

Patient Trigger Indicator (Plus and Comprehensive Models)

The Patient Trigger indicator changes to when the transducer interface is

connected and ready to be connected to the patient and indicates a

transducer interface is not connected.

when the

675-120 Rev. G

Page 27

Service Manual 17

Alarm Conditions

Audible and visible alarm indications are given to alert the Operator to specified

conditions that affect the operation of the unit. The electronic alarm limits are

automatically set after two minutes without Operator inputs but the Operator can

manually set the alarm parameters for certain conditions if required. The IFSD has

the following alarms:

• an audible W histle which sounds a constant tone when the gas imbalance

limits are exceeded.

• an audible Alarm which sounds a constant tone or two different intermittent

tones; medium or high level (medium level sounds beep.beep.beep every 15

seconds and high level sounds beep .beep .beep beep beep every 10 seconds).

• a visual Warning Bar which flashes red continuously, flashes intermittently or

comes on continuously.

• an Al arm Button on the touch screen status bar which flashes continuously.

Other indications are given to indicate the status of the condition. Refer to Table 2 for

alarms and indications for specified conditions.

Diagnostic Screen

A diagnostic screen is provided for low level calibration, test procedures for valves

and an error log. Figure 5 shows the screen display. Labeling of Diagnostic screen

will be the same regardless of configuration.

Figure 5: Diagnostic Screen

675-120 Rev. G

Page 28

18 Infant Flow

Box

Description

PCB. Position 1 is on and 0 is off.

INDICATOR

contrast.

successfully completed and a if the calibration fails.

Box

Description

S/W

The S/W box shows the version and serial number of the loaded firmware.

(E2P).

PT

The PT box shows the status of the Patient Trigger module.

inspiratory time, and breath rate (controlled by DIP 1).

(BLL) and if the backlight is operative (BLF - 1 for fail, O for on).

(BAT), the battery charge status (CHG) and the temperature (TMP).

8.2 and 10 V).

RS232

The RS232 box shows factory set data.

values.

(OSEN) and the software offset (OFFS) and gain (GAI N) values.

for the zero valve and the Z sensor (ZSEN) voltage.

for the dump valve and the D sensor (DSEN) voltage.

for the pressure assist valve and the P sensor (PSEN) voltage.

Table 2 - Diagnostics Screen Boxes

DIPS The DIPS box shows the position of the DIP switches on the main processor

®

LP SiPAP Model M675

CONTRAST

CALIBRATION

INDICATOR

The contrast indicator box is for use in the factory for setting the screen

The calibration indicator box shows

during calibration, a when

The following display boxes show if the values are within t he set parameters, a

if the values are outside the set parameters, a if the function is not

calibrated and a

if the function is disabled on the DIP switch.

Table 3 - Additional Diagnostics Screen Boxes

H/W The H/W box shows the status of the watchdog t i mer (WDG) and the EEPROM

CONFIG The CONFIG box shows the softw are con figurati on based on the DIP swit ch

settings and requirements. LAB = INTL or US (controlled by DIP 3), which is the

Comprehensive or Plus model; tBiP = 1 or 0 (controlled by DIP 2 and 5), which

indicates Triggered BiPhasic is enabled (1) or disabled (2); APB = 1 or 0

(controlled by D IP 2 ), w hi ch in dicates that Apnea BiPhasic is enabled (1) or

disabled (0 ); The re maining sy mbols provi de the de fault and r ange s for

LCD The LCD box shows the ambient light sensor voltage (AMB), the back light level

PSU The PSU box shows the external power supply voltage (EXT), the battery voltage

RAILS The RAILS box shows the ground voltage (GND), and the control voltages (6.5,

PRESSURE The PRESSURE box shows cm H2O pressure value, the voltage from the

pressure sensor (PSEN) and the software offset (OFFS) and gain (GAIN)

OXYGEN The OXYGEN box shows the FiO2 %, the voltage from the oxygen sensor

ZVALVE The ZVALVE box shows if the Z DRIVE is operative (ZDRV - 1 for fail, O for on)

