Canon NP6317 Service Handbook

REVISION 0

APR. 1999

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-23B5-000

IMPORTANT

THIS DOCUMENTATION IS PUBLISHED BY CANON INC ., J APAN, TO SERVE AS A SOURCE

OF REFERENCE FOR WORK IN THE FIELD.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY SLIGHTLY

FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER

PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMA TION CONTAINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

THIS DOCUMENT ATION IS INTENDED FOR ALL SALES AREAS, AND MA Y CONTAIN INFORMATION NOT APPLICABLE TO CERTAIN AREAS.

COPYRIGHT © 1999 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly supervised to avoid disclosure of confidential

information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

OFFICE IMAGING PRODUCTS QUALITY ASSURANCE CENTER

CANON INC.

5-1, Hakusan 7-chome, Toride-shi, Ibaraki 302-8501 Japan

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CONTENTS

CHAPTER 1 MAINTENANCE AND INSPECTION

1

2

A. PERIODICALLY REPLACED

PARTS.......................................... 1-1

B. DURABLE PARTS........................1-2

C. BASIC PROCEDURE FOR

PERIODIC SERVICING...............1-3

CHAPTER 2 STANDARDS AND ADJUSTMENT

A. MECHANICAL .............................2-1 B. ELECTRICAL ............................ 2-15

CHAPTER 3 FUNCTION AND ARRANGEMENT OF THE

ELECTRICAL PARTS

A. SENSORS, FUSES AND

LAMPS.........................................3-1

B. CLUTCHES, SOLENOIDS, FANS,

MOTORS AND HEATERS ........... 3-2

D. PERIODIC SERVICING

SCHEDULE ................................. 1-4

E. BASIC IMAGE ADJUSTMENT

PROCEDURE .............................. 1-5

F. POINTS TO CHECK FOR

PERIODIC MAINTENANCE ........1-6

C. SWITCHES, CIRCUIT BREAKERS,

COUNTERS, ETC........................3-3

D. PCBS. ..........................................3-4

3

4

5

CHAPTER 4 IMAGE TROUBLESHOOTING

A. INITIAL CHECK ...........................4-1

B. SAMPLES OF IMAGE FAULTS ...4-4

CHAPTER 5 OPERATION TROUBLESHOOTING

A TROUBLESHOOTING OF

MALFUNCTION ........................... 5-1

6

C. TROUBLESHOOTING OF IMAGE

FAULTS ........................................4-5

7

8

i

CHAPTER 6 TROUBLESHOOTING FEEDING PROBLEMS

A. PAPER JAMS...............................6-1 B. INCORRECT PAPER FEED

OPERATION ................................6-5

CHAPTER 7 SERVICE MODE

A. Outline ..........................................7-1

B. Using the Service Mode............... 7-1

CHAPTER 8 SELF DIAGNOSIS

APPENDIX

A. GENERAL TIMING CHART ........ A-1

B. LIST OF SIGNALS/

ABBREVIATIONS ....................... A-3

C. Guide to Service Mode ................7-2

C. GENERAL CURCUIT

DIAGRAM ................................... A-5

D. SOLVENTS AND OILS LIST....... A-7

E. SPECIFICATIONS ...................... A-8

ii

CHAPTER 1 MAINTENANCE AND INSPECTION

CHAPTER 1 MAINTENANCE AND INSPECTION

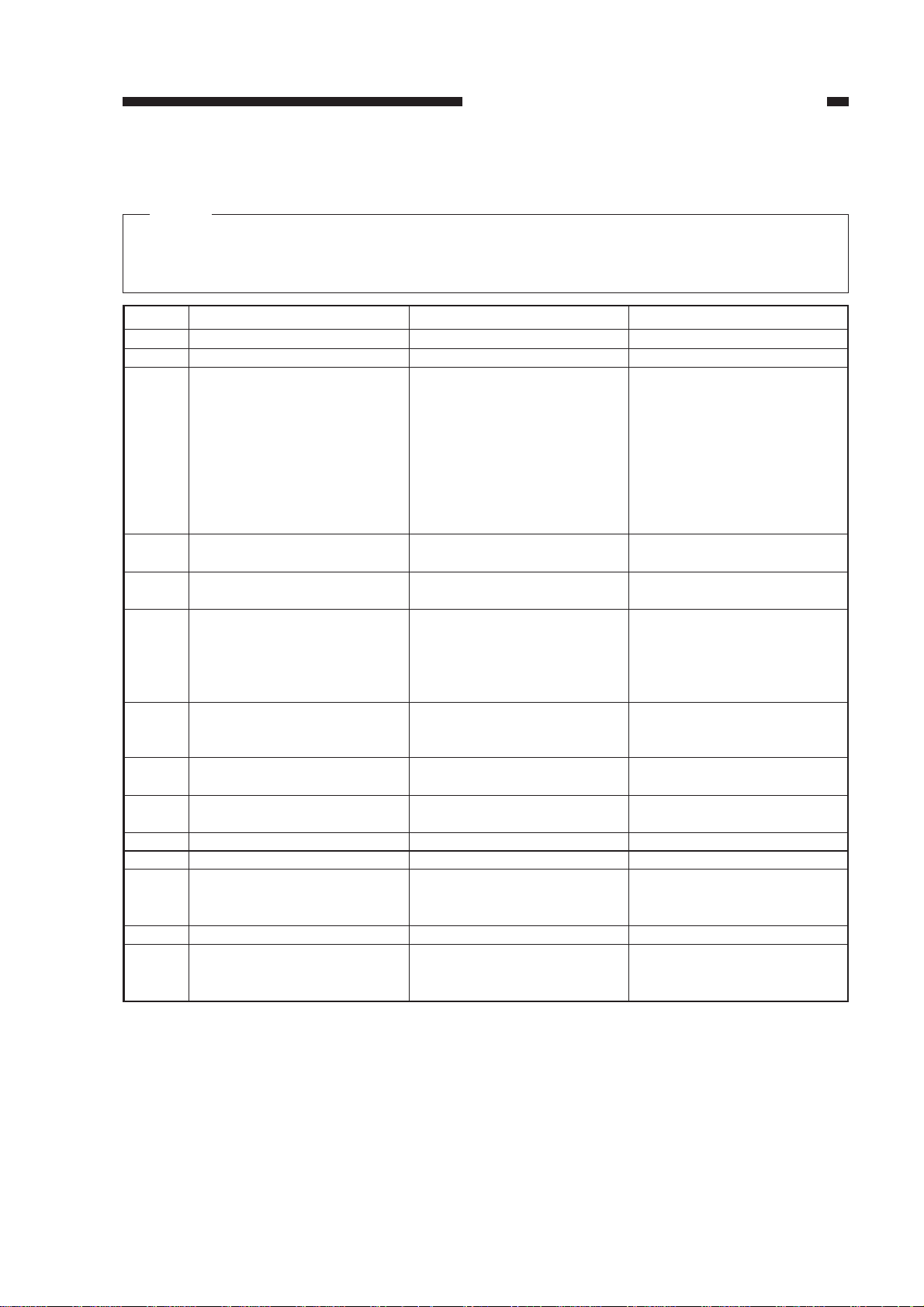

A. PERIODICALLY REPLACED PARTS

To maintain the copier at its peak performance, the parts listed in the following chart must be

replaced periodically. Although the deterioration of a part may not be visible, it can seriously

hamper the performance of the copier if not replaced on schedule.

Parts should be replaced during the regular service visit that is closest to the end of the service

life of the part.

as of March 1999

1

No.

1

2

3

4

5

Description

Ozone filter

Optical fan filter

Static charge eliminator

Transfer corona wire

Developing cylinder

spacer roller

Part No.

FF2-5595-00P

FA0-0339-00P

FF1-9438-070

FY3-0040-000

FS2-6019-000

Quantity

1

1

1

AR

2

Repacement

60,000

60,000

60,000

60,000

300,000

Remarks

Or 1year

Table 1-1

Note:

The above values are estimates and are subject to change depending on future data.

1-1

CHAPTER 1 MAINTENANCE AND INSPECTION

B. DURABLE PARTS

The values shown in the table below indicate the expected average life (number of copies) of

parts which may require replacement at least once during the warranty period due to deterioration

or damage but which can be simply replaced to restore the performance of the copier.

as of March 1999

Service life

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Description

Oil-applying roller (fixing

assembly)

Scanner drive cable

Scanning lamp (scanner)

Paper pick-up roller

(pick-up assembly)

Upper fixing roller

bearing (fixing assembly)

Pre-exposure lamp

Upper fixing roller (fixing

assembly)

Lower fixing roller

(fixing assembly)

Upper separation claw

(fixing assembly)

Lower separation claw

(fixing assembly)

Multi feeder roller

Pad (multi feeder)

Thermistor assembly

Heat sink roller

Part No.

FA5-1952-000

FC2-9799-00P

FH7-3114-000

FC2-9750-00P

FS1-1240-000

FG2-3009-00P

FC2-8962-00P

FC2-9774-00P

FB1-0301-000

FA2-9037-000

FB1-8581-000

FF3-3698-00P

FF3-2855-00P

FB3-4494-00P

Quantity

1

1

1

2

2

1

1

1

5

5

1

1

1

1

(number of

copies)

30,000

100,000

100,000

100,000

100,000

200,000

200,000

200,000

200,000

200,000

90,000

90,000

100,000

100,000

Remarks

Must be replaced at the

same time

Table 1-2

Note:

The above values are estimates and are subject to change depending on future data.

1-2

CHAPTER 1 MAINTENANCE AND INSPECTION

C. BASIC PROCEDURE FOR PERIODIC SERVICING

Note:

i. Perform periodic servicing after every 15,000 copies, as a general rule.

ii. Before making a service call, check the service log and take along any replacement parts

that are likely to be needed:

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Procedure

Note the operator's comments.

Record the counter reading.

Make DIRECT and two-page

overlay test copies.

Clean the corona assemblies.

Clean separation feeder assemblies.

Clean fixing and delivery

assemblies.

• Paper guide plate

• Separation claws (upper and

lower)

Perform the periodic servicing

appropriate to the number of

copies. (See p. 6-4.)

Clean the copyboard cover and

the copyboard glass.

Check the amount of waste

toner.

Make test copies.

Make sample copies.

Select sample copies to keep for

the users record.

Clean up around the copier.

Record the final counter value.

Fill in the service sheet and

check out with the person in

charge.

Check

Condition of copier

Number of miscopies

a.Image density

b. Dirty background

c.Clarity of letters

d.Leading edge blank area

e.Left and right margins

f. Fixing, synchronizing, and

soiling of back

g. Unusual noise

h. Operation of counter

Remarks

Standard: 2.0 ±1.5 mm

(DIRECT)

Standard: 10.0 ±2.0 mm

(DIRECT), front side

Dry wipe using lint-free paper;

then clean using alcohol.

Alcohol

Table 1-3

1-3

CHAPTER 1 MAINTENANCE AND INSPECTION

D. PERIODIC SERVICING SCHEDULE

Note:

Do not use solvents or oils other than those specified.

