Page 1

Bird Sentry™ Blender

User’s Guide

Page 2

Bird Sentry™ Blender

This document is protected by United States and International Copyright laws.

This document may not be copied, reproduced, translated, stored in a retrieval system, transmitted in any

form, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

written permission of CareFusion. Information in this document is subject to change without notice.

This document is for informational purposes only and should not be considered as replacing or

supplementing the terms and conditions of the License Agreement.

© 1997–2010 CareFusion Corporation or one of its subsidiaries. All rights reserved. The CareFusion logo

and Bird Sentry are trademarks or registered trademarks of CareFusion Corporation or one of its

subsidiaries. All other trademarks are the property of their respective owners.

USA

CareFusion

22745 Savi Ranch Parkway

Yorba Linda, California 92887-4668

Authorized European Representative

CareFusion Germany 234 GmbH

Leibnizstrasse 7

97204 Hoechberg, Germany

District Court Wuerzburg HRB7004

800.231.2466 tel

+1.714.283.2228 tel

+1.714.283.8493 fax

carefusion.com

Literature number: L1383 Revision D

+49.931.4972.0 tel

+49.931.4972.423 fax

ii L1383 Rev. D

Page 3

Bird Sentry™ Blender

Revision History

Date Revision Description

February 1997 A Initial release.

March 1997 B

January 1998 C

September 2010 D Rebranded the document to the CareFusion style.

L1383 Rev. D

iii

Page 4

Bird Sentry™ Blender

Warranty

THE BIRD SENTRY™ BLENDER IS WARRANTED TO BE FREE FROM DEFECTS IN MATERIAL AND

WORKMANSHIP AND TO MEET THE PUBLISHED SPECIFICATIONS FOR ONE (1) YEAR.

The liability of CareFusion under this warranty is limited to replacing, repairing or issuing credit, at the

discretion of CareFusion, for parts that become defective or fail to meet published specifications during the

warranty period; CareFusion will not be liable under this warranty unless (A) CareFusion is promptly

notified in writing by Buyer upon discovery of defects or failure to meet published specifications; (B) the

defective unit or part is returned to CareFusion, transportation charges prepaid by Buyer; (C) the defective

unit or part is received by CareFusion for adjustment no later than four (4) weeks following the last day of

the warranty period; and (D) examination by CareFusion of such unit or part shall disclose, to its

satisfaction, that such defects or failures have not been caused by misuse, neglect, improper installation,

unauthorized repair, alteration or accident.

Any authorization of CareFusion for repair or alteration by the Buyer must be in writing to prevent voiding

the warranty. In no event shall CareFusion be liable to the Buyer for loss of profits, loss of use,

consequential damage or damages of any kind based upon a claim for breach of warranty, other than the

purchase price of any defective product covered hereunder.

CareFusion warranties as herein and above set forth shall not be enlarged, diminished or affected by, and

no obligation or liability shall arise or grow out of the rendering of technical advice or service by CareFusion

or its agents in connection with the Buyer's order of the products furnished hereunder.

Limitations of Liabilities

This warranty does not cover normal maintenance such as cleaning, adjustment or lubrication and

updating of equipment parts. This warranty shall be void and shall not apply if the equipment is used with

accessories or parts not manufactured by CareFusion or authorized for use in writing by CareFusion, or if

the equipment is not maintained in accordance with a prescribed schedule of maintenance.

The warranty stated above shall extend for a period of one (1) year from date of shipment with the

following exceptions:

1. Components for monitoring of physical variables such as temperature, pressure, or flow are warranted

for ninety (90) days from date of receipt.

2. Elastomeric components and other parts or components subject to deterioration, over which CareFusion

has no control, are warranted for sixty (60) days from date of receipt.

THE FOREGOING IS IN LIEU OF ANY WARRANTY, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT

LIMITATION, ANY WARRANTY OF MERCHANTABILITY, EXCEPT AS TO TITLE, AND CAN BE AMENDED

ONLY IN WRITING.BY A DULY AUTHORIZED REPRESENTATIVE OF CareFusion.

iv L1383 Rev. D

Page 5

Bird Sentry™ Blender

EMC Notice

This equipment generates, uses, and can radiate radio frequency energy If not installed and used in

accordance with the instructions in this manual, electromagnetic interference may result. The

equipment has been tested and found to comply with the limits set forth in IEC 601-1-2 for

Medical Products. These limits provide reasonable protection against electromagnetic interference

when operated in the intended use environments described in this manual.

MRI Notice

This equipment contains electromagnetic components whose operation can be affected by intense

electromagnetic fields.

Do not operate the Bird Sentry blender unattended in an MRI environment or in the vicinity of highfrequency surgical diathermy equipment, defibrillators, or shortwave therapy equipment.

Electromagnetic interference could disrupt the operation of the Bird Sentry blender.

Regulatory Notice

Federal law restricts the sale of this device except by and on order of a physician.

Declaration of Conformity Notice

This medical equipment complies with the Medical Device Directive, 93/42/EEC, and the following

Technical Standards, to which Conformity is declared:

IEC 601-1-2

IEC 601-1-2: 1993

ISO 9001: 1994

EN 46001, MDD-Annex-II

Type of Equipment: Medical Equipment, O

Blender/Monitor

Trade name: Bird Sentry

Model No.: 15625 Series

If you have any questions regarding the Declaration of Conformity for this product, please contact

CareFusion Corporation.

2

L1383 Rev. D

v

Page 6

Bird Sentry™ Blender

Read this entire manual before attempting to operate or service the Bird Sentry™

blender:

Attempting to operate the Bird Sentry blender without fully understanding its features and

functions may result in unsafe operating conditions.

Read the Safety Information section. It lists warnings, cautions, and notes pertinent to the safe

servicing of the Bird Sentry blender.

If you have a question regarding the installation, setup, operation, or maintenance of the Bird

Sentry blender, contact customer service at the following numbers:

Technical Support

Hours: 7:00 a.m. to 4:30 p.m. (PST), Monday through Friday

Tel.: 714.283.2228 or 800.231.2466

(Follow the prompts to technical support.)

Fax: 714.283.8471

support.vent.us@carefusion.com

CareFusion Helpline

Hours: 24 hours, 7 days a week

Tel.: 800.231.2466 or 800.328.4139

vi L1383 Rev. D

Page 7

Bird Sentry™ Blender

Safety Information

Review the following safety information before operating the Bird Sentry blender:

Definitions

Warning! Identifies a condition or practice that could result in serious adverse reactions or

potential safety hazards.

Caution! Identifies a condition or practice that could result in damage to the Bird Sentry blender

or other equipment.

Note: Identifies supplemental information to help you better understand how the Bird Sentry

blender works.

Warnings

The following warnings apply any time you operate or service the Bird Sentry blender:

● To avoid explosion, do not operate the Bird Sentry blender in the presence of flammable

anesthetics or in an atmosphere of explosive gases. Operating the Bird Sentry blender in

flammable or explosive atmospheres may result in fire or explosion.

● Do not operate the Bird Sentry blender unless qualified personnel are in attendance to promptly

respond to alarms, inoperative conditions, or sudden malfunctions. Patients on life-support

equipment should be visually monitored at all times.

● Do not ignore audible alarms occurring by the Bird Sentry blender. Alarms indicate conditions

that require your immediate attention.

● Do not use parts, accessories, or options that have not been authorized for use with the Bird

Sentry blender. Using unauthorized parts, accessories, or options may be harmful to the patient

or damage the Bird Sentry blender.

● Check all audible and visual alarms daily to make sure they are operating properly. If an alarm

fails to activate, contact your CareFusion Certified Service Technician.

● Consult a physician to determine concentration of inspired oxygen to be delivered.

● Do not operate the Bird Sentry blender without setting the adjustable alarms. All adjustable

alarms must be set to ensure safe operation.

● Explosion hazard. DO NOT gas sterilize the Bird Sentry blender.

● DO NOT steam autoclave or otherwise subject the Bird Sentry blender to temperatures above

122°F (50°C).

● If the air or oxygen gas source fails, the pressure differential alarm will sound alerting the

clinician that a condition has occurred that may significantly alter the FIO, and flow output from

the Bird Sentry blender.

