NP-4050

SERVICE

MANUAL

(for 220/240)

REVISION 1

COPYRIGHT

CANON NP-4050 REV, I JAN. 1993 PRINTED IN JAPAN

1993 CANON INC.

JAN. 1993

Canon

FYS-13BF-010

,/--.

,,/-‘\

I. FEATURES

1. Full range of basic features plus four front-loading cassette holders.

- The front loading system (4cassette, maximumof 500 sheets each) enabled acompact design for space

saving.

. As many as 40 copies (A4, horizontal) may be produced for high-speed copying operation.

- The copies may be reduced or enlarged between 50% and 200% in the zoom mode or produced at eight

fixed ratios.

. The copy paper may be as large as A3 or as small as postcards, and it may be tracing paper or OHP.

- The machine’s duplexing unit is designed compact with the adoption of the set-b&system.

2. Variety of additional features including an LCD with dialog-type messages.

- Prompts are given on the display for ease of operation.

- Dates and times may be displayed.

- Some of the modes available to enable efficient copying work include the following:

automatic paper selection, automatic reproduction selection, automatic two-sided/overlay (it A4 or 85,

20 copies continuous; if A3 or B4,i copy), two-page separation, binding, frame erasing, photo, zoom

program, auto cassette change, pre-heat, ID (25 max.), weekly timer (automatic power-otf time), mode

memory, etc.

3. Options for full automatic copying work.

* The machine’s new communication systemforthe RDF, sorter, stapler folder, andotheroptions enables

high-speed system operation.

See “System Configuration.”

COPYRIGHT 0 1923 CANON INC.

CANOII HP-4050 REV.0 JULY 1991 PRINTEO IN JAPAN llMPAlME AU JAPONI

l-l

I GENERAL DESCRIPTION

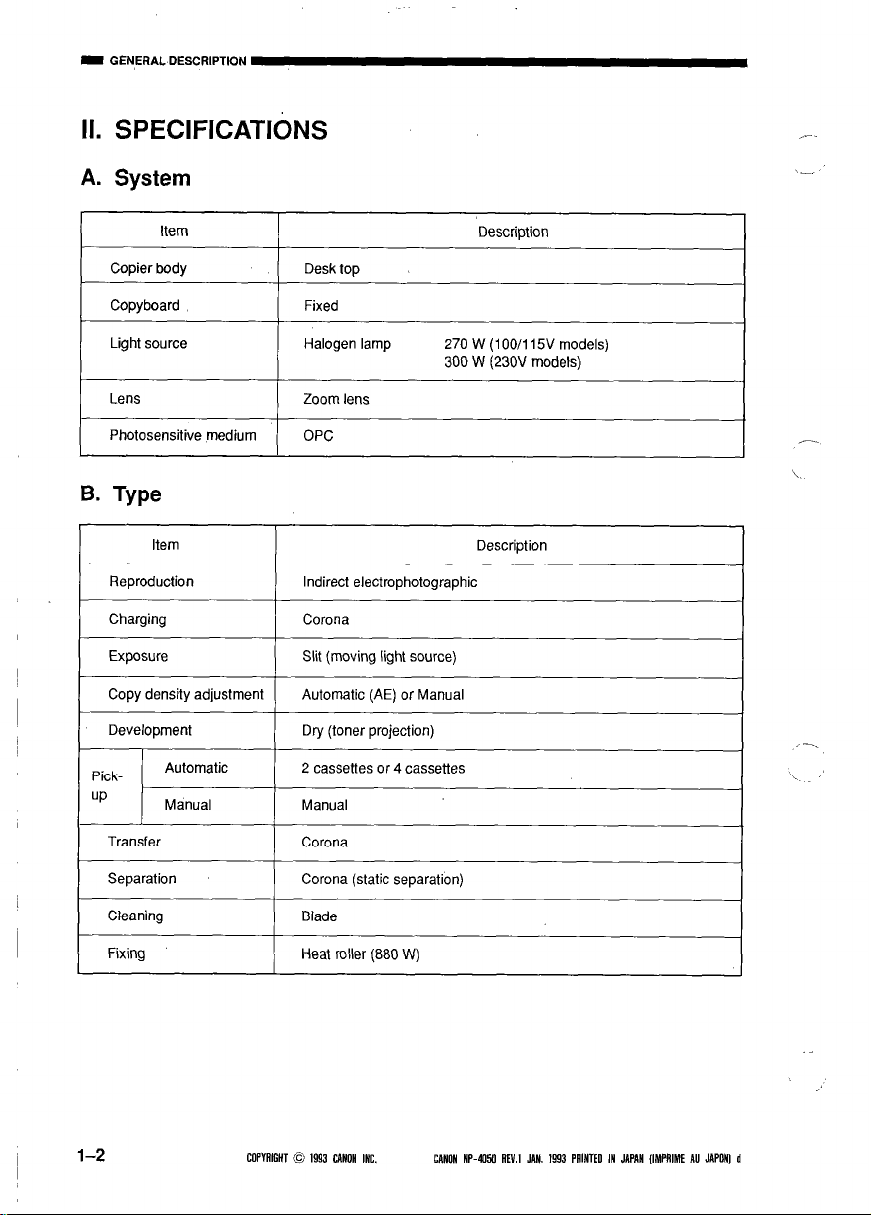

II. SPEClFlCATlbNS

A. System

Item

Copier body

Copyboard

Light source

Lens

Photosensitive medium

B. Type

Item Description

Reproduction

Charging

Exposure Slit (moving light source)

Copy density adiustment

Development

Desk top

Fixed

Halogen lamp

Zoom lens

OPC

Indirect electrophotographic

Corona

Automatic (AE) or Manual

Dry (toner projection)

-,

Description

270 W (100/l 15V models)

300 W (230V models)

,_

Pickup

I

l-2

Automatic

Manual

Transfer

Separation

Cleaning

Fixing

2 cassettes or 4 cassettes

Manual

Corona

Corona (static separation)

Blade

Heat roller (880 W)

COPYRIGHT 0 1903 CANON INC. CANON HP-4050 NEV.1 JAN. 1993 PAINTED IN JAPAN (IMPRIME AU JAPONI d

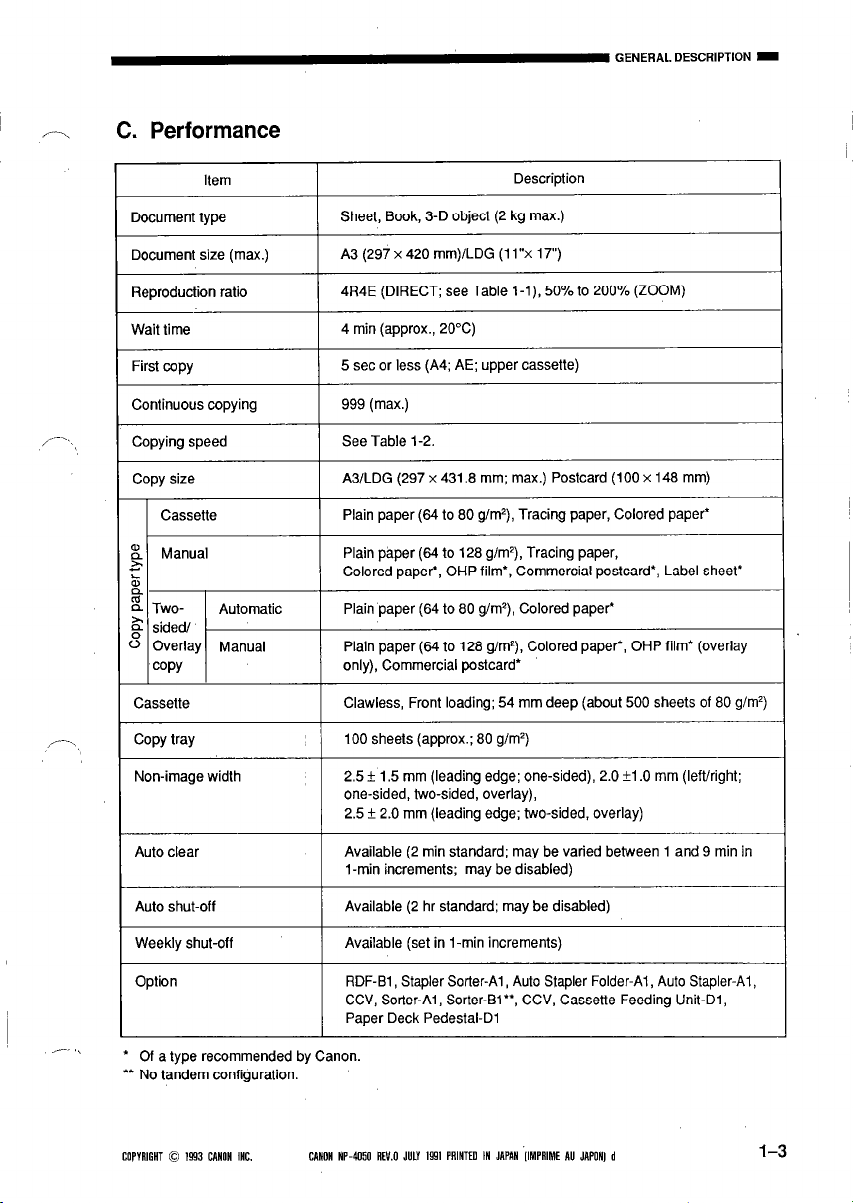

C. Performance

Item

Document type

Document size (max.)

Reproduction ratio

Wait time

First copy

Continuous copying

Copying speed

Copy size

Cassette

g Manual

,x

&

4

a Two-

Automatic

$ sided/

0 Overlay Manual

COPY

Cassette

Copy tray

Description

Sheet, Book, 3-D object (2 kg max.)

A3 (297 x 420 mm)/LDG (11”~ 17”)

4R4E (DIRECT; see Table l-l), 50% to 200% (ZOOM)

4 min (approx., 20°C)

5 set or less (A4; AE; upper cassette)

999 (max.)

See Table 1-2.

A3/LDG (297 x 431.8 mm; max.) Postcard (100 x 148 mm)

Plain paper (64 to 80 g/m*), Tracing paper, Colored paper’

Plain paper (64 to 128 g/m’), Tracing paper,

Colored paper’, OHP film*, Commercial postcard’, Label sheet*

Plain paper (64 to 80 g/m2), Colored paper’

Plain paper (64 to 128 g/m2), Colored paper*, OHP film’ (overlay

only), Commercial postcard’

Clawless, Front loading; 54 mm deep (about 500 sheets of 80 g/m2)

100 sheets (approx.; 80 g/m’)

Non-image width

2.5 f 1.5 mm (leading edge: one-sided), 2.0 fl .O mm (left/right;

one-sided, two-sided, overlay),

2.5 f 2.0 mm (leading edge; two-sided, overlay)

Auto clear

Available (2 min standard; may be varied between 1 and 9 min in

1-min increments; may be disabled)

Auto shut-off

Weekly shut-off

Option

Available (2 hr standard; may be disabled)

Available (set in I-min increments)

RDF-Bl , Stapler Sorter-Al, Auto Stapler Folder-Al, Auto Stapler-Al,

CCV, Sorter-Al, Sorter-Bl”, CCV, Cassette Feeding Unit-Dl,

Paper Deck Pedestal-D1

* Of a type recommended by Canon.

** No tandem configuration.

COPYRIGHT 0 1593 CAHOH INC.

CANON NP-4050 REV.0 JULY 1991 PRINTEO IN JAPAN ‘IIMPAIME AU JAPONI d

1-3

I GENERAL DESCRIPTION

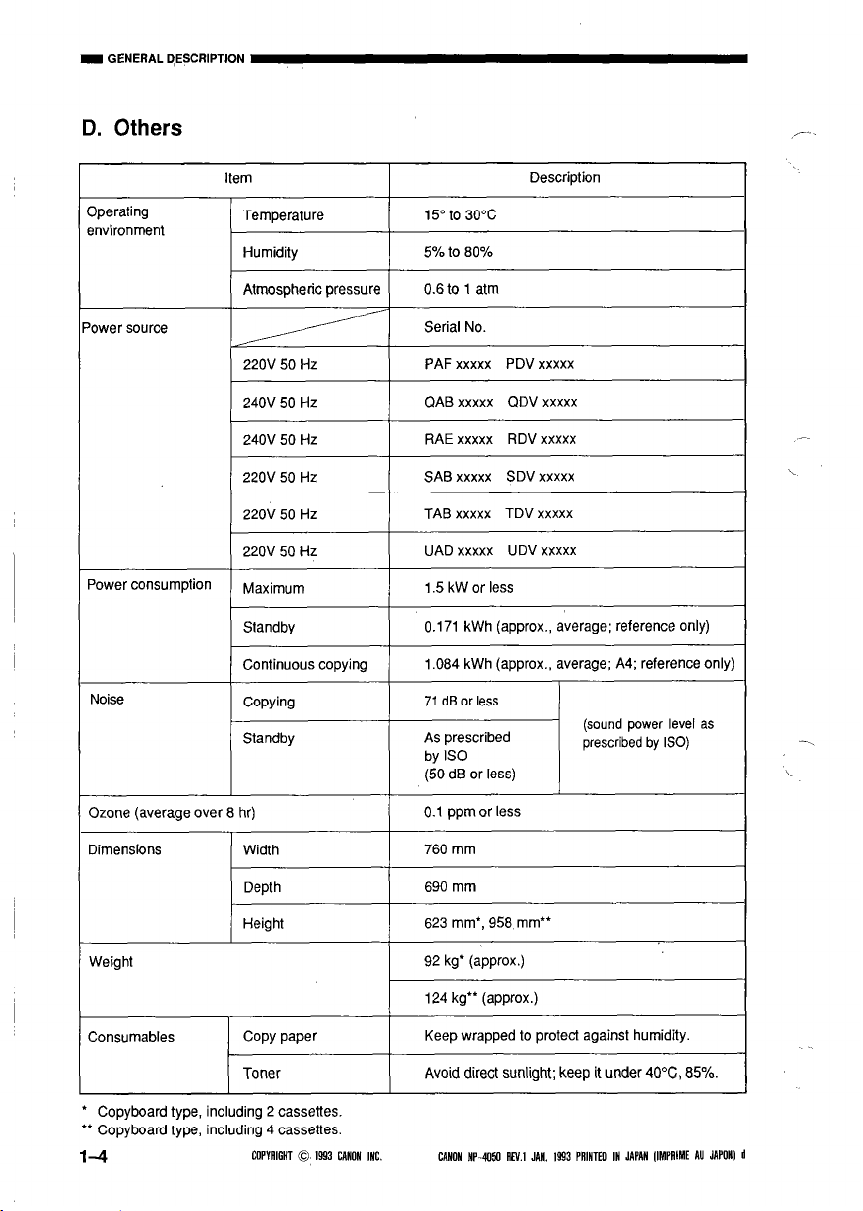

D. Others

environment

Height

Weight

Consumables

Copy paper

Toner

* Copyboard type, including 2 cassettes.

‘* Copyboard type, including 4 cassettes.

l-4

COPYAIGHT 0 1993 CANON INC.

(sound power level as

prescribed by ISO)

623 mm’, 958 mm”

92 kg’ (approx.)

124 kg” (approx.)

Keep wrapped to protect against humidity.

Avoid direct sunlight; keep it under 40X, 85%.

