Canon POD Deck Lite-C1 Service Manual

POD Deck Lite-C1

Service Manual

Revision 2.0

1x

1x

Introduction

Introduction

Important Notices

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair

of products.

This manual covers all localities where the products are sold. For this reason, there may be information in this manual that does

not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products.

When changes occur in applicable products or in the contents of this manual, Canon will release technical information as the

need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or

translated into another language, in whole or in part, without the consent of Canon Inc.

Copyright CANON INC. 2015

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Explanation of Symbols

The following symbols are used throughout this Service Manual.

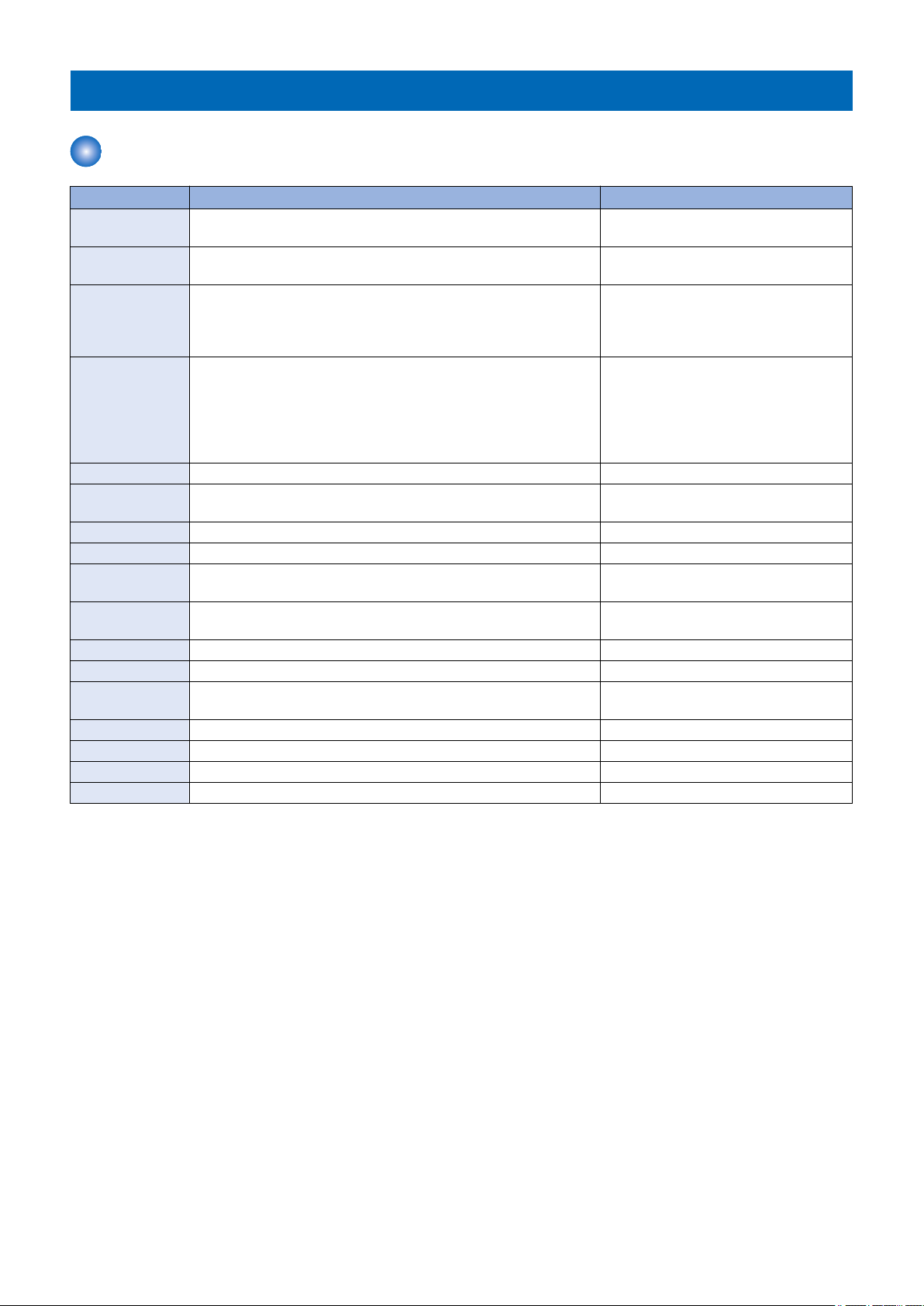

Symbols Explanation Symbols Explanation

Check.

Remove the claw.

Check visually.

Check a sound. Push the part.

Insert the claw.

1x

1x

1x

1x

1x

1x

1x

1x

Introduction

Symbols Explanation Symbols Explanation

Disconnect the connector. Connect the power cable.

Connect the connector. Disconnect the power cable.

Remove the cable/wire from the

cable guide or wire saddle.

Install the cable/wire to the cable

guide or wire saddle.

Remove the screw.

Install the screw.

Cleaning is needed. Measurement is needed.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and

mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol, the arrow

indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit

door, which results in supplying the machine with power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low".

(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the operations

of the microprocessors used in the machines are not discussed: they are explained in terms of from sensors to the input of

the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and

major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service

Information bulletins and be able to identify and isolate faults in the machine.

Turn on the power.

Turn off the power.

Loosen the screw.

Tighten the screw.

Contents

Contents

Safety Precautions...............................................................................................1

Points to Note about Turning Off the Main Power Switch................................................................... 2

Notes Before Servicing........................................................................................................................2

Notes On Assembly/Disassembly....................................................................................................... 2

Points to Note at Cleaning...................................................................................................................3

1. Product Overview.............................................................................................4

Features.............................................................................................................................................. 5

Features...............................................................................................................................................5

Specifications...................................................................................................................................... 6

Specifications....................................................................................................................................... 6

Names of Parts....................................................................................................................................7

External View........................................................................................................................................7

Cross Section....................................................................................................................................... 9

Option Construction...........................................................................................................................10

2. Technology..................................................................................................... 11

Basic Configuration........................................................................................................................... 12

Functional Construction....................................................................................................................... 12

Overview of the Electrical Circuitry....................................................................................................... 12

Component Configuration.................................................................................................................... 13

Controls.............................................................................................................................................15

Overview............................................................................................................................................ 15

Pickup/Feed Control............................................................................................................................15

Paper Presence/Absence Detection Control..........................................................................................16

Paper Surface Detection Control.......................................................................................................... 16

Lifter Control.......................................................................................................................................17

Remaining Paper Level Detection Control.............................................................................................17

Switching the Paper Size.....................................................................................................................18

Compartment Open/Close Control........................................................................................................19

Air Assist Control................................................................................................................................ 20

Cassette Heater Control (Option) ........................................................................................................ 22

Power Supply..................................................................................................................................... 23

Fan.................................................................................................................................................... 24

Jam Detection ....................................................................................................................................24

Upgrading..........................................................................................................................................26

Upgrading...........................................................................................................................................26

3. Periodical Service.......................................................................................... 27

List of Work for Scheduled Servicing................................................................................................ 28

4. Disassembly/Assembly................................................................................. 29

Removing from the Host Machine.....................................................................................................30

i

Contents

Removing from the Host Machine.........................................................................................................30

List of Parts....................................................................................................................................... 32

External Covers.................................................................................................................................. 32

Consumable Parts and Cleaning Points................................................................................................33

Main Units.......................................................................................................................................... 34

Sensors..............................................................................................................................................35

Solenoids........................................................................................................................................... 36

Motors................................................................................................................................................37

Fans...................................................................................................................................................38

PCBs..................................................................................................................................................39

Switches.............................................................................................................................................40

Others................................................................................................................................................ 41

External Covers.................................................................................................................................42

Removing the Left Upper Cover........................................................................................................... 42

Removing the Front Cover...................................................................................................................42

Removing the Right Cover...................................................................................................................43

Removing the Rear Cover....................................................................................................................44

Removing the Upper Cover .................................................................................................................45

Consumable Parts and Cleaning Points............................................................................................47

Removing the Deck Pickup Roller........................................................................................................ 47

Removing the Deck Feed Roller...........................................................................................................49

Removing the Deck Separation Roller.................................................................................................. 51

Main Units......................................................................................................................................... 54

Removing the Pickup Assembly........................................................................................................... 54

Opening the Compartment...................................................................................................................56

Removing the Compartment................................................................................................................ 56

Heaters..............................................................................................................................................60

Removing the Cassette Heater............................................................................................................ 60

Removing the Air Heater .....................................................................................................................61

Solenoids...........................................................................................................................................64

Removing the Compartment Open Solenoid......................................................................................... 64

Removing the Deck Pickup Release Solenoid ...................................................................................... 65

Motors............................................................................................................................................... 67

Removing the Deck Lifter Motor........................................................................................................... 67

Fans.................................................................................................................................................. 69

Removing the Pickup Release Solenoid Cooling Fan ............................................................................69

Lifter Wire .........................................................................................................................................71

Removing the Lifter Wire..................................................................................................................... 71

Installation of the Lifter Wire.................................................................................................................74

PCBs................................................................................................................................................. 84

Removing the Deck Driver PCB........................................................................................................... 84

Removing the Paper Width Detection PCB........................................................................................... 84

5. Adjustment..................................................................................................... 87

Adjustment ....................................................................................................................................... 88

Overview............................................................................................................................................ 88

Actions when Replacing the Parts.....................................................................................................90

Front Cover........................................................................................................................................ 90

Pickup Assembly.................................................................................................................................90

ii

Contents

Compartment......................................................................................................................................93

Deck Driver PCB ................................................................................................................................94

Paper Width Detection PCB.................................................................................................................94

Other Adjustment ............................................................................................................................. 96

Adjusting the Pressure of the Deck Separation Roller............................................................................ 96

Adjusting the Paper Separation ...........................................................................................................96

6. Installation.................................................................................................... 100

How to Utilize this Installation Procedure........................................................................................101

Description on the Parts Included in the Package................................................................................ 101

Symbols in the Illustration.................................................................................................................. 101

Checking before Installation............................................................................................................102

Checking the Installation Space..........................................................................................................102

Points to Note on Installation..............................................................................................................102

Checking the Power Supply............................................................................................................... 103

Check Items When Turning OFF the Main Power................................................................................ 103

Product Name...................................................................................................................................103

Unpacking Procedure......................................................................................................................104

Unpacking Procedure........................................................................................................................ 104

Checking the Contents....................................................................................................................105

imageRUNNER ADVANCE 8500 Series............................................................................................. 105

imagePRESS C10000VP / C8000VP Series....................................................................................... 107

Installation Procedure......................................................................................................................109

imageRUNNER ADVANCE 8500 Series............................................................................................. 109

imagePRESS C10000VP / C8000VP Series....................................................................................... 119

Checking after Installation...............................................................................................................132

imageRUNNER ADVANCE 8500 Series............................................................................................. 132

imagePRESS C10000VP / C8000VP Series....................................................................................... 132

Paper Positioning Check / Adjustment Procedure.......................................................................... 133

imageRUNNER ADVANCE 8500 Series............................................................................................. 133

imagePRESS C10000VP / C8000VP Series....................................................................................... 136

Cassette Heater Assembly..............................................................................................................139

Check Items when Turning OFF the Main Power.................................................................................139

Checking the Supplied Parts.............................................................................................................. 139

Removing from the Host Machine.......................................................................................................139

Installation Procedure........................................................................................................................140