● If either the air or oxygen source pressure is reduced or increased sufficiently to create a

pressure differential of 20 PSI or more, an audible alarm will sound. This condition may

significantly alter the FIO and flow output from the Bird Sentry blender.

● DO NOT use humidified oxygen to calibrate this system. If calibrated with humidified oxygen,

subsequent oxygen readings will be higher than the true oxygen level.

L1383 Rev. D

vii

Page 8

Bird Sentry™ Blender

● DO NOT tape, obstruct or remove the reed alarm during clinical use.

● DO NOT occlude the sensor port on the side of the Bird Sentry blender.

● Do not routinely disconnect or remove O

sensors from the Bird Sentry blender. If the sensor

2

must be disconnected, the full "warm-up" period, as stated in the sensor specifications, may be

required after the sensor is reconnected.

● The mixed gas bleed continuously bleeds to atmosphere at the oxygen concentration setting of

the control knob. Bleeding oxygen into any closed area could increase the risk of fire or

explosion. Do not operate this device in the presence of any flame or source of ignition; or

when using devices such as electrosurgical equipment or defibrillators.

Cautions

● Do not attempt to clean the Bird Sentry blender with cleaning agents that contain phenols,

ammonia chloride, or chloride compounds, or that contain more than 2% glutaraldehyde.

These agents may damage the plastic components and control panel overlays.

● Dropping or severely jarring the sensor after calibration may shift the calibration point enough

to require recalibration.

● Using the Bird Sentry blender to analyze and monitor oxygen concentrations other than at the

sensor port of the unit will require recalibration of the sensor.

● Always operate the Bird Sentry blender with clean, dry medical grade gases. Contaminates or

moisture can cause defective operation. Oxygen should have a minimum dew point of -80°F (62°C) or moisture content less than 7.9 PPM (0.0059mg/L). Oxygen "purity" should be at least

99.6% and air used should be medical grade. Water vapor content must not exceed a dew

point of 5°F (3°C) below the lowest ambient temperature to which the delivery system is

exposed. Particulate content must not exceed that which would be found immediately

downstream of a 15 micron absolute filter. Refer to CGA commodity specifications G-4.3 and

G7.1 for more information. Water vapor content of medical air or 0, supply to the blender must

not exceed 5.63 x 103 milligrams H2O per cubic meter of non-condensable gas.

● When disassembling, care must be exercised to prevent damaging the printed circuit board. All

work must be accomplished in a static safe environment.

● This device has not been tested in the presence of gases other than air or oxygen.

Notes

● The Bird Sentry blender is tested for compliance with ISO 11195:1995, clause 6, and meets

requirements regarding reverse gas flow as delivered.

● Applicable parts used in the Bird Sentry blender have been cleaned and degreased for oxygen

service. Any lubricants used are designed specifically for the application. Do not use anything

other than CareFusion specified lubricants when servicing the Bird Sentry blender.

● As long as the total pressure of the gas mixture being monitored is constant, the Bird Sentry

blender will accurately read oxygen concentrations. However, if the total pressure varies the

reading will fluctuate proportionately as the sensor actually measures the partial pressure of

oxygen in the mixture. The sensor readings will also change proportionately with barometric

pressure changes. Because of this, daily calibration of the sensor is recommended.

viii L1383 Rev. D

Page 9

Bird Sentry™ Blender

● Users are advised to use pressure regulators, set to 50 ±5 PSIG(3.4± .4 BAR), which display

system pressure.

● All specifications assume the following standard environ mental conditions, unless specified

otherwise. Ambient and sample gas temperatures of 77°F (25°C); barometric pressure of 30:Hg

(760mmHg); sea level altitude; ambient relative humidity of 50%; sample gas relative humidity

of 0%

● It is important to note that the oxygen concentration selection scale is provided only as a

guideline for selecting 0, concentrations. The clinician should use the display panel of the Bird

Sentry blender to adjust the O

Equipment Symbols

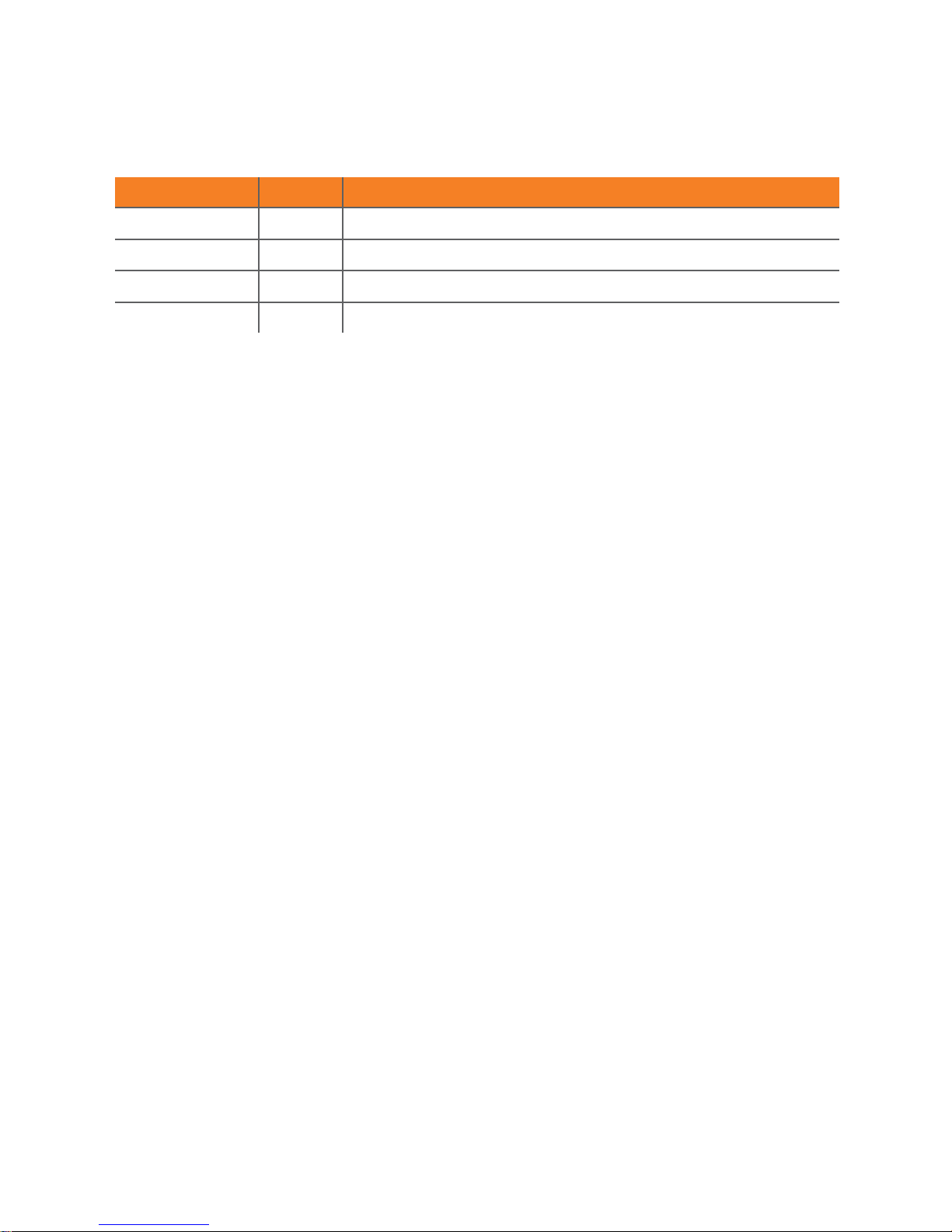

The following symbols appear on the Bird Sentry blender.

Symbol Compliance Meaning

concentration to the desired setting.

2

IEC 578

Symbol #03- O

2

IEC 417

Symbol #5016

IEC 417

Symbol #5034

IEC 878

Symbol #01-08

IEC 878

Symbol #01-07

Attention, consult the accompanying

documents.

Fuse

Input

Standby (circuitry off) position of the

On/Off switch. It does NOT switch the

blenders mixing ability to turn power

off.

On condition for the display circuitry

of the equipment.

CareFusion products symbol Lock (used to prevent accidental

changes to set values.)

The front panel Lock icon is

illuminated when the control panel is

locked.

CareFusion product symbol Silence condition of the audible alarm

for a period of up to two minutes

(120 sec.)

