Canon NP6218 Service Handbook

REVISION 0

COPYRIGHT © 1996 CANON INC. CANON NP6218 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

MAY 1997

FY8-23AP-000

COPYRIGHT © 1997 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly

supervised to avoid disclosure of

confidential information.

IMPORTANT

THE DOCUMENTATION IS PUBLISHED BY CANON INC., JAPAN, TO SERVE AS A SOURCE OF

REFERENCE FOR WORK IN THE FIELD.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY SLIGHTLY FROM

ACTU AL MA CHINE VALUES OR THOSE FOUND IN AD VER TISING AND O THER PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED TO

THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

THIS DOCUMENTATION IS INTENDED FOR ALL SALES AREAS, AND MAY CONTAIN

INFORMATION NOT APPLICABLE TO CERTAIN AREAS.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPT.1.

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride-shi, Ibaraki 302 Japan

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

i

CONTENTS

CHAPTER 1 MAINTENANCE AND INSPECTION

A. Image Adjustment Basic

Procedure....................................1-1

B. Periodical Servicing......................1-2

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A. Image Adjustment ........................2-1

1. Adjusting the Image Leading

Edge Margin ([3], No.305;

registration ON timing)............2-1

2. Adjusting the Leading Edge

Non-Image Width ([3], No.306;

blank shutter ON timing)........2-2

3. Adjusting the Image Trailling

Edge Non-Image Width

([3], No.309;blank shutter

timing) .....................................2-3

4. Adjusting the Left/Right

Registration.............................2-4

5. Adjusting the Left/Right Margin

(No.311;left/right margin)........2-5

6. Adjusting the Scanning Lamp

Intensity...................................2-6

7. AE Adjustment ........................2-7

B. Exposure System.......................2-11

1. Routing the Scanner Drive

Cable.....................................2-11

2.

Adjusting the Mirror Position

optical distance between No.1

mirror and No.2/No.3 mirror)

...2-12

3. Adjusting the Scanner Cable

Tension..................................2-13

4.

Assembling the Mirror Positioning

Tool

........................................2-13

5. Points to Note When Attaching

the Fluorescent Lamp Heater/

Scanning Lamp.....................2-14

6. Positioning the Change

Solenoid ................................2-16

C.

Image Formation System

.............2-17

1. Positioning the Blank Shutter

Solenoid ................................2-17

2. Routing the Blank Shutter

Cable.....................................2-18

3. Positioning the Solenoid for the

Primary Charging Roller ........2-18

4. After Replacing the Drum

Unit........................................2-19

5. Attaching the Drum Heater ...2-19

D. Pick-Up/Feeding System ............2-21

1. Orientation of the Pick-Up

Roller.....................................2-21

2. Orientation of the Multifeeder

Pick-up Roller........................2-21

3. Positioning the paper Guide

Plate Cam (multifeeder)........2-22

E. Fixing System.............................2-23

1. Points to Note when Attaching

the Fixing Film.......................2-23

2. Points to Note when Attaching

the Heater Connector............2-23

3. Adjusting the Fixing Film Drive

Roller Pressure .....................2-24

4. Points to Note after Replacing

the Fixing Upper Unit............2-25

5. Adjusting the Nip...................2-26

6. Routing the Drive Belt...........2-27

7. Storing the Fixing Heater

Registance ............................2-27

8. Setting the Fixing Heater

Temperature Control Value....2-28

F. Electrical .....................................2-31

1. After Replacing the PCB.......2-31

2. Clearing the Back-Up RAM...2-31

3. Checking the

Photointerrupters...................2-32

4. Adjusting the Multifeeder

Paper width Sensor...............2-39

5. Setting the Paper Size for the

Universal Cassette................2-40

1

2

3

4

5

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF THE ELECTRICAL PARTS

A. Sensors........................................3-2

B. Clutches, Solenoids, and

Switches.......................................3-4

C. Motors, Heaters, and Lamps ........3-6

D. PCBs ............................................3-8

E. Cassette Feeding Module-A2.....3-10

CHAPTER 4 SERVICE MODE

A. Outline..........................................4-1

B. Using Service Mode.....................4-1

1. Activating Service Mode .........4-1

2. Selecting a Service Mode.......4-2

3. Selecting Items........................4-2

4. Using Adjustment Mode [3]

and Specification Mode [5]......4-2

5. Using Operation/Inspection

Mode [4]..................................4-2

F. Variable Registors (VR) and check

Pins by PCB...............................3-12

1. DC controller PCB.................3-12

2. Composite power supply

PCB.......................................3-13

6. Clearing Stored Error..............4-2

7. Recording on the Service

Mode Label .............................4-3

C. Control Display Mode [1] ..............4-4

D. I/O Mode [2] .................................4-6

E. Adjustment Mode [3]....................4-9

F. Operation/Inspection Mode [4]...4-12

G. Specification Settings Mode [5]..4-14

H. Counter Mode [6].......................4-15

CHAPTER 5 SELF DIAGNOSIS

A. Copier...........................................5-1

B. Self Diagnosis (ADF)....................5-5

APPENDIX

A. GENERAL TIMING CHART.........A-1

B.

SIGNALS AND ABBREVIATIONS

C. GENERAL CIRCUIT DIAGRAM ..A-3

D. SPECIFICATIONS .......................A-5

A. Copier .....................................A-5

1. Type ....................................A-5

..A-2

C. Self Diagnosis (Sorter).................5-6

2. System...............................A-5

3. Features.............................A-6

4. Others ................................A-7

B.

