Page 1

®

JANUARY 29, 2007

M-4000

FIREYE

M4RT1

FLAME SAFEGUARD CONTROLS

WARNING: Selection of this control for a particular application should be made by a competent professional, licensed by a state or other government agency. Inappropriate application

of this product could result in an unsafe condition hazardous to life and property.

DESCRIPTION

The Fireye® M4RT1 Flame Safeguard Control is a compact burner management system. It is

designed to provide automatic ignition and continuous flame monitori ng for commercial sizes of

heating and process burners that use gaseous fuels.

Flame monitoring is accomplished by a Flame Rod detector, the built in amplifier and programmer.

Control functions and timing are factory set with onboard jumpers. Functions such as recycle/nonrecycle, purge timing, and pilot trial for ignition (P.T.F.I.) time are determined by the jumpers. Flame

Failure Response Time (F.F.R.T.) is fixed at three seconds. LED indicator lights indicate the operating status of the control.

In the event of ignition failure, or following a safety shutdo wn, the unit locks out, activating an

alarm circuit. Cycling the power OFF and back on will reset the control. A manual reset option can

be special ordered. Remote reset (via remote pushbutton) is also available as a special order option.

A detailed description of the programmer sequence is found later in this document. Test jacks are

provided to permit flame signal measurement during operation.

The M4RT1 control incorporates a safety checking circuit that is operative on each start. If flame

(real or simulated) is detected prior to a start or during the purge, the fuel valves will not be energized, and the unit will lock out.

All M4RT1 controls do not require a wiring base due to the terminals included on the relay board.

See INST ALLATION OF CONTROL, SCANNERS, AND FLAME DETECTORS (page 2) for temperature and wiring requirements.

1

Page 2

SPECIFICATIONS

Supply:

120V (min. 102, max. 132) 50/60 Hz

Table 1: AMBIENT TEMPERATURE LIMITS

MAXIMUM MINIMUM

Control 140°F (60°C) - 40°F (- 40°C)

Flame Rod

(Tip 2460 F)

Power Consumption: 12 VA (Operating)

Shipping Weight (Approx.): 2.2 lbs. (1.4kg)

Table 2: LOAD RATINGS

Fireye Terminal Typical Load Maximum Rating & 120V 60 Hz

3 or 4

Individual or combined

5 Main Fuel Valve(s)

8 Motor or contactor

A Alarm 50 VA, pilot duty

1500°F (816°C) - 40°F (- 40°C)

Pilot valve(s)

Solenoid valve

Ignition Transformer

Minimum load requirement = 100mA

®

125 VA pilot duty (solenoid valve) plus

250 VA (Transformer)

125 VA pilot duty (solenoid) or

25 VA pilot duty (solenoid) and

400 VA (opening) motorized

Motor normally energized and de-energized by the

operating control whose rating must be suitable. Terminal 8 rated to de-energize 9.8 FLA, 58.8 LRA, on safety

lockout.

APPROVALS

Underwriters Laboratories Inc.

Recognized Components Guide MCCZ2

File MP1537

ORDERING INFORMATION

CONTROL:

M4RT1 120 VAC (min.102, max 132) Supply, 50 Hz/60 Hz.

FLAME DETECTORS:

69ND1-1000K4 12 inch flame rod, 1/2” NPT connector

69ND1 -1000K6 18 inch flame rod, 1/2” NPT connector

69ND1-1000K8 24 inch flame rod, 1/2” NPT connector

2

Page 3

INSTALLATION OF CONTROL, SCANNERS, AND FLAME DETECTORS

Wiring Base

Mount the control in an enclosure/burner panel that provides the proper protection fo r the control.

The location should be free from moisture, excessive vibration and within the specified ambient temperature rating. The control may be mounted in any angular position.

All wiring should comply with applicable electrical codes, regulations, and local ordinances. Use

moisture resistant wire suitable for at least 90 degrees C. Circuit recommendations are found on

pages 10 through 11. Consult the factory for assistance with non-standard applications.

WARNING: Installer must be trained and qualified. Follow the burner manufacturer's instructions, if supplied. Otherwise, proceed as follows.

WARNING: Controls require safety limits utilizing isolated mechanical contacts. Solid state

limit switches are not acceptable and should not be used due to their high leakage currents.

WARNING: Remove power from the control before proceeding.