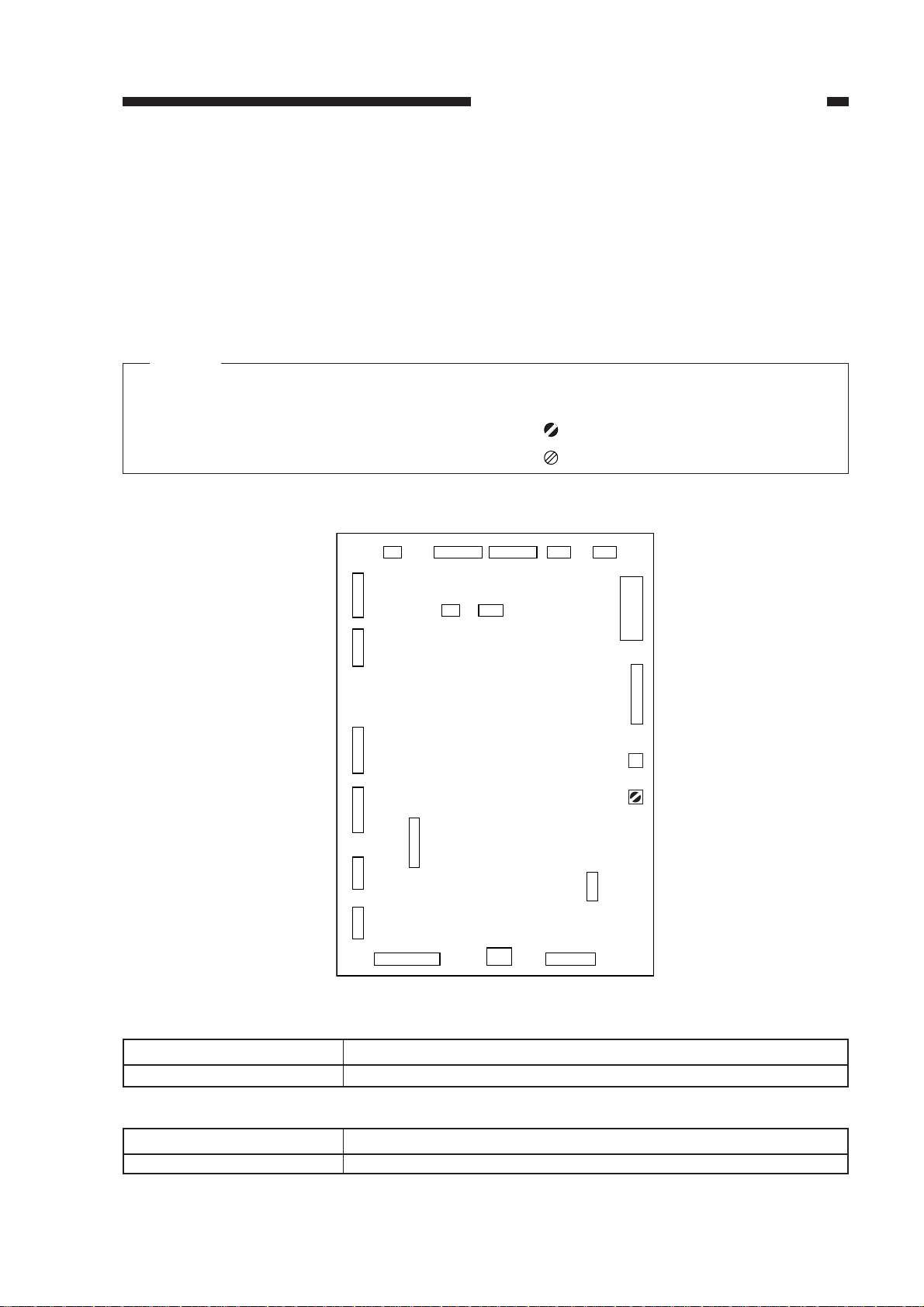

: Clean : Replace : Lubricate : Adjust : Check

Unit

External

Scanner drive

assembly

Feeder

Optical path

Corona assemblies

Developing assembly

Fixing assembly

Drum unit

Description

Copyboard glass

Ozone filter

Scanner rails

Transfer guide

Feeder belt

Feeder frame

Scanning lamp reflector

Scanning lamp side

reflector

Mirror 1 to 6

Lens

Dustproofing glass

Primary corona assembly

Primary corona wire

Transfer corona assembly

Transfer corona wire

Static charge eliminator

Spacer rollers (front and

rear)

Upper fixing roller

Lower fixing roller

Paper guide plate

Separation claws

(upper and lower)

Lower face of drum unit

Periodic servicing

Every *

15,000

copies

Remarks

Every

30,000

copies

Clean with alcohol.

Replace yearly.

Clean with alcohol then

apply high vis cosity

lubricating oil (TKN-

0451).

Damp cloth

Clean with a blower

brush. If very dirty, clean

with alcohol.

Clean mirror 6 with the

mirror cleaning tool.

Dry wipe using lint-free

paper; then clean using

alcohol.

Damp cloth

Clean with alcohol.

Clean with cleaning oil.

Clean with MEK.

* Items to be cleaned every 15,000 copies or every 6 months, whichever comes first.

Table 1-4

1-4

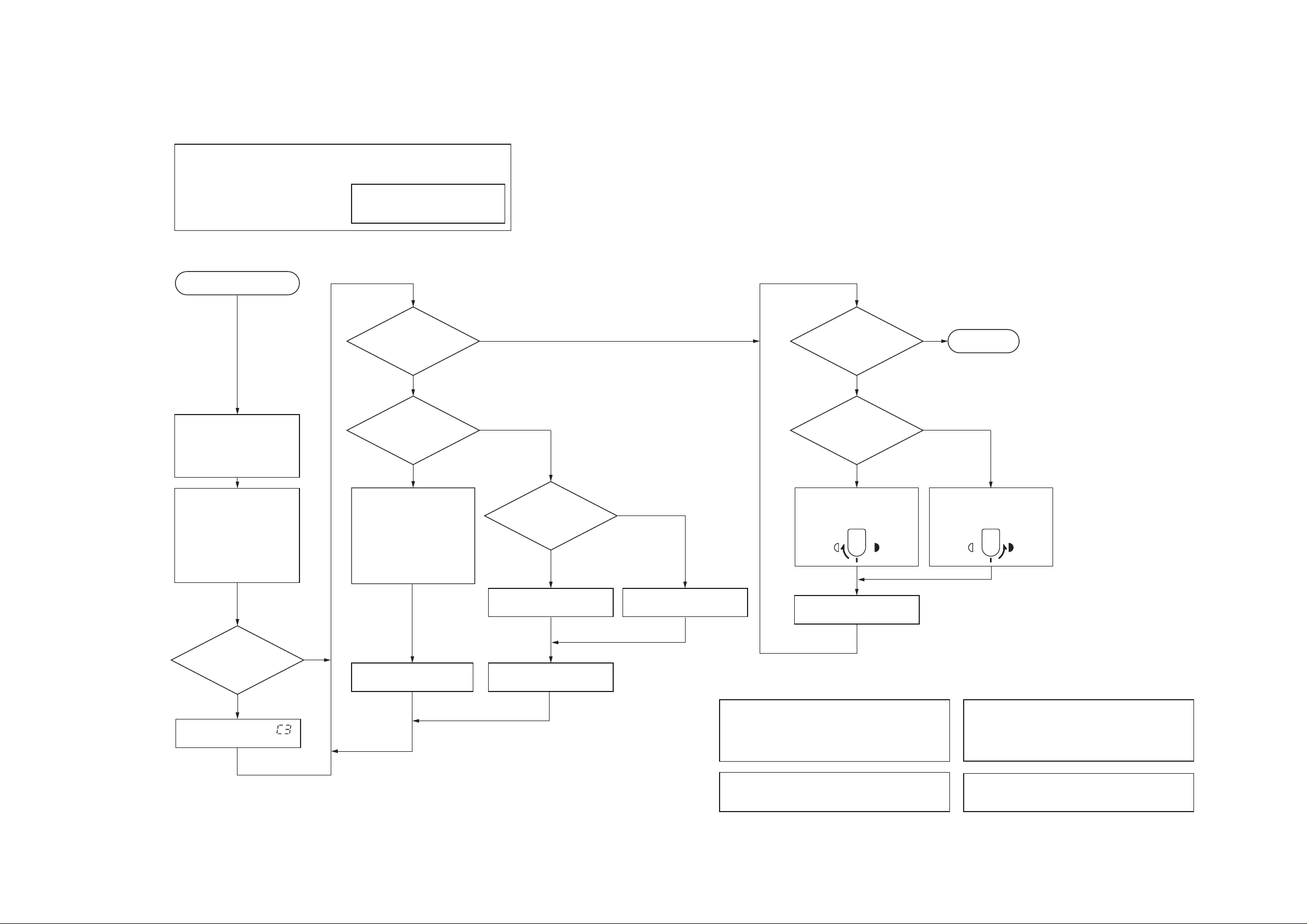

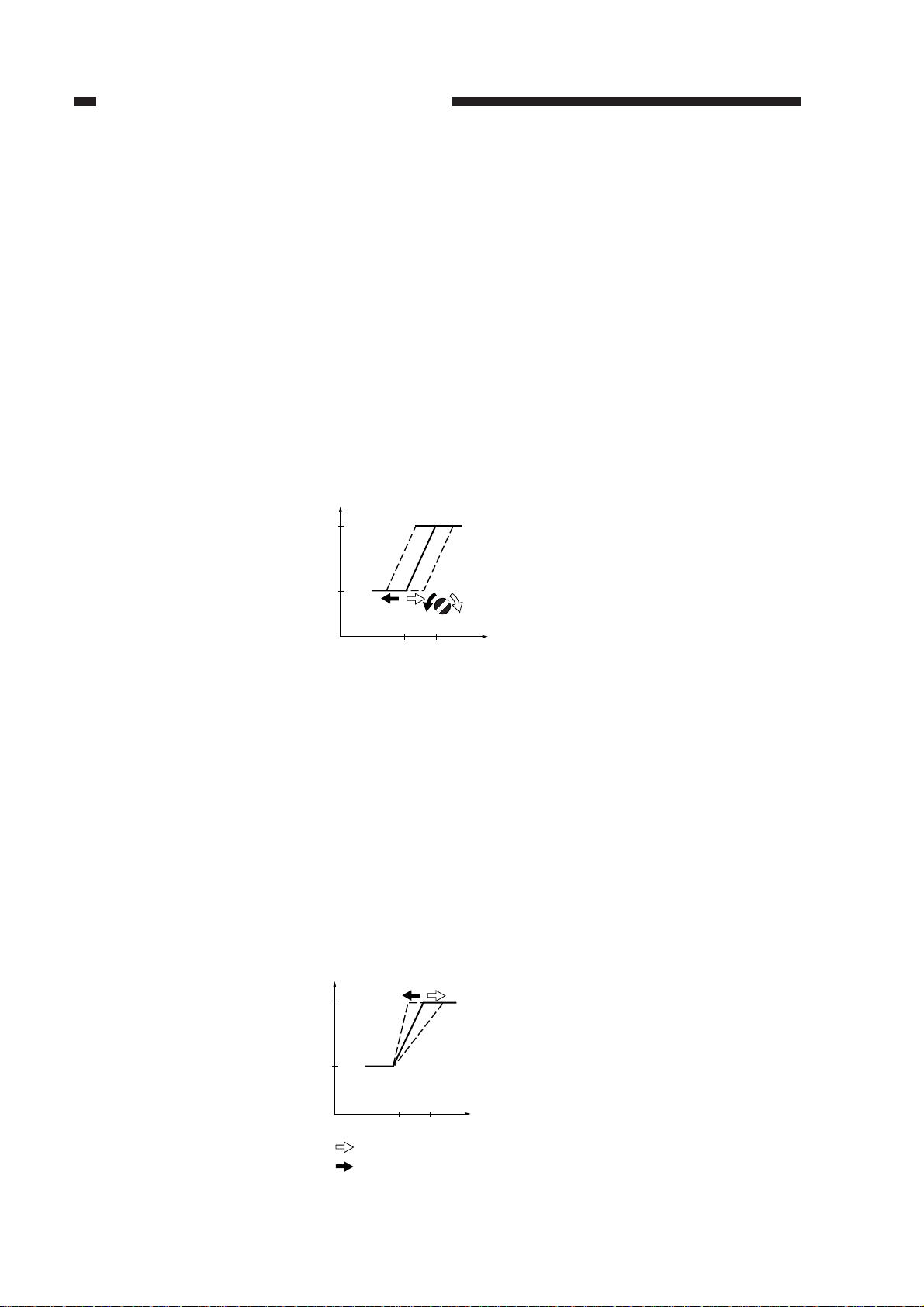

E. BASIC IMAGE ADJUSTMENT PROCEDURE

Pre-check

Adjusting side-to side

density

Adjusting the density

Clean the corona wires.

