NP6020

SERVICE

MANUAL

(for'2201240V)

REVISION 0

I

COPYFtIGHT 1993 CANON INC.

CANON NP6020 REV.0 MAY 1993 PRINTED IN JAPAN

MAY 1993

Canon

FY8-13CT-000

Download Free Service Manual and Resetter Printer at http://printer1.blogspot.com

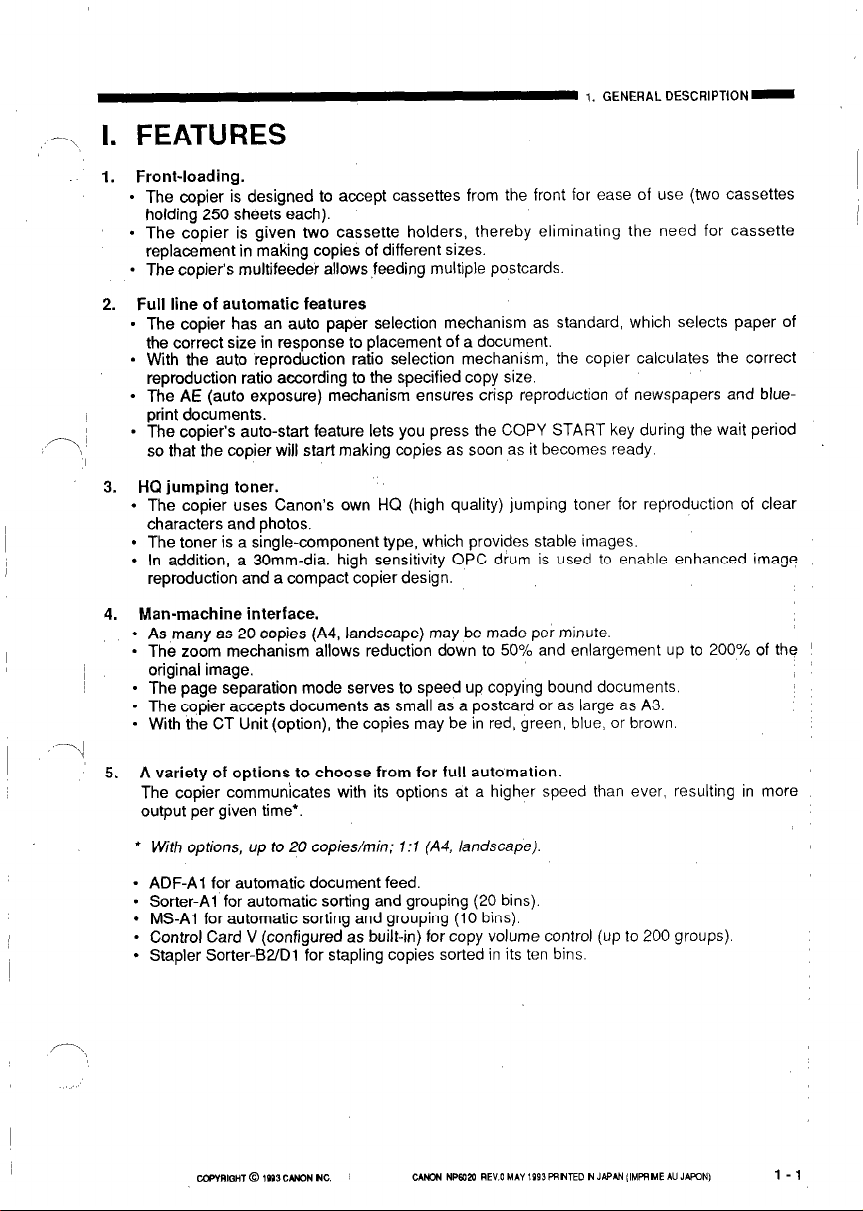

---\/ I. FEATURES

Front-loading.

1.

- The copier is designed to accept cassettes from the front for ease of use (two cassettes

holding 250 sheets each).

l The copier is given two cassette holders, thereby eliminating the need for cassette

replacement in making copies of different sizes.

* The copier’s multifeeder allows Jeeding multiple postcards.

2. Full line of automatic features

- The copier has an auto paper selection mechanism as standard, which selects paper of

the correct size in response to placement of a document.

- With the auto reproduction ratio selection mechanism, the copier calculates the correct

reproduction ratio according to the specified copy size.

* The AE (auto exposure) mechanism ensures crisp reproduction of newspapers and blue-

print documents.

I\

-’ I

- The copier’s auto-start feature lets you press the COPY START key during the wait period

:

so that the copier will start making copies as soon as it becomes ready.

HQ jumping toner.

3.

- The copier uses Canon’s own HQ (high quality) jumping toner for reproduction of clear

characters and photos.

l The toner is a single-component type, which provides stable images.

l In addition, a 30mm-dia. high sensitivity OPC drum is used to enable enhanced image

reproduction and a compact copier design.

4. Man-machine interface.

l As many as 20 copies (A4, landscape) may be made per minute.

- The zoom mechanism allows reduction down to 50% and enlarqement up to 200% of the

original image.

- The page separation mode serves to speed up copying bound documents.

- The copier accepts documents as small as a postcard or as large as A3.

* With the CT Unit (option), the copies may be in red, green, blue, or brown

‘1

A variety of options to choose from for full automation.

5.

The copier commun/cates with its options at a higher speed than ever, resulting in more

output per given time’.

1. GENERAL DESCRIPTION -

* With options, up to 20 copies/min; 1:1 (A4, landscape).

* ADF-Al for automatic document feed.

- Sorter-Al for automatic sorting and grouping (20 bins)

l MS-Al for automatic sorting aid grouping (70 bins).

* Control Card V (configured as built-in) for copy volume control (up to 200 groups).

l Stapler Sorter-BNIl for stapling copies sorted in its ten bins.

- 1. GENERAL DESCRlPTlON

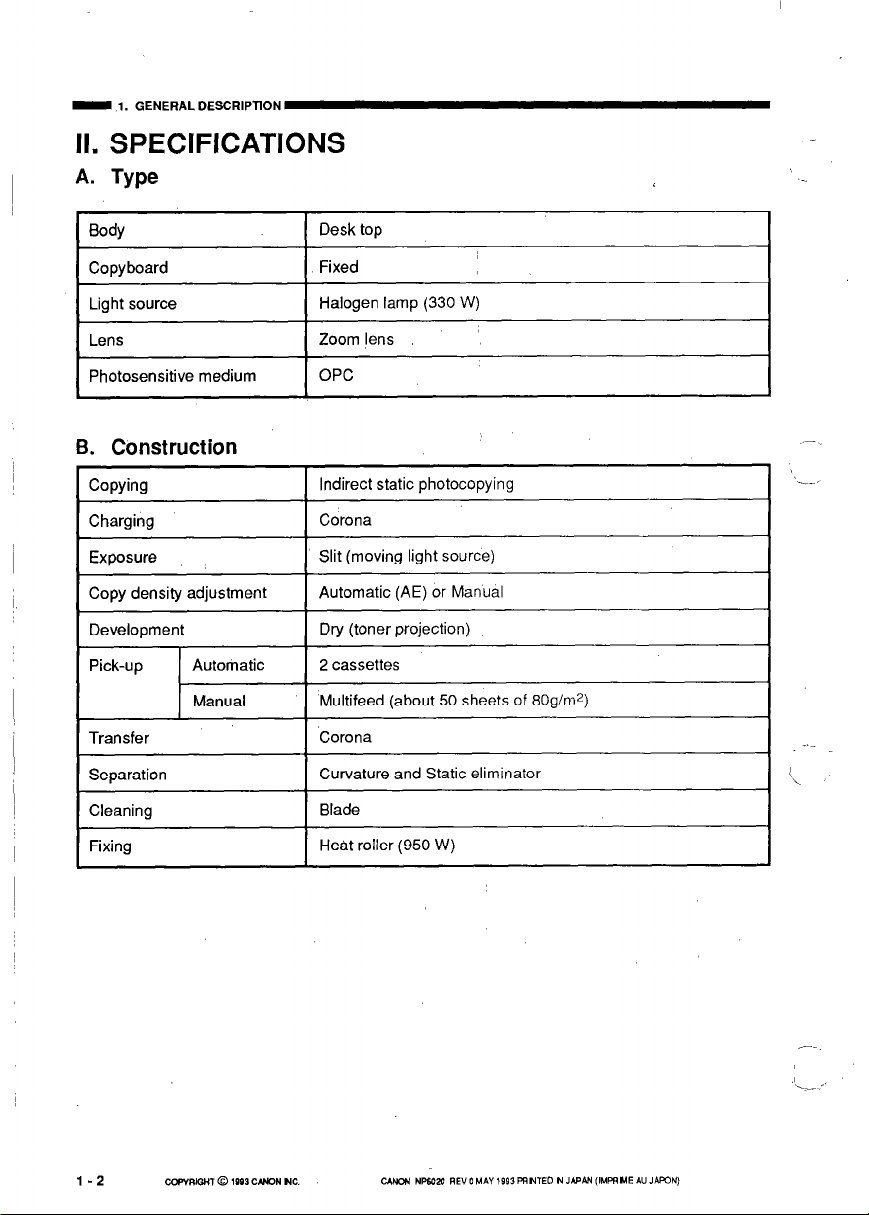

II. SPECIFICATIONS

A. Type

Body

Copyboard

Light source

Lens

Photosensitive medium

6. Construction

Copying

Charging

Exposure

Copy density adjustment

Development

Pick-up

Transfer

Separation

Automatic

Manual

Desk top

Fixed

Halogen lamp (330 W)

Zoom lens

OPC

Indirect static photocopying

Corona

Slit (moving light source)

Automatic (AE) or Manual

Dry (toner projection)

2 cassettes

Multifeed (about 50 sheets of 80g/m2)

Corona

Curvature and Static eliminator

Cleaning

Fixing

Blade

Heat roller (950 W)

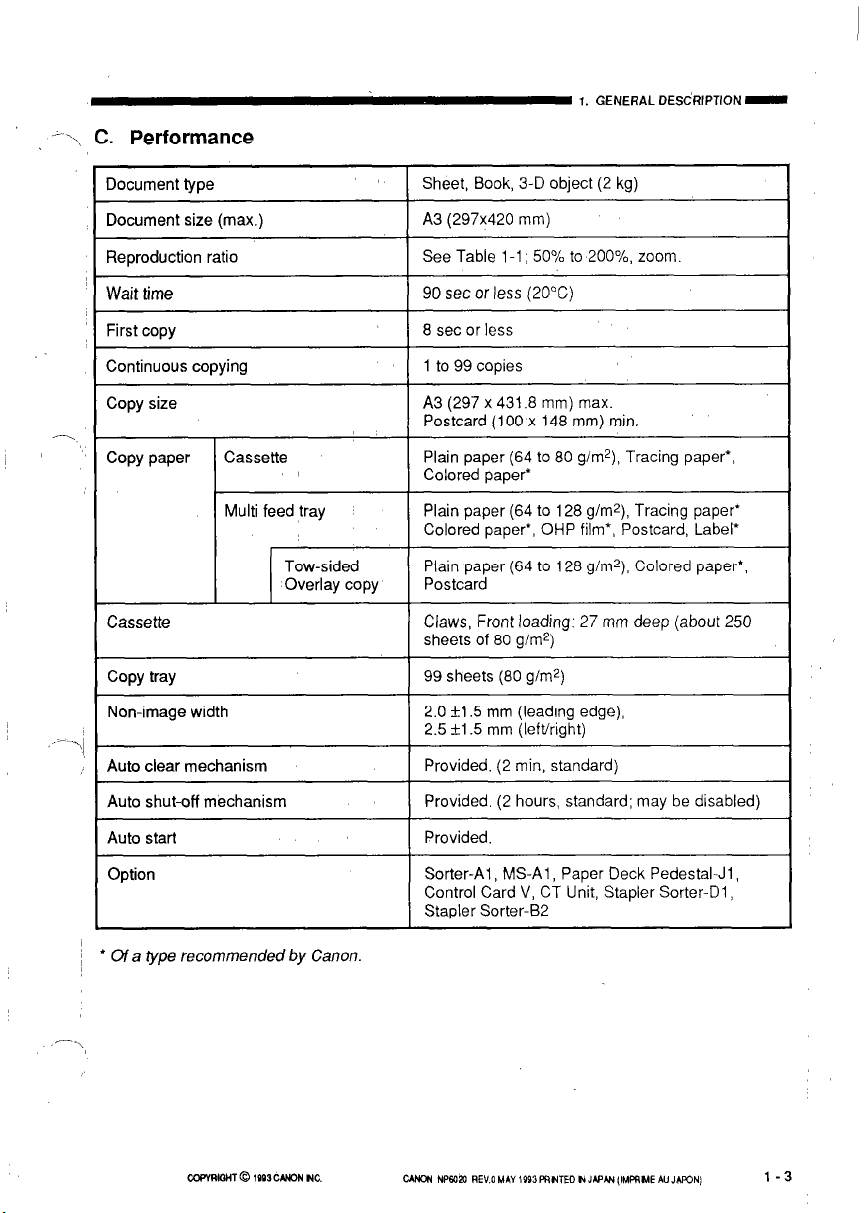

C. Performance

1. GENERAL DESdRlPTlON -

Document type

Document size (max.)

