REVISION 0

APR. 1999

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-13G5-000

IMPORTANT

THIS DOCUMENTATION IS PUBLISHED BY CANON INC ., J APAN, TO SERVE AS A SOURCE

OF REFERENCE FOR WORK IN THE FIELD.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY SLIGHTLY

FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER

PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMA TION CONTAINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

THIS DOCUMENT ATION IS INTENDED FOR ALL SALES AREAS, AND MA Y CONTAIN INFORMATION NOT APPLICABLE TO CERTAIN AREAS.

COPYRIGHT © 1999 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly supervised to avoid disclosure of confidential

information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPARTMENT 3

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

OFFICE IMAGING PRODUCTS QUALITY ASSURANCE CENTER

CANON INC.

5-1, Hakusan 7-chome, Toride-shi, Ibaraki 302-8501 Japan

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

INTRODUCTION

This Service Manual contains basic data and figures for the Stapler Sorter-J1/K1/E3

needed to service the machine in the field.

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Chapter 7

Chapter 8

Chapter 9

Chapter 10

General Description

shows how to operate the copier, and explains how copies are made.

Basic Operation

workings.

Exposure System

lens drive unit and scanner drive unit. It also explains the timing at which

these drive units are operated, and shows how they may be disassembled/

assembled and adjusted.

Image Formation System

It also explains the timing at which the various units involved in image

formation are operated, and shows how they may be disassembled/

assembled and adjusted.

Pick-Up/Feeding System

is picked up to when a copy is delivered in view of the functions of electrical

and mechanical units ahd in relation to their timing of operation. It also shows

how these units may be disassembled/assembled and adjusted.

Fixing System

media in view of the functions of electrical and mechanical units and in

relation to their timing of operation. It also shows how these units may be

disassembled/assembled and adjusted.

explains the principles used to fuse toner images to tranfer

Externals/Auxiliary Mechanisms

explains the principles used for the copier’s various control mechanisms in

view of the functions of electrical and mechanical units and in relation to their

timing of operation. It also shows how these units may be disassembled/

assembled and adjusted.

Installtion

the copier may be installed using step-by-step instructions.

introduces requirements for the site of installation, and shows how

Maintenance and Servicing

consumables/durables and scheduled servicing charts.

Troubleshooting

adjustments, and problems identification (image fault/malfunction).

introduces the copier's features and specifications,

provides outlines of the copier's various operational

discusses the principles of operation used for the copier's

discusses the principles of how images are formed.

explains the principles used from when copy paper

shows the copier's external parts, and

provides tables of periodically replaced parts and

provides tables of maintenance/inspection, standards/

Appendix contains diagrams showing electrical parts arrangement, tables of

signals, tables of special tools, tables of solvents/oils, and a general timing

chart.

The descriptions in this Service Manual are subject to change without notice for

product improvement or other purposes, and major changes will be communicated in the

from of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins and be able to identify and

isolate faults in the machine.

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

i

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES ..................................1-1