CANON NP-4050 AN.1 JAN. IS93 PRINTED IN JAPAN IIMPAIME AU JAPONI d

GENERAL DESCRIPTION I

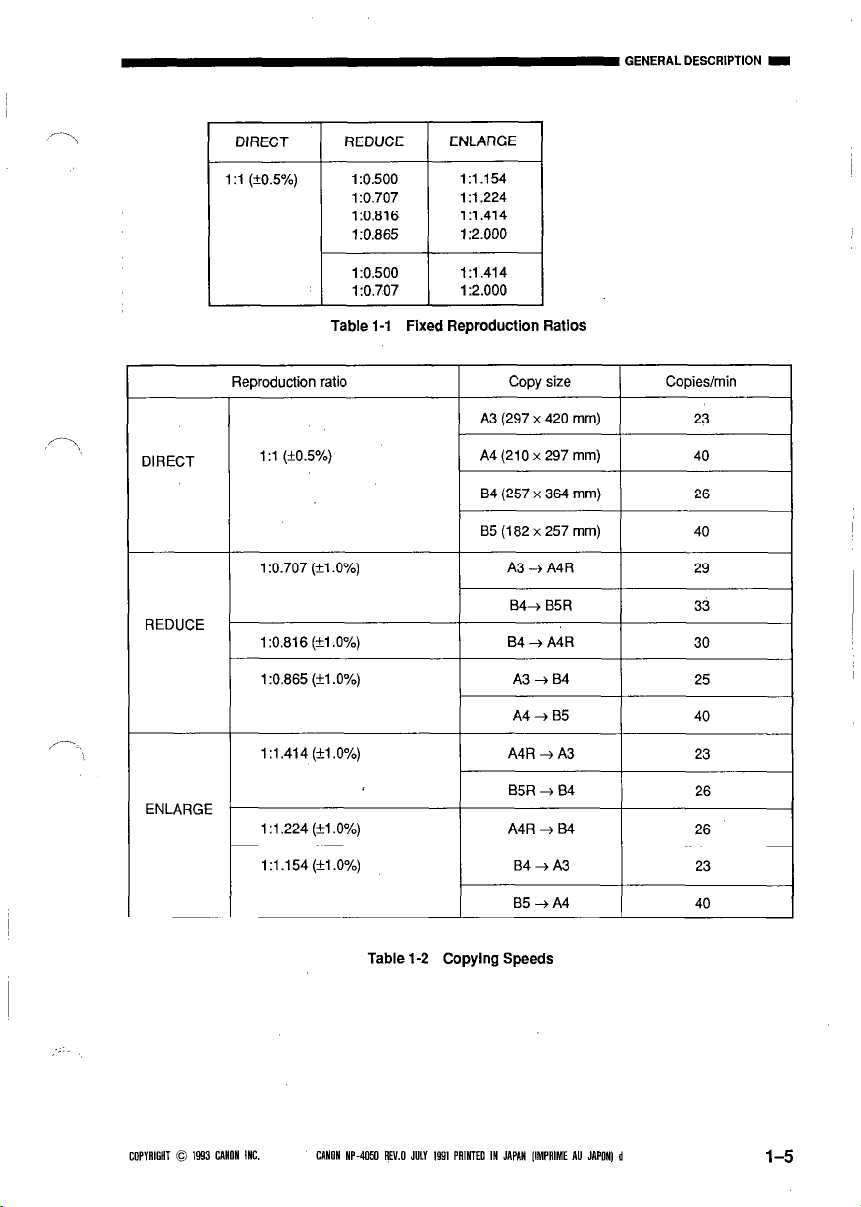

DIRECT

REDUCE

ENLARGE

1 :I (+o.s%) 1:0.500 1:1.154

1:0.707 1 :I ,224

1:0.816 1:1.414

1:0.865 1:2.000

1:0.500 1:1.414

1:0.707 I :2.000

Table 1-l Fixed Reproduction Ratios

Reproduction ratio

I

Copy size

I

Copieslmin

Table 1-2 Copying Speeds

CCIPK~ICHT 0 IS93 CANON INC. CANON HP-4050 REV.0 JULY 1991 PRINTED IN JAPAN [IMPRIME AU JAPON) d

1-5

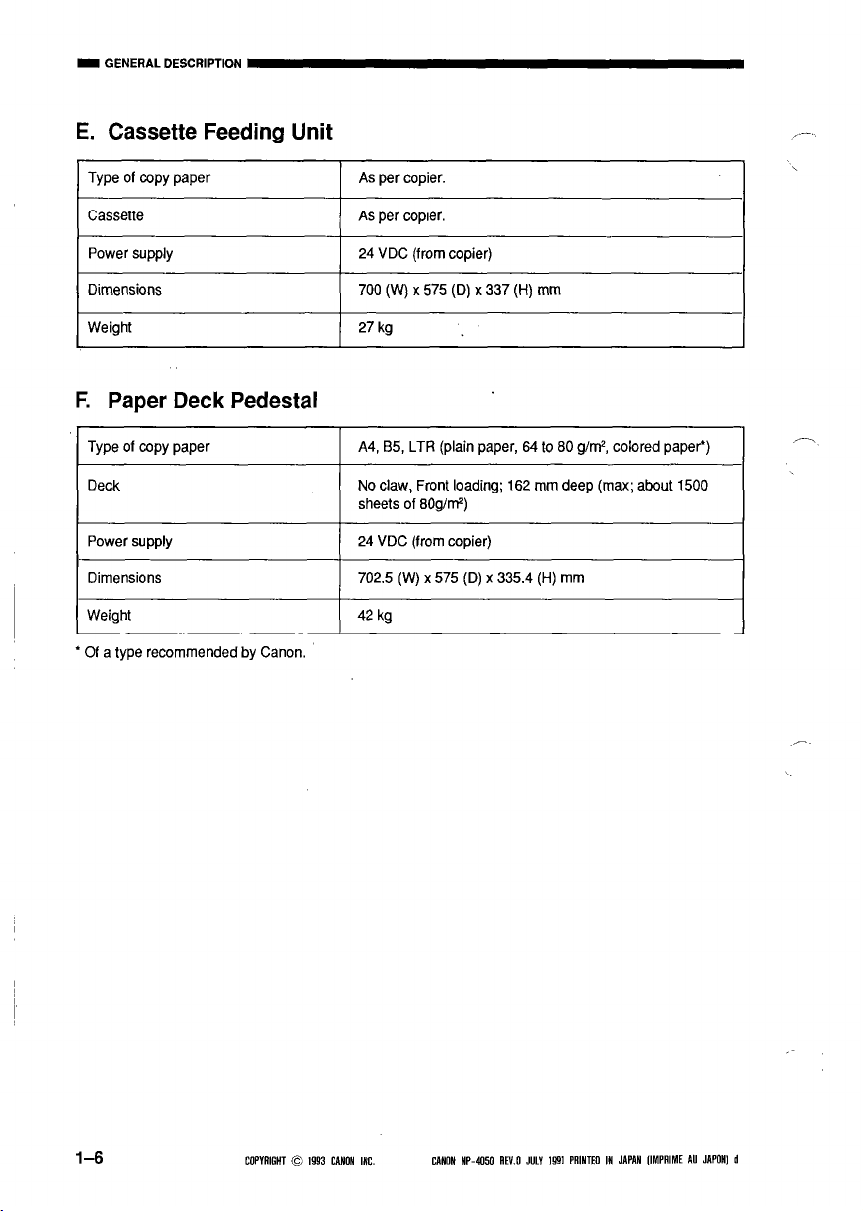

E. Cassette Feeding Unit

Type of copy paper As per copier.

Cassette

Power supply

Dimensions

Weight

As per copier.

24 VDC (from copier)

700 (W) x 575 (D) x 337 (t-t) mm

27 kg

F. Paper Deck Pedestal

Type of copy paper

Deck No claw, Front loading; 162 mm deep (max; about 1500

Power supply 24 VDC (from copier)

Dimensions 702.5 (W) x 575 (D) x 335.4 (H) mm

Weight

l of a type recommended by Canon.

A4, 85, LTR (plain paper, 64 to 80 g/M, colored paper*)

sheets of SOgM’)

42 kg

l-6

COPYRIGHT 0 1993 CANON INC.

CANON HP-4050 AN.0 JULY 1991 PAINTEO 111 JAPAN [IMPAIME AU JAPONI d

,--_

x

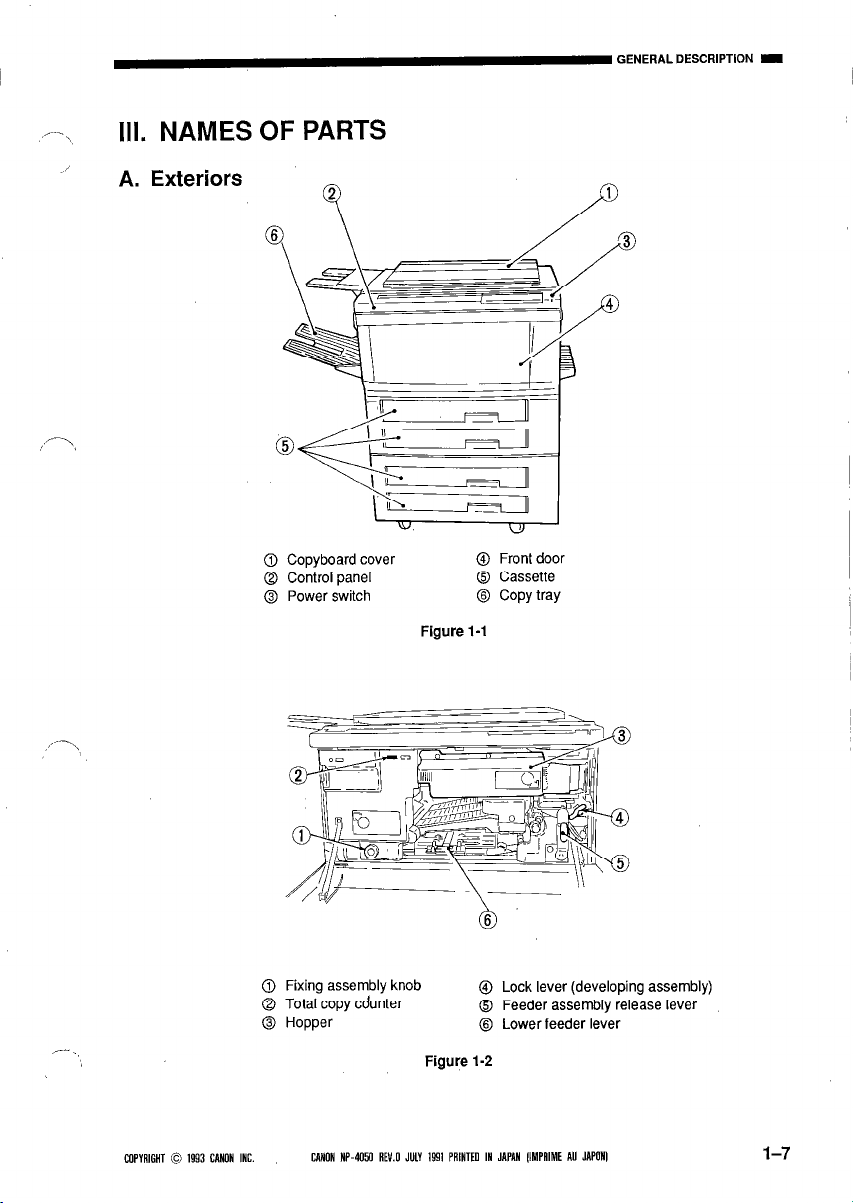

III. NAMES OF PARTS

A. Exteriors

GENERAL DESCRIPTION I

Q

0 Copyboard cover

Q Control panel

@ Power switch

@ Fixing assembly knob

Q Total copy cdunter

@ Hopper

Figure 1-l

Figure 1-2

@ Front door

@ Cassette

@ Copy tray

Lock lever (developing assembly)

@

Feeder assembly release lever

0

Lower feeder lever

@

COPYRIGHT 0 1993 CANON INC.

CANON NP-4050 REV.0 JULY 1991 PRINTEO IN JAPAN IIMPAIME AU JAPONI

l-7

I GENERAL DESCRIPTION

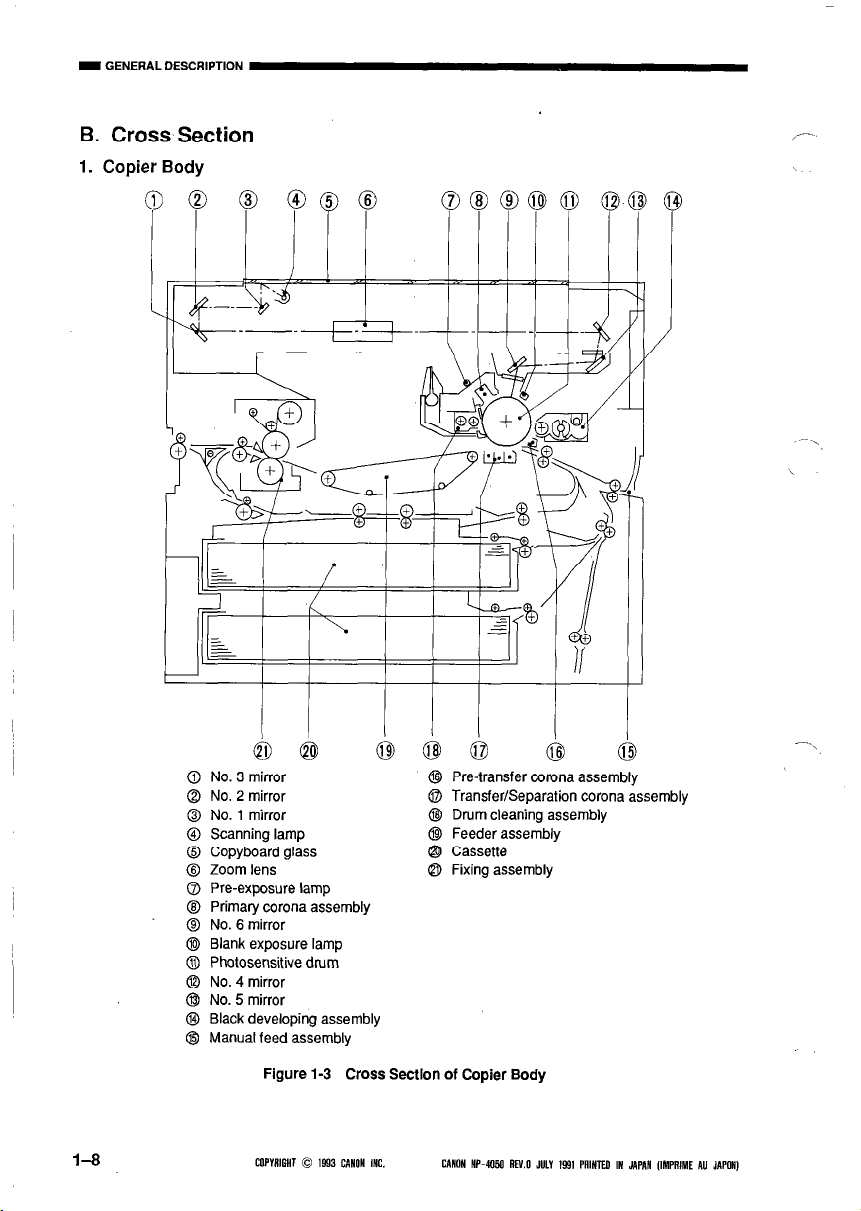

B. Cross Section

1. Copier Body

1-8

No. 3 mirror

No. 2 mirror

No. 1 mirror

Scanning lamp

Copyboard glass

Zoom lens

Pre-exposure lamp

Primary corona assembly

No. 6 mirror

Blank exposure lamp

Photosensitive drum

No. 4 mirror

No. 5 mirror

Black developing assembly

Manual feed assembly

Figure 1-3 Cross Section of Copier Body

COPYRIGHT 0 1993 CAIIOH INC.