Reproduction ratio

Wait time

First copy

Continuous copying

Copy size

COPY paper

Cassette

Copy tray

Non-image width

Cassette

Multi feed tray

Tow-sided

Overlay copy

Sheet, Book, 3-D object (2 kg)

A3 (297x420 mm)

See Table l-l ; 50% to 200%, zoom.

90 set or less (20°C)

8 set or less

1 to 99 copies

A3 (297 x 431.8 mm) max.

Postcard (100 x 148 mm) min.

Plain paper (64 to 80 g/m”), Tracing paper*,

Colored paper*

Plain paper (64 to 128 g/me), Tracing paper’

Colored paper*, OHP film*, Postcard, Label’

Plain paper (64 to 128 gim2), Colored paper*,

Postcard

Claws, Front loading: 27 mm deep (about 250

sheets of 80 g/m*)

99 sheets (80 g/m*)

2.0 +1.5 mm (leading edge),

2.5 +1.5 mm (left/right)

Auto clear mechanism

Auto shut-off mechanism

Auto start

Option

* Of a type recommended by Canon.

Provided. (2 min. standard)

Provided. (2 hours, standard; may be disabled)

Provided.

Sorter-Al, MS-Al, Paper Deck Pedestal-J1 ,

Control Card V, CT Unit, Stapler Sorter-D1

Stapler Sorter-62

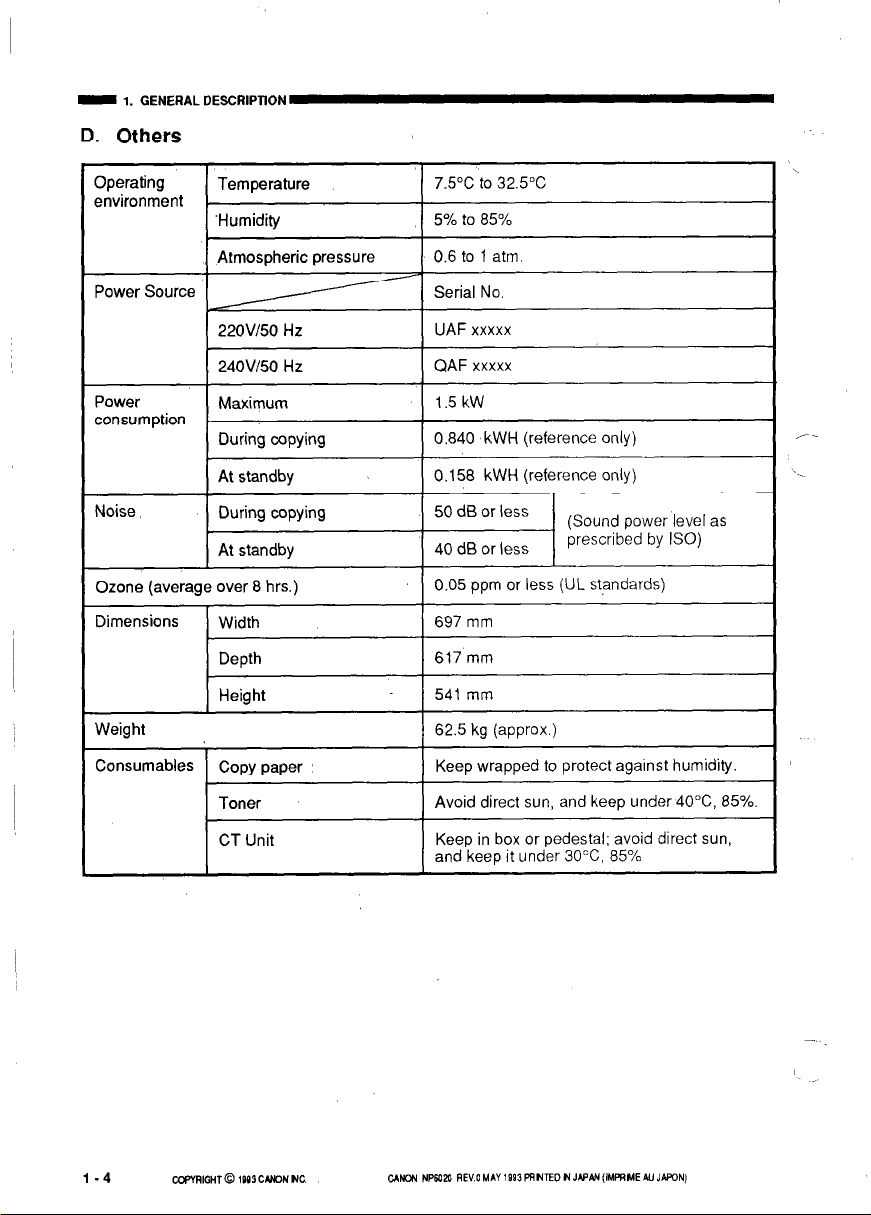

D. Others

(Sound power level as

prescribed by ISO)

Consumables

Keep in box or pedestal; avoid direct sun,

and keep it under 30% 85%

I

I, GENERAL DESCRIPTION -

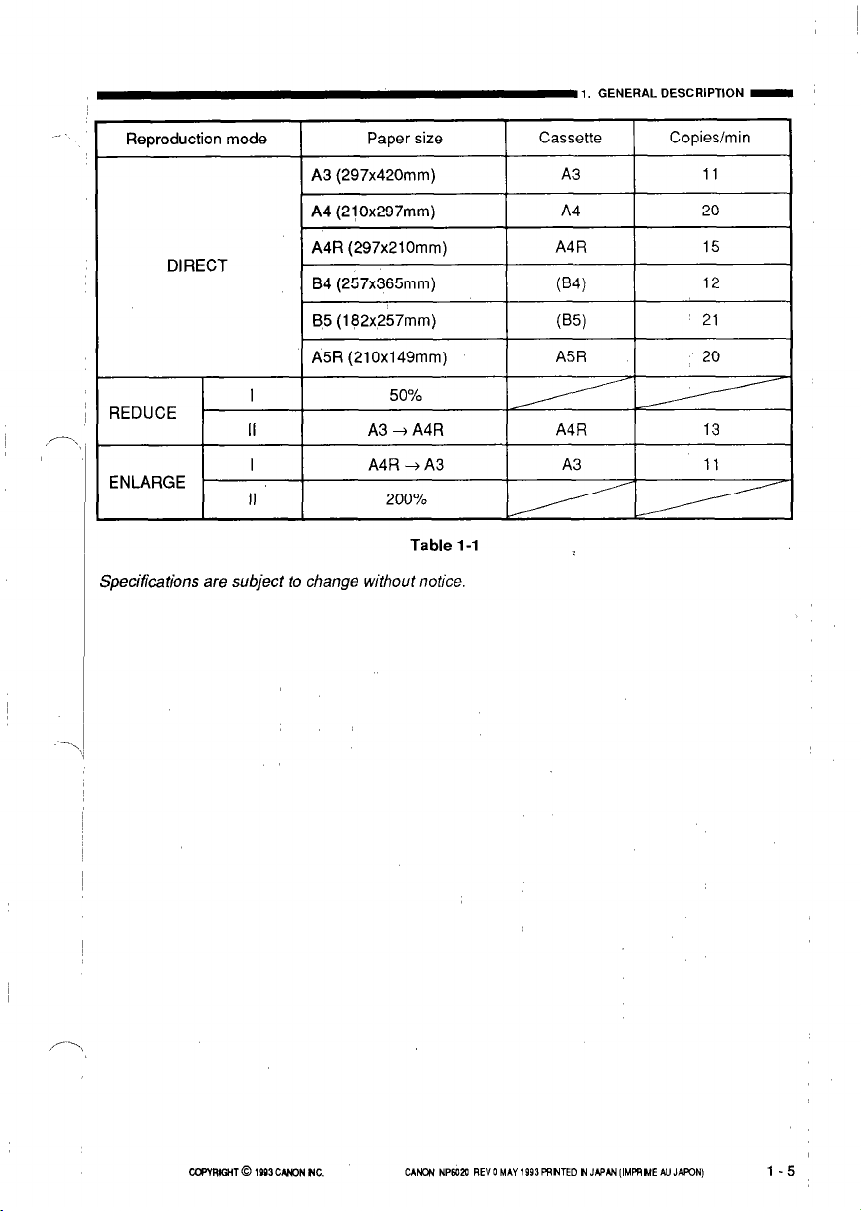

Reproduction mode

DIRECT

I

I

REDUCE

II A3 + A4R

I

ENLARGE

~pecificafions are subjecf lo change without notice.

II

Paper size

A3 (297x420mm)

A4 (21Ox297mm)

A4R (297x210mm)

84 (257x365mm)

85 (1 e2x257mm)

A5R (21Ox149mm)

50%

A4R --3 A3 A3 11

200%

Table l-1

Cassette Copies/min

A3

A4

A4R

I

(84)

(85)

A5R

I

A4R 13

I

I

11

20

15

12

21

20

-1. GENERAL DESCRIPTION

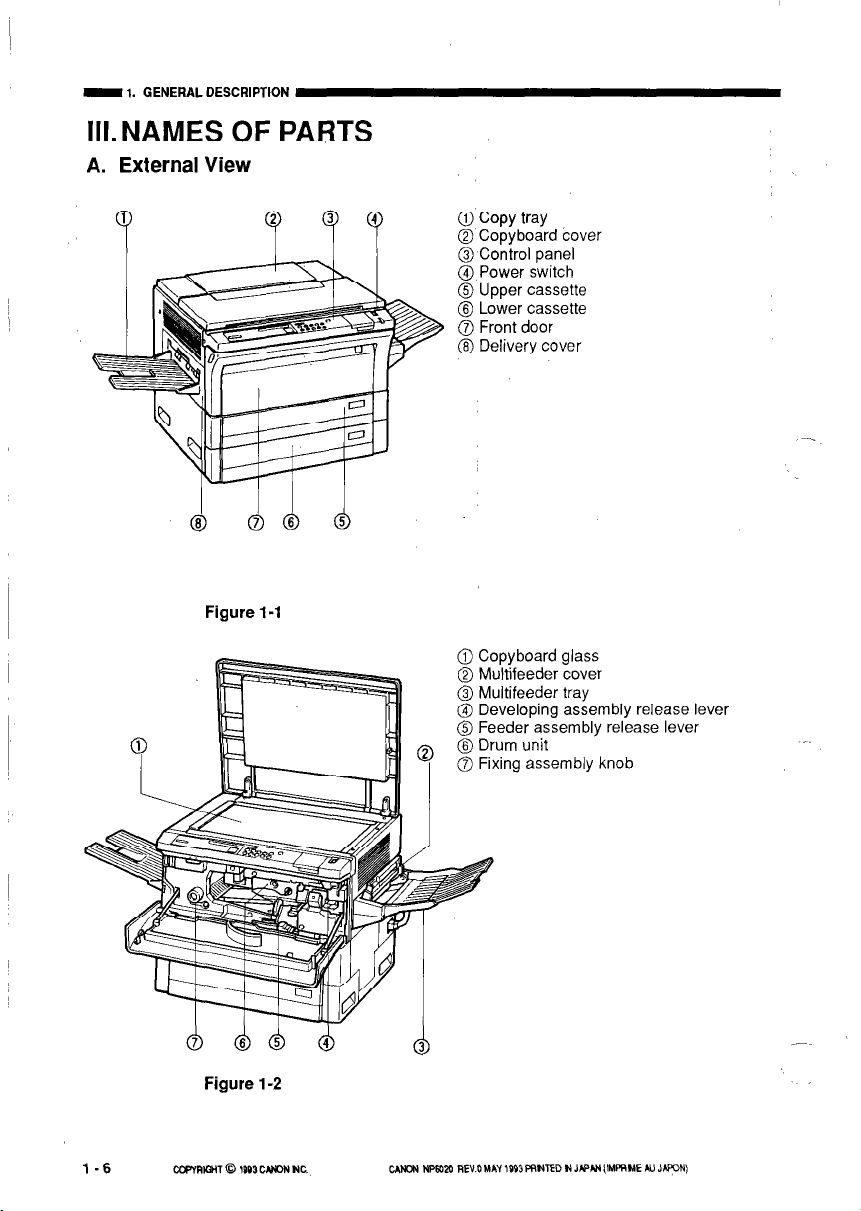

III. NAMES OF PARTS

A. External View

Figure l-1

@ Control panel

@ Power switch

@ Upper cassette

@ Lower cassette

@ Front door

@ Delivery cover

@ Copyboard glass

@ Multifeeder cover

@ Multifeeder tray

@! Developing assembly release lever

Feeder assembly release lever

Figure l-2

@ Fixing assembly knob

,--

,, .=,

B. Cross-Sectional View

j\

I

,

I

1. GENERAL DESCRIPTION -

Figure 1-3

@ No. 3 mirror

@ No. 2 mirror

@ No. 1 mirror

@ Scanning lamp

@ Copyboard glass

@ Copyboard cover

0 Lens

@ Pre-exposure lamp

@ Primary corona unit

@ No. 6 mirror

No. 5 mirror

0

No. 4 mirror

Registration roller

Q

Multifeeder tray

Vertical feed roller 1

Q

Vertical feed roller 2

Cassette 1 pick-up roller

0

Cessette 2 pick-up roller

63

Feeder roller

63

Transfer corona unit

@

CANON NPS020 REV0 MAY 1993PRNTED NJWNN(IMFRMEW JUUN) I-7

@ Static eliminator

@ Photosensitive drum

@ Cassette 1

Q Cassette 2

@ Feeder unit

@ Ozone filter

@ Exhaust fan

@ Fixing unit

@ Delivery roller

- 1. GENERAL DESCRIPTION

IKOPERATION

A. Control Panel

Figure l-4

SORT/GROUP/STAPLE SORT key

Press it to select the sort group, staple sort

or non-sort mode. The indicator remains

unlit when the non-sort mode is selected.

