Page 1

Alaris® System Maintenance v9.5.X

Software User Manual

Model 8975, v9.5.X

Guardrails

Compatible with v9.X Alaris

®

Suite MX

®

PC units

May 2010

Part Number: 11614346

Page 2

Alaris® System

Maintenance v9.5.X

Software User Manual

Part Number: 11614346

Alaris and Guardrails are

registered trademarks of

CareFusion Corporation or

one of its subsidiaries.

Masimo is a registered

trademark of Masimo

Corporation. Nellcor is a

registered trademark of

Nellcor Puritan Bennett,

Inc. Microstream is a

registered trademark of

Oridion Medical 1987 Ltd.

All other trademarks are

the property of their

respective owners.

CareFusion

San Diego, California

United States

888.876.4287

carefusion.com

© 2007-2010 CareFusion

Corporation or one of its

subsidiaries.

All rights reserved.

The information in this document is subject to change and does not represent a

commitment on the part of CareFusion to provide additional services or

enhancements. The screens illustrated in this document are for reference purposes

only and might be different than the screens displayed on your computer.

Documentation provided with this product might reference product not present in

your facility or not yet available for sale in your area.

If difficulties are encountered while using this software, refer to the applicable

®

Alaris

System Directions for Use (DFU) and/or service manual and related

service bulletin(s) before contacting CareFusion Technical Support. If necessary,

contact a CareFusion representative. Provide a description of the difficulty

experienced, any messages that were displayed at the time of the difficulty, and

the software version. Before you return the software to CareFusion, contact

CareFusion Customer Care to get a return authorization number. Put the software

in its original packaging (if available), write the return authorization number on

the package, and return it to the nearest facility.

Customer Advocacy - North America

(Clinical and technical feedback.)

Phone: 888.876.4287

E-mail: CustomerFeedback@carefusion.com

Customer Advocacy - International

(Clinical and technical feedback.)

E-mail: cai@carefusion.com

Technical Support - North America

(Maintenance and service information support; troubleshooting.)

Phone, United States: 888.876.4287

Phone, Canada: 800.387.8309

Technical Support - United Kingdom

(Maintenance and service information support; troubleshooting.)

Phone: 0800 389 6972

E-mail: UK-Technical-Support@carefusion.com

Customer Care - North America

(Product return, service assistance, and order placement.)

Phone, United States: 888.876.4287

Phone, Canada: 800.387.8309

Customer Care - United Kingdom

(Product return, service assistance, and order placement.)

Phone: 0800 917 8776

E-mail: UK-Customer-Service@carefusion.com

Technical Support and Customer Service - International

(Maintenance and service information support.

Product return, service assistance, and order placement)

www.carefusion.com/customer-support/customer-service

Authorized European Representative

CareFusion

The Crescent, Jays Close

Basingstoke, Hampshire RG22 4BS

United Kingdom

Page 3

Content s

Chapter 1—Introduction

Defined Terms...................................................... ...................................................... ...................................2

About the Software............................................................. ...........................................................................3

Feature Summary ...........................................................................................................................................4

Warnings........................................................................................................................................................5

Cautions.........................................................................................................................................................6

Chapter 2—Installation and Setup

System Requirements ....................................................................................................................................8

Hardware Requirements ...................................................... .... ..............................................................8

Software Requirements..........................................................................................................................8

Install Software—Standard Installation...................................................................... ..... .... ..........................9

Install Software—Custom Installation ........................................................................................... .............12

Install Centralized System Maintenance Software Database on a Dedicated Server.........................12

Install Client Tools on Biomedical Technician Workstation...............................................................13

Configure Database Settings................................................................................................................15

Upgrade/Reinstall Software.........................................................................................................................17

Uninstall Software.......................................................................................................................................18

System Maintenance Software CD......................................................................................................18

Windows Operating System .................................................................................... ............................19

Uninstall AlarisSM9DB Database Instance.................................................................................................20

Chapter 3—Overview

Start System Maintenance Software............................................................................................................22

Menu Bar.....................................................................................................................................................23

Chapter 4—PC Unit Connection

Hardware Connections................................................... ...................................................... ........................26

Multiple PC Unit Connections.....................................................................................................................27

Alaris® System Maintenance v9.5.X Software User Manual i

Page 4

Contents

Chapter 5—Application and Database Settings

Application Settings.....................................................................................................................................30

Database Settings.........................................................................................................................................31

Open Database Settings.......................................................................................................................31

Add a Database Definition...................................................................................................................32

Delete a Database Definition...............................................................................................................32

Set Active Database Definition............................................................................................................32

Test Database Definition Connection..................................................................................................32

Migrate MSW Databases.............................................................................................................................33

Chapter 6—Preventive Maintenance

Introduction..................................................................................................................................................36

General Steps.......................................................................................................................................37

Run/Abort Tasks..................................................................................................................................39

Run Tasks Concurrently............................................................................................................39

Abort Tasks ...............................................................................................................................40

Coloring Scheme..................................................................................................................................40

Preventive Maintenance...............................................................................................................................41

PC Unit ................................................................................................................................................41

Test Equipment .........................................................................................................................41

Pump Module.......................................................................................................................................47

Test Equipment .........................................................................................................................47

Load Administration Set ...........................................................................................................51

Rate Accuracy Test Setup .........................................................................................................52

Patient-Side Occlusion Pressure Test Setup..............................................................................55

Fluid-Side Occlusion Test Setup...............................................................................................57

PCA Module........................................................................................................................................59

Test Equipment .........................................................................................................................59

Syringe Module....................................................................................................................................67

Test Equipment .........................................................................................................................67

Pressure Test/Calibration Setup ................................................................................................75

SpO

Module........................................................................................................................................77

2

Test Equipment .........................................................................................................................77

Disposable SpO

EtCO

Module......................................................................................................................................84

2

Test Equipment .........................................................................................................................84

Leak-Down Test........................................................................................................................87

Flow Test/Calibration Setup......................................................................................................89

Auto-ID Module and Handheld Scanner................................................... ..... .... .................................91

Sensor Modification and Test Point..............................................................82

2

Chapter 7—Data Sets and Alerts

Transfer a Data Set ......................................................................................................................................96

Download Alerts.......................................... ...................................................... ..........................................99

ii Alaris® System Maintenance v9.5.X Software User Manual

Page 5

Contents

Chapter 8—Flash Firmware

Flash Firmware......................................................................................... ..... ............................................106

PC Unit 8000 (PCU1.0).....................................................................................................................106

PC Unit 8015 (PCU1.5).....................................................................................................................111

Chapter 9—Configure Components

Configuration Packages.............................................................................................................................118

Components of a Configuration Package ..........................................................................................119

Add a New Configuration Package ...................................................................................................120

Delete a Configuration Package ........................................................................................................120

Export a Configuration Package........................................................................................................120

Import a Configuration Package........................................................................................................121

Export or Import Components of a Configuration Package..............................................................121

Copy a Configuration Package.............................................................. ............................................122

Copy a Component of a Configuration Package ...............................................................................122

Specify Network Settings ..................................................................................................................123

Create a Network Profile.........................................................................................................123

Datalink Settings .....................................................................................................................123

Security Settings......................................................................................................................125

Network Settings...................................................................................... ..... ..........................128

Server Settings.........................................................................................................................129

Wireless Network Setting on PC Unit—Disable, Enable, View Status............................................130

Enable Wireless Network........................................................................................................130

Disable Wireless Network.......................................................................................................131

Specify Auto-ID Module Settings .....................................................................................................133

Formatting Rules.....................................................................................................................133

Specify Firmware Files......................................................................................................................137

Specify a Data Set File.......................................................................................................................137

Chapter 10—Calibration

Introduction................................................................................................................................................140

Pump Module Calibration..........................................................................................................................141

Test Equipment..................................................................................................................................141

Patient-Side Occlusion Pressure Calibration Setup—Pump Module............................................. ...145

PCA Module Calibration...........................................................................................................................148

Test Equipment..................................................................................................................................148

Syringe Module Calibration ......................................................................................................................154

Test Equipment..................................................................................................................................154

EtCO

Module Calibration ........................................................................................................................161

2

Test Equipment..................................................................................................................................161

Chapter 11—Tasks

Task Groups...............................................................................................................................................166

Create a New Task Group..................................................................................................................166

Delete a Task Group..........................................................................................................................167

Rename a Task Group........................................................................................................................167

Alaris® System Maintenance v9.5.X Software User Manual iii

Page 6

Contents

Tasks List...................................................................................................................................................168

Edit Tasks List...................................................................................................................................168

Change Tasks List Order ...................................................................................................................168

Task Information .......................................................................................................................................170

PC Unit Tasks....................................................................................................................................170

Transfer Network Configuration—Error Handling...........................................................................174

Pump Module Tasks ..........................................................................................................................175

Syringe Module and PCA Module Tasks..........................................................................................178

SpO

Module Tasks...........................................................................................................................182

2

EtCO

Module Tasks.........................................................................................................................183

2

Auto-ID Module and Handheld Scanner Tasks.............................................. .... ..... ..........................184

Test Equipment..........................................................................................................................................185

Chapter 12—Reports and Logs

Reports.......................................................................................................................................................188

Report Types......................................................................................................................................188

Run Reports .......................................................................................................................................188

Logs ...........................................................................................................................................................190

Log Definitions..................................................................................................................................190

Example Log......................................................................................................................................193

Glossary...............................................................................................................................................199

iv Alaris® System Maintenance v9.5.X Software User Manual

Page 7

Chapter 1

Introduction

Alaris® System Maintenance v9.5.X Software User Manual 1

Page 8

Chapter 1—Introduction Defined Terms

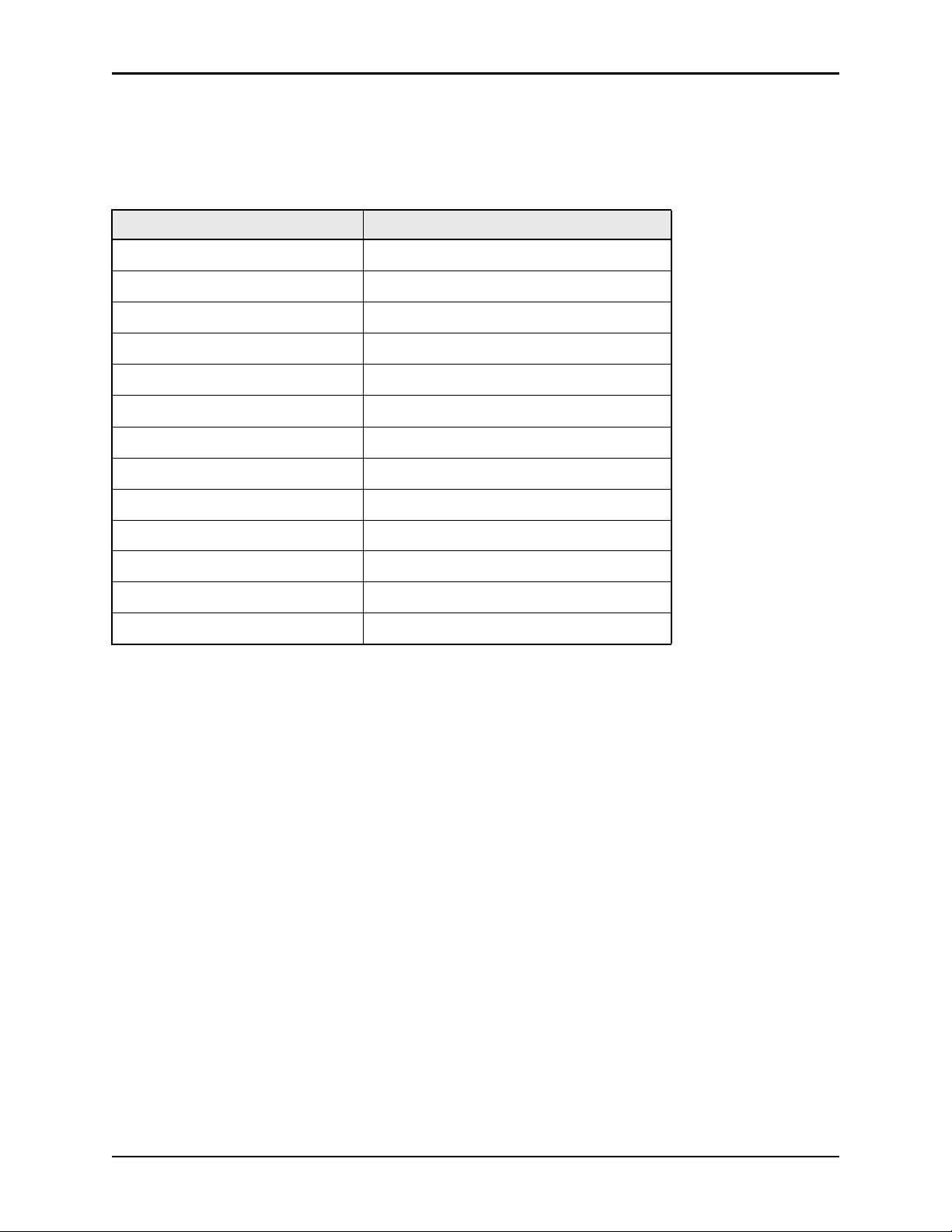

Defined Terms

The following table identifies the defined terms used throughout this document for certain trademarked

products and product features.