Q Pre-transfer corona assembly

@I Transfer/Separation corona assembly

8 Drum cleaning assembly

@I Feeder assembly

0 Cassette

@I Fixing assembly

CANON HP-4050 RN.0 JULY 1991 PAINTEA IN JAPAN IIMPAIME AU JAPON)

-I’\

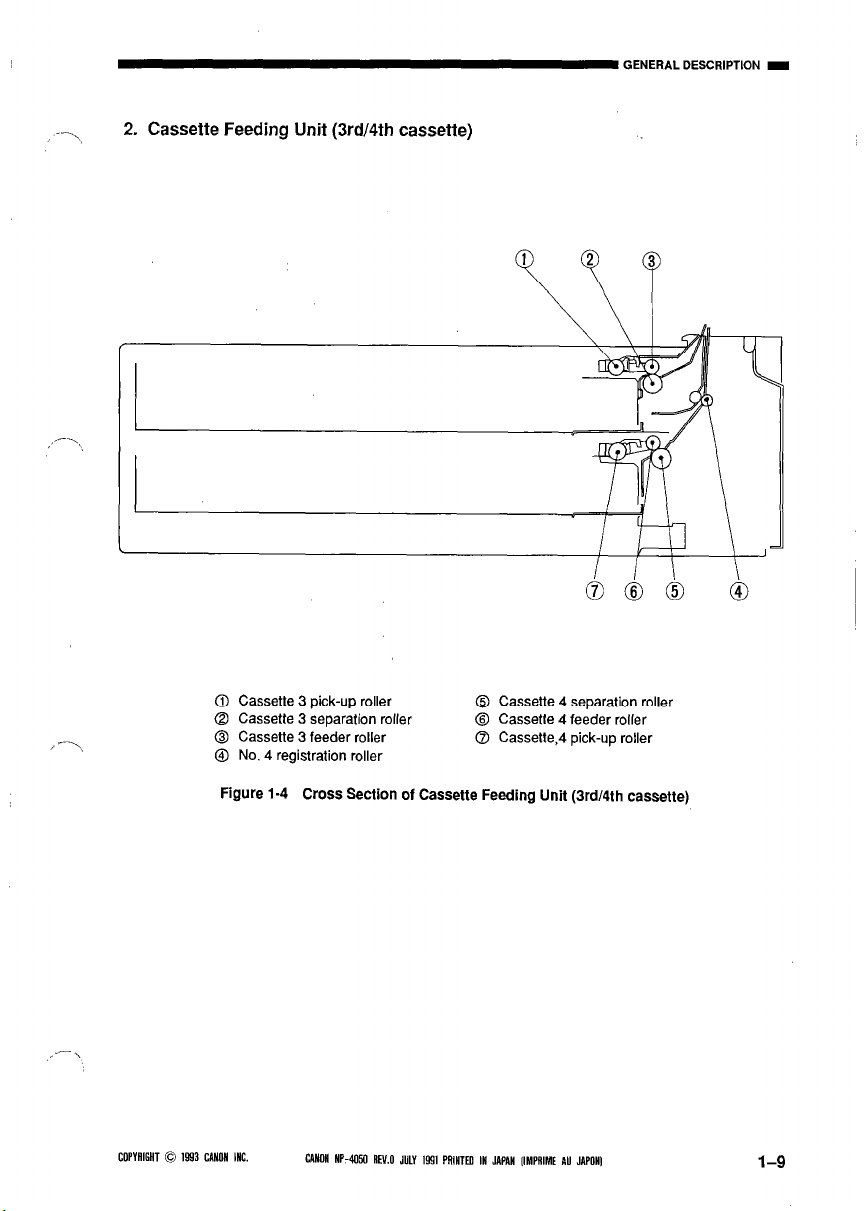

2. Cassette Feeding Unit (3rd/4th cassette)

j---Y

@ Cassette 3 pick-up roller

Q Cassette 3 separation roller

@ Cassette 3 feeder roller

@ Cassette 4 separation roller

Q Cassetle 4 feeder roller

0 Cassette,4 pick-up roller

@ No. 4 registration roller

Figure l-4 Cross Section of Cassette Feeding Unit (3rd/41h cassette)

.-

COPYAIGHT 0 1993 CANON INC.

CANON HP-4OSO AN.0 JULY 1991 PRINTEM IN JAPAN [IMPRIME AU JAPONI

l-9

IGENERALDESCAIPTION

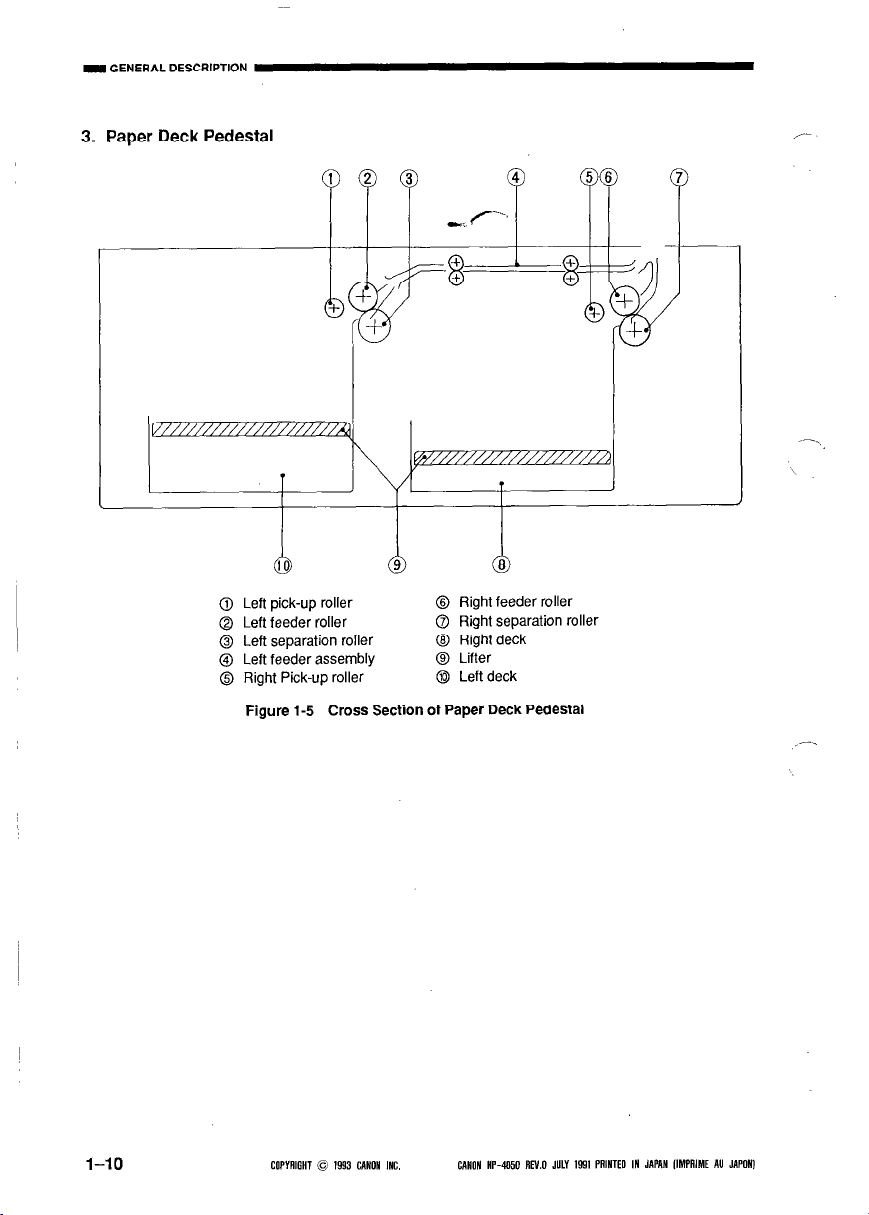

3. Paper Deck Pedestal

l-10

Left pick-up roller

Left feeder roller

Left separation roller

Left feeder assembly

Right Pick-up roller

Figurel-5 Cross Section of Paper Deck Pedestal

COPYAIGHT 0 1993 CANON INC.

@ Right feeder roller

@ Right separation roller

@ Right deck

@ Lifter

@ Left deck

CANON HP-4050 REV.0 JULY 1931 PRINTED IN JAPAN IIMPAIME AU JAPONI

GENERALDESCRIPTION I

.‘7,

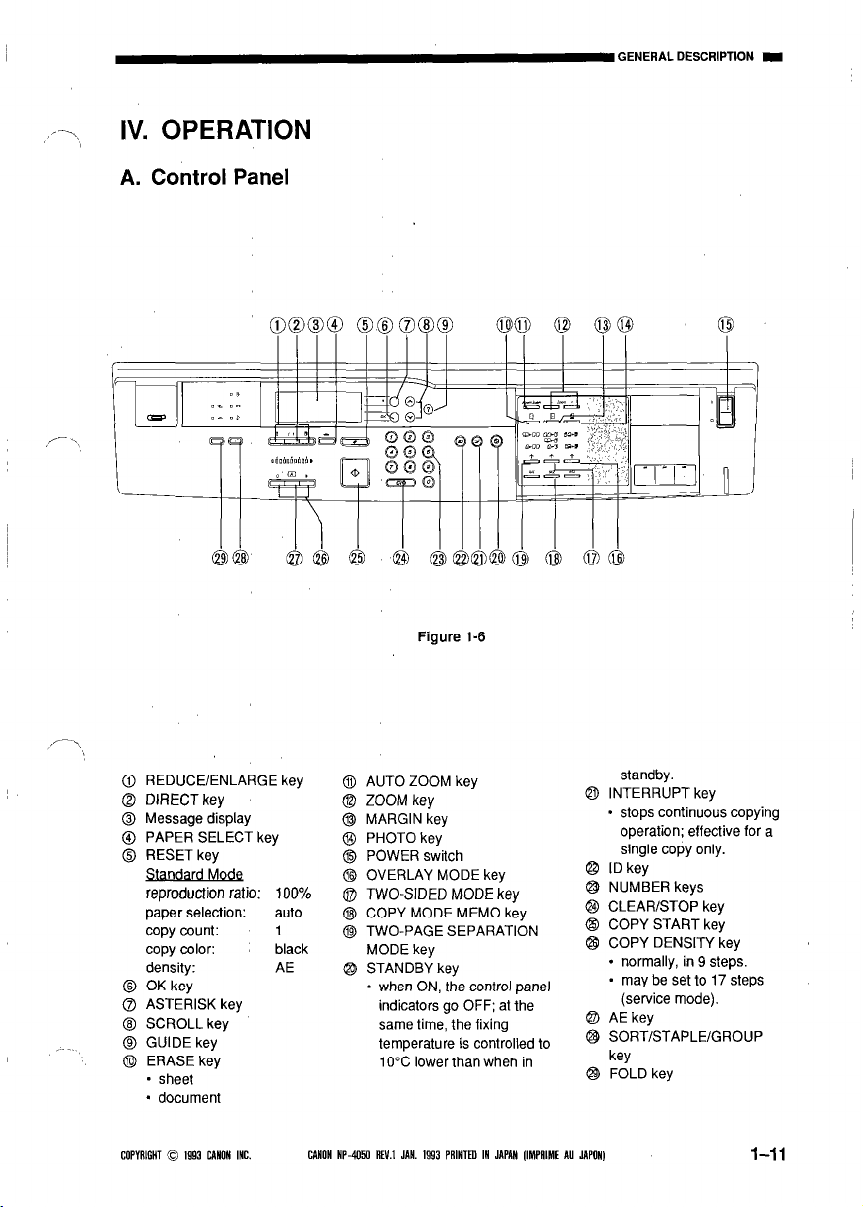

IV. OPERATION

A. Control Panel

Figure I-6

REDUCE/ENLARGE key

DIRECT key

Message display

PAPER SELECT key

RESET key

Standard MoQ

reproduction ratio: 100%

paper selection: auto

copy count:

copy color: black

density: AE

OK key

ASTERISK key

SCROLL key

GUIDE key

ERASE key

- sheet

- document

COPYRIGHT 0 IQ93 CANON INC.

@I AUTO ZOOM key

@I ZOOM key

@ MARGIN key

@ PHOTO key

@ POWER switch

Q OVERLAY MODE key

0 TWO-SIDED MODE key

1

@I COPY MODE MEMO key

@ TWO-PAGE SEPARATION

MODE key

@ STANDBY key

- when ON, the control panel

indicators go OFF; at the

same time, the fixing

temperature is controlled to

10°C lower than when in

CANON HP-4050 REV.1 JAN. 1993 PAINTED IN JAPAN IIMPAIME AU lAPON

standby.

@I INTERRUPT key

- stops continuous copying

operation; effective for a

single copy only.

@ IDkey

@ NUMBER keys

@I CLEAR/STOP key

@I COPY START key

@ COPY DENSITY key

* normally, in 9 steps.

- may be set to 17 steps

(service mode).

@ AE key

‘23 SORT/STAPLE/GROUP

key

8 FOLD key

1-11

6. Making Copies

Press the POWER switch to the ‘ON’ position.

1)

- The WAIT indicator starts to glow green when

the temperature of the fixing assembly

reaches a specific value.

- Normally, the watt time is about 4 min (at

20°C ambient temperature).

Lit the copyboard cover, and place the docu-

2)

ment face down along the size index.

Press the DIRECT, REDUCE, ENLARGE, or

3)

ZOOM key to suit the size of the copy paper.

Select the cassette holder if to specify the size

4)

of copy paper.

- Replace the cassette if necessary.

