Page 1

A

L

A

R

M

IN

FU

S

E

S

T

A

N

D

B

Y

CHANNEL

SELECT

CHANNEL

OFF

PAUSE

RESTART

RATE (mL/h)

A

L

A

R

M

I

N

FU

S

E

S

T

A

N

D

B

Y

CHANNEL

SELECT

CHANNEL

OFF

PAUSE

RESTART

RATE (mL/h)

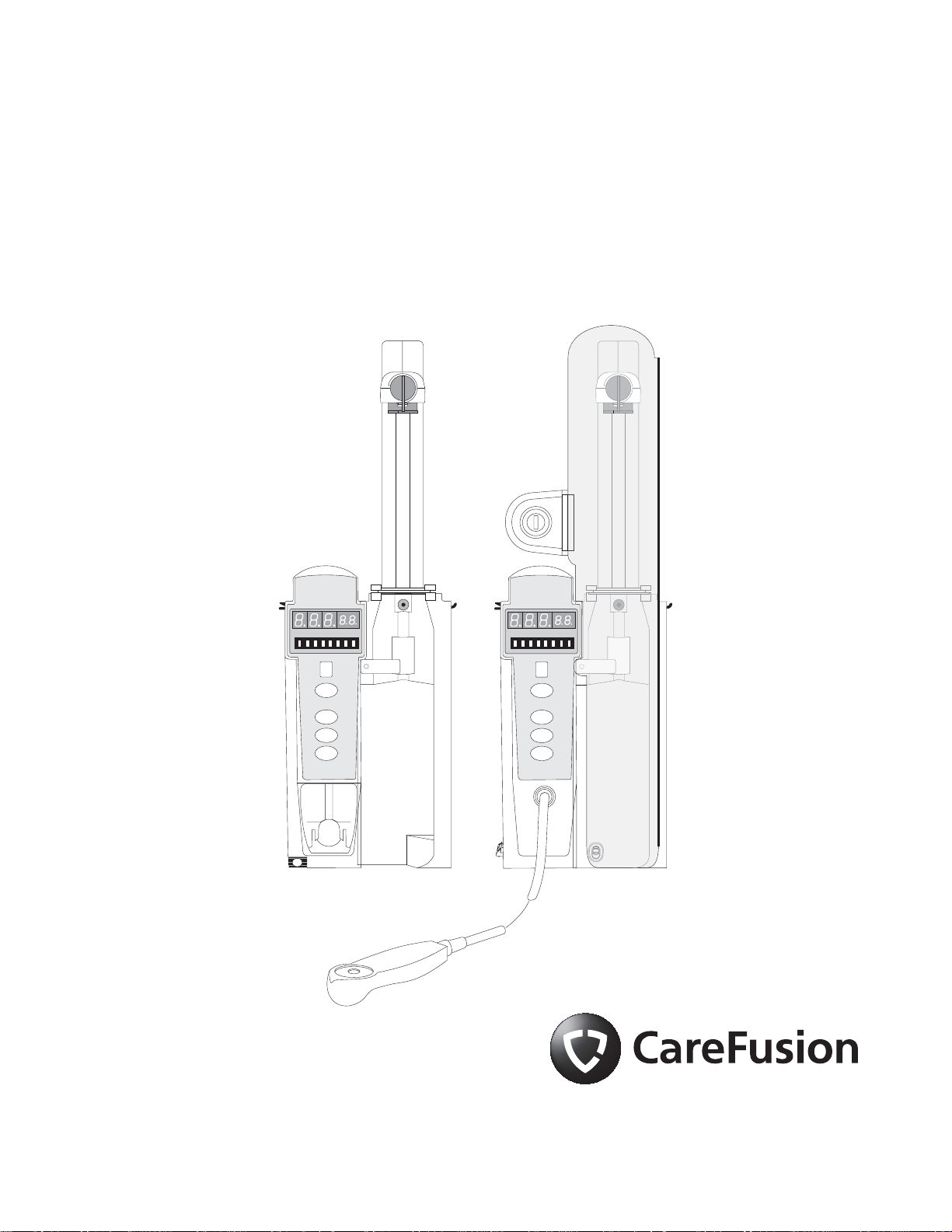

Technical Service Manual

Alaris®Syringe Module, 8110 Series

Alaris

Supports: Guardrails® (Suite v7 or Later)

November 2010

®

PCA Module, 8120 Series

Page 2

General Contact Information

CareFusion

San Diego, California

http://www.carefusion.com/alaris

Customer Advocacy - North America

E-Mail: CustomerFeedback@carefusion.com

Maintenance and service information support; troubleshooting.

Clinical and technical feedback.

Phone: 888.876.4287

Technical Support - North America

United States:

Phone:

888.876.4287

Instrument return, service assistance, and order placement.

United States:

Phone: 888.876.4287

Canada:

Phone:

800.387.8309

Customer Care - North America

Canada:

Phone: 800.387.8309

Page 3

TABLE OF CONTENTS

i

Chapter 1 - General Information

1.1 Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Precaution Definitions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Operating Features, Controls and Indicators

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

1.5 Accessories

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.6 Alarms, Errors, Messages

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.6.1 Silencing Alarms

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.7 Trumpet and Start-Up Curves

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

Chapter 2 - Checkout and Configuration

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 New Instrument Checkout

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 Configuration Options and Defaults - Syringe Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3.1 Factory Default Setting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.4 Configuration Setup - Syringe Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.4.1 All Mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4.2 Auto Pressure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4.3 Back Off

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4.4 Fast Start

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.4.5 KVO

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.4.6 Max Rate

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.4.7 Near End

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4.8 Pressure Limit - Disc

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.4.9 Pressure Limit - No Disc

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.4.10 Priming

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.5 Configuration Setup - Shared Infusion Pump and Syringe

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.6 Configuration Options and Defaults - PCA Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Chapter 3 - Preventive Maintenance

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Regular and Preventive Maintenance Inspections, Calibration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Cleaning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Chapter 4 - Principles of Operation

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 General Information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 Display Board Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

Page 4

ii

TABLE OF CONTENTS

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

Chapter 4 - Principles of Operation (Continued)

4.3.1 Microcontroller

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3.2 LED Display Driver

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3.3 Comparator/Safety Monitor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3.4 Status and Backlight LEDs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2

4.4 Logic Board Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.5 Drivetrain Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.6 Drive Head

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.7 Plunger Head Board Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4

4.8 Force Sensor Subsystem

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.9 Pressure Sensor Subsystem (Syringe Module Only)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.10 Patient Handset Circuit and Door Lock Sensor Circuit (PCA Module Only)