Product/Feature Defined Term

Alaris® Auto-ID module

®

Alaris

EtCO2 module

®

PCA module

Alaris

®

Alaris

PC unit

®

Pump module

Alaris

®

Alaris

SpO2 module

®

Syringe module

Alaris

Alaris® System Maintenance

Guardrails

Guardrails

Guardrails

Guardrails

®

alert

®

clinical advisories

®

CQI report

®

data set

Guardrails® Editor software

Auto-ID Module

Module

EtCO

2

PCA Module

PC Unit

Pump Module

SpO

Module

2

Syringe Module

System Maintenance Software

Alert

Clinical Advisories

CQI Report

Data Set

Editor Software

2Alaris

®

System Maintenance v9.5.X Software User Manual

Page 9

About the Software Chapter 1—Introduction

About the Software

This software is provided under and subject to a license from CareFusion.

System Maintenance Software version 9.5.X allows you to perform routine maintenance on an

®

Alaris

tool for the Alaris

serial cable between the personal computer and a PC Unit.

The System Maintenance software kit includes:

A USB serial adapter (not supplied) can be used to connect one or more PC Units to a personal computer

equipped with System Maintenance Software. The USB serial adapter must meet the following

specifications:

System. The functionality of this software replaces maintenance software (MSW) and the Flash

®

System. To use this software, you install it on a personal computer and then connect a

• System Maintenance software CD-ROM

• Serial cable

• This Software User Manual (pdf on CD-ROM and printed version)

• Plugs into a USB port on a personal computer.

• Provides RS-232 male DB9 port(s) for direct connection to PC Units.

• Draws its power from USB connection—a power adapter is not required.

Alaris® System Maintenance v9.5.X Software User Manual 3

Page 10

Chapter 1—Introduction Feature Summary

Feature Summary

System Maintenance software can be used to perform the following functions:

• Maintain the PC Unit.

• Upgrade firmware on the PC Unit and attached modules.

• Perform preventive maintenance/check-in.

• Set and check preventive maintenance reminder dates.

• Troubleshoot and repair instruments.

• Module Calibration, as applicable.

• Set up, test, and configure the Auto-ID Module.

• Download and view instrument logs.

• Download CQI data logs.

• Transfer Data Sets from the personal computer to the PC Unit.

• Configure wireless network settings.

• Test communications board interaction with a wireless network.

• Disable Wireless Network configuration option.

• Support wireless protocols for b, b/g, a/b/g, and d networks.

• Support wireless security for WEP, WPA, and WPA2.

Perform all pre-inspections before instrument use. A qualified technician or biomedic al en gin e er mus t

perform inspections at least once a year or as required in accordance with CareFusion guidelines.

NOTE

• Inspections are intended to comply with requirements specified by the

Joint Commission on Accreditation of Healthcare Organizations

(JCAHO).

• You can purchase a service agreement from CareFusion for preventive

maintenance inspections.

4Alaris

®

System Maintenance v9.5.X Software User Manual

Page 11

Warnings Chapter 1—Introduction

Warnings

Warnings provide information needed to safely and effectively use the Alaris® product.

A WARNING is an alert to a potential

hazard which could result in serious personal injury and/or product

damage if proper procedures are not followed.

WARNING

• At no time should the System Maintenance software be used while the

• System Maintenance software and procedures are intended to be

• Prior to use, CareFusion recommends that you become familiar with

• The instrument case should only be opened by qualified service

• To ensure proper calibration, run the post tests for the Pump Module

• Ensure that the instrument is in operational status before returning it to

®

Alaris

performed only by qualified personnel, or under direct supervision by

qualified personnel.

each instrument and accessory used with the System Maintenance

software. For specific instrument warnings, cautions, inspection

requirements, and other related instrument information, refer to the

applicable Alaris

personnel using proper grounding techniques. When the instrument

case is opened, electrical shock hazard exists which can result in

serious injury to persons and instrument component damage.

and the accuracy tests for the Syringe Module after calibrat ion. These

tests are displayed in the default Calibration test lists.

patient use.

System is connected to a patient.

®

System DFU and/or service manual.

• Your PC Unit might not be co mpatible with every module. To de ter min e

module compatibility, refer to the app licable Alaris

®

System DFU.

Alaris® System Maintenance v9.5.X Software User Manual 5

Page 12

Chapter 1—Introduction Cautions

Cautions

Cautions provide information needed to safely and effectively use the Alaris® product.

A CAUTION is an alert to a potential

hazard which could result in minor personal injury and/or product

damage if proper procedures are not followed.

CAUTION

• Loading the System Maintenance Software is considered a non-clinical

service activity. Interconnecting a medical device with a personal computer

might cause the safety or electromagnetic environment to change while the

connection exists. The threat of higher leakage currents or EMI disturbance

levels might be present. Remove the connection at both ends before patient

use.

• By default, the System Maintenance Software is set to automatically clear

logs after they are downloaded. Once log entries have been cleared, they

cannot be downloaded again from the instrument. The log entries remain in

the database and can be displayed using the View Reports tab in the main

window.

• Only one PC Unit should be connected to a group of attached modules at

any given time. Connection of multiple PC Units to each other will cause

damage to the IUI connectors.

• Only one SpO

• If a Pump Module fails the patient-side occlusion or rate accuracy verification

(RAV) tests, calibration is required. Failure to calibrate and retest the

instrument might result in improper instrument operation.

Module can be connected to the PC Unit at any one time.

2

• For tests that require water, use distilled water at room temperature between

41°F and 104°F (5°C to 40°C). If water is not within this temperature range,

the reading might be inaccurate.

• If multiple instances of the System Maintenance Software are running

(typically on different personal computers), it is possible to assign dif ferent IP

addresses to the same PC Unit. To ensure this does not occur, assign each

PC Unit a single, unique IP address.

NOTE: If the System Maintenance Software instances are connected to the

same System Maintenance Software databases, this problem cannot occur.

• Calibration verifications perform strenuous tests on the Syringe Module and

PCA Module. In some cases, these tests differ from the check-in/preventive

maintenance tests.

• Following calibration, use calibration verifications (rather than check-in/

preventive maintenance verifications) to verify correct calibration.

• Use of accessories or cables ot he r th an thos e spec ifie d mig ht res ult in

degraded electromagnetic compatibility performance or safety of the Alaris

®

System.

• The flow rate out of the gas source and into the EtCO

Module must be

2

greater than 0.5 liter/minute to ensure accurate readings. It is r ecommended

to place a flow meter between the gas source and th e “T” in the line (b reather

line).

6Alaris

®

System Maintenance v9.5.X Software User Manual

Page 13

Chapter 2

Inst allation and Setup

Alaris® System Maintenance v9.5.X Software User Manual 7

Page 14

Chapter 2—Installation and Setup System Requirements

System Requirements

To run the System Maintenance software, the personal computer must meet the following minimum

hardware and software requirements.

CAUTION

For optimum performance of the System Maintenance Software, ensure that the

personal computer is equipped with the required hardware and software, and do

not use the personal computer with unspecified accessories or cables. Use of

accessories or cables other than those specified might result in degraded

electromagnetic compatibility performance or safety of the Alaris

Hardware Requirements

The personal computer on which you install the System Maintenance Software must meet the following

requirements:

• processor, Pentium Class, 1 GHz or faster

• RAM, 512 MB minimum

• HDD (hard disk drive), 5 GB minimum of free space after the operating system is installed

•CD-ROM drive

• video card, SVGA

• monitor, minimum resolution 1024 x 768; color depth set greater than 256 colors

• port: configurable RS-232, 9-pin, serial communications; or USB

• cable, serial communications (provided)

®

System.

NOTES

• If the personal computer has a serial port, use a serial-to-serial cable.

• If the personal computer has a USB port, use a serial-to-USB cable or a

serial-to-serial cable with a USB converter. USB converter products are not

supported by CareFusion.

• keyboard

•mouse

• printer and printer connection (optional)

Software Requirements

One of the following operating systems:

®

• Microsoft

• Microsoft

• Microsoft

Other software:

• Adobe Acrobat Reader v9.X

Windows 2000 Professional with Service Pack 4

®

Windows XP with Service Pack 2

®

Windows 2003 Server with Service Pack 1

8Alaris

®

System Maintenance v9.5.X Software User Manual

Page 15

Install Software—Standard Installation Chapter 2—Installation and Setup

Install Software—Standard Installation

Follow these steps to install the System Maintenance Software on a personal computer for the first time. If

you plan to migrate another version of the System Maintenance database, install the System Maintenance

Software and migrate the data using the Migrate MSW file feature (

Read all prompts carefully. During installation it is recommended that no other applications are running

and that virus checking is disabled.

1. Insert the System Maintenance Software CD into the CD-ROM drive of the personal computer. If the

installation program automatically starts, go to the next step. If the installation program does not

automatically start, choose

Alternatively, browse to the

and then click

OK.