DVALVE The DVALVE box shows if the D DRIVE is operative (DDRV - 1 for fail, O for on)

PVALVE The PVALVE box shows if the P DRIVE is operative (PDRV - 1 for fail, O for on)

675-120 Rev. G

Page 29

Service Manual 19

Chapter 5 – Theory of Operation

Gas Flow

With the oxygen and air connections connected and the power switch ed on, oxygen

and air at 386 kPa (56 psig) flows to the blender. The air passes thr ough a water trap

with an integral filter where any moisture in the air is removed. Oxygen and air are

filtered before entering a non-return valve in the blender. The blender mixes the

oxygen and air in the proportion set by the position of the FiO

blender supplies blended gas between 2.5 and 30 LPM.

The blender incorporates an alarm/bypass module. If a single gas supply fails or

there is an imbalance between the inlet gas pressures exceeding 200 kPa (30 psig),

the module directs the flow through a reed whistle to warn the Operator of the

condition and at the same time connects the inlet gas at the hig her pressure to the

blender outlet.

The blended gas is filtered before passing through a flow control to an oxygen

analyzer. The oxygen analyzer utilizes a galvanic fuel cell to measure and display

the measured delivered oxygen concentration.

control valve. The

2

A vent valve on the exhaust manifold incorporates a solenoid operated pilot valve

and a large orifice spool valve. The vent valve is normally held in the open position

by a spring to vent high flow rates with low pressure drops so that the patient

pressure is minimal. The electrically actuated pilot valve is operated by blended gas

so that the vent valve continues to operate if one gas supply is lost.

Blended gas flows through an electronically operated dump valve which is normally

in the closed position. If over pressurization occurs, the sensors detect the condition

and the controller signals the dump valve to open, sounds an alarm buzzer and at

the same time closes the vent valve to rapidly reduce the patient pressure to near

zero. When the over pressure condition stops, the controller signals the vent valve to

open and the dump valve to close.

The NCPAP flowmeter is set by the Operator to the required flow. The flow rate is

shown on the gauge on the flowmeter. When the flowmeter control knob is turned

fully clockwise, the flow of gas is turned off.

675-120 Rev. G

Page 30

20 Infant Flow

®

LP SiPAP Model M675

Figure 6: IFSD Gas Flow Schematic

675-120 Rev. G

Page 31

Service Manual 21

The patient pressure is shown on the touch screen and is monitored by a pressure

sensor which sends the signal to the main processor. A zeroing valve automatically

checks the pressure readings against atmospheric pressure to ensure accuracy of

the patient pressure readings.

A mechanical pop-off valve is factory set to limit the delivered pressure to a safe

level sufficient to achieve the maximum required patient pressure at the generator.

Adjustment of the pop-off valve is not required by Operators.

Auxiliary Output (Opti ona l)

Blended gas flows through a fixed flow control and non-return valve to a standard

DISS fitting on the back panel to supply a maximum 15 LPM for delivery to the

patient via other sources.

Inspiratory Pressure

Blended gas passes through a variable outlet flow control and through the NCPAP

Pres High Flowmeter. The NCPAP Pres High Flowmeter is set by the Operator to the

required flow. The outlet from the NCPAP Pr es High Flowmeter when not delivering to

the patient flows through a restrictor to exhaust, allowing the flowmeter to be

adjusted without delivering gas to the patient. The flow rate is shown on the gauge

on the flowmeter. When the flowmeter control knob is turned fully clockwise, the flow

of gas is turned off. The flow is directed to the patient via a high speed selector valve

which operates when requested by the NCPAP Pres high timing.

WARNING!

The NCPAP Pres high must be adjusted to zero w hen not required for the

patient.

Triggered BiPhasic

For BiPhasic Tr, a micro controller provides reliable indications of breaths derived

from the patient abdominal respiratory sensor. It sends signals to operate the

NCPAP Pres high valve to provide a timed sigh.

WARNING!

Under extreme conditions (minimum supply pressure and maximum gas

demand, including auxiliary output) output flow rates may reduce.

