Canon np6560 Service Handbook

REVISION 0

COPYRIGHT © 1997 CANON INC. CANON NP6560/NP6360/NP6260 REV.0 NOV.1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

NOV. 1997

FY8-23AS-000

COPYRIGHT © 1997 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly

supervised to avoid disclosure of confidential information.

IMPORTANT

THIS DOCUMENTATION IS PUBLISHED BY CANON INC., JAPAN, TO SERVE AS A SOURCE OF

REFERENCE FOR WORK IN THE FIELD.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY SLIGHTLY FROM

ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER PRINTED

MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED TO

THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

THIS DOCUMENTATION IS INTENDED FOR ALL SALES AREAS, AND MAY CONTAIN

INFORMATION NOT APPLICABLE TO CERTAIN AREAS.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPARTMENT 1

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride-shi, Ibaraki 302 Japan

COPYRIGHT © 1997 CANON INC. CANON NP6560/NP6360/NP6260 REV.0 NOV.1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

i

CONTENTS

CHAPTER 1 MAINTENANCE AND INSPECTION

A. Scheduled Servicing Char t ..........1-1

1. Copier......................................1-1

2. Paper Deck-A1........................1-3

B. Periodically Replaced Parts .........1-4

C. Consumables and Durables.........1-5

1. Copier......................................1-5

2. Paper Deck-A1........................1-6

D. Image Adjustment Basic

Procedure .....................................1-7

E. Points to Note for

Scheduled Servicing ....................1-8

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A. Image Adjustment ........................2-1

1. Adjusting the Image Leading

Edge Margin ............................2-1

2. Adjusting the Image Leading

Edge Non-Image Width

(registration)............................2-1

3. Adjusting the Left/Right

Registration (left/right front

deck paper deck, cassette).....2-2

3-1.Adjusting the Left/Right

Registration (paper deck-A1)...2-3

4. Adjusting the Left/Right

Registration (holding tray

position;2nd side of two-

sided/overlay copies)...............2-4

5. Adjusting the Left/Right

Margin .....................................2-4

6. Executing AE Automatic

Adjustment ..............................2-5

7. Adjusting the AE Slope...........2-6

B. Exposure System.........................2-7

1. Routing the Scanner Drive

Cable.......................................2-7

2. Orientation of the Heat

Absorbing Glass ......................2-8

3. Adjusting the Tension of the

Scanning Lamp Cable.............2-8

4. Adjusting the Position of the

Mirror.......................................2-9

5. Cleaning the Mirror (No.5

mirror) ....................................2-10

6. Routing the Light-Blocking

Belt........................................2-10

7. Routing the Lens X Direction

Drive Belt...............................2-11

8. Adjusting the Position of the

Scanner Locking Solenoid

(SL1) .....................................2-11

C. Image Formation System...........2-12

1. Grid Wire of the Primary

Charging Assembly...............2-12

2. Adjusting the Height of the

Charging Wire .......................2-14

3. Adjusting the Position of the

Blanking Exposure Lamp......2-15

4. Position of the Roller

Electrode...............................2-16

5. Adjusting the Position of the

Cleaning Assembly Side

Seal.......................................2-16

6. Cleaning the Cleaner Side

Scraper..................................2-17

D. Pick-Up/Feeding System ............2-19

1. Orientation of the Cassette/

Front Paper Deck Pick-Up

Roller.....................................2-19

2. Orientation of the Cassette/

Front Paper Deck Separation

Roller.....................................2-20

3. Orientation of the Feeding

Roller (cassette/ front paper

deck)......................................2-20

4. Orientation of the Multifeeder

Pick-Up Roller.......................2-21

4-1.Orientation of the Paper

Deck-A1 Pick-Up Roller ........2-21

1

2

3

4

5

5. Rotation of the Multifeeder

✽4✽;cassette/

multifeeder) ...........................2-57

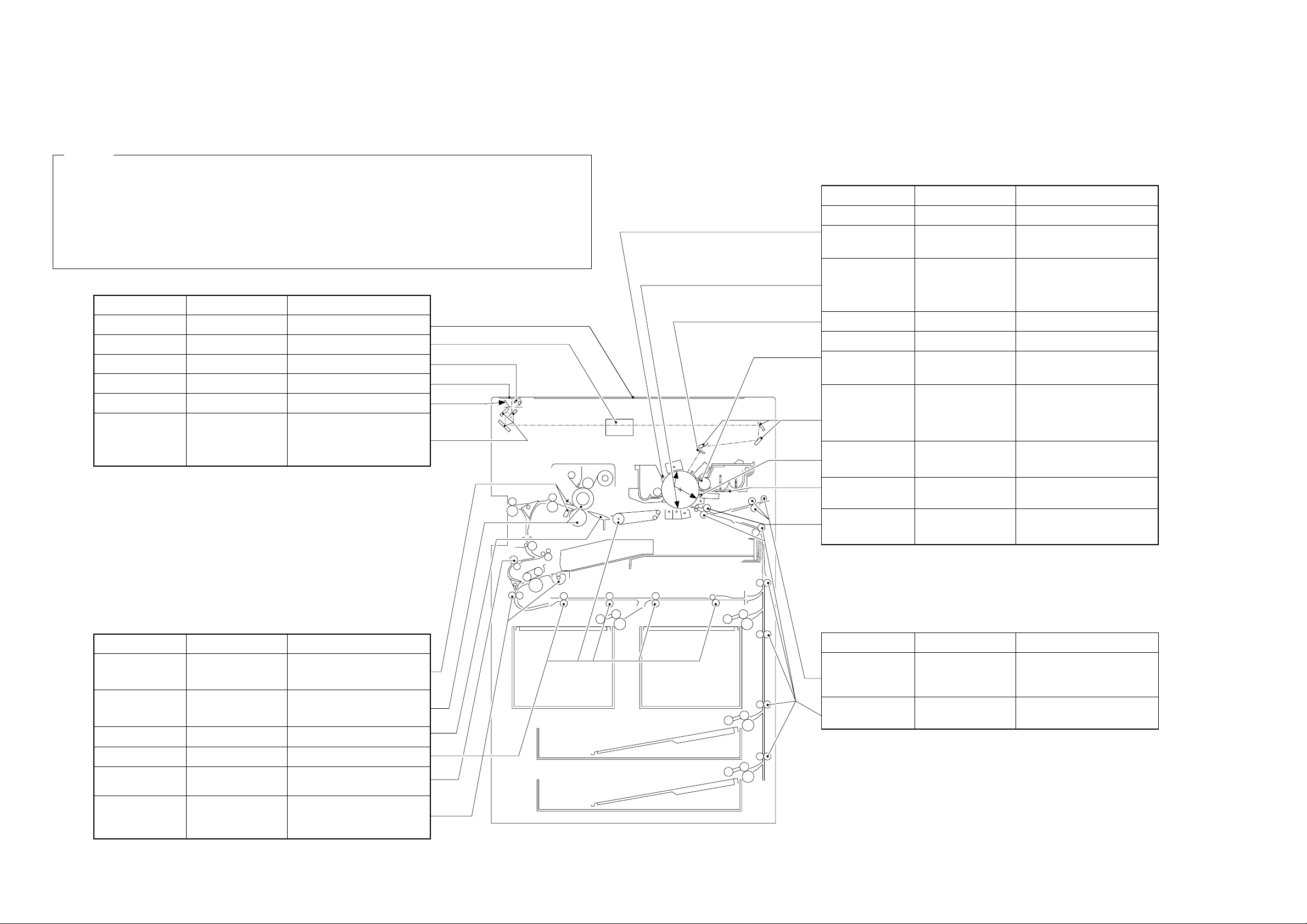

A. Sensors........................................3-2

B. Switches and Solenoids...............3-6

C. Motors and Fans ........................3-10

D. Clutches .....................................3-12

E. Lamps, Heaters, and

Photosensors .............................3-14

F. PCBs..........................................3-16

G. Paper Deck-A1...........................3-18

1. Sensors and Switches ..........3-18

2. Motors, Clutches, Solenoids,

and PCBs..............................3-20

H. Variable Resistors (VR),

Light-Emitting Diodes (LED),

and Check Pins by PCB.............3-22

1. DC Controller PCB................3-22

2. AC Driver PCB......................3-25

3. DC Power Supply PCB .........3-25

4. Control CPU PCB .................3-26

5. Holding Tray Driver PCB .......3-27

6. Potential Measurement

PCB.......................................3-28

7. HVT1 PCB.............................3-29

8. HVT2 PCB.............................3-30

9. Inverter PCB..........................3-30

Feeding Roller .......................2-22

5-1.Orientation of the Paper

Deck-A1 Feeding Roller........2-22

6. Adjusting the Separation

Roller Pressure of the

Cassette/Front Paper Deck...2-23

7. Adjusting the Separation

Roller Pressure of the

Holding Tray...........................2-24

8. Pick-Up/Feeding Roller of

the Multifeeder ......................2-24

9. Adjusting the Position of the

Pick-Up Roller Releasing

Solenoid (cassette) ...............2-25

9-1.Adjusting the Position of the

Pick-Up Roller Releasing

Solenoid (front paper deck)...2-26

9-2.Adjusting the Position of the

Pick-Up Roller Releasing

Solenoid (paper deck-A1) .....2-26

10.Adjusting the Position of the

Pick-Up Roller Releasing

Solenoid (multifeeder)...........2-27

11.Routing the Timing Belt of the

Side Guide (multifeeder

assembly)..............................2-28

12.Adjusting the Position of the

Solenoid (delivery paper

deflecting plate solenoid) ......2-28

13.Adjusting the Position of the

Holding Tray Paper Deflecting

Plate Drive Solenoid..............2-29

14.Adjusting the Position of the

Holding Tray Assembly Side

Guide Plate ...........................2-29

15.Adjusting the Position of the

Holding Tray Paper Jogging

Plate......................................2-30

16.Adjusting the Timing Belt of

the Holding Tray Paper

Jogging Guide Plate..............2-30

17.Adjusting the Position of the

Holding Tray Paper Jogging

Plate Solenoid.......................2-31

18.Drive Belt...............................2-31

E. Fixing System.............................2-33

1. Points to Note When Installing

the Fixing Heater...................2-33

2. Adjusting the Position of the

Fixing Assembly Inlet

Guide.....................................2-33

3. Adjusting the Lower Roller

Pressure (nip)........................2-35

4. Adjusting the Fixing Clutch ...2-36

F. Electrical System........................2-37

1. When Replacing the DC

Controller PCB......................2-37

2. Checking the Surface

Potential Control System.......2-37

3. Checking the Potential

System ..................................2-41

4. Potential Control System

Conversion Table...................2-43

5. Checking the Environment

Sensor...................................2-48

6. Checking the

Photointerrupters...................2-49

7. Registering the Paper Width

Basic V alue (

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

ii

10.Lamp Regulator PCB............3-31

11.Counter PCB.........................3-31

CHAPTER 4 SERVICE MODE

12.Side Deck Driver

(paper deck-A1) ....................3-32

A. Outline..........................................4-1

B. Using Service Mode.....................4-2

C. Using Adjustment Mode and

Options Mode...............................4-2

D. Display Mode ( ).................4-4

1

✽

✽

CHAPTER 5 SELF DIAGNOSIS

A. Copier...........................................5-1

B. RDF-D1........................................5-6

APPENDIX

A. GENERAL TIMING CHART I .......A-1

B.