. . . . . . . . . . . . . . . . . . . . . . 4-5

Chapter 5A

- Corrective Maintenance - Syringe Module

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-1

5.2 Disassembly/Reassembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-2

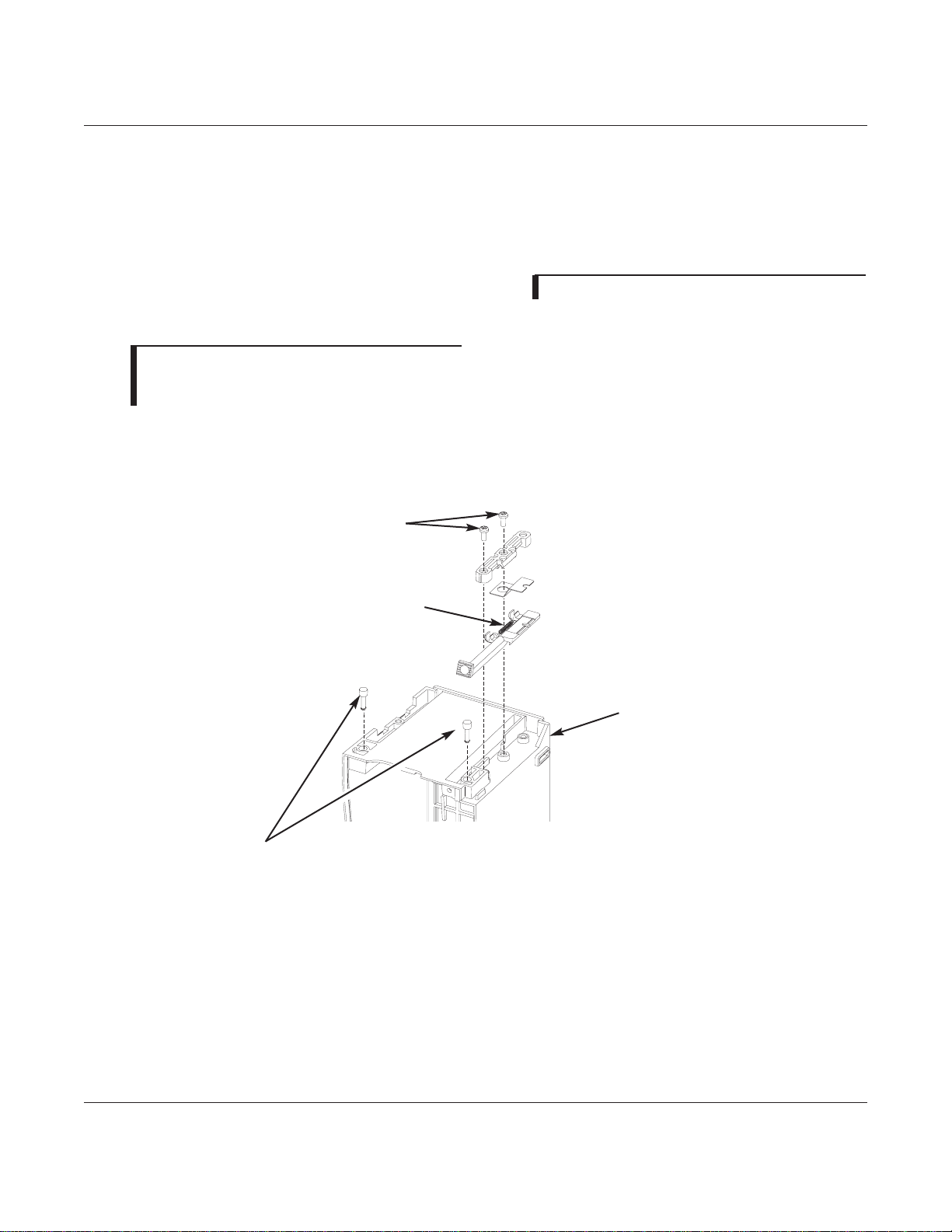

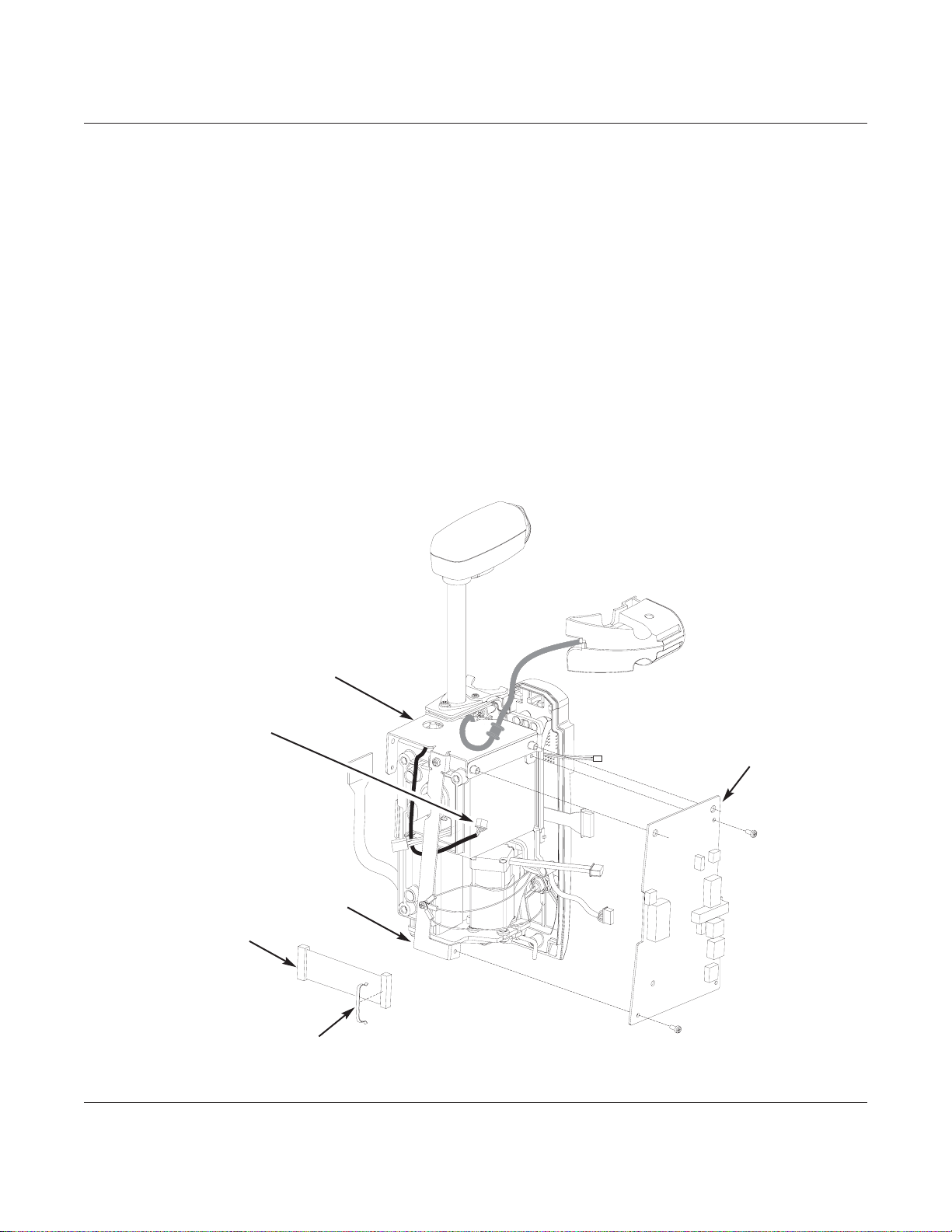

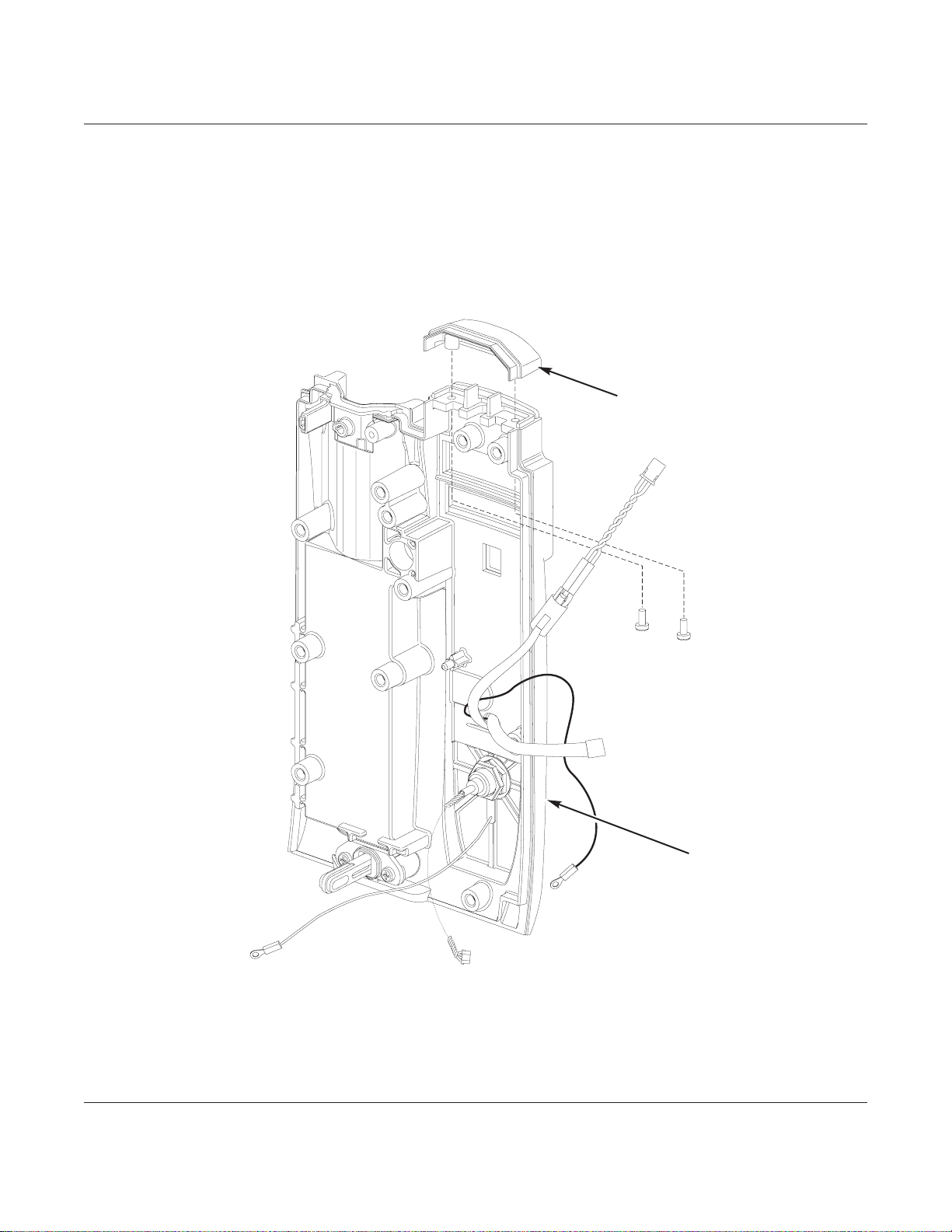

5.2.1 Removing Latch Assembly and Feet

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-3

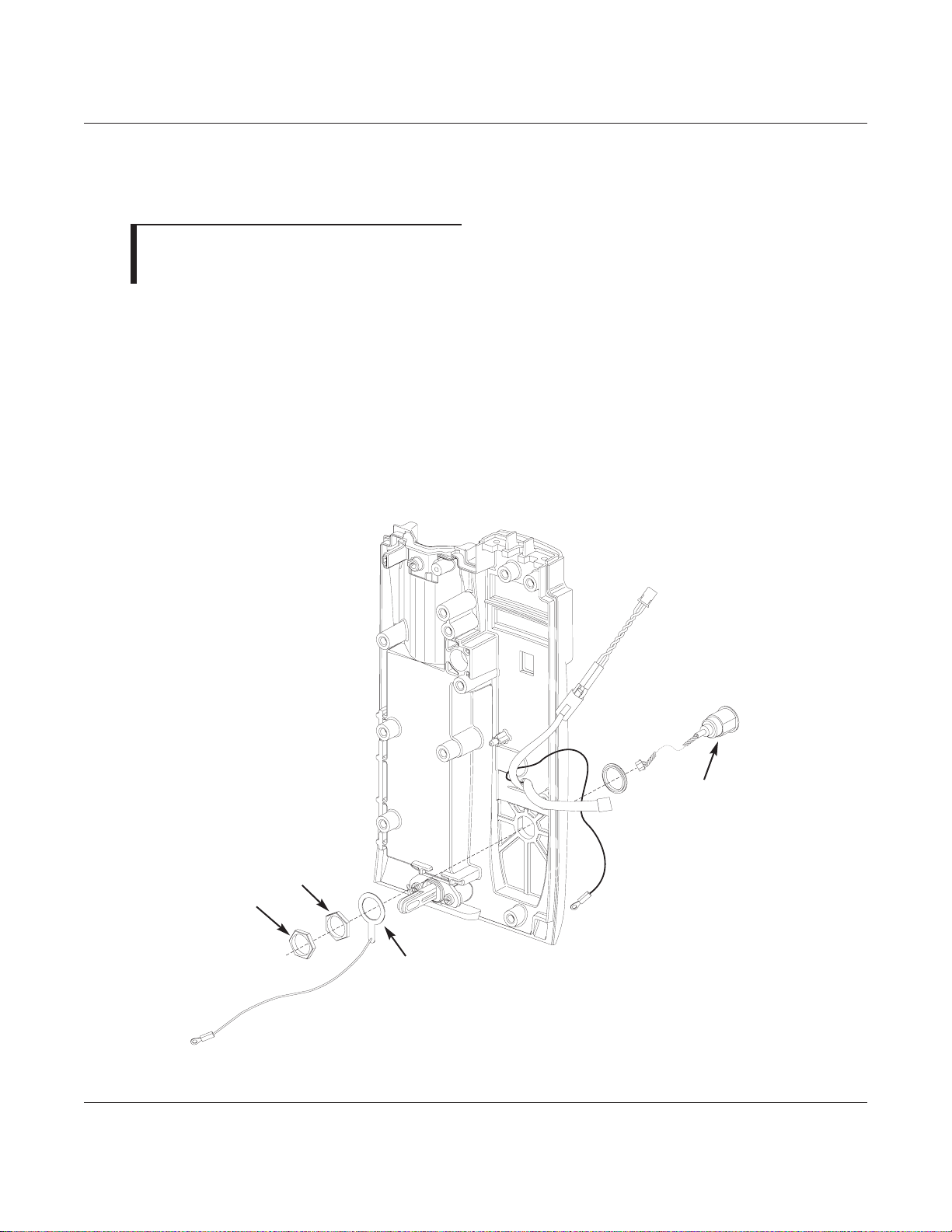

5.2.2 Removing IUI Connector Assemblies

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-4

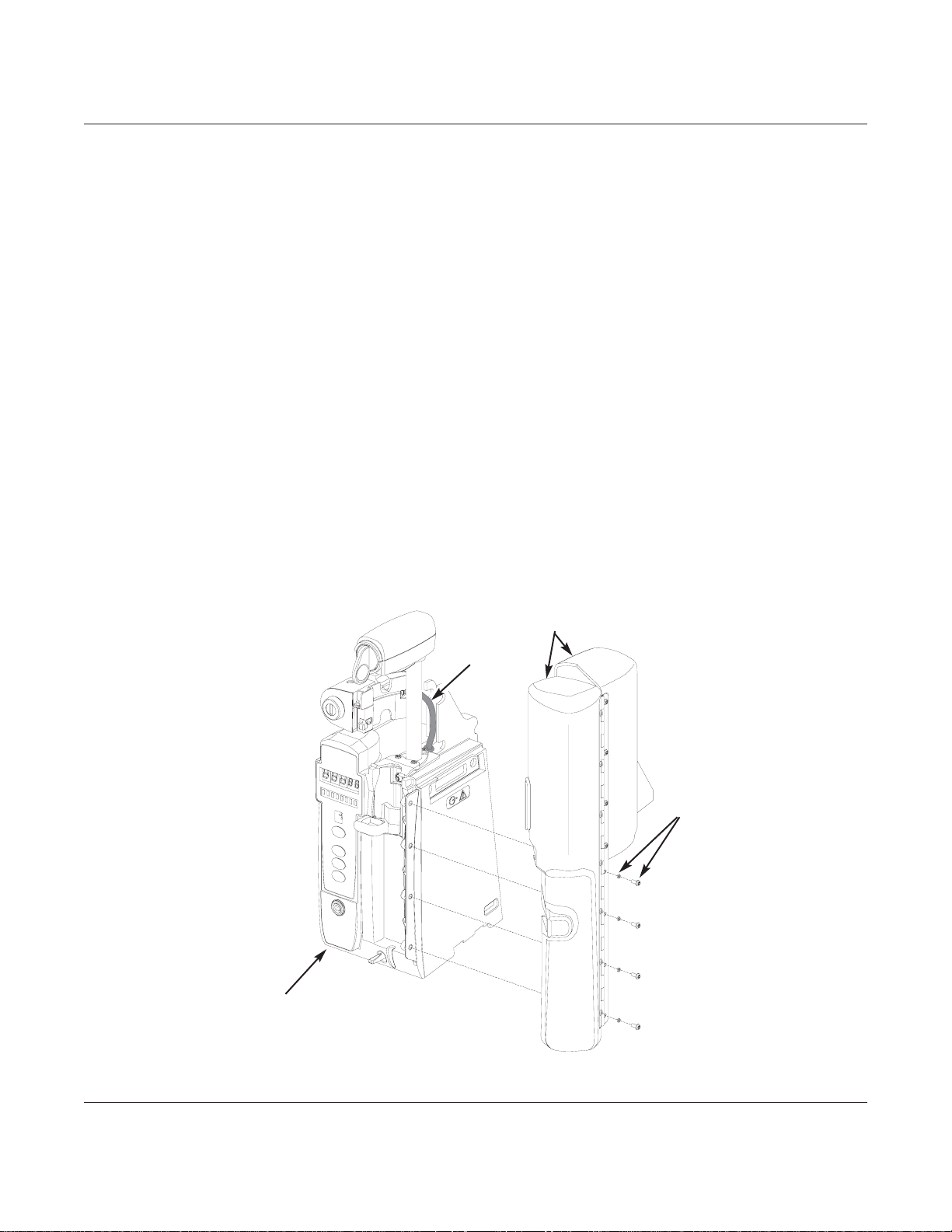

5.2.3 Separating Rear Case from Chassis Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-5

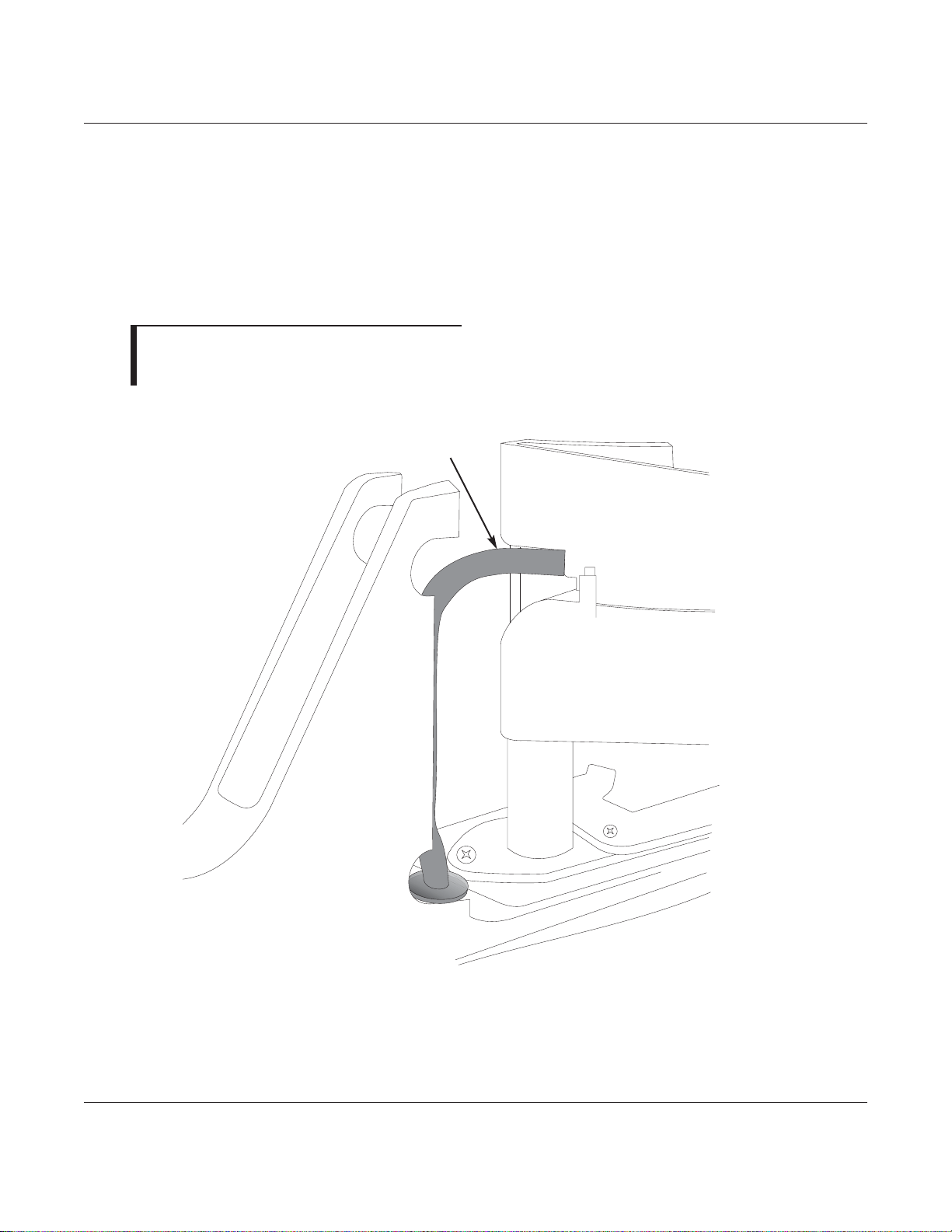

5.2.4 Removing Handle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-6

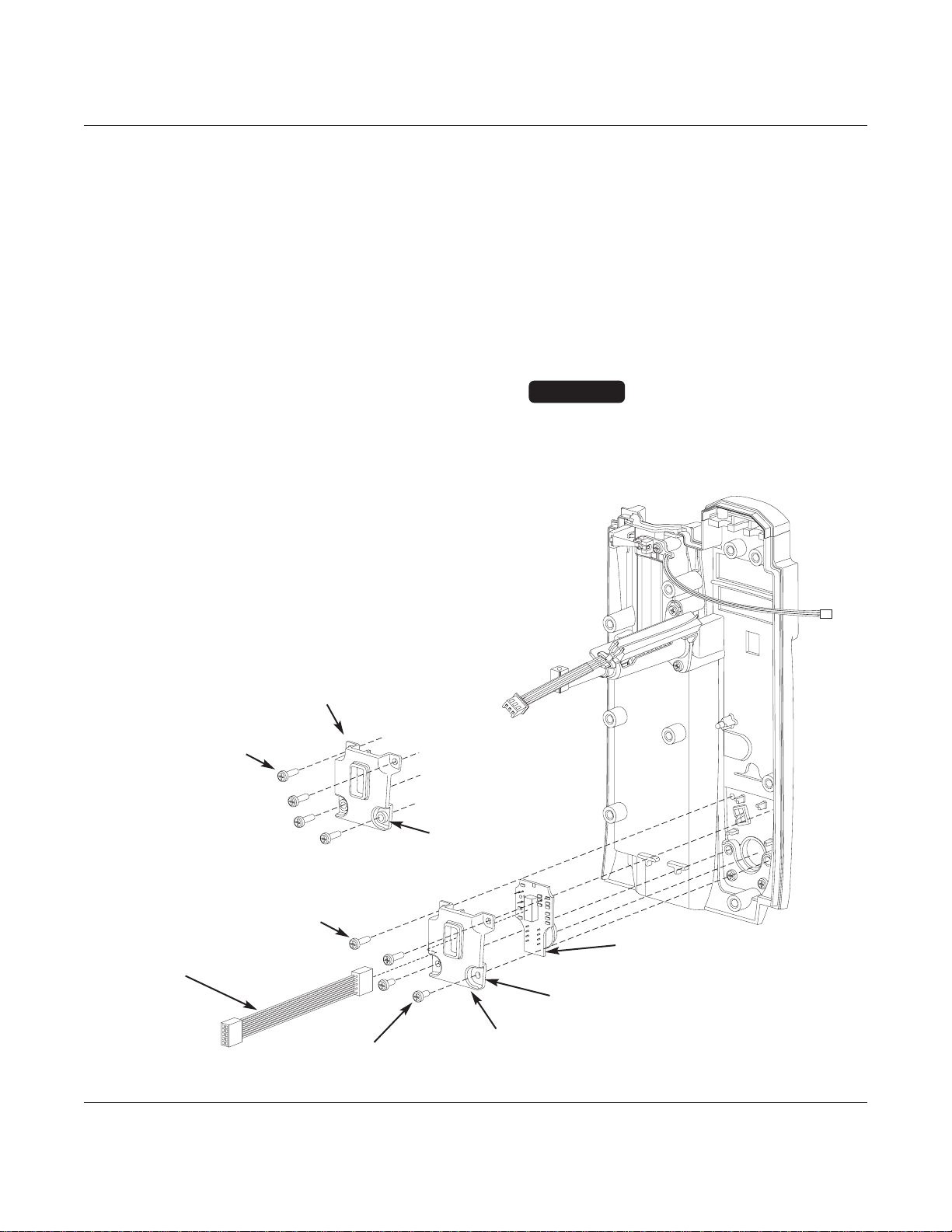

5.2.5 Removing Flex Cable Retainer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-7

5.2.6 Removing IUI Board Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-8

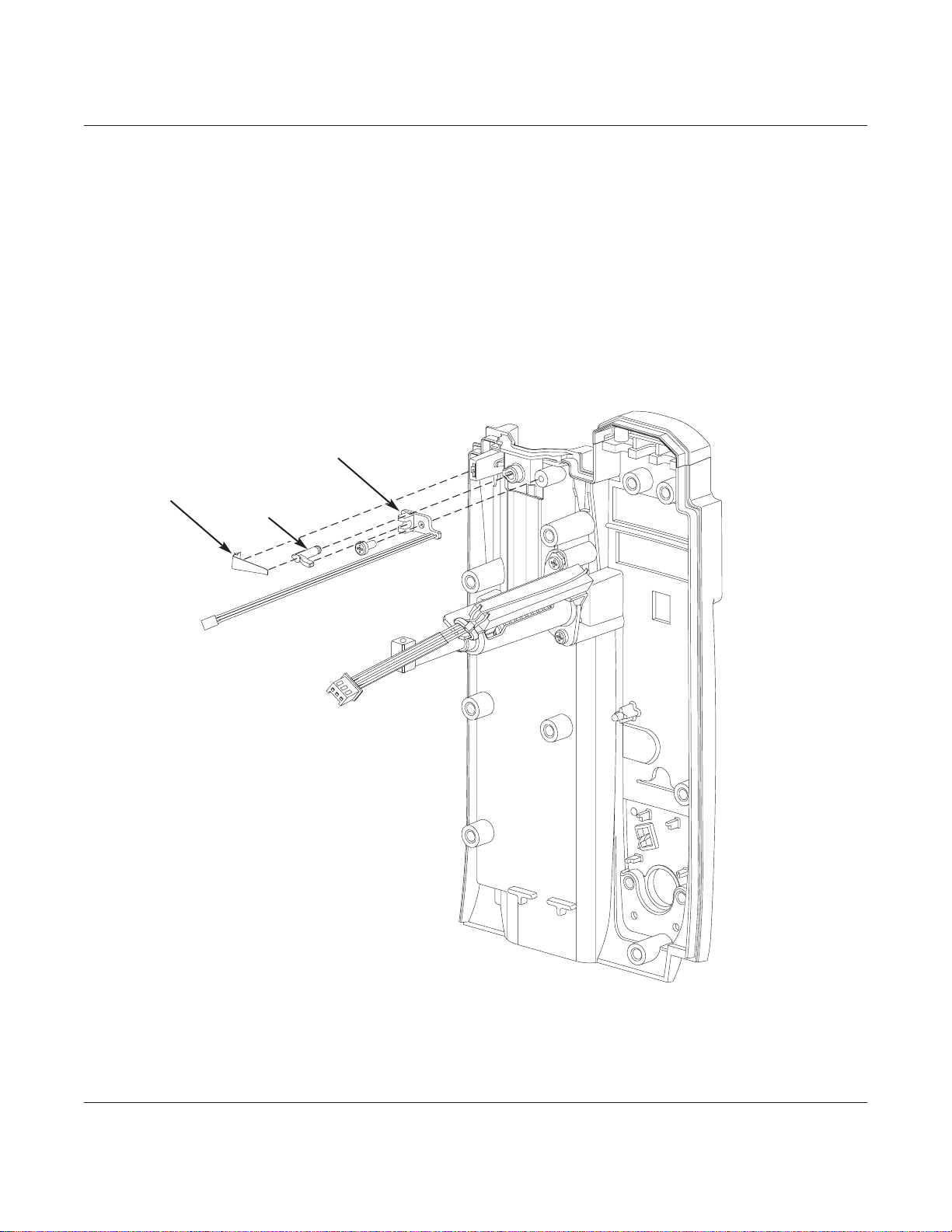

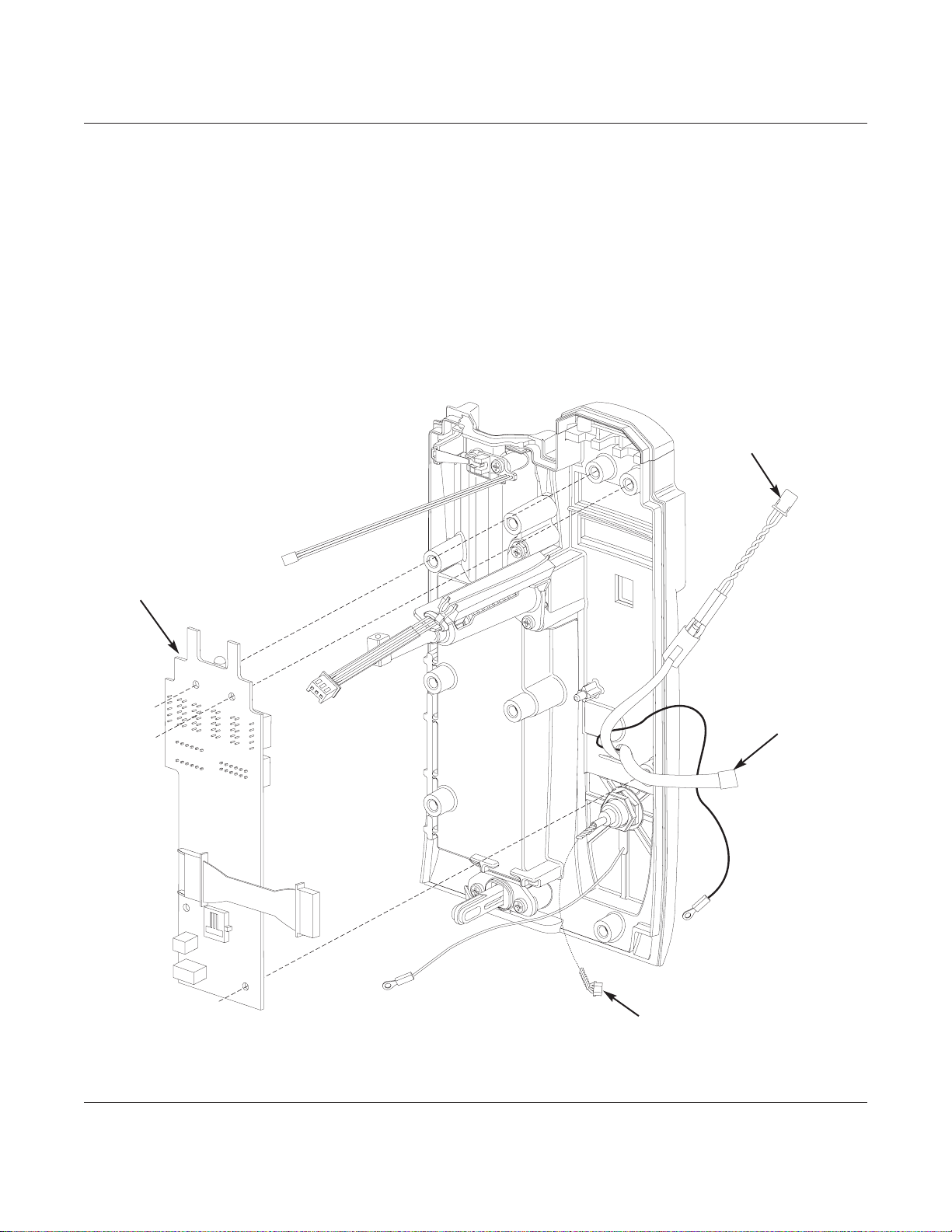

5.2.7 Removing Logic Board Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-9

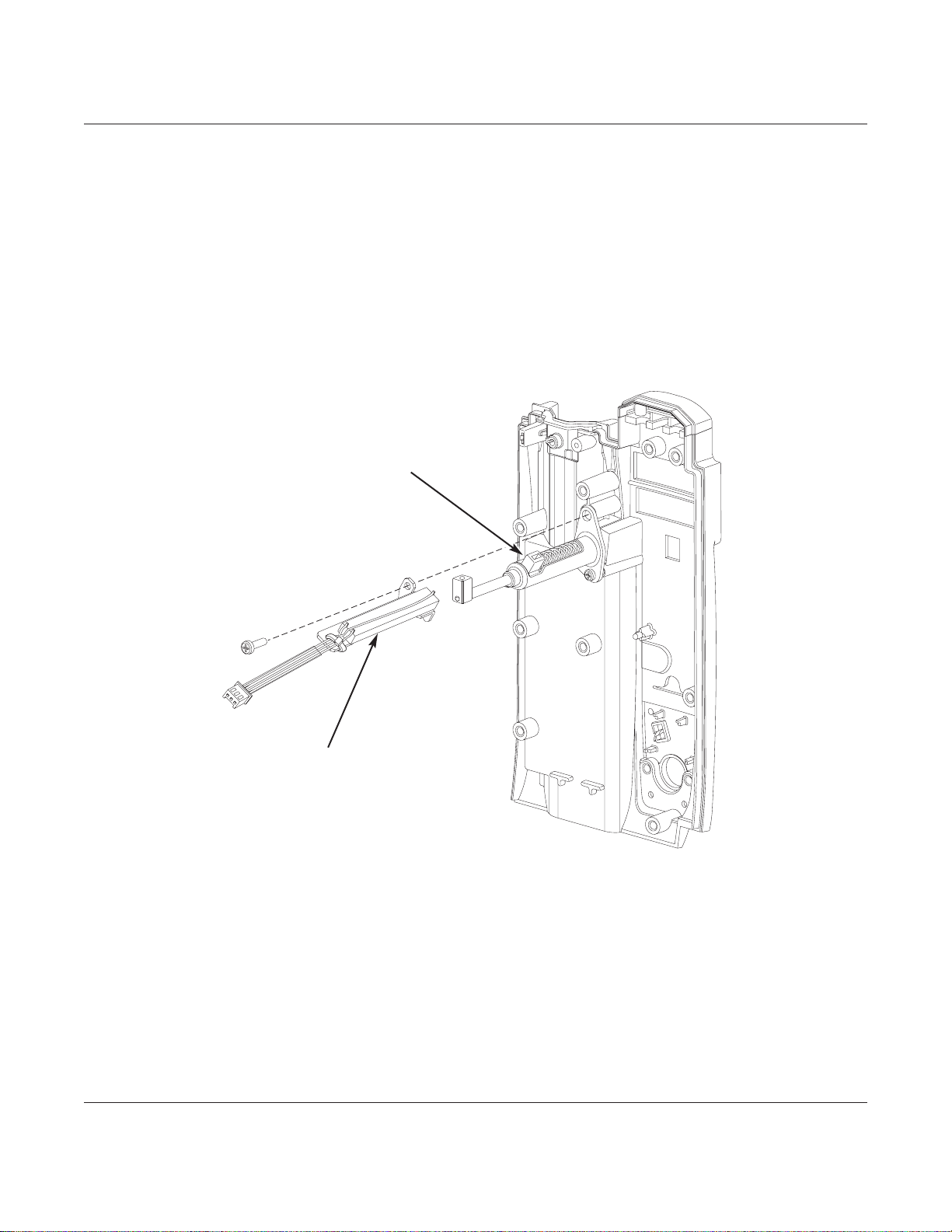

5.2.8 Removing Internal Frame Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-10

5.2.9 Removing Drivetrain Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-11

5.2.10 Removing Display Board Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-12

5.2.11 Removing Pressure Sensor Board Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-13

5.2.12 Removing Top Disk Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-14

5.2.13 Removing Sensor Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-15

5.2.14 Removing Syringe Size Sensor Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-16

5.2.15 Removing Syringe Barrel Clamp Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-17

5.2.16 Removing Status Indicator Lens

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-19

5.2.17 Removing Housing Assembly and Guide Rod

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-20

5.2.18 Removing Motor/Pulley Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-21

5.2.19 Removing Leadscrew Assembly and Bottom Plate

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-22

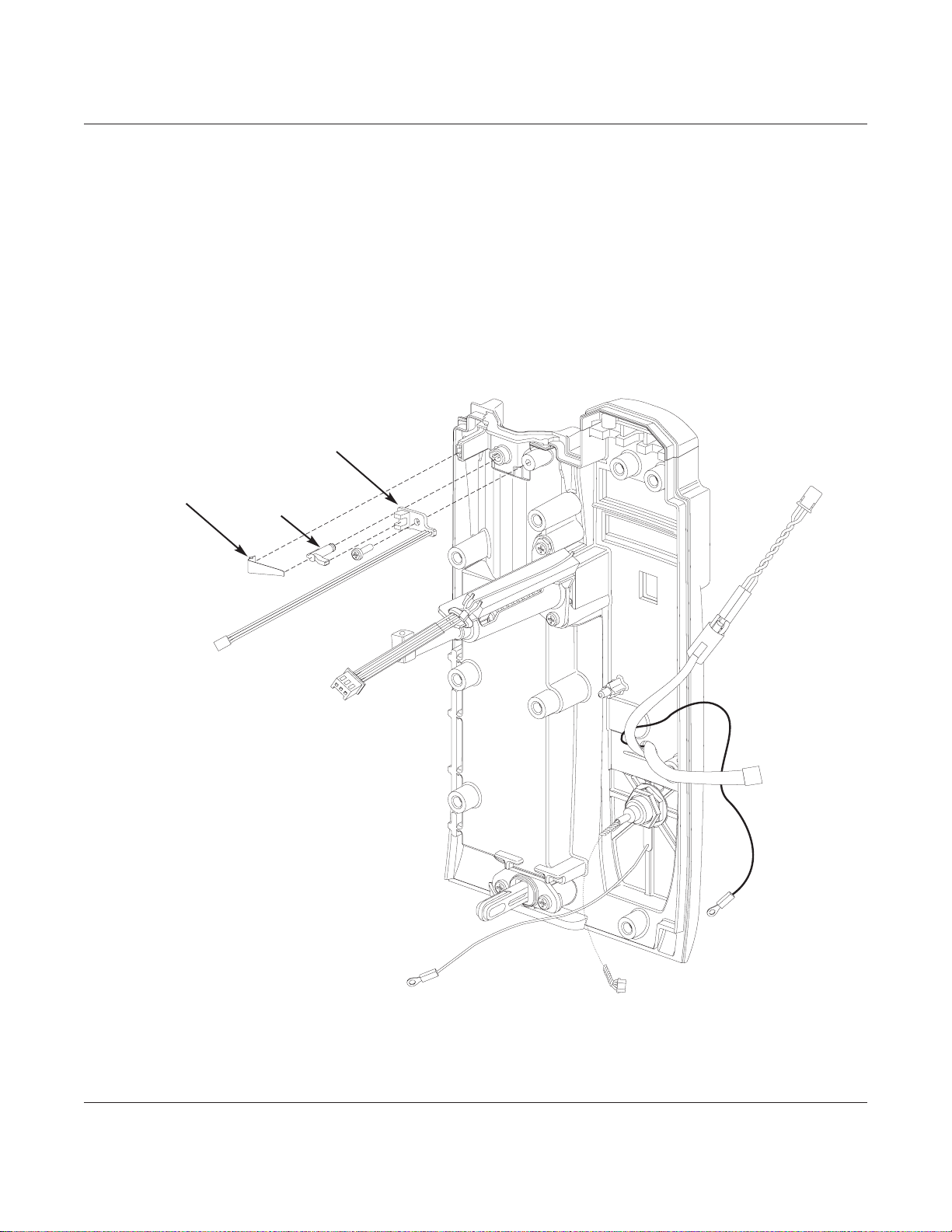

5.2.20 Removing Linear Sensor Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-23

5.2.21 Removing Force Sensor and Actuator Knob Assemblies

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-24

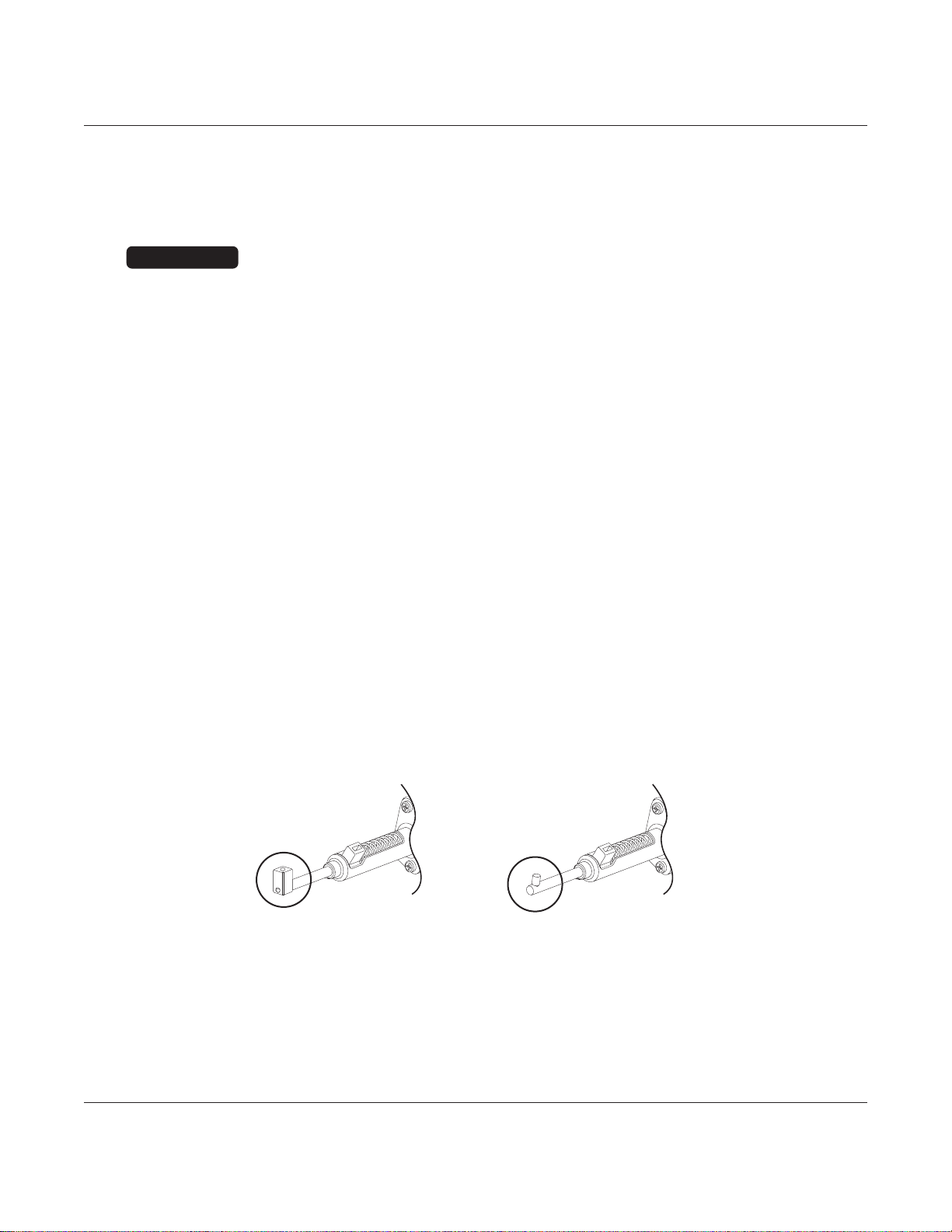

5.2.22 Removing Actuator Knob Assembly Parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-25

Page 5

TABLE OF CONTENTS

iiiAlaris

®

Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

Chapter 5B - Corrective Maintenance - PCA Module

5.1 Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-1

