Canon NP6621 Service Handbook

SERVICE

HANDBOOK

REVISION 0

FEB. 1998

COPYRIGHT © 1998 CANON INC. CANON NP6621 REV.0 FEB. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-23AT-000

IMPORTANT

THE INFORMATION CONTAINED HEREIN IS PUBLISHED BY CANON, INC., JAPAN, AND IS

FOR REFERENCE USE ONLY. SPECIFICATIONS AND OTHER INFORMATION CONTAINED

HEREIN MAY VARY SLIGHTLY FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN

ADVERTISING AND OTHER PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

COPYRIGHT © 1998 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be

strictly supervised to avoid

disclosure of confidential

information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPARTMENT 1

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride-shi Ibaraki, 302-0023 Japan

COPYRIGHT © 1998 CANON INC. CANON NP6621 REV.0 FEB. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

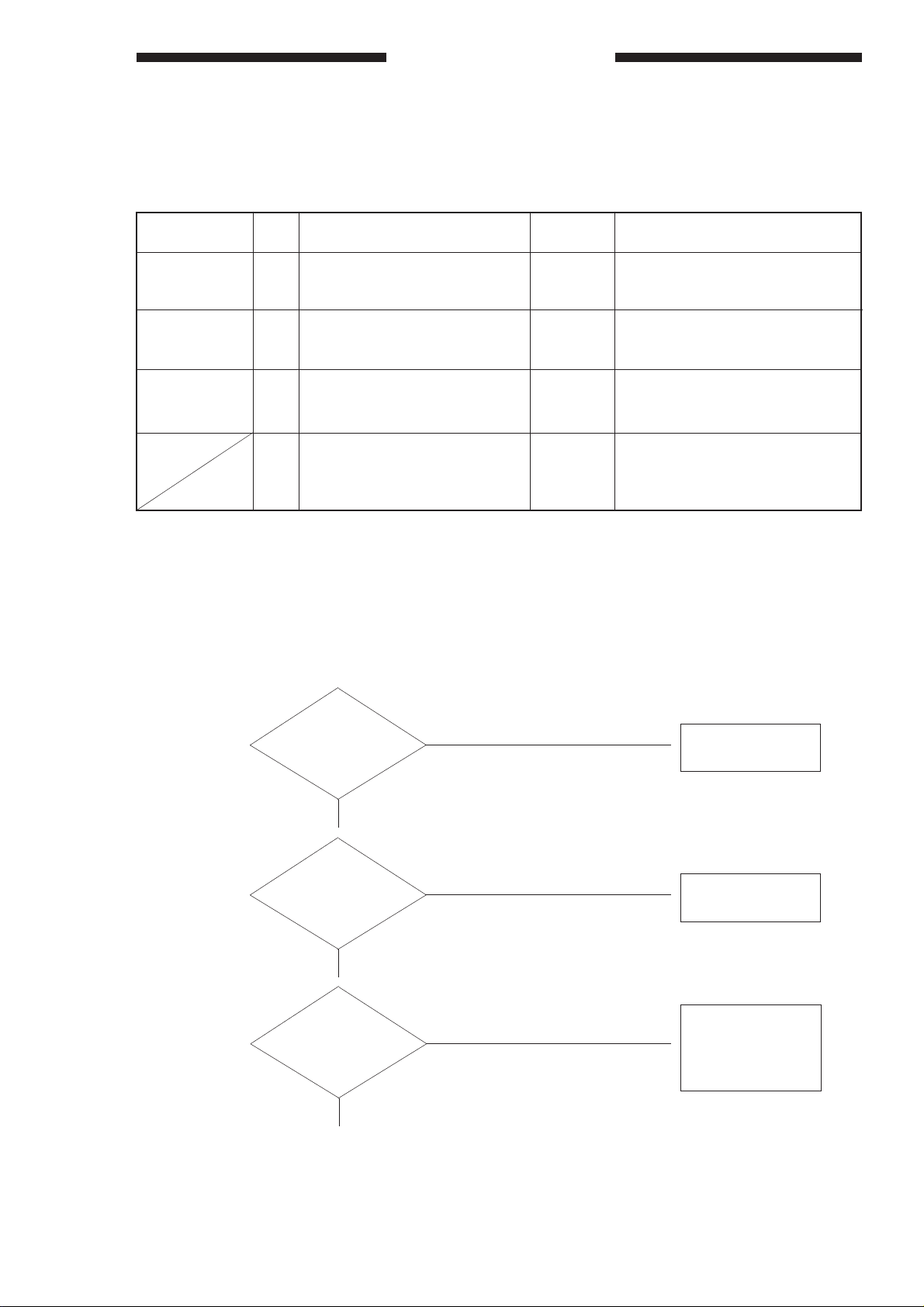

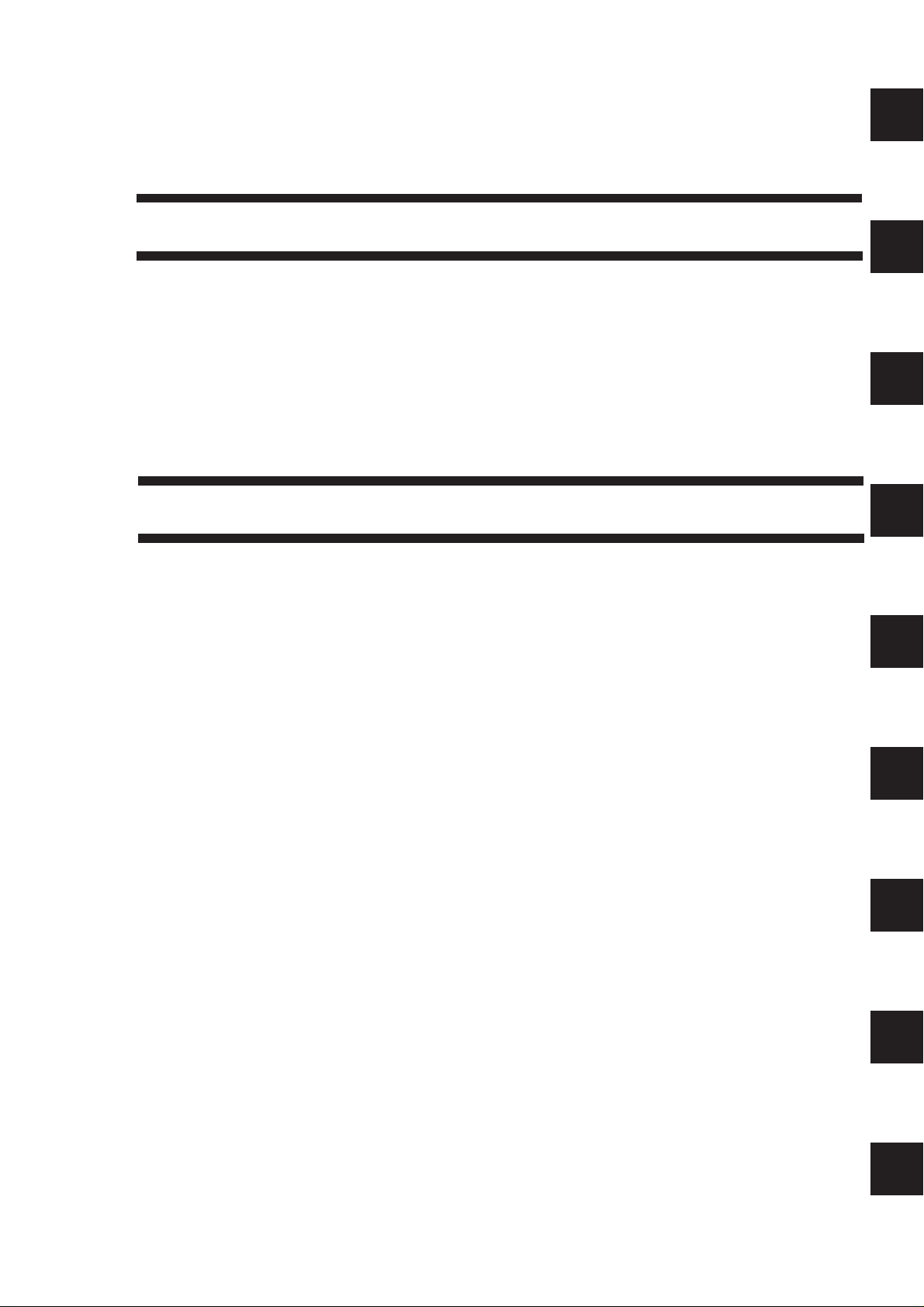

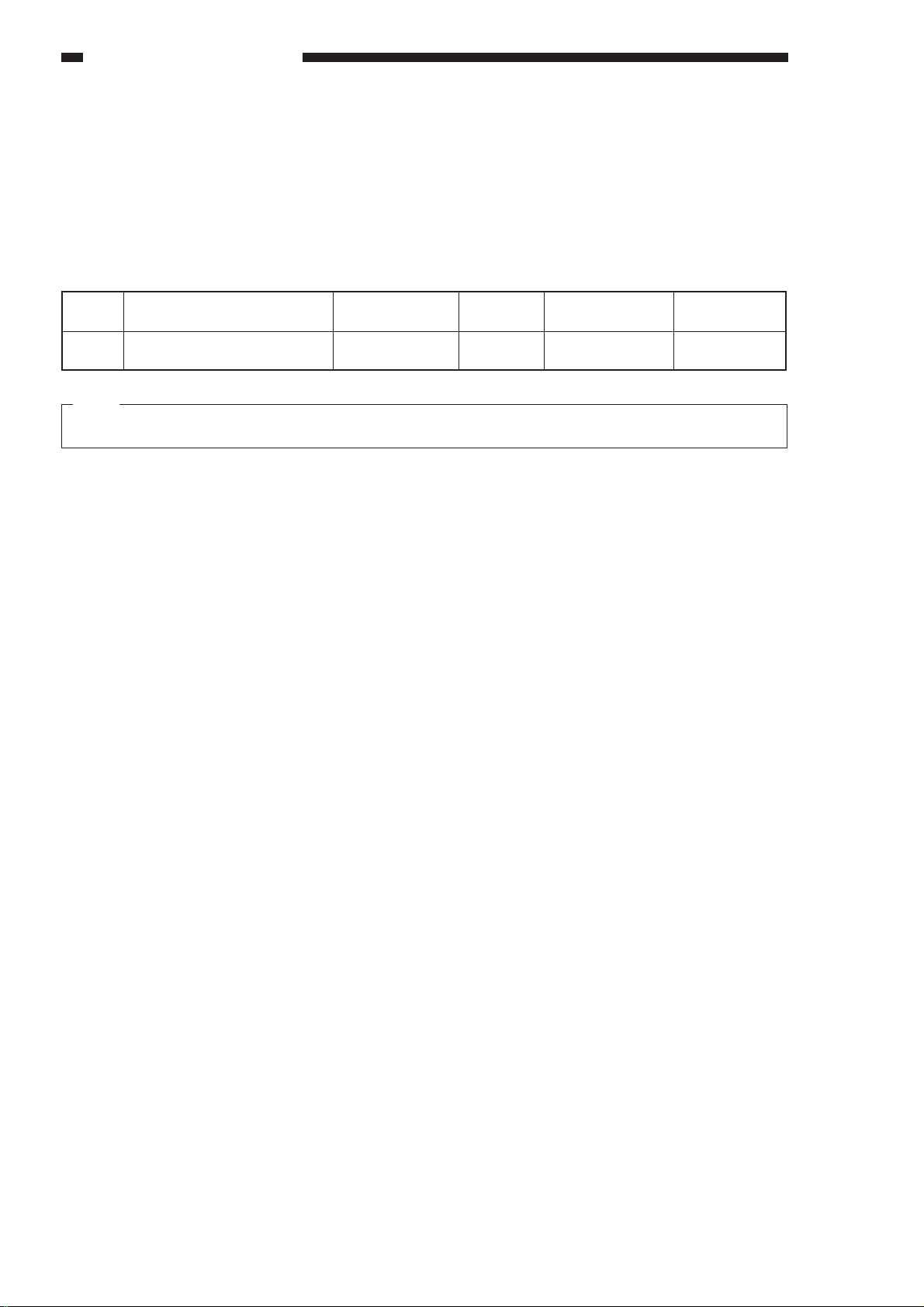

Guide To Tables

In this Handbook, work procedures are given in the form of tables instead of flow charts used generally.

Familiarize yourself by studying the example below.

EX. AC power is absent.

Cause

Power plug

Step

1

Checks

Is the power plug connected to

Yes/No

NO

Connect the power plug.

Remedy

the power outlet?

Covers

2

Are the front door and delivery

NO

Close the door or the cover.

cover closed properly?

Power source

3

Is the rated voltage present at

the power outlet?

4

Is the rated voltage present

NO

YES

The problem is not of the copier.

Advise the customer as such.

Go to step 6.

between J1-1 and -2 (near

cord plate)?

■ To find out the cause (problem part) of a single problem, refer to the item under “Cause.” For “AC power

is absent,” the cause may be the power plug, covers, power source, or others.

■ To find out the checks to make or remedies to provide for a single problem, refer to the “Checks” and

“Remedy”; make checks, answer to the questions YES or NO, and provide remedies accordingly. If the

answer is otherwise, proceed to the next step.

<Step>

<Checks>

<Yes/No>

<Remedy>

Is the power plug

1

2

3

connected to the

power outlet?

YES

▼

Are the front door

and delivery cover

closed properly?

YES

▼

Is the rated voltage

present at the power

outlet?

YES

▼

NO

NO

NO

Connect the power

▼

plug.

Close the door or

▼

the cover.

The problem is not

of the copier. Advise

▼

the customer as

such.

■ Checks on the voltage using a meter call for special note; the description “Check the voltage between

J109-1 (+) and J109-2 (–) on the DC controller PCB” means that the positive probe of the meter should

be placed on J109-1 (+) and the negative probe, on J109-2 (–).