Start > Run, then type

Setup.exe program on the System Maintenance Software CD, click Open,

d:\Setup.exe

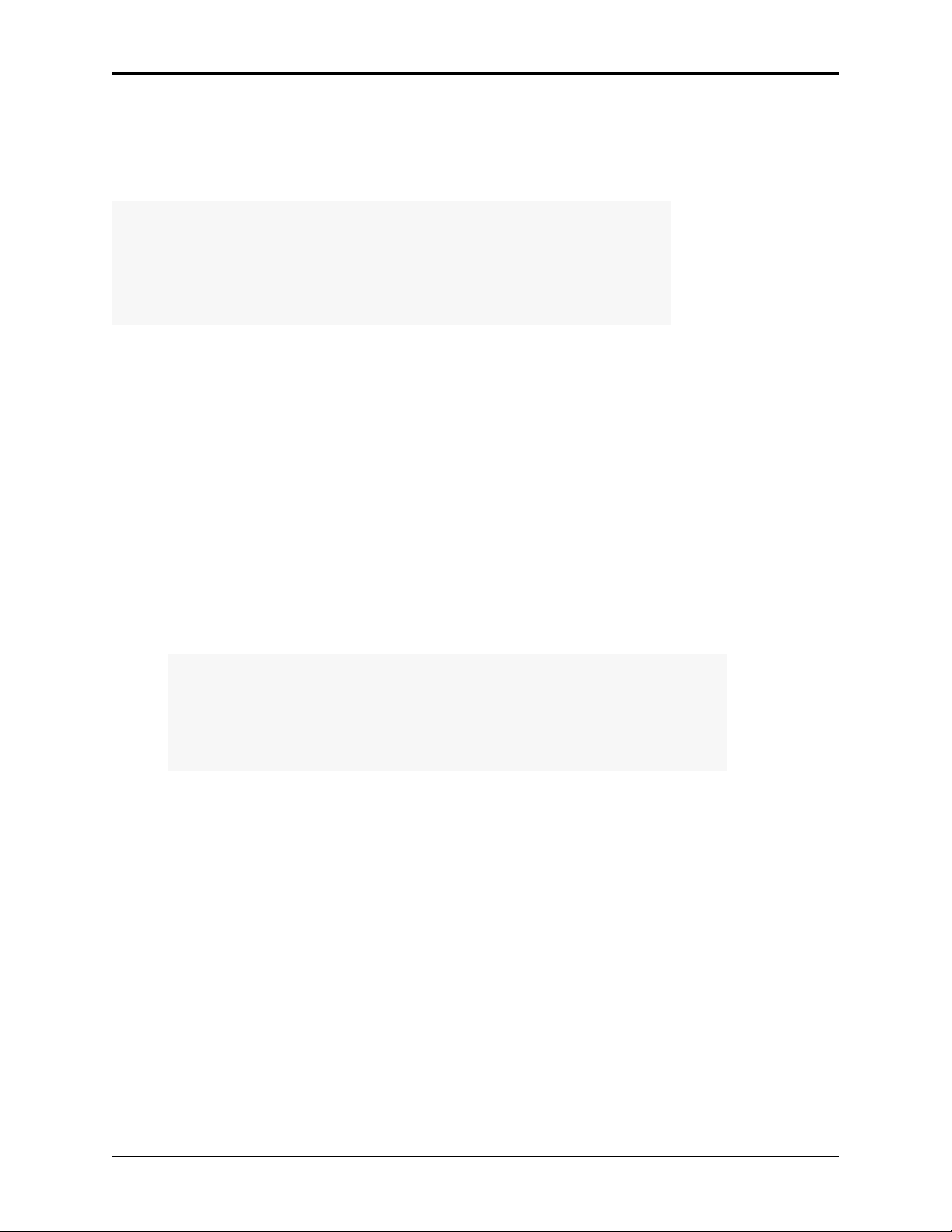

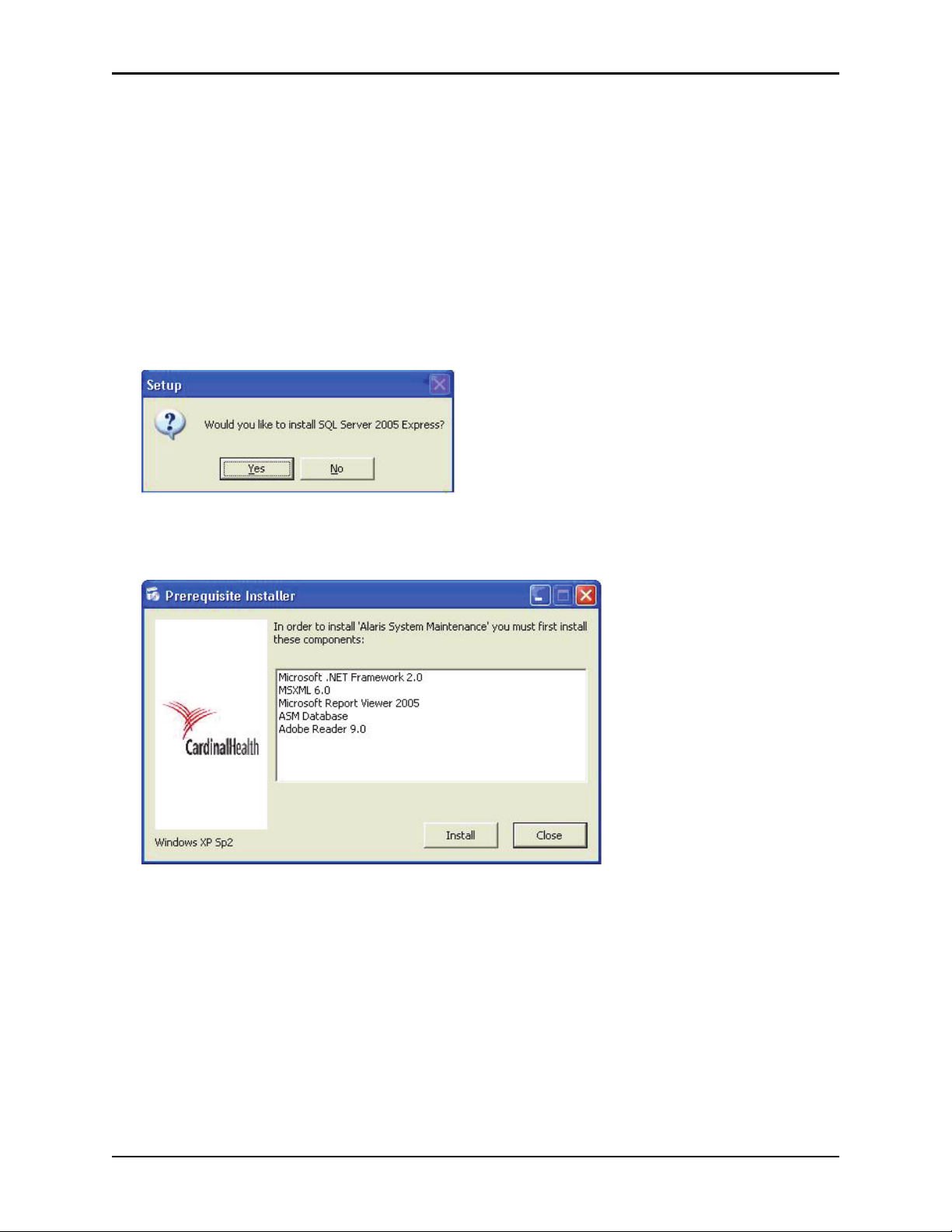

2. When you are asked if you want to install SQL Server 2005 Express, click

Options > Migrate MSW Data).

(where d: is CD drive).

Yes.

3. If you are prompted to install prerequisite components, click

®

Microsoft

.NET Framework 2.0, MSXML 6.0, Microsoft Report Viewer 2005, ASM Database (SQL

Server Express 2005), and Adobe Reader 9.0.

Install. The components include

Alaris® System Maintenance v9.5.X Software User Manual 9

Page 16

Chapter 2—Installation and Setup Install Software—Standard Installa ti on

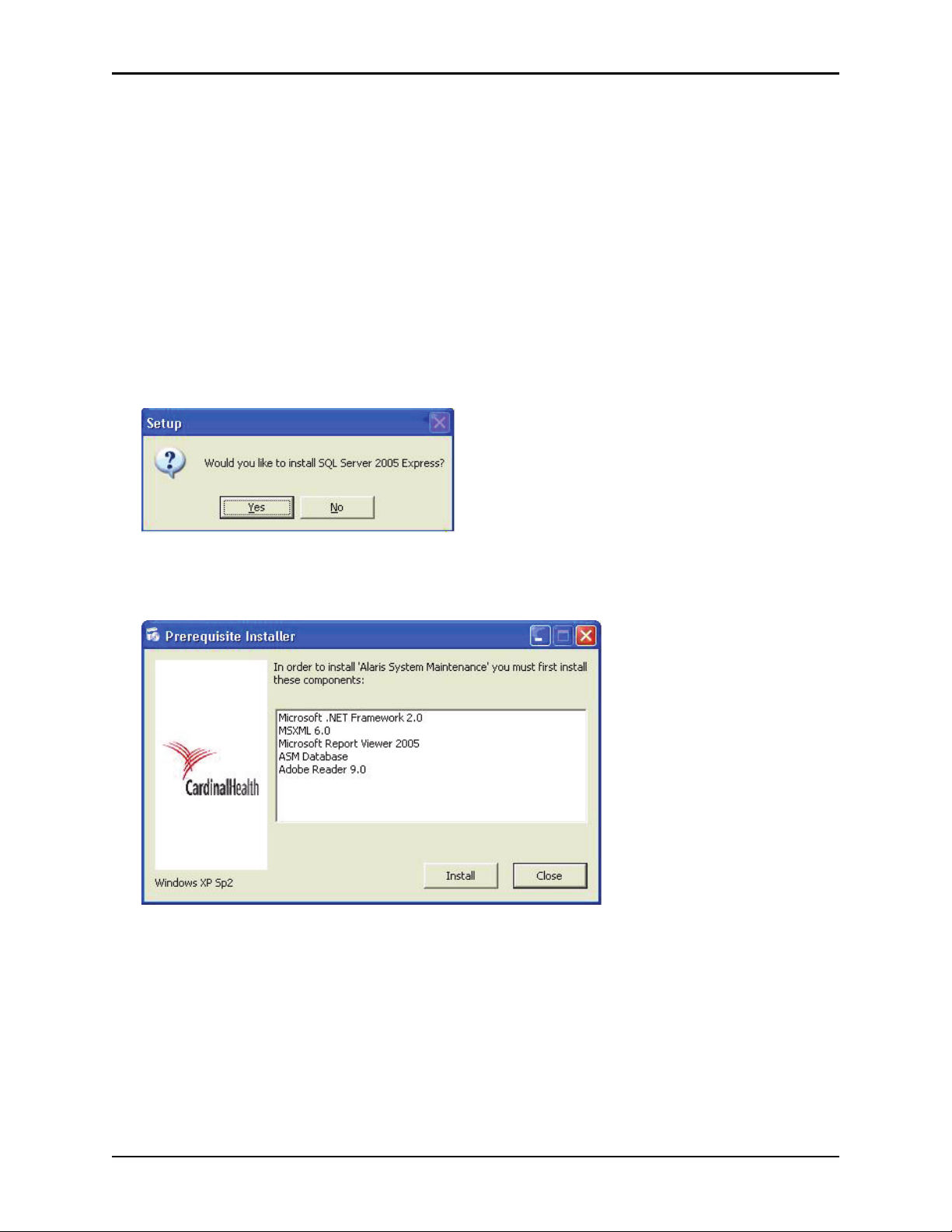

4. After installing prerequisites, or if prerequisites are already installed, the installation Setup Wizard

Welcome window is displayed. Click

Next.

5. Select the features that you want to install:

• Full Install—installs System Maintenance databases and client tools.

• Database—installs only System Maintenance databases.

• Client Tools—installs only System Maintenance client tools.

To install only the database, click

Database and click the red X.

Client Tools and click the red X. To install only the client tools, click

10 Alaris® System Maintenance v9.5.X Software User Manual

Page 17

Install Software—Standard Installation Chapter 2—Installation and Setup

6. Click Browse to choose a location other than the default installation directory. The default directory is

C:\Program Files\Cardinal Health\Alaris Products\Alaris System Maintenance\ .

