Canon NP6218 Service Manual

SERVICE

MANUAL

REVISION 0

FY8-13EX-000

MAY 1997

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

IMPORTANT

THIS DOCUMENTATION IS PUBLISHED BY CANON INC., JAPAN, TO SERVE AS A SOURCE OF

REFERENCE FOR WORK IN THE FIELD.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY SLIGHTLY FROM

ACTU AL MA CHINE VALUES OR THOSE FOUND IN AD VER TISING AND O THER PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED TO

THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

THIS DOCUMENTATION IS INTENDED FOR ALL SALES AREAS, AND MAY CONTAIN

INFORMATION NOT APPLICABLE TO CERTAIN AREAS.

COPYRIGHT © 1997 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly

supervised to avoid disclosure of

confidential information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPT. 1

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIV.

CANON INC.

5-1, Hakusan 7-chome, Toride-shi, Ibaraki 302 Japan

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

General Description

introduces the copier's features and specifications,

shows how to operate the copier, and explains how copies are made.

Chapter 2

Basic Operation

provides outlines of the copier's various mechanical

workings.

Chapter 3

Exposure System

discusses the principles of operation used for the

copier's lens drive unit and scanner drive unit.It also explains the timing

at which these drive units are operated, and shows how they may be

disassembled/assembled and adjusted.

Chapter 4

Image Formation System

discusses the principles of how images are

formed.It also explains the timing at which the various units involved in

image formation are operated, and shows how they may be

disassembled/assembled and adjusted.

Chapter 5

Pick-Up/Feeding System

explains the principles used from when copy

paper is picked up to when a copy is delivered in view of the functions of

electrical and mechanical units and in relation to their timing of operation.

It also shows how these units may be disassembled/assembled and

adjusted.

Chapter 6

Fixing System

explains the principles used to fuse toner images to

transfer media in view of the functions of electrical and mechanical units

and in relation to their timing of operation.It also shows how these units

may be disassembled/assembled and adjusted.

Chapter 7

Externals/Auxiliary Mechanisms

shows the copier's external parts, and

explains the principles used for the copier's various control mechanisms

in view of the functions of electrical and mechanical units and in relation

to their timing of operation.It also shows how these units may be

disassembled/assembled and adjusted.

Chapter 8

Installation

introduces requirements for the site of installation, and shows

how the copier may be installed using step-by-step instructions.

INTRODUCTION

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

i

This Service Manual contains the bsic facts and figures about the plain paper copier

NP6218, and is compiled to serve as a handy reference for servicing the machine in the

field.

The NP6218 is designed to enable fully automated copying work and may be

configured with the following accessories:

1. Cassette Feeding Module-B2*

2. Cassette Feeding Module-A2*

3. Control Card IV N

4. ADF-E1

5. Staple Sorter B2/D1

6. MS-B1

7. Remote Diagnostic Device II

This manual is limited to the descriptions of the NP6218, Cassette Feeding ModuleB2/Cassette Feeding Module-A2.

* May not be available in some areas but discussed in this manual.

This Service Manual covers the copier only, and consists of the following chapters:

Chapter 1

Chapter 9

Maintenance and Servicing

provides tables of periodically replaced parts

and consumables/durables and scheduled servicing charts.

Chapter 10

Troubleshooting

provides tables of maintenance/inspection,

standards/adjustments, and problem identification (image

fault/malfunction).

Appendix contains a general timing chart and general circuit diagrams.

In addition to the above chapters, this SERVICE MANUAL contains a set of

appendixes consisting of a general timing chart and general circuit diagrams.

A separate document entitled SERVICE HANDBOOK is also available for

troubleshooting problems in the copier.

The following rules apply throughout this volume:

1. Each chapter contains sections explaining the purpose of specific functions and the

relationship between electrical and mechanical systems with reference to the

timing of operation.

In the diagrams, represents the path of mechanical drive—where a

signal name accompanies the symbol , the arrow indicates the direction

of the electric signal.

The expression “turn on the power”means flipping on the pow er switch, closing the

front door, and closing the delivery unit door, which will result in supplying the

machine with power.

2. In the digital circuits, ‘1’is used to indicate that the voltage level of a given signal is

“High,” while ‘0’ is used to indicate “Low.” (The voltage value, however, differs from

circuit to circuit.)

In practically all cases, the internal mechanisms of a microprocessor cannot be

checked in the field.Therefore, the operations of the microprocessors used in the

machines are not discussed: they are explained in terms of from sensors to the

input of the DC controller PCB and from the output of the DC controller PCB to the

loads.

The contents of this manual may be updated from time to time to reflect improv ements

rendered to the copier; a Service Information bulletin will be issued as necessary to

cover major changes.

All service persons are expected to be thoroughly familiar with the information

contained in this manual, SERVICE HANDBOOK, and Service Information bulletins, for

quick response to the user’s needs.

ii

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

System Configuration

ADF-E1

Sends originals one by one from

a stack set on its tray

Stapler Sorter B2/D1, MS-B1

Automatically sorts or (page collation)

or groups up to 10 sets of copies;

with the sorting function,

the sorted copies may

automatically be stapled.

(Not applicable to MS-B1.)

Control Card IV N

Allows the user to control

copy volume.

Cassette Feeding Module-A2

Adds additional two cassettes.

Cassette Feeding Module-B2

Adds an additional cassette.

The NP6218 may be configured with the following systems options:

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

iii

1. GENERAL DESCRIPTION

iv

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV.0 MAR. 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

v

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES.........................................1-1

II. SPECIFICATIONS ..............................1-2

A. Copier............................................1-2

1. Type..........................................1-2

2. System .....................................1-2

3. Features ...................................1-3

4. Others.......................................1-4

B. Cassette Feeding Module-B2/

Cassette Feeding Module-A2 ........1-5

III. NAMES OF PARTS ............................1-6

A. Exterior View .................................1-6

B. Cross Section ................................1-7

1. Body .........................................1-7

2. Cassette Feeding Module-A2...1-8

IV. OPERATION.......................................1-9

A. Control Panel.................................1-9

B. Operation Mode.............................1-10

C. Making Two-Sided/Overlay

Copies (manual)............................1-11

D. User Mode.....................................1-12

1. Outline......................................1-12

2. Common Operations................1-13

3. Changing the Auto Clear

Time ( )..............................1-13

4. Changing the Auto Power-Off

Time ( )..............................1-13

5. Zoom Fine-Adjustment ( )..1-14

6. Tur ning On and Off the Auto

Cassette Change Mechanism

( ).......................................1-15

7. Tur ning On/Off the Auto Sor t/

Non-Sort (with ADF and sor ter

installed—option) ( ) ..........1-16

8. Cleaning the Feeder (with ADF

installed—option) ( ) ..........1-16

9. Selecting the Density

Adjustment Method for

Standard Mode ( ) .............1-17

10.Initializing User Mode ( )....1-17

11.Quick Guide to User Mode .......1-18

E. Handling the Toner Bottle ..............1-19

V. WARNINGS AND ACTIONS ..............1-19

VI. ROUTINE MAINTENANCE BY THE

USER..................................................1-19

VII. IMAGE FORMATION..........................1-20

A. Outline ...........................................1-20

CHAPTER 2 BASIC OPERATION

I. BASIC CONSTRUCTION ...................2-1

A. Functional Constr uction .................2-1

B. Outline of the Electr ical Circuitr y...2-2

C. Basic Sequence of Operations

(2 copies continuous, AE) .............2-3

D. Main Motor Control Circuit.............2-4

1. Outline......................................2-4

2. Mechanism...............................2-4

E. Inputs to the DC Controller PCB ...2-5

1. Inputs to the DC Controller

PCB (1/3)..................................2-5

2. Inputs to the DC Controller

PCB (2/3)..................................2-6

3. Inputs to the DC Controller

PCB (3/3)..................................2-7

F. Outputs from the DC Controller

PCB...............................................2-8

1. Outputs from the DC

Controller PCB (1/3).................2-8

2. Outputs from the DC

Controller PCB (2/3).................2-9

3. Outputs from the DC

Controller PCB (3/3).................2-10

G. Inputs to and Outputs from the

1-Cassette Unit Driver PCB...........2-11

1. Inputs to and Outputs from

the 1-Cassette Unit Driver

PCB (1/1)..................................2-11

H. Inputs to and Outputs from the

2-Cassette Unit Driver PCB...........2-12

1. Inputs to and Outputs from

the 2-Cassette Unit Driver

PCB (1/2)..................................2-12

2. Inputs to and Outputs from

the 2-Cassette Unit Driver

PCB (2/2)..................................2-13

CHAPTER 3 EXPOSURE SYSTEM

I. BASIC OPERATION...........................3-1

A. Varying the Reproduction Ratio ....3-1

II. LENS DRIVE SYSTEM ......................3-1

A. Outline ...........................................3-1

B. Lens Motor Dr ive Circuit ................3-3

1. Keeping the Lens Motor

Stationary .................................3-3

2. Driving the Lens Motor.............3-3

C. Basic Sequence of Operations

(lens drive system;non-Direct)......3-4

III. SCANNING DRIVE SYSTEM.............3-5

A. Dr iving the Scanner.......................3-5

1. Outline......................................3-5

2. Relationship between the

Scanner Sensor and Signals....3-6

3. Basic Sequence of

Operations (scanner)................3-6

4. Driving the Scanner Motor .......3-7

5. Scanner Operations in Page

Separation Mode (non-AE,

page separation, A4, 2 copies)..3-8

CHAPTER 4 IMAGE FORMATION SYSTEM

IV. DISASSEMBLY AND ASSEMBLY......3-9

A. Scanner Dr ive Assembly...............3-9

1. Detaching the Scanner Drive

Motor ........................................3-9

2. Detaching the Scanner Cable..3-10

3. Assembling the Mirror

Position Tool .............................3-12

4. Routing the Scanner Cable......3-13

5. Adjusting the Position of the

Mirrors (optical length of No.

