Canon NP6512 Service Handbook

REVISION 0

A UG. 1999

COPYRIGHT © 1999 CANON INC. CANON NP6512/6612/7120/7130/7130F REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-23B7-000

IMPORTANT

THIS DOCUMENTATION IS PUBLISHED BY CANON INC., JAPAN, TO SERVE AS A SOURCE

OF REFERENCE FOR WORK IN THE FIELD .

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY SLIGHTLY

FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER

PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMA TION CONTAINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

THIS DOCUMENT ATION IS INTENDED FOR ALL SALES AREAS, AND MA Y CONTAIN INFORMATION NOT APPLICABLE T O CERTAIN AREAS.

COPYRIGHT © 1999 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly supervised to avoid disclosure of confidential

information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride-shi, Ibaraki 302-8501 Japan

COPYRIGHT © 1999 CANON INC. CANON NP6512/6612/7120/7130/7130F REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

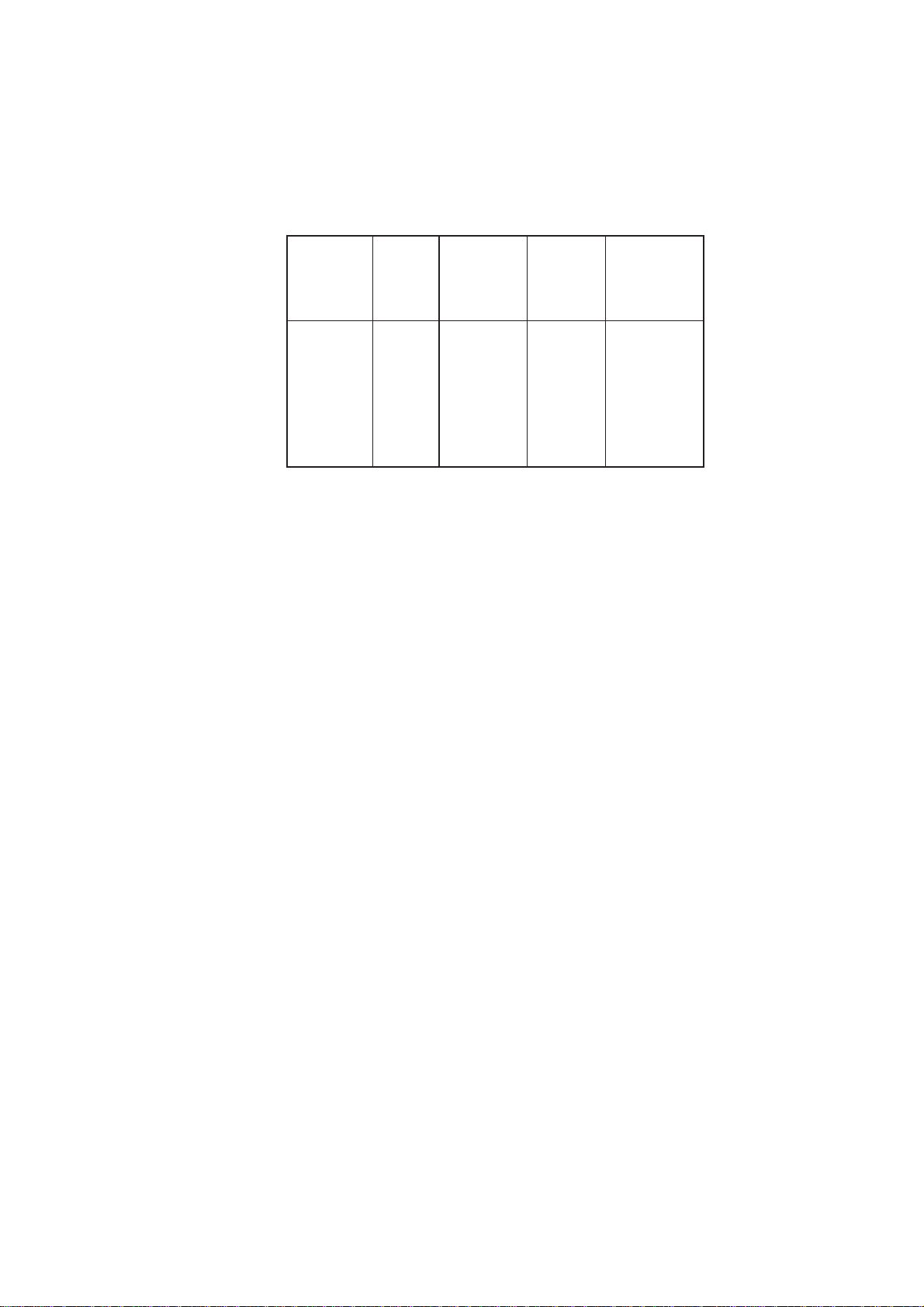

• This service handbook covers the models shown in the following table. Be sure to have

a good understanding of the difference from model to model before referring to this

handbook.

Model

NP6512

NP6612

NP7120

NP7120

NP7130

NP7130

NP7130F

Type

code

TWA

TXA

PUB

PUC

NVF

PTZ

NVH

Default

ratio

2R2E

2R2E

2R2E

2R2E

3R1E

2R2E

3R1E

ADF as

standard

√

√

The notation “√” indicates that the item in question is available.

Cassette

250 sheets

250 sheets

Universal

Universal

500 sheets

500 sheets

500 sheets

i

CONTENTS

CHAPTER 1 MAINTENANCE AND INSPECTION

1

2

A. Periodically Replaced Parts .........1-1

B. Durables and Consumables .........1-1

C. Scheduled Servicing .................... 1-1

D. Image Adjustment Basic

Procedure..................................... 1-3

E. Points to Note for Servicing .........1-4

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A. Mechanical................................... 2-1

B. ADF ........................................... 2-26

C. Electrical ................................... 2-37

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF

ELECTRICAL PARTS

A. Sensors and Solenoids................ 3-1

B. Switches.......................................3-2

C. Lamp, Heater, Motor, Etc. ............3-3

D. PCBs ............................................3-4

E. ADF ..............................................3-5

F. Variable Resistors (VR) and

Check Pins by PCB......................3-6

3

4

5

CHAPTER 4 SERVICE MODE

A. Outline..........................................4-1

B. Using Service Mode.....................4-1

C. Adjustment Mode (30) .................4-4

CHAPTER 5 SELF DIAGNOSIS

A. Self Diagnosis ..............................5-1

APPENDIX

A. General Timing Chart.................. A-1

B. Signals and Abbreviations .......... A-3

C. General Circuit Diagram ............. A-5

D. Operation/Inspection Mode (40) ..4-5

E. Machine Settings Mode (50)........4-6

F. Counter Mode (60).......................4-6

D . Special T ools ............................... A-7

E. Solvents/Oils ............................... A-8

F. Specifications.............................. A-9

iii

CHAPTER 1 MAINTENANCE AND INSPECTION

CHAPTER 1 MAINTENANCE AND INSPECTION

A. Periodically Replaced Parts

The machine does not have parts which must be replaced on a periodical basis.

B. Durables and Consumables

The machine does not have items designated as durables or consumables.

C. Scheduled Servicing

The machine does not have any parts which require scheduled servicing.

1

1-1

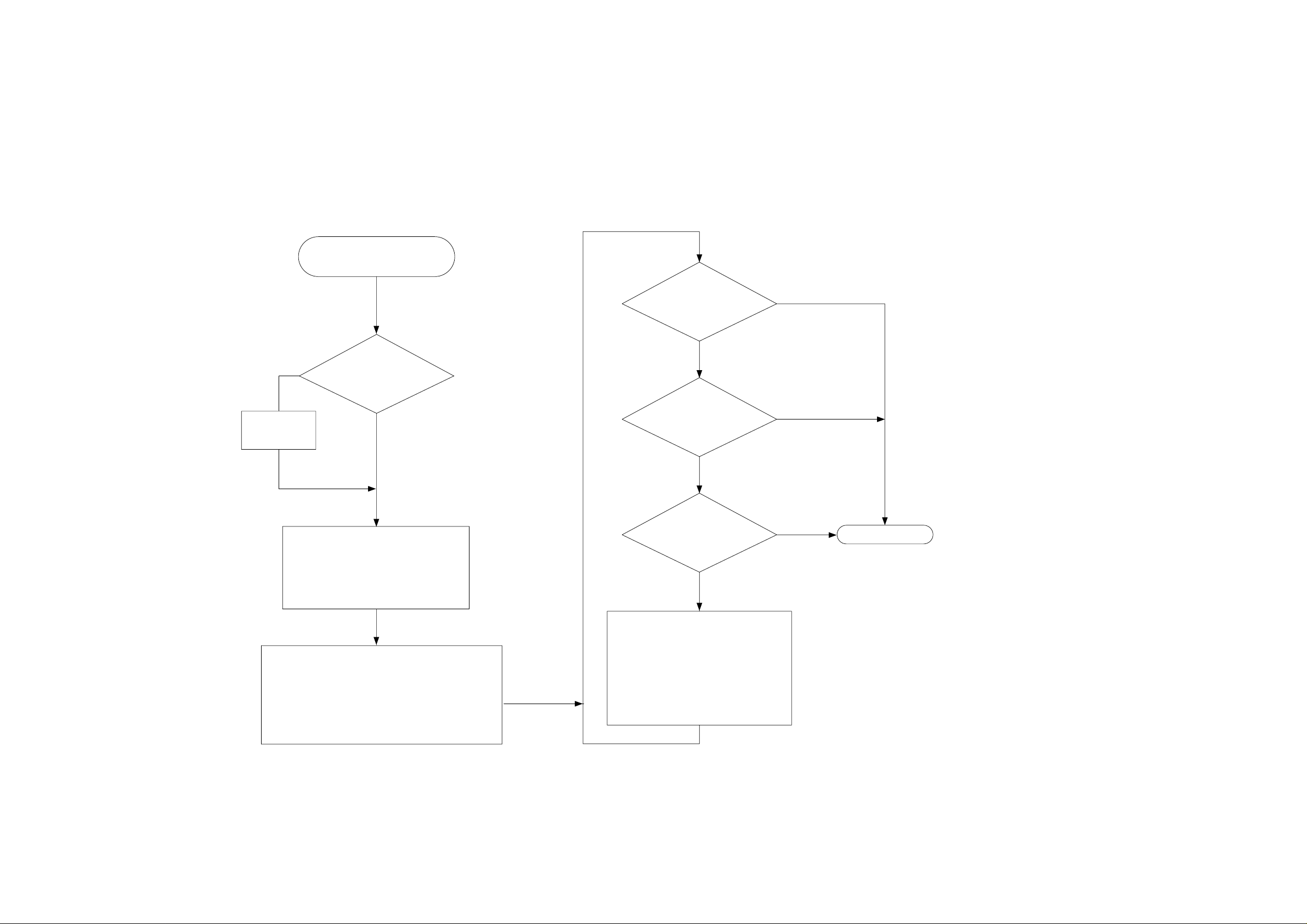

Making Pre-Checks Adjusting the Optimum Density

Clean the parts.

D. Image Adjustment Basic Procedure

NO

Set it at

the center.

Select non-AE, and set the copy density

adjusting lever to the middle index; then,

make two to three copies of the Test

Sheet (NA-3).

Scanning system,

pickup/feeding system,

delivery assembly

Is the copy density

correction dial (VR107)

centered?

YES

Is gray scale No. 9

barely visible?

NO

Can the

deviation be corrected

using the copy density correction

dial (VR107)?

NO

Is the optimum

density obtained by intensity

adjustment?

(Note 2)

NO

YES

YES

YES

END

Check the following:

1. Density of gray scale No. 9

2. Presence/absence of difference between front

and rear (Note 1)

3. Density of gray scale No. 1 (good or bad; Note 1)

4. Fogging of background (Note 1)

Check the following:

1. Drum unit

2. Scanning lamp

3. AE sensor PCB

4. DC controller PCB

5. Composite power supply PCB

(See the appropriate troubleshooting

procedure.)