Cassette Feeding Module-B2/

Cassette Feeding Module-A2

....A-8

ii

1-1

1

CHAPTER 1 MAINTENANCE AND INSPECTION

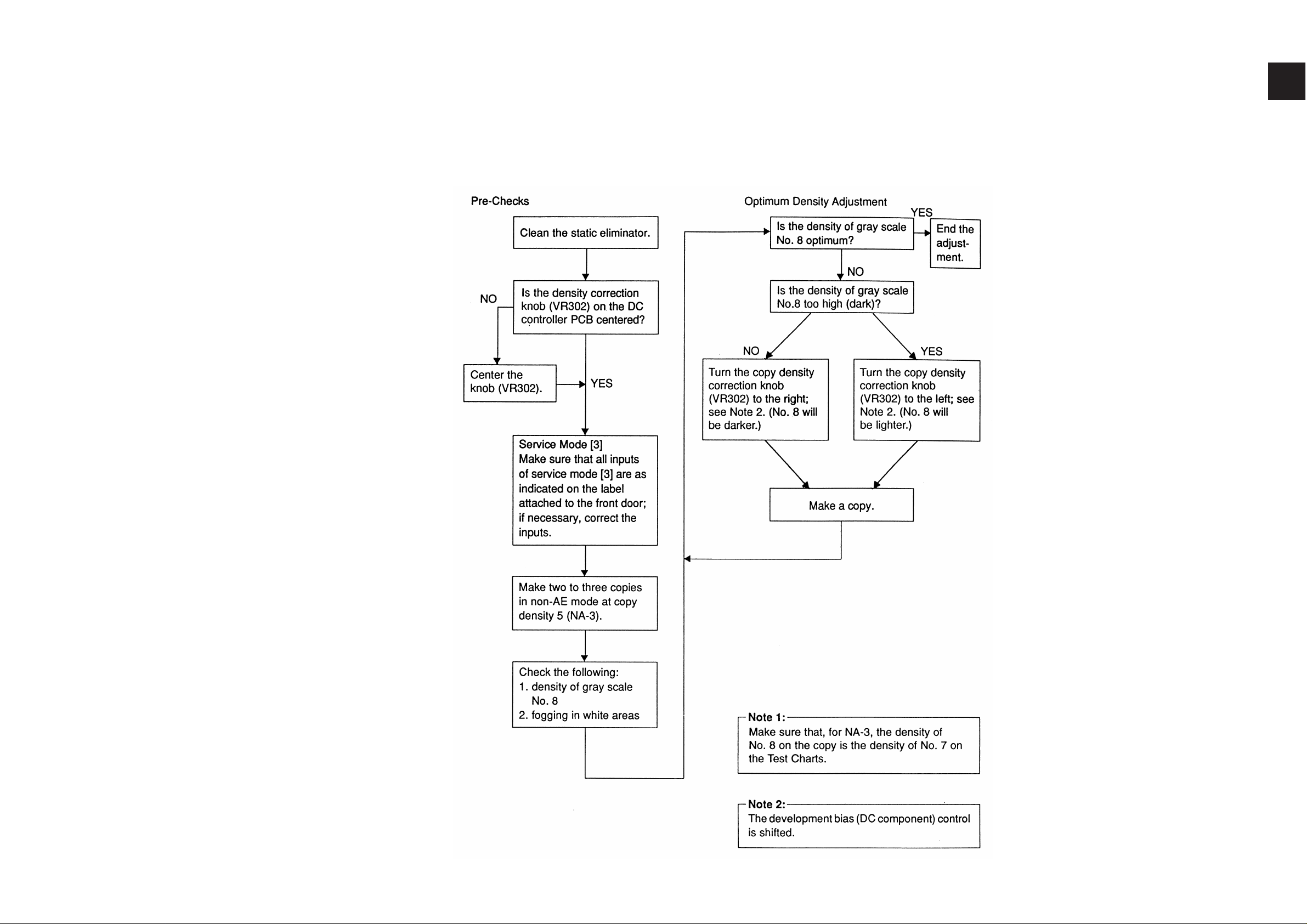

A. Image Adjustment Basic Procedure

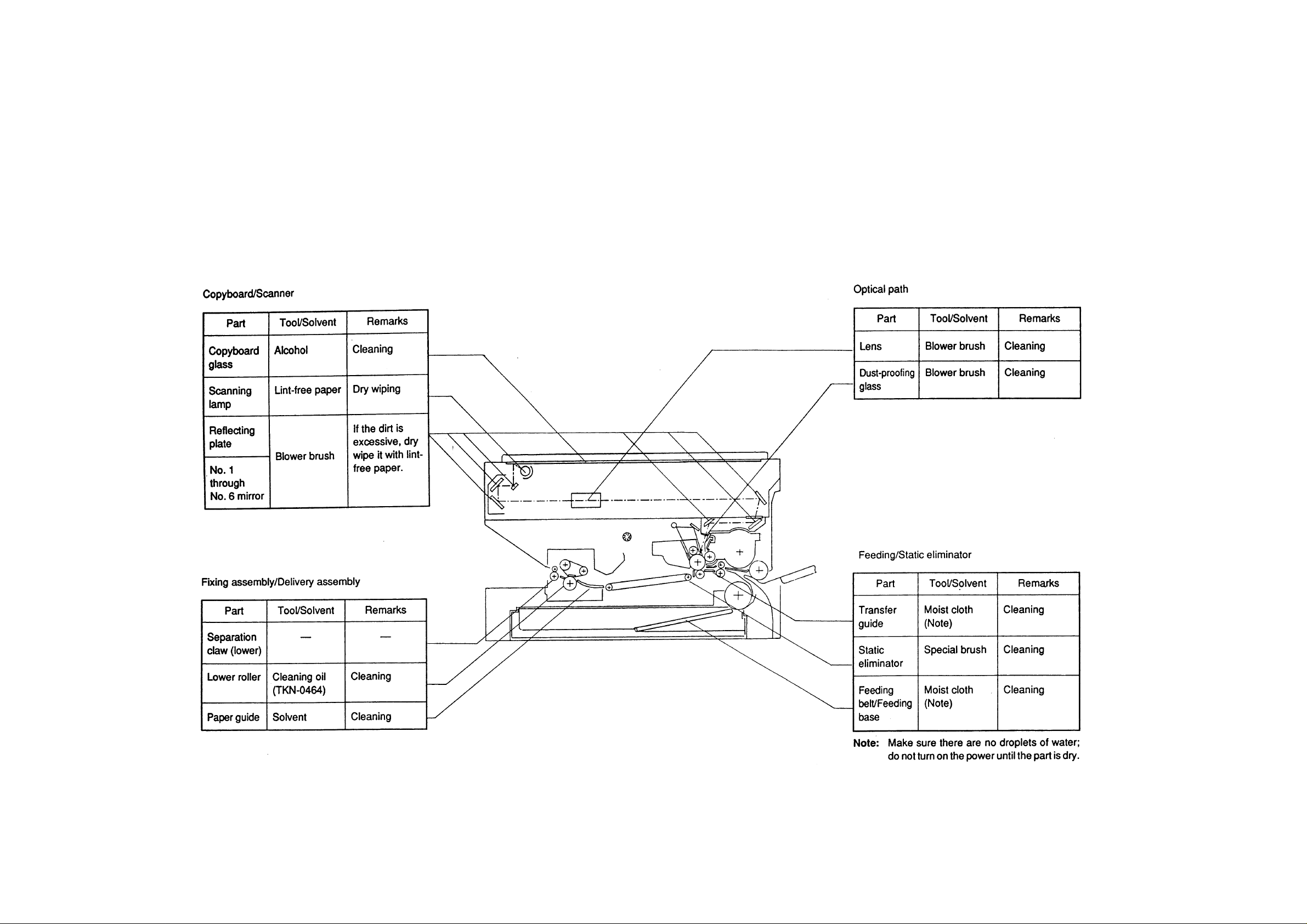

B. Periodical Servicing

1-2

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A. Image Adjustment

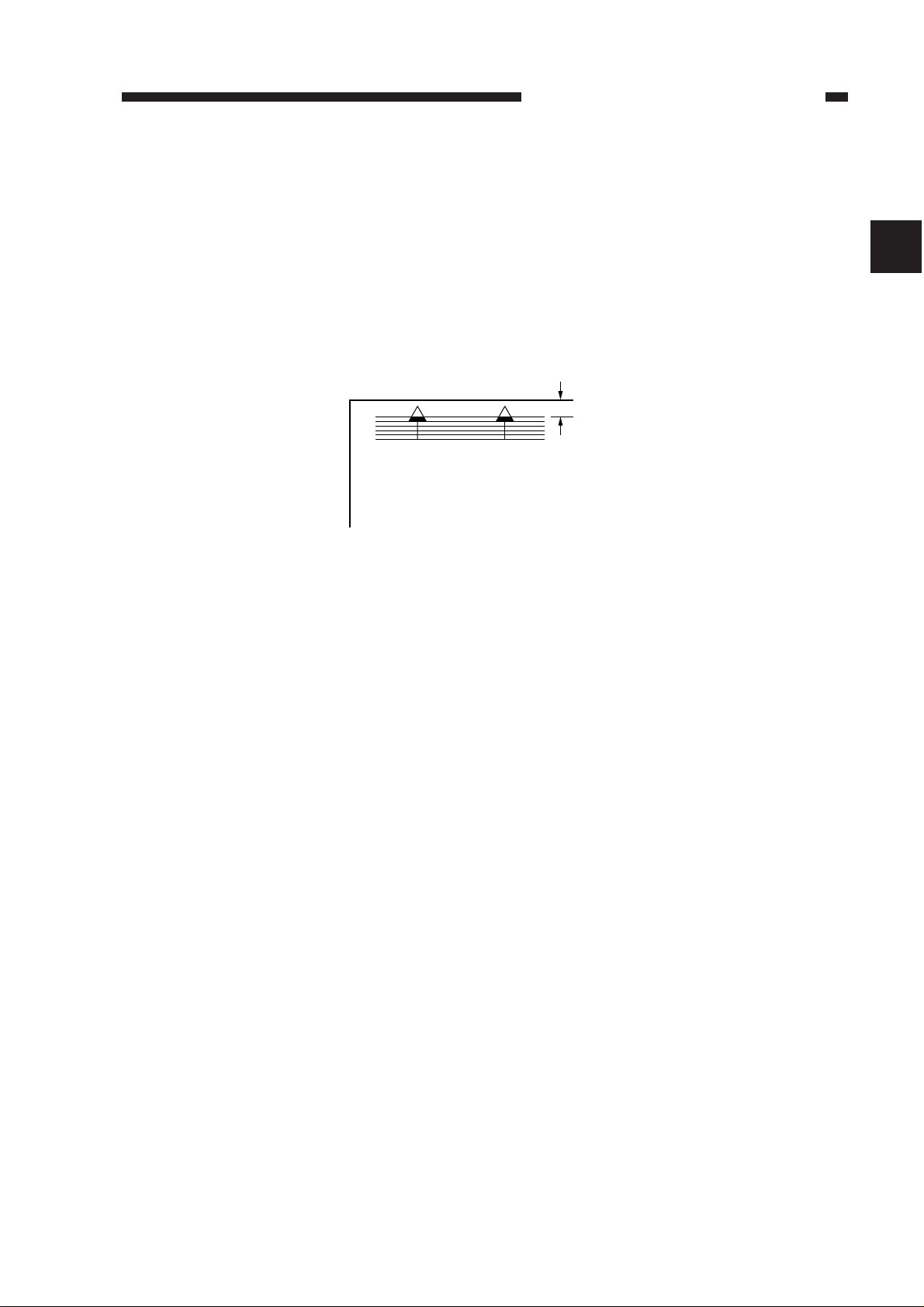

1. Adjusting the Image Leading Edge Margin ([3], No. 305; registration ON timing)

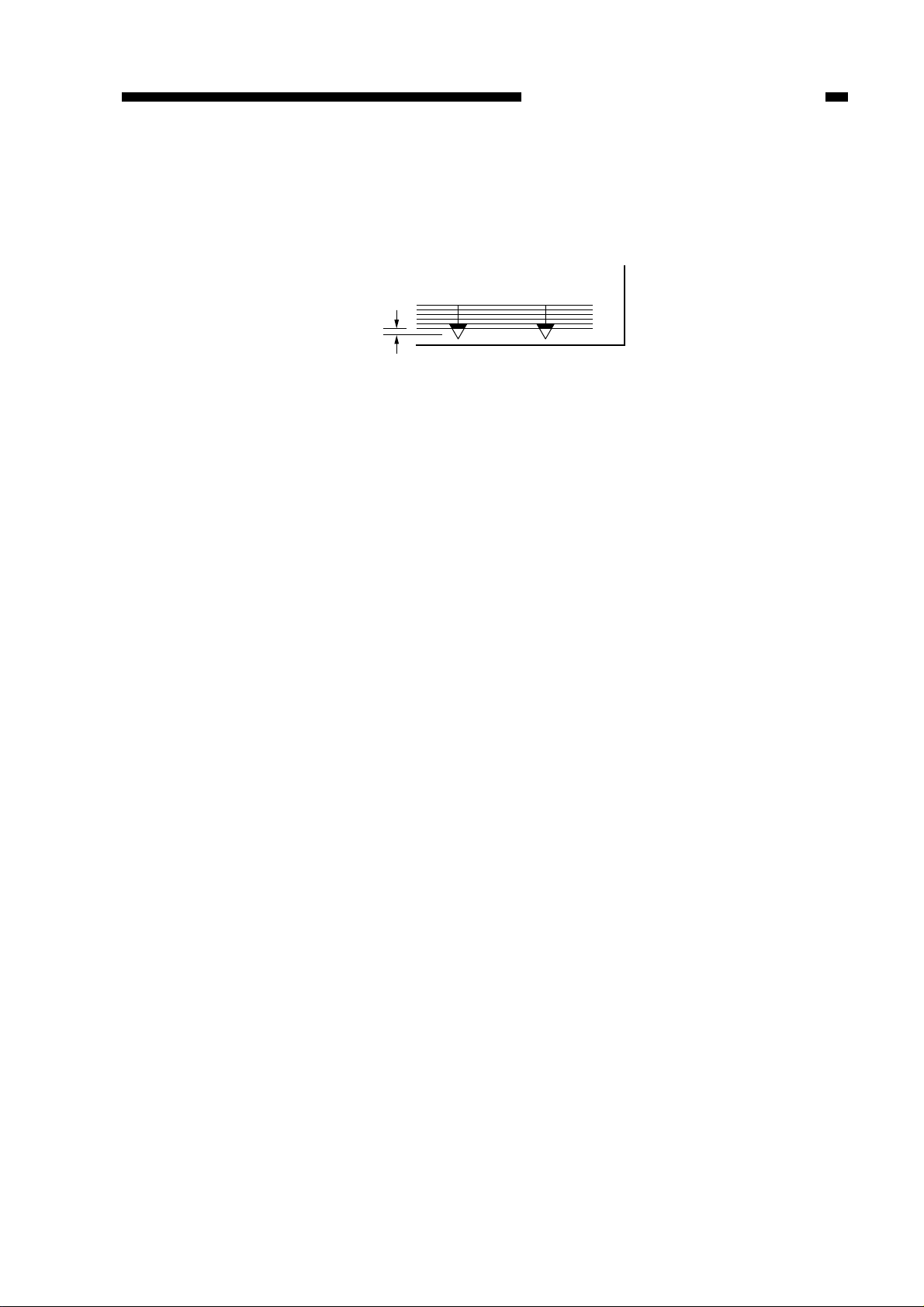

Activate [3] in service mode, and select ‘No. 305’ (leading edge margin adjustment),

and make adjustments so that the image position is as indicated in Figure 2-1 when the

Test Sheet is copied in Direct.

Figure 2-1

Making Adjustments

1) Activate [3] in service mode, and select ‘No. 305’ using the keypad.

• The copy count indicator flashes ‘No. 305’.

2) Press the Start key.

3) Change the value using the keypad.

• The value flashes.

• If the value is negative, ‘%’ turns on. To enter a negative value, press the % key,

then enter the value using the keypad.

4) Press the AE key.

• The value flashes as soon as it is entered.

• Press the Start key to start copying operation.

5) To change a value continuously, repeat steps 1) through 4).

6) Press the Clear key to return to selecting items.

The relationship between the setting and the image position is as follows:

• For each ‘1’ in the setting, the position shifts about 0.27 mm.

• ‘+’ shifts the image forward.

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2-1

2

2.5±1.5mm

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2.0±1.0mm

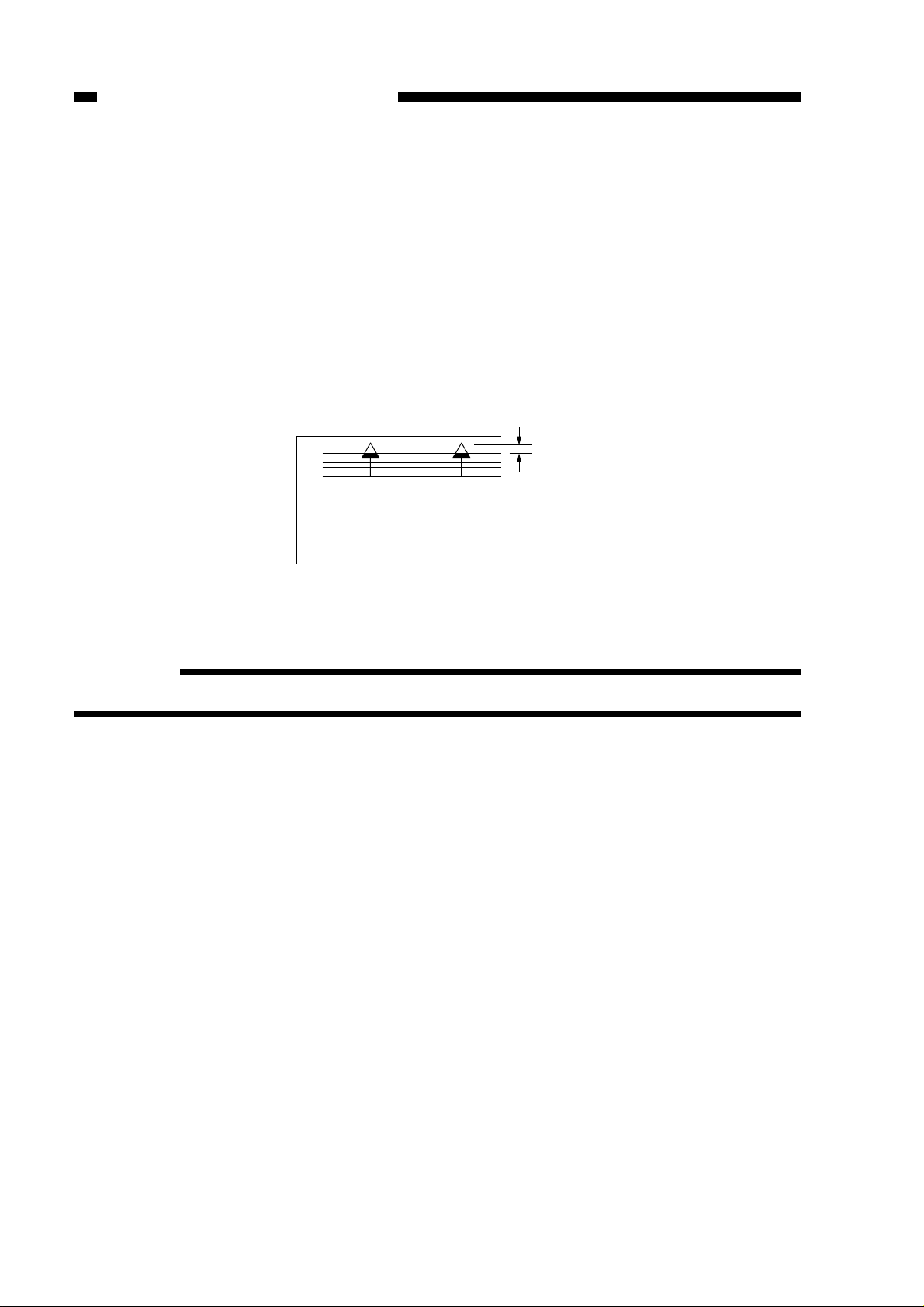

2. Adjusting the Leading Edge Non-Image Width ([3], No. 306; blank shutter ON

timing)

Activate [3] in service mode, select ‘No. 306’ (leading edge non-image width

adjustment), and make adjustments so that the image leading edge non-image width is

as indicated in Figure 2-2 when the Test Sheet is copied in Direct.

The copier varies the image leading edge non-image width by varying the timing at

which the blank shutter is closed.

You must make this adjustment whenever you have replaced the blank shutter

solenoid or the blank exposure assembly.

Leading Edge Non-Image Width

Figure 2-2

Reference:

6 mm or less in Reduce/Enlarge mode.

Making Adjustments

1) Activate [3] in service mode, and select ‘No. 306’ using the keypad.

• The copy count indicator flashes ‘No. 306’.

2) Press the Start key.

3) Change the value using the keypad.

• The value flashes.

• If the value is negative, ‘%’ turns on. To enter a negative value, press the % key,

then enter the value using the keypad.

4) Press the AE key.

• The value flashes as soon as it is entered.

• Press the Start key to start copying operation.

5) To change a value continuously, repeat steps 1) through 4).

6) Press the Clear key to return to selecting items.

The relationship between the setting and the image position is as follows:

• For each ‘1’ in the setting, the position shifts about 0.27 mm.

• ‘+’ increases the non-image width.

