Page 1

8400STº

&

8400ST%

VOLUME

SERVICE

NOTE:

This

to

The

information

the

8400ST®°i

8400ST®

alsoapplies

is

located

name

is

referred

to

in

the

VENTILATOR

MANUAL

to

the

8400ST%;,

back

throughout

of

the

manual

Specific

the

contents

information

under

Addendums.

of

this

manual.

pertaining

only

©

1995

Bird

Products

Corporation

EE

aa

Bird

1100

(619)

(800/

©

Products

Corporation

Bird

Center

778-7200 M TLX:

328-4139 m FAX:

Drive,

Palm

Springs,

9103805605

(619)

778-7269

CA

92262

Page 2

Page 3

Bird

Products

Corporation

MANUAL

REVISION

8400ST

Service

/8400STi

Manual

Date

March

1998

Revision

pee

Rev.

Pages

D

Service

Manual

本

March

1898

Rev.

D

Page 4

Page 5

This

_

Corporation

Products

activity

trained

CORPORATION

UNAUTHORIZED

UNAUTHORIZED

service

Corporation

on

or

WARNING

manual

trained

its

products

authorized

is

and

IS

NOT

REPAIRS,

PROCEDURES.

intended

authorized

does

personnel.

not

by

other

RESPONSIBLE

for

condone

than

OR

use

service

Bird

BIRD

ANY

!

by

Bird

or

approve

Products

PRODUCTS

REPAIRS

Products

personnel.

FOR

Bird

of

service

Corporation

ANY

MADE

BY

Use

installation,

and

the

injury

shall

All

Products

warranty

of

the

equipment

equipment.

including

bear

maintenance

(see

warranty

incorrect

removal,

full

responsibility

card)

Corporation

status

part

servicing,

may

This

of

result

may

death.

performed

must

the

or

the

in

damage

also

The

be

service

subject

result

purchaser

and

within

authorized

representative

unit.

failure

checkout

liability

to

or

in

damage

and

the

applicable

exercise

or

calibration

possible

to

installer

for

the

above.

in

advance

in

order

due

care

malfunction

property

of

warranty

by

to

in

of

parts

and

these

Bird

parts

period

retain

the

of

the

Page 6

Page 7

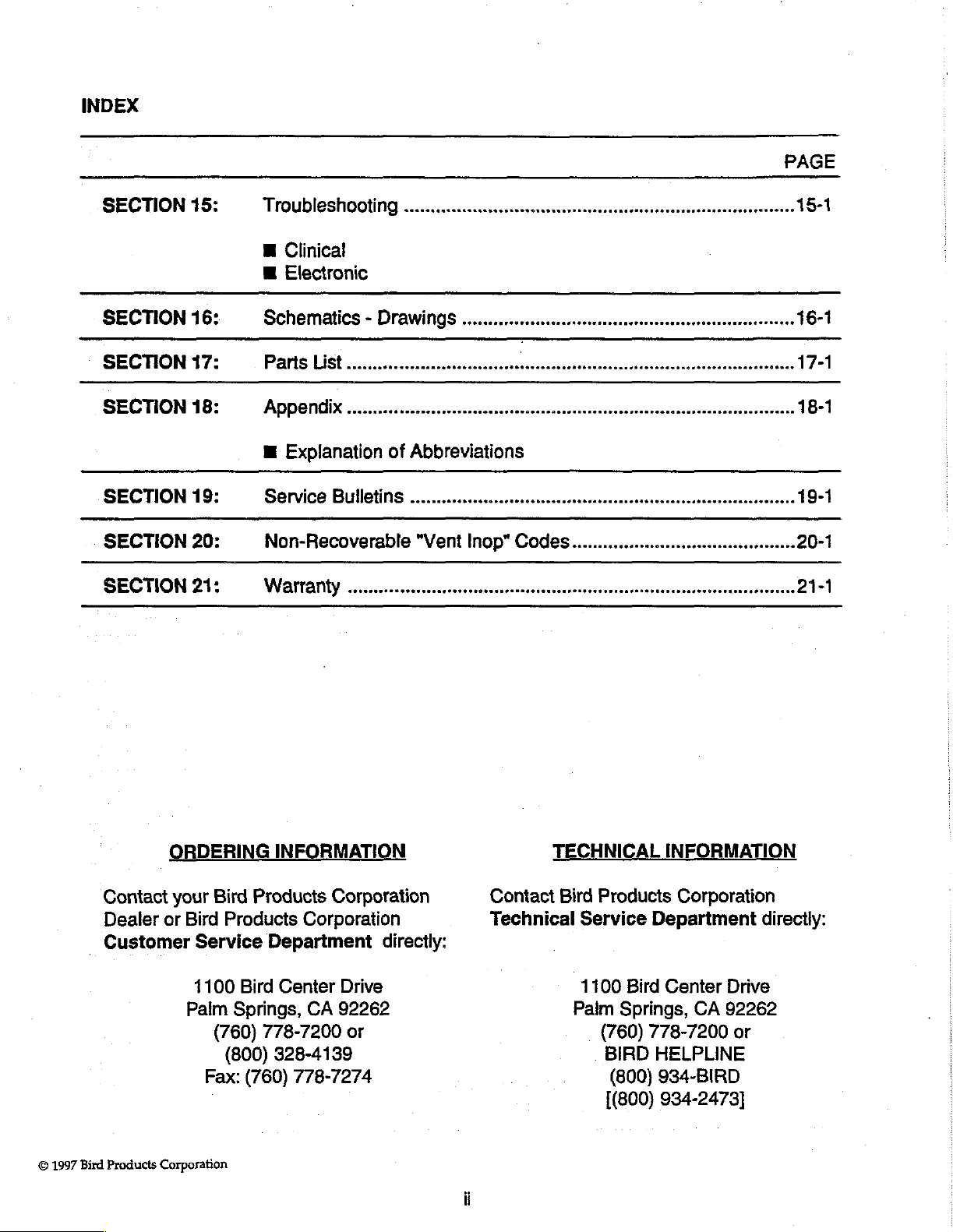

CONTENTS

-

GENERAL

SECTION

INFORMATION

1:

Introduction,

-

Overhaul

Definition

.ee

of

Repair - Maintenance

PAGE

'

1-1

SECTION

SECTION

SECTION

SECTION

SECTION

SECTION

MAINTENANCE

SECTION

SECTION

2:

3:

4:

5:

6:

7:

8:

9:

SpecificationS

Description

Assembly

Overview

System

M

PNEUMALIC

E

8400ST

Warnings,

Cleaning

OVERHAUL

Maintenance

8400ST

of

the

Display,

Instructions

of

the

8400ST

OperatiOn

....ononoocononcnonnnonoranonnroncnanaconconoconcanocraronon

Circuit

Cauiions

and

Boards

and

Sterilization

Service

Tools & Equipment

Controls

nr

Volume

Theory

NoteS

..........

Policy

List

ーー

昌和

and

Alarm

2-1

Indicator...............

3-1

4-1

Ventilator

ee

nora

onareorancoronons

of

Operation.............................

irene

rire

rire

receiver

ee

rene

nine

eeeeeneno

아아아

once

5-1

5-2

5-9

6-1

7-1

8-1

9-1

SECTION

SECTION

SECTION

SECTION

SECTION

10:

11:

12:

13:

14:

NES

Disassembly

Assembly

Critical

μμ

Component

Operational

&

Performance

画

Pre-CalbratiOn

B

Calibration

m

Post

Calibration/Final

E

Pertormance

IM

inserer

Removal/Replacement

Verification

TeSt

Procedures

issssseisnsnesnesnse

μϱ””ϱϱϱϱἛϱἛϱρρυ---

sise

Assembly

κ

μμ

μμ

esse

neee

aeeereeemeeremerenesenn

ke

ste v snes

steen

renen

Procedures..............

sarao

esser

sr

10-1

11-1

12-1

13-1

14-1

sense

Page 8

INDEX

SECTION

SECTION

SECTION

SECTION

SECTION

SECTION

SECTION

15:

16:

17:

18:

19:

20:

21:

Troubleshootind

m

Clinica!

m

Electronic

Schemalics・

DrawindS

AS

APPend

m

Explanation

Service

Non-Recoverable

Warranty

ϱ.ϱϱΓϱΓϱϱϱίμυ-

of

Bulletins

.......--cccsececetecsscessecesesssecccasesesesseresstseetareesaetesorsnsssseeessess

PAGE

ito

ee

rroccrnicroniono

A

15-1

16-1

17-1

18-1

Abbreviations

"sise

"Ventinop"Codes..............................-0004.......

19-1

20-1

21-1

O

1997

Contact

Dealer

_

Customer

Bird

Products

ORDERING

your

Bird

or

Bird

Products Corporation

Service

1100

Paim

(760)

(800)

Fax:

Corporation

INFORMATION

Products

Department

Bird

Center

Springs,

778-7200

328-4139

(760)

778-7274

Corporation

directly:

Drive

CA

92262

or

TECHNICAL

Contact

Bird

Technical

Paim

Products

Service

1100

Bird

Springs,

(760)

778-7200

BIRD

(800)

[(800)

INFORMATION

Corporation

Department

Center

CA 92262

directly:

Drive

or

HELPLINE

934-BIRD

934-2473]