Note:

1. The machine is not equipped with a function to

correct image faults. See the appropriate

troubleshooting procedure.

2. See p. 2-38.

1-3

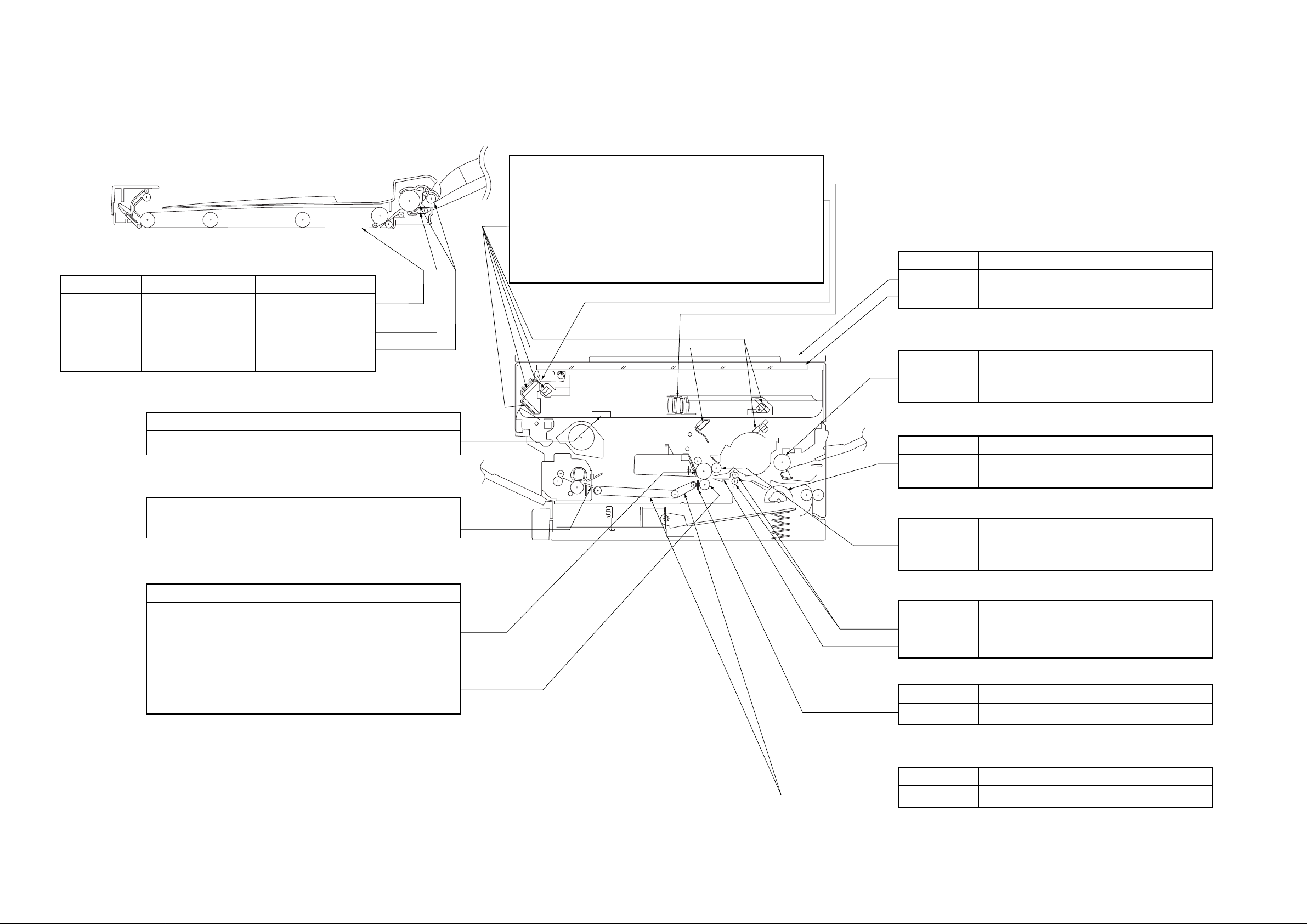

E. Points to Note for Servicing

Optical path

Part Tools/sovents Work/remarks

ADF

Item Tool/solvent

Feeding belt

Separation pad

Pickup roller Cloth moistened with

*Be sure to wring it well.

Cloth moistened with

water*

Cloth

water* or alcohol

Electrical unit

Part

AE sensor

Fixing assembly

Part

Inlet guide

Dry-wiping.

Cleaning.

Cleaning.

Tools/sovents

Blower brush

Tools/sovents

Solvent

Work/remarks

Work/remarks

Cleaning.

Work/remarks

Cleaning.

Lens

Reflecting plate

No. 1/No. 6 mirror

Scanning lamp

Blower brush

Blower brush

Blower brush or alcohol

and lint-free paper

Moist cloth

Cleaning.

Cleaning.

Cleaning with a blower

blush; if dirt cannot be

removed, use alcohol and

lint-free paper.

Cleaning.

Part Tools/sovents Work/remarks

Copyboard cover

Copyboard glass

Multifeeder assembly

Part Tools/sovents Work/remarks

Multifeeder

pickup roller

Cassette pickup assembly

Part Tools/sovents Work/remarks

Cassette pickup

roller

Developing assembly

Part Tools/sovents Work/remarks

Alcohol

Alcohol

Moist cloth (well-wrung)

or alcohol

Moist cloth (well-wrung)

or alcohol

Cleaning.

Cleaning.

Cleaning.

Cleaning.

Drum unit/Transfer charging roller

Part

Photosensitive

drum

Transfer charging

roller

Tools/sovents

Toner

Lint-free paper

Work/remarks

Do not use solvent; in

principle, do not touch or

clean. Never expose to

light.

Cleaning; do not use

water or solvent. Do not

touch, and take care not

to soil with solvent and oil.

Developing

cylinder

Transfer guide assembly

Part Tools/sovents Work/remarks

Registration roller

Transfer guide

Static eliminator

Part Tools/sovents Work/remarks

Static eliminator

Feeding assembly

Part Tools/sovents Work/remarks

Feed belt

Alcohol Cleaning.

Moist cloth

Moist cloth

Special brush Cleaning.

Moist cloth Cleaning.

Cleaning.

Cleaning.

1-4

CHAPTER 2 STANDARDS AND ADJUSTMENTS

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A. Mechanical

1. Copier

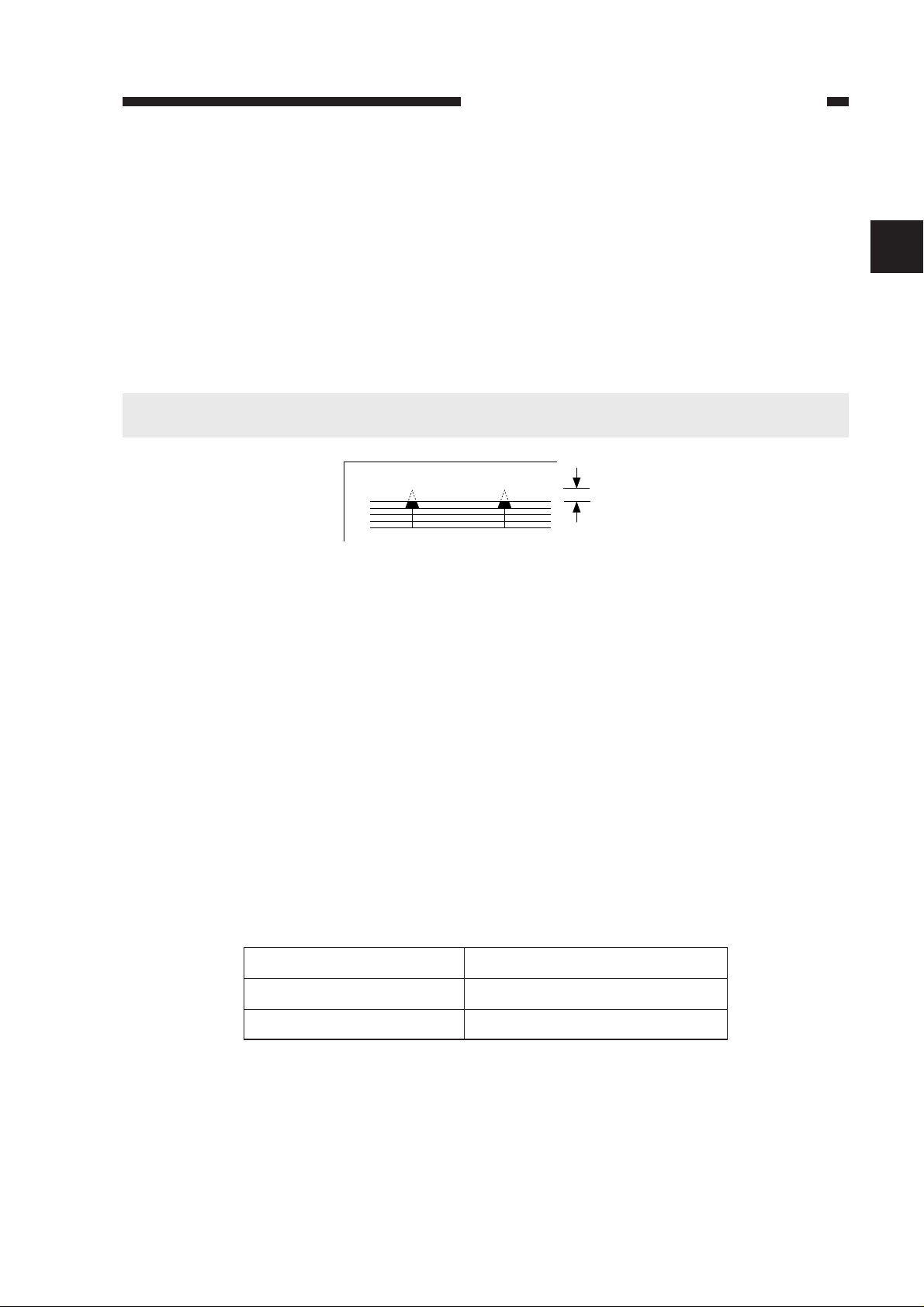

a. Leading Edge Non-Image Width

Make adjustments so that the leading edge non-image width is 2.0 ±1.5 mm when the Test

Sheet is copied in Direct.

Caution:

If you have performed this adjustment, be sure to adjust the image leading edge margin.

2.0±1.5mm

2

Figure 2-1

Making Adjustments

1) Select '31' in service mode.

• The display will indicate '31'.

2) Press the Copy Start key.

• The existing setting will flash.

3) Change the setting by the +/- key.

• The setting may be between 0 and 99.

• For each '1', the non-image width will change by 0.24 mm.

4) Press the AE key.

• The setting will stop flashing and will remain on, indicating that it has been stored in

memory.

5) As necessary, press the Clear/Stop key once to return to item selection; or, press it once again

to end service mode.