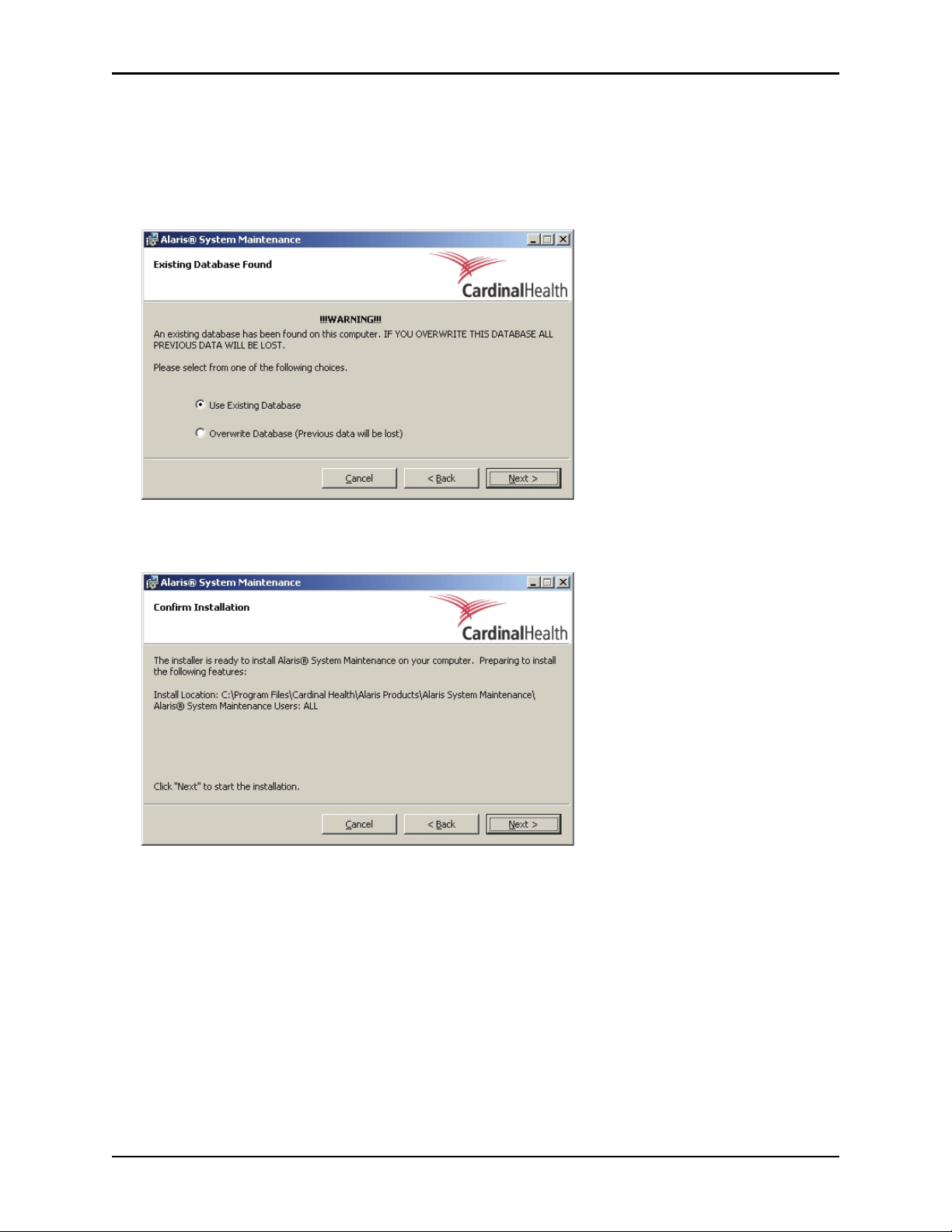

If an existing database is found, the following window is displayed. You can use the existing database

(default) or overwrite the existing database (previous data will be lost). If a previous System

Maintenance database was not found, this window will not be displayed.

7. Click

8. Click

Next to begin installation of the components of the System Maintenance Software.

Next to confirm installation.

When the installation is finished, an "Installation Complete" message is displayed. It is recommended

that you restart your computer if prompted to do so.

Alaris® System Maintenance v9.5.X Software User Manual 11

Page 18

Chapter 2—Installation and Setup Install Software—Custom Installation

Install Software—Custom Installation

Install Centralized System Maintenance Software Database on a Dedicated Server

1. Insert the System Maintenance Software CD into the CD-ROM drive of the personal computer. If the

installation program starts automatically, go to the next step. If the installation program does not start

automatically , choose

browse to the

OK.

Setup.exe program on the System Maintenance Software CD, click Open, and then click

Start > Run, then type

d:\Setup.exe

(where d: is CD drive). Alternatively,

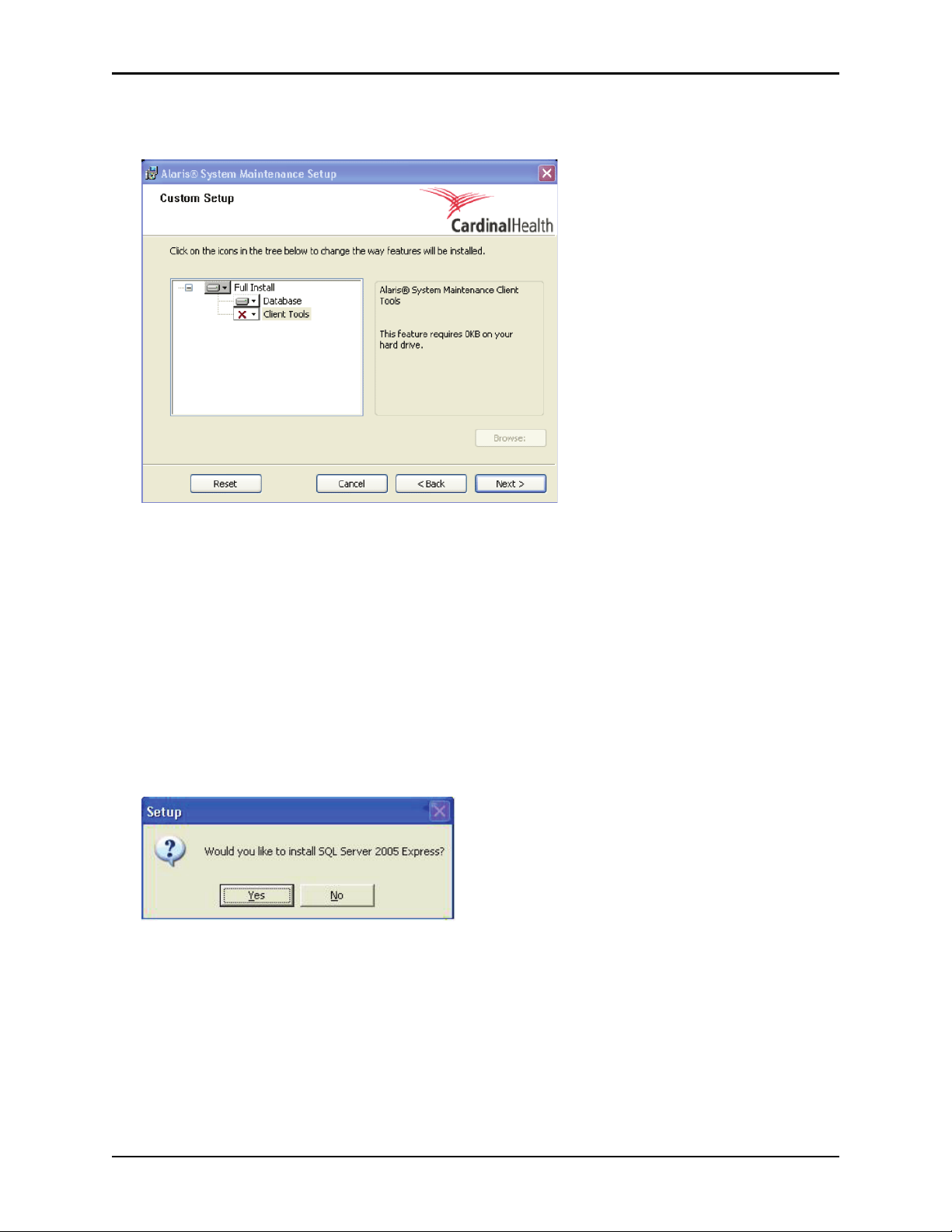

2. When you are asked if you want to install SQL Server 2005 Express, click

3. If you are prompted to install prerequisite components, click

Install. The components include

Yes.

Microsoft .NET Framework 2.0, MSXML 6.0, Microsoft Report Viewer 2005, ASM Database (SQL

Server Express 2005), and Adobe Reader 9.X.

®

4. Wait until the installation is completed. When the Alaris

displayed, click

12 Alaris® System Maintenance v9.5.X Software User Manual

Next.

System Maintenance welcome wizard is

Page 19

Install Software—Custom Installation Chapter 2—Installation and Setup

5. On the Custom Setup window, ensure that Client Tools is not selected (unless you want to also install

the client tools on the same computer as the System Maintenance database).

6. Click

7. Click

Next.

Finish.

Install Client Tools on Biomedical Technician Workstation

Follow these steps to install the client tools on the Biomedical Technician Workstation.

1. Insert the System Maintenance Software CD into the CD-ROM drive of the personal computer. If the

installation program starts automatically, go to the next step. If the installation program does not start

automatically , choose

browse to the

OK.

Setup.exe program on the System Maintenance Software CD, click Open, and then click

Start > Run, then type

2. When you are asked if you want to install SQL Server 2005 Express, click

d:\Setup.exe

(where d: is CD drive). Alternatively,

No.

Alaris® System Maintenance v9.5.X Software User Manual 13

Page 20

Chapter 2—Installation and Setup Install Software—Custom Installation

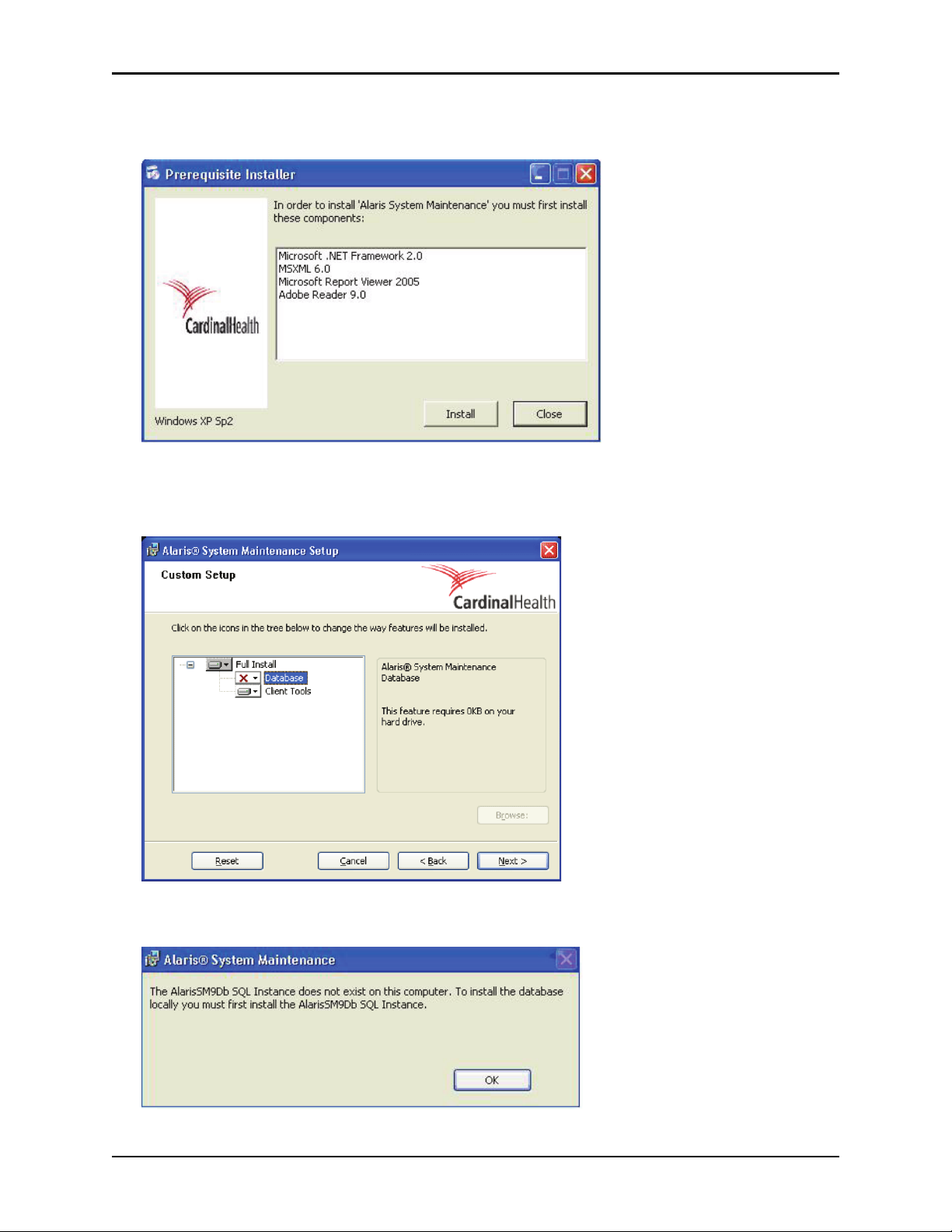

3. If you are prompted to install prerequisite components, click Install. The components include

Microsoft .NET Framework 2.0, MSXML 6.0, Microsoft Report Viewer 2005, and Adobe Reader 9.0.