Make the following copies

(using test sheet NA-2 or

NB-3)

Copy density 5: 2 copies

Copy density 1: 1 copy

Check the following :

1. Differences in density

between the near and

far sides of the copies.

2. Density of gray scale

No. 10.

3. Fogging in blank areas.

Adjust Service mode ( ).

(See p. 2-1.)

Return copy density

to 5.

Replace the grid plate and

grid mounting panel.

Check for stains on the

scanning lamp, reflector

plate, and mirror; clean

them if necessary.

Is the top

margin of the copy

at copy density 1 within

the standard?

Make one copy.

YES

NO

Replace the drum unit.

Make one copy.

Mount the drum unit

and make one copy.

Is there a

difference in density

in the image area of a

reduced copy?

NO

NO

Is there a

difference in density

on the near and far sides

of the copies?

Is the

distance bet-

ween the primary

corona grid and the photo-

sensitive drum

correct?

NO

YES

YES

(Note 1)

YES

Turn the copy density knob

clockwise. (Note 2)

(The image will become

lighter.)

Turn the copy density knob

counterclockwise. (Note 3)

(The image will become

darker.)

Is the

density of gray

scale No. 10 too dark?

(See Note 3.)

YES

Is the

density of gray

scale No. 10 correct?

(See Note 3.)

NO

NO

(See Note 4.)

YES

End.

Image adjustment should be performed using the following settings:

1. Manual (non AE) exposure

2. Density cursor setting : 5

3. DIRECT reproduction ratio

Adjust the image by the following

procedure when the photosensitive drum has been replaced.

Make this adjustment with the

upper front panel and front door

installed.

Note 1 : The distance between the grid and

photosensitive drum is determined by

the spacer mounted on the grid.

Check for deterioration or damage to

the spacer.

This changes the developing bias, but

not the intensity of the scanning

lamp.

Note 2 :

No. 10 on the gray scale of a copy

should reproduce the density of No. 8

on the gray scale of the test sheet,

and no fogging in the background

should be visible.

Note 3 :

Turning the copy density knob clockwise too far past the proper position

will result in fogging in blank areas.

Note 4 :

Figure 1-1

1-5

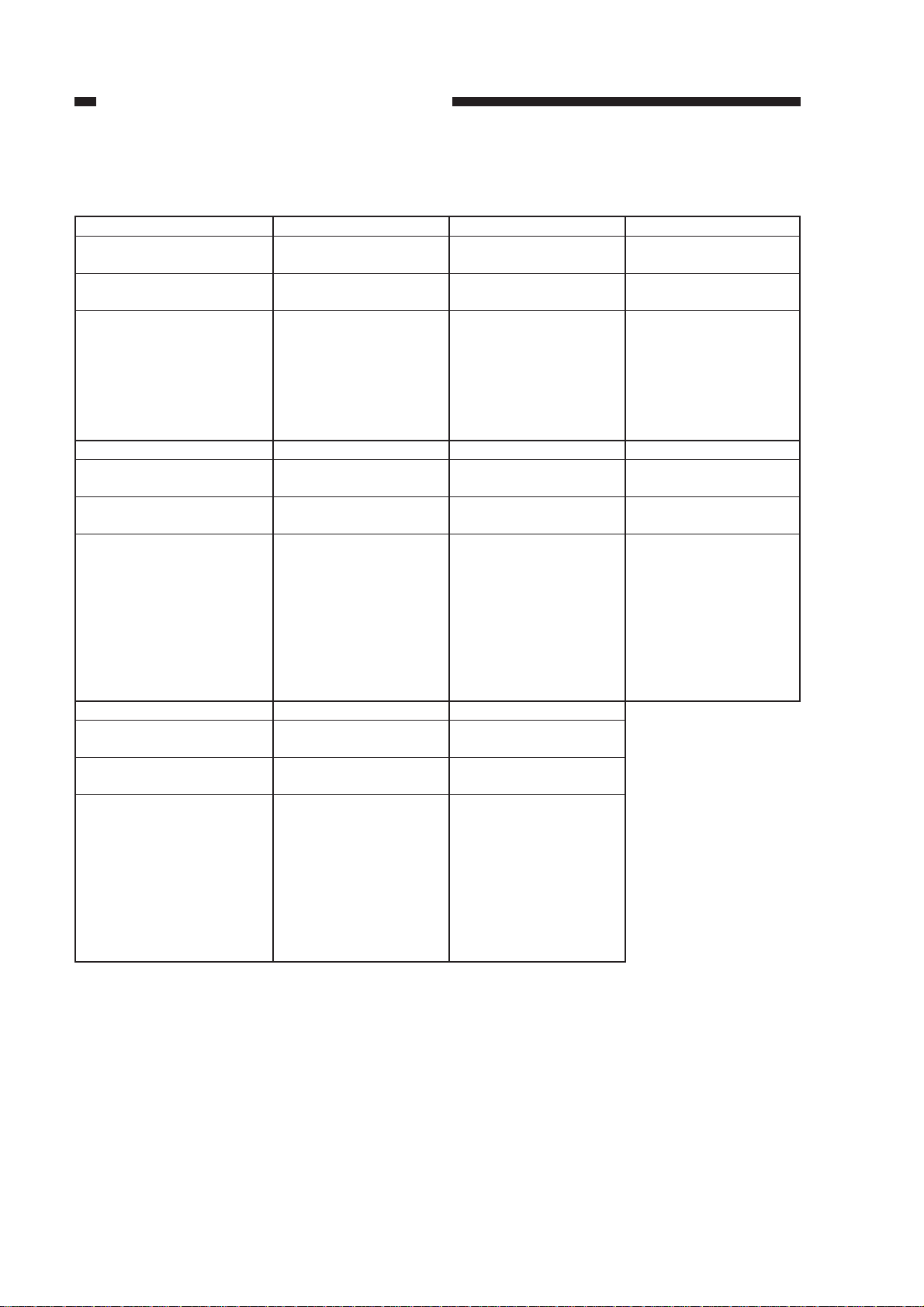

F. POINTS TO CHECK FOR PERIODIC MAINTENANCE

Copyboard/Scanner

Location

Copyboard glass

Reflectors

Mirrors 1, 2 and

3

Tool/Cleaner

Alcohol

Blower brush

Blower brush or

alcohol and

lint-free paper

Action/Remarks

Cleaning

Cleaning

Clean with a

blower brush.

If dirt cannot be

removed with a

blower brush,

clean with

alcohol.

Fixing assembly and Paper pick-up assembly

Optical path

Location

Lens

Dust-proofing

glass

Mirror 4/5

carriage

Mirror 6

Blower brush or

alcohol and

lint-free paper

Mirror

creaning tool

Corona assemblies

Location

Developing

rollers

Primary corona

assembly

Transfer corona

assembly

Alcohol

Alcohol and lintfree paper

Tool/Cleaner

Tool/Cleaner

Action/Remarks

Clean with a

blower brush.

If dirt cannot be

removed with a

blower brush,

clean with

alcohol.

Cleaning

Action/Remarks

Cleaning

Wipe with a dry

cloth; then, clean

with lint-free

paper moistened

with alcohol.

Location

Separation claws

Upper fixing

roller, lower

fixing roller

Paper guide plate

Heat sink roller Cleaning oil

Tool/Cleaner

MEK

Cleaning oil

(TKN-0464)

MEK Cleaning

(TKN-0464)