II. SPECIFICATIONS .......................1-2

A. Type .......................................1-2

B. System ..................................1-2

C. Performance ..........................1-2

D. Others....................................1-3

III. NAMES OF PARTS......................1-5

A . External View ........................1-5

CHAPTER 2 BASIC OPERATION

I. BASIC OPERATION ....................2-1

A. Functions...............................2-1

B. Outline of Electric Circuitry ...2-2

C. Inputs to DC Controller .........2-4

CHAPTER 3 EXPOSURE SYSTEM

B. Cross Section.......................1-6

IV. OPERATION ................................1-8

A. Control Panel.........................1-8

B. Daily Inspection to Be

Performed by the User ....... 1-10

V. IMAGE FORMATION ................ 1-11

A. Outline................................ 1-11

D. DC Controller Outputs...........2-6

E. Basic Sequence of Operations

(Direct, Continuous Copying

(2 sheets)) .............................2-9

I. BASIC OPERATION ...................3-1

A. Changing the Reproduction

Ratio......................................3-1

II. LENS DRIVE SYSTEM................ 3-2

A. Outline...................................3-2

B. Basic Lens Drive System

Operation (change of

reproduction ratio).................3-3

III. SCANNER DRIVE SYSTEM .......3-4

A. Outline...................................3-4

B. Relation Between Scanner

Sensor and Signals...............3-5

C. Basic Scanner Operation ......3-6

D. Scanner Movement for

Two-Page Separation Mode

(copy count "2").....................3-7

IV. No. 4/5 MIRROR DRIVE

SYSTEM ......................................3-8

V. DISASSEMBLY AND

ASSEMBLY ............................... 3-11

A. Lens Drive Assembly ......... 3-11

B. Scanner Drive Assembly.... 3-14

C. Exposure Assembly ........... 3-17

D. Blank Assembly.................. 3-19

E. No. 4/5 Mirror Mount........... 3-20

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

iii

CHAPTER 4 IMAGE FORMATION SYSTEM

I. PROCESSES...............................4-1

A. Outline................................... 4-1

B. Basic Operation of Image

Formation System

(black developing assembly,

2 copies)................................4-2

II. CONTROLLING THE SCANNING

LAMP ...........................................4-3

A. Outline...................................4-3

B. Mechanism............................4-4

III. PRIMARY/TRANSFER

CORONA CURRENT AND GRID

BIAS VOLTAGE CONTROL

SYSTEM ......................................4-5

A. Outline...................................4-5

B. Switching Primary/Transfer

Corona Current ON/OFF.......4-5

C. Maintaining Primary/Transfer

Corona Current Constant......4-6

D. Controlling Grid Bias

Voltage ..................................4-7

IV. CONTROLLING DEVELOPING

BIAS ............................................. 4-8

A. Outline................................... 4-8

B. Operation .............................. 4-9

V. DOCUMENT DENSITY

MEASUREMENT SYSTEM ...... 4-11

A. Outline................................ 4-11

B. Operation ........................... 4-11

C. Reading the Output of the AE

Sensor................................ 4-12

D. Adjustment ......................... 4-13

VI. DEVELOPING ASSEMBLY/

DRUM CLAENER ..................... 4-14

A. Outlines .............................. 4-14

B. Remaining T oner Sensor.... 4-14

C. Torque Limiter..................... 4-15

VII. BLANKING................................ 4-16

A. Outline................................ 4-16

B. Movement of the Blank

Exposure Mechanism ........ 4-17

VIII.DISASSEMBLY AND

ASSEMBLY ............................... 4-19

A. Main Motor Assembly ......... 4-19

B. Corona System .................. 4-20

C. Primary/Transfer Corona

Assembly............................ 4-22

D. Development System......... 4-25

CHAPTER 5 PICK-UP/FEEDING SYSTEM

I. PAPER PICK-UP ASSEMBLY AND

FEEDER.......................................5-1

A. Outline...................................5-1

B. Pick-up and Feeder

Operation ..............................5-3

C. Identifying the Paper Size.....5-4

D. Pick-Up from the

Multifeeder.............................5-5

II. JAM DETECTION ........................5-7

A. Pick-up Assembly Delay

Jam........................................5-8

B. Delivery Assembly Stationary

Jam........................................5-9

C. Delivery Assembly Delay

Jam..................................... 5-10

III. FEEDER SYSTEM .................... 5-11

A. Pick-up Assembly............... 5-11

B. Feeder Assembly ............... 5-17

iv

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 6 FIXING SYSTEM

I. BASIC OPERATIONS ..................6-1

A. Outline................................... 6-1

B. Operation of Fixing Assembly

Temperature Control

System ..................................6-3

CHAPTER 7 EXTERNALS/AUXILIARY MECHANISMS

I. POWER SUPPLY .........................7-1

A. AC Driver DC Power

Supply ...................................7-1

II. DISASSEMBLY AND

ASSEMBLY .................................. 7-3

CHAPTER 8 INSTALLATION

I. LOCATION ...................................8-1

II. UNPACKING AND INSTALLING

THE COPIER ...............................8-2

A. Unpacking ............................. 8-2

B. Mounting the Drum ...............8-4

C. Checking the Operation ........ 8-5

D . Adding T oner .........................8-6

III. DISASSEMBLY AND

ASSEMBLY .................................. 6-4

A. Fixing Assembly....................6-4

A. External Covers.....................7-4

B. Control Panel.........................7-7

C. Copyboard Cover ..................7-9

D. Fans .......................................7-9

E. PCBs .................................. 7-11

E. Checking the Image ..............8-7

F. Universal Cassette Code

Setting "123" .........................8-8

III. RELOCATING THE COPIER .......8-9

IV. INST ALLING THE CONTROL

CARD-V .................................... 8-10

CHAPTER 9 MAINTENANCE AND SERVICING

I. PERIODICALLY REPLACED

PARTS.......................................... 9-1

II. DURABLE PARTS ........................9-2

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

III. BASIC PROCEDURE FOR

PERIODIC SERVICING...............9-3

IV. PERIODIC SERVICING

SCHEDULE .................................9-4

v

CHAPTER 10 TROUBLESHOOTING

I. MAINTENANCE AND

INSPECTION ............................ 10-1

A. Basic Image Adjustment

Procedure........................... 10-1

B. Points to Check for Periodic

Maintenance....................... 10-2

II. STANDARDS AND

ADJUSTMENT.......................... 10-3

A. Mechanical ......................... 10-3

B. Electrical........................... 10-17

III. IMAGE

TROUBLESHOOTING............ 10-21

A. Initial Check...................... 10-21

B. Samples of Image

Faults................................ 10-24

C. Troubleshooting of Image

Faults................................ 10-25

IV. OPERATION

TROUBLESHOOTING............ 10-37

A. Troubleshooting of

Malfunction....................... 10-37

V. TROUBLESHOOTING FEEDING

PROBLEMS ............................ 10-56

A. Paper Jams ...................... 10-56

VI. INCORRECT PAPER FEED

OPERATION ........................... 10-60

VII. FUNCTION AND ARRANGEMENT

OF THE ELECTRICAL

PARTS..................................... 10-62

A. Sensors, Fuses and

Lamps............................... 10-62

B. Clutches, Solenoids, Fans,

Motors and Heaters ......... 10-63

C. Switches, Circuit Breakers,

Counters, Etc. .................. 10-64

D. PCBs ................................ 10-65

VIII.SERVICE MODE ..................... 10-66

A. Outline.............................. 10-66

B. Using the Service Mode... 10-66

C. Guide to Service Mode .... 10-67

IX. SELF DIAGNOSIS.................. 10-69

APPENDIX

A. GENERAL TIMING CHART ........ A-1

B. LIST OF SIGNALS/

ABBREVIATIONS ....................... A-3

C. GENERAL CURCUIT

DIAGRAM ................................... A-5

D. SOLVENTS AND OILS LIST....... A-7

vi

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1

GENERAL DESCRIPTION

I. FEATURES .................................. 1-1

II. SPECIFICATIONS ....................... 1-2

A. Type ....................................... 1-2

B. System .................................. 1-2

C. Performance .......................... 1-2

D. Others .................................... 1-3

III. NAMES OF PARTS......................1-5

A . External View ........................1-5

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

B. Cross Section.......................1-6

IV. OPERATION ................................1-8

A. Control Panel.........................1-8

B. Daily Inspection to Be

Performed by the User ....... 1-10

V. IMAGE FORMATION ................ 1-11

A. Outline................................ 1-11

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES

1. Copies as large as A3 in size (DIRECT) may be made, and the copyboard is of a

fixed type.

• Although compact in design, the copier enables making copies as large as A3 in size in the

DIRECT mode.

• The copyboard is of a fixed type so that pages of a book may be copied with much ease.

2. Zooming between 50% and 200%.

• Copies may be made in reproduction rations of between 50% and 200%, selectable in 1%

increments.

3. Front loading for faster supply of paper.

• Paper is loaded from the front of the copier so that the cassette* may be replenished with

paper without wasting time. The design also saves space.

*Universal and its capacity is 500 sheets.

4. Single-component fine particle toner for high resolution.

• Images are developed using the single component toner projection method. Further, the

copier uses toner of extremely fine particles for enhanced image quality.

5. Multifeeder (stack bypass) pick-up.

2

• As many as 50 copies (80 g/m

) may be made continuously using the multifeeding mecha-

nism.

6. Low warm-up time

• The copier warms up in than 25 sec.

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-1

CHAPTER 1 GENERAL DESCRIPTION

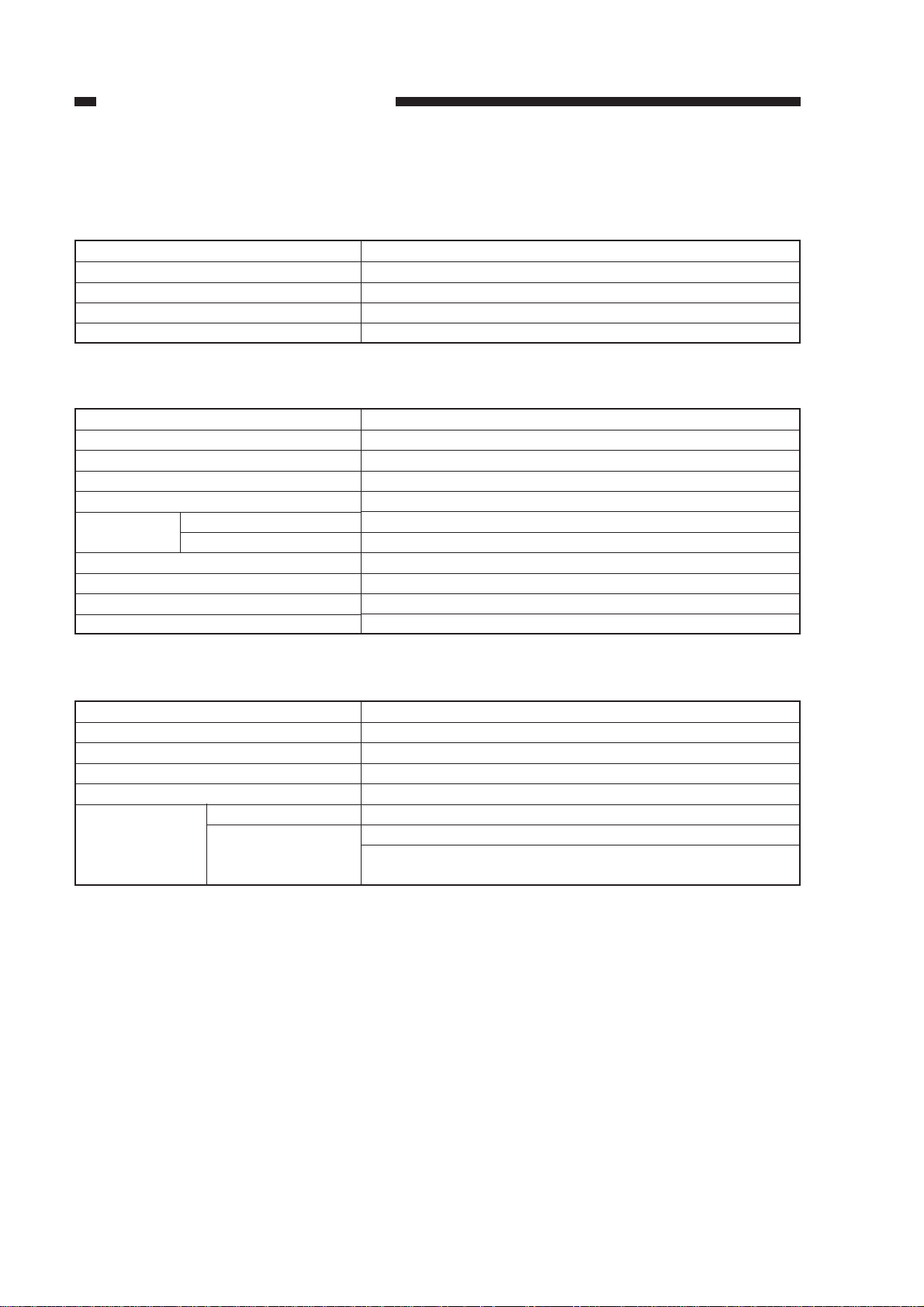

II. SPECIFICATIONS

A. Type

Body

Copyboard

Light sourse

Lens

Photosensitive medium

B. System

Reproduction

Charging

Exposure

Copy density adjustment

Development

Pick-up Automatic

Manual

Transfer

Separation

Drum cleaning

Fixing

C. Performance

Desktop

Fixed

Halogen lamp

Single lens + mirror movement

OPC

Indirect electrostatic method

Corona

Slit (moving light source)

Auto or manual

Dry

Exclusive cassette

Multifeeder

Corona

Curvature and Static eliminator

Blade

Heat roller (900W)

Type of document

Document size

Wait time

First copy

Continuous copying

Type of copy

paper

* Use of tracing paper may cause double feeding. If thin paper or OHP film, feed one sheet at a time.