Operation without E lectrical Power

The IF SD can be used without electrical power. In this mode, NCPAP Pres low flow

only is delivered, set by the NCPAP Pres Low Flowmeter and the required FiO

In this mode, visual indications and warnings are not given except for the gas failure

alarm.

level.

2

675-120 Rev. G

Page 32

22 Infant Flow

Electronic Functions

Sensors mounted on the valve/sensor PCB monitor pressure, flow rate and oxygen.

Sense signals for each of the valves allow the micro-controller to monitor the valve’s

state and determine whether the valve is connected or short circuited. Current to the

valve sensor PCB is limited via the fuses below a 10 VA limit to ensure safety in a

possible oxygen enriched environment.

The patient trigger PCB interfaces with the main processor PCB via a 20 way head.

Communication between the two PCB’s is via a CAN bus. The main processor PCB

also supplies +5 V power to this PCB and monitors other control signals.

®

LP SiPAP Model M675

Figure 7: IFSD Electronic Enclosure

675-120 Rev. G

Page 33

Service Manual 23

Electrical Layo ut

Figure 8 shows the electrical wiring and PCB connector layout.

Figure 8: IFSD Electrical Wiring Diagram

675-120 Rev. G

Page 34

24 Infant Flow

BiPhasic

BiPhasic

Fault lockout

Unit inoperable by

Error code(s)

alternates

Unit restricted to

Error code(s)

Patient trigger

Battery status

Unit will not

Fault Management

When a software detectable fault condition occurs, the unit still allows a basic level of

treatment to the patient. Table 4 shows the fault conditions and the level of control

available.

Table 4 - Faults, Available Modes and Control Functions

Measurements Software Control Modes

®

LP SiPAP Model M675

Alarm Functionality FiO2 CmH2O NCPAP

screen shows

error

code(s).

shown

on mode

selection

screen.

Status bar

mode

shown

on mode

selection

screen.

Status bar

mode

software, operable

in

unpowered

NCPAP and

NCPAP+Apnea

modes.

(NCPAP+Apnea,

BiPhasic+Apnea

and

BiPhasic Tr)

modes not

available.

X X X X X X

NCPAP+

Apnea

X

+ Apnea

X X

Tr

X

675-120 Rev. G

shows

discharged

battery.

operate

on battery power

when external

power

supply is

removed.

Page 35

Service Manual 25

Chapter 6 – Operational Setup

The operating procedures below show the procedures for all models. Reference

should only be made to the procedures for the model in use. Read the Warnings and

Cautions at the beginning of this manual before you start the procedures.

Preparing and Connecting the Equipment

1 Connect the Medical Air and Oxygen hoses to the IFSD connections on the

back panel.

WARNING!

Only use the supplied AC cable to connect to the power supply.

2 Connect the power supply cable to a suitable power supply outlet. The green

power light will come on regardless of the position of the power switch.

3 Connect the patient circuit to the IFSD as required. Figure 9 shows a typical

configuration, the actual configuration may vary dependent on the type of ancillary

equipment used and the clinical needs prescribed for the patient. For functional

test purposes, the Generator nasal prongs can be occluded to simulate patient

responses.

4 If desired, connect the transducer module to the sensor and to the IFSD.

WARNING!

The Infant Flow LP SiPAP system is compatible only with the Infant

Flow LP Generator. The prescribed nCPAP level will not be obtained if

other variable generators are used.

675-120 Rev. G

Page 36

26 Infant Flow

Infant Flow® LP Generator

Infant Flow® LP

®

LP SiPAP Model M675

SiPAP Driver or

SiPAP Driver

Figure 9: Patient Connections

675-120 Rev. G

or Generator

WARNING!

Check that the water trap is empty before use and empty it fr equently

during use.

Page 37

Service Manual 27

5 Make sure that the water trap is empty. If necessary, empty any water from the

trap (refer to Chapter 3, Maintenance).

6 Gas Flow Pressure Setting

The IFSD provides a virtually constant airway pressure irrespective of patient

demand or expiratory flows via the specially designed generator and nasal prongs. This

is the reason for the IFSD’s ability to provide superior NCPAP. The IFSD is subject to

a direct relationship between controlled enriched gas flow and NCPAP pressure.