Relationship between Setting and Leading Edge Non-Image Width

Setting

Higher

Leading edge non-image width

Increases

Lower

Decreases

Table 2-1

2-1

CHAPTER 2 STANDARDS AND ADJUSTMENTS

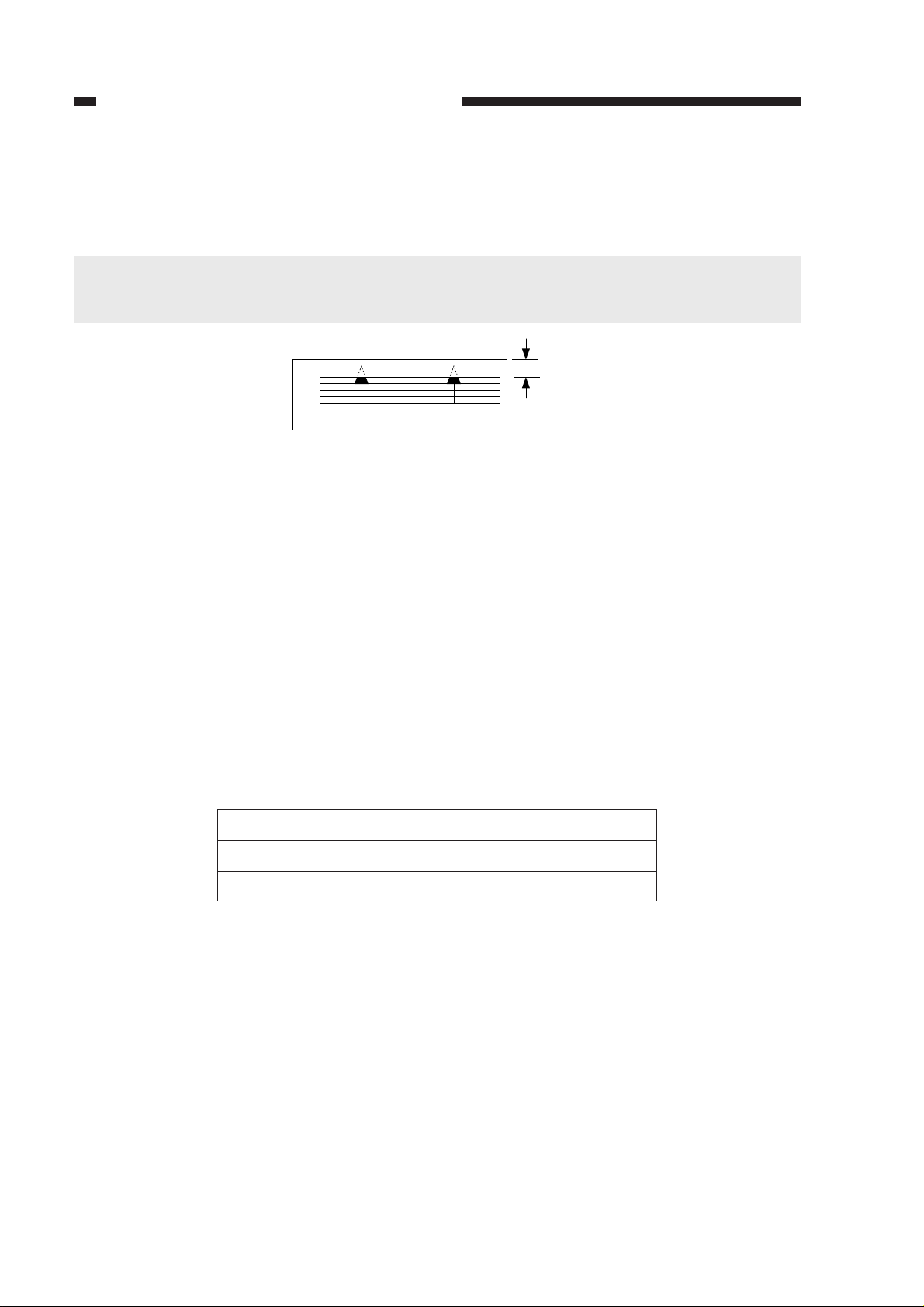

b. Image Leading Edge Margin (registration activation timing)

Make adjustments so that the leading edge margin is 2.5 ±1.5 mm when the Test Sheet is

copied.

Caution:

Be sure to check that the leading edge non-image width is as indicated before performing this

adjustment.

2.5±1.5mm

Figure 2-2

Making Adjustments

1) Select '30' in service mode.

• The display will indicate '30'.

2) Press the Copy Start key.

• The existing setting will flash.

3) Change the setting using the +/- key.

• The setting may be between 0 and 99.

• The setting will change by 0.24 mm in terms of margin for each '1'.

4) Press the AE key.

• The setting will stop flashing and will remain on, indicating it has been stored in memory.

5) As necessary, press the Clear/Stop key once to return to item selection; or, press it once again

to end service mode.

Relationship between Settings and Image Leading Edge Margin

Setting

Higher

Lower

Image leading edge margin

Decreases

Increases

Table 2-2

2-2

CHAPTER 2 STANDARDS AND ADJUSTMENTS

c. Adjusting the Mirror Position (optical length between No. 1 mirror and No. 2 mirror)

If you have replaced the scanner drive cable, you must adjust the mirror position, by changing

the position of the cable retainer of the No. 1 mirror mount.

Reference:

1. As more and more copies are made, the cable tends to become slack, requiring adjustment.

2. If the optical length between the No. 1 mirror and the No. 2 mirror is not correct, the horizontal

reproduction ratio will be wrong, causing poor sharpness or blurred images.