Page 9

SECTION

Introduction

1

8400ST / 8400STi

Volume

Ventilator

Service

Manual

Page 10

Page 11

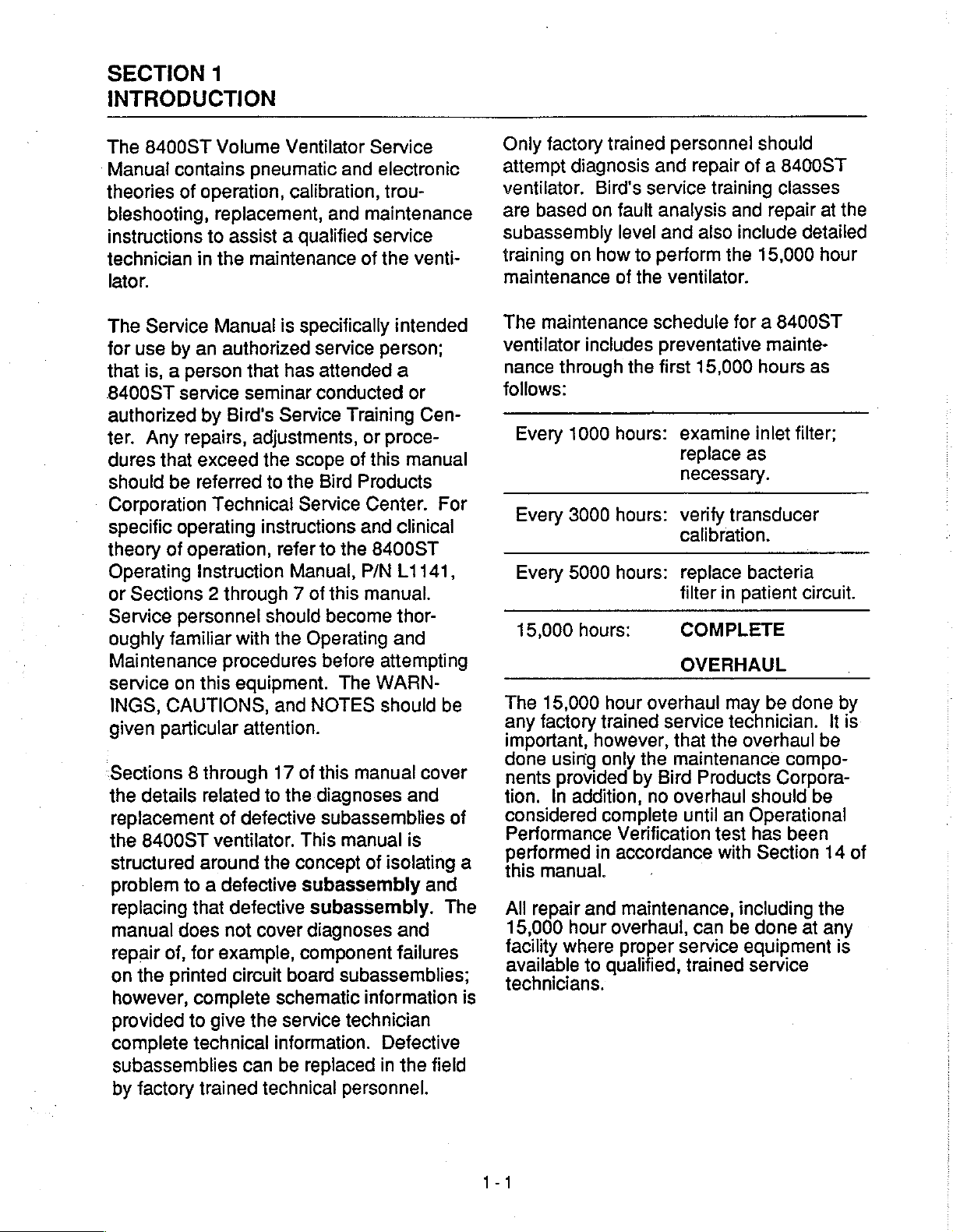

SECTION

1

INTRODUCTION

The

8400ST

Manual

theories

bleshooting,

instructions

technician

lator.

The

Service

for

use

that

is, a person

8400ST

authorized

ter.

Any

dures

should

that

be

Corporation

specific

theory

of

Operating

or

Sections 2 through 7 of

Service

oughly

familiar

Maintenance

service

INGS,

given

CAUTIONS,

particular

‘Sections 8 through

the

details

replacement

the

8400ST

structured

problem

replacing

manual

repair

on

of,

the

printed

however,

provided

complete

subassemblies

by

factory

Volume

contains

of

operation,

replacement,

to

assist a qualified

in

the

Manual

by

an

authorized

that

service

repairs,

exceed

referred

operating

operation,

Instruction

personnel

on

to a

that

does

for

complete

to

technical

seminar

by

Bird’s

Technical

with

procedures

this

equipment.

attention.

related

of

defective

ventilator.

around

defective

defective

not

example,

circuit

give

can

trained

pneumatic

maintenance

adjustments,

the

to

instructions

should

the

and

17

to

the

cover

schematic

the

information.

technical

Ventilator

Service

and

calibration,

and

maintenance

service

of

is

specifically

service

has

attended

conducted

Service

Training

or

scope

the

Service

of

Bird

this

Products

Center.

and

refer

to

the

8400ST

Manual,

P/N

this

manual.

become

Operating

before

The

NOTES

of

this

manual

the

diagnoses

subassemblies

This

manual

concept

of

subassembly

subassembly.

diagnoses

component

board

subassemblies;

information

service

be

technician

replaced

personnel.

electronic

trou-

the

venti-

intended

person;

a

or

Cen-

proce-

manual

For

clinical

L1141,

thor-

and

attempting

WARN-

should

isolating

Defective

in

be

cover

and

of

is

a

and

The

and

failures

is

the

field

Only

factory

attempt

ventilator.

are

diagnosis

based

Bird's

on

subassembly

training

on

how

maintenance

The

maintenance

ventilator

nance

includes

through

follows:

Every

Every

Every

15,000

1000

3000

5000

hours:

The 15,000

any

factory

important,

done

using

nents

tion.

in

considered

trained

however,

only

provided

addition,

complete

Performance

performed

this

manual,

All

repair

15,000

facility

available

in

and

hour

where

to

technicians.

trained

personnel

and

repair

service

fault

analysis

level

and

also

to

perform

of

the

ventilator.

schedule

preventative

the

first

15,000

hours:

examine

replace

necessary.

hours:

verify

calibration.

hours:

replace

filter

COMPLETE

OVERHAUL

hour

overhaul

service

that

the

maintenance

by

Bird

Products Corpora-

no

overhaul

until

Verification

accordance

maintenance,

overhaul,

proper

qualified,

can

service

trained

should

of a 8400ST

training

and

classes

repair

include

the

15,000

for a 8400ST

mainte-

hours

inlet

as

transducer

bacteria

in

patient

may

be

done

technician.

the

overhaul

compo-

should

an

Operational

test

has

been

with

Section

including

be

done

equipment

service

at

the

detailed

hour

as

filter;

circuit.

by

It

is

be

be

14

of

the

at

any

is

Page 12

Page 13

SECTION

2

Specifications

8400ST / 8400STi

Volume

Ventilator

Service

Manual

Page 14

Page 15

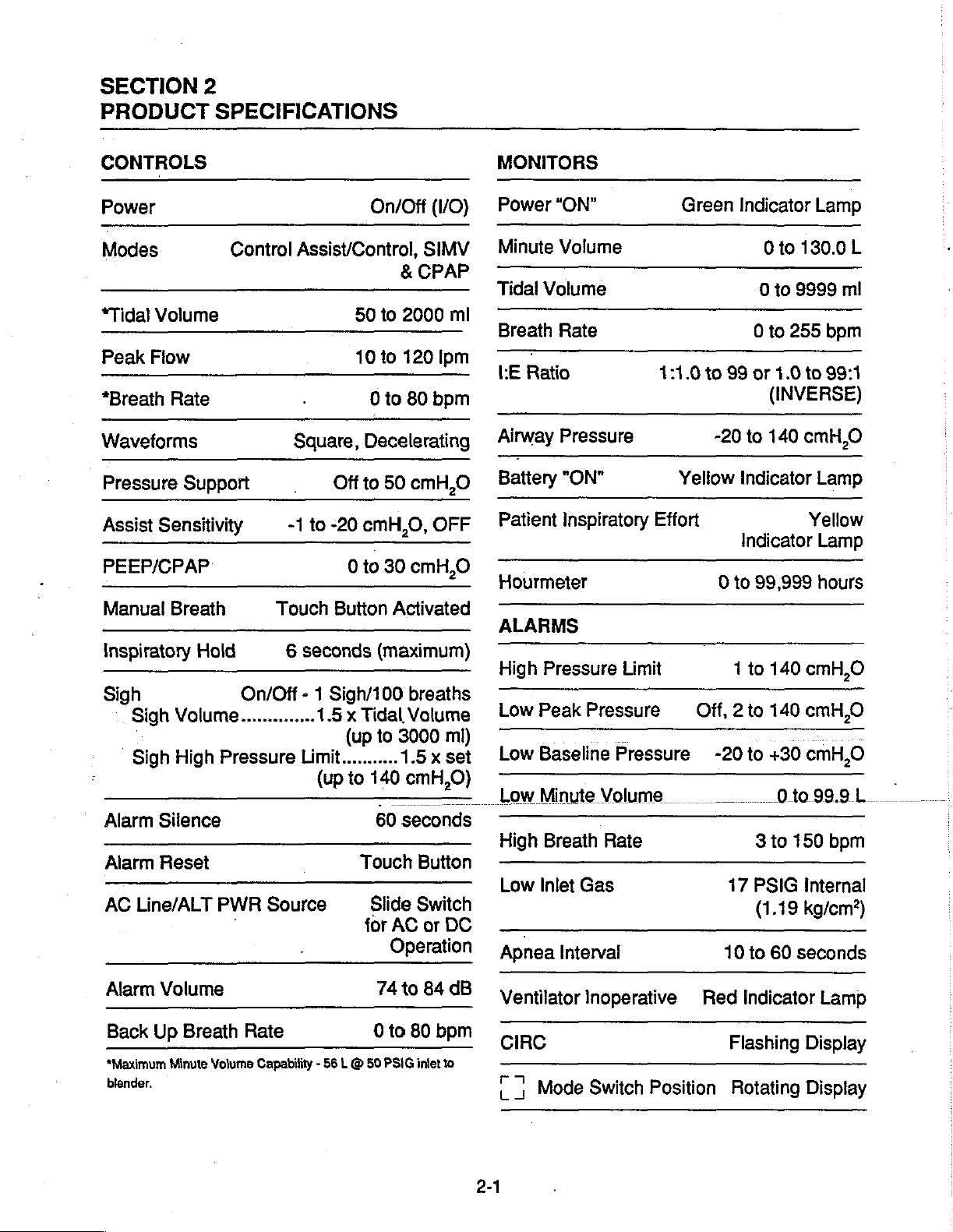

SECTION

PRODUCT

2

SPECIFICATIONS

CONTROLS

Power

Modes

*Tidal

Peak

*Breath

Volume

Flow

Rate

Waveforms

Pressure

Assist

Support

Sensitivity

PEEP/CPAP

Manual

Inspiratory

Sigh

Alarm

Alarm

AC

Alarm

Back

“Maximum

blender.

