654321

Shift Tray-E1

Service Manual

Contents

1 Product Specications ----------------------------------------------------1-2

Names of Parts

--------------------------------------------------------------- 1-2

Basic Construction

--------------------------------------------------------- 2-2

2 Basic Operation ------------------------------------------------------------2-3

3 Maintenance and Inspection --------------------------------------------3-2

Scheduled Servicing Chart --------------------------------------------------------------- 3-2

4 Outline of Electrical Components --------------------------------------4-2

Removing from the Host Machine

--------------------------------------------4-2

Removing the Shift Tray ------------------------------------------------------------------- 4-2

Drive System

------------------------------------------------------------------ 4-4

Removing the Shift Tray ------------------------------------------------------------------ 4-4

Electrical System

--------------------------------------------------------------4-7

Removing the Shift Tray ------------------------------------------------------------------ 4-7

5 Adjustment at Time of Parts Replacement --------------------------5-2

6 Installation

Shift Tray-E1Shift Tray-E1

-------------------------------------------------------------------6-2

Checking the Contents

-------------------------------------------------------------- 6-2

Checking before Installation

-------------------------------------------------------- 6-3

Installation Procedure

--------------------------------------------------------------- 6-3

1

1

Product Specication

Specication

Names of Parts

■

■

1

1

1-2

1-2

Product Specications

Specications

Item Description

Method of stacking Sorting by shifting trays

face up/ face down stacking

Mode of stacking non-sort, sort (stack shift)

Source of drive ascent/descent: by coil spring (descent by paper weight)

shift movement: by motor

Size of paper for stack*1 non-sort: A3, A4, A4R, A5R, B4, B5, B5R, 11x17, LGL, LTR,

LTR-R, STMT-Rsort: A3,A4, B4, B5, 11x17, LGL, LTR

Paper type plain paper (64 to 90g/m2), recycled paper (64 to 80g/m2), eco

paper, tracing paper, transparency, colored paper, postcard,

double-postcard, 4-plane postcard, label paper, thick paper (91

to 200g/m2)

Weight of Paper for stack 64g/m2 to 200g/m2

Movement of offset in units of sets

Maximum number of sets in stack sort:500sheets(64g/m2 paper)

non-sort:250sheets(64g/m2 paper)

Accuracy of alignment sort:50mm or less(delivery direction)

20mm or more(shift direction,between stacks)

between stacks-5mm or less(shift direction,within stack)

non-sort:100mm or less

Tray full detection*2 by reection type sensor (2 pc.) monitoring height of stack

Power supply DC24V/DC5V(from host machine)

Maximum power consumption 12W or less

Dimensions 365.3mm(W)x547mm(D)x255.7mm(H)

Weight 4.2kg

Operation environment same as host machine

*1: tranceparencies, postcards and label papers may not be sorted.

*2: the machine stops printing when the stack exceeds a specic height.