Nomograms illustrating the relationship between constant airway pressure and flow

settings are shown in Figure 10 and Figure 11. Example: 8 LPM gas flow provides 5

cm H

O NCPAP.

2

Verify the type of IFSD you are using, LP SiPAP or 675–CFG–XXX, to determine

which nomogram to use.

Note:

Individual devices have a tolerance of up to ± 10% from that illustrated in the

nomogram and in particular, at pressures below 2 cm H

2

O.

Figure 10: Flow Pressure Nomogram for 675-CFG-XXX

675-120 Rev. G

Page 38

28 Infant Flow

performance.

Flow Pressure Nomogram (for

reference only) to show typical flow

pressure relationships. This is not

meant to establish actual product

®

LP SiPAP Model M675

Figure 11 – Flow Pressure Nomogram for LP SiPAP

Individual devices have a tolerance of up to ±15 percent from that illustr ated in the

nomogram and, in particular, at pressures below 2cmH

2

O.

675-120 Rev. G

Page 39

Service Manual 29

Switching On the IFSD

WARNING!

Do not attach the Generator to the patient until the initial set up is

complete.

Put the power switch on the back panel to the position.

• the warning bar comes on

• the green power light remains on

• the audible alarm sounds

The unit carries out a full functional check. If the checks are not successful (prog r am

memory fault, power supply not connected or emergency battery voltage low), the

screen remains black and the warning bar stays on.

If the checks are successful, the warning bar goes off and the screen changes to the

Power Up Screen.

After two seconds the screen changes to the Power Up Check Screen.

During the power up checks:

• the screen image is shown in negative

• the warning bar comes on for one second

• the Apnea light comes on for one second

• the audible alarm sounds for one second

• the dump valve is tested

• the pressu r e is set to zero

After two seconds the screen changes to the Start Up Screen.

• the alarm limits are disabled

A flashing question mark alternating with a red cross appears under the first

adjustment to be made.

To calibrate

the O2 fuel cell, refer to the section “Calibration” on page 41.

Note:

Where a mode is not applicable (e.g. Patient Trigger), the button is blank and the

icons are not shown.

675-120 Rev. G

Page 40

30 Infant Flow

User Verification Test

WARNING!

Do not attach the Infa nt Flow® LP Generator or the I nfant Flow® Generator

to the patient until User Verification and initial setup into NCPAP mode is

complete.

CAUTION!

Although failure of any of the above tests will not prevent the ventilator from

functioning, it should be checked to make sure it is operating correctly before use

on a patient.

Power-on Check

This test is run automatically on power up of the driver and automatically performs

the following checks:

• Flash ROM

®

LP SiPAP Model M675

• Hardware Input s/Out puts

• Audible and visual alarms indicators

• Test and calibrat ion of pressure sensor

• Test of dump val ve

The unit carries out a full functional check during this time. If unsuccessful, the

screen remains darkened and the warning bar remains on. In this case, check for the

following;

• Power Supply not connected

• Battery voltage low

If the checks are successful, the screen changes to Power Up Screen. After two

seconds, the screen changes to Power Up Check Screen.

During the Power Up check:

• Screen image shown in negative

• Warning bar comes on for one second

• Transducer Assembly LED comes on for one second

• Audible alarm sounds for one second

• Dump valve is tested

• Pressure is set to zero

After two seconds screen changes to Set Up Screen. Alarm limits are disabled and a

flashing question mark appears under the NCPAP / Pres Low flowmeter screen

indicator.

675-120 Rev. G

Page 41

Service Manual 31

Two Point O2 Sensor Calibratio n

1. Enter the Calibration Screen from the Setup Screen by pressing the calibration

button on the lower right hand corner of the touch screen.

2. Ensure there is a min i mum 8 LPM set on the NCPAP/PRES Low Flowmeter. In

addition, ensure there is a minimum of 3 LPM set on the NCPAP/High

Flowmeter.

3. Adjust the %O

calibration by touching the associated flashing button.

4. Adjust the %O

touching the associated flashing button.