Replaceable Fuse

The M4RT1 is designed with a field replaceable fuse. The fuse is located on the printed circuit

board. The fuse will blow as a result of an overload conditio n on Terminals 3, 4 or 5. To replace the

fuse, remove power from the system. Using a small screwdriver or similar tool, remove th e fuse

from its holder. Install a Fireye replacement fuse (P/N 23-176) or equivalent 8 amp fuse (e.g. Littlefuse 225008P, 8 amp, 125V).

®

WARNING: Turn off the power when installing or removing the control.

INSTALLATION - 69ND1 FLAME ROD

The 69ND1 flame rod proves a gas pilot flame and/or main gas flame. It is a spark plug type unit

consisting of

a spark plug connector for making electrical connections. The 69ND1 is available in 12,″ 18″ or 24″

lengths.

The flame rod may be located to monitor only the gas pilot flame or both the gas pilot and main gas

flames. It is mounted on a

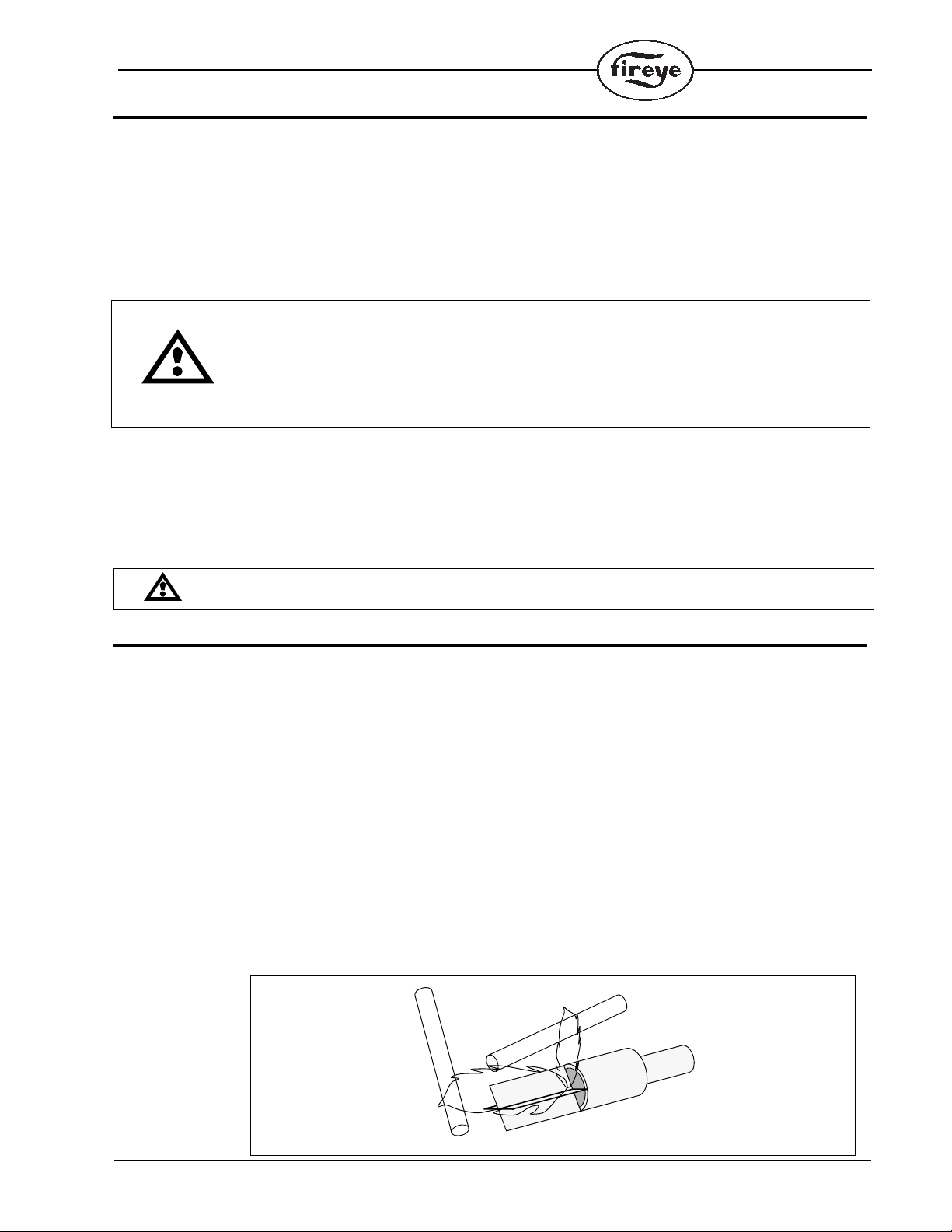

The following instructions should be observed:

1. Keep flame rod as short as possible.

2. Keep flame rod at least

3. Flame rod should enter the pilot flame from the side so as to safely prove an adequate pilot

flame under all draft conditions.