Breath

Hold

Sigh

Volume..............

Sigh

High

Silence

Reset

Line/ALT

Volume

Up

Breath

Minute

Volume

Control

Assist/Control,

Square,

-1

Touch

6

On/Off

Pressure

PWR

]

Rate

- 1

Limit...........

Source

Capability - 56 L @

50

10

Decelerating

Off

to

to

-20

cmH,O,

0

to

Button

seconds

Sigh/100

1.5x

Tidal

(up

(up

to

Touch

for

On/Off

(VO)

SIMV

&

CPAP

to

2000

to

120

Ipm

0

to

80

bpm

50

cmH,O

OFF

30

cmH,O

Activated

(maximum)

breaths

Volume

to

3000

1.5x

140

cmH,O)

-

60

seconds

Button

Slide

Switch

AC

or

Operation

74

to

84

0

to

80

bpm

50

PSIG

intet

ml

mi)

set

DC

dB

to

MONITORS

Power

Minute

-

Tidal

Breath

“ON”

Volume

Volume

Rate

ーー

LE Ratio

Airway

Battery

Patient

Pressure

"ON"

Inspiratory

Hourmeter

ALARMS

.

High

Pressure

Low

Peak

Low

Baseline

Low

Minute

High

Breath

Low

Inlet

Apnea

Interval

Ventilator

CIRC

|;

Mode

1:1.0

Effort

Limit

Pressure

-

Pressure

Volume

Rate

Gas

Inoperative

Switch

Position

Green

to

99

-20

Yellow

0

Off,

-20

17

10

Red

Flashing

Rotating

Indicator

0

to

130.0

0

to

9999

0

to

255

or

1.0

to

(INVERSE)

to

140

cmH,0

Indicator

Yellow

Indicator

to

99,999

1

to

140

cmH,O

2 to

140

cmH,O

to

+30

cmH,O

01099.9L

Sto

150

PSIG

(1.19

to

Internal

kg/cm?)

60

seconds

Indicator

Display

Display

Lamp

L

mi

bpm

99:1

Lamp

Lamp

hours

7

bpm

Lamp

2-1

Page 16

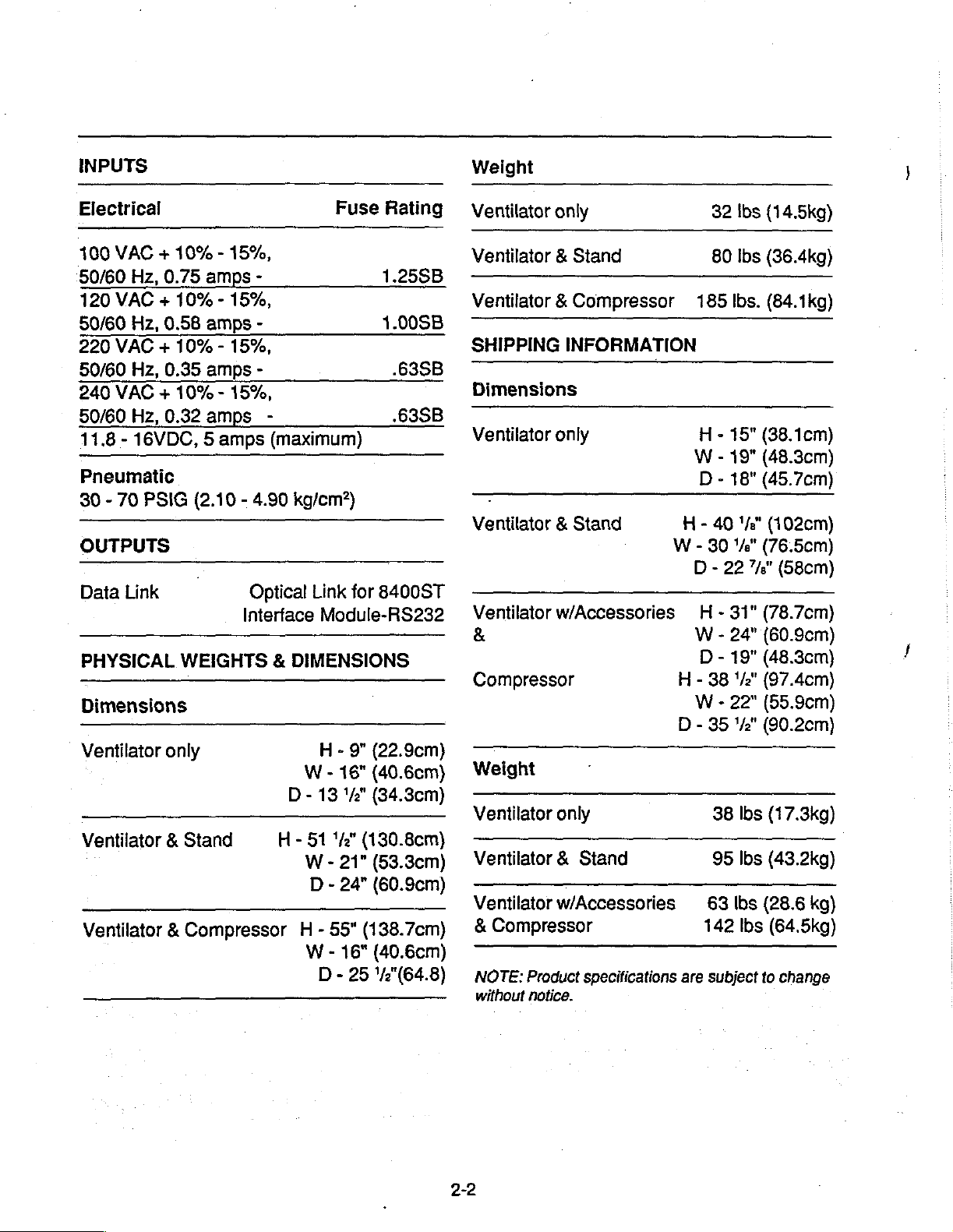

INPUTS

Electrical

100

VAC + 10% - 15%,

§0/60

120

50/60

220

50/60

240

50/60

11.8 - 16VDC, 5 amps

Hz,

0.75

amps

VAC + 10% - 15%,

Hz,

0.58

amps

VAC + 10% - 15%,

Hz,

0.35

amps

VAC + 10% - 15%,

Hz,

0.32

amps

Pneumatic

30 - 70

OUTPUTS

Data

PSIG

Link

(2.10 - 4.90

Optical

Interface

PHYSICAL

WEIGHTS & DIMENSIONS

Dimensions

Ventilator

only

Ventilator & Stand

Ventilator & Compressor

-

-

-

-

(maximum)

kg/cm?)

Link

Module-RS232

H - 9"

W - 16"

D-

13

H - 51

W - 21”

D - 24"

Н - 55"

W - 16"

D - 25

Fuse

Rating

1.25SB

1.00SB

.63SB

.63SB

for

8400ST

(22.9cm)

(40.6cm)

1/2"

(34.3cm)

1/2"

(130.8cm)

(53.3cm)

(60.9cm)

(138.7ст}

(40.6cm)

'/2"(64.8)

Weight

Ventilator

Ventilator & Stand

Ventilator & Compressor

SHIPPING

Dimensions

Ventilator

Ventilator & Stand

Ventilator

&

Compressor

Weight

Ventilator

Ventilator & Stand

Ventilator

&

Compressor

NOTE:

without

only

INFORMATION

only

w/Accessories

only

w/Accessories

Product

notice.

specifications

32

80

185

H - 15"

W - 19"

D - 18"

H-40'/"

W - 30

D - 22

-

W - 24"

D - 19"

H - 38

W - 22"

D - 35

38

95

63

142

are

subject

Ibs

(14.5kg)

Ibs

(36.4kg)

Ibs.

(84.1kg)

(38.1cm)

(48.3cm)

(45.7cm)

(102cm)

‘/e"

(76.5cm)

7%"

(58cm)

31"

(78.7ст)

(60.9cm)

(48.3cm)

‘/2"

(97.4cm)

(55.9cm)

"42"

(90.2cm)

lbs

(17.3kg)

Ibs

(43.2kg)

lbs

(28.6

lbs

(64.5kg)

to

change

kg)