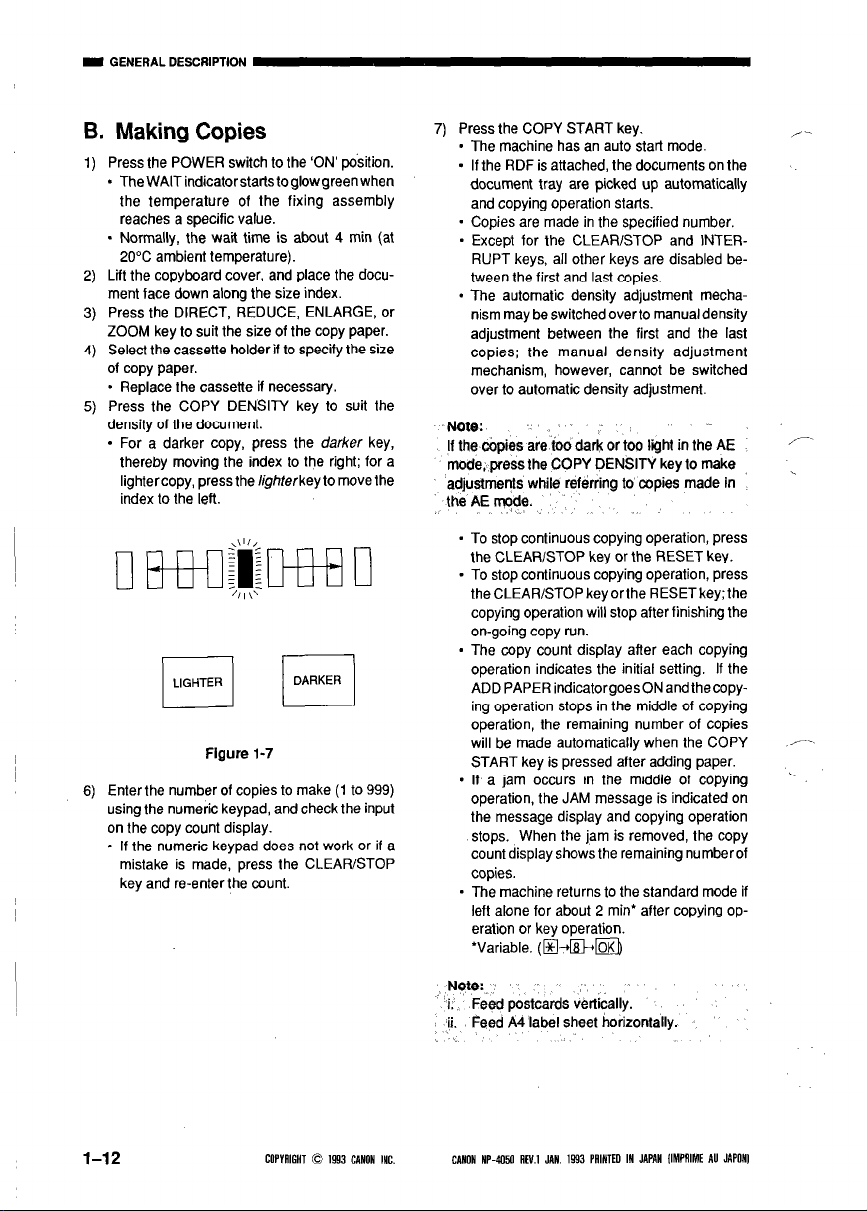

Press the COPY DENSITY key to suit the

5)

density of the document.

- For a darker copy, press the darker key,

thereby moving the index to the right; for a

lightercopy, press the lighterkeyto move the

index to the left.

7) Press the COPY START key.

. The machine has an auto start mode.

- If the RDF is attached, the documents on the

document tray are picked up automatically

and copying operation starts.

- Copies are made in the specified number,

- Except for the CLEAR/STOP and INTER-

RUPT keys, all other keys are disabled be-

tween the first and last copies.

- The automatic density adjustment mecha-

nism may be switched overto manual density

adjustment between the first and the last

copies; the manual density adjustment

mechanism, however, cannot be switched

over to automatic density adjustment.

Note:

tf the copies are too dark or too tffht in the AE

mode, press the COPY DENSITY key to make

adjustments white referring to copies made in

the AE yde.

t.

“.

/

‘-

,

- To stop continuous copying operation, press

the CLEAR/STOP key or the RESET key.

s To stop continuous copying operation, press

theCLEAR/STOPkeyorthe RESETkey;the

copying operation will stop after finishing the

on-going copy run.

- The copy count display after each copying

operation indicates the initial setting. If the

ADD PAPER indicatorgoesON andthecopy-

ing operation stops in the middle of copying

operation, the remaining number of copies

Figure l-7

I

Enter the number of copies to make (1 to 999)

6)

using the numeric keypad, and check the input

on the copy count display.

0 If the numeric keypad does not work or if a

mistake is made, press the CLEAR/STOP

key and re-enter the count.

will be made automatically when the COPY

START key is pressed after adding paper.

. If a jam occurs in the middle of copying

operation, the JAM message is indicated on

the message display and copying operation

stops. When the jam is removed, the copy

count display shows the remaining numberof

copies.

- The machine returns to the standard mode if

left alone for about 2 min’ after copying op-

eration or key operation.

‘Variable. (m-@-+m

--

’

1-12

COPMIGHT 0 1993 CANON INC.

Note:

i: Feed postcards vertically.

‘ii. Feed A4 label sheet horizontally.

CANON HP-4050 AEV.1 JAN, 1593 PAINTED IN JAPAN IIMPRIME AU JAPONI

,.

,--,

*-I

,,---,

C. Auto Start Mode

The auto start mode may be activated while the

copier is in the following wait states: during the wait

period after power-on, during the wait period after

deactivation of the pre-heat mode, and during the

cleaning operation of the wire.

Set the documents during the wait period, set

the copy modes, and press the COPY START key.

The WAIT indicator will change from green to

orange to indicate that the auto start mode has been

activated: no interrupt command will be accepted.

Copying operation will start automatically using

the preselected copy modes as soon as the copier

enters the standby mode.

The automatic start mode may be deactivated

using the CLEAR/STOP key or the RESET key.

D. Making Two-Sided/Overlay

Copies Manually

Two-sided or overlay copies may be made

manually; note the following:

i. Orientthecopycorrectly; i.e., turnoverthecopy

without changing its rear/front orientation.

ii. Make sure that the paper is not moist.

iii. Make sure that the paper is not curled.

iv. Cool the copy sufficiently after first copy run,

and correct the curl, if any, before the second

copy run (OHP film, in particular).

v. Use paper of 60 to 12Og1m2.

E. Storing the ID Mode

‘I

As many as 25 4-digit ID numbers may be

stored; copies may be made only in response to any

of the stored numbers, and an accumulative count

of copies undereach number may also be obtained.

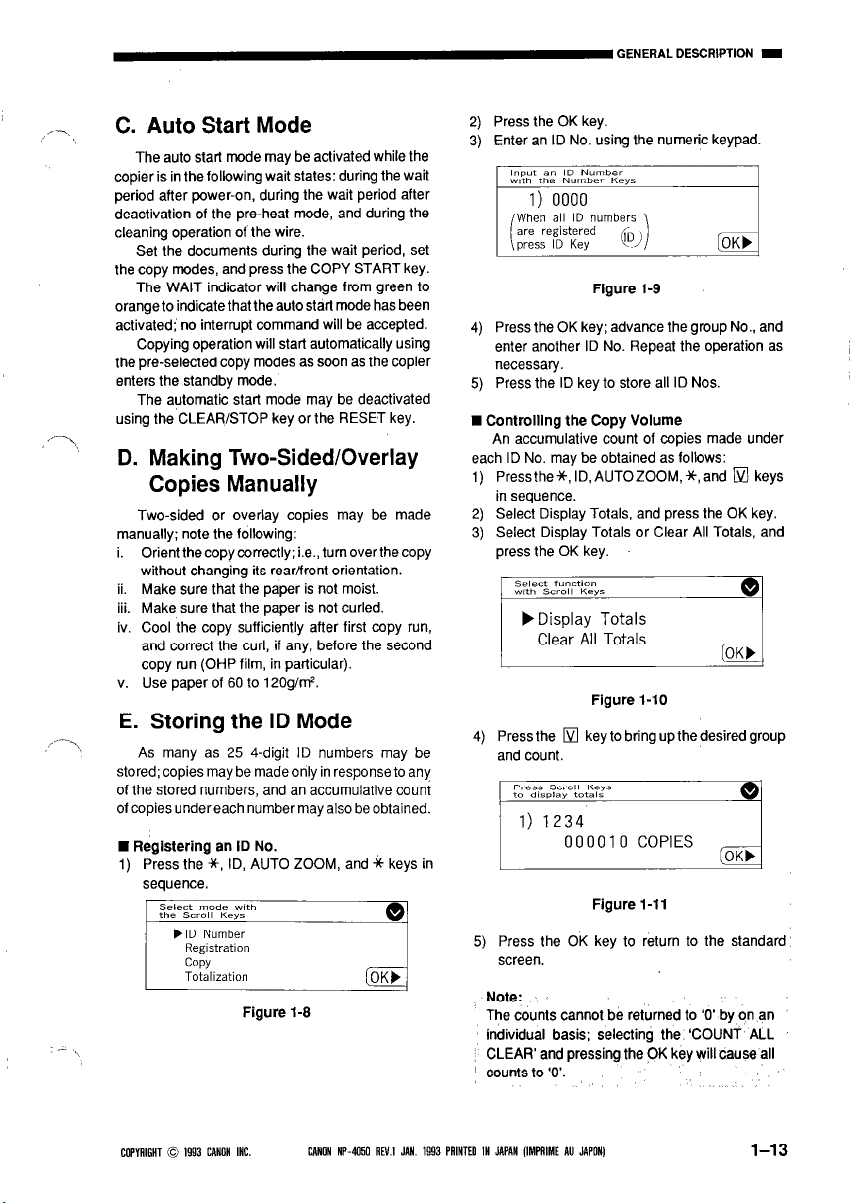

n Registering an ID No.

1) Press the *, ID, AUTO ZOOM, and * keys in

sequence.

,ID Number

Registration

COPY

Totalization

Figure l-9

2) Press the OK key.

3) Enter an ID No. using the numeric keypad.

Figure I-9

4) Press the OK key; advance the group No., and

enter another ID No. Repeat the operation as

necessary.

5) Press the ID key to store all ID Nos.

n Controlllng the Copy Volume

An accumulative count of copies made under

each ID No. may be obtained as follows:

Pressthe*,~ID.AUTOZOOM,*,and [ZZI keys

in sequence.

Select Display Totals, and press the OK key.

Select Display Totals or Clear All Totals, and

press the OK key.

Figure l-10

Press the q key to bring up the desired group

and count.

000010 COPIES

Figure l-11

Press the OK key to return to the standard

5)

screen.

Note:

The counts cannot be returned to ‘0’ by on an

individual basis; selecting the ‘COUNT ALL

CLEAR’ and pressing the PK key will cause all

I counts to ‘0’.

COPYAIGHT 0 1993 CANON INC.

CANON HP-4050 REV.1 JAN. 1993 PAINTED IN JAPAN IIMPRIME AU JAPON)

1-13

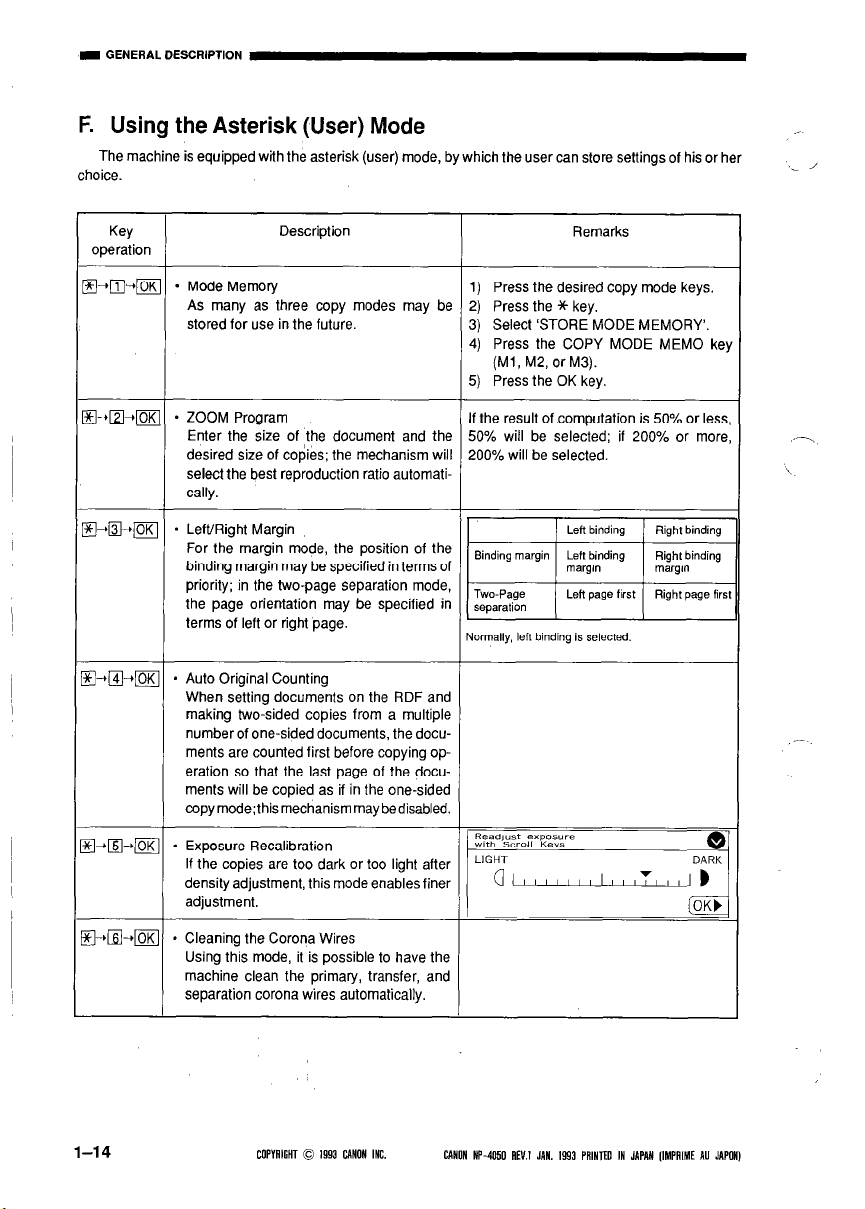

F. Using the Asterisk (User) Mode

The machine is equipped with the asterisk (user) mode, by which the user can store settings of his or her

Key

operation

@ii-l

o-+n+m[

q -rO-tjOK

~-@l--rpiJ

Description Remarks

- Mode Memory

1) Press the desired copy mode keys.

As many as three copy modes may be 2) Press the *key,

stored for use in the future. 3) Select ‘STORE MODE MEMORY’.

4) Press the COPY MODE MEMO ke)

(Ml, M2, or M3).

5) Press the OK key.

- ZOOM Program

If the result of computation is 50% or less

Enter the size of the document and the 50% will be selected; if 200% or more

desired size of copies; the mechanism will

200% will be selected.

select the best reproduction ratio automatically.

- Left/Right Margin

For the margin mode, the position of the

binding margin may be specified in terms of

priority; in the two-page separation mode,

the page orientation may be specified in

terms of left or right page.

* Auto Original Counting

When setting documents on the RDF and

making two-sided copies from a multiple

number of one-sided documents, the documents are counted first before copying operation so that the last page of the documents will be copied as if in the one-sided

copymode;thismechanismmaybedisabled.

~

Normally, left binding is selected.

--,

i

.-

?+rn-,@

* Exposure Recalibration

If the copies are too dark or too light after

density adjustment, this mode enables finer

adjustment.

~-~i?-~ * Cleaning the Corona Wires

Using this mode, it is possible to have the

machine clean the primary, transfer, and

separation corona wires automatically.

1-14 COPYAlGHT 0 1993 CdNON INC.