2-2

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2.5±

1.5mm

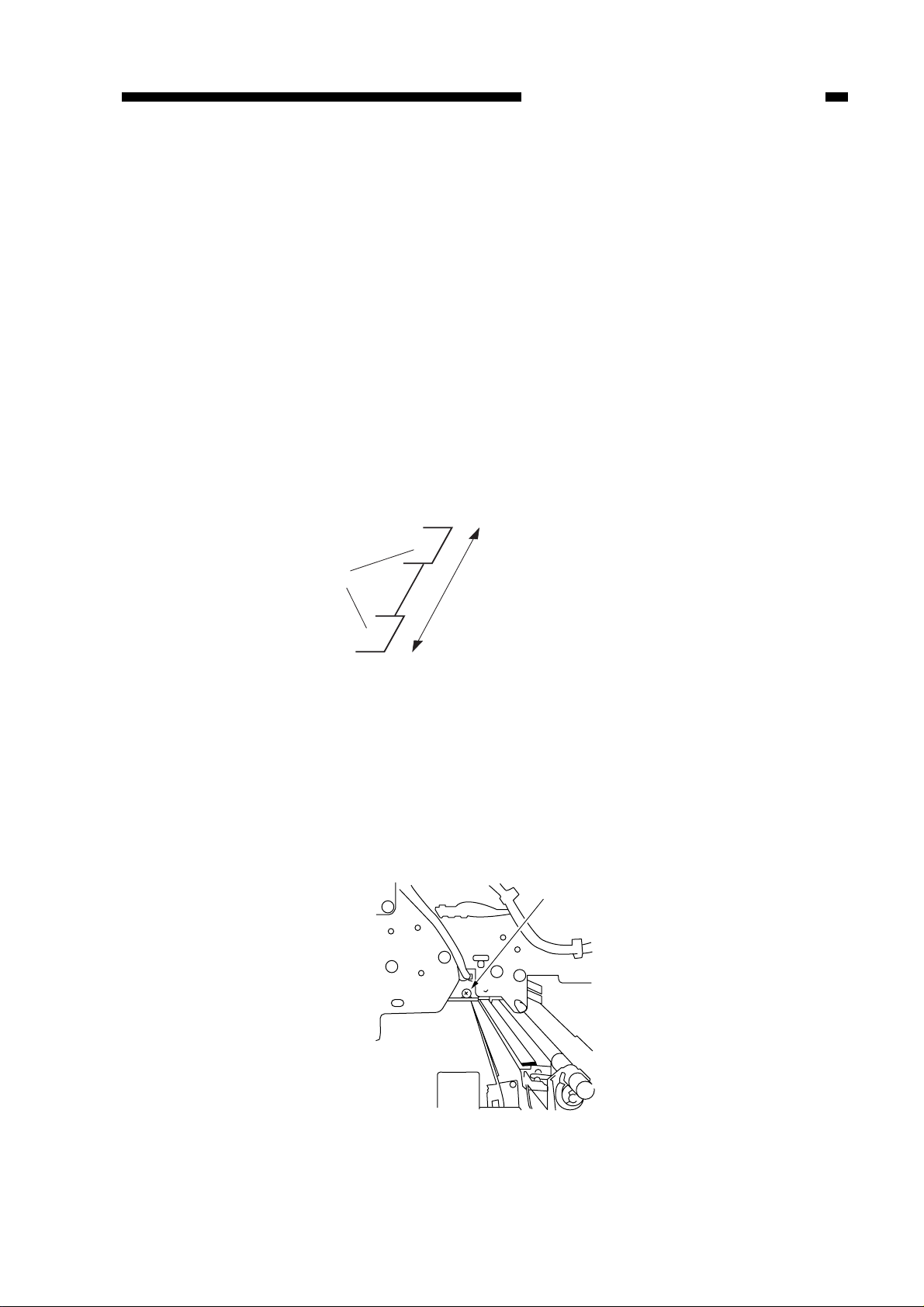

3. Adjusting the Image Trailing Edge Non-Image Width ([3], No. 309; blank shutter

timing)

Trailing Edge Non-Image Width

Figure 2-3

Activate [3] in service mode, and select ‘No. 309’ (leading edge non-image width

adjustment); make adjustments so that the image trailing edge non-image width is as

indicated in Figure 2-3 when the Test Sheet is copied in Direct.

The copier varies the image trailing edge non-image width by varying the timing at

which the blank shutter is opened.

Making Adjustments

1) Activate [3] in service mode, and select ‘No. 309’ using the keypad.

• The copy count indicator flashes ‘No. 309’.

2) Press the Start key.

3) Change the value using the keypad.

• The value flashes.

• If the value is negative, ‘%’ turns on. To enter a negative value, press the % key,

then enter the value using the keypad.

4) Press the AE key.

• The value flashes as soon as it is entered.

• Press the Start key to start copying operation.

5) To change a value continuously, repeat steps 1) through 2).

6) Press the Clear key to return to selecting items.

The relationship between the setting and the image position is as follows:

• For each ‘1’ in the setting, the position shifts about 0.27 mm.

• ‘+’ decreases the trailing edge non-image width.

2-3

CHAPTER 2 STANDARDS AND ADJUSTMENTS

q

(-)

(+)

0±1.5mm

0

2

4

6

8

10

q

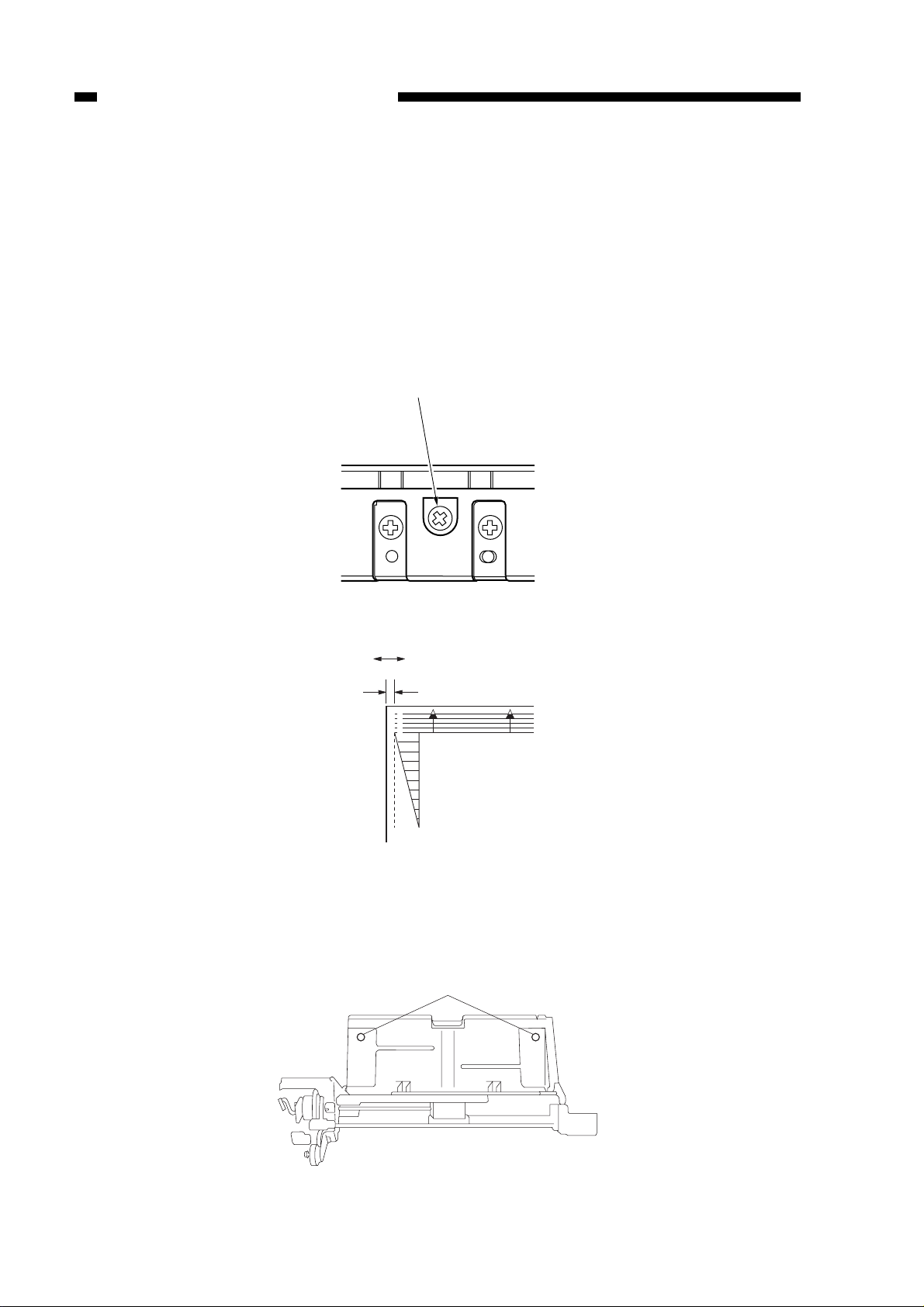

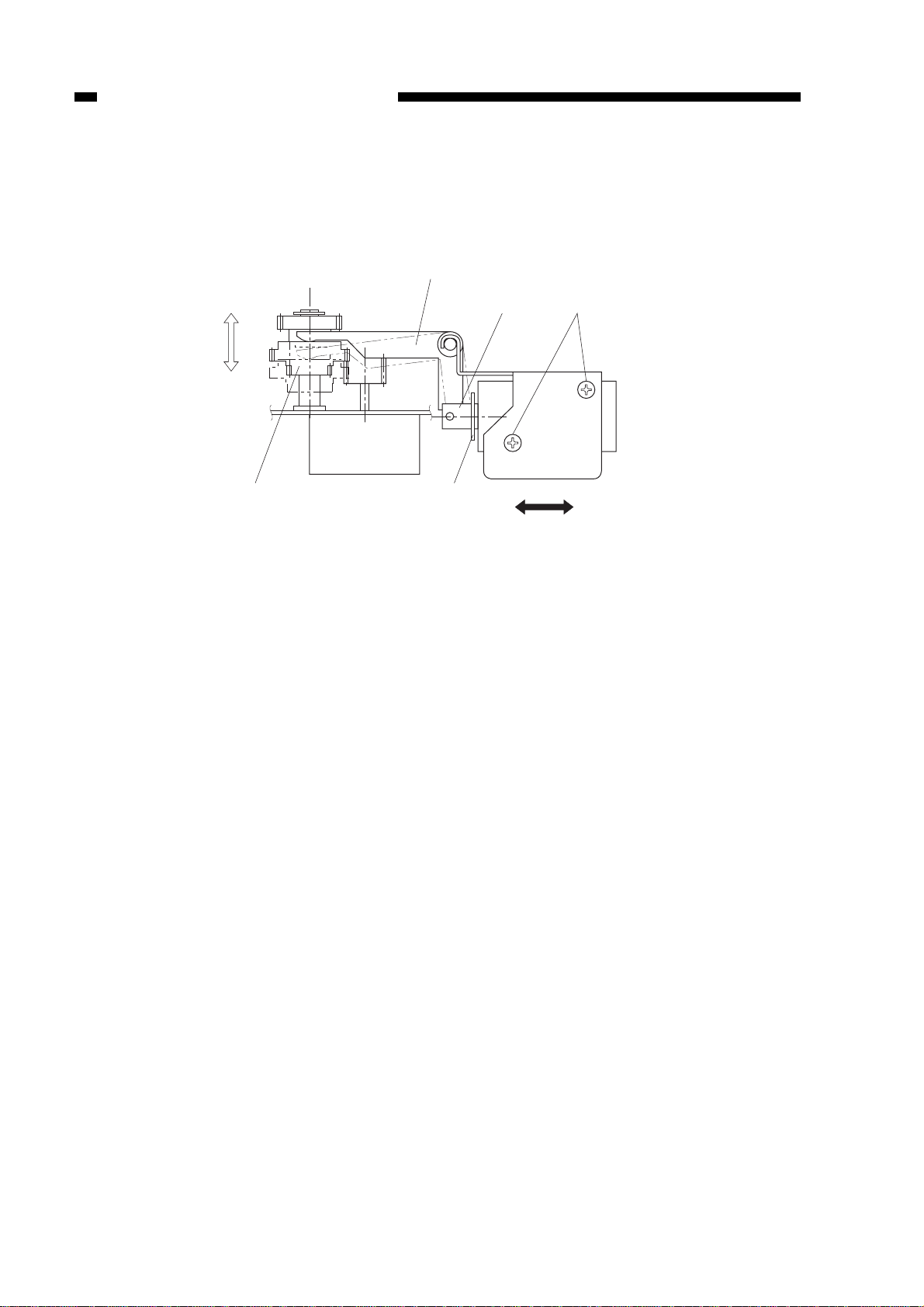

4. Adjusting the Left/Right Registration

Make adjustments so that the position of the image is as indicated in Figure 2-5 when

the Test Sheet is copied in Direct.

a. Pick-Up from the Cassette

Turn the screw 1 sho wn in Figure 2-4 to adjust the position of the cassette hook plate.

standard: 0.±1.5 mm

clockwise turn: paper moves in the direction of – shown in Figure 2-5.

counterclockwise turn: paper moves in the direction of + in Figure 2-5.

Figure 2-4

Figure 2-5

b. Pick-Up from the Multifeeder

Loosen the screw 1, and move the position of the tray so that it is 0 ±1.5 mm.

2-4

Figure 2-6

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Shutter

Adjust the distance between the

two shutters in the blanking

assembly.

q

5. Adjusting the Left/Right Margin (No. 311; left/right margin)

Select ‘No. 311’ (left/right margin adjustment); make adjustments so that the left/right

margin is 2.5 ±1.5 mm when the Test Sheet is copied in Direct.

You must adjust the left/right registration before making this adjustment.

Making Adjustments

a. Margin (adjusting the width)

1) Activate [3] in service mode, and select ‘No. 311’ using the keypad.

2) Press the Start key.

3) Enter a value using the keypad.

• If the value is negative, ‘%’ turns on. To enter a negative value, press the % key,

then enter the value using the keypad.

The relationship between the setting and the image position is as follows:

• For each ‘1’ in the setting, the margin (one side) shifts about 0.37 mm.

• range: 0 to 15 mm

• ‘+’ increases the margin.

• ‘–’ decreases the margin.