Page 17

SECTION

3

Description

and

of

Alarm

the

Display,

Controls

Indicator

8400ST / 8400STi

Volume

Ventilator

Service

Manual

Page 18

Page 19

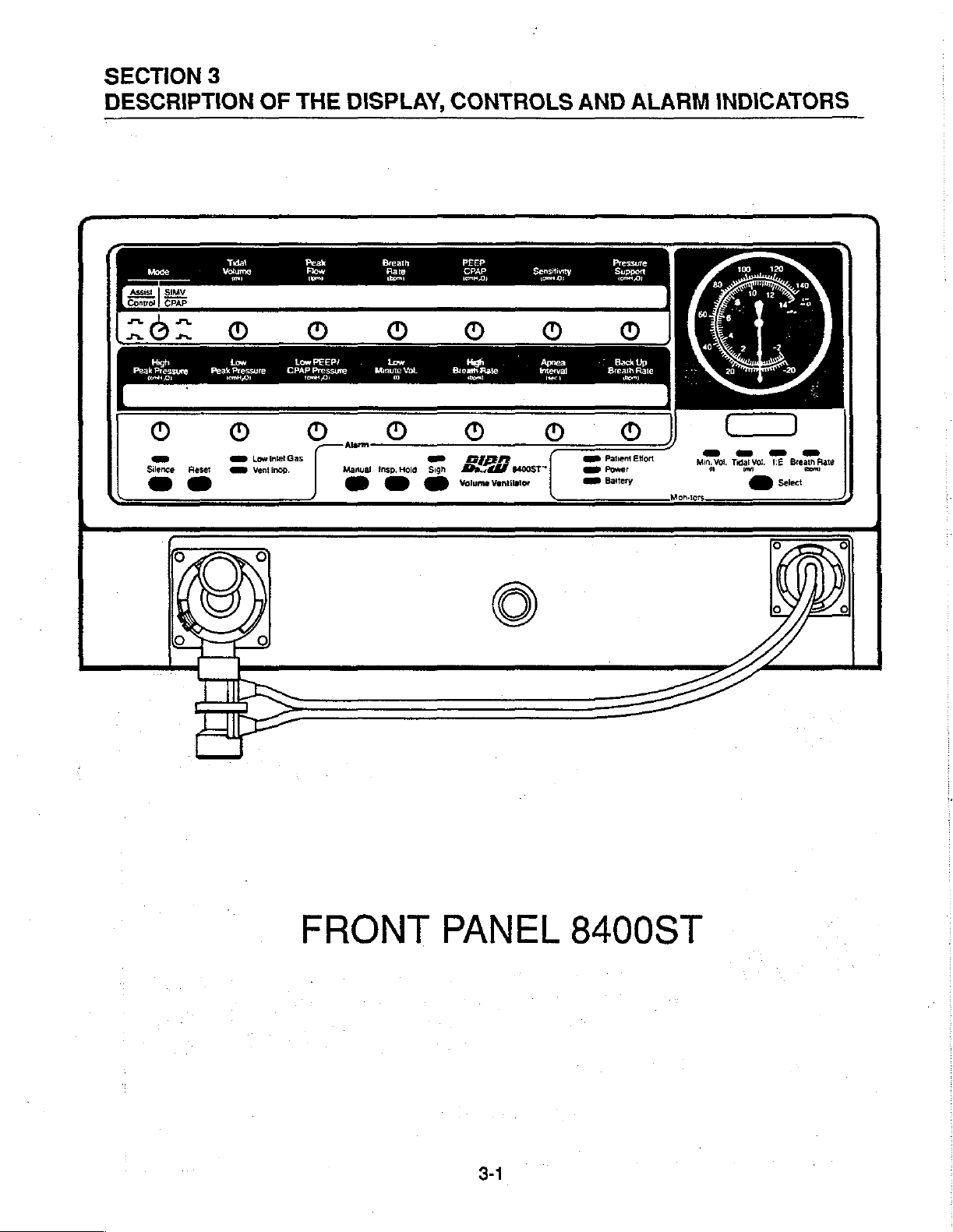

SECTION

DESCRIPTION

Assist | SIMV

Control | CPAP

3

OF

THE

DISPLAY,

CONTROLS

AND

ALARM

INDICATORS

FRONT

PANEL

8400ST

3-1

Page 20

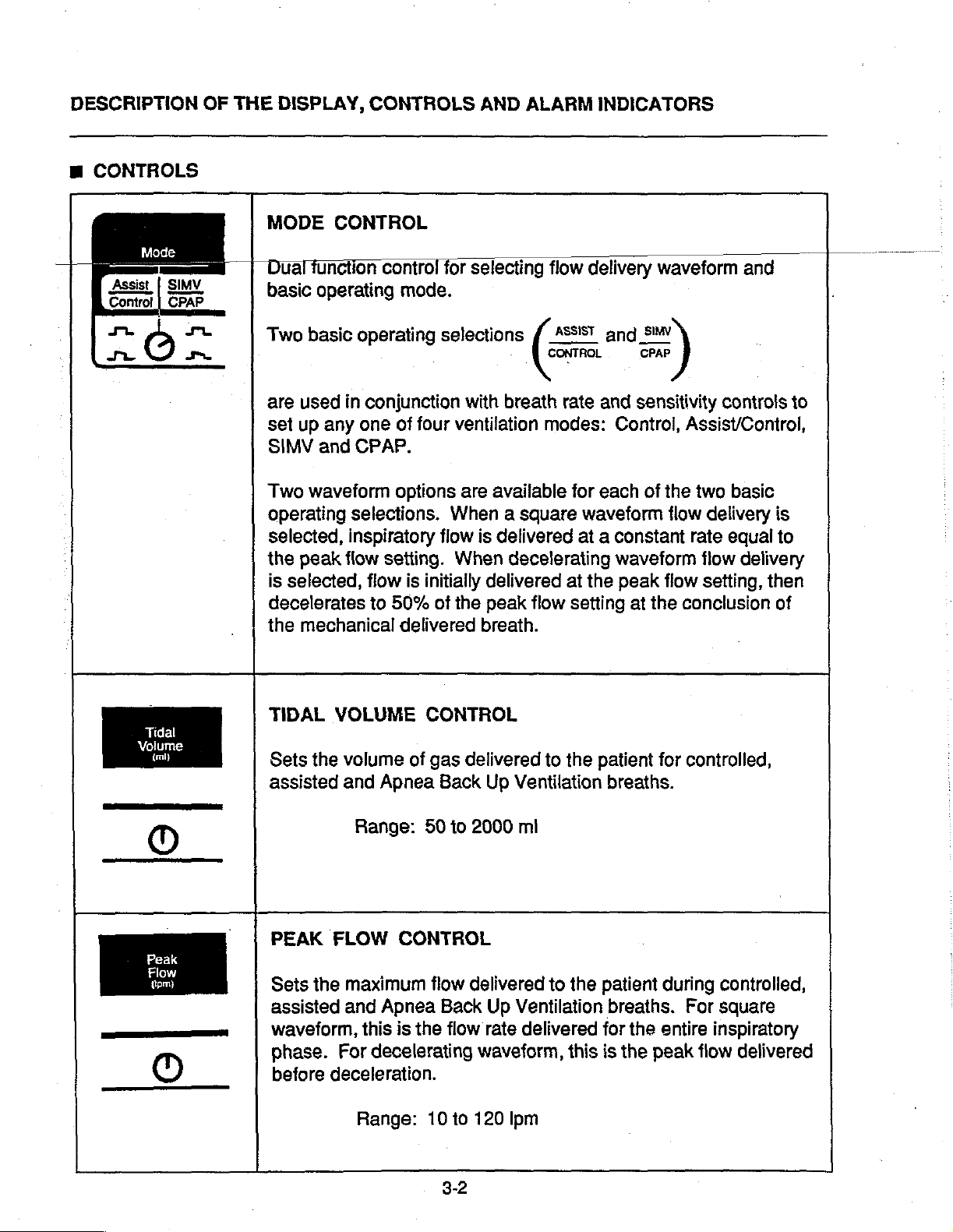

DESCRIPTION

E

CONTROLS

OF

THE

DISPLAY,

CONTROLS

AND

ALARM

INDICATORS

Control | CPAP

MODE

Dual

basic

Two

are

set

SIMV

Two

operating

selected,

the

is

selected,

decelerates

the

CONTROL

function

operating

basic

used

up

any one

and

waveform

peak

mechanical

control

operating

in

conjunction

CPAP.

selections.

inspiratory

flow

setting.

flow

to

for

mode.

selections

with

of

four

ventilation

options

is

50%

delivered

are

When a square

flow

When

initially

of

the

selecting

available

is

delivered

delivered

peak

breath.

flow

(=

CONTROL

breath

modes:

decelerating

flow setting

delivery

and

rate

and

for

each

waveform

at a

constant

waveform

at

the

waveform

引

CPAP

sensitivity

Control,

peak

at

Assist/Control,

of

the

two

flow

rate

flow

the

conclusion

and

controls

basic

delivery

equal

flow

delivery

setting,

then

to

is

to

of

Tidal

Voll

KM

~

O

Peak

Flow

(Ut

TIDAL

Sets

assisted

ㅣ

PEAK

Sets

assisted

waveform,

phase.

before

VOLUME

the

volume

and

Range:

FLOW

the

maximum

and

this

For

deceleration.

Range:

of

Apnea

CONTROL

Apnea

is

decelerating

CONTROL

gas

delivered

Back

50

to

2000

flow

delivered

Back

the

flow

10

to

3-2

to

Up

Ventilation

mi

to

Up

Ventilation

rate

delivered

waveform,

120

lpm

the

patient

the

for

this

for

breaths.

patient

breaths.

is

the

the

during

entire

peak

controlled,

controlled,

For

square

inspiratory

flow

delivered

Page 21

_©_

Rate

MM

ーー

©

PEEp

eno)

.

7

_—-

ce

a

BREATH

Sets

the

patient

of

ventilation.

PEEP/CPAP

Establishes

exhalation

baseline

SENSITIVITY

Sets

spontaneous

RATE

number

per

minute

Range:

the

and

pressure.

Range: 0 to

the

trigger

CONTROL

of

ventilator

in

the

0 to

CONTROL

pressure

the

start

CONTROL

level

below

(CPAP),

initiated

Control,

80

bpm

in

the

of

the

next

30

cmH,O

baseline

pressure

breaths

Assist/Control

patient

supported,

circuit

inspiration.

pressure

and

to

be

delivered

and

SIMV

between

Also

known

for

the

assisted

to

the

modes

the

end

of

as

initiation

of

breaths.

©

PRESSURE

Pressure

Support

lO

Back

Up

Breath

Rate

tbpml

Sets

breath.

NOTE:

total

NOTE:

inspiratory

BACK

Sets

Back

lower

Range:

the

inspiratory

This

control

Range:

This

patient

the

Up

than

pressure

Pressure

time

UP

BREATH

breath

Breath

the

-1

to

SUPPORT

patient

is

OFF, 0 to

control

control

sets

Support

limit.

RATE

rate

to

Rate

-20

cmH,O,

CONTROL

circuit

functional

50

the

pressure

equals

(See

be

cannot

Breath

PEEP + Pressure

in

the

Description

used

be

Rate

OFF

pressure

in

SIMV/CPAP

cmH,O

8400ST

during

set

to

setting.

during a spontaneous

mode

level

above

Support.

has a preset 3 second

of

Indicators

Apnea

any

Back

value

only.