5. Return to the Start up Screen by pressing the Exit button.

control to 21%. Allow the %O2 display to stabilize. Confirm the

2

control to 100%. Allow the %O2 display to stabilize. Confirm by

2

Note:

If O2 calibration fails, a red “X” is shown.

If the internal oxygen cell is depleted or damaged, it may not be possible to calibrate

the O

button. This will disable oxygen monitoring and the audible oxyg en alarms unt il the

device is powered off. Whenever the device is operating with oxygen monitor and

alarms disabled, a fault code E55 displays, and measured FiO

sensor. The internal oxygen monitor may be disabled using the Disable O2

2

displays as dashes.

2

WARNING!

When the Infant Flow® LP SiPAP system unit or SiPAP system unit (part

number 675-CFG-xxx) is connected to a patient and the internal oxygen

monitor is disabled, the Infant Flow® LP SiPAP system unit or SiPAP

system unit must be used with an external oxygen monitor.

If calibration is attempted, and fails, or if the oxygen cell fails while the device is in

normal use, a Fault Code E55 displays, as tabulated in appendix D, and a high

priority alarm is indicated visually and audibly. To enable continued operation, the

internal oxygen monitoring may be disabled by pressing and holding the alarm mute /

reset button for three seconds. This disables the internal oxygen monitor and alarms

and clears the alarm condition. The E55 code remains to indicate that the oxygen

monitor is inoperative. An external oxygen monitor must be used.

675-120 Rev. G

Page 42

32 Infant Flow

Leak Test

1. Have the patient circuit and generator assembled as shown in Figure 3.

2. Connect the patient interface (prong or mask) to the generator (see Chapter 5,

Step by Step Fixation) and occlude the opening to the patient.

3. If not powered up already, switch on the power to the driver.

4. For LP SiPAP, adjust the NCPAP/Pres Low Flowmeter to 9 LPM. Verify that the

measured pressure is 5 ±1 cmH

confirm.

For SiPAP, part number 675-CFG-XXX, adjust the NCPAP/Pres Low Flowmeter

to 8 LPM. Verify that the measured pressure is 5 ±1 cmH

associated flashing screen icon to confirm.

O. Touch the associated flashing screen icon to

2

®

LP SiPAP Model M675

O. Touch the

2

5. Adjust %O

control as prescribed for the current patient. Verify that the blender

2

setting and the measured oxygen value are within 3%. Touch the associated

flashing screen icon to confirm.

6. Adjust the Pres High Flowmeter as prescribed for the current patient. Touch the

associated flashing screen icon to confirm.

7. If desired, connect the Transducer Interface to the front panel of the driver if

breath monitoring is required during treatment. Touch the associated flashing

screen icon to confirm.

8. The display screen changes to the Alarm Set/Confirm Screen. Press the NCPAP

button or Alarm Mute/Reset button to set alarms and begin monitoring.

9. Monitored parameter for CPAP should be 4-5 cmH

O. If not, check circuit for

2

leaks or blockages, (including the humidification system).

10. Remove the occlusion to the patient interface. The monitored CPAP display

should be 0-2 cmH

O. If not, check that the interface is not still occluded.

2

675-120 Rev. G

Page 43

Service Manual 33

Alarm Test Initial Settings

Air Supply Pressure

O

2

Supply Pressure

Patient Circuit

Generator

Infant Flow® LP Generator

8 LPM for SiPAP

% O2

Pres High Flowmeter

Mode

Alarms Test

WARNING!

Prior to patient application, ensure that all User Verification testing and

calibration procedures are successfully completed. User Verification

testing and calibration procedures must be done off patient.

Note:

Following each alarm verification test, ensure that control settings and alarm limits

are reset as instructed before proceeding to the next test.

> 30 psig (2.1 bar)

> 30 psig (2.1 bar)

Infant Flow® LP Patient Circuit

NCPAP / Pres Low Flowmeter

9 LPM for LP SiPAP or

30%

3 LPM

NCPAP

Perform the Alarms Test on the Infant Flow® LP SiPAP system or Infant Flow SiPAP

system using the following steps and the initial settings provided above.