1, 2, and 3 mirrors)...................3-16

6. Cleaning the Scanner No.6

Mirror........................................3-17

B. Lens Dr ive Assembly.....................3-18

1. Detaching the Lens Drive

Motor ........................................3-18

2. Routing the Lens Cable............3-20

3. Adjusting the Position of the

Change Solenoid ......................3-21

I. PROCESSES .....................................4-1

A. Outline ...........................................4-1

B. Basic Sequence of Operations

(image formation system) ..............4-3

C. Controlling the Scanning Lamp.....4-4

1. Outline......................................4-4

2. Tur ning On and Off the

Scanning Lamp ........................4-5

3. Pre-Heating Control

(scanning lamp) ........................4-5

4. Sequence of Operations

(scanning lamp pre-heating

control;AE, A4, continuous,

2 copies) ...................................4-5

5. Controlling the Intensity of the

Scanning Lamp (FL1)...............4-7

6. Controlling the Fluorescent

Lamp Heater.............................4-8

7. Fluorescent Lamp Automatic ...4-9

8. Fluorescent Lamp Protection

Mechanism...............................4-9

D. Controlling the Primary Charging

Roller Bias.....................................4-10

1. Outline......................................4-10

2. Tur ning On and Off the Pr imar y

Charging Roller Bias ................4-11

3. Controlling the Primary

Charging Roller Bias to a

Constant V oltage......................4-11

4. Switching the Primary Charging

Roller Bias Application Voltage

Level.........................................4-11

5. Application V oltage Level

(APVC) for the Primary

Charging Roller and Scanning

Lamp On Voltage Level

Automatic Correction ................4-12

E. Controlling the Transfer Roller Bias...4-13

1. Outline......................................4-13

2. Tur ning On and Off the

Transfer Roller Bias..................4-15

3. Controlling the Transfer Bias

to a Constant Voltage...............4-15

4. Controlling the Transfer Bias

Voltage Level Correction

(ATVC control)..........................4-15

5. Current Limiter Circuit

(transfer bias)...........................4-15

6. Current Limiter Circuit

(cleaning bias)..........................4-15

F. Controlling the Static Eliminator

Bias................................................4-16

vi

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

1. Outline......................................4-16

2. Switching the Static Eliminator

Bias V oltage Level....................4-17

3. Ensuring Proper Separation of

Thin Paper ................................4-17

G. Controlling Blank Exposure...........4-18

1. Outline......................................4-18

2. Blanking (Whiting) of Non-

Image Areas for Reduction.......4-19

3. Blanking (Whiting) Out the

Leading/Trailing Edges and

between Copies........................4-19

H. Controlling the Primary Corona

Roller Cleaning Mechanism ..........4-20

1. Outline......................................4-20

2. Primary Charging Roller

Cleaning Operation ..................4-20

I. Releasing the Transfer Roller........4-21

1. Outline......................................4-21

II. DEVELOPING ASSEMBLY AND

CLEANING ASSEMBLY .....................4-22

A. Outline ...........................................4-22

B. Controlling the Toner Level

Detection .......................................4-23

C. Controlling the Development

Bias................................................4-25

1. Outline......................................4-25

2. Tur ning On and Off the DC

Component of the Developing

Bias and Controlling the

Voltage to a Constant Level.....4-25

3. Tur ning On and Off the AC

Component of the

Development Bias....................4-26

4. Controlling the Voltage Level

of the DC Component of the

Development Bias....................4-26

D. Automatic Control of Copy

Density...........................................4-27

1. Outline......................................4-27

2. Control Method .........................4-27

3. AE Adjustment..........................4-29

III. DISASSEMBLY AND ASSEMBLY......4-30

A. Illumination Assembly....................4-30

1. Detaching the Scanning

Lamp/Fluorescent Lamp

Heater.......................................4-30

2. Points to Note When Attaching

the Fluorescent Lamp

Heater/Scanning Lamp.............4-32

3. Detaching the Blank Exposure

Assembly..................................4-34

4. Detaching the Blank Exposure

Lamp ........................................4-35

5. Detaching the Blank Shutter

Solenoid ...................................4-36

6. Positioning the Blank Shutter

Solenoid ...................................4-37

7. Routing the Blanking Cable......4-38

8. Positioning the Left/Right

Margin ......................................4-38

B. Dr um Unit ......................................4-39

1. Detaching the Drum Unit ..........4-39

2. Cleaning ...................................4-40

C. Primary Corona Assembly.............4-41

1. Detaching the Primary Corona

Assembly..................................4-41

2. Cleaning the Cleaning Pad and

the Primary Corona Roller .......4-42

3. Positioning the Solenoid for the

Primary Charging Roller...........4-43

D. Transfer Charging Assembly .........4-44

1. Detaching the Transfer Roller...4-44

2. Attaching the Drum Heater.......4-44

E. Developing System........................4-47

1. Removing the Developing

Assembly..................................4-47

2. Removing the Blade

Assembly..................................4-47

3. Removing the Developing

Cylinder Side Seal....................4-48

4. Installing the Side Seal and

the Blade Assembly..................4-51

CHAPTER 5 PICK-UP/FEEDING SYSTEM

I. PICK-UP/FEEDING SYSTEM............5-1

A. Outline ...........................................5-1

II. PICK-UP OPERATION (COPIER)......5-3

A. Outline ...........................................5-3

B. Sequence of Operations (pick-up/

feeding assembly;A4, 2 copies) ....5-4

III. PICK-UP FROM THE CASSETTE

FEEDING MODULE-A2......................5-5

A. Pick-Up Operation .........................5-5

B. Sequence of Operations

(cassette 2;A4, 2 copies)..............5-6

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

IV. MULTIFEEDER...................................5-7

A. Outline ...........................................5-7

B. Identifying the Size of Paper on

the Multifeeder...............................5-8

C. Sequence of Operations

(multifeeder;A4, 2 copies).............5-9

V. IDENTIFYING THE CASSETTE

SIZE....................................................5-10

VI. IDENTIFYING JAMS..........................5-12

A. Pre-Registration Delay Jam...........5-12

B. Pre-Registration Timing Jam.........5-13

vii

C. Pre-Registration Stationary Jam ...5-13

D. Separation Delay Jam...................5-14

E. Separation Stationar y Jam............5-14

F. Delivery Delay Jam........................5-15

G. Delivery Stationar y Jam ................5-15

VII. DISASSEMBLY AND ASSEMBLY......5-16

A. Pick-Up Assembly .........................5-16

1. Detaching the Pick-Up Roller

Unit...........................................5-16

2. Detaching the Pick-Up Roller...5-19

3. Points to Note When Attaching

the Pick-Up Roller ....................5-20

4. Detaching the Pick-Up Clutch ...5-20

5. Detaching the Separation Pad ..5-21

6. Adjusting the Left/Right

Registration ..............................5-22

B. Multifeeder Assembly ....................5-23

1. Detaching the Multifeeder

Assembly..................................5-23

2. Detaching the Multifeeder

Pick-Up Roller Unit...................5-24

3. Detaching the Multifeeder

Pick-Up Roller ..........................5-25

4. Points to Keep Note When

Attaching the Multifeeder

Pick-Up Roller ..........................5-26

5. Detaching the Separation Pad ..5-26

6. Detaching the Multifeeder

Drive Unit..................................5-27

7. Detaching the Multifeeder

Clutch .......................................5-28

8. Positioning the Multifeeder

Assembly (paper guide plate

cam) .........................................5-29

9. Adjusting the Left/Right

Registration ..............................5-30

10.Points to Note When Attaching

the Multifeeder Assembly Rack

Plate .........................................5-30

C. Registration Roller Assembly........5-31

1. Detaching the Registration

Clutch .......................................5-31

2. Detaching the Upper

Registration Roller ....................5-31

3. Detaching the Lower

Registration Roller ....................5-33

D. Feeding Assembly.........................5-34

1. Detaching the Feeding Belt ......5-34

E. Cassette Unit.................................5-36

1. Detaching the Copier from

the Cassette Unit......................5-36

2. Detaching/Attaching the

Pick-Up Roller ..........................5-36

3. Detaching the Pick-Up Clutch..5-36

CHAPTER 6 FIXING SYSTEM

I. BASIC OPERATIONS.........................6-1

A. Outline ...........................................6-1

B. Controlling the Fixing Heater

Temperature ..................................6-3

C. Controlling the Supply Power for

the Fixing Heater...........................6-5

D. Detecting Overheating at the End

of the Fixing Heater.......................6-6

E. Protection Mechanism...................6-6

1. Thermistor (TH1, TH2).............6-6

2. Thermal Fuse (FU1).................6-6

3. Heater ON Detection Circuit

(230V model only)....................6-6

F. Correcting Displacement of the

Fixing Film.....................................6-7

1. Outline......................................6-7

2. Controlling the Fixing Film

Motor ........................................6-10

II. DISASSEMBLY AND ASSEMBLY......6-11

A. Fixing Assembly ............................6-11

1. Construction1 ...........................6-11

2. Detaching the Upper Fixing

Unit...........................................6-12

3. Detaching the Fixing Film,

Tension Roller, Drive Roller,

Fixing Cleaning Brush, and

Fixing Heater Unit ....................6-13

4. Points to Note When Attaching

the Fixing Film .........................6-20

5. Points to Note When Attaching

the Heater Connector...............6-20

6. Points to Note When Replacing

the Fixing Upper Unit ...............6-21

7. Adjusting the Fixing Film Drive

Roller Pressure.........................6-21

8. Detaching the Lower Fixing

Unit...........................................6-23

9. Detaching the Separation

Claw/Lower Fixing Claw and

Fixing Cleaning Roller..............6-24

10.Adjusting the Lower Fixing

Roller Nip..................................6-25

B. Delivery Assembly.........................6-27

viii

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

ix

CHAPTER 7 EXTERNALS/AUXILIARY MECHANISMS

I. POWER SUPPLY ...............................7-1

A. Outline ...........................................7-1

B. Power Supply Circuit Assembly.....7-2

C. Detecting Errors in the Power

Supply PCB...................................7-4

1. Communication Error between

DC Controller PCB and

Composite Power Supply PCB ..7-4

2. Error in the High-Voltage

Output Data..............................7-4

3. Low-Voltage Output Data Error..7-4

4. Overcurrent in the Low-voltage

Power Supply ...........................7-4

D. Protection Mechanisms for the

Power Supply Circuit .....................7-5

II. DISASSEMBLY AND ASSEMBLY......7-6

A. Exter nal Covers.............................7-6

B. Control Panel.................................7-9

1. Detaching the Control Panel....7-9

C. Fans...............................................7-10

1. Detaching the Exhaust Fan ......7-10

D. Main Motor/Main Drive Assembly..7-11

1. Detaching the Main Motor Unit..7-11

2. Detaching the Main Drive

Assembly..................................7-11

3. Routing the Drive Belt..............7-13

E. Cassette unit .................................7-14

1. Detaching the Pick-Up Drive

Unit...........................................7-14

2. Detaching the Cassette Motor..7-15

3. Detaching the Cassette Driver

PCB..........................................7-16

F. DC Controller PCB........................7-17

1. Detaching the DC Controller

PCB..........................................7-17

2. Points to Note When

Replacing the DC Controller

PCB..........................................7-17

G. Composite Power Supply PCB......7-18

1. Detaching the Composite

Power Supply PCB...................7-18

2. Points to Note When Handling

the Composite Power Supply

PCB..........................................7-20

H. AE Sensor PCB .............................7-21

1. Points to Note When

Replacing the AE Sensor.........7-21

I. Intensity Sensor PCB....................7-21

1. Points to Note When Replacing

the Intensity Sensor .................7-21

I. SELECTING THE SITE......................8-1

II. UNPACKING AND INSTALLING

THE COPIER......................................8-2

A. Unpacking and Removing Fixings ..8-2

B. Turning On the Copier...................8-5

C. Checking the Images and

Operations.....................................8-8

D. Attaching the Drum Unit................8-9

E. Changing the Cassette Size..........8-10

III. RELOCATING THE COPIER..............8-13

IV. REPLACING THE DRUM UNIT..........8-14

V. INSTALLING THE CONTROL CARD

IV N.....................................................8-17

VI. CASSETTE HEATER KIT 5

INSTALLATION PROCEDURE...........8-19

A. Unpacking ......................................8-19

B. Installation (to a Cassette

Feeding Module-A2/B2).................8-20

VII. INSTALLING THE REMOTE

DIAGNOSTIC DEVICE II....................8-26

A. Unpacking ......................................8-26

B. Installation to the Copier ...............8-27

CHAPTER 8 INSTALLATION

CHAPTER 9 MAINTENANCE AND SERVICING

I. PERIODICALLY REPLACED

PARTS ................................................9-1

A. Periodically Replaced Parts...........9-1

II. DURABLES ........................................9-2

A. Copier............................................9-2

B. Cassette Feeding Module-B2/

Cassette Feeding Module-A2 ........9-3

III. PERIODICAL SERVICING.................9-4

IV. SERVICING CHART ...........................9-5

V. NOTES ON DRUM KIT ......................9-6

CHAPTER 10 TROUBLESHOOTING

I. MAINTENANCE AND INSPECTION..10-3

A. Image Adjustment Basic

Procedure....................................10-3

B. Periodical Servicing.....................10-4

II. STANDARDS AND ADJUSTMENTS..10-5

A. Image Adjustment .......................10-5

1. Adjusting the Image Leading

Edge Margin ([3], No.305;

registration ON timing)...........10-5

2. Adjusting the Leading Edge

Non-Image Width ([3], No.

