MF735C Series

Service Manual

Revision 2.0

1x

1x

Introduction

Introduction

Important Notices

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair

of products.

This manual covers all localities where the products are sold. For this reason, there may be information in this manual that does

not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products.

When changes occur in applicable products or in the contents of this manual, Canon will release technical information as the

need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

The copyright of this document belongs to Canon Inc. This document may not be copied, reproduced or translated into another

language, in whole or in part, without the prior consent of Canon Inc.

Copyright CANON INC. 2017

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

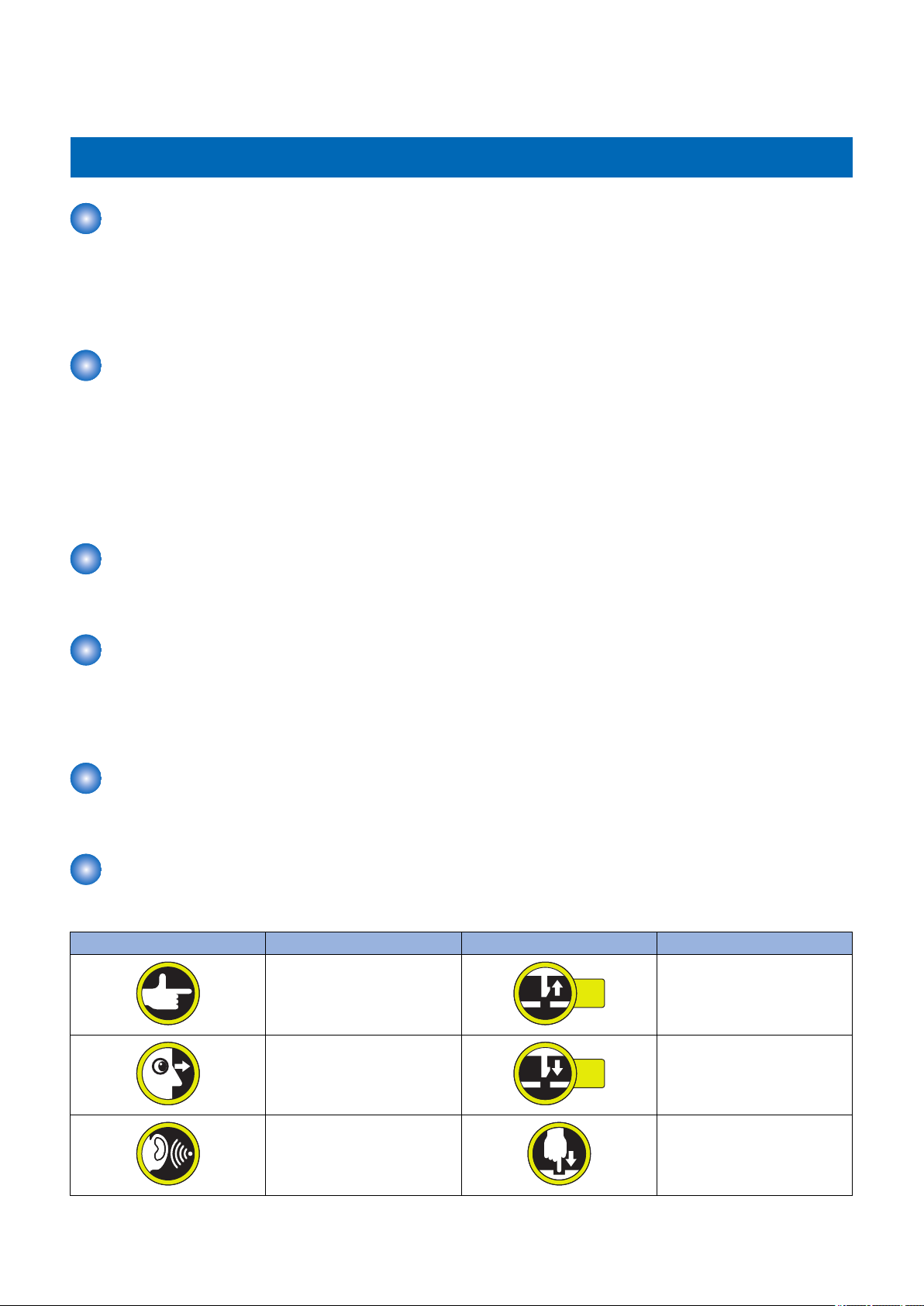

Explanation of Symbols

The following symbols are used throughout this Service Manual.

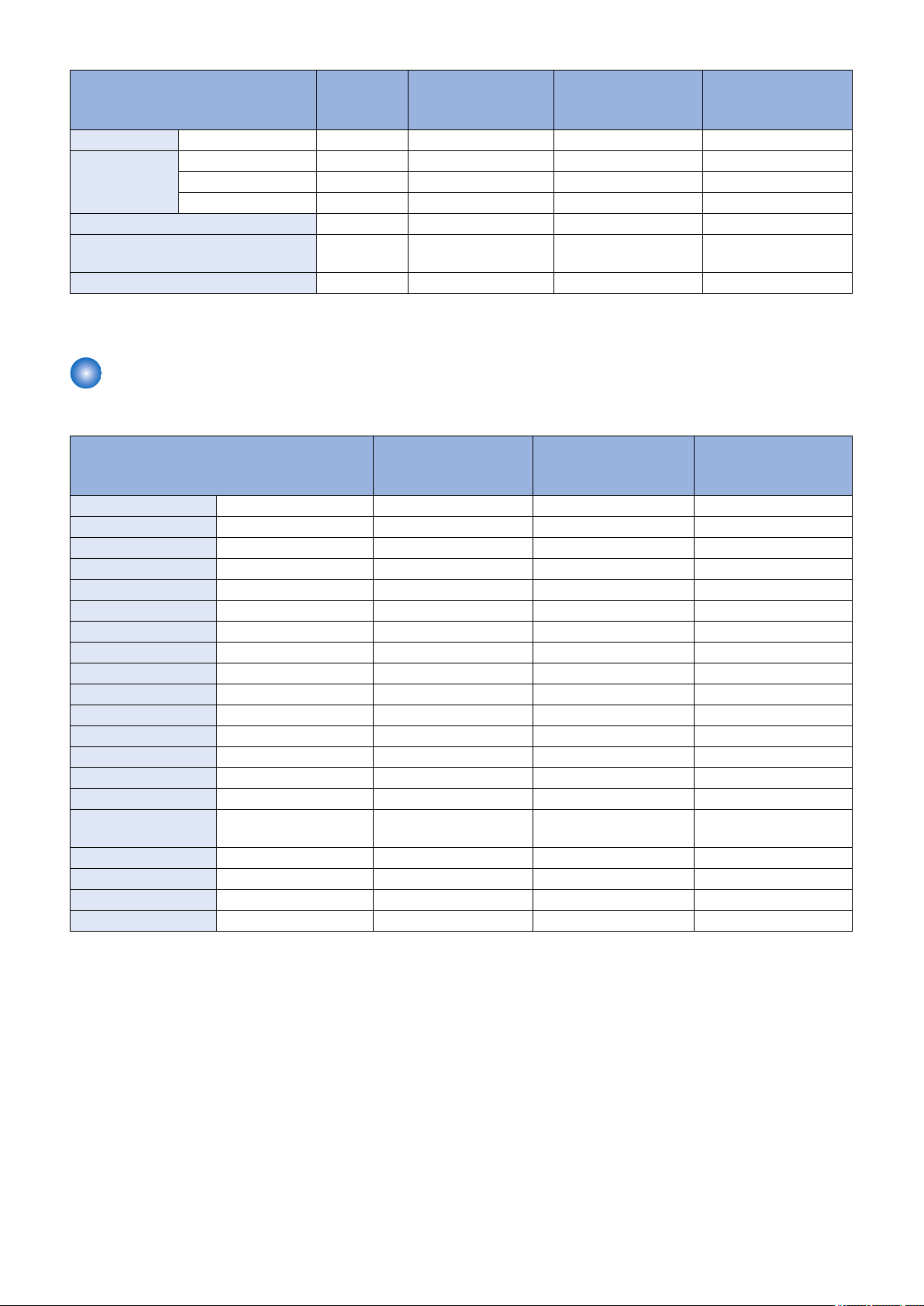

Symbols Explanation Symbols Explanation

Check.