5.2 Disassembly/Reassembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-2

5.2.1 Removing Latch Assembly and Feet

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-3

5.2.2 Removing IUI Connector Assemblies

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5B-4

5.2.3 Removing Handle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-5

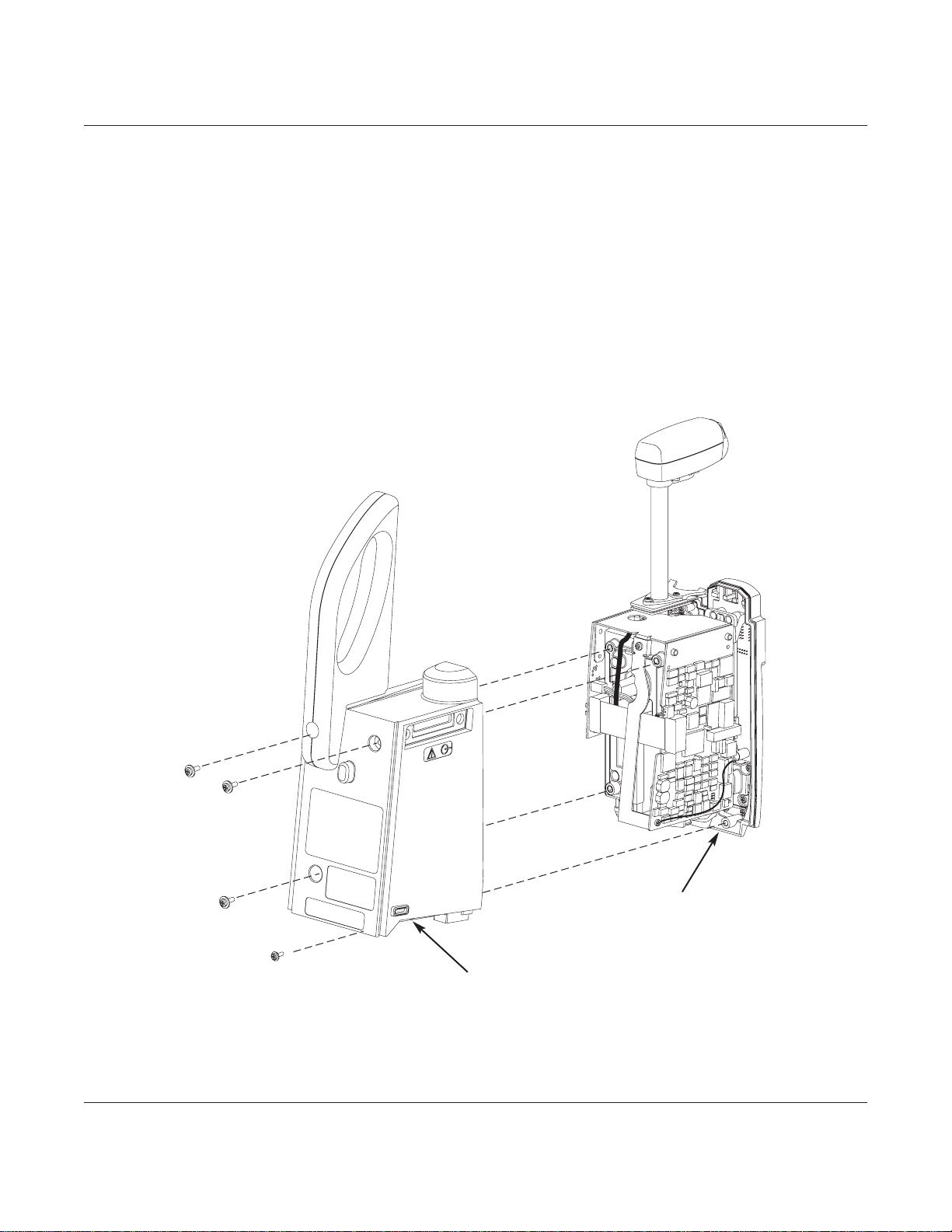

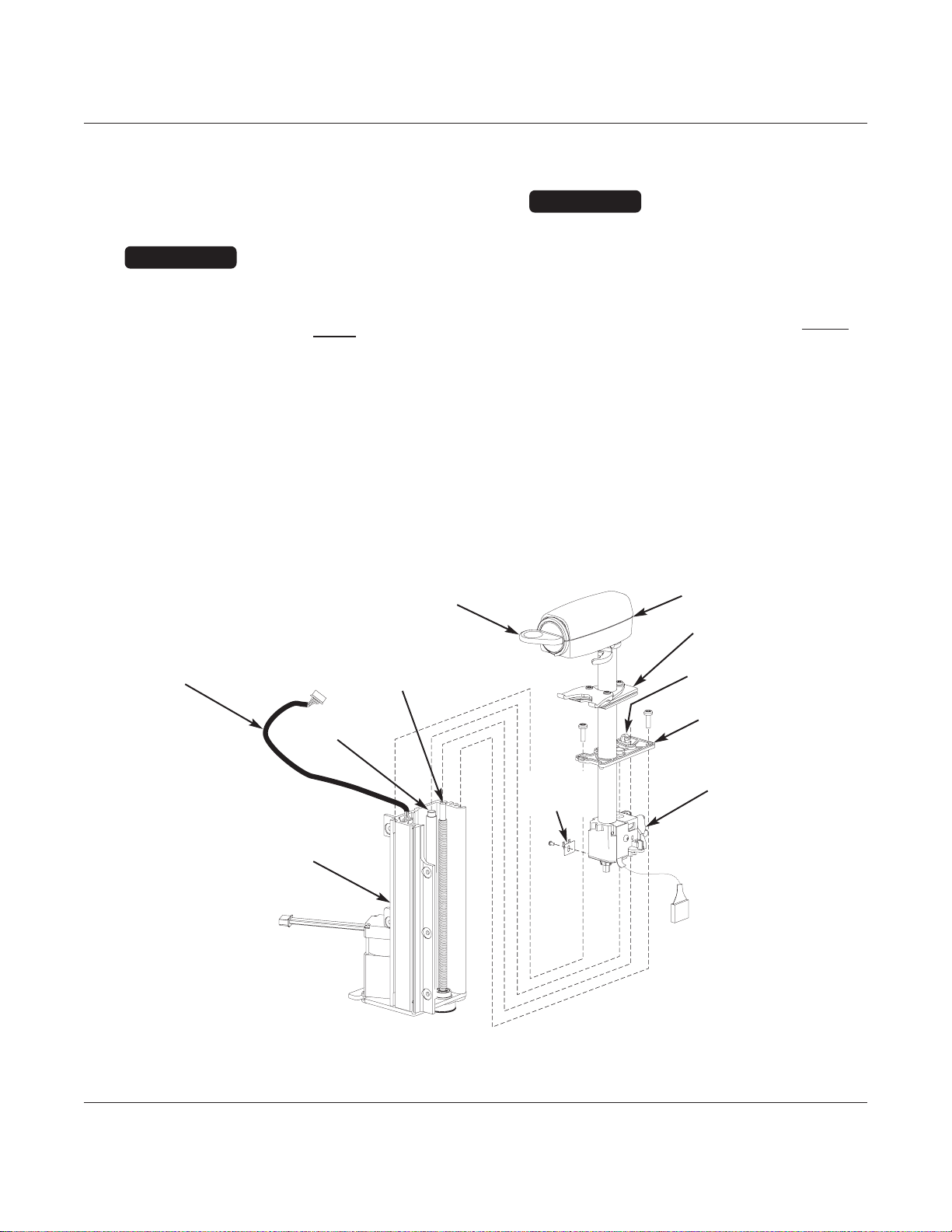

5.2.4 Removing Door Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-6

5.2.5 Removing Rear Case

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-8

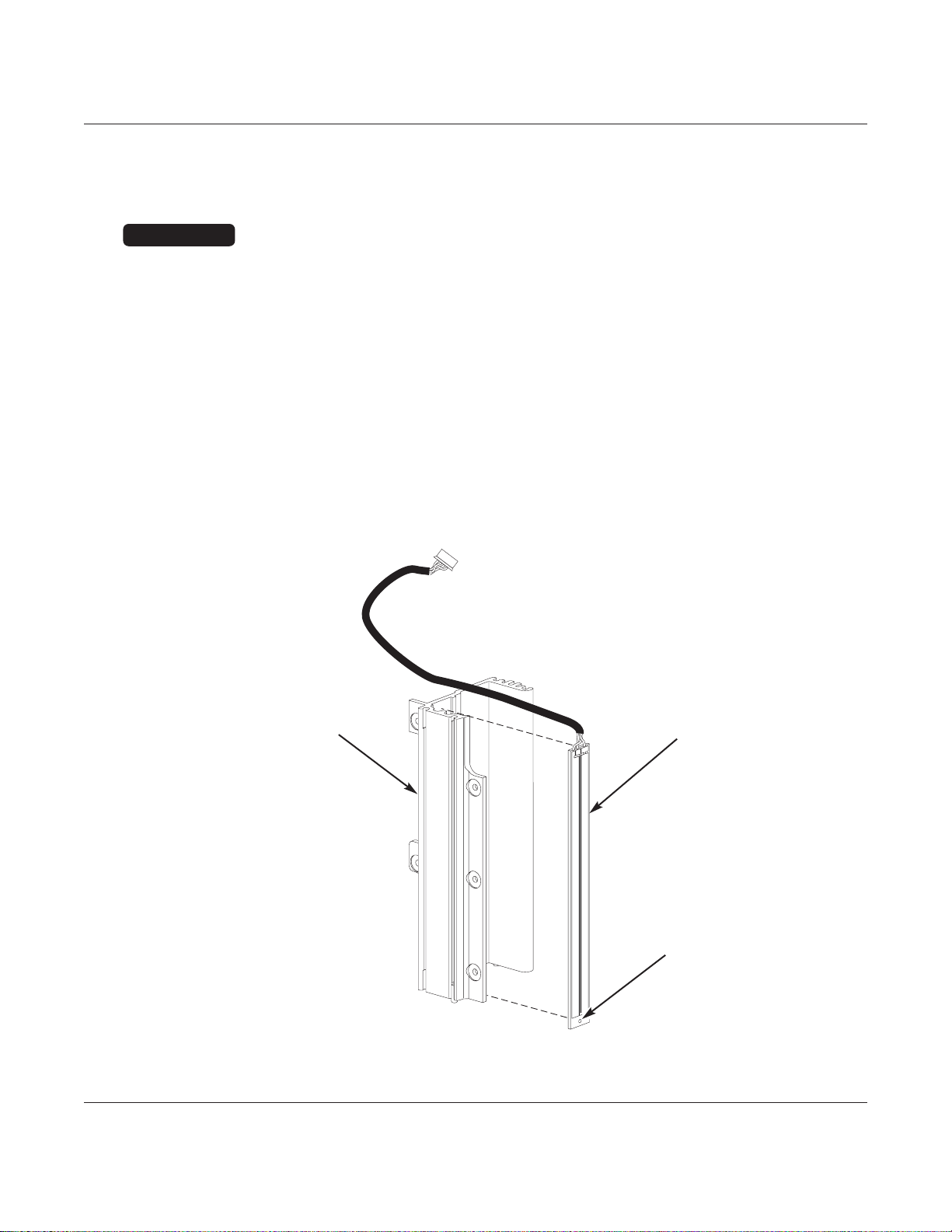

5.2.6 Removing Flex Cable Retainer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5B-9

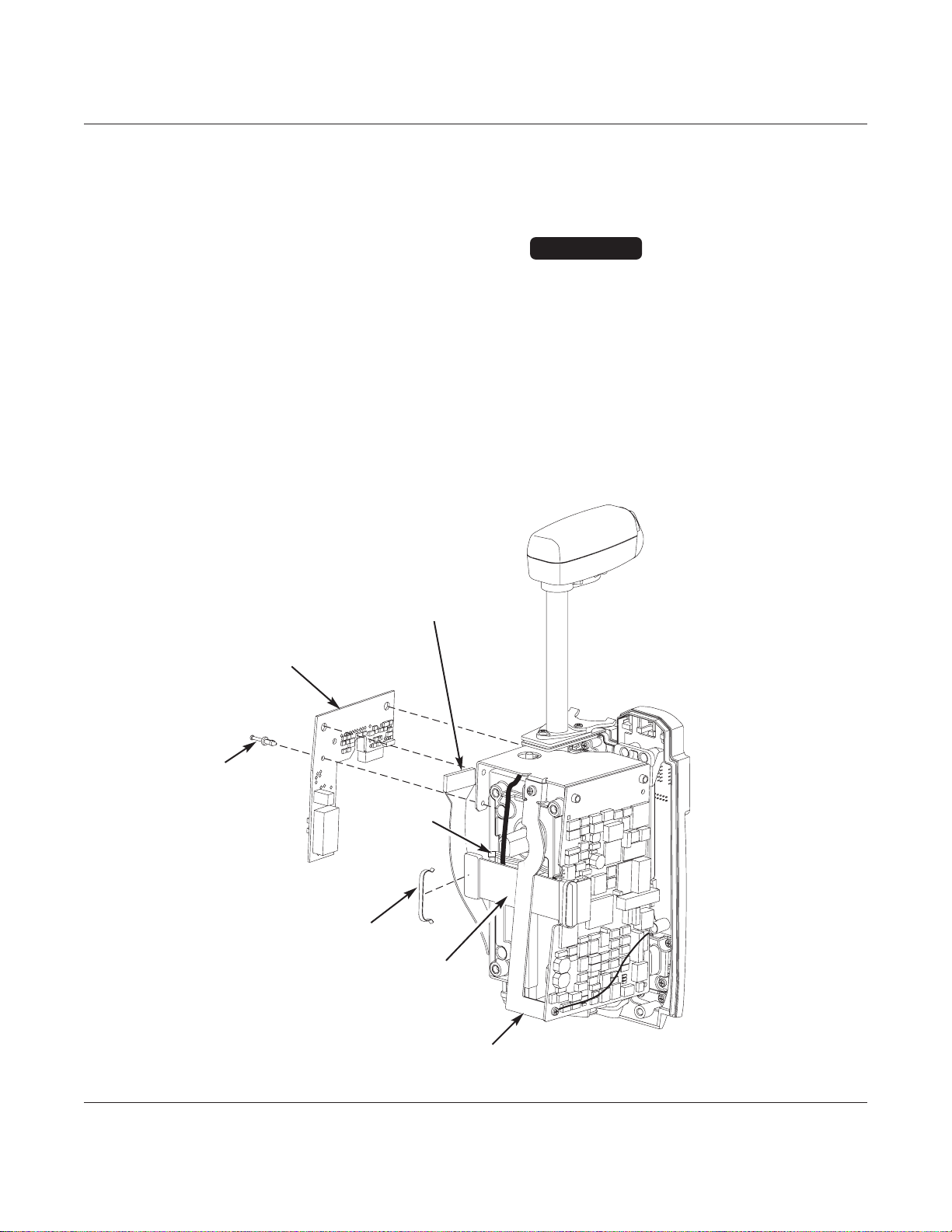

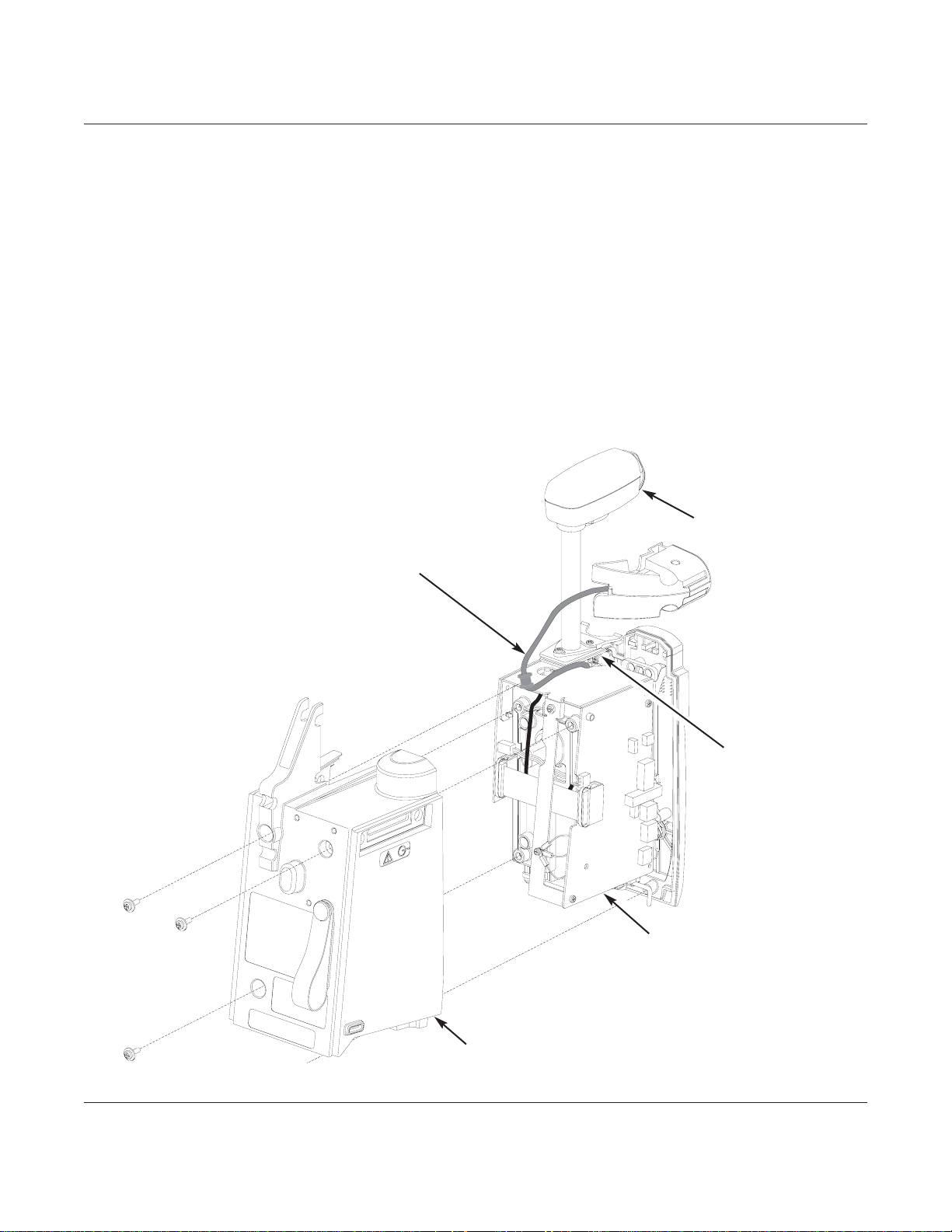

5.2.7 Removing IUI Board Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-10

5.2.8 Removing Logic Board Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-11

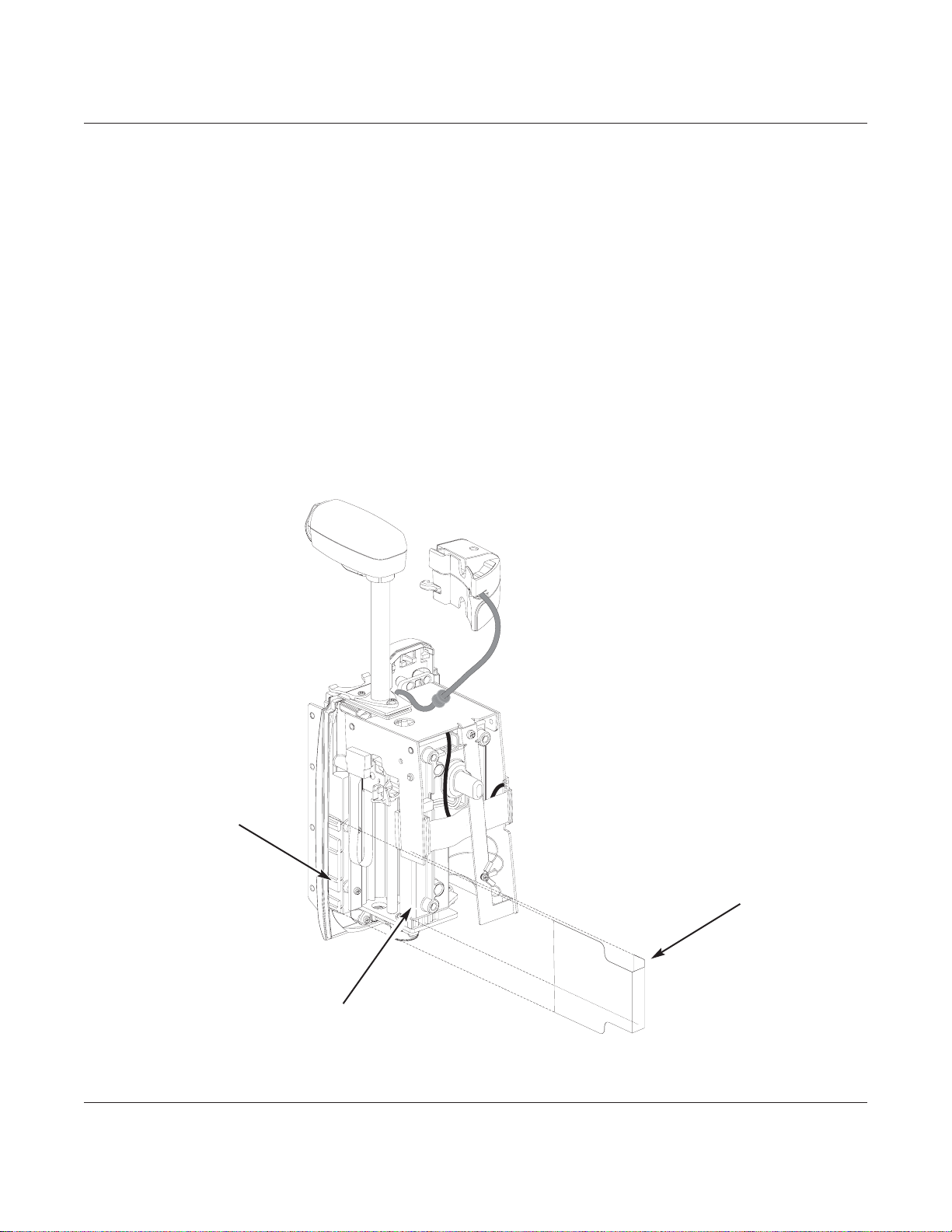

5.2.9 Removing Internal Frame Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-12

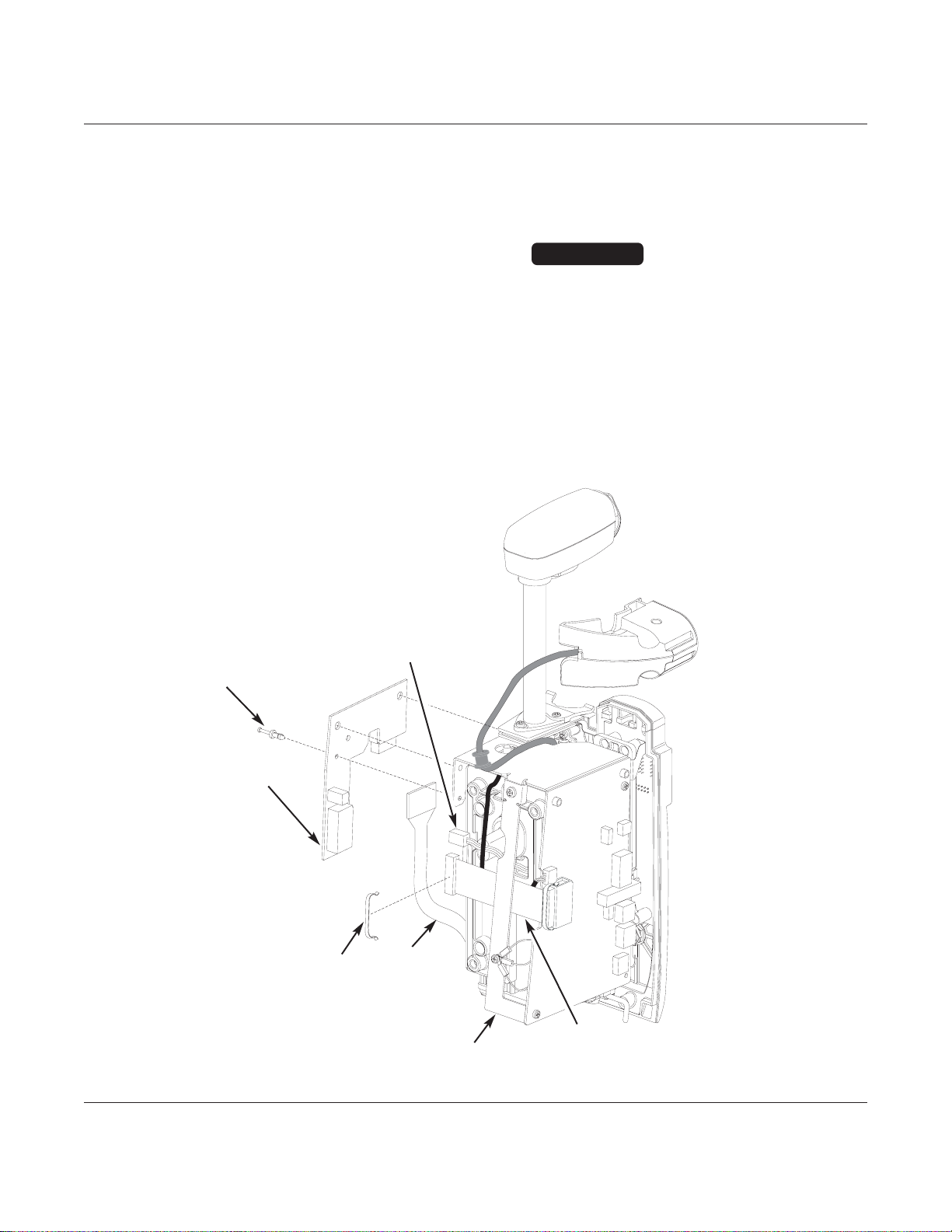

5.2.10 Removing Lock Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-13

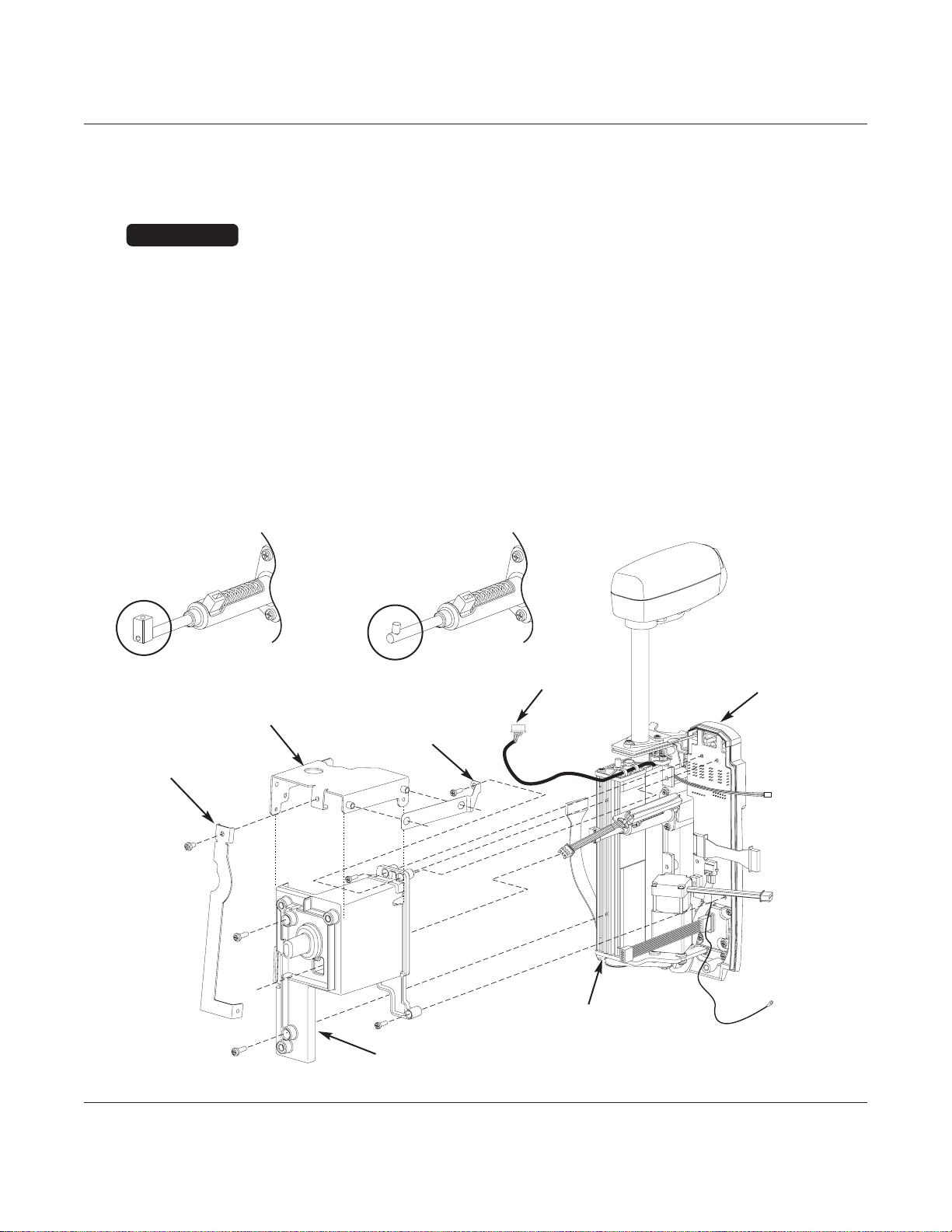

5.2.11 Removing Latch Module and Drivetrain Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-14

5.2.12 Removing Display Board Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-15

5.2.13 Removing Sensor Board Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-16

5.2.14 Removing Syringe Size Sensor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-17

5.2.15 Removing Syringe Barrel Clamp Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-18

5.2.16 Removing Status Indicator Lens

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-20

5.2.17 Removing Handset Harness

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-21

5.2.18 Removing Latch Lever Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-22

5.2.19 Removing Housing Assembly and Guide Rod

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-23

5.2.20 Removing Motor/Pulley Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-24

5.2.21 Removing Leadscrew Assembly and Bottom Plate

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-25

5.2.22 Removing Linear Sensor Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-26

5.2.23 Removing Force Sensor and Actuator Knob Assemblies

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-27

5.2.24 Removing Actuator Knob Assembly Parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-28

Chapter 6 - Troubleshooting

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Chapter 7A

- Illustrated Parts Breakdown - Syringe Module

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-1

7.2 Illustrations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-1

7.3 Parts List