APPENDICES....................................................................................................144

Service Tools...................................................................................................................................145

Solvents and Oils.............................................................................................................................. 145

Special Tools.................................................................................................................................... 145

General Circuit Diagram..................................................................................................................146

General Circuit Diagram (1/3 )............................................................................................................146

General Circuit Diagram (2/3).............................................................................................................147

General Circuit Diagram (3/3).............................................................................................................148

iii

Safety Precautions

Points to Note about Turning Off the

Main Power Switch............................2

Notes Before Servicing......................... 2

Notes On Assembly/Disassembly.........2

Points to Note at Cleaning.................... 3

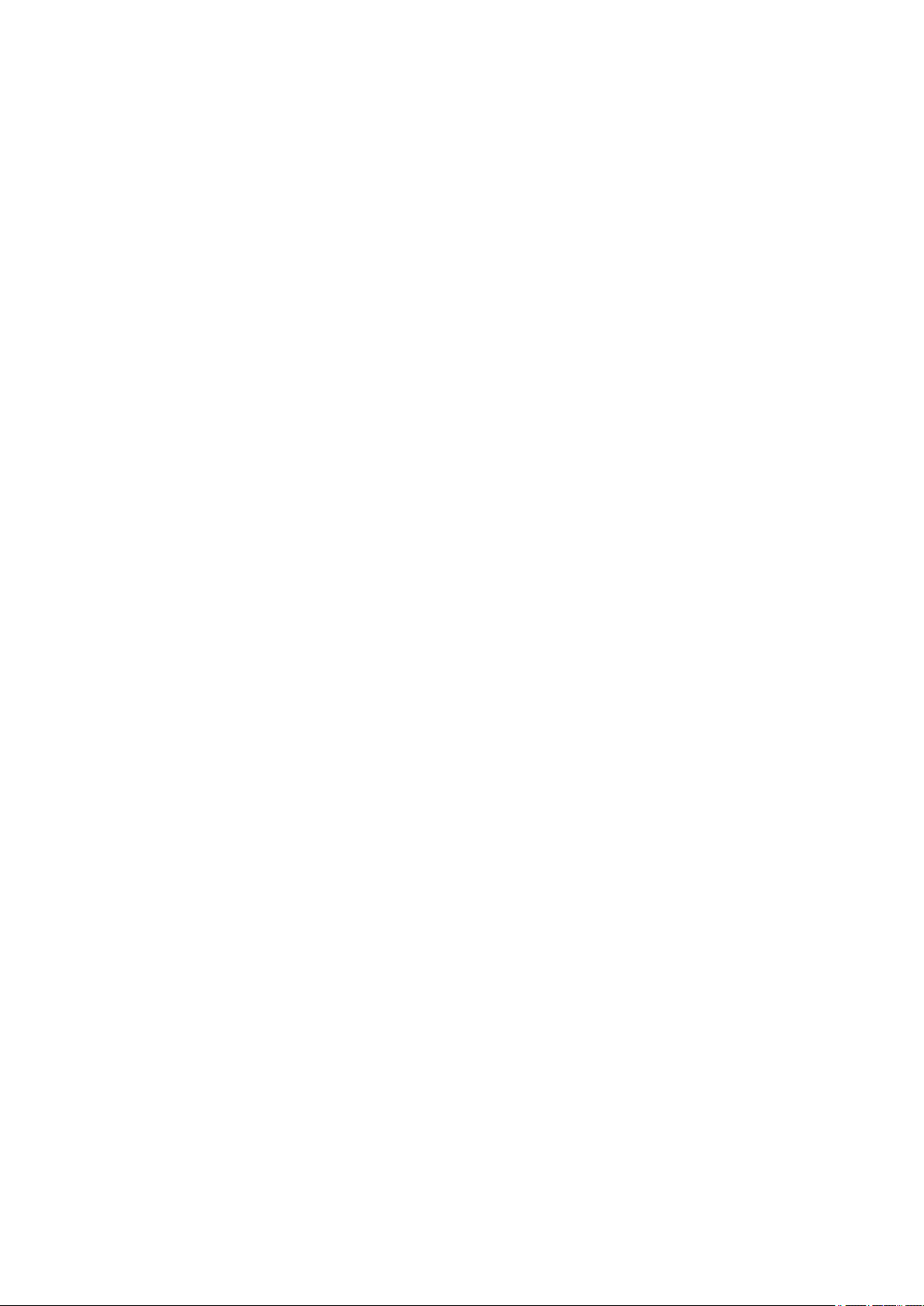

Leakage Breaker

Safety Precautions

Points to Note about Turning Off the Main Power Switch

This equipment does not have a main power switch, but it has only a leakage breaker. This equipment is powered when the main

power switch of the host machine is turned on. The leakage breaker detects overcurrent and power leakage.

NOTE:

Explain to the customer that the leakage breaker must be checked once or twice a month and the result must be recorded.

Notes Before Servicing

CAUTION:

At servicing, be sure to turn off the power source according to the specified steps and disconnect the power plug.

CAUTION:

Do not turn off the power switch when downloading is under way. Turning off the main power switch while downloading is

under way can disable the machine.

Notes On Assembly/Disassembly

Follow the items below to assemble/disassemble the device.

1. Disconnect the power plug to avoid any potential dangers during assembling/disassembling works.

2. If not specially instructed, reverse the order of disassembly to reinstall.

2

Safety Precautions

3. Ensure to use the right screw type (length, diameter, etc.) at the right position when assembling.

4. To keep electric conduction, binding screws with washers are used to attach the grounding wire and the varistor. Ensure to

use the right screw type when assembling.

5. Unless it is specially needed, do not operate the device with some parts removed.

6. Never remove the paint-locked screws when disassembling.

Points to Note at Cleaning

CAUTION:

When performing cleaning using organic solvent such as alcohol, be sure to check that the component of solvent is

vaporized completely before assembling.

3

1

Product Overview

Features................................................5

Specifications........................................6

Names of Parts..................................... 7

Option Construction............................ 10

1. Product Overview

Features

Features

• The various paper sizes from the A5 to 13"X19"(330.0X482.6mm) are supported. In addition, the custom paper size is

supported, too.

• The high stacking of maximum 3,500 sheets (80 g/m2) is possible.

• The user can change the stacking paper size easily by the side and rear guide plates with the free stop mechanism and the

automatic paper size detection function.

• The envelope can be picked up by attaching the optional Envelope Feeder Attachment.

• The replacement work of the consumable parts is easy.

5

Specifications

Specifications

Item Specifications Remarks

Pickup method Retard separation + Air assist (switches between warm and cool cur-

rents to suit paper type/environment)

Paper accommodation

Paper type Thin paper (52 to 79 g/m2), Plain paper (80 to 105 g/ m2), Heavy paper

Paper size 13 X 19 (330.2 X 482.6 mm), SRA3 (320 X 450 mm), 12 X 18 (304.8

Paper weight 52 g/m2 to 300 g/m2

Stacking height 385 mm (height to bottom of arrow on stack limit label) Envelope: 100

Stacking capacity Approx. 3500 sheets (equivalent of 80 g/m2)

Size switching Switching the guide plates by the user operation

Paper size detection

Remaining paper

level detection

Operation switch Compartment open button

Display None

Ecological consideration

Dimensions (W) 717 X (D) 686 X (H) 568 mm

Weight Approx. 76 kg

Power supply AC 100 to 240 V 50/60 Hz 2.4A

Operating noise Host machine noise + 2.5 dB

Front loading

(106 to 300 g/m2), Color paper, Recycled paper, Pre-punched paper,

Transparency, Label paper, Tab paper, Bond paper, Letterhead, Coated paper, Textured paper, Vellum paper, Envelopes*1

X 457.2 mm), A3, A4, A4R, A5R, B4, B5, B5R, 11 X17 (279 X 432 mm),

LGL, LTR, LTRR, EXEC, STMTR, 8K, 16K, 16KR, Envelopes (Monarch, COM10, ISO-C5, DL, Kakugata 2, Nagagata 3, Yougatanaga 3,

10 X 13 (254 X 330.2 mm)*2, 9 X 12 (228.6 X 304.8 mm), 6 X 9 (152.4

X 228.6 mm))*1, Custom size (100 X 148 mm to 330.2 X 487.7 mm)

mm*1

Yes (Paper width: detected by the volume sensor, Paper length: detected by the photo-interrupter)*1

Yes

Environment sensor, Air heater (standard), Cassette heater (option,

supplied as the service parts)

Center reference

Different depending on the host machine.

*1: Only when the optional Envelope Feeder Attachment is installed.

Different depending on the host machine.

*1: Only when the optional Envelope Feeder Attachment is installed.

*2: Do not use the Envelope Feeder Attachment.

*1: When the paper is Yougatanaga 3, the

stack height is 160 mm or less.

*1: The size of envelope and custom size

paper are not detected.

1. Product Overview

6

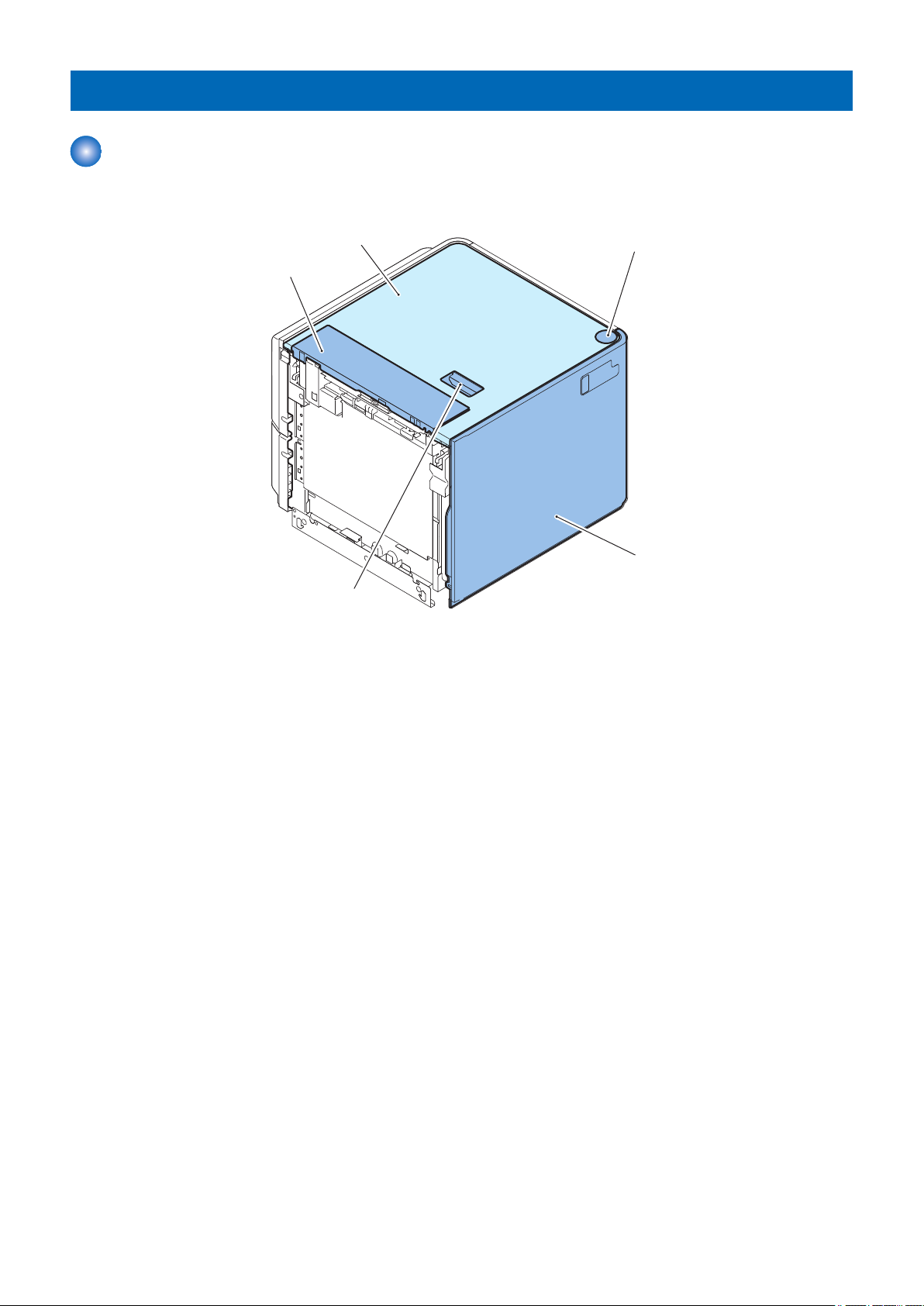

Names of Parts

[5]