Action/Remarks

Cleaning

Cleaning

Cleaning

Static charge

ellminator

Primary corona

grid

Blower brush

Blower brush

Cleaning

Separation and transfer assemblies

Location

Transter guide

Feeder belt

Feeder assembly

Tool/Cleaner

Damp cloth

Action/Remarks

Cleaning

1-6

Figure 1-2

CHAPTER 2 STANDARDS AND ADJUSTMENT

CHAPTER 2 STANDARDS AND ADJUSTMENT

A. MECHANICAL

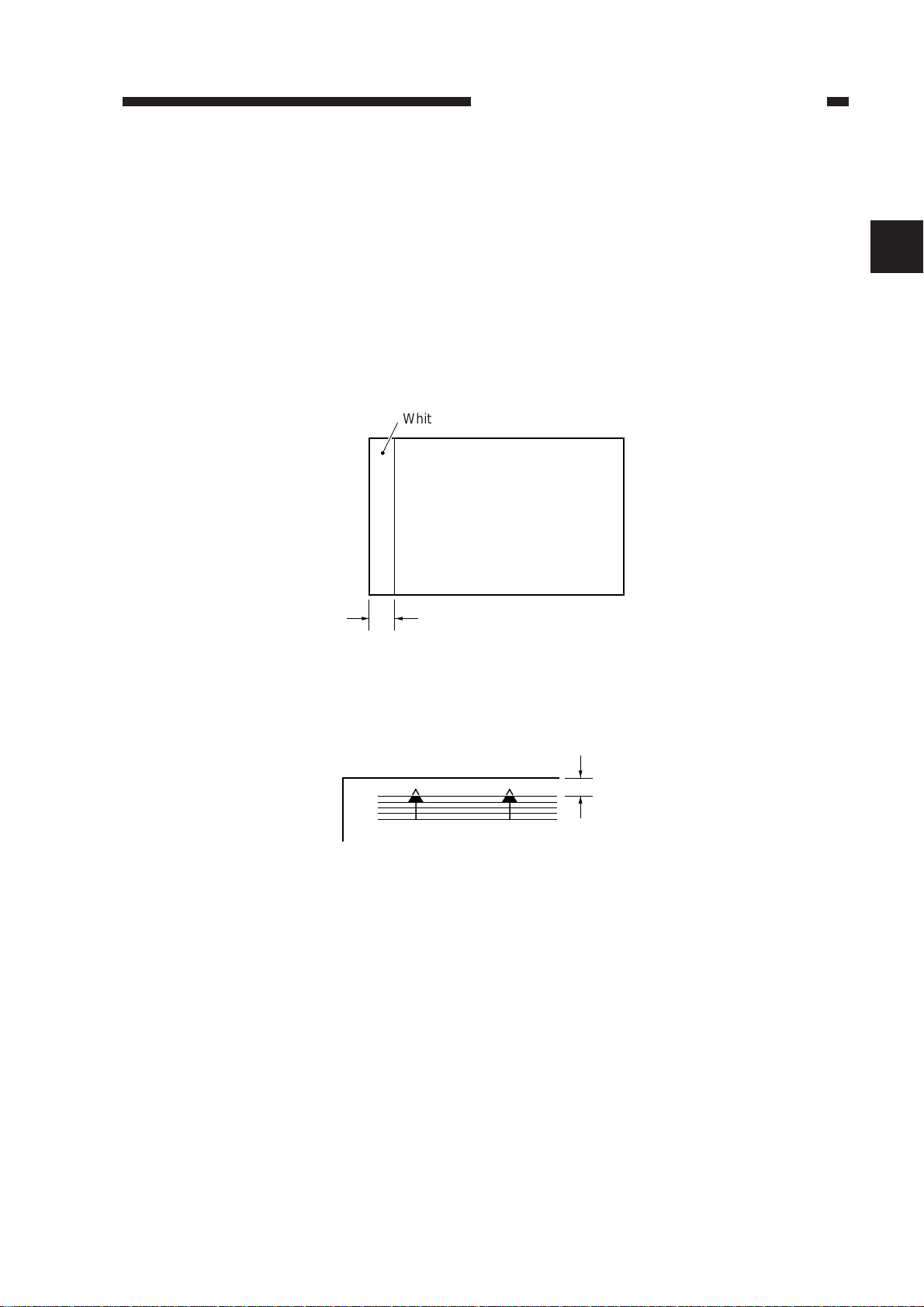

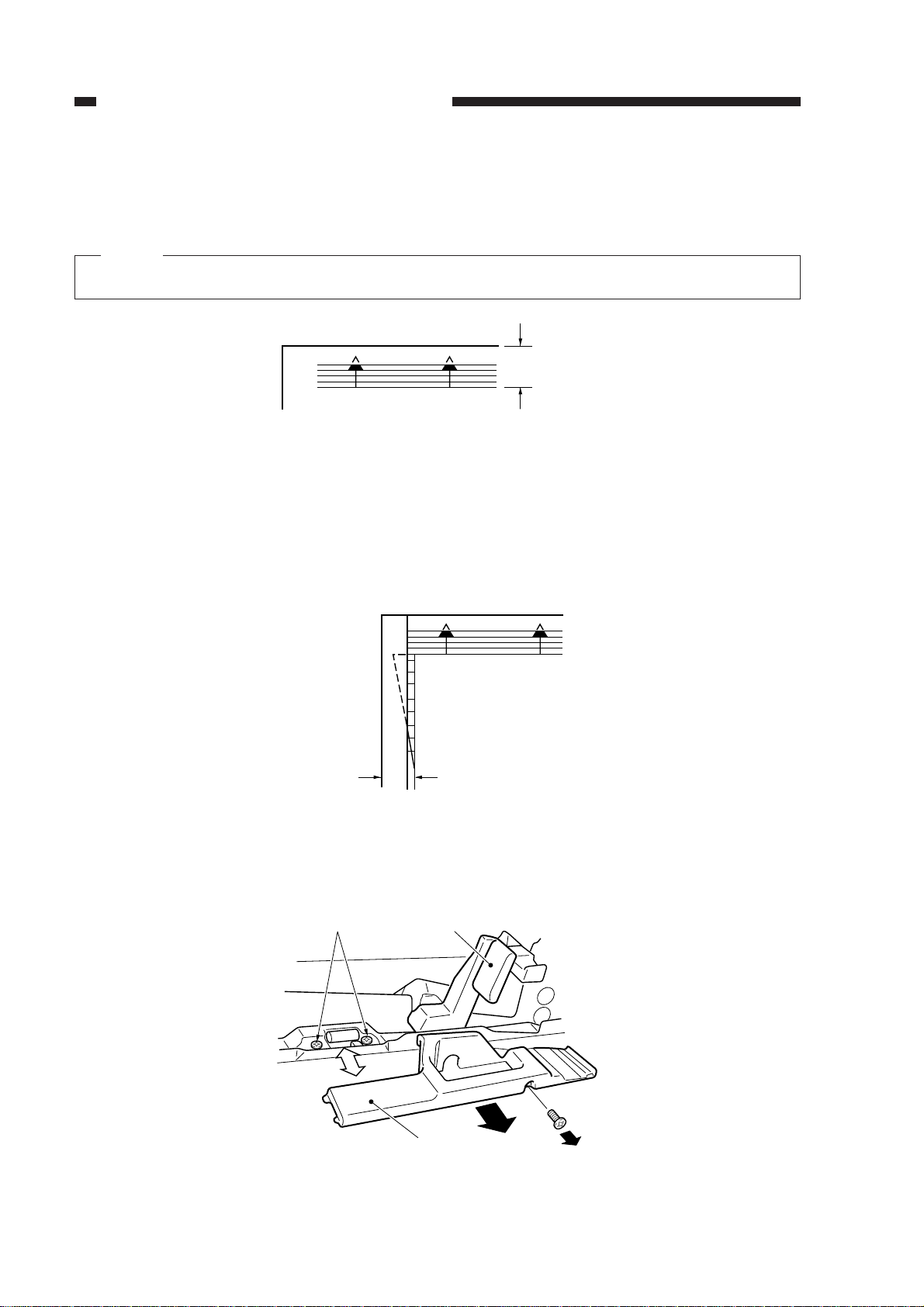

1. Leading Edge Non-Reproduced Area

There is a white strip on the bottom of the copyboard glass in the position shown in the figure

below. If bias is being applied to the grid of the primary corona while the scanner is passing over

the white strip, the leading edge of the copy will be reproduced blank. If the leading edge nonimage width is outside the standards, adjust the timing at which the grid bias goes from OFF to ON

in the service mode (C3).

White strip

Surface of copyboard glass

2

Approx. 10mm

Figure 2-1

The standard leading edge non-reproduced area on a DIRECT copy of the test sheet is 2.0 ±1.5

mm.

2.0 ±1.5 mm

Figure 2-2

A higher setting (C3) increases the leading edge non-image width; in units of 0.25 mm.

2-1

CHAPTER 2 STANDARDS AND ADJUSTMENT

2. Leading Edge Registration

Make adjustments in the service mode (C2) so that the distance shown is 10.0 ±1.5 mm when

the test sheet is copied in DIRECT.

Note:

Adjust the leading edge non-reproduced area before making this adjustment.

10.0 ±1.5 mm

Figure 2-3

A higher setting in the service mode (C2) increases the leading edge margin.

3. Side-to-Side Registration

a. Cassette Feeding

The standard near side registration on a DIRECT copy of the test sheet is 10.0 ±2 mm.

0

2

4

6

8

10 ±2 mm

10

Figure 2-4

Loosen the two screws, and adjust the latch assembly for the cassette found on the back of the

bottom plate by sliding it.

Screws

Feeder release

lever

2-2

Cover

Figure 2-5

CHAPTER 2 STANDARDS AND ADJUSTMENT

b. Multifeeder Feeding

The standard near side registration on a DIERCT copy of the test sheet is 10.0 ±2 mm.

0

2

4

6

8

10 ±2 mm

10

Figure 2-6

Loosen the screw, and adjust the multifeeder side guide by sliding it. Then, tighten the screw.

Side guide

Figure 2-7

Screw

2-3

CHAPTER 2 STANDARDS AND ADJUSTMENT

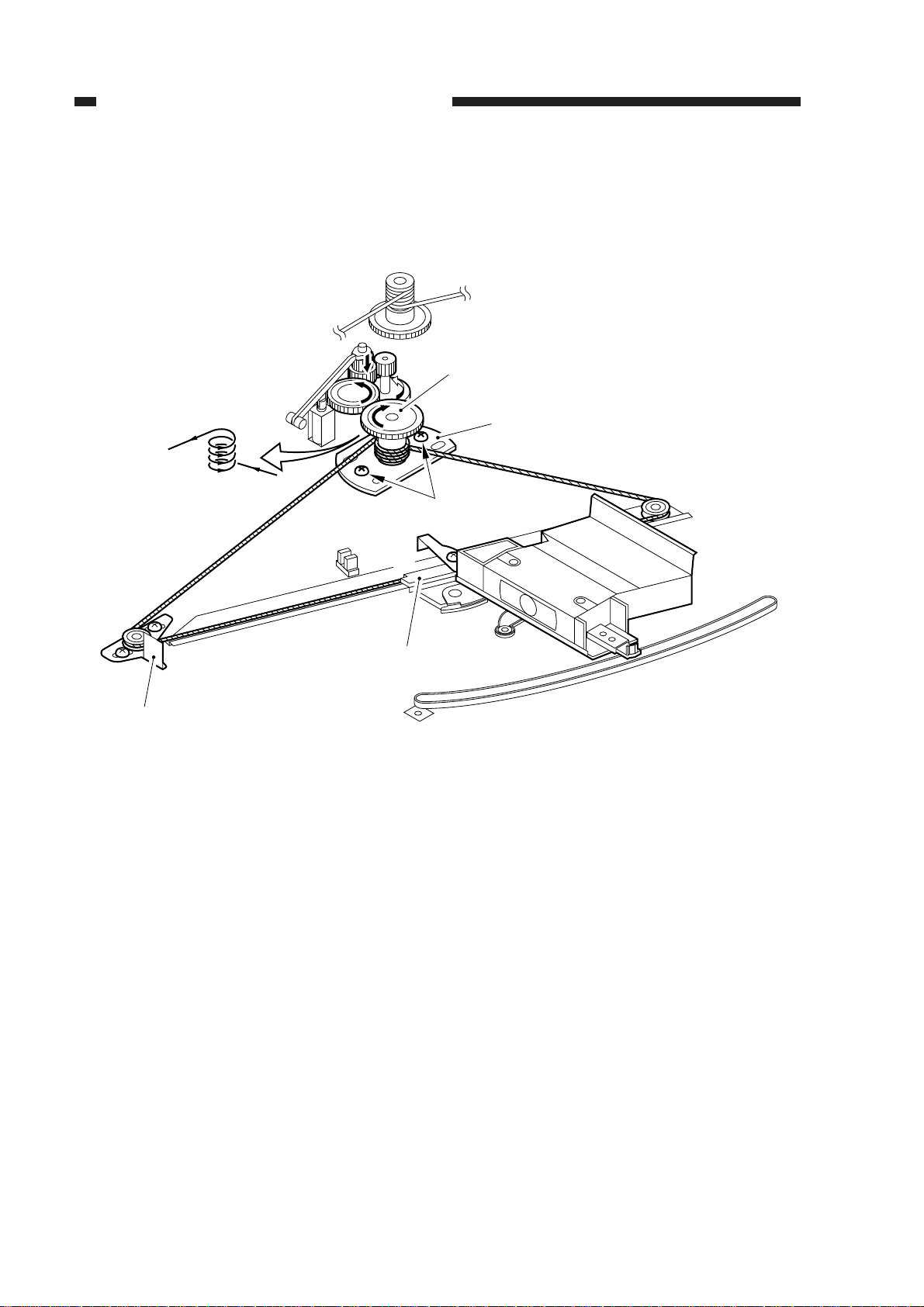

4. Installing the Lens Drive Cable

This unit has been accurately adjusted at the factory with special gauges. Do not remove parts

other than those shown below, nor loosen any other screws.

Lens pulley

Lens pulley

[2]

4 turns

Mounting screws

fixing plate

[4]

[3]

Cable fixing

Pulley mount

Figure 2-8

a. Removing the Lens Cable

1) Remove the two screws and remove the lens cover.

2) Mark the positions of the pulley fixing base and the wire fixing piece with a scriber.

3) Remove the two screws keeping the pulley fixing base.

4) Remove the cable.

b. Attaching the Lens Cable

1) Remove the two screws keeping the lens pulley fixing plate, and remove the lens pulley.

2) Wind the lens cable around the lens pulley as shown in Figure 2-8, and secure it with the two

fixing screws.

3) Shift the pulley fixing base to the position of the scriber mark; then, fix it with the two fixing

screws.