SIGNALS AND ABBREVIATIONS

1. Signals....................................A-3

2. Abbreviations..........................A-4

C. GENERAL CIRCUIT DIAGRAM ..A-5

D. PAPER DECK-A1 GENERAL

CIRCUIT DIAGRAM.....................A-7

..A-3

E. I/O Display Mode ( ).........4-17

F. Adjustment Mode ( ) .........4-53

G. Function Mode ( ).............4-62

H. Options Mode ( ) ..............4-66

I. Counter Mode ( )..............4-72

2

✽

✽

3

✽

✽

4

✽

✽

5

✽

✽

6

✽

✽

C. Sorter ...........................................5-8

E. SPECIFICATIONS .......................A-9

A.Copier ..........................................A-9

1. Type ........................................A-9

2. Mechanisms............................A-9

3. Performance .........................A-10

4. Others...................................A-13

B.Paper Deck-A1 ...........................A-16

iii

iv

CHAPTER 1 MAINTENANCE AND INSPECTION

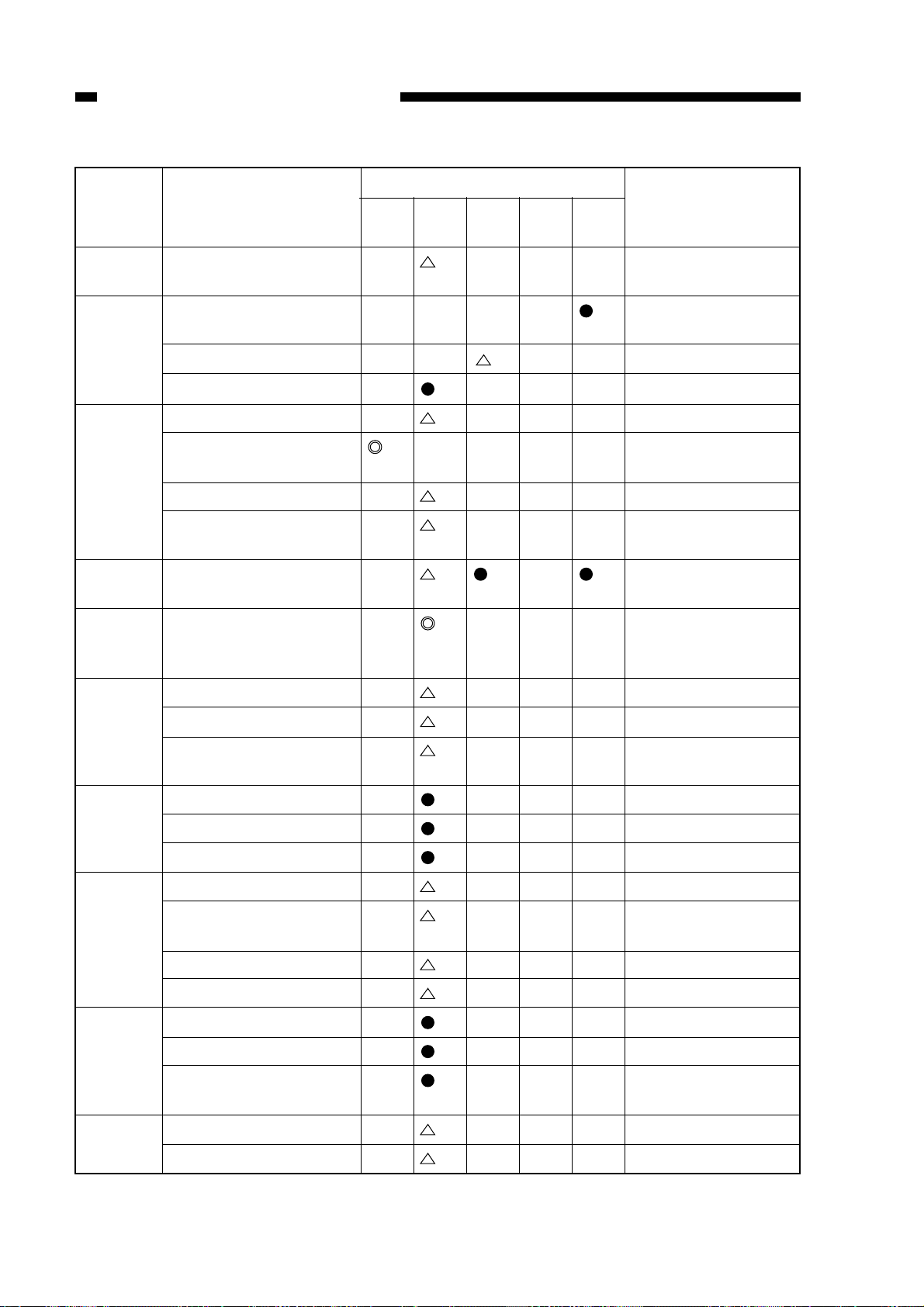

A. Scheduled Servicing Chart

Do not use solvents or oils other than those specified.

1. Copier

: Clean : Replace : Oil : Adjust : Inspect

Note 1: Take care not to touch the mirrors or the lenses.

CHAPTER 1 MAINTENANCE AND INSPECTION

1-1

Caution:

Unit

Optical

path

Use

alcohol;

then,

apply oil.

Charging

assembly

Photosen

sitive

drum

Developing

assembly

Part

No. 1/No. 6 mirror

Dust-proofing glass

Heat absorbing glass

Standard white plate

Reflecting shade

(scanning lamp)

Scanner rail

Scanner cable

Charging wire (primary,

pre-transfer, transfer,

separation)

Grid wire (primary)

Shielding plate (each

charging assembly)

Roller electrode waste

toner case (pre-transfer

charging assembly)

Photosensitive rum

Anti-stray toner sheet

(primary charging

assembly)

Slip ring

Developing cylinder

Developing roller

Remarks

Use blower brush; for

No. 5 mirror, use

mirror cleaning tool.

Use alcohol; then,

apply lubricant.

Check and adjust if

for initial 250,000.

Use solvent.

Use alcohol; then,

apply BARRIERTAIMI.

at instal-

lation

every

250,000

every

500,000

every

750,000

every

1,000,000

Intervals

1

CHAPTER 1 MAINTENANCE AND INSPECTION

Unit

Part

at instal-

lation

Intervals

every

250,000

every

500,000

every

750,000

every

1,000,000

Remarks

Developing

assembly

Cleaner

Fixing

assembly

Delivery

assembly

Waste toner

collection

assembly

Anti-stray toner sheet

(developing assembly)

Blade

Side scraper assembly

Separation claw

Inlet guide

Fixing Cleaning belt

Thermistor

Oil receptacle

Separation claw

(upper/lower)

Waste toner

Copyboard glass

*

(upper)

*Replace edge.

Apply toner.

Remove paper lint.

Take up during

installation.

(lower)

Remove as

necessary.

Externals

Pick-up

assembly

Feeding

assembly

Holding

tray

Hopper

Ozone filter

Air filter (scanner

cooling fan)

Pick-up roller

Feeding roller

Separation roller

Transfer guide/roll

Registration roller

(upper/lower)

Feeding belt

Feeding roller

Pick-up roller (crescent)

Upper separation belt

Separation lower

feeding roller

Toner supply mouth

Toner receptacle

1-2

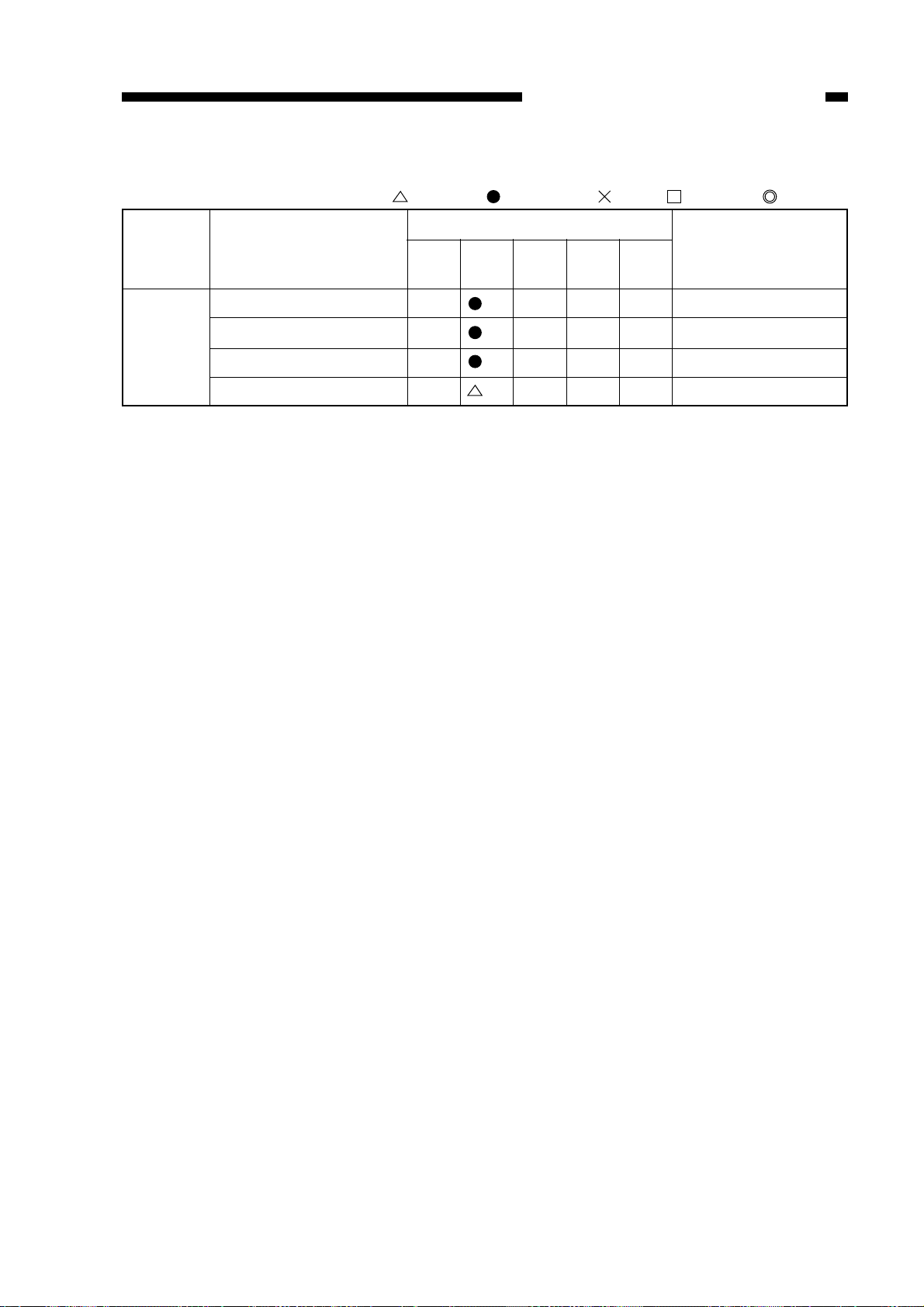

2. Paper Deck-A1

Unit

Pick-up roller

Part

CHAPTER 1 MAINTENANCE AND INSPECTION

: Clean : Replace : Oil : Adjust : Inspect

Intervals

at instal-

lation

every

250,000

every

500,000

every

750,000

every

1,000,000

Remarks

Pick-up

assembly

Feeding roller

Separation roller

Vertical path, roll

1-3

CHAPTER 1 MAINTENANCE AND INSPECTION

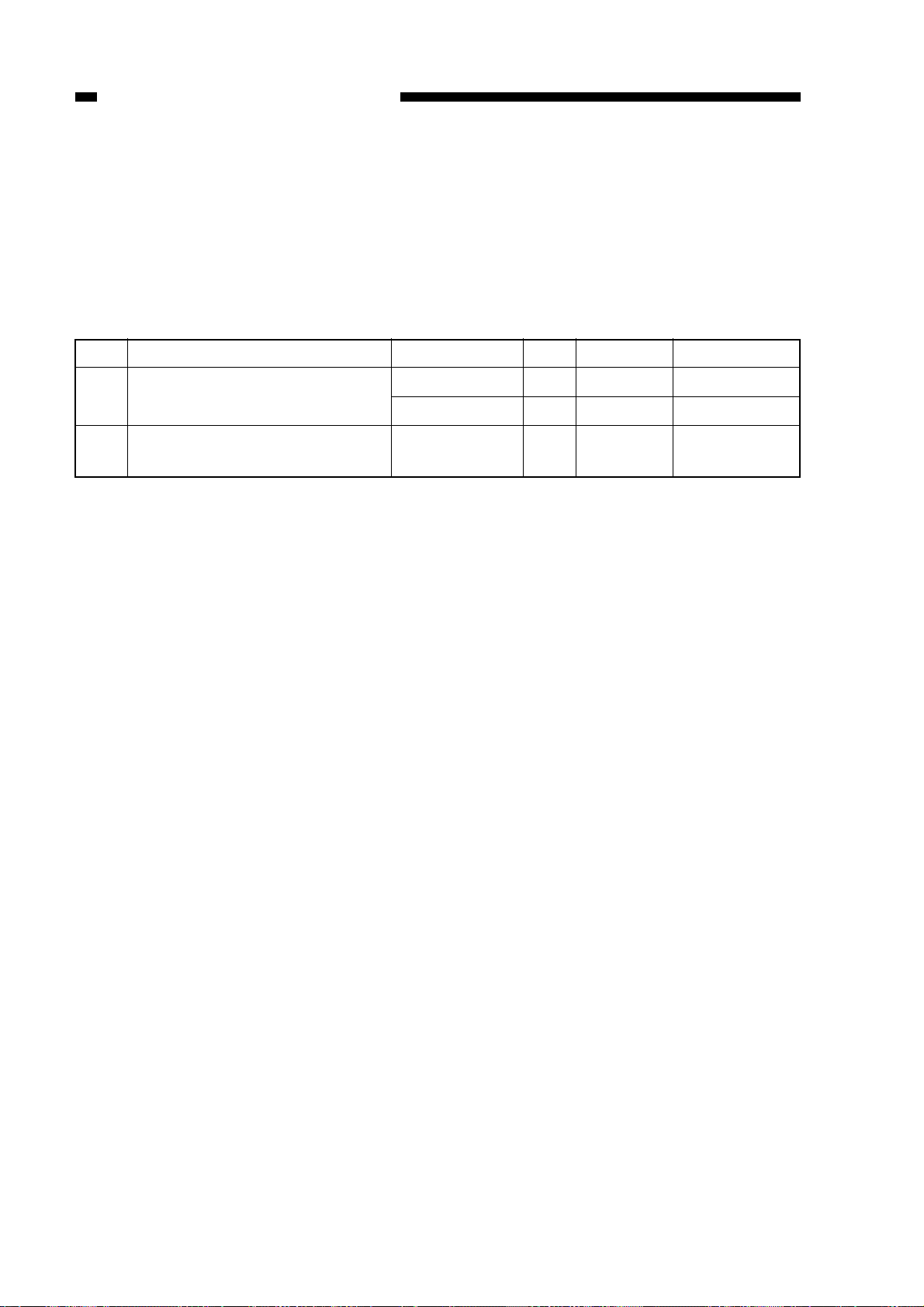

B. Periodically Replaced Parts

Some parts of the machine must be replaced on a periodical basis to maintain the

performance of the machine at a specific level regardless of the presence/absence of

damage (when they fail, they will affect the performance to a significant degree).