●

T-1-1T-1-1

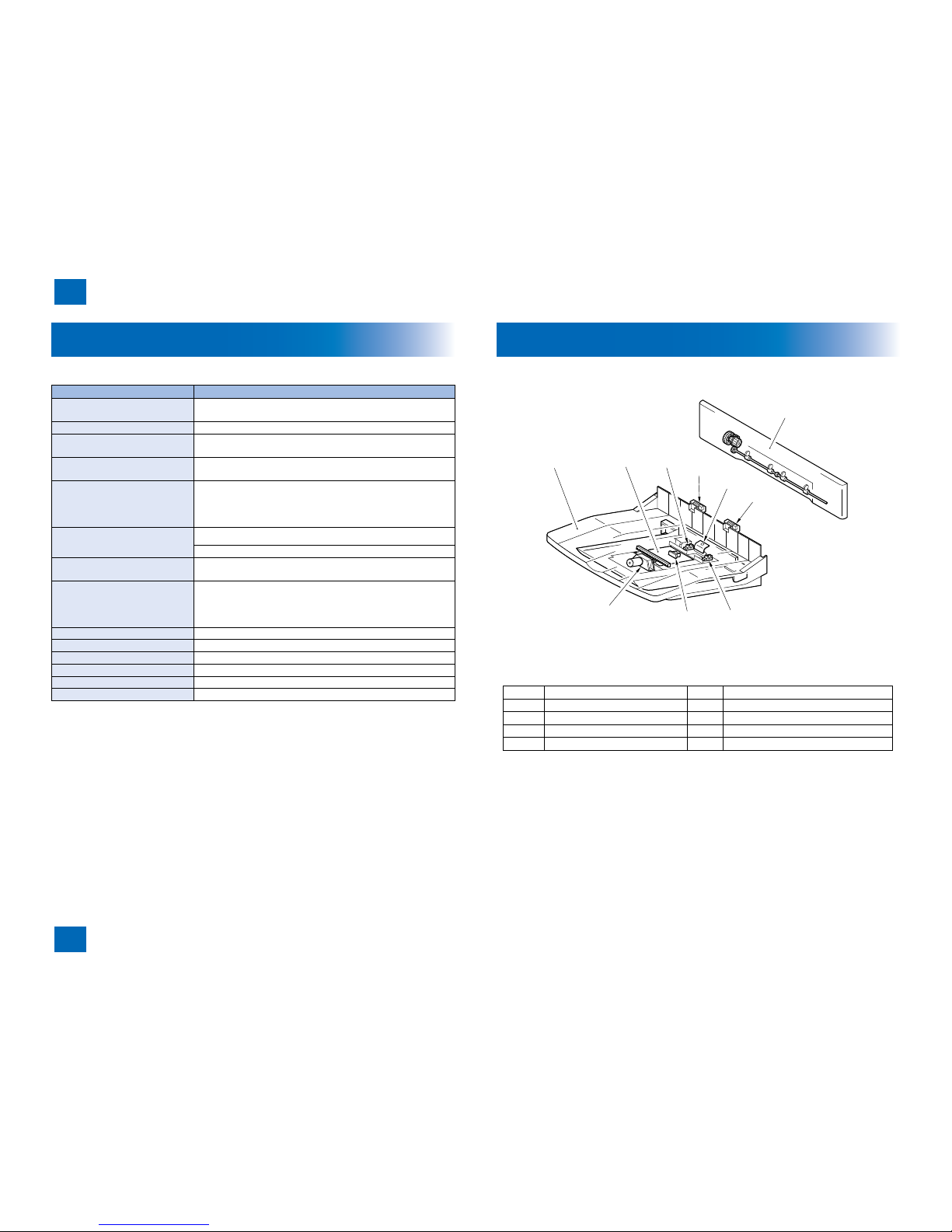

Names of Parts

Names of Parts

[10]

[5]

[1]

[7]

[3]

[8]

[2]

[6]

[9]

[4]