Figure 2-7

b. Left/Right Margin

Turn the blank shutter adjustment screw located on the front side plate shown in

Figure 2-8 so that the value is as specified.

clockwise turn:moves the margin toward the front.

counterclockwise turn:moves the margin toward the rear.

a full turn: shifts the margin by about 1 mm.

Figure 2-8

2-5

❋ Without this adjustment, exposure value becomes invalid.

3) Tur n VR301 on the DC controller so that the image is optimum.

• If the image is too light, turn the VR slightly clockwise.

• If the image is too dark, turn the VR slightly counterclockwise.

Reference:

1. The term optimum image refers to a copy whose gray scale No. 8 corresponds to

gray scale No. 4 through 7 of the Test Sheet without fogging.

2. An excessive turn on the VR could put out the lamp. If that is the case, turn it

clockwise until it stops, and turn off and then on the power for re-adjustment.

Caution:

Be sure to execute AE adjustment after these adjustments.

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2-6

Shutter

The entire shutters are

shifted.

Figure 2-9

Caution:

After the adjustments (both a and b), turn on and off the power switch or change

the reproduction ratio so that the blank exposure assembly performs home

positioning.

6. Adjusting the Scanning Lamp Intensity

Turn VR301 on the DC controller as follows whenever you have replaced the

scanning lamp, intensity sensor, or DC controller.

1) Set Test Sheet NA3 on the copyboard, and close the copyboard cover.

2) Adjust the copy density (AE off) to electrical central position (service mode 1/0 mode

[2] No. 212 Value = 153~159).

CHAPTER 2 STANDARDS AND ADJUSTMENTS

7. AE Adjustment

Adjust the AE mechanism using the following three service modes:

q AE Basic Adjustment

No. 410.............scanner forward stop

No. 408........scanning lamp on check

No. 208.....AE sensor voltage display

No. 301lamp intensity automatic adjustment at time of AE scan

w Copy Density in AE Mode (No. 302)

(developing bias) reference adjustment

e Copy Density in AE Mode

(developing bias) slope adjustment

If the copy density is not optimum after executing AE basic adjustment q (No. 410,

No. 408, No. 208, No. 301), execute w and then , if necessary, e, i.e., No. 302 and No.

303.

If you have replaced the AE sensor, scanning lamp, or DC controller, adjust the

scanning lamp intensity (VR 301); then, execute AE basic adjustment q, scanner

forward stop (No. 410), scanning lamp on check (No. 408), AE sensor voltage display

(No. 208), and lamp intensity automatic adjustment (No. 301).

Go through the following when making adjustments; Table 2-1 is a list of service

modes excluding scanner forward stop (No. 410), list of service modes excluding

scanner forward stop (No. 410), scanning lamp on check (No. 408), and AE sensor

voltage display (No. 208).

a. AE Basic Adjustment (No. 410, No. 408, No. 208, No. 301)

In this adjustment, the intensity of the scanning lamp is read by the lamp intensity

sensor and the voltage of the AE sensor unit is adjusted by VR 391 on the DC controller.

After the adjustment, execute the lamp intensity automatic adjustment for AE scans.

1) Place the Test Sheet NA-3 on the copyboard, and close the copyboard.

Adjust to the appropriate copy density in non-AE mode (settings) by suing bias

adjustment knob “VR302”. Then press the service mode switch (SW302) to activate

service mode.

2) Enter ‘4’ using the keypad, and press the AE key.

• The display indicates ‘401’.

3) Enter ‘410’ using the keypad.

• The display indicates ‘410’.

4) Press the Start key once.

• The scanner moves forward.

Caution:

Each press moves the scanner forward; do not press more than once.

5) Enter ‘408’ using the keypad, and press the Start key.

• The display indicates ‘ON’, and turns off after about 1.5 sec.

6) Press the Clear key twice.

• The display indicates ‘4’.

7) Press ‘2’ on the keypad, and press the AE key.

• The display indicates ‘201’.

2-7

CHAPTER 2 STANDARDS AND ADJUSTMENTS

VR391

8) Enter ‘208’ using the keypad, and press the start button.

• The display indicates ‘208’.

9) Press the Start key.

• The display indicates ‘0–255’.

10)Turn VR391 on the DC controller so that the reading on the display is ‘100~105’.

Figure 2-10 DC Controller PCB

11)Turn off and on the power switch.

• This turns off and on the scanning lamp.

12)Press the ser vice mode switch.

• The copier enters service mode, and the display indicates ‘1’.

13)Enter ‘3’ using the keypad, and press the AE key.

• The display indicates ‘301’.

14)Press the Start key.

Caution:

Wait until initial rotation is over.

• After initial rotation is over, the AE indicators starts to flash.

15)Press the AE key; the following take place to indicate that the optimum intensity is

adjusted automatically:

• The AE indicator stops flashing and remains on.

• The scanner moves to the AE measurement position.

• When the intensity has stabilized, the reading taken b y the AE sensor is stored in

memory.

• The lamp is turned off, and the scanner is returned to its original position.

16)When the above has ended, press the clear key twice.

• The display indicated ‘3’.

17)Enter ‘1’ using the keypad, and press the AE key.

• The display indicates ‘101’.

18)Enter ‘116’ using the keypad, and press the Start key.

• Make sure that the display indicates ‘68–72’; otherwise, start with step 2) of

operation/inspection mode for re-adjustment.

2-8

CHAPTER 2 STANDARDS AND ADJUSTMENTS

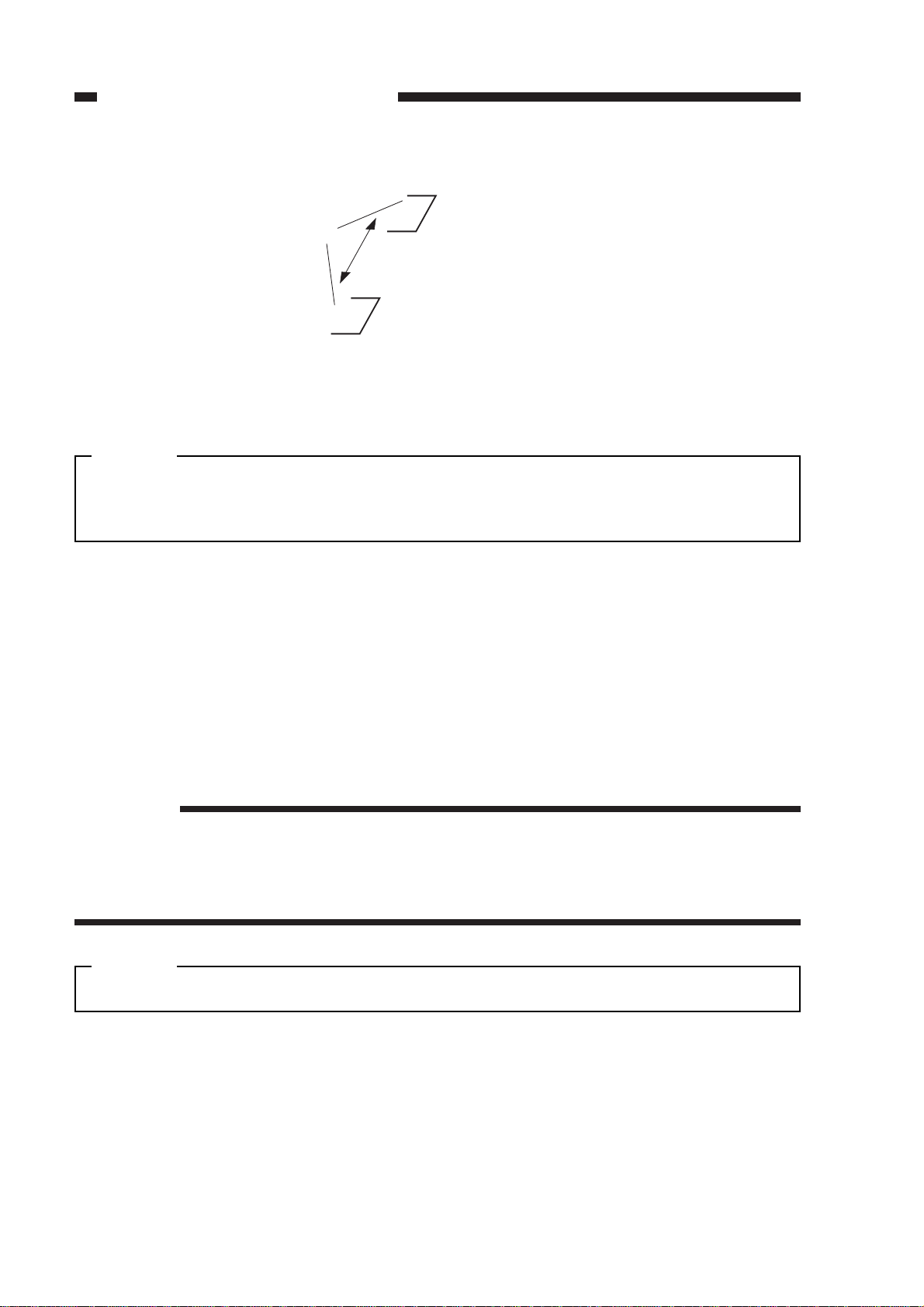

b. Copy Density (development bias) Reference Point Adjustment for AE Mode (No.

302)

1) If the indication is not in the 300’s , activ ate adjustment mode (service mode) as in the

case of ‘No. 301’.

2) Press [2] on the keypad.

• The copier indicates ‘302’.

3) Press the Start key.

• The copier indicates the current setting.

4) Change the setting using the keypad, and press the AE key.

• A higher setting causes the AE copies to be darker.

• default: 0

range: –26 to +26

• If the setting is negative, the ‘%’ is indicated. To enter a negative value, press the

‘%’ key, and enter a setting.

• When the copier has read the setting, the indication stops flashing and remains

on.

5) Record the new setting on the service mode label.

6) To end, press the Clear key.

• The copier returns to selection mode, and indicates ‘302’.

• As necessary, execute ‘No. 303’.

c. Copy Density (development bias) Slope Adjustment for AE Mode (No. 303)

1) If the indication is not in the 300’s , activ ate adjustment mode (service mode) as in the

case of No. 301.

2) Press [3] on the keypad.

• The copier indicates ‘303’.

3) Press the Start key.

• The copier indicates the current setting.

4) Change the setting with the keypad, and press the AE key.

• A larger setting causes the AE copies to be darker.

• default:.........................................0

range:...........................–26 to +26

• If the setting is negative, ‘%’ is indicated. To enter a negative value, press the ‘%’

key, and enter a setting.

• When the copier has read the setting, the indication stops flashing and remains

on.

5) Record the new settings on the service mode label.

6) Press the Reset key.

• The copier de-activates service mode.

2-9

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Lighter

Copy

density 5

Darker

Test Chart Density of

original

9

Test Chart

Density of

original

Lighter

Copy

density 5

Darker

9

q

w

Test Chart

Density of

original

Lighter

Copy

density 5

Darker

9

Newspaper

w

q

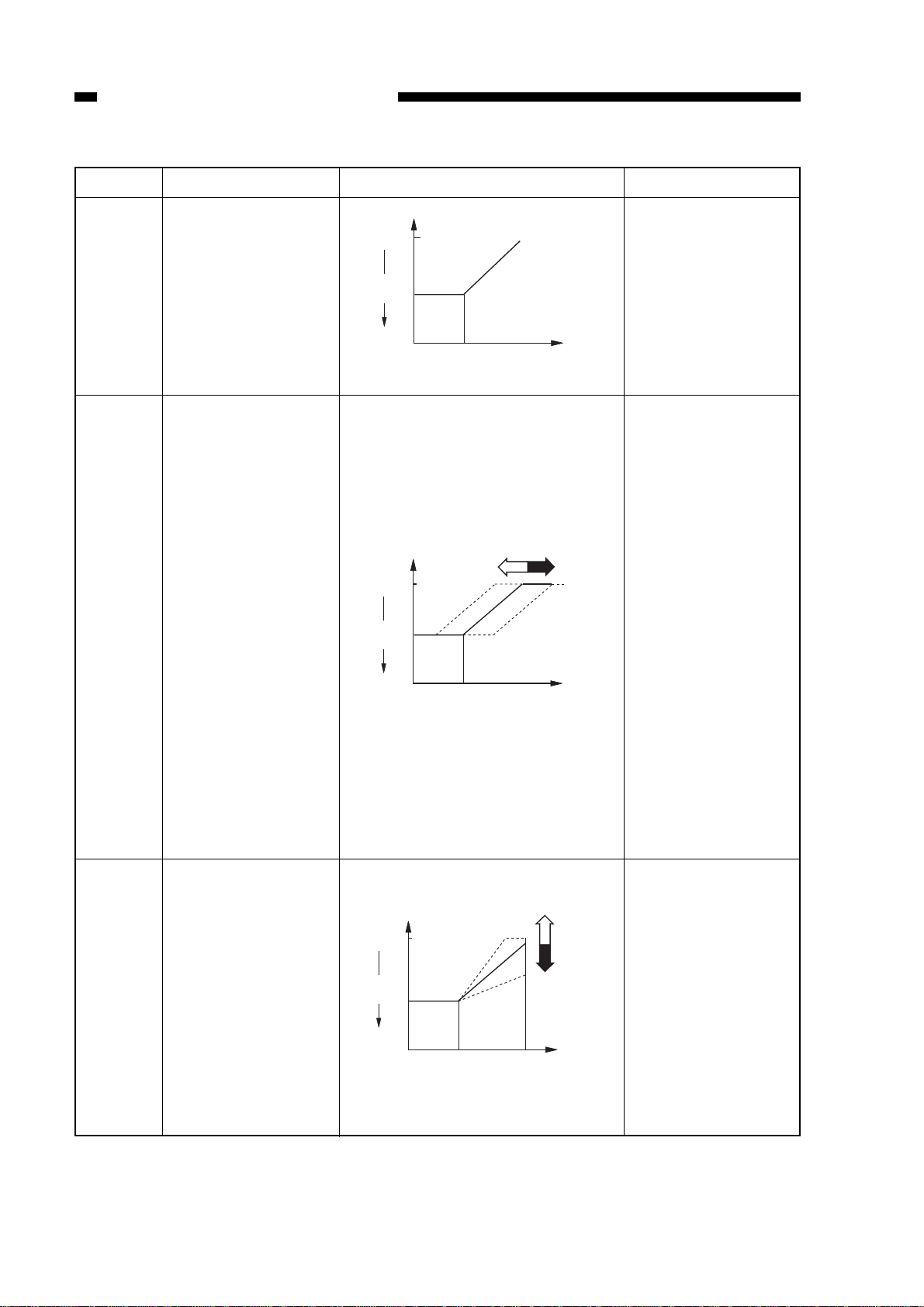

Item

No. 301

No. 302

Function

Automatic lamp

intensity adjustment

for AE scans

Copy density

(development bias)

reference point

adjustment for AE

mode

Description

Remarks\

The lamp intensity

is automatically

adjusted so that the

copies of the Test

Chart will be made

at density 5.

q A lower setting in

service mode causes

the AE copies to be

darker.

w A higher settings

in service mode

causes the AE copies

to be lighter.

default: 0

range: –26 to +26

No. 303

Copy density

(development bias)

slope adjustment for

AE mode

2-10

Table 2-1

After adjustment with

the test sheet NA-3,

using AE mode,

density adjustment

should show ‘5

’.