Schedule the replacement so that it coincide with a scheduled service visit.

as of November 1997

No.

1

2

Parts name

Primary/pre-transfer/transfer/

separation charging wire

Primary charging assembly grid

wire

Part number

FY3-0030-000

FY3-0040-000

FY1-0883-000

Q’ty

AR

AR

AR

Life (copies)

250,000

250,000

500,000

Remarks

100V

120/230V

Note: The above values are all estimates and are subject to change based on future

data.

Table 1-1

1-4

CHAPTER 1 MAINTENANCE AND INSPECTION

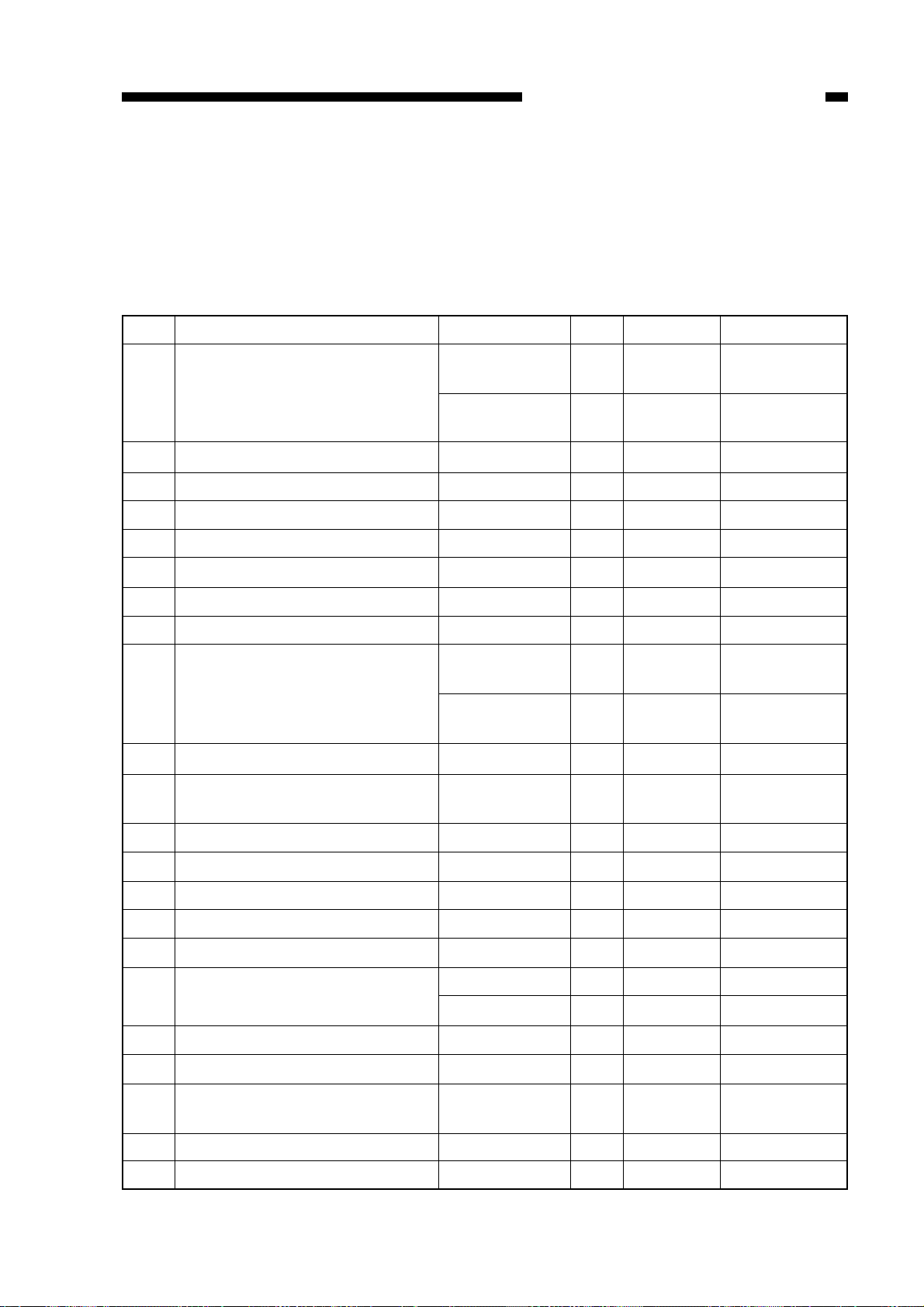

C. Consumables and Durables

Some parts of the machine may need replacement once or more because of wear or

damage. Use the table as a reference, and replace them as needed.

1. Copier

as of November 1997

No.

1

2

3

4

5

6

7

8

9

10

Parts name

Multifeeder pick-up roller

Multifeeder feeding roller

Multifeeder separation roller

Scanning lamp

Scanning lamp

Cleaner separation claw

Fixing cleaning belt

Delivery upper separation claw

Pick-up roller (paper deck,

cassette)

Feeding roller (paper deck, cassette)

Parts number

FF5-1220-000

FF5-1221-000

FB2-7522-000

FB2-7545-000

FH7-3333-000

FH7-3282-000

FB2-6899-000

FA3-8908-000

FC1-0391-030

FF5-1220-000

FF5-1221-000

FB2-7695-000

Q’ty

1

1

2

1

1

1

3

1

6

4

4

8

Life (copies)

120,000

120,000

120,000

120,000

250,000

250,000

250,000

250,000

500,000

250,000

250,000

250,000

Remarks

Front

Actual number of copies.

Rear

Actual number of copies.

Actual number of copies.

Actual number of copies.

100V/120V

220V/240V

Rear

Actual number of copies.

Front

Actual number of copies.

Actual number of copies.

Separation roller (paper deck,

11

cassette)

Duplexing pick-up crescent roller

12

Duplex upper separation belt

13

Duplexing feeding roller

14

Primary charging wire cleaner 1

15

Primary charging cleaner 2

16

Transfer charging wire cleaner

17

Separation charging wire cleaner

18

Pre-transfer charging wire cleaner

19

Pre-transfer charging assembly

20

scraperr

Upper fixing roller

21

22

Lower fixing roller

FB2-7777-000

FC2-1532-000

FA5-5427-000

FC2-1533-000

FF2-3552-000

FF2-3551-000

FF2-3551-000

FF2-3552-000

FF5-3090-000

FF5-3090-000

FB4-3689-000

FB4-3690-000

FB3-9164-000

Table 1-2a

4

2

8

1

2

2

1

1

2

1

1

1

1

250,000

250,000

250,000

250,000

500,000

500,000

500,000

500,000

500,000

500,000

500,000

500,000

500,000

Actual number of copies.

Actual number of copies.

Actual number of copies.

Actual number of copies.

1-5

CHAPTER 1 MAINTENANCE AND INSPECTION

No.

23

24

25

26

27

28

29

30

31

32

33

34

Parts name

Heat insulating bush (front,

rear)

Fixing main thermistor (TH1)

Fixing sub thermistor (TH2)

Pick-up clutch (left deck, cassette)

Pick-up clutch (right deck)

Cleaning blade

Primary charging assembly

Transfer/separation charging

assembly

Pre-transfer charging assembly

Fixing thermal switch

Delivery lower separation claw

Developing cylinder

Parts number

FB4-3689-000

FH7-7349-000

FG5-8812-000

FH7-5763-000

FH7-5729-000

FB2-8453-000

FG5-4378-030

FG5-9592-000

FG5-8809-000

FH7-7154-000

FA2-9037-000

FG5-8230-020

Q’ty

2

1

1

3

1

1

1

1

1

1

2

1

Life (copies)

500,000

500,000

500,000

1,000,000

1,000,000

1,000,000

1,000,000

1,000,000

1,000,000

1,000,000

1,000,000

1,000,000

Remarks

Simultaneously

w/ upper fixing

roller.

Actual number of copies.

Actual number of copies.

Use both edges;

500,000 for each

.

Developing assembly roll

35

2. Paper Deck-A1

No.

1

2

3

Side paper deck pick-up roller*

Side paper deck feeding roller

Side paper deck separation

roller

Parts name

* Exercise care during replacement; the pick-up roller of the side paper deck and

the pick-up roller of the machine must be oriented differently.

FB2-6933-000

Table 1-2b

Parts number

FF5-1220-000

FF5-1221-000

FB2-7695-000

FB2-7777-000

Table 1-2c

2

Q’ty

1

1

2

1

1,000,000

as of November 1997

Life (copies)

250,000

250,000

250,000

250,000

Remarks

Front

Actual number of copies.

Rear

Actual number of copies.

Actual number of copies.

Actual number of copies.

1-6

1-7

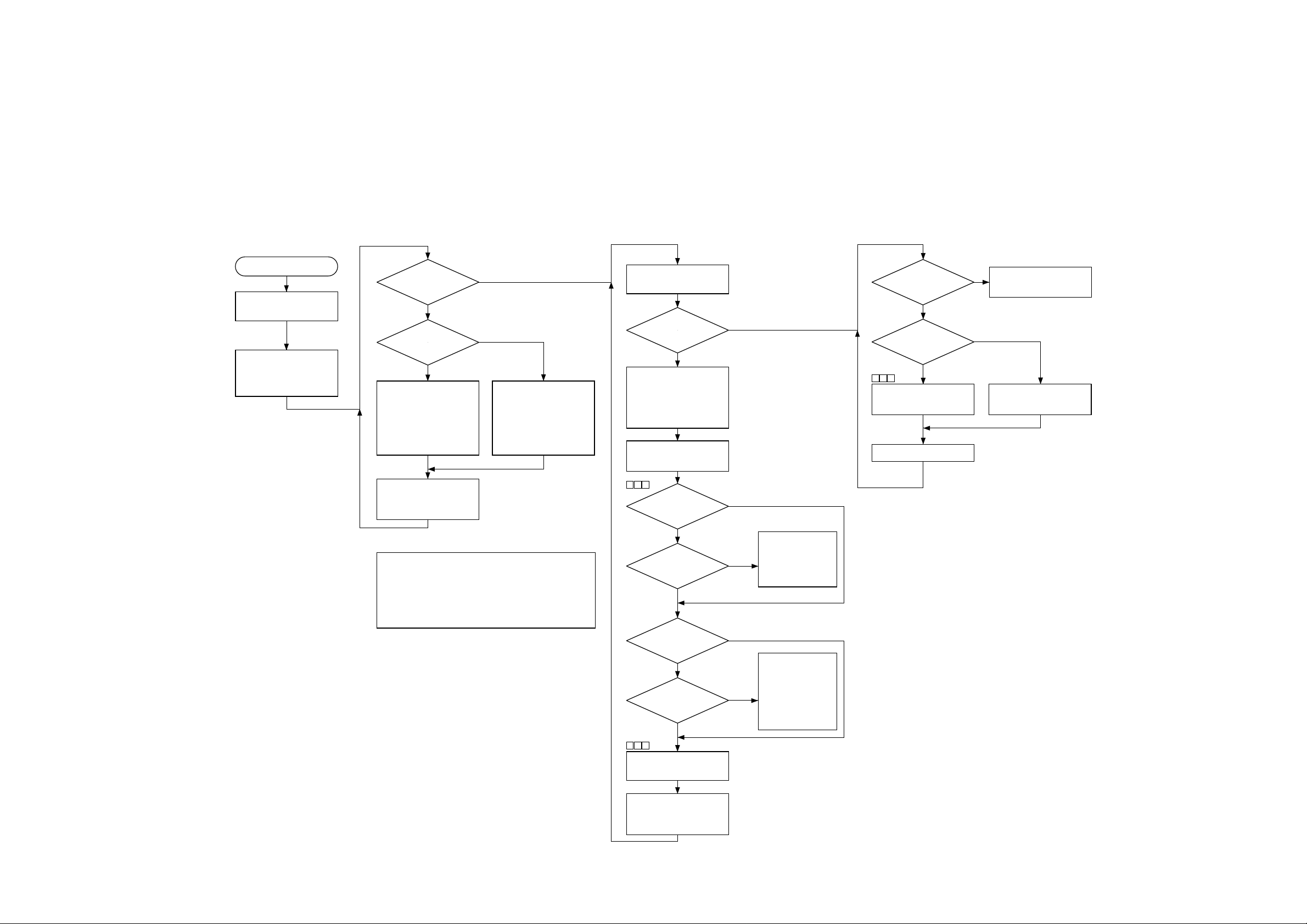

D.Image Adjustment Basic Procedure

■ Non-AE, Copy Density at 5

Is there a

difference in density

between front

and rear?