306;blank shutter ON

timing).....................................10-6

3. Adjusting the Image Trailling

Edge Non-Image Width ([3],

No.309;blank shutter

timing).....................................10-7

4. Adjusting the Left/Right

Registration............................10-8

5. Adjusting the Left/Right Margin

(No.311;left/right margin).......10-9

6. Adjusting the Scanning Lamp

Intensity..................................10-10

7. AE Adjustment .......................10-11

B. Exposure System ........................10-15

1. Routing the Scanner Drive

Cable......................................10-15

2. Adjusting the Mirror Position

optical distance between No.1

mirror and No.2/No.3 mirror)..10-16

3. Adjusting the Scanner Cable

Tension...................................10-17

4. Assembling the Mirror

Positioning Tool ......................10-17

5. Points to Note When Attaching

the Fluorescent Lamp Heater/

Scanning Lamp......................10-18

6. Positioning the Change

Solenoid .................................10-20

C. Image Formation System............10-21

1. Positioning the Blank Shutter

Solenoid .................................10-21

2. Routing the Blank Shutter

Cable......................................10-22

3. Positioning the Solenoid for the

Primary Charging Roller .........10-22

4. After Replacing the Drum

Unit.........................................10-23

5. Attaching the Drum Heater ....10-23

D. Pick-Up/Feeding System .............10-25

1. Orientation of the Pick-Up

Roller......................................10-25

2. Orientation of the Multifeeder

Pick-up Roller.........................10-25

3. Positioning the paper Guide

Plate Cam (multifeeder).........10-26

E. Fixing System..............................10-27

1. Points to Note when Attaching

the Fixing Film ........................10-27

2. Points to Note when Attaching

the Heater Connector .............10-27

3. Adjusting the Fixing Film Drive

Roller Pressure ......................10-28

4. Points to Note after Replacing

the Fixing Upper Unit .............10-29

5. Adjusting the Nip....................10-30

6. Routing the Drive Belt............10-31

7. Storing the Fixing Heater

Registance .............................10-31

8. Setting the Fixing Heater

Temperature Control Value .....10-32

F. Electrical......................................10-35

1. After Replacing the PCB........10-35

2. Clearing the Back-Up RAM....10-35

3. Checking the

Photointerrupters ....................10-36

4. Adjusting the Multifeeder

Paper width Sensor ................10-43

5. Setting the Paper Size for the

Universal Cassette.................10-44

III. TROUBLESHOOTING IMAGE

FAULTS .............................................10-45

A. Initial Checks...............................10-45

1. Site Environment....................10-45

2. Checking the Originals...........10-45

3. Checking the Copyboard

Cover and the Copyboard

Glass......................................10-45

4. Checking the Paper................10-45

5. Others.....................................10-46

B. Samples of Image Faults.............10-48

C. Troubleshooting Faulty Images....10-49

1. The copy is too light

(half-tone only). ......................10-49

2. The copy is too light

(black solid also).....................10-50

3. The copy is too light

(overall, extremely).................10-50

4. The copy has uneven density

(front too dark)........................10-52

5. The copy has uneven density

(front too light)........................10-52

6. The copy is foggy (overall).....10-53

7. The copy is foggy (vertical). ...10-54

8. The copy has black lines

(vertical; thick fuzzy lines). .....10-54

9. The copy has black lines

(vertical, fine)..........................10-54

x

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

10.The copy has white spot

(vertical)..................................10-55

11.The copy has white lines

(vertical)..................................10-55

12.The copy has white spots

(horizontal). ............................10-56

13.The back of the copy is

soiled......................................10-57

14.The copy has a fixing fault.....10-58

15.The leading edge of the copy

is displaced. ...........................10-58

16.The leading edge of the copy

is displaced. ...........................10-58

17.The leading edge of the copy

is displaced. ...........................10-58

18.The copy has a blurred

image......................................10-59

19.The copy is foggy

(horizontal). ............................10-60

20.The copy has poor

sharpness. ..............................10-61

21.The copy is blank...................10-62

22.The copy is solid black...........10-62

IV. TROUBLESHOOTING

MALFUNCTIONS.............................10-63

A. Troubleshooting Malfunctions......10-63

1. E000.......................................10-63

2. E001.......................................10-64

3. E002, E003 ............................10-64

4. E004.......................................10-65

5. E007.......................................10-65

6. E010.......................................10-66

7. E030.......................................10-66

8. E064.......................................10-67

9. E202 (keys on control panel

invalidated).............................10-67

10.E210.......................................10-68

11.E220.......................................10-68

12.E240.......................................10-68

13.E261.......................................10-69

14.E710, E711, E712, E717 .......10-69

15.E803.......................................10-69

16.AC power supply is absent.....10-70

17.DC power supply is absent....10-71

18.The blank shutter fails to

move.......................................10-72

19.The photosensitive drum fails

to rotate..................................10-72

20.The pick-up operation fails

(from cassette). ......................10-73

21.The pick-up operation from

the multifeeder fails. ...............10-73

22.The scanner fails to move

forward/in reverse. ..................10-74

23.The registration roller fails to

rotate......................................10-74

24.The scanning lamp fails to

turn on....................................10-75

25.The lens fails to move............10-75

26.The fixing heater fails to

operate...................................10-76

27.The pre-exposure lamp fails

to turn on................................10-76

28.The add paper indicator fails

to turn off................................10-76

29 The jam message fails to turn

off. ..........................................10-77

V. TROUBLESHOOTING FEEDING

PROBLEMS.....................................10-78

A. Jams (copy paper).......................10-78

1. Pick-Up Assembly..................10-79

2. Separation/Feeding

Assembly ................................10-80

3. Fixing/Delivery Assembly.......10-80

B. Feeding Faults .............................10-81

1. Double feeding.......................10-81

2. Wrinkling.................................10-81

VI. ARRANGEMENT AND FUNCTIONS

OF THE ELECTRICAL PARTS.........10-82

A. Sensors .......................................10-82

B. Clutches, Solenoids, and

Switches......................................10-84

C. Motors, Heaters, and Lamps .......10-86

D. PCBs ...........................................10-88

E. Cassette Feeding Module-A2......10-90

F. Var iable Registors (VR) and

check Pins by PCB......................10-92

1. DC controller PCB ..................10-92

2. Composite power supply

PCB........................................10-93

VII. SERVICE MODE..............................10-94

A. Outline .........................................10-94

B. Using Ser vice Mode....................10-94

1. Activating Service Mode.........10-94

2. Selecting a Service Mode......10-95

3. Selecting Items.......................10-95

4. Using Adjustment Mode [3]

and Specification Mode [5].....10-95

5. Using Operation/Inspection

Mode [4].................................10-95

6. Clearing Stored Error.............10-95

7. Recording on the Service

Mode Label ............................10-96

C. Control Display Mode [1] .............10-97

D. I/O Mode [2] ................................10-99

E. Adjustment Mode [3] ...................10-102

F. Operation/Inspection Mode [4]....10-105

G. Specification Settings Mode [5]...10-107

H. Counter Mode [6] ........................10-108

VIII. SELF DIAGNOSIS............................10-109

A. Copier..........................................10-109

B. Self Diagnosis (ADF)...................10-113

C. Self Diagnosis (Sorter)................10-114

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

xi

APPENDIX

A. GENERAL TIMING CHART................A-1

B. SIGNALS AND ABBREVIATIONS......A-2

C. GENERAL CIRCUIT DIAGRAM.........A-3

not available

D . SPECIAL TOOLS................................A-5

E. SOLVENTS/OILS................................A-6

xii

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIMÉ AU JAPON)

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1

GENERAL DESCRIPTION

I. FEATURES.........................................1-1

II. SPECIFICATIONS ..............................1-2

A. Copier............................................1-2

B. Cassette Feeding Module-B2/

Cassette Feeding Module-A2 ........1-5

III. NAMES OF PARTS ............................1-6

A. Exter ior View .................................1-6

B. Cross Section ................................1-7

IV. OPERATION.......................................1-9

A. Control Panel.................................1-9

B. Operation Mode.............................1-10

C. Making Two-Sided/Overlay

Copies (manual)............................1-11

D. User Mode.....................................1-12

E. Handling the Toner Bottle..............1-19

V. WARNINGS AND ACTIONS...............1-19

VI. ROUTINE MAINTENANCE BY THE

USER..................................................1-19

VII. IMAGE FORMATION..........................1-20

A. Outline...........................................1-20

This chapter introduces features and specifications, and explains how the machines are operated

and copies are made.

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES

The copier becomes ready to make copies as soon as it is turned on. When fitted

with options, it provides a maximum of four paper sources.

1. Multiple front loading and multifeeder for space saving.

• The cassette may be slid out to the front for paper supply work.

• With the adjustable cassette and the multifeeder, various types of paper may be

used.

2. Office amenities and ecology.

• The copier is equipped with a heating mechanism, which makes the copier ready

for copying work at power-on without wait time.

• The copier is designed compact, enabling effective use of office space.

• The use of roller charging has proved to reduce the generation of ozone

significantly. (1/100 to 1/1000 compared to other Canon copiers)

• As the pick-up mechanism, center-reference is adopted in consideration of the use

of recycled paper.

• A significant number of parts are made of plastic in an effort to promote recycling.

• The copier is designed as a clamshell type to facilitate clearing of jammed paper.

3. Dependable high image quality.

• The new HQ (high-quality) toner ensures faithful reproduction of solid black, text,

and photos.

• In addition to Canon’s own single-component toner projection development

method, the use of auto image control (AIC) ensures stable reproduction of images.

4. Practical basic features.

• As many as 18 copies (A4, horizontal) may be made per minute.

• Copies may be as large as A3/Ledger or as small as A5/STMT, accommodating

postcards.

• The AE mechanism promises enhanced reproduction of newspapers or diazo

originals.

• Using page separation mode, a book may be copied with its left and right pages

processed separately.

• Copies may be made in zoom between 49% and 204%.

• The zoom fine-adjustment mechanism ensures better control for faithful

reproduction of originals.

• The auto power-off mechanism helps further saving of energy.

• The interrupt mechanism enables cutting in on a continuous copying session.