L1383 Rev. D

ix

Page 10

Bird Sentry™ Blender

Bird Sentry™ Blender

x L1383 Rev. D

Page 11

Bird Sentry™ Blender

Contents

Revision History .............................................................................................................. iii

Warranty ....................................................................................................................... iv

Limitations of Liabilities .................................................................................................. iv

EMC Notice .................................................................................................................... v

MRI Notice ...................................................................................................................... v

Regulatory Notice ............................................................................................................ v

Declaration of Conformity Notice .................................................................................... v

Technical support ........................................................................................................... vi

CareFusion helpline ........................................................................................................ vi

Safety Information ......................................................................................................... vii

Chapter 1: Introduction ....................................................................................................... 1

Intended Use .................................................................................................................. 1

Front Panel Functional Description ................................................................................... 2

Bottom View ................................................................................................................... 4

Disposable Galvanic O

Sensor ......................................................................................... 5

2

What You Will Need to Operate the Blender .................................................................... 6

What to Do If the Blender Fails ........................................................................................ 6

How to Get Help ............................................................................................................. 6

Chapter 2: Operating Procedures ......................................................................................... 7

Monitoring ..................................................................................................................... 7

Alarm Setting Procedure .................................................................................................. 7

Basic Operation ............................................................................................................... 8

Alarms and Conditions .................................................................................................... 8

Calibration Procedures .................................................................................................... 9

Automatic Calibration to Known Concentration ............................................................. 10

Chapter 3: Pressure Differential Alarm/Bypass Check .......................................................... 11

Chapter 4: Troubleshooting ............................................................................................... 13

Chapter 5: Cleaning the Bird Sentry Blender ...................................................................... 15

Chapter 6: Servicing and Maintaining the Bird Sentry Blender ............................................. 17

Maintenance ................................................................................................................. 17

Disposable Galvanic O

Sensor Cable ............................................................................. 17

2

Servicing ....................................................................................................................... 18

L1383 Rev. D

xi

Page 12

Bird Sentry™ Blender

Chapter 7: Appendices ...................................................................................................... 19

Glossary ....................................................................................................................... 19

Specifications ................................................................................................................ 19

Setup and Installation ................................................................................................... 21

Theory of Operations .................................................................................................... 22

Flow Characteristics ...................................................................................................... 25

xii L1383 Rev. D

Page 13

Bird Sentry™ Blender

Chapter 1: Introduction

The Bird Sentry blender is a compact air/oxygen gas mixing device which incorporates the use of a

battery powered oxygen analyzer/monitor. The gas mixing device (blender) provides for precise mixing

of medical grade air and oxygen, while the analyzer measures the selected oxygen concentrations from

the blender's gas flow and samples and displays these measured concentrations on a digital display.

The monitor provides high and low alarm limits which, when exceeded, cause an audible/ visual alarm

to activate.

The Bird Sentry blender design allows for a wide scope of applications including:

● Free-flow oxygen administration

● Mechanical ventilation of adults, pediatrics, and neonates.

● Continuous Positive Airway Pressure (CPAP)

Intended Use

The Bird Sentry blender is designed to provide a continuous air/oxygen gas mixture to infant, pediatric,

and adult patients. It is a restricted medical device intended for use by qualified, trained personnel,

under the direction of a physician, in institutional environments where the delivery and monitoring of

air/oxygen mixtures is required.

L1383 Rev. D

1

Page 14

Chapter 1: Introduction Bird Sentry™ Blender

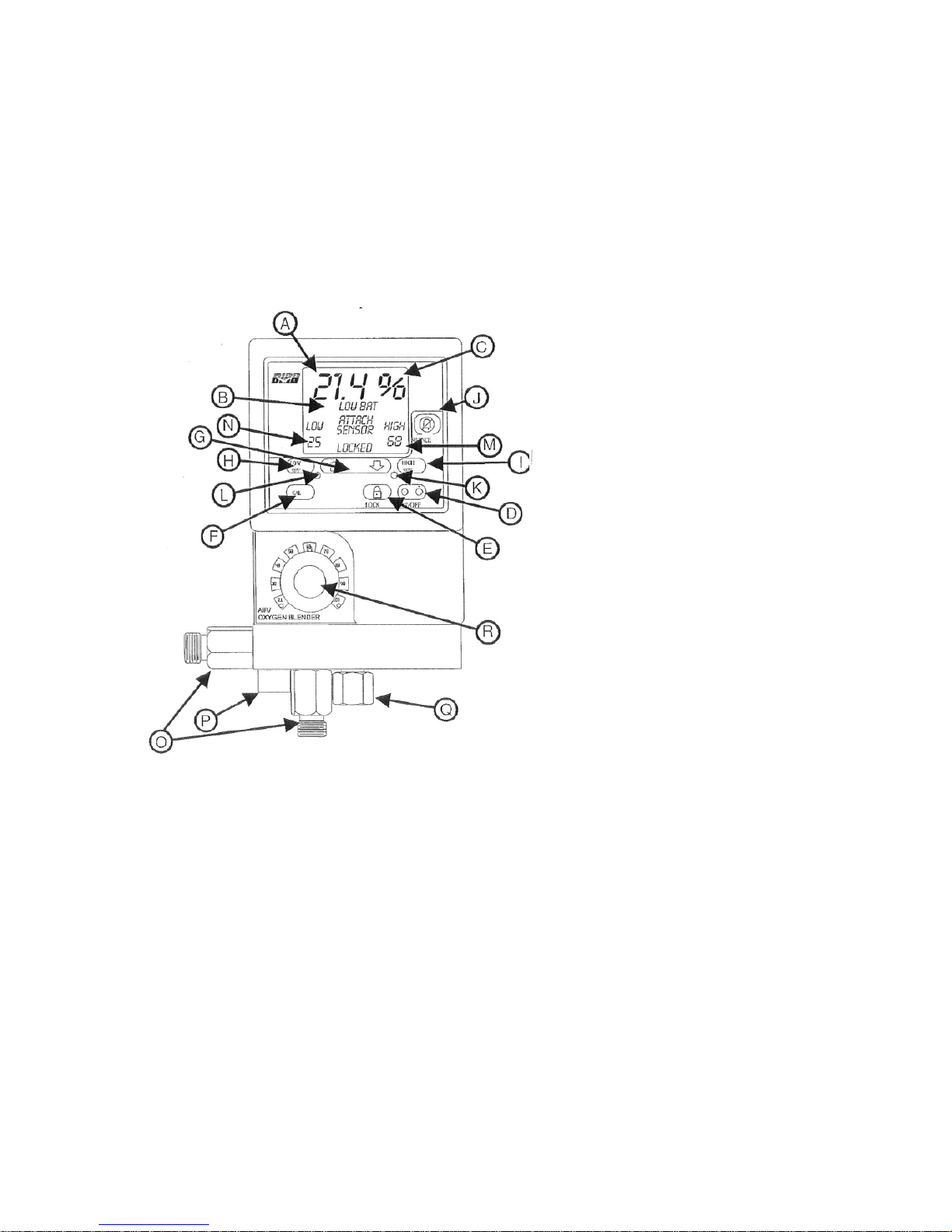

Front Panel Functional Description

A Display

A digital liquid crystal display provides direct readout of oxygen concentrations in the range of 0 to

100%. It also displays CAL when the calibration mode is entered.

B Battery Low Indicator

The low battery indicator appears on the LCD display when the power supply voltage drops below

acceptable limits. When the LOW BAT icon is visible, the batteries should be replaced.

Figure 1 Front panel

C % Sign

In the calibration mode, the% sign flashes every second.

D Power ON/OFF Key

This key is used to turn on or off. The blender will continue to function and deliver mixed gas with

display turned to OFF. When the ON/OFF key is pressed once, the Bird Sentry blender will start to

display the oxygen concentration and the keypad is activated. If the ON/OFF key is pressed again,

the Bird Sentry blender reverts to the display power off mode.

E Lock Key

Pressing the LOCK key will unlock the keypad and cause the LOCKED icon to disappear from the

LCD readout. The Bird Sentry blender can then be calibrated and alarm settings can be changed if

desired. If no other keys are pressed within 10 seconds, the LOCKED icon will reappear and the

unit will revert to the LOCKED mode. When the unit is in the unlocked state, pressing the LOCK

key will also cause the LOCKED icon to reappear.