®

4. Wait until the installation is completed. When the Alaris

displayed, click

5. On the Custom Setup window, ensure that

Next.

Database is not selected.

System Maintenance welcome wizard is

6. If the Database option is selected and you chose not to install SQL Server 2005 Express, a message is

displayed. Click

14 Alaris® System Maintenance v9.5.X Software User Manual

Ok to close the message window.

Page 21

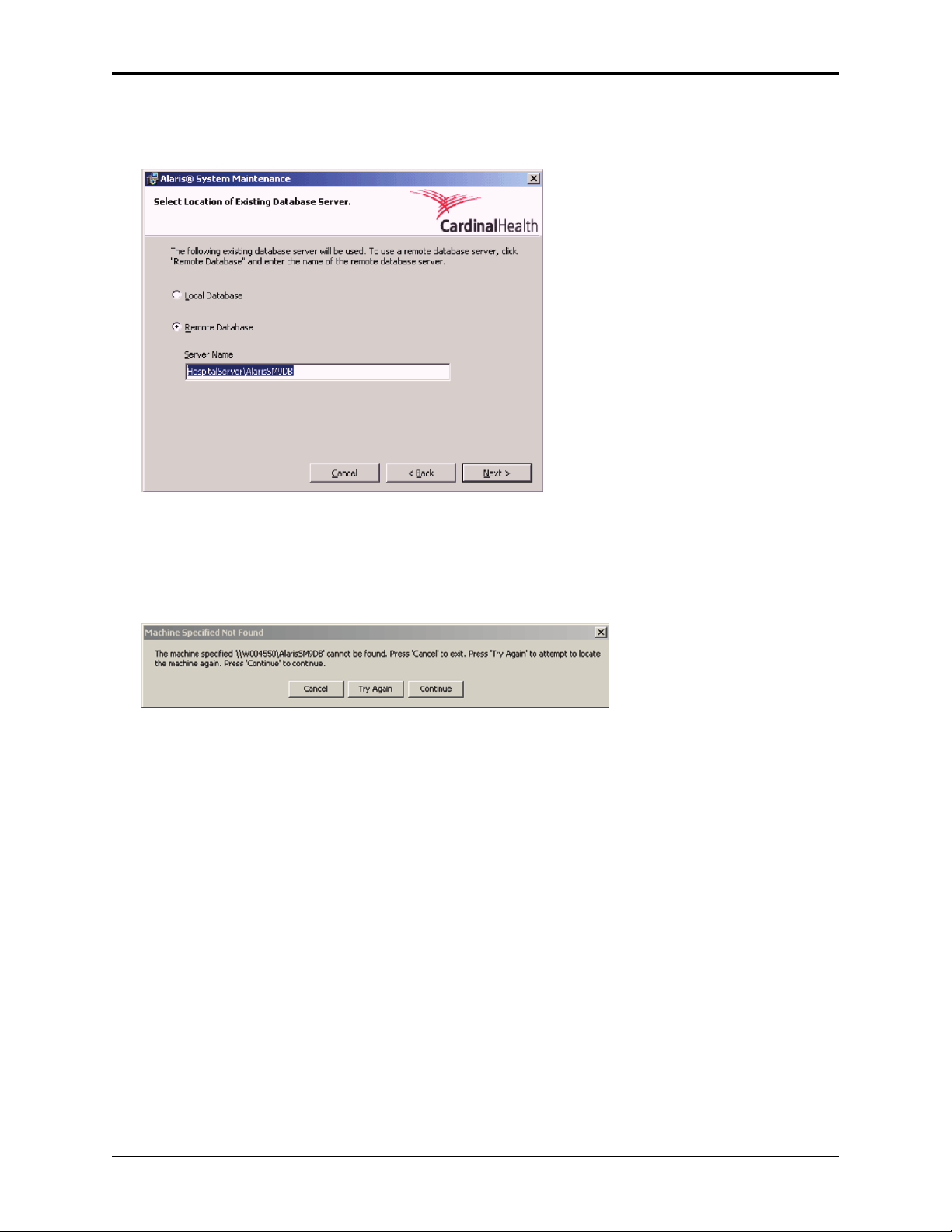

Install Software—Custom Installation Chapter 2—Installation and Setup

7. Click Next.

A window that asks you to select the database server is displayed.

8. Choose the

Example:

Remote Database option. Enter the server name and SQL instance.

HospitalServer\AlarisSM9DB

9. Click Next.

A "Machine Specified Not Found" message is displayed.

10. Click

11. Click

12. Click

Continue.

Next to confirm.

Finish.

Configure Database Settings

Follow these steps to configure the database settings.

1. Start the System Maintenance Software.

2. If you are asked to select another database, click

3. If you are not asked, choose

Options > Database Settings on the main menu.

Yes.

The Database Settings dialog box is displayed.

4. Click

Add to configure the connections for the Maintenance database, the Maintenance Log database,

and the CQI Database.

Alaris® System Maintenance v9.5.X Software User Manual 15

Page 22

Chapter 2—Installation and Setup Install Software—Custom Installation

Hospital Server

Database Field Values

Maintenance database SQL Server field =

Database field = Maintenance

Maintenance Log database SQL Server field =

Database field = MaintenanceLog

CQI Database SQL Server field =

Database field = CQI

<HospitalServer>\AlarisSM9DB

<HospitalServer>\AlarisSM9DB

<HospitalServer>\CQI9DB

Standalone Computer

Database Field Values

Maintenance database SQL Server field =

Database field = Maintenance

Maintenance Log database SQL Server field =

Database field = MaintenanceLog

CQI Database SQL Server field =

Database field = CQI

NOTE

(local)\AlarisSM9Db

(local)\AlarisSM9Db

(local)\CQI9DB

If a database does not exist on your local database server, the "(local)" SQL

Service field is replaced with the SQL Server name where the database is

installed.

Alaris

5. Click

®

Server (wireless)

Database Field Values

CQI Database SQL Server field =

Database field = CQI

Test Connection to verify the connection to the database.

<AlarisAPPSServer>

16 Alaris® System Maintenance v9.5.X Software User Manual

Page 23

Upgrade/Reinstall Software Chapter 2—Installation and Setup

Upgrade/Reinstall Software

Before you can upgrade or reinstall the System Maintenance Software, you must uninstall the existing

software.

NOTE

Uninstalling the AlarisSM9DB database is NOT required to upgrade/reinstall the

software (Uninstall AlarisSM9DB Database Instance on page 20).

1. Uninstall the existing software (see Uninstall Software on page 18).

2. Install/reinstall the software (see Install Software—Standard Installation on page 9 or Install

Software—Custom Installation on page 12).

Alaris® System Maintenance v9.5.X Software User Manual 17

Page 24

Chapter 2—Installation and Setup Uninstall Software

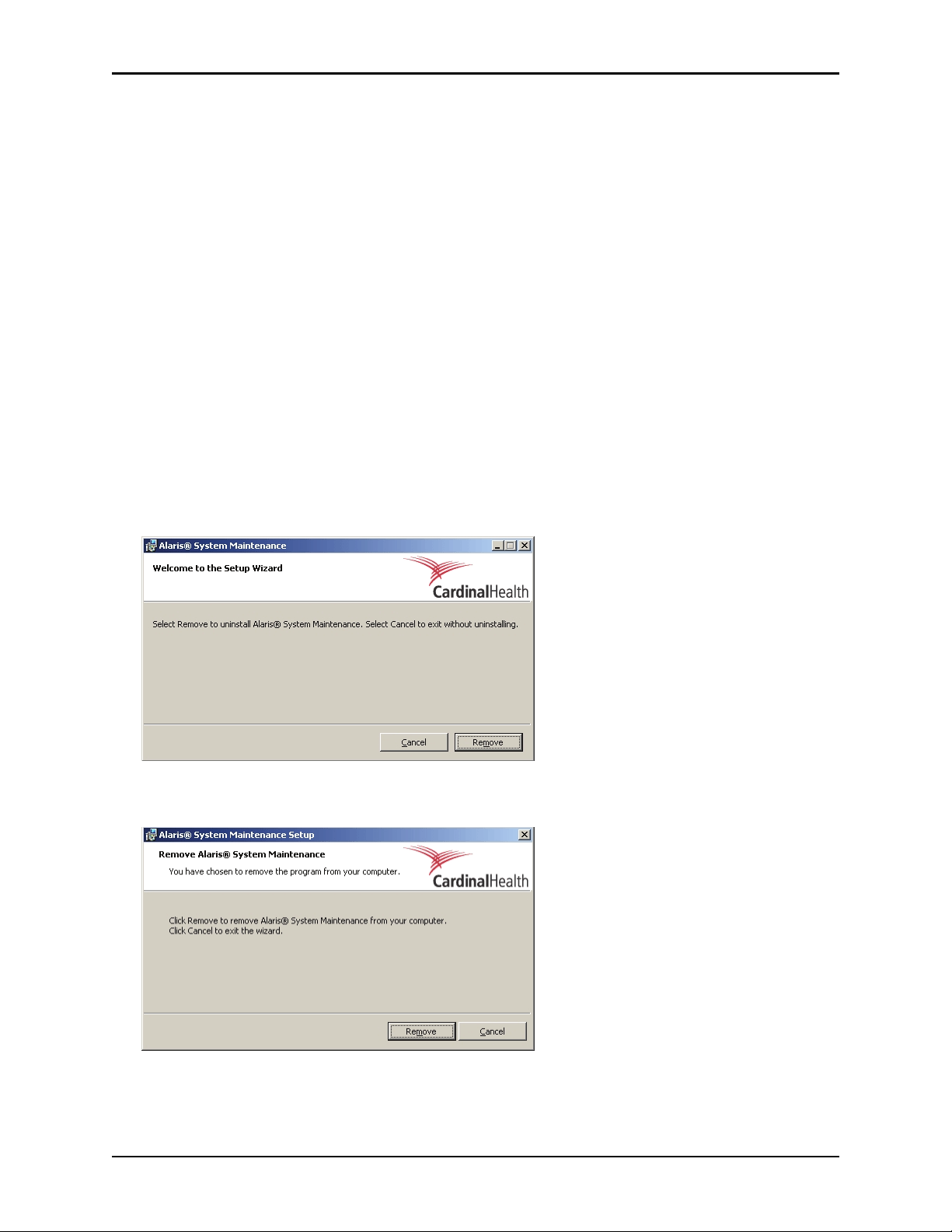

Uninstall Software

There are two ways to uninstall the System Maintenance Software. The method that you use depends on

the version of software that you are uninstalling.

• System Maintenance Software CD: Use this method if the software being removed and the

software that will be installed are the same software version.

• Windows Operating System: Use this method if the software being removed will be replaced with

a different version of the software.

System Maintenance Software CD

1. Insert the System Maintenance Software CD into the CD-ROM drive of the personal computer. The

installation program starts automatically. If the installation program does not start, choose

then type

the System Maintenance Software CD, click

d:\Setup.exe

(where d: is CD drive). Alternatively, browse to the Setup.exe program on

Open, and then click OK.