4. If the flame is nonluminous (air and gas mixed before bu rning), the electro de tip should ext end

at least

1

/2″ NPT mount, a KANTHAL flame rod, a glazed porcelain insulating rod holder and

1

/2″ into the flame, but not more than halfway through.

CORRECT

POSITION

OF ROD

1

/2″ NPT coupling.

1

/2″ from any refractory.

WRONG POSITION

OF ROD

INADEQUATE FLAME

PILOT BURNER

CORRECT POSITION

OF PILOT FLAME

3

Page 4

®

5. If the flame is partly luminous, the electrode tip should extend only to the edge of the flame. It is

not necessary to maintain absolutely uninterrupted contact with the flame.

6. It is preferable to angle the rod downward to minimize the effect of sagging and to prevent it

from coming in contact with any object.

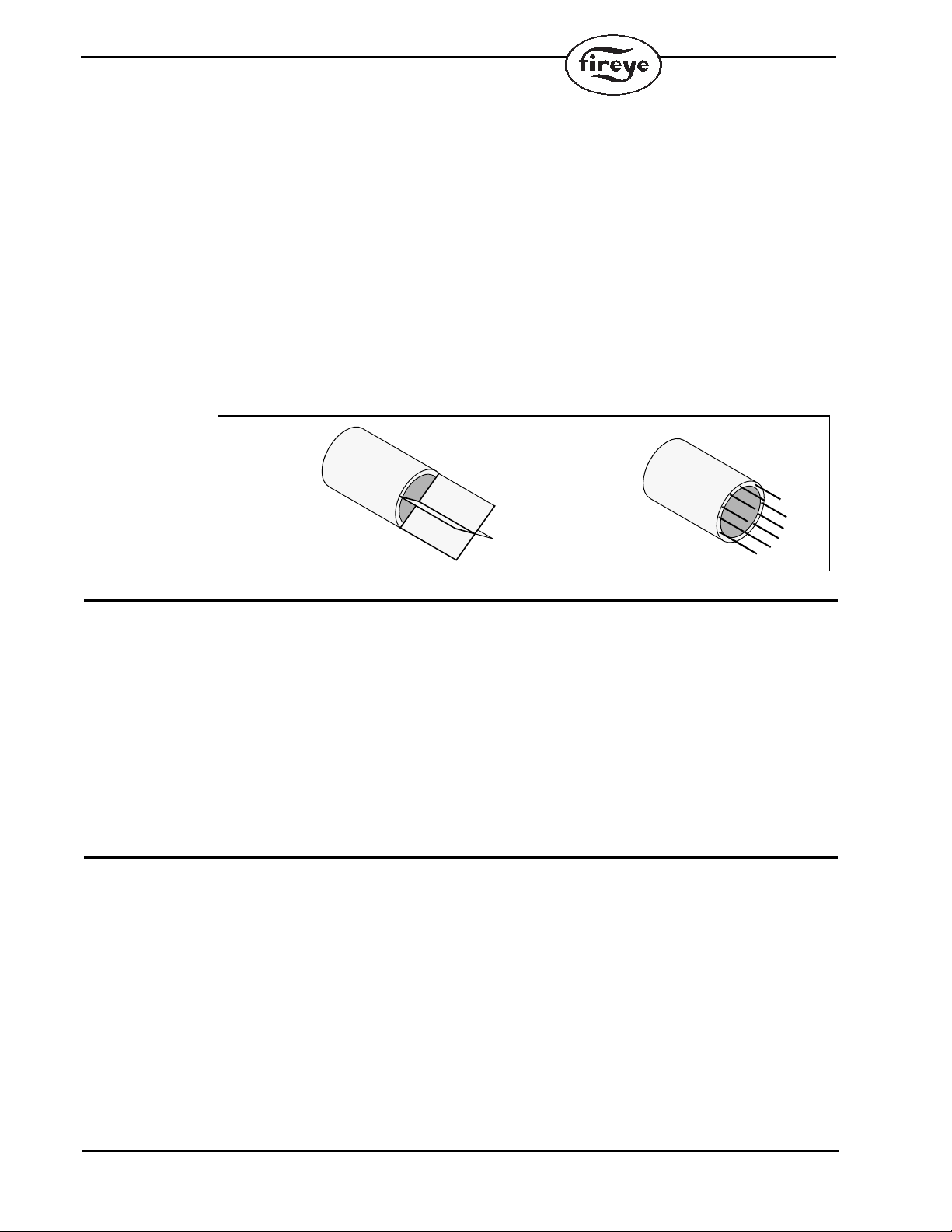

7. An adequate grounding surface for the flame must be provided. The grounding surface in actual

contact with the flame must be at least four times greater than the area of the portion of the

flame rod in contact with the flame. It is essential to adjust the flame rod and ground area ratio

to provide a minimum signal reading of 6.0 VDC.

Note: Interference fr om the ignition spark can alter the true signal reading by adding to, or subtracting from it. This trend sometimes may be reversed by interchanging the primary wires (line voltage)

to the ignition transformer . This interfer ence can also be r educed by the addition of grounded shielding between the flame rod and ignition spark.

8. Proven types of flame grounding adapters, as shown below, may be used to provide ad equate

grounding surface. High temperature stainless steel should be used to minimize the effect of

metal oxidation. This assembly may be welded directly over the pilot or main burner nozzle.

WIRING OF FLAME RODS

For proper operation of flame rectification systems, it is necessary to maintain at least 20 megohms

insulating resistance in the flame rectification circuit.

1. The scanner should be wired using metal cable or rigid conduit.

2. High voltage wiring must not be installed in the same conduit with scanner wiring.

Selection of Scanner Wire

1. Use #14, 16, or 18 gauge wire with 90 C, 600 volt insulation for up to 20 feet distance.

2. The type of insulation used with flame rectification is i mportant, since it must protect against

current leakage resistance to ground. Use Belden 8254-RG62 Coaxial Cable (or equal) for runs