i

ii

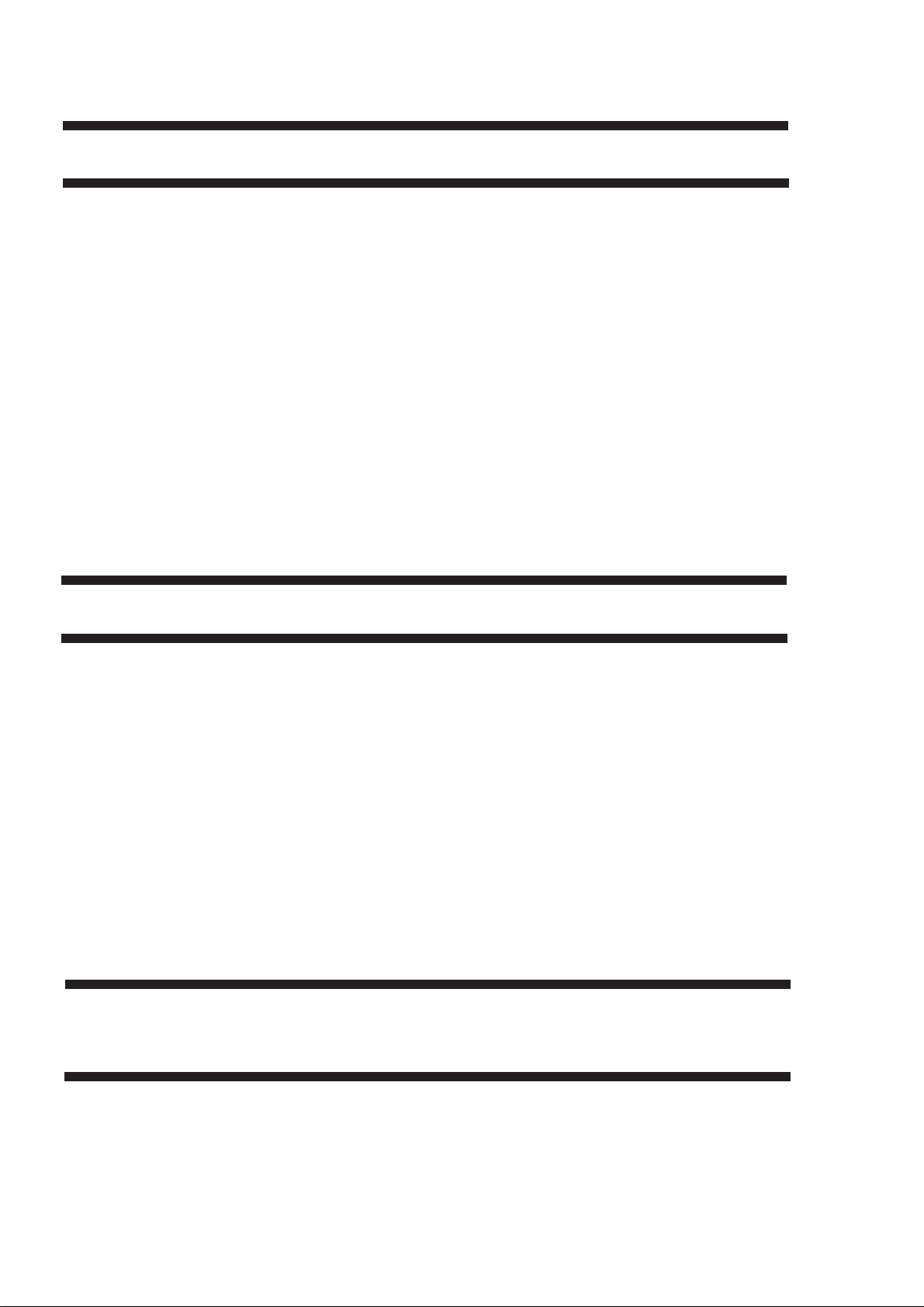

CONTENTS

CHAPTER 1 MAINTENANCE AND INSPECTION

1

2

I. SERVICING CHART .................................1-1

II. PERIODICALLY REPLACED PARTS....... 1-2

A. Periodically Replaced Parts ................1-2

III. DURABLES ...............................................1-3

A. Copier ..................................................1-3

B. Cassette Feeding Module-B2/

Cassette Feeding Module-A2/

Cassette Feeding Unit-K1 ...................1-4

C. Paper Deck Pedestal-K1.....................1-4

IV. MAINTENANCE AND INSPECTION ........1-5

A. Image Adjustment Procedure..............1-5

B. Points to Note for Servicing Work .......1-6

CHAPTER 2 STANDARDS AND ADJUSTMENTS

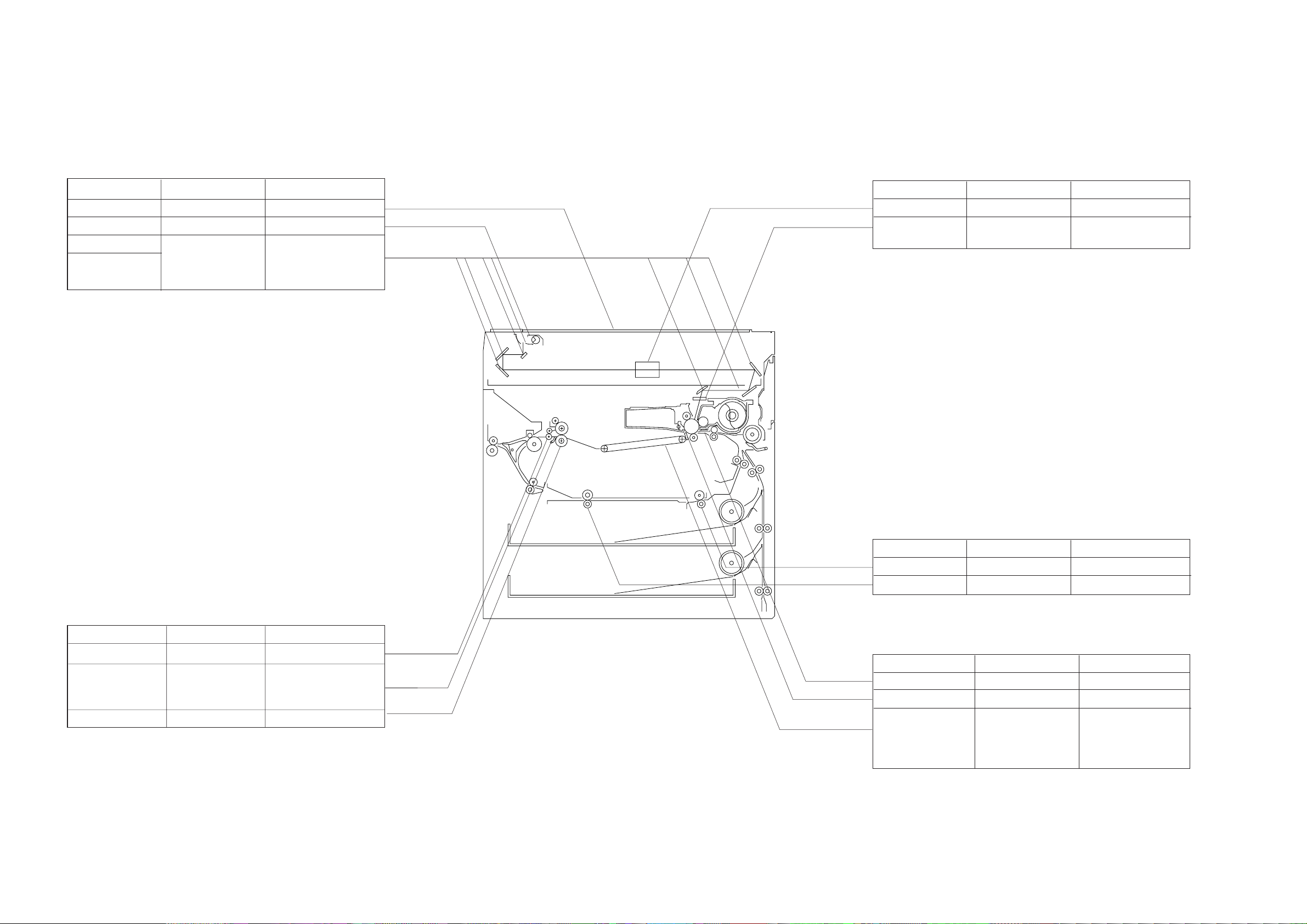

A. Mechanical................................................. 2-1

1. Adjusting the Image Leading

Edge Margin ([3], No.305;

registration ON timing).........................2-1

2. Adjusting the Leading Edge

Non-Image Width ([3], No.306;

blank shutter ON timing)...................... 2-1

3. Adjusting the Image Trailing

Edge Non-Image Width ([3], No.309;

blanking shutter timing) .......................2-2

4. Adjusting the Left/Right

Registration ......................................... 2-2

5. Adjusting the Left/Right Margin

(No.311 left/right margin

adjustment)..........................................2-3

6. Routing the Scanner Drive Cable........2-4

7. Adjusting the Mirror Position

(optical length between No.1mirror

and No.2/3 mirror) ...............................2-5

8. Adjusting the Scanner Cable

Tension................................................2-5

9. Orienting the Pick-Up Roller................2-5

10. Orienting the Multifeeder

Pick-Up Roller......................................2-6

11. Positioning the Multifeeder Assembly

Paper Guide Plate Cam ......................2-6

12. Positioning the Blanking

Shutter Solenoid .................................. 2-7

13. Positioning the Change Solenoid ........2-7

14. Routing the Blanking Shutter Cable ....2-8

15. Adjusting the Lower Fixing Roller

Nip ....................................................... 2-8

16. Points to Note After Replacing

the Upper Fixing Unit...........................2-9

17. Mounting the Oil Application Solenoid ..2-9

18. Routing the Drive Belt .......................2-10

19. Positioning the Primary Charging

Roller Cleaning Solenoid...................2-11

20. After Replacing the Drum Unit...........2-12

21. Installing the Drum Heater.................2-12

22. Assembling the Mirror Positioning

Tool....................................................2-13

23. Positioning the Paper Deflecting

Plate Solenoid (SL8) ......................... 2-13

24. Setting the Deck Size ........................ 2-13

25. Adjusting the Deck Registration ........2-14

B. Electrical .................................................. 2-15

1. Adjustment after Replacing PCBs.....2-15

2. Adjusting the Scanning Lamp

Intensity ............................................. 2-15

3. AE Adjustment...................................2-15

4. Multifeeder Paper Width Sensor

Adjustment.........................................2-19

5. Setting the Paper Size for the

Universal Cassette ............................2-20

6. Initializing the Back-Up RAM.............2-21

7. Checking the Photointerrupters.........2-21

3

4

5

6

7

8

iii

CHAPTER 3 IMAGE FAULTS

A. Initial Checks .............................................3-1

B. Samples of Image Faults...........................3-4

C.

Troubleshooting Image Faults ......................

1. The copy is too light (half-tone

areas only)...........................................3-5

2. The copy is too light (including

solid black)........................................... 3-6

3. The copy is too light (overall,

extremely)............................................3-6

4. The copy has uneven density

(darker at front)....................................3-7

5. The copy has uneven density

(lighter at front). ................................... 3-7

6. The copy is foggy (overall). ................. 3-8

7. The copy has vertical fogging.............. 3-9

8. The copy has black lines

(vertical, fuzzy, thick). .......................... 3-9

9. The copy has black lines

(vertical, fine). ....................................3-10

3-5

10. The copy has white spots (vertical). ..3-11

11. The copy has white lines (vertical). ...3-11

12. The copy has white spots

(horizontal)......................................... 3-12

13. The back of the copy is soiled. .......... 3-13

14. The copy has a fixing fault.................3-14

15. The leading edge of the copy

is displaced........................................3-15

16. The leading edge of the copy

is displaced........................................3-15

17. The leading edge of the copy

is displaced........................................3-15

18. The copy has blurred images. ...........3-16

19. The copy has horizontal fogging. ......3-16

20. The copy has poor sharpness. ..........3-17

21. The copy is blank...............................3-18

22. The copy is solid black. ..................... 3-18

CHAPTER 4 TROUBLESHOOTING MALFUNCTIONS

1. E000 .......................................................... 4-1

2. E001 .......................................................... 4-2

3. E002, E003 ................................................ 4-2

4. E004 .......................................................... 4-3

5. E010 .......................................................... 4-4

6. E064 .......................................................... 4-5

7. E202 (The keys on the control panel are

locked.) ...................................................... 4-5

8. E210 .......................................................... 4-6

9. E220 .......................................................... 4-6

10. E240 ..........................................................4-6

11. E260 ..........................................................4-7

12. E261 ..........................................................4-7

13. E710, E711, E712, E717 ........................... 4-8

14. E802 ..........................................................4-8

15. AC power is absent. ..................................4-9

16. DC power is absent. ................................ 4-10

17. The blanking shutter fails to operate. ......4-10

18. The photosensitive drum fails to rorate. .. 4-11

19. Pick-up operation fails (from cassette). ...4-11

20. Pick-up operation fails (multifeeder). .......4-12

21. The scanner fails to move forward/

in reverse. ................................................4-12

22. The registration roller fails to operate. ..... 4-13

23. The scanning lamp fails to turn ON. ........4-13

24. The lens fails to move. ............................. 4-14

25. The fixing heater fails to operate. ............4-14

26. The pre-exposure lamp fails to turn ON. . 4-15

27. The ADD PAPER message fails to turn

OFF.......................................................... 4-15

28. The JAM message fails to turn OFF........4-15

CHAPTER 5 TROUBLESHOOTING FEEDING

FAULTS

A. Copy Paper Jams ......................................5-1

1. Pick-Up Assembly ............................... 5-2

2. Separation/Feeding Assembly ............5-3

3. Fixing/Delivery Assembly .................... 5-3

4. Duplexing Unit (during stacking

operation) ............................................ 5-4

5. Duplexing Unit (during re-pick

up operation) ....................................... 5-4

iv

B. Feeding Faults............................................5-5

1. Double Feeding ...................................5-5

2. Wrinkles...............................................5-5

C. Paper Deck................................................5-6

1. Pick-up fails (from deck). ..................... 5-6

2. Paper jams when pick-up is from the

paper deck...........................................5-7

3. Double feeding (paper deck). ..............5-8

4. Wrinkling (paper deck).........................5-8

5. The ‘ADD PAPER’ message fails to

turn off (paper deck). ...........................5-9

6. The lifter fails to rise (paper deck). ....5-10

CHAPTER 6 ARRANGEMENT AND FUNCTIONS OF

THE ELECTRICAL PARTS

A. Sensors...................................................... 6-2

B. Clutches, Solenoids,

and Switches .............................................6-4

C. Motors, Heaters, and Lamps ..................... 6-6

D. PCBs..........................................................6-8

CHAPTER 7 SERVICE MODE

A. Outline ....................................................... 7-1

B. Using Service Mode .................................. 7-1

C. Control Display Mode (‘1’) .........................7-3

D. I/O Mode (‘2’).............................................7-6

CHAPTER 8 SELF DIAGNOSIS

A. Copier Self Diagnosis ................................8-1

B. Self Diagnosis on the Cassette Feeding

Unit ............................................................ 8-4

E. Cassette Feeding Module-A2 .................. 6-10

F. Cassette Feeding Unit-K1 .......................6-12

G. Paper Deck Pedestal-K1 .........................6-14

H. Variable Resistors (VR) and

Check Pins by PCB. ................................ 6-16

E. Adjustment Mode (‘3’).............................. 7-10

F. Operation/Inspection Mode (‘4’) ..............7-13

G. Machine Settings Mode (‘5’) ....................7-14

H. Counter Mode (‘6’)................................... 7-16

C. RDF/ADF Self Diagnosis...........................8-5

D. Sorter Self Diagnosis................................. 8-6

APPENDIX

A. GENERAL TIMING CHART ..................... A-1

B. SIGNALS AND ABBREVIATIONS ........... A-2

C. GENERAL CIRCUIT DIAGRAM............... A-5

D. SPECIFICATIONS .................................... A-7

I. Copier.................................................. A-7

II. Cassette Feeding Module-B2/

Cassette Feeding Module-A2/

Cassette Feeding Unit-K1 ................ A-11

III. Paper Deck Pedestal-K1 .................. A-11

E. SPECIAL TOOLS ................................... A-12

F. SOLVENTS/OILS ................................... A-13

v

vi

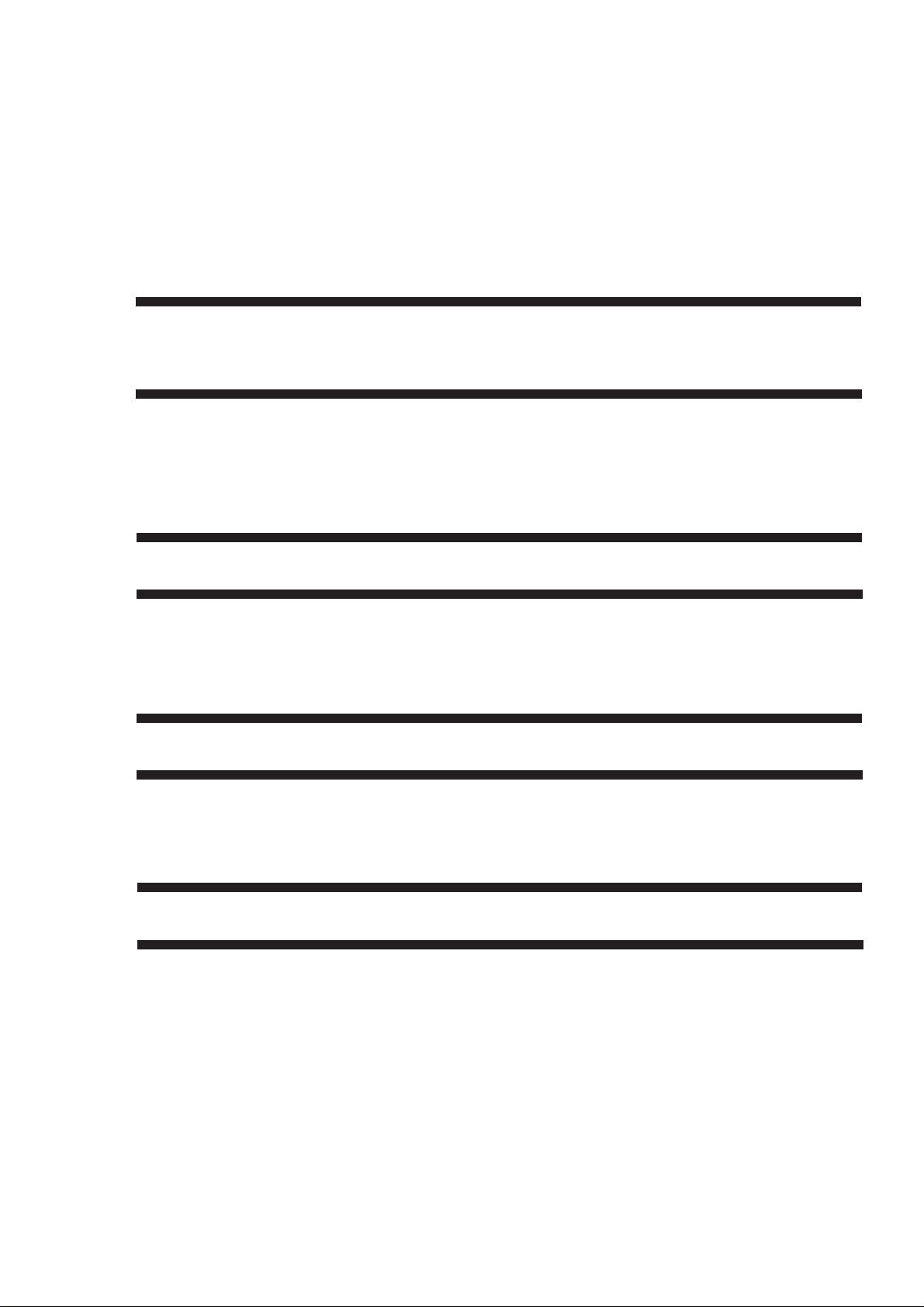

MAINTENANCE AND INSPECTION

CHAPTER 1 MAINTENANCE AND INSPECTION

I. SERVICING CHART

Caution:

Do not use solvents or oils other than those specified.