In non-AE mode,

density ‘5’ must also

be apprppriate

(adjusted with knob

VR302).

q A higher setting

in service mode

causes copies of a

newspaper to be

lighter.

w A lower setting

in service mode

causes copies of a

newspaper to be

darker.

default: 0

range: –26 to +26

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Screw

Loosen the

screw,and shift

it down.

Re-tighten

the screw.

Attach the mirror

positioning tool.

Set screws

Loosen the set

screws to enable

free rotation.

Put the steel ball

into the hole in

the pulley; wind

the cable nine

times toward the

inside, and four

times toward the

outside; then, snap

on the pulley clip.

Pulley clip

Steel ball

34±1mm

o

y

u

r

!1

t

q

!0

w

e

i

Wire spring

Wire spring

Hook

Hook

Cable

Cable

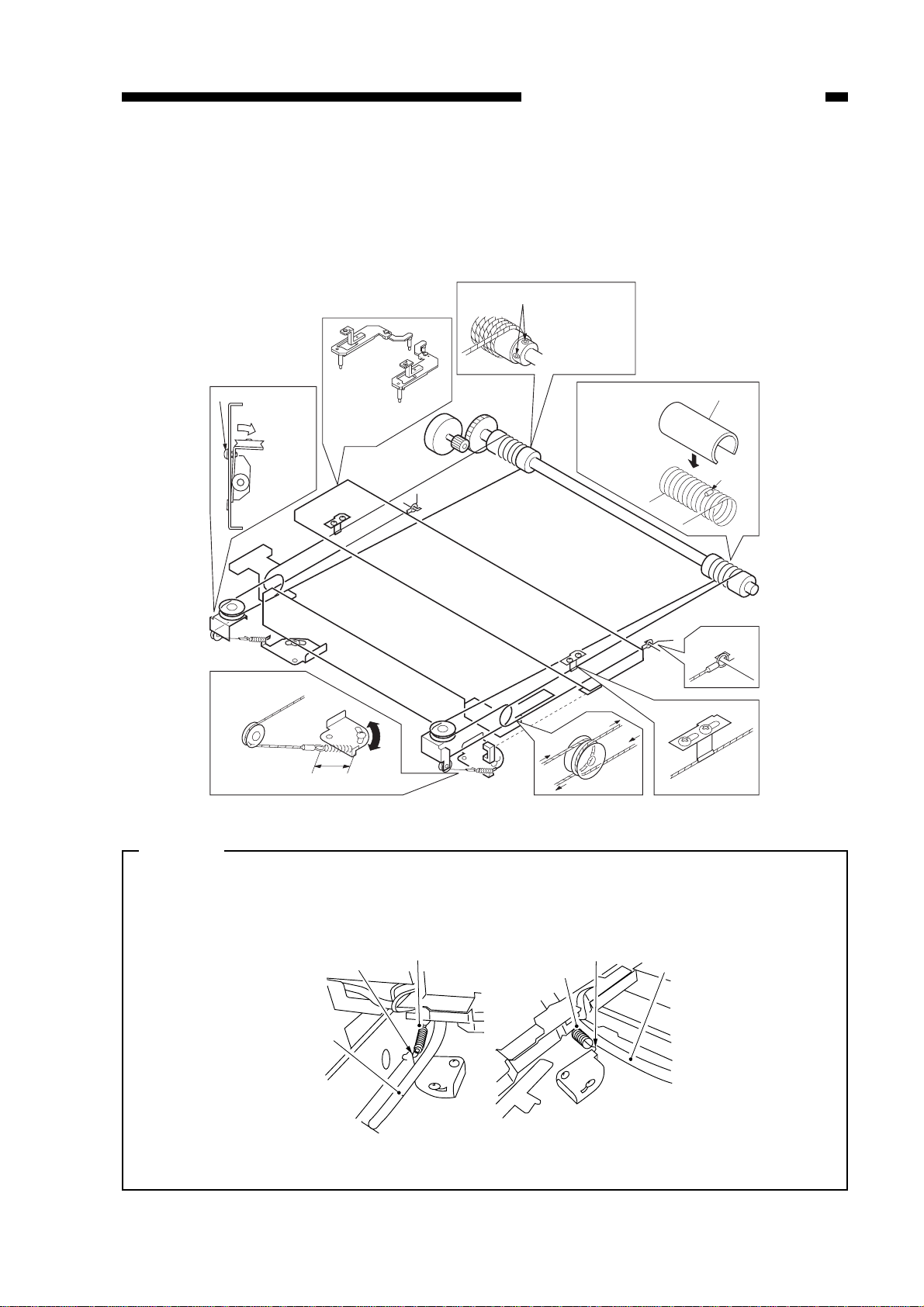

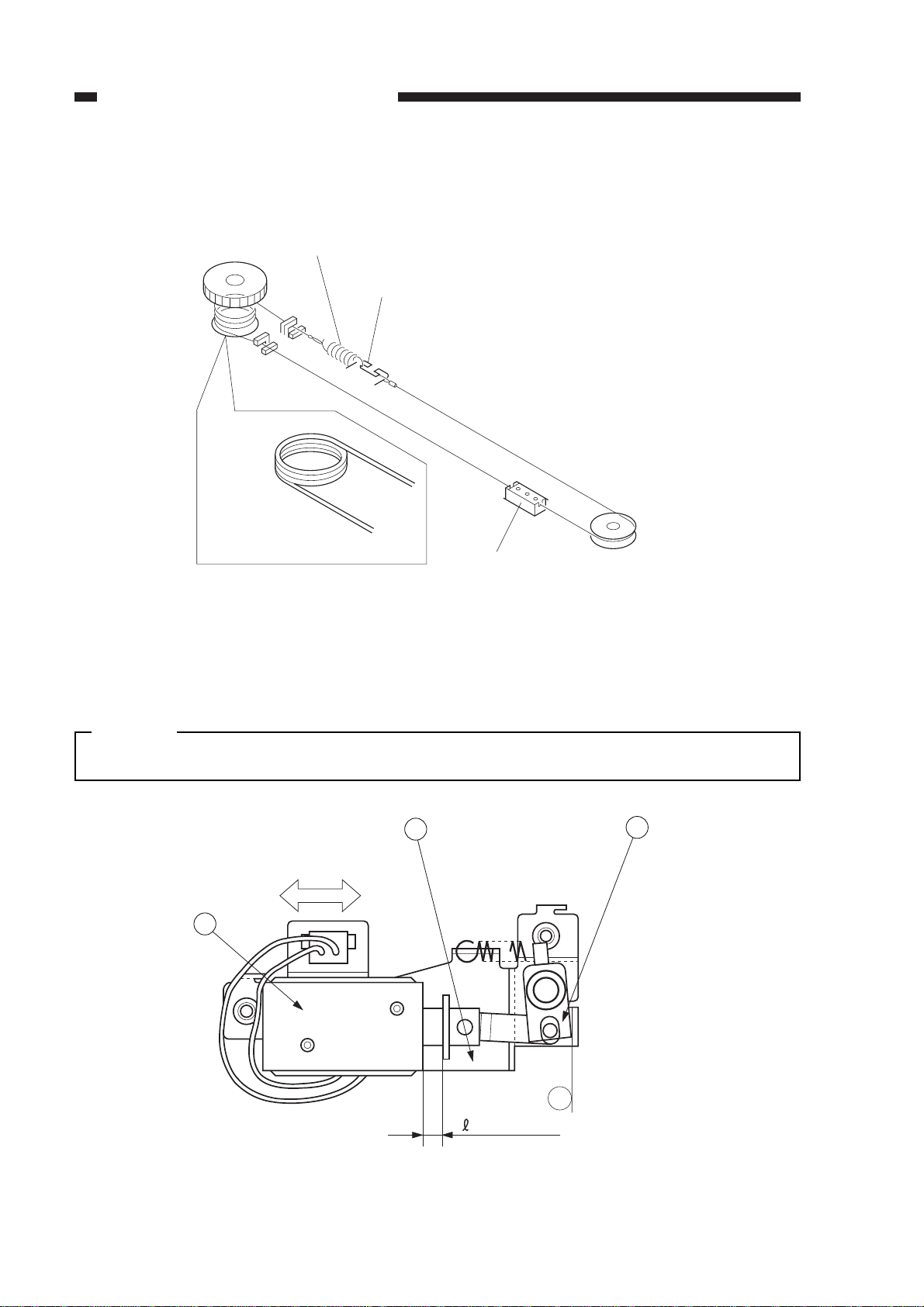

B. Exposure System

1. Routing the Scanner Drive Cable

Route the cable as shown by q through !0; then, adjust the cable tension and mirror

position as described.

Caution:

Figure 2-11

When attaching the wire spring, pay attention to the orientation of the spring; see

the diagrams below. If not attached correctly, its hook tip could interfere with the

cable.

Figure 2-12

2-11

CHAPTER 2 STANDARDS AND ADJUSTMENTS

q

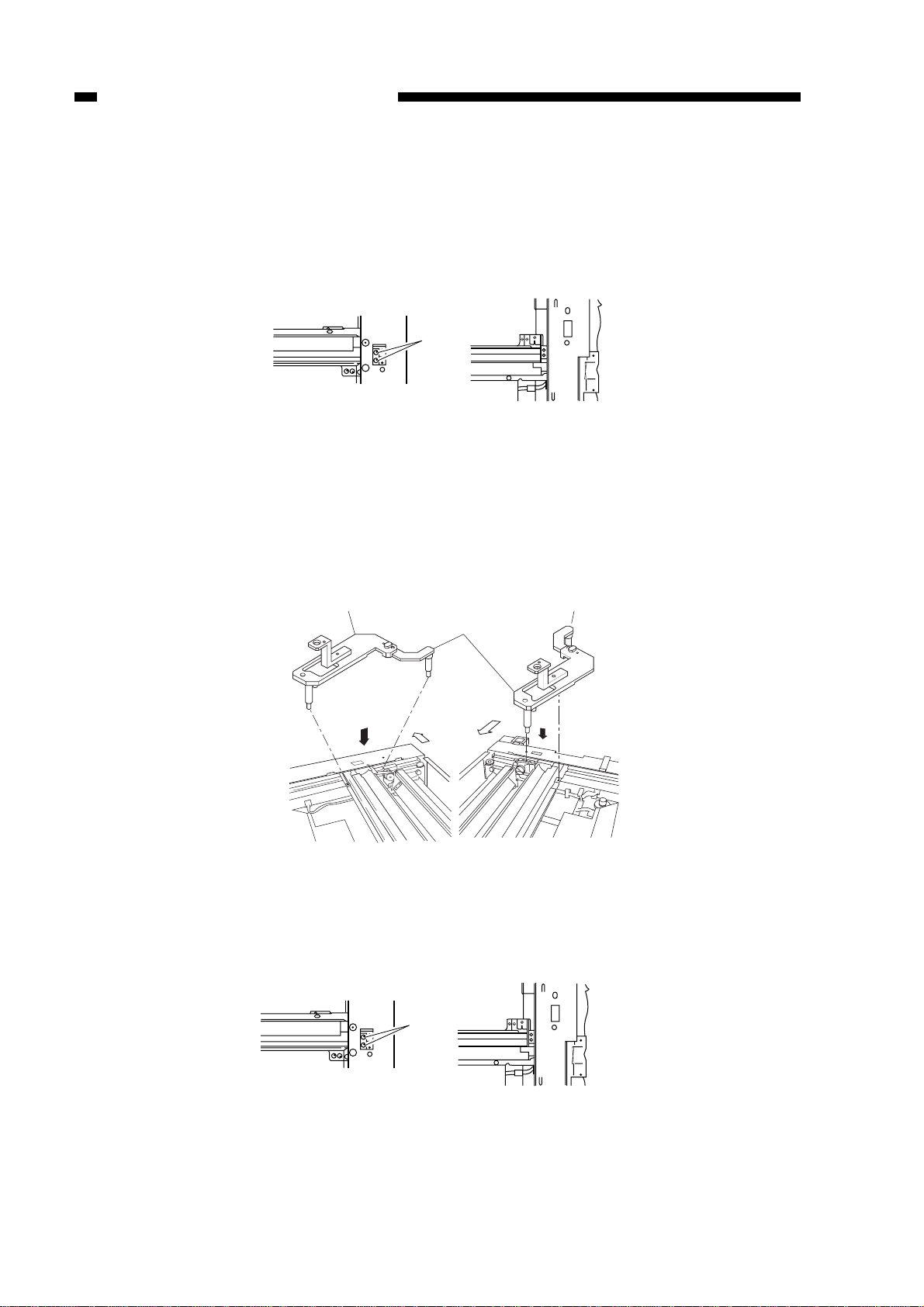

(front) (rear)

(front)

Mirror positioning tool (front) Mirror positioning tool (rear)

(front)

w

e

(front) (rear)

2. Adjusting the Mirror Position (optical distance between No. 1 mirror and No.

2/No. 3 mirror)

1) Keep the mirror positioning tool handy.