2 L1383 Rev. D

Page 15

Bird Sentry™ Blender Chapter 1: Introduction

F Calibrate Key

When the keypad is unlocked, the CAL key is used in conjunction with the UP and DOWN arrow

keys to calibrate the Bird Sentry blender. When the CAL key is pressed, CAL appears on the LCD

readout for one second, and then the measured calibration. The % sign will flash at a one per

second rate. When the calibration value is set, pressing the CAL or LOCK key will cause the unit to

exit the calibrate mode and return to normal operation. The unit will also revert to normal

operation if 10 seconds elapse and no keys are pressed.

G Up and Down Arrow Keys

The UP and DOWN arrow keys are used to adjust settings or to calibrate the Bird Sentry blender.

When used after pressing the CAL key, pressing these keys raise or lower the displayed oxygen

value in 0.1% increments. When either of these keys is held down for more than one second, the

display scrolls at a rate of 0.4% per second. When used after pressing either the LOW SET or HIGH

SET keys, pressing the UP or DOWN arrow key raises or lowers the displayed alarm setting in 1%

increments. In the alarm set mode, holding these keys down for more than one second causes the

display to scroll at a rate of 4% per second.

H LOW SET Key

When the keypad is unlocked, pressing the LOW SET key will cause the LOW icon to flash. The low

alarm setting can then be changed using the UP and DOWN arrow keys. When the low alarm

value is set and the LOW SET or LOCK key is pressed again, the Bird Sentry blender exits the alarm

set mode and returns to normal operation. The Bird Sentry blender will also revert to normal

operation (storing the most recent alarm value) if 10 seconds elapse and no keys are pressed.

I HIGH SET Key

When the keypad is unlocked, pressing the HIGH SET key will cause the HIGH icon to flash. The

high alarm setting can then be changed using the UP and DOWN arrow keys. When the high

alarm value is set and the HIGH SET or LOCK key is pressed again, the unit exits the alarm set

mode and returns to normal operation. The unit will revert to normal operation (storing the most

recent alarm value) if 10 seconds elapse and no keys are pressed.

J Silence Key

In an alarm condition, pressing the SILENCE key will deactivate the alarm beep, but the alarm LED

and display will continue to flash. In 120 seconds, the alarm beeper will sound again. This process

will be repeated until the alarm condition is cancelled. The concentration must be raised 0.1%

higher than the alarm setting (in the presence of a low alarm condition) or 0.1% lower than the

alarm setting (in the presence of a high alarm condition).

K High Alarm Visual Display

A red indicator light which illuminates when the high alarm limit has been exceeded.

L Low Alarm Visual Display

A red indicator light which illuminates when the low alarm limit has been exceeded.

M High Alarm Display

The high alarm setting is displayed at all times just below the HIGH icon on the LCD readout. The

indicated value represents the oxygen percentage at which the high alarm will be activated in the

High Alarm Set mode. The high icon will flash at a one-second rate. The high alarm value will flash

in conjunction with the high alarm LED.

L1383 Rev. D

3

Page 16

Chapter 1: Introduction Bird Sentry™ Blender

N Low Alarm Display Control

The low alarm setting is displayed at all times just below the LOW icon on the LCD readout. The

indicated value represents the oxygen percentage at which the low alarm will be activated. In the

Low Alarm Set mode, the LOW icon will flash at a one-second rate. In a low alarm condition, the

low alarm value will flash in conjunction with the low alarm LED.

O Outlet Port

A diameter indexed (DISS) oxygen fitting that, when connected with a pneumatic metering device

(such as a flow meter or ventilator), delivers flows from the Bird Sentry blender from 2–100 LPM.

P Medical Air Inlet Connector

A diameter indexed (DISS) air fitting for connection to an air-inlet hose from the air-gas source.

Q Oxygen Inlet Connector

A diameter indexed (DISS) oxygen fitting for the connection of an oxygen-inlet hose from the

oxygen-gas source.

R Oxygen Concentration Selector Control

A knob that allows selections of mixed oxygen concentrations from 21 to 100%.

Note:

The oxygen-concentration selection scale is provided only as a guide for selecting O2

concentrations. You should use the Bird Sentry blender display panel to adjust the O

concentration as needed.

2

Bottom View

A Dovetail Mount Adapter

An adapter that allows the Bird Sentry blender to be mounted onto a mating bracket for

mounting to a rail or ventilator system.

Figure 2 Bottom view

4 L1383 Rev. D

Page 17

Bird Sentry™ Blender Chapter 1: Introduction

B Outlet Port

See Figure 1, letter O.

C O

Sensor Port

2

A sampling port for the oxygen sensor. It allows 3 LPM of mixed gas from the blender to flow over

the sensor membrane. The port is located on the back side of the plate.

D Medical Air Inlet Adapter

See Figure 1, letter P.

E Oxygen Inlet Adapter

See Figure 1, letter Q.

F Pressure Differential Reed Alarm Cap

An audible alarm that, when activated, indicates that a pressure differential of 20 PSI or more

exists between the two gas-source pressures.

Disposable Galvanic O2 Sensor

The sensor is a galvanic, partial pressure sensor that is specific to oxygen. It consists of two electrodes

(a cathode and an anode), a Teflon membrane and an electrolyte. Oxygen diffuses through the Teflon

membrane and immediately reacts at a gold cathode. Oxygen ions are transported in the unique

electrolyte solution to a lead anode where oxidation occurs, generating an electrical current. Since the

sensor is specific to oxygen, the current generated is proportional to the amount of oxygen present in

the sample gas. When no oxygen is present, there is no chemical reaction and therefore, no current is

produced. In this sense, the sensor is self-zeroing.

Figure 3 Disposable galvanic O2 cell

A Disposable Galvanic O2 Cell (Refer to Figure 3)

A replaceable cartridge which contains the active elements of the galvanic oxygen sensor. When

exhausted, the cell is discarded and replaced with a new cell.

L1383 Rev. D

5

Page 18

Chapter 1: Introduction Bird Sentry™ Blender

What You Will Need to Operate the Blender

●

Pressurized Oxygen

oxygen at a line pressure of 40 to 60 PSIG (2.8 to 4.2 bar).

●

Pressurized Air

to 60 PSIG (2.8 to 4.2 bar).

. The compressed oxygen source must provide clean and dry, medical grade

. The air source must provide clean and dry, medical grade air at a line pressure of 40

What to Do If the Blender Fails

If a condition is detected that could possibly prevent the blender from continuing to operate safely, it

sounds an alarm. If at any time, ERX (Er1, Er4, etc.) appears on the LCD, contact a service technician,

certified by CareFusion.

Warning!

Do not operate the blender unless qualified personnel are in attendance to promptly respond to

alarms, inoperative conditions, or sudden malfunctions.

How to Get Help

If you have a question regarding the installation, setup, operation, or maintenance of the Bird Sentry blender,

contact customer service at the following numbers:

Technical support:

Hours: 7:00 a.m. to 4:30 p.m. (PST), Monday through Friday

Tel. 714.283.2228

(Follow the prompts to technical support.)

Fax 714.283.8471

support.vent.us@carefusion.com

CareFusion helpline:

Hours: 24 hours, 7 days a week

Tel. 800.231.2466 or 800.328.4139

6 L1383 Rev. D

Page 19

Bird Sentry™ Blender

Chapter 2: Operating Procedures

Before placing the Bird Sentry blender into clinical use, the performance check described in Chapter 3

should be performed. Refer to Appendix C for Setup and Installation.

Monitoring

To begin monitoring, press the ON/OFF button located on the front panel (if necessary). Monitoring will

begin immediately.

Should oxygen level exceed either the HIGH or LOW alarm set points, the red alarm indicator on the

front panel will illuminate indicating either a high or low concentration reading, and an oxygen level

returns to within limits or the limits are adjusted.

To conclude monitoring, press the ON/OFF button located on the front panel.

This will place the blender in a standby mode in which the display and alarm circuits are not functional,

but the gas-blender supply hoses will continue to supply mixed gas if the inlet hoses have not been

disconnected.