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-1

CHAPTER 1 GENERAL DESCRIPTION

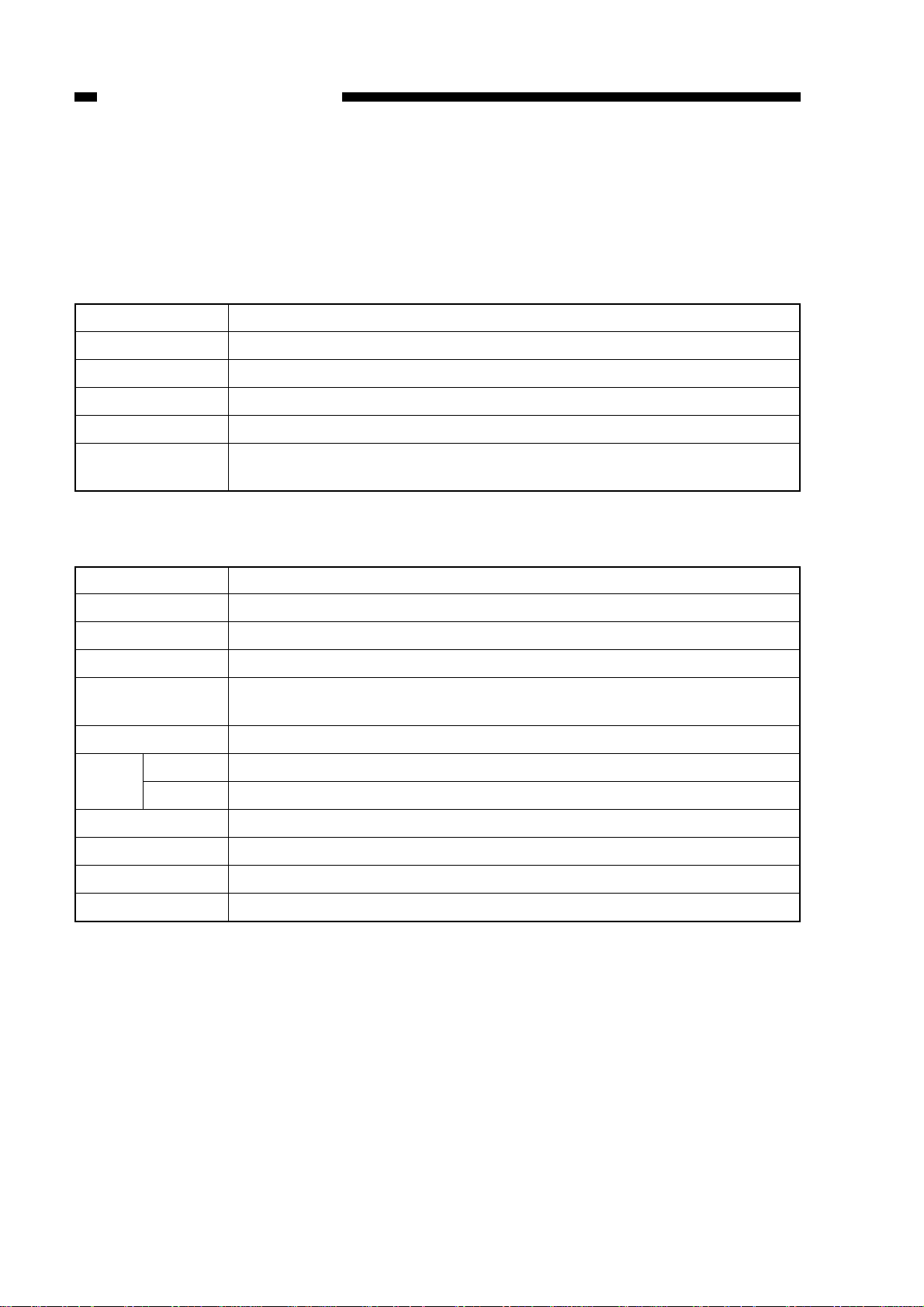

II. SPECIFICATIONS

A. Copier

1. Type

Item

Body

Copyboard

Light source

Lens

Photosensitive

medium

2. System

Item

Copying

Charging

Exposure

Copy density

adjustment

Development

Description

Desk top

Fixed

Fluorescent lamp

Zoom

OPC (ø30)

Description

Indirect electrophotographic

Roller (direct charging)

Slit (moving light source)

Automatic (AE) or manual

Dry (toner projection)

Pick-up

Transfer

Separation

Cleaning

Fixing

Auto

Manual

1 cassette

Multifeeder

Roller

Curvature + static eliminator

Cleaning blade

Fixing (by plane-shaped heater; 1100 W max.)

1-2

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

3. Features

Caution:

1. Use Canon-recommended paper.

2. Remove curling before feeding for a second time.

3. Fan out the transparencies before setting them on the multifeeder to prevent

adhesion.

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

1-3

Item

Original type

Maximum original

size

Reproduction ratio

Wait time

First copy

Continuous copying

Copying speed

Copy size

Cassette

Manual

Two-sided/ Manual

overlay

Cassette

Multifeeder

Copy tray

Non-image One-sided

width

Multi manual

Auto clear

Auto power-off

Option

Specification

Sheet, book, 3-D object (2 kg max.)

A3 (297

× 420 mm)/LDG (11" × 17")

Center reference

Direct, 2R2E (Table 1-201)

Zoom 49% to 204%

0 sec

8.2 sec or less (11.6 sec or less at power-on; A4, Direct, non-AE,

from cassette)

100 (max.; upper limit may be varied in service mode)

See Table 1-202.

Cassette: A3/11" × 17" to A5/STMT 3.94" × 5.88"

Manual: A3/11" × 17" to postcard (vertical)

Plain paper (64 to 80 g/m

2

), tracing paper (SM1), colored paper,

recycled paper (64 to 80 g/m

2

), ecology paper (80 g/m2)

Plain paper (64 to 80 g/m

2

), tracing paper (SM1, GNT80), colored

paper, recycled paper (64 to 80 g/m

2

), ecology paper (80 g/m2),

transparency, postcard, label sheet, thick paper (81 to 128 g/m

2

)

Plain paper (64 to 80 g/m

2

), colored paper, postcard, recycled paper

(64 to 880 g/m

2

), ecology paper (80 g/m2)

34 mm deep (approx.; about 250 sheets of 80 g/,m

2

paper),

clawless, front loading (center reference)

5 mm high (max.; about 50 sheets of 80 g/m

2

), clawless (center

reference)

100 sheets (approx.; A3 size, 80 g/m

2

)

2.0 ±1.0 mm (leading edge), 2.5 ±1.5 mm (left/right, trailing edge)

2.0 ±1.0 mm (leading edge), 3.5 ±1.5 mm (left/right, trailing edge)

Available (2 min standard; may be varied between 1 to 9 min in 1-

minute increments; may be disabled)

Available (5 min standard; may be varied in user mode to 2, 5, 10,

15, 30, 60, 120 min)

Cassette Feeding Module-B2, Cassette Feeding Module-A2, Control

Card IV N, Stapler Sorter B2/D1, MS-B1 ADF-E1

Copy paper

CHAPTER 1 GENERAL DESCRIPTION

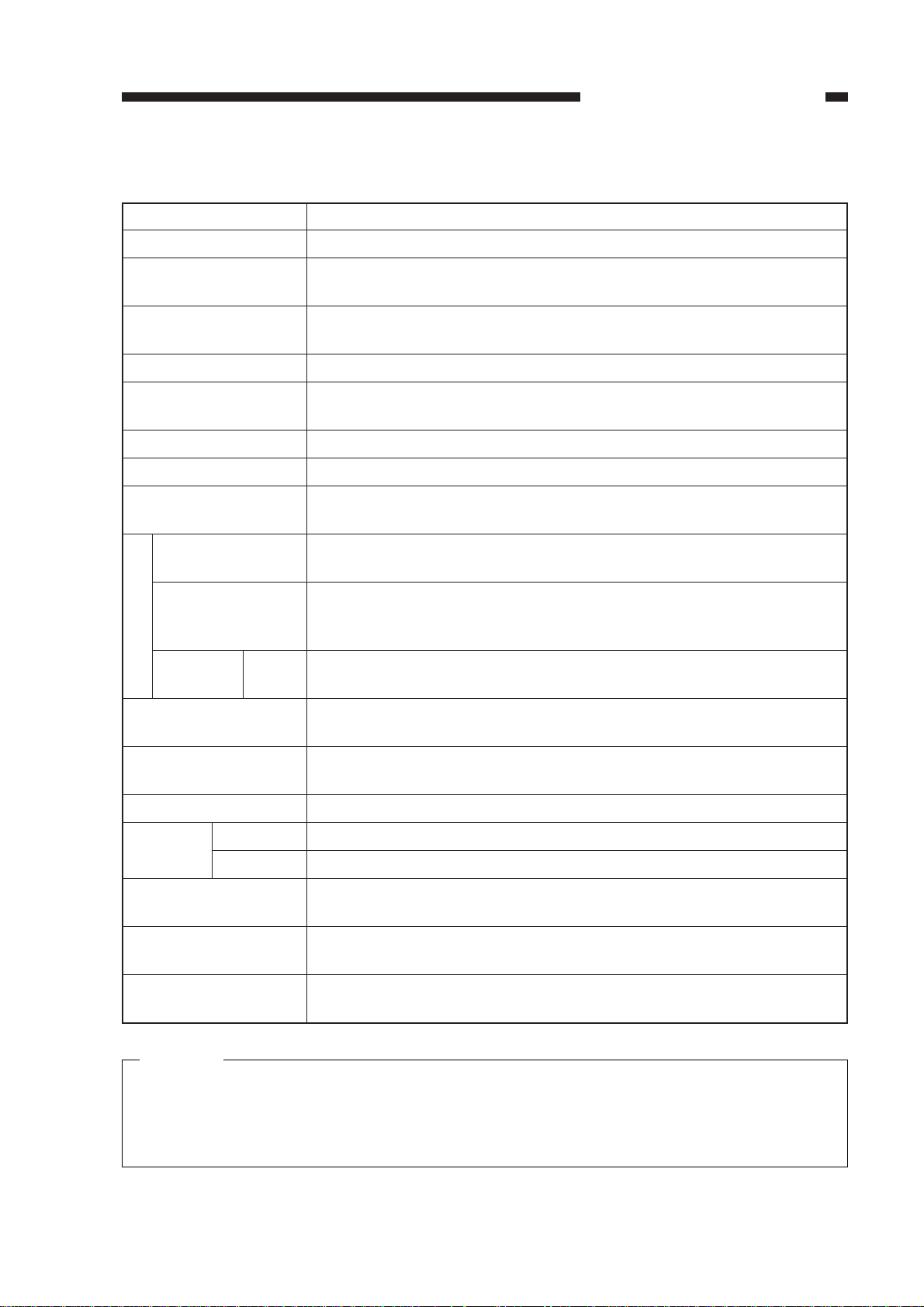

4. Others

Item

Operating environment

Temperature

Humidity

Atmospheric

pressure

Power supply

230 V (50Hz)

Power consumption Maximum

Standby

Continuous

Noise Copying

Standby

Ozone (average over 8 hr)

Dimensions Width

Depth

Height

Weight

Specifications

7.5°C to 32.5°C/45.5°F to 90.5°F

5% RH to 85% RH

810.6 hPa to 1013.3 hPa (0.8 to 1 atm)

Serial numbers

UCDXXXXX

1.5 kW or less

97.2 kJ per hr (27 wh average; reference only)

2088 kJ (580 wh average; reference only)

49.7 dB or less (1 m front) Sound power level by

—

ISO method

0.01 ppm or less (average); 0.02 ppm or less (max.)