(See “4 Assembling the Mirror Positioning Tool on P. 2-13.”)

2) Move the No. 1 mirror mount forward, and match the long hole in the front side plate

and the cable fixing screw q.

Figure 2-13

3) Loosen the set screw on the pulley.

4) Set the mirror positioning tool w to the No. 1 mirror mount and the No . 2 mirror mount

(both front and rear).

Figure 2-14

5) Attach the scanner cable fixing to the No. 1 mirror mount using two screws e (both

front and rear).

Figure 2-15

2-12

CHAPTER 2 STANDARDS AND ADJUSTMENTS

q

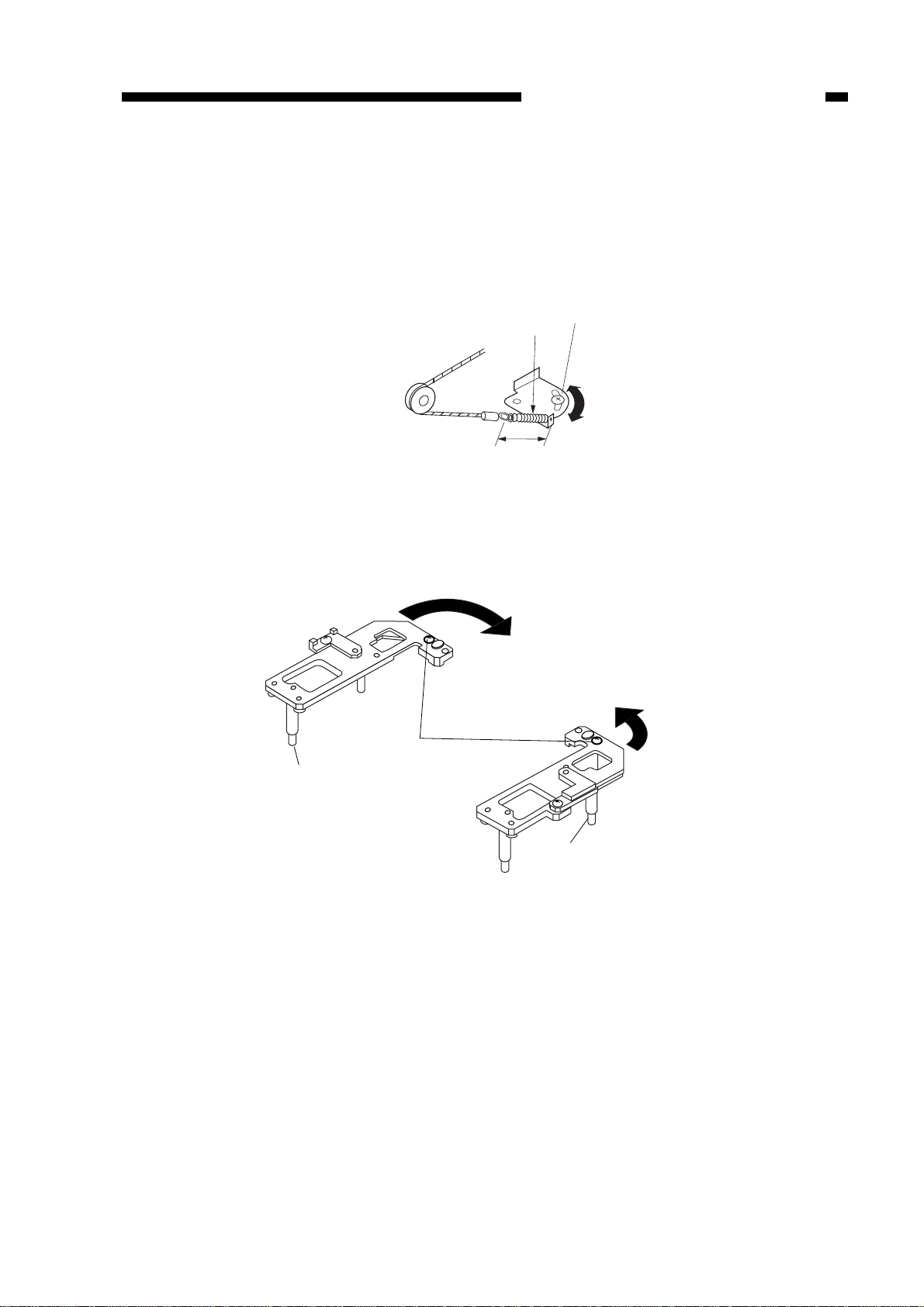

w

34±1mm

A

A

B

B

Position B

Longest pin

Medium-Length pin

6) Tighten the screw on the pulley.

7) Detach the positioning tool (FY9-3009).

3. Adjusting the Scanner Cable Tension

Move the tension plate and tighten the scre w w so that the distance across the ends

of the cable spring q is 34 ±1 mm as indicated in Figure 2-16.

Figure 2-16

4. Assembling the Mirror Positioning Tool

1) Remove the screw found in position B.

Figure 2-17

2) Fit the screw removed in step 1) in position A, and tighten it slightly.

3) Extend the arm accommodated by the main frame unit it butts against the stopper as

in Figure 2-18.

2-13

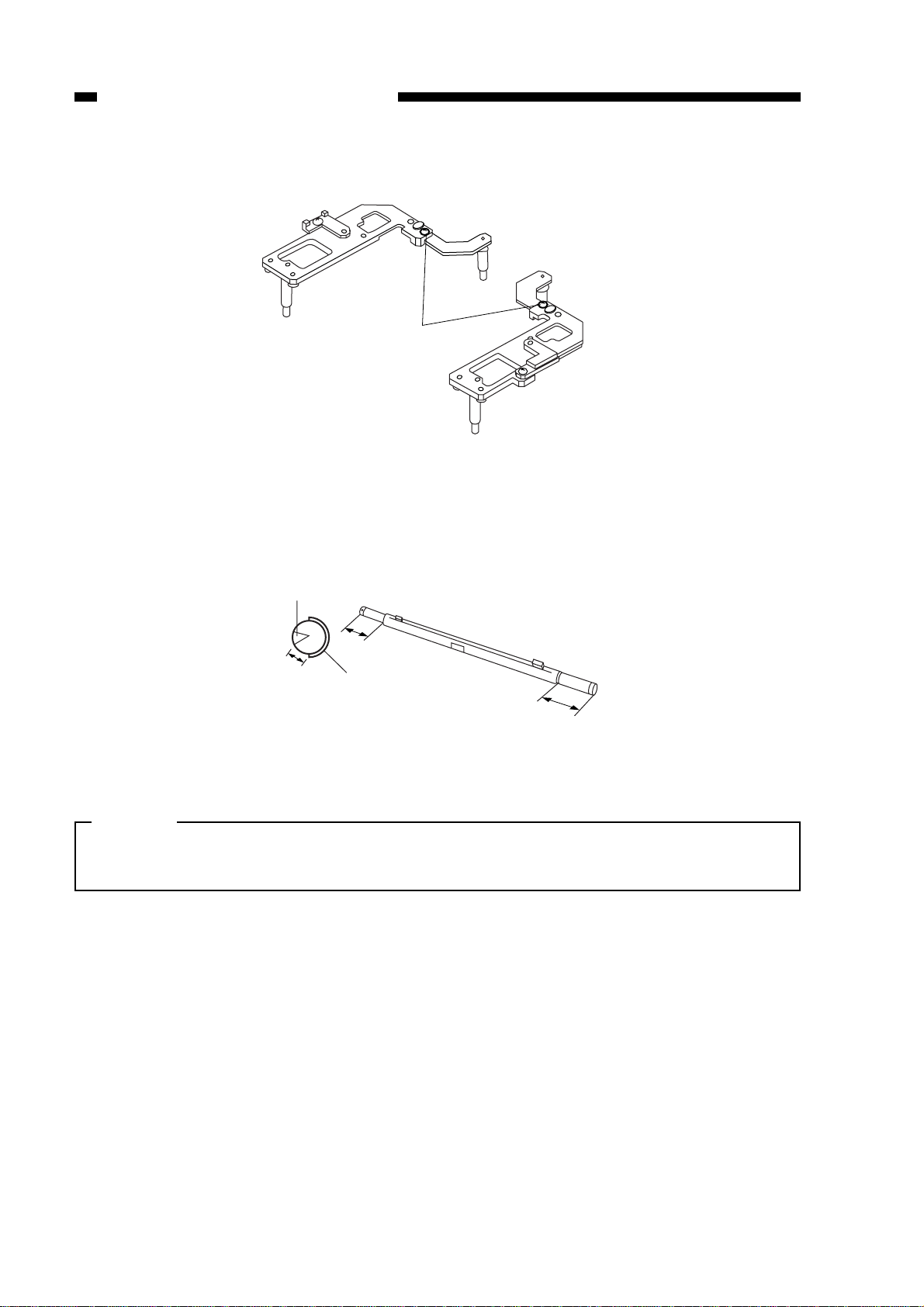

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A

A

B

B

Position A

Lightemitting

portion

Fluorescent

heater

1~5mm

60mm

60mm

4) Tighten the screw.

Figure 2-18

5. Points to Note When Attaching the Fluorescent Lamp Heater/Scanning Lamp

• Attach the heater to the lamp as follows:

Figure 2-19

Caution:

Do not touch the fluorescent lamp. (Use lint-free paper.)

Do not block the light-emitting portion by the fluorescent lamp heater.

2-14

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Light-emitting portion

Light adjustment sensor

Fluorescent lamp heater

Attach the scanning lamp so that its light-emitting portion (open side) is to the left

when viewed from the front of the copier as shown in Figure 2-20.

Figure 2-20 (front view)

Caution:

Do not touch the fluorescent lamp. (Use rint-free paper)

Be sure to adjust the gain and AE whenever you have replaced the fluorescent

lamp. (See P. 2-7.)

• Make sure that the cut-off of the fluorescent heater is correctly oriented in relation

to the intensity adjustment sensor.

Figure 2-21

Reference:

The fluorescent lamp heater will not operate unless the copier’s heater switch is

turned on.

2-15

CHAPTER 2 STANDARDS AND ADJUSTMENTS

t

q

w

e

r

AB

a

b

6. Positioning the Change Solenoid

Make adjustments by loosening the two screws t so that the gear r butts against

the direction of b by the arm e when the steel core q of the solenoid is fully pushed in

the direction of B, i.e., when the E-ring comes into contact with the solenoid.

Figure 2-22

2-16

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A

C. Image Formation System

1. Positioning the Blank Shutter Solenoid

Adjust the position of the blank shutter solenoid so that the bottom A is 9.5 ±0.5 mm

on both sides when the solenoid is moved in the direction of ON; try not to force down

the shutter.

After adjustments, make sure that the solenoid moves smoothly.

Figure 2-23a

Figure 2-23b

2-17

R in Figure 2-25 is 5.5 ±0.2 mm when the joint q is butted

against a of the solenoid support plate w.

Caution:

Be sure to make the adjustment whenever you have replaced the solenoid.

Figure 2-25

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2-18

Attach the spring to

the outside of the

sides shutter.

Slide shutter (rear)

Wind 3.5 times.

Slide shutter (front)

a

= 5.5 ± 0.2

2

1

3

2. Routing the Blank Shutter Cable

Figure 2-24

3. Positioning the Solenoid for the Primary Charging Roller

Loosen the two screws used to fix the solenoid e in place, and move the solenoid in