* sorting

z- grouping

0 staplesorting

PAGE OPERATlON key

Press it to seled the page separation mode.

JAM indicator

CONTROL CARD indcator

ADD PAPER indicator

ADD TONER in&&r

COPY COUNT/RATIO indiitor

It indiites the reproc+Jdon ratio when the %

key is pressed.

COPY START key

- glows orange when the copier is not ready

for copying.

- gk3ws green when the copier is ready for

copying.

RESET key

Press it to reset the copier to its default

settings.

Default Settings

* copy count 1

- DIRECT

- AE (may be turned OFF using ‘C15’ of

service mode)

CLEARSTOP key

STANDBY key

POWER switch

POWER indicator

The indicator remains ON while the power is

on.

Numeric keypad

% key

Press it to check the reproduction ratio on the

copy count indicator.

The display changes to the copy count 2 set

after the key is released.

ZOOM key

Press it to select a desired reproduction ratio

between 50% and 200% in 1% increments.

AUTO RATIO key

Press it to select or deselect the auto

reproduction ratio mode.

The key is effective when the ADF is

attached.

PAPER SELECT/JAM indicator

,A LED goes ON to indicate the locatin of

the paper or flashes to indicate the location of

the jam, if any.

PAPER SELECT key

Press it to select automatic paper selection

(may be turned OFF using ‘CO7 of service

mode) or cassette or multifeeder as the

source of paper.

ENLARGE key

DIRECT key

REDUCE key

AE (automatic exposure; density adjusbnent)

key

COPY DENSITY lever

’

’ -.

B.

*-j 1)

,,=7,

j/

’ ‘3)

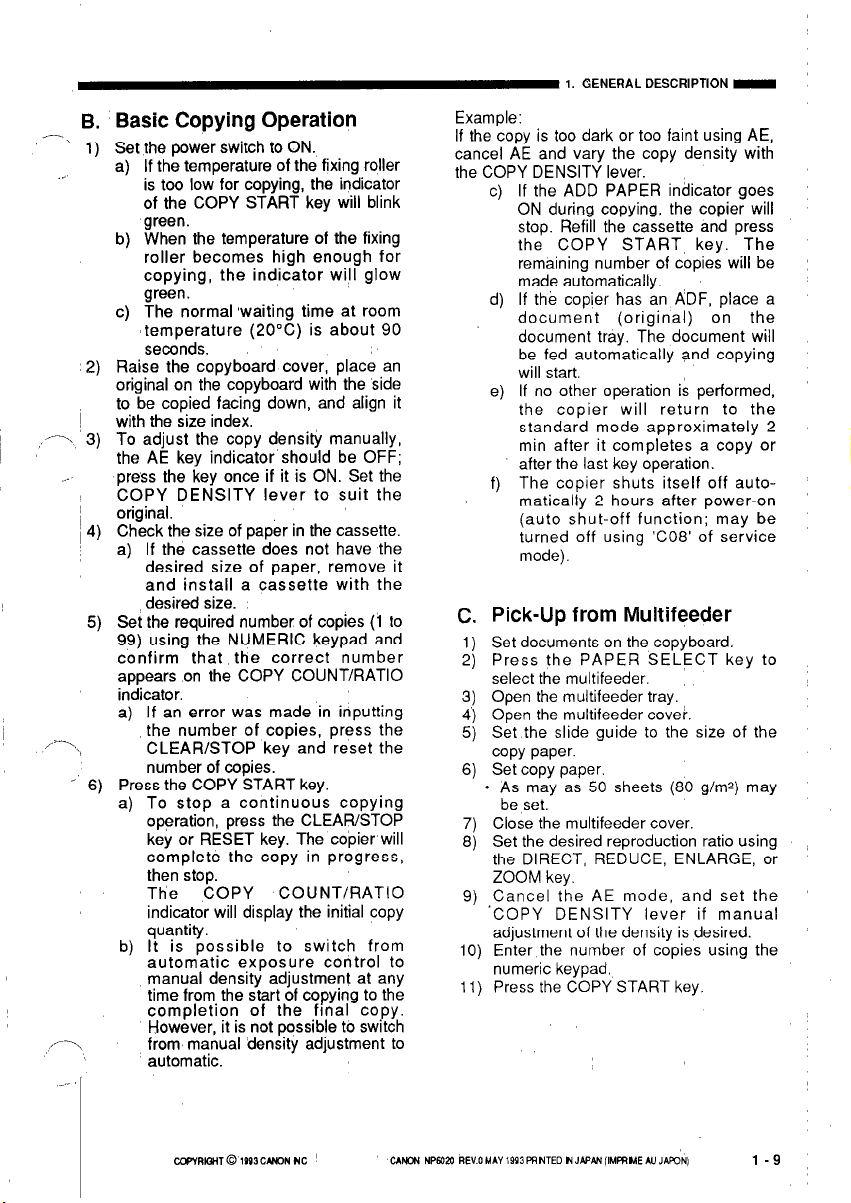

Basic Copying Operation

Set the power switch to ON.

If the temperature of the fixing roller

is too low for copying, the indicator

of the COPY START key will blink

green.

When the temperature of the fixing

roller becomes high enough for

copying, the indicator will glow

green.

The normal *waiting time at room

‘temperature (20°C) is about 90

seconds.

Raise the copyboard cover, place an

2)

original on the copvboard with the side

to be copied facing down, and align it

with the size index.

To adjust the copy density manually,

the AE key indicator should be OFF;

press the key once if it is ON. Set the

COPY DENSITY lever to suit the

original.

Check the size of paper in the cassette.

a) If the cassette does not have the

desired size of paper, remove it

and install a cassette with the

desired size.

Set the required number of copies (1 to

5)

99) using the NUMERIC keypad and

confirm that the correct number

appears on the COPY COUNT/RATIO

indicator.

a) If an error was made in inputting

the number of copies, press the

CLEAR/STOP kev and reset the

number of copies. _

Press the COPY START key.

To stop a continuous copying

operation, press the CLEAWSTOP

key or RESET key. The copier will

complete the copy in progress,

then stop.

COPY COUNT/RATIO

The

indicator will display the initial copy

quantity.

It is possible to switch from

automatic exposure control to

manual density adjustment at any

time from the start of copying to the

completion of the final copy.

However, it is not possible to switch

from manual density adjustment to

automatic.

Example:

If the copy is too dark or too faint using AE,

cancel AE and vary the copy density with

the COPY DENSITY lever.

If the ADD PAPER indicator goes

ON during copying, the copier will

stop. Refill the cassette and press

the COPY START key. The

remaining number of copies will be

made automatically.

If the copier has an ADF, place a

document (original) on the

document tray. The document will

be fed automatically and copying

will start.

If no other operation is performed,

the copier will return to the

standard mode approximately 2

min after it completes a copy or

after the last key operation.

The copier shuts itself off automatically 2 hours after power-on

(auto shut-off function; may be

turned off using ‘CO8’ of service

mode).

Pick-Up from Multifeeder

C.

Set documents on the copyboard.

:;

Press the PAPER SELECT kev to

select the multifeeder.

Open the multifeeder tray.

Open the multifeeder cover.

:;

Set the slide guide to the size of the

5)

copy paper.

Set copy paper.

6)

0 As may as 50 sheets (80 g/mz) may

be set.

Close the multifeeder cover.

Set the desired reproduction ratio using

87;

the DIRECT, REDUCE, ENLARGE, or

ZOOM key.

Cancel the AE mode, and set the

9)

COPY DENSITY lever if manual

adjustment of the density is desired.

Enter the number of copies using the

19)

numeric keypad.

Press the COPY START key.

11)

l-9

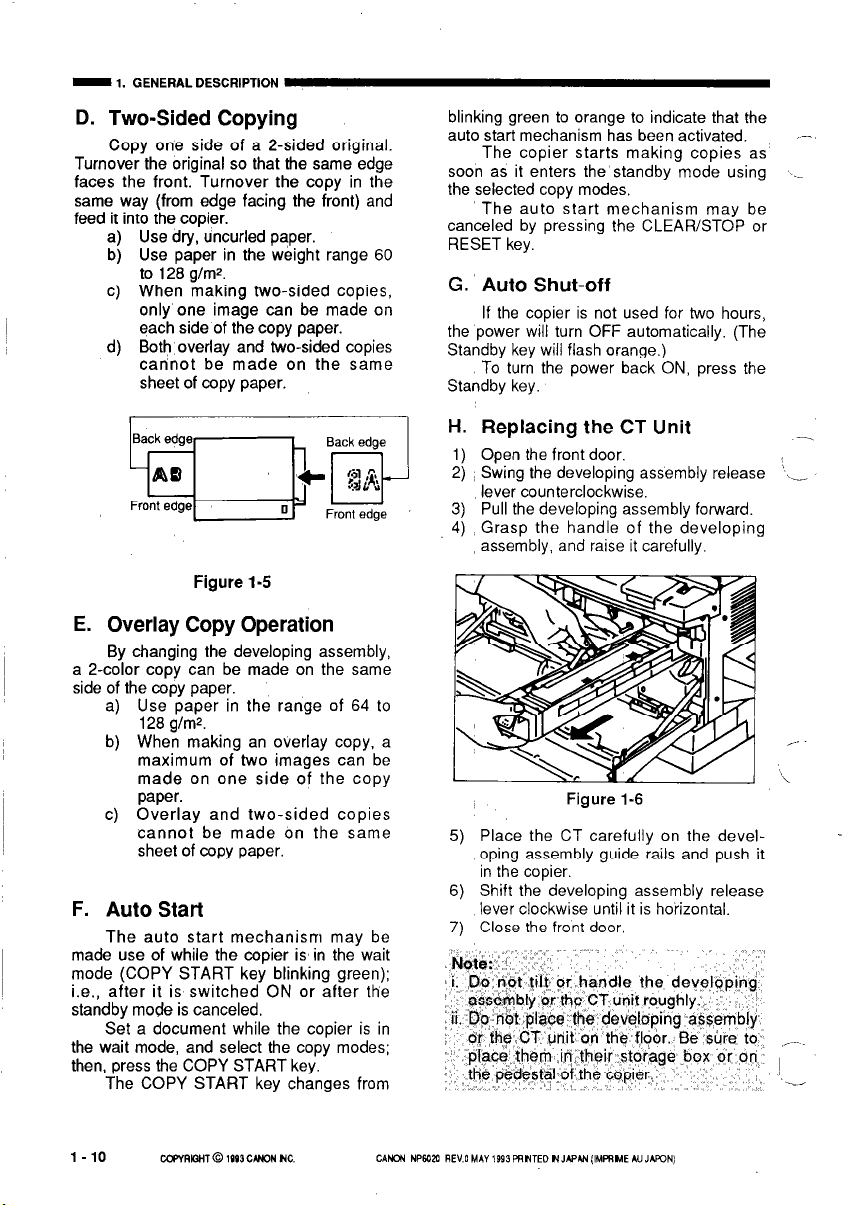

D. Two-Sided Copying

Copy one side of a 2-sided original.