Is it low (light)

at the rear?

Turn the adjusting screw

at the rear of the primary

charging assembly

clockwise, and turn the

adjusting screw at the

front counterclockwise

the same degree (1.5 mm

max. each).

Make two to three

copies of the Test

Sheet.

Check the height of the

charging wire.

Turn the adjusting screw

at the rear of the primary

charging assembly

counterclockwise, and

turn the adjusting screw

at the front clockwise the

same degree (1.5 mm

max. each).

Turn off and then on the

machine, and make a

copy.

Note 1:

Note 2:

Check the copy paper

and the transfer system.

Is the density

of gray scale No. 1

too low (light)?

Clean the standard white

plate, mirror, lens, dustroofing glass, scanning

lamp, reflecting plate, and

heat absorbing glass.

Turn off and then on the

machine, and make a

copy.

Is 'VDM' 'VDT'

±10 V?

Is 'PLMT' '1'?

Is 'VL1M' 'VL1T'

±10 V?

Is 'VL1M" 'VL1T'

±10V?

Check the potential

control system; if

normal, replace the

photosensitive

drum.

Check the scanning

lamp and the

potential control

system; if normal,

replace the

photosensitive

drum.

Increase the value of

'VDT-SW'.

Turn off and on the

machine, and make a

copy.

Increase the value of

'LIGHT_5'.

Decrease the value of

'LIGHT_5'.

Is the density

of gray scale No. 10

proper?

Is the density

of gray scale No. 10

too high (dark)?

Execute AE adjustment.

(See p. 11-9.)

<Pre-Checks>

<Density slope>

<

Solid black

>

NO

YES

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

NO

YES

*1*

*3*

*5*

Clean the charging wire.

Make a copy.

If the difference still exists after turning the screw

1.5 mm (each; a full turn causes a 0.7mm

difference), check the charging assemblies,

scanning lamp, and scanner for dirt.

When turning the screw counterclockwise, take

care so that the wire is not 7.5mm or less in

height.

E. Points to Note for Scheduled Servicing

Cleaning

Parts Tools/chemicals

Remarks

Multifeeder tray,

pick-up roller,

feeding roller

Vertical path roller

Alcohol, lint-free

paper

Alcohol, lint-free

paper

Cleaning

Cleaning

Parts Tools/chemicals

Remarks

Pre-exposure lamp

Primary charging

assembly,

transfer/separation

charging assembly, pretransfer charging assembly

Dust-proofing glass

Blanking exposure lamp

No. 4 through No. 6

mirrors

Roller electrode

Developing

assembly mount

Registration roller

Moist cloth (Note)

Alcohol, lint-free

paper

Lint-free paper

Blower brush or lintfree paper

Alcohol, lint-free

paper

Cleaning

Dry wiping; then, using lintfree paper moistened with

alcohol

Cleaning

Cleaning with blower brush; if

necessary, using lint-free

paper. For No. 5 mirror, use

mirror cleaning tool

Dispose of toner collecting on

roller electrode

Cleaning

Cleaning

Note: Make sure no droplets of water remain.

Parts

Copyboard glass

Tools/chemicals

Remarks

Cleaning

Alcohol

Lens

Heat absorbing glass

Standard white plate

Reflecting plate

Blower brush

Lint-free paper

Lint-free paper

Blower brush

Cleaning

Dry wiping

Dry wiping

Cleaning

No. 1 through No. 3

mirrors

Blower brush or lint-

free paper

Cleaning with blower brush; if

necessary, lint-free paper

Parts Tools/chemicals

Remarks

Separation claw

Upper roller,

lower roller

Feeding assembly

Re-pick up assembly,

refreshing roller

Re-pick up assembly,

pick-up roller,

registration roller

Solvent and lint-free

paper

Cleaning oil, lint-free

paper

Moist cloth (Note)

Alcohol, lint-free paper

Paper guide

Solvent, lint-free paper

Alcohol, lint-free paper

Cleaning

Cleaning

Cleaning

Cleaning

Cleaning

Cleaning

Anti-stray toner

(primary charging

assembly)

Cleaning

Anti-stray toner

sheet (developing

assembly)

Cleaning

Caution:

• Make thorough checks of the block (front, rear) for melting by leakage, deformation by heat, tears, and

yellowing.If any fault is found, replace it.

• Be sure to check and clean the inner side as well as the outer side of the block (front, rear).

• Do NOT use a cloth coated with metal powder for cleaning.

• Do NOT use a moist cloth for cleaning.Use lint-free paper, and clean.(Be sure that the par t is fully dry

before putting it back into the machine.

• Try to finish all work (scheduled servicing/maintenance) within a specific per iod of time.

1-8

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A. Image Adjustment

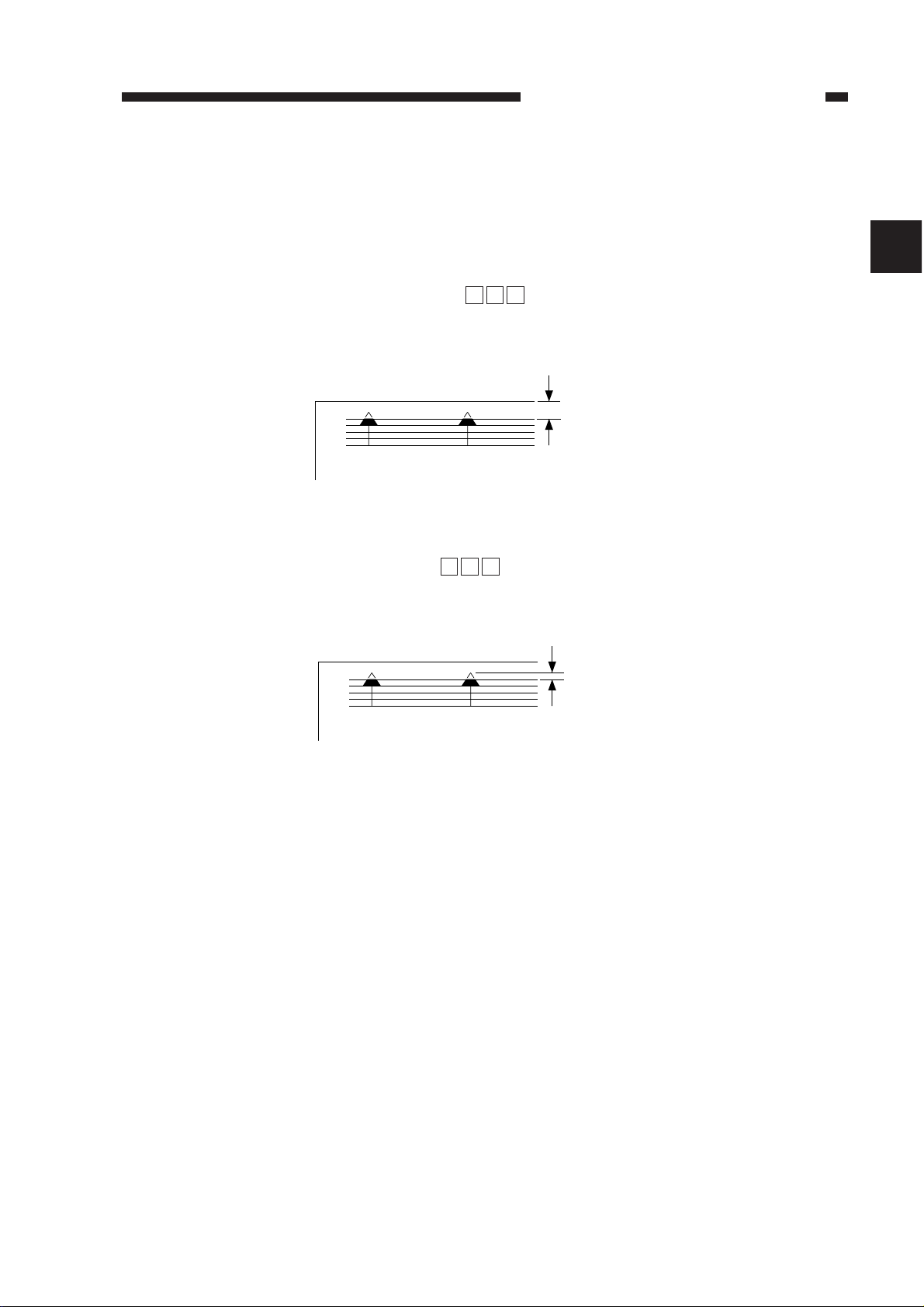

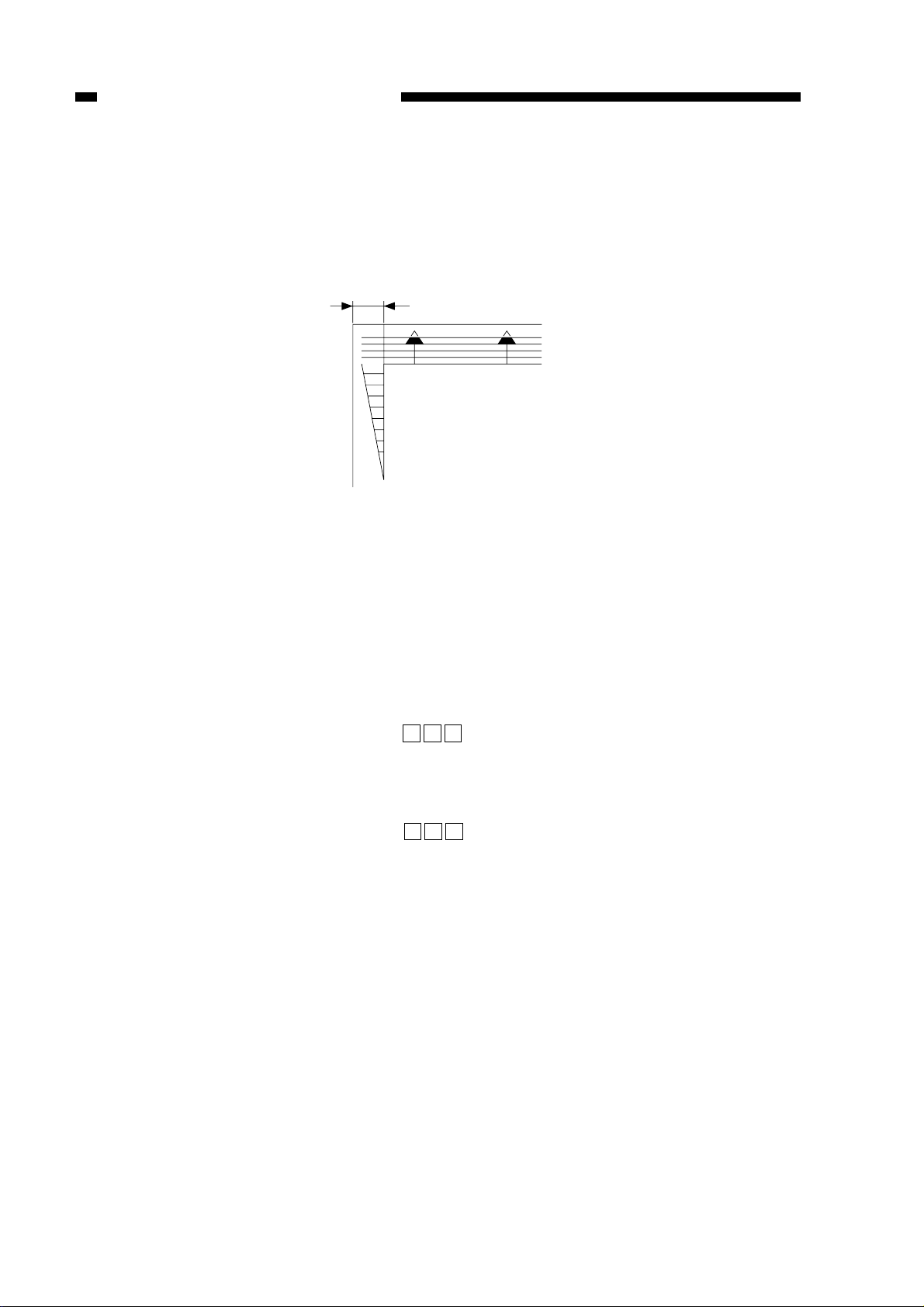

1. Adjusting the Image Leading Edge Margin

Select ‘LE_BLANK’ in service mode ( ).

