CaptiveAire NLINE Installation Manual

Standard and Modular Centrifugal Untempered Supply Fans

Installation, Operation, and Maintenance Manual

Standard Untempered Supply Fan

Modular Untempered Supply Fan

Save these instructions

RECEIVING AND INSPECTION

WARNIN

G!!

INLINE Filtered Supply Fan

Upon receiving unit, check for any interior and exterior damage, and if found, report it

immediately to the carrier. Also check that all accessory items are accounted for and are

damage free. Turn the blower wheel by hand to verify free rotation and check the damper (if

supplied) for free operation.

Installation of this ventilator should only be performed by a qualified professional who has

read and understands these instructions and is familiar with proper safety precautions.

Improper installation poses serious risk of injury due to electric shock, contact with rotating

equipment, and other potential hazards. Read this manual thoroughly before installing or

servicing this equipment. ALWAYS disconnect power prior to working on fan.

. This document is the property of the owner of this equipment and is

required for future maintenance. Leave this document with the owner when installation or

service is complete.

A0011038

April 2011 Rev. 11

TABLE OF CONTENTS

WARRANTY .................................................................................................................................................. 3

INSTALLATION ............................................................................................................................................. 4

Mechanical ................................................................................................................................................ 4

Site Preparation .................................................................................................................................... 4

Intake Assembly ................................................................................................................................... 4

Curb and Ductwork ............................................................................................................................... 4

Recommended Supply Ductwork Sizes ............................................................................................... 4

Roof Mount Installation ......................................................................................................................... 5

Wall Mount Installation ......................................................................................................................... 5

Indoor (Inline) Installation ..................................................................................................................... 6

Installation with Exhaust Fan ................................................................................................................ 6

Electrical ................................................................................................................................................... 7

Copper Wire Ampacity ......................................................................................................................... 7

PSC (Permanent Split Capacitor) Motor Speed Control ...................................................................... 8

ECM (Electronically Controlled Motor) Speed Control ......................................................................... 8

Motorized Intake Damper ..................................................................................................................... 8

Fan to Building Wiring Connection ....................................................................................................... 9

OPERATION ............................................................................................................................................... 10

Start Up ................................................................................................................................................... 10

Special Tools Required ...................................................................................................................... 10

Start Up Procedure ............................................................................................................................. 10

Pulley Adjustment ............................................................................................................................... 11

Pulley Alignment ................................................................................................................................. 11

Proper Belt Tension ............................................................................................................................ 11

Pulley Setscrew Torque ..................................................................................................................... 11

Pulley Combination Chart ................................................................................................................... 12

Troubleshooting ...................................................................................................................................... 13

Troubleshooting Chart ........................................................................................................................ 13

MAINTENANCE .......................................................................................................................................... 14

General Maintenance ............................................................................................................................. 14

2 weeks after startup .............................................................................................................................. 14

Every 3 months ....................................................................................................................................... 14

Filter Quantity Chart ........................................................................................................................... 15

Yearly ...................................................................................................................................................... 15

Start-Up and Maintenance Documentation ............................................................................................ 16

Job Information ................................................................................................................................... 16

Fan Unit Information ........................................................................................................................... 16

Maintenance Record .......................................................................................................................... 16

Factory Service Department ............................................................................................................... 16

2

WARRANTY

This equipment is warranted to be free from defects in materials and workmanship, under normal use and

service, for a period of 12 months from date of shipment. This warranty shall not apply if:

1. The equipment is not installed by a qualified installer per the MANUFACTURER’S installation

instructions shipped with the product,

2. The equipment is not installed in accordance with federal, state and local codes and regulations,

3. The equipment is misused or neglected,

4. The equipment is not operated within its published capacity,

5. The invoice is not paid within the terms of the sales agreement.

The MANUFACTURER shall not be liable for incidental and consequential losses and damages

potentially attributable to malfunctioning equipment. Should any part of the equipment prove to be

defective in material or workmanship within the 12-month warranty period, upon examination by the

MANUFACTURER, such part will be repaired or replaced by MANUFACTURER at no charge. The

BUYER shall pay all labor costs incurred in connection with such repair or replacement. Equipment shall

not be returned without MANUFACTURER’S prior authorization and all returned equipment shall be

shipped by the BUYER, freight prepaid to a destination determined by the MANUFACTURER.

3

INSTALLATION

It is imperative that this unit is installed and operated with the designed airflow and electrical supply in

accordance with this manual. If there are any questions about any items, please call the service

department at 1-866-784-6900 for warranty and technical support issues.

Mechanical

WARNING: DO NOT RAISE VENTILATOR BY THE INTAKE HOOD, BLOWER OR

MOTOR SHAFT, OR BEARINGS – USE LIFTING LUGS PROVIDED OR A SLING

Site Preparation

1. Provide clearance around installation site to safely rig and lift equipment into its final position.

Supports must adequately support equipment. Refer to manufacturer’s estimated weights.