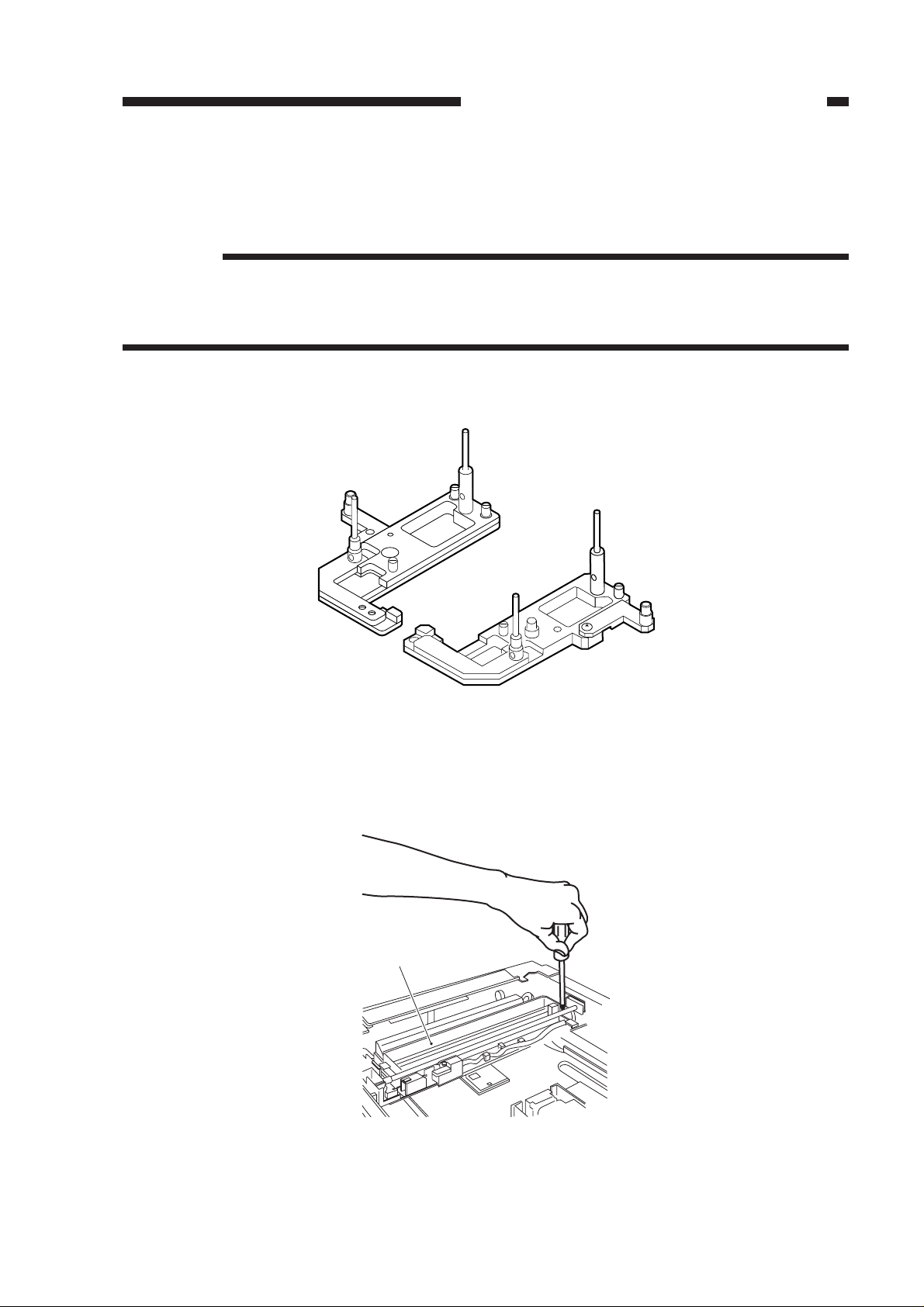

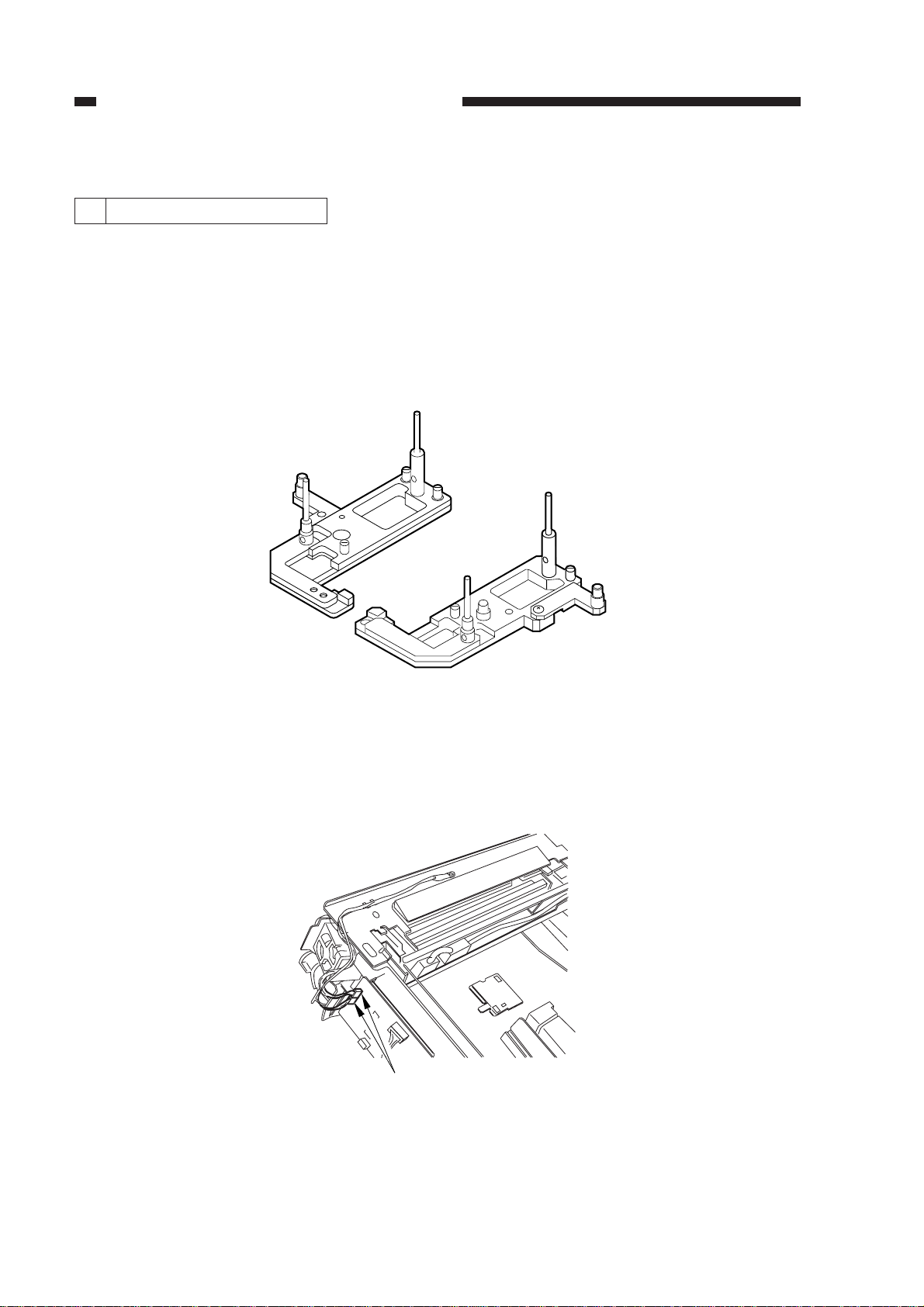

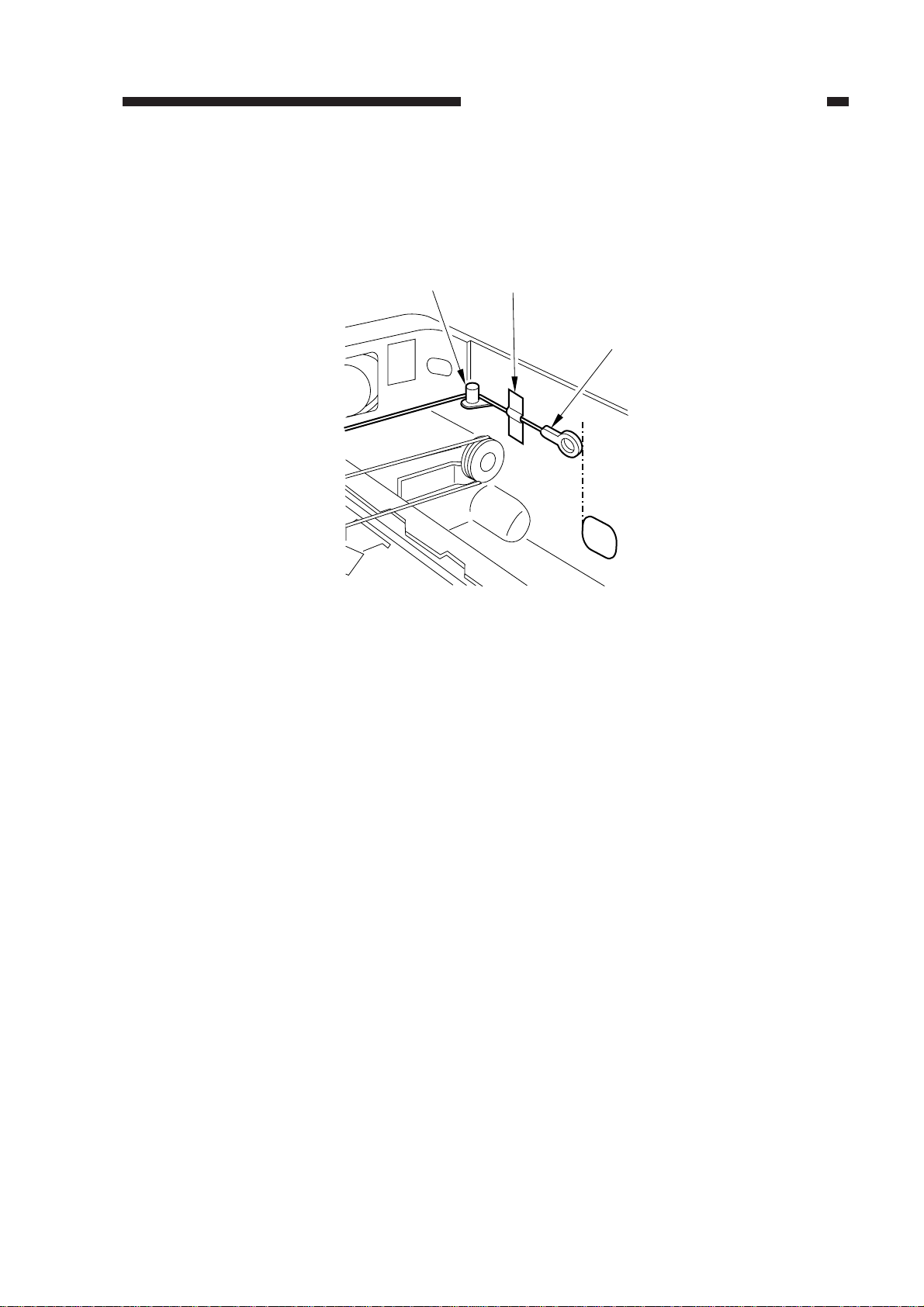

1) Fit the mirror positioning tool (FY9-3009) as shown.

Figure 2-3

2) Remove the copyboard glass.

3) Loosen the screws used to secure the cable retainer at the rear and the front of the No. 1 mirror

mount [1].

[1]

Figure 2-4

2-3

CHAPTER 2 STANDARDS AND ADJUSTMENTS

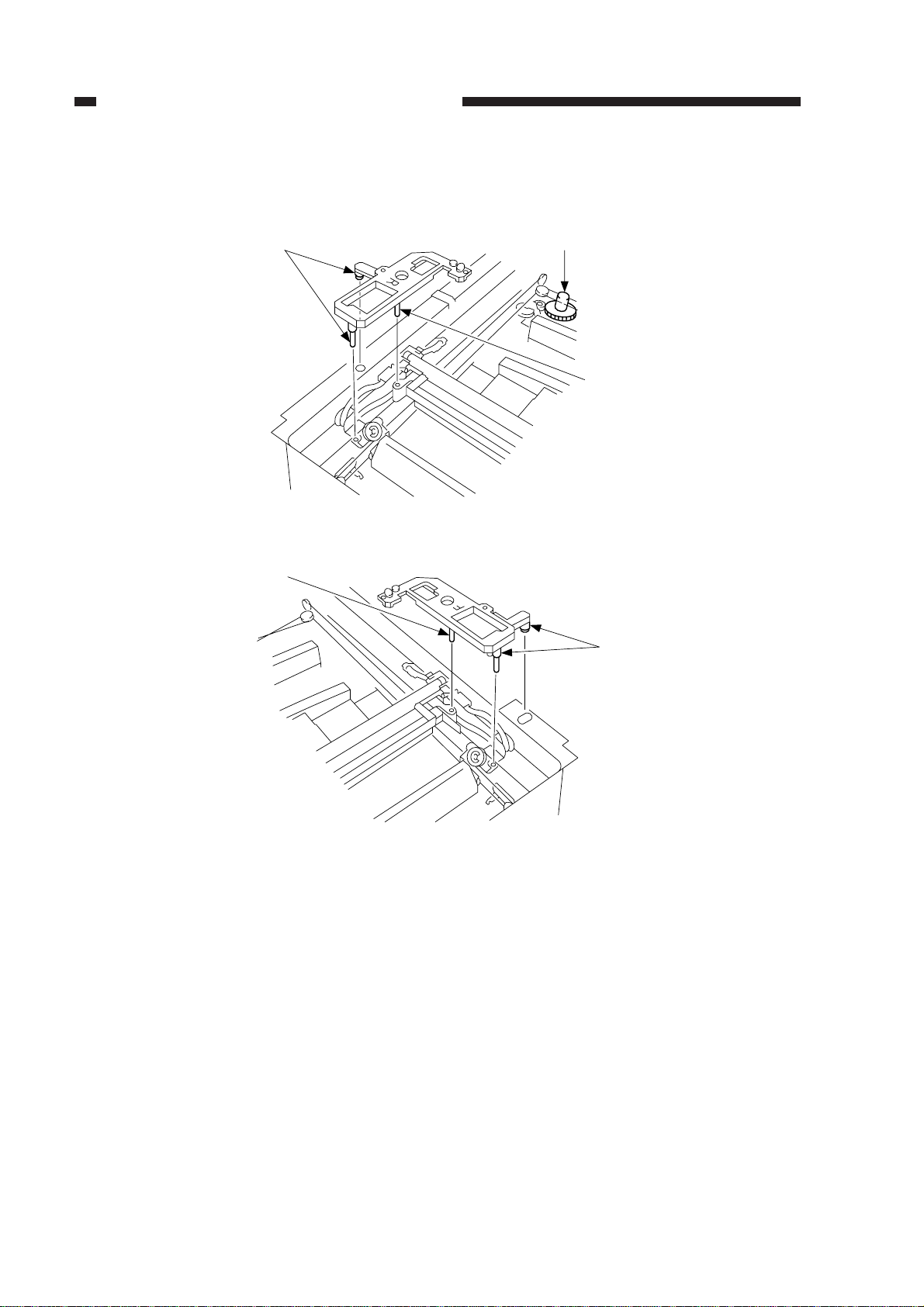

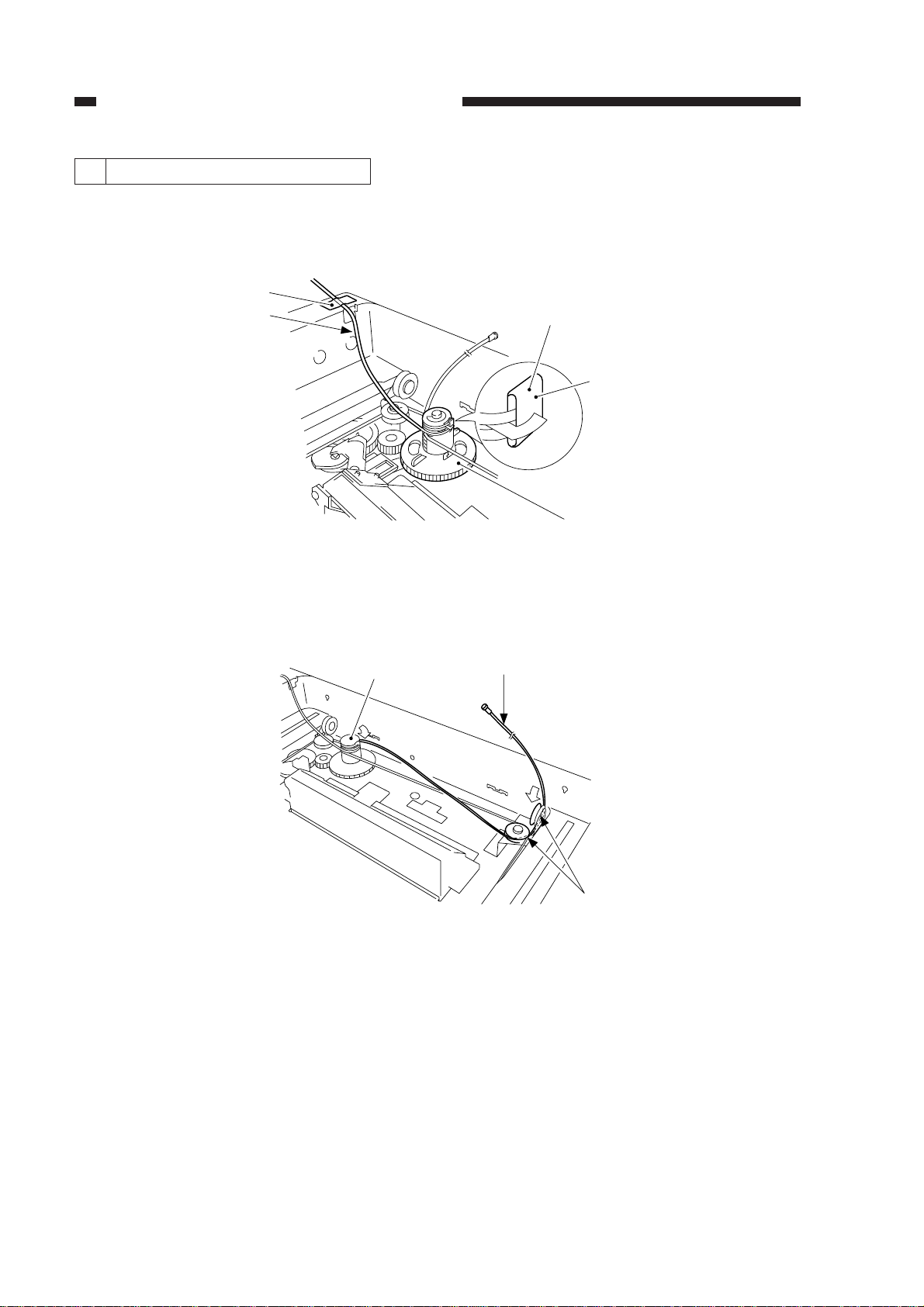

4) Turn the cable drive pulley [3] so that the three shafts [2] of the mirror positioning tool for the

front and the rear may be arranged as shown.