Remove the claw.

Check visually.

Check a sound. Push the part.

Insert the claw.

1x

1x

1x

1x

1x

1x

1x

1x

Introduction

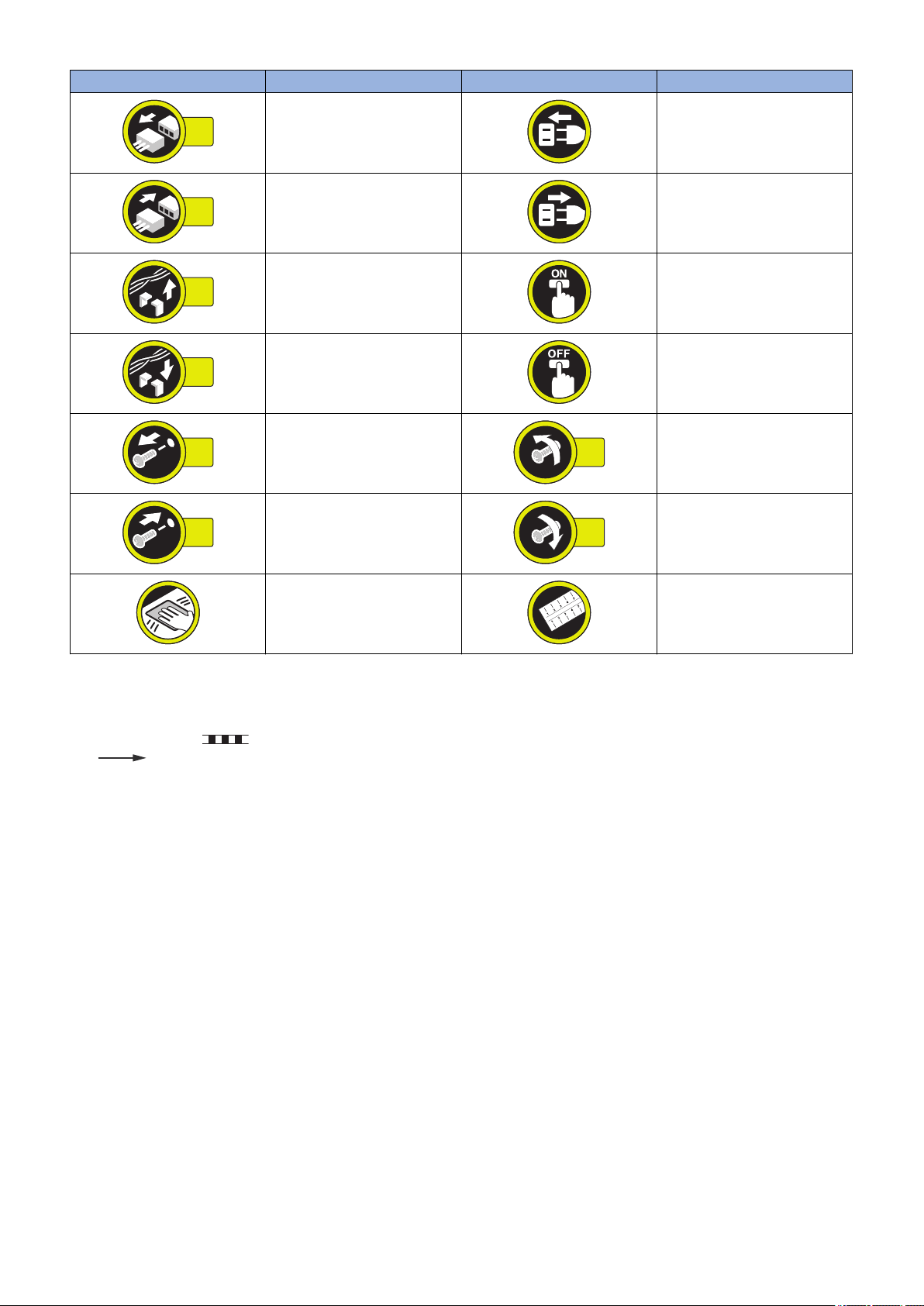

Symbols Explanation Symbols Explanation

Disconnect the connector. Connect the power cable.

Connect the connector. Disconnect the power cable.

Remove the cable/wire from the

cable guide or wire saddle.

Install the cable/wire to the cable

guide or wire saddle.

Remove the screw.

Install the screw.

Cleaning is needed. Measurement is needed.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and

mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol, the arrow

indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit

door, which results in supplying the machine with power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low".

(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the operations

of the microprocessors used in the machines are not discussed: they are explained in terms of from sensors to the input of

the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and

major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service

Information bulletins and be able to identify and isolate faults in the machine.

Turn on the power.

Turn off the power.

Loosen the screw.

Tighten the screw.

Contents

Contents

Safety Precautions...............................................................................................1

Laser Safety........................................................................................................................................ 2

How to Handle the Laser Scanner Unit...............................................................................................2

Toner Safety........................................................................................................................................2

About Toner..........................................................................................................................................2

Handling Adhered Toner........................................................................................................................2

Notes When Handling a Lithium Battery............................................................................................. 3

Notes on Assembly/Disassembly........................................................................................................3

1. Product Overview.............................................................................................4

Product Lineup.................................................................................................................................... 5

Host Machine........................................................................................................................................5

Option.................................................................................................................................................. 5

Features...............................................................................................................................................6

Specifications...................................................................................................................................... 7

Specifications of Host Machine.............................................................................................................. 7

Paper type............................................................................................................................................8

Paper size............................................................................................................................................ 9

Parts Name....................................................................................................................................... 10

External view...................................................................................................................................... 10

Cross Section View............................................................................................................................. 12

Control Panel......................................................................................................................................13

2. Technical Explanation (Device).................................................................... 15

Basic Configuration........................................................................................................................... 16

Functional Configuration......................................................................................................................16

Original Exposure/Feed System........................................................................................................17

Original Exposure System....................................................................................................................17

Original Feed System ......................................................................................................................... 19

Laser Exposure System.................................................................................................................... 22

Functional Configuration......................................................................................................................22

Failure Detection.................................................................................................................................22

Controller System..............................................................................................................................24

Configuration/Function.........................................................................................................................24

Main Controller PCB............................................................................................................................25

Motor Control......................................................................................................................................25

Door Open Detection...........................................................................................................................26

Fan Control.........................................................................................................................................26

Low-voltage Power Supply Control.......................................................................................................26

Protection Function............................................................................................................................. 27

Power-saving Mode.............................................................................................................................27

Image Formation System.................................................................................................................. 29

Major Components..............................................................................................................................29

Image Formation Process....................................................................................................................29

i

Contents

High Voltage Power Supply Control......................................................................................................29

Image Stabilization Control.................................................................................................................. 30

Cartridge............................................................................................................................................ 32

Pickup Feed System......................................................................................................................... 35

Overview............................................................................................................................................ 35

Parts Configuration..............................................................................................................................36

Drive Configuration..............................................................................................................................37

Layout of Sensors............................................................................................................................... 38

Lifter Control.......................................................................................................................................38

Cassette Detection..............................................................................................................................39

Cassette Pickup Control...................................................................................................................... 40

Multi-purpose Tray Pickup Control........................................................................................................40

Skew Correction..................................................................................................................................41

Arch Control........................................................................................................................................42

Delivery Tray Full Detection................................................................................................................. 43

Jam Detection.....................................................................................................................................43

Fixing System....................................................................................................................................45

Functional Configuration......................................................................................................................45

Fixing Temperature Control................................................................................................................. 45

Protection Function............................................................................................................................. 46

Fixing Assembly Failure Detection........................................................................................................46