1. Make appropriate connections for air and O

gas supply. Connect power cord to

2

appropriate AC outlet. Attach patient circuit, generator and patient interface

(mask or prong) as shown in Figure 3. Occlude the opening to the patient .

2. Power up the driver and allow Power On Check to complete.

3. Low airway pressure alarm: From NCPAP operating mode, with alarms set,

remove occlusion from opening to patient. Verify that the low airway pressure

alarm activates. Restore the patient interface occlusion and press the Alarm

Mute / Silence button for 3 seconds to reset the alarms.

4. High airway pressure alarm: Adjust the NCPAP / Pres Low Flowmeter to 11

LPM. Verify that the high airway pressure alarm activates. Return the NCPAP /

Pres Low Flowmeter to 9 LPM for LP SiPAP or 8 LPM for SiPAP and press the

Alarm Mute / Silence button for 3 seconds to reset the alarms.

5. High %O

activates. Return the O

Alarm: Adjust the % O2 control to 35%. Verify that the High %O2 alarm

2

control setting to 30%. Reset alarms by pressing the

2

Alarm Mute / Reset button for 3 seconds.

675-120 Rev. G

Page 44

34 Infant Flow

6. Low % O2 Alarm: Adjust the % O2 control to 25%. Verify that the Low %O2 alarm

activates. Return the O

control setting to 30%. Reset alarms by pressing the

2

Alarm Mute / Reset button for 3 seconds.

7. Loss AC Alarm: Disconnect the AC power cor d from the wall outlet. Verify that

the Loss AC alarm activates. Reconnect the AC power cord. Clear the alarm by

pressing the Alarm Mute / Reset button.

8. High Circuit Pressure Alarm: Increase nCPAP pressure to 11.1 cmH

increasing the NCPAP/PRES Low Flowmeter. Verify that the High Circuit

pressure alarm activates. Return NCPAP/PRES Low Flowmeter to 8 LPM and

press the Alarm Mute/Silence button for three seconds to reset the alarms.

Note:

If staff is using a transducer (P/N 677-002) for Apnea Monitoring, proceed to

step 9. If staff is not using a transducer, mark N/A on checkout sheet and testing

is finished.

9. Low Breath Rate (Apnea) Alarm: Attach the transducer and abdominal sensor to

the unit. Set Mode to BiPhasic+Apnea/LBR (U.S. Configuration) or Biphasic +

LBR, rate 30 Bpm, T-High 0.3 seconds and Tapnea or TLBR to 20 sec.

Manually squeeze the abdominal sensor to simulate a spontaneous breath. No

alarms should be active. Change the mandatory rate control to setting for rate to

1 Bpm and stop squeezing the abdominal sensor. Verify that the Low Breath

rate alarm activates after the default interval of 20 seconds. Return the rate

control to 30 Bpm and clear the alarm by pressing the Alarm Mute / Reset

button for 3 seconds.

®

LP SiPAP Model M675

O by

2

675-120 Rev. G

Page 45

Service Manual 35

TEST

PASS

FAIL

N/A

Automated Tests

Power On Check

Manual Tests

Two Point O2 Sensor Calibration

Patient Circuit Leak test

Manual Alarms Checks

Low Airway Pressure Alarm

High Airway Pressure Alarm

High O

2

Alarm

Low O

2

Alarm

Loss AC Alarm

High Circuit Pressure A larm

Low Breath Rate (Apnea) Alarm

Infant Flow® LP SiPAP/SiPAP User Verification Test Checklist

Driver Serial Number:_____________________ Test Date:_________________

Signature of tester:_______________________________________________

Title___________________________________________________________

675-120 Rev. G

Page 46

36 Infant Flow

Setting up the Equipment

The procedures show the screen set up for all modes. If a mode is not applicable to

the model in use, go to the next applicable step.

Adjust the NCPAP Pres Low Flowmeter to indicate the required flow rate. When

®

LP SiPAP Model M675

done, touch the flashing

The button icon changes to a

Set the FiO

confirm each time.

and NCPAP Pres high flow as appropriate, touching the button to

2

button to confirm the initial setting

and the next button starts flashing.