Cassette

Multifeed tray

Sheet, Book, 3-D object (2 kg)

A3 max.

25 sec (approx.; at 20°C)

9.4 sec (A4, AE ON/OFF, 1:1)

99 copies

A3 (max.), A6 (min.;148x105 mm)

Plain paper (64 to 80 g/m2), Tracing paper, Colored paper

Plain paper (64 to 128 g/m

OHP film*, Label sheet

2

), Tracing paper*, Colored paper,

1-2

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

Two-sided

copying

Overlay

copying

Cassette

Copy tray

Non-image

width (1st side)

Auto clear

Auto shutoff

Option

Multifeed tray

Multifeed tray

Claw

Standard

Universal

Leading edge

Left/Right

Plain paper (64 to 128 g/m2), Colored paper

Plain paper (64 to 128 g/m2), Colored paper

Provided

60 mm deep (about 500 sheets of 80 g/m2 paper)

Yes

100 sheets (approx.; A4, 80 g/m2)

2.0 ±1.5 mm or less

2.5 ±1.5 mm or less

Provided (2 min, standard)

Yes

ADF-A1, MS-A1, Stapler Sorter D3, CC-V

D. Others

Power supply

230V 50Hz

230V 50Hz

Power

consumption

Noise (sound power level as prescribed by ISO)

Ozone

Dimensions

Weight

Operating

environment

Others

Maximum

Copying

Standby

Width

Depth

Height

Temperature

Humidity

Atmospheric

pressure

Serial Numbers

UFW xxxxx

QFE xxxxx

1.5kW or less

55 dB or less

40 dB or less

0.05 ppm or less (UL standards)

610 mm

617 mm

416 mm

50 kg or less

15.0° to 30°C

5% to 80%

0.6m to 1

Keep copy paper wrapped to protect against moisture.

0.05ppm or less (UL standards)

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-3

CHAPTER 1 GENERAL DESCRIPTION

Reproduction mode

DIRECT

REDUCE

II

ENLARGE

II

A3 (297x420mm)

A4 (210x297mm)

B4 (257x365mm)

B5 (182x257mm)

A5R (210x149mm)

50%

I

A3 → A4

A4 → A3

I

200%

Paper size

Cassette

A3

A4

B4

B5

A5R

A4R

A3

Copies/min

9

17

10

17

16

10

9

1-4

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

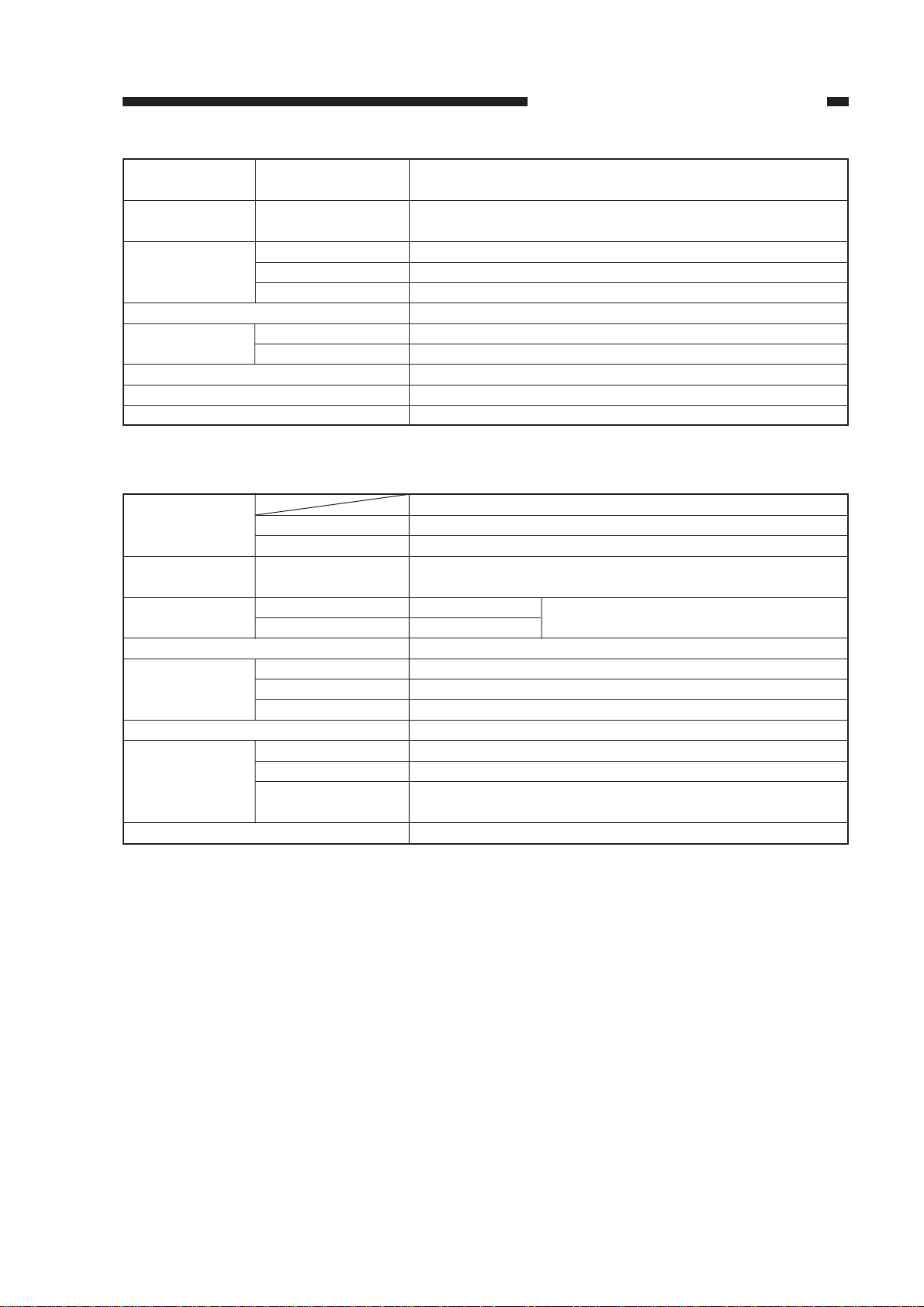

III. NAMES OF PARTS

A. External View

[1] [2] [3]

[6] [5] [4]

CHAPTER 1 GENERAL DESCRIPTION

[1] Copy tray

[2] Copyboard cover

[3] Control panel

[4] Cassette

[5] Front cover

[6] Delivery cover

[1]

[12]

[11]

[10]

[9]

Figure 1-301

[2] [3]

[6]

[8]

[7]

Figure 1-302

[5]

[4]