2. Consider general service and installation space when locating unit.

3. Locate unit close to the space it will serve to reduce long, twisted duct runs.

4. Do not allow air intake to face prevailing winds. Support unit above ground or at roof level high

enough to prevent precipitation from being drawn into its inlet. The inlet must also be located at

least 10 feet away from any exhaust vents. The fan inlet shall be located in accordance with the

applicable building code provisions for ventilation air.

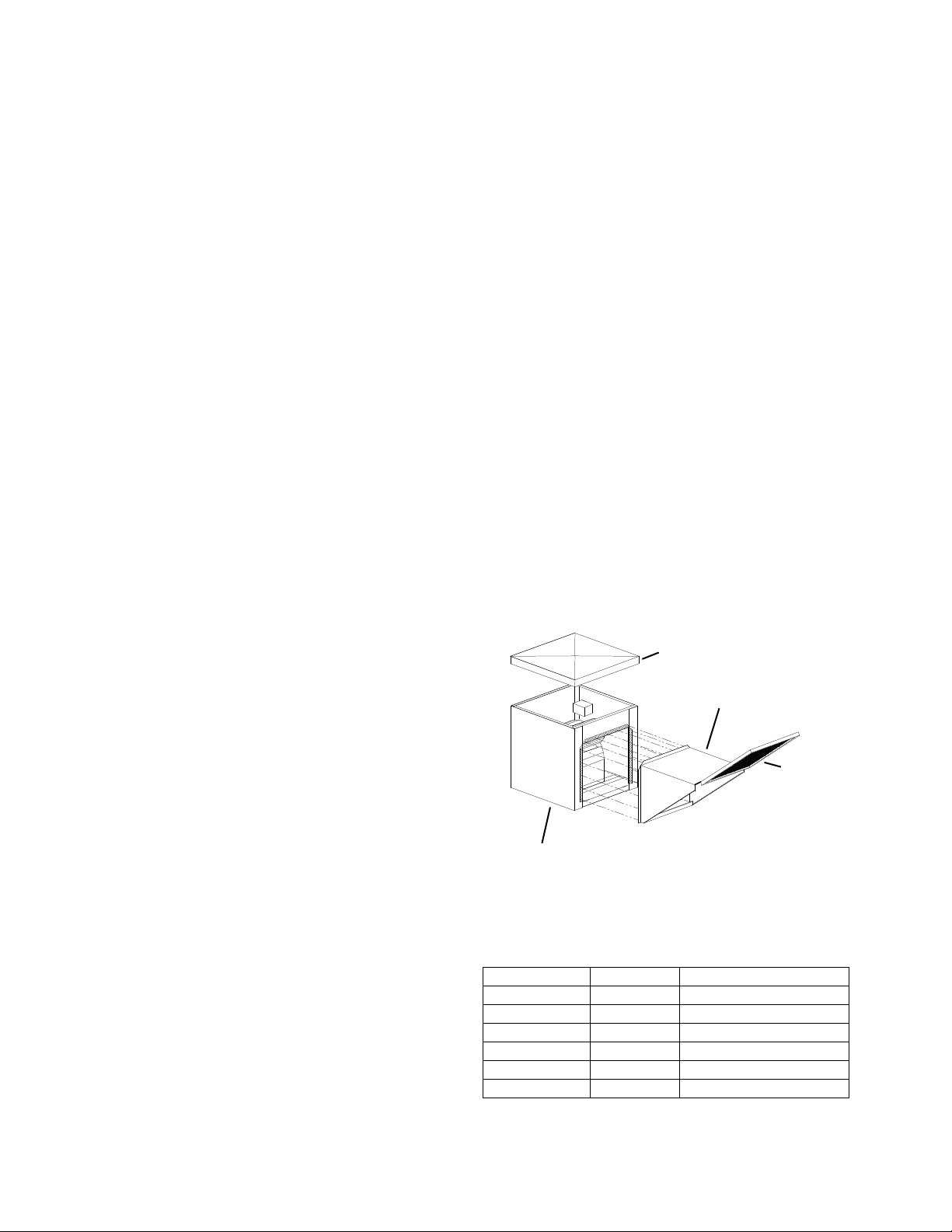

Intake Assembly

Filters and intake hoods for standard supply fans are shipped inside the supply fan housing for protection

during shipping. Modular intakes are shipped on a separate skid. Upon unit arrival, follow the following

procedure to assemble the intake to the fan:

1. Remove the fan top (standard supply fans

only).

2. Remove the intake hood and filters from the

fan housing.

3. Re-install the fan top (standard supply fans

only).

4. Apply silicone or weather-proof gasket on the

back side of the flanges of the intake hood.

5. Screw the flanges of the intake hood to the

unit at the hatched areas shown with the

supplied sheet metal screws. Place caulk on

the outside of the screws to prevent water

leaks. Slide the filters down the filter track as

shown.

Curb and Ductwork

This fan was specified for a specific CFM and static

pressure. The ductwork attached to this unit will

significantly affect the airflow performance.