: clean : replace ✩ : lubricate : adjust : inspect or clean

Unit

External

Pick-up

assembly

Scanner drive

assembly

Feeding

assembly

Parts

Copyboard glass

Pick-up roller

Scanner rail

Transfer guide assembly

Feeding belt

Feeding assembly mount

every

20,000

every

60,000

✩

every

100,000

every

year

Remarks

Use alcohol.

Use alcohol solution;

then, apply lubricant.

Use a moist cloth.

1

Optical

assembly

Drum kit

Charging

assembly

Developing

assembly

Fixing

assembly

Reflecting plate for original exposure

Side reflecting plate for

original exposure

No. 1 through No. 6 mirrors

Lens

Dust-proofing glass

Clearner base

Drum support shaft

Charging roller

Charging roller cleaner

Static eliminator

Developing spacer

Upper fixing roller

Lower fixing roller

Separation claw (lower, upper)

Fixing inlet guide

Use a blower brush; if

the soiling is excessive,

use alcohol.

Actual use of the drum

kit.

Use a cotton wad.

Use cleaning oil.

Use solvent.

Delivery

assembly

Duplexing

Delivery guide/ tray

Fixing feeding spacer

Delivery spacer

Set-back roller

Re-pick-up roller

Use alcohol.

Use alcohol.

1–1

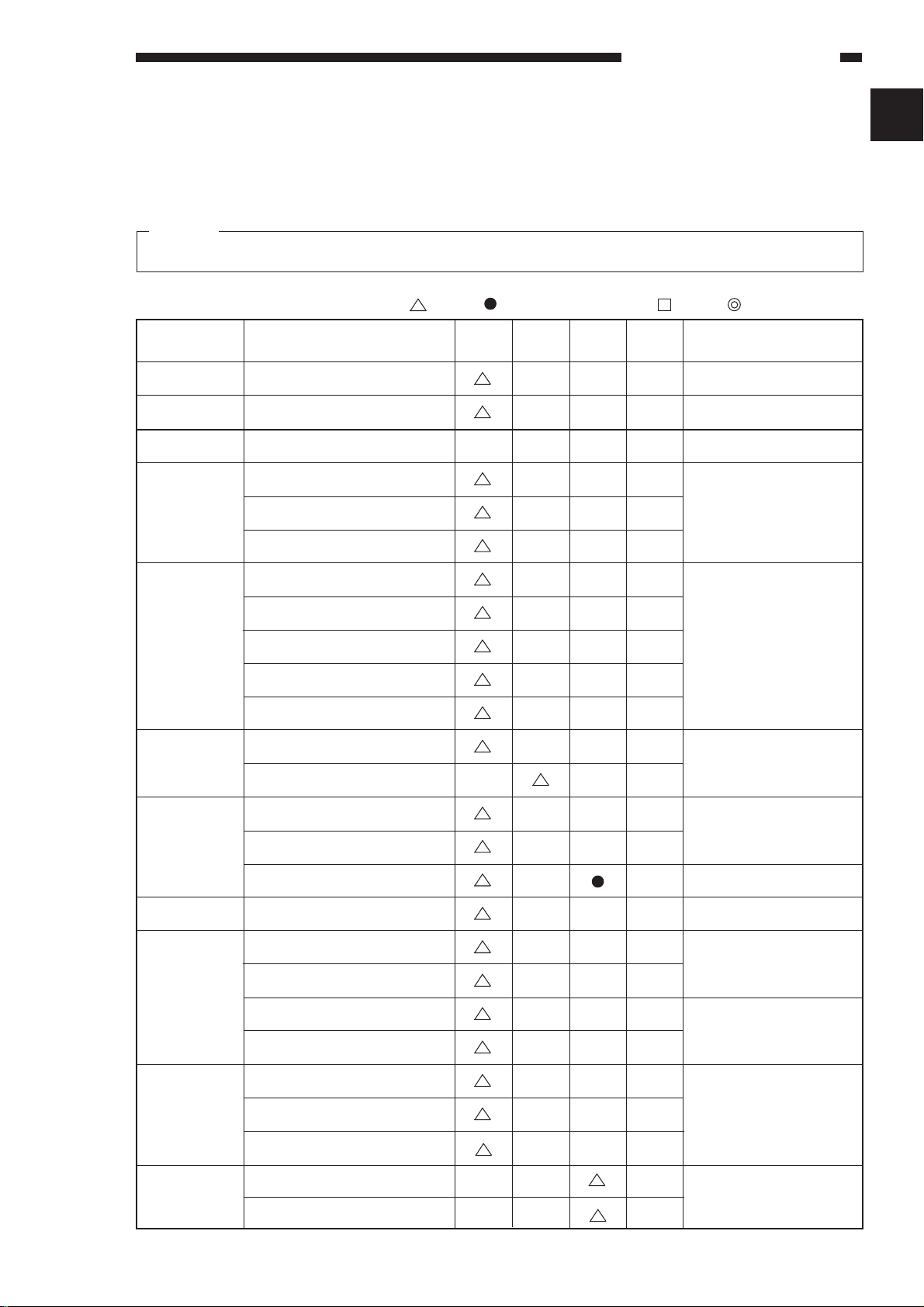

MAINTENANCE AND INSPECTION

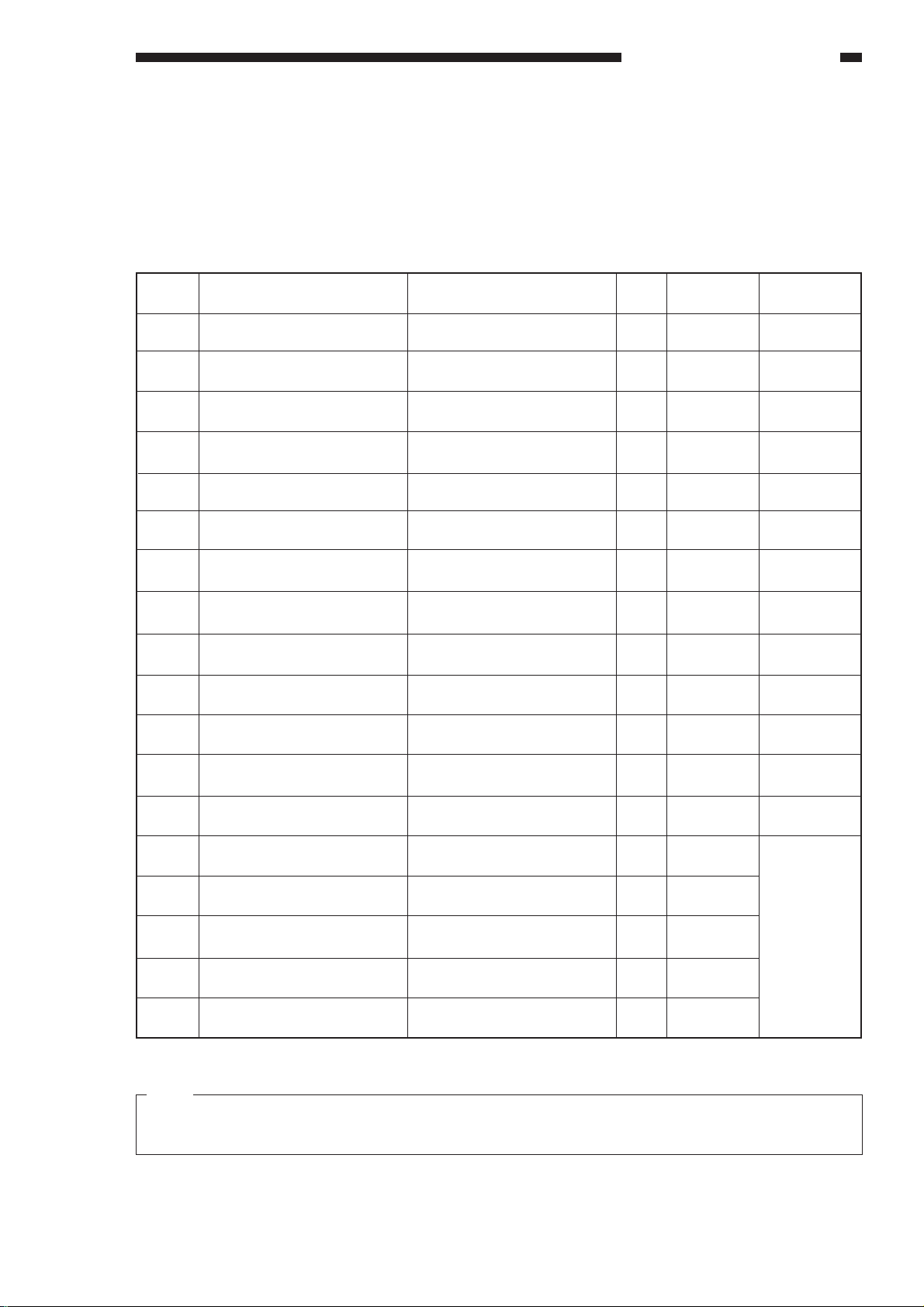

II. PERIODICALLY REPLACED PARTS

Some parts of the copier must be replaced on a periodical basis to ensure a specific level of performance;

replace them as indicated regardless of the presence of visible damage.

Plan the replacement to coincide with a scheduled visit.

A. Periodically Replaced Parts

No.

1

Static eliminator

Note:

The above values are estimates only and subject to change based on the future data.

Parts name

Parts No.

FG5-2912-020

Q’ty

1

Life (copies)

100,000

as of FEB. 1998

Remarks

1–2

MAINTENANCE AND INSPECTION

III. DURABLES

The parts shown in the table may require replacement because of deterioration or damage over the period

of warranty; replace them when they fail using the table as a guide.

A. Copier

No.

1

Pick-up roller

2

Pick-up separation pad

3

Multifeeder pick-up roller

4

Multifeeder separation pad

5

Halogen lamp

6

Fixing cleaning roller

7

Oil-applying roller

8

Transfer roller

9

Upper fixing unit

10

Lower fixing roller

Parts name

Parts No.

FB3-8771-00P

FG5-6792-020

FB1-8581-000

FB2-2167-000

FH7-3271-000

FB3-4494-00P

FA0-0353-00P

FB2-2223-000

FG5-2928-140

FB2-2316-000

Q’ty

2

2

1

1

1

1

1

1

1

1

as of FEB. 1998

Life (copies)

100,000

100,000

100,000

100,000

100,000

100,000

60,000

100,000

200,000

200,000

Remarks

See Note 1.

See Note 1.

See Note 1.

See Note 1.

11

12

13

14

14-1

14-2

14-4

15

Note:

1. The life represents the number of copies actually made using the part.

2. The above values are estimates only and subject to change based on future data.

Upper fixing separation claw

Lower fixing separation claw

Pre-exposure lamp

Developing assembly

Developing cylinder

Side seal

Developing blade unit

Scanner cooling fan filter

FB1-0301-000

FB1-7275-000

FG5-2891-000

FG5-3275-04P

FB2-3834-000

FB2-3825-00P

FG5-7012-00P

FC2-8902-00P

4

4

1

1

1

2

1

1

200,000

200,000

200,000

100,000

100,000

100,000

100,000

100,000

Replace with

item 12 or

12-1 through

12-4.

1–3

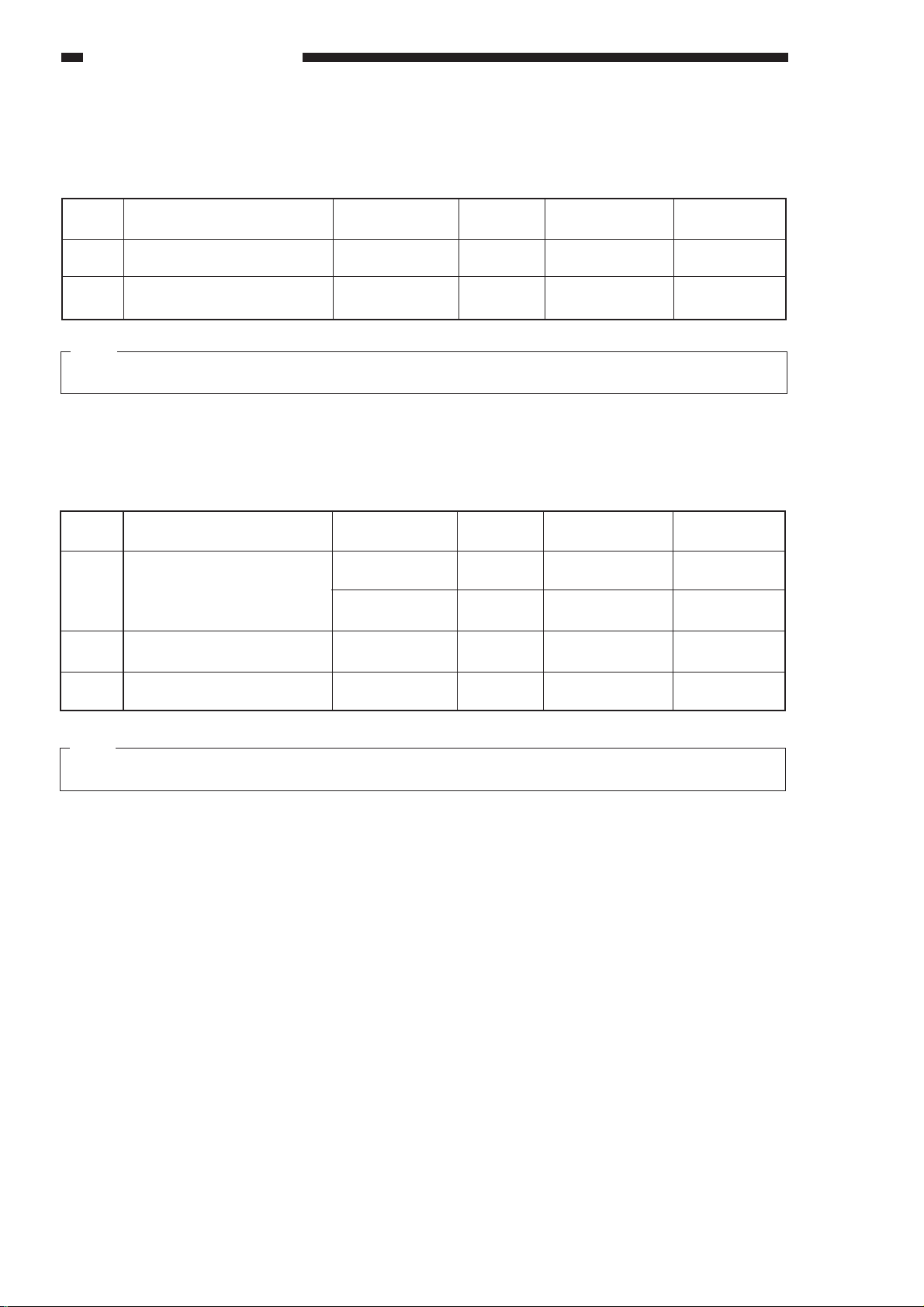

MAINTENANCE AND INSPECTION

B. Cassette Feeding Module-B2/Cassette Feeding Module-A2/

Cassette Feeding Unit-K1

as of FEB. 1998

No.

1

Pick-up roller

2

Pick-up separation pad

Note:

The above values are estimates only and subject to change based on future data.

Parts name

Parts No.