[4]

[1]

[2]

[3]

External View

■ Front

1. Product Overview

[1] Left upper cover

[2] Upper cover

[3] Compartment open button

[4] Front cover

[5] Deck release lever

7

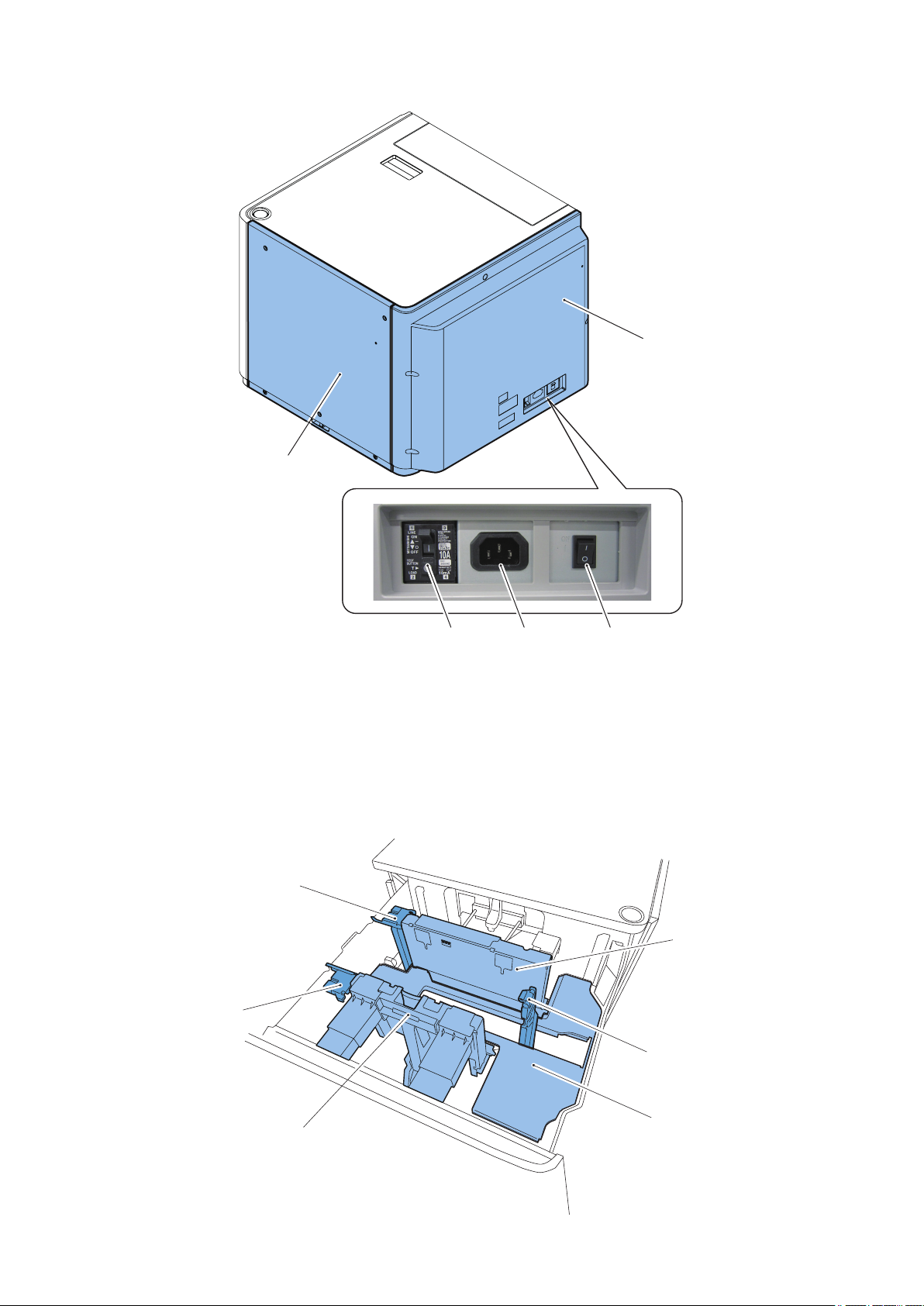

■ Rear

[2]

[1]

[3][4][5]

[4]

[2]

[5]

[1]

[6]

[3]

1. Product Overview

[1] Rear cover

[2] Right cover

[3] Cassette heater switch

[4] Power socket

[5] Leakage breaker

■ Internal

8

[1] Side guide plate (rear)

[2]

[4]

[3]

[1]

[5] [6]

[2] Rear guide plate

[3] Lifter

[4] Side guide plate (front)

[5] Envelope side guide plate (front)

[6] Envelope side guide plate (rear)

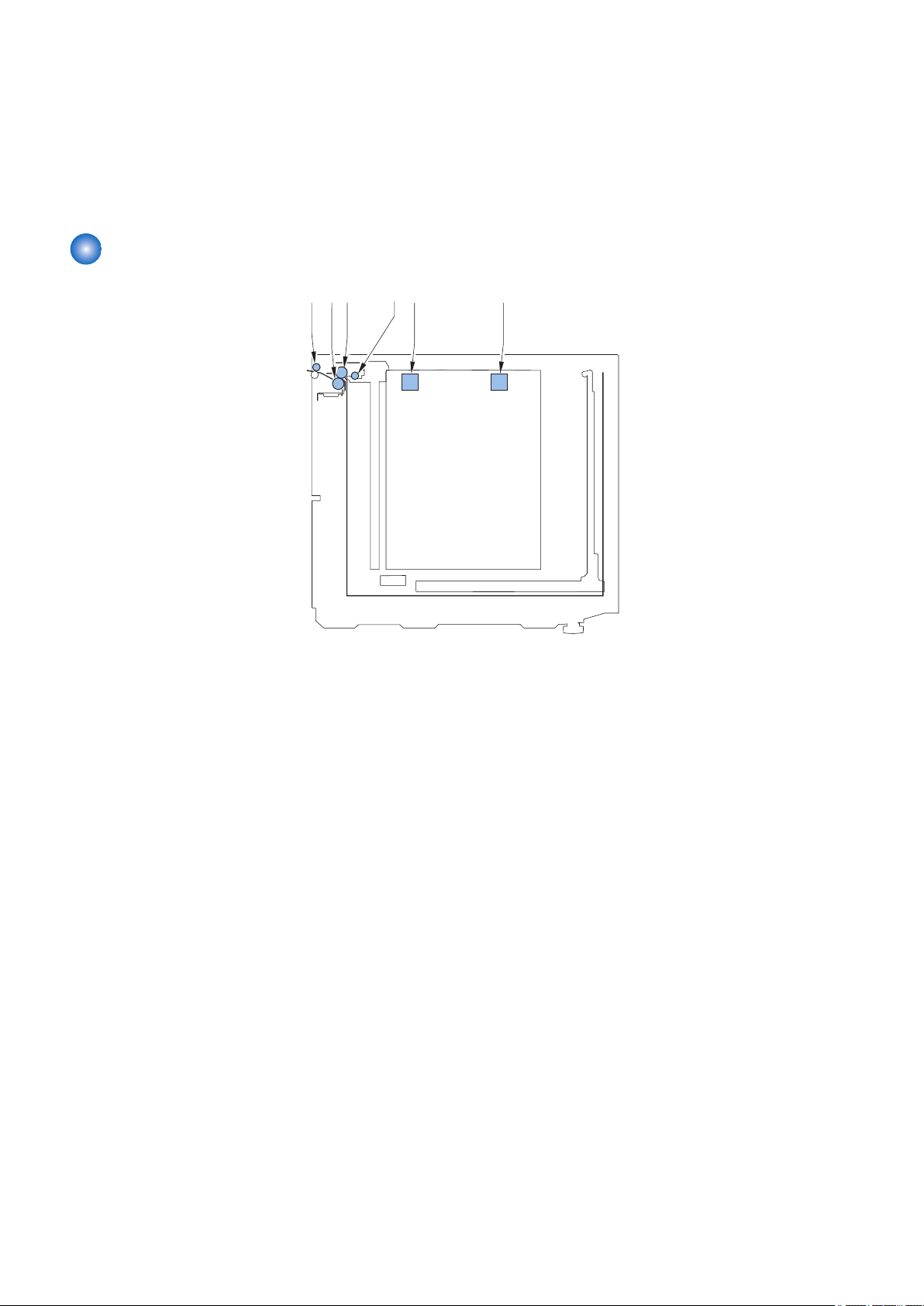

Cross Section

1. Product Overview

[1] Deck pull-out roller

[2] Deck separation roller

[3] Deck feed roller

[4] Deck pickup roller

[5] Blow-out vent (warm air)

[6] Blow-out vent (cool air)