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-1

7.4 Ordering Parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-2

Page 6

iv

TABLE OF CONTENTS

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

Chapter 7B - Illustrated Parts Breakdown - PCA Module

7.1 Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-1

7.2 Illustrations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-1

7.3 Parts List

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-1

7.4 Ordering Parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7B-2

List of Figures

4-1 Block Diagram: Syringe and PCA Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

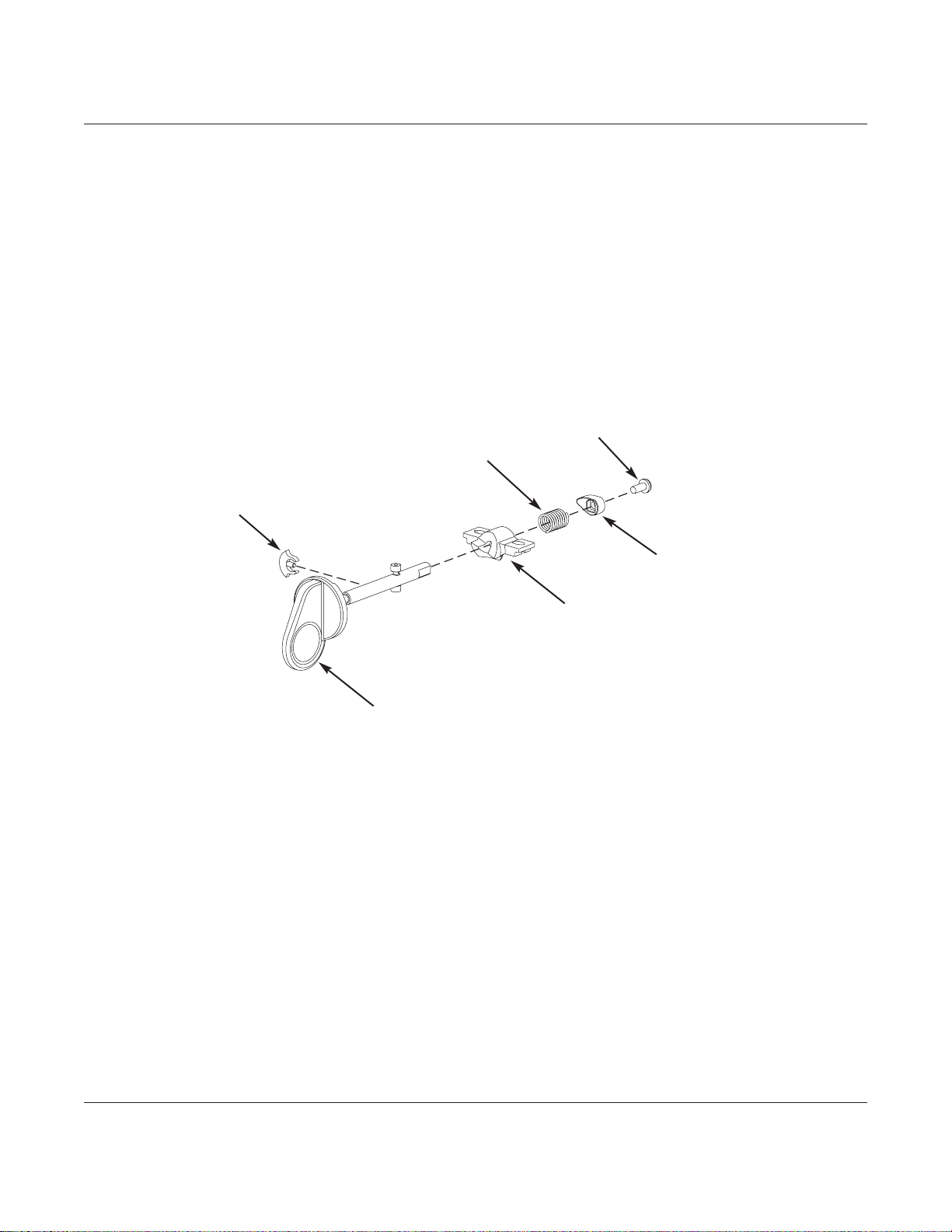

7A-1 Actuator Knob Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-7

7A-2 Housing Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-8

7A-3 Drivetrain Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-9

7A-4 Front Case Assembly - Part 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-11

7A-5 Front Case Assembly - Part 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-12

7A-6 Top Disk Holder - Front Case Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-13

7A-7 Front Case, Syringe Barrel Clamp Assembly, Top Disk Holder -- Interchangeability . . . . . . . . . . 7A-14

7A-8 Front Case Assembly Kit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-15

7A-9 Drivetrain Assembly - Front Case Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-16

7A-10 Internal Frame Assembly - Front Case Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-17

7A-11 Logic Board and IUI Board Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-18

7A-12 Flex Cable Retainer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-19

7A-13 Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-20

7A-14 Rear Label Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-22

7A-15 Display Board Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-23

7A-16 IUI Interface Board Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-24

7A-17 Logic Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-25

7B-1 Actuator Knob Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-7

7B-2 Housing Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-8

7B-3 Drivetrain Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-9

7B-4 Front Case Assembly - Part 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-11

7B-5 Front Case Assembly - Part 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-12

7B-6 Latch Module Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-13

7B-7 Drivetrain Assembly - Front Case Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-14

7B-8 Internal Frame Assembly - Front Case Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-15

7B-9 Logic Board and IUI Board Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-16

7B-10 Flex Cable Retainer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-17