CANON NWC50 AN.1 JAN. 1543 PAINTED IN JAPAN lIMPRIME AU JAPON)

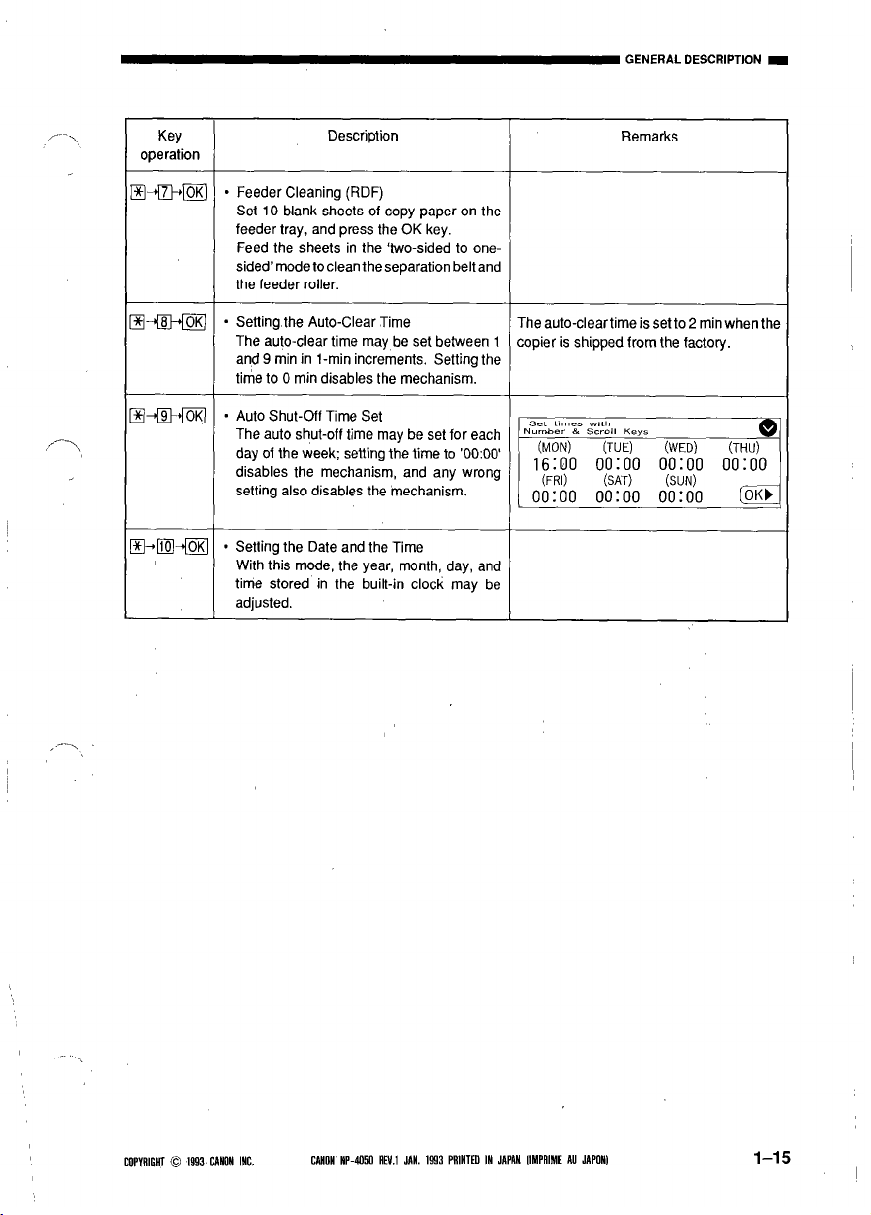

Key

operation

-

Description Remarks

- Feeder Cleaning (RDF)

I

Set 10 blank sheets of copy paper on the

feeder tray, and press the OK key.

Feed the sheets in the ‘two-sided to onesided’ mode to clean the separation belt and

the feeder roller.

- Setting the Auto-Clear Time

The auto-clear time may be set between 1

and 9 min in 1-min increments. Setting the

tiie to 0 min disables the mechanism.

. Auto Shut-Off Time Set

The auto shut-off time may be set for each

day of the week; setting the lime to ‘0O:OO

disables the mechanism, and any wrong

setting also disables the mechanism.

) Setting the Date and the Time

1

With this mode, the year, month, day, and

time stored in the built-in clock may be

adjusted.

The auto-clear time is set to 2 min when the

copier is shipped from the factory.

COPYAlGHT 0 1993 UWON INC.

CANON IIP-405D ilE’J.1 #II. 1993 PRINTED IN JAWLN IIMPAIME AU JAPON)

1-15

I GENERAL DESCAIPTIDN

V. WARNINGS AND COR-

RECTIONS

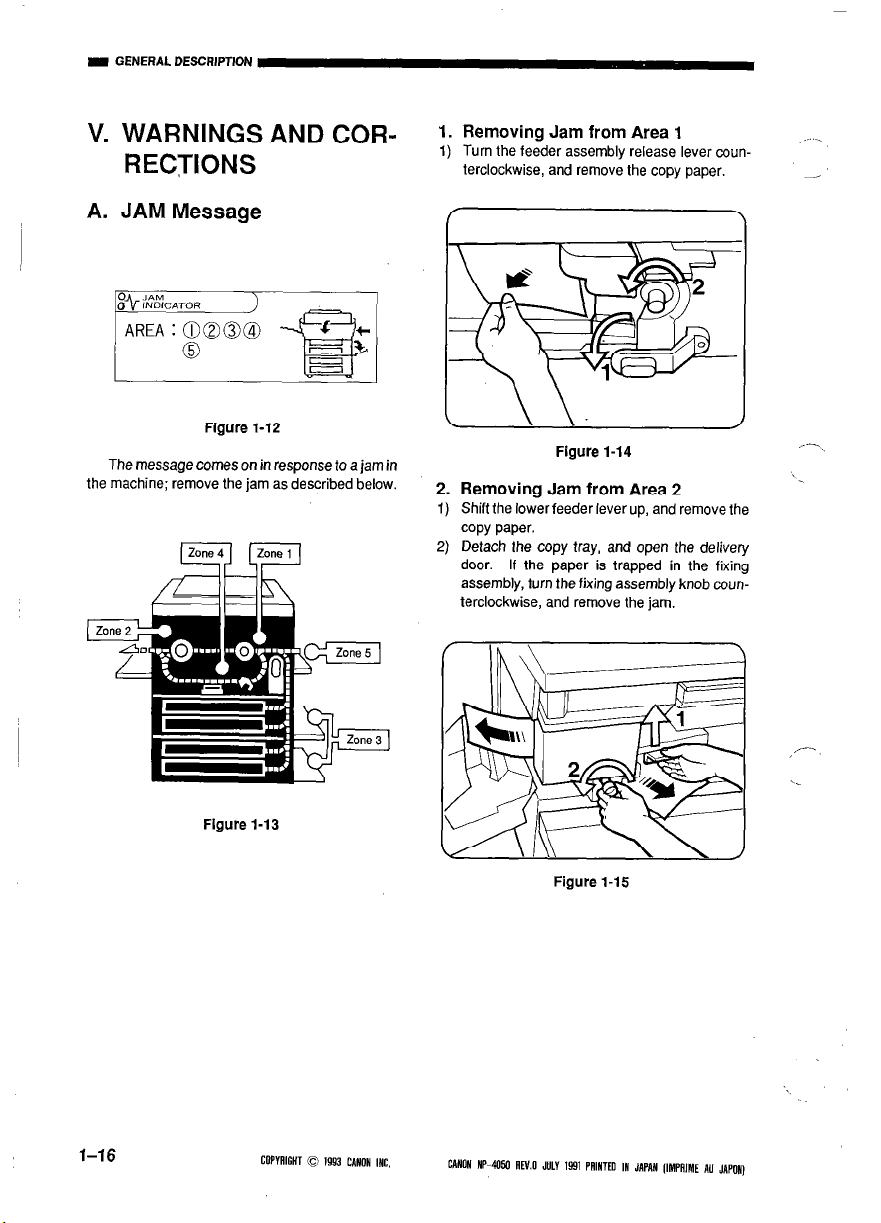

A. JAM Message

Figure 1-12

The message comes on in response to a jam in

the machine; remove the jam as described below.

1

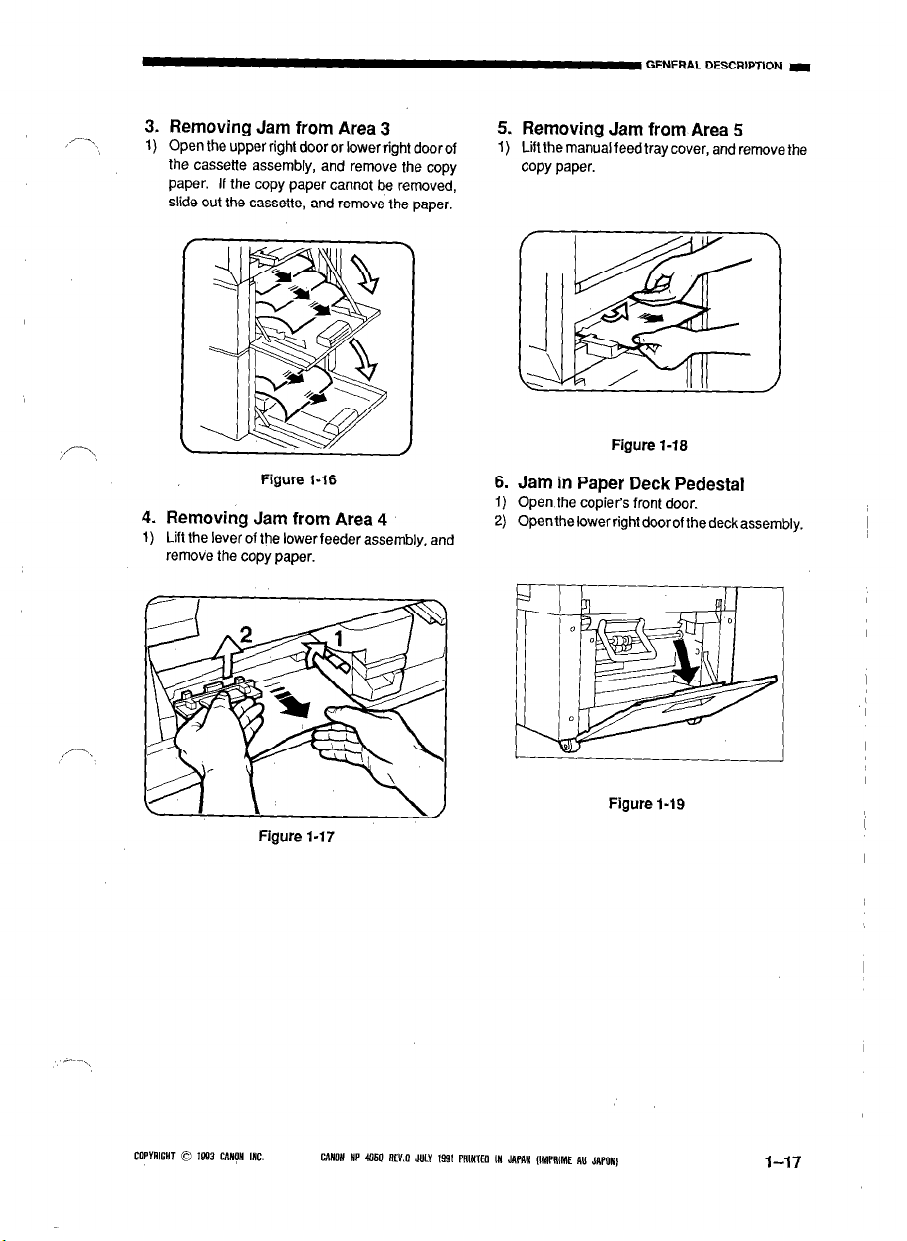

1. Removing Jam from Area 1

1) Turn the feeder assembly release lever counterclockwise, and remove the copy paper.

/

Figure 1-14

2.

Removing Jam from Area 2

Shift the lowerfeeder lever up, and remove the

1)

copy paper.

Detach the copy tray, and open the delivery

2)

door. If the paper is trapped in the fixing

assembly, turn the fixing assembly knob coun-

terclockwise, and remove the jam.

,- .

-

\

/-.

‘_.

l-16

Figure I-13

COPYAIGHT 0 1993 CANON INC.

3

,-

\.

Figure 1-15

CANON NP-4050 flu.0 JULY 1991 PAINTED IN JAPAN (IMPRIME AU JAPON)

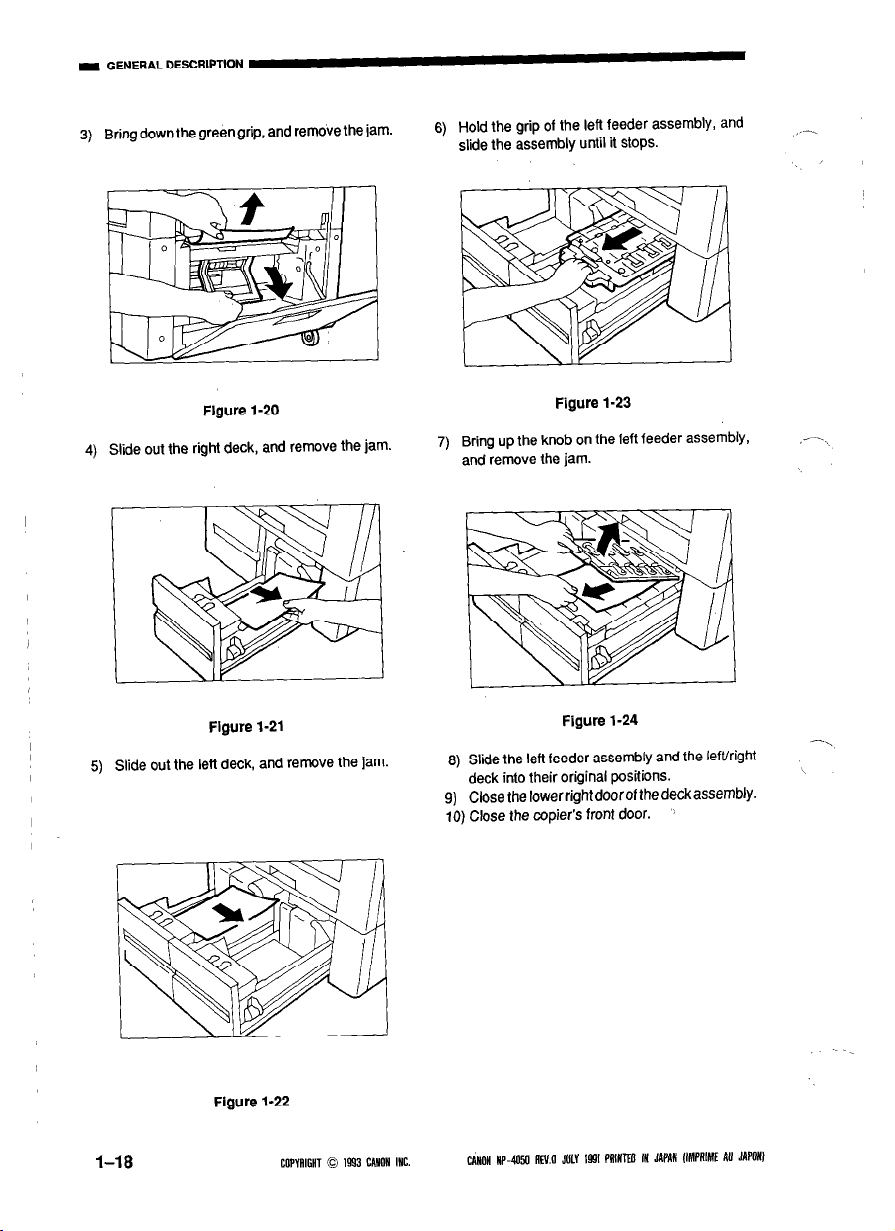

3. Removing Jam from Area 3

Open the upper right door or lower right door of

1)

the cassette assembly, and remove the copy

paper. If the copy paper cannot be removed,

slide out the cassette, and remove the paper.

5. Removing Jam from Area 5

1) Lift the manual feed tray cover, and remove the

copy paper.

Figure l-18

Figure l-16

4. Removing Jam from Area 4

1) Lift the lever of the lower feeder assembly, and

remove the copy paper.