9

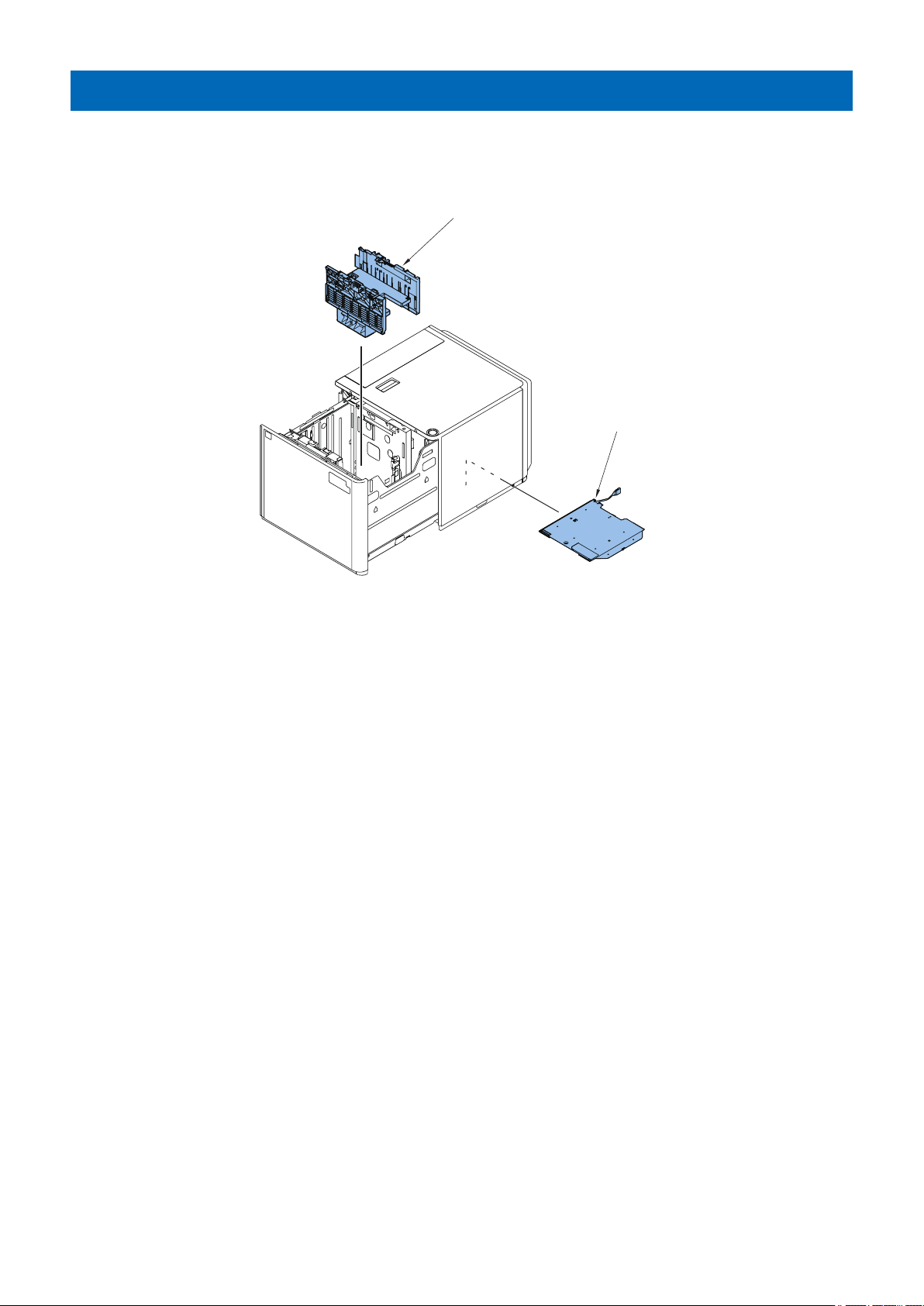

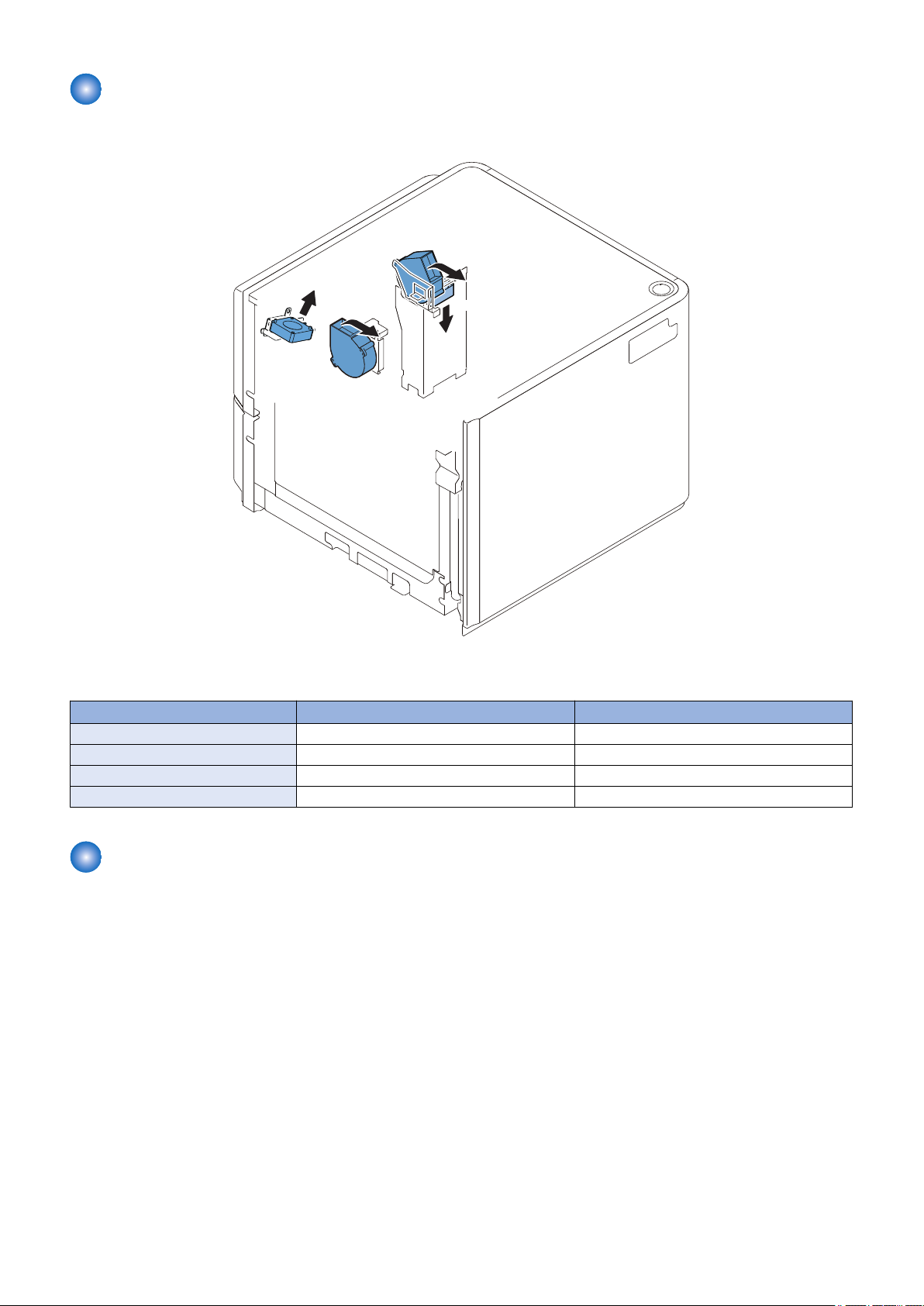

Option Construction

Cassette Heater

Envelope Feeder Attachment-G1

The following optional equipment can install to the this equipment.