[1] Copyboard glass

[2] Power indicator

[3] Power switch

[4] Right cover

[5] Multifeeder tray

[6] Developing assembly

release lever

[7] Developing assembly

[8] Transfer/separation

assembly

[9] Primary corona assembly

cleaner

[10] Feeder assembly release

lever

[11] Copy density knob

[12] Fixing assembly knob

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-5

CHAPTER 1 GENERAL DESCRIPTION

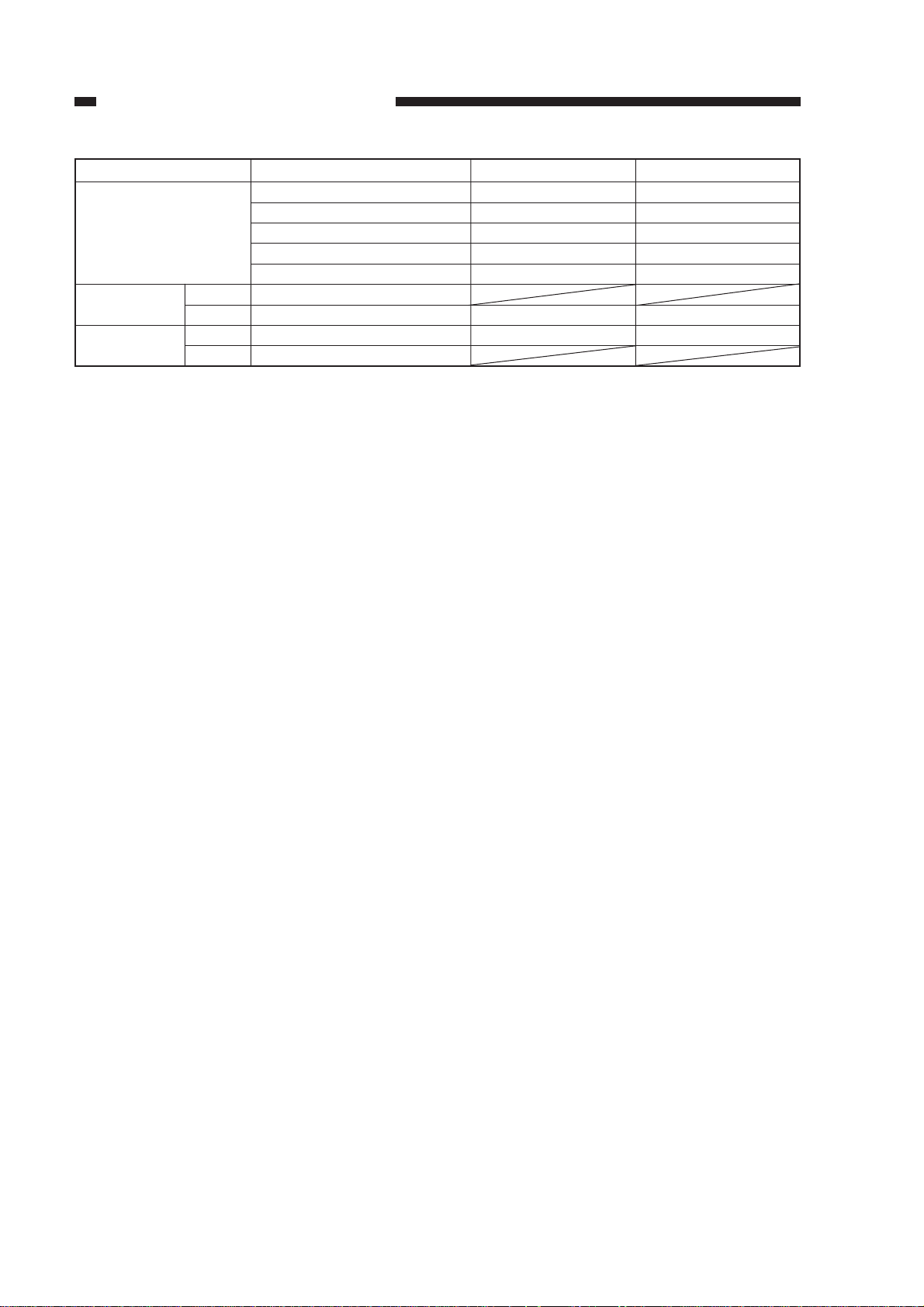

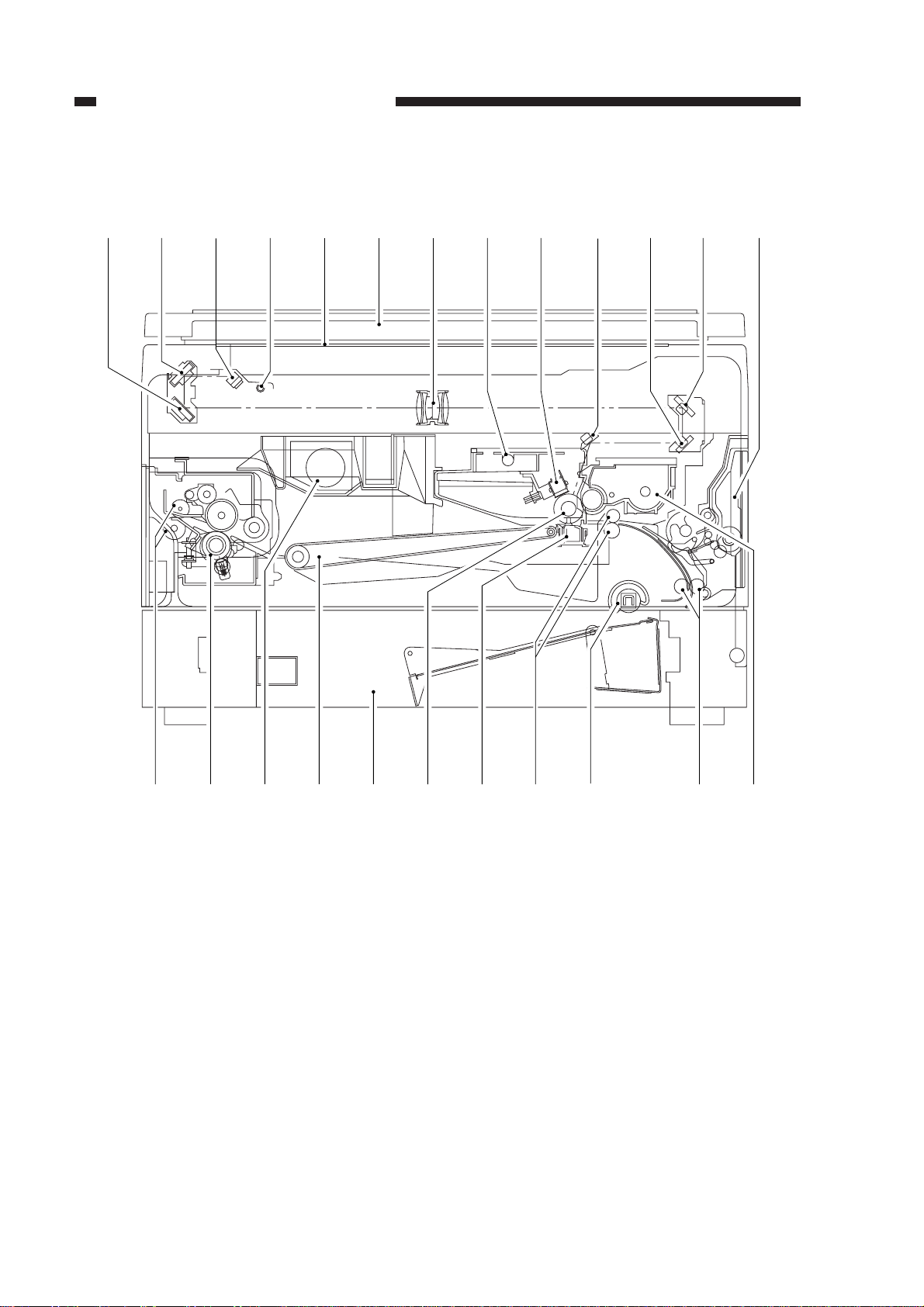

B. Cross Section

[1] [3] [5] [6] [7] [8] [9] [11] [12] [13]

[10][4][2]

[1] No. 3 mirror

[2] No. 2 mirror

[3] No. 1 mirror

[4] Scanning lamp

[5] Copyboard glass

[6] Copyboard cover

[7] Lens

[8] Pre-exposure lamp

[9] Primary corona

assembly

1-6

[15][24] [23] [22] [21] [20] [19] [18] [17] [16] [14]