WARNING!

Ensure that the pressure is consistent with the flow rate.

WARNING!

Verify that the displayed value for delivered FiO2 corresponds to the value

set on the blender. Refer to Faults and Indications.

If an alarm is activated, the button displays a flashing cross. The alarm condition

must be cleared before the setting is confirmed (refer to Table 1).

WARNING!

The indicates a connection between the transducer interface and the

unit. It does not indicate correct positioning of the abdominal respiratory

sensor.

Note:

All triggered modes (NCPAP+Apnea, BiPhasic+Apnea, BiPhasic Tr) are

automatically confirmed with a

When all of the initial settings have been confirmed (NCPAP Pres low, FiO2, NCPAP

Pres high and/or Respiratory sensor) the screen changes to the Adjust Screen.

• The alarm limits remain disabled.

To set the alarm limits, touch the NCPAP button or the alarm button f or three

seconds. If a button is not touched within two minutes, the alarm limits will be

automatically set.

if the patient trigger is connected.

Note:

NCPAP+Apnea, BiPhasic+Apnea, BiPhasic Tr selection buttons are not lit if the

transducer interface box is not connected to the IFSD.

675-120 Rev. G

Page 47

Service Manual 37

When the alarm limits have been set, the screen changes to the Mode Selection

Screen and defaults to the nCPAP mode.

• The alarm limits are set.

Touch NCPAP, NCPAP+Apnea, BiPhasic, BiPhasic+Apnea, or BiPhasic Tr to enter

the Parameter Set up Screen for each mode.

Note:

When the Mode Selection screen is showing, NCPAP treatment will always be

delivered.

After two minutes if the Operator has not made any inputs, the screen changes to the

Locked Screen.

• The key pad is locked.

• The display remains as shown for patient monitoring.

Touch the

• The display returns to the Mode Selection Screen.

button for three seconds to unlock the key pad.

Note:

If a high priority alarm occurs, the keypad automatically unlocks.

Setting the NCPAP Parameters

For NCPAP+Apnea function the transducer interface and the abdominal respiratory

sensor must be connected.

From the Mode Select Screen touch the NCPAP + Apnea

The screen changes to the Parameter Set Up Screen and shows:

• The patient respiration rate (Rsp).

• The delay time for the alarm to come on Tapnea.

• The Inspiratory time for a manual sigh.

Use the

buttons to set the alarm delay time.

button.

Confirm the settings by touching the flashing

been accepted, the screen changes to the Locked Screen.

Touch the

• The display changes to the Parameter Adjust Screen.

675-120 Rev. G

button. When the settings have

button to unlock the key pad.

Page 48

38 Infant Flow

Note:

If a high priority alarm occurs, the key pad automatically unlocks.

To return to the Mode Selection Screen, touch the button.

Setting the BiPh asic Parameters

For BiPhasic+Apnea function the transducer interface and the abdominal respiratory

sensor must be connected.

®

LP SiPAP Model M675

From the Mode Select Screen touch the Biphasic

The screen changes to the Parameter Set Up Screen and shows:

• The NCPAP Pres high inspiration time (T

• The NCPAP Pres high respiration rate (R)

• The Inspiration/Expiration ratio (I/E)

-High)

button.

Note:

If a transducer interface is connected to the unit, is displayed and BiPhasic +

Apnea monitoring mode is enabled. In addition to the above parameters, the screen

shows:

• The detected breath bar graph.

• The detected breath rate (Rsp)

• The delay time for the alarm to come on (Tapnea)

Push the individual buttons to select between the parameters T

Tapnea. Use the buttons to set the parameter for T-High, Rate, and

Tapnea.

-High, Rate, and

Note:

The I/E rate changes accordingly.

Confirm the BiPhasic settings by touching the flashing BiPhasic or BiPhasic + Apnea

button.

When the settings have been accepted, the screen changes to the locked screen

and treatment starts.

To adjust the parameters, touch the

The screen changes to the BiPhasic or BiPhasic + Apnea Adjust Screen.

Parameters T

675-120 Rev. G

-High and Rate can now be adjusted.

button.