585 mm/23.0 in

622 mm/24.5 in

345 mm/13.6 in

48 kg (approx.)

Consumables Copy paper

Cartridge

Reproduction ratio DIRECT

REDUCE I

REDUCE II

ENLARGE I

ENLARGE II

ZOOM

Table 1-201 Standard Reproduction Ratios

Keep wrapped to protect against humidity.

Avoid direct rays of the sun; keep at 40°C/104°F,

85% RH.

1: 1 (±0.5%)

1: 0.500

1: 0.707

1: 1.414

1: 2.000

49% to 204% (1% increments)

1-4

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

Reproduction ratio

DIRECT 1: 1 (±0.5%)

REDUCE 1: 0.500 (+1.0%)

1: 0.707 (+1.0%)

ENLARGE 1: 2.000 (+1.0%)

1: 1.414 (+1.0%)

Table 1-202 Copying Speed

Specifications subject to change without notice.

Copy size

A3 (297 × 420)

A4 (210 × 297)

A5 (148 × 210)

A4R (297 × 210)

A5R (210 × 148)

A3 → A5R

A3 → A4R

A4 → A5

A5R → A3

A4R → A3

A5 → A4

Copies/min

10

18

21

14

18

20

12

12

11

10

19

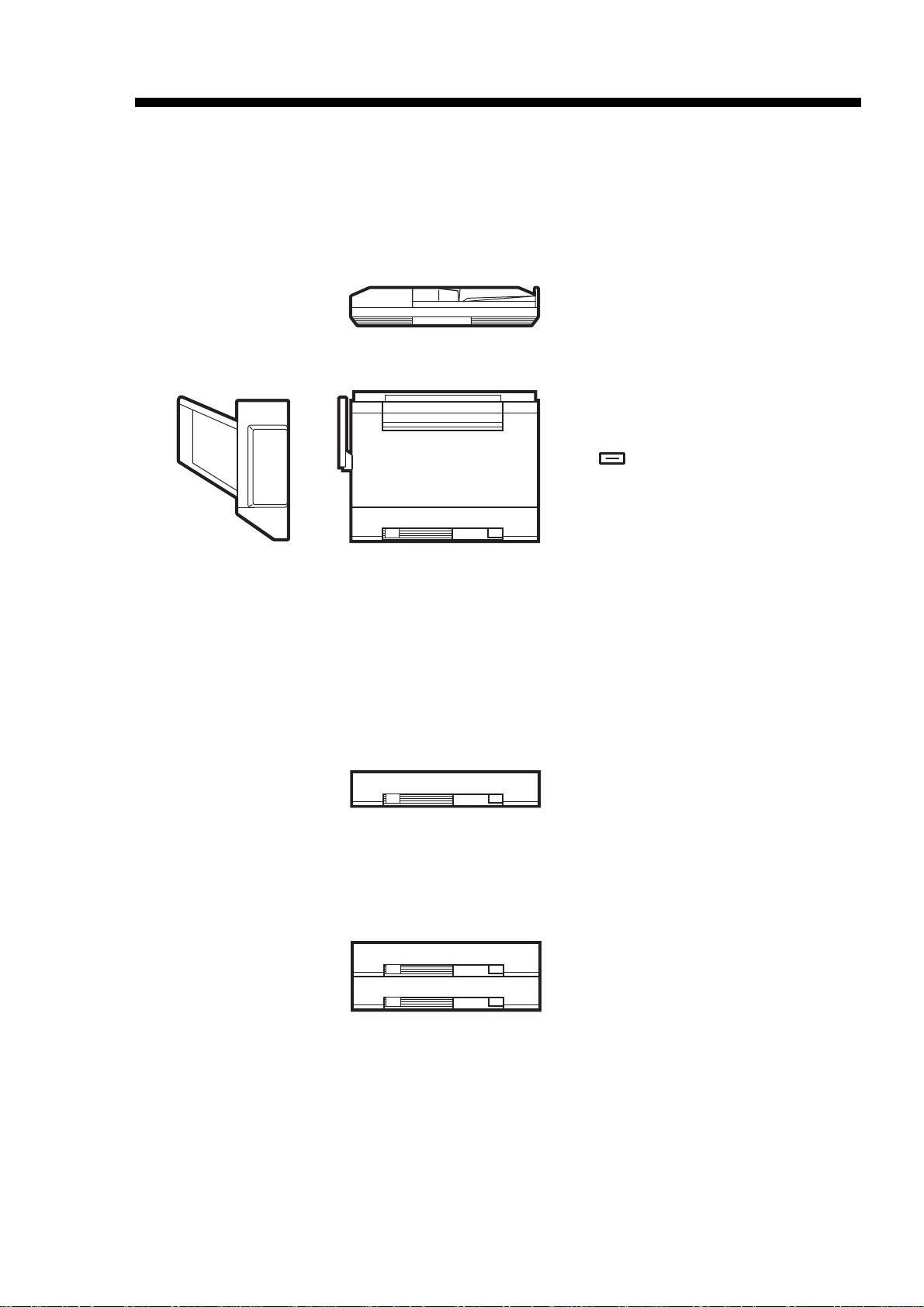

B. Cassette Feeding Module-B2/Cassette Feeding Module-A2

Copy paper

Cassette

Power supply

Dimensions

Weight

As per copier.

As per copier.