[10] No. 6 mirror

[11] No. 5 mirror

[12] No. 4 mirror

[13] Multifeeder tray

[14] Developing assembly

[15] Feeder roller 1

[19] Photosensitive drum

[20] Cassette

[21] Feeder assembly

[22] Exhaust fan

[23] Fixing assembly

[24] Delivery roller

[16] Pick-up roller

[17] Registration roller

[18] Transfer corona

assembly

Figure 1-303

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

Blank Page

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-7

CHAPTER 1 GENERAL DESCRIPTION

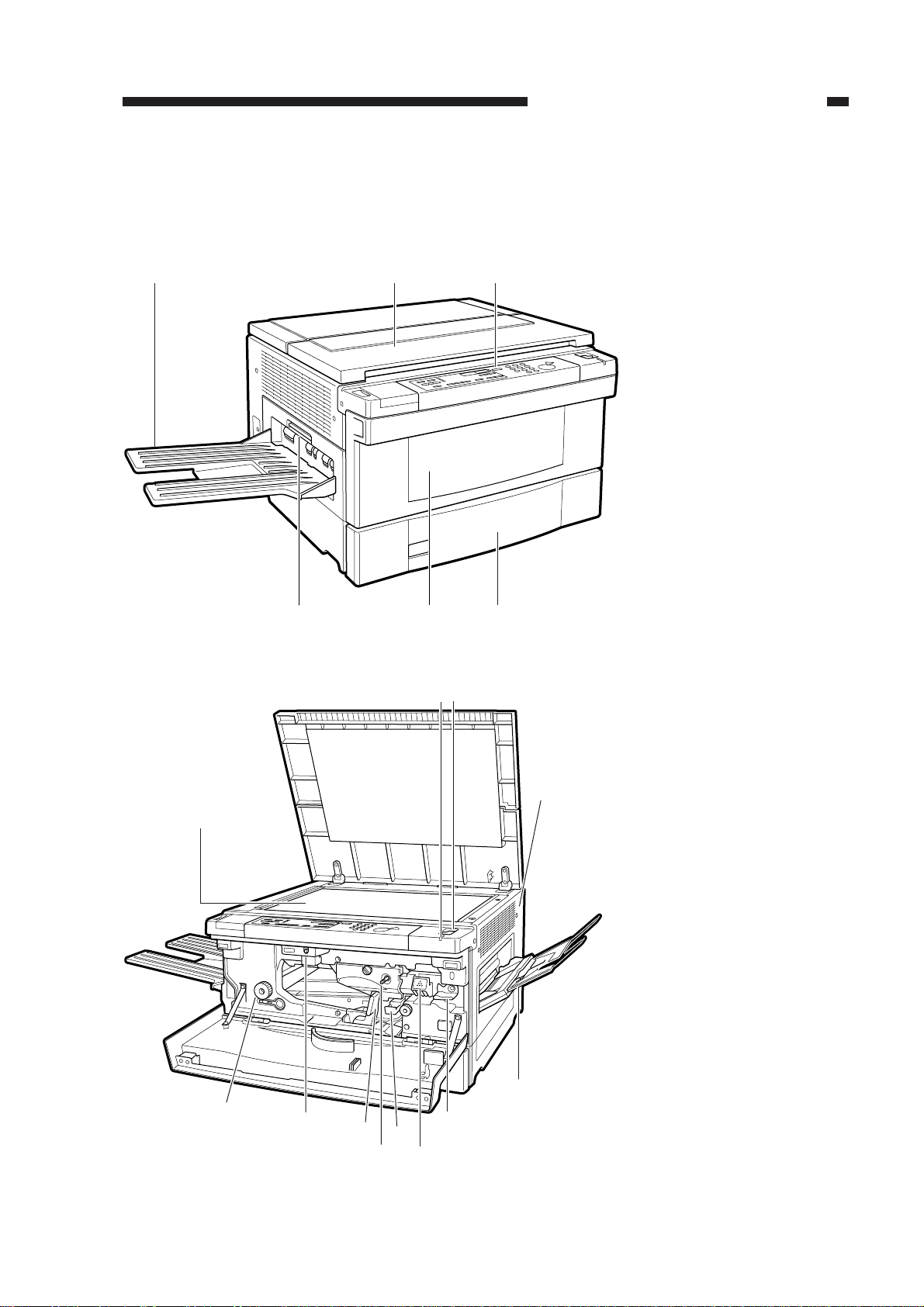

IV. OPERATION

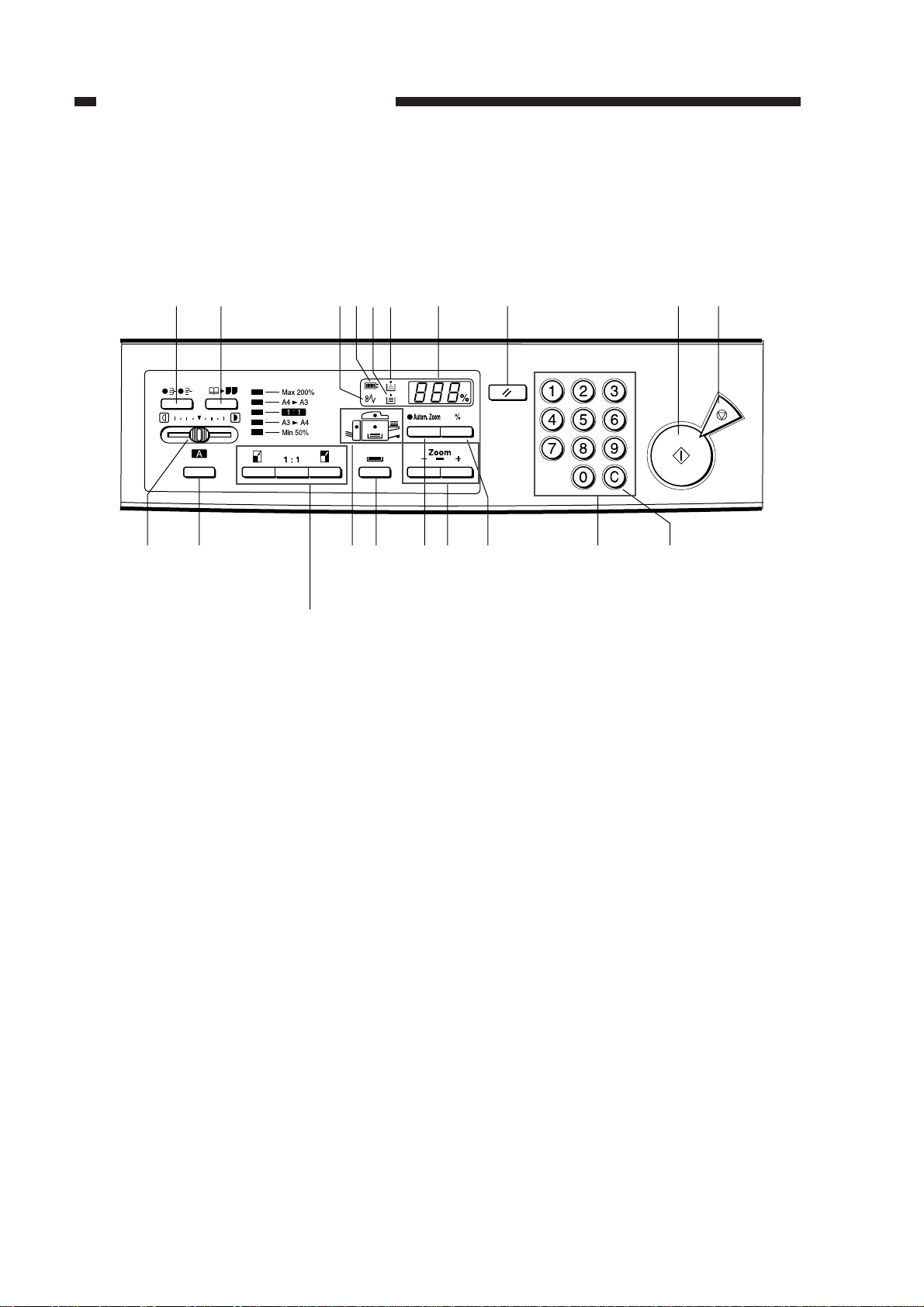

A. Control Panel

[1] [2] [3][4] [5] [6] [7] [8] [9] [10]