PEEP.

in

this

Up

Ventilation.

(other

than

The

section.)

zero)

3-3

Page 22

DESCRIPTION

w

ALARMS

High

Peak

Pressure

temH.0O)

OF

THE

DISPLAY,

HIGH

This

alarm

patient

immediately:

1.

Both

2.

The

ratory

ventilator

kinks

and

.

If

the

normal

mains

seconds

longer

CONTROLS

PRESSURE

establishes

system.

audible

ventilator

flow

or

the

patient

ventilation

above

than 3 seconds,

Once

and

will

is

stopped

is

operating

occlusions,

audible

and/or

portion

pressure

the

is

AND

LIMIT

the

maximum

violated,

visual

be

High

indicators

forced

and

correctly

patient

of

resets

will

resume.

Pressure

above

the

ALARM

ALARM

the

following

into

an

the

exhalation

and

pressure

the

alarm

to

baseline

If

the

Alarm

baseline

following

INDICATORS

allowable

events

will

be

activated.

exhalation

valve

there

pressure

are

will

be

will

cease.

within 3 seconds,

ventilator

Limit

will

occur:

pressure

state,

opens.

no

reset

pressure

for

more

plus 3 cmH,O

in

will

occur

i.e.,

If

patient

to

baseline

than

the

inspi-

the

circuit

re-

0.3

for

M

The

to

decrease,

valve,

Ш

At

attempt

the

M

Once

m

The

the

The

value

times

breath.

safety

back

baseline

to

give

sequence

corrected,

High

reset

button

of

the

the

set

High

The

value

Range: 1 to

Silence:

Audible:

Visual:

system

via a bleed

to

baseline

pressure + 3

another

will

repeat

the

Pressure

is

activated.

alarm

setting

Pressure

cannot

140

Yes

Intermittent

Flashing

solenoid

orifice

pressure.

breath.

as

ventilator

Limit

exceed

cmH,O

Digital

will

cmH,0,

explained

indicator

is

automatically

Limit

“Beep”

open

in

the

mainflow

the

If

the

problem

will

resume

will

upon

the

the

140

Display

and

pressure

outlet

ventilator

is

above.

normal

remain

delivery

cmH,O

flashing

increased

maximum.

will

check

will

reset

not

resolved,

operation.

until

to

1'/2

of a Sigh

begin

and

NOTE:

This

alarm

cannot

be

set

below

3-4

PEEP

+1

cmH,

0.

Page 23

Low

Peak

Pressure

{emtt20)

|

9

Low

PEEP/

CPAP

Pressure

ο

χο

O

LOW

The

tails

breath.

LOW

The

pressure

ventilation

:

PEAK

Low

Peak

to

exceed

This

Range:

Silence:

Audible:

Visual:

PEEP/CPAP

Low

PEEP/CPAP

drops

cycle

Range:

Silence:

PRESSURE

Pressure

the

alarm

alarm

is

Off, 2 to

Yes

Intermittent

Flashing

PRESSURE

below

for

longer

-20

to

Yes

ALARM

alarm

setting

active

the

for

140

Digital

Pressure

alarm

than

+30

cmH,O

is

activated

during

all

breath

cmH,O

“Beep”

Display

ALARM

Alarm

setting

0.5

seconds.

if

the

the

inspiratory

types.

-

is

activated

at

any

time during

airway

phase

if

the

pressure

of

a

airway

the

Audible:

Visual:

NOTE:

to

detect

controlled.

LOW

‘Low

Minute

Vol.

m

This

ured

not

applies

Low

return

MINUTE

alarm

by

exceed

is

the

the

to

all

Range: 0 to-99.9

Silence:

Audible:

Intermittent

Flashing

PEEP/CPAP

of

ventilatory

VOLUME

activated

volume

breath

monitoring

alarm

types.

Yes

Intermittent

“Beep”

Digital

alarm

drive

ALARM

whenever

setting.

L

The

“Beep”

Display

can

be

of a patient

the

minute

system

at

Low

set

below

previously

ventilation,

the

exhalation

Minute

Volume

zero

baseline

being

as

meas-

valve,

Alarm

does

Visual:

Flashing

Digital

3-5

Display

Page 24

DESCRIPTION

OF

THE

DISPLAY,

CONTROLS

AND

ALARM

INDICATORS

High

Breath

Rate

{bpm)

Apnea

Interval

{sec.)

HIGH

The

(spontaneous

|

9

APNEA

This

or

audible

is

BREATH

High

Breath

Range: 3 to

Silence:

Audible:

Visual:

INTERVAL

alarm

spontaneous)

initiated.

sets

and

visual

Apnea

Range:

Silence:

Audible:

Visual:

RATE

Rate

plus

the

are

10

Flashing

ALARM

alarm

machine)

150

Yes

Intermittent

Flashing

apnea

sensed

alarm

Interval

to

60

Yes

Intermittent

is

activated

exceeds

bpm

“Beep”

Digital

time

interval.

within

is

activated

alarm

Digital

is

seconds

“Beep”

Display;

the

Display

If

the

selected

and

Apnea

active

in

if

the

alarm

no

breaths

all

modes.

total

breath

setting.

(either

time

interval,

Back

Up

rate

machine

an

Ventilation

"AP"

alternates

FLOW

The

ducer.

operation

Depression

alarm

Depression

until a flow

ventilator.

TRANSDUCER

8400ST

If

the

of

Ш

An

audible

“.--”

appears

window.

m

The

Monitor

and

Breath

for

60

transducer

is

designed

flow

transducer

the

ventilator,

alarm

in

section

Rate.

of

the

Alarm

seconds.

of

the

Alarm

DISCONNECT

to

sounds

the

Low

Silence

Reset

assembly

with

operate

assembly

the

will

with

following

Minute

sequentially

button

button

is

again

Apnea

Volume

Interval

ALARM

or

without

is

disconnected

will

occur:

display

will

silence

will

defeat

connected

setting

the

alarm

only

the

the

flow

trans-

during

setting

audible

to

display

I:E

Ratio

audible

the

alarm

Page 25

ALARM

SILENCE

ALARM

LOUDNESS

Sitence

Reset

e

)

Allows

nal.

period

NOTE:

power

button

sumed.

ALARM

Resets

no

ventilator

Will

ALARM

Located

audible

the

Activating

will

to

for

longer

not

operator

restore

Duration:

During

the

ventilator,

3-5

seconds

RESET

the

visual

exists.

operation.

reset a Ventilator

LOUDNESS

on

the

alarm

to

this

control

the

60

an

alarm

alarm

Resets

Defeats

rear

panel,

level.

temporarily

audible

seconds

condition

continuous

will

indication

disable

again,

silence

Apnea

Inoperative

the

within

alarm.

resulting

depression

the

of

Back

flow

transducer

alarm

the

audible

the

60

second

from

of

alarm

any

Up

condition.

loudness

until

alarm

ventilation

disconnect

knob

alarm

silence

loss

of

electrical

the

alarm

power

condition

is

which

to

normal

alarm.

varies

sig-

silence

re-

the

D

Low

Inlet

Gas

CEB

Ventlnop.

LOW

Alarm

pressure

drops

and

visual

alarm

a)

b)

c)

d)

Range:

INLET

is

below

can

Low

Clogged

Regulator

System

GAS

activated

drops

16

Ventilator

be

caused

inlet

inlet

pressure

Silence:

Audible:

Visual:

74dB

below

PSIG

gas

malfunction

to

84dB © 1

ALARM

whenever

17

PSIG

(1.12

Inoperative

by

any

pressure

filter

iransducer

No

Continuous

Flashing

3-7

meter

ventilator

(1.19

kg/cm?).

kg/cm?)

of

LED

for 1 second,

state

the

following

malfunction

Tone

interna!

will

be

signaled.

conditions:

system

If

this

pressure

an

audible

gas

The

Page 26

DESCRIPTION

«ib

Low

Inlet

GERD

Vent

Inop.

OF

Gas

THE

DISPLAY,

VENTILATOR

This

delivery

patient

The

following

*a)

*b)

c)

*

These

ventilator

been

CONTROLS

INOPERATIVE

alarm

Ventilator

condition

and

activate a safety

to

breathe

Inoperative

conditions

Loss

of

electrical

Extended

PSIG

cm?)

Asystem

system,

corrected.

(1.12

for i sec.

either

are

recoverable

will

resume

AND

causes

spontaneously

state

occur:

power

low

ventilator

kg/cm?)

failure

or

is

detected

electrical

Ventilator

normal

ALARM

ALARM

the

ventilator

system,

from

will

be

inlet

gas

greater

or

operation

than

by

the

mechanical,

Inoperative

INDICATORS

to

cease

allowing

“room”

activated

pressure,

ventilator

once

the

air.