3. Technical Explanation (System)................................................................... 48

Overview of System Management.................................................................................................... 49

Version Upgrade............................................................................................................................... 50

Function Overview.............................................................................................................................. 50

Version Upgrade Using UST................................................................................................................51

Version Upgrade via Internet................................................................................................................51

Version Upgrade Using USB................................................................................................................52

Setting Information Export/Import Function (DCM)........................................................................... 54

Overview............................................................................................................................................ 54

Import/Export Procedure from [Settings/Registration] of Remote UI........................................................ 56

Procedure for Exporting/Importing Service Mode Setting Information......................................................59

List of Items Which Can Be Imported....................................................................................................60

Monitoring Function (e-Maintenance/imageWARE Remote)............................................................ 68

Overview of System............................................................................................................................ 68

Servicing Notes...................................................................................................................................69

Setting Procedure............................................................................................................................... 69

Maintenace.........................................................................................................................................70

4. Periodical Service.......................................................................................... 72

Periodically Replaced Parts.............................................................................................................. 73

Consumable Parts.............................................................................................................................74

Periodical Services............................................................................................................................75

5. Parts Replacement and Cleaning................................................................. 76

List of Parts....................................................................................................................................... 77

Major Units......................................................................................................................................... 77

Layout Drawing of Electrical Components.............................................................................................79

ii

Contents

External Cover System......................................................................................................................85

Removing the Toner Cartridge............................................................................................................. 85

Removing the Left Cover..................................................................................................................... 86

Removing the Right Cover...................................................................................................................88

Removing the Rear Cover Unit.............................................................................................................90

Removing the Cartridge Cover ............................................................................................................ 91

Removing the Cartridge Tray............................................................................................................... 93

Removing the Upper Front Cover.........................................................................................................94

Removing the Upper Left Front Cover.................................................................................................. 95

Removing the Upper Right Front Cover................................................................................................ 95

Removing the Upper Cover Unit ..........................................................................................................96

Original Exposure/Feed System........................................................................................................97

Removing the ADF Unit + Reader Unit................................................................................................. 97

Separating the ADF Unit + Reader Unit................................................................................................ 98

Removing the ADF Roller Unit............................................................................................................100

Removing the ADF Pickup Roller....................................................................................................... 102

Removing the ADF Separation Roller................................................................................................. 103

Removing the ADF Separation Pad Unit............................................................................................. 105

Removing the ADF Upper Cover Unit................................................................................................. 106

Removing the ADF Feed Unit.............................................................................................................107

Removing the ADF CIS (For the duplex scanning model).....................................................................108

Removing the ADF Drive Unit............................................................................................................ 112

Removing the Reader Upper Cover Unit............................................................................................. 114

Removing the Reader CIS................................................................................................................. 115

Removing the Reader CIS Timing Belt................................................................................................118

Removing the Reader Scanner Motor.................................................................................................118

Controller System............................................................................................................................120

Removing the Controller Cover ..........................................................................................................120

Removing the Wireless LAN PCB (Wi-Fi model only)...........................................................................121

Removing the Wireless LAN Support Plate (Wi-Fi model only)............................................................. 121

Removing the Main Controller PCB.................................................................................................... 122

Removing the Main Controller Support Plate.......................................................................................122

Removing the Engine Controller PCB................................................................................................. 123

Removing the Low Voltage Power Supply Unit.................................................................................... 123

Removing the Control Panel Unit........................................................................................................125

Removing the OFF Hook PCB (Fax model only)..................................................................................127

Removing the NCU PCB (Fax model only)..........................................................................................128

Removing the Speaker (Fax model only).............................................................................................128

Removing the USB PCB.................................................................................................................... 129

Removing the Cartridge Fan.............................................................................................................. 130

Removing the Power Supply Fan....................................................................................................... 131

Removing the Driver PCB.................................................................................................................. 132

Removing the Power Switch Unit........................................................................................................133

Removing the Environment Sensor.....................................................................................................133

Removing the Memory Relay PCB..................................................................................................... 134

Laser Exposure System.................................................................................................................. 136

Removing the Laser Scanner Unit...................................................................................................... 136

Image Formation System................................................................................................................ 142

Removing the Secondary Transfer Roller............................................................................................142

Removing the Secondary Transfer Feed Unit...................................................................................... 143

Removing the ITB Unit.......................................................................................................................144

iii

Contents

Removing the Color Displacement Density Sensor Unit....................................................................... 146

Removing the Developing Motor.........................................................................................................147

Removing the Drum Motor................................................................................................................. 149

Fixing System..................................................................................................................................151

Removing the Fixing Assembly.......................................................................................................... 151

Removing the Fixing Power Supply Unit............................................................................................. 153

Removing the Fixing Motor................................................................................................................ 154

Pickup Feed Delivery System......................................................................................................... 155

Removing the Cassette Pickup Roller/Feed Roller Unit ....................................................................... 155

Removing the Cassette Separation Roller Unit ................................................................................... 156

Removing the Duplex Reverse Drive Unit........................................................................................... 158

Removing the Pickup Motor............................................................................................................... 159

Removing the Re-Pickup Unit............................................................................................................ 160

Removing the Lifter Drive Unit............................................................................................................162

Removing the Cassette Pickup Unit....................................................................................................164

Removing the Multi-purpose Tray Pickup Roller.................................................................................. 166

Removing the Multi-purpose Tray Separation Pad............................................................................... 167

Removing the Registration Unit.......................................................................................................... 168

6. Adjustment................................................................................................... 172

Adjustment at Parts Replacement...................................................................................................173

After Replacing the Control Panel.......................................................................................................173

After Replacing the ITB Unit...............................................................................................................173

After Replacing the Color Displacement Density Sensor Unit............................................................... 173

Engine Controller PCB.......................................................................................................................173

Main Controller PCB..........................................................................................................................173

After Replacing the ADF Unit............................................................................................................. 179

After Replacing the Reader CIS Unit...................................................................................................182

After Replacing the Reader Upper Cover Unit..................................................................................... 186

After Replacing the Reader Unit......................................................................................................... 191

After Replacing the ADF CIS Unit.......................................................................................................198

7. Troubleshooting...........................................................................................202

Test Print.........................................................................................................................................203

Engine Test Print...............................................................................................................................203

Controller test print............................................................................................................................ 204

Cartridge Log Report......................................................................................................................... 214

Troubleshooting Items.....................................................................................................................216

Recurring faulty image.......................................................................................................................216

Confirming nip width..........................................................................................................................216

Action When Hue Differs between the Front and Back Sides of the Output Image at Duplex Copy

(For the duplex scanning ADF model)............................................................................................. 217

Debug Log.......................................................................................................................................219

Function Overview.............................................................................................................................219

Conditions for collecting logs..............................................................................................................219

Collection procedure..........................................................................................................................219

8. Error/Jam/Alarm........................................................................................... 221

Overview......................................................................................................................................... 222

iv

Contents

Error/Jam/Alarm Log indication.......................................................................................................... 222

JAM/ERR LOG REPORT...................................................................................................................223

Location Code...................................................................................................................................224

Pickup Position Code.........................................................................................................................224

Error Code.......................................................................................................................................225

Error Code Details.............................................................................................................................225

Jam Code........................................................................................................................................232

Jam Code Details..............................................................................................................................232

Alarm Code..................................................................................................................................... 235

Alarm Code Details........................................................................................................................... 235

9. Service Mode................................................................................................ 236

Overview......................................................................................................................................... 237

Entering Service Mode...................................................................................................................... 237

Service Label....................................................................................................................................237

Remote UI Service Mode...................................................................................................................237

COPIER (Service mode for copier)................................................................................................. 240

DISPLAY (State display mode)...........................................................................................................240

I/O (I/O display mode)........................................................................................................................242

ADJUST (Adjustment mode).............................................................................................................. 243

FUNCTION (Operation / inspection mode).......................................................................................... 285

OPTION (Specification setting mode)................................................................................................. 302