• Envelope Feeder Attachment-G1 : User installation

• Cassette heater : Supplied as the service parts

1. Product Overview

10

2

Technology

Basic Configuration.............................12

Controls...............................................15

Upgrading............................................26

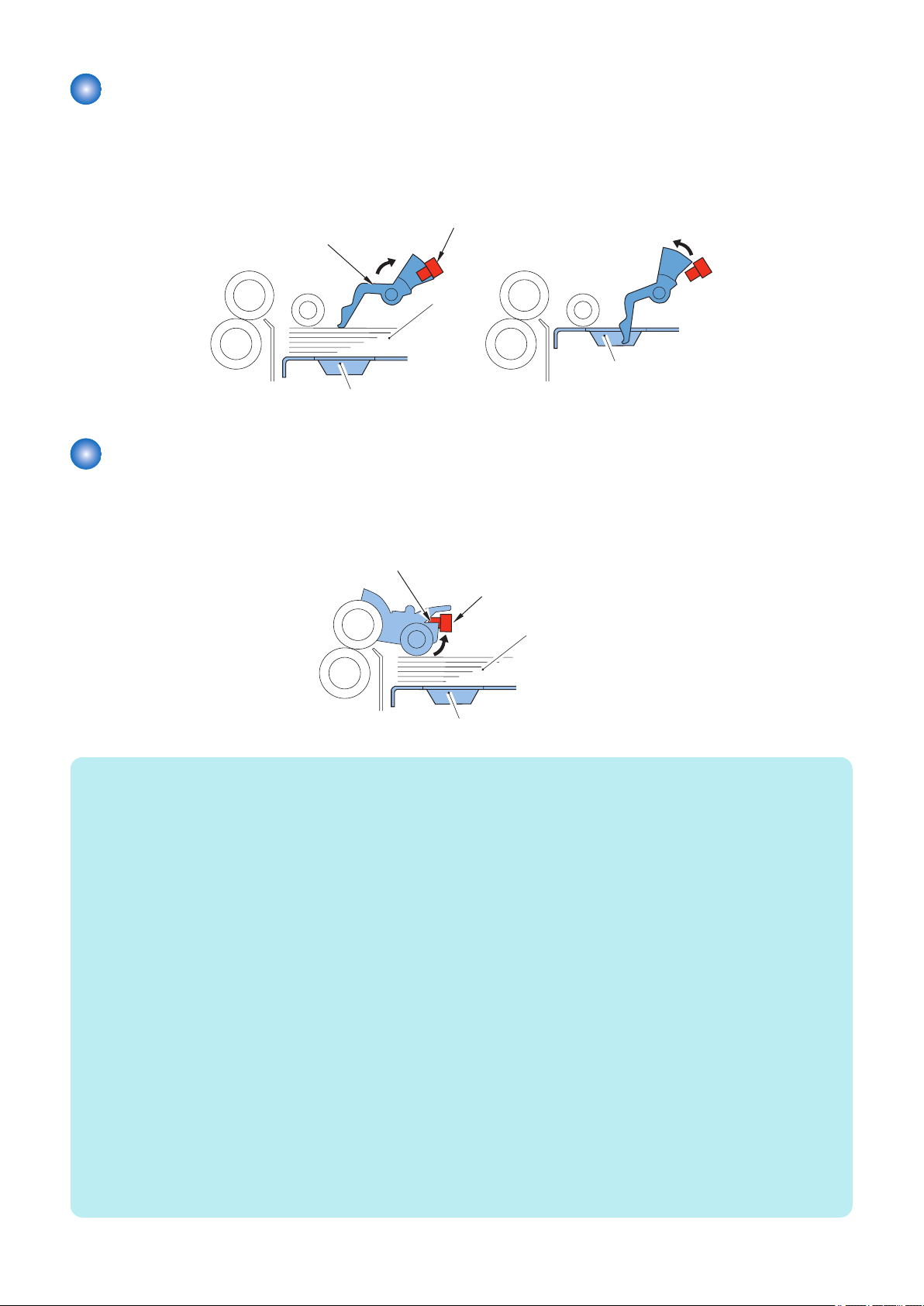

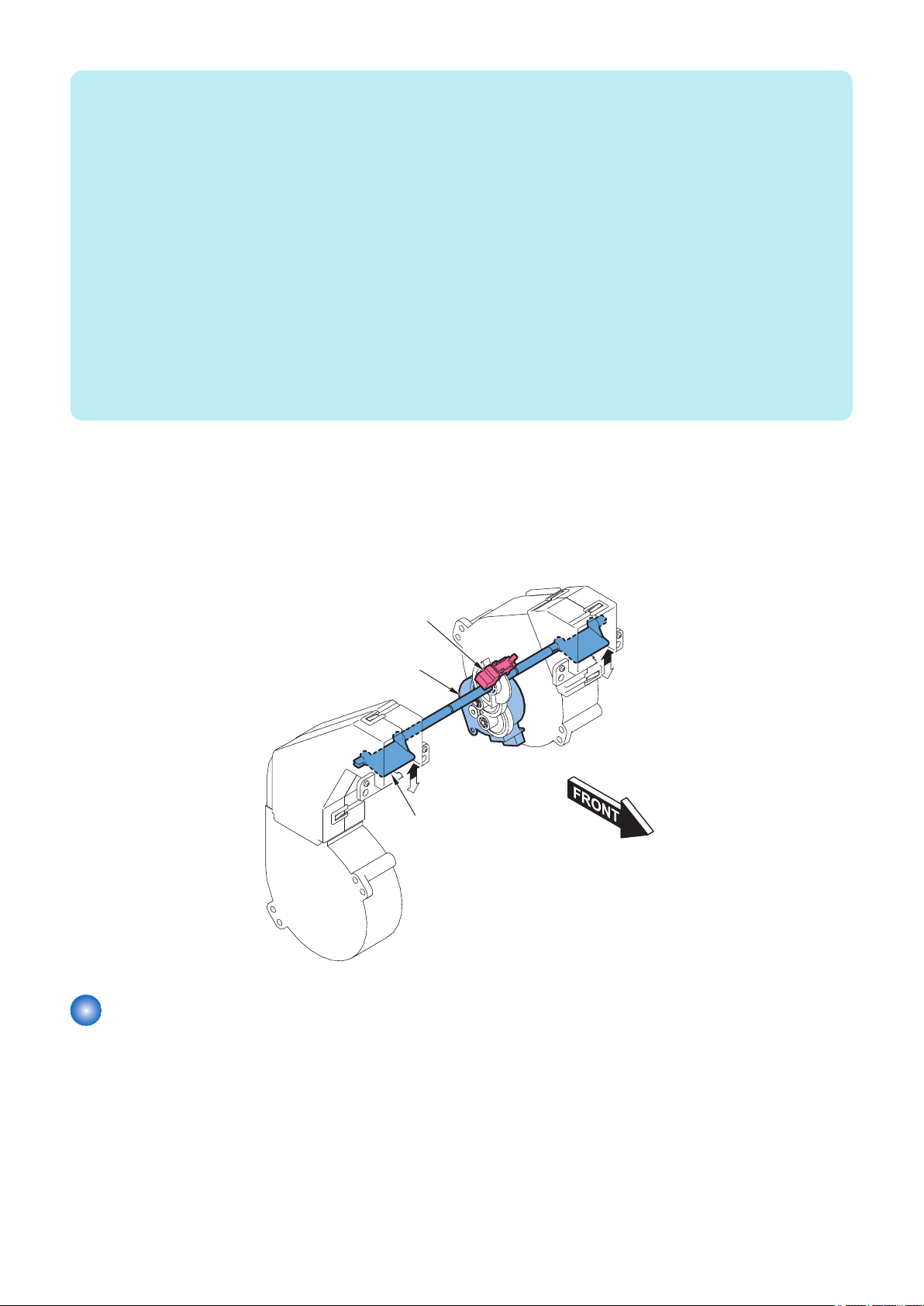

1.Pickup/feed system 2.Compartment system

3.Deck control system

2. Technology

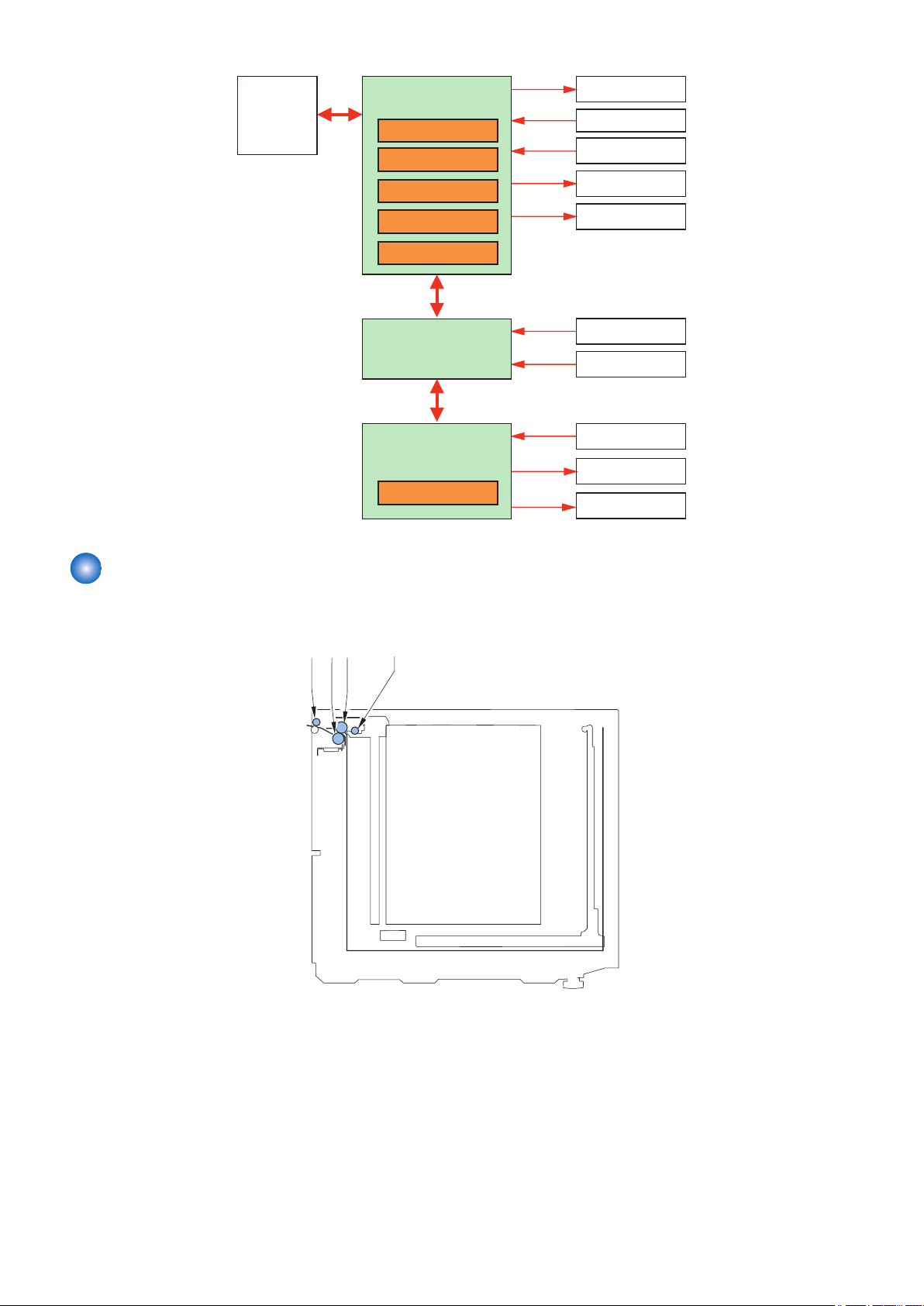

Basic Configuration

Functional Construction

The POD Deck Lite is grouped into the following 3 blocks: Pickup/feed system, Compartment system, Deck control system.

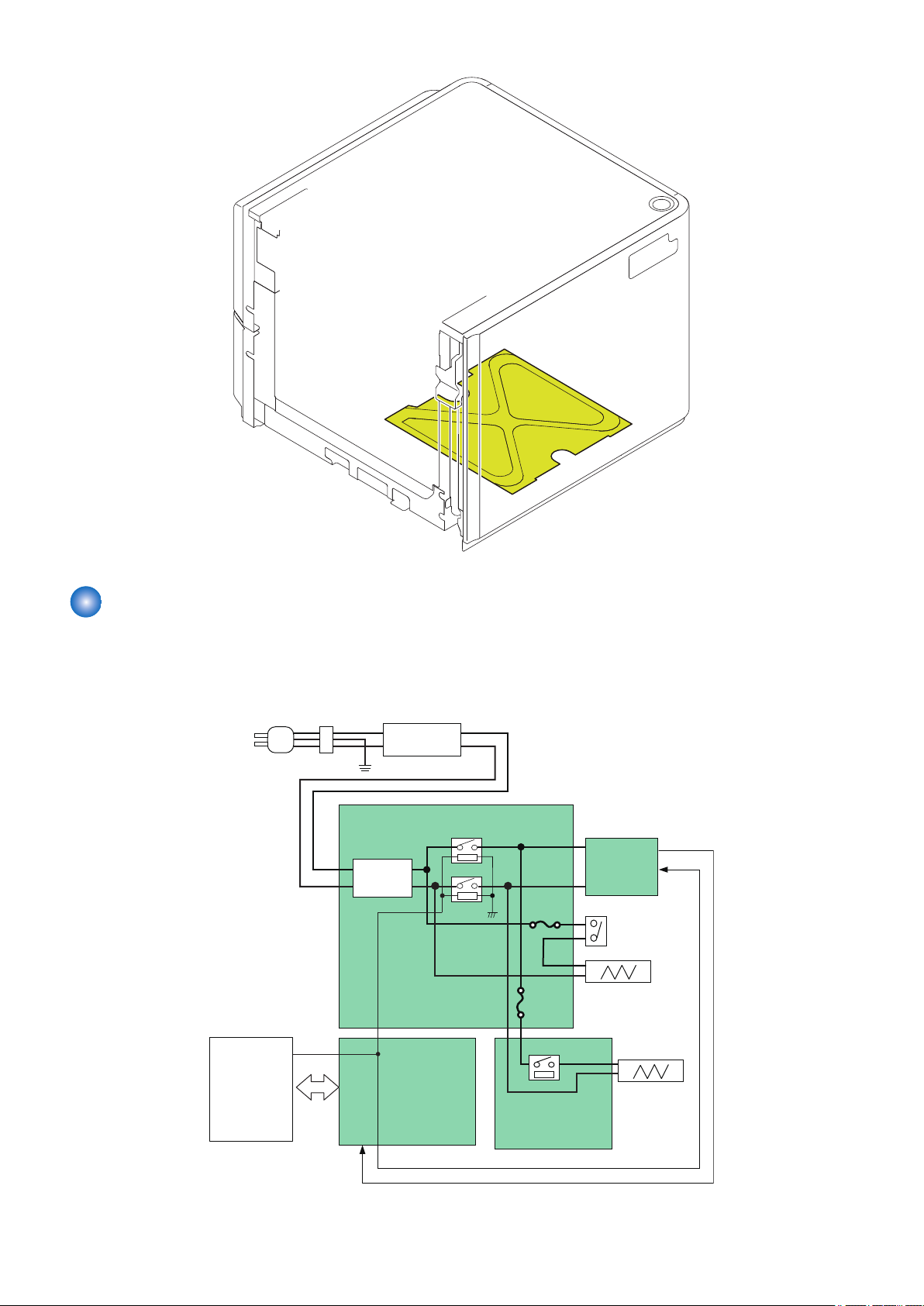

Overview of the Electrical Circuitry

The operating sequence for the Paper Deck Unit is controlled by the DC controller PCB in the host machine. The DC controller

PCB is equipped with CPU. The electric control for the Paper Deck Unit is controlled by the deck driver PCB. The deck driver

PCB is equipped with EEPROM.

NOTE:

The EEPROM stores the following adjustment value.