FB2-2251-000

FG5-3614-000

Q’ty

1 through 3

1 through 3

Life (copies)

100,000

100,000

C. Paper Deck Pedestal-K1

No.

1

2

Parts name

Pick-up roller

Feeding roller

Parts No.

FF5-1220-000

FF5-1221-000

FB1-7061-000

Q’ty

1

1

1

Life (copies)

100,000

100,000

100,000

Remarks

Actual usage

Actual usage

as of FEB. 1998

Remarks

Rear

Front

Separation roller

3

Note:

The above values are estimates only and subject to change based on future data.

FB1-7060-020

1

100,000

1–4

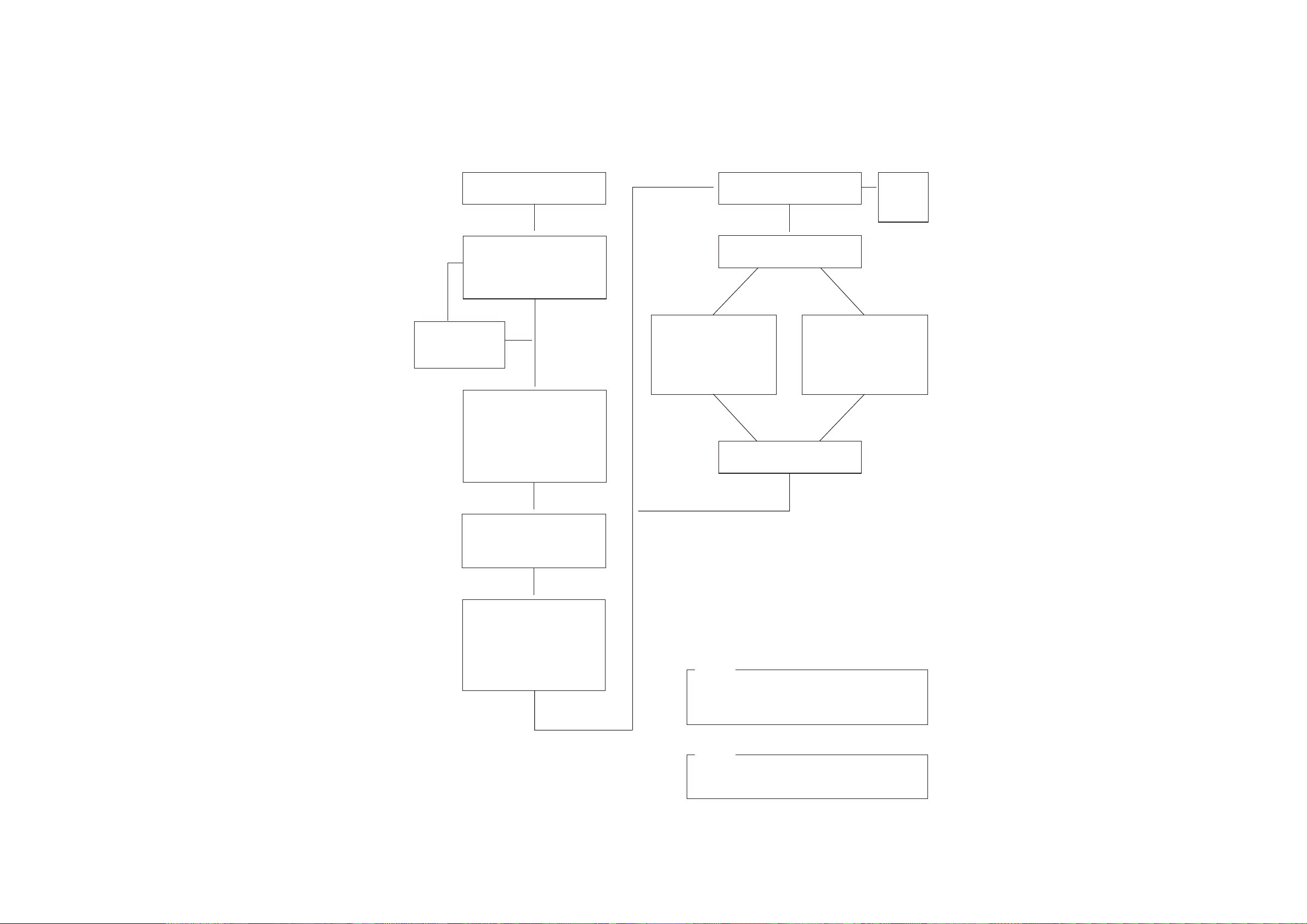

MAINTENANCE AND INSPECTION

IV. MAINTENANCE AND INSPECTION

A. Image Adjustment Procedure

Pre-Checks

Clean the static eliminator.

NO

Is the density correction volume (VR850) on the service

switch PCB centered on the

black dot?

▼

Adjust pointer to

black dot on

panel.

Make sure that all input

values of service mode [3]

are as indicated on the

label attached to the front

door; if different, correct

them.

▼

▼

▼

YES

Optimum Density Adjustment

Is the density of gray scale

▼

No. 8 optimum?

Is the density of gray scale

too high (dark)?

NO

▼

Turn the copy density

correction volume

(VR850) clockwise so

that No. 8 darkens.

(Note 2).

Make one copy.

YES

End the

▼

adjustment.

NO

▼

YES

▼

Turn the copy density

correction volume

(VR850) counterclockwise so that No. 8

lightens. (Note 2)

▼

▼

▼

Make two to three copies

in non-AE and at copy

density 5. (NA-3)

▼

Check the following:

1. density of gray scale

No. 8

2. presence/absence of

fogging in white background

▼

Note 1:

For NA-3 (Test Charts), make sure that No. 8 on

the copy is of the same density as No. 4 through

No. 7 of the charts.

Note 2:

A shift is made in the control of the developing

bias (DC component).

1–5

B. Points to Note for Servicing Work

MAINTENANCE AND INSPECTION

Copyboard, Scanner

Item Tool/Solvent Work/Remarks

Copyboard glass

Scanning lamp

Reflecting plate

No. 1 though

6 mirrors

Alcohol

Lint-free paper

Blower brush

Cleaning

Dry wiping

If excessive, dry wiping

with lint-free paper

Optical path

Item

Lens

Dust-proofing

glass

Tool/Solvent Work/Remarks

Blower brush

Blower brush

Cleaning

Cleaning

Fixing/Delivery assembly

Item

Separation claws

Upper fixing

roller,lower

fixing roller

Paper guide plate

Tool/Solvent

MEK

Cleaning oil

(TKN-0464 )

MEK

Work/Remarks

Cleaning

Cleaning

Cleaning

Duplexing unit

Item

Re-pick up roller

Set-back roller

Feeding assembly, Static eliminator

Item

Transfer guide

Static eliminator

Feeding belt,

Feeding assembly

mount, Transfer

charging assembly,

Rail

Note:

Make sure no droplets of water remain; if any,

do not turn on the power.

Tool/Solvent Work/Remarks

Alcohol

Alcohol

Tool/Solvent Work/Remarks

Moist cloth (Note)

Special brush

Moist cloth (Note)

Cleaning

Cleaning

Cleaning

Cleaning

Cleaning

1–6

STANDARDS AND ADJUSTMENTS

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A. Mechanical

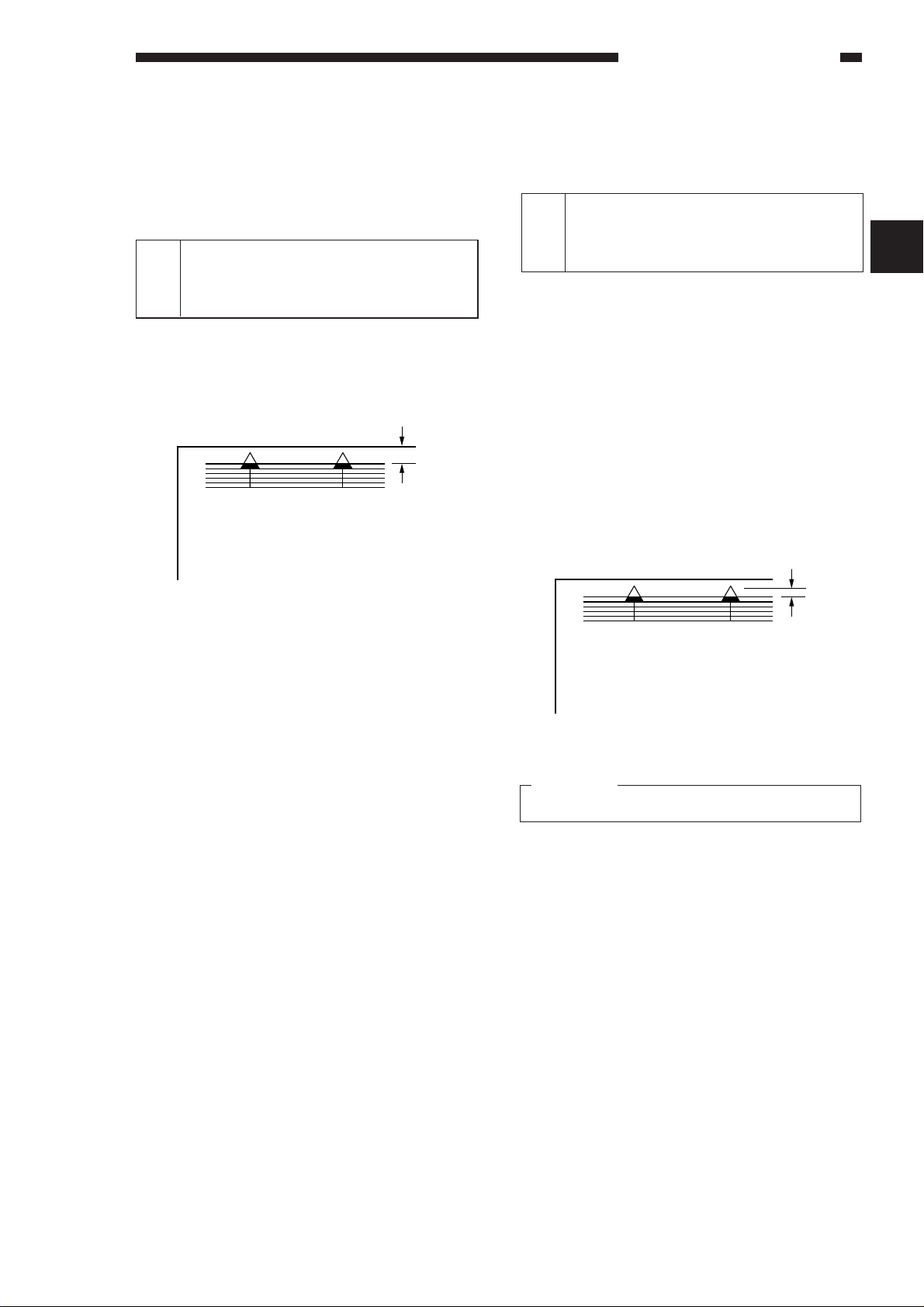

1 Adjusting the Image Leading

Edge Margin ([3], No. 305;

registration ON timing)

Select service mode ([3] No. 305; leading edge

margin adjustment). Make adjustments so that the

image position is as indicated in Figure 2-200 when

the Test Chart is copied in DIRECT.

2.5±1.5mm

Figure 2-200

Making Adjustments

1) Choose service mode [3], and select No. 305

using the numeric keypad.

• The copy count display flashes ‘No. 305’.

2) Press the Start key.

• The display flashes the present value.

• If the value is negative, ‘%’ is flashed.

To enter a negative value, press the % key,

and then enter the value using the numeric

keypad.

4) Press the AE key.

• The value is stored and the display remains

ON.

• Copying starts when the start key is pressed.

5) To enter a value once again, repeat steps 1)

and 4).

6) Press the Clear key to return to item selection.

The following is the relationship between the

settings and the image positions:

• For each ‘1’, the image position changes by

about 0.27 mm.

• For a ‘+’, the image position advances.

2 Adjusting the Leading Edge Non-

Image Width ([3], No. 306; blank

shutter ON timing)

Select service mode ([3] No. 306; leading edge

non-image width), and make adjustments so that

the leading edge non-image width is as indicated in

Figure 2-201 when the Test Sheet is copied in

DIRECT.

The machine adjusts the leading edge nonimage width taking advantage of the timing at which

the blanking shutter closes.

You must make this adjustment whenever you

have replaced the blanking shutter solenoid or the

blank exposure assembly.

Leading Edge Non-Image Width

2.5±1.5mm

Figure 2-201

Reference:

In enlargement/reduction mode, 6 mm or less.

Making Adjustments

1) Select service mode ([3] No. 306).

• The copy count display flashes ‘No. 306’.

2) Press the Start key.

3) Change the setting using the numeric keypad.

• The display flashes the present value.

• If the value is negative, ‘%’ is flashed.

To enter a negative value, press the % key,

and then enter the value using the numeric

keypad.

4) Press the AE key.

• The value is stored and the display remains

ON.

• Copying starts when the start key is pressed.

5) To enter a value once again, repeat steps 1) and

2).

2

2–1

STANDARDS AND ADJUSTMENTS

6) Press the Clear key to return to item selection.

The following is the relationship between the

settings and the image positions:

• For each ‘1’, the image position changes by

about 0.27 mm.

• For a ‘+’, the leading edge non-image width

increases.

3 Adjusting the Image Trailing

Edge Non-Image Width ([3] No.

309; blanking shutter timing)

Trailing Edge Non-Image Width

2.5±

1.5mm

• For each ‘1’, the image position changes by

about 0.27 mm.

• For a ‘+’, the trailing edge non-image width

decreases.

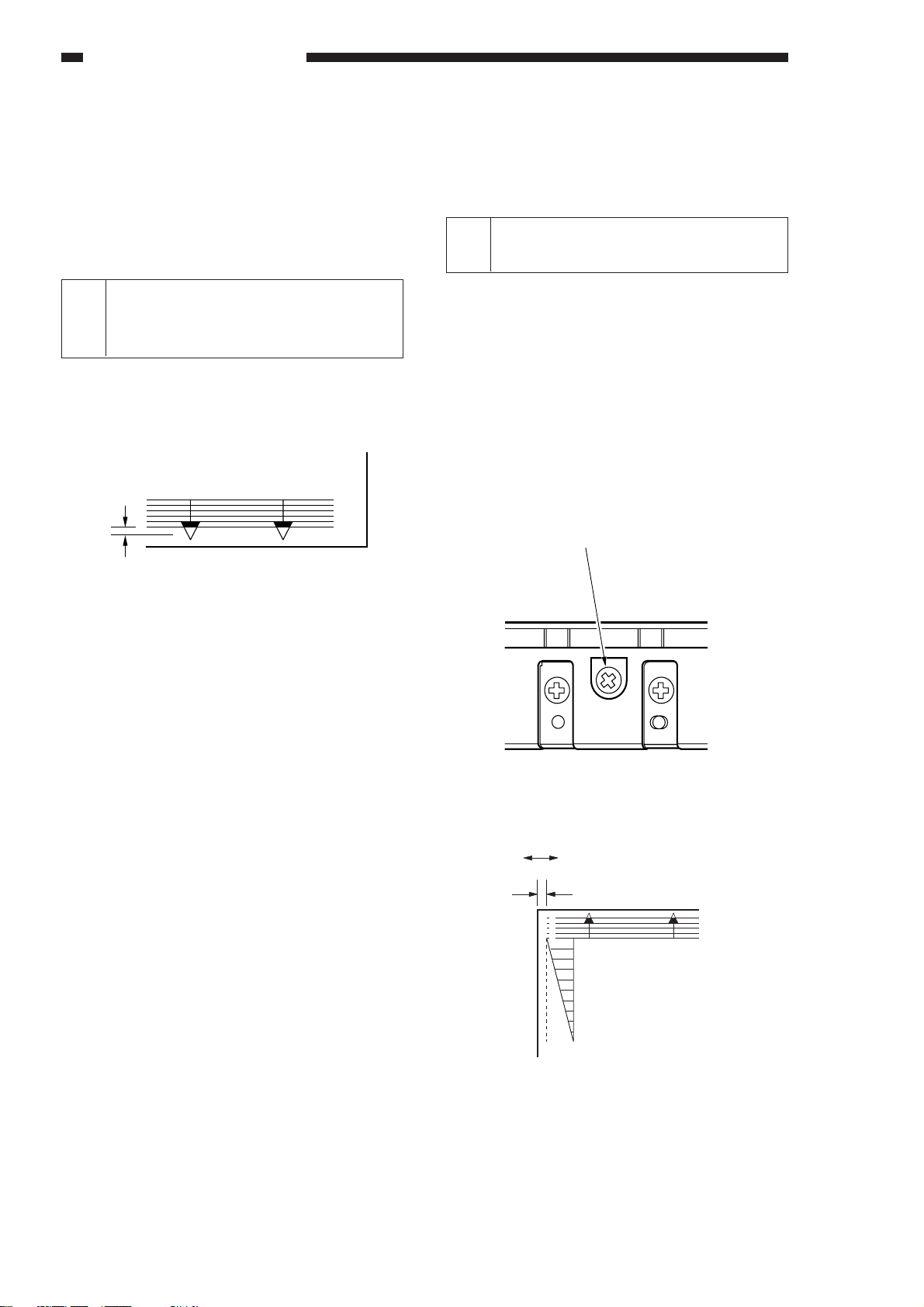

4 Adjusting the Left/Right Regis-

tration

Make adjustments so that the image position is

as indicated in Figure 2-204 when the Test Sheet is

copied in DIRECT.

a. Pick-Up from the Cassette

Turn the screw q shown in Figure 2-203 to

adjust the position of the cassette hook.

standard: 0 ±1.5 mm

CW turn: moves the paper in the direction of

(–) shown in Figure 2-204.