Turnover the original so that the same edge

faces the front. Turnover the copy in the

same way (from edge facing the front) and

feed it into the copier.

a) Use dry, uncurled paper.

b) Use paper in the weight range 60

to 128 glmz.

c) When making two-sided copies,

only one image can be made on

each side of the copy paper.

d) Both overlay and two-sided copies

cannot be made on the same

sheet of copy paper.

Figure l-5

E. Overlay Copy Operation

By changing the developing assembly,

a P-color copy can be made on the same

side of the copy paper.

Use paper in the range of 64 to

128 glm2.

When making an overlay copy, a

maximum of two images can be

made on one side of the copy

paper.

Overlay and two-sided copies

cannot be made on the same

sheet of copy paper.

F. Auto Start

The auto start mechanism may be

made use of while the copier isin the wait

mode (COPY START key blinking green);

i.e., after it is switched ON or after the

standby mode is canceled.

Set a document while the copier is in

the wait mode, and select the copy modes;

then, press the COPY START key.

The COPY START key changes from

blinking green to orange to indicate that the

auto start mechanism has been activated.

The copier starts making copies as

soon as it enters the standby mode using

the selected copy modes,

The auto start mechanism may be

canceled by pressing the CLEAR/STOP or

RESET key.

G. Auto Shut-off

If the copier is not used for two hours,

the power will turn OFF automatically. (The

Standby key will flash orange.)

To turn the power back ON, press the

Standby key.

H. Replacing the CT Unit

1) Open the front door.

2) Swing the developing assembly release

lever counterclockwise.

3) Pull the developing assembly forward.

4) Grasp the handle of the developing

assembly, and raise it carefully.

Figure l-6

5) Place the CT carefully on the developing assembly guide rails and push it

in the copier.

6) Shift the developing assembly release

lever clockwise until it is horizontal.

7) Close the front door.

1 i. ,D’o nbt~tilt~“or.handle the developing

“i as&mbly prthe CT unit roughly.’

: ii. Dp”not .plaq the develapinng assembly

dr the’,,CTunit on’the floor.: Be sure to 1

” .:place”,them ,in,their~storage.box or on, ,.

1) the pede’stal~of,the.cqpier, ‘_

_“)” _“’ :““*^‘^,3

,‘,

,-

\__

’ .__

,---

I.__

V. WARNING INDICATOR AND

REQUIRED ACTION

A. Jam Indicatorh

If an area of this indicator flashes while

copying is taking place, it is likely that the

paper has jammed at the position represented by the part that is flashing. Check

and take action as follows.

Sorter JAM indicator

Feeding unit indicator

Figure 1-7

: separation ‘area,. be very careful not,$

1. GENERAL DESCRIPTION -

Figure 1-8

Close the copy delivery assembly.

Check if there is paper jammed in the

separation/feeder area. If there is,

swing the feeder release lever counter-,

clockwise to open the feeder, then

remove the jammed paper. Be careful

not to tear the paper.

Note-: ’ ,I,:-‘ .“, “, ;’ ‘” :I^ “,” ((1; ;,;,;

When removing jammed paper from the’1

touch the photbsehsitivedrum.~ :(

(. S_”

,“I,/ ;

When clearing a paper jam which has

occurred in an option unit (sorter or ADF),

refer to the SERVICE MANUAL for the

option unit.

l Multifeeder indicator

* ADF unit document JAM indicator

- Copier paper JAM indicator

l Right door OPEN indicator

l Feeding unit indicator

- Sorter JAM indicator

If paper jams inside the copier, check

the paper pick-up area, separation feeder

area, fixing/copy delivery area, and cartridge

area; and remove all jammed paper.’

1) Open the front door.

2) Remove the copies from the copy tray.

3) Operate the release and open the copy

delivery assembly.

4) Check if there is copy paper jammed in

the fixing assembly. If there is paper

jam in it, turn the knob of the fixing

rollers counterclockwise to remove the

jammed paper.

Figure 1-9

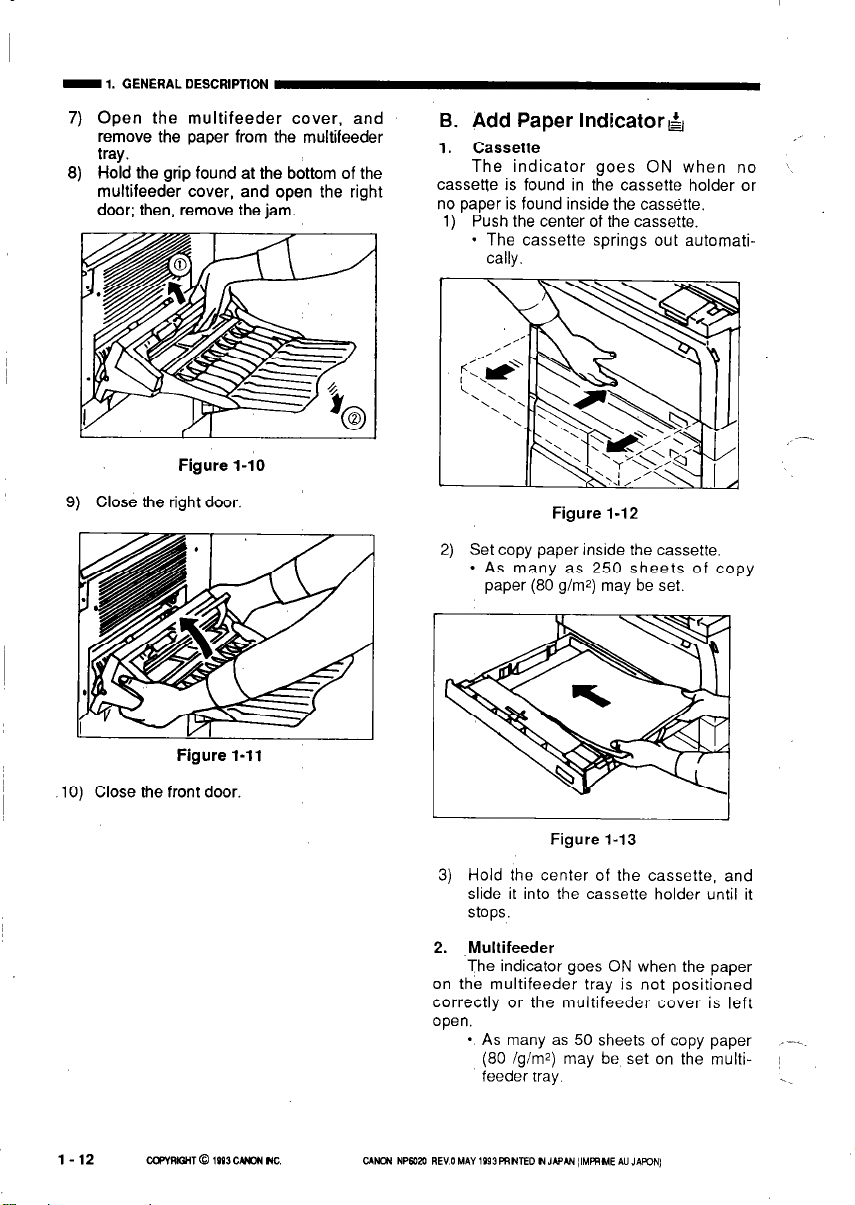

7) Open the multifeeder cover, and

remove the paper from the multifeeder

tray.

8) Hold the grip found at the bottom of the

multifeeder cover, and open the right

door; then, remove the jam.

Figure l-10

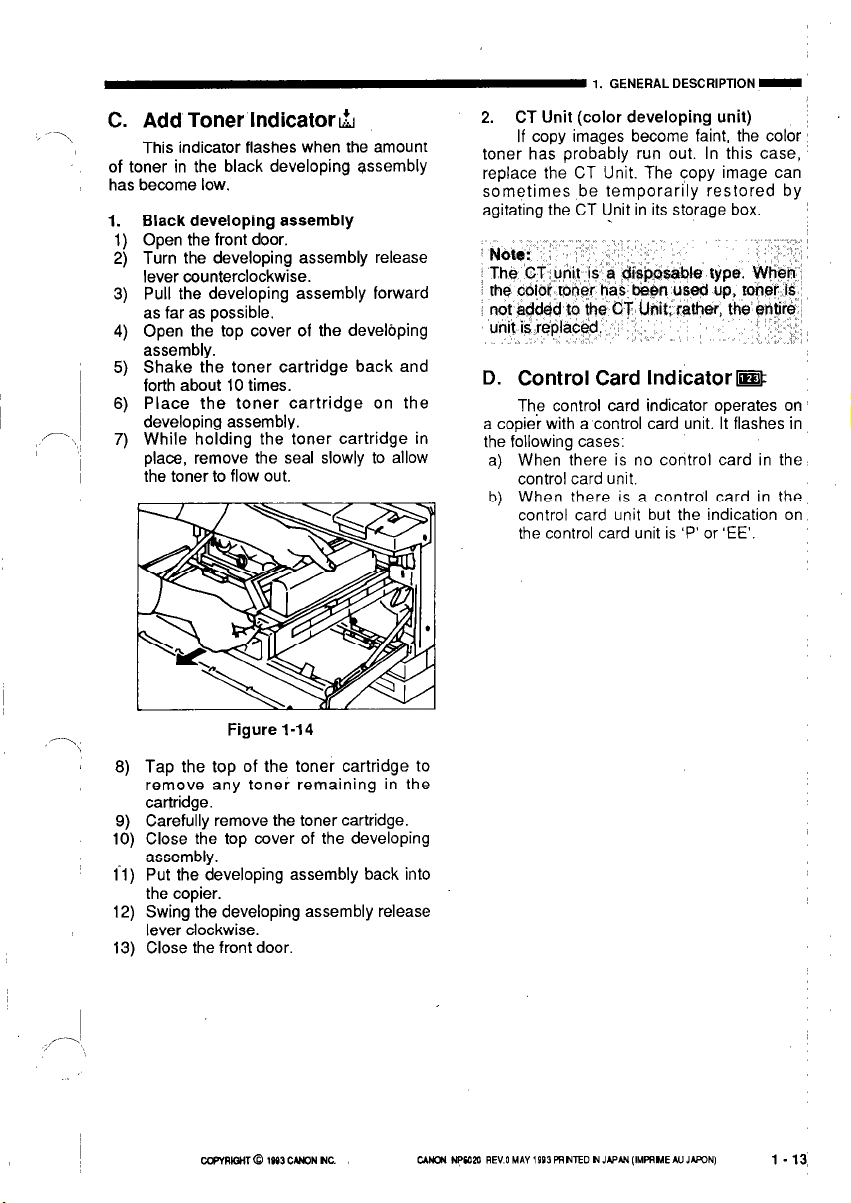

B. Add Paper Indicator&

Cassette

1.

The indicator goes ON when no ‘\

cassette is found in the cassette holder or

no paper is found inside the cassette.

1) Push the center of the cassette.

- The cassette springs out automati-

cally.

,’

,_--

9) Close the right door.

Figure l-11

-10) Close the front door.

Figure l-l 2

2) Set copy paper inside the cassette.

* As many as 250 sheets of copy

paper (80 g/m*) may be set.

Figure I-13

3) Hold the center of the cassette, and

slide it into the cassette holder until it

stops.

2. ~Multifeeder

The indicator goes ON when the paper

on the multifeeder tray is not positioned

correctly or the multifeeder cover is left

open.

. As many as 50 sheets of copy paper

(80 iglmz) may be set on the multifeeder tray.

1-12

C. Add Toner Indicator&

This indicator flashes when the amount

of toner in the black developing assembly

has become low.

Black developing assembly

1.

Open the front door.

Turn the developing assembly release

:;

lever counterclockwise.

Pull the developing assembly forward

3)

as far as possible.

Open the top cover of the developing

4)

assembly.

Shake the toner cartridge back and

5)

forth about 10 times.

Place the toner cartridge on the

3)

developing assembly.

While holding the toner cartridge in

7)

place, remove the seal slowly to allow

the toner to flow out.

CT Unit (color developing unit)

2.

If copy images become faint, the color ~

toner has probably run out. In this case,

replace the CT Unit. The copy image can

sometimes be temporarily restored by

agitating the CT Unit in its storage box.

The ‘CT : unit is‘ a &sjras&fe’ type. Wheh i

’ the color toner has be&n used up, toner ii.:

not a&fad to the dT.Unit; rather, the entfr&

unit is replaced: ;, ,”

_, ^, ‘,‘(

_I,, ;I I ibi i

D. Control Card Indicator IEB

The control card indicator operates on

a copier with a control card unit. It flashes in

the following cases:

When-there is no control card in the

4

control card unit.