• ID for model discrimination

• Small size AD value/large size AD value (volume value of the free size detection PCB)

• Remaining paper level adjustment value (up/down movement distance of the lifter)

• Wind-power correction value of the warming/cooling fan

12

Host

machine

Deck driver

PCB(PCB1)

Box driver

PCB(PCB2)

Sensor

Motor

Switch

Motor

Sensor

Sensor

Switch

Fan

Solenoid

Fan

ASIC

Motor driver

DC/DC converter

Regulator

EEPROM

Swing driver

PCB(PCB6)

Motor driver

[2]

[4]

[3]

[1]

2. Technology

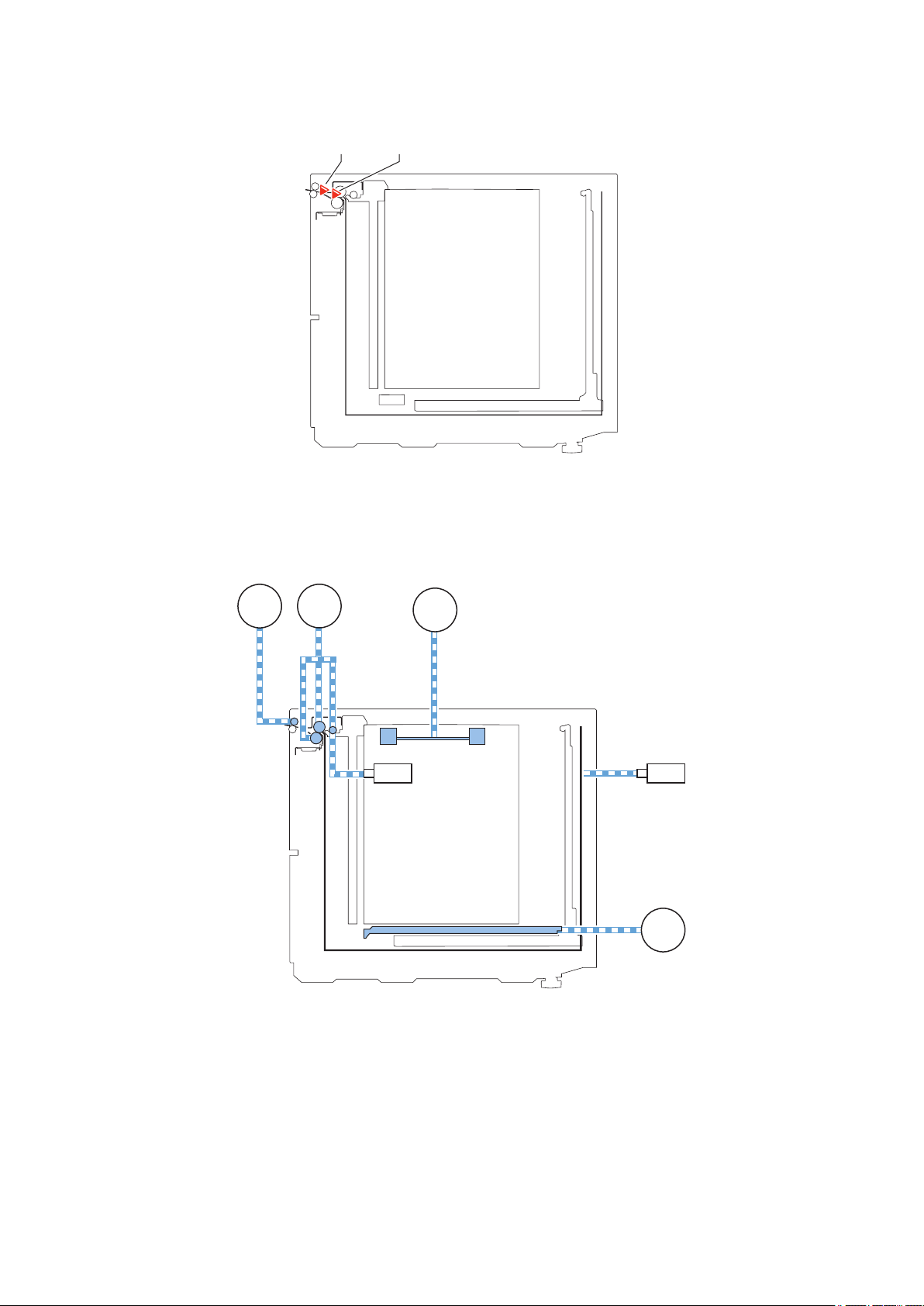

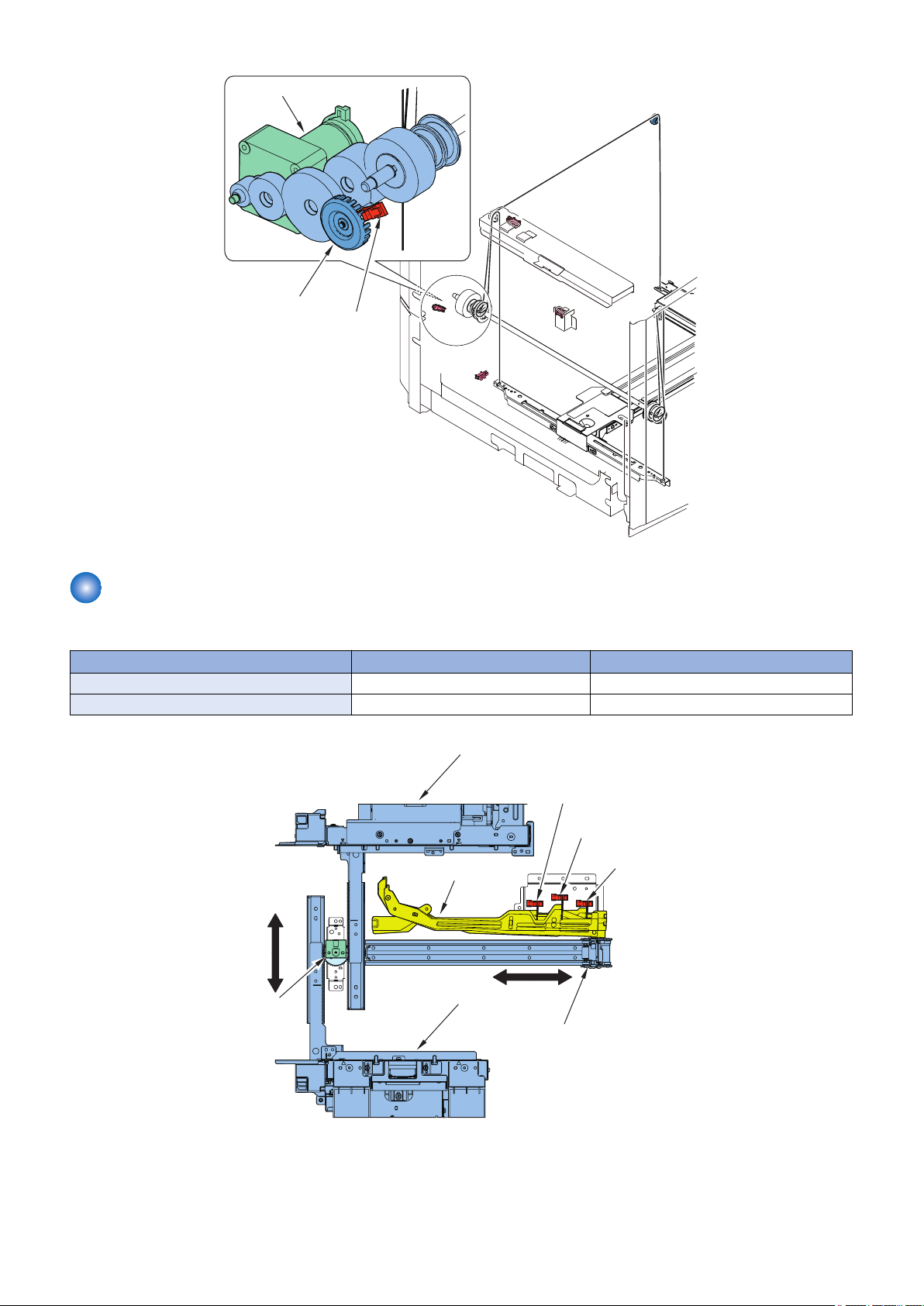

Component Configuration

■ Roller Layout

[1] Deck pull-out roller

[2] Deck separation roller

[3] Deck feed roller

[4] Deck pickup roller

13

■ Sensor Layout

SR6

SR7

M2

SL2

M1

M4

M3

SL1

Only the optical sensors on the feed path are shown below.

SR6 Deck pull-out sensor

SR7 Deck pickup sensor

2. Technology

■ Drive Configuration

M1 Deck pickup motor

M2 Deck pull-out motor

M3 Deck lifter motor

M4 Swing motor

SL1 Compartment open solenoid

SL2 Deck pickup release solenoid

14

M2

SL2

M1

Deck pull-out

roller

Deck separation roller

SR6

Deck feed roller

Deck pickup roller

2. Technology

Controls

Overview

Item Reference

1. Pickup/Feed System Pickup/feed control “Pickup/Feed Control” on page 15

Paper presence/absence detection control “Paper Presence/Absence Detection Control” on page

16

Paper surface detection control “Paper Surface Detection Control” on page 16

2. Compartment system Lifter control “Lifter Control” on page 17

Remaining paper level detection control “Remaining Paper Level Detection Control” on page 17

Switching the paper size “Switching the Paper Size” on page 18

Compartment open/close control “Compartment Open/Close Control” on page 19

Air assist control “Air Assist Control” on page 20

Swing operation “Swing Operation” on page 22

3. Deck control system Cassette heater control (option) “Cassette Heater Control (Option) ” on page 22

Power supply “Power Supply” on page 23

4. Others Fan control “Fan” on page 24

Jam detection “Jam Detection ” on page 24

Pickup/Feed Control

The paper deposited in the compartment is held up by the work of the lifter, and is kept to a specific level.When the start key on

the host machine is pressed, and the drive of the deck pickup motor (M1) starts to rotate the pickup roller to pick up paper. At

this time, the deck feed roller and the deck separation roller operate to make sure that only a single sheet of paper is picked up

and moved. When the deck pull-out sensor (SR6) detects paper at the time of heavy paper (151 g/m2 or more) and transparency

setting, the deck pickup release solenoid (SL2) goes on to move the deck pickup roller away from the stack of paper. The deck

pull-out roller starts to rotate when the deck pull-out motor (M2) goes on. After pickup, the paper is moved as far as the registration

roller of the host machine.

NOTE:

Service Mode

• Setting of Deck Pickup Roller eng/diseng

To set whether to disengage the Pickup Roller of the POD Deck Lite every time paper is picked up.

Lv2) COPIER > OPTION > FEED-SW > DK1-PSP

< Setting value >

0 to 1

• 0: Disengaged only for heavy paper (151 g/m2 or more) and transparency

• 1: Disengaged regardless of paper type

< Use case >

• When Pickup Roller trace occurs on the 2nd sheets and later

< Caution >

• If the machine is continued to be used while the setting value is 1, the life of the solenoid becomes shorter.

15

Deck paper

sensor(SR15)

<Paper presence>

Paper detecting lever

Paper

<Paper absence>

Lifter

Lifter

Paper level sensor (SR3)

Detection flag

Paper

Lifter

2. Technology

Paper Presence/Absence Detection Control

The presence/absence of paper inside the compartment is checked by the deck paper sensor (SR15) of the pickup assembly.

When the paper runs out and the paper detecting lever of the pickup assembly passed the deck paper sensor (SR15) as a result,

the host machine indicates the absence of paper on its control panel.

Paper Surface Detection Control

The paper level sensor (SR3) mounted at the pickup assembly is used to detect the paper surface. When the detection flag of

the pickup roller holder is pushed up by the top surface of paper with the upward movement of the lifter, the paper level sensor

(SR3) detects it and the lifter stops to keep the top surface of paper at the pickup position.