24

PSIG

conditions,

the

normal

non-apneic

if

any

less

(1.68

control

conditions

of

the

than

kg/

The

gas

16

have

Silence:

]

Audible:

Visual:

“CIRC”

This

faults

pressure

pressure

displayed

alarm.

transducer

alarm:

DISPLAY

alarm

m

While

than

longer

detects

by

comparing

transducer

mismatch

in

The

Inspiration:

in

29

than

a)

Loss

b)

Loss

c)

System

Continuous

Flashing

possible

pressure

occurs, a “CIRC”

the

“Monitors”

following

and

the

machine

the

inspiratory

cmH,O

100

above

msec,

of

Electrical

of

Iniet

failure:

Alarm

LED

patient

measurements

and

the

machine

display

differences

pressure

phase,

or 9 cmH,O

the

alarm

Power:

Gas

Pressure:

no

circuit

pressure

message

window

between

transducer

if

the

below

will

yes

no

or

pressure

from

transducer.

will

along

the

machine

activate.

with an

airway

pressure

airway

transducer

the

airway

be

visually

pressure

will

activate

pressure

Ifa

audible

the

is

more

for

3-8

Page 27

“CIRC”

DISPLAY

m

Exhalation:

(Cor't)

While

than

longer

Once

tion

machine

PEEP

10 - 12

an

attempt

mismatch

pressures

mal

The

a)

b)

in

29

than 1 second,

activated,

phase

ventilation.

following

with

pressure)

control.

seconds,

to

condition

drops

Blocked

Occluded

breathing

the

exhalation

cmH,O

above

the

the

higher

fed

If

the

the

allow

the

below

conditions

airway

or

kinked

circuit

phase,

or 9 cmH,O

the

alarm

ventilator

to

mismatch

safety

patient

no

longer

PEEP

pressure

is

of

the

the

exhalation

and

to

exists

+ 3

can

cause

inspiratory

if

the

machine

below

will

activate.

immediately

two

pressures

servo

condition

exhalation

breathe

cmH,O

sensing

continues

spontaneously.

and

the

the

this

alarm

port

or

expiratory

pressure

airway

forced

(either

for

purposes

valves

higher

unit

will

to

be

is

pressure

to

the

exhala-

airway

for

greater

will

be

opened

When

of

the

two

resume

activated:

limb

of

more

for

or

of

than

nor-

*

in

the

c)

NOTE:

the

0.05

rise

to

patient

“CIRC”

lieved.

the

ventilator

not

resolved,

been

Transducer

pressure

Silence:

Audible:

Visual:

When

to

0.1

100

cmH,O.

airway

alarm

Once

implemented.

failure

transducer)

Flashing

the

airway

Ipm

pressure.

notification, a solenoid

the

pressure

resets

the

process

(either

No

Intermittent

pressure

Purge

The

pressure

Approximately

and

attempts

"BEEP"

Digital

Flow

causes

is

relieved

will

repeat

airway

Display

sensing

seen

opens

back

to

cycle

until

pressure

port

becomes

the

manometer

on

the

manometer

10

seconds

and

pressure

to

baseline

again.

corrective

or

machine

from

If

the

action

blocked,

pressure

is

not

the

is

re-

+3

cmH,O,

blockage

has

to

is

Page 28

DESCRIPTION

OF

THE

DISPLAY,

MODE/WAVEFORM

CONTROLS

AND

ALARM

DISCREPANCY

INDICATORS

DISPLAY

M

INDICATORS

Rotating

gives

properly

waveform

audible

is

attained.

Should

lator

tings

audible

Should

ventilator

waveform

alerts

PRESSURE

illumination

visual

located

selection.

alarm

the

is

in

operation,

for

mode

alerts

the

power-up, a default

will

will

be

Silence:

Audible:

Visual:

of

indication

in

one

Accompanying

that

will

mode

mode

switch

the

and

waveform.

will

be

activated.

switch

be

selected.

activated.

Yes

Intermittent

Rotating

corner

SUPPORT

one

corner

that

the

mode

of

the

available positions

only

reset

when

not

be

properly

8400ST

not

square

INSPIRATORY

will

Concurrently,

be

properly

position

Concurrently,

“BEEP”

illumination

in

of a four

selection

the

stay

“Monitors”

corner

visual

correct

positioned

in

the

the

positioned

of

SIMV

the

visual

of

one

TIME

square,

switch

for

mode

display

switch

previous

and

corner

display

LIMIT

positioning

while

visual

during

decelerating

and audible

of a

is

not

and

is

an

venti-

set-

and

initial

four

window.

Pressure

inspiratory

the

peak

tial

air

terminated

flash.

em

Patient

Effort

PATIENT

Indicates

ity

setting.

breath

Support

time

value

leak

in

and

EFFORT

when

This

types:

on

the

limit.

Should

during

the

the

an

Assisted,

that

system),

Pressure

INDICATOR

inspiratory

indicator

3-10

8400ST

inspiratory

breath

the

Pressure

Support

effort

will

flash

Pressure

incorporates a preset 3 second

flow

fail

to

(as

might

Support

control

meets

at

Supported

or

the

initiation

reach

occur

with a substan-

breath

digital

exceeds

of

and

Spontaneous.

25%

will

display

the

sensitiv-

the

following

of

be

will

Page 29

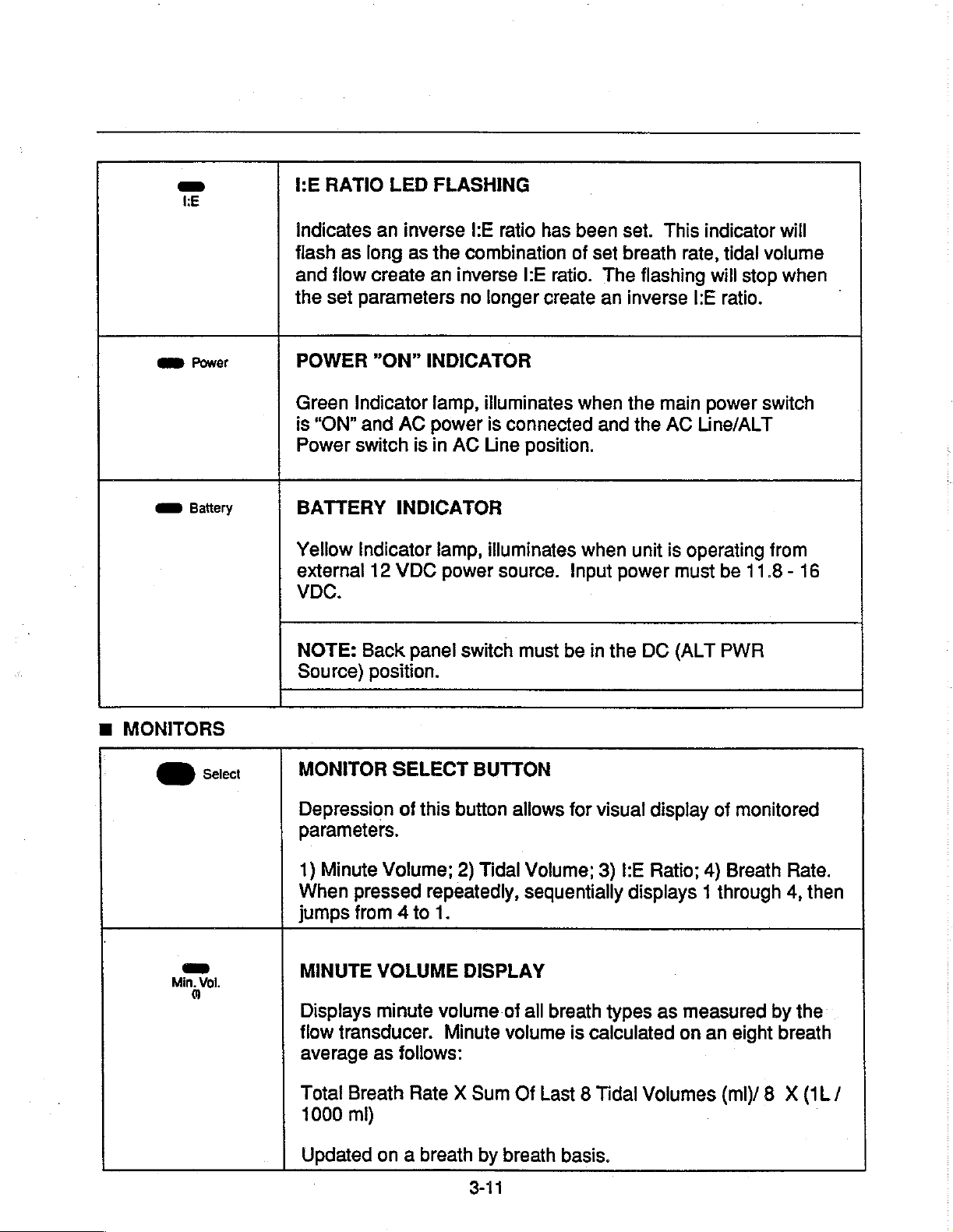

-

EE

RATIO

LED

FLASHING

m

MONITORS

am

Power

am

Battery

O

+.

Indicates

flash

as

and

flow

the

set

POWER

Green

is

“ON”

Power

BATTERY

Yellow

external

VDC.

NOTE:

Source)

MONITOR

an

inverse

long

as

the

create

parameters

"ON”

Indicator

and

switch

Indicator

12

Back

position.

an

INDICATOR

lamp,

AC

power

is

in

INDICATOR

lamp,

VDC

SELECT

power

panel

l'E

ratio

combination

inverse

no

AC

switch

BUTTON

l'E

longer

illuminates

is

connected

Line

position.

illuminates

source.

must

has

been

of

set

ratio.

create

when

when

Input

be

in

set.

breath

The

an

inverse

the

and

power

the

This

rate,

flashing

main

the

AC

unit

is

operating

must

DC

(ALT

indicator

tidal

volume

will

stop

l'E

ratio.

power

Line/ALT

switch

be

11.8 - 16

PWR

will

when

」

from

Depression

parameters.

1)

Minute

When

on

Min,

Vol.

jumps

MINUTE

Displays

flow

transducer.

average

Total

1000

Updated

Breath

mi)

of

this

Volume;

pressed

from 4 to

VOLUME

minute

as

on a breath

repeatedly,

follows:

Rate X Sum

button

2)

Tidal

1.

DISPLAY

volume

Minute

by

3-11

allows

of

volume

Of

breath

for

visual

Volume;

sequentially

all

breath

Last 8 Tidal

3)

:E

types

is

calculated

basis.

displays 1 through

display

Ratio;

as

Volumes

4)

measured

on

of

monitored

Breath

an

eight

(ml)/8 X (1L/

Rate.

4,

by

the

breath

then

Page 30

DESCRIPTION

an

Tidal

OF

Vol.

THE

TIDAL

Displays

volume

a

DISPLAY,

VOLUME

tidal

monitoring

breath

by

CONTROLS

DISPLAY

volume

system.

breath

basis.

for

AND

all

breath

The

ALARM

types

tidal

INDICATORS

as

measured

volume

display

by

the

is

updated

on

Range: 0 to

-

=

Breath | Rate

EE

RATIO

Displays

and

by

breath

will

BREATH

Displays

eight

formula:

the

expiratory

display

the

breath

8

Breaths/Sum

DISPLAY

value

time

basis.