greater than 20 feet. Maximum wiring run not to exceed 100 feet.

MAINTENANCE

Type 69ND1 Flame Rod

The flame rod and its insulator should be kept clean by washing routinely with soap and water. Rods

should be routinely replaced as they oxidize.

Flame Signal Strength

Routine observation of the flame signal strength will forewarn any deterioration in the capability of

the flame detector or its application.

BOMB FIN

GROUNDING

ASSEMBLY

THREADED ROD

ASSEMBLY

Periodic Safety Check

It is recommended that a procedure be established to test the complete flame safeguard system at

least once a month. This test should verify the proper operation of all limit switches and safety interlocks as well as flame failure protection and fuel safety shutoff valve tightness.

4

Page 5

RESET

®

In the event of a lockout condition, the M4RT1 can be reset via a minimum one second power interruption to terminal 7.

RESET OPTIONS (Special Order)

1. Optional M4RT1 reset push button. When this optional reset pushbutton is installed, the M4RT1

can be reset by depressing this button for a minimum of one second.

2. Remote reset option. With this option, the M4RT1 is provided with two additional screw termi-

nals. Using those terminals, a remote, dry contact pushbutton switch can be connected. The

maximum wire length is 100 feet (no.18 AWG wire size is recommended).

CAUTION: Remote reset is recommended only on a control solely for proved ignition programming (pilot ignited burner) or a control for use only with appliances in which unburned

fuel cannot accumulate and that is intended for installation in inaccessible locations such as

open-flame, ceiling-suspended gas heaters.

W ARNING: Selection of the Purge time and Recycle / Non-Recycle operation for a particular

application, by changes to the factory default jumpers described below, should only be performed by a competent professional, licensed by a state or other government agency. Inappropriate selection of these safety critical parameters could result in an unsafe condition

hazardous to life and property.

PROGRAMMER JUMPER SETTINGS

The M4RT1 has a series of 8 jumpers that are used to configure the Pu rg e timing, Pilot Trial for Ignition (PTFI) timing, and recycle or non-recycle operation.

Purge Timing

Jumpers JP1 through JP5 are used to select the Purge timing for the M4RT1. The available Purge

timing selections are 5, 7, 30, 60, and 240 seconds and any additive combination of those ti mes.