2. Enter information about installation as prompted, including destination.

Start > Run,

3. When the message that a previous installation has been detected is displayed, click

Remove to

completely remove the existing System Maintenance Software and its components. Existing data is

preserved.

4. Clicking Remove displays the following confirmation window. Click Remove again to initiate the

uninstall process.

5. When a message that indicates the software has been successfully uninstalled is displayed, click

18 Alaris® System Maintenance v9.5.X Software User Manual

Finish.

Page 25

Uninstall Software Chapter 2—Installation and Setup

Windows Operating System

1. Choose Start > Settings > Control Panel.

2. Double-click

3. Click Alaris

Add or Remove Programs.

®

System Maintenance.

4. Click

Remove.

5. Follow the prompts to complete the uninstallation procedure.

Alaris® System Maintenance v9.5.X Software User Manual 19

Page 26

Chapter 2—Installation and Setup Uninstall AlarisSM9DB Database Instance

Uninstall AlarisSM9DB Database Instance

NOTE

All data will be lost when uninstalling the AlarisSM9DB database. Ensure that the

database is backed up for future reference.

Use this procedure to uninstall the AlarisSM9DB database instance of Microsoft SQL Server 2005 Express

and the following software:

• Microsoft SQL Server Native Client (if applicable)

• Microsoft SQL Server Setup Support Files (if applicable)

• Microsoft SQL Server VSS Writer (if applicable)

To uninstall the software:

1. Choose

2. Double-click

Start > Settings > Control Panel.

Add or Remove Programs.

3. Select the software (listed above) that you want to uninstall.

4. Click

Remove.

5. Follow the prompts to complete the removal procedure.

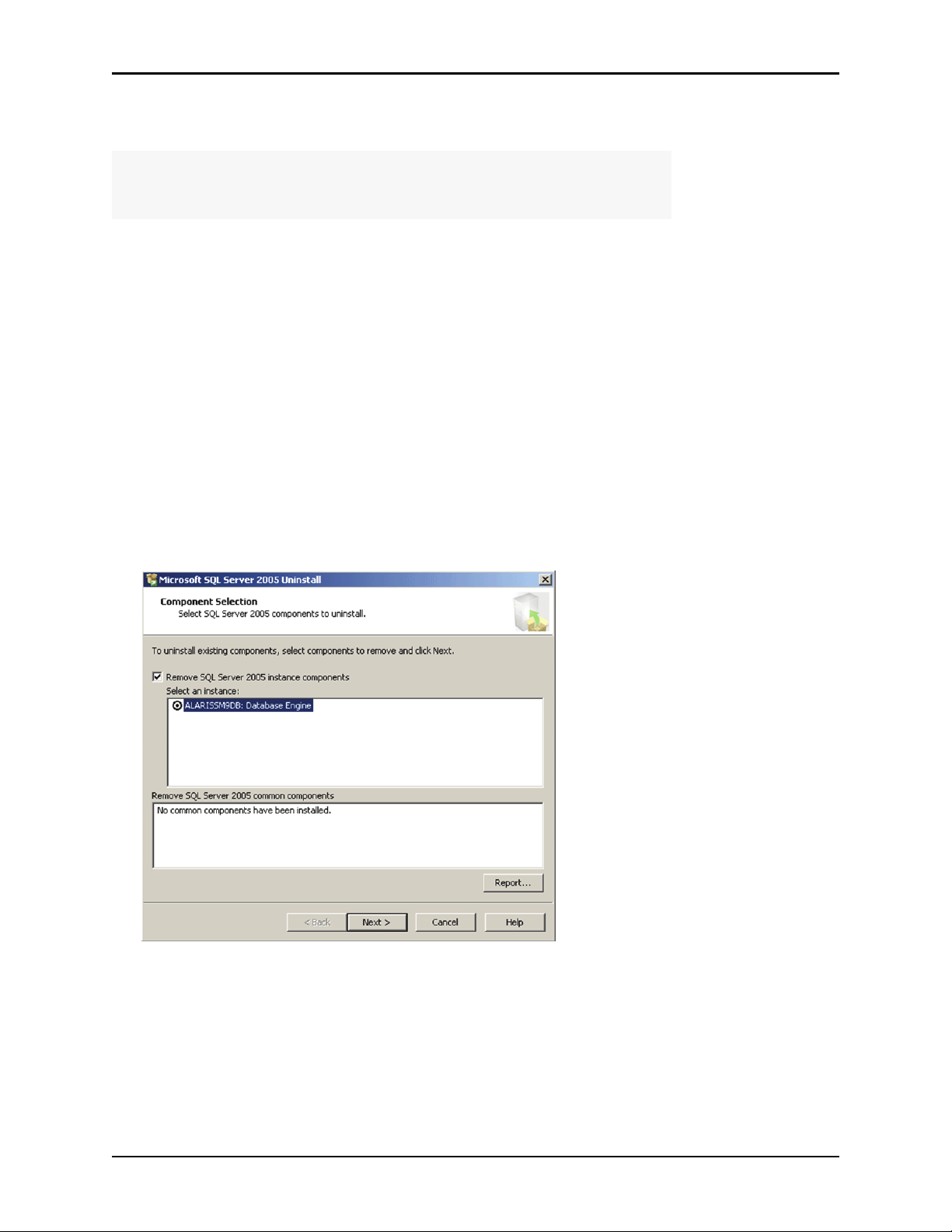

If you are uninstalling Microsoft SQL Server 2005, when the following dialog box is displayed, select

the instance named "AlarisSM9DB" and then click

Next to continue with the removal procedure.

20 Alaris® System Maintenance v9.5.X Software User Manual

Page 27

Chapter 3

Overview

Alaris® System Maintenance v9.5.X Software User Manual 21

Page 28

Chapter 3—Overview Start System Maintenance Software

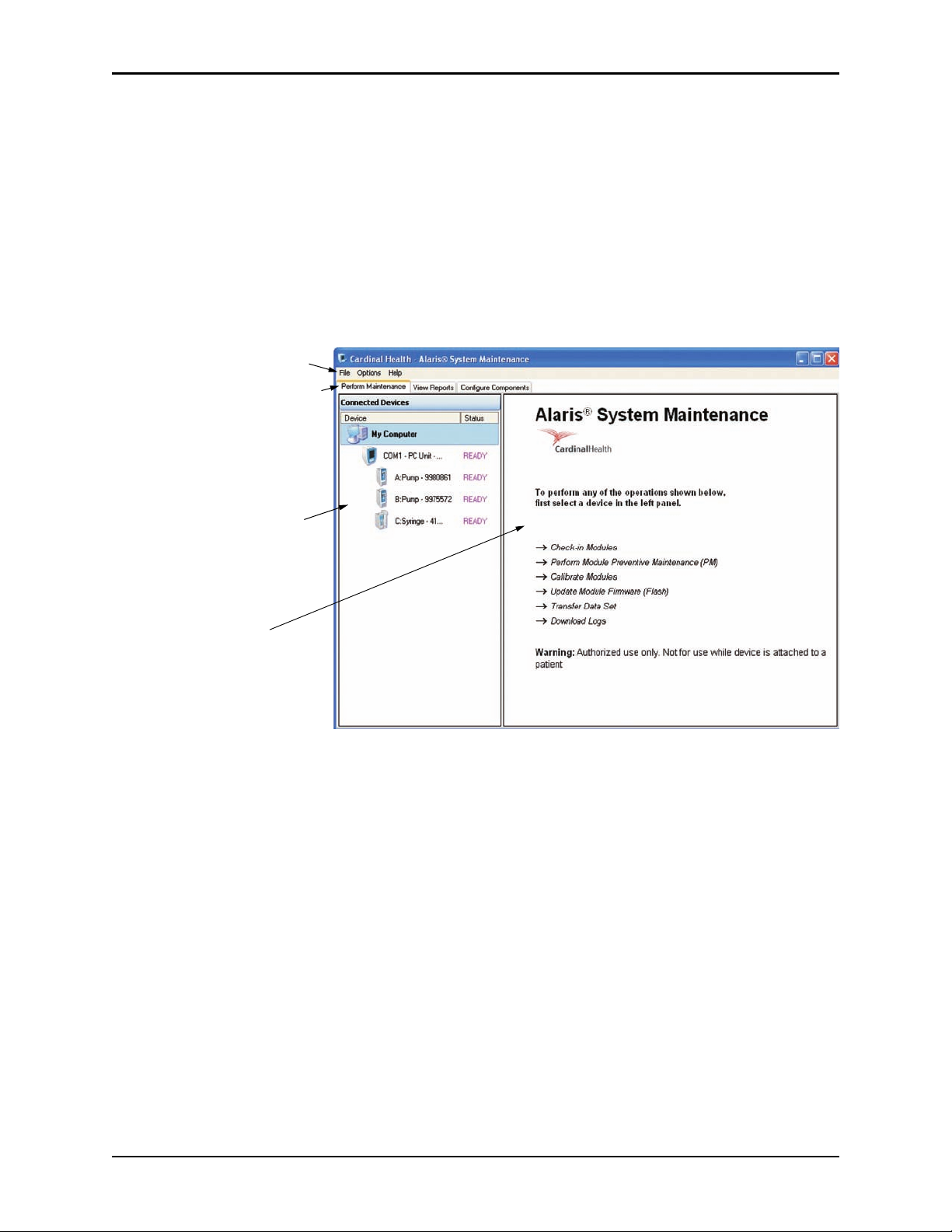

Menu Bar

Tabs in the main window let you

perform maintenance tasks, view

reports from the maintenance

database, configure task lists,

and configure device parameters

The Connected Devices pane

contains a list of the d evices th at

are connected to each of the

communication ports on the

personal computer.

This pane contains task

instructions, input fields, and

report data.

Start System Maintenance Software

1. On the personal computer desktop, double-click the Alaris® System Maintenance icon (or choose the

program from the

A series of status boxes is displayed as the System Maintenance Software scans for communication

ports and establishes communication with connected devices.

When the startup routine is complete, the main window of the System Maintenance Software is

displayed.

Start menu).

2. To check the version of System Maintenance Software, choose

Maintenance.

Help > About Alaris® System

22 Alaris® System Maintenance v9.5.X Software User Manual

Page 29

Menu Bar Chapter 3—Overview

Menu Bar

• File

Refresh (F5)—Refresh all ports.

°

Refresh Selected Port (Ctrl + F5)—Refresh the port that is selected in the Connected Devices pane.

°

Exit (Alt + F4)—Exit the software.

°

•Options

Application Settings—See Application Settings on page 30.

°

Database Settings—See Database Settings on page 31.

°

Export—Export the CQI Database as well as information for all devices that have been connected

°

to the PC Unit.

Import—Import the CQI Database as well as information for all devices that have been connected

°

to the PC Unit.

Migrate MSW Data—Import a previous maintenance software v8 database.

°

•Help

About Alaris

®

System Maintenance—View version and copyright information.

Alaris® System Maintenance v9.5.X Software User Manual 23

Page 30

Chapter 3—Overview Menu Bar

This page intentionally left blank.

24 Alaris® System Maintenance v9.5.X Software User Manual

Page 31

Chapter 4

PC Unit Connection

Alaris® System Maintenance v9.5.X Software User Manual 25

Page 32

Chapter 4—PC Unit Connection Hardware Connections

PC Unit (back)

Communications

port (remove rubber

plug if present)

Serial cable

(both ends shown)

Hardware Connections

This section describes how to connect a PC Unit to the personal computer.

WARNING

At no time should the System Maintenance Software be used while the

®

Alaris

1. If a rubber plug is covering the communications port, remove it.

System is connected to a patient.

2. Connect the small end of the serial cable to the communications port on the back of the PC Unit.

3. Connect the large end of the serial cable to a serial port on the personal computer.

4. If the PC Unit is not on, press the

System On key .

5. If the System Maintenance Software is not running, start it.

6. Press F5 to refresh the ports.

Information about the PC Unit and attached modules is displayed in the Connected Devices pane.