Alarm Setting Procedure

Low Alarm Setting

To adjust the low alarm setting:

1. Press the LOCK key to unlock the keypad.

2. Press the LOW SET key. The LOW icon will start to flash.

3. Use the UP and DOWN arrow keys to set the low alarm to the desired value. Pressing the arrow

keys changes the value in 1% increments. If the keys are held down for more than 1 second, the

display will scroll at a rate of 4% per second.

Note:

If 10 seconds elapse between key actuations, the system will store the latest low alarm

value and will revert to normal operation. If this occurs inadvertently, simply repeat the

alarm-setting procedure.

The low alarm value cannot be set lower than 18%, nor can it be set closer than 1% from the

high alarm value. For example, if the high alarm is set at 25%, the system will not accept a low

alarm setting greater than 24%.

4. When the low alarm value is set, press the LOW SET or LOCK key again to accept the low alarm

setting and return to normal operation.

Note:

To automatically set the low alarm to 18% without scrolling the display, hold the LOW SET

key down and press the arrow key when the LOW icon is flashing.

L1383 Rev. D

7

Page 20

Chapter 2: Operating Procedures Bird Sentry™ Blender

High Alarm Setting

To adjust the high alarm setting:

1. Press the LOCK key to unlock the keypad.

2. Press the HIGH SET key. The HIGH icon will start to flash.

3. Use the UP and DOWN arrow keys to set the high alarm to the desired value.

The high alarm value cannot be set closer than 1% from the low alarm value. For example, if the

low alarm is set at 50%, the system will not accept a high alarm setting less than 51%. Setting the

high alarm to 100% turns off or deactivates the high alarm.

4. When the high alarm value is set, press the HIGH SET key again to accept the high alarm setting

and return to normal operation.

Note:

To automatically set the high alarm to 50% without scrolling the display, hold the HIGH

SET key down, and then press the DOWN ARROW key when the HIGH icon is flashing. To

automatically turn off the high alarm or set it to 100%, hold the HIGH SET key down and

then press the UP ARROW key when the HIGH icon is flashing.

Basic Operation

To check the oxygen concentration of a sample gas:

1. Place the sensor probe in the sensor port on the Bird Sentry blender. If using a standard T adapter

in an alternate location, make sure the sensor is mounted in the adapter with the flow diverter

pointing downward. This will prevent moisture from draining into the sensor membrane.

Note:

It is important that a tight fit exists between the probe and the T adapter

2. Initiate flow of the sample gas to the sensor.

3. Using the ON/OFF key, make sure the Bird Sentry blender is in the Power On mode.

4. Allow the oxygen reading to stabilize. This will normally take about 30 seconds or more.

Alarms and Conditions

In the event of either a low-alarm or high-alarm condition, the corresponding LED will begin to flash,

accompanied by the alarm buzzer. Pressing the SILENCE key will deactivate the buzzer, but the LED and

the alarm value digits on the display will continue to flash until the alarm condition has been rectified.

If the alarm condition still exists 120 seconds after silencing the alarm buzzer, the buzzer will start to

sound again.

Note:

A low alarm condition will remain until the actual concentration is 0.1% higher than the low

alarm setting. A high alarm condition will remain until the actual concentration is 0.1% lower

than the high alarm setting.

8 L1383 Rev. D

Page 21

Bird Sentry™ Blender Chapter 2: Operating Procedures

Calibration Procedures

The Bird Sentry blender should be calibrated before being placed into clinical use. Thereafter,

CareFusion recommends calibration of the unit on a daily basis. Frequent calibration will have no

adverse effect on the performance of the Bird Sentry blender.

Calibration should also be performed upon replacement of a sensor or when point-of-use elevation

changes by more than 500 feet or 150 meters. The sensor is best calibrated while mounted in the Bird

Sentry sensor port. As in normal operation, the oxygen sensor responds best when installed in a vertical

position with the sensor facing down.

It is best to calibrate the Bird Sentry blender using the sensor port, and with a technical grade oxygen

standard (99.996% or better) at a pressure and flow similar to your application. Calibration of the unit

at lower concentrations or with room air is less desirable.

● Ensure that gas supply lines are connected and the sensor is plugged into the O

● Turn on both gas supplies, turn on the Bird Sentry blender, and rotate the FiO

sensor port.

2

control knob to the

2

100 stop. Turn off the air supply.

● If the LOCKED icon is displayed, press the LOCK key. The icon should disappear.

● Press the CAL key, the CAL icon will be displayed momentarily which will be followed by a flashing

%icon.

● Pressing the UP and DOWN arrow keys will adjust the displayed oxygen concentration as required

to 100.0%.

● After the value is set, press the CAL or LOCK keys to return to normal operation.

Note:

If 10 seconds elapse between key actuations, the system will store the latest calibration

value and will revert to normal operation. If this occurs inadvertently, repeat the calibration

procedure.

Note:

If CAL followed by Er flashes on the display after entering the calibration value, the system

has determined that the entered value will not allow operation within the specified output

range of the sensor. This situation may occur if:

● The operator has inadvertently entered the wrong concentration for the calibration gas.

● The concentration of the calibration gas is not correct.

● The sensor is in need of replacement.

● The operator attempted to adjust the analyzer before allowing sufficient time for the calibration

gas to purge out the previous sample.

● The flow and pressure of the calibration gas was not properly regulated. Check these items and

repeat calibration. If calibration error continues to occur, contact technical support.

L1383 Rev. D

9

Page 22

Chapter 2: Operating Procedures Bird Sentry™ Blender

Automatic Calibration to Room Air

The Bird Sentry blender can be quickly calibrated to room air (20.9%) using a quick shortcut command.

This function saves time by setting the calibration value to 20.9% without scrolling the display. To use

this function:

1. Place the external probe in room air.

2. Press the LOCK key to unlock the keypad.

3. Press and hold down the CALIBRATE key. When the 96 icon starts to flash, press the DOWN arrow

key to set the calibration value to 20.9%.

4. Release both the CALIBRATE key and the DOWN arrow key.

The unit will automatically enter the LOCKED condition and return to normal operation.

Automatic Calibration to Known Concentration

The Bird Sentry blender can be quickly calibrated to the previous calibration value if a known, reliable

standard is used for successive calibrations. This quick key function saves times by setting the

calibration value to the last calibration value used, without scrolling the display. To use this function;

1. Introduce the previously used oxygen % standard to the sensor.

2. Press the LOCK key to unlock the keypad.

3. Press and hold down the CALIBRATE KEY. When the 96 icon starts to flash, press the arrow key to

set the calibration value to the primary setting.

4. Release both the CALIBRATE key and the DOWN arrow key.

The unit will automatically enter the LOCKED condition and return to normal operation.

Caution!

Do not use humidified oxygen to calibrate this system. If calibrated with humidified

oxygen, subsequent oxygen readings will be higher than the true oxygen level.

Dropping or severely jarring the sensor after calibration may shift the calibration point

enough to require recalibration.

Variations in inlet gas source pressures will alter the accuracy of the oxygen readings of the

Bird Sentry blender.

Using the Bird Sentry blender to analyze and monitor oxygen concentrations other than at

the sensor port of the unit will require recalibration of the sensor.

10 L1383 Rev. D

Page 23

Bird Sentry™ Blender

Chapter 3: Pressure Differential Alarm/Bypass Check

Before placing the Bird Sentry blender into clinical use, periodically perform the following tests.

Warning!

If the Bird Sentry blender does not function as described in this chapter, contact your

CareFusion distributor or CareFusion. DO NOT use the Bird Sentry blender until correct

performance has been verified.

Connect the 50 ±5 PSIG (3.4 ±0.3 BAR) oxygen and air supply sources to the inlet connectors located

on the bottom of the Bird Sentry blender. Ensure the Bird Sentry blender is properly placed in sensor

port and Bird Sentry display is on.

Note:

Before proceeding, ensure that the high-alarm set point control is OFF (--) and that the low

alarm set point control is below 20.

PROCEDURE BIRD SENTRY™ RESPONSE

1. Adjust the oxygen concentration such that

the display reads 60% O

±3%.

2

2. Disconnect the 50 PSIG AIR source from the

Bird Sentry blender.

3. Reconnect 50 PSIG AIR source to the Bird

Sentry blender.

4. Disconnect 50 PSIG OXYGEN source from the

Bird Sentry blender.