Figure l-17

6.

Jam in Paper Deck Pedestal

Open the copiers front door.

1)

Openthelowerrightdoorof thedeckassembly.

2)

Figure 1-19

)

CllPYAlCHT 0 1993 CUNpN INC. CANON HP-4050 RB.0 JULY 1991 PRINTEO IN JilfflW IIMPMIP RU JUPM)

1-17

- GENERAL DESCRIPTION

3)

Bring down the green grip, and remove the jam.

Figure l-20

4)

Slide out the right deck, and remove the jam.

Hold the grip of the left feeder assembly, and

6)

slide the assembly until it stops.

Figure 1-23

Bring up the knob on the left feeder assembly,

7)

and remove the jam.

,-.

Figure 1-21

Figure 1-24

I

5) Slide out the left deck, and remove the jam.

Figure 1-22

1-18

COPYNIGHT 0 1593 CMION INC.

3) Slide the left feeder assembly and the left/right

deck into their original positions.

9) Close thelowerrightdoorolthedeckassembly.

10) Close the copier’s front door.

CANON HP-4050 RfWl JULY 1991 PNlh’M IN JAbIN llhfPRlMl AU JAW

\

GENERAL D&CRIPTION I

-\

,’

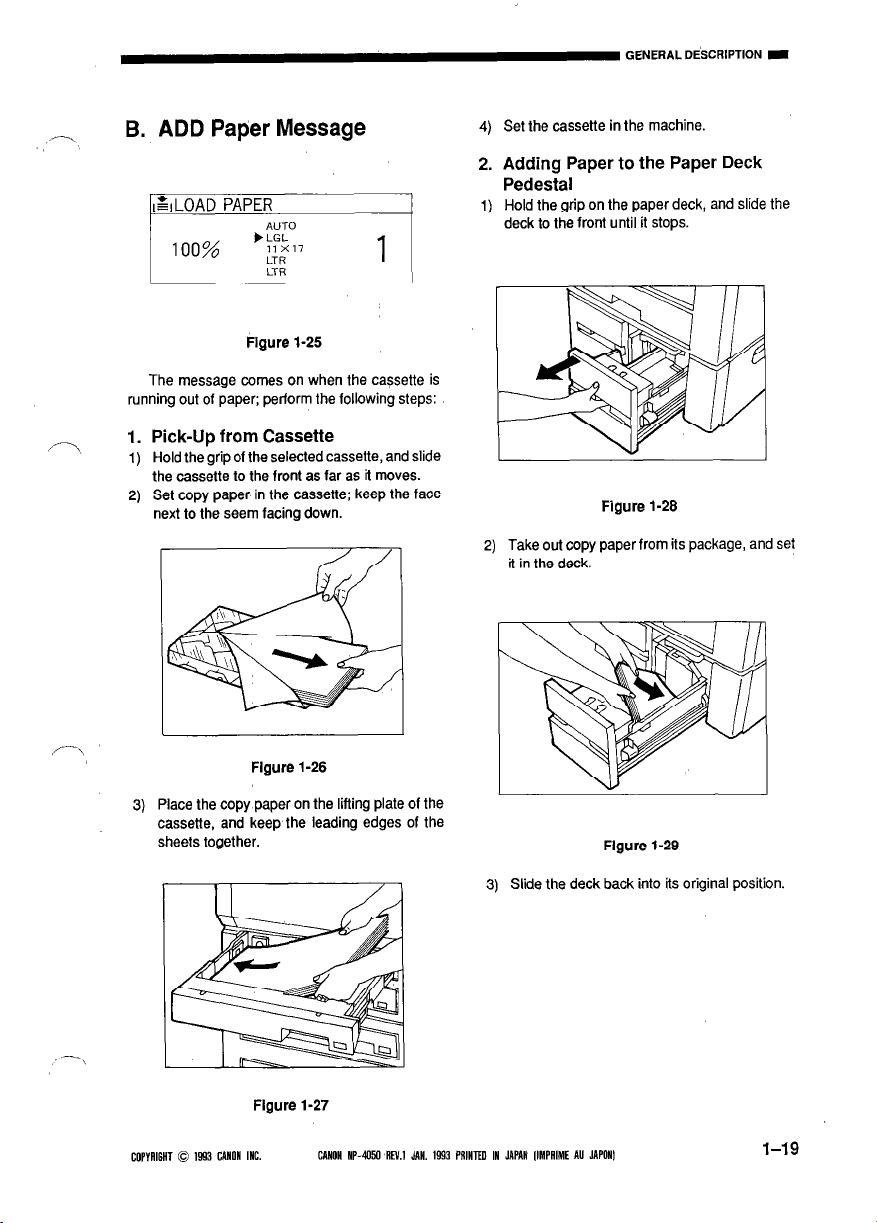

B. ADD Paper Message

Set the cassette in the machine.

4)

Adding Paper to the Paper Deck

2.

Pedestal

Hold the grip on the paper deck, and slide the

1)

deck to the front until it stops.

Figure 1-25

The message comes on when the cassette is

running out of paper; perform the following steps:

1. Pick-Up from Cassette

1)

Hold the grip of the selected cassette, and slide

the cassette to the front as far as it moves.

2)

Set copy paper in the cassette; keep the face

next to the seem facing down.

2)

Take out copy paper from its package, and set

it in the deck.

Figure 1-28

,‘-\

3)

Place the copy paper on the lifting plate of the

cassette, and keep the leading edges of the

sheets together.

COPYAIGHT 0 1593 CANON INC.

Figure 1-26

Figure 1-27

CANON HP450 AN.1 JAN. 1543 PRINTED IN JAPAN IlMPAlMt AU JAPONI

I

Flgure 1-29

3) Slide the deck back into its original position.

l-19

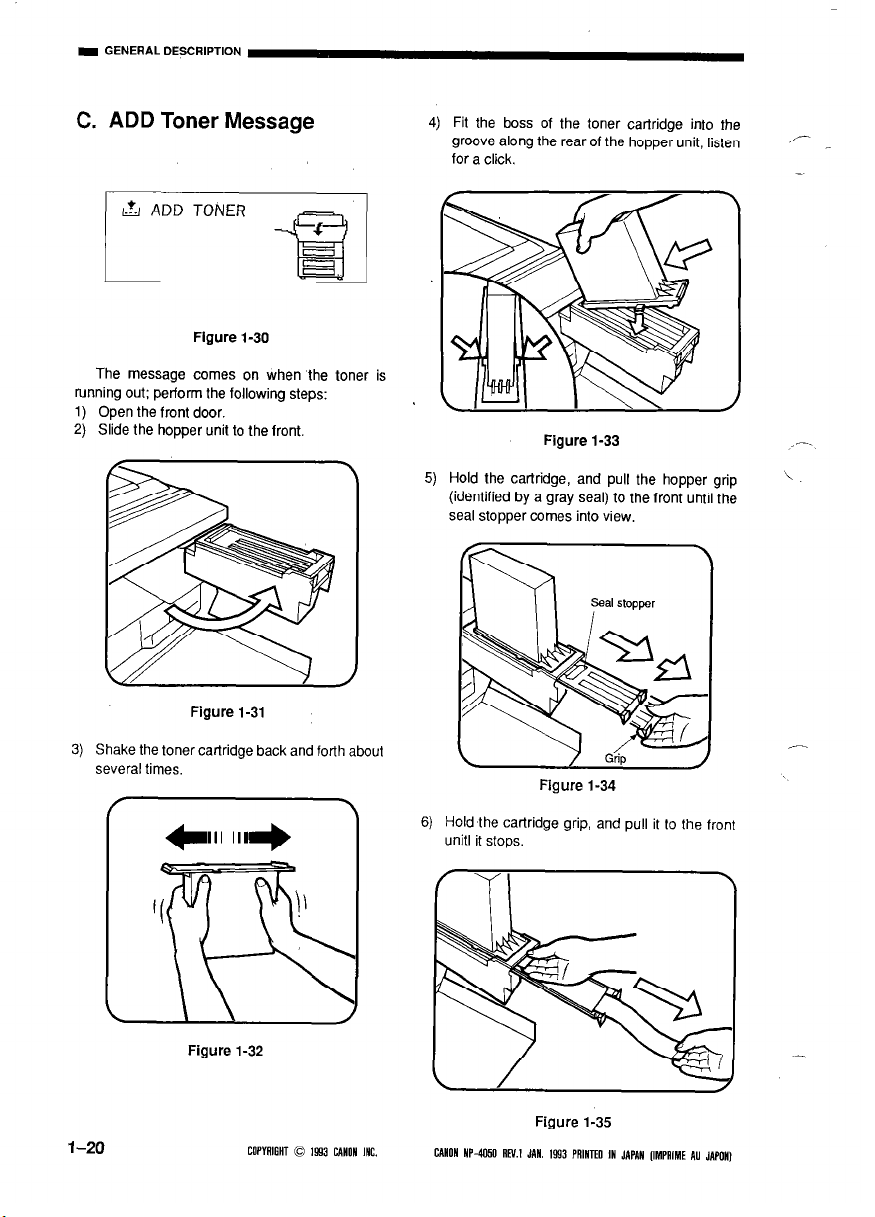

C. ADD Toner Message

Figure I-30

The message comes on when the toner is

running out; perform the following steps:

1) Open the front door.

Slide the hopper unit to the front.

2)

4) Fit the boss of the toner cartridge into the

groove along the rear of the hopper unit; listen

for a click.

Figure 1-33

Hold the cartridge, and pull the hopper grip

5)

(identified by a gray seal) to the front until the

seal stopper comes into view.

r

_

,-.

\

Figure 1-31

Shake the toner cartridge back and forth about

3)

several times.

Figure 1-32

l-20 COPVAIGNT 0 1993 CANOH INC.

Figure 1-34

Hold the cartridge grip, and pull it to the front

6)

unit1 it stops.

Figure 1-35

CANON HP-4050 REV.1 JAN. 1993 PAINTEO IN JAPAN IIMPGIME AU J,lPON)

,,--\

7) Tap on the top of the toner cartridge lightly until

all toner inside the toner cartridge has dropped

into the hopper unit.

8) Push the hopper grip to the rear until the toner

cartridge becomes unlocked.

9) Lift the front of the toner cartridge, and detach

the seal stopper from the hopper carefully.

IO) Set the hopper unit to the machine.

1 I) Close the front door.

Note:

For black loner used at time of installat$ sees

CHAPTER 5.

I)).,,

VI. ROUTINE MAINTE-

NANCE BY THE

USER

Advise the user to clean the following at least

once a week.

1.

Copyboard Glass

Clean it with a moist cloth; then, dry wipe k.

2.

Copyboard Cover

Clean it using mild detergent solution; then,

dry wipe it.

COPYAIGHT 0 1993 CANON INC.

CANON NW050 AE’J.I JAN. 1993 PRINTED IN JAPAN [IMPRIME AU JAPONI

1-21

‘-1

,/--Y,

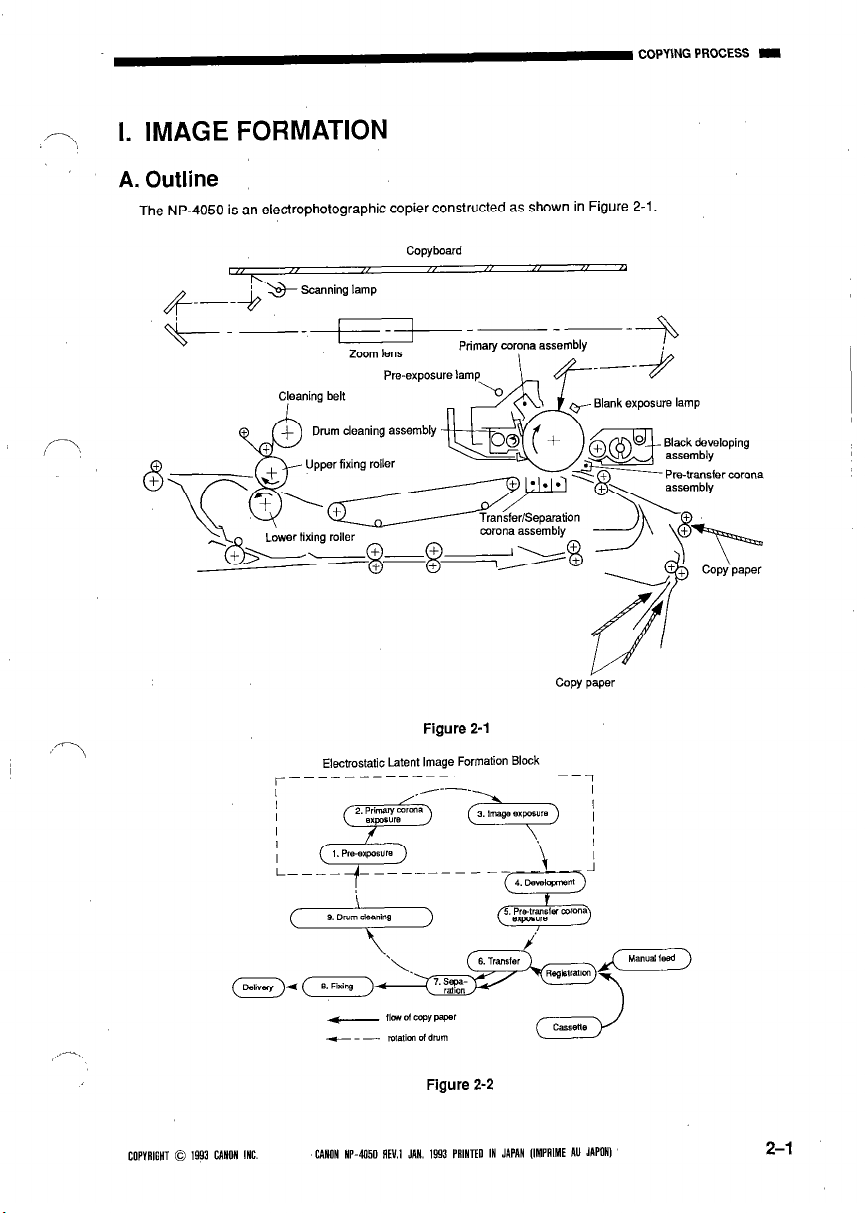

I. IMAGE FORMATION

A. Outline

The NP-4050 is an electrophotographic copier constructed as shown in Figure 2-I.

Copyboard

I

_~---

Zoom lens

Drum cleaning assembly

Primary corcma assembly

Blank exposure lamp

COPY paper

:“‘>

Figure 2-I

Electrostatic Latent Image Formation Block

_______________---_~_-_

./-”

Figure 2-2

COPYRIGHT 0 1993 CANON INC.