7B-11 Rear Case - Front Case Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-18

7B-12 Door Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-19

7B-13 Handle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-21

7B-14 Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-22

Page 7

TABLE OF CONTENTS

List of Figures (continued)

7B-15 Key Kit and Handset

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-23

7B-16 Display Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-24

7B-17 IUI Interface Board Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7B-25

7B-18 Logic Board Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-26

List of Tables

1-1 Abbreviations, Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

5A-1 Required Materials, Supplies and Tools - Syringe Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-2

5A-2 Torque Values - Syringe Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-26

5A-3 Level of Testing Guidelines- Syringe Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-27

5B-1 Required Materials, Supplies and Tools - PCA Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-2

5B-2 Torque Values - PCA Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-29

5B-3 Level of Testing Guidelines- PCA Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-30

6-1 Technical Troubleshooting Guide

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-2 Subsystem Codes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-3 Error Code Matrix

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-4 Error Codes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

7A-1 Parts List - Syringe Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A-3

7B-1 Parts List - PCA Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7B-2

vAlaris

®

Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

Page 8

vi

TABLE OF CONTENTS

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

THIS PAGE

INTENTIONALLY

LEFT BLANK

Page 9

1 GENERAL INFORMATION

Page 10

Page 11

Chapter 1 — GENERAL INFORMATION

CAUTION

To avoid damaging the keypad, do not use sharp

objects (pens, pencils, etc.) to activate switches.

1.1 INTRODUCTION

This manual describes how to service the

®

Alaris

8110 Series) and Alaris

Module”,

Syringe Module (“Syringe Module”,

®

PCA Module (“PCA

8120

Series). Use this manual in

conjunction with the following Alaris

documents and software:

• Alaris

®

Point-of-Care unit (“PC Unit”,

Series) / Alaris®Pump Module (“Pump

Module”,

8100 Series) Technical Service

Manual

®

• Alaris

System Directions for Use (DFU)

• Maintenance Software and User Manual

(Software v7.x or later)

PRODUCT NAME NOTE: The “Alaris

System” was formerly known as the “Medley

System” and is described in the Alaris

System DFU.

This manual is intended for personnel

experienced in analysis, troubleshooting,

and repair of analog/digital microprocessorbased electronic equipment.