[21][22]

[20]

[19]

[18]

[11][12][13][14][15][16][17]

Figure 1-401

1-8

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

No. Name

[1] Sort/Group key

[2] Two-Page Separation key

[3] Paper Jam indicator

[4] Control Card Check indicator

[5] Paper Out indicator

[6] Toner Out indicator

[7] Copy quantity/Copy ratio display

[8] Reset key

[9] Start key

[10] Stop key

[11] Clear key

[12] Number keys

[13] Percent key

[14] Zoom keys

[15] Autom. Zoom key

[16] Paper Select key

[17] Paper Supply/Jam Location indica-

tor

[18] Enlarge key

[19] 1:1 (Direct) Copy key

[20] Reduce key

[21] AE (Automatic Exposure) key

[22] Exposure lever

Description

Press to select or cancel the Sort or Group mode.

* To use the Sort or Group mode, your copier must be

equipped with the optional Sorter or Stapler Sorter.

Press to select or cancel the Two-Page Separation mode.

Flashes when a paper jam occurs.

Flashes when the Control Card is not fully inserted.

Flashes when there is no paper in the selected paper supply (paper cassette or stack bypass).

Flashes when toner needs to be added.

Displays the number of copies to be made, and the selected enlargement/reduction ratio.

Also, when the copier is not functioning properly, the Service Call message will appear here.

Press to return the copier to the Standard mode.

Press to begin copying.

Press to stop the copier before copying is complete.

Press to change the number of copies to be made to one.

Press to input the number of copies to be made.

Press to display the selected enlargement/reduction ratio.

Press to reduce or enlarge copy images by any ratio from

50% to 200%, selectable in 1% increments.

Press to select or cancel Automatic Zoom.

* To use Automatic Zoom, your copier must be equipped

with the optional Automatic Document Feeder (ADF).

When copying using the stack bypass or a universal cas-

sette, you cannot use Automatic Zoom.

Press to select the paper supply (paper cassette or stack

bypass).

Lights to show the selected paper supply (paper cassette

or stack bypass).

If a paper jam occurs, flashes to show jam location.

* This indicator will also flash to inform the user of vari-

ous errors.

Press to enlarge copy images using a fixed enlargement

ratio.

Press to make copies the same size as the original.

Press to reduce copy images using a fixed reduction ratio.

Press to select or cancel Automatic Exposure Control.

Use to manually adjust the lightness/darkness of copies.

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-9

CHAPTER 1 GENERAL DESCRIPTION

B. Daily Inspection to Be Performed by the User

Carefully instruct the user to be sure to clean the following parts of the copier once a week.

1. Primary Corona Assembly

Slide in and out the wire cleaner to clean the corona wires.

2. Copyboard Glass

Clean the copyboard glass with a moist cloth; then, wipe it dry.

3. Copyboard Cover

Clean the copyboard cover with a mild detergent solution; then, wipe it dry.

4. Transfer Corona Assembly

Remove the transfer corona assembly from the copier; then, slide the knob (wire cleaner) at the

bottom of the transfer corona assembly back and forth to clean the corona wires.

Further, clean the static eliminator using the cleaning brush (accessory).

1-10

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

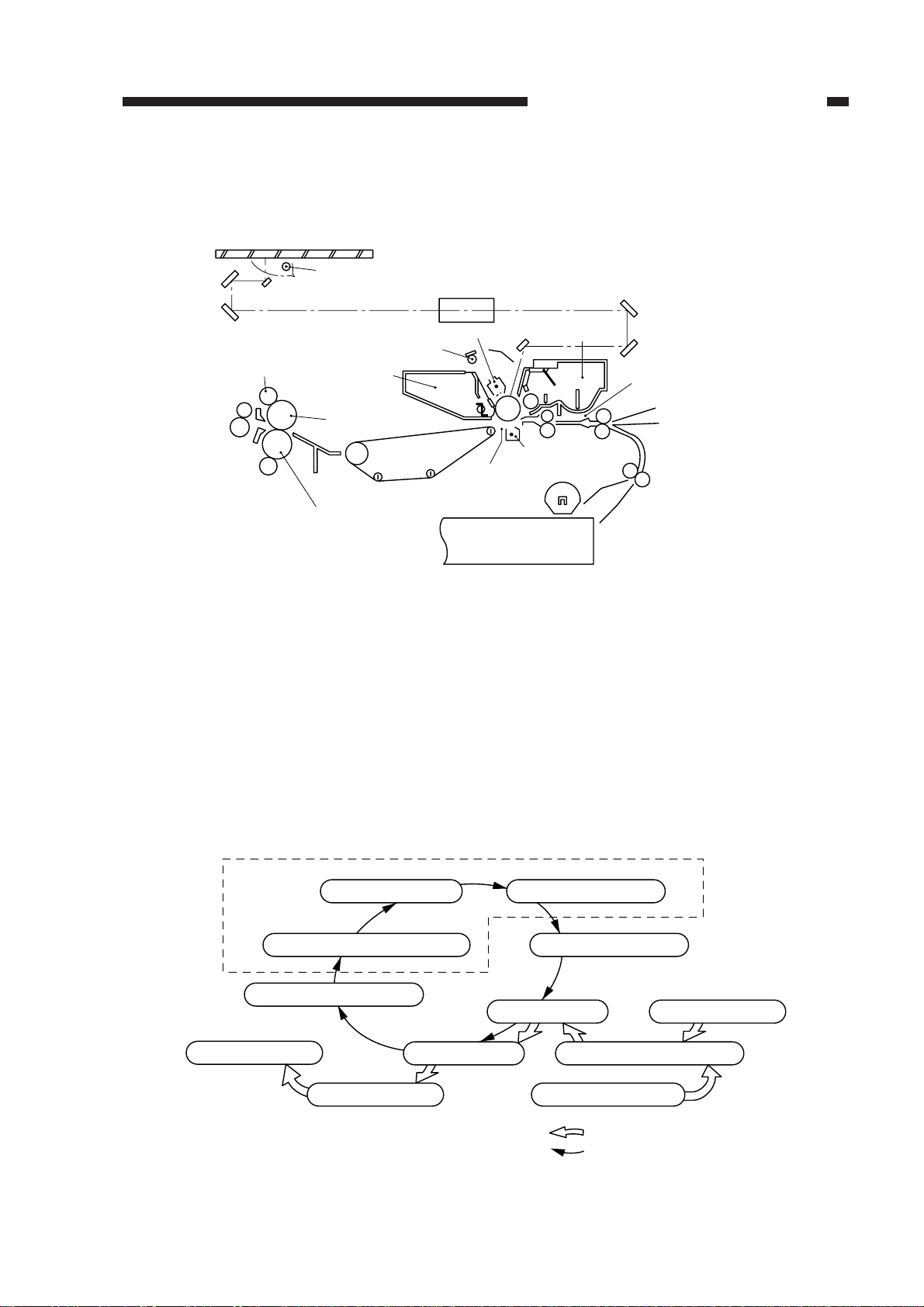

V. IMAGE FORMATION

A. Outline

Copyboard glass

Scanning lamp

CHAPTER 1 GENERAL DESCRIPTION

Lens

+

Developing

assembly

+

+

+

Picture to be changed

(1 register station only)

+

+

+

+

Cleaning roller

+

+

+

+

+

+

Upper fixing roller

Primary corona assembly

Pre-exposure lamp

Drum cleaner

Upper fixing roller

+

Transfer corona assembly

Static charge

eliminator

Figure 1-501

This copier consists of the units shown in Figure 1-501.

The image forming process is divided into the eight steps shown below.