COUNTER (Counter mode)............................................................................................................... 314

FEEDER (ADF service mode).........................................................................................................320

ADJUST (Adjustment mode).............................................................................................................. 320

FUNCTION (Operation / inspection mode).......................................................................................... 321

FAX (FAX service mode).................................................................................................................322

SSSW (Bit switch registration mode).................................................................................................. 322

MENU (Menu switch registration mode).............................................................................................. 323

NUM (Numeric parameter setting mode).............................................................................................323

NCU (NCU parameter setting mode).................................................................................................. 324

TESTMODE (Service mode for test print, operation check, etc.)....................................................328

PRINT (Print test mode).....................................................................................................................328

FAX (FAX test mode).........................................................................................................................332

10. Installation.................................................................................................. 337

Copy Control Interface Kit-C1......................................................................................................... 338

Points to Note at Installation...............................................................................................................338

Installation Outline Drawing................................................................................................................338

Checking the Contents...................................................................................................................... 338

Check Item When Turning OFF the Main Power..................................................................................338

Installation Procedure........................................................................................................................338

MiCARD Attachment Kit-B1............................................................................................................ 345

Points to Note at Installation...............................................................................................................345

Installation Outline Drawing................................................................................................................345

Checking the Contents...................................................................................................................... 345

Check Item When Turning OFF the Main Power..................................................................................345

Installation Procedure........................................................................................................................345

Copy Card Reader-F1.....................................................................................................................351

v

Contents

Points to Note at Installation...............................................................................................................351

Installation Outline Drawing................................................................................................................351

Checking the Contents...................................................................................................................... 351

Check Item When Turning OFF the Main Power..................................................................................351

Installation Procedure........................................................................................................................352

Setting after Installation..................................................................................................................... 362

APPENDICES....................................................................................................363

Service Tools...................................................................................................................................364

Special Tools.................................................................................................................................... 364

Solvents and Oil List..........................................................................................................................364

General Circuit Diagram..................................................................................................................365

Backup Data List............................................................................................................................. 368

Soft counter specifications.............................................................................................................. 370

vi

Safety Precautions

Laser Safety..........................................2

How to Handle the Laser Scanner Unit

...........................................................2

Toner Safety..........................................2

Notes When Handling a Lithium

Battery............................................... 3

Notes on Assembly/Disassembly..........3

Safety Precautions

Laser Safety

Since radiation emitted inside this machine is completely confined with protective housings and external covers, the laser beam

cannot escape from the machine during any phase of normal use by users.

Therefore, this machine is classified as a Class 1 laser product under the international standard IEC60825-1 that is regarded as

safe during normal use.

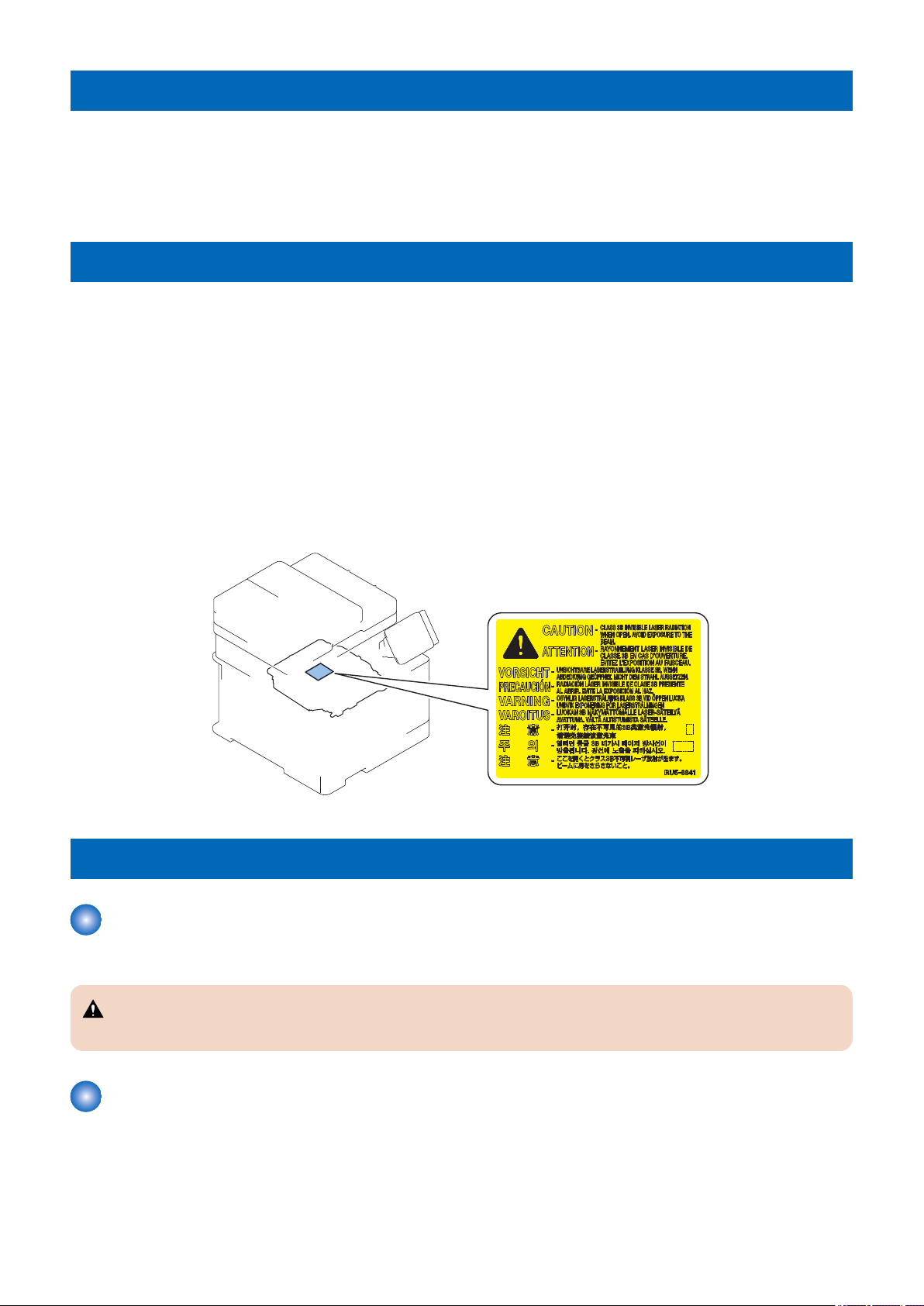

How to Handle the Laser Scanner Unit

This machine is classified as a Class 1 laser product.

However, the laser scanner unit contains source of Class 3B laser beam and exposure to the beam may cause eye injuries.

Therefore, be sure not to disassemble the laser scanner unit. No adjustment can be made to the laser scanner unit in the machine

in the field.

The label shown in the following figure is affixed on the laser scanner unit.

Dieses Gerät ist der Klasse 1 der Laserprodukte zugeordnet.

Allerdings enthält die Laserscannereinheit eine Laserstrahlquelle der Klasse 3B, die Augenschäden verursachen kann, wenn

man in diesen Strahl blickt.

Deshalb darf die Laserscannereinheit nicht zerlegt werden. An der Laserscannereinheit kann keine Justage vor Ort vorgenommen

werden.

Der in folgendem Bild dargestellte Aufkleber ist auf der Laserscannereinheit angebracht.

Toner Safety

About Toner

Toner is a nontoxic matter composed of plastic, iron and a trace of pigments.

CAUTION:

Never throw toner in flames to avoid explosion.

Handling Adhered Toner

• Use dry tissue paper to wipe off toner adhered to skin or clothes and wash in water.

• Never use warm water for cleaning up toner to prevent toner particles from being gelated to soak into fibers permanently.

• Toner particles are reactive with vinyl polymers. Avoid contacting these materials.

2

Notes When Handling a Lithium Battery

Dispose of used batteries according to the instructions.

CAUTION:

Risk of explosion if battery is replaced by an incorrect type.