26 Alaris® System Maintenance v9.5.X Software User Manual

Page 33

Multiple PC Unit Connections Chapter 4—PC Unit Connection

Multiple PC Unit Connections

You can connect as many PC Units as there are available serial COM ports on the personal computer. To

view all available COM ports:

1. On the main menu, click

2. In the drop-down menu labeled

Options > Application Settings.

Show only connected ports, click False.

3. Close the Application Settings window.

After a File/Refresh, a list of all available COM ports is displayed in the Connected Devices pane,

whether or not they have a PC Unit attached.

4. Connect the PC Units to the available ports.

5. Press F5 to refresh the view for all ports, or press Ctrl+F5 to refresh only the port that is selected in the

Available Devices pane. These options are also available in the

File menu.

When a port refresh is selected, a list of connected devices is displayed in the Connected Devices pane.

If problems occur when using the refresh feature while connected to a 4-port replicator, consider

restarting the System Maintenance Software to restore the connection.

Alaris® System Maintenance v9.5.X Software User Manual 27

Page 34

Chapter 4—PC Unit Connection Multiple PC Unit Connections

This page intentionally left blank.

28 Alaris® System Maintenance v9.5.X Software User Manual

Page 35

Chapter 5

Application and Database Settings

Alaris® System Maintenance v9.5.X Software User Manual 29

Page 36

Chapter 5—Application and Database Settings Application Settings

Application Settings

Use the Application Settings dialog box to configure the available application options for the System

Maintenance Software. To open the Application Settings dialog box:

1. On the main menu, choose

Options > Application Settings.

The Application Settings dialog box is displayed.

2. To change an application setting, click the column to the right of that setting and make the appropriate

change.

3. Close the Application Settings dialog box to save your changes.

Setting Description

Flash

• Allow serial number update If true, the device serial number can be set through flash

tasks.

• Default SpO

General

• Beep for user input If true, causes application to beep when a running task

• Beep on finished task If true, causes application to beep when a task finishes.

• Enable task list edit button If true, task list edit button is enabled, allowing Task

Module for Flash When flashing the firmware on an SpO2 Module, either

2

®

Nellcor

firmware.

requires attention.

List to be edited.

or Masimo® can be selected as the default

• Show only connected ports If true, only communication ports that have devices

Log Downloading

• Clear downloaded CQI logs If true, CQI logs are cleared from connected devices

• Clear downloaded logs If true, all battery, error, and event logs (other than CQI

Package Components

Ignore incomplete packages If true, any empty packages are ignored and do not

connected to them are displayed in the Connected

Devices pane. If false, all available ports are displayed.

If either clear downloaded logs setting is set to

the software automatically clears the log during

download. If you are performing an instrument

investigation, CareFusion recommends that the logs not

be cleared until the investigation is completed.

after download.

logs) are cleared from connected devices after

download. This setting does not affect whether CQI logs

are cleared after downloading. The clearing of CQI logs

after downloading is managed separately from all other

settings used to clear logs.

produce an error.

True

,

30 Alaris® System Maintenance v9.5.X Software User Manual

Page 37

Database Settings Chapter 5—Application and Database Settings

Select a tab to display the list

of database definitions for the

selected System Maintenance

Softw are database.

Database definitions relating

to the selected tab display

here. The active definition has

Default set to Yes.

Database Settings

Multiple database definitions can be defined for the three System Maintenance Software databases

(Maintenance database, Maintenance Log database, and CQI database). Each definition contains the server

name and authentication for the databases. Once defined, the user can select which database to use from

this list of defined databases.

Once defined, do not change database settings unless you have a valid reason for doing so. For example,

you may need to select a site-specific database in an environment that supports multiple hospital sites.

The System Maintenance Software automatically connects to the default database locations, but additional

customizing may need to occur if your database definition is different from these default parameters.

Open Database Settings

On the main menu, choose Options > Database Settings.

The Database Selection dialog box is displayed.

Alaris® System Maintenance v9.5.X Software User Manual 31

Page 38

Chapter 5—Application and Database Settings Database Settings

Add a Database Definition

1. Click the tab of the desired System Maintenance Software database.

2. Click

3. Select an SQL Server.

4. Select a Database name on this SQL Server.

5. Click

6. Click

Add.

The Database Settings dialog box is displayed.

Test Connection to test the connection to the server.

OK to acknowledge the test connection.

7. Click

OK to save the definition.

Delete a Database Definition

1. Click the tab of the desired System Maintenance Software database.

2. Click the database definition that you want to delete.

3. Click

Delete.

A confirmation dialog box is displayed.

4. Click

OK to delete the database definition.

Set Active Database Definition

1. Click the tab of the desired System Maintenance Software database.

2. Click the database definition to make it active.

3. Click

Set Default.

The System Maintenance Software now uses the selected definition as the active database and begins

logging data to it as data is collected.

Test Database Definition Connection

1. Click the tab of the desired System Maintenance Software database.

2. Click the database definition to select it.

3. Click

Test Connection.

If the connection fails, check the database definition for errors.

32 Alaris® System Maintenance v9.5.X Software User Manual

Page 39

Migrate MSW Databases Chapter 5—Application and Database Settings

Migrate MSW Databases

There are two separate MSW application databases, MSW and MSW Log. Use the following procedure to

migrate the MSW databases to the System Maintenance Software database.

1. On the main menu, click

The Database Selection screen is displayed:

Options > Migrate MSW Data.

2. If the desired MSW or MSW Log databases are not listed, continue with the following steps;

otherwise, proceed to step 3.

NOTE

The desired MSW databases (MSW and MSW Log) must be configured as

default DB.

Alaris® System Maintenance v9.5.X Software User Manual 33

Page 40

Chapter 5—Application and Database Settings Migrate MSW Databases

a. Click the tab for the applicable database and then click Add. The Database Settings screen is

displayed.

b. Select the desired server from the SQL Server drop-down list.

c. From the Database name drop-down list, select MTR for the MSW database or IMSLog for the

MSW Log database.

NOTE

If the required database is not in the Database name drop-down list, the selected

SQL Server is not correct.

d. Click

Test Connection to have the software verify that the MSW database configuration is correct.

3. Click on desired database.

4. Click

Migrate—located at the bottom of the Database Selection screen—to start data migration.

The data migration progress screen is displayed. When the migration process is complete, the

application displays the status of the migration.

34 Alaris® System Maintenance v9.5.X Software User Manual

Page 41

Chapter 6

Preventive Maintenance

Alaris® System Maintenance v9.5.X Software User Manual 35

Page 42

Chapter 6—Preventive Maintenance Introduction—

Introduction

WARNING

At no time should the System Maintenance Software be used while the

®

Alaris

Preventive maintenance can be performed on connected modules by selecting from a list of automated

tasks. Tasks can be individual tasks that exist in the list of master tasks or task groups that contain a

collection of the individual tasks required to maintain devices.

Standard task groups include:

System is connected to a patient.

Check-in

Preventive Maintenance

Calibration

T asks required to check any module newly received into

the facility . Run check-in on a newly received module to

confirm that it was not damaged during transport and is

ready to be put into use. System Maintenance Software

guides you through check-in.

The final task in the Check-in task group allows you to

set a Preventive Maintenance (PM) Reminder Date to

remind the user when preventive maintenance is due.

Tasks required to perform regular maintenance on a

module.

Run preventive maintenance tests a minimum of once a

year to confirm that modules are performing correctly.

System Maintenance Software guides you through

preventive maintenance tests.

Final task in Preventive Maintenance task group allows

you to set the next PM Reminder Date to remind the

user when preventive maintenance is due.

T asks required to test whether calibration is required and

to calibrate connected modules.

The calibration task group applies to EtCO

Syringe Module, PCA Module, and Pump Module.

Module,

2

36 Alaris® System Maintenance v9.5.X Software User Manual

Page 43

Introduction—General Steps Chapter 6—Preventive Maintenance

General Steps

The main window is shown below. When you click a node such as My Computer in the Connected Devices

pane, information on how to proceed is displayed in the right pane.

1. Click the

Perform Maintenance tab.

2. Select the module (device).

The Tasks list is displayed.

NOTE

• The tasks in the Tasks list vary depending on which module you have

selected and how the tasks are configured.

• You can edit the Tasks list, if desired (see Tasks List on page 168).

Alaris® System Maintenance v9.5.X Software User Manual 37

Page 44

Chapter 6—Preventive Maintenance Introduction—General Steps

3. Click Preventive Maintenance in the Tasks list (Pump Module screen used as an example in following

illustration).

NOTE

As a shortcut, you can double-click the task to select it and start it immediately.

4. If Preventive Maintenance was not automatically started, click

Start Selected Tasks.

5. Follow all on-screen instructions carefully to ensure the successful completion of the task.

If a task fails, the System Maintenance Software asks you if you want to rerun the failed task.

NOTE

At the end of some tests you are asked to indicate if the test passed or failed.

Other tests automatically indicate a pass or fail result.

To rerun the task, click Yes.

°

To continue to the next task in a task group, click No.

°

To correc t a failure, abort the selected task and refer to the applicable Technical Service Manual.

°

38 Alaris® System Maintenance v9.5.X Software User Manual

Page 45

Introduction—Run/Abort Tasks Chapter 6—Preventive Maintenance

6. When finished, click Reset Selected Tasks to return a module to the READY state (Pump Module screen

used as an example in following illustration).

Run/Abort Tasks

Run Tasks Concurrently

You can run selected tasks concurrently on different connected modules. One PC Unit and a serial port is

needed for each module being tested. Once you have started selected tasks on one connected device, select

other devices in the Connected Devices pane and start tasks for those devices, if desired.

The status bar displays devices that are currently running tasks. If attention is required by a device to

continue a task, the device progress bar and the Details Pane Task button for that task will be orange.

Select the device in the Connected Devices pane to display its task instructions and follow the displayed

task instructions.

The System Maintenance Software sounds an alarm when a device needs attention or when a task is

finished, if these options are set. For information on setting these options, see Application Settings on

page 30.

Alaris® System Maintenance v9.5.X Software User Manual 39

Page 46

Chapter 6—Preventive Maintenance Introduction—Coloring Scheme

Abort Tasks

You can abort (cancel) any running task that is currently selected in the Connected Devices pane.

Abort Selected Tasks.

Click

The status of the task is reset to

CANCEL.

Coloring Scheme

The preventive maintenance test results are identified using the following color scheme:

Blue—test passed

Brown—test aborted

Red—test failed

Orange—test is running, but waiting for user input

Purple—test has not yet been run

Green—test is automatically running (not requiring user input at this time)

Example:

40 Alaris® System Maintenance v9.5.X Software User Manual

Page 47

Preventive Maintenance—PC Unit Chapter 6—Preventive Maintenance

Preventive Maintenance

To perform preventive maintenance, see the procedure in this section that applies to the module being

tested:

PC Unit on page 41

Pump Module on page 47

PCA Module on page 59

Syringe Module on page 67

Module on page 77

SpO

2

EtCO

Module on page 84

2

Auto-ID Module and Handheld Scanner on page 91

PC Unit

Test Equipment

Test Equipment Manufacturer Model Number Application

analyzer, electrical safety Fluke BioMedical 232D or equivalent ground tests

1. In the Connected Devices pane, click the PC Unit to be tested.

2. Click

Preventive Maintenance in the Tasks list (double-click to begin testing immediately).

3. Follow the instructions displayed on the screen for each test.

NOTE

See PC Unit Tasks on page 170 for an explanation of each task.

Alaris® System Maintenance v9.5.X Software User Manual 41

Page 48

Chapter 6—Preventive Maintenance Preventive Maintenance—PC Unit

If the test failed, click Abort Selected Tasks—in

the T asks list—to discontinue testing. Correct the

failure(s) before continuing with the tests.

4. Instrument Inspection:

42 Alaris® System Maintenance v9.5.X Software User Manual

Page 49

Preventive Maintenance—PC Unit Chapter 6—Preventive Maintenance

'Sandwiching'—the PC Unit has one module

attached to each side.