Step 1: Pre-exposure

Step 2: Primary corona (negative DC)

Step 3: Image exposure

Step 4: Developing (positive plus AC)

Step 5: Transfer (negative DC)

Step 6: Separation

Step 7: Fixing

Step 8: Drum cleaning

Electrostatic latent image formation block

8. Drum cleaning

Copy delivery

2. Primary corona

1. Pre-exposure

6. Separation

7. Fixing

3. Image exposure

4. Developing

5. Transfer

Registration

Cassette

Flow of copy paper

Direction of rotation of drum

Figure 1-502

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Multifeeder

1-11

CHAPTER 2

BASIC OPERATION

In outline diagrams, represents mechanical drive paths, and indicates

electrical signal paths.

Signals in digital circuits are identified as ‘1’ for High and ‘0’ for Low. The voltage of

signals, however, depends on the circuit.

Nearly all operations of the product are controlled by a microprocessor; the

internal workings of the processor are not relevant to the serviceman’s work and,

therefore, are left out of the discussions. By the same token, no repairs are

prescribed for the PCBs at the user’s premises; for this reason, PCBs are discussed

by means of block diagrams rather than circuit diagrams.

For the purpose of explanation, discussions are divided into the following: from

sensors to DC controller PCB input ports; from DC controller output ports to loads;

and minor control circuits and functions.

I. BASIC OPERATION ....................2-1

A. Functions...............................2-1

B. Outline of Electric Circuitry ...2-2

C. Inputs to DC Controller .........2-4

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

D. DC Controller Outputs...........2-6

E. Basic Sequence of Operations

(Direct, Continuous Copying

(2 sheets)) .............................2-9

CHAPTER 2 BASIC OPERATION

I. BASIC OPERATION

A. Functions

The copier can be divided into four functional sections: paper pick-up and feed system, expo-

sure system, image formation system, and control system.