CANON NP-4050 AEV.1 JAN, 1993 PAINTED IN JAPAN IIMPAIME AU JAW 2-l

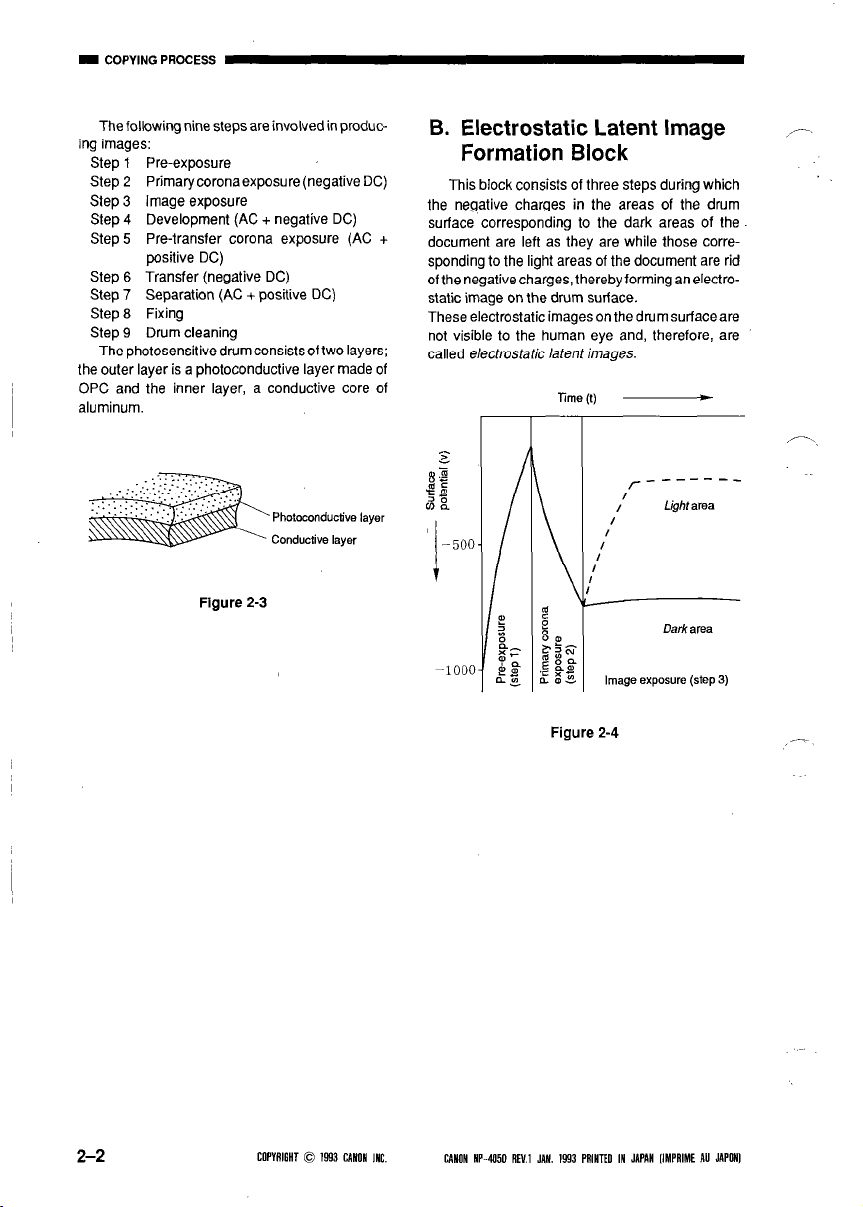

The following nine steps are involved in produc-

ing images:

Step 1 Pre-exposure

Step 2 Primarycoronaexposure(negativeDC)

Step 3 Image exposure

Step 4 Development (AC + negative DC)

Step5 Pre-transfer corona exposure (AC +

positive DC)

Step 6 Transfer (negative DC)

Step 7 Separation (AC + positive DC)

Step 8 Fixing

Step 9 Drum cleaning

The photosensitive drum consists of two layers;

the outer layer is a photoconductive layer made of

OPC and the inner layer, a conductive core of

aluminum.

Photoconductive layer

Conductive layer

Figure 2-3

B. Electrostatic Latent Image

Formation Block

This block consists of three steps during which

the negative charges in the areas of the drum

surface corresponding to the dark areas of the

document are left as they are while those corresponding to the light areas of the document are rid

of the negative charges, thereby forming an electro-

static image on the drum surface.

These electrostaticimageson thedrumsurfaceare

not visible to the human eye and, therefore, are

called elecffosfatic latent images.

lime (1) -

/--------

Lightarea

I

Image exposure (step 3)

2-2

COPYRIGHT 0 1993 CANON MC.

Figure 2-4

CANON HP-4050 REV.1 JAN. 1993 PAINTED IN JAPAN IIMPAIME AU JAPONI

COPYING PROCESS I

‘-\

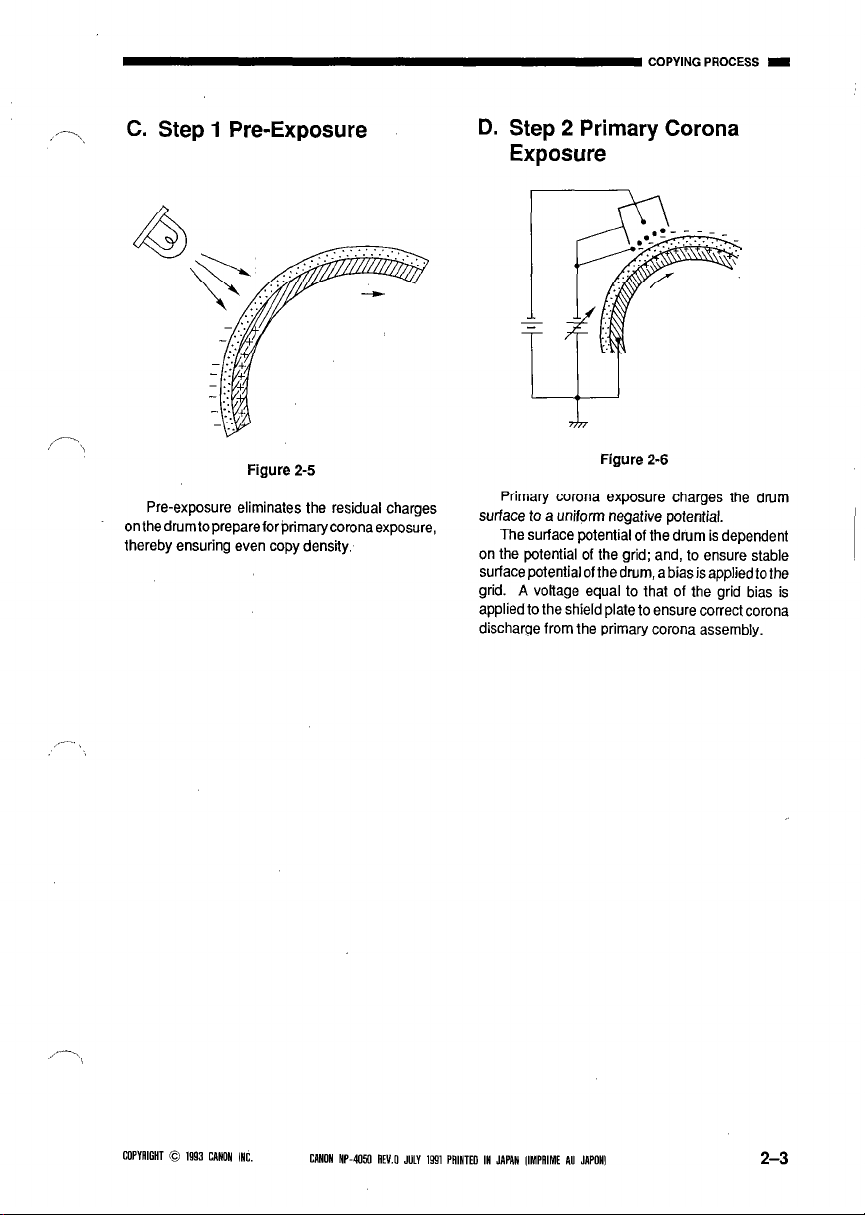

C. Step 1 Pre-Exposure

D. Step 2 Primary Corona

Exposure

Figure 2-5

Pre-exposure eliminates the residual charges

onthedrumtoprepareforprimarycoronaexposure,

thereby ensuring even copy density.

Primary corona exposure charges the drum

surface to a uniform negative potential.

The surface potential of the drum is dependent

on the potential of the grid; and, to ensure stable

surface potential of the drum, a bias is applied to the

grid. A voltage equal to that of the grid bias is

applied to the shield plate to ensure correct corona

discharge from the primary corona assembly.

Ffgure 2-6

COPYNIGHT D 1993 CANON INC.

CANON HP-4050 REV.0 JULY 1591 PNINTB IN JAPAN [IMPRIME AU JAPONI

2-3

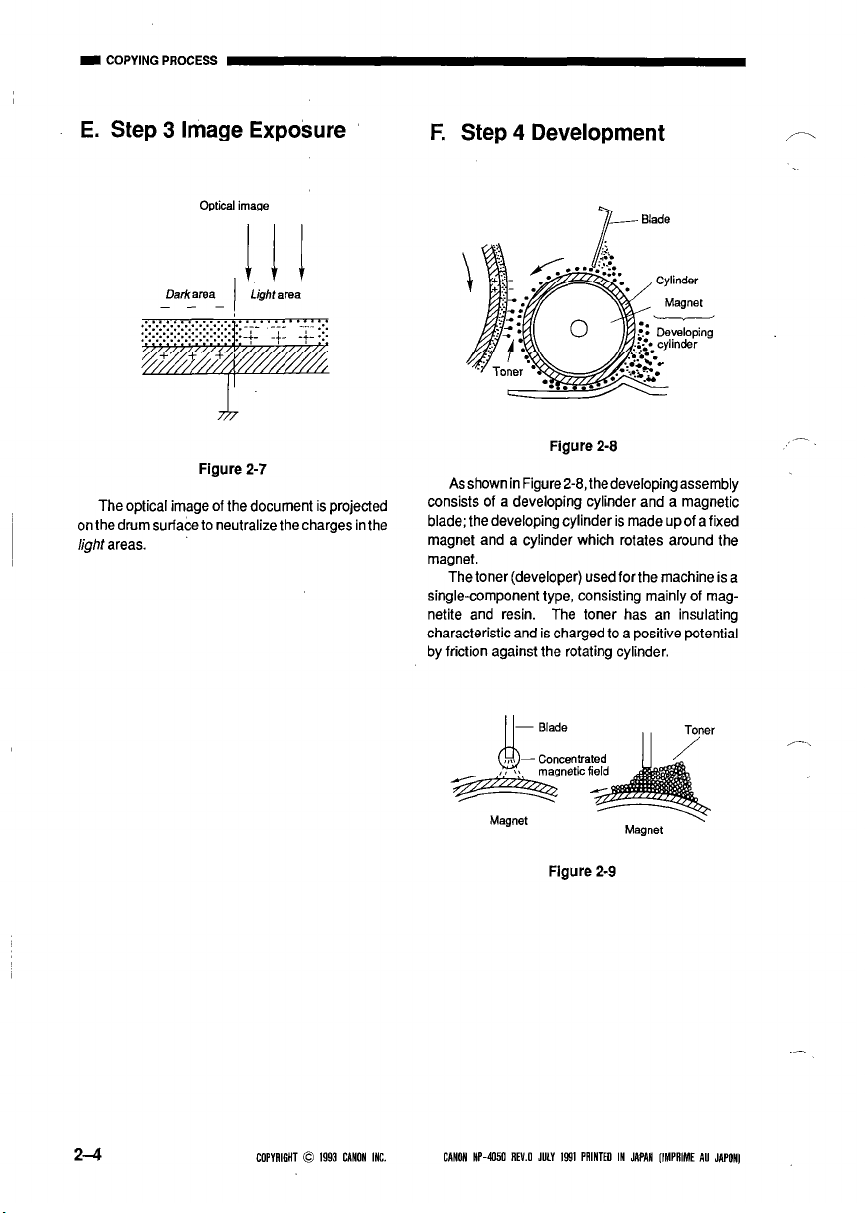

E. Step 3 Image Exposure

F. Step 4 Development

/-

Figure 2-7

The optical image of the document is projected

on the drum surface to neutralize the charges in the

light areas.

Figure 2-8

Asshown in FigureZ-9, thedevelopingassembly

consists of a developing cylinder and a magnetic

blade; the developing cylinder is made up of a fixed

magnet and a cylinder which rotates around the

magnet.

The toner (developer) used for the machine is a

single-component type, consisting mainly of magnetite and resin. The toner has an insulating

characteristic and is charged to a positive potential

by friction against the rotating cylinder.

Figure 2-9

_-.

2-4

COPYAIGHT 0 1993 CANON INC.

CANON HP-4tXC REV.0 JULY 1991 PAINTEO IN JAPAN [IMPRIME AU JAPON)

,/- 1,

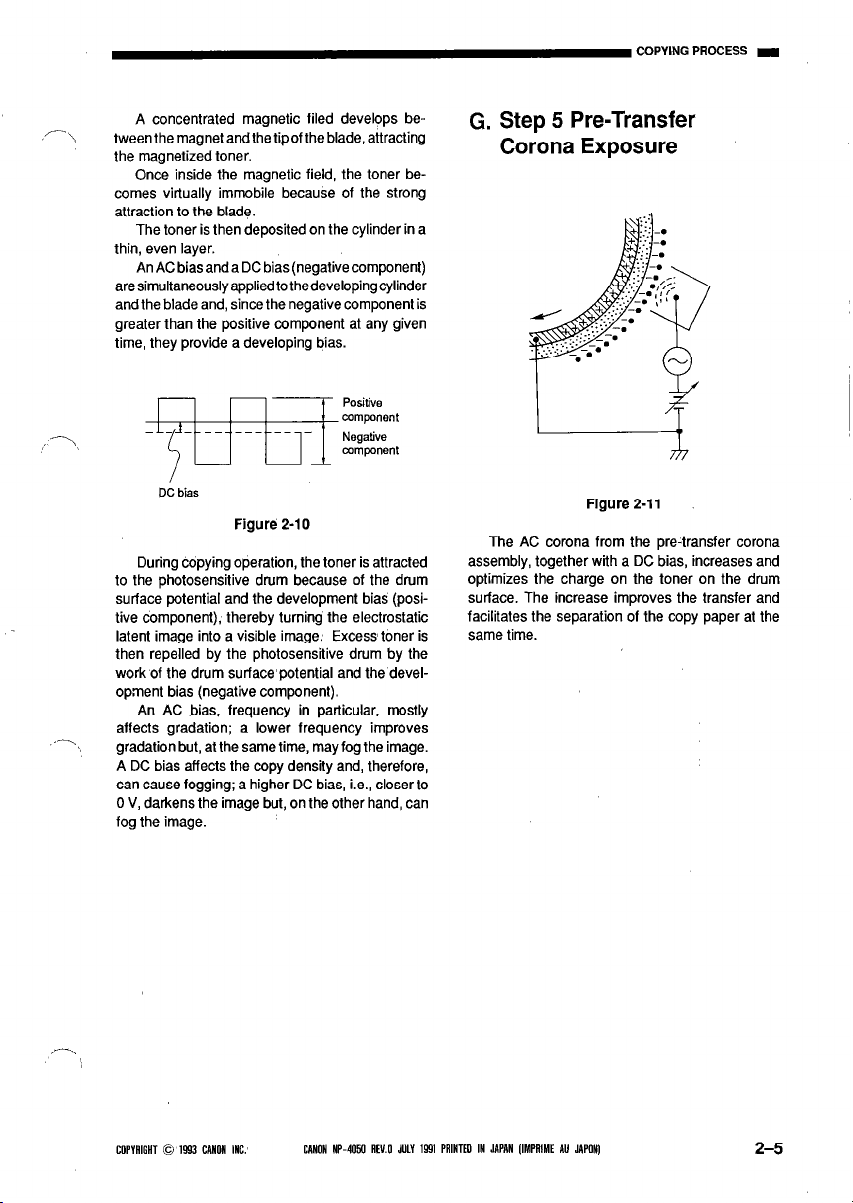

A concentrated magnetic filed develops betweenthe magnet and the tipof the blade, attracting

the magnetized toner.