CCW turn: moves the paper in the direction of

(+) indicated in Figure 2-204.

q

Figure 2-202

Select service mode ([3] No. 309; leading edge

non-image width adjustment), and make adjustments so that the image trailing edge non-image

width is as indicated in Figure 2-202 when the Test

Sheet is copied in DIRECT.

The machine adjusts the image trailing edge

non-image width by taking advantage of the timing

at which the blanking shutter opens.

Making Adjustments

1) Select service mode ([3] No. 309).

• The copy count display flashes ‘No. 309’.

2) Press the Start key.

3) Change the setting using the numeric keypad.

• The display flashes the value.

• If the value is negative, ‘%’ is flashed.

To enter a negative value, press the % key,

and then enter the value using the numeric

keypad.

4) Press the AE key.

• The value is stored and the display remains

ON.

• Copying starts when the start key is pressed.

5) To enter a value once again, repeat steps 1)

and 2).

6) Press the Clear key to return to item selection.

The following is the relationship between the

settings and the image positions:

(-)

Figure 2-203

(+)

0±1.5mm

0

2

4

6

8

10

Figure 2-204

2–2

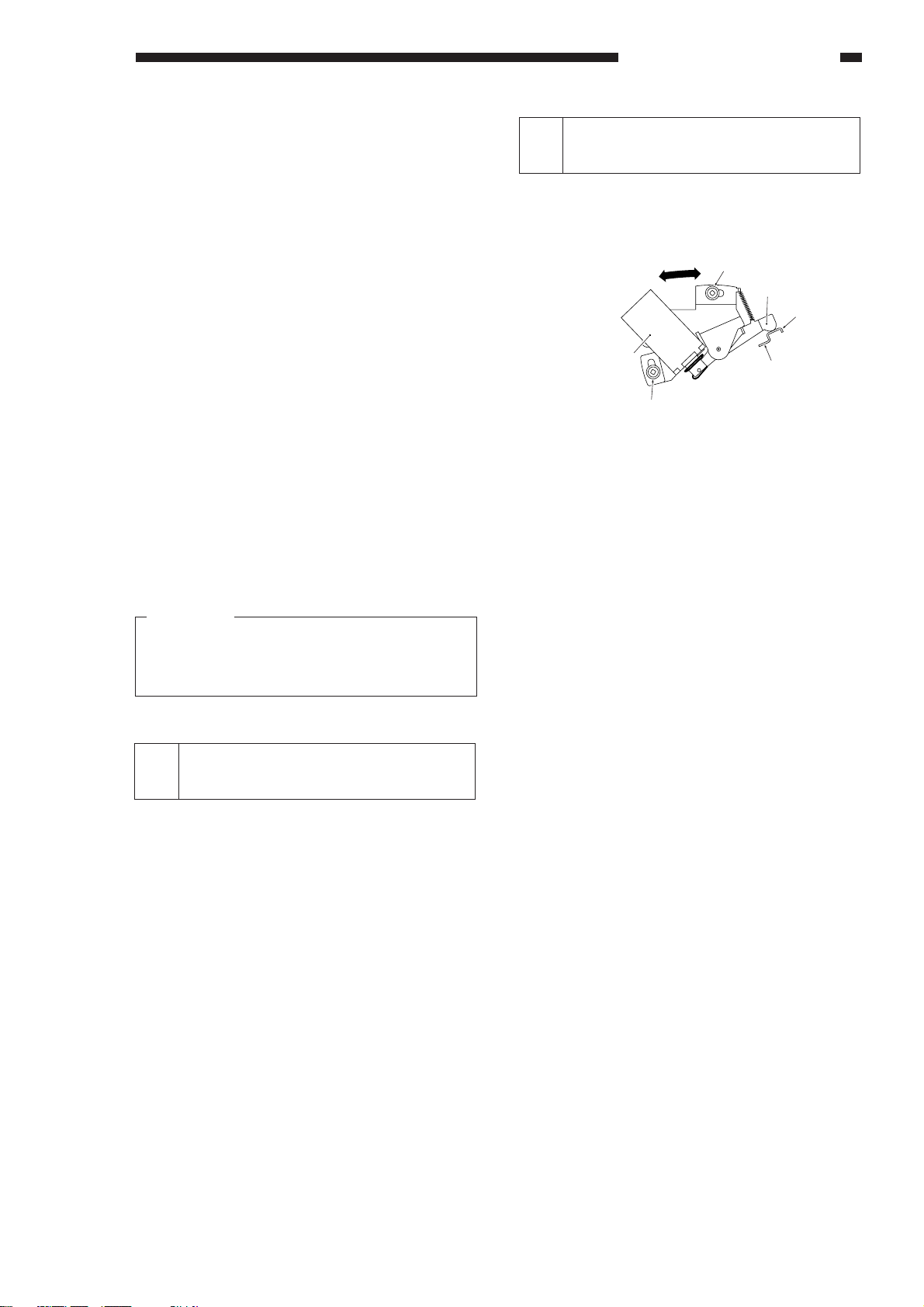

b. Pick-Up from the Multifeeder

Shutter

Adjust the distance between the

two shutters in the blanking

assembly.

Shutter

The entire shutters are

shifted.

Loosen the screw q, and move the position of

the tray so that the measurement is 0 ±1.5 mm.

q

Figure 2-205

c. Duplexing Pick-up

Start service mode (No. 329), and make adjustments so that the measurement (Figure 2-204) is 0

±1.5 mm.

Unit: 0.27 mm

STANDARDS AND ADJUSTMENTS

Figure 2-206

b. Adjusting the Position of the Left/Right

Margin

Turn the blanking adjusting screw on the machine front side plate shown in Figure 2-207 so that

the dimension is as specified:

CW: moves the margin to the front.

CCW: moves the margin to the rear.

full turn: moves the margin by about 1 mm.

5 Adjusting the Left/Right Margin

(No. 311 left/right margin adjustment)

Select service mode (No. 311 left/right margin

adjustment), and make adjustments so that the left/

right margin is 2.5 ±1.5 mm when the Test Sheet is

copied in DIRECT.

You must first adjust the “left/right registration”

before making this adjustment.

Making Adjustments

a. Margin (adjusting the width)

1) Select service mode ([3] No. 311).

2) Press the Start key.

3) Enter the new setting using the numeric key-

pad.

• If the value is negative, ‘%’ is flashed.

To enter a negative value, press the % key,

and then enter the value using the numeric

keypad.

The following describes the relationship between the settings and the margin:

• For each ‘1’ in the setting, the margin changes

to the side by about 0.37 mm.

• The settings may be between 0 and 15 mm.

• ‘+’ increases the margin.

• ‘-’ decreases the margin.

q

Figure 2-207

Figure 2-208

Note:

For both a. and b., turn ON and OFF the power

switch after making the adjustments or try a

different reproduction ratio to move the home

position of the blank exposure assembly.

2–3

STANDARDS AND ADJUSTMENTS

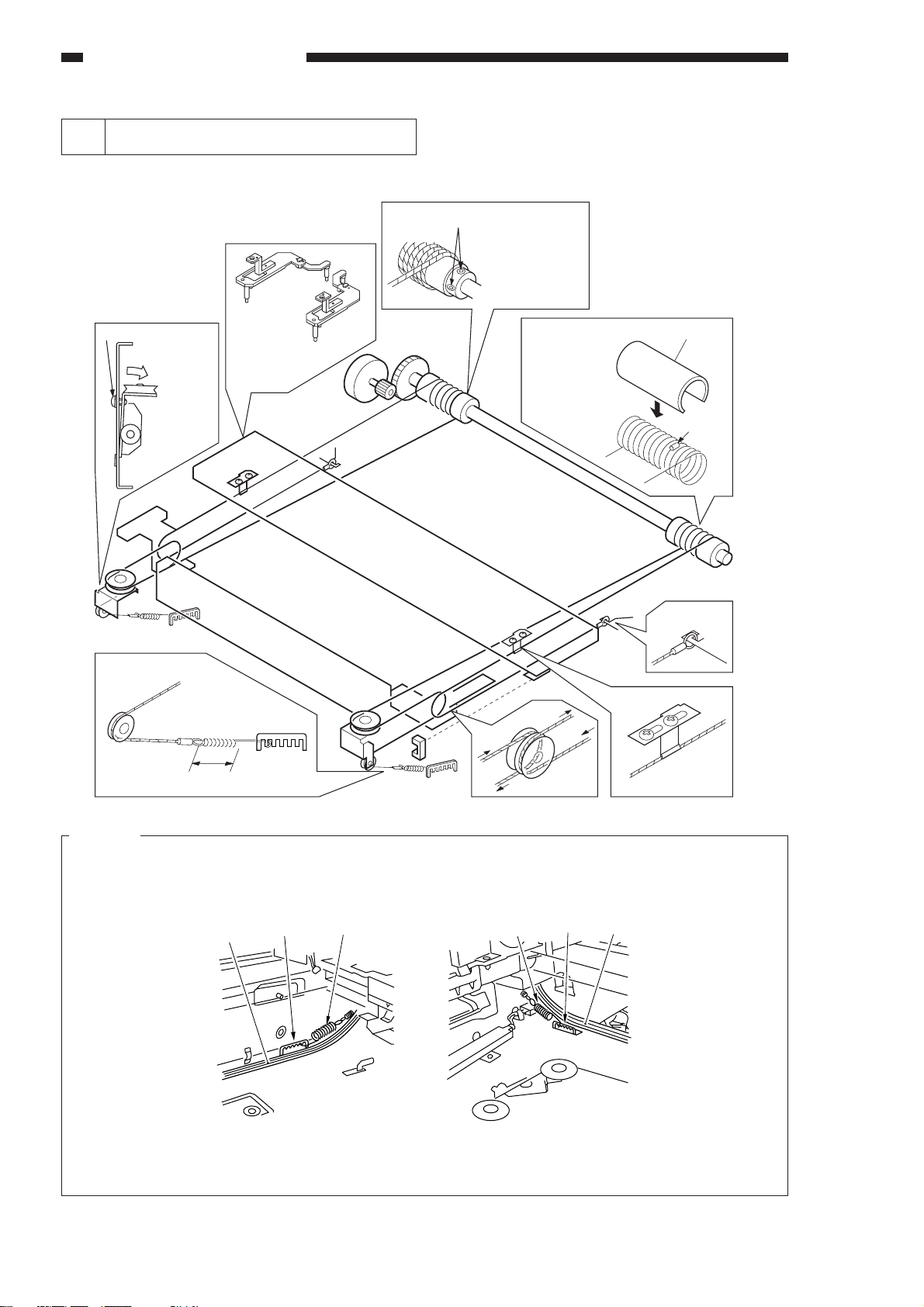

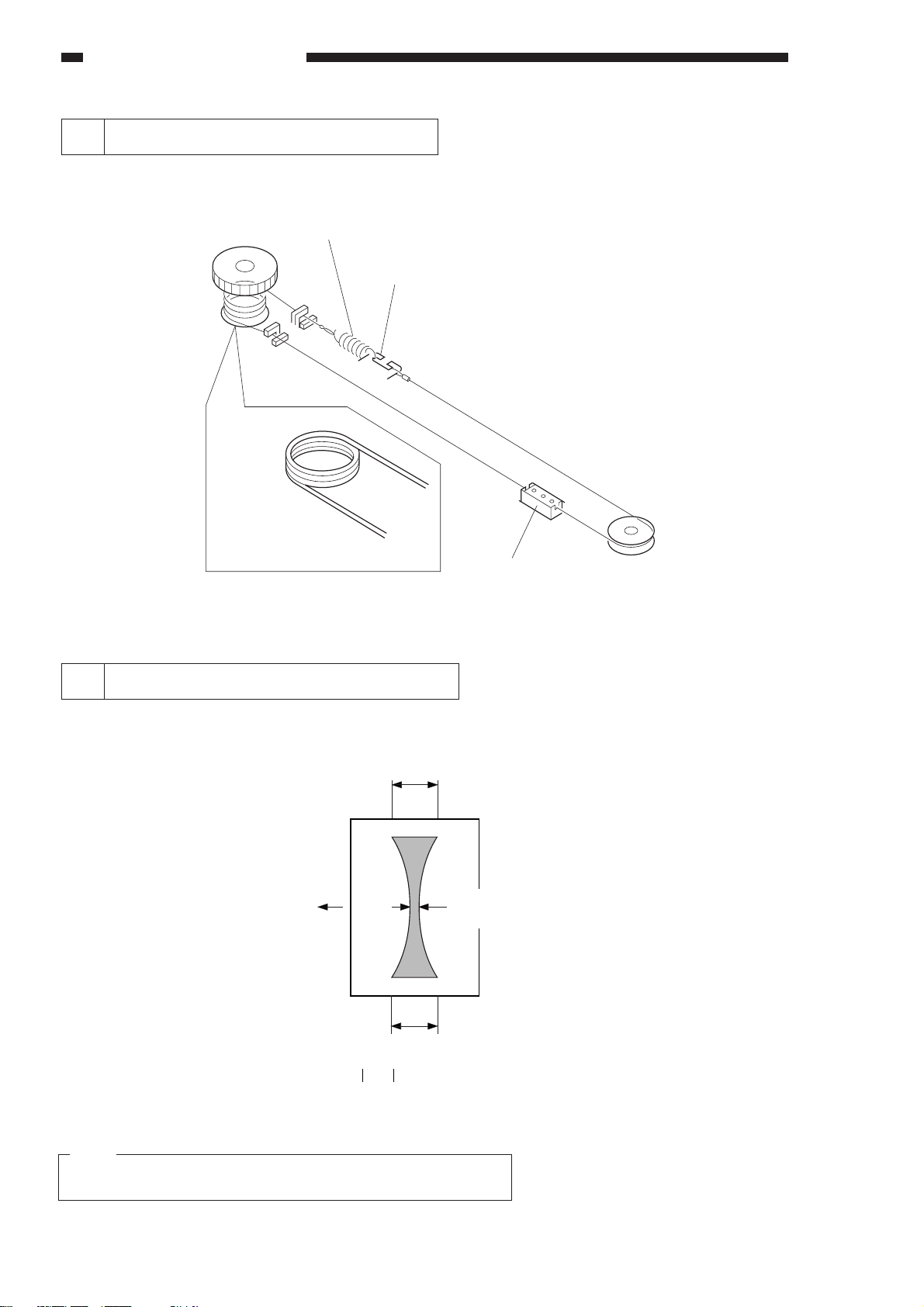

6 Routing the Scanner Drive Cable

Route the cable as indicated by the numbers q through !1, and perform “Adjusting the Cable tension”

and “Adjusting the Mirror Position” as described.

Screw

e

Loosen the

screw,and shift

it down.

i

Re-tighten

the screw.

Attach the mirror

positioning tool.

w

Set screws

Loosen the set

screws to enable

free rotation.

Put the steel ball

into the hole in

the pulley; wind

the cable nine

times toward the

inside, and four

times toward the

outside; then, snap

on the pulley clip.

!0

Pulley clip

Steel ball

q

t

o

y

r

34±1mm

u

Figure 2-209

Caution:

Pay attention to the direction of the wire spring when installing the cable spring. (Follow the illustrations

given below.) Installing the spring in the wrong direction can cause the hook tip of the spring to interfere

with the cable.