[3][2]

[2]

Figure 2-5 (rear)

[2]

[2]

Figure 2-6 (front)

2-4

CHAPTER 2 STANDARDS AND ADJUSTMENTS

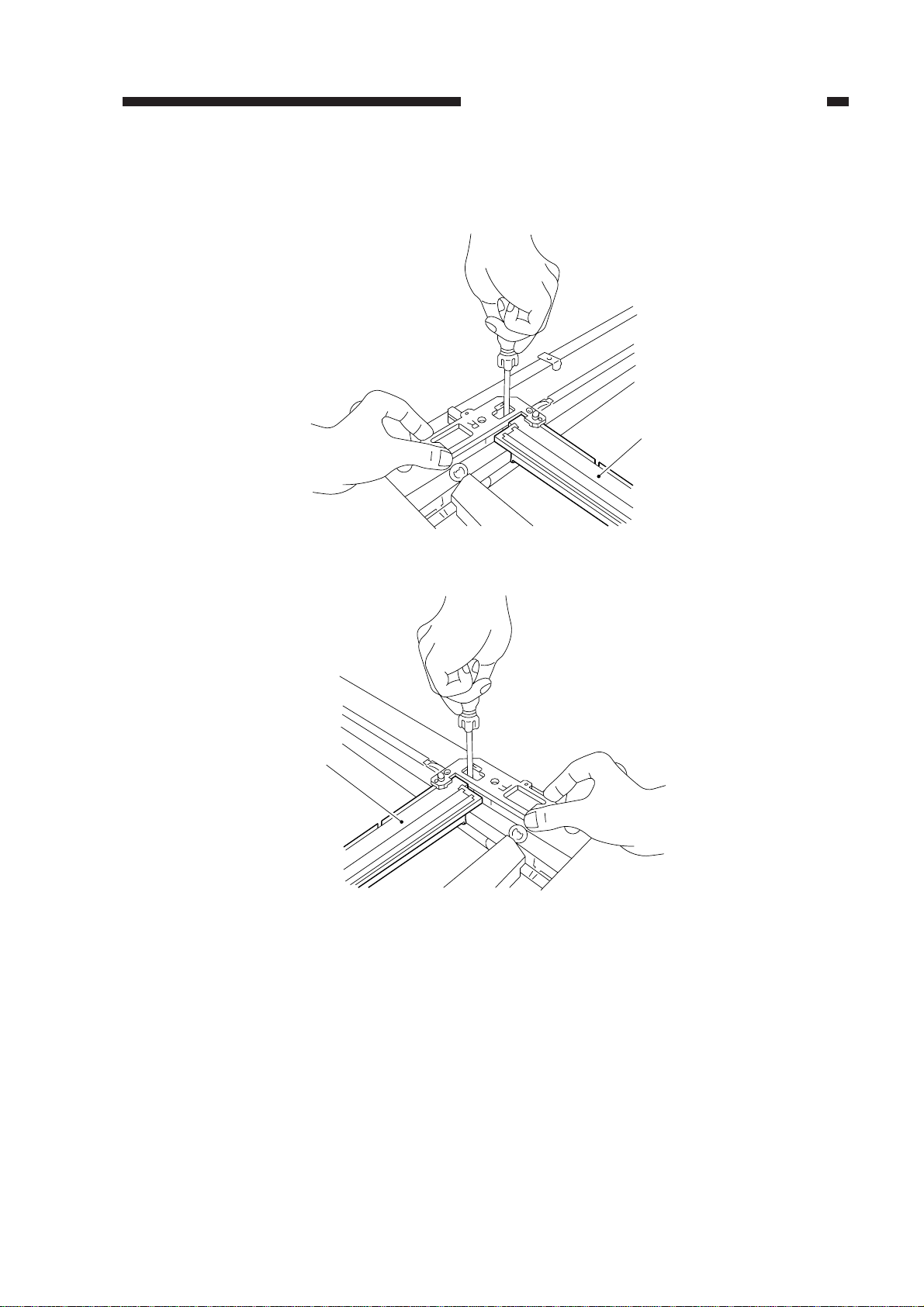

[1]

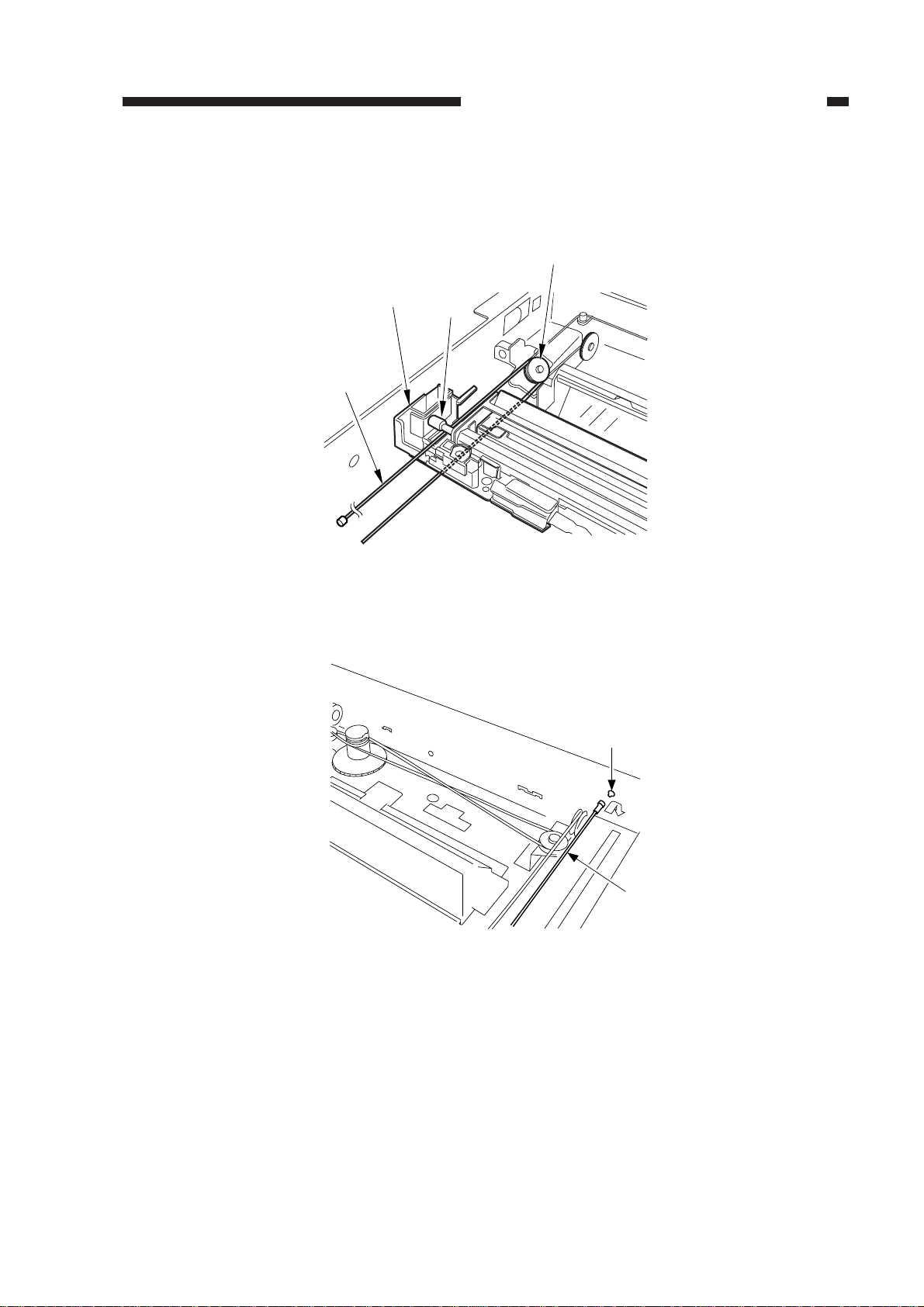

5) While keeping the condition of 4), tighten the positioning screw at the rear and the front of the

No. 1 mirror mount [1].

[1]

Figure 2-7 (rear)

Figure 2-8 (front)