Make adjustments so that the image leading edge margin is 4.5 ±1.5 mm when the

Test Sheet is copied in Direct.

(unit: 0.1 mm)

Figure 2-1

2. Adjusting the Image Leading Edge Non-Image Width (registration)

Select ‘REGIST’ in service mode ( ).

Make adjustments so that the image leading edge non-image width is 4.5 ±1.5 mm

when the Test Sheet is copied in Direct.

(unit: 0.1 mm)

Figure 2-2

4.5±1.5mm

✽

3

✽

✽

3

✽

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2-1

2

4.5±1.5mm

Adjusting plate

Screw

Adjusting plate

Screw

10±1.5mm

0

2

4

6

8

10

CHAPTER 2 STANDARDS AND ADJUSTMENTS

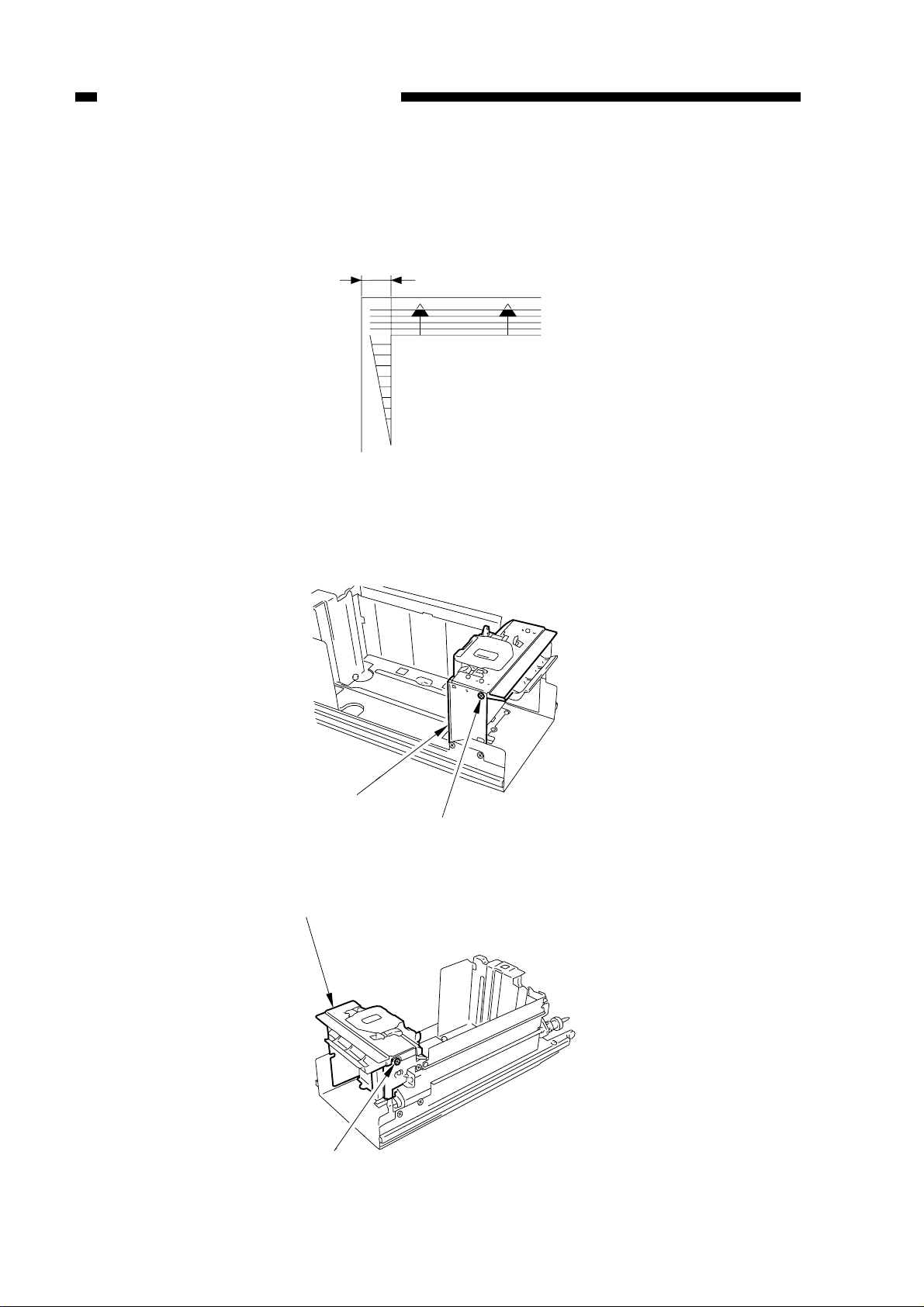

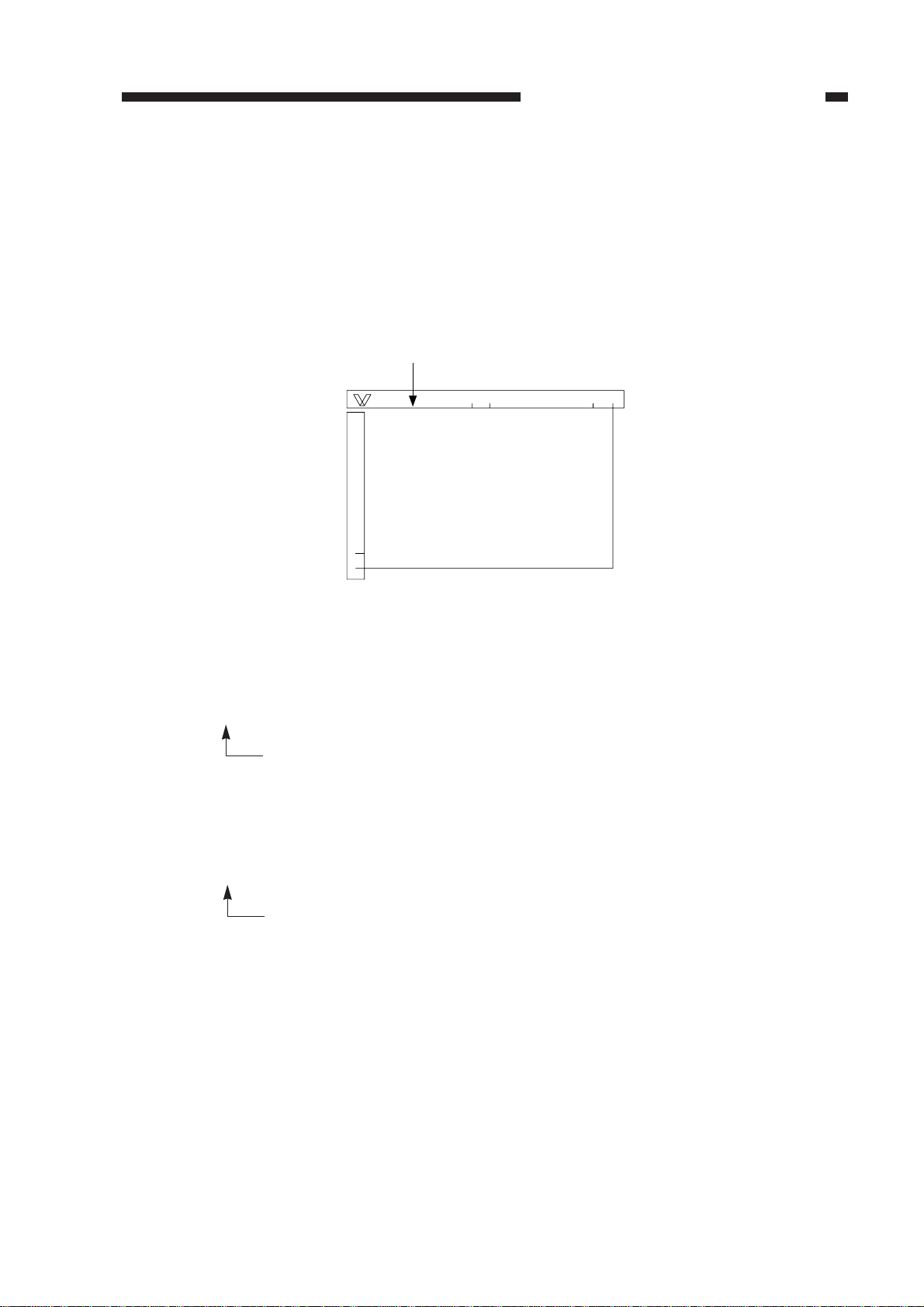

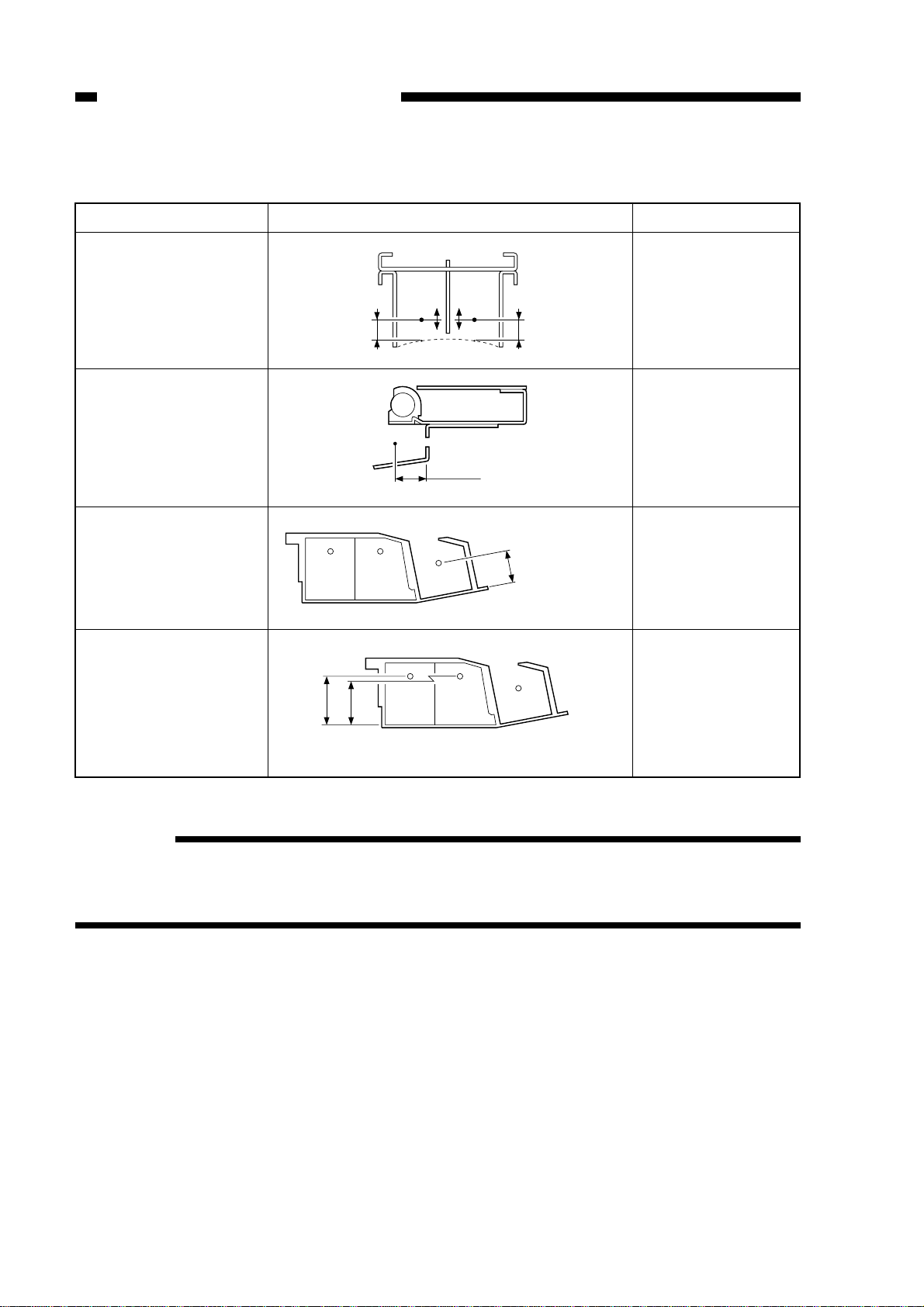

3. Adjusting the Left/Right Registration (left/right front deck paper dec k, cassette)

Make adjustments by moving the horizontal registration adjusting plate of each

left/right paper deck/cassette so that the distance between the line in the copy image and

the the edge of copy paper is 10 ±1.5 mm.