Once inside the magnetic field, the toner becomes virtually immobile because of the strong

attraction to the blade.

The toner is then deposited on the cylinder in a

thin, even layer.

An AC bias and a DC bias (negative component)

aresimultaneouslyappliedtothedevelopingcylinder

and the blade and, since the negative component is

greater than the positive component at any given

time, they provide a developing bias.

G. Step 5 Pre-Transfer

Corona Exposure

DC bias

Figure 2-10

During copying operation, the toner is attracted

to the photosensitive drum because of the drum

surface potential and the development bias (posi-

tive component), thereby turning the electrostatic

latent image into a visible image. Excess toner is

then repelled by the photosensitive drum by the

work of the drum surface’potential and the devel-

opment bias (negative component).

An AC bias, frequency in particular, mostly

.-,

affects gradation; a lower frequency improves

, gradation but, at the same time, may fog the image.

A DC bias affects the copy density and, therefore,

can cause fogging; a higher DC bias, i.e., closer to

0 V, darkens the image but, on the other hand, can

fog the image.

Figure 2-11

The AC corona from the pre-transfer corona

assembly, together with a DC bias, increases and

optimizes the charge on the toner on the drum

surface. The increase improves the transfer and

facilitates the separation of the copy paper at the

same time.

COPYAlGHT 0 1993 CANON INC.’

CANON HP-4050 AEY.0 JULY 1591 PAINTED IN JAPAN [IMPRIME AU JAPON)

2-5

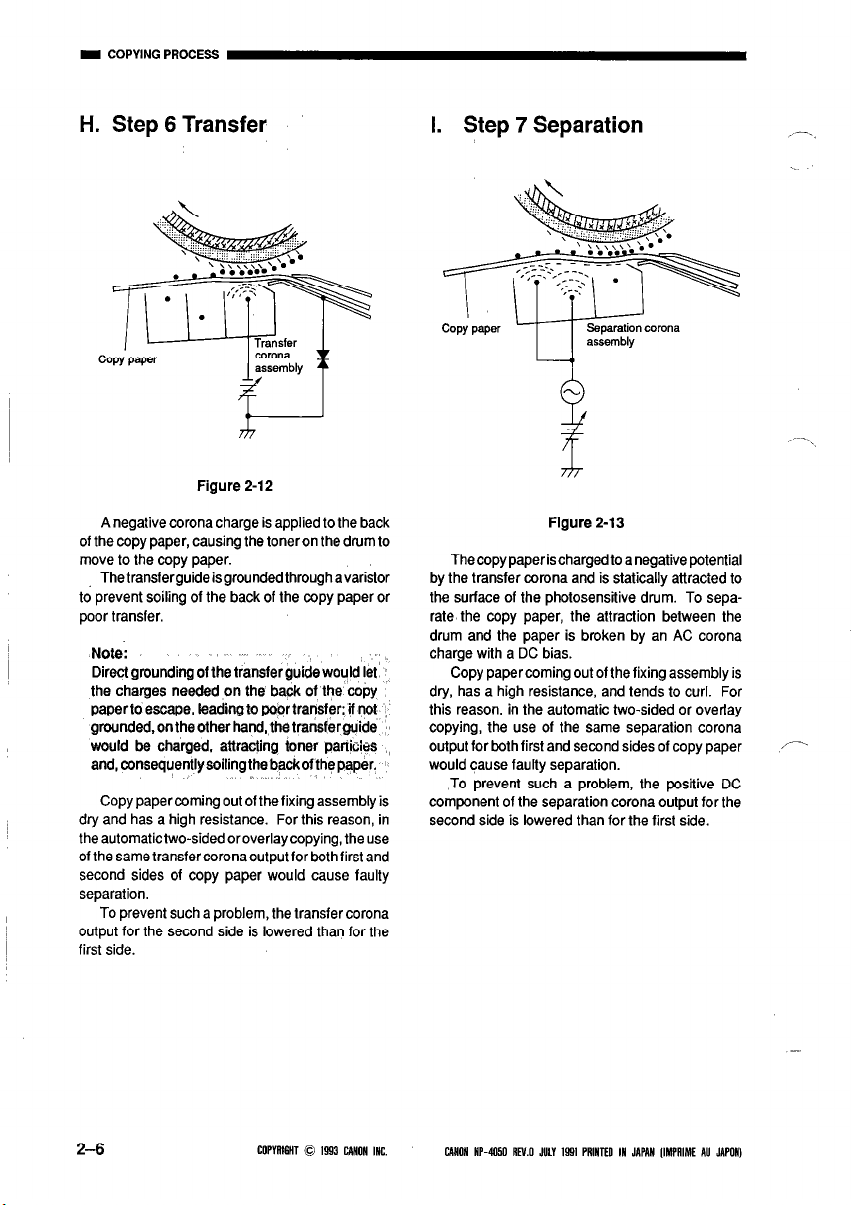

H. Step 6 Transfer

Figure 2-12

I. Step 7 Separation

/-._

A negative corona charge is applied to the back

of the copy paper, causing the toneron the drum to

move to the copy paper.

Thetransferguideisgroundedthroughavaristor

to prevent soiling of the back of the copy paper or

poor transfer.

Note:

Directgroundingof the transferguide’would let’

the charges needed on the back of the copy ,.

paper to escape, leading to pobr transfer; if not

grounded,ontheotherhand,thetransferguide :I8

would be charged, attracting foner panicies ,,

and, consequentlysoilingthebackofthepaper. 1

Copy paper coming out of the fixing assembly is

dry and has a high resistance. For this reason, in

the automatictwo-sided oroverlaycopying, the use

of the same transfercoronaoutputfor bothfirst and

second sides of copy paper would cause faulty

separation.

To prevent such a problem, the transfer corona

output for the second side is lowered than for the

first side.

,b

Flgure 2-13

The copy paper is charged to a negative potential

by the transfer corona and is statically attracied to

the surface of the photosensitive drum. To separate the copy paper, the attraction between the

drum and the paper is broken by an AC corona

charge with a DC bias.

Copy paper coming out of the fixing assembly is

dry, has a high resistance, and tends to curl. For

:

this reason, in the automatic two-sided or overlay

copying, the use of the same separation corona

output for both first and second sides of copy paper

would cause faulty separation.

To prevent such a problem, the positive DC

component of the separation corona output for the

second side is lowered than for the first side.

P

2-6

COPYRI6HT 0 1993 CANON INC.

CANON HP-4050 AN.0 JULY 1991 PAINTED IN JAPAN IIMPAIME AU JAPON)

,/-- \

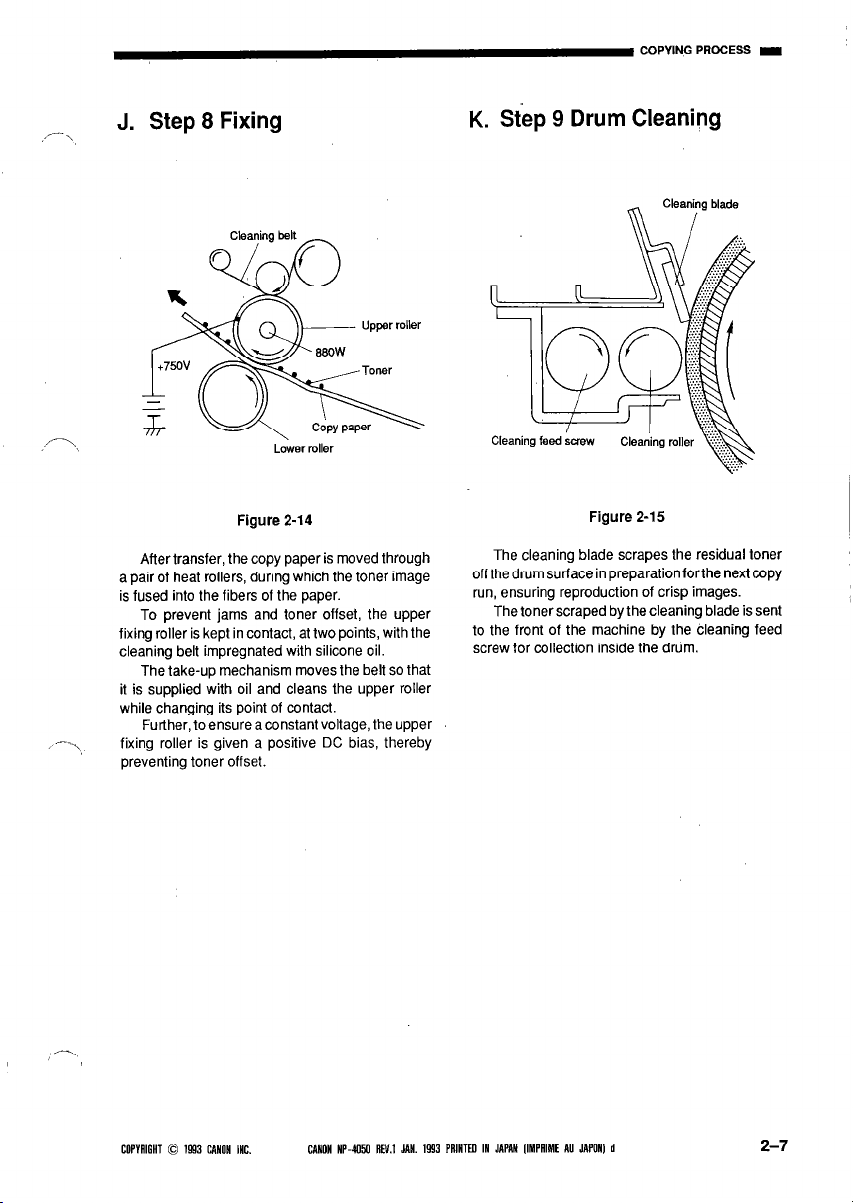

J. Step 8 Fixing

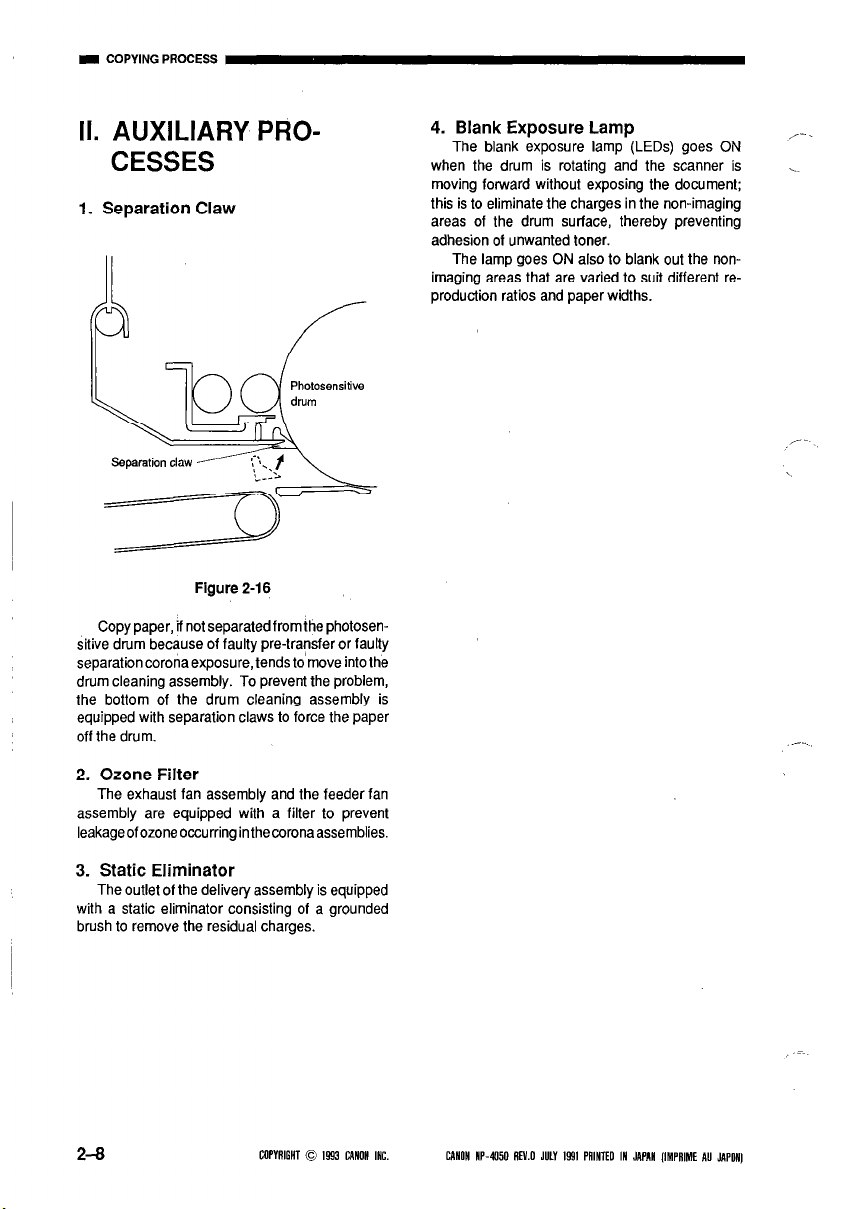

K. Step 9 Drum Cleaning

’

-...,

,-..

Figure 2-14

Aftertransfer, the copy paper is moved through

a pair of heat rollers, during which the toner image

is fused into the fibers of the paper.

To prevent jams and toner offset, the upper

fixing roller is kept in contact, at two points, with the

cleaning belt impregnated with silicone oil.

The take-up mechanism moves the belt so that

it is supplied with oil and cleans the upper roller

while changing its point of contact.

Further, to ensure aconstant voltage, the upper

fixing roller is given a positive DC bias, thereby

preventing toner offset.

Figure 2-15

The cleaning blade scrapes the residual toner

off the drum surface in preparationforthe next copy

run, ensuring reproduction of crisp images.

The toner scraped by the cleaning blade is sent

to the front of the machine by the cleaning feed

screw for collection inside the drum.

COPYAIGHT 0 1993 CANON INC.

CANON NP-4050 REV.1 YN. 1993 PAINTELI IN JAPAN IIMPAIME AU JAPON) d

2-7

II. AUXILIARY PRO-

CESSES

1. Separation Claw

b

Figure 2-16

Copy paper, if not separated from the photosensitive drum because of faulty pre-transfer or faulty

separation corona exposure, tends to’move into the

drum cleaning assembly. To prevent the problem,

the bottom of the drum cleaning assembly is

equipped with separation claws to force the paper

off the drum.

4. Blank Exposure Lamp

The blank exposure lamp (LEDs) goes ON

when the drum is rotating and the scanner is

moving forward without exposing the document;

this is to eliminate the charges in the non-imaging

areas of the drum surface, thereby preventing

adhesion of unwanted toner.

The lamp goes ON also to blank out the nonimaging areas that are varied to suit different reproduction ratios and paper widths.

2. Ozone Filter

The exhaust fan assembly and the feeder fan

assembly are equipped with a filter to prevent

leakageofozoneoccurringinthecoronaassemblies.

3. Static Eliminator

The outlet of the delivery assembly is equipped

with a static eliminator consisting of a grounded

brush to remove the residual charges.

2-8

COPYRIGHT 0 1993 CANON INC. CANON HP-4050 RN.0 JULY 1931 PAINTED IN JAPAN lIMPRIME AU JAPON)

Loading...

Loading...