2-5

CHAPTER 2 STANDARDS AND ADJUSTMENTS

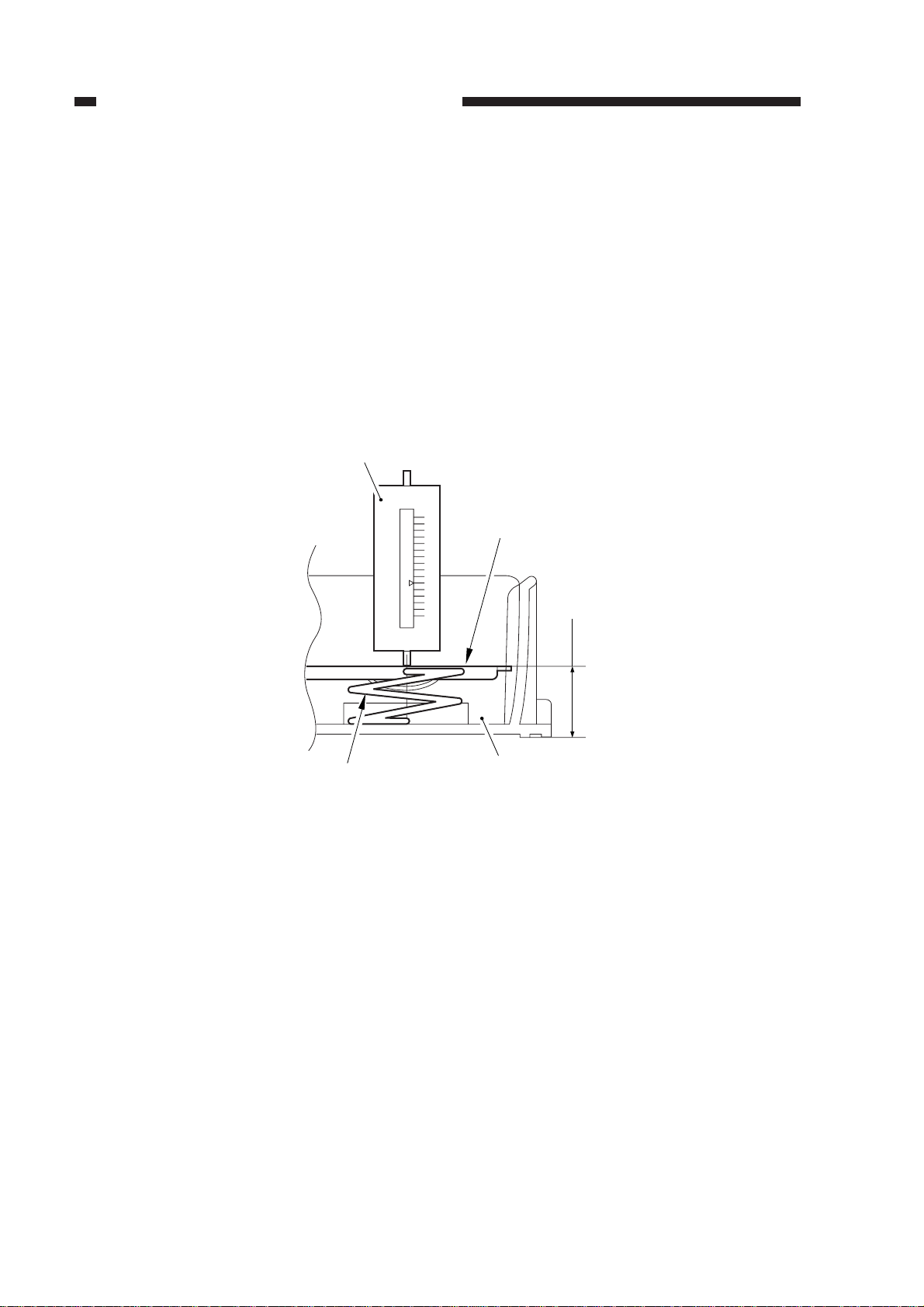

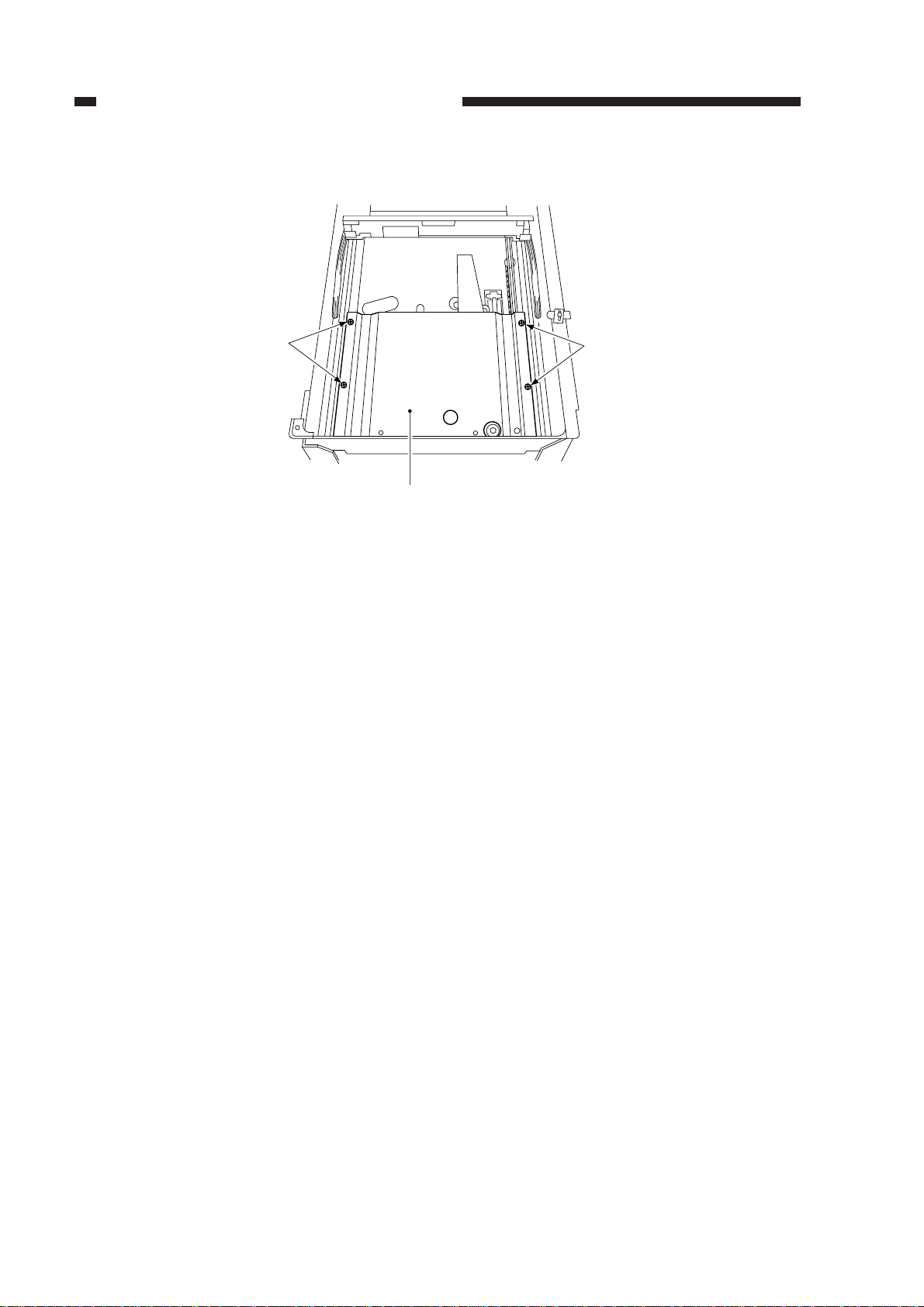

d. Checking the Force of the Cassette Spring

If the force of the spring used to hold up the holding plate of the cassette is not correct, pickup

faults or the like can occur.

If a fault is suspected, check the force of the spring using a spring gauge (CK-0054), and

replace the spring if it is not as indicated:

Standard: 970 ±150 g

Making Measurements

Push the spring gauge against the middle of the spring as shown, and check to make sure that

the reading of the spring gauge is 970 ±150 g when the holding plate is 18 mm away from the

bottom of the cassette.

Spring gauge

(CK-0054)

Holding plate

Cassette spring

18mm

Cassette

Figure 2-9

2-6

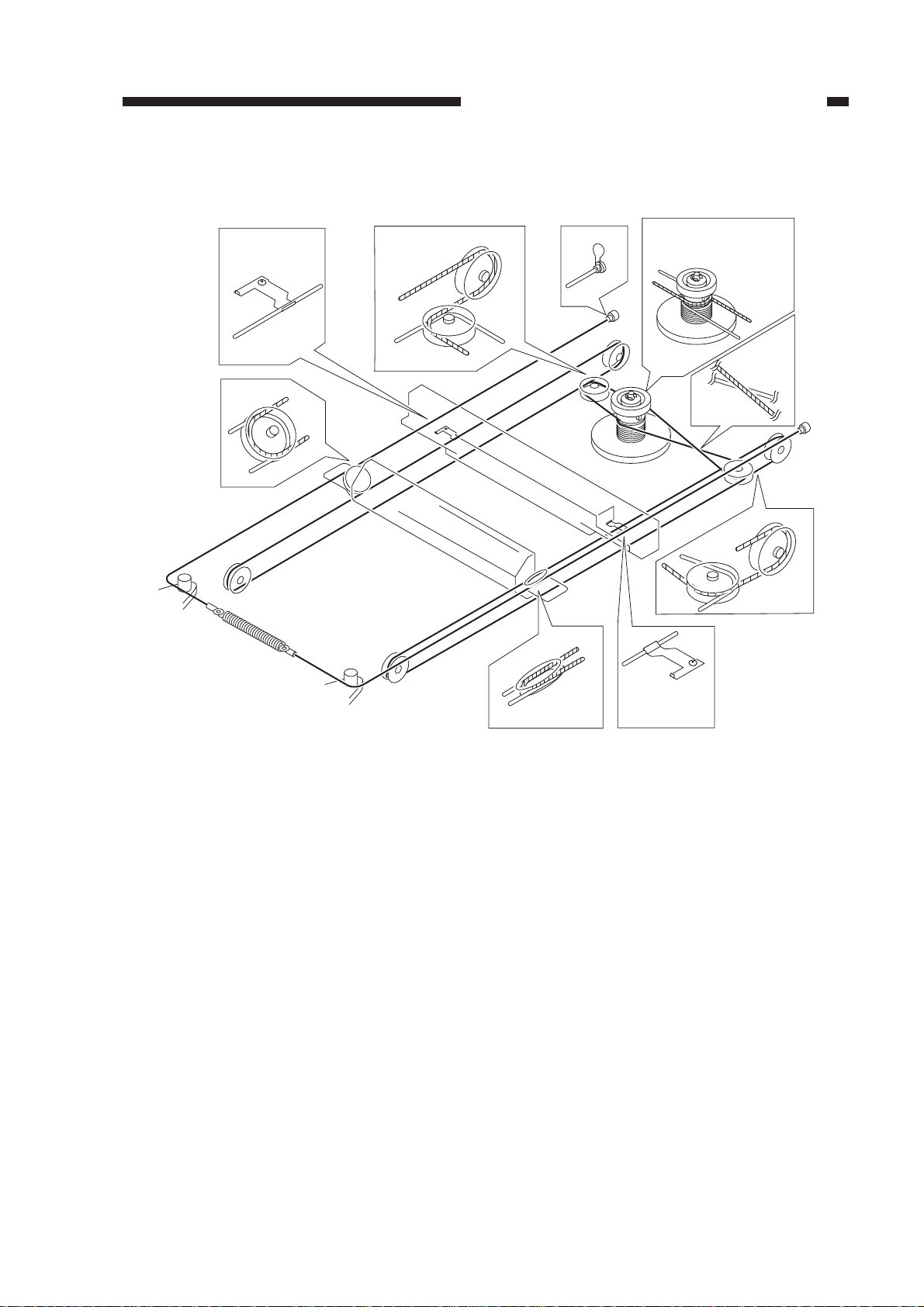

e-1. Routing the Scanner Drive Cable

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Wind 1.5 times. (black

cable)

Wind 7.5 times. (silvercolored cable)

Figure 2-10

2-7

CHAPTER 2 STANDARDS AND ADJUSTMENTS

e-2. Routing the Scanner Drive Cable

1. Before Starting the Work

Prepare the following:

• Mirror positioning tool (FY9-3009)

• Cable clip (FY9-3017)

• Adhesive tape

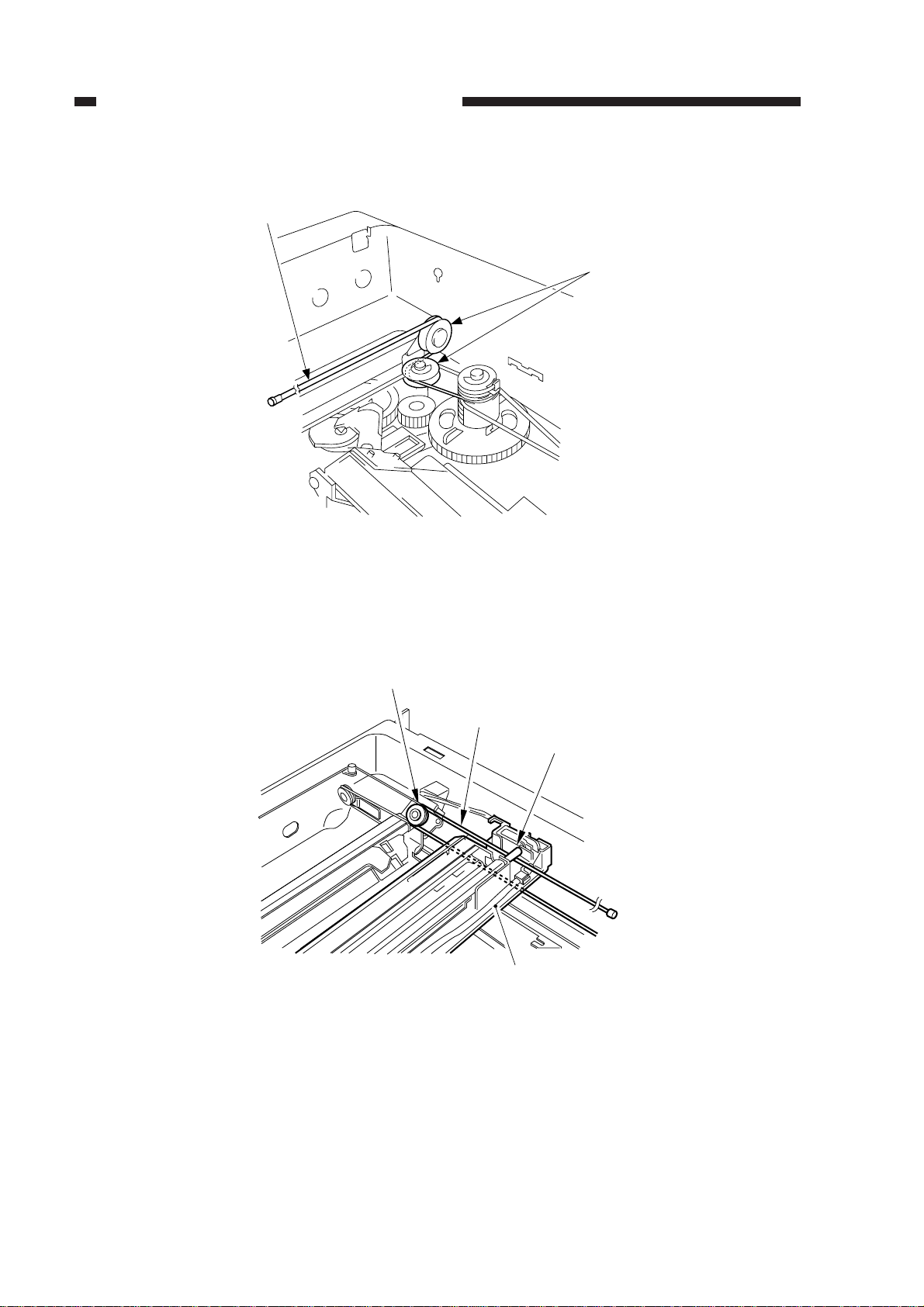

1) Set the mirror positioning tool as shown.