Cable

Hook

Cable spring Cable spring

Hook

Cable

!1

2–4

(front) (rear)

Figure 2-210

STANDARDS AND ADJUSTMENTS

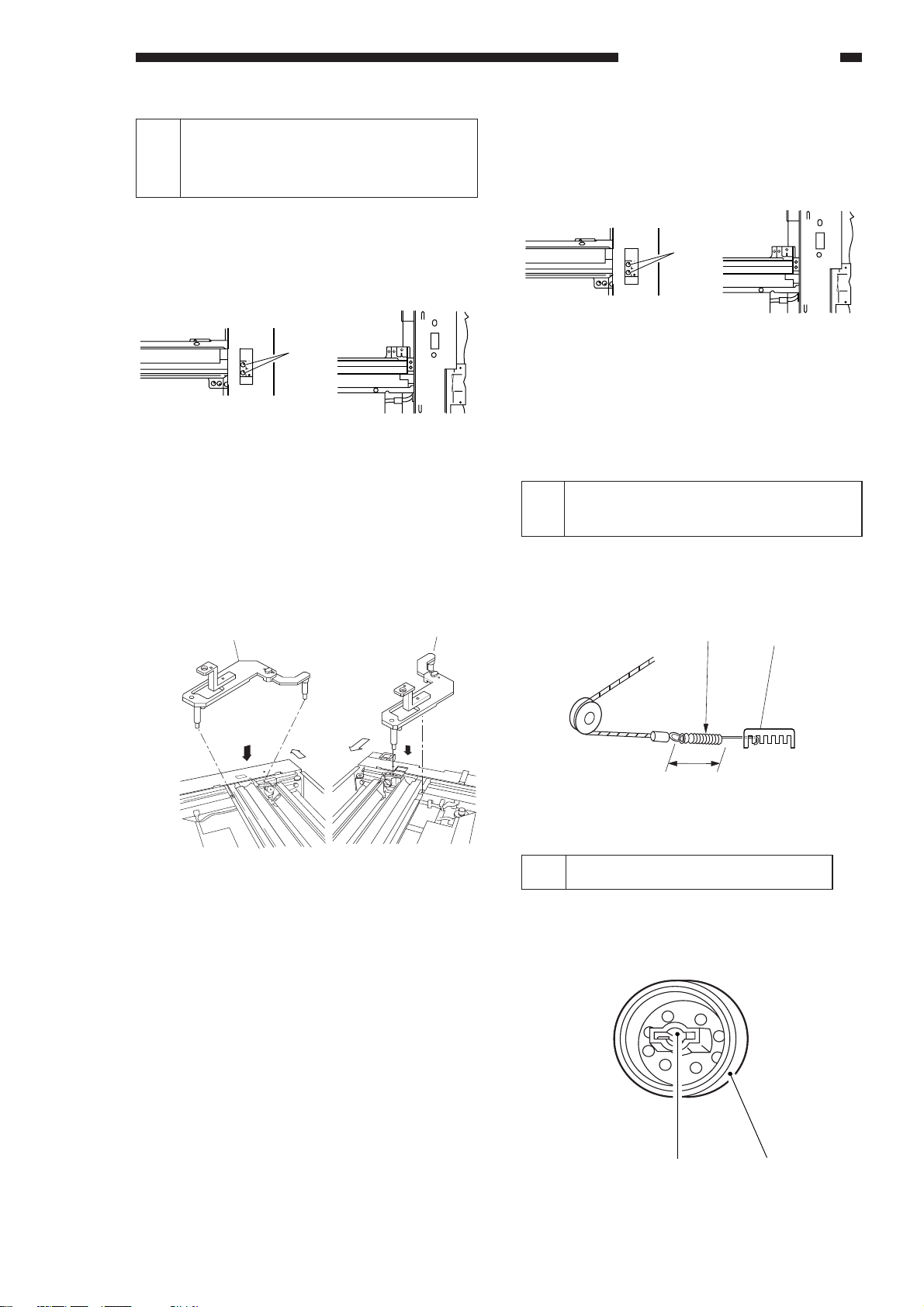

7 Adjusting the Mirror Position (op-

tical length between No. 1 mirror

and No. 2/3 mirror)

1) Keep the mirror positioning tool at hand.

2) Move the No. 1 mirror mount in the forward

direction, and match the angular hole in the

front side plate and the cable fixing screw q.

q

(front) (rear)

Figure 2-211

3) Loosen the set screw on the pulley.

4) Attach the mirror positioning tool w to the No. 1

mirror mount and the No. 2 mirror mount (both

front and rear).

5) Install the metal fixing of the scanner cable to

the No. 1 mirror mount using two screws e

(both front and rear).

e

(front) (rear)

Figure 2-213

6) Tighten the set screw of the pulley.

7) Remove the tool (FY9-3009).

8 Adjusting the Scanner Cable

Tension

Pull the tension spring so that both ends of the

cable spring q is 34 ±1 mm, and tighten the screw

w.

Mirror positioning tool (front)

(front) (rear)

Figure 2-212

Mirror positioning tool (rear)

(front)

(front)

q

34±1mm

Figure 2-214

w

9 Orienting the Pick-Up Roller

When installing the pick-up roller q, make sure

that the face indicated in Figure 2-215 is toward the

rear.

w

Figure 2-215

q

2–5

STANDARDS AND ADJUSTMENTS

130.5±0.5mm

Paper guide

plate cam

Hole

10 Orienting the Multifeeder Pick-

Up Roller

When installing the multifeeder pick-up roller q,

make sure that the side with a cross w on its collar

is toward the rear.

w

q

(front)

Figure 2-216

11 Positioning the Multifeeder As-

sembly Paper Guide Plate Cam

Temporarily fix the screw with a hex nut of the

spring clutch assembly in place, and rotate the

control ring. At this time, i.e., while the claw of the

control ring is engaged with the solenoid plate,

make adjustments so that the hole (or black dot) in

the cam and the hole in the multifeeder drive unit

match; then, tighten the part in place.

Caution:

If the adjusting hole is not furnished with a black

dot for reference, make adjustments as

instructed while making sure that the paper

guide plate cam of the multifeeder assembly is

located as shown.

Figure 2-218

Holes (or hole and black dot) matched

Horizontal line

Gear

Control ring

Screw w/hex nut

Gear

Paper guide plate cam

Claw

Solenoid plate

Figure 2-217

2–6

STANDARDS AND ADJUSTMENTS

A

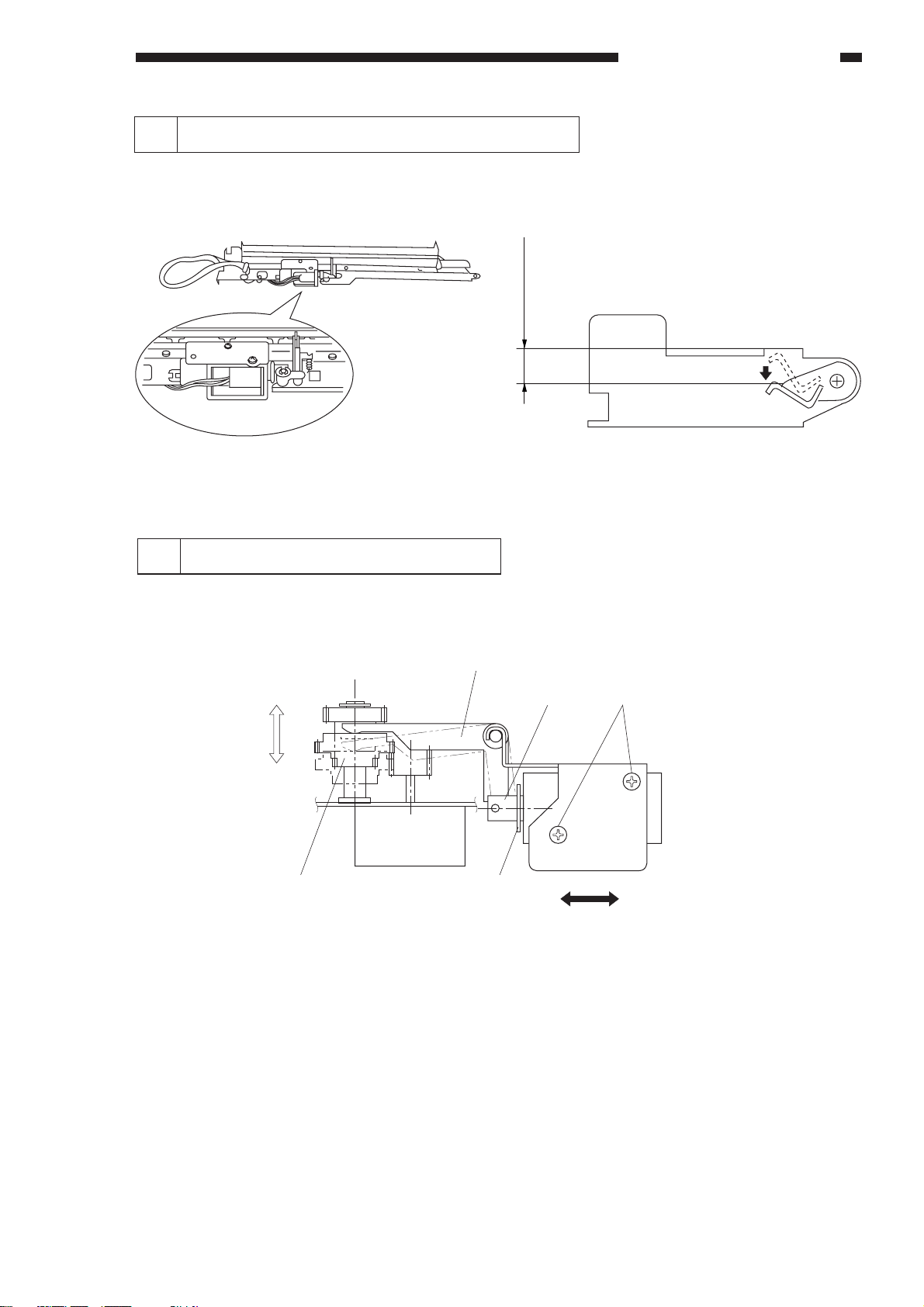

12 Positioning the Blanking Shutter Solenoid

Adjust the position of the solenoid so that bottom A is 9.5 ±0.5 mm for both sides of the shutter when the

solenoid is moved to the ON direction. Avoid forcing the shutter down when taking measurements.

After adjustment, make sure that the solenoid moves smoothly.

Figure 2-219

Figure 2-220

13 Positioning the Change Solenoid

Loosen the two screws t, and make adjustments so that the gear r moves until it stops in the direction

of b along the arm e when the steel core q of the solenoid is fully pushed in the direction of B, i.e., when the

E-ring w comes into contact with the solenoid.

e

a

b

r

w

q

AB

t

Figure 2-221

2–7

STANDARDS AND ADJUSTMENTS

14 Routing the Blanking Shutter Cable

Attach the spring to

the outside of the

sides shutter.

Slide shutter (rear)

Wind 3.5 times.

Slide shutter (front)

Figure 2-222

15 Adjusting the Lower Fixing Roller Nip

If fixing faults occur, make the following adjustments:

The nip is correct if it is as indicated in Figure 2-223; otherwise, turn the bolt to adjust.

c

A4

paper

Feeding

direction

Center of copy

b

paper

a

b : 4.5±0.5mm

a-c : 0.5mm or less

Figure 2-223

Note:

a and c represent points 10 mm from either edge of the paper.

2–8

STANDARDS AND ADJUSTMENTS

Oil application

Solenoid

Screw

Screw

Lever

Contact

Support

a. Measuring the Nip

Measure the nip when the machine is turned on

for the first time in the morning.

1) Open the copyboard cover, and make an A4

(SM0-1) solid black copy.

2) Place the copy in the cassette tray face down

(solid black facing downward).

3) Press the service mode switch (SW850) with a

hex key.

• The machine starts service mode and indi-

cates ‘1’.

4) Press ‘4’ on the numeric keypad.

• The display indicates ‘4’.

5) Press the AE key.

• The machine enters operation/inspection

mode and indicates ‘401’.

6) Press ‘6’ on the numeric keypad.

• The display indicates ‘406’.

7) Press the Start key.

• The paper will be fed from the cassette, and

the machine will be ready to accept new

settings as in Figure 2-223. (The paper will be

discharged.)