®

System

8000

®

®

™

CAUTION

Any attempt to service this product by anyone

other than an authorized CareFusion Service

Representative while the product is under

warranty may invalidate the warranty.

If either module requires service while under

warranty, it must be serviced only by

CareFusion authorized service

personnel. Refer to the “Warranty” and

“Service Information” sections of the Alaris

®

System DFU.

The Alaris®System is a modular infusion

and monitoring system intended for use in

adult, pediatric and neonatal healthcare.

The Syringe Module is intended for facilities

that use syringe pumps to deliver fluids,

medications, blood, and blood products

using continuous or intermittent delivery

through clinically acceptable routes of

administration, such as intravenous (

intra-arterial (

IA), subcutaneous, epidural,

IV),

enteral, or irrigation of fluid spaces.

Alaris®Syringe Module (8110 Series)

Alaris®PCA Module (8120 Series)

Technical Service Manual

1-1

Page 12

The PCA Module is intended for facilities

that use syringe pumps to deliver fluids or

medications using continuous or intermittent

delivery through clinically acceptable routes

of administration, such as intravenous (

IV),

subcutaneous, or epidural.

Refer to the product-specific (Syringe

Module or PCA Module) section of the

Alaris

®

System DFU for a list of features and

detailed information regarding setup and

operation.

1.2 PRECAUTION DEFINITIONS

Refer to the Alaris

®

System DFU .

1.3 SPECIFICATIONS

Refer to the product-specific section of the

Alaris

®

System DFU.

1.4 OPERATING FEATURES, CONTROLS

AND INDICATORS

Refer to the product-specific section of the

Alaris

®

System DFU.

1.5 ACCESSORIES

The Syringe Module uses standard, singleuse, disposable syringes (with luer-lock

connectors) and administration sets

designed for use on syringe pumps.

The PCA Module uses standard or pre-filled,

single-use disposable syringes (with luerlock connectors) and non-dedicated

administration sets with integrated antisiphon valves designed for use on syringetype PCA devices. For specific

administration set instructions, reference the

directions for use provided with the set.

1.6 ALARMS, ERRORS, MESSAGES

Alarm messages are displayed on the

scrolling Message Display bar. Refer to the

product-specific section of the Alaris

®

System DFU for detailed information.

1.6.1 Silencing Alarms

All alarms can be temporarily silenced by

pressing the

SILENCE key on the PC Unit.

1.7 TRUMPET AND START-UP CURVES

Refer to the product-specific section of the

Alaris

®

System DFU.

Use only specified syringes and

administration sets with the Syringe and

PCA Modules. Using other syringes or

administration sets can cause improper

instrument operation, inaccurate fluid

delivery or pressure sensing, or other

potential hazards. For a list of compatible

syringes, refer to the product-specific

section of the Alaris

®

System DFU. For a list

of compatible administration sets, refer to

the module’s Administration Set

Compatibility Card/Insert (provided

separately).

WARNING

If an alarm condition on the module occurs

while the audio alarm is silenced, the only

alarm indications will be visual displays and

symbols related to the alarm condition.

WARNING

GENERAL INFORMATION

1-2 Alaris

®

Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

1.1 INTRODUCTION (Continued)

Page 13

GENERAL INFORMATION

1-3Alaris

®

Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

CHSE HD cheese head (screw)

DB0 database zero

DFU Directions for Use

IA intra-arterial

IUI inter-unit interface

NEOI near end of infusion

TR HD truss head (screw)

VDAC voltage DAC

Table 1-1. Abbreviations, Acronyms

Various abbreviations and acronyms are used throughout this manual. The following are those that are

not commonly known or easily recognized.

Page 14

GENERAL INFORMATION

1-4 Alaris

®

Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

THIS PAGE

INTENTIONALLY

LEFT BLANK

Page 15

2 CHECKOUT & CONFIGURATION

Page 16

Page 17

Chapter 2 — CHECKOUT AND CONFIGURATION

CAUTION

Should an instrument be jarred severely or

dropped, remove it from use immediately. It

should be thoroughly tested and inspected by

qualified service personnel to ensure proper

function prior to reuse.

2.1 INTRODUCTION

This chapter describes initial setup and

configuration for the Syringe and PCA

Modules.

NOTE: Due to product changes over time,

configurations described in this chapter may

differ from the instrument under service. If

there are any questions, contact CareFusion

Technical Support.

2.2 NEW INSTRUMENT CHECKOUT

Prior to placing a new instrument in use,

perform a check-in procedure using the

Maintenance Software.

When powering up the instrument, verify the

instrument beeps and all display

LED

segments flash. This confirms that the

instrument has performed its self test and is

operating correctly. During operation, the

instrument continually performs a self test,

and will alarm and display a message if it

detects an internal malfunction.

Contact CareFusion authorized service

personnel if the instrument has physical

damage, fails to satisfactorily pass the

startup sequence, fails a self test, or

continues to alarm.

®

Syringe Module (8110 Series)

®

PCA Module (8120 Series)

Alaris

Technical Service Manual

2-1Alaris

Page 18

2.3 CONFIGURATION OPTIONS AND

DEFAULTS - SYRINGE MODULE

NOTES:

• Changes to the factory default values are

retained after a power cycle.

• If Factory Default is Yes, then all the

configuration settings are set to their

factory default.

• If Factory Default is No, then one or

more of the configuration settings has

been changed. Setting Factory Default

to Yes sets all configuration settings to

their factory default.

• With the Profiles feature enabled, the

settings are configured independently for

each profile. A hospital-defined, bestpractice data set must be uploaded to

enable the Profiles feature. Date and

Time is a system setting and is the same

in all profiles.

Refer to the Alaris®System DFU for the

following:

• System Settings

• Shared Infusion Settings (Pump Module

and Syringe Module)

• Syringe Module Settings

2.3.1 Factory Default Setting

To allow changes to System Configuration

parameters:

1. Hold

OPTIONS key at power up.

2. Press Factory default soft key.

3. Press No soft key.

4. To accept change, press

EXIT soft key.

• Option setting changes and main

System Config - Module

screen

displays.

2.4 CONFIGURATION SETUP - SYRINGE

MODULE

NOTES:

• Pressing the EXIT soft key while in a

System Config - Module screen

immediately powers the system down, with

no “Powering Down” display.

• Pressing the EXIT soft key while in a

System Config - Syringe screen returns

the display to the main System Config -

Module screen.

CHECKOUT AND CONFIGURATION

2-2

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

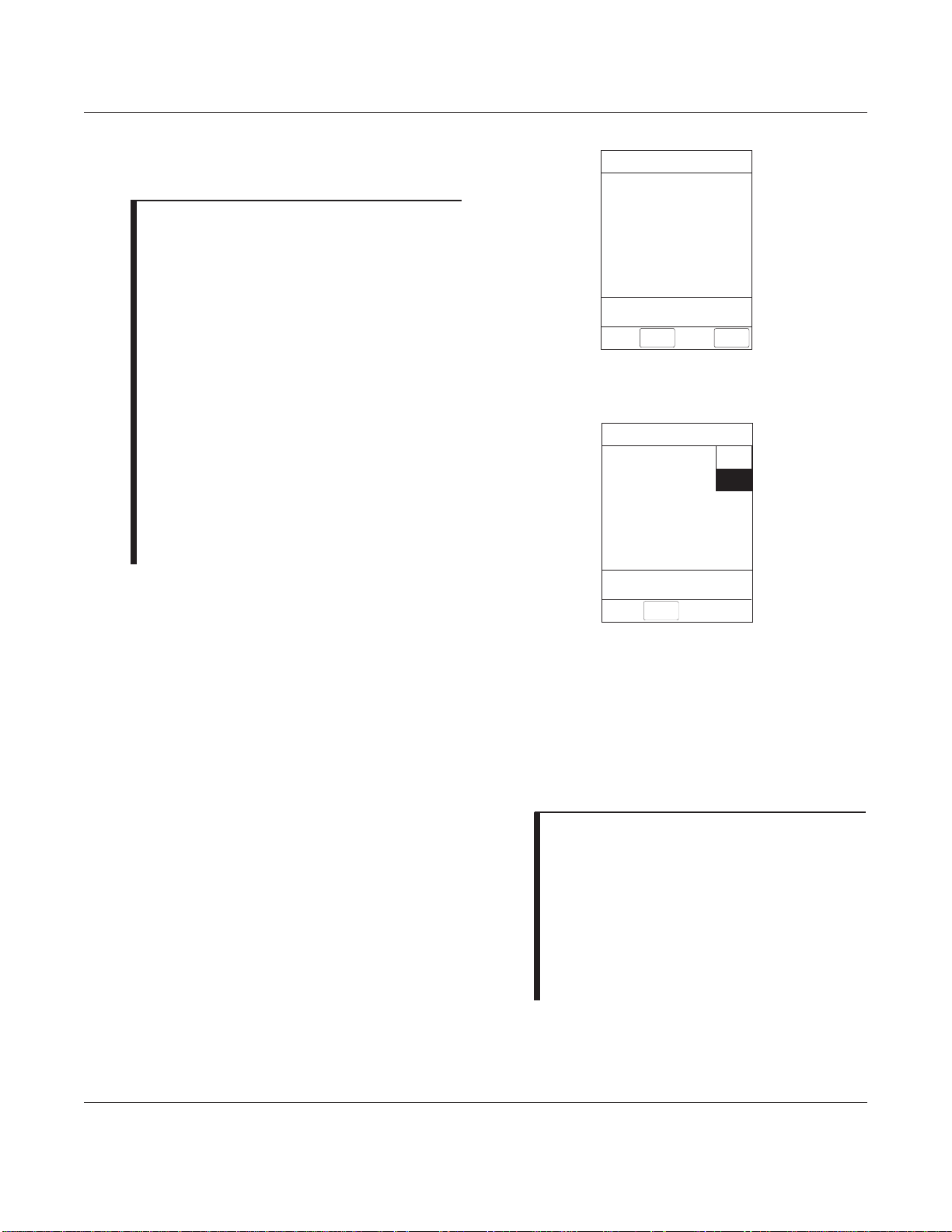

>Select an Option

or EXIT

EXIT

Factory default:

Yes

System Config - Module 1 of 2

PC Unit

Shared Infusion Settings

Pump Module

SPO2 Module

PAGE

DOWN

EXIT

System Configuration

Factory Default

Settings?

Yes

No

Selection of Yes sets all

System Configuration

parameters to the factory

default setting.

Page 19

NOTES: (Continued)

• Pressing the

CONFIRM soft key while in a

System Configuration option screen:

♦ accepts existing setting or setting

change

♦ displays next option setting screen (if

applicable) or returns display to System

Config - Syringe screen

• Pressing the PC Unit

CANCEL key while in

a System Configuration option screen:

♦ leaves setting unchanged

♦ returns display to System Config -

Syringe screen

To access System Configuration options:

1. Hold

OPTIONS key at power up.

2. Press

PAGE DOWN soft key.

3. Press Syringe Module soft key.

4. To view additional options, press

PAGE

DOWN

soft key.

2.4.1 All Mode

Enabling All mode allows

ALL to be

selected as the volume to be infused (VTBI),

to deliver the entire contents of the syringe.

CHECKOUT AND CONFIGURATION

2-3

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

2.4 CONFIGURATION SETUP - SYRINGE

MODULE (Continued)

If KVO and ALL modes are both enabled,

the

ALL mode will not deliver the entire

syringe contents. A small percentage of the

syringe contents will be left available for

KVO operation.

CAUTION

System Config - Module 1 of 2

Factory default:

Shared Infusion Settings

PC Unit

Pump Module

SPO2 Module

>Select an Option

or EXIT

EXIT

No

PAGE

DOWN

System Config - Syringe 1 of 2

All Mode:

Auto Pressure:

Back Off:

Fast Start:

KVO:

>Select an Option

or EXIT

EXIT

Disabled

Disabled

Disabled

Disabled

Disabled

PAGE

DOWN

System Config - Syringe 2 of 2

Max rate:

Near End:

Pressure limit-Disc:1000

Pressure limit-NoDisc: Med

Priming: Disabled

>Select an Option

or EXIT

PAGE

EXIT

UP

999 mL/h

Disabled

mmHg

System Config - Module 2 of 2

Syringe Module

EtCO2 Module

>Select an Option

or EXIT

PAGE

EXIT

UP

Page 20

1. After accessing System Config Syringe options display, press All Mode

soft key.

2. To change option setting, press soft key

next to applicable option (Enable or

Disable).

• Option setting changes and System

Config - Syringe page

1 displays.

2.4.2 Auto Pressure

Enabling Auto Pressure allows the Auto

Pressure option to be displayed in the

Pressure Limit screen when a pressure

sensing disc is in use. Auto Pressure

automatically sets the alarm limit for a

shorter time to alarm, as follows:

• If current pressure is

100 mmHg or less,

system adds

30 mmHg to current

pressure, to create a new alarm limit.

• If current pressure is greater than

100 mmHg, system adds 30% to current

pressure, to create a new alarm limit.

1. After accessing System Config -

Syringe options display, press Auto

Pressure soft key.

2. To change option setting, press soft key

next to applicable option (Enable or

Disable).

• Option setting changes and System

Config - Syringe page 1 displays.

2.4.3 Back Off

When Back Off mode is enabled and a

pressure sensing disc is in use, the motor

reverses plunger movement during an

occlusion until the pressure returns to

preocclusion levels, automatically reducing

bolus flow.

1. After accessing System Config -

Syringe options display, press Back Off

soft key.

2. To change option setting, press soft key

next to applicable option (Enable or

Disable).

• Option setting changes and System

Config - Syringe page

1 displays.

CHECKOUT AND CONFIGURATION

2-4

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

2.4 CONFIGURATION SETUP - SYRINGE

MODULE (Continued)

2.4.1 All Mode (Continued)

System Configuration - Syringe

Back Off mode

Enable

Disable

Allows use of the

back off feature.

System Configuration - Syringe

Auto Pressure

Enable

Disable

Allows use of the

auto pressure feature.

System Config - Pump 2 of 3

System Configuration - Syringe

All mode

Allows use of the

All mode feature.

Enable

Disable

Page 21

2.4.4 Fast Start

When Fast Start mode is enabled and a

pressure sensing disc is in use, the

instrument runs at an increased rate when

an infusion starts, taking up any slack in the

drive mechanism.

1. After accessing System Config -

Syringe options display, press Fast

Start soft key.

2. To change option setting, press soft key

next to applicable option (Enable or

Disable).

• Option setting changes and System

Config - Syringe page

1 displays.

2.4.5 KVO

Enabling

KVO allows some infusions to

automatically switch into

KVO (keep vein

open) mode upon completion. The

KVO

option setting cannot be changed after the

instrument is powered on and a profile

selected.

NOTE: In the following procedure, the KVO

option is changed to Enable. Changing the

option setting to Disable, disables the

Change Rate and Change Volume soft

keys, as displayed in step 1.

1. After accessing System Config -

Syringe options display, press KVO soft

key.

2. To change option setting, press soft key

next to applicable option (Enable or

Disable).

CHECKOUT AND CONFIGURATION

2-5

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

System Configuration - Syringe

Fast Start mode

Enable

Disable

Allows use of the

fast start feature.

System Configuration - Syringe

KVO

Enable

Disable

Change

Rate

Change

Volume

Rate:

1 mL/h

Volume:

2%

Allows use of the KVO feature.

CONFIRM

System Configuration - Syringe

KVO

Enable

Disable

Change

Rate

Change

Volume

Rate:

1 mL/h

Volume:

2%

Allows use of the KVO feature.

CONFIRM

2.4 CONFIGURATION SETUP - SYRINGE

MODULE (Continued)

If

KVO and ALL modes are both enabled,

the

ALL mode does not deliver the entire

syringe contents, leaving a small

percentage of the syringe contents

available for

KVO

operation.

CAUTION

Page 22

CHECKOUT AND CONFIGURATION

2-6

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

3. To change

KVO rate, press Change

Rate soft key and enter new rate (

0.01 to

2.5 mL/h in 0.01 mL/h increments).

NOTE: Flow rates less than 0.01

mL/h

are available only with a 1cc syringe.

For larger syringes, the lower limit

adjusts to

0.1 mL/h.

4. To change

KVO

volume, press Change

Volume soft key and enter new volume

level (

0.5 to 5%).

5. To accept changes(s), press

CONFIRM

soft key.

• Settings change and System Config

- Syringe page

1 displays.

2.4.6 Max rate

The Maximum rate value identifies the

maximum rate at which a bolus dose can be

delivered. When the Max Rate option is

selected during bolus dose programming,

the bolus is delivered at the maximum rate

for an automatically calculated duration.

1. After accessing System Config -

Syringe options display, page

2, press

Max rate soft key.

2. To change maximum rate, press

Change Value soft key and enter new

rate (

0.1 to 99.9 mL/h in 0.1 mL/h

increments;

100 to 999 mL/h in 1 mL/h

increments).

2.4 CONFIGURATION SETUP - SYRINGE

MODULE (Continued)

2.4.5 KVO (Continued)

System Configuration - Syringe

Change

Value

Maximum rate

adjustment

Maximum

rate:

mL/h

___

System Configuration - Syringe

Change

Value

Confirm

Maximum rate

adjustment

Maximum

rate:

mL/h

999

System Configuration - Syringe

KVO

Enable

Disable

Change

Rate

Change

Volume

Rate:

2 mL/h

Volume:

_5%

Allows use of the KVO feature.

CONFIRM

-- Continued Next Page --

System Configuration - Syringe

CONFIRM

Enable

Disable

Change

Rate

Change

Volume

KVO

Rate:

_2mL/h

Volume:

2%

Allows use of the KVO feature.

Page 23

3. To accept change, press Confirm soft

key.

• Setting changes and System Config

- Syringe page

2 displays.

2.4.7 Near End

Enabling Near-End-of-Infusion (

NEOI)

allows an alert to be set from

1 to

60

minutes before the infusion is complete.

The alert occurs at the configured time or

when

25% of the VTBI remains, whichever

occurs later.