When there is a control card in the

b)

control card unit but the indication on

the control card unit is ‘P’ or ‘EE’.

Figure l-14

Tap the top of the toner cartridge to

8)

remove any toner remaining in the

cartridge.

Carefully remove the toner cartridge.

Close the top cover of the developing

2,

assembly.

Put the developing assembly back into

ii)

the copier.

Swing the developing assembly release

12)

lever clockwise.

Close the front door.

13)

I 1. GENERAL DESCRIPTION

VI. DAILY INSPECTION TO BE PERFORMED BY

THE CUSTOMER

Carefully instruct the customer to be

sure to clean th’e following parts of the

copier once a week.

1. Primary Corona Assembly

Slide in and out the wire cleaner to

clean the corona wires.

2. Copyboard Glass

Clean the copyboard glass with a moist

cloth, then wipe it dry.

3. Copyboard Cover

Clean the copyboard cover with a mild

detergent solution, then wipe it dry.

4. Transfer Corona Assembly

Remove the transfer corona assembly

from the copier, then slide the knob

(wire cleaner) at the bottom of the

transfer corona assembly back and

forth to clean the corona wires.

Further, clean the static eliminator

using the cleaning brush (accessory).

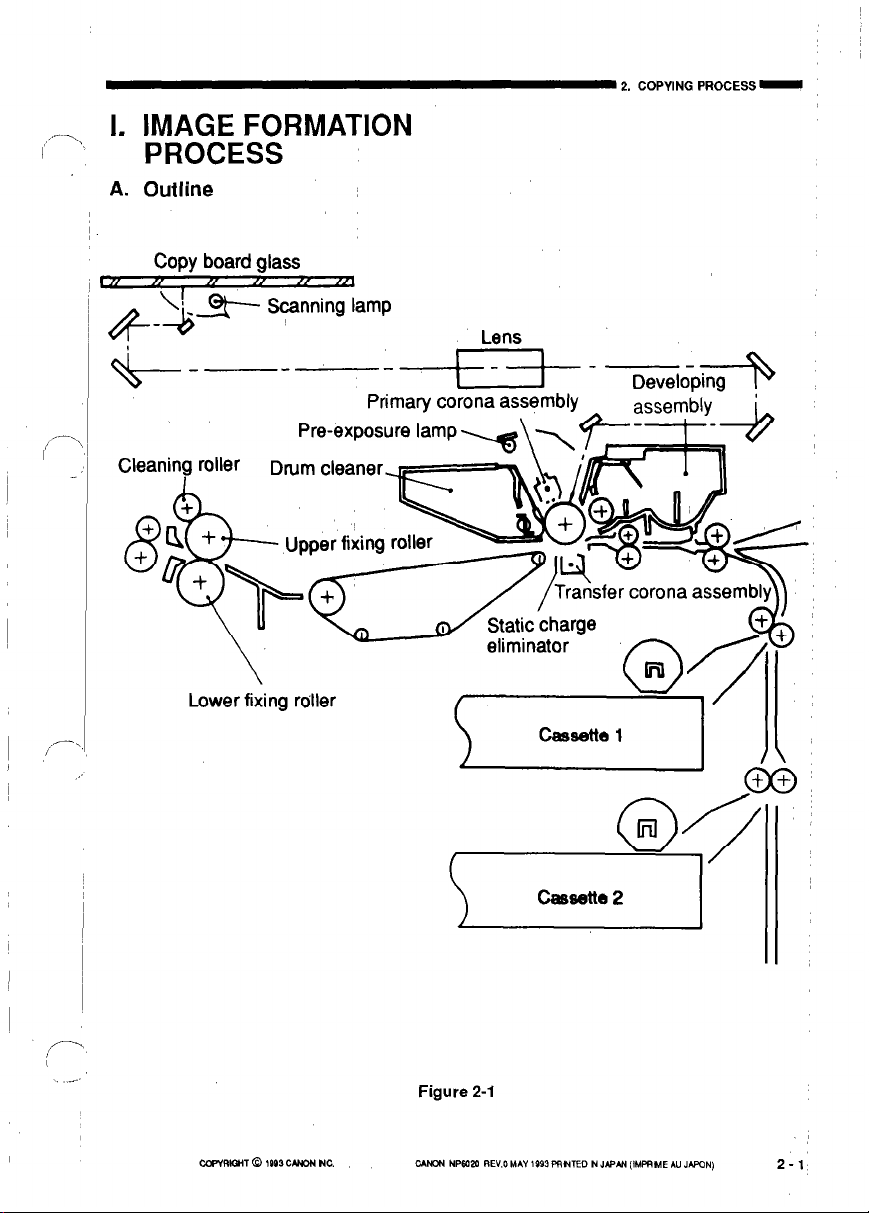

,,_~, I. IMAGE FORMATION

(/

PROCESS

A. Outline

2. COPYING PROCESS -

$,_- - _+-.+

Primary corona assembly _

Developing

.r>

Figure 2-1

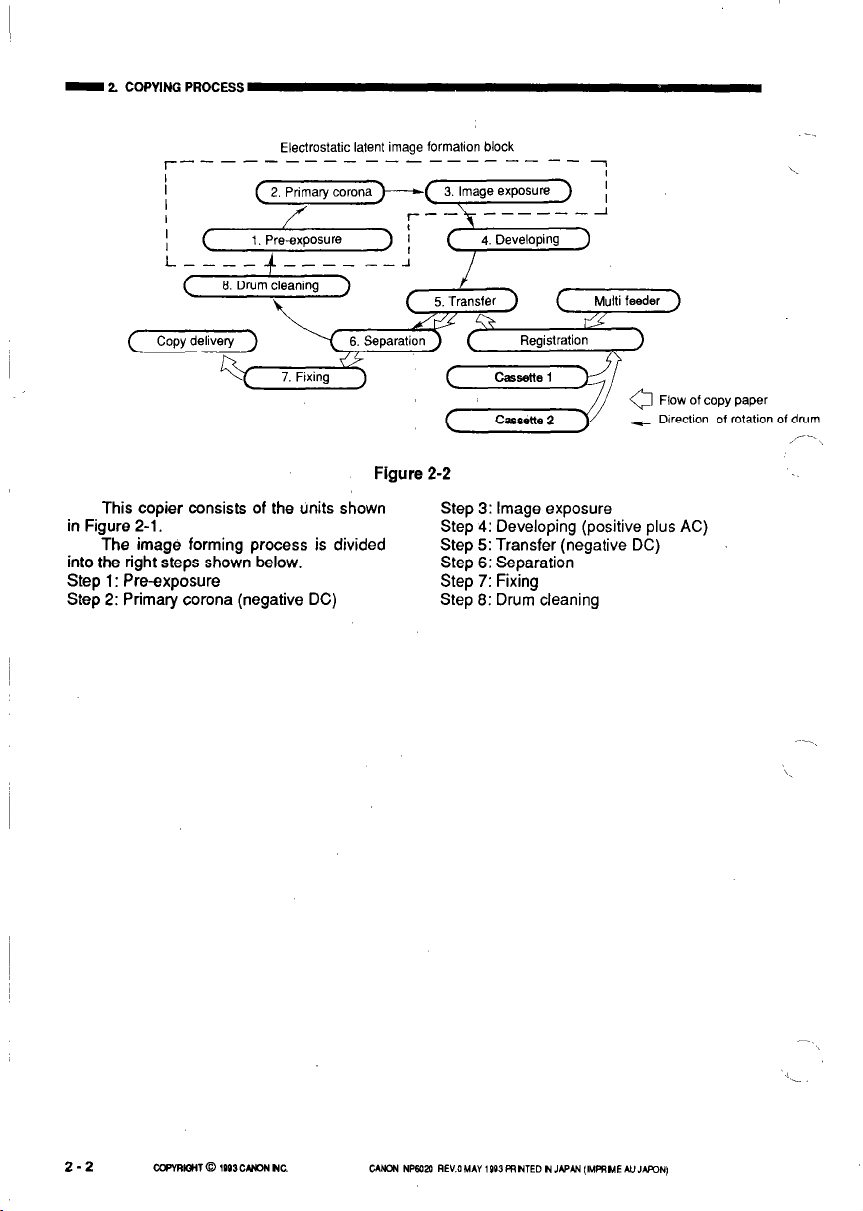

- 2 COPYING PROCESS

~------__-_-- ------ --7

Electrostatic latent image formation block

2. Primary corona

+ Direction of rotation of drum

Figure 2-2

This copier consists of the units shown Step 3: Image exposure

in Figure 2-l. Step 4: Developing (positive plus AC)

The image forming process is divided

Step 5: Transfer (negative DC)

into the right steps shown below. Step 6: Separation

Step 1: Preexposure

Step 7: Fixing

Step 2: Primary corona (negative DC) Step 8: Drum cleaning

/_.

\

2. COPYING PROCESS 0

,-..\

i i/.-- \

The outer surface of the photosensitive

drum is a layer of organic photoconductor

(OPC). The base is an aluminum (conductive) cylinder.

Photoconductive

layer

Base

Figure 2-3

B. Electrostatic Latent Image

Formation Block

~

This stage consists of three steps. At

the end of the stage, the drum has a pattern

of negative electrical charges on its surface

corresponding to the dark parts of the

document image. The light areas of the

document image are represented on the

drum by the absence of charges.

The pattern of negative charges cannot

be seen by the eye, hence it is called an

electrostatic latent image.

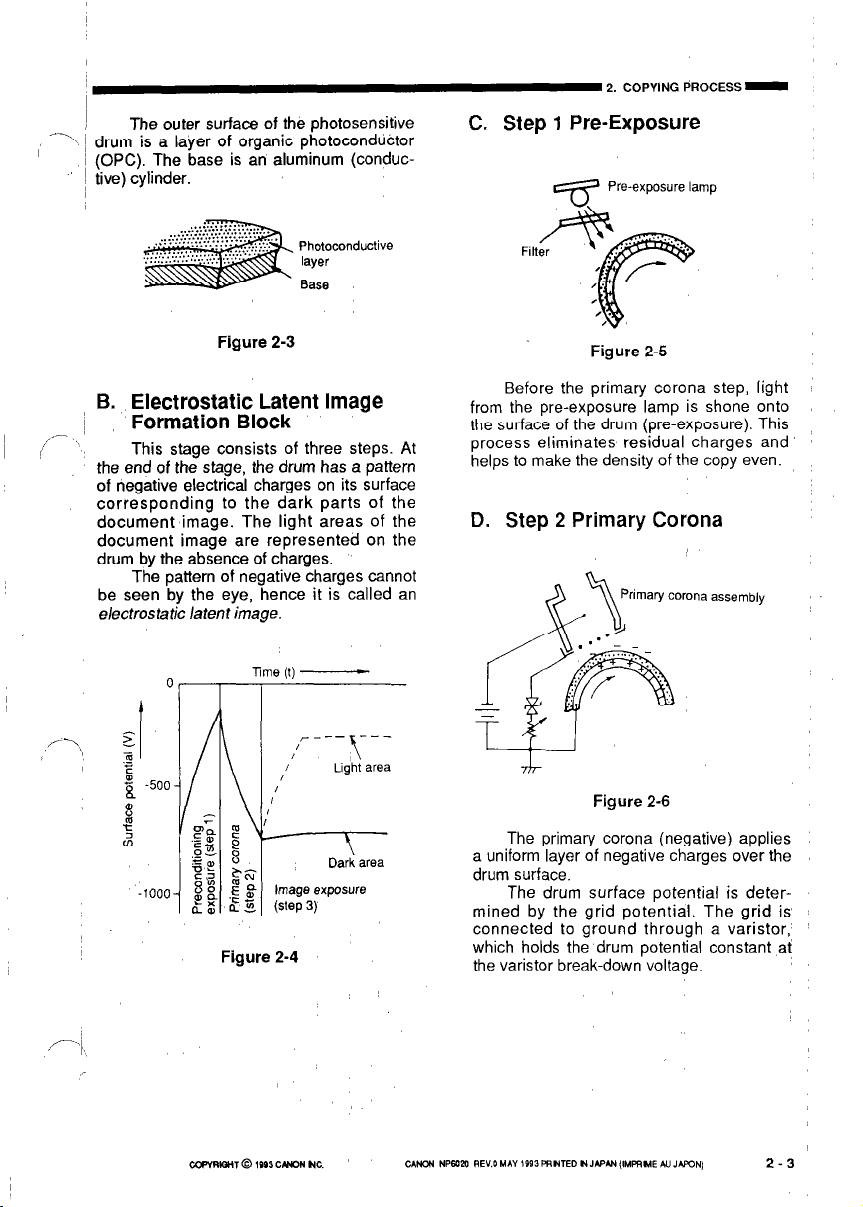

Of-

Time (1) -

C. Step 1 Pre-Exposure

Figure 2-5

Before the primary corona step, light

from the pre-exposure lamp is shone onto

the surface of the drum (pre-exposure). This

process eliminates residual charges and’

helps to make the density of the copy even.