5. Simultaneous Display:

If you want the test to run continuously, click the

Run test in continuous mode checkbox.

• Look for missing pixels (display elements) as each screen is displayed.

• The Model 8000 displays dark gray and light gray screens. The Model 8015 displays dark gray,

light gray, white, red, green, and blue screens.

• If the screen brightness or contrast appears weak, check the contrast setting (refer to applicable

®

Alaris

System DFU).

6. IUI Connectors:

Alaris® System Maintenance v9.5.X Software User Manual 43

Page 50

Chapter 6—Preventive Maintenance Preventive Maintenance—PC Unit

If the audio is weak, check the audio volume

setting (refer to applicable Alaris

®

System DFU).

7. Alarm:

8. Keypad:

NOTE

Press and hold the Tamper Switch (on back of PC Unit) for at least two seconds,

until there is a response to the test.

Press each key one time.

• Green text—the key was pressed one time and passed the test.

• Red text—the key was pressed two times, or it was pressed one time and failed the test. If the text

is red because you pressed the key more than one time, you can indicate that the test has passed.

9. Nurse Call:

This test is performed only if a Nurse Call is installed and applies only to the Model 8000.

44 Alaris® System Maintenance v9.5.X Software User Manual

Page 51

Preventive Maintenance—PC Unit Chapter 6—Preventive Maintenance

Use a Fluke Biomedical Model 232D or

equivalent electrical safety analyzer to measure

the ground leakage current. Refer to the test

equipment’s operation manual for the proper

measurement technique.

The line voltage must be the same as the voltage

that powers the tester and then passes to the

instrument being tested.

Use the following table—in place of the

requirements identified by the software—to

determine the leakage current requirements for

normal and reversed line polarity. The limits are

100 µA below the IEC/UL 60601-1 standard

limits to account for test variances.

AC Supply

Leakage Current—

Maximum

Japan 100 VAC 400

µA

North America 120 VAC 200

µA

Rest of World 230 VAC 400

µA

Australia

New Zealand

240 VAC 400

µA

Use a Fluke Biomedical Model 232D , an Ohm

Meter, or an equivalent electrical safety analyzer

to measure the ground resistance between the

ground pin on power cord plug or power cord

receptacle, and the rear panel of the PC Unit. Refer

to the test equipment’s operation manual for the

proper measurement technique.

The maximum allowable resistance is 1 Ohm.

10. Ground Leakage:

The ground leakage test is not performed by the System Maintenance Software. The leakage current

table provided below reflects IEC/UL 60601-1 requirements. The limits identified in the table are to be

used in place of the 100 µA leakage current limit specified by the software.

11. Ground Resistance:

The ground resistance test is not performed by the System Maintenance Software. Use the following

instructions and illustration to perform this test—in place of the instructions displayed by the software.

Alaris® System Maintenance v9.5.X Software User Manual 45

Page 52

Chapter 6—Preventive Maintenance Preventive Maintenance—PC Unit

The following illustration is a partial view of the rear of the PC Unit. In the illustrated example of

a ground contact, a Kelvin Clip is clipped to a speaker slot on the rear panel. The only acceptable

ground contact area is the rear panel—gold anodized color metal (shaded area in illustration).

NOTE

The following illustration reflects the use of the Kelvin Clip that is provided with

the Fluke tester. If another tester or Ohm Meter is used, the test measures the

resistance between the rear panel (shaded area in illustration) and the ground pin

on the power cord plug or power cord receptacle.

12. Set PM Reminder:

• If

Enable Maintenance Reminder is selected, a Data Set is loaded and the configuration option for

the Data Set is set to Disable. The Data Set setting overrides the System Maintenance Software

selection.

• The next maintenance reminder date defaults to 12 months. The reminder can be set to an earlier

date but it cannot be set to a date past the 12-month default.

46 Alaris® System Maintenance v9.5.X Software User Manual

Page 53

Preventive Maintenance—Pump Module Chapter 6—Preventive Maintenance

Pump Module

Test Equipment

Test Equipment Manufacturer Model/Part Number Application

gauge

, pressure, digital

(peak hold)

hemostat N/A N/A fluid-side occlusion test

IV pole, standard CareFusion 903-0336 or equivalent rate, pressure, and occlusion tests

Either of the following:

• Heise

(www.heise.com)

• Ashcroft

(www.ashcroft.com)

• PTE-1 (accuracy from 0.1 to

0.025% span)

• 2089, 2086, or 2084 (accuracy

from ±0.05%, 0.10%, or

0.25% of span)

• or an equivalent gauge with:

(a) unit of measure in mmHg

(b) accuracy of ±1%

(c) range of 0-1500 mmHg

pressure test

IV sets

• IV set, standard,

without check valve

• IV set, calibration

• IV set, calibration

IV solution container

(bag preferred)

luer lock, female,

1/8"-27 NPT

reducer, female,

1/4" NPT (F) x

1/8" NPT (F)

scale, digital Acculab

tubing, silicone CareFusion 303109 or equivalent pressure test

T-fitting CareFusion 303815 or equivalent pressure test

valve, 3-way CareFusion 97555 or equivalent pressure test

• CareFusion

• CareFusion

• CareFusion

N/A N/A rate and pressure tests

Cole-Parmer

(www.coleparmer.com)

Cole-Parmer

(www.coleparmer.com)

(www.acculab.com)

• 2210-0500

• 8100-RCS

• 8100-PCS

K-45503-78 or equivalent pressure test

K-06349-91 or equivalent pressure test

VIC-212 (VICON Series) or

equivalent with accuracy of

±0.01g

rate and pressure tests

rate and pressure tests

Alaris® System Maintenance v9.5.X Software User Manual 47

Page 54

Chapter 6—Preventive Maintenance Preventive Maintenance—Pump Module

1. In the Connected Devices pane, click the Pump Module to be tested.

2. Click

Preventive Maintenance in the Tasks list (double-click to begin testing immediately).

3. Follow the instructions displayed on the screen for each test.

NOTE

See Pump Module Tasks on page 175 for an explanation of each task.

4. Instrument Inspection:

48 Alaris® System Maintenance v9.5.X Software User Manual

Page 55

Preventive Maintenance—Pump Module Chapter 6—Preventive Maintenance

If the test failed, click Abort Selected Tasks to discontinue testing. Correct the failure(s) before

continuing with the tests.

5. Simultaneous Display:

If you want the test to run continuously, select

Run test in continuous mode.

• Channel ID display—all segments must light.

• Scrolling display and Rate display—must flash dashes and zeros.

• Lighthouse LED’s—all LEDs must light.

Alaris® System Maintenance v9.5.X Software User Manual 49

Page 56

Chapter 6—Preventive Maintenance Preventive Maintenance—Pump Module

’Sandwiching’—the module being tested is connected

between the PC Unit and another module.

If the audio is weak, check the audio volume

setting (refer to applicable Alaris

®

System DFU).

6. IUI Connectors:

7. Alarms:

If the audio is weak, check the audio volume setting (refer to applicable Alaris

®

System DFU).

8. Keypad:

Press each key one time.

• Green text—the key was pressed one time and passed the test.

• Red text—the key was pressed two times, or it was pressed one time and failed the test. If the text

is red because you pressed the key more than one time, you can indicate that the test has passed.

50 Alaris® System Maintenance v9.5.X Software User Manual

Page 57

Preventive Maintenance—Pump Module Chapter 6—Preventive Maintenance

Ensure that the pumping

segment is vertical across the

center of the pressure sensors.

Ensure that the tubing is fully

inserted in the Air-in-Line

Sensor.

9. Door Ajar-Flo-Stop Sensors:

54

Load Administration Set

Install an administration set as shown for any Pump Module test. Unless otherwise specified, in order

to run a Pump Module test, the set must be loaded and the Pump Module door must be closed.

Alaris® System Maintenance v9.5.X Software User Manual 51

Page 58

Chapter 6—Preventive Maintenance Preventive Maintenance—Pump Module

10. Air-in-Line Sensor:

11. Rate Accuracy

CAUTION

If the Pump Module fails the rate accuracy test, calibration is required. Failure to

perform calibration tests might result in improper operation.

:

Set up the Pump Module for the Rate Accuracy test.

Rate Accuracy Test Setup

CAUTION

• If the Pump Module fails the rate accuracy verification test, calibration is

required. Failure to perform calibration tests might result in impro per

operation.

• To ensure accurate rate calibration, use only rate calibration sets. Rate

accuracy calibration sets are valid for 60 calibrations and must be replaced

after 60 uses.

• Use distilled water at room temperature of 41°F to 104°F (5°C to 40°C). If the

water temperature is not within this range, the readings might be inaccurate.

Use this setup to perform the following tests:

• Rate accuracy verification—Tasks: Rate Accuracy, Check-in, and Preventive Maintenance.

• Rate accuracy calibration pre-test—Task: Rate Accuracy Pre-Test.

• Rate accuracy calibration—Task: Rate Calibration.

• Rate accuracy calibration post-test—Task: Rate Accuracy Post-Test.

All tests use a standard set except for the rate accuracy verification (Task: Preventive Maintenance)

and the rate accuracy calibration. These tests require the use of the Model 8100-RCS rate calibration

set.

Verify that the scale is calibrated according to the manufacturer's instructions. Prime the fluid lines and

keep them free of air bubbles while running the test.

If the rate accuracy calibration pre-test fails, perform the rate accuracy calibration. Following

calibration, run the rate accuracy calibration post-test using a different rate calibration set to test the

module with the newly calibrated parameters.

—See the test setup illustration on the following page.—

52 Alaris® System Maintenance v9.5.X Software User Manual

Page 59

Preventive Maintenance—Pump Module Chapter 6—Preventive Maintenance

20±1 inch

1

4

7

CLEAR

2

5

8

0

3

6

9

.

ENTER

CANCEL

SYSTEM

PUMP

PUMP

RESTART

CHANNEL

OFF

CHANNEL

SELECT

PAUSE

RESTART

CHANNEL

OFF

CHANNEL

SELECT

PAUSE

Top of cup must be

level with CHANNEL

SELECT key .

Distance is from top

of Pump Module

Ensure that the set is properly loaded (see Load

Administration Set on page 51). Ensure that

there are no air bubbles in the set when priming

is completed.

The

Expected Volume is identified on the label

attached to the characterized set.

Error message—first occurrence

If an error message appears after clicking

Next, perform the following steps.

NOTE

If this is not the first occurrence of an error message and the following procedure

has already been performed, perform Error message—repeat occurrence.

Alaris® System Maintenance v9.5.X Software User Manual 53

Page 60

Chapter 6—Preventive Maintenance Preventive Maintenance—Pump Module

Ensure that the distilled water is dripping into the

cup and that the tubing is not resting on the scale.

a. Click OK and visually confirm that:

• The set is properly loaded in the Pump Module.

• There are no air bubbles in the set.

b. Click

Yes on the message that appears.

c. Detach and reattach the Pump Module with set installed.

d. Repeat the rate accuracy test after the Pump Module reinitializes.

Error message—repeat occurrence

If an error message appears after clicking

Next, manually connect to the Maintenance Mode and

retest, as follows:

a. Abort the selected task.

a. Exit the System Maintenance Software.

b. Turn off the PC Unit.

c. Ensure that the serial cable is connected between the communications port on the PC Unit and

the computer.

d. Press and hold the Tamper Switch and the System On key on the PC Unit until the PC Unit

beeps once and displays the Maintenance Mode screen.

e. Press the Proceed soft key and then press the External Communications soft key.

f. Start the System Maintenance Software.

g. Perform Preventive Maintenance.

When performing the Rate Accuracy test, follow the instructions to ensure that the set is

properly loaded and that there are no air bubbles in the set when priming is completed.

54 Alaris® System Maintenance v9.5.X Software User Manual

Page 61