2-4

5. Installing the Scanner Drive Cable

CHAPTER 2 STANDARDS AND ADJUSTMENT

[6]

[2]

Lower grove

[1]

Pulley 2

Screw A

[3]

Mark the position

Screws B

Scanner pulley

[4]

4 turns

Pulley 1

[6]

Pulley 3

[5]

Top groove

Figure 2-9

2-5

CHAPTER 2 STANDARDS AND ADJUSTMENT

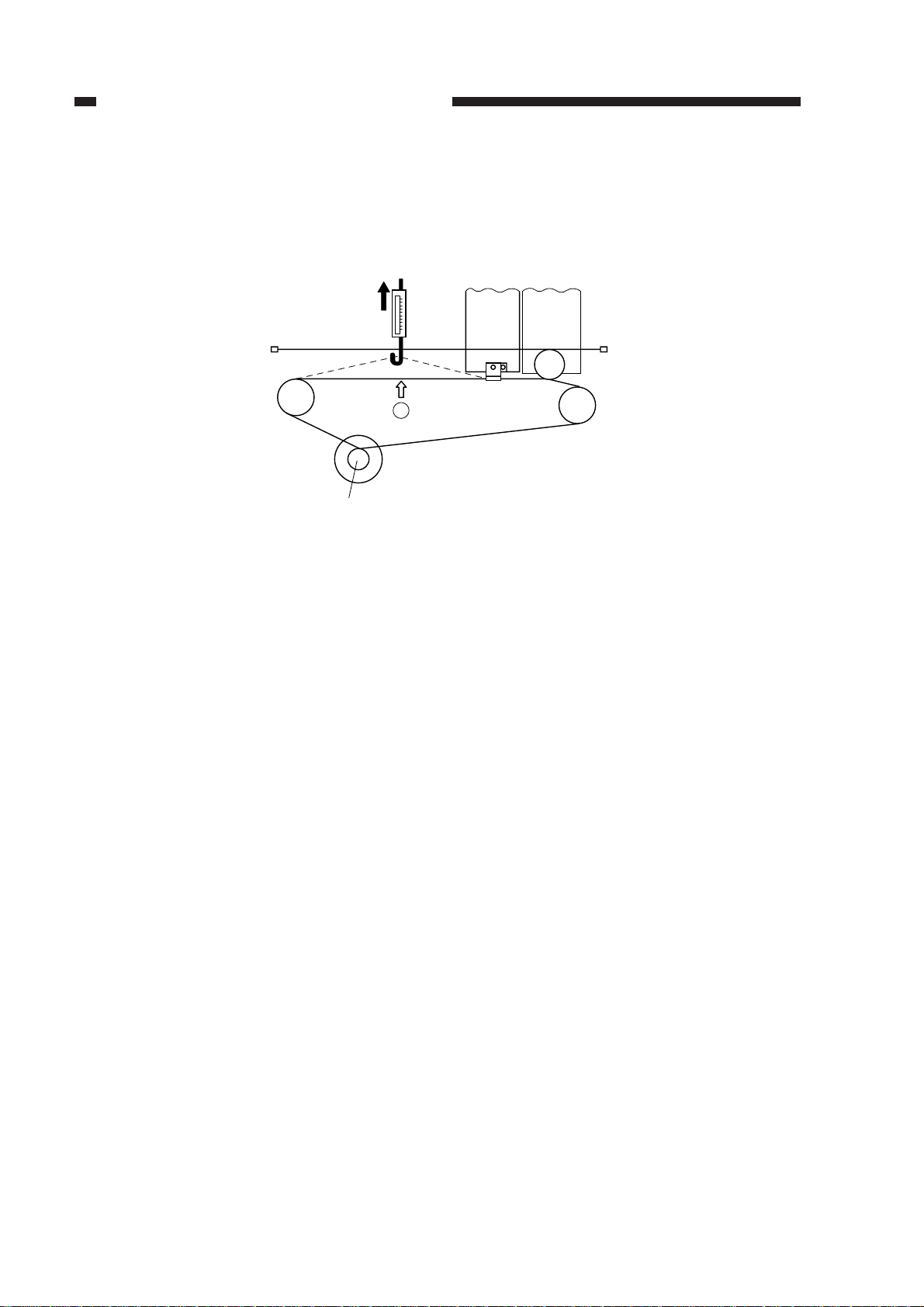

6. Adjusting the Tension of the Scanner Drive Cable

Move the mirror 1 mount to the home position (start position). As shown in Figure 2-10, pull at

point [A] (approximate center) of the free cable with a spring gauge so that the cable lengths touch

each other. If the reading on the spring balance is not about 1.0 ±0.5 kg, loosen the screws [B] of

Figure 2-9, turn screw [A] to achieve this reading, and then tighten the screws [B].

1.0 ±0.5 kg

Pulley 2

A

Scanner drive capstan

Figure 2-10 Top View

Scanner

Mirror

2/3

mount

Pulley 1

Pulley 2

2-6

CHAPTER 2 STANDARDS AND ADJUSTMENT

7. Adjusting the Position of the Mirrors and Lens

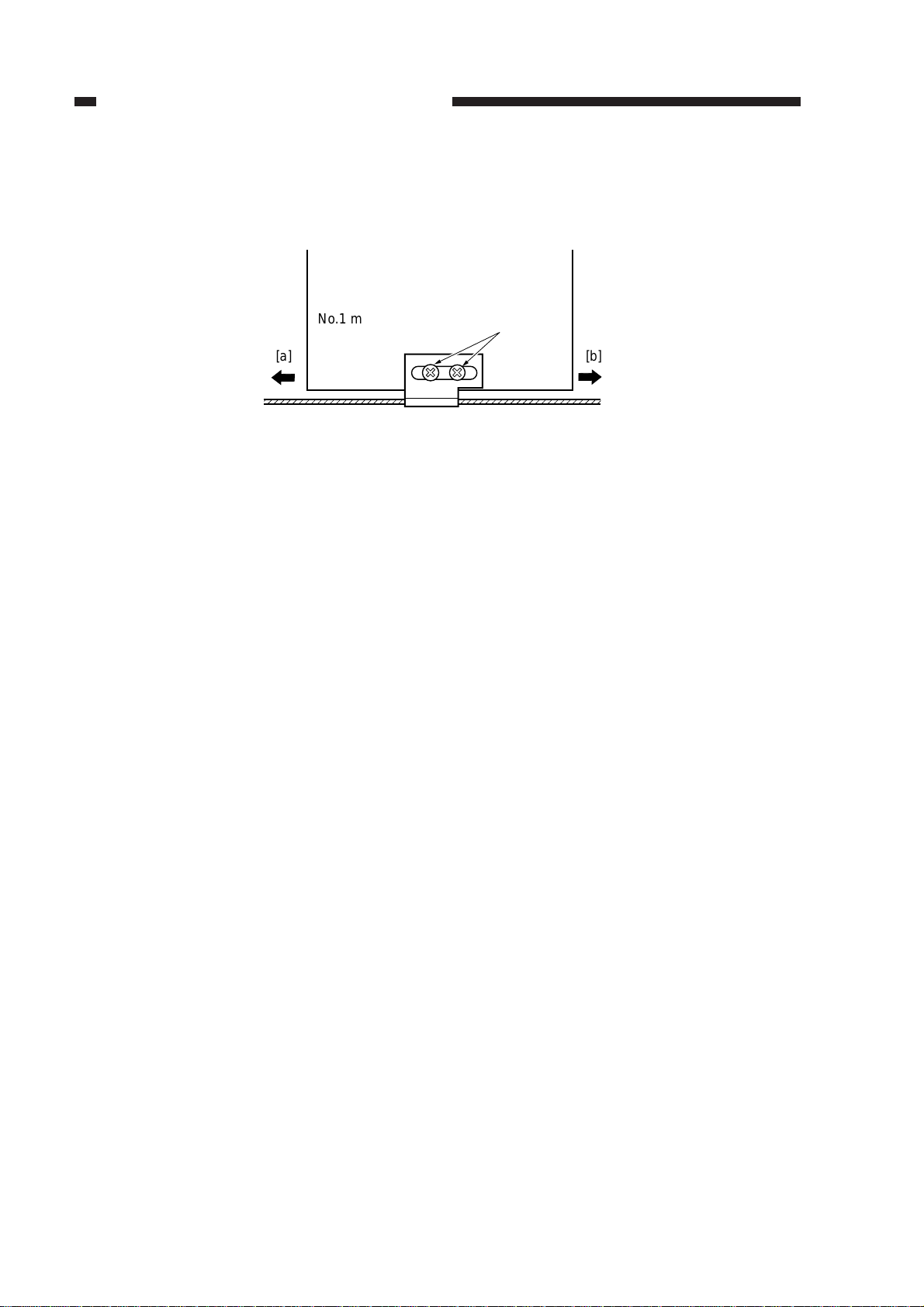

a. Adjusting the Position of the No.1 Mirror Mount (length of optical path between

mirrors 1 and 2)

Adjust the tension of the scanner drive cable before making this adjustment. Adjust the position of the scanner (mirror 1) by altering the tension of the scanner drive cable. (Loosen the cap

screws.)

For reference:

1. The cable will stretch after a large number of copies have been made, making readjustment

necessary.

2. An incorrect distance between mirror 1 and mirror 2 will cause an incorrect side-to-side repro-

duction ratio and poor focus, resulting in poor sharpness and fuzziness in the copy image.

1) Draw lines 10 mm from each edge of a piece of copy paper (A3), as shown in Figure 2-11.

1 cm 1 cm

Lines

Figure 2-11

2) Make a copy of the paper with the lines marked on it. (A)

3) Place a blank sheet of paper on the copyboard and feed the marked sheet of paper into the

copier. (Use manual feed.) (B)

• Passing the sheet through the copier indicates the amount of shrinkage due to heat.

4) Align the lines on the left side of the copy sheet (A) and the sheet passed through the copier (B).

If the lines on the right do not match adjust the position of the scanner so that the dimensions x

and y equal.

x

Sheet A

y

Sheet B

x=y Correct

x>y Move the scanner in direction a.

x<y Move the scanner in direction b.

Figure 2-12

2-7

CHAPTER 2 STANDARDS AND ADJUSTMENT

For reference:

If the distance between the mirrors is short, the image will be enlarged. If the distance is long,

the image will be reduced.

No.1 mirror mount

[a] [b]

Mirror drive cable

(front)

(rear)

Fixing screws

Figure 2-13 Top View

2-8

CHAPTER 2 STANDARDS AND ADJUSTMENT

b. Adjusting the Direct Copy Ratio (lens position)

1) Make a Direct copy.

2) Check the copy ratio. If the copy ratio is not appropriate, perform the following steps:

3) Enter service mode C10 (lens home position adjustment).

4) Try increasing or decreasing the value using the +/- keys. The (-) key moves the lens position

for enlargement (0.113%).

5) Exit from the service mode; and then turn the main switch to OFF/ON.

6) Make a Direct copy.

7) Check the copy ratio. If the copy ratio is appropriate, go to c. "Adjusting Focus (No. 4 and 5

mirror position)."

If the copy ratio is not appropriate, repeat step 4) and later.

c. Adjusting the Focus (No. 4 and 5 mirror position)

1) Make a Direct copy.

2) Check the copy ratio. If the copy ratio is not appropriate, perform the following steps:

3) Enter service mode C11 (mirror home position sensor adjustment).

4) Try increasing or decreasing the value using the +/- keys. The (-) key moves the mirror position

to the right by 0.05 mm (i.e., increases the optical path length by 0.1 mm).

5) Exit from the service mode; and then turn the main switch to OFF/ON.

6) Make a direct copy.

7) Check the copy ratio. If the copy ratio is appropriate, go to d. "Adjusting the Lens and Mirror

Position (50%)."

If the copy ratio is not appropriate, repeat step 4) and later.

d. Adjusting the Lens and Mirror Position (50%)

1) Make a 50% copy.

2) Check the copy ratio. If the copy ratio is not appropriate, perform the following steps:

3) Enter service mode C7 (copy ratio adjustment (50%)).

4) Try increasing or decreasing the value using the +/- keys. The (-) key moves the mirror and lens

position for enlargement (0.037%).

5) Exit from the service mode; and then turn the main switch to OFF/ON.

6) Make a 50% copy.

7) Check the copy ratio. If the copy ratio is appropriate, go to e. "Adjusting the Lens and Mirror

Position (200%)."

If the copy ratio is not appropriate, repeat step 4) and later.

e. Adjusting the Lens and Mirror Position (200%)

1) Make a 200% copy.

2) Check the copy ratio. If the copy ratio is not appropriate, perform the following steps:

3) Enter service mode C8 (lens ratio adjustment (200%)).

4) Try increasing or decreasing the value using the +/- keys. The (-) key moves the mirror and lens

position for enlargement (0.15%).

5) Exit from the service mode, and then turn the main switch to OFF/ON.

6) Make a 200% copy.

7) Check the copy ratio if the copy ratio is appropriate, finish the adjustment. If the copy ratio is

not appropriate, repeat step 4) and later.