Selecting two or more Purge timing jumpers will result in a Purge time period equal to the sum of the

jumpers selected. Selection of a Purge time is accomplished by cutting or not installing the associated jumper. The factory set, default Purge time of 5 seconds (JP1 not installed) is always selected.

The Table below lists all available Purge times and how to select those by cutting jumpers JP2

through JP5.

Purge Time (seconds) JP2 JP3 JP4 JP5

5 Installed Installed Installed Installed

12 Cut Installed Installed Installed

35 Installed Cut Installed Installed

42 Cut Cut Installed Installed

65 Installed Installed Cut Installed

72 Cut Installed Cut Installed

95 Installed Cut Cut Installed

102 Cut Cut Cut Installed

245 Installed Installed Installed Cut

252 Cut Installed Installed Cut

275 Installed Cut Installed Cut

282 Cut Cut Installed Cut

305 Installed Installed Cut Cut

312 Cut Installed Cut Cut

335 Installed Cut Cut Cut

342 Cut Cut Cut Cut

5

Page 6

Pilot Trial for Ignition

Jumpers JP6 and JP7 are used by the factory only to select the PTFI for the M4RT1. The available

PTFI timing selections are 5 and 10 seconds. The factory set, default PTFI time is 10 seconds (JP6

installed, JP7 not installed). The PTFI time may only be set by the factory.

Recycle/Non-recycle Operation

Jumper JP8 is used to select either Recycle or Non-Recycle operation of the M4RT1. The factory

set, default is Recycle operation (JP8 installed). To select Non-Recycle operation, cut jumper JP8.

LED INDICATOR LIGHTS

The M4RT1 has 5 LED lights to indicate the operating status of the control. The function of these

lights are:

Opr Ctrl (Operating Control): This LED is lighted whenever input terminal 7 is energized. The

burner system safety interlocks and operating control should be wired in series and connected to the

M4RT1 terminal 7.

Air Flow: This LED is lighted whenever all of these conditions exist:

— Input terminal 7 is energized (operating control and safety interlocks closed).

— Input terminal 6 is energized (proof of airflow switch is closed).

— Output terminal 8 is energized (blower motor).

PTFI: This LED is energized only during the Pilot Trial For Ignition Period.

Flame: This LED is lighted whenever an adequate flame signal is detected between the M4RT1

terminals S1 & S2.

Alarm: This LED is energized whenever a safety lockout occurs. (See APPLICATION AND

FUNCTION section).

NOTE: The M4RT1 is not powered until the user’s operating control is energized.

®

APPLICATION AND FUNCTION

The M4RT1 provides prepurge, ignition and flame safeguard for heating and process gas fired burners. The “recycle” or “non-recycle” operation is determined by the #8 jumper on the top PCB. Purge

timing, as well as trial for ignition timing is also set by the jumpers. See JUMPER SETTINGS on

page 5.

The M4RT1 amplifier circuitry is designed to utilize a flame rod for flame detection. The Flame Failure Response Time (F.F.R.T.) is fixed at 3 seconds.

Pilot Ignited Burners - “Recycle” Operation

With jumper #8 in the “recycle” position, the typical wiring arrangement illustrated on page 10 for

pilot ignited burners provides the following function:

1. With power applied to Terminal 7 (Opr Ctrl LED lighted), the burner motor circu it (Terminal 8)

is energized. The control then waits for the proof of airflow input (Terminal 6) to be energized

2. The Pre-Purge timing starts when terminal 6 is energized.

3. Following the prepurge period (as determined by jumpers #1 through #5), KL-1 closes, ener-

gizing Terminal 3 which powers the pilot gas valve and Terminal 4 which powers the spark ignition. A five or ten sec. (as determined by jumpers #6 or #7) trial for ign ition is initiated (

LED lit).

4. When pilot flame is detected (Flame LED lit), KF-1 closes, energizing Terminal 5 which powers

the main fuel valve, KF-2 opens de-energizing Terminal 4 which shuts off the spark ignition.

5. When the operating control opens its circuit, or if a power failure occurs, the entire system is de-

energized. Power interruptions in the millisecond range do not affect the operation of the control. Power interruptions of longer duration will cause the control to recycle.