The following warnings are given to comply with Safety Principles (EN60950-1).

CAUTION:

Wenn mit dem falschen Typ ausgewechselt, besteht Explosionsgefahr.

Gebrauchte Batterien gemäß der Anleitung beseitigen.

Safety Precautions

Notes on Assembly/Disassembly

Follow the items below to assemble/disassemble the device.

1. Disconnect the power plug to avoid any potential dangers during assembling/disassembling works.

2. If not specially instructed, reverse the order of disassembly to reinstall.

3. Ensure to use the right screw type (length, diameter, etc.) at the right position when assembling.

4. To keep electric conduction, binding screws with washers are used to attach the grounding wire and the varistor. Ensure to

use the right screw type when assembling.

5. Unless it is specially needed, do not operate the device with some parts removed.

6. Never remove the paint-locked screws when disassembling.

3

1

Product Overview

Product Lineup......................................5

Specifications........................................7

Parts Name......................................... 10

Product Lineup

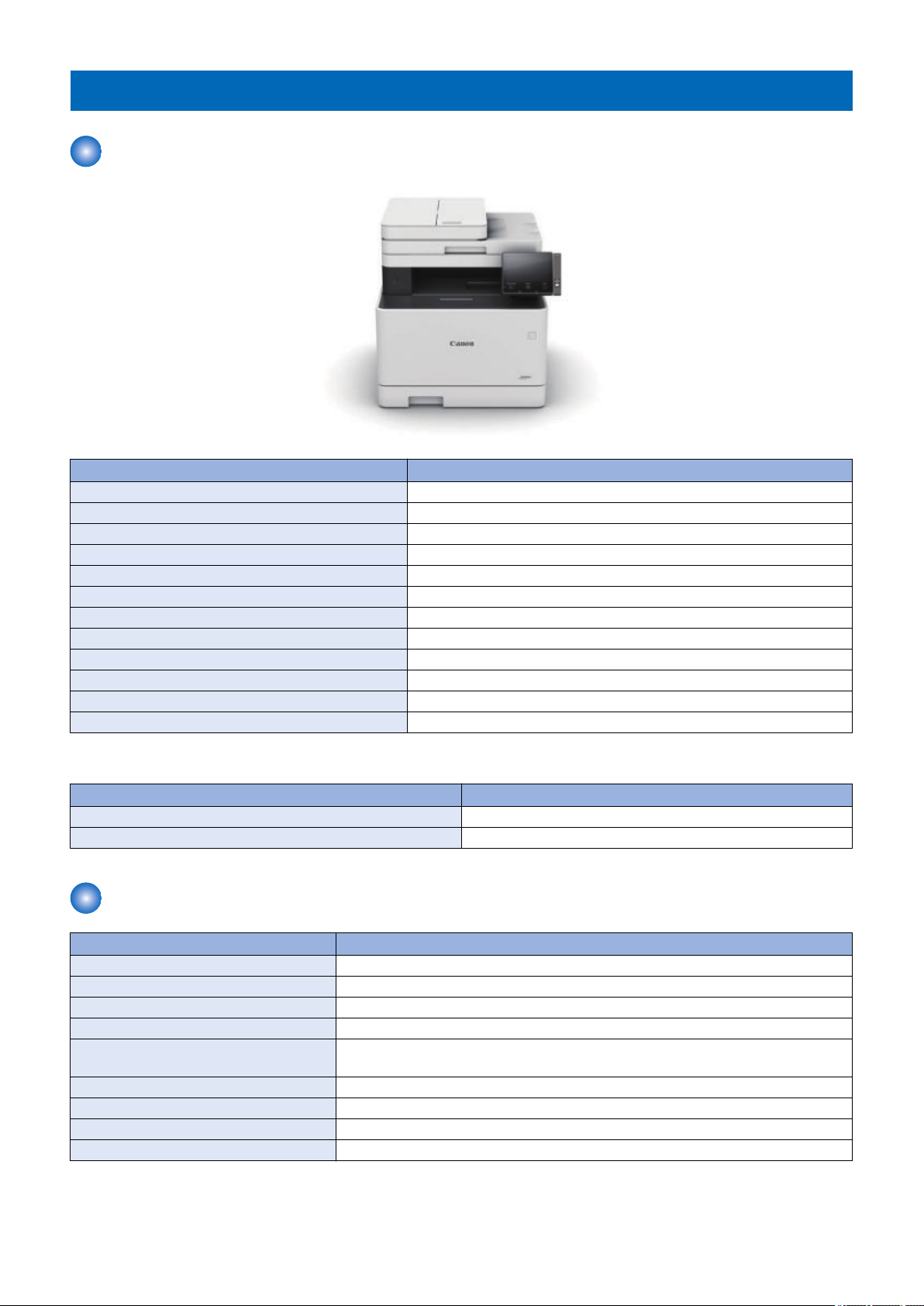

Host Machine

MF735Cdw /MF735Cx

Copy Yes

Print Yes

Fax Yes

Remote UI Yes

ADF 2-sided scanning

2-sided printing Yes

Control Panel 5 inch Touch Panel

NFC Yes

Backup of counter Yes

MEAP -

Network Yes

Wireless LAN Yes

1. Product Overview

PDL

MF735Cdw / MF735Cx

PS Yes

PCL Yes

Option

Name Description

Cassette Feeding Module-AF1 550 sheets (80 g/m2) of paper can be placed

Copy Card Reader Attachment-J1 Except KOR model

Copy Control Interface Kit-C1 Except KOR model

Copy Card Reader-F1 Except KOR model

MiCARD Attachment Kit-B1 Attachment kit for MiCARD Reader

Except KOR model

HANDSET KIT 3 Long cord Cool White AE model only

TELEPHONE 6 KIT Long cord Cool White EUR/TWN model only

Barcode Printing Kit-E1 Except KOR model

Send PDF Security Feature Set-E1

5

1. Product Overview

Features

Middle Class A4/LTR Color Laser MFP

1. Improved Control Panel operability

Improved operability by adopting the Large 5 inch Color Touch Panel.

2. 1-path simultaneous duplex reading

Increased productivity in 2-sided original reading by adopting the 1-path ADF (Scan, Send, Copy).

3. Support for mobile print

Printing from smartphones, tablets and PCs via an application such as Apple AirPrint, proprietary application, Google Cloud

Print and Mopria Print becomes available.

4. Support for wireless LAN

Communication via mobile device and wireless LAN becomes available by connecting a wireless LAN router to the network

to which this machine is connected.

5. NFC (Near Field Communication)

Printing can be performed by touching a mobile device where Canon PRINT Business is installed.

6

Specifications

Specifications of Host Machine

Item Specification / Function

Copyboard Fixed

Device Installation Desktop

Light source LED (RGB)

Photoreceptor OPC drum (φ24)

Image scanning CIS (color)

Light exposure method Laser beam exposure

Charging method Roller charging

Developing method Contact development

Transfer method Primary transfer: Sequential 4 colors transfer to Intermediate Transfer Belt

Secondary transfer: 4-color batch transfer onto the transfer material by the Transfer Roller

Separation method Curvature separation

Cassette paper feed Simple separation retard

MP Tray paper feed Pad separation method

Drum cleaning method Cleaning blade

Transfer cleaning method Cleaning brush and roller

Fixing method On-demand fixing

Paper delivery method Face-down

Toner level sensor Mounted

Toner type Non-magnetic one-component toner

Toner supply method All-in-one cartridge (drum + toner)

Toner save mode N/A

Document types Sheet / book

Maximum document size Copyboard Glass: 216 mm × 297 mm

Feeder: 216 mm × 356 mm

Document size sensor N/A

Image size magnification Zoom: 25 to 400% (1% increment)

Warm-up Time *1 13 seconds or less

Recovery Time *2 Approx. 6.1 seconds

Reading resolution 600 x 600 dpi (Maximum)

Reading Speed Fixed (A4/LTR):

• N/A

Continuous reading, SEND:

• Color: 10 images / minute (A4/LTR)