34 V DC, 24V, 5V (from copier)

Cassette Feeding Module-B2:585W × 622D × 105H (mm) /23.0in x 24.5in x 8.3in

Cassette Feeding Module-A2:585W × 622D × 210H (mm) /23.0in x 24.5in x 4.1in

Cassette Feeding Module-B2: 9kg

Cassette Feeding Module-A2:16kg

Table 1-203

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-5

CHAPTER 1 GENERAL DESCRIPTION

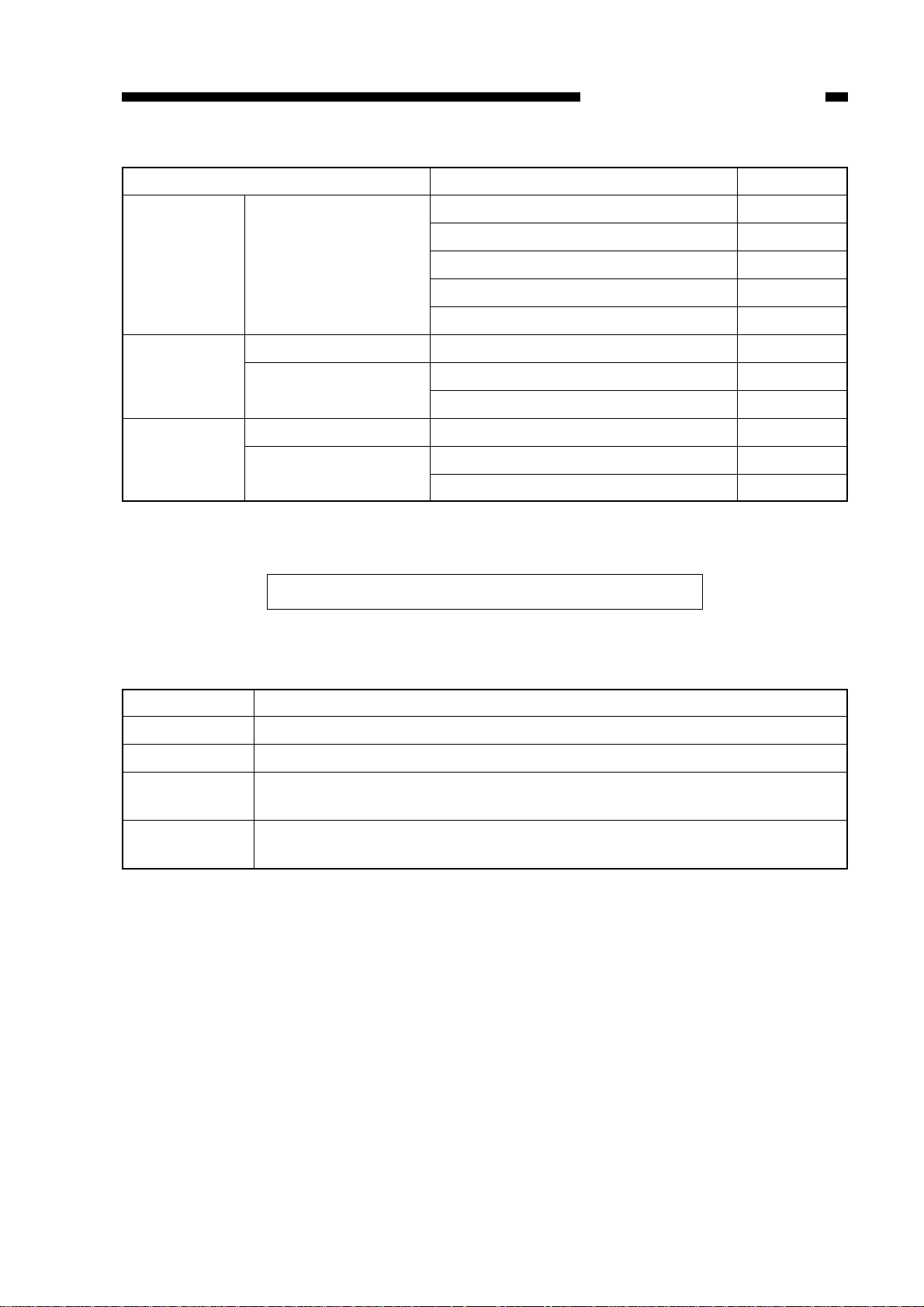

q Copyboard cover

w Power switch

e Clip tray

r Multifeeder

t Cassette

y Front door

u Control panel

i Copyboard glass

q Open/close lever

w Copy density correction knob

e Static eliminator cleaner

r Heater switch

t Copy tray

y Static eliminator

III. NAMES OF PARTS

A. Exterior View

Figure 1-301

1-6

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

Figure 1-302

B. Cross Section

1. Body

CHAPTER 1 GENERAL DESCRIPTION

q No. 3 mirror

w No. 2 mirror

e No. 1 mirror

r Scanning lamp

t Copyboard glass

y Copyboard cover

u Lens

i Exhaust fan

o Pre-exposure lamp

!0 Primar y charging roller

!1 Reflecting plate

!2 No. 6 mirror

!3 Developing cylinder

!4 Developing assembly

!5 No. 5 mirror

!6 No. 4 mirror

!7 Multifeeder tray

!8

Multifeeder pick-up roller

!9 Cassette pick-up roller

@0 Registration roller

@1 Transfer roller

@2

Separation static eliminator

@3 Photosensitive drum

@4 Feeding assembly

@5 Cassette

@6 Fixing film

@7 Film tension roller

@8 Film pressure roller

@9 Film drive roller

#0 Delivery roller

Figure 1-303

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-7

CHAPTER 1 GENERAL DESCRIPTION

6

4

2

1

3 5

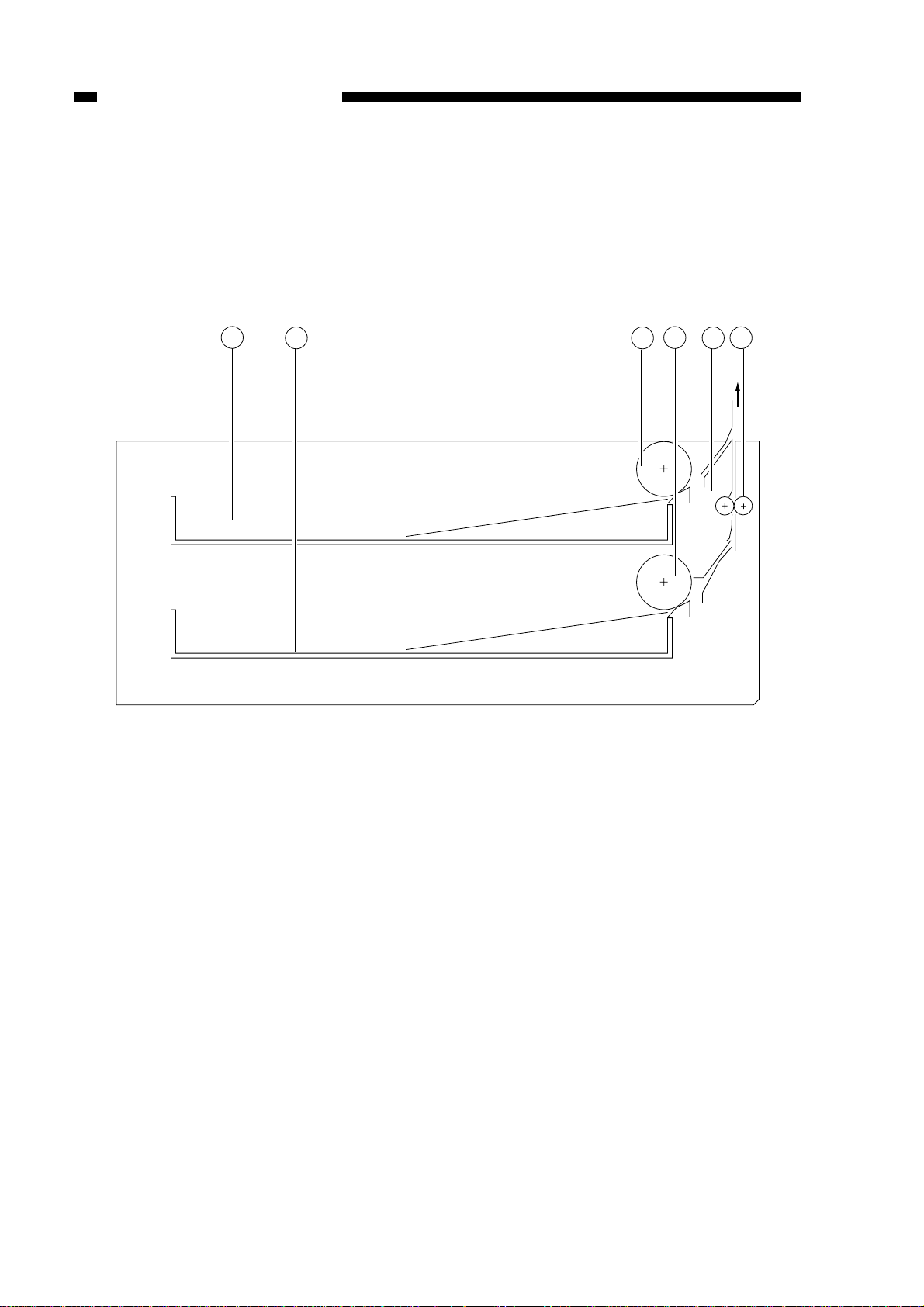

2. Cassette Feeding Module-A2

q Cassette 2

w Cassette 3

e Cassette 2 pick-up roller

1-8

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

r Cassette 3 pick-up roller

t Drive roller

y Feeding roller

Figure 1-304

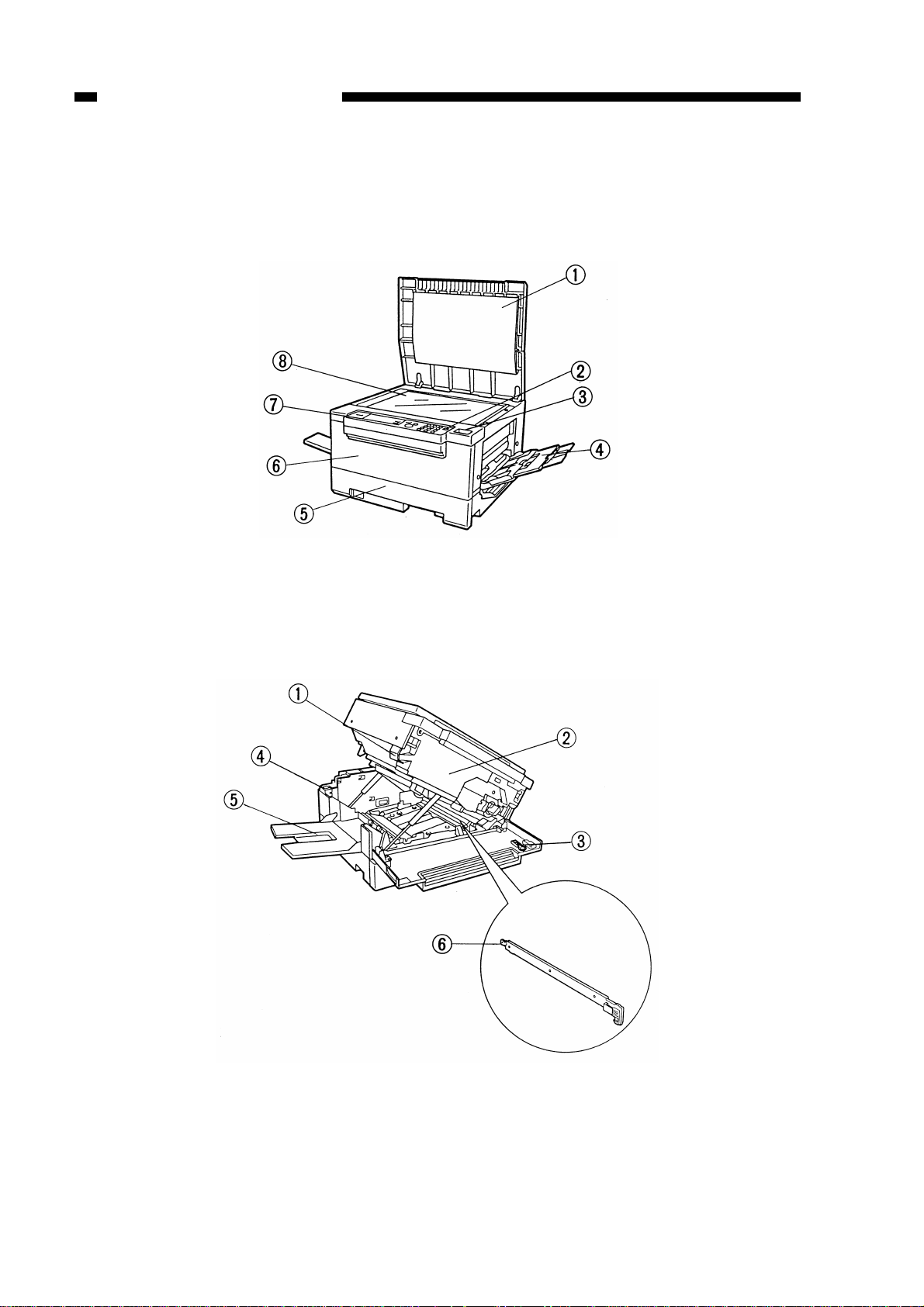

IV. OPERATION

1 2 3

4 5 6

7 8 9

C 0

Max 200%

A4

1:1

Min 50%

A3 A5 A4

A3 A4 A4 A5

A

1:1

123

Autom. Paper

A3