NOTE: In the following procedure, the Near

End option is changed to Enable. Changing

the option setting to Disable disables the

Change Time soft key, as displayed in

step

1.

1. After accessing System Config -

Syringe options display, page

2, press

Near End soft key.

2. To change option setting, press soft key

next to applicable option (Enable or

Disable).

3. To change Alert Time, press Change

Time soft key and enter new time

(

1 to 60 minutes).

4. To accept changes(s), press

CONFIRM

soft key.

• Settings change and System Config

- Syringe page

2 displays.

2.4 CONFIGURATION SETUP - SYRINGE

MODULE (Continued)

2.4.6 Max rate (Continued)

CHECKOUT AND CONFIGURATION

2-7

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

System Configuration - Syringe

Maximum rate

adjustment

Maximum

rate:

99.9

mL/h

Change

Value

Confirm

System Configuration - Syringe

CONFIRM

Enable

Disable

Change

Time

DisableDisable

Near-End-of

Infusion

Alert Time:

2 min

Allows use of the Near-End-of

Infusion feature.

System Configuration - Syringe

CONFIRM

Enable

Disable

Change

Time

DisableDisable

Near-End-of

Infusion

Alert Time:

2 min

Allows use of the Near-End-of

Infusion feature.

System Configuration - Syringe

CONFIRM

Enable

Disable

Change

Time

DisableDisable

Near-End-of

Infusion

Alert Time:

10 min

Allows use of the Near-End-of

Infusion feature.

Page 24

2.4.8 Pressure Limit - Disc

This option allows setting an occlusion

pressure point when a pressure sensing

disc is in use.

1. After accessing System Config -

Syringe options display, page

2, press

Pressure limit-Disc soft key.

2. To change pressure limit, press Change

Value soft key and enter new limit (

25 to

1000 mmHg in 1 mmHg increments).

3. To accept change, press

CONFIRM soft

key.

• Setting changes and System Config

- Syringe page

2 displays.

2.4.9 Pressure limit - No Disc

This option allows setting an occlusion

pressure point when no

pressure sensing

disc is in use.

1. After accessing System Config -

Syringe options display, page

2, press

Pressure limit-NoDisc soft key.

2. To change pressure limit (occlusion

pressure set point), press applicable soft

key (Low, Med, High).

3. To accept change, press

CONFIRM soft

key.

• Setting changes and System Config

- Syringe page

2 displays.

2.4 CONFIGURATION SETUP - SYRINGE

MODULE (Continued)

CHECKOUT AND CONFIGURATION

2-8

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

System Configuration - Syringe

Pressure Limit Selection

(no disc)

CONFIRM

High

Med

Low

System Configuration - Syringe

Pressure Limit Selection

(no disc)

CONFIRM

Low

High

Med

System Configuration - Syringe

Pressure Limit Selection

(disc present)

Change

Value

Current limit

_ 600

mmHg

CONFIRM

System Configuration - Syringe

Pressure Limit Selection

(disc present)

Change

Value

Current limit

1000

mmHg

CONFIRM

Page 25

2.4.10 Priming

Enabling Priming mode allows a limited

volume of fluid to be delivered to prime the

administration set before connecting to a

patient or following a syringe change. When

priming, a single continuous press of the

PRIME soft key delivers up to

2 mL of

priming fluid.

1. After accessing System Config -

Syringe options display, page

2, press

Priming soft key.

2. To change option setting, press soft key

next to applicable option (Enable or

Disable).

• Option setting changes and System

Config - Syringe page

2 displays.

2.5 CONFIGURATION SETUP - SHARED

INFUSION - PUMP AND SYRINGE

MODULES

Refer to the

8000/8100 Series Technical

Service Manual.

2.6 CONFIGURATION OPTIONS AND

DEFAULTS - PCA MODULE

NOTE: With the Profiles feature enabled, the

settings are configured independently for

each profile. A hospital-defined, bestpractice data set must be uploaded to enable

the Profiles feature. Date and Time is a

system setting and is the same in all profiles.

System Settings: Refer to the PC Unit

section of the Alaris®System

DFU.

PCA Module Settings: Refer to the PCA

Module section of the Alaris

®

System DFU.

PCA Module Configuration Parameters:

Select system configuration settings for the

PCA Module during data set development,

then upload them as part of the data.

CHECKOUT AND CONFIGURATION

2-9

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

2.4 CONFIGURATION SETUP - SYRINGE

MODULE (Continued)

System Config - Pump 2 of 3

System Configuration - Syringe

Priming mode

Allows use of the

priming feature.

Enable

Disable

Page 26

CHECKOUT AND CONFIGURATION

2-10

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

THIS PAGE

INTENTIONALLY

LEFT BLANK

Page 27

3 PREVENTIVE MAINTENANCE

Page 28

Page 29

Chapter 3 — PREVENTIVE MAINTENANCE

WARNING

Failure to perform regular and preventive

maintenance inspections may result in improper

instrument operation.

3.1 INTRODUCTION

Perform regular and preventive

maintenance inspections to ensure that the

Syringe and PCA Modules remain in good

operating condition:

• Perform regular inspections before each

use.

• Perform preventive maintenance

inspections annually.

These requirements and guidelines are

intended to complement the intent of Joint

Commission on Accreditation of Healthcare

Organizations (

JCAHO) requirements.

3.2 REGULAR AND PREVENTIVE

MAINTENANCE INSPECTIONS,

CALIBRA TION

Use the Maintenance Software to perform

calibration and preventive maintenance.

Contact CareFusion Technical Support

for help obtaining or using Maintenance

Software.

3.3 CLEANING

Refer to the Alaris

®

System DFU.

®

Syringe Module (8110 Series)

®

PCA Module (8120 Series)

Alaris

Technical Service Manual

3-1Alaris

Page 30

PREVENTIVE MAINTENANCE

3-2

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

THIS PAGE

INTENTIONALLY

LEFT BLANK

Page 31

4 PRINCIPLES OF OPERATION

Page 32

Page 33

Chapter 4 — PRINCIPLES OF OPERATION

4-1Alaris

®

Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

4.1 INTRODUCTION

This chapter describes the principles of

operation for the Syringe and PCA Modules.

Refer to the PC Unit/Pump Module

(

8000

/8100 Series) Technical Service Manual

for PC Unit information.

4.2 GENERAL INFORMATION

The Syringe and PCA Modules function as

part of the Alaris

®

System, and function only

when attached to a PC Unit.

• PCA Module: the PCA Module includes

a locking security door and patient

handset. Only one PCA Module can be

attached to the PC Unit, and the PCA

Module must be attached directly to the

right of the PC Unit.

• Syringe Module: the Syringe Module

includes a pressure sensing subsystem

for use with administration sets that

include pressure discs. Up to four

Syringe Modules can be attached to the

PC unit.

• Both modules can be used in conjunction

with any combination of other Alaris

®

Modules.

Both modules are appropriate for

intermittent or continuous delivery of

IV

fluids. Both modules can provide smooth

delivery of small quantities of

IV fluid within a

very low contained volume. Both modules

include these advanced features: bolus

delivery, drug library, drug dose calculator,

loading dose, titrate without stopping,

syringe size detector, one-handed syringe

loading, several modes of delivery, multichannel coordinated infusion, and dose

limits.

Page 34

PRINCIPLES OF OPERATION

4.2 GENERAL INFORMATION (Continued)

Both the Syringe and PCA Modules include

display, logic, drivetrain, drive head, plunger,

and force sensor subsystems.

NOTE: All circuit boards in the Syringe and

PCA Modules are not field repairable and

must be returned to a CareFusion

Service Center for repair.

4.3 DISPLAY BOARD ASSEMBL Y

The keypad sends signals to the

microcontroller on the Display Board, whose

function is to manage displayed information.

The Logic Board provides

5V power to the

Display Board through a 10-pin connector.

4.3.1 Microcontroller

The Display Board's microcontroller

provides four keypad functions: Channel

Select, Pause, Channel Off, and Restart.

The microcontroller controls the keypad

backlight and the Alarm, Infusing, and

Standby

The microcontroller controls the

LEDs.

LED display

driver for the Channel Identification

(Channel ID) and 7–segment rate displays.

The microcontroller also drives the scrolling

alphanumeric display that shows module

status (such as "

CHANNEL MALFUNCTION").

"

INFUSION COMPLETE" or

The microcontroller performs safety

monitoring and generates alerts (including

the Alarm LED and applicable error

messages) if critical circuitry does not

function properly.

The display driver uses a discrete resistor

for brightness control. Module software

provides three brightness levels: low (

full brightness), used when the PC Unit is

operating on battery power; medium (

full brightness), used when the PC Unit is

operating on AC power; and high (100%

brightness) is the maximum level possible.

Rate:

The display driver controls the five

7

–segment displays used for the Rate

display: three

7–segment displays and two

small 7–segment displays (the smaller

displays show fractional digits). The five

displays show infusion rates from

to 999 mL/h. The Rate display is readable in

normal hospital lighting conditions from a

distance of

15 feet and provides a 45°

viewing angle.

Channel Identification:

The display driver controls the

Channel

A

through H. The Channel

ID display, which can display letters

14–segment

ID display is

readable in normal hospital lighting

conditions from a distance of

provides a

viewing angle.

45°

15 feet and

4.3.3 Comparator/Safety Monitor

The comparator/safety monitor circuit

detects short or open failures of the Alarm

LED or rate display and sends that

information to the microcontroller. This

ensures correct alarm notification and

prevents the module from displaying an

invalid infusion rate.

4.3.4 Status and Backlight LEDs

27% of

47% of

0.01 mL/h

4.3.2 LED Display Driver

The microcontroller communicates serially

with the LED driver for the

7-segment LED display.

4-2

Alaris®Syringe Module (8110 Series)

®

PCA Module (8120 Series)

Alaris

Technical Service Manual

8-digit,

A constant current drives and ensures

consistent brightness levels for the three

status

LEDs (Alarm, Infusing, Standby) and

the keypad backlight LED.

Page 35

4.4 LOGIC BOARD ASSEMBLY

The Logic Board receives its power from the

8V supply on the PC Unit via the IUI

connector. The Logic Board contains

DC-to-

DC converters to convert the +8V supply to

+3.3V, +5V, and

+15V supplies,

and a

variable voltage supply to the motor. The

Logic Board also contains an inverting

circuit to produce a -

5V supply. The field-

programmable gate array (

FPGA) on the

Logic Board controls the supply voltages

(

5V, 3.3V) to the digital and analog sensors.

The Logic Board monitors the supply

voltages and analog sensor signals, and

sets up the nominal power level for any

particular pumping rate. Incoming analog

sensor signals (from the pressure sensor,

force sensor, syringe sizer, and plunger

position sensor) are filtered and buffered,

and then fed to the

ADC as inputs.

The Logic Board includes a processor, a

1M x 8 flash ROM, 512K x 8 static RAM, and

a watchdog timer circuit. The watchdog

timer circuit has a 1.6–second timeout that

can put the Syringe or PCA Module into a

safe state if the Logic Board main processor

fails.

The Logic Board reads and writes to the

FPGA via I/O address space. The FPGA

contains the digital logic for generating

control signals for ADC, DAC, sensors, motor

feedback circuitry, module detection and

identification circuit interface, and 10-phase

step signals for the motor drive circuitry.

The

FPGA also generates a master RESET

signal for the module.

The Logic Board’s main processor

communicates with the Display Board’s

microcontroller via a serial channel. The

Logic Board provides the Power-On Reset

signal to the Display Board. Upon keypad

input to the Display Board, the Logic Board

receives a Channel Off signal to stop the

motor.

The Logic Board contains

IUI interface

circuitry that allows it to communicate with

the PC Unit.

The digital sensor interface on the Logic

Board contains current sense circuitry,

which reads output signals from the

photointerrupters on the lever detect sensor,

nut engaged sensor, and flange sensor. On

the Syringe Module only, the Logic Board

also reads signals from the

SET IN sensor

(pressure sensor).

The motor drive circuitry on the Logic Board

uses a variable voltage supply to drive a

5

-phase stepper motor and save power,

depending on the torque loading. A

combination of software settings and motor

feedback loop circuitry adjusts the motor

supply voltage in response to detected

motor loading. The motor feedback loop

starts with a nominal voltage based on

pumping rate, and adjusts motor voltage as

needed to maintain constant peak motor

current levels, independent of torque load.

The motor feedback loop keeps the voltage

range constant for any given pumping rate.

4.5 DRIVETRAIN ASSEMBLY

The drivetrain is a linear positioning device.

The geared stepper motor powers the

drivetrain, and the linear motion of the

drivetrain controls the drive head to push

the syringe plunger accurately and with

enough force to deliver medication from

many different syringes. Because system

positioning is open loop, the mechanical

parts and assembly must maintain a high

degree of accuracy.

PRINCIPLES OF OPERATION

4-3

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

Page 36

4.6 DRIVE HEAD

The drive head captures the syringe by the

syringe plunger and uses the drivetrain to

drive the plunger in a controlled fashion.

The drive head has claw-like arms (plunger

grippers) that capture the syringe plunger.

The plunger grippers allow the drive head to

capture a wide variety of syringes (see the

Syringe or PCA Module section of the

Alaris

®

System DFU and Set Compatibility

Card for more information on suitable

syringes).

To load a syringe into the drive head, the

gripper control/drive head release lever

rotates

90° clockwise. This rotates an inner

shaft, which is connected to a slide plate.

Two holes in the slide plate interface with

two pinion gears that make direct contact

with the plunger grippers. Once the slide

plate moves back, the gears rotate and the

plunger grippers open to accept the syringe

plunger flange.

Once the syringe is loaded, a plunger detect

flag interfaces with an optical switch to

indicate that a syringe is properly loaded

into the plunger grippers. The drive head

also includes a flag that indicates the drive

head position, preventing an infusion from

beginning prematurely.

Several other components of the drive head

control the opening and closing of the split

nuts on the leadscrew. A pull rod cam

attached to the end of the rotating shaft in

the drive head interfaces with a rod and

head piece that can rotate to lift the rod

attached to the drivetrain carriage and cam

lock at the other end, allowing the split nuts

to open. Once the rotating shaft rotates

clockwise to load a syringe and then

released, a torsion spring returns the gripper

control to its original position. This torsion

spring ensures that the gripper control

returns to its vertical (closed) position and

confirms that the split nuts are closed.

The drivetrain is contained in the lower and

upper housings. The lower housing is also

attached to the drive tube that connects to

the drivetrain carriage at the opposite end.

A plastic sleeve over the drive tube provides

environmental and

ESD protection to the flex

circuit routed up to the drive head.

4.7 PLUNGER HEAD BOARD ASSEMBLY

A strain gauge on the Plunger Head Board

senses the force applied to the syringe

plunger: the greater the force, the more

negative the amplifier output . The resulting

signal is inverted and offset on the Logic

Board.

The optical switches on the Plunger Head

Board detect whether a syringe is properly

loaded and whether the plunger grippers are

position to capture a syringe plunger. When

either optical switch is unblocked, currentsensing circuitry on the Logic Board detects

a current from the switch.

4.8 FORCE SENSOR SUBSYSTEM

The force sensor subsystem includes a

force sensor mounted in the drive head,

rather than at the drivetrain as in other

designs.

The cantilevered force sensor contact plate

pivots on a lock plate mounted to the

underside of the lower housing. The force

sensor is positioned so that the cantilevered

contact plate acts as a moment arm from

the pivot point, providing mechanical

advantage from the syringe force to the

force sensor.

PRINCIPLES OF OPERATION

4-4

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

Page 37

This mechanical advantage amplifies the

input for a given force from a syringe, which

improves system resolution. Improved

resolution is particularly beneficial for

smaller syringes with lower syringe forces.

A protrusion on the contact plate

concentrates force from all syringe sizes to

a specific location on the contact plate,

which minimizes the effect of variations in

syringe loading and in the syringe push

button geometry inherent in plastic syringes.

The protrusion also creates a longer

moment arm for smaller size syringes,

because they contact the protrusion further

from the contact plate pivot. This increases

the sensor force of small size syringes,

allowing better system resolution. A silicone

seal is also trapped between the force

sensor and the lower housing.

4.9 PRESSURE SENSOR SUBSYSTEM

(SYRINGE MODULE ONLY)

The pressure sensor subsystem includes

the Pressure Sensor Board Assembly, disc

detect system, and related hardware. The

pressure sensor subsystem is only activated

when an administration set with a pressure

disc is used and the pressure disc is

installed, and enhances overall pressure

detection in the patient line.

The Pressure Sensor Board includes: a

pressure sensing transducer that makes

intimate contact with a flexible membrane

(pressure disc) on the administration set.

The pressure of the fluid in the

administration set is transmitted through the

membrane and into the gel of the sensor,

where it is measured by a piezoresistive

pressure transducer.

Circuitry on the Pressure Sensor Board

amplifies pressure transducer output. The

board also includes an optical switch that

detects the presence of an administration

set pressure disc.

4.10 PATIENT HANDSET CIRCUIT AND

DOOR LOCK SENSOR CIRCUIT (PCA

MODULE ONLY)

The PCA Module Logic Board includes a

patient handset circuit, which senses

whether a dose request cord is attached. A

button on the dose request cord allows a

patient to request a dose of analgesia

according to clinician-programmed

parameters.

The PCA Module Logic Board also includes

a door lock sensor circuit that detects the

position of the door lock (

UNLOCK,

PROGRAM, or LOCK):

•

UNLOCK allows syringe loading or

unloading, or access to the latch that

allows the PCA Module to be detached.

•

PROGRAM allows changes to

programmed parameters without

interrupting an infusion.

•

LOCK is the only position that allows an

infusion to start.