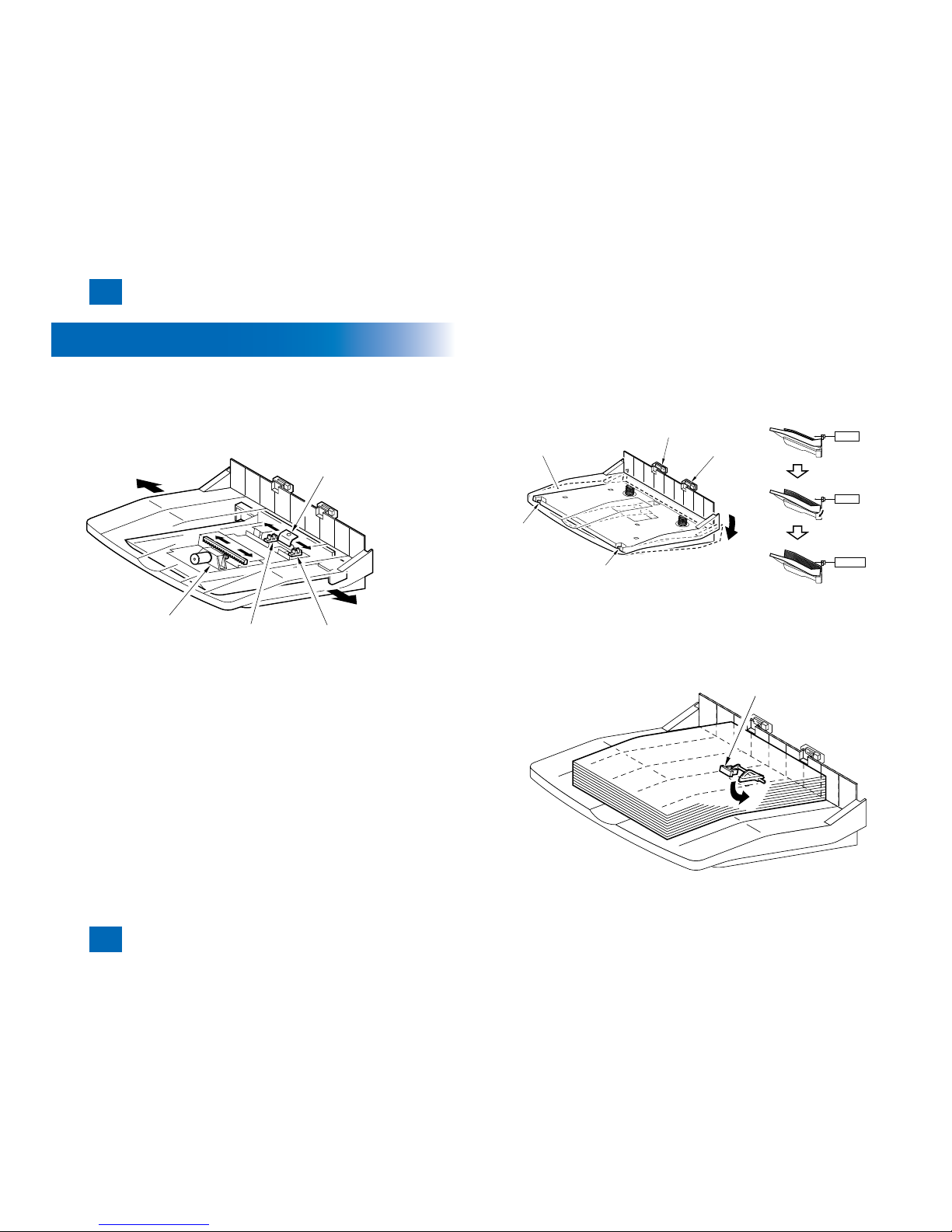

[1] Tray [2] Tray full sensor (front)

[3] Tray full sensor (rear) [4] Tray drive unit

[5] Shift tray drive PCB [6] HP sensor (front)