A4

A4

R

A5

A5

R

A4

R

%

Autom. Zoom

Zoom

+–

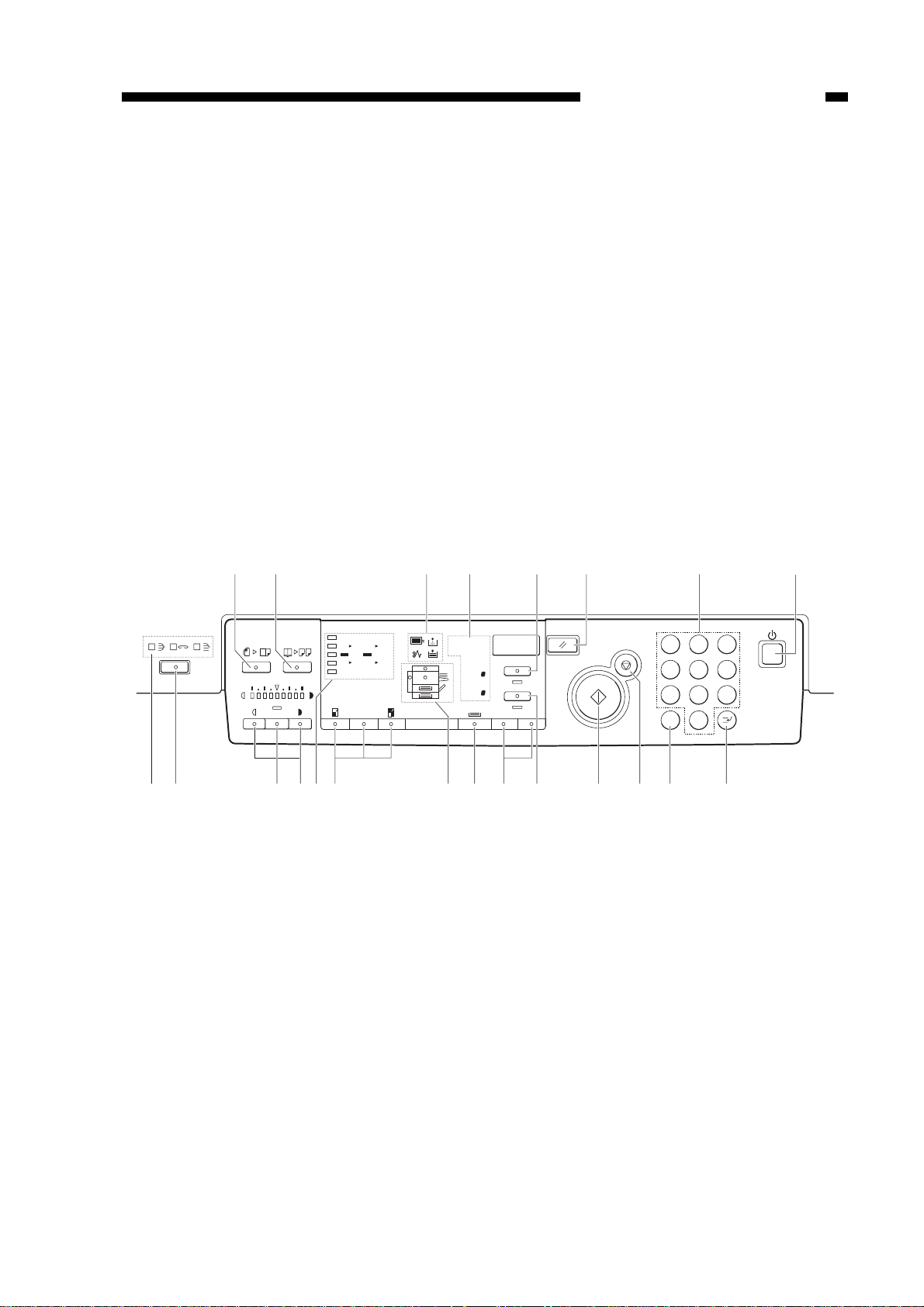

qw er t y u i

o!1!2

!0@1@2 !3!4!5!6!7!8!9@0

q Image Compose key

w Page Separate key

e Warning indicator

r Display

t % key

y Reset key

u Keypad

i Power switch

o Interrupt key

!0 Clear key

!1 Stop key

!2 Star t key

!3 Auto Ratio key

!4 Zoom key

!5 Paper Select key

!6 Cassette/Jam indicator

!7 Direct key

!8 Reduce/Enlarge key

!9 Copy density key

@0 AE key

@1 Sor ter key

@2 Sor ter indicator

A. Control Panel

CHAPTER 1 GENERAL DESCRIPTION

Figure 1-401

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-9

CHAPTER 1 GENERAL DESCRIPTION

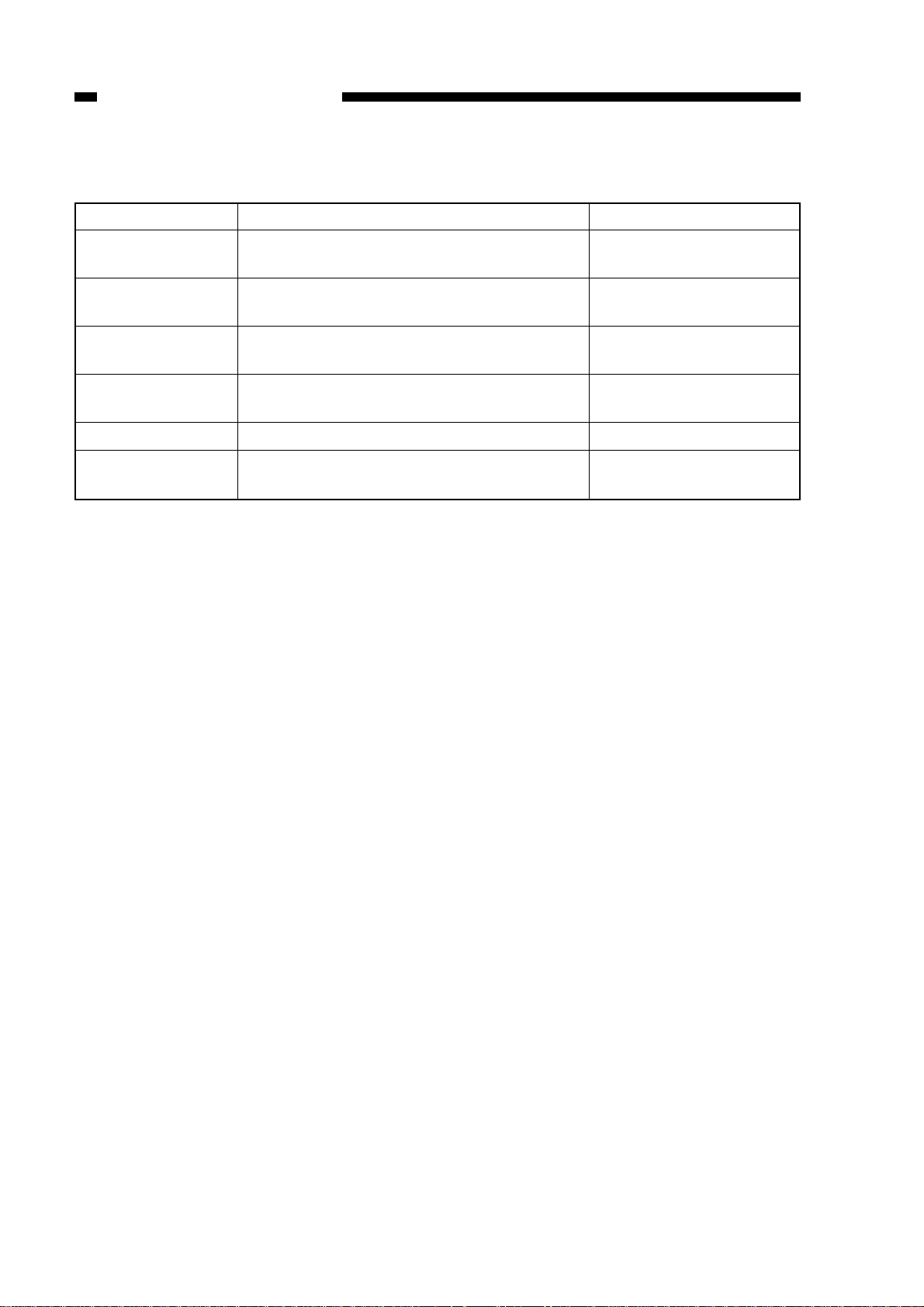

B. Operation Mode

Mode

Image Composition

mode

Page Separation

mode

Interrupt mode

Auto Ratio mode

AE mode

Sort/staple

sort/group mode

Description

Press to set/reset image composition mode.

Press to set/reset page separation mode.

Press to interrupt an ongoing copying

session.

Press it to set/reset auto ratio mode.

Press to set/re-set AE mode or user mode.

Press it to select/reset sort, staple sor t, or

group mode.

Table 1-401

Remarks

Only when an ADF

(accessory) is installed.

Only when an ADF

(accessory) is installed.

Only when an sorter

(accessory) is installed.

1-10

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

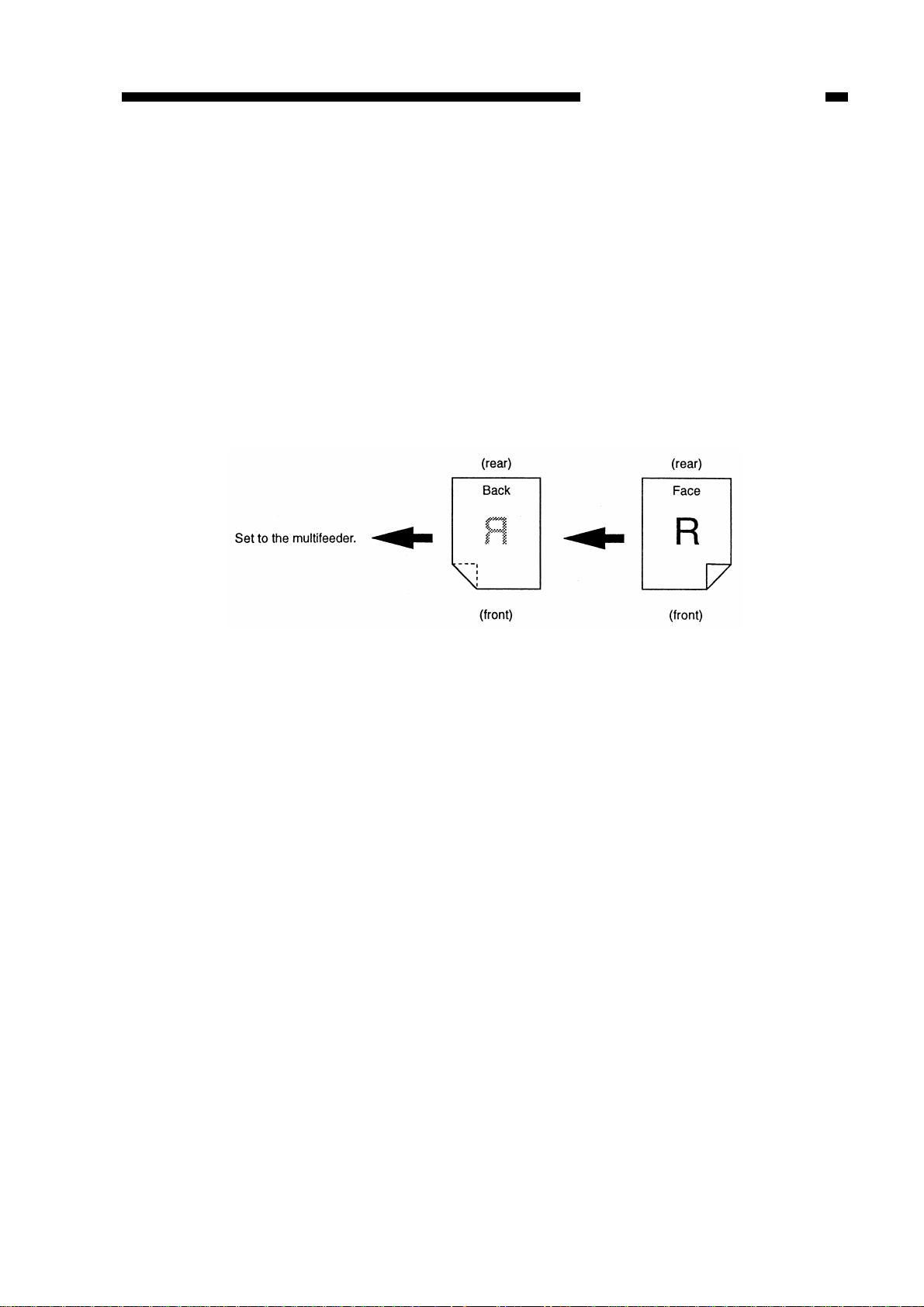

C. Making Two-Sided/Overlay Copies (manual)

You can make two-sided or overlay copies by manually feeding paper. You must,

however, keep the following in mind when making such copies:

q Be sure to orient the paper the same way for both sides when turning it over.

w Make sure that the paper has not absorbed moisture.

e Make sure that the paper has no curling.

r After copying on the first side, sufficiently cool the paper; then, correct any curling

before feeding it for a second time.

t Use paper of 60 to 128 g/m

y Correct any curling on postcards or thick paper (128 g/m

second side.

2

.