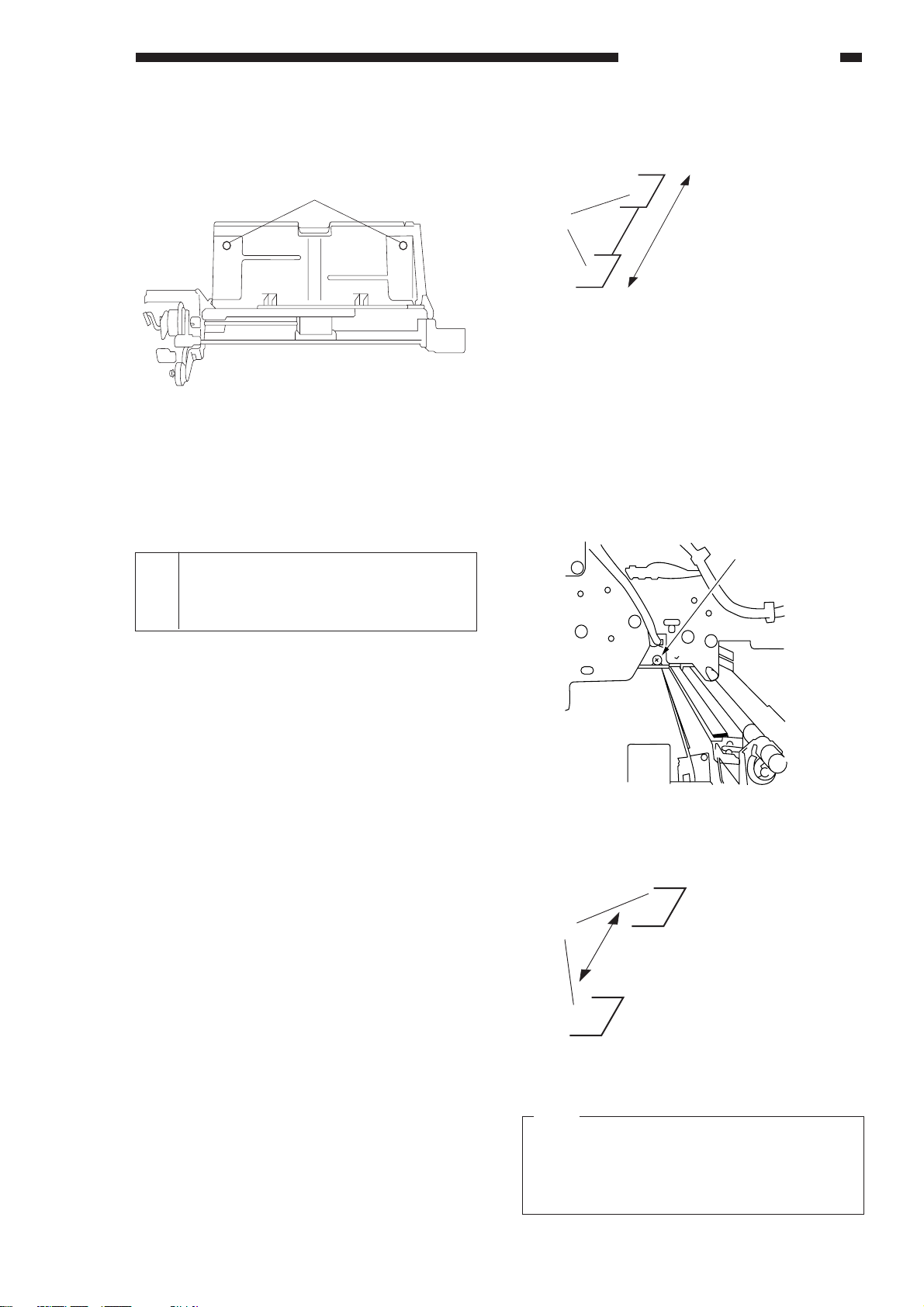

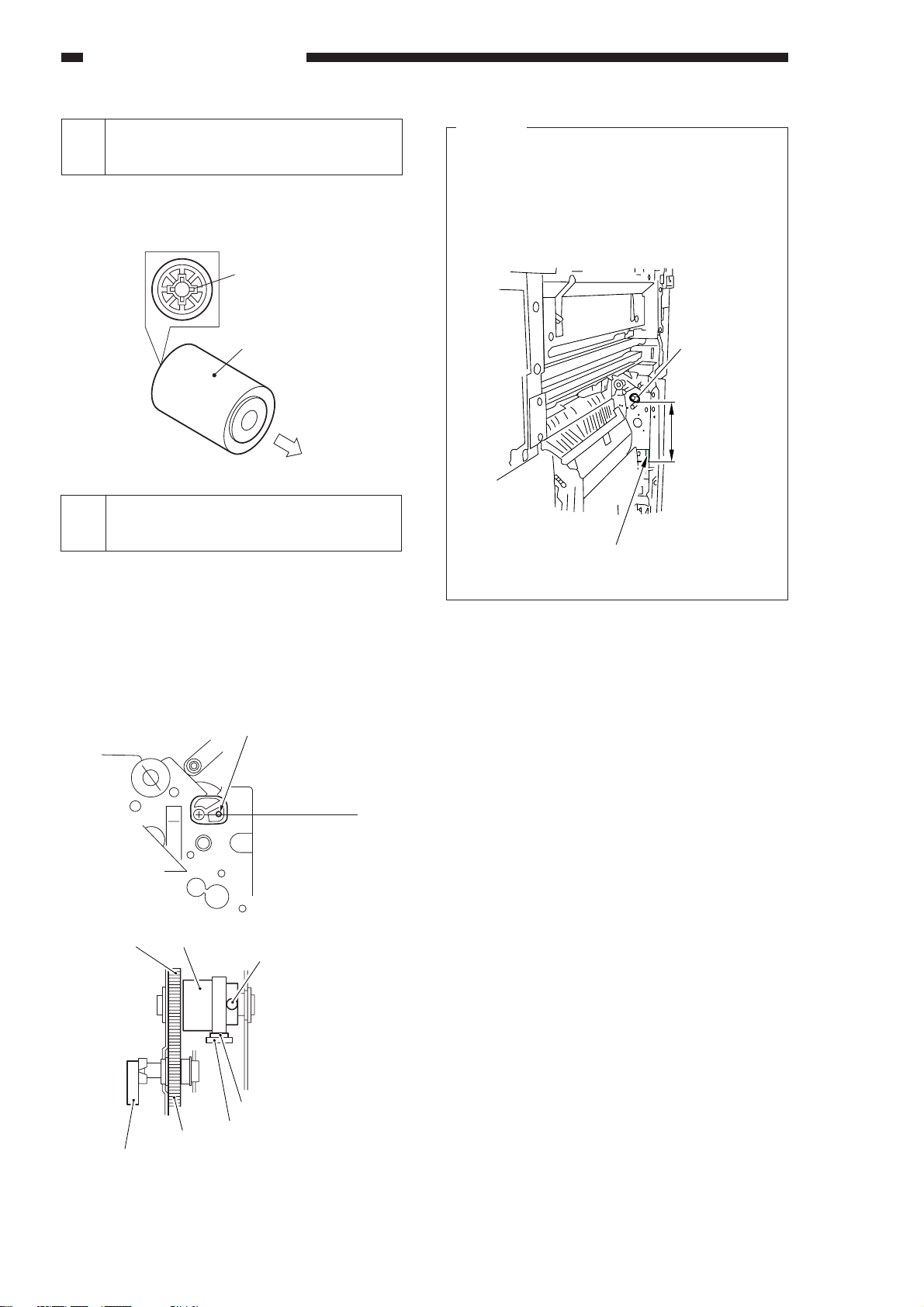

17 Mounting the Oil Application

Solenoid

Screw the oil application solenoid in place where

its lever is lightly in contact with the support of the oil

application roller.

Figure 2-224

Reference:

The paper stops while half of it is held between

the fixing rollers; it will then be discharged fully

about 10 sec later.

8) Measure the nip.

16 Points to Note After Replacing

the Upper Fixing Unit

If you replaced the upper fixing unit, you must

enter the temperature offset value of the heater

using service mode No. 304. (See p. 7-10)

2–9

STANDARDS AND ADJUSTMENTS

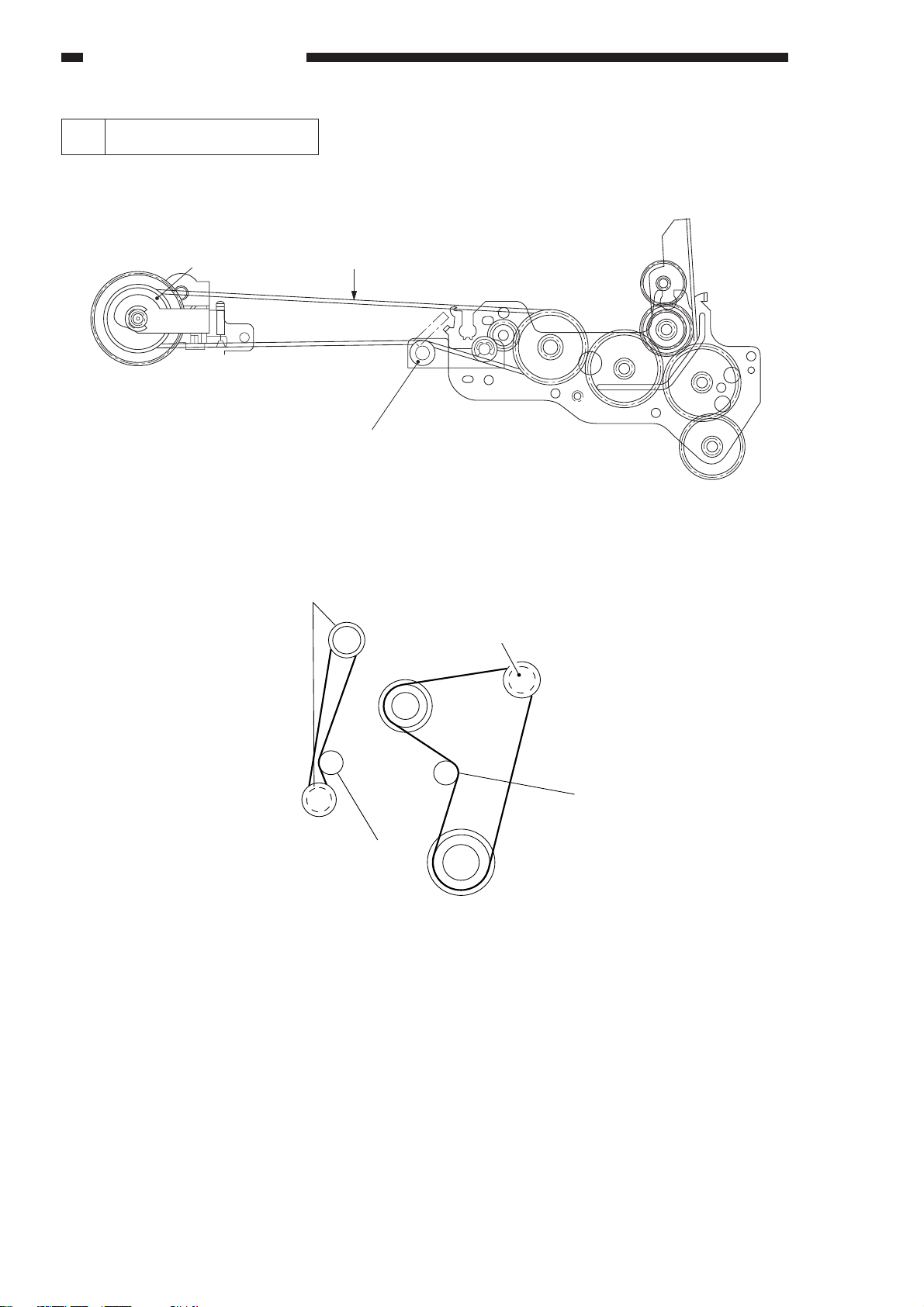

18 Routing the Drive Belt

Be sure to attach the drive belt on the pulley and the tensioner as indicated in Figures 2-225 and 2-226.

Pulley

Vertical path roller gear

Drive belt

Tensioner

Figure 2-225

Main motor

2–10

Tensioner

Vertical path roller

clutch (CL7)

Figure 2-226

STANDARDS AND ADJUSTMENTS

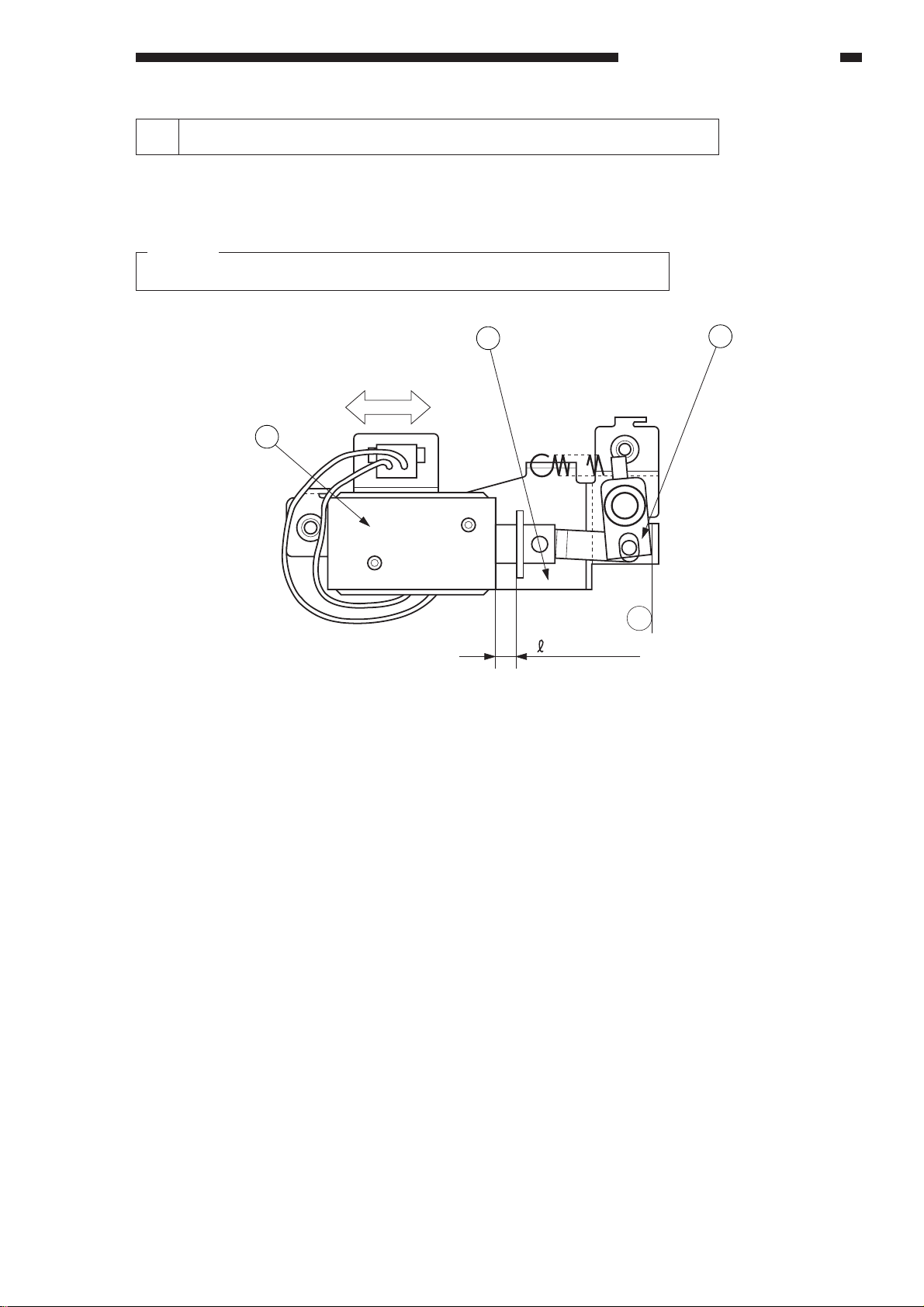

19 Positioning the Primary Charging Roller Cleaning Solenoid

Loosen the two screws used to fix the solenoid e in place, and move the solenoid in the direction of the

arrow B so that the l in Figure 2-227 is 5.5 ±0.2 mm when the joint q is forced against the a section of the

solenoid support plate w.

Caution:

You must make this adjustment whenever you have replaced the solenoid.

2

1

B

3

a

= 5.5 ± 0.2

Figure 2-227

2–11

STANDARDS AND ADJUSTMENTS

7

20 After Replacing the Drum Unit

Whenever you have replaced the drum unit,

record the date and the counter reading on the label

that comes with the drum unit; attach the label to the

front cover of the new drum unit, and perform the

Image Adjustment Basic Procedure.

Figure 2-228

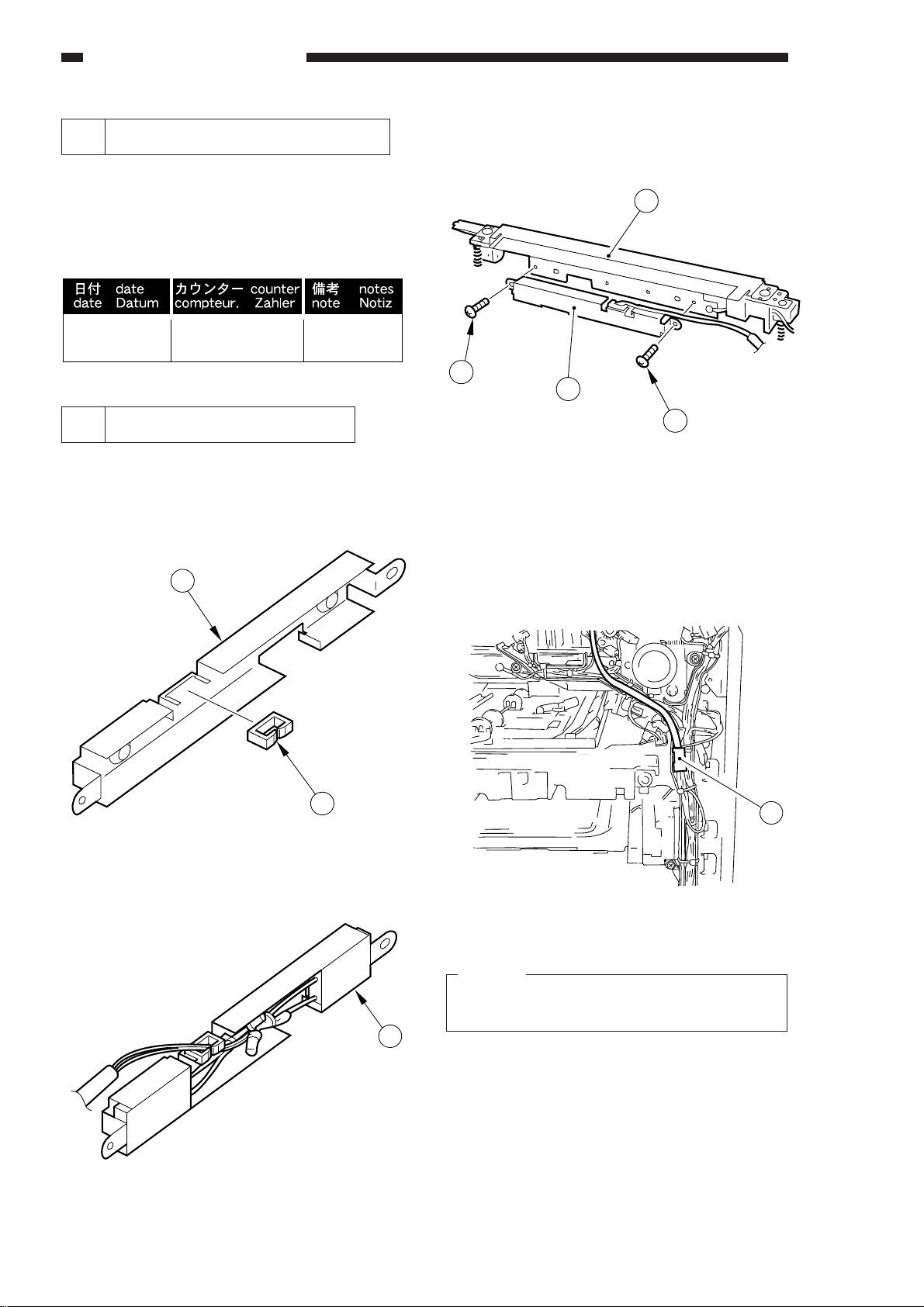

21 Installing the Drum Heater*

*This may not be available for sale in some areas.

1) Remove the transfer guide from the copier.