[7] HP sensor (rear) [8] Light-blocking plate

[9] Paper sensor [10] Shift Drive unit

●

F-1-1F-1-1

2

2

Functions

Basic Construction

Basic Operation

■

■

2

2

2-2

2-2

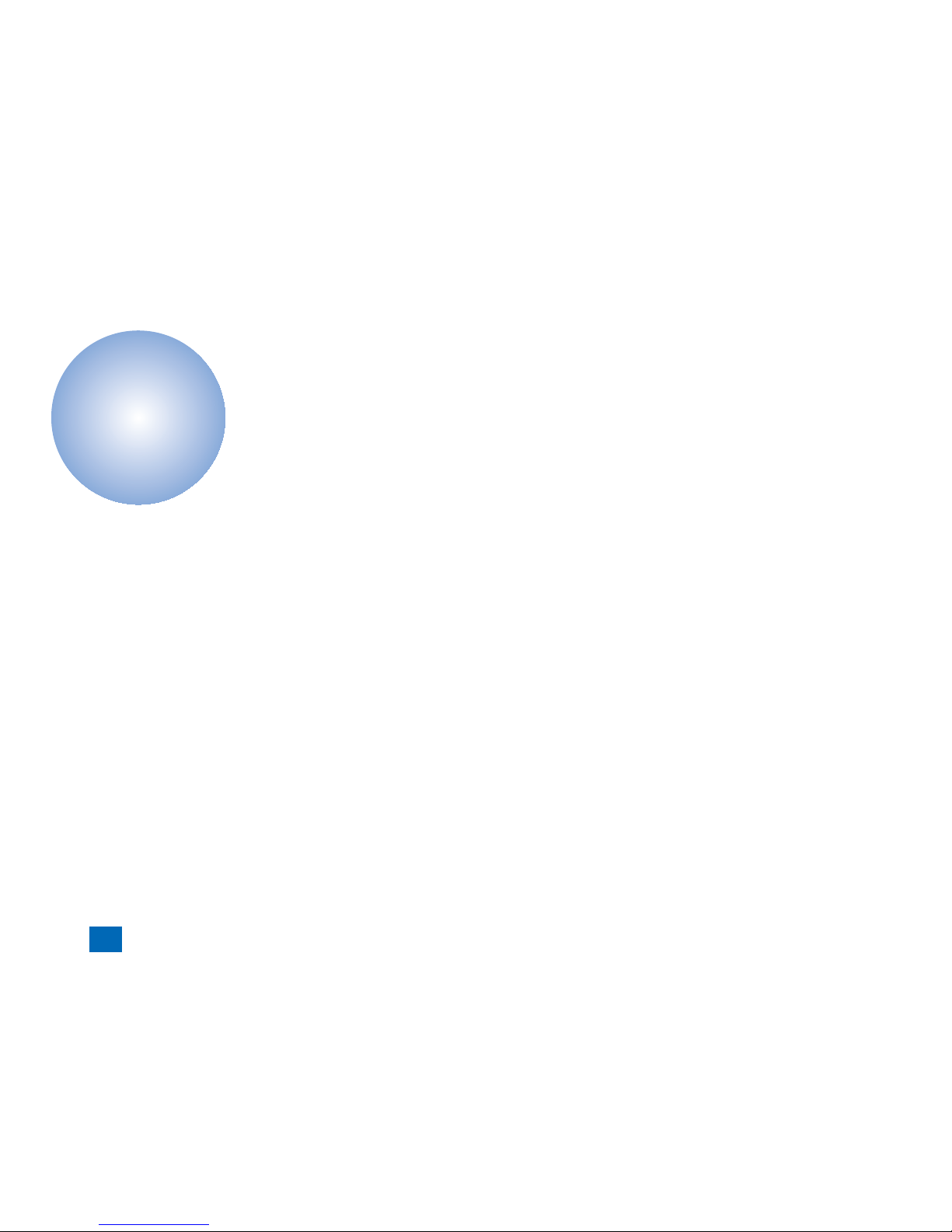

Basic Construction

Inputs to and Outputs from the Shift Tray Driver

PCB

+5V

HP sensor

(front)

PS101

J103

-6

-5

-4

J203

-1

-2

-3

J204

-1

-2

-3

J206

-1

-2

-3

J207

-1

-2

-3

J208

-1

-2

-3

STHPR

+5V

HP sensor

(rear)

PS102

J103

-3

-2

-1

STHPL

when tray is HP at front, '1'.

when tray is HP at rear, '1'.

+5V

Tray paper

sensor

PS103

J104

-6

-5

-4

SPEXIST*

J205

N.C. N.C.

-1

-2

-3

-4

-4

-3

-2

-1

when paper is present in tray, '0'.

+5V

+5V

Tray full sensor

(rear)

PS104

J104

-3

-2

-1

SPCFULL*

when stack of sheets exceeds limit, '0'.

when stack of sheets exceeds limit, '0'.

tray moves to front when +24 V is applied to SDCM1

tray moves to rear when +24 V is applied to SDCM2

Tray full sensor

(front)

PS105

J106

-3

-2

-1

SPSFULL*

Shift motor

J105

-1

-2

SDCM1

SDCM2

M101

Shift tray driver PCB

●

F-2-1F-2-1

Outline of the Electrical Circuitry

The circuit shown below is used to drive the shift motor according to the shift control signal

from the host machine and also to send various sensor signals associated with the shift

operation to the host machine.