D. Step 2 Primary Corona

Primary corona assembly

Figure 2-4

Dark area

Figure 2-6

The primary corona (negative) applies

a uniform layer of negative charges over the

drum surface.

The drum surface potential is determined bv the arid ootential. The grid is

connected to ground through

which holds the drum potential

the varistor break-down voltage.

a varistor,,

constant at

- 2. COPYING PROCESS

E. Step 3 Scanning Exposure

Optical image

Figure 2-7

Light from the original is projected onto

the drum surface. Charges in these light

areas on the drum are neutralized by drum

photosensitive effects.

F. Step 4 Developing

} $$Jp’“Q

toner mixed together in a fixed ratio. The

main component of the toner is resin. The

toner is charged to a positive potential and ,

the iron powder to a negative potential by

friction with the rotating cylinder.

Figure 2-9

A concentrated magnetic field develops

between the magnet and the edge of the

blade. This field attracts the charged

developer.

The developer is held virtually immobile

by the magnetic field, forming a curtain

along the edge of the blade. As the cylinder

rotates, this curtain skims the toner particles

on its surface to a thin uniform layer.

An AC bias plus a negative DC bias are

applied simultaneously to the developing

cylinder so that the waveform of the

developing bias has a larger negative

excursion than positive.

/---

’

_

Figure 2-8

As shown in Figure 2-8, the developing

assembly consists of a developing cylinder

(a stationary magnet surrounded by a

rotating sleeve) and a blade made of

magnetic material. Black toner is a single

component type consisting of a fine powder

of mixed magnetite and resin binder. The

toner has insulating properties and is

charged to a positive potential by friction

with the rotating cylinder.

Color developer is a two-component

type consisting of iron powder (carrier) and

.q++fjyg

DC bias

Figure 2~10

During copying toner is attracted to the

drum by the charges on the drum surface

and by repulsion due to the developing bias

(during the positive excursion), transforming

the latent electrostatic image into a visible

image. Excess toner particles are attracted

back to the cylinder from the drum due to

the charges on the drum surface and the

developing bias (during the negative

excursion).

The DC bias affects copy density and

fogging: As the DC bias becomes less

negative (approaching OV), the density and

degree of fogging both increase.

_’

_

2. COPYING PROCESS -

,?

i “-\

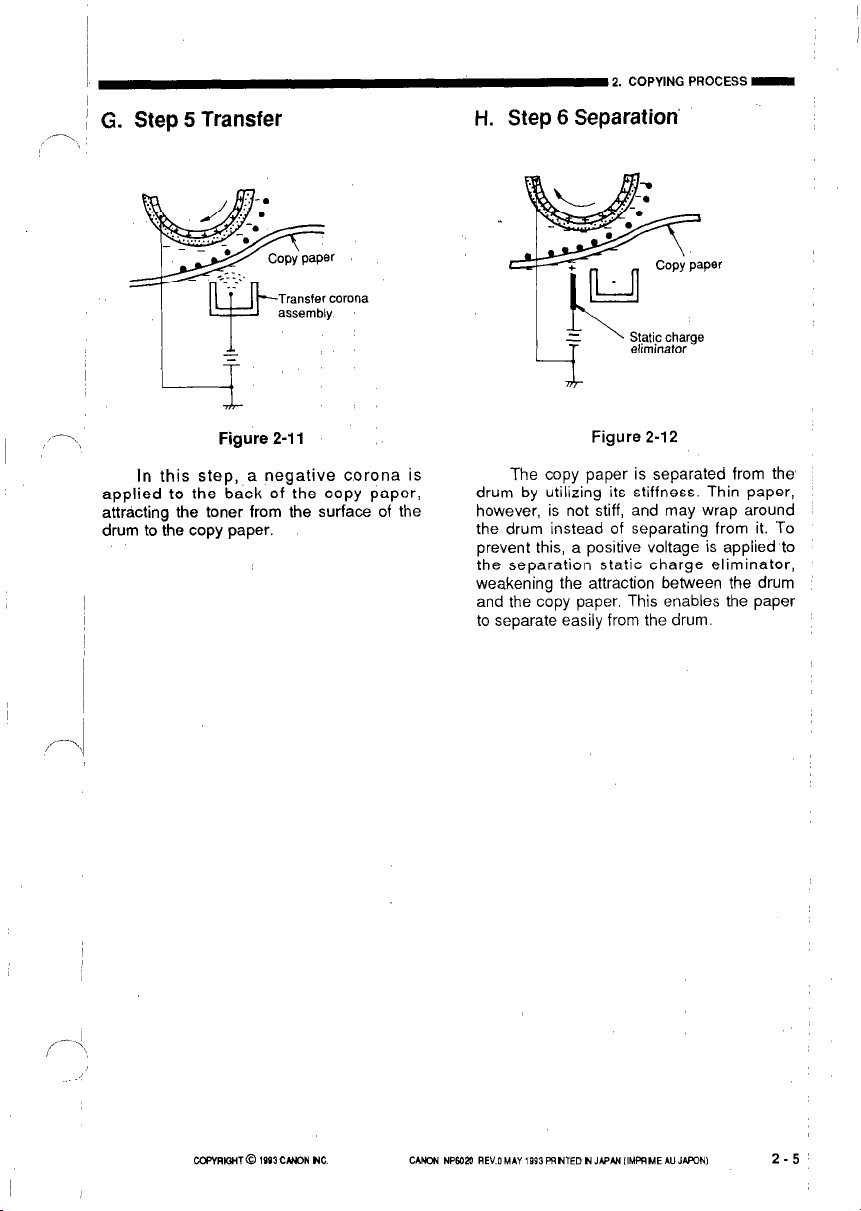

( G. Step 5 Transfer

Transfer coro”a

Figure 2-l 1

In this step, a negative corona is

applied to the back of the copy paper,

attracting the toner from the surface of the

drum to the copy paper.

H. Step 6 Separation’

g \

Static charge

eliminator

4

Figure 2-12

The copy paper is separated from the

drum by utilizing its stiffness. Thin paper,

however, is not stiff, and may wrap around

the drum instead of separating from it. To

prevent this, a positive voltage is applied’to

the separation static charge eliminator,

weakening the attraction between the drum

and the copy paper. This enables the paper

to separate easily from the drum.

- 2. COPYING PROCESS

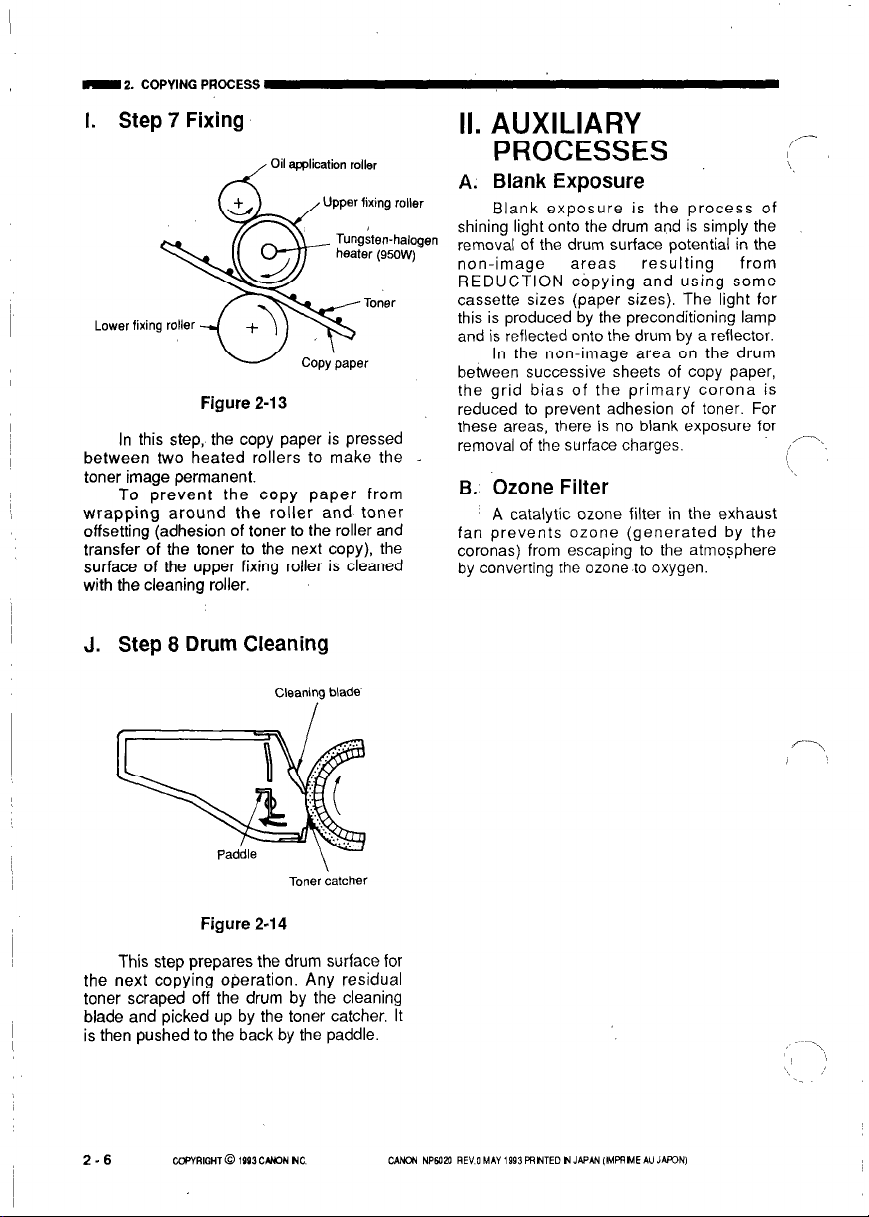

I. Step 7 Fixing

Oil application roller

&

1

Lower fixing roller

+

\

%I

Figure 2-13

In this step, the copy paper is pressed

between two heated rollers to make the _

toner image permanent.

To prevent the copy paper from

wrapping around the roller and toner

offsetting (adhesion of toner to the roller and

transfer of the toner to the next copy), the

surface of the upper fixing roller is cleaned

with the cleaning roller.

Upper iixing roller

Tungsten-halogen

heater (950W)

TClWJr

WY paper

J. Step 8 Drum Cleaning

Cleaning blade’

II. AUXILIARY

PROCESSES [

A. Blank Exposure

Blank exposure is the process of shining light onto the drum and is simply the removal of the drum surface potential in the non-image areas resulting from REDUCTION cbpying and using some cassette sizes (paper sizes). The light for this is produced by the preconditioning lamp and is reflected onto the drum by a reflector.

In the non-image area on the drum

between successive sheets of copy paper,

the grid bias of the primary corona is

reduced to orevent adhesion of toner. For

these areas, there is no blank exposure for

removal of the surface charges.

B. Ozone Filter

A catalytic ozone filter in the exhaust

fan prevents ozone (generated by the

coronas) from escaping to the atmosphere

by converting the ozone to oxygen.

_

/‘-

/

Toner catcher

Figure 2-14

This step prepares the drum surface for

the next copying operation. Any residual

toner scraped off the drum by the cleaning

blade and picked up by the toner catcher. It

is then pushed to the back by the paddle.

\

‘1

,

-..

~

I

~ I. BASIC OPERATION

‘--\ A. Functions

The copier can ,be divided into four functional sections: paper pick-up and feed system,

exposure system, image formation system, and control system.

3. OPERATIONS AND TlMfNG -

___ _ _ -_{ ]T5a~e7GKa~ti-i s ysim

system

1 Primary coronaA j

I

I

I

I

I

/‘?