Flexible ductwork and square elbows should not be

used. Also, transitions and turns in ductwork near

the fan outlet will cause system effect and will

drastically increase the static pressure and reduce

airflow. The chart to the right shows the minimum

fan outlet duct sizes and straight lengths

recommended for optimal fan performance.

FAN TOP

INTAKE HOOD

FILTER(S)

SUPPLY FAN

Recommended Supply Ductwork Sizes

Blower Size Duct Size Straight Duct Length

10 14 x 14 48 in.

12 16 x 16 54 in.

15 20 x 20 72 in.

18 24 x 24 86 in.

20 26 x 26 108 in.

25 32 x 32 168 in.

4

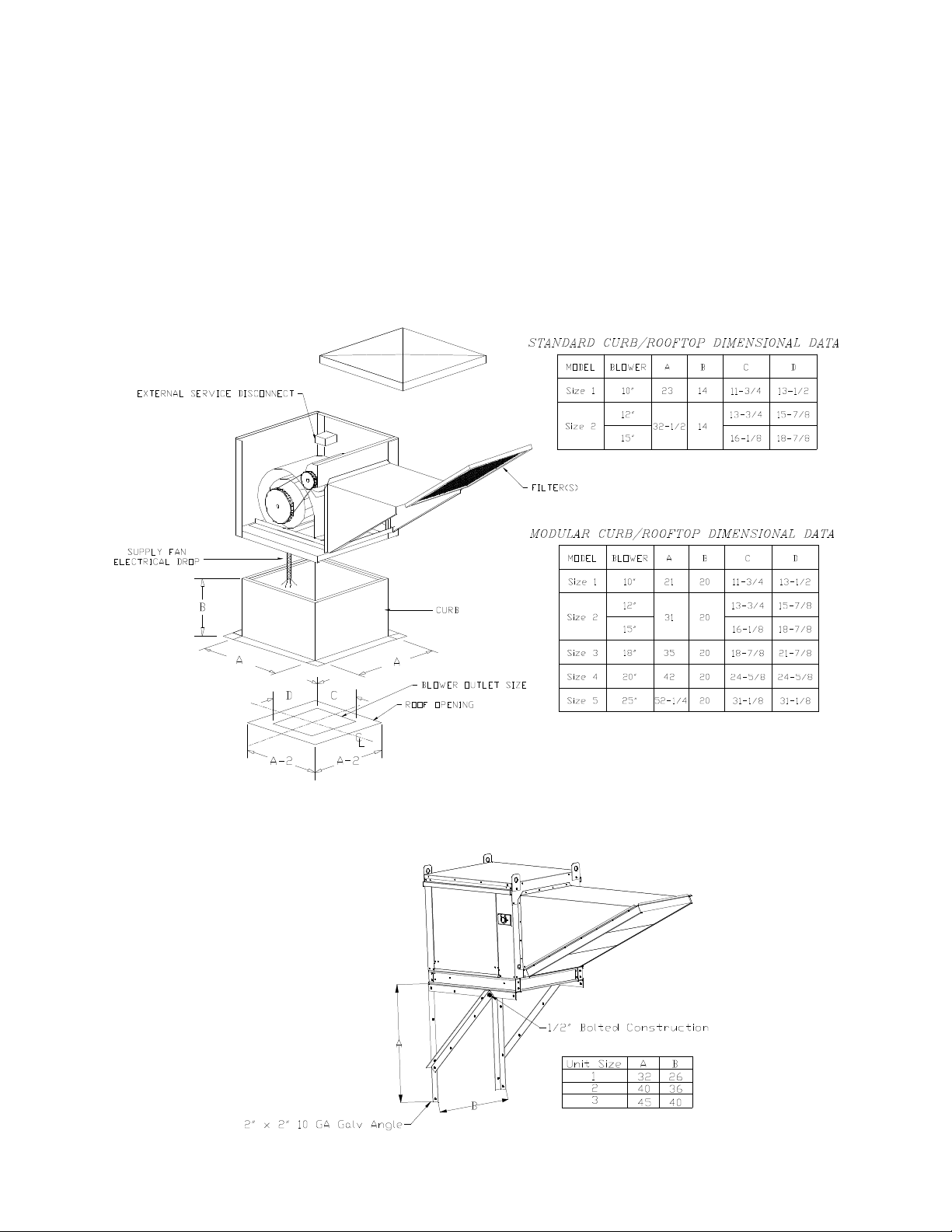

Follow SMACNA guides and recommendations for the remaining duct run. Fans designed for

rooftop installation should be installed on a prefabricated or factory built roof curb. Follow curb

manufacturer’s instructions for proper curb installation. The unit should be installed on a curb and/or rail

elevated not less than 14” above any surface. Be sure duct connection and fan outlet are properly

aligned and sealed. Secure fan to curb through vertical portion of the ventilator base assembly flange

using a minimum of eight (8) lug screws, anchor bolts, or other suitable fasteners (not furnished). Shims

may be required depending upon curb installation and roofing material. Check all fasteners for tightness.

The diagrams below show different mechanical installation configurations.

Roof Mount Installation

Wall Mount Installation

5

Loading...

Loading...