the direction of B so that the

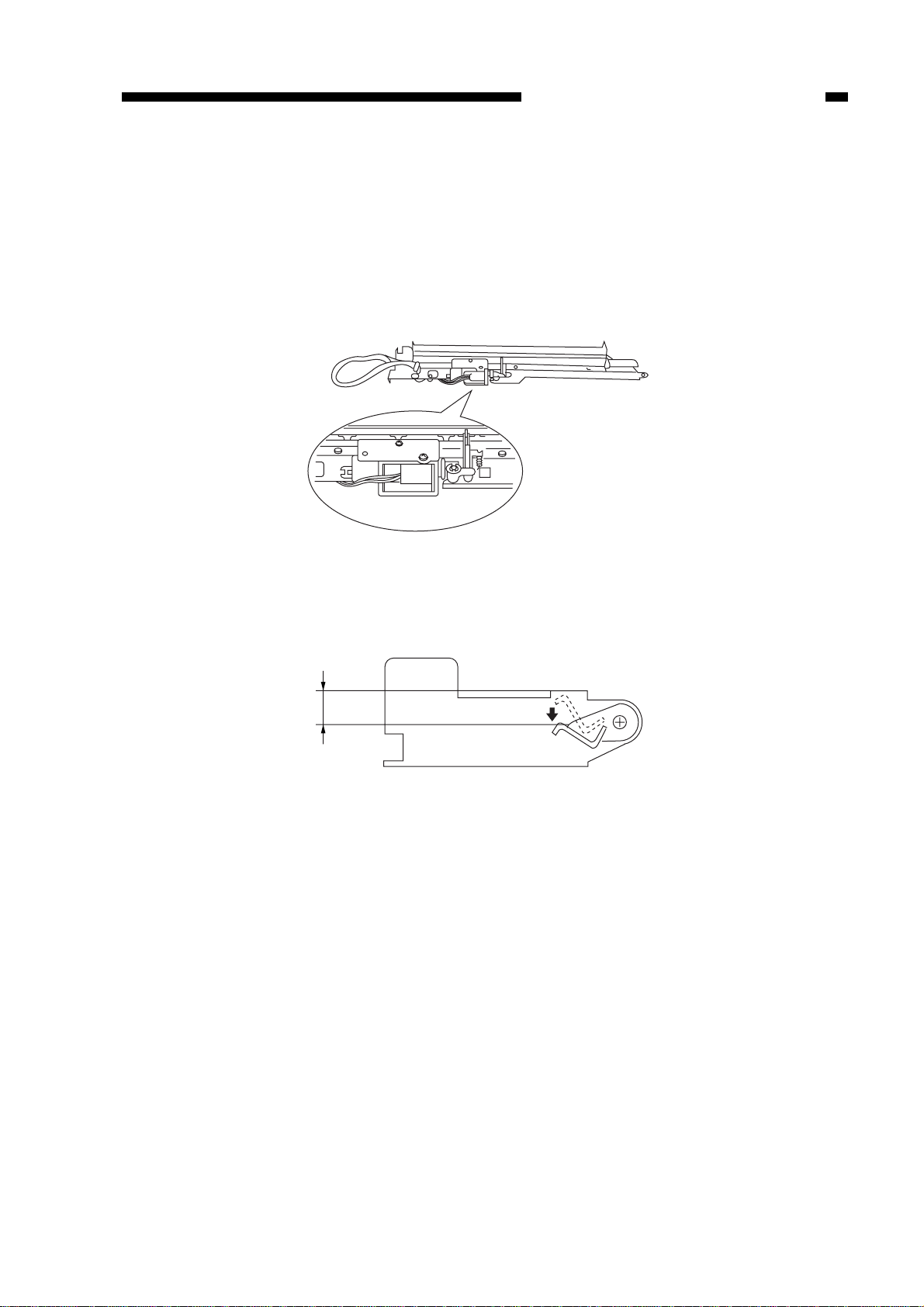

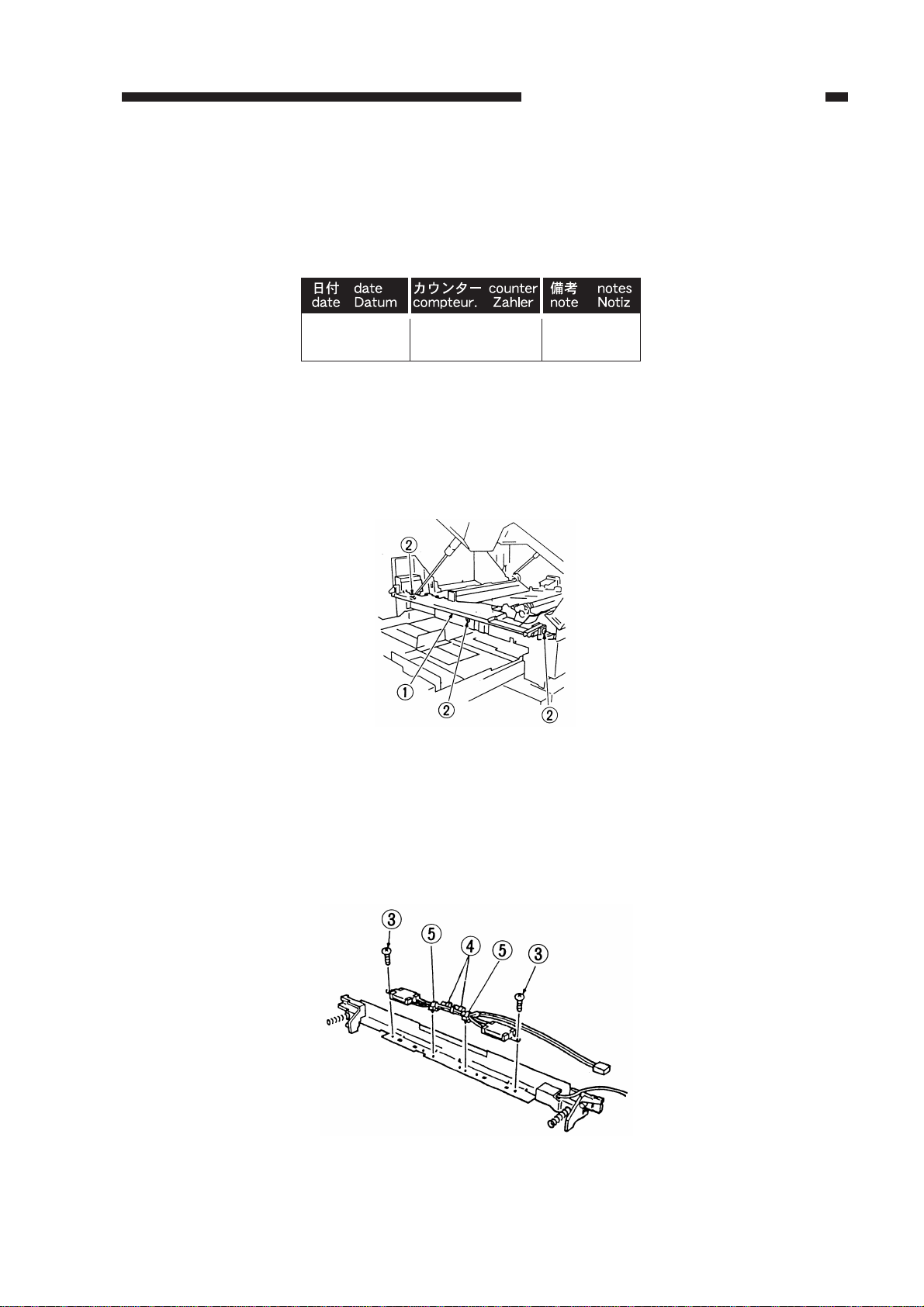

4. After Replacing the Drum Unit

Whenever you have replaced the drum unit, enter the date of replacement and the

current counter reading on the label (Figure 2-26) that came with the drum unit; attach

the label to the front cover of the ne w drum unit, and perform the image basic adjustment

procedure.

Figure 2-26

5. Attaching the Drum Heater

1) Detach the front cover.

2) Open the copier’s top body by operating the copier open/close lever.

3) Remove the two fixing screws

w, and detach the harness cover q.

Figure 2-27

4) Detach the transfer roller and the static eliminator.

5) Detach the transfer guide.

6) Butt the two heaters against the transfer guide as shown in Figure 2-28, and fix the

two mounts with two screws e; further, fix the harness in place using two harness

bands r (front, rear).

Figure 2-28

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2-19

CHAPTER 2 STANDARDS AND ADJUSTMENTS

7) Fix the harness in place using two SK binders (WT2-5145; front, rear) t; then, insert

it into the transfer guide.

Caution:

When fixing the harness in place, make sure that the cap portions of the terminals

alternate; keeping them in parallel will bring them in contact with the transfer roller.

8) Fix the harness with two SK binder t (front, rear) in place, and insert it into the

transfer guide.

Figure 2-29

9) Connect the connector y as shown in Figure 2-30.

Figure 2-30

Caution:

When attaching the transfer guide to the copier after attaching the drum heater,

make sure that the spring at the rear is firmly in the groove.

2-20

CHAPTER 2 STANDARDS AND ADJUSTMENTS

w

q

(front)

q

w

D. Pick-Up/Feeding System

1. Orientation of the Pick-Up Roller

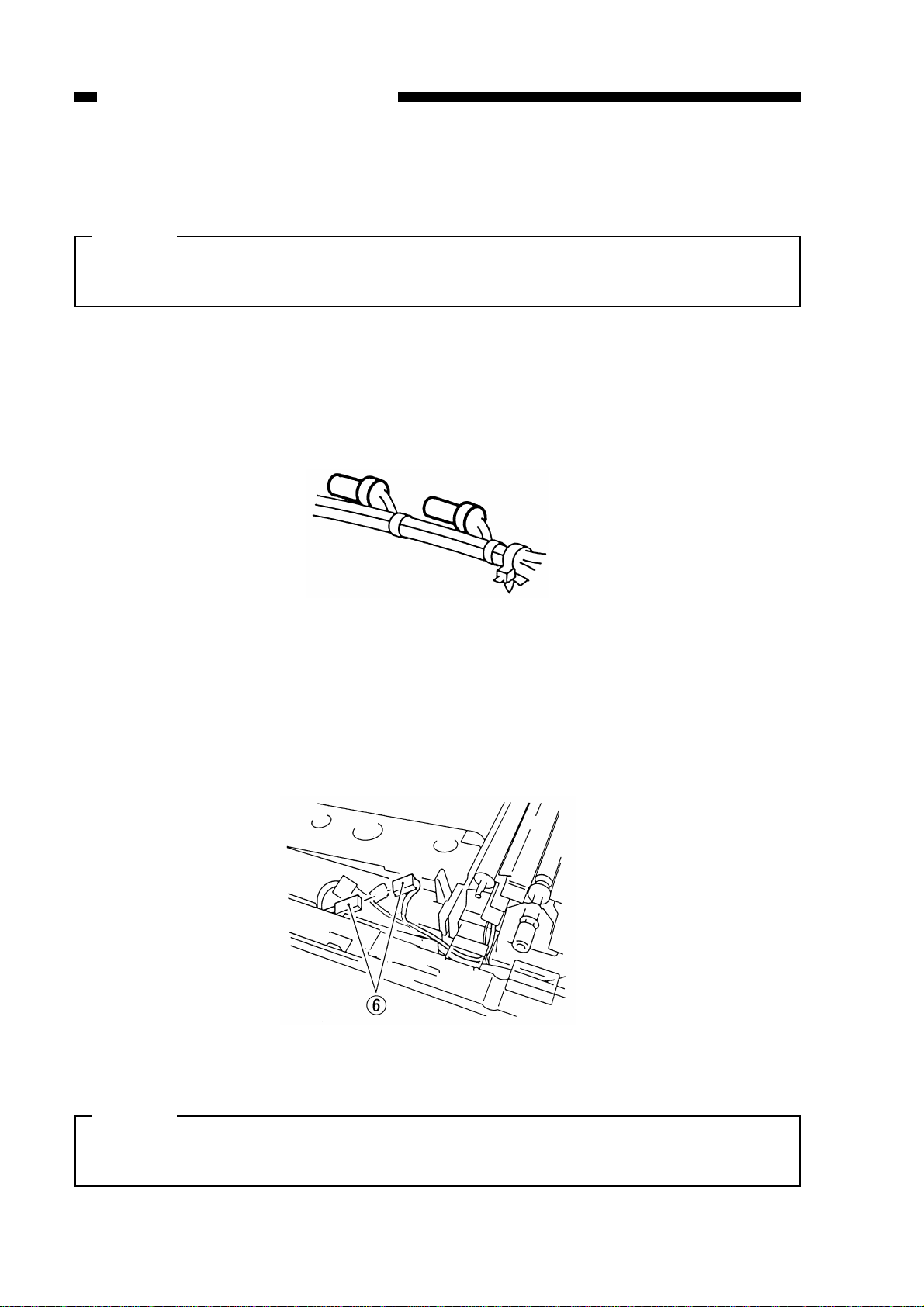

Attach the pick-up roll q so that the side w shown in Figure 2-31 is toward the rear.

Figure 2-31

2. Orientation of the Multifeeder Pick-Up Roller

Attach the multifeeder pic k-up roller q so that the side with the collar with a cross w

is toward the rear.

Figure 2-32

2-21

CHAPTER 2 STANDARDS AND ADJUSTMENTS

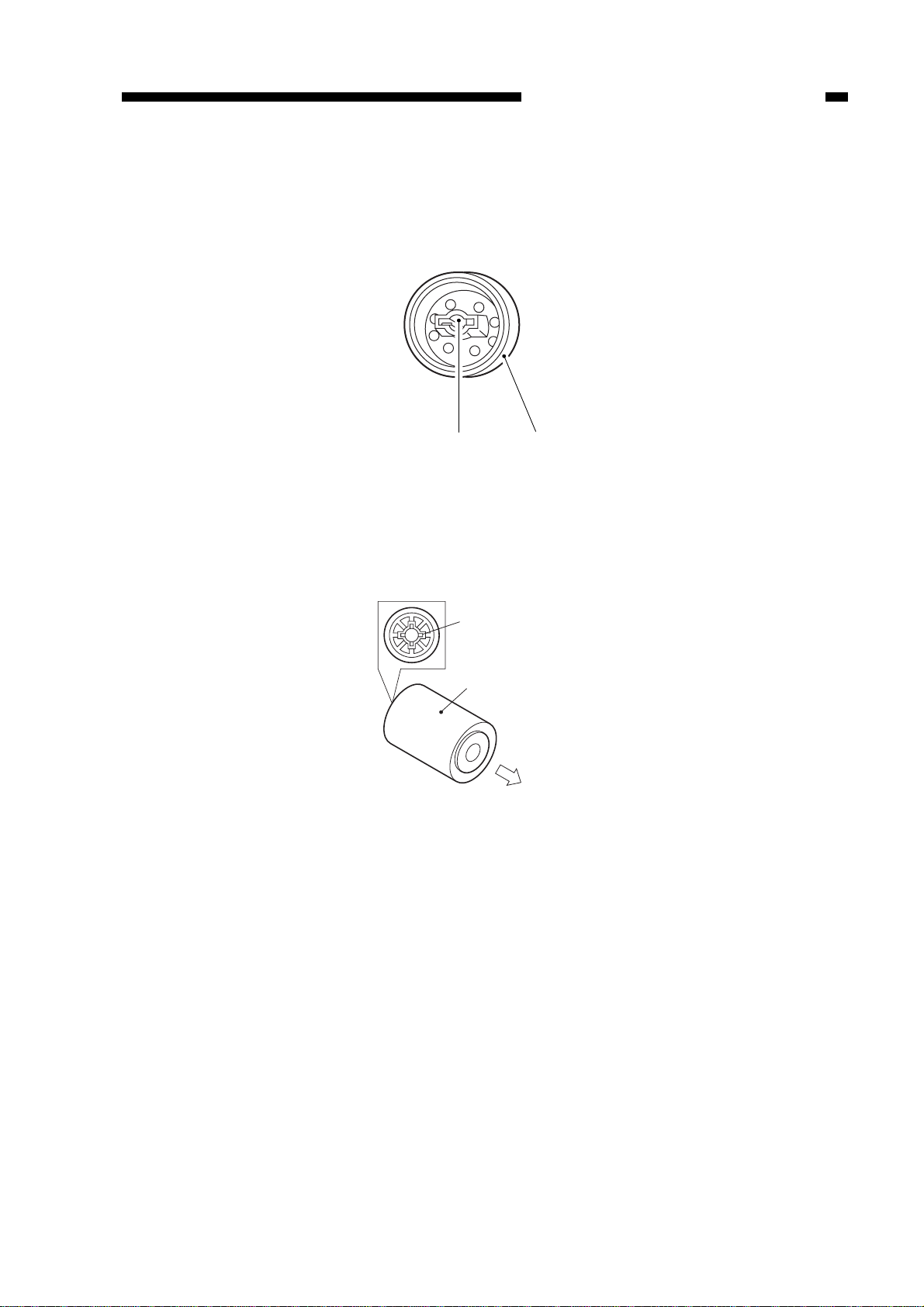

3. Positioning the Paper Guide Plate Cam (multifeeder)

Temporarily fix the screw with a hex nut of the spring clutch assembly in place; turn

the control ring. Make adjustments so that the hole in the cam and the hole in the

multifeeder drive unit match as indicated in Figure 2-33 when the claw of the control ring

is engaged with the solenoid; then, fix in place.