2-9

CHAPTER 2 STANDARDS AND ADJUSTMENT

8. No. 4/5 Mirror Mount

The screws [A] that keeps the No. 4/5 mirror mount [1] to the lens base plate must not be

loosened in the field. If they are loosened, readjusting the mirror mechanical axis is not possible in

the filed.

[1]

[A][A]

[A]

Figure 2-14

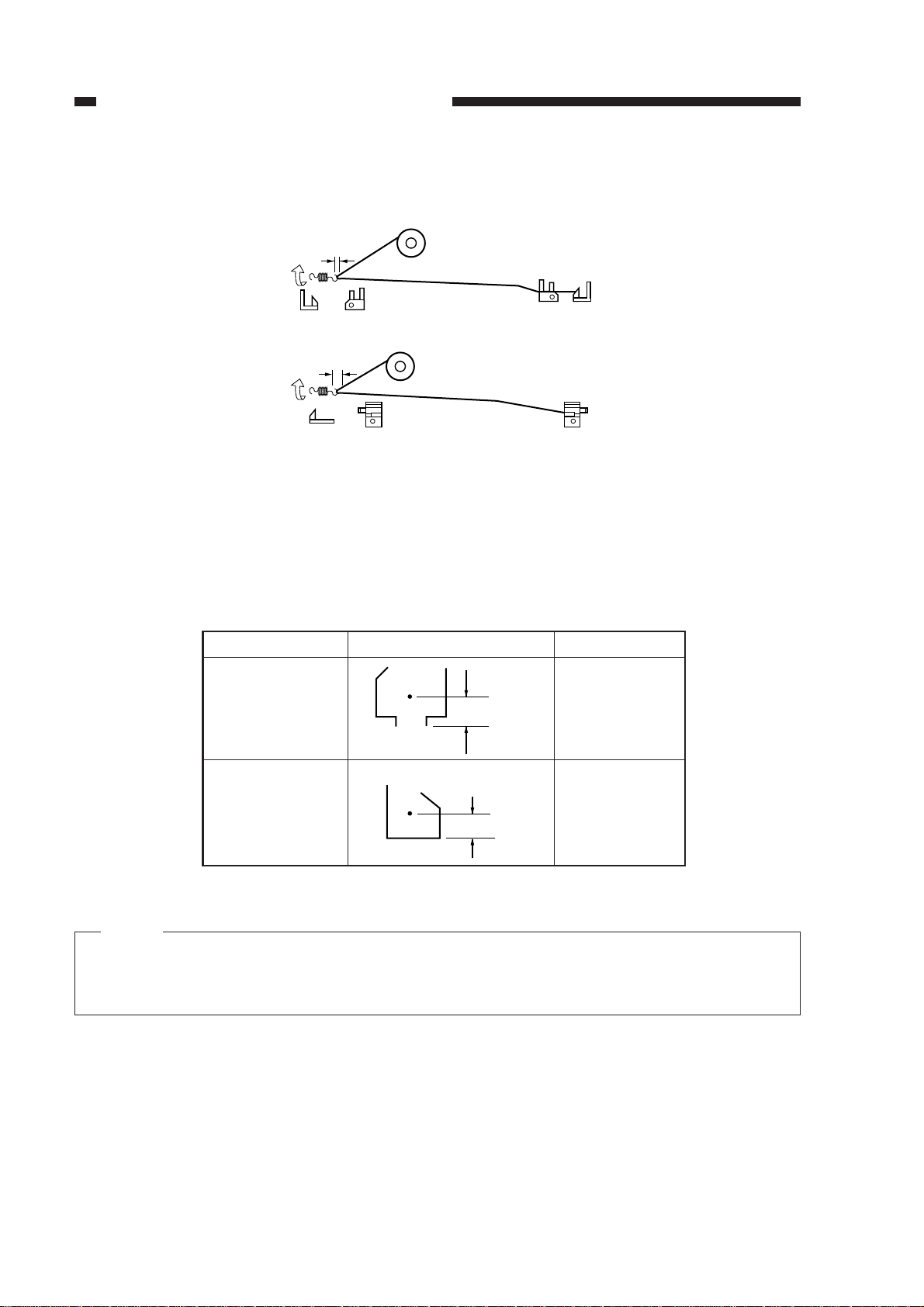

9. Adjusting the Tension of the Belt

The main motor drives the drum via a timing belt.

Adjust the tension of the belt by selecting the mounting hole of the main motor so that when the

center of the timing belt is pushed down with a force of 500g, the distance between the two runs of

the belt is between 20 and 25 mm.

Tension decreases

Spring scal

500g

Belt

Drum drive unit

Main motor mounting holes

Tension Increases

Dimension

20 to 25 mm

Main motor

Figure 2-15

2-10

CHAPTER 2 STANDARDS AND ADJUSTMENT

10. Installation Position of the Transfer Guide

When installing the transfer guide, ensure that the clearance between the transfer assembly

roller and the photosensitive drum is about 1.8 ±0.2 mm, as shown in Figure 2-16.

Photosensitive drum

Lower transfer guide

1.8 ±0.2 mm

Transfer assembly roller

Figure 2-16

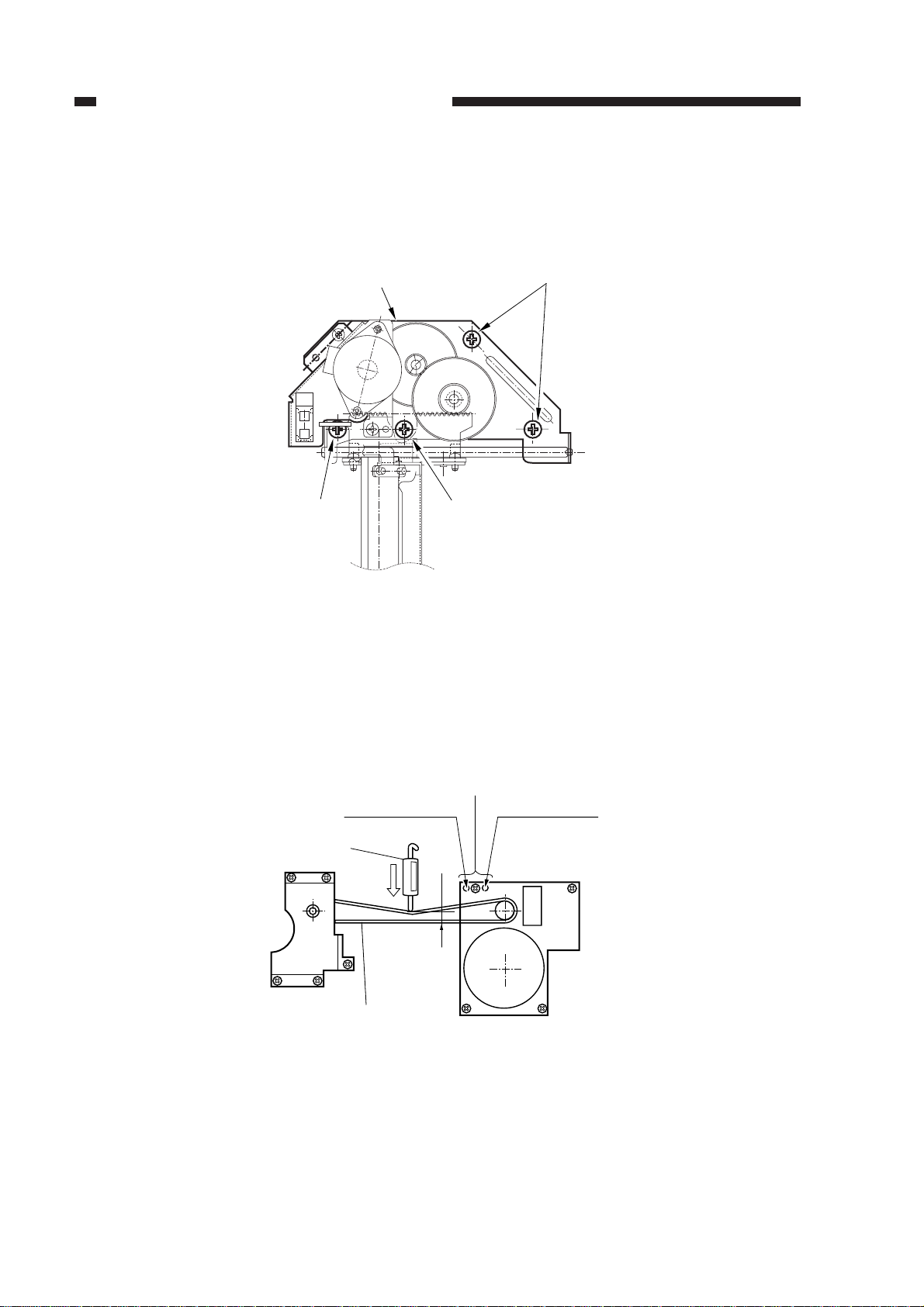

11. Installation Position of the Scanner Drive Assembly

Loosen the four screws of the scanner drive assembly; then, while pushing the scanner drive

assembly against the rear plate (direction of arrow [1]), move it in the direction of the manual feed

tray (direction of arrow [2]) so that it touches the pulley base and the lens gear. In this condition,

tighten the screws, and confirm that there is play between the lens gear and the gear of the lens drive

capstan.

Pulley base

[1]

Pulley gear

Lens base

Lens gear

Shaft

[2]

Scanner drive

assembly

Figure 2-17

2-11

CHAPTER 2 STANDARDS AND ADJUSTMENT

12. Installing the Corona Wires in the Primary and Transfer Corona Assemblies

Primary corona assembly

(about 2 mm)

Trasnfer corona assembly

(about 5 mm)

Figure 2-18

• The corona wire must not be bent or twisted, and the gold plating must not be peeling off.

• The corona wire must not be slack. (The length of the corona wire tension spring should be

about 12 mm.)

• The corona wire must be in the V groove of the height adjusting piece.

13. Adjusting Height of the Corona Wires

Corona assembly

Primary corona

assembly

Transfer corona

assembly

Standard position

Approx. 10.5 mm

Approx. 10 mm

Allowable range

±2 mm

±2 mm

Figure 2-19

Note:

The height (position) of the corona wire of the primary and transfer corona assemblies can be

adjusted by turning the screw at the back of the corona wire.

Turning the screw once causes the height of the corona wire to change by about 0.7 mm.