• B&W: 20 images / minute (A4)

• B&W: 21 images / minute (LTR)

Print resolution 600 x 600 dpi

First copy time Color: Approx. 11.3 seconds(A4), Approx. 11.1 seconds(LTR)

B&W: Approx. 9.8 seconds(A4), Approx. 9.5 seconds(LTR)

First print time Color: Approx. 8.6 seconds(A4), Approx. 8.5 seconds(LTR)

B&W: Approx. 8.3 seconds(A4), Approx. 8.1 seconds(LTR)

Print Speed *3 At 1-sided printing:

• Color/B&W: Approx. 27 sheets/min.(A4), Approx. 28 sheets/min.(LTR)

At 2-sided printing:

• Color/B&W: Approx. 21.9 sheets/min.(A4), Approx. 23.1 sheets/min.(LTR)

Available paper type for cassette

Available paper type for Multi-purpose Tray

Available paper size in cassette

Thin paper, Recycled paper, Color paper, Plain paper, Heavy paper, Coated paper, Label, Envelope

(Refer to “Paper type” on page 8)

Thin paper, Recycled paper, Color paper, Plain paper, Heavy paper, Coated paper, Label, Envelope

(Refer to “Paper type” on page 8)

A4, B5, A5, LGL, LTR, STMT, EXEC, OFFICIO, B-OFFICIO, M-OFFICIO, GLTR, GLGL, FLS, AFLS,

indLGL, K16, Postcard, Envelopes (COM10, Monarch, Nagagata 3, Yougatanaga 3, C5, DL), Custom

Paper Size

(Refer to “Paper size” on page 9)

1. Product Overview

7

1. Product Overview

Item Specification / Function

Multi-purpose tray paper size A4, B5, A5, LGL, LTR, STMT, EXEC, OFFICIO, B-OFFICIO, M-OFFICIO, GLTR, GLGL, FLS, AFLS,

indLGL, K16, Envelopes (COM10, Monarch, Nagagata 3, Yougatanaga 3, C5, DL), Custom Paper Size

(Refer to “Paper size” on page 9)

Cassette capacity

Multi-purpose Tray capacity

Delivery tray stacking capacity *4

Continuous copying 1 to 99 sheets

Automatic 2-sided Available (A4, B5, LGL, LTR, EXEC, FLS)

Memory capacity 1 GB

Sleep mode Available

Allowable environmental

temperature

Allowable humidity 20 to 80% in relative humidity (no condensation)

Power rating Rated input voltage:

Maximum power consumption

Average power at operation 120 V : Approx. 520 W

Average power at standby 120 V : Approx. 20.6 W

Average power at sleep

mode

Power consumption at Main

Power Switch OFF

Dimensions (W x D x H) 471 × 469 × 460 mm

Weight

(Excluding toner cartridges)

Cassette: 250 sheets (60 to 90 g/m2)

Option: 550 sheets (60 to 90 g/m2)

50 sheets (60 to 90 g/m2)

150 sheets (75 g/m2)

10 to 30 deg C

120 V system: 120 to 127 V (60Hz)

200 V system: 220 to 240 V (50/60Hz)

1500 W or lower

230 V : Approx. 560 W

230 V : Approx. 17.7 W

Approx. 1.0 W

0.3 W or lower

Approx. 26.5 kg

*1 : Warm-up time is an interval between when the machine is turned ON and when the main screen appears on the display.

Warm-up time may vary depending on the use conditions and environment of the machine.

*2 : Time for recovery from sleep to standby.

*3 : The print speed may become lower depending on the settings such as output resolution, paper size, type, orientation, and

number of sheets printed. In the case of 2-sided printing, 1 page on the front side and 1 page on the back side are output as

1 sheet.

*4 : The actual stack capacity varies depending on the site environment and the type of paper used.

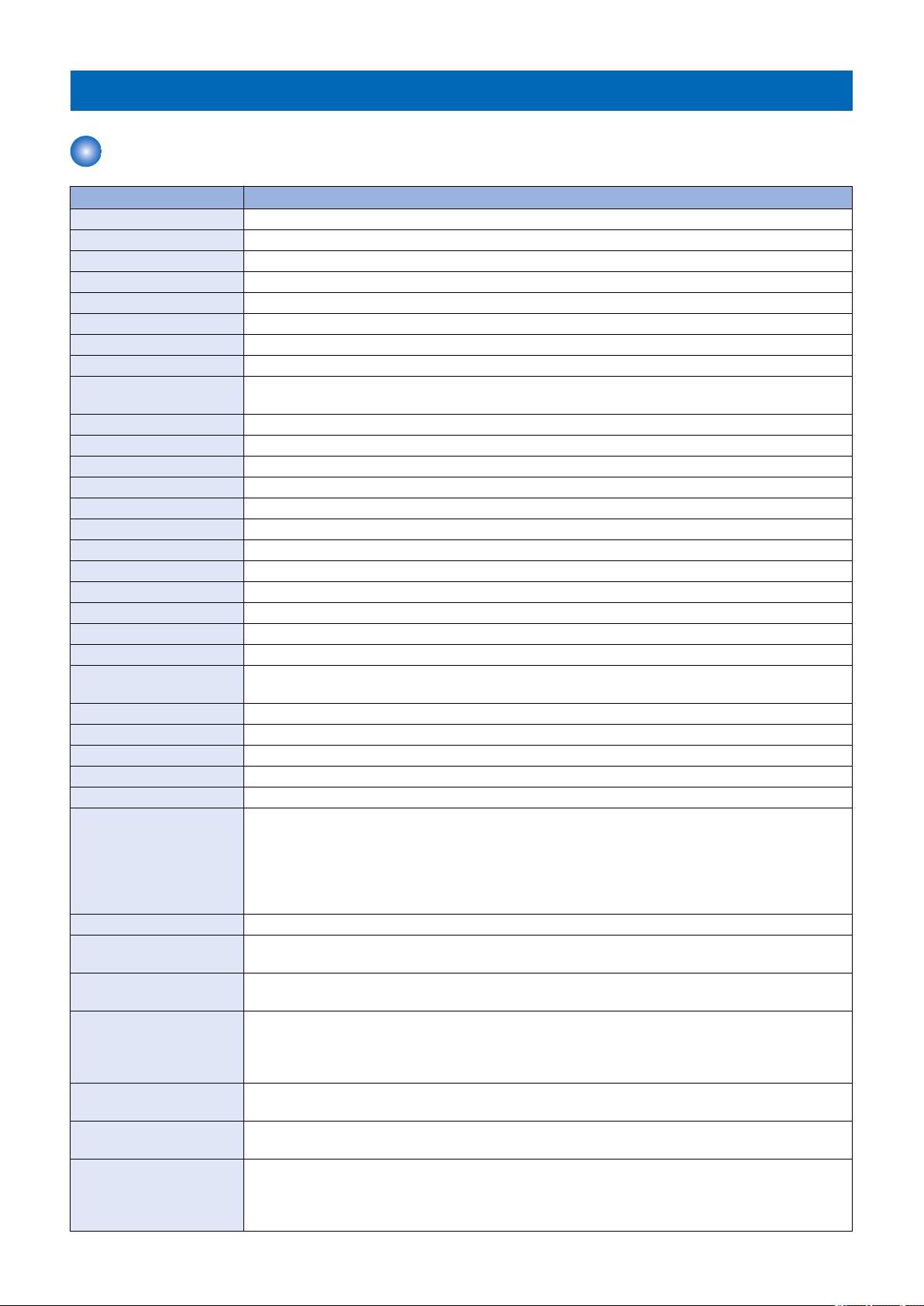

Paper type

(Yes: Pickup possible -: Pickup not possible)