5. Reconnect 50 PSIG OXYGEN to the Bird

Sentry blender.

6. Adjust the air and oxygen inlet regulators to

0 PSIG.

7. Remove the air-inlet hose from the regulator,

and insert the end into a beaker of water.

8. Slowly raise the pressure of oxygen regulator

to 50 PSIG and back to 0 PSIG while

observing air hose end in beaker.

9. Dry and reattach the air inlet hose to the

regulator.

No response.

Audible alarm sounds.

Display reads 100% O

±2%.

2

Audible alarm stops. Verify that the display

panel reads 50% ±5%.

Audible alarm sounds.

Display reads 20.9% ±2%.

Audible alarm stops. Verify that the display

panel reads 60% ±5%.

No response.

No response.

No bubbles should be observed. Audible

alarm sounds.

No response.

10. Remove the oxygen-inlet hose from the

regulator, and insert the end into beaker of

water.

L1383 Rev. D

No response.

11

Page 24

Chapter 3: Pressure Differential Alarm/Bypass Check Bird Sentry™ Blender

PROCEDURE BIRD SENTRY™ RESPONSE

11. Slowly raise the pressure of air regulator to

50 PSIG and back to 0 PSIG while observing

the oxygen hose end in beaker.

12. Dry and reattach the oxygen inlet hose to the

regulator.

No bubbles should be observed. Audible

alarm sounds.

No response.

12 L1383 Rev. D

Page 25

Bird Sentry™ Blender

Chapter 4: Troubleshooting

Problem Potential causes and solutions

Oxygen concentration discrepancy between

oxygen concentration selection knob and

actual reading on display.

1. Monitor out of calibration. Calibrate. Refer

to Ch.2, Calibration Procedure.

2. Sensor exhausted. Replace. Refer to Ch. 6,

Service and Maintenance.

3. Outlet flows are below specified range.

Correct flow. Must be above 2 LPM.

4. Gas supply contaminated. Contact

CareFusion Corporation for repair of the

Bird Sentry blender.

5. Bird Sentry blender operation out of

calibration. Contact CareFusion distributor

or CareFusion Corporation for repair.

Pressure Differential Alarm Sounding. 1. Inlet pressure differences of 20 PSI or

more. Correct pressure difference.

2. Pressure alarm not calibrated properly.

Contact CareFusion distributor or

CareFusion Corporation for repair.

3. Bird Sentry blender operation out of

calibration. Contact CareFusion distributor

or CareFusion Corporation for repair.

Bird Sentry blender in bypass mode, no audible

pressure differential alarm.

Reed alarm cap damaged or defective.

Contact CareFusion distributor or CareFusion

Corporation for repair.

Selected oxygen concentration accurate only

when gas pressures are equal.

Bird Sentry blender balance module not

functioning properly. Contact CareFusion

distributor or CareFusion Corporation for

repair.

Blank display. 1. Battery not installed. Install. Refer to

Appendix C, Setup and Installation,

Battery Installation.

2. Battery completely dead. Replace. Refer to

Appendix C, Setup and Installation,

Battery Installation.

3. Monitor defective. Contact CareFusion

distributor or CareFusion Corporation for

repair.

Partial or distorted display. Monitor damaged. Contact CareFusion

distributor or CareFusion Corporation for

repair.

L1383 Rev. D

13

Page 26

Chapter 4: Troubleshooting Bird Sentry™ Blender

Problem Potential causes and solutions

Sensor will not calibrate. 1. Sensor cell exhausted. Replace.

Refer to Ch. 6, Service and Maintenance.

2. Sensor cable or holder defective. Return to

CareFusion Corporation.

3. Monitor defective. Contact CareFusion

distributor or CareFusion Corporation for

repair.

Sensor will calibrate, but takes too long to

return to 21% ±2% oxygen in air (2 to 5

minutes) when performing the daily check

procedure.

Sensor will calibrate, but does not return to

21% ±2% oxygen in air (2 to 5 minutes) when

performing daily check procedure.

Sensor will calibrate, but reading at any

constant level drifts more than±3% over a 24

hour period.

Sensor exhibits greater than 1% oxygen

interference in the presence of gases or vapors

listed in the sensor specifications.

Disposable oxygen sensor damaged or

defective. Replace. Refer to Ch. 6, Service and

Maintenance, Disposable Galvanic O

Sensor

2

Cable.

Disposable oxygen sensor damaged or

defective. Replace.

1. Barometric pressure change since last

calibration. Recalibrate.

2. Room or gas temperature went below

59°F (15°C) or above 104°F (40°C).

Correct temperature and recalibrate.

1. Sensor defective. Replace.

2. The Bird Sentry blender requires internal

adjustment. Contact CareFusion

distributor or CareFusion Corporation for

repair.

14 L1383 Rev. D

Page 27

Bird Sentry™ Blender

Chapter 5: Cleaning the Bird Sentry™ Blender

Warning!

Explosion hazard. DO NOT gas sterilize the Bird Sentry blender.

The Bird Sentry blender should be kept clean and free of dust. The exterior of the Bird Sentry blender

may be cleaned with a soft cloth lightly dampened with warm soapy water or mild disinfectant. An allpurpose cleaner may be used on the exterior of the Bird Sentry blender. Store the Bird Sentry blender in

a clean, dry place when not in use.

Note:

Only the exterior of the Bird Sentry blender may be cleaned by using an all-purpose cleaner.

1. Do not steam autoclave or otherwise subject the Bird Sentry sensor to temperature over 120°F

(50°C),

2. Do not immerse the Bird Sentry blender or sensor into liquid decontamination agents.

3. Do not use any strong solvent cleaners on labels.

L1383 Rev. D

15

Page 28

Chapter 5: Cleaning the Bird Sentry™ Blender Bird Sentry™ Blender

Bird Sentry™ Blender

16 L1383 Rev. D

Page 29

Bird Sentry™ Blender

Chapter 6: Servicing and Maintaining the Bird Sentry™ Blender

Warning!

There are no user-serviceable components inside this device. All service should be referred to a

CareFusion trained hospital/dealer service technician or CareFusion.

If you have any problems operating the Bird Sentry blender, read the instructions again or consult the

troubleshooting guide in Chapter 4.

Caution!

If the Bird Sentry blender does not function as outlined in Chapter 2, contact a CareFusion

trained service technician or CareFusion Corporation for service.

Maintenance

The Bird Sentry blender has been designed to provide the maximum amount of utilization with a

minimum of maintenance. It is a good idea, however, to keep it clean and free of dust. Refer to

Chapter 5 on cleaning the Bird Sentry blender.

The Bird Sentry blender, like other pieces of Health Care equipment, will require routine maintenance

over a period of time. Before placing the Bird Sentry blender into clinical use, and periodically

thereafter, please follow the performance check guidelines listed in Chapter 3.

When using the Bird Sentry blender with a medical grade compressed air source, and air inlet watertrap/filter is recommended to be attached to the air inlet of the Bird Sentry blender before use.

Contaminants from hospital air lines may compromise the function of the Bird Sentry blender.

Elastomer components such as 0-rings are designed to function satisfactorily for a minimum of two (2)

years. CareFusion Corporation recommends that the Bird Sentry blender be overhauled and serviced at

a minimum of every two (2) years under the best circumstances.

Warning!

Do not routinely disconnect or remove O2 sensors for the Bird Sentry blender. If the sensor must

be disconnected, the full "warm-up" period, as stated in the sensor specifications, may be

required after the sensor is reconnected.

Disposable Galvanic O2 Sensor Cable

The Disposable Galvanic Sensor is designed to provide a minimum of 750,000 O2 hours of service

(approximately 2 years of use). Disposable Galvanic O

problems listed in Chapter 4, Troubleshooting, dictate the need to do so.

Sensor should be replaced whenever any of the

2

L1383 Rev. D

17

Page 30

Chapter 6: Servicing and Maintaining the Bird Sentry™ Blender Bird Sentry™ Blender

To replace the Disposable Galvanic O

Sensor. Refer to Figure 6.1.

2

1. Remove the sensor from the sensor monitor port.

2. Remove and discard the used Disposable Galvanic Sensor Refill.

3. Install a new Disposable Galvanic O

4. Calibrate the sensor following the instructions for daily calibration listed in Chapter 3, Performance

Servicing

Caution!