Figure 2-3

a. Left/Right Front Paper Deck

Figure 2-4a

2-2

Figure 2-4b

q and the locking pick w of the

inside unit. (The cassette 4 is not equipped with a locking pick.)

2) Detach the paper size plate of the cassette, and turn the horizontal adjusting screw

with a screwdriver e.

Figure 2-5

3-1 Adjusting the Left/Right Registration (paper deck-A1)

1) Make a copy of the Test Sheet, and check to mak e sure that the left/right registration

between copy image and paper deck is 0 ±1.5 mm or less.

2) If the left/right registration is not as specified, adjust the position of the latch plate of

the deck opening solenoid by turning the two adjusting screws. (At this time, use the

scale on the latch plate as a reference.)

Figure 2-5a (rear left of compartment)

Screws

Latch plate

Scale

q

q

w

e

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2-3

b. Cassette

Turn the horizontal registration adjusting screw of each cassette, and make

adjustments so that the copy image and the edge of copy sheet is 0 ± 1.5mm when the

Test Sheet is copied in Direct.

1) Slide out the cassette, and loosen the two screws

CHAPTER 2 STANDARDS AND ADJUSTMENTS

4. Adjusting the Left/Right Registration (holding tray position; 2nd side of twosided/overlay copies)

Loosen the two screws, and move the guide plate of the holding tray assembly so

that the distance between the line in the copy image and the edge of the copy paper is

0 ±2.0 mm in Direct.

10±2.0mm

0

2

4

6

8

10

Figure 2-6

5. Adjusting the Left/Right Margin

Make adjustments so that the image left/right margin is 2.75 ±2.5 mm when the Test

Sheet is copied in Direct.

Be sure to adjust the left/right registration before making this adjustment.

a. Front Margin Adjustment (left margin)

Select ‘F-BLANK’ in service mode ( ), and change the setting. Increasing the

✽

✽

3

setting increases the front margin.

(unit: 0.1 mm)

b. Adjusting the Rear Margin (right margin)

Select ‘R-BLANK’ in service mode ( ), and change the setting. Increasing the

✽

✽

3

setting increases the rear margin.

(unit: 0.1 mm)

2-4

← (✽: START)

(0: F5, 1:F9).

4) Place the Test Sheet on the copyboard, and close the copyboard cover.

Figure 2-7

5) Press the user mode key

✽ once.

•The scanning lamp turns on, and auto adjustment is executed.

AE_ADJ: 1 ← (✽: START)

Changes to ‘1’.

6) Place a newspaper on the copyboard, and close the copyboard cover.

7) Press the user mode key

✽ once.

•The scanning lamp turns on, and automatic adjustment is executed.

AE_ADJ: 0 ← (✽: START)

Changes to ‘0’.

8) Press the Reset key twice to end service mode.

NA-3

Test Sheet

Butted.

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2-5

6. Executing AE Automatic Adjustment

1) Open the front door, and insert the door switch actuator into the door switch actuator.

2) Push the service mode switch over the cover.

3) Select the following in service mode:

AE_ADJ:0

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Copy

paper

L

Side guide plate (front)

Side guide plate (rear)

7. Adjusting the AE Slope

After executing AE auto adjustment, make a copy of a newspaper (or a rather dark

original). If the copy is foggy or too light, perform the following:

1) Open the front door, and insert the door switch actuator into the door switch assembly.

2) Press the service mode switch over the cover with a clip.

3) Select ‘AE_SLOP’ in service mode ( ).

✽

✽

3

4) Place a newspaper (or a relatively dark original) on the copyboard.

5) Change the setting using the numeric keypad, and press the user mode key (

✽).

q If you decrease the setting in adjustment mode,

→Copies of a newspaper will be lighter.

w If you increase the setting in adjustment mode,

→Copies of a newspaper will be darker.

Note:

You may press the Copy Start key to make copies.

6) Press the Reset key twice to end service mode.

8. Adjusting the Distance between the Side Guide Plates of the Holding Tra y Assembly

If a sheet of paper of a width different from the specified dimension (because of poor

cutting) is used and tends to cause a fault during re-pick up , check the distance between

the side guide plates of the holding tray assembly.

1) After copying on the first side of a two-sided copy, slide out the holding tray, butt the

copy paper on the holding tra y against the side guide plate at the rear, and check that

the copy paper is 1.2 to 2.0 mm away (L) from the side guide plate at the front.

2) If the distance (L) is not between 1.2 and 2.0 mm, select 'paper size_PSZ' in service

mode (*3*), and change the setting so that the distance is 1.2 to 2.0 mm.

3) A higher setting will increase the distance between the side guide plates in 0.367 mm

increments.

Caution:

a. Each setting is effective only for the respective size. Adjust for the size suffering

from re-pick up fault only.

a. If no re-pick up fault is noted, it is best to leave the setting as it is. An increase in

the distance between copy paper and the front side guide plate will cause

variation in registration for 2nd sides, while a decrease in the distance will affect

the alignment of the stack of sheets.

2-6

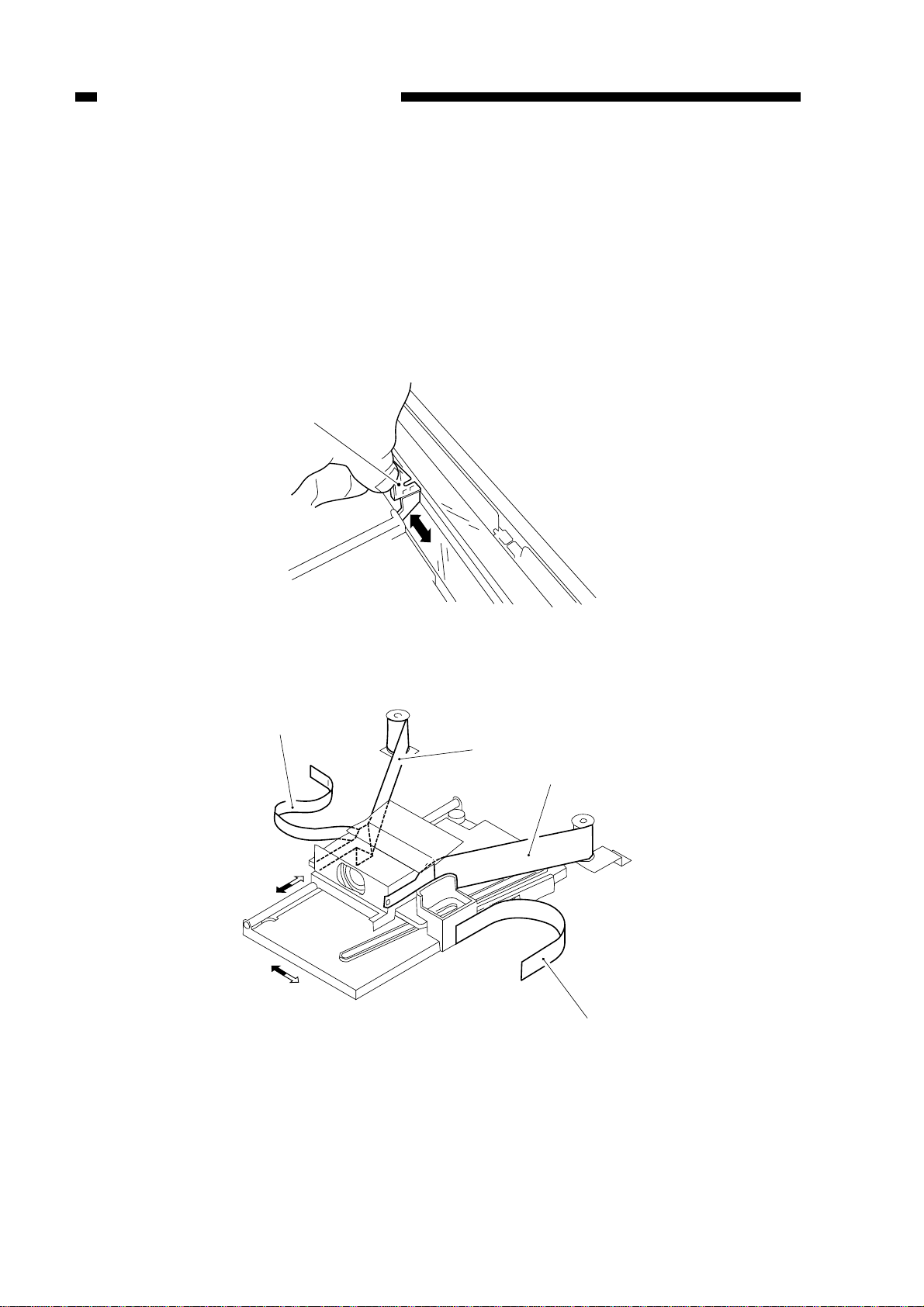

Figure 2-8a

1

3

4

8

5

6

2

7

6

2

Fix in place temporaily

Wind eight times

Steel ball

CHAPTER 2 STANDARDS AND ADJUSTMENTS

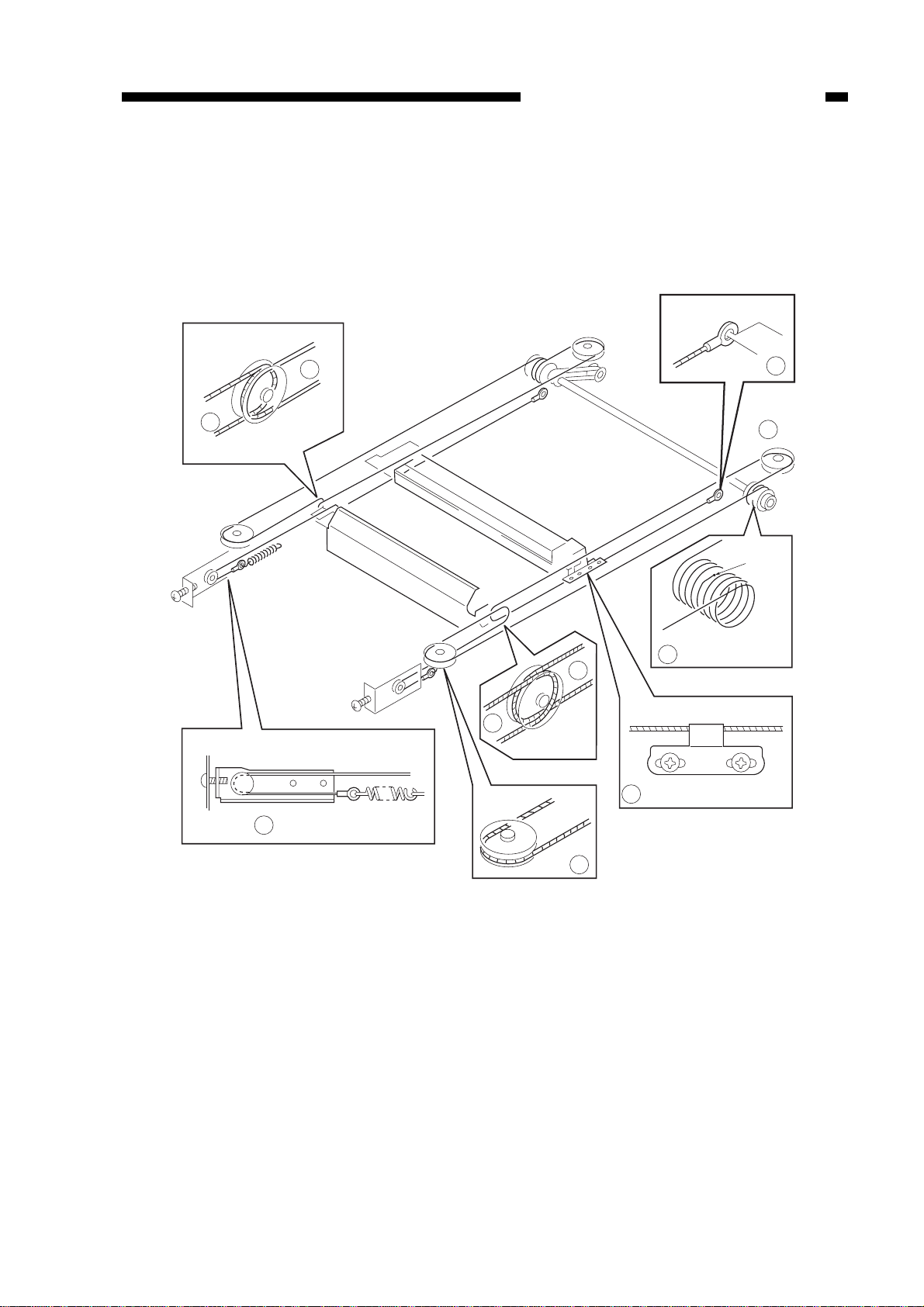

B. Exposure System

1. Routing the Scanner Drive Cable

Route the cable as indicated (q through i), and adjust the tension of the cable and

the position of the mirror.