PRINCIPLES OF OPERATION

4-5

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

4.8 FORCE SENSOR SUBSYSTEM

(Continued)

Page 38

PRINCIPLES OF OPERATION

4-6

Alaris®Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

THIS PAGE

INTENTIONALLY

LEFT BLANK

Page 39

PRINCIPLES OF OPERATION

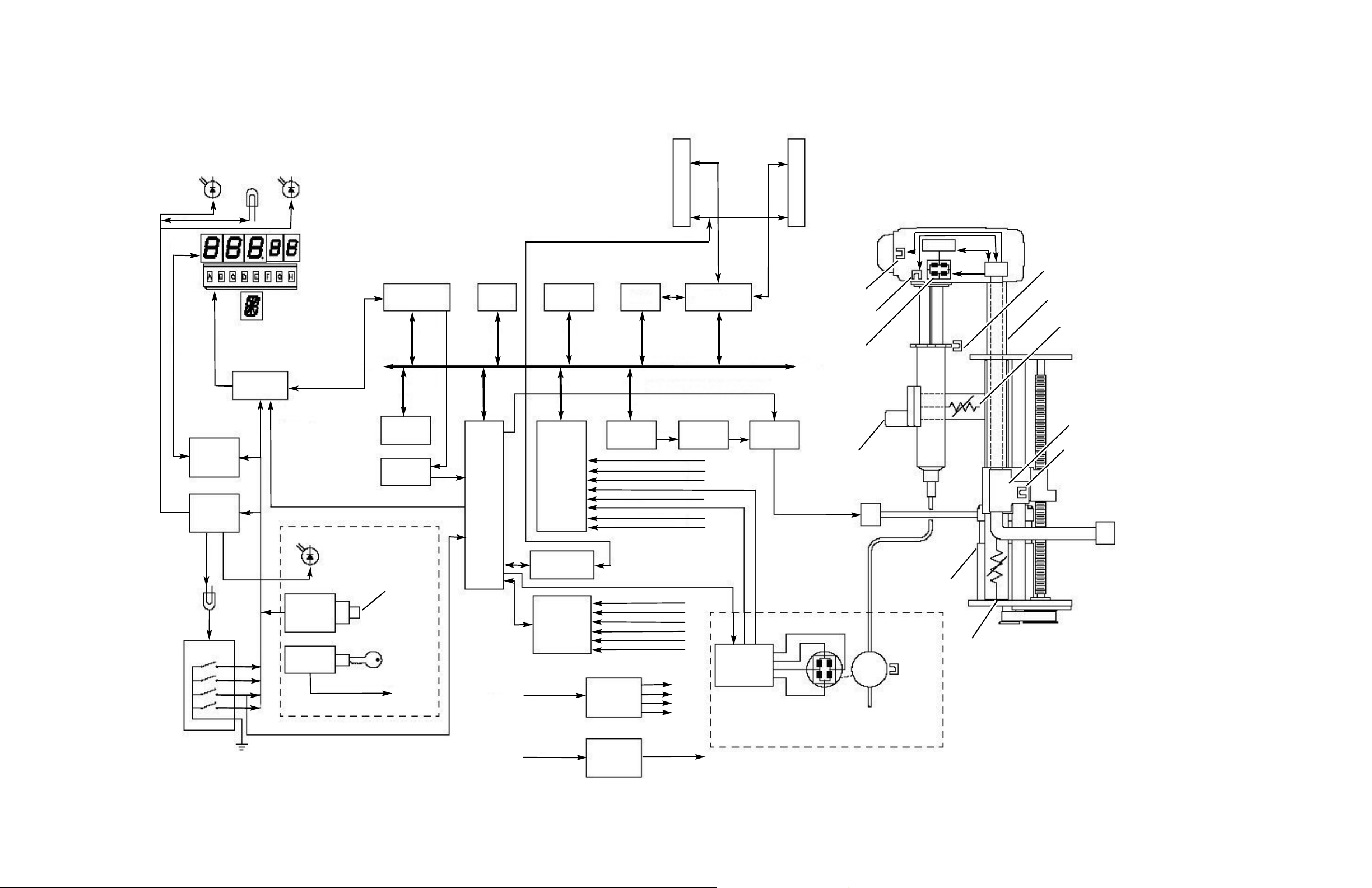

Figure 4-1. Block Diagram: Syringe and PCA Modules

4-7

Alaris®Syringe Module (8110 Series)

Alaris®PCA Module (8120 Series)

Technical Service Manual

ALARM

LED (red)

INFUSE

LED (green)

STANDBY

LED (yellow)

7-segment

driver/check

circuit

LED

driver/check

circuit

Display board

microcontroller

7-Segment

Displays

Scrolling

Displays

Channel

ID Display

Keypad

backlight

Keypad

Select

Pause

Channel Off

Restart

Handset

LED

Patient

Handset

Circuit

Door Lock

Sensor Circuit

Door Lock Sensor

Patient Switch

Model 8120 PCA Module Only

Channel Off

Power On Reset

FPGA

Logic board

microcontroller

Address

Latch

Watchdog/

System Reset

Address/

Data/Control Bus

Flash

ROM

Static RAM DUART

Transceiver

Left IUI Connector

Right IUI Connector

12-Bit ADC

8 Channel

8-Bit DAC

(parallel) &

Amp

Variable

Motor

Voltage Drive

5-Phase

Stepper

Motor Driver

Unit Detect

& ID Circuit

Sensors Signal

Conditioning &

Drive Circuit

Force Sensor Out

Plunger Sensor Position

Motor Drive Voltage

Pressure Disc Sensor (8110 only)

Syringe Size Sensor

Pressure Sensor Current Sense

+3.3V

+5V

Plunger Detect Sensor

Lever Detect Sensor

Flange Sensor

Split Nut Engaged Sensor

Set In Sensor (8110 only)

Door Lock Sensor (8120 only)

DC/DC

Converter &

Regulators

2.5V

Reference

Circuit

+3.3 V

+5V

-5 V

+15 V

From IUI Connectors

5V +2.5V Ref

Model 8110 Syringe Module Only

Amp, Current

Sense & Test

Circuit

Pressure

Disc

Set In

Sensor

Motor

Connection

Flex Cable

Connection

Plunger

Position

Sensor

5-Phase

Stepper Motor

Syringe Barrel

Gripper

Split Nut Engaged

Sensor

Carriage Flex

Circuit

Drivetrain

Assembly

Flange Sensor

Flex Cable

Syringe Size

Sensor

Flex

Cable

Drive Head

Amp

Plunger

Force

Sensor

Plunger Detect

Sensor

Lever Detect

Sensor

Page 40

PRINCIPLES OF OPERATION

4-8 Alaris

®

Syringe Module (8110 Series)

Alaris

®

PCA Module (8120 Series)

Technical Service Manual

THIS PAGE

INTENTIONALLY

LEFT BLANK

Page 41

5A CORRECTIVE MAINTENANCE

SYRINGE MODULE

Page 42

Page 43

Chapter 5A — CORRECTIVE MAINTENANCE

Syringe Module

5A-1

Alaris®Syringe Module (8110 Series)

Alaris®PCA Module (8120 Series)

Technical Service Manual

WARNING

Disconnect the instrument from the Alaris

®

System before performing maintenance. Only

qualified personnel using proper grounding

techniques should open the instrument case.

CAUTION

CMOS devices are sensitive to static electrical

charges and may be damaged during repair if the

repair activity is not performed in an electrostatic

discharge (

approved

ESD) protected environment using

ESD protective procedures, including

personnel grounding.

NOTES:

• Replacing the Complete Housing Assembly,

Force Sensor Assembly or Logic Board

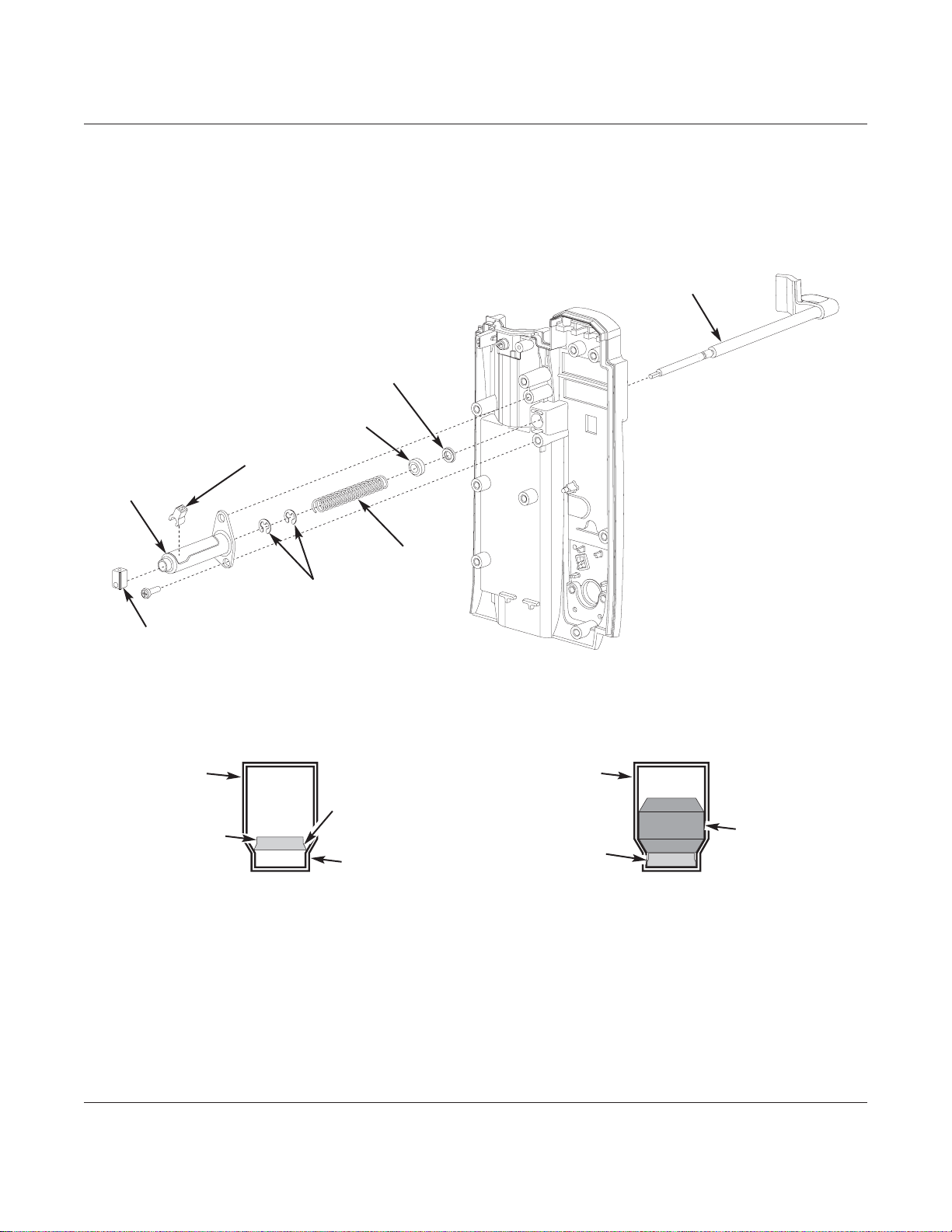

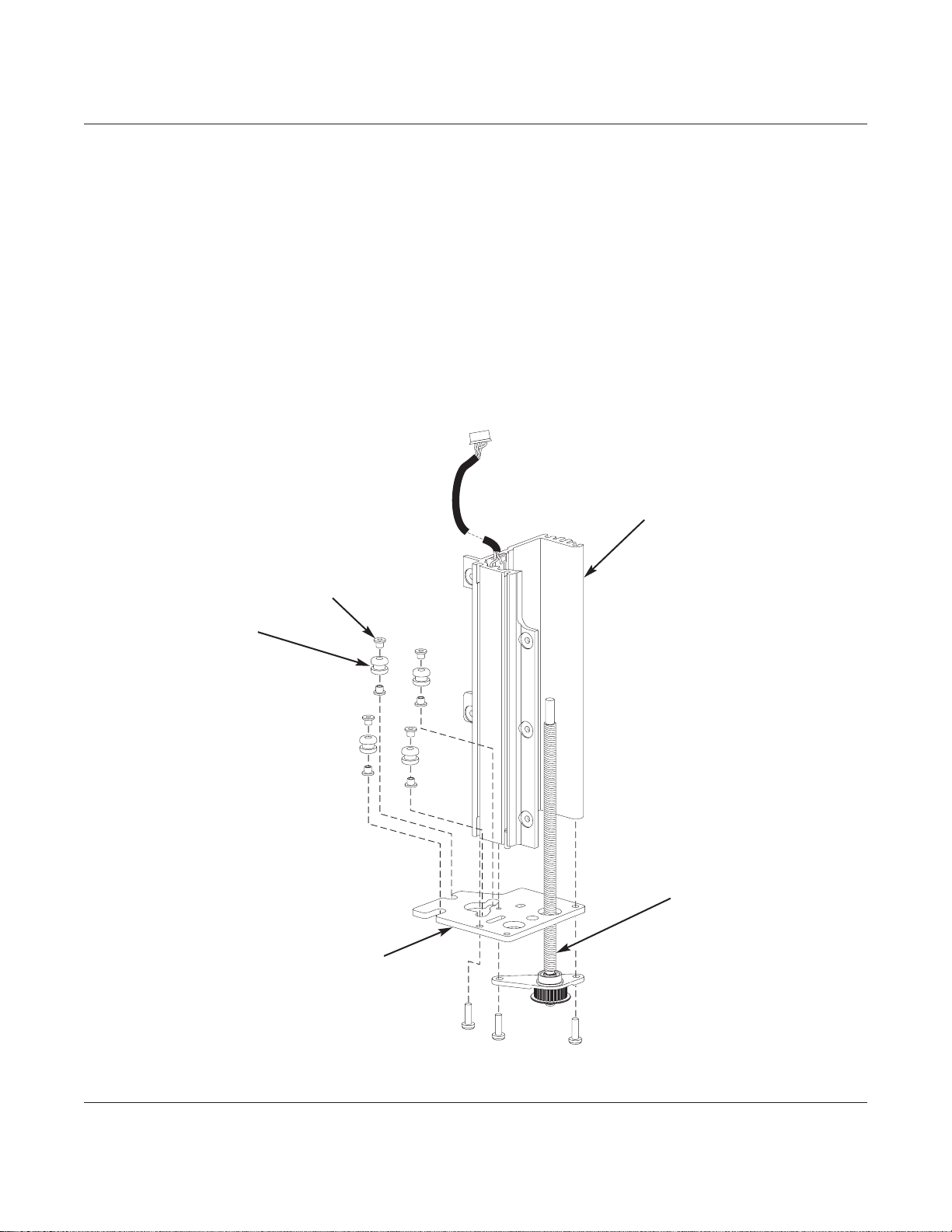

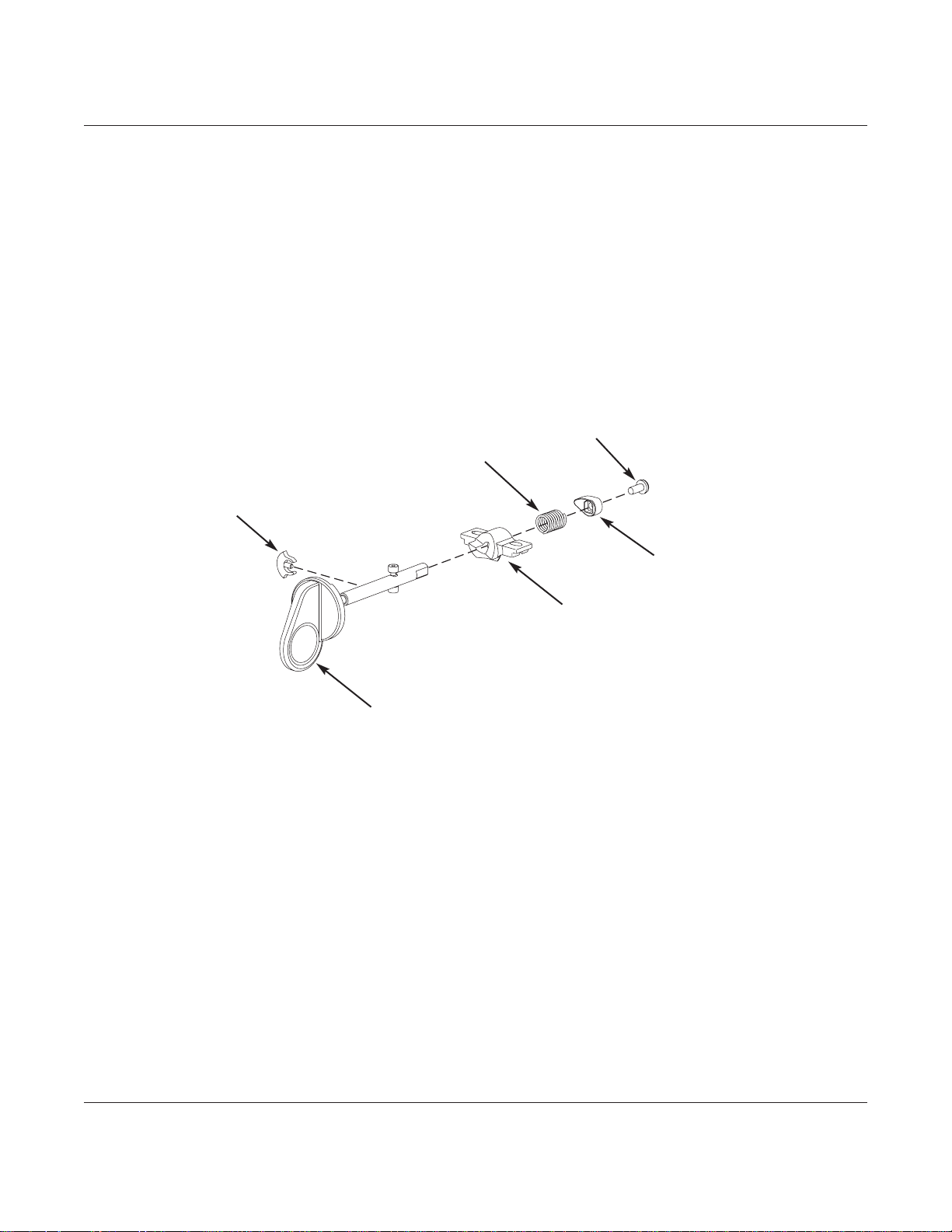

Assembly in a Syringe Module with version