Figure 2-11

2) Prepare about five strips of adhesive tape (each one about 20 x 50 mm).

3) Remove the copyboard glass.

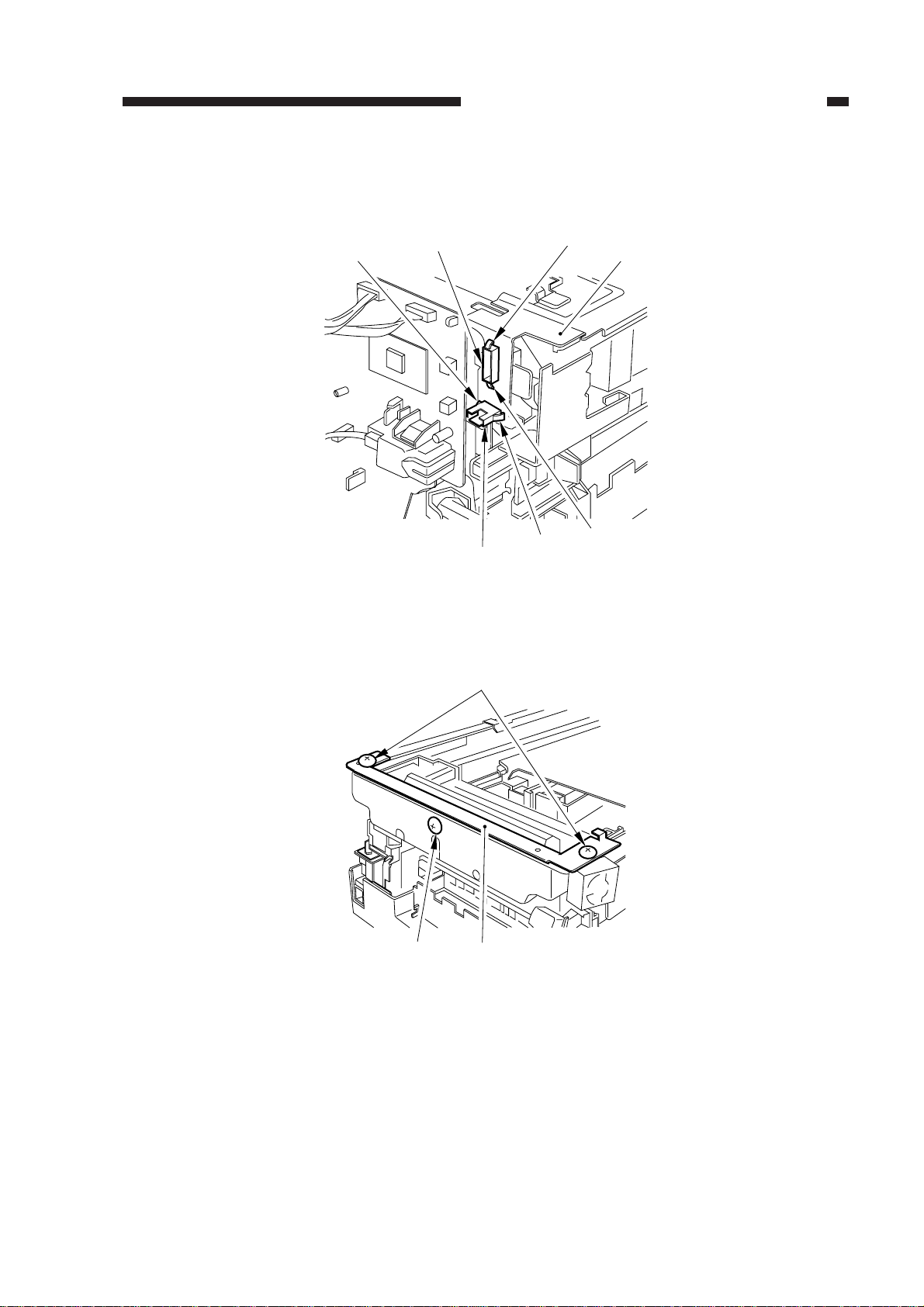

4) Disconnect the connectors (J101, J131) [1] from the DC controller PCB.

[1]

Figure 2-12

2-8

CHAPTER 2 STANDARDS AND ADJUSTMENTS

5) If the machine is equipped with an ADF, free the hook [2], and disconnect the two relay connectors [3] from the left upper stay [4].

[2]

[2]

[2]

[2]

[3]

[3]

Figure 2-13

6) Remove the three screws [5], and detach the left upper stay [4].

[5]

[4]

[4][5]

Figure 2-14

2-9

CHAPTER 2 STANDARDS AND ADJUSTMENTS

7) Remove the four screws [7], and detach the lens cover [8].

[7]

[7]

[8]

Figure 2-15

2-10

CHAPTER 2 STANDARDS AND ADJUSTMENTS

[1]

[3]

Top view

[3]

2. Routing the Reversing Cable

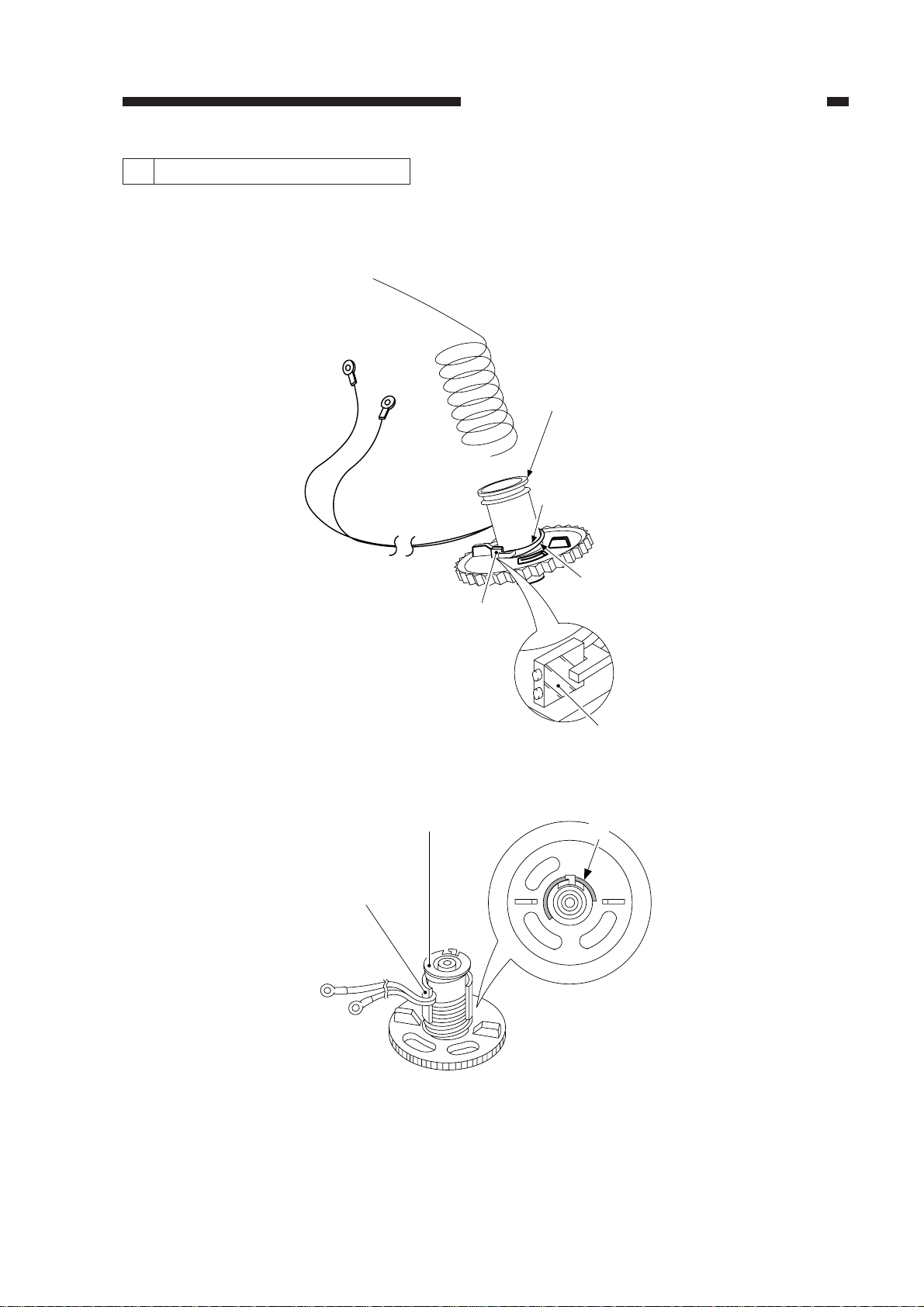

1) Wind the reversing cables (silver-colored) [2] on the cable drive pulley [1] 7.5 times with the

longer of the two on top; then, secure it in position with a cable clip [3].

[1]

Longer end

[2]

Figure 2-16

Shorter end

Face with a marking

Figure 2-17

2-11

CHAPTER 2 STANDARDS AND ADJUSTMENTS

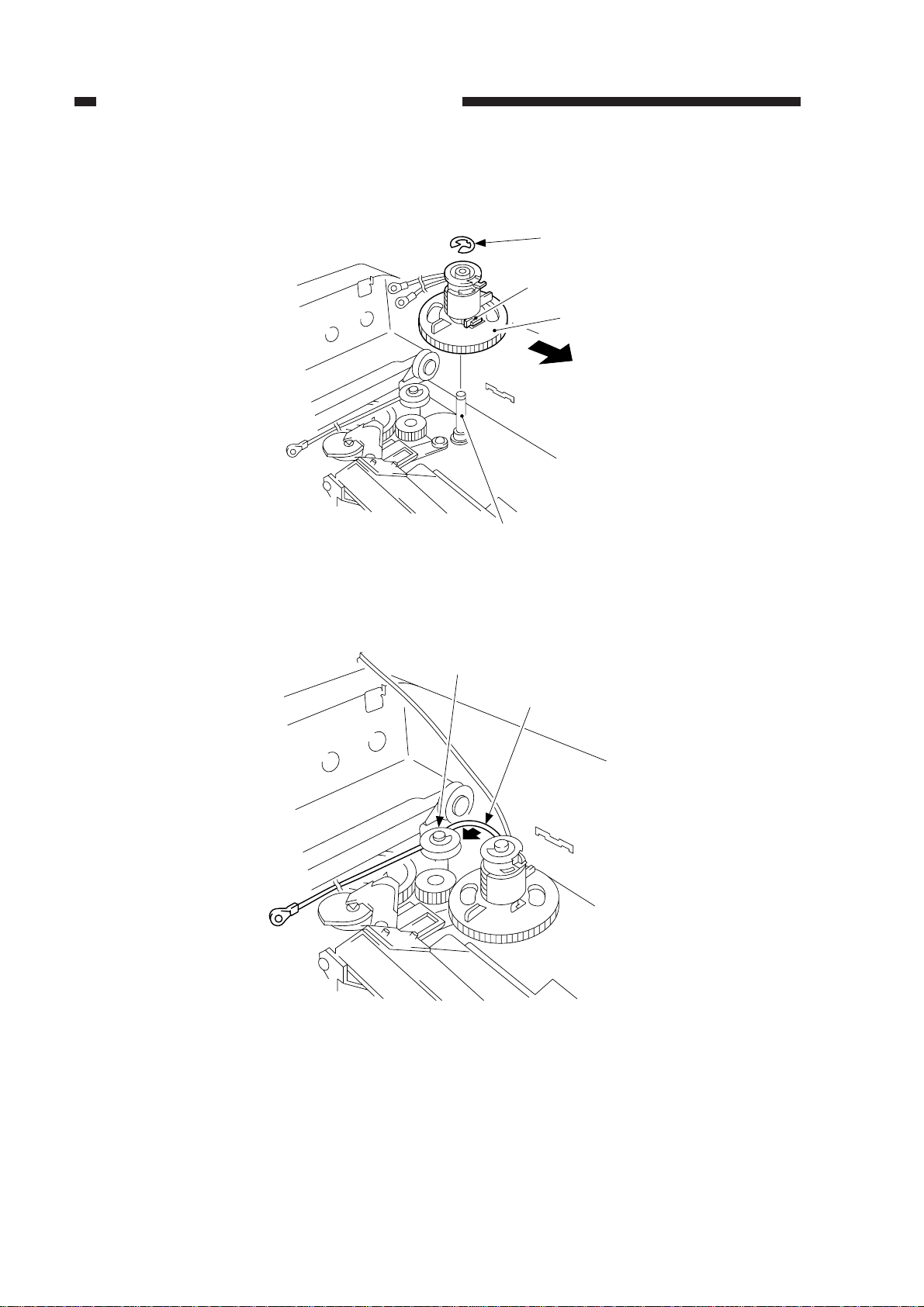

2) Put the cable drive pulley [1] into the shaft [4], and secure it in position with an E-ring [5].