NOTE:

Service Mode

• Adjustment of paper surface height: Deck

Lv2) COPIER > ADJUST > FEED-ADJ > DK1-PKLV

To adjust the pickup position of the POD Deck Lite

+: Move up ( When a pickup failure occurs )

-: Move down ( When double feed occurs)

< Setting value >

-10 to -1: Move down by 1 mm, 0: 0 mm, 1: Move up by 1 mm, 2 to 10: Move up by 2 mm

< Use case >

When a pickup failure occurs, When double feed occurs

< Caution >

If the value is too large, double feed may occur. If the value is too small, a pickup failure may occur.

• Set paper surface level down: Deck standby

Lv2) COPIER > OPTION > FEED-SW > DK1-LDWN

To set whether to lower the paper surface level in the POD Deck Lite below pickup position during standby. When a trace which

looks like that the Pickup Roller had contact with a paper occurs, set 1. It returns to pickup position at the time of starting a job.

< Setting value >

0 to 1

0: Normal (Pickup Roller is in contact), 1: Paper surface level moves down

< Use case >

When Pickup Roller trace occurs on transparency paper.

< Caution >

When 1 is set, FCOT becomes longer.

16

SR13

SW4

SR9

SR2

SR3

SR4

SR5

SR8

M3

2. Technology

Lifter Control

■ Moving Up the Lifter

The lifter starts to move up when the compartment open/close switch (SW4) and the compartment open/close sensor (SR9)

detect that the compartment has been set in place.The lifter then stops when the paper level sensor (SR3) detects the top surface

of the stack of paper placed on the lifter.The deck lifter upper limit sensor 1/2 (SR4/5) is used to prevent damage otherwise caused

by the failure of the lifter to stop after the sensor lever blocks the paper level sensor (SR3).The machine is also equipped with a

protective mechanism by means of an obstacle sensor (SR8) used to prevent damage to the lifter cable and resin gears lest a

foreign object inside the compartment should hit the ceiling before the paper level sensor (SR3) detects the top surface of the

stack of paper.

■ Moving Down the Lifter

The lifter starts to move down when the compartment open switch is pushed until the lifter passes through the sensor lever of

the relay paper sensor (SR2). When paper is supplied in this condition, the lifter moves down to the position where the paper

passes through the sensor lever as the paper pushes the sensor lever. The lifter keeps moving down until the lifter passes through

the deck lifter lower position sensor (SR13) which detects maximum paper supply position each time when paper is supplied.

Remaining Paper Level Detection Control

The level of the paper remaining is detected by counting the pulses of the encoder for the lifter motor rotation sensor (SR14) that

represent the distance of movement of paper from the deck lifter lower position sensor (SR13) to the paper level sensor (SR3).The

encoder for the lifter motor rotation sensor (SR14) rotates in synchronization with the deck lifter motor (M3).When the relay paper

sensor (SR2) became OFF from ON during paper feed, the count value of the pulse is reset for the correction of the detection

error by the wire growth.The lifter position information is memorized in the EEPROM of the deck driver PCB. Therefore the lifter

position control is not performed after sleep again.The level of the paper remaining is indicated on the display on the host machine.

17

SR2

SR3

SR13

SR14

Encoder

Deck lifter motor (M3))

Lifter motor rotation

sensor(SR14)

Side guide plate (rear)

Side guide plate (front)

Rear guide plate

Paper width

detection PCB

(PCB7)

Paper size sensor 1(SR10)

Sensor flag

Paper size

sensor 2(SR11)

Paper size

sensor 3(SR12)

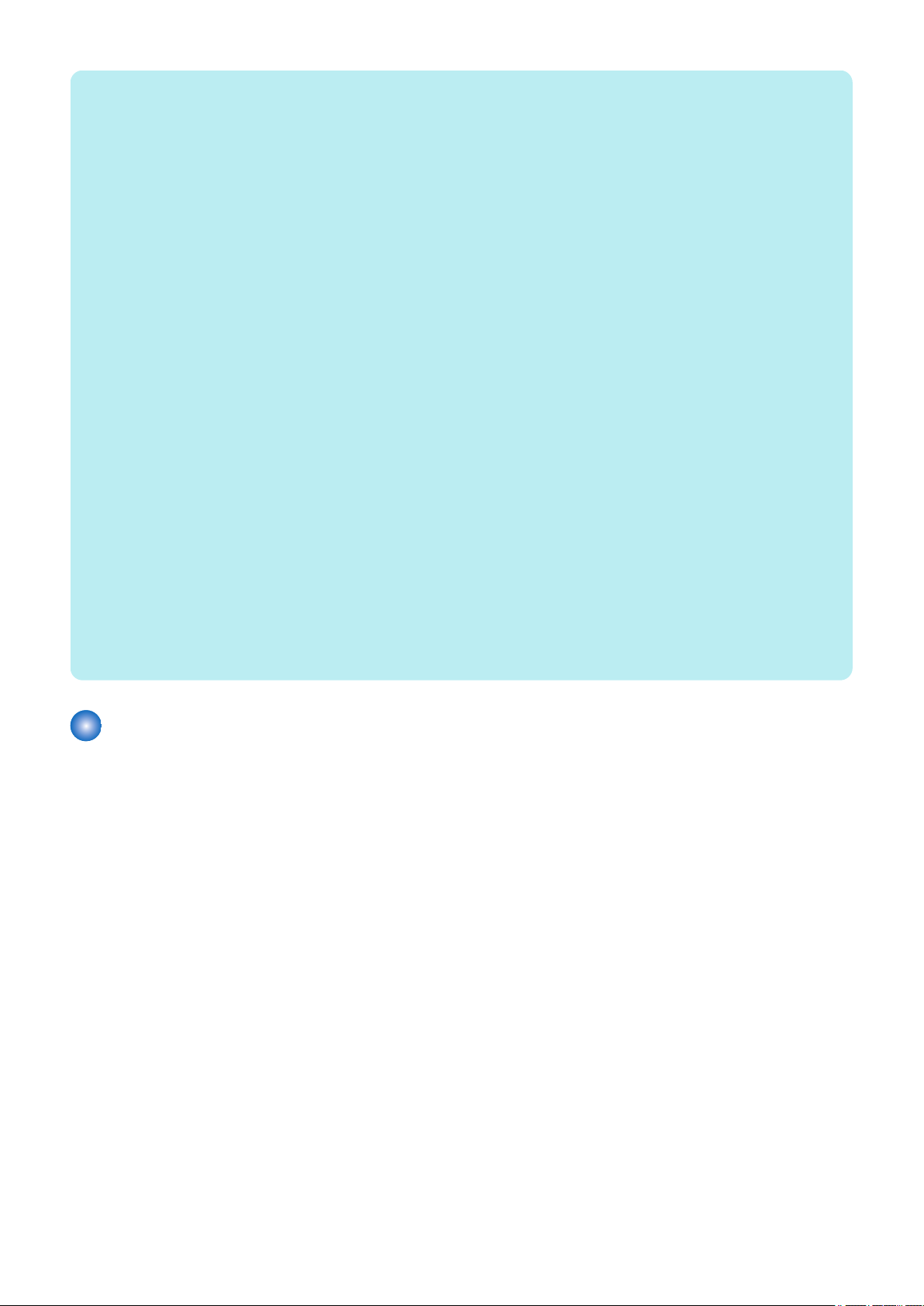

2. Technology

Switching the Paper Size

Paper size can be automatically detected by adjusting the position of the guide plate.

Paper size sensor 1/2/3 (SR10/11/12) Size for feed direction ON / OFF combination of sensors

Paper width detection PCB (PCB7) Size for width direction Volume

Sensor name Description Detection method

18

NOTE:

Service mode

• Adjsutment of POD Deck Lite A4 paper width

(Lv1) COPIER> ADJUST> CST-ADJ> PDK-A4

< Use case >

• When replacing the DC Controller PCB/clearing RAM data.

• When replacing the Paper Width Sensor PCB or registering a new value.

< Caution >

After the setting value is changed, write the changed value in the service label.

• Registration of POD Deck Lite A4 standard width

(Lv1) COPIER> FUNCTION> CST> PDK-A4

< Use case >

• When replacing the DC Controller PCB/clearing RAM data.

• When replacing the Paper Width Sensor PCB or registering a new value.

< Caution >

After execution, check the registered value by COPIER> ADJUST> CST-ADJ> PDK-A4, and write it down on the service

label.

• Adjsutment of POD Deck Lite A5R paper width

(Lv1) COPIER> ADJUST> CST-ADJ> PDK-A5R

< Use case >

• When replacing the DC Controller PCB/clearing RAM data.

• When replacing the Paper Width Sensor PCB or registering a new value.

< Caution >

After the setting value is changed, write the changed value in the service label.

2. Technology

• Registration of POD Deck Lite A5R standard width

(Lv1) COPIER> FUNCTION> CST> PDK-A5R

< Use case >

• When replacing the DC Controller PCB/clearing RAM data.

• When replacing the Paper Width Sensor PCB or registering a new value.

< Caution >

After execution, check the registered value by COPIER> ADJUST> CST-ADJ> PDK-A5R, and write it down on the service

label.

Compartment Open/Close Control

When the compartment open switch is pushed, the deck lifter motor (M3) starts to rotate to cause the lifter to move down. When

1 sec passes thereafter, the compartment open solenoid (SL1) goes on to release the lock of the compartment. When the lock

is released, the force of the spring causes the compartment to move forward by several centimeters.When the relay paper sensor

(SR2) or the deck lifter lower position sensor (SR13) goes on in response, the lifter stops to move down.The lock of the

compartment is released a moment later to prevent the paper from becoming trapped by a guide or the like, possibly occurring

if the compartment was let to open before the paper has dropped.When the compartment open/close switch (SW4) and the

compartment open/close sensor (SR9) go on by pushing the compartment with hands to set it in the equipment to close the

compartment, the lifter moves up to the pickup position.The compartment open indicator (LED100) on the open switch PCB

flashes while the compartment is being opened/closed, and remains on as long as the compartment remains open.