I

I

\

I

Cassette 1

cassene 2

Figure 3-l

-3. OPERATIONS AND TIMING

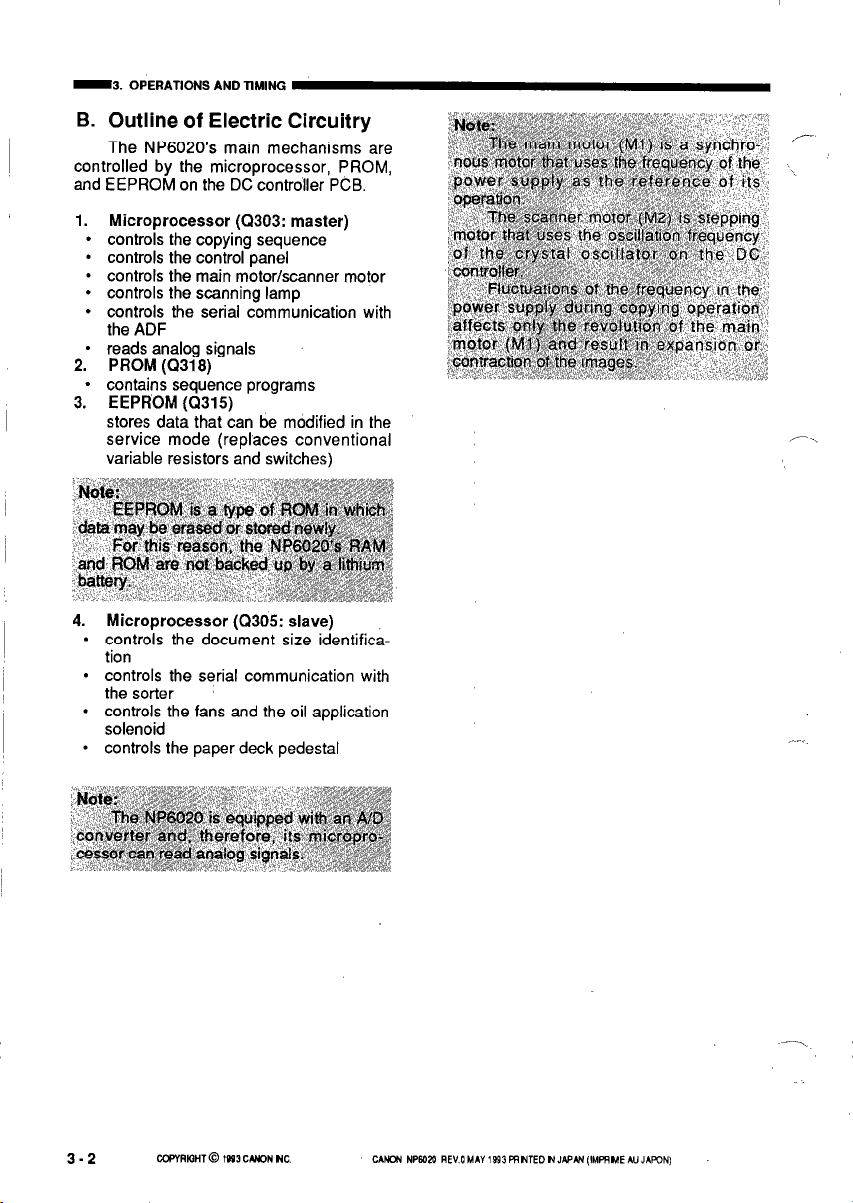

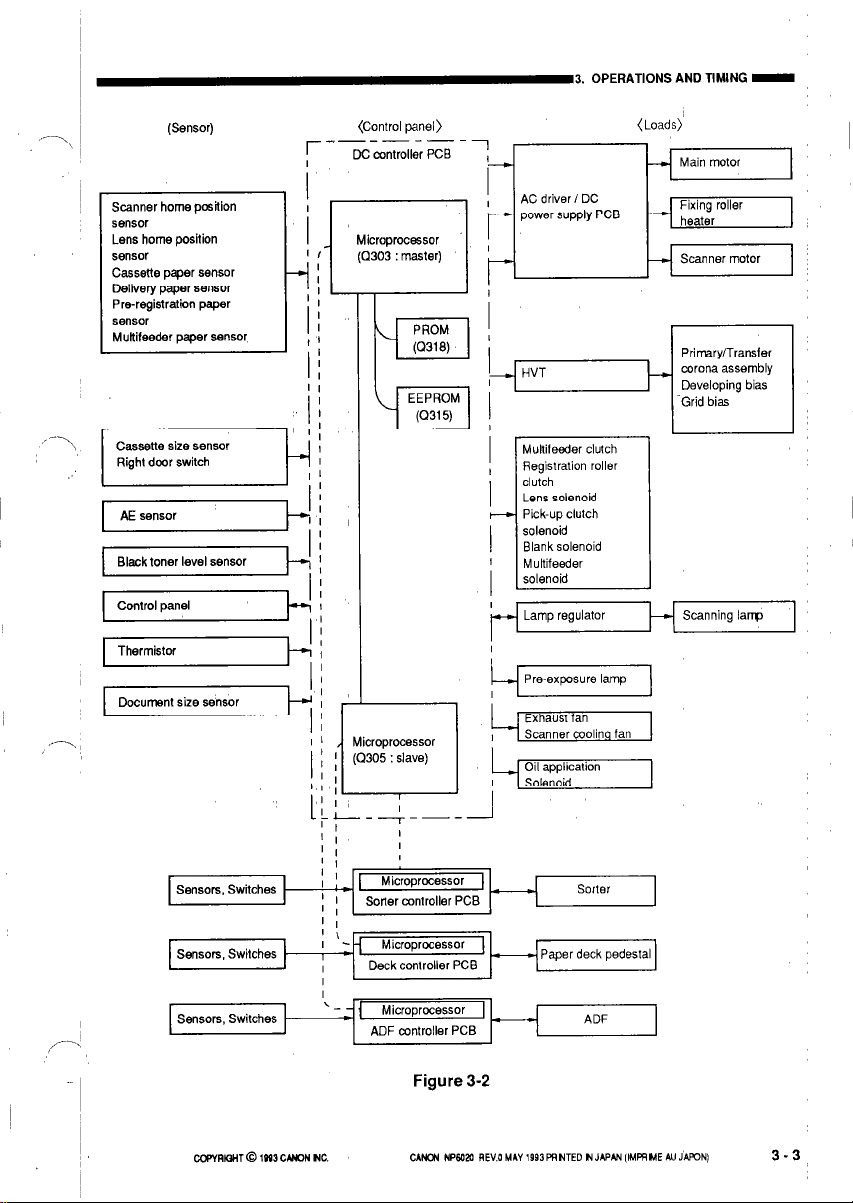

B. Outline of Electric Circuitry

The NP6020’s main mechanisms are

controlled by the microprocessor, PROM,

and EEPROM on the DC controller PCB.

1.

Microprocessor (Q303: master)

.

controls the copying sequence

.

controls the control panel

.

controls the main motor/scanner motor

.

controls the scanning lamp

.

controls the serial communication with

the ADF

.

reads analog signals

2.

PROM ((2318)

.

contains seauence oroorams

3.

EEPROM (d315) ’ ”

stores data that can be modified in the

service mode (replaces conventional

variable resistors and switches)

Microprocessor ((2305: slave)

controls the document size identification

controls the serial communication with

the sorter

controls the fans and the oil application

solenoid

controls the paper deck pedestal

-.

I

I

3. OPERATIONS AND TlhUNG -

I

“-\ 1

(Sensor)

Scanner home position

sensor

Lens home position

sensor

Cassette paper sensor

Delivery paper sensor

Pre-registration paper

sensor

Multifeeder paper sensor

AE sensor

Black toner level sensor

Control panel

Thermistor

(Control panel)

_-__---

r

DC controller PCB

I

(Loads)

Scanner motor

J

Lamp regulator Scanning larrp

Microprocessor

(Q305 : slave)

1

I 1

’ I

I I_

’ I

Sorter controller PCB

’ I

’ I

I ‘-

I

Deck controller PCB

I

I

I

\_

{ Microprocessor

ADF controller PCB

--l----

1

I

I

Microprocessor

Figure 3-2

‘r--

Sensors. Switches

-3. OPERATIONS AND TIMING

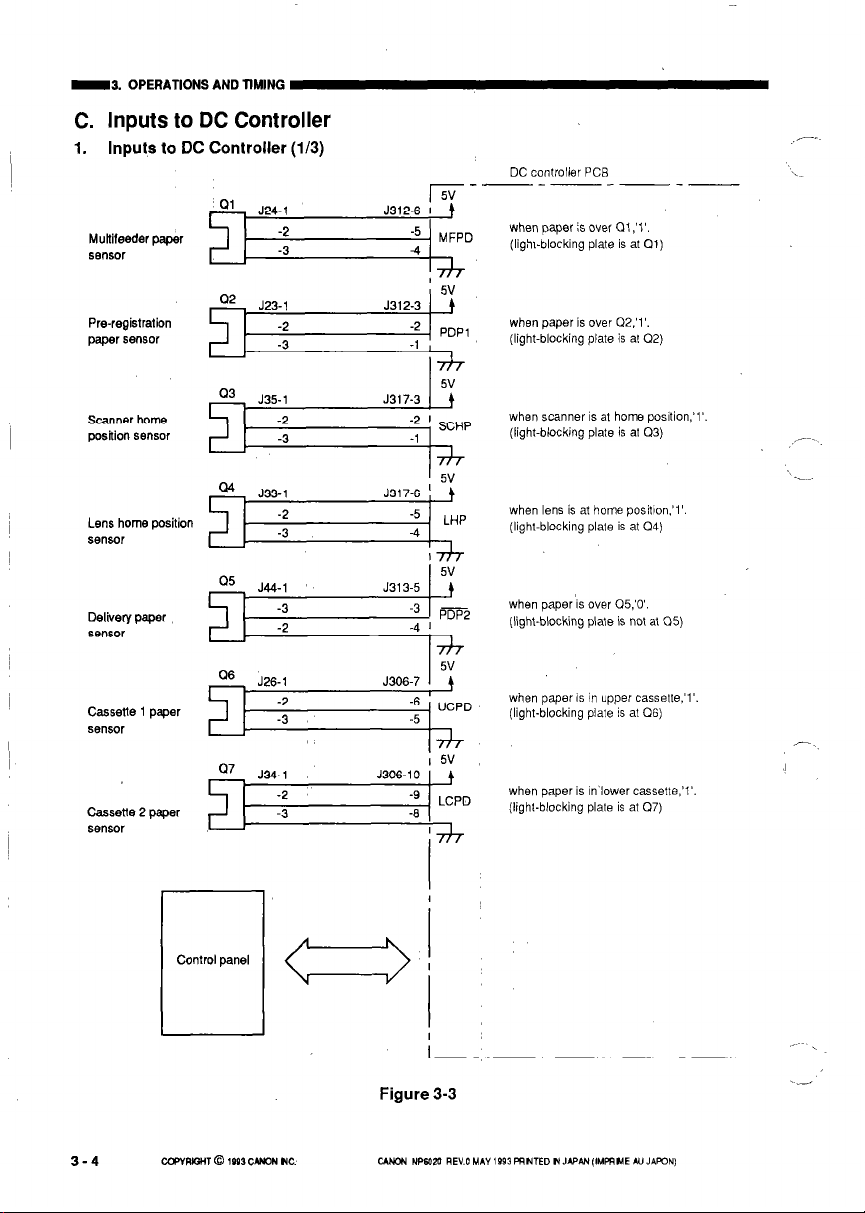

C. Inputs to DC Controller

Inputs to DC Controller (l/3)

1.

a2

Pm-registration

paper Sensor

Scanner home

position sensor

Lens home position

sensor

Delhy paper

sensor

cassette 1 paper

sensor

J23-1

-2

-3

’ 5v

J312-3 f

-2

-1

POP1

DC controller PCB

when papet is we, Qi ,‘I’.

(light-blocking plate is at (31)

when paper is over Q2,‘l’.

(light-blocking plate is at Q2)

when scanner is at home position.‘l’.

(light-blocking plate is at 03)

when lens is at home positlon.‘l’

(light-blocking plate is at 04)

when pap&is over Cl5,‘o’.

(light-blocking plale is not at Q5)

when paper IS in upper casselte,‘l’.

(light-blocking plate is at 06)

7.

--

Control panel

when paper is in‘lower cassette,‘l’.