PTFI

6

Page 7

®

6. In the event the pilot flame is not detected by the end of trial for ignition period (PTFI), the pilot

gas valve (Terminal 3) and spark ignition (Terminal 4) are de-energized. A safety shutdown

occurs followed in approximately 30 seconds by a safety lo ckout that de-energizes the blower

motor (Terminal 8) and energizes the lockout alarm circuit (Alarm LED lighted).

7. In the event of a flame failure during a firing period, the pilot and main fuel valves are de-ener-

gized. Following the prepurge period (as determined by jumpers #1 through #5), with proven air

flow (Air Flow LED lit), the pilot gas valve and spark ignition are re-energized and a five or ten

sec. (as determined by jumpers #6 or #7) trial for ignit ion is initiated (PTFI LED lit). If pilot

flame is detected (Flame LED lit), the main fuel valve is energized, the spark igni tion is de-energized. In the event the pilot flame is not detected by the end of trial for ignition period (PTFI),

the pilot gas valve (Terminal 3) and spark ignition (Terminal 4) are de-energized. A safety shutdown occurs followed in approximately 30 seconds by a safety lockout that de-energizes the

blower motor (Terminal 8) and energizes the lockout alarm circuit (Alarm LED lighted).

8. Manual Reset (supply power cycled off/on) is required following any safety lockout.

NOTE: Wait 10 seconds after lockout before restarting the control.

Pilot Ignited Burners - “Non-recycle” Operation

The function of “non-recycle” pilot ignited burners is the same as described for the “recycle” controls, except that the “non-recycle” operation will lock out following any flame failure. “Recycle” or

“non-recycle” operation is determined by the position of jumper #8. See Programmer jumper settings on page 5.

Direct Spark Ignited Burners - “Recycle” Operation

With jumper #8 in the “recycle” position, the typical wiring arrangement illustrated on pages 10 and

11 for direct spark ignited burners provides the following function:

1. With power applied to Terminal 7 (Opr Ctrl LED lighted), the burner motor circuit (Terminal 8)

is energized. The control then waits for the proof of airflow input (Terminal 6) to be energized.

2. The Pre-Purge timing starts when terminal 6 is energized.

3. Following the selected prepurge period (as determined by jumper #1 through #5), KL-1 closes,

energizing T erminal 3 which powers the primary main fuel valve, and Terminal 4 which powers

the spark ignition. A five or ten second (as determined by jumper #6 and #7) trial for igniti on is

initiated (PTFI LED lit).

4. When pilot flame is detected (Flame LED lit), KF-1 closes, energizing Terminal 5 which pow-

ers the secondary main fuel valve, and KF-2 opens, de-energizing Terminal 4 which shuts off

the spark ignition.

5. When the operating control opens its circuit, or if a power failure occurs, the control is de-ener-

gized. Power interruptions in the millisecond range do not affect the operation of the control.

Power interruptions at longer duration will cause the control to recycle.

6. In the event the pilot flame is not detected by the end of trial for ignition period (PTFI), the pilot

gas valve (Terminal 3) and spark ignition (Terminal 4) are de-energized. A safety shutdown

occurs followed in approximately 30 seconds by a safety lo ckout that de-energizes the blower

motor (Terminal 8) and energizes the lockout alarm circuit (Alarm LED lighted).

Direct Spark Ignited Burners - “Non-recycle” Operation

The function of “non-recycle” direct spark ignited burners is the same as described for the “recycle”

controls, except that the “non-recycle” operation will lock out following any flame failure. “Recycle” or “non-recycle” operation is determined by the position of jumper #8. See Programmer Jumper

Settings on page 5.

7

Page 8

TIMING CHART

Selectable Recycle/Non-Recycle operation on loss of flame after Terminal 5 energized. Recycle on

loss of air flow after flame proven.

INSTALLATION TESTING

Use of Test Meter

Testing the Fireye M4RT1 Control requires the use of a test AC-DC multimeter, with a 1,000 ohm/

volt DC rating or greater, or a digital meter with 500K input impedance or greater.

With the test meter on the DC scale, and the test meter leads inserted into the test jacks. A steady DC

voltage reading of 6 to 18 volts should be obtained when the control is detecting flame, and zero

volts when no flame is present.

With the test meter on the AC scale, line and load voltages may be measured at the identified test

points on the chassis.

On the M4RT1 control, a micro-ammeter may be connected in series with the wire to Terminal S2.