Type of paper Paper set-

tings in this

machine

Thin paper 60 to 70 g/m2 Thin 1 Yes Yes Yes

60 g/m2 Thin 2 *1 Yes Yes Yes

52 to 59 g/m2 Thin 3 Yes - -

Recycled 60 to 75 g/m2 Recycled 1 Yes Yes Yes

71 to 82 g/m2 Recycled 2 Yes Yes Yes

Color 71 to 82 g/m2 Color Yes Yes Yes

Plain 71 to 82 g/m2 Plain 1 Yes Yes Yes

83 to 90 g/m2 Plain 2 Yes Yes Yes

Heavy paper 91 to 119 g/m2 Heavy 1 Yes Yes Yes

120 to 128 g/m2 Heavy 2 Yes Yes Yes

Standard Cassette/

Cassette Feeding

Module-AF1 (option)

Multi-purpose Tray Auto 2-sided printing

8

1. Product Overview

Type of paper Paper set-

tings in this

machine

Heavy paper

Coated 100 to 120 g/m2 Coated 1 Yes Yes Yes

Label paper Label paper Yes Yes -

Envelope (Nagagata 3, Yougatanaga 3,

C5)

Envelope (COM10, Monarch, DL) Envelope 2 Yes Yes -

129 to 163 g/m2 Heavy 3 Yes Yes Yes

121 to 150 g/m2 Coated 2 Yes Yes Yes

151 to 200 g/m2 Coated 3 Yes Yes Yes

Envelope 1 Yes Yes -

Standard Cassette/

Cassette Feeding

Module-AF1 (option)

Multi-purpose Tray Auto 2-sided printing

*1: When the paper of 60 g/m2 is curled while <Thin 1> is set, select <Thin 2>.

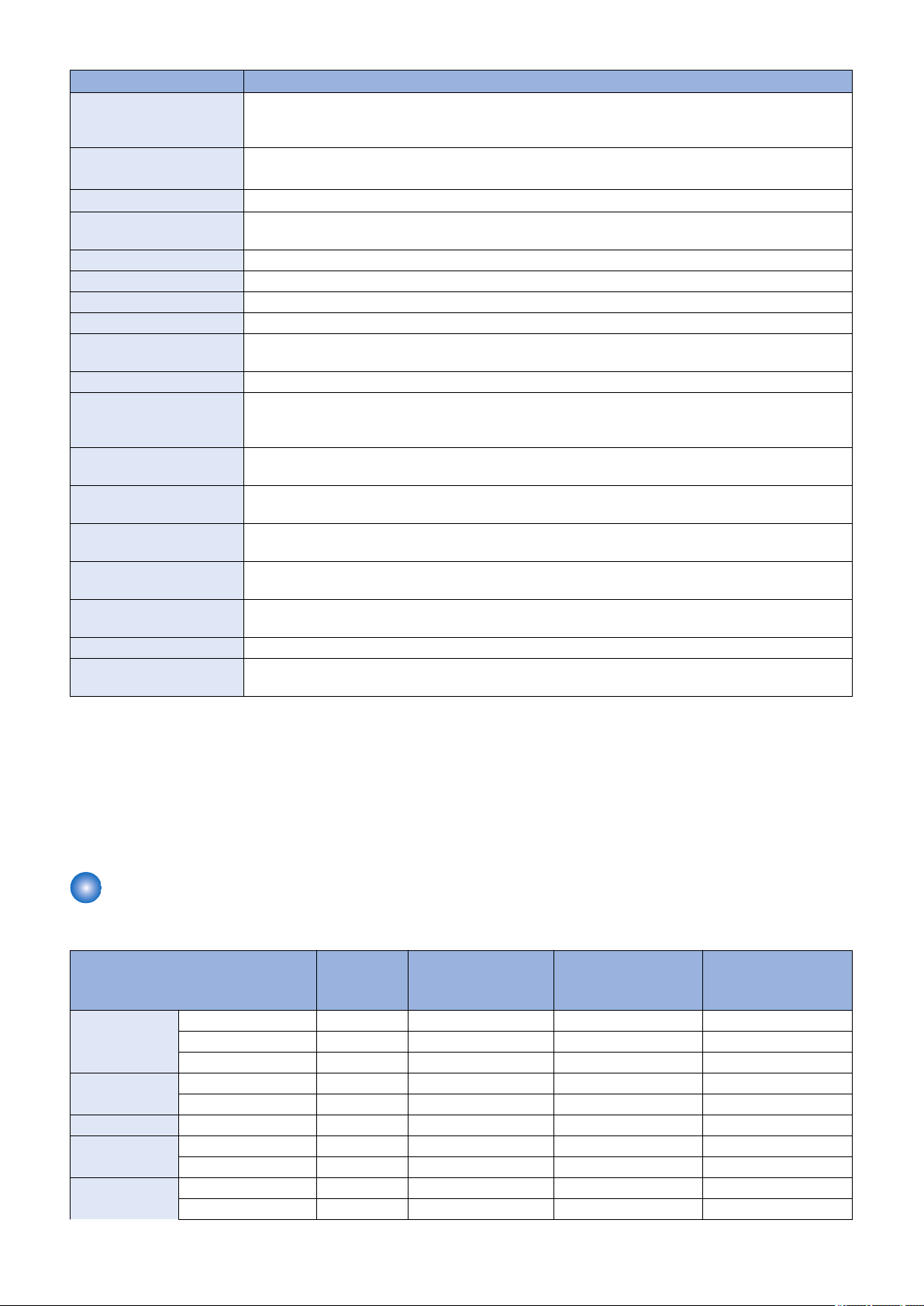

Paper size

(Yes: Pickup possible -: Pickup not possible)

Paper size Standard Cassette/

Cassette Feeding Mod-

ule-AF1 (option)

A4 210.0 mm x 297.0 mm Yes Yes Yes

B5 182.0 mm x 257.0 mm Yes Yes Yes

A5 148.0 mm x 210.0 mm Yes Yes -

LGL 215.9 mm x 355.6 mm Yes Yes Yes

LTR 215.9 mm x 279.4 mm Yes Yes Yes

STMT 139.7 mm x 215.9 mm Yes Yes -

EXEC 184.2 mm x 266.7 mm Yes Yes Yes

OFFICIO*4 215.9 mm x 317.5 mm Yes Yes Yes

B-OFFICIO*4 216 mm x 355 mm Yes Yes Yes

M-OFFICIO*4 216 mm x 341 mm Yes Yes Yes

G-LTR*4 203.2 mm x 266.7 mm Yes Yes Yes

G-LGL*4 203.2 mm x 330.2 mm Yes Yes Yes

FLSC 215.9 mm x 330.2 mm Yes Yes Yes

AFLS*4 206 mm x 338 mm Yes Yes Yes

Indian LGL*4 215.0 mm x 345.0 mm Yes Yes -

Envelope No.10

(COM10)

Envelope Monarch 98.4 mm x 190.5 mm Yes Yes -

Envelope C5 162.0 mm x 229.0 mm Yes Yes -

Envelope DL 110.0 mm x 220.0 mm Yes Yes -

Custom paper - Yes *1 Yes *2 Yes *3

104.7 mm x 241.3 mm Yes Yes -

Multi-purpose Tray Auto 2-sided printing

*1: 100 × 148 mm to 215.9 × 355.6 mm

*2: 676.2 × 127 mm to 215.9 × 355.6 mm

*3: 176 × 250 mm to 215.9 × 355.6 mm

*4: Only when the user-defined size is configured on the driver

9

Parts Name

[1]

[3]

[2]

[5]

[6]

[7]

[8]

[10]

[9]

[4]

[11]

[12]

[13]

[5]