Shift drive PCB

Motor drive

circuit

J102

J101 J201

J202

Motor drive

signal

Sensor signal

A24V

A5V

To host machine

To host machine

Sensor

Shift motor

M

●

•

F-2-2F-2-2

2

2

2-3

2-3

Basic Operation

Shift Movement

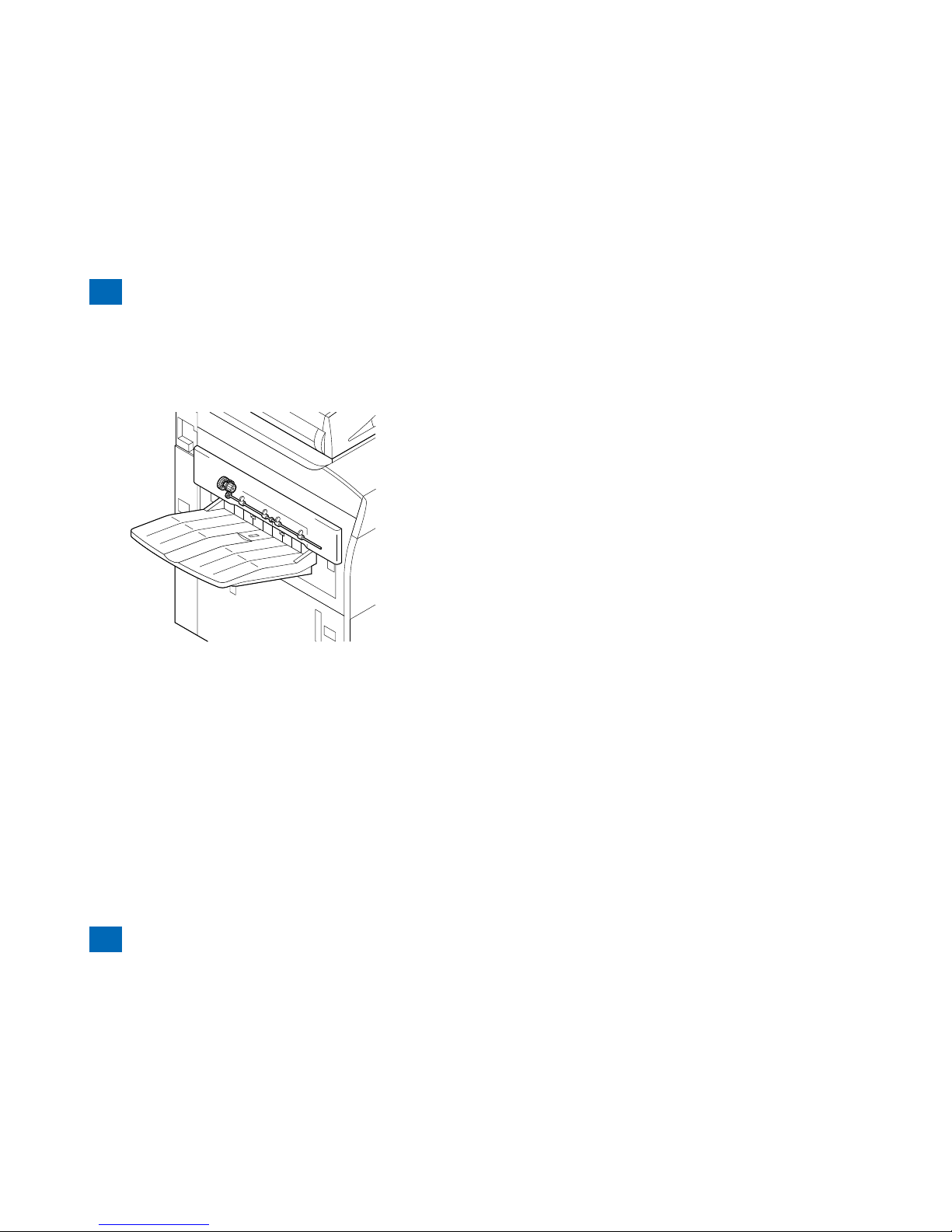

The machine moves the tray to the front and the rear to sort stacks (offset). The tray is

driven by a DC motor, and the rotation of the motor is converted into liner movement

by means of a rack and pinion gear mechanism. The location of the tray (front, rear) is

monitored by the HP sensor mounted to the front and the rear.

Light-blocking plate

HP sensor (rear)

PS102

HP sensor (front)

PS101

Tray drive unit

●

•

F-2-3F-2-3

Placement of Paper

The machine's tray is held up by the work of a coil spring. When paper is placed, the tray

moves down under the weight of the paper. The height of the stack in the tray is monitored

by the tray full sensor (reection type photo sensor), and the shift tray driver PCB sends the

tray full signal to the host machine when the top of the stack reaches a specic height.

Room for

more paper

Tray full sensor (rear)

PS104

Tray full sensor (front)

PS105

Shift

Shift

Tray

Room for

more paper

No room

for paper

Detecting the Presence/Absence of Paper

The presence/absence of paper in the tray is detected by the paper sensor mounted to the

tray.

Tray paper sensor

PS103

●

•

●

•

F-2-4F-2-4

F-2-5F-2-5

2

2

2-4

2-4

Delivery Movement

The paper from the host machine is delivered to the tray through the shift drive unit, which

is driven by the host machine's gear mechanism.