2-12

CHAPTER 2 STANDARDS AND ADJUSTMENT

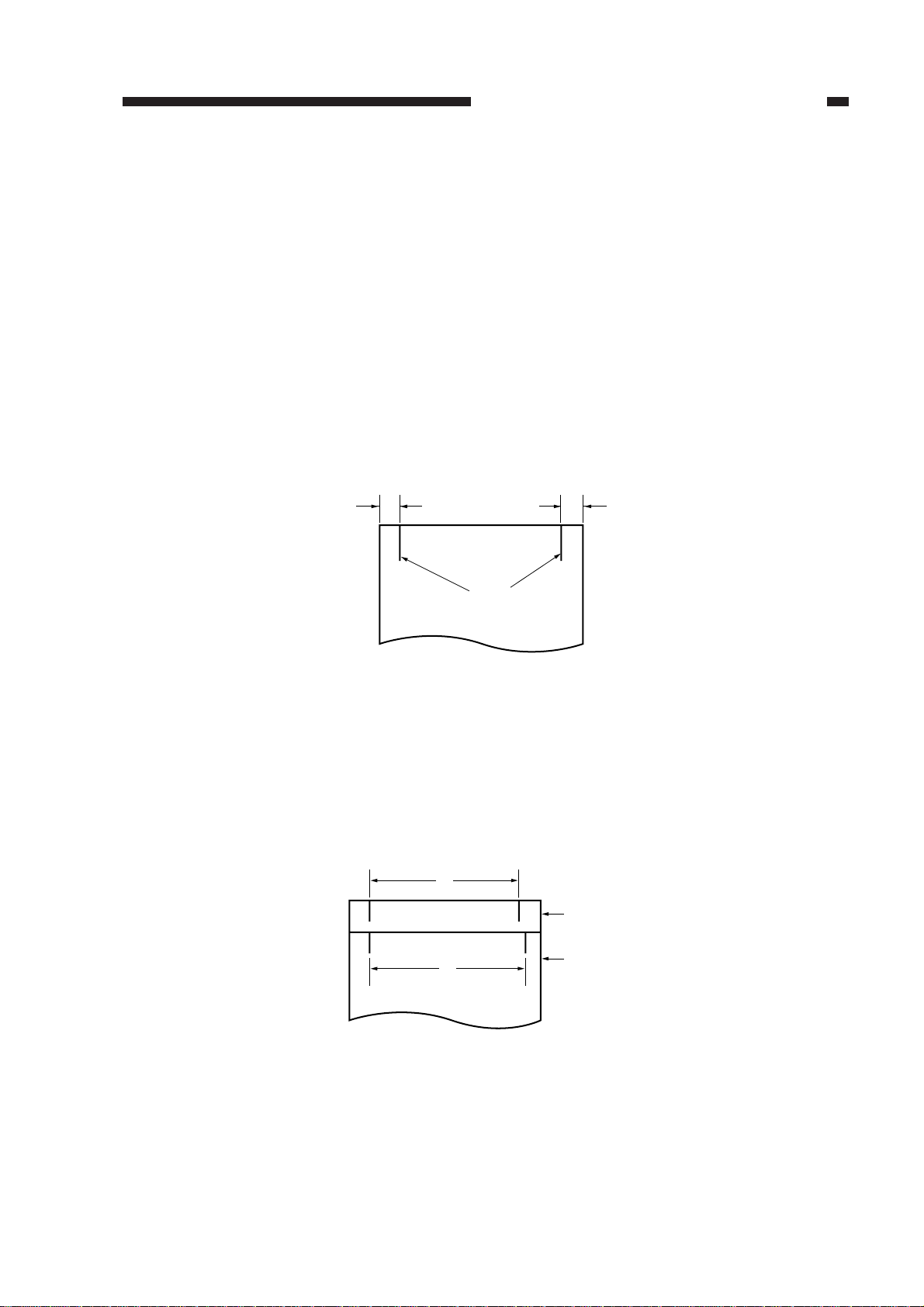

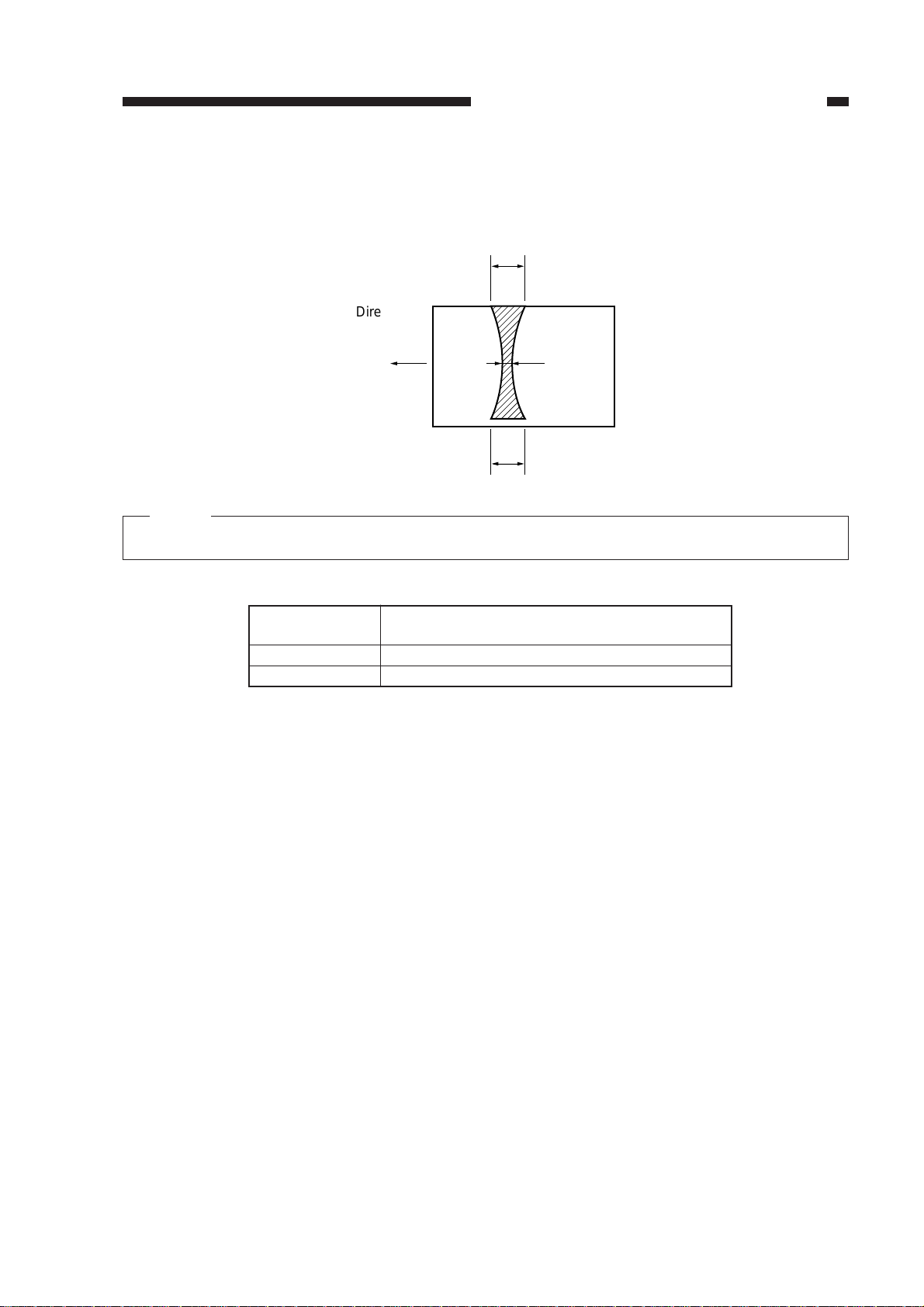

14. Adjusting the Fixing Assembly Roller Pressure (adjusting the nip width)

The nip width should conform to the dimension shown in Table 2-1. Adjust the nip width with

the bolts if it is out of standard.

c

Direction of

advance of

paper

A3 size

baCenter of

copy paper

Note:

a and c are 10 mm from both edges of the copy paper.

Figure 2-20

Dimension

b

|a-c|

Measure after the upper and lower rollers have

been adequately heated. (10 blank copies)

5.0 ±0.5 mm

0.5 mm or less

Table 2-1

■ Measuring the Nip Width

If the rollers are cool, leave the copier ON. Wait for 15 minutes; then make 20 copies, and

measure the nip width.

Measuring Procedure

1) Open the copyboard cover and make an A3 size solid black copy.

2) Set the solid black copy to the multifeeder.

3) Select the service mode C13.

3-1) Detach the VR cover from the rear of the left cover.

3-2) Press the service switch (SW300) on the DC controller PCB.

3-3) Select the service mode C13 using the 10-key or the zoom key.

4) Press the COPY START key.

• The solid black paper is automatically picked up from the multifeeder.

• Then the solid black paper is stopped at the fixing roller and, after a specific period, is delivered.

2-13

CHAPTER 2 STANDARDS AND ADJUSTMENT

15. Degree of Arching (multifeeder)

Make the following adjustments if the copy paper picked up from the multifeeder moves askew

or wrinkles are noted on the leading edge of the copy paper; the adjustments are made by changing

the degree of arching of the copy paper between the multifeeder pick-up roller and the registration

roller.

2

1) Set 50 sheets of A4 paper (80 g/m

) on the multifeeder tray.

2) Press the PAPER SELECT key on the control panel to select the multifeeder.

3) Press the COPY START key.

4) Check that the leading edge of the copy paper butts against registration roller and arches; at the

time, turn the copier OFF.

5) Measure the distance between A (trailing edge of the second sheet) and B (trailing edge of the

first sheet).

Registration roller

Arching

Multifeeder

roller

70 to 75

[B]

[A]

Figure 2-21

6) Turn the copier ON, and select C4 in the service mode.

7) Enter a setting so that the measurement between A and B (step 5) is between 70 and 75 mm.

Note:

A higher setting increases the measurement, i.e., the multifeeder clutch OFF timing is delayed (in units of 0.25mm).

2-14

CHAPTER 2 STANDARDS AND ADJUSTMENT

J315

20 11

110

31

J352

J318

81

J300

16

J30261

J316

111

J305

81

J304J303

5

1

J301

41 19

J307

81

J306

71

J312

113

J311

110

J309

12

J30812J310

13

J31315J314

15

J317

14

SW300VR301

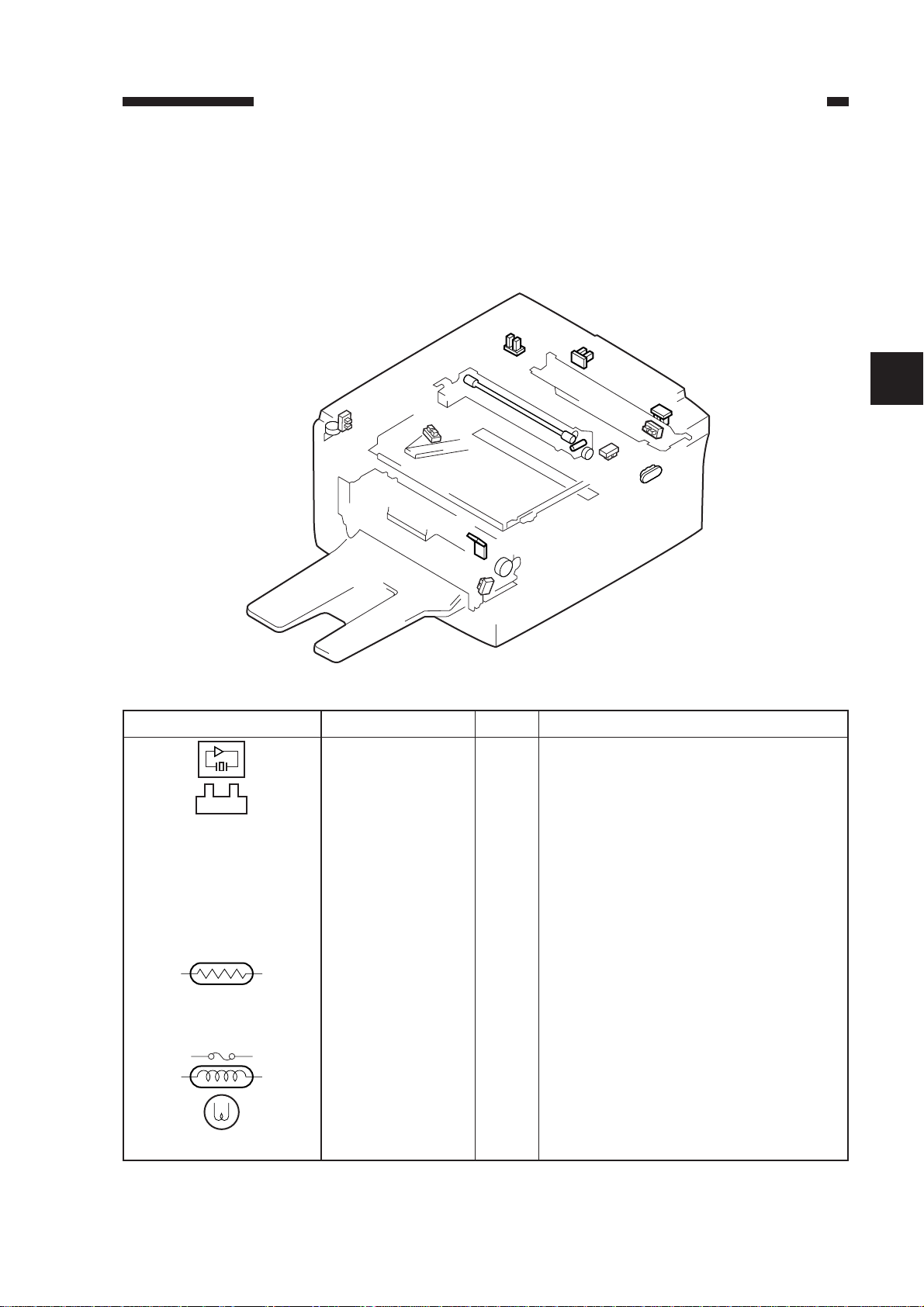

B. ELECTRICAL

1. List of PCBs/VRs/LEDs/Check Pins

Variable resistors, LEDs and check pins which are used for adjustments in the field are listed

below.