Figure 2-33

2-22

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Film end aligned.

Screw

Heater connector

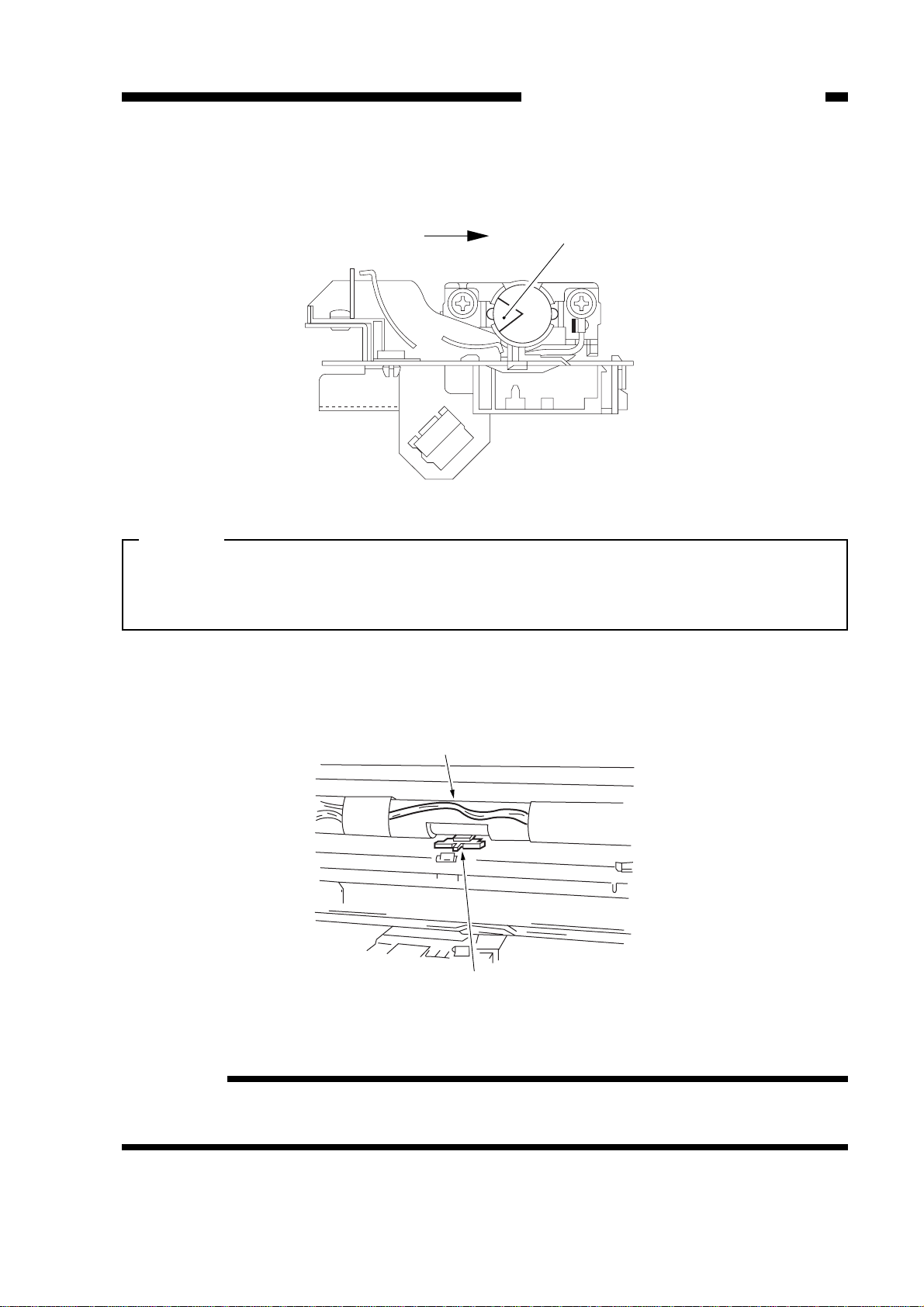

E. Fixing System

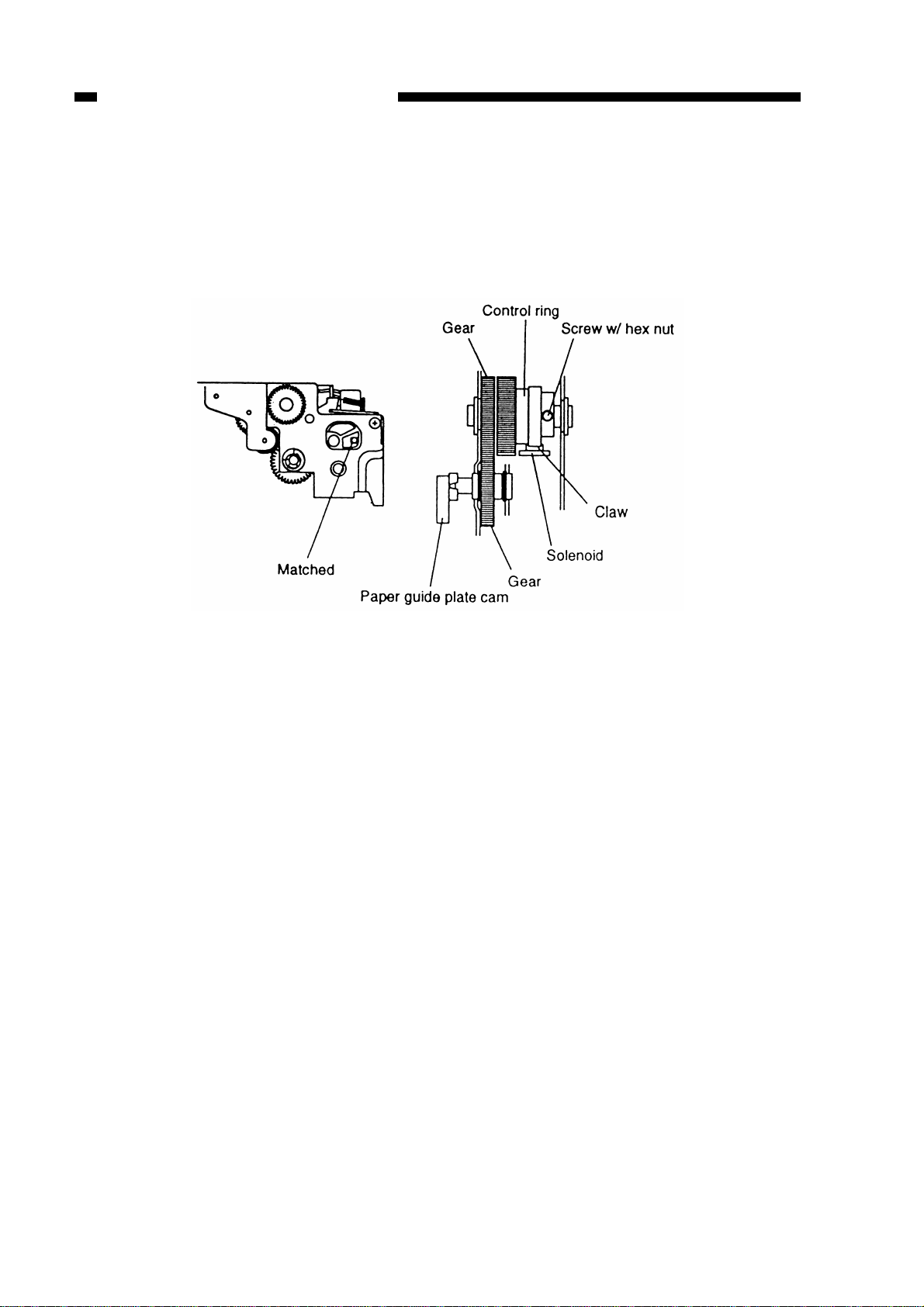

1. Points to Note When Attaching the Fixing Film

Orient it so that the cut-off is toward the rear.

Make sure that the end toward the front is along the middle groove.

Figure 2-34

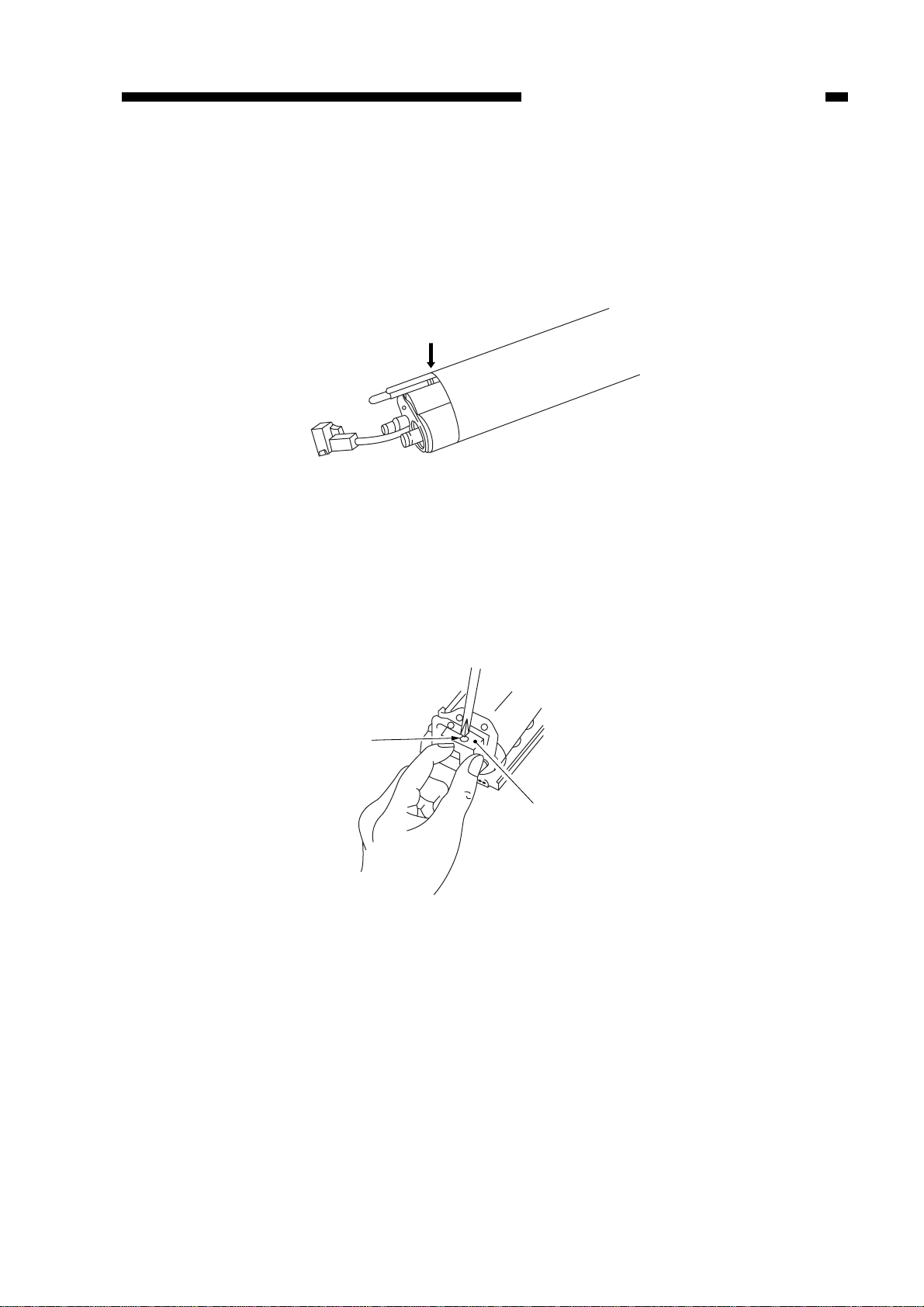

2. Points to Note When Attaching the Heater Connector

• When attaching the heater connector to the fixing heater, tak e care not to damage

the heater.

• When tightening the screw, hold the connector making sure that both its top and

bottom are free of pressure; do not tighten the screw excessively.

Figure 2-35

2-23

Loading...

Loading...