●

•

•

F-2-6F-2-6

3

3

Periodical Servicing

Maintenance and Inspection

■

3

3

3-2

3-2

Maintenance and Inspection

Periodical Servicing

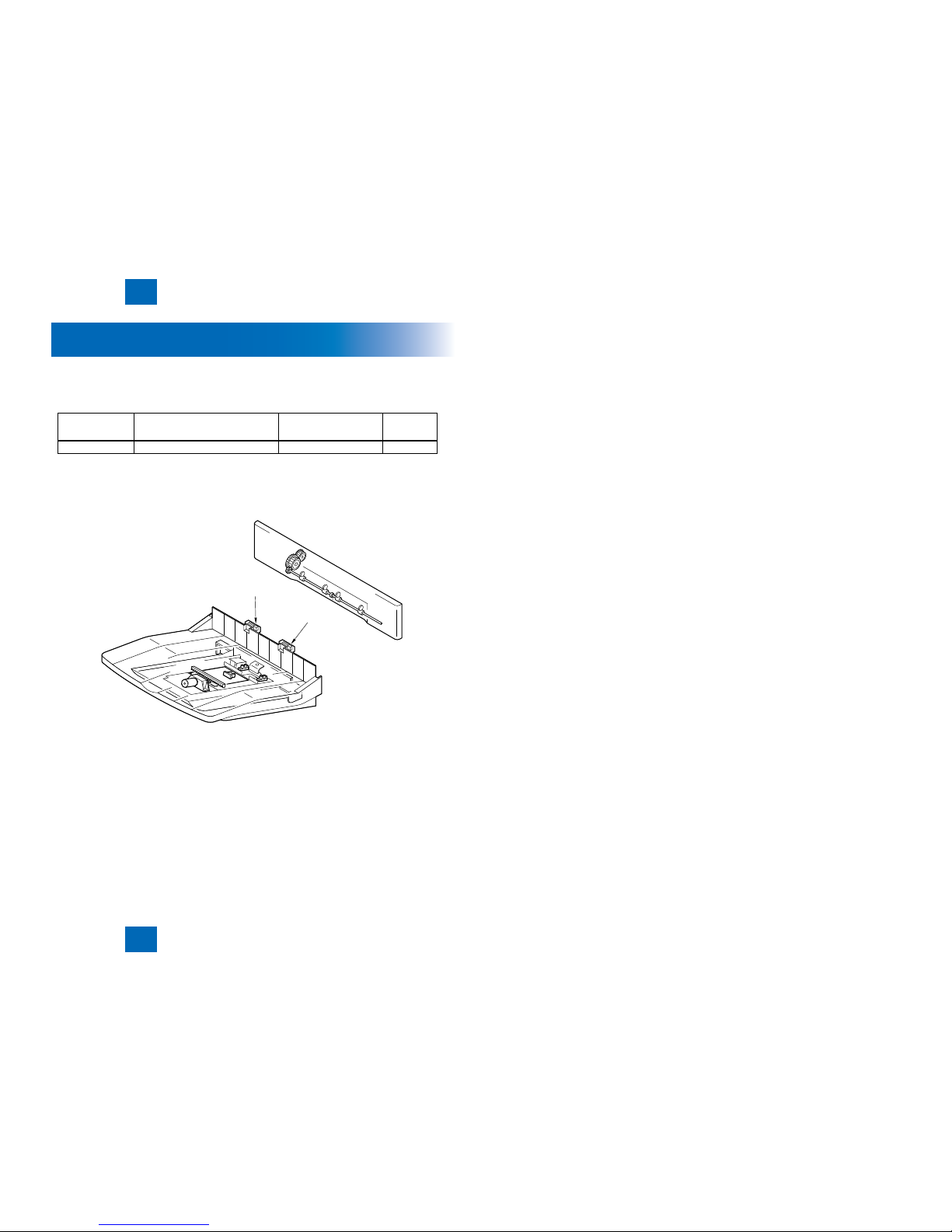

Scheduled Servicing Chart

Illust No. Parts name

Sch edul ed servicin g

250,000

Remarks

1 Tray full sensor (front/rear) clean

The following gure shows the locations of the parts that require scheduled servicing:

[1]

[1]

●

■

F-3-1F-3-1

Loading...

Loading...