Figure 2-9

2-7

A

A

10 mm

10 mm

(rear)

(front)

Mirror mount

(rear)

(front)

White paint

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2. Orientation of the Heat Absorbing Glass

When replacing the heat absorbing glass, make sure that the white paint marking is

toward the rear of the machine.

Figure 2-10

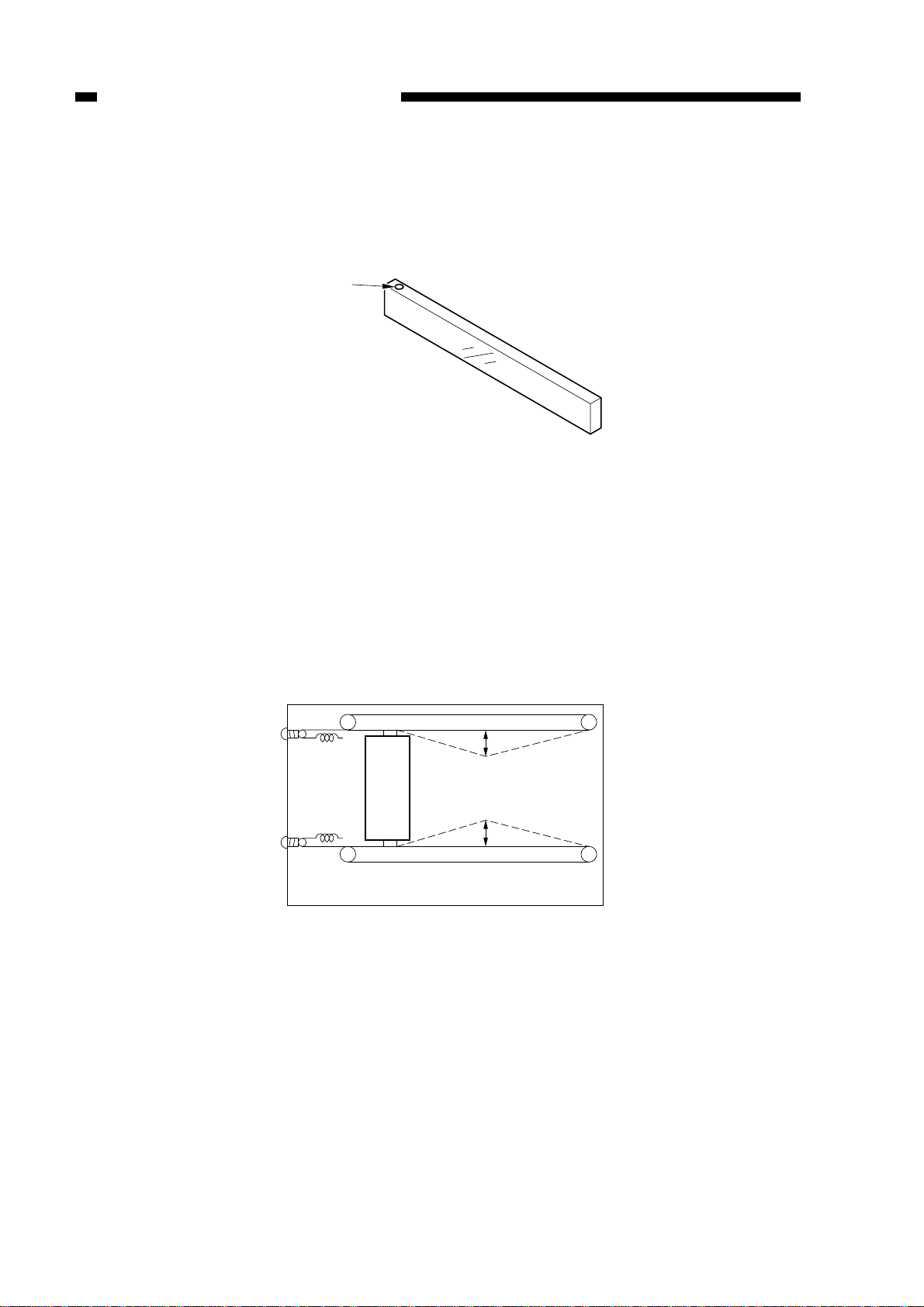

3. Adjusting the Tension of the Scanning Lamp Cable

1) Remove the two mounting screws, and remove the left cover.

2) Loosen the fixing screw on the tension spring bracket.

3) Tur n the tension adjusting screw so that the reading is as indicated.

• Turn the tension adjusting screw A so that the reading of the spring gauge is 200

±50 g when the center of the scanner cable is pulled about 10 mm.

2-8

Figure 2-11

CHAPTER 2 STANDARDS AND ADJUSTMENTS

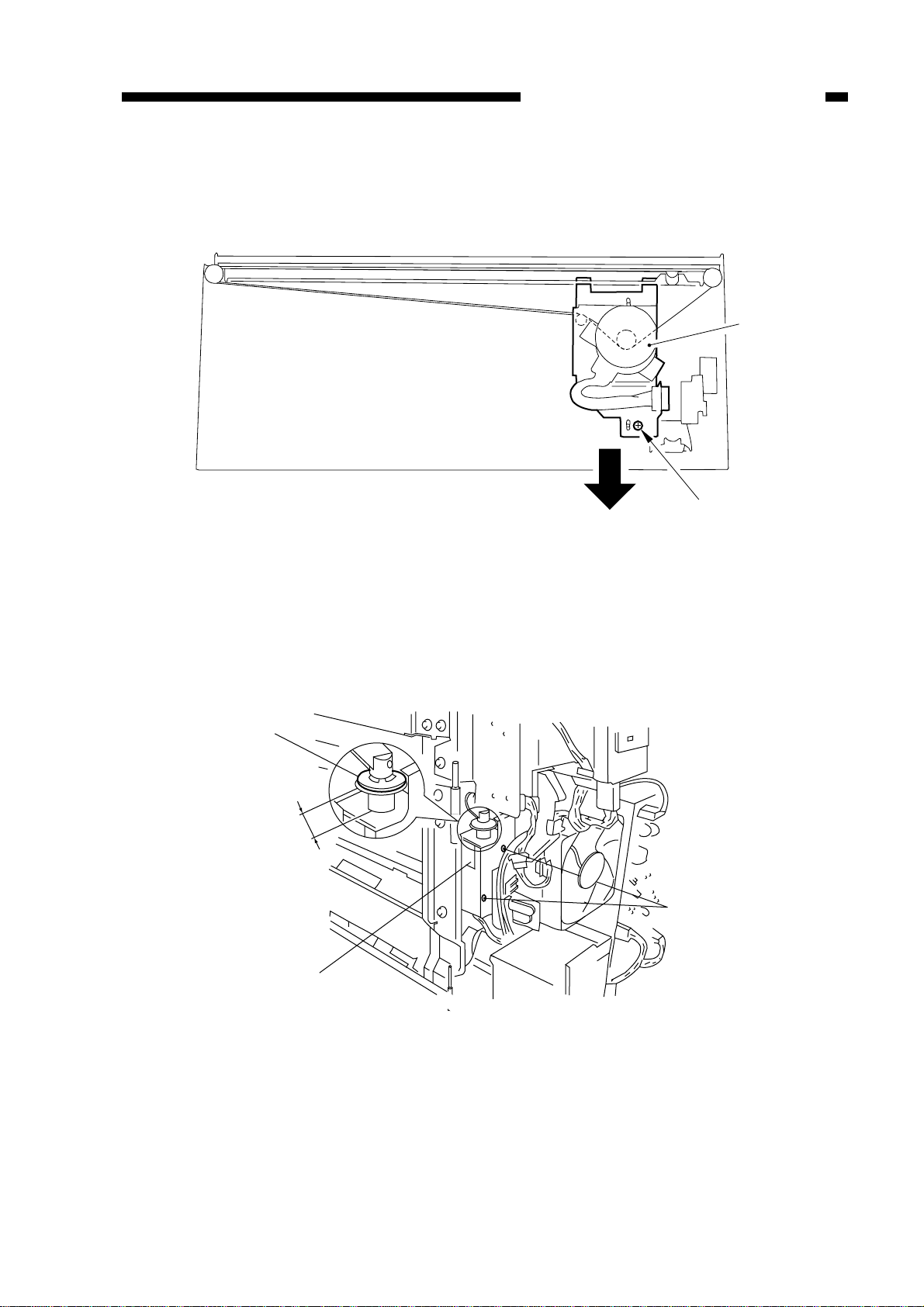

4. Adjusting the Position of the Mirror

You must always adjust the position of the mirror whenever you have installed the

scanner drive cable.

1) Move the No. 1 mirror mount and the No. 2/No. 3 mirror to the left.

2) Set the mirror positioning tool (front, rear; FY9-3011) as shown.

Figure 2-12

Figure 2-13

2-9

q

w

e

r

q

CHAPTER 2 STANDARDS AND ADJUSTMENTS

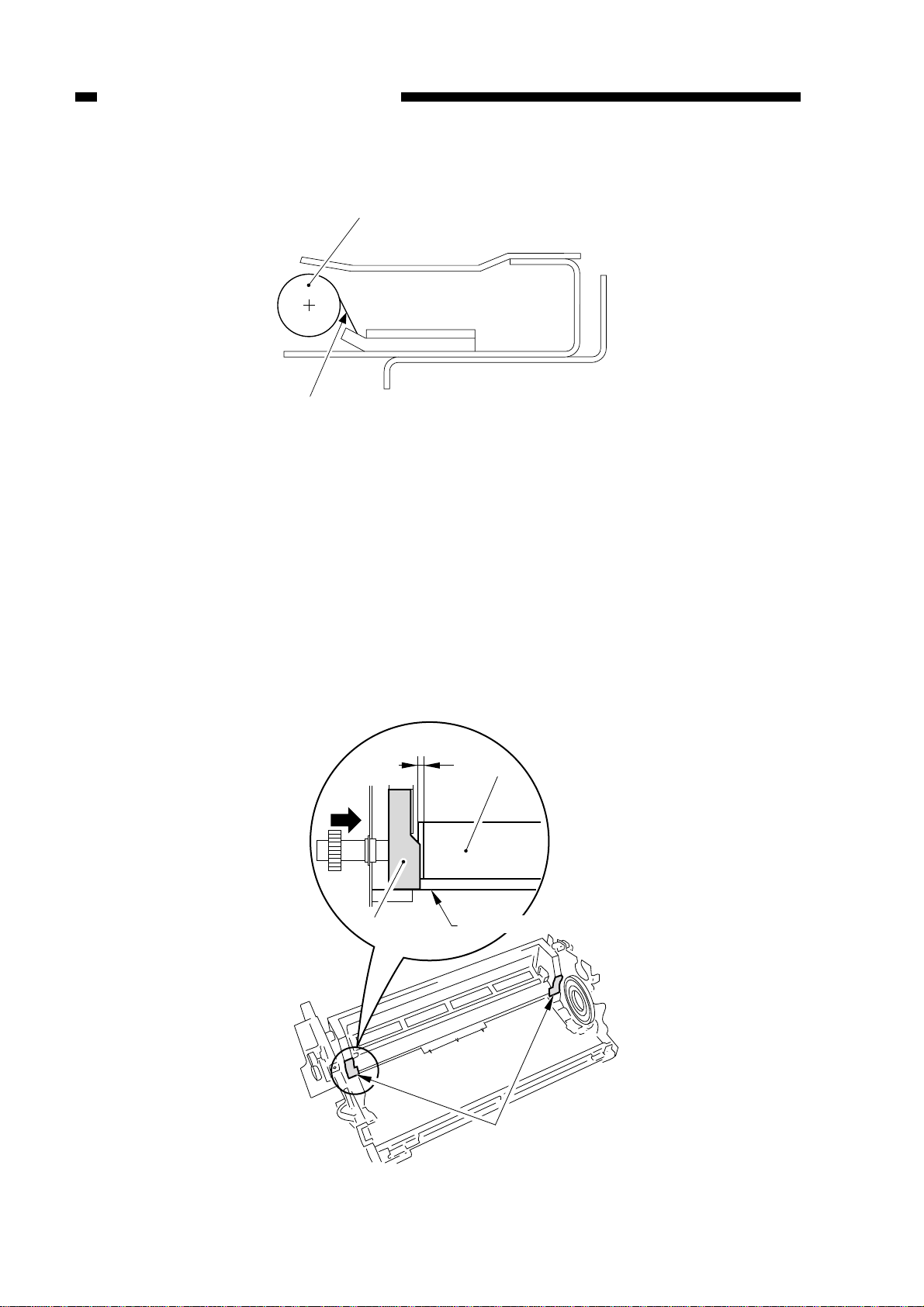

5. Cleaning the Mirror (No. 5 mirror)

1) Remove the copyboard glass.