2) Install the cord clamp w to the heater holder q.

1

4) Install the heater holder t to the transfer guide

y with two screws r.

6

4

5

4

Figure 2-231

5) Install the transfer guide to the copier.

6) Connect the connector u of the heater to the

copier’s connector.

2

Figure 2-229

3) Remove the transfer roller and the static eliminator.

3

Figure 2-230

2–12

Figure 2-232

Caution:

As necessary, keep the heater harness in place

on the cord guide using tie-wraps.

STANDARDS AND ADJUSTMENTS

2 1

3

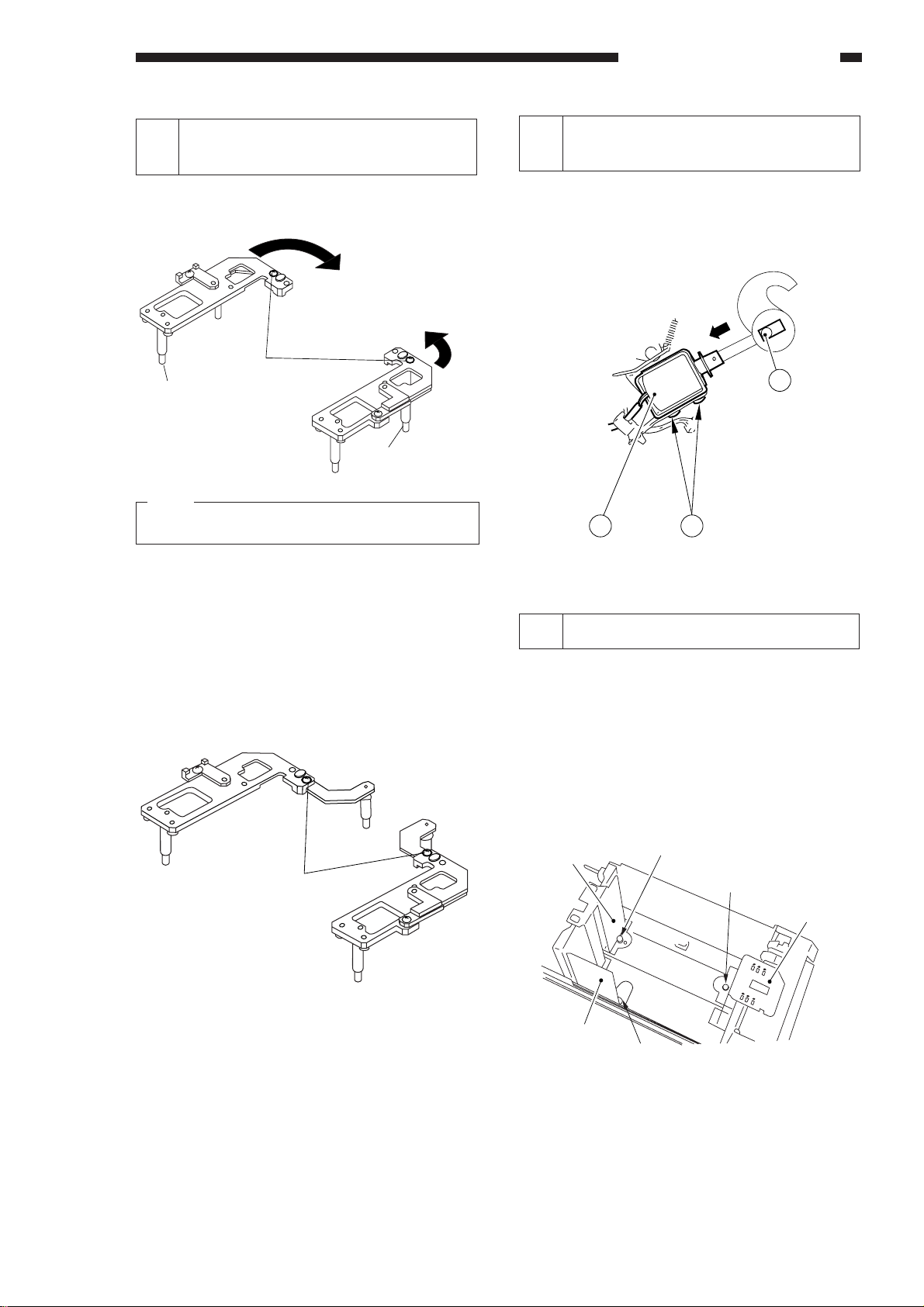

22 Assembling the Mirror Position-

ing Tool

1) Remove the screw from position B indicated in

Figure 2-233.

B

A

A

Position B

Longest pin

Note:

Shortest pin not used.

Figure 2-233

B

Medium-Length pin

23 Positioning the Paper Deflecting

Plate Solenoid (SL8)

Loosen the two screws q, push the solenoid

plunger to the arrow until the pin e reach to the

bottom of slot, and fix the screw.

Figure 2-235

2) Fit the screw removed in step 1) in position A;

then, tighten it slightly.

3) Spread the arm out of the main frame until it

comes into contact with the stopper as indicated in Figure 2-234.

4) Fix the screw in place.

B

A

A

B

Position A

Figure 2-234

24 Setting the Deck Size

To change the paper deck size, change the

position of the guide plate at the front, rear, and rear

left.

1) Slide out the deck toward the front until it stops.

2) Remove the mounting screw from the guide

plate at the front, rear, and rear left; then, detach

the guide plates.

Guide plate (rear)

Guide plate (left)

Screw

Screw

Guide plate (front)

Screw

Figure 2-236

2–13

STANDARDS AND ADJUSTMENTS

3) Fix each guide plate in position referring to the

size indexes on the base plate, front side plate,

and guide plates.

A4

LTR

B5

B5

LTR

A4

LTR

A4

8) Install the switch cover.

9) Attach the size seal to the front cover of the

deck.

10) Switch on the copier, and check that the new

deck size is indicated in the message display.

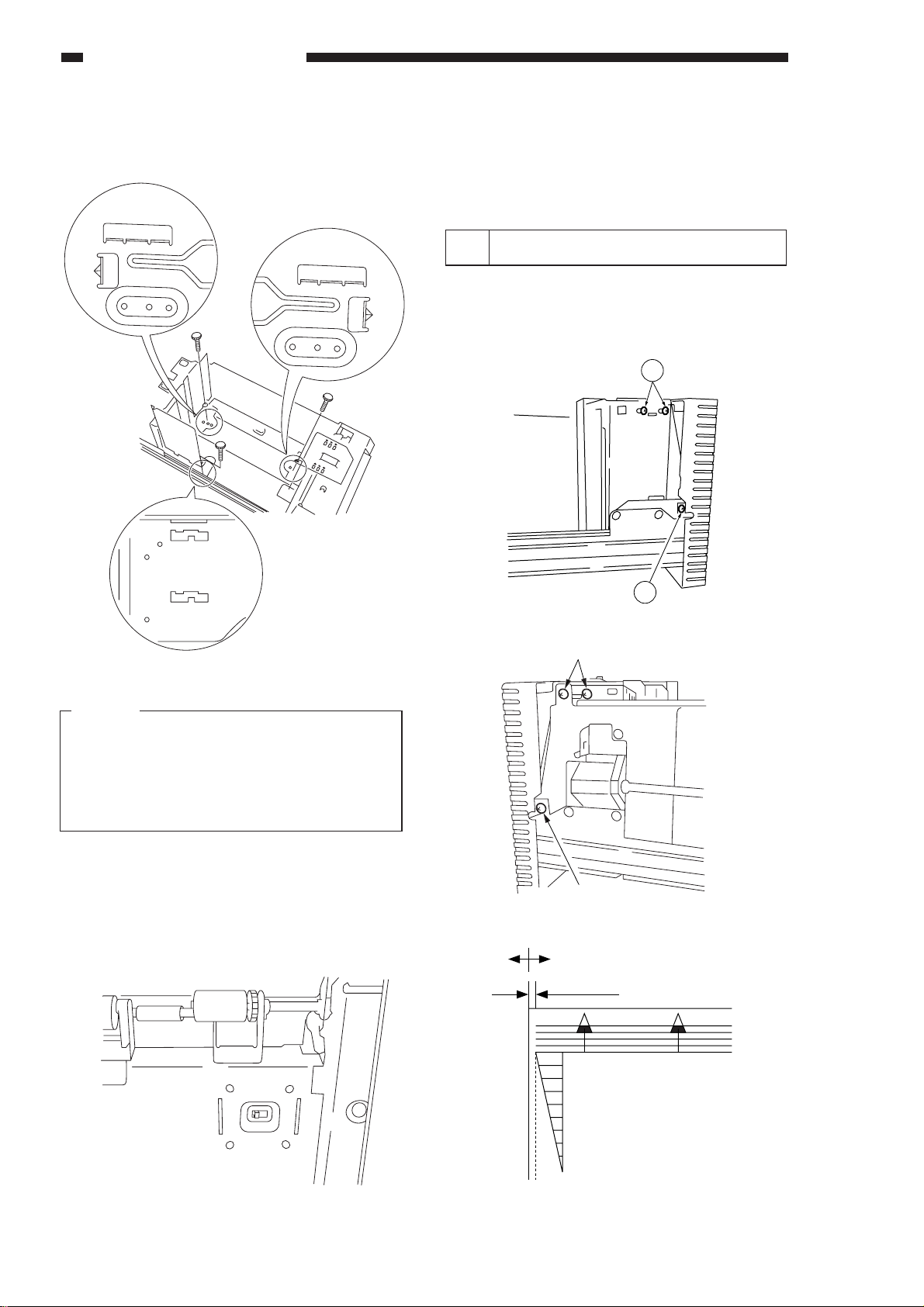

25 Adjusting the Deck Registration

Detach the deck front cover, and loosen the

mounting screws on both left and right of the deck

(6 in total); then, move the latch assembly to the

front and rear until the standards shown in Figure 2239 are met.

3

B5

Figure 2-237

Caution:

Make sure that the front and rear guide plates

are attached as follows:

• Perpendicular to the base plate of the deck.

• Parallel to the metal plates at the front and the

rear.

4) Place paper in the deck, and slide the deck into

the pedestal.

5) Open the right door of the deck.

6) Remove the switch cover.

7) Set the deck size switch to reflect the new paper

size.

3

Figure 2-239 (left)

Screws

Screw

Figure 2-239 (right)

(-) (+)

0±1.5mm

2–14

Figure 2-238

0

2

4

6

8

10

Figure 2-240

STANDARDS AND ADJUSTMENTS

B. Electrical

1 Adjustment after Replacing

PCBs

You must perform the following adjustments

whenever you have replaced the following PCBs:

a. DC Controller PCB

1) Start service mode (adjustment mode [3]), and

enter the settings indicated on the Service

Mode label attached behind the front door.

2) Perform the multifeeder paper width sensor

adjustment.

3) Perform scanning lamp intensity adjustment.

4) Perform AE adjustment.

As necessary, change the settings of service

mode and user mode.

Caution:

If you changed any of the settings indicated in

the Service Mode label, be sure to record the

new settings on the label.

b. Composite Power Supply PCB

1) Select service mode No. 315 through No. 318

(adjustment mode [3]), and enter the settings

indicated on the label attached to the composite

power supply PCB.

Be sure to record any new settings in the Ser-

vice Mode label.

2 Adjusting the Scanning Lamp

Intensity

Select service mode No. 407.

1) Place the Test Sheet NA3 on the copyboard,

and close the copyboard cover.

2) Turn OFF AE, and make copies in continuous

mode at copy density 5 and VR850 (DC bias) is

at center.

3) Press the zoom + key or zoom - key so that the

optimum image is obtained.

• If the image is too light, press the zoom + key.

• If the image is too dark, press the zoom - key.

Reference:

1. What is referred to as optimum image is an

image in which gray scale No. 8 on the copy

corresponds to gray scale No. 4 through

No. 7 on the Test sheet whtile the copy is

free of fogging.

2. Turning the VR excessively can cause E220

to be displayed. If this is the case, turn the

VR 301 to the center position, turn OFF/ON

the power, and make adjustments once

again.

Caution:

After making the adjustment, be sure to perform

AE adjustment.

3 AE Adjustment

c. AE Sensor PCB

1) Perform AE adjustment.

Caution:

If you changed any of the settings indicated in

the Service Mode label, be sure to record the

new settings on the label.

d. Light Adjustment Sensor PCB

1) Perform scanning lamp intensity adjustment.

2) Perform AE adjustment.

Caution:

If you changed any of the settings indicated on

the Service Mode label, be sure to record the

new settings on the label.

Perform AE adjustment using the following three

service modes:

q AE Basic Adjustment

No. 410 scanner forward stop

No. 408 scanning lamp ON check

No. 208 AE sensor voltage display

No. 301 AE scan lamp intensity automatic ad-

justment

w No. 302 AE mode copy density (developing

bias) reference adjustment

e No. 303 AE mode copy density (developing

bias) slope adjustment

If the copy density is not optimum after performing AE basic adjustment q No. 410, No. 408, No.

208, and No. 301, try w No. 302 and e No. 303 in

sequence.

2–15

STANDARDS AND ADJUSTMENTS

If you have replaced the AE sensor, scanning

lamp, or DC controller or if you performed scanning

lamp intensity adjustment (VR301), you must perform

• AE basic adjustment,

• No. 410 scanning forward stop,

• No. 408 scanning lamp ON check,

• No. 208 AE sensor voltage indication, and

• No. 301 AE scanning lamp intensity automatic

adjustment.

Go through the steps that follow when making

these adjustments. Table 2-201 gives a list of three

service modes excluding No. 408 scanning lamp

ON check and No. 208 AE sensor voltage indication.

a. AE Basic Adjustment (No. 410, No. 408,

No. 208, No. 301)

In this adjustment, the intensity of the scanning

lamp is read by the lamp intensity sensor, and the

voltage of the AE sensor unit is adjusted using

VR860/851 on the service switch PCB.

After making the adjustment, you must perform

AE scan lamp intensity automatic adjustment.

1) Place the Test Sheet NA-3 on the copyboard,

and close the copyboard.

Press the service mode switch (SW850) to start

service mode.

2) Press ‘4’ on the numeric keypad, and press the

AE key.

• The display indicates ‘401’.

3) Press ‘410’ on the numeric keypad.

• The machine indicates ‘410’.

4) Press the Start key once.

• The scanner moves forward.

Caution:

Each press on the Start key causes the scanner

to move forward. Be sure not to press it more

than once.

9) Press the Start key.

• The display indicates ‘0’ through ‘255’.

10) Adjust VR860/851 on the Service switch PCB

so that the display indicates ‘100’ through ‘105’.

11) Turn OFF/ON the power switch.

• This turns OFF the scanning lamp and turns

ON the power once again.

12) Press the service mode switch.

• The machine start service mode and indi-

cates ‘1’.

13) Press ‘3’ on the numeric keypad, and press the

AE key.

• The display indicates ‘301’.

14) Press the Start key.

Caution:

Wait until initial rotation ends.

• After initial rotation, the AE indicator starts to

flash.

15) Press the AE key so that the following takes

place to perform automatic adjustment.

• The AE indicator stops flashing and remains

ON.

• The scanner moves to the AE measurement

point.

• When the intensity has stabilized, the reading

of the AE sensor is stored.

• The lamp turns OFF, and the scanner returns.

16) After the above ends, press the Clear key twice.

• The display indicates ‘3’.

17) Press ‘1’ on the numeric keypad, and press the

AE key.

• The display indicates ‘1’.

18) Press ‘116’ on the numeric keypad, and press

the Start key.

• Make sure that the display indicates ‘68’

through ‘72’. If not, start with step 2) of operation/inspection mode and make adjustments

once again.

5) Press ‘408’ on the numeric keypad, and press

the Start key.

• The display indicates ‘ON’, and the scanning

lamp turns ON about 1.5 sec later.

6) Press the Clear key twice.

• The display indicates ‘4’.

7) Press ‘2’ on the numeric keypad, and press the

AE key.

• The display indicates ‘201’.

8) Press ‘208’ on the numeric keypad.

• The machine indicates ‘208’.

2–16

b. AE Mode Copy Density (developing bias)

Reference Point Adjustment (No. 302)

1) If the display does not indicate ‘300’s’, start

adjustment mode of service mode as you would

for No. 301.

2) Press ‘2’ on the numeric keypad.

• The display indicates ‘302’.

3) Press the Start key.

• The display indicates the current setting.

4) Change the setting using the numeric keypad,

and press the AE key.

• To increase the setting, press the AE key.

Loading...

Loading...