Range:

RATE

If

- - -

-.

DISPLAY

average

average)

9999

m!

calculated

for

machine

breath

1:1.0

breath

for

Of

The

as

rate

is

to

99,

rate

all

breath

Last 8 Breath

the

breaths

set

to

or

1:0

per

types

ratio

between

only.

"0",

then

to

99:1

minute

according

Periods

inspiratory

Updated

KE

(calculated

(min)

on a breath

ratio

window

on an

to

the

time

following

Updated

NOTE:

tected

zero,

tion

will

m

MISCELLANEOUS

AIRWAY

Displays

on a breath

If

an

inspiration

within

the

apnea

begin.

PRESSURE

airway

Range: - 20

the

Apnea

alarm

pressure.

by

breath

(mechanical

interval

will

be

DISPLAY

to

140

3-12

basis.

or

spontaneous)

setting

initiated

cmH,O

and

the

Apnea

breath

Back

is

rate

not

will

display

Up

ventila-

de-

Page 31

Manual

MANUAL

BREATH

BUTTON

Used

Tidal

settings.

ratory

ignored.

Manual

state.

insp.

Hold

INSPIRATORY

When

occur

the

first.

pressure

to

deliver a single,

Volume,

Manual

or

minimum

Manuai

Breath

ihis

button

after

the

button

lation

During

interval

inadvertent

SIGH

is

During

valve

will

from

the

inspiratory

timer

apnea

“ON/OFF”

Waveform

Breath

exhalation

Breath

is

non-functional

HOLD

is

depressed

end

of

the

released

the

inspiratory

remain

the

will

or 6 seconds

airway

hold,

also

be on

alarms.

BUTTON

operator

and

Peak

requests

phases

available

BUTTON

and

next

volume

hoid,

closed

to

pressure

both

hold

initiated

Flow

are

which occur

of

all

in all

modes

during

both

allow

the

to

Ventilator

held,

an

mandated

has

elapsed,

the

flow

reading

manometer.

breath

prevent

controlled

per

during

breath

of

inspiratory

valve

of

rate

breath

breath.

contro!

types

ventilation.

Inoperative

breath

whichever

and

static

timer

stacking

panel

the

inspi-

are

hold

will

until

either

occurs

the

exha-

inspiratory

and

apnea

and

Activates

once

equal

equal

matically

cmH,O)

modes

AC

LINE

ALT

PWR

SOURCE

12-16

VDC

AC/DC

Switches

external

the

automatic

every

to

to

100

1'/2 x the

the

Peak

increased

during a Sigh

of

ventilation.

Range:

SWITCH

power

power

breaths.

Tidal

source

supply.

Flow

to

1'/ x set

breath.

75

to

3-13

Volume

setting.

Sigh

The

3000

from

function

Sigh

breath

setting,

The

high

value

Sigh

function

mi

AC

LINE

allowing a Sigh

is a controlled

delivered

pressure

(up

to a maximum

available

to

12

VDC

at a

limit

alternate

breath

breath

flow

rate

is

auto-

of

140

in

all

Page 32

DESCRIPTION

OF

THE

DISPLAY,

CONTROLS

AND

ALARM

INDICATORS

DATA

LINK

HOURS

DATA

Provides

HOURMETER

The

is

operated.

hour.

actual

nance

POWER

Power

cord

DC

LINK

.

optical

hourmeter

activated

and

INPUT

whenever

The

The

hourmeter

usage

schedules.

MODULE

module

encloses

.

connection

records

meter

hours

turns

RECEPTACLE

the

is

allows

as

well

AC

fuse

the

package

.

of

the

8400ST

total

hours

ventilator

non-resettable

the

clinician

as

for

power

On(l)

of

is

AC

and

establishing

and

for

over

to

other

ventilator

line

records

to

determine

Off(O),

current

devices.

operation.

or

12VDC

to

routine

accepts

protection.

-

battery

the

whole

the

mainte-

power

It

Allows

emergency

for

attachment

or

transport

of

an

external

application.

12

VDC

power

supply

for

3-14

Page 33

SECTION

4

Assembly

Instructions

8400ST / 8400STi

Volume

Ventilator

Service

Manual

Page 34

Page 35

SECTION

ASSEMBLY

4

INSTRUCTIONS

Prior

to

setting

Ventilator,

and

understand

Cautions

the

and

6

up

the

8400ST

operator

Section 6 -

Notes.”

1.

directed

the

Then

>.

this

İ

pins

diagonal

shown.

to

“

3.

onto

04820)

place

screws

with

Volume

must

first

“Warnings,

Assemble

on

Addenda

go

to

step 2 on

page.

(P/N

04825)

corners

Finger

secure.

Install

ventilator

stand

and

with

(P/N

9/16"

Allen

read

stand

page

A-1

Section.

tighten

(P/N

secure

two

(2)

03275)

wrench.

as

in

as

in

NOTE:

position

to

in

Alignment

ventilator

stand.

pins

(P/N

in

place

一

for

4.

Install

MicroBlender

female

bracket

ventilator

(P/N

04820).

5.

Attach

supply

09520)

adapter

then

connect

adaptorto

outlet

croBlender

other

hose

to

fitting

lator.

hose

oxygen

(P/N

00060)

inlets.

04875)

attachment

the

3800

into

dovetail

provided

stand

one end

hose

(P/N

to

90°

elbow

(P/N

00066),

elbow

auxiliapy 一 一

of

3800

and

end

of

supply

DISS

at

Next,

(P/N

hose

(Not

back

connect

02899)

assembly

to

shown.)

Male

of

on

of

Mi-

the

venti-

air

and

blender

一

一

WARNING:

WHEN

DER

8400ST

CONNECT

BLENDER

AUXILIARY

BLENDER

TION

OXYGEN

FLOW

4-1

USING

IN

CONJUNCTION

VOLUME

WILL

SETTINGS

THE

P/N

09520,

HOSE

OUTLET

AUXILIARY

ENSURE

DELIVERY

3800

VENTILATOR,

ASSEMBLY,

OF

MICROBLEN-

WITH

THE

VENTILATOR/

OF

THE

OUTLET

ACCURACY

AT

THE

THE

VENTILATOR.

THE

ALWAYS

TO

THE

BLENDER.

CONNEC-

OF

LOWER

6/97

Page 36

ASSEMBLY

WARNING:

ASSEMBLY

INSTRUCTIONS

6.

Install

Humidifier

into

female

provided

tor

Stand

04820).

7.

Wick

and

Heater

Assembly

as

follows:

OF

THE

HUMIDIFIER

the

Heated

Controller

dovetail

on

Ventila-

(P/N

Installation

Module

Instructions body.

c)

Insert a new

below.

packaged,

*

Peel

*

“Pop”

*

Insert

top

*

Gently

meets

3/8

below

bend

of

For

open

wick

wick

of

main

top

inch

the

or

wick

wick

the

individually

sterilized

bag.

into

through

Do

not

insert

body.

push

the

cap.

of

the

wick

main

fold

exposed

by

forcing

following

wick:

cylindrical

bottom

wick

Approximately

will

body.

it

further.

the

wick

through

in

until

extend

Do

not

portion

steps

shape.

of

main

it

HEATER

TION

OTHER

MAY

TER

FEED

TION

a)

or

b)

MODULE

OF

THE

THAN

CAUSE

SYSTEM

OF

THE

Inspect

center

is

tip

card

and

Twist

main

facing

the

body

the

AND/OR

WICK

IN A SEQUENCE

DESCRIBED

A

FAILURE

AND

HEATER

metal

of

occluded

water

top

cap.

replace

top

cap

so

that

rear

of

INSER-

BELOW

OF

THE

MALFUNC-

MODULE.

feed

tube

If

the

tube

deformed,

or

with

new

clockwise

the

inlet

the

Heater

WA-

in

is

dis-

Top

onto

port

Module.

bent

Cap.

the

is

d)

Float

Apply

assembly

Float

e)

Hand-tighten

Cap

Heater

8.

Attach

midifier

Outlet

Controller

ports

pad

should

even

pressure

for

insertion

Assembly.

the

Assembly

Module.

the

Heater

with

positioned

be

free

Dual

on

the

Module

inlet

the

as

shown.

of

damage.

to

upper

into

Float

Humidifier

to

lower

Bottom

the

Hu-

and

float

Page 37

00423

04709.

To

Heated

Inlet

20225

(Labeled~"To

09534

\

|

N

|

Humidifier

09531

09531

09532

To

Ventilator

Outlet

|

04709

Port

Flow

Humidifier")

Exhalation

\

Valve

20005

20107

(Diaphragm

not

09531

;

09413

'

09413

10081R

Transducer

(not

included)

Body

pictured

20107)

Out

09531

Assembly

TH

2

===

In

=

OIE

N

=

n

*

ο

Transducer

/

ο

ὁ

ο

O

OO

—,

—

기

ㅇㅇ

1

Connector

\

©

A

-

04709

|

09532

Fa

0%

P/N

10172

Kit

(autoclavable)

20225

09531

04709

09534

00423

Patient

Patient

Circuit

90°

Mainflow

22mm

Breathing

includes:

“Wÿye”

Tubing - 30"

Elbow

adapter

Bacteria

I.D.

Cuff

Circuit

w/temp

port

Smooth-Bor®

Filter

Adapter

09532

09413

20005

20107

4-3

Circuit

Watertrap

Exhalation

Exhalation

Tubing - 18"

Vaive

Valve

Smooth-Bor®

Body

Diaphragm

Page 38

ASSEMBLY

9.

Assemble

tor

breathing

a)

Attach

04709)

"Το

of

b)

Attach

(P/N

adapter,

mainflow

c)

Insert

onto

bacteria

male

(P/N

Attach

Humidifier

d)

Connect

(P/N

Heater

one

NOTE:

(P/N

the

Bird

09413)

inspiratory

breathing

densate

from

INSTRUCTIONS

the

8400ST

circuit

90°

to

as

elbow

ventilator

Humidifier",

adapter

directed

one end

09532)

and

to

the

bacteria

the

22mm

outflow

side

filter,

end

of

90°

04709)

entire

into

assembly

Heater

one

end

09531)

to

Module,

leg

of

watertrap

breathing

have

been

and

expiratory

circuit

to

collect

the

humidifier

Volume

follows:

adapter

outlet

with

male

down.

of

short

circuit

the 90°

other

filter

elbow

end

(P/N

female

of

the

mainflow

then

connect

elbow

cuff

adapter

(P/N

to

Module.

of

circuit

outlet

and

of

the

(P/N

circuit

water

incorporated

limbs

excess

gas.