19

SW5

Spring

Compartment open/close arm

Compartment open solenoid(SL1)

Compartment open/close sensor(SR9)

Compartment open/close

detection switch(SW4)

Fan safety switch(SW5)

2. Technology

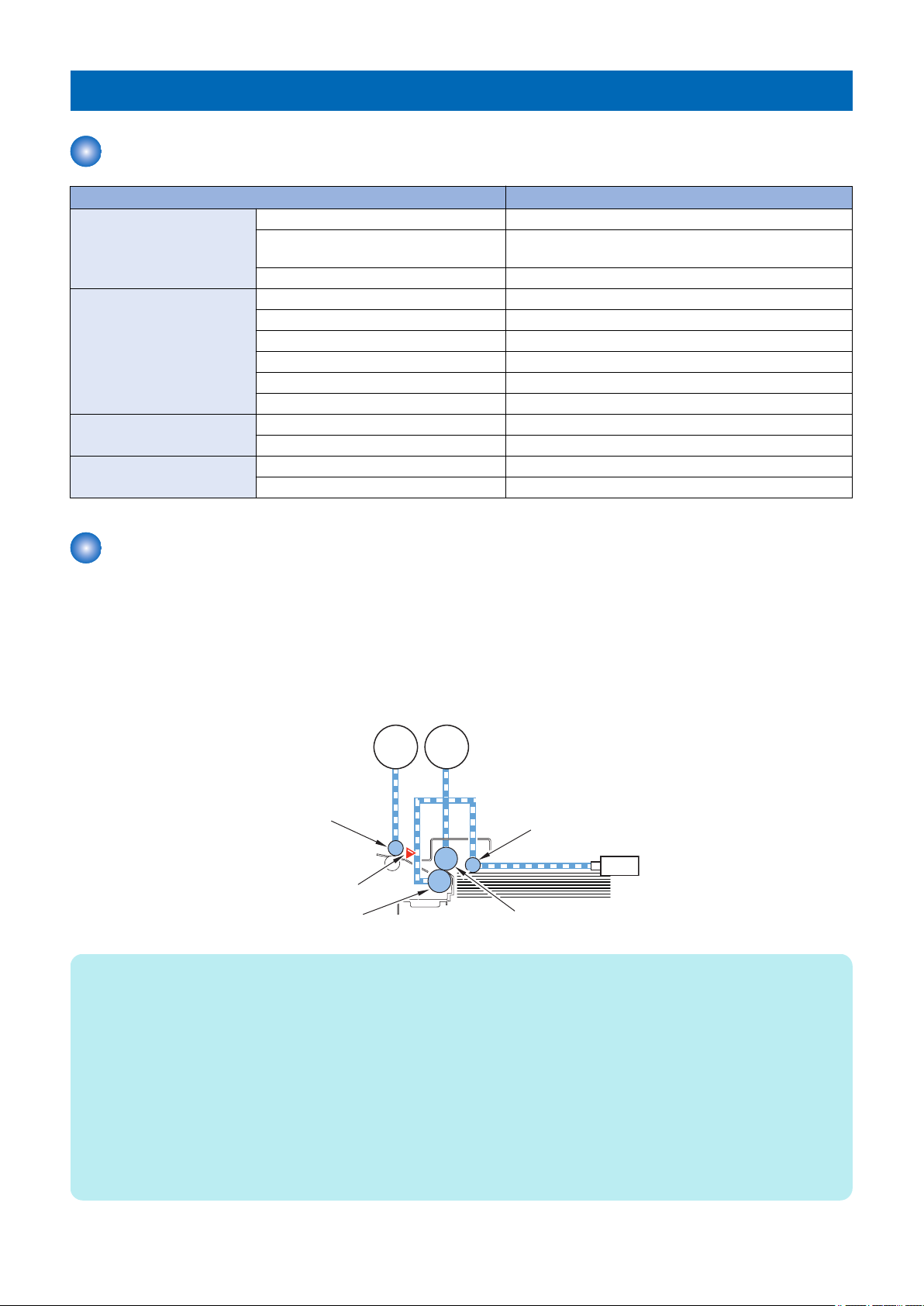

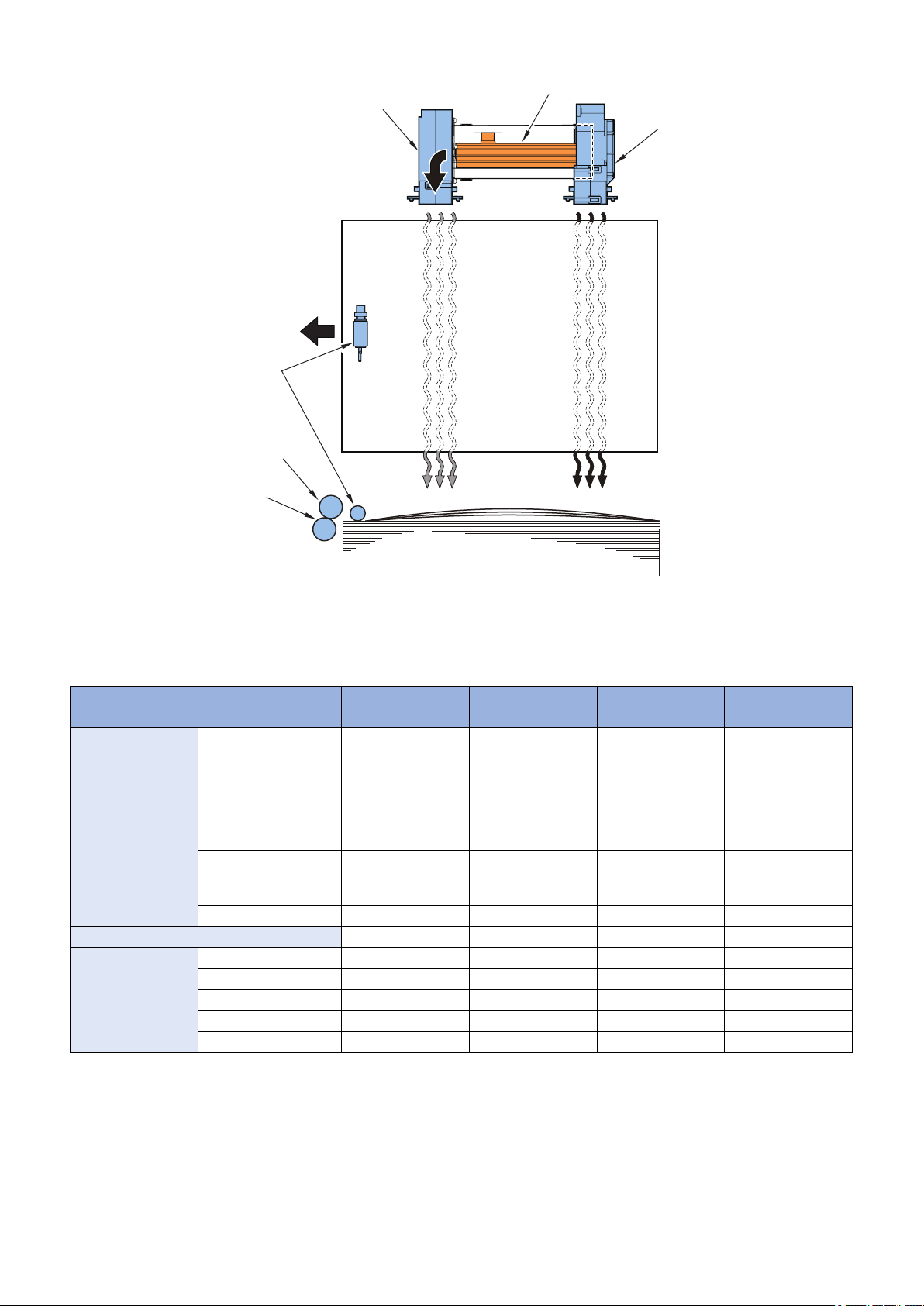

Air Assist Control

■ Overview

To facilitate separation of paper, the machine executes air assist control.

The fans (FM2, FM3) are combined to blow air against the paper so that the paper is shifted slightly to lose attraction, ultimately

preventing double-feeding.

To facilitate separation of paper in the high humidity environment, an air heater unit (H2) is equipped as standard.

A warming fan (FM2) with an air heater blows hot wind against paper to reduce the humidity, thus facilitating separation of paper.

20

Cool airWarm air

Pickup direction

Paper

Pickup roller

Feed roller

Separation rolle

Warming fan(FM2)

Air heater(H2)

Cooling fan(FM3)

2. Technology

■ Air Assist Control

The air assist control mechanism is turned on by the DC controller PCB of the host machine and by way of the deck driver PCB.

The air assist mechanism consists of the following control items:

Paper type*3 Warming fan

(FM2)

Non coated paper Thin paper (52 to 79 g/

m2), Plain paper (80 to

105 g/m2), Heavy paper (106 to 150 g/ m2),

Pre-punched paper,

Coated paper ON*1 ON*1 ON*2 ON

Special paper Transparency ON ON OFF ON

Bond paper, Vellum paper

Heavy paper (151 to

300 g/m2), Letterhead,

Textured paper

Recycled paper ON ON OFF ON

Textured paper ON ON OFF ON

Label paper ON ON OFF ON

Postcard OFF OFF OFF ON

Envelope OFF OFF OFF OFF

OFF OFF OFF OFF

ON*1 ON*1 OFF ON

*1: Switches the wind-power of fan according to the detected temperature and humidity of the environment sensor (SR18).

*2: Switches the ON/OFF and wind-power of fan according to the detected temperature and humidity of the environment sensor

(SR18).

*3: Different depending on the host machine.

Cooling fan (FM3) Air heater (H2) Swing motor (M4)

21

Swing motor(M4)

Swing HP sensor(SR16)

Shutter

2. Technology

NOTE:

Service Mode

• ON/OFF of POD Deck Lite air assist

(Lv.2) COPIER > OPTION > FEED-SW > DK1-AIR

• Deck Air Float Fan airflow amnt: dwstm

(Lv.2) COPIER > OPTION > FEED-SW > DK1-ALVD

• Deck Air Float Fan airflow amnt: upstream

(Lv.2) COPIER > OPTION > FEED-SW > DK1-ALVU

To adjust the airflow amount of the Air Floatation Fan of the POD Deck Lite.

When making an adjustment, be sure to adjust the setting of DK1-ALVD and DK1- ALVU at the same time.

<Setting value >

-10 to 10 [default: 0]

<Use case >

When double-feed occurs

<Caution >

If the value is large, uneven transfer may occur. If the value is small, double feed may occur.

■ Swing Operation

This equipment combines the air blowing operation against paper with the swing operation of the shutter to improve separation

of paper. The swing motor (M4) drives the shutter to move up and down.

The direction of air blow against paper changes up or down repeatedly, vibrating the paper for easier separation.

The swing HP sensor (SR16) detects a failure of up and down operation of the shutter and the home position of the shutter.

Paper type: Different depending on the host machine.“Air Assist Control” on page 21

Cassette Heater Control (Option)

To facilitate separation of paper in a high humidity environment, a cassette heater unit is available optionally. When the cassette

heater (H1) is powered, the temperature in the deck becomes suitable and thereby the humidity lowers, facilitating separation of

paper. When the cassette heater switch mounted at the rear of this equipment is set at OFF, the cassette heater (H1) is not

powered. When the cassette heater switch is set to ON, the cassette heater is continuously powered.

22

H1

Deck driver

PCB (PCB1)

Air heater driver

PCB (PCB5)

Inlet

Leakage breaker

ELCB1

AC relay PCB (PCB4)

DC power

supply PCB

(UN1)

RL1

RL2

Cassette heater

switch(SW2)

Cassette heater(H1)

Air heater

(H2)

RL3

Remote signal

Host machine

24䠲

Noise

filter

2. Technology

Power Supply

The machine's AC power is supplied by an external power outlet, and it is sent through a leakage breaker (ELCB1) to reach the

AC relay PCB.The machine's DC power supply is sent to the individual loads from the DC power supply PCB through the deck

driver PCB (or directly).

23

Fan

FM3

FM1

FM2

FM4

■ Location of Fans

2. Technology

■ Function of Fans

No. Name Function

FM1 Power supply cooling fan Cool the DC power supply PCB

FM2 Warming fan Improve separating performance of the paper

FM3 Cooling fan Improve separating performance of the paper

FM4 Pickup release solenoid cooling fan Cool the deck pickup release solenoid (SL2)

Jam Detection

The machine uses the following 2 sensors to make sure that paper moves smoothly inside it.The presence/absence of a jam is

checked using the signals coming from the host machine at such times as programmed in the host machine. When the host

machine detects a jam, the machine discharges all paper that has been picked up before the jam paper, and then stops the

operation. The host machine offers instructions on how to remove jams on its control panel display.

24

Loading...

Loading...