2) Remove the lens hood.

3) Remove the mirror guide plate.

4) Move the lens stage in the direction of Enlarge.

5) Remove the screw, and remove the mirror cleaning tool.

6) While butting the mirror cleaning tool q against the No. 5 mirror as shown, clean the

mirror by moving the tool in the direction of the arrow.

At this time, be sure that your finger or the cleaning tool will not touch the No. 4

mirror.

6. Routing the Light-Blocking Belt

Figure 2-14

2-10

q Light-blocking belt 1 e Light-blocking belt 3

w Light-blocking belt 2 r Light-blocking belt 4

Figure 2-15

E-ring

Standards

(8.5 ±0.5 mm;

from bottom of

clamp to top of

solenoid)

Scanner locking

solenoid

Loosen these

two screws to

adjust.

q

w

Own weight

CHAPTER 2 STANDARDS AND ADJUSTMENTS

7. Routing the Lens X Direction Drive Belt

Fix the lens X direction drive motor q with the mounting screw w where the motor

has lowered on its own weight.

Figure 2-16

8. Adjusting the Position of the Scanner Locking Solenoid (SL1)

1) Remove the rear cover.

2) Remove the multifeeder assembly. (See Ser vice Manual Chapter 5.)

3) Adjust the stroke of the scanner locking solenoid as indicated.

Figure 2-17

2-11

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Screw

Screws

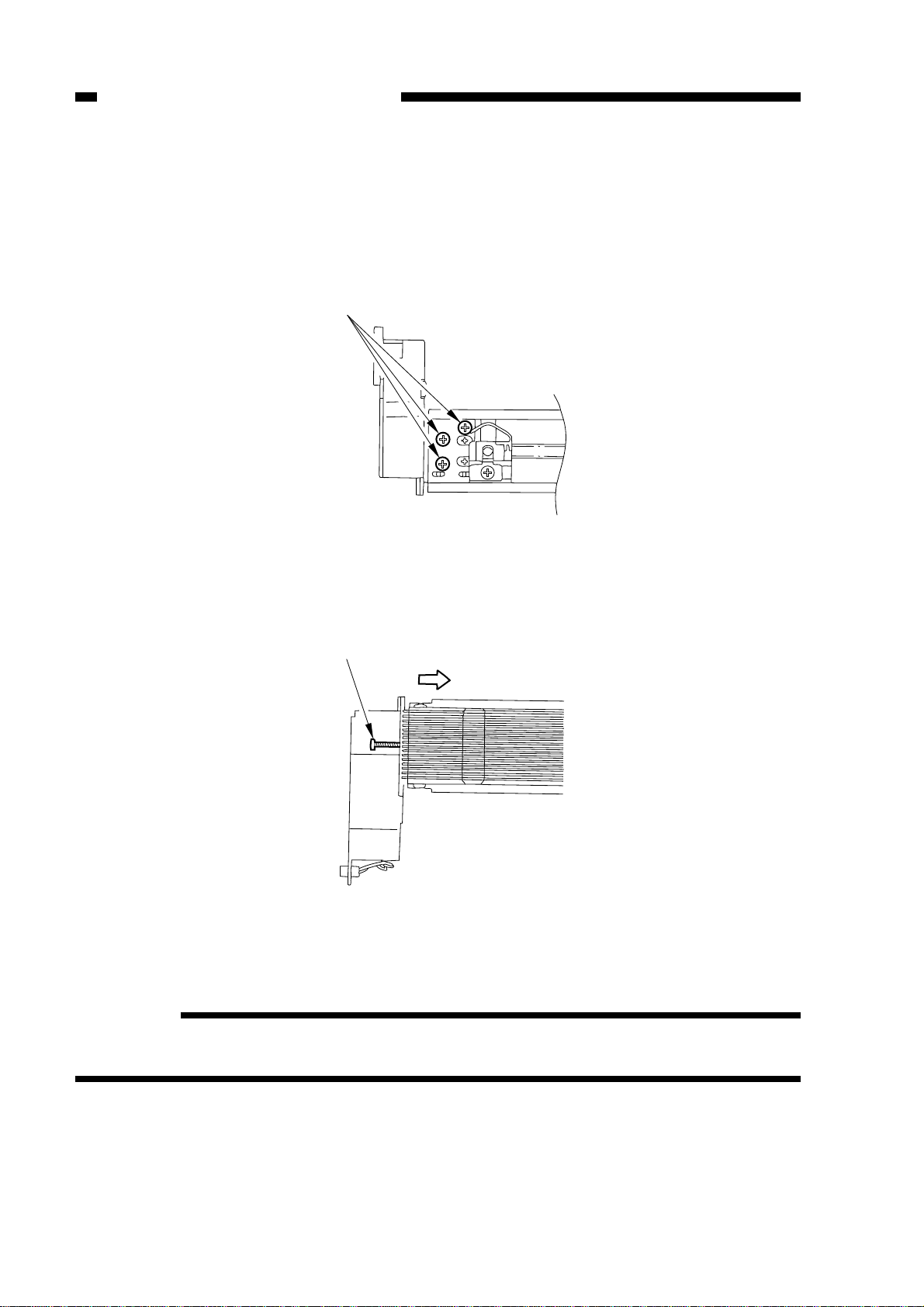

C. Image Formation System

1. Grid Wire of the Primary Charging Assembly

1) Loosen the two mounting screws used to fix the left/right shielding plate in place.

2) Loosen the three mounting screws used to fix the motor unit in place at the front.

Figure 2-18

3) Loosen the mounting screw, and move the assembly in the direction indicated in

Figure 2-19; then, fix it in place temporarily.

Figure 2-19

4) Free a length of charging wire (about 5 cm) from the charging wire reel (0.1mm dia.);

then, form a loop at its end (2mm dia.)

Reference:

To form a loop, wind the charging wire around a hex key three to four times, and

twist the charging wire.

5) Cut the twisted charging wire (excess) with a nipper.

2-12

Stud A

Screw

B

CHAPTER 2 STANDARDS AND ADJUSTMENTS

6) Hook the loop on the stud A shown in Figure 2-20.

Figure 2-20

7) After routing the wire for 31 runs, lead it through section B, give it a 1/2 turn, lead it

between washer and motor unit, wind it once around the mounting screw clockwise,

and fix it in place with the mounting screw.

8) Cut the excess charging wire with a nipper.

9) Tighten the mounting screw loosened in step 8).

Take care to avoid deformation (slack) of the charging assembly. Try to tighten the

mounting screw (front) on the shielding plate (left, right) earlier.

2-13

CHAPTER 2 STANDARDS AND ADJUSTMENTS

7.5+1.5

-0mm

7.5+1.5

-0mm

9.5+1.0

-0mm

10.5±0.5mm

A:16.2±0.5mm B:14.9±0.5mm

AB

2. Adjusting the Height of the Charging Wire

Charging assembly

Primary

Pre-transfer

Transfer

Separation

Height of charging wire

Tolerance

±1mm

No adjusting

mechanism

±2mm

±2mm

Table 2-1

Reference:

You can adjust the height (position) of the primary, transfer/separation charging wire

by turning the screw behind the charging assembly. A full turn changes the position

of the charging wire by about 0.7 mm.

2-14

Adjusting screw

0

2

4

6

8

12

10

0

2

3

6

8

12

10

W1 W1

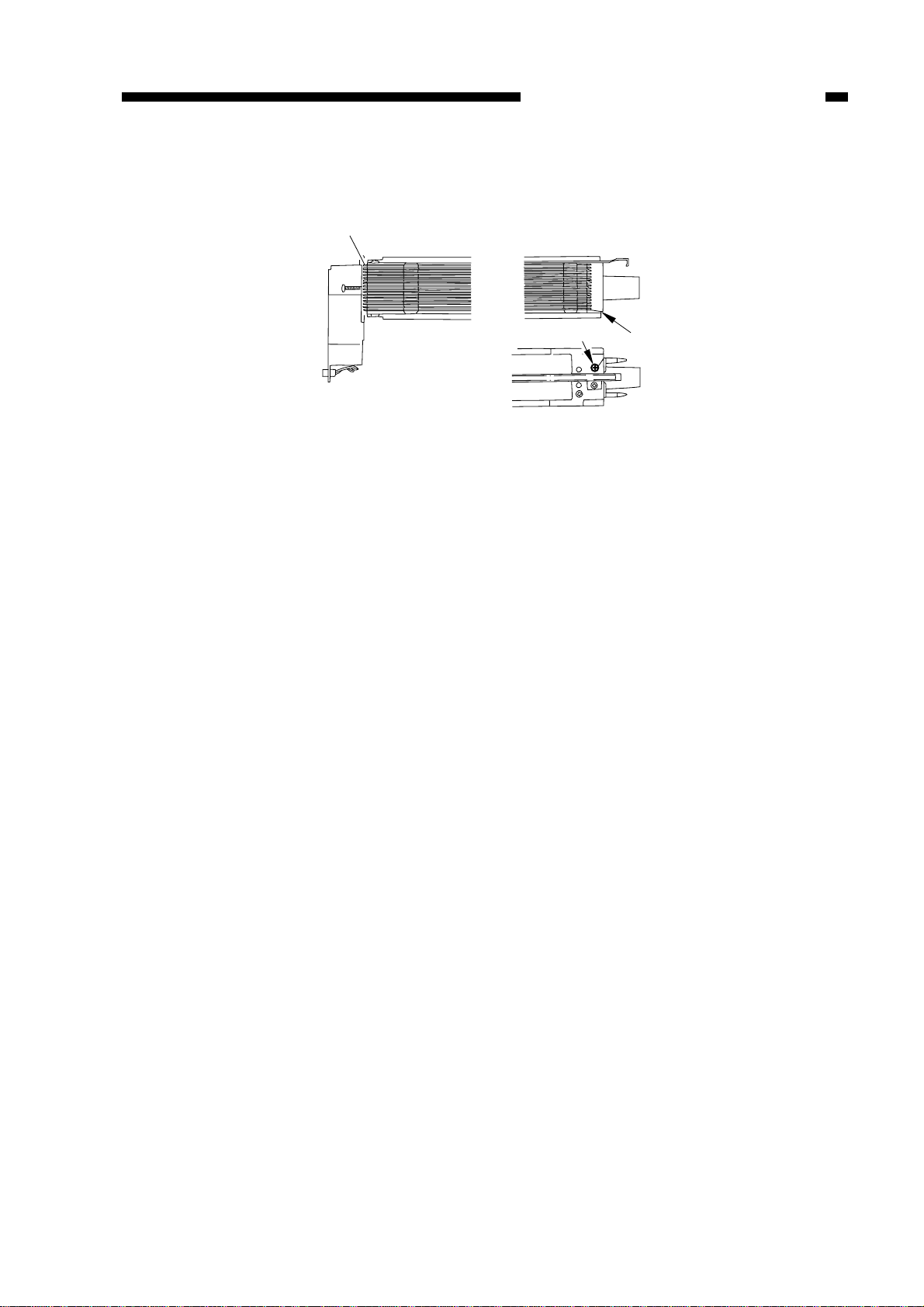

CHAPTER 2 STANDARDS AND ADJUSTMENTS

3. Adjusting the Position of the Blanking Exposure Lamp

1) Place the Test Sheet on the copyboard.

2) Select A4 copy paper.

3) Make a copy, and check that the left/right registration is correct.

4) Make a copy in Direct.

5) Check the image, and measure the non-image width shown in Figure 2-21.

Standard

Paper

All sizes

Left/right non-image width (W1)

2.75 ± 2.5mm

(w/ standard frame erasing)

Table 2-2

Figure 2-21

6) If the non-image width is not as specified, turn the adjusting screw to adjust the

position of the blanking exposure lamp assembly.

Figure 2-22

2-15

q

w

e

r

q

: 0~0.5mm

Roller electrode

Scraper

CHAPTER 2 STANDARDS AND ADJUSTMENTS

4. Position of the Roller Electrode

Figure 2-23

5. Adjusting the Position of the Cleaning Assembly Side Seal

1) Attach the side seal q to the location indicated (both ends; make sure that the edge

of the seal is as follows):

• If you are replacing the side seal at the front, push the magnetic roller w toward the

rear; then, work so that the inner edge of the side seal is within the washer area e.

•

If you are replacing the side seal q at the rear, push the magnetic roller w toward the

front; then, work so that the inner edge of the side seal is within the washer area e.

2) Make sure that the bottom edge of each side seal q is 0 to 0.5 mm r away from the

corner of the cleaner housing.

3) Fix the size seal q (both front and rear) to the cleaner housing at the location

indicated.

2-16

Figure 2-24

Loading...

Loading...