When putting the cable drive pulley into the shaft, be sure that the hook is at the front.

[5]

Hook

[1]

(front)

[4]

Figure 2-18

3) Hook the shorter end [6] on the pulley [7].

[7]

[6]

2-12

Figure 2-19

CHAPTER 2 STANDARDS AND ADJUSTMENTS

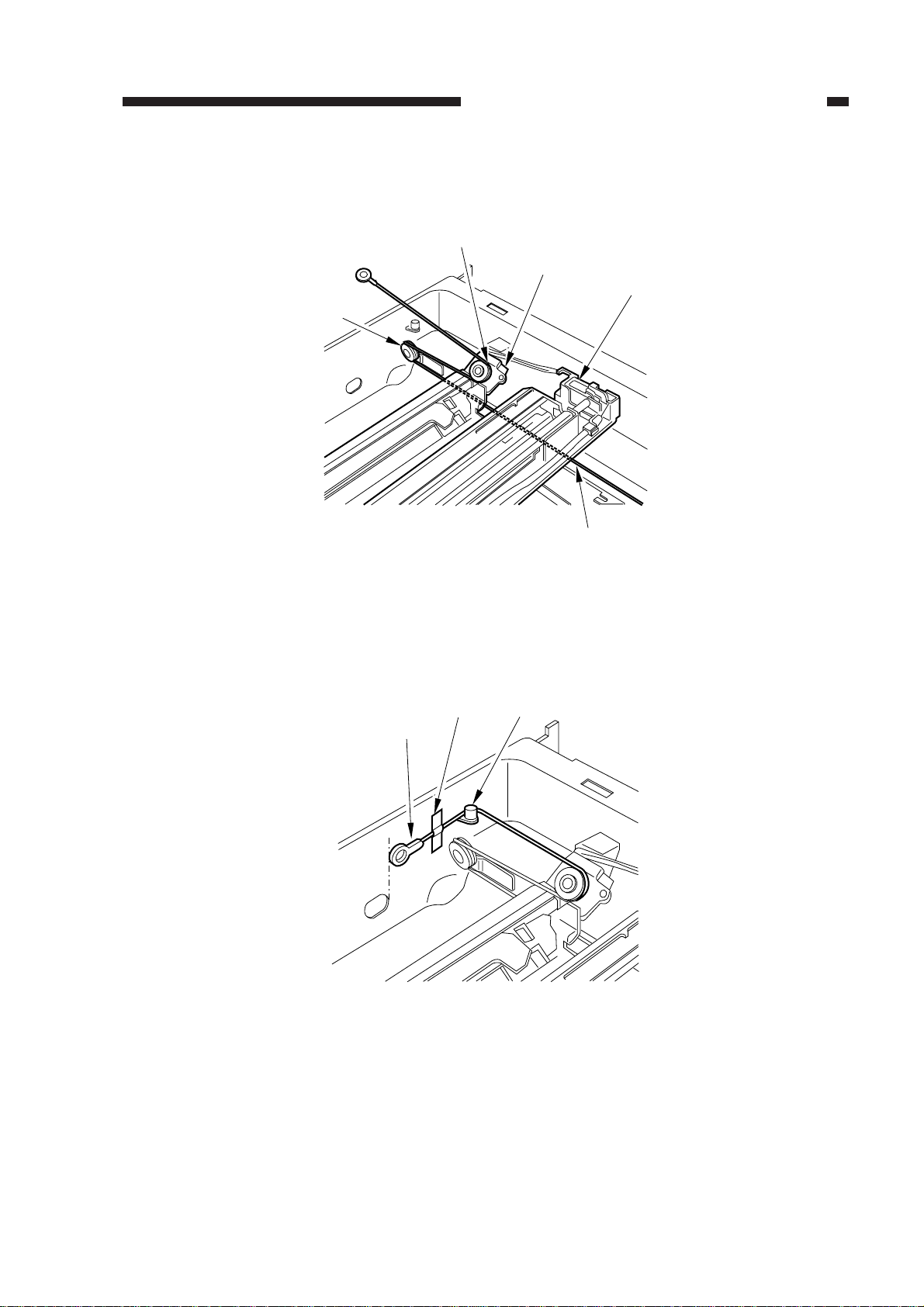

4) Lead the shorter end [6] under the No. 1 mirror mount [8] and the No. 2/3 mirror mount [9];

then, hook it on the left rear pulley [10] and the pulley [11] of the No. 2/3 mirror mount.

[11]

[9]

[8]

[10]

[6]

Figure 2-20

5) After fitting the shorter end [6] on the cable hook [12], secure its end with adhesive tape [13].

Be sure that the secured end of the cable is found where the hole in the left side plate and the tip

of the cable matches.

[12][13]

[6]

Figure 2-21

2-13

CHAPTER 2 STANDARDS AND ADJUSTMENTS

6) Lead the longer end [14] along the cable drive pulley [1], and hook it on the pulley [15] on the

right front side.

[14]

[15]

[1]

Figure 2-22

7) Lead the longer end [14] under the No. 1 mirror mount [8] and the No. 2/3 mirror mount [9];

then, hook it on the pulley [16] on the left front side and the pulley [17] of the No. 2/3 mirror

mount.

[17]

[8]

[14]

[9]

[16]

Figure 2-23

2-14

CHAPTER 2 STANDARDS AND ADJUSTMENTS

8) Hook the longer cable [14] on the cable hook [18]; then, secure its end to the left side with

adhesive tape [19].

Be sure that the secured end of the cable is found where the hole in the left side plate and the tip

of the cable matches.

[18]

Figure 2-24

[19]

[14]

2-15

CHAPTER 2 STANDARDS AND ADJUSTMENTS

3. Routing the Forwarding Cable

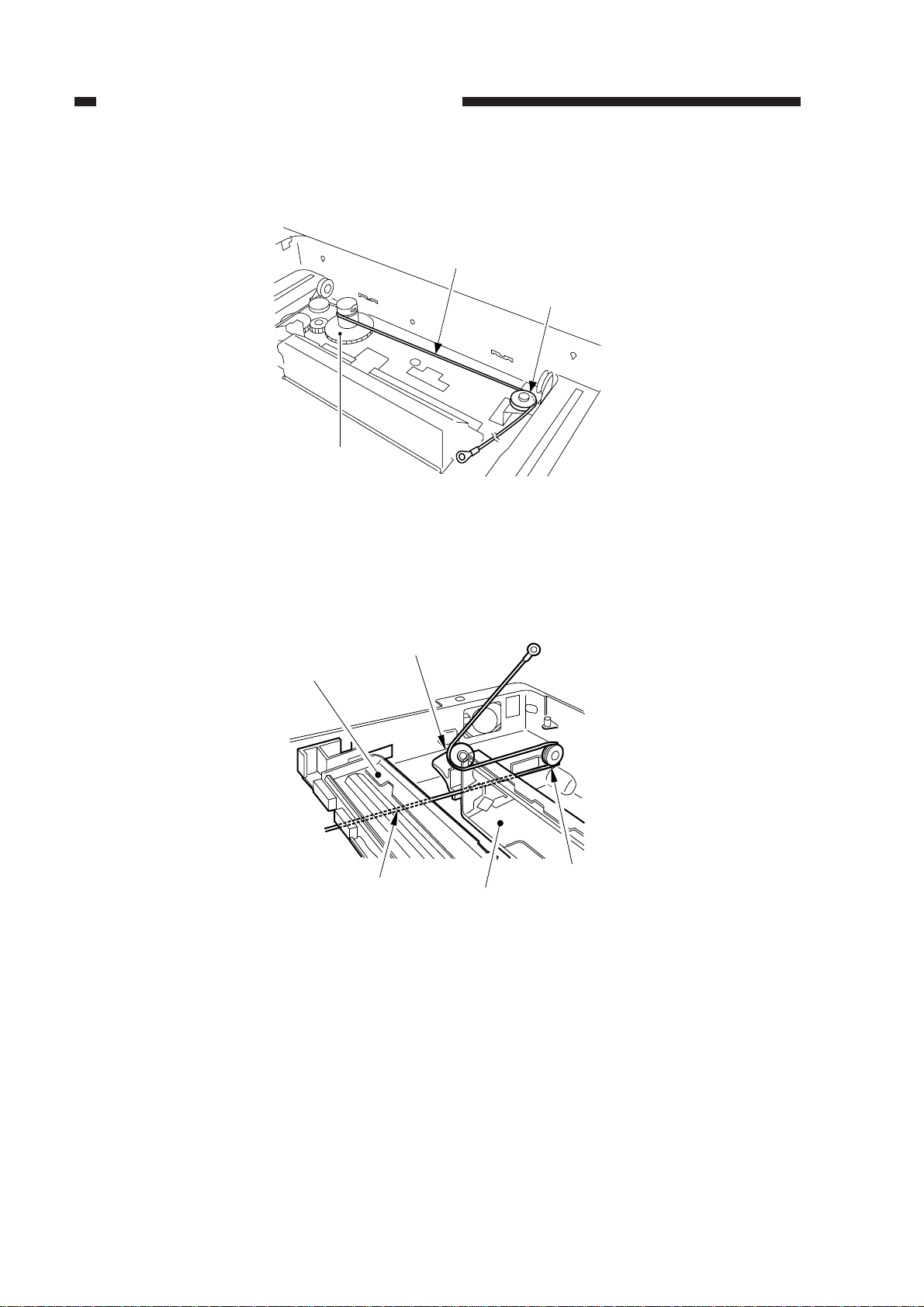

1) Fit the longer end forwarding cable (black) [2] on the top hook of the cable drive pulley [1], and

wind it 1.5 times. Then, secure the shorter end [3] as shown with adhesive tape [4].

[4]

[3]

Face without a marking

[2]

[1]

Figure 2-25

2) Lead the longer end [5] along the cable drive pulley [1] as shown, and hook it on the pulley [6]

on the right front side.

[1]

[5]

[6]

Figure 2-26

2-16

CHAPTER 2 STANDARDS AND ADJUSTMENTS

3) Lead the longer end [5] under the No. 1 mirror mount [7]; then, hook it on the pulley [8] of the

No. 2/3 mirror mount, and lead it between the No. 1 mirror mount [7] and the scanning lamp

[9].

[8]

[7]

[5]

[9]

Figure 2-27

4) Hook the end of the longer end [5] on the hole [10] on the right side.

[10]

Figure 2-28

[5]

2-17

CHAPTER 2 STANDARDS AND ADJUSTMENTS

5) Free the shorter end [3], and hook it on the pulley [11] on the right rear side.

[3]

[11]

Figure 2-29

6) Lead the shorter end [3] under the No. 1 mirror mount [7], and hook it on the pulley [12] of the

No. 2/3 mirror mount as shown; then, lead it between the No. 1 mirror mount [7] and the

scanning lamp [9].

[12]

[3]

[9]

[7]

Figure 2-30

2-18

Loading...

Loading...