Normal flame will produce a meter reading between 4 and 10 micro-amps.

®

PROGRAMMING SEQUENCE

AIR

7

FLOW

ON

PROVEN

8

T

E

3

R

M

I

4

N

A

L

5

S

SELECTABLE

PURGE

PURGE

COMPLETE

SELECTABLE PTFI

5 OR10 SEC

FIRING

PERIOD

OFF

7

Flame Signal Testing

1. Manually shut off the main fuel valve for a pilot ignited burner, or the secondary fuel valve for a

direct spark ignited burner.

2. Set the test meter on the DC scale and insert the test leads into the test jacks on the amplifier

module. (If the meter reads backwards, reverse the meter leads). Red - Plus, Black - Negative.

3. Initiate a normal startup.

4. When flame is established, the test reading should be normal: a steady DC voltage reading of 6

to 18 volts.

5. Inadequate flame signal may be improved by:

a Assuring that the flame detector and wiring installati ons have followed the instructions on

pages 3 and 4.

b Assuring that the flame detector is clean and within the ambient temperature limits.

c Assuring that the flame is sufficiently large to detect.

d Assuring that the flame quality (fuel to air ratio, combustion air velocity) is satisfactory.

8

Page 9

®

Minimum Pilot Test

This test insures that the flame detector will not sense a pilot flame too small to l ight th e main fl ame

reliably. It must be made on every new installation as well as following the repositioning of the flame

detector. This procedure should not be used on a direct spark ignited burner.

1. Manually shut off the fuel to the main burner.

2. Connect a test meter to the test jacks.

3. Initiate a normal startup.

4. Reduce the fuel to the pilot until the DC voltmeter reads approximately 6 volts or when the pilot

is at the minimum to provide a reliable main flame light-off. See WARNING below. This is the

minimum pilot.

5. Slowly turn on the main fuel and insure that the main flame lights off promptly and normally.

WARNING: If light off is delayed, shut off the power to the installation. Realign the flame

detector so that pilot flame detection requires a larger pilot flame. Repeat this test until the

main flame lights reliably with minimum pilot.

W ARNING: The minimum pilot test must be accomplished by a trained and qualified burner

technician.

6. After the minimum pilot test is completed satisfactorily, increase the pilot flame to normal size,

and observe that the main flame is properly established during a normal cycle ("Run-Check"

switch in the "Run" position).

Flame Failure Test

1. T emporarily connect spark ignition and pilot valve to Terminal #3.

2. Initiate a normal startup.

3. Manually shut off all fuel and observe the loss of flame signal on the test meter.

4. If flame signal does not reduce to zero within the flame failure response time of the control, a

grounded metallic shield may need to be inserted between the flame ro d and spark ignition to

prevent interference.

5. IMPORTANT: When the test is completed, reconnect the spark ignition to Terminal #4.

9

Page 10

FIGURE 1. TYPICAL WIRING ARRANGEMENT FOR PILOT IGNITED BURNER.

BURNER

CONTROL

SWITCH

DISCONNECT MEANS

& OVERLOAD

PROTECTION REQUIRED

LIMIT

SWITCHES

OPERATING

CONTROL

BURNER MOTOR

OR

CONTACTOR

LOCKOUT

ALARM

FUEL

INTERLOCKS

AIR FLOW

SWITCH

KF-1

KF-2

S1

S2

3

5

4

7

KB

8

2

KA

A

6

FLAME

AMPLIFIER

KL-1

ELECTRONIC

CIRCUIT

®

PILOT

GAS VALVE

MAIN

FUEL VALVE

SPARK

IGNITION

FLAME ROD

120V (MC120))

50/60 Hz

SUPPLY

H

N

KL KF

Use moisture resistant wire suitable for at least 90°C.

CAUTION: When powered, 260 VAC across S1, S2.