2

) before copying on the

Figure 1-405

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-11

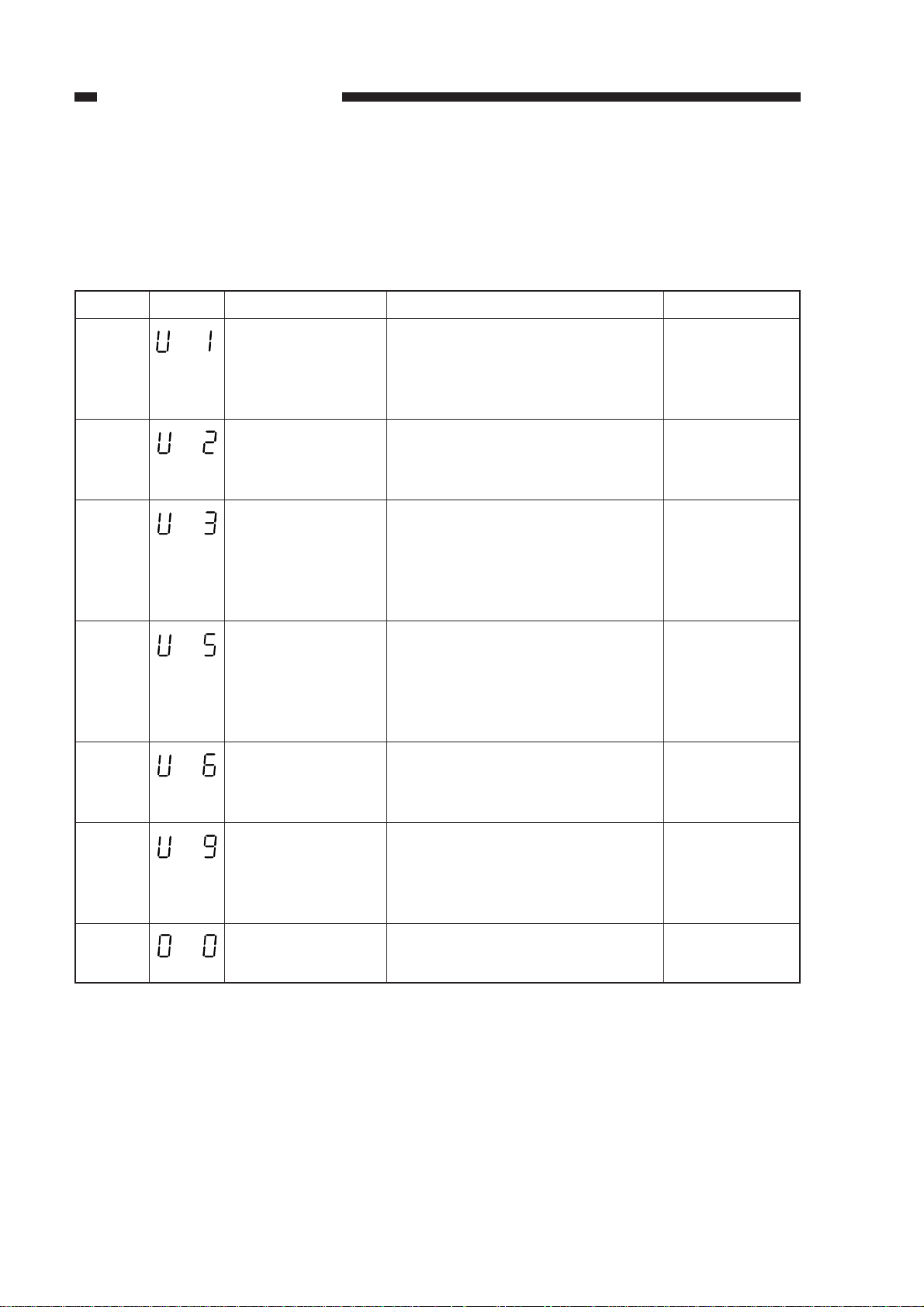

D. User Mode

1. Outline

The copier provides user mode, which allows the user to change various settings or

to make various adjustments on his/her own; see Table 1-402.

Table 1-402

Display

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

Menu No.

1

2

3

5

6

9

0

1-12

Function

Changing the auto

clear time

Changing the auto

power-off time

Fine adjusting

(zoom)

Tur ning on/off

auto sort/non-sor t

(with ADF* and

sorter* installed)

*Accessory

Cleaning the feeder

(with ADF* installed)

Option

Selecting a density adjustment

method for

standard mode

Initializing user

mode

Description

You may set the auto clear time

between 1 and 9 min in 1-min

increments. Setting it to ‘0’

disables the function.

You can set the auto power-off

time to either 2, 5, 10, 15, 30, 60,

or 120 min.

You can correct a slight discrepancy between original and copy

sizes (direct); enlarge in X direction and reduce in Y direction

independent of each other.

You may specify whether to

evecute auto sort/non-sort.

Use it to clean the pick-up

assembly of the ADF.

You can specify either AE or

manual for density adjustment for

standard mode.

You can return settings changed

in user mode to initial settings.

Default settings

2 min

5 min

± 0%

On

AE

CHAPTER 1 GENERAL DESCRIPTION

2. Common Operations

a. Keys to Use in User Mode

• Clear Key

Use it to return to the previous step; or, use it to clear a setting entered by mistake

when making mode settings.

• Start Key

Use it to accept a selected item when making user mode settings.

• AE Key

Use it to return to copy mode when making user mode settings.

b. Operation

1) Hold down the AE key for about 4 sec or more.

• This will turn on the display, indicating “ ”.

2) Enter the menu number of each function using the keypad.

3) Press the Start key.

• The current setting of the respective function appears.

4) Enter a new setting using the appropriate key.

5) Press the start key.

• The copy count/ratio indictor turns on to indicate the user mode being changed.

• The setting of the respective user mode is changed.

6) Press the AE key.

• The copier returns to standby state.

3. Changing the Auto Clear Time ( )

1) Hold down the AE key for 4 sec or more.

• “ ” appears on the display.

2) Press the Start key.

• The display indicates the current setting (if initial, indicates ‘1-2’).

3) Enter a desired setting using the keypad.

• The display indicates the new setting (if 5 min, indicates ‘1-5’).

4) Press the Start key. “ ”

5) Press the AE key.

• The copier returns to standby state.

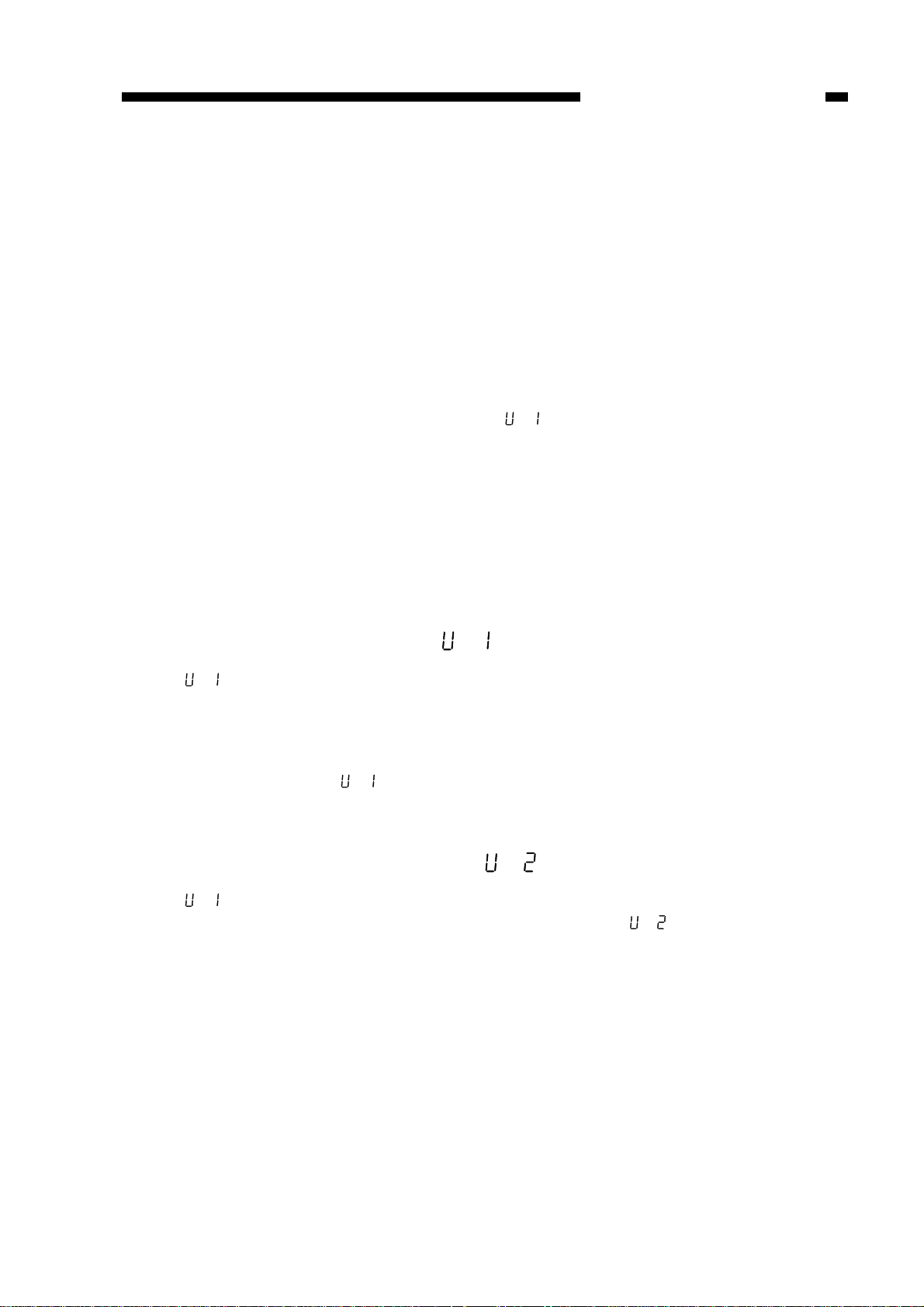

4. Changing the Auto Power-Off Time ( )

1) Hold down the AE key for 4 sec or more.

• “ ” appears on the display.

2) Enter ‘2’ using the keypad so that the display indicates “ ”.

3) Press the Start key.

• The display indicates the current setting (if initial, indicates ‘2-2’).

4) Enter a desired setting using the keypad.

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-13

CHAPTER 1 GENERAL DESCRIPTION

Auto power-off time (min)

2

5

10

15

30

60

120

Settings

2-1

2-2

2-3

2-4

2-5

2-6

2-7

Table 1-403

• The display indicates the new setting (if 10 min, indicates ‘2-3’).

5) Press the Start key.

• The auto power-off time is changed, and the display returns to “ ”.

6) Press the AE key.

• The copier returns to standby state.

Reference:

If you want to disab le the auto po w er-off function, use service mode (See p . 10-109.).

5. Zoom Fine-Adjustment ( )

1) Hold down the AE key for 4 sec or more.

• The display indicates “ ”.

2) Enter ‘3’ using the keypad so that the display indicates “ ”.

3) Press the Start key.

• The display indicates ‘3-1’ suggesting the direction of adjustment.

Direction of adjustment

X direction (horizontal)

Y direction (vertical)

Display

3-1

3-2

Table 1-404

Further, the copy density indicator shows the current setting. (See Figure 1-406.)

4) Press the copy density key to adjust the reproduction ratio in X direction. (See Figure

1-406.)

5) Press the Start key.

• The reproduction ratio in X direction is fine-adjusted, and the display indicates ‘3-

2’.

Further, the copy density indicator shows the current setting. (See Figure 1-406.)

6) Press the Density key to adjust the reproduction ratio in Y direction. (See Figure 1-

406.)

1-14

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

7) Press the Start key.

• The zoom reproduction is fine-adjusted, and the display returns to “ ”.

8) Press the AE key.

• The copier returns to standby state.

The fine-adjustment reproduction ratios as shown in the copy density display are as

follows:

■ Zoom Fine-Adjustment (Reduce) ■ Zoom Fine-Adjustment (Enlarge)

Press the Lighter key. Press the Darker key.

Figure 1-402

6. Turning On and Off the Auto Cassette Change Mechanism ( )

1) Hold down the AE key for 4 sec or more.

• The display indicates “ ”.

2) Enter

r using the keypad so that the display indicates “ ”.

3) Press the Start key.

• The display indicates the current setting (if initial setting, ‘4-1’).

Table 1-405

COPYRIGHT © 1997 CANON INC. CANON NP6218 REV. 0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

1-15

Initial setting

(±0%)

-0.2%

-0.4%

-0.6%

-0.8%

-1.0%

Initial setting

(±0%)

+0.2%

+0.4%

+0.6%

+0.8%

+1.0%

State of auto cassette change function

On

Off

Settings

4-1

4-0

Loading...

Loading...