When disassembling, care must be exercised to prevent damaging printed circuit board. All

work must be accomplished in a static safe environment.

1. Remove batteries. Refer to Appendix C.

2. Remove galvanic sensor from sensor port and disconnect from coiled cable. Refer to page 6-2.

3. Using a 11/16 inch wrench, remove bottom port connector. Exercise caution as bottom outlet

4. Using a proper screwdriver (Phillips), remove four (4) cross-recessed screws holding front bezel to

5. Carefully pull front bezel forward and disconnect red and black cables from the battery case. Set

Sensor as shown in Fig. 6.1, taking care not to be used with

2

excessive force when plugging and/or threading the mini plug into the O

sensor.

2

Check.

block is attached by this connector. Remove and discard three (3) o-rings from connector. Remove

and discard sensor port bleed muffler from bottom outlet block by carefully prying out ring clip.

Set block and connector aside for cleaning and reassembly.

main case.

all parts aside for reassembly.

6. Neither the circuit board or keypad are serviceable. If it determined that the keypad or circuit

board are defective, with proper screwdriver (Phillips) remove four (4) cross-recessed screws

holding the circuit board to front bezel. Package the keypad and circuit board carefully in proper

static safe materials and return to CareFusion Corporation. Contact CareFusion for a returned

goods authorization before sending the unit in for service.

7. Using a hex tool, remove the two (2) hex screws from the rear of the case. Exercise caution as the

MicroBlender will be loose and is heavy. Slide the MicroBlender out from the case and two (2)

screws aside for reassembly.

The MicroBlender is now serviceable as a 3800 High Flow MicroBlender. The 3800 MicroBlender must

be serviced by CareFusion certified technicians. Please refer to L1009 for proper cleaning and service.

18 L1383 Rev. D

Page 31

Bird Sentry™ Blender

Chapter 7: Appendices

Glossary

Term Description

Air/ O2 Mixture of compressed air and oxygen

°C Degrees Celsius

CGA Compressed Gas Association

DISS Diameter Indexed Safety System

°F Degrees Fahrenheit

FIO2 Fractional Concentration of Inspired Oxygen

O2 Oxygen

LPM Liters-per-minute

P/N Part number

PSIG Pounds Per Square Inch Gauge

Specifications

Instrument Specifications

Weight (unpackaged) 4.5lbs. (2 kg.)

Power source Two AA alkaline batteries, 1.5 V each

Battery life 1500 hours (continuous operation, no alarming)

Oxygen measurement range 0 to 100% oxygen

Display resolution 0.1% oxygen

O2 Concentration adjustment range 21 to 100% O2

Gas supply pressure range 30-75 PSIG (2.0 to 5.2 BAR) (air and oxygen must be

Pressure drop Less than 6 PSI (0.4 BAR) at 50 PSIG (3.4 BAR) supply

within 20 PSI (1.3 BAR) Do not operate the blender

outside the supply pressure range (30-75 PSIG). Do not

operate unit between 0 and 30 PSIG or above 75 PSIG

supply pressures. Optimal performance is with gases at 50

PSIG nominal.

pressures and 40 LPM flow rate (Refer to Appendix E)

Bleed flow 11-13 LPM at 50 PSIG (3.4 BAR)

Outlet flow range 2-100 LPM with supply pressures at 50 PSIG (3.4 BAR) air

L1383 Rev. D

and 50 PSIG ( 3.4 BAR) O

2

19

Page 32

Chapter 7: Appendices Bird Sentry™ Blender

Mixed gas stability* ±1% oxygen

Ambient operating conditions

Temperature range 59 to 104°F (15 to 40°C)

Relative humidity range 5-95%, non-condensing

Ambient storage conditions

Temperature range 5 to 122°F (-15°C to 50°C)

Relative humidity range 5-95%, non-condensing

*The delivered oxygen concentration will remain constant within ±1% of the set point value with

constant inlet pressures. The displayed value may vary more than this due to sensor accuracy, age,

of the sensor, environmental conditions and length of time since last sensor calibration.

Alarm Specifications

Pressure differential alarm activation When supply pressures differ by 20 PSI (1.3 BAR) or more

activation

High low concentration alarm range 18 to 99% oxygen

O2 Sensors

Oxygen measurement accuracy ±2% oxygen

Linearity ±1% oxygen when temperature and pressure are held

constant

Potential error due to changes in

sensor temperature

Response time at 77°F (25°C) to 90%

of final reading

Ambient operating temp. range 59 to 104°F (15 to 40°C)

Ambient operating humidity range 0 to 100% (non-condensing)

Ambient storage temp. range 50 to 122°F (–15 to 50°C)

Monitored gas temp. range 59 to 104°F (15 to 40°C)

Monitored gas humidity range 0 to 100%(non-condensing)

Caution!

The use of oxygen sensors not recommended by CareFusion Corporation for use with the Bird

Sentry blender may result in performance that does not meet the specifications listed in this

manual. CareFusion Corporation recommends that only those sensors labeled as Bird

equipment be used with the Sentry.

This device has not been tested in the presence of gases other than air or oxygen.

±3% oxygen, maximum

≤20 seconds

20 L1383 Rev. D

Page 33

Bird Sentry™ Blender Chapter 7: Appendices

Note:

All specifications assume the following standard environmental conditions unless specified otherwise.

● Ambient and sample gas temperatures of 77°F (25°C)

● Barometric pressure of 30Hg (760mm Hg)

● Ambient relative humidity of 50%

● Sample gas relative humidity of 0%

Disposable Galvanic O2 Sensors

Expected useful life 750,000 O2% hours* (approx. two-years average use)

Shelf life The date by which the sensor must be placed into service to achieve

one year service life is marked on each sensor package.

Sensor warm-up time One minute, nominal time required after the initial installation of

sensor before specifications are applicable.

Setup and Installation

Battery Installation

Remove the battery cover located at the left side facing out by inserting a screwdriver (at location

noted) and prying. Observing correct polarity, install two (2) standard "AA" 1.5V alkaline batteries and

replace cover.

L1383 Rev. D

21

Page 34

Chapter 7: Appendices Bird Sentry™ Blender

Bird Sentry™ Blender Setup

The Bird Sentry blender is easily setup and adapts to most hospital rail mount and ventilator systems.

The inlet fittings (air and oxygen) located on the bottom of the unit conform to Diameter Indexed

Safety System (D.I.S.S.) standards as specified by Compressed Gas Association (C.G.A.) to discourage

inadvertent connections of either gas supply.

Mount the Bird Sentry blender in a convenient location such that all displays are easily visible and all

controls and the sensor and sensor receptacle are readily accessible. Check that the available room light

is sufficient to view all displays.

Sensor Installation

Be sure to use a fresh O2 sensor. Plug the sensor cable into the cable port on the sensor. Insert the

sensor into the sensor port on the right side of the Bird Sentry blender. Allow the sensor a period of

adjustment as listed in the specifications section on page 19 and stated in Chapter 3, Performance

Check.

Theory of Operations

The Bird Sentry blender is able to provide oxygen concentrations by means of a single control, and is

also capable of analyzing and monitoring these concentrations. The Bird Sentry blender mixes medical

grade compressed air and oxygen to provide a mixed gas source from 21% to 100% oxygen.