FIGURE 2. TYPICAL WIRING ARRANGEMENT FOR DIRECT SPARK IGNITED BURNER

DISCONNECT MEANS

& OVERLOAD

PROTECTION REQUIRED

120V (MC120)

50/60 Hz

SUPPLY

LIMIT

SWITCHES

BURNER

CONTROL

SWITCH

H

N

OPERATING

CONTROL

BURNER MOTOR

OR

CONTACTOR

LOCKOUT

ALARM

FUEL

INTERLOCKS

AIR FLOW

SWITCH

KF-1

KF-2

S1

S2

3

5

4

7

KB

8

2

KA

A

6

FLAME

AMPLIFIER

KL-1

ELECTRONIC

CIRCUIT

KL KF

FLAME ROD

PRIMARY MAIN

FUEL VALVE

SECONDARY

MAIN FUEL

VALVE (IF USED)

SPARK

IGNITION

FOR INTERMITTENT IGNITION, CONNECT

TO TERMINAL 3

10

Use moisture resistant wire suitable for at least 90°C.

CAUTION: When powered, 260 VAC across S1, S2.

CAUTION: Control wiring procedur es which deviate from those shown in the diagrams may

bypass safety functions designed in the control. Check with the Fireye Represen tative befor e

deviating from the recommended wiring diagrams.

Page 11

FIGURE 3. ALTERNATE WIRING ARRANGEMENT

A. FOR MANUAL START

S1

A START-STOP STATION MAY BE ADDED TO REQUIRE

OPERATOR START-UP EACH TIME THE BURNER FIRES.

S2

®

B. MULTIPLE BURNER SYSTEMS

HOTNEUTRAL

MOTOR

AIR FLOW

SWITCH

3

5

4

PILOT

VALVE

MAIN

FUEL VALVE

IGNITION

HOT

START

STOP

7

8

2

LR-1

LR-2

ON-OFF

LIMIT SW

ALARM

NEUTRAL

A

6

LATCH

RELAY COIL

S1

S2

3

5

4

PILOT

GAS VALVE

IGNITION

S1

S2

3

5

4 IGNITION

MAIN GAS VALVE

G

MANUAL RESET

MAIN GAS VALVE

PILOT

GAS VALVE

START

LIMIT

SWITCH

COIL OF MOTOR

CONTACTOR

STOP

AIR FLOW

SWITCH

LR-1

7

8

2

A

6

LATCH

RELAY

R

MULTIPLE BURNER SYSTEMS UTILIZING SEMI-AUTOMATIC OPERATION INCORPORATE THE FIREYE

MODULAR M-SERIES II CONTROLS IN A CASCADING SEQUENCE WHEN PILOT #1 IS PROVEN. TRIAL

FOR IGNITION FOR PILOT #2 BEGINS. WHEN ALL PILOTS ARE PROVEN THE SAFETY SHUTOFF VALVE

MAY BE MANUALLY OPENED. FLAME FAILURE OF ANY BURNER WILL TRIP THE MAIN FUEL VALVE AND

SOUND ALARM.

THE TOTAL CONNECTED LOAD MUST NOT EXCEED THE RATING OF THE FIRST CONTROL.

7

8

2

A

6

HOT

R

RA

S.P.D.T.

ALARM SILENCE

SWITCH

ALARM

Use moisture resistant wire suitable for at least 90°C.

CAUTION: Control wiring procedures which deviate fr om those shown in the diagrams may

bypass safety functions designed in the control. Check with the Fireye Representative before

deviating from the recommended wiring diagrams.

11

Page 12

®

NOTICE

WARRANTIES

When Fireye products are combined with equipment manufactured by others and/or integrated into

systems designed or manufactured by others, the Fireye warranty, as stated in its General Terms and

Conditions of Sale, pertains only to the Fireye products and not to any oth er equipment or to the

combined system or its overall performance.

FIREYE guarantees for one year from the date of installation or 18 months from date of manufacture

of its products to replace, or, at its option, to repair any product or part thereof (except lamps, electronic tubes and photocells) which is found defective in material or workmanship or which otherwise

fails to conform to the description of the product on the face of its sales order. THE FOREGOING

IS IN LIEU OF ALL OTHER WARRANTIES AND FIREYE MAKES NO WARRANTY OF

MERCHANTABILITY OR ANY OTHER WARRANTY, EXPRESS OR IMPLIED. Except as

specifically stated in these general terms and conditions of sale, remedies with respect to any product

or part number manufactured or sold by Fireye shall be limited exclusively to the right to replacement or repair as above provided. In no event shall Fireye be liable for consequential or special damages of any nature that may arise in connection with such product or part.

12

FIREYE M-4000

®

3 Manchester Road JANUARY 29, 2007

Derry, New Hampshire 03038 Supersedes Jan. 18, 2007

www.fireye.com

Loading...

Loading...