Exposure systemControl system

Control panel

Control circuit

Paper delivery

tray

Copy delivery

assembly

Fixing assembly

Scanner

Pnimary corona

Cleaning unit

Feeder

Cassette

Copybord

Optical

system

Photosensi-

tive drum

Transfer and

separation

assembly

Image tormation

system

Developing

assembly

Pick-up

control

assembly

Paper pick-up and feed system

Multifeeder

assembly

Figure 2-101

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-1

CHAPTER 2 BASIC OPERATION

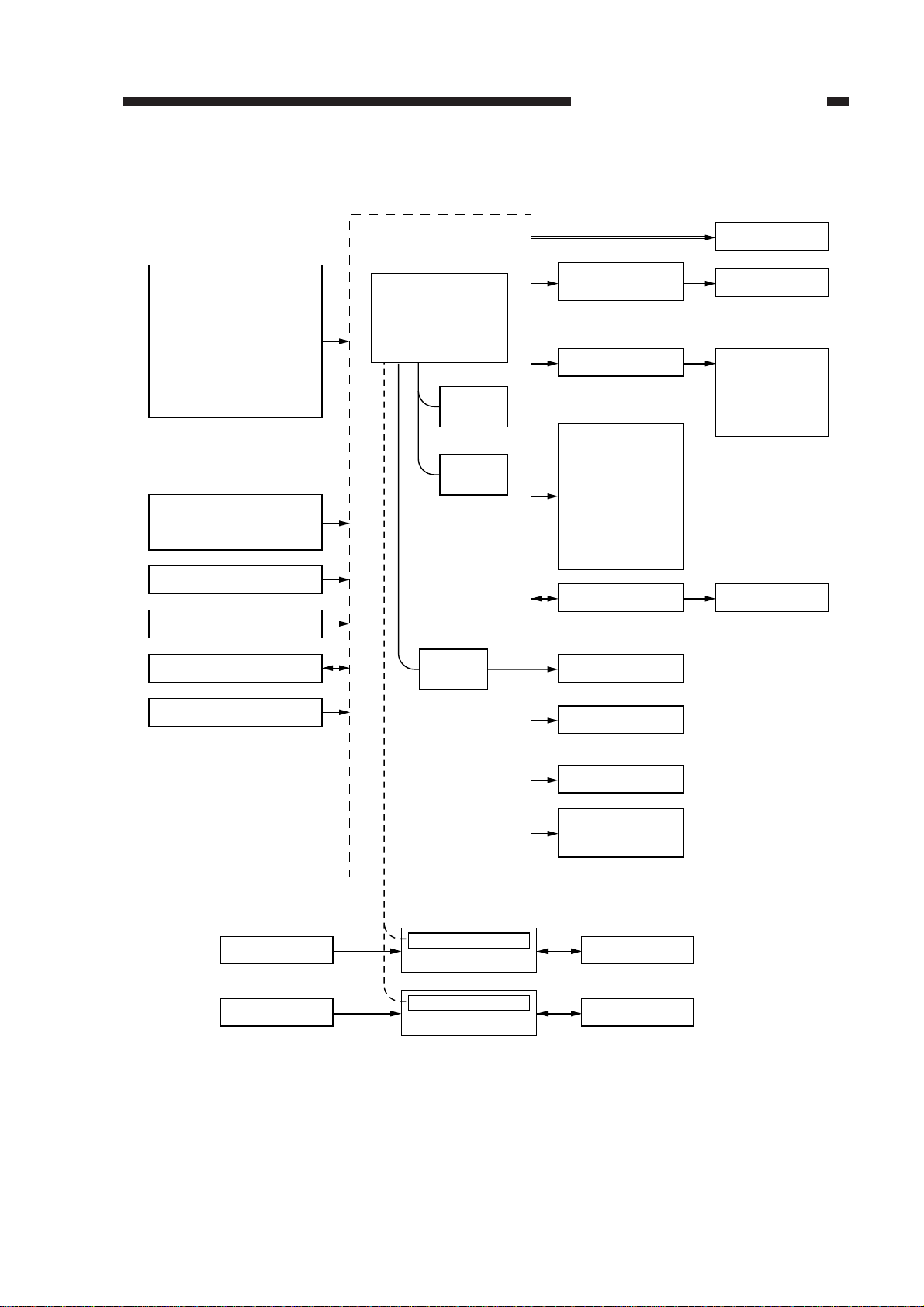

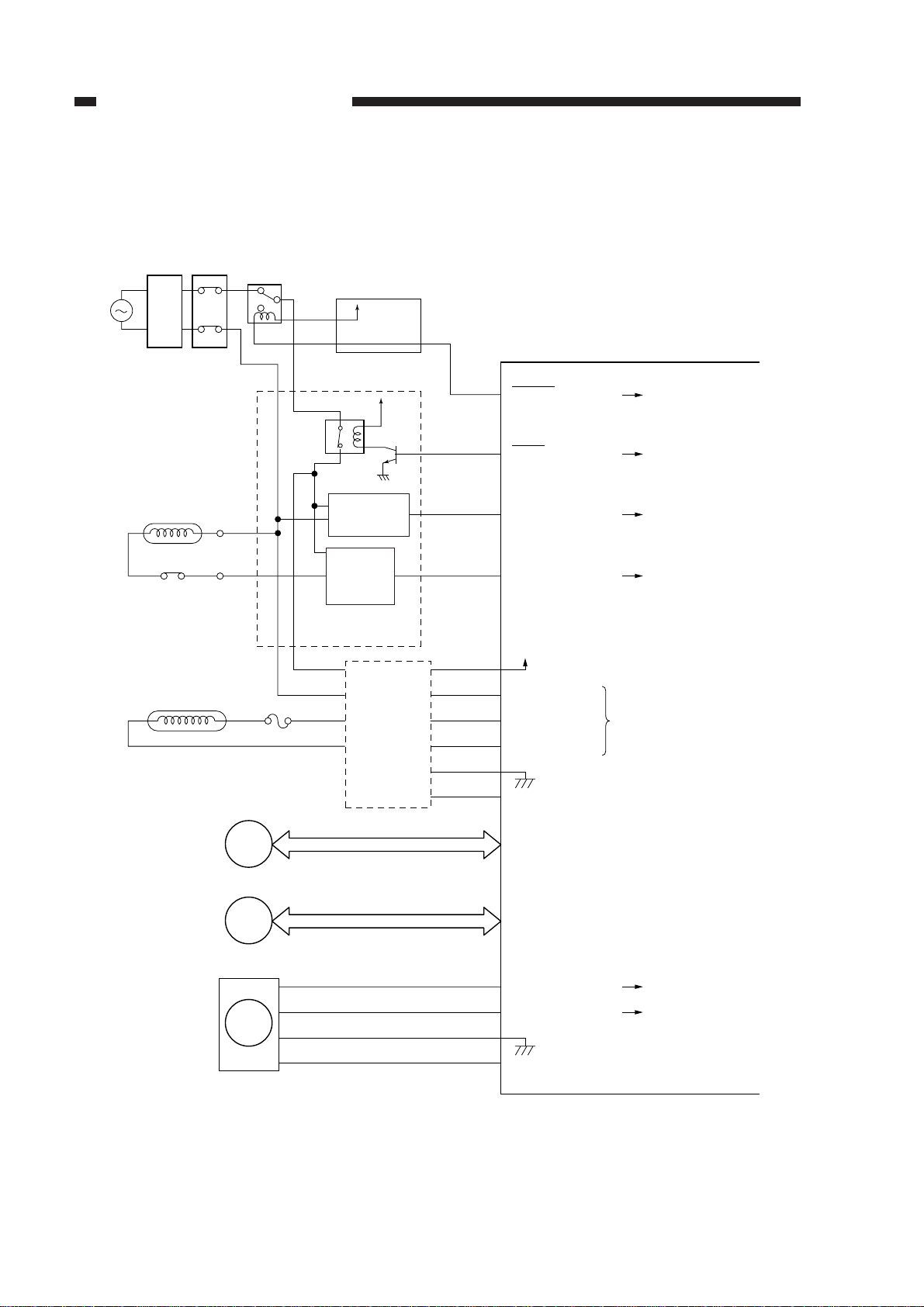

B. Outline of Electric Circuitry

The NP-6317's main mechanisms are controlled by the microprocessor, PROM, and

EEPROM on the DC controller PCB.

1. Microprocessor (Q300)

• controls the copying sequence

• controls the control panel

• controls the main motor/scanner motor/mirror motor

• controls the scanning lamp/fuser lamp

• reads the analog signals

2. PROM (Q301)

• contains the sequence program

3. EEPROM (Q317)

• stores data that can be modified in the service mode (replaces conventional variable resistors

and switches)

Note:

EEPROM is a type of ROM in which data may be erased or stored newly.

For this reason, the NP-6317's RAM and RAM are not backed up by a lithium battery.

Note:

The NP-6317 is equipped with an A/D converter and, therefore, its microprocessor can read

analog signals.

Note:

The main motor (M1) is a brushless motor.

The scanner motor (M2) and mirror motor (M3) are stepping motors which use the oscillation

frequency of the crystal oscillator on the DC controller.

2-2

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 BASIC OPERATION

<Sensors>

Scanner home position sensor

Lens home position sendor

Cassette paper sensor

Delivery paper sensor

Pre-registration paper sensor

Multifeeder paper densor

Mirror home position sensor

Cassette size sensor

Right door switch

AE sensor

Black toner level sensor

<Control panel> <Loads>

DC controller PCB

AC driver/DC

power supply PCB

Microprocenssor (Q300)

HVT

PROM

(Q301)

EEPROM

(Q317)

Registration roller clutch

Lens solenoid

Pick-up clutch solenoid

Blank solenoid

Multifeeder solenoid

Lamp regulator Scanning lamp

Main motor

Fixing roller heater

Primary/Transfer

corona assembly

Developing bias

GND bias

Conntrol panel Scanner motor

Thermistors

Driver

(Q324)

Microprocessor

Sorter controller PCB

Microprocessor

ADF controller PCB

Mirror motor

Pre-exposure lamp

Exhaust fan

Scanner cooling fan

Figure 2-102

SorterSensors, Switches

ADFSensors, Switches

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-3

CHAPTER 2 BASIC OPERATION

C. Inputs to DC Controller

1. Inputs to DC Controller (1/2)

Q1

J24-1 J311-5

Multifeeder paper sensor

-2 -4

-3 -3

5V

MFPD

DC controller PCB

when paper is over Q1, "1"

(light-blocking plate is at Q1)

Pre-registration paper

sensor

Right door sensor

Mirror home position

sensor

Scanner home position

sensor

Lens home position

sensor

Q2

J23-1 J304-9

-2 -8

-3 -7

Q3

J27-1 J311-8

-2 -7

-3 -6

Q4

J801-1 J312-3

-2 -2

-3 -1

Q5

J35-1 J312-6

-2 -5

-3 -4

Q6

J33-1 J312-9

-2 -8

-3 -7

5V

PRP

5V

RDC

5V

MHP

5V

SCHP

5V

LHP

when paper is at Q2, "1"

(light-blocking plate is at Q2)

when night door is closed, "1"

(light-blocking plate is at Q3)

when mirror motor is at home position, "1"

(light-blocking plate is at Q4)

when scanner is at home position, "1"

(light-blocking plate is at Q5)

when lens is at home position, "1"

(light-blocking plate is at Q6)

Cassette paper sensor

Delivery paper sensor

2-4

Q7

J26-1 J303-7

-2 -6

-3 -5

Q8

J44-1 J314-5

-3 -3

-2 -4

5V

CPEP

5V

DLP

when paper is in cassette, "1"

(light-blocking plate is at Q7)

when paper is at Q8, "0"

(light-blocking plate is not at Q8)

Figure 2-103

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2. Inputs to DC Controller (2/2)

CHAPTER 2 BASIC OPERATION

DC controller PCB

AE sensor

Black toner

leveol sensor

Thermistor 2

(auxiliary)

Thermistor 1

(main)

Cassette size

sensor

AE

24V

-

+

TS1

TH2 (NTC2)

TH1(NTC1)

CST(SW3)

J701-4 J312-13

-2 -11

-1

-3 -12

J39-3 J303-3

-2 -2

-1 -1

J45-1 J317-1

-2 -2

-4 J317-4

-3 -3

J28-3 J313-2

-4 -3

-5 -4

-6 -5

-2 -1

-10

24V

AE

AEGIN

5V

BTEP

TH2

TH1

CSZ1

CSZ2

CSZ3

CSZ4

oscillation signal

See p. 3-25

The voltage lowers as the fixing

heater temperature rises.

Reads the cassette size; see p. 3-32.

Figure 2-104

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-5

CHAPTER 2 BASIC OPERATION

D. DC Controller Outputs

1. DC Controller Out Puts (1/3)

Noise

Fixing roller heater

Thermoswitch 1

Scanning lamp

filter

LA1

DS1

F1

LA2

SW1

J509-1

J4-1

-2

J201-1

F2

J202-3

Thermoswitch 2

Control panel PCB

24V

Power supply

assembly

24V

K100

Fixing heater

ON detection

circuit

Fixing

heater drive

circuit

-2

Lamp driver unit

-1

J503-1J509-2

J203

J316-11

J318-3

-1

-4

-5

-3

-2

-6

-2

-1

J305

-6

-3

LAMP-CHECK

-2

ZERO-CROSS

-4

LIGHT

-5

-1

LAMP-SHIFT

PWOFF

HTPT

HTCK

HTRD

24V

DC controller PCB

when "0" AC power OFF (main

switch).

when "0" AC power OFF (power

supply unit).

when "0" fixing roller heater ON.

when "1" fixing roller heater ON.

See p. 3-20.

2-6

Scanner motor

Mirror motor

Main motor

MMLOCK

-2

MMD

-3

-4

+24V

See p. 3-9.

See p. 3-9.

when "0" main motor is moving.

when "1"

main motor ON.

M2

M3

M1

J351-1

J301-1

-2

-3

-4

Figure 2-105

COPYRIGHT © 1999 CANON INC. CANON NP6317 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Loading...

Loading...