22 L1383 Rev. D

Page 35

Bird Sentry™ Blender Chapter 7: Appendices

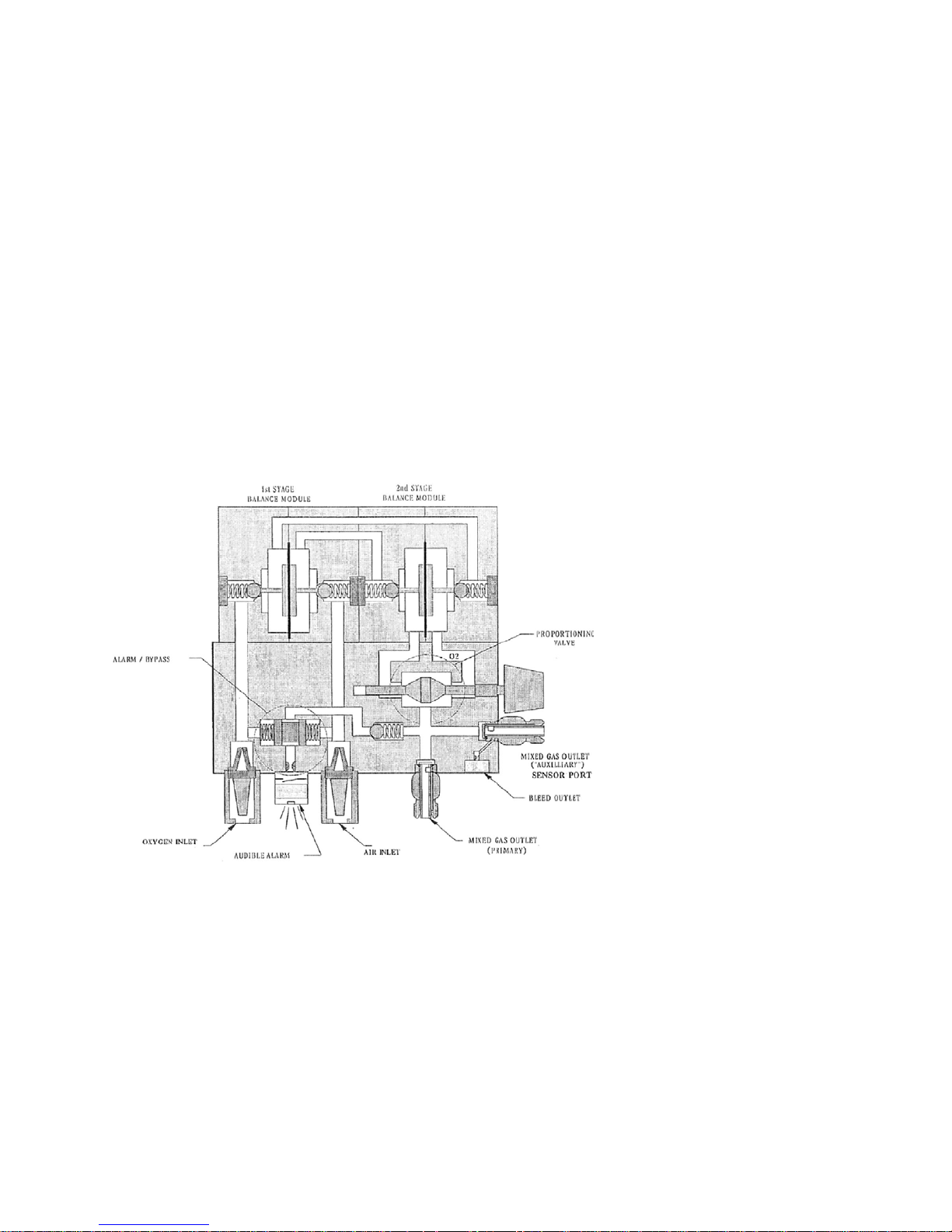

Mixing Operation

The Bird Sentry blender is designed to utilize two (2) 50 PSIG (3.4 BAR) gas sources. The two (2) gas

sources enter through the diameter indexed air and oxygen inlet connectors located on the bottom of

the Bird Sentry blender.

Each inlet connector incorporates a 30 micron particulate filter. Once through the filters, each gas

passes through a duckbill check valve which prevents possible reverse gas flow from either the air or

the oxygen supply systems.

The two (2) gases then pass through a two-stage balance regulator. The purpose of this regulator is to

equalize the operating pressures of the air and oxygen gas sources. Once these pressures have been

balanced, the gases are proportioned according to the oxygen concentration selected on the oxygen

concentration selection knob. The oxygen concentration knob allows the clinician to select a desired

oxygen concentration from 21% to 100% O

. From this point, the mixed gas flows to the outlet port.

2

Gas Outlet

There are two (2) gas outlets on the Bird Sentry blender: one on the bottom of the unit and one on the

left side (facing the unit). These outlets are capable of delivering combined metered flows of 2-100

liters per minute (LPM) of mixed gases. These outlet ports are fitted with an automatic shut off valve.

The flow of gas from either outlet port is automatically initiated by attaching a pneumatic device (such

as a flow meter) to the outlet port. Regardless of whether or not the outlet has any device connected

to it, a minimal gas bleed flow of 1143 LPIVI flows from the sensor port on the right side of the Bird

Sentry blender. It is from this bleed flow that the gas is sampled and analyzed by the Bird Sentry

analyzer and monitor functions.

Alarm/Bypass Function

The Bird Sentry blender includes a pressure differential alarm which provides an audible alarm if gas

source pressures differ by 20 PSI (1.3 BAR) (nominal) or more, or if there is a gas supply failure of one

of the source gases. This alarm is generated by a reed alarm located in a cap on the bottom of the Bird

Sentry blender. The primary purpose of the alarm is to audibly warn the operator of an excessive

pressure drop or depletion of either source gas pressure. The alarm will also activate when there is an

elevation of either source gas pressure resulting in a differential of 20 PSI (1.3 BAR)(nominal) or more.

Should both gas pressures increase or decrease simultaneously, an alarm will not activate. If either

source gas pressure drops, the outlet pressure will drop similarly as the mixed gas is always balanced to

that of the lower gas source.

The gas bypass function operates in unison with the alarm. Once the pressure alarm is activated, the

bypass function is actuated and the gas with the higher pressure flows directly to the outlet port,

bypassing the mixing function of the Bird Sentry blender. The oxygen concentration flowing out of the

Bird Sentry blender will be that of the gas with the higher pressure. The Bird Sentry blender in the

pressure alarm/bypass mode will deliver oxygen (100%) or medical air (21%) until pressures have been

restored to a differential of 6 PSI (.4 BAR).

If the Bird Sentry blender is set to deliver 21% and the OXYGEN source pressure is reduced enough to

produce a 20 PSI (1.3 BAR) differential, the unit may not alarm because it will continue to deliver 21%

concentration according to the setting. If the setting is moved slightly from 21%, the pressure

differential alarm will sound. Similarly, if the Bird Sentry blender is set to deliver 100% and the AIR

source pressure is reduced or lost, the unit may not alarm because it will continue to deliver 100%

concentration.

L1383 Rev. D

23

Page 36

Chapter 7: Appendices Bird Sentry™ Blender

Electrical Block Diagram

This diagram is intended to assist the user in understanding the general functioning of the Bird Sentry

circuitry. The user and technician are both cautioned that there are no serviceable components on the

circuit board. Any service requirements should be referred to CareFusion Corporation.

24 L1383 Rev. D

Page 37

Bird Sentry™ Blender Chapter 7: Appendices

Flow Characteristics

Note:

Graphs are typical of a representative sample. Minor variations are to be expected.

L1383 Rev. D

25

Page 38

Chapter 7: Appendices Bird Sentry™ Blender

Bird Sentry™ Blender

26 L1383 Rev. D

Page 39

Bird Sentry™ Blender

Index

A

gas outlet, 23

getting help, vi, 6

alarm

bypass function, 23

pressure differential, 11

setup procedure, 7

specifications, 20

alarms and conditions, 8

B

battery, installing, 21

bypass check, 11

C

C.G.A., 22

calibration

automatic to known concentration, 10

automatic to room air, 10

procedures, 9

cleaning the blender, 15

Compressed Gas Association, 22

D

D.I.S.S., 22

Diameter Indexed Safety System (D.I.S.S.), 22

disposable galvanic O

sensor, 5, 21

2

H

high alarm, setup procedure, 8

I

installing the blender, 21

L

low alarm, setup procedure, 7

M

maintaining the blender, 17

mixing operation, 23

monitoring, 7

MRI, v

O

O2 sensor, 5, 20

operation, basic, 8

P

panel, front, 2

E

electromagnetic interference, v

EMC, v

F

flow characteristics, 25

front panel, 2

G

galvanic O2 sensor, 5

Galvanic O

disposing, 17

Sensor Cable

2

L1383 Rev. D

S

sensor, 5

installing, 22

servicing the blender, 18

setting up the blender, 21

support, technical, vi, 6

symbols, equipment, ix

T

technical support, vi, 6

troubleshooting, 13

27

Page 40

Chapter 7: Appendices Bird Sentry™ Blender

Bird Sentry™ Blender

28 L1383 Rev. D

Loading...

Loading...