VRs and check pins not listed here are used only for factory adjustments, which require special

tools and measuring instruments, as well great care and precision. Do not attempt to adjust such

parts.

Notes:

1. Leakage current may flow through some LEDs and cause them to glow dimly even though

they are supposed to be OFF.

2. VRs which can be adjusted in the field................

VRs which should not be adjusted in the field.....

a. DC Controller PCB

.

.

Figure 2-22

Adjusting AE refence point

Table 2-2

Press to enter or leave the SERVICE mode.

Purpose

Purpose

VR No

VR301

SW No

SW300

Table 2-3

2-15

CHAPTER 2 STANDARDS AND ADJUSTMENT

2. AE Adjustment

Make the following adjustments when the AE sensor or the DC controller PCB has been re-

placed.

1) Remove the potentiometer cover at the back of the left cover.

2) Set the power switch ON.

• Wait until the WAIT period has ended.

3) Place an MB-3 or MA-2 test sheet on the copyboard, and lower the copyboard cover.

4) Press switch SW300 on the DC controller PCB.

• "0" will appear on the COPY COUNT/RATIO indicator on the control panel.

• If "0" does not appear, press the "0" number key on the control panel so that "0" appears.

5) Press the SORT/GROUP key on the control panel.

• The scanner will move forward to the AE measuring position; then, the scanning lamp will go

ON. (Note)

6) Adjust VR301 on the DC controller so that "19" appears on the COPY COUNT/RATIO indicator.

For reference:

7.7

Copy density

5

VR301

Test sheet Sheet of newspaper

Document density

Figure 2-23

7) Press the SORT/GROUP key.

• The scanning lamp will go OFF, and the scanner will return to the home position.

8) Remove the test sheet, place a sheet of newspaper on the copyboard, and lower the copyboard

cover.

9) Press the SORT/GROUP key.

• The copier will perform the same operations as described in step 5).

10) Make a note of the numerical value displayed on the COPY COUNT/RATIO indicator.

11) Press the SORT/GROUP key.

• "0" will appear on the COPY COUNT/RATIO indicator.

12) Press the "1" number key.

• "1" will appear on the COPY COUNT/RATIO indicator.

13) Enter the value recorded in step 10) using the NUMERIC keypad.

7.7

2-16

Copy density

5

Document density

Test sheet Sheet of newspaper

When the setting is lowered.

When the setting is raised.

Figure 2-24

CHAPTER 2 STANDARDS AND ADJUSTMENT

3. Lamp Brightness Adjustment (50%, 200%)

Before adjusting the lamp brightness (50%, 200%), adjust the optimum exposure in the direct

reproduction ratio (F5, w/o AE, copy density knob is centered, using the NA3 chart). Then, perform the adjustment below.

a. Adjusting the Lamp Brightness (50%)

1) Make a 50% copy.

2) Check the exposure; if it is not satisfactory, perform the following:

3) Enter service mode C24.

4) Modify the value using the +/- keys (increasing the value makes the copy density lighter;

standard value is 110 to 120, variation of then steps is equivalent to approximately one step of

F of the exposure lever on the control panel).

5) Make a 50% copy; if the copy density is not yet satisfactory, repeat steps 3) to 4).

b. Adjusting the Lamp Brightness (200%)

1) Make a 200% copy.

2) Check the exposure; if the density is not satisfactory, perform the following:

3) Enter service mode C25.

4) Modify the value by +/- keys (increasing the value makes the copy density lighter, standard

value is 140 to 170, variation of then steps is equivalent to approximately one step of F of the

exposure lever on the control panel).

5) Make a 200% copy; if the copy density is not yet satisfactory, repeat steps 3) to 4).

2-17

CHAPTER 2 STANDARDS AND ADJUSTMENT

4. Checking Photointerrupters

No.

Purpose

(+) lead

(-) lead

Check; operation is normal

if the meter needle swings to

the right

No.

Purpose

(+) lead

(-) lead

Check; operation is normal

if the meter needle swings to

the right

No.

Purpose

(+) lead

(-) lead

Check; operation is normal

if the meter needle swings to

the right

Q1

Multifeeder paper sensor

(MFPD)

J311-5

J311-4

With the copier in

STANDBY, raise and

lower the arm manually.

• Arm raised: voltage

approx. 0.6V

• Arm lowered: voltage

approx. 0V

Q4

Mirror home position

sensor (MHP)

J312-2

J312-1

Move the mirror carriage.

• When the light-block-

ing plate is in Q4: voltage approx. 5V

• When the light black

plate is not in Q4: voltage approx. OV

Q7

Cassette paper sensor

(CPEP)

J303-6

J303-5

Remove the cassette with

the copier in

STANDBY, move the

arm up and down manually.

• Arm raised: voltage

approx. 0.6V

• Arm lowered: voltage

approx. 0V

Q2

Pre-registration paper

sensor (PDP1)

J304-8

J304-7

With the copier in

STANDBY, raise and

lower the arm manually.

• Arm raised: voltage

approx. 5V

• Arm lowered: voltage

approx. 0V

Q5

Scanner home position

sensor (SCHP)

J312-5

J312-4

With the copier in

STANDBY, move the

scanner by hand.

• Scanner in HOME po-

sition: voltage approx.

5V

• Scanner not in HOME

position: voltage

approx. 0V

Q8

Delivery paper sensor

(PDP2)

J314-5

J314-6

Remove the delivery

cover; with the copier in

STANDBY, raise and

lower the arm manually.

• Arm raised: voltage

approx. 0V

• Arm lowered: voltage

approx. 0.6V

Q3

Right door sensor

(RDC)

J311-7

J311-6

Open and close the right

door.

• When opening the

door: voltage approx.

0V

• When closing the door

voltage approx. 5V

Q6

Lens home position sensor (LHP)

J312-8

J312-9

With the copier in

STANDBY: insert a

sheet of copy paper into

the Q4 section.

• With paper in Q4: volt-

age approx. 5V

• With no paper in the

Q4: voltage approx. 0V

2-18

Table 2-4

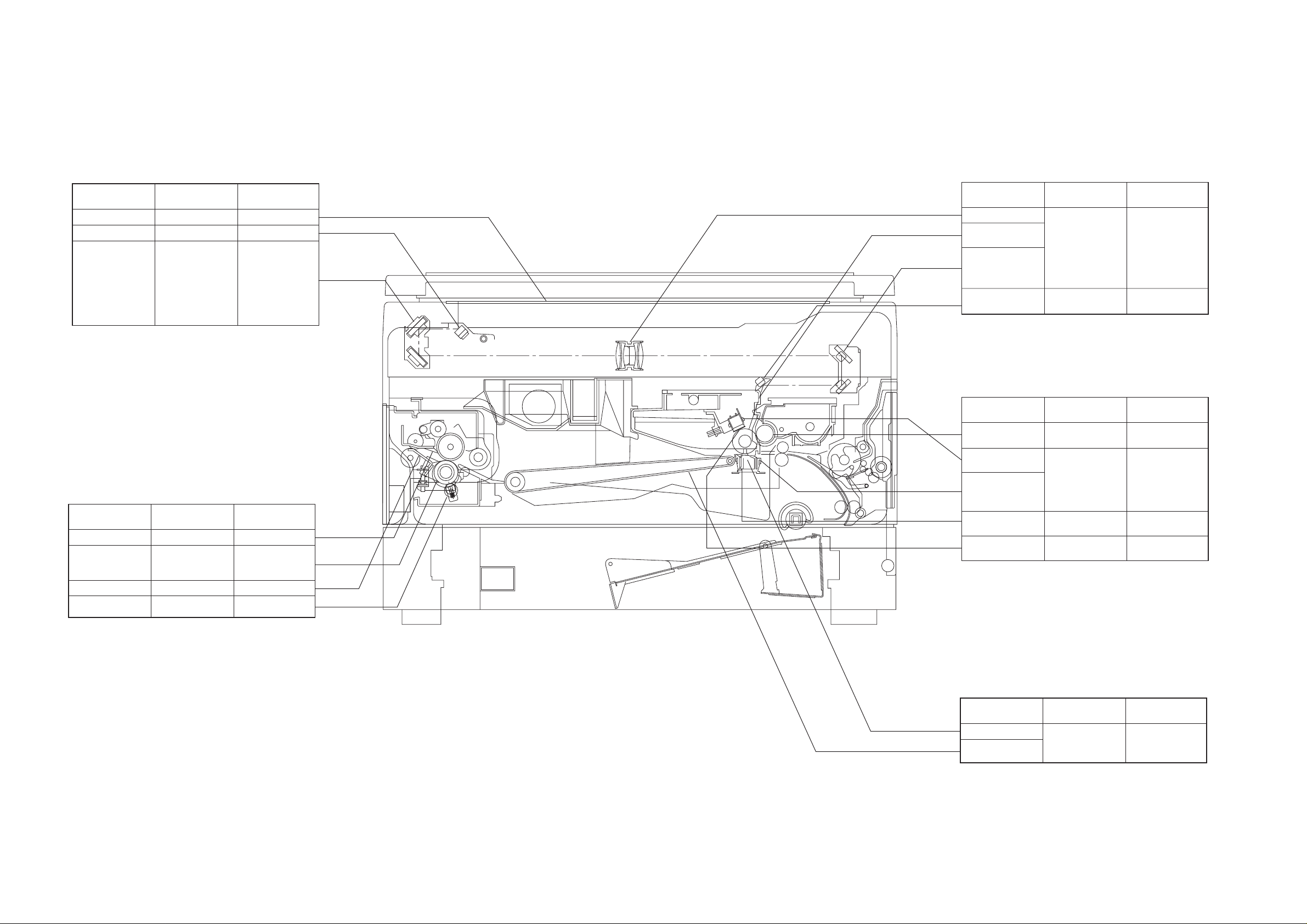

CHAPTER 3 FUNCTION AND ARRANGEMENT OF THE ELECTRICAL PARTS

CHAPTER 3 FUNCTION AND ARRANGEMENT OF THE

ELECTRICAL PARTS

A. SENSORS, FUSES AND LAMPS

Q4

LA1

Q5

Q6

TH2

TH1

Q8

Q3

FU2

LA731~LA738

Q2

Q7

Q1

TS1

Figure 3-1

Symbol Function

Name

Black toner level

sensor

Photointerrupter

Thermistor

Thermoswitch

Lamp

Code

TS1

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

TH1

TH2

F2

LA2

LA731

|

LA738

Senses the toner in the development

assembly

Multifeeder paper sensor

Pre-resistrarion paper sensor

Right door sensor

Mirror home position sensor

Scanner home position sensor

Lens home position sensor

Cassette paper sensor

Delivery paper sensor

Upper fixing roller temperature sensor 1

(main)

Upper fixing roller temperature sensor 2

(auxiliary)

Scanning lamp over temperature protector

Scanning lamp

Pre-exposure lamp

|

Pre-exposure lamp

3

3-1

Loading...

Loading...