(lighl-blocking plate is at Cl7)

a’

I_-_-____

~

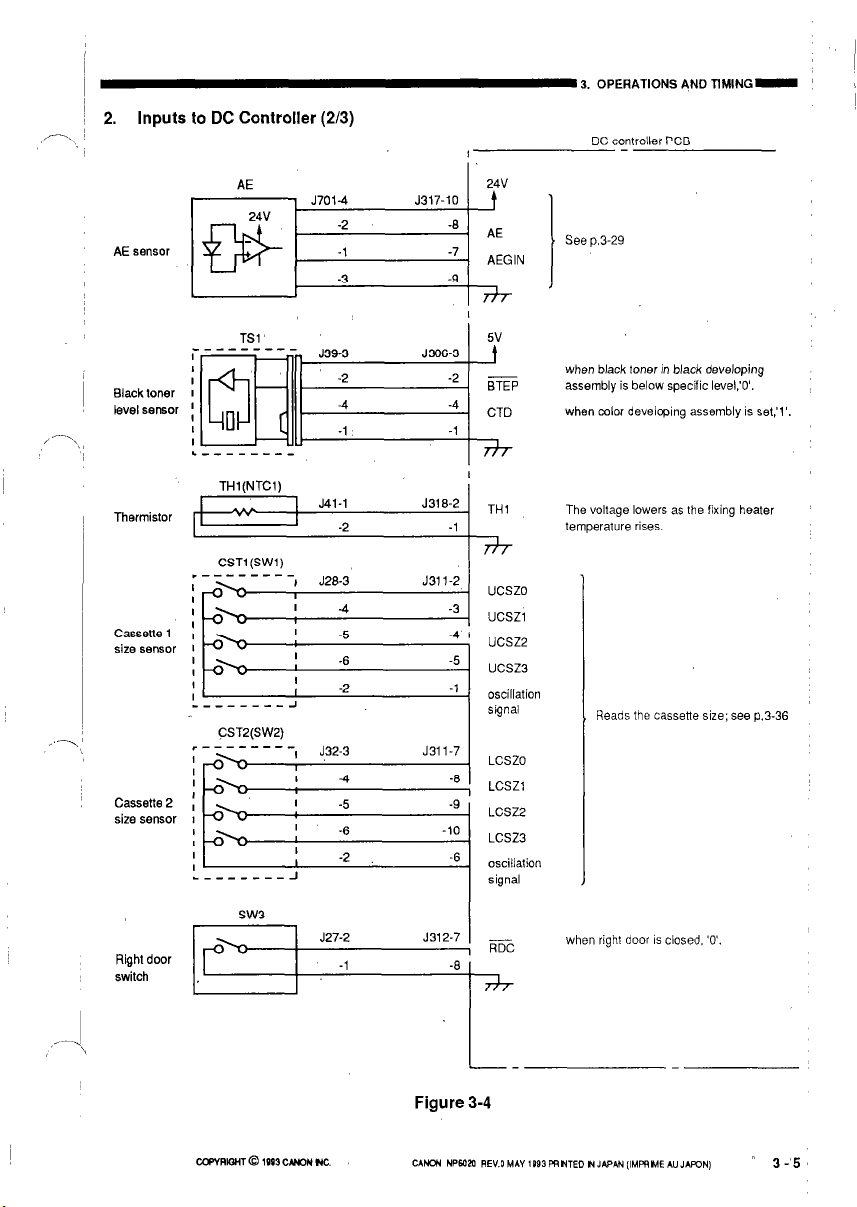

2. Inputs to DC Controller (213)

AE

AE sensor

TSI I 5v

Black toner

level sensor

3. OPERATIONS AND TIMING-

I

24V

I’

DC controller PCS

when black toner in black developing

assembly is below specific level,‘0’.

when color developing assembly is set,‘l’.

Thermistor

Cassette 1

size sensor

cassette 2

size sensor

Right door

switch

THl(NTC1)

I ,._..”

I’

CSTl(SW1)

._______-

!rO\o

I I -5

I-0

I I -6 -5

I-o UCSZB

, I

I

,__-e---J

CSTZ(SW2)

r________

I 1 1-o LCSZO

I I 4 -8

I-0

I I -5 -9

I-0

I I -6 -10

I-o

I

I .

,_____--J

1 J41-1 J318-2

I

-2 -1

J28-3 J311-2

I

I

I -4 -3

I -2 -1

J32-3 J311-7

I

1 -2 -6

I

I

Ttil

ucszo

UCSZl

-4 ’ ucszz

oscillation

signal

LCSZl

LCSZZ

LCSZ3

_ oscillation

signal

The voltage lowers as the fixing heater

temperature rises.

Reads the cassetre size; see p.3.36

when right door IS closed, ‘0’.

~

- 3. OPERATION6 AND TIMING

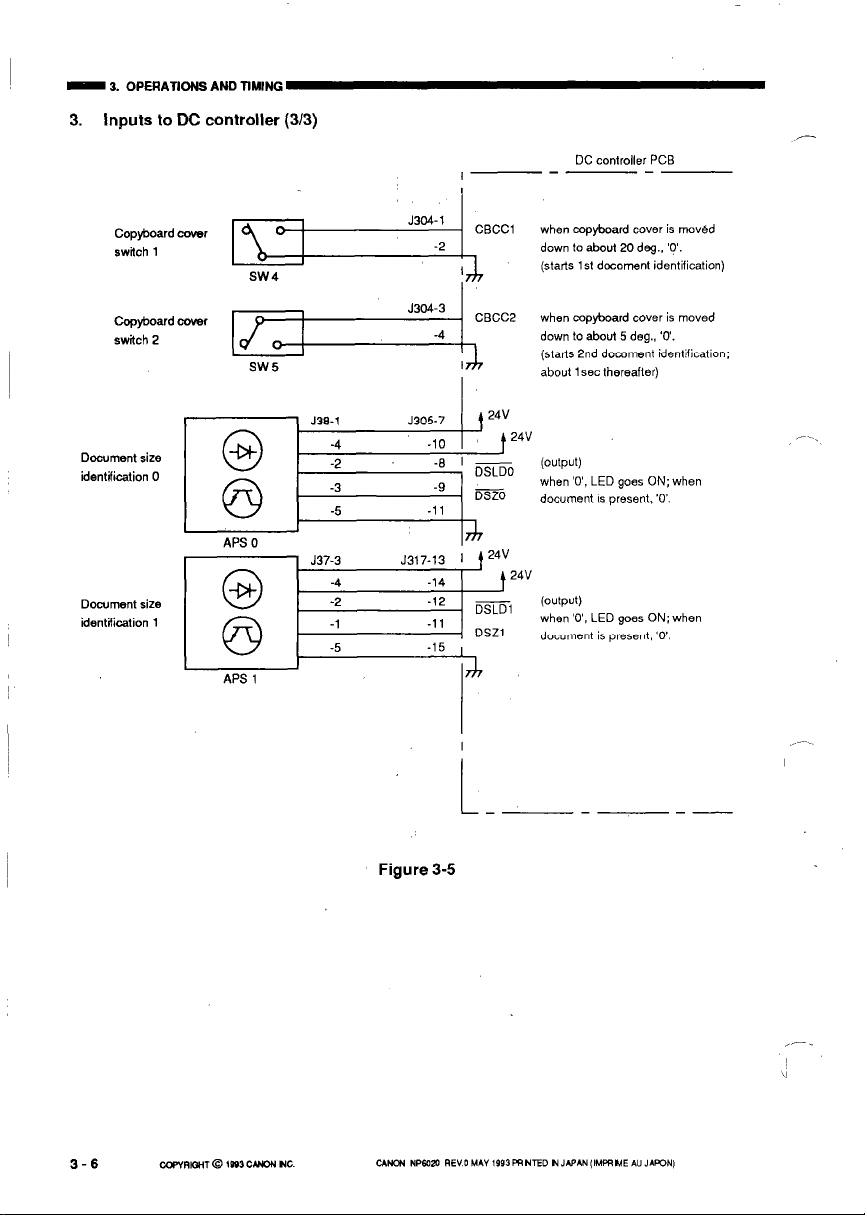

3. Inputs to DC controller (313)

DC controller PCS

Copyboard CM.W

swath,

Document size

identiiication 0

APS 1

J38-1

when copyboard cover is moved

down to about 20 deg., ‘0’.

(starts 1st docomenl identification)

when copyboard cover is moved

down to about 5 deg., ‘0’.

(starts 2nd document identification:

about lsec thereafter)

-10

-8 I -

24V

DSLDO

24V

(output)

when ‘o’, LED goes ON; when

document is present, ‘0’.

(output)

when ‘0, LED goes ON; when

document is present, ‘0’.

J305-7

-2

Figure 3-5

1

:page3.17

I

D. DC Controller Outputs

..-\, ~

DC Controller Outputs (l/3)

1.

DSW(SW2)

SW1

3. OPERATIONS AND TIMING-

DC controlier PC6

-___-___

MMD when ‘l’, main motor ON

I ___._.\~

Fixing roller heater

Scanner motor

Thermo-switch

-4. KD when ‘1’.

@&--%jq+

1

L___________I

AC driver/DC paver

supply PCB

Figure 3-6

I

fixing roller healer ON

AC driver OFF

See page 3-24

~-~

- 3. OPERATIONS AND TMING

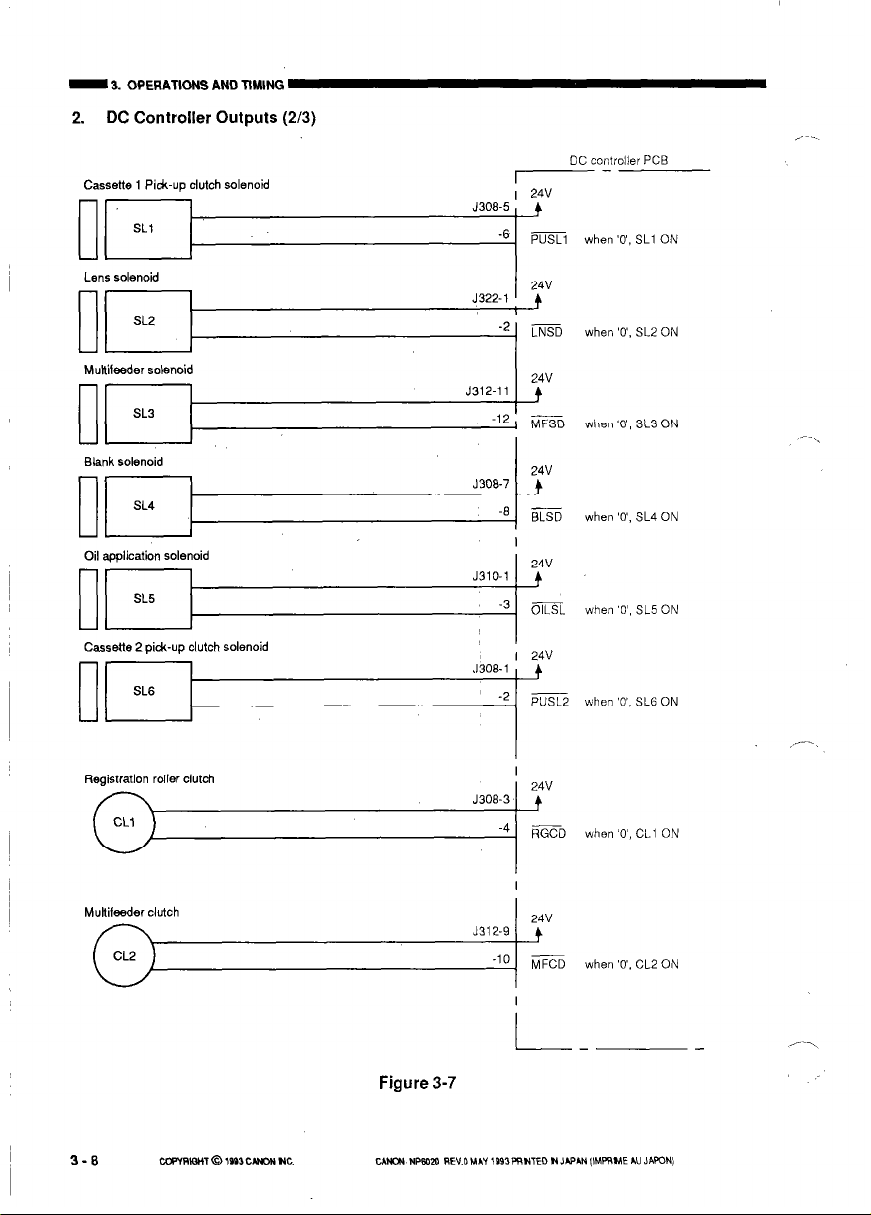

2. DC Controller Outputs (2/3)

Cassette 1 Pick-up clutch solenoid

Lens solenoid

DC contmller PCB

MuWeeder solenoid

-’ LNsD

J312-11 )

-” , i?% when’0 SL3ON

when 0, SL2 ON

24V

I

~

DC Controller Outputs (313)

3.

Scanner cooling fan

Exhaust fan

J309-1

J323-1 I

3. OPERATIONSANDTIMING-

r----------

24V

I

24V

DC controllel PCB

when ‘0’. FM1 ON

when ‘O’, FM2 ON

_________-_____--________,J,3,

I

I

I

I

I

I

1

I

I

1 LA731-LA739

____________-_____---__I

H V T

Pm-exposure lamps LA2

J304 ’

I -2 -6

I

I

I

I

; -1 -5 ’ _

I

I

Figure 3-8

I

24V

PEXP

I

See page 3-25

i______--__

when ‘0’. Pm-exposure lamps ON

Loading...

Loading...