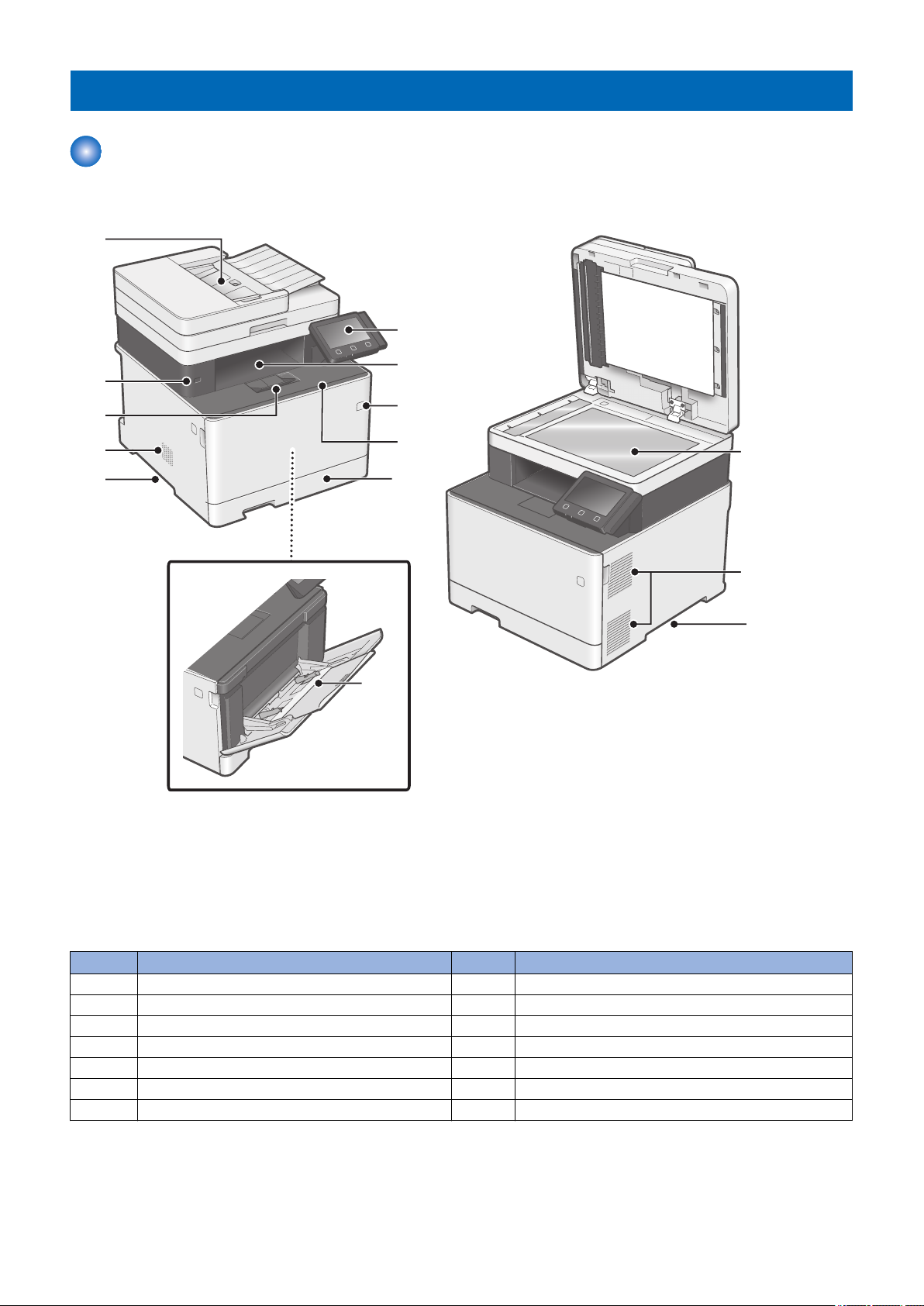

External view

■ Front side of the machine

1. Product Overview

No. Name No. Name

1 Feeder 8 Power Switch

2 USB port (for USB device) 9 Front Cover

3 Delivery Stopper 10 Pickup Cassette

4 Speaker 11 Multi-purpose Tray

5 Handle for carrying 12 Copyboard Glass

6 Control Panel 13 Ventilation hole

7 Delivery Tray

10

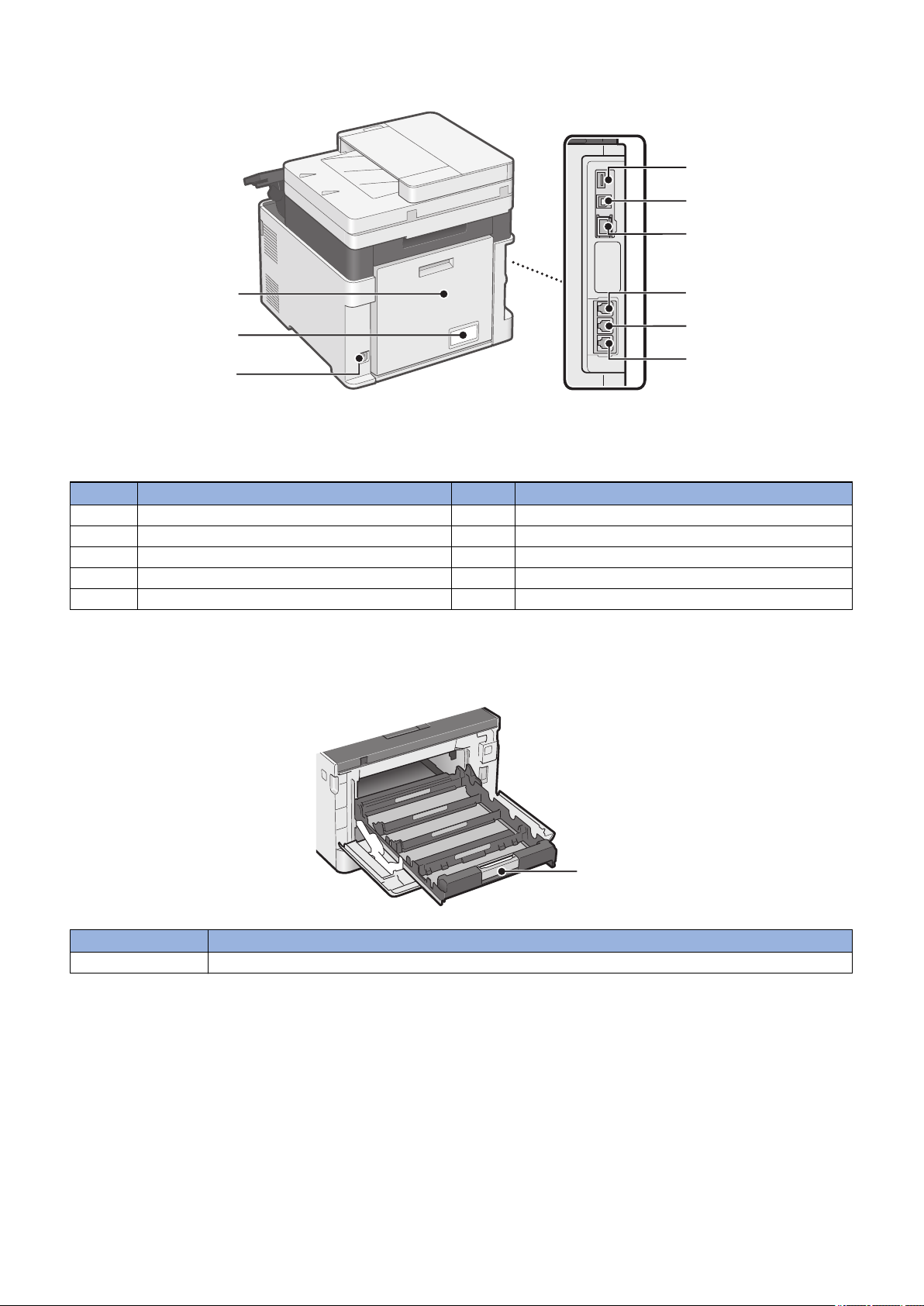

■ Rear side of the machine

[2]

[4]

[5]

[6]

[7]

[8]

[9]

[3]

[1]

[1]

1. Product Overview

No. Name No. Name

1 Rear Cover 6 LAN Port

2 Rating name plate label 7 Terminal for Handset

3 Power Socket 8 Terminal for external telephone

4 USB port (for USB device) 9 Terminal for telephone line

5 USB port (for PC)

■ Inside of the host machine

No. Name

1 Toner Cartridge Tray

11