Ventila-

(P/N

labeled

portion

tubing

to

the

09534).

adapter

22mm

00423).

inlet

of

tubing

Humidifier

other

end

to

09413).

traps

into

of

the

con-

tory

other

ing

NOTE:

(P/N

Once

20005)

Exhalation

safety

tab

will

placement.

i)

Connect

patient

to

and

valve

10.

Secure

into

the

patient

sensor

plug

side

of

patient

end

to

watertrap

。

/

the

Exhalation

is

properly

Valve

remaining

the

Assembly, a spring

engage

the

circuit

other

body

end

on

remote

"Wye"

into

the

Humidifier

“Wye”,

one

leg

of

(P/N

9)

09413).

Install

tion

Diaphragm

(P/N

onto

h)

Install

'

last

leg

tion

(P/N

onto

Valve

installed

and

ensure

piece

tubing

of

to

front

of

(P/N

watertrap,

exhalation

of

ventilator.

temperature

and

insert

Controller.

and

remain-

Exhala-

Valve

20107)

ventilator.

Exhala-

Valve

into

the

Body

20005)

ventilator.

Body

the

loaded

the

09531)

sensor

remote

e)

NOTE:

(P/N

20225)

of

Humidifier

f}

Connect

tubing

leg

end

“Wye”

Inspiratory

second

(P/N

09531)

of

watertrap,

to

inspiratory

(P/N

20225).

side

has a large

Temperature

Connect a third

tubing

(P/N

09531)

piece

to

and

side

of

patient

port

Probe.

piece

to

of

patient

remaining

the

other

of

patient

“Wye”

for

attachment

of

circuit

the

expira-

©

11.

Flow

installation:

Transducer

(P/N

a)

10081R)

Install

portion

Fiow

Assembly

connector)

the

ticle

ventilator

and

wise

position.

male

of

the

Transducer

(gray

female

on

front

casting

turn

clock-

to

lock

into

recep-

of

into

Page 39

NOTE:

be

alignment.

NOTE:

sure

the

above

When

heard

Position

lines

right

and

side

properly

the

so

that

of

installed, a click

reference

b)

the

Flow

they

are

the

ventilator

marks

Attach

end

Transducer

Assembly

the

Valve

(P/N

outlet

sure

arrow

body

transducer

pointing

direction

flow.

Transducer

directed

will

opposite

of

Flow

Exhalation

Body

20005)

port.

that

on

of

the

in

towards

as

shown

will

be

into

Be

the

the

flow

is

the

of

gas

Pres-

in

c)

Ensure

secure.

WARNING:

BEFORE

“PRESSURE

CIRCUIT

HEATER

LEAK

DAMAGED

SECTION

For

additional

Heated

MicroBlender,

instruction

L1001 - Bird

L1008 - Bird

PATIENT

INCLUDING

MODULE

DUE

TO

COMPONENTS.

14 - PERFORMANCE

Humidifier

manuals:

Instruction

Instruction

all

connections

APPLICATION,

TEST”

THE

HUMIDIFIER

FOR

MISASSEMBLY

information

and

refer

to

Heated

3800

on

Bird

the

following

Humidifier

Manual

MicroBlender

Manual

are

PATIENT

POSSIBLE

OR

(SEE

TEST)

the

Bird

3800

AIR

Page 40

Page 41

SECTION

5

Overview

Ventilator

of

the

System

8400ST

Operation

Volume

8400ST / 8400STi

Volume

Ventilator

Service

Manual

Page 42

Page 43

SECTION

OVERVIEW

m

PNEUMATIC

OPERATION

E

INTRODUCTION

The

8400ST

tronically

vated

range

system

a

main

processor

control

controls

breath

valve

motion

controlled,

device

of

patients.

is

based

processor, a flow

and a display/exhalation

processor.

overall

rate

timing

control

of

flow

5

OF

THE 8400ST

THEORY

Volume

capable

processors

and

Ventilator

pneumatically

of

The

on

three

The

ventilator

and

exhalation

VENTILATOR

OF

is

an

elec-

acti-

supporting a wide

electronic

microprocessors:

valve

main

functions

volume

control

control

control

valve

processor

such

while

valves.

the

the

actual

as

SYSTEM

The

main

Control

gas

the

flow

Exhalation

The

shown

nents

and

OPERATION

pneumatic

electro-mechanical

Valve

delivery

Flow

Control

from

the

main

flow

in

Figure

are

described

keyed

system

and

to

the

patient

Valve.

of

to

the

Exhalation

patient

Valve

gas

1.

The

numbers

is

based

valves,

is

controlled

while

is

controlled

through

Pneumatic

in

the

following

in

on

the

Valve.

all

exhaled

by

the

8400ST

Figure

two

Flow

All

by

the

is

compo-

pages

1.

FIGURE

ЖОСЯ

PRESSURE

SENSE

LINES

1.

PNEUMATIC

SCHEMATIC,

5-1

8400ST

VOLUME

VENTILATOR

Page 44

OVERVIEW

M

GAS

INLET

Blended

gas

connected

The

ventilator

the

3800

MicroBlender

PSIG

mixed

ized,

of

the

cm2)

inlet

gas

the

alternate

delivering

range

to

of

the

tor.

The

incoming

a

Coalescing

liquid

stream.

the

removal

nants.

and

This

filter

bowl. A drain

of

NOTES:

m

Coalescing

filtering

microns

microns.

aerosol

and

OF

THE

FILTER

ILL.

8400ST

(2)

n

VENTILATOR

from

an

external

to

the

Blended

is

designed

pressure

from

flow

30-70

blended

blended

Filter

solid

contamination

accumulated

to

any

other

device

in

excess

PSIG

gas

(2)

particles

filter

is

particles

solid

particles

operating

the

gas

which

is

99.97%

source

Gas

Inlet

to

be

used

at

blender.

source

must

of

(2.10-4.90

inlet

passes

from

provided

liquid

down

down

is

be

capable

75

Ipm

to

the

through

reduces

the

gas

is

collected

for

contami-

efficient

to

.75

to

is

(1).

with

50

When

util-

within

kg/

ventila-

both

in

in

.3

SYSTEM

E

The

ambient

PSIG.

in

the

applied

E

"

Filtered

Accumulator

mulator

augmenting

inspiration

MicroBlender

proximately

pressures

cm2)

deliver

flow

the

phase.

vessel,

panied

shown

OPERATION

RELIEF

Relief

event

Valve

if

the

This

to

the

VALVE(3)

protects

excessive

ACCUMULATOR(4)

gas

then

(4).

is

to

store

the

flow

75

of

50

respectively,

flow

rates

capacity

accumulator

Since

charging

by

large

on

page

(3)

vents

inlet

pressure

the

unit.

passes

The

pressurized

blender

demands.

is

capable

lpm

with

and

35

while

up

to

is

provided

during

the

Accumulator

and

pressure

5-3,

Figure

inlet

gas

exceeds

pneumatic

inlet

pressure

into a 1.1

purpose

flow

of

inlet

PSIG

the

120

the

discharging

of

the

gas

during

The

3800

delivering

and

(3.50-2.45

ventilator

Ipm.

This

from

gas stored

exhalation

is a rigid

variations

2.

to

100

system

is

liter

Accu-

for

high

ap-

outlet

can

extra

is

accom-

as

kg/

in

m

The

flow

of

gas

filter

is

from

the

be

removed

contamination.

and

through

inside

out.

examined

the

coalescing

The

filter

must

internally

for

tions

the

the

5-2

It

should

shown

accumulator

patient

be

noted

in

circuit.

that

the

pressure

Figure 2 occur

and

are

not

transmitted

only

fluctua-

within

to

Page 45

120 —

Flow

ο

(Ipm)

Inspiratory

©

Inspiration

Phase

;

<

Exhalation

Phase

>

T

M

σι

+

©

n

Pressure

一

(PSIG)

D

인

Accumulator

M

REGULATOR(5)

FIGURE

2.

ACCUMULATOR

PRESSURE

WITH

Tim

RESPECT

3.

Pilot

Valve.

4.

Driving

ducer

E

PULSATION

~

TO

PATIENT

pressure

pressure

sensing

DAMPENER(6)

INSPIRATORY

for

actuating

for

the

lines

purge

the

Flow

Trans-

functions.

FLOW

Satety

A

precision

establishes

.

PSIG

used

1.

2.

(1.40

for

the

Aprecise

the

Flow

of

accurate

Driving

Pressure

pneumatic

the

system

kg/cm2).

following

stable

Control

pressure

Line

flow

Purge

supply

Valve

control.

for

Regulator

pressure

This

pressure

functions:

pressure

for

purposes

the

airway

function.

(5)

at

20

is

to

-

The

chamber

200

of

very

turn

in

order

pressure.

tions,

5-3

Pulsation

with a volume

ml.

The

Flow

fast

changes

forces

the

to

maintain a constant

During

pressure

Dampener

Control

regulator

these

fluctuations

(6)

of

in

gas

to

transient

is a rigid

approximately

Valve

is

flow

which

respond

system

flow

occur

due

capable

in

rapidly

condi-

to

the

Page 46

OVERVIEW

OF

THE

8400ST

VENTILATOR

SYSTEM

OPERATION

response

tion

Flow

mizing

M

FLOW

time

Dampener

Control

the

pressure

CONTROL

of

the

acts

Vaive

and

À

Gas

flow

to

the

patient

Flow

Control

electro-mechanical

of

the

electro-mechanical

formed

tling

flow

Valve

to

linear

through a variable

(7).

device.

motion

Regulator.

as a buffer

Regulator

fluctuations.