Page 49

Service Manual 39

Note:

The I/E rate changes accordingly.

To return to the Mode Selection Screen, touch the button.

Note:

The button is shown with a pink background if an alarm condition occurs. If this

occurs, the button cannot be operated until the alarm condition has been cleared or

silenced using the alarm button.

After two minutes if the Operator has not made any inputs, the screen changes to the

Locked Screen.

• The key pad is locked.

• The display remains as shown for patient monitoring.

Touch the

• The display returns to the BiPhasic or BiPhasic + Apnea Adjust Screen.

button to unlock the keypad.

Note:

If a high priority alarm occurs, the keypad automatically unlocks.

Setting the Trigg er ed BiPhasic Parameters

From the Mode Select Screen touch the BiPhasic Tr button.

Note:

The transducer interface must be connected to enter this mode.

The screen changes to the Parameter Set Up Screen and shows:

• The patient’s respiration rate (Rsp)

• The NCPAP Pres high inspiration time (T

• The NCPAP Pres high backup respiration rate (Rb)

• The delay time for the apnea alarm to come on (Tapnea)

-High)

Press each individual button to select between the parameters T

Tapnea. Use the

Confirm the BiPhasic Tr settings by touching the flashing BiPhasic Tr button.

When the settings have been accepted, the screen changes to the locked screen

and treatment starts.

675-120 Rev. G

-High, Rb and

buttons to set the parameter for T-High, Rb and Tapnea.

Page 50

40 Infant Flow

To adjust the parameters, touch the button.

The screen changes to the BIPHASIC TR Adjust Screen.

®

LP SiPAP Model M675

Parameters T

To return to the Mode Selection Screen, touch the button.

-High, Rb and Tapnea can now be adjusted.

Note:

The button is blank if an alarm condition occurs. If this occurs, the button

cannot be operated until the alarm condition has been cleared or silenced using the

alarm button.

After two minutes if the Operator has not made any inputs, the screen changes to the

Locked Screen.

• The key pad is locked.

• The display remains as shown for patient monitoring.

Touch the

• The display returns to the BiPhasic Tr Adjust Screen.

button to unlock the key pad.

Note:

If a high priority alarm occurs, the key pad automatically unlocks.

675-120 Rev. G

Page 51

Service Manual 41

Calibration

WARNING!

Calibration must only be done when the unit is not connected to the

patient.

From the Start Up Screen touch the button.

The screen changes to the Calibration Screen.

• The alarm limits are disabled.

Turn the FiO

Turn the FiO

Touch the

The screen returns to the Start Up Screen.

control to 21 and confirm by touching the flashing button.

2

control to 100 and confirm by touching the flashing button.

2

button.

Note:

If the calibration procedure fails, a red is shown in the applicable button. Recalibrate and if necessary, replace the O

fuel cell.

2

Giving a Manual Timed Sigh

In the Mode Select or Adjust screens of NCPAP+Apnea, BiPhasic+Apnea or BiPhasic

Tr - touch the

button to give the patient a manual timed sigh.

Operation Without Electrical Power

The IFSD can be used without mains or battery power. To use the IFSD in this

mode, set the required NCPAP flow on the NCPAP Pres Low Flowmeter and the

required FiO

except for the gas failure alarm /bypass whi ch wi ll operate un til pressures are b alanced.

level. All audible and visual indications and warnings are not given

2

675-120 Rev. G

Page 52

42 Infant Flow

Fault Indications

Refer to Table 1 (all models) and Table 2 (BiPhasic and BiPhasic T r models only) for

the fault indications for specific faults and the procedures for resetting or canceling.

Discharged Battery

When the battery voltage is too low to power the circuits, the screen changes to the

Power Down Screen.

• All functions and controllable inputs are disabled.

• The controller waits for the power source to be connected.

• When external power is restored, the screen changes to the Power Up

Screen.

• The screen goes blank when the battery power is too low to power the Power

Down Screen.

Fault Lockout

®

LP SiPAP Model M675

If a fault occurs which is detectable by the software and prevents the unit from

operating correctly, the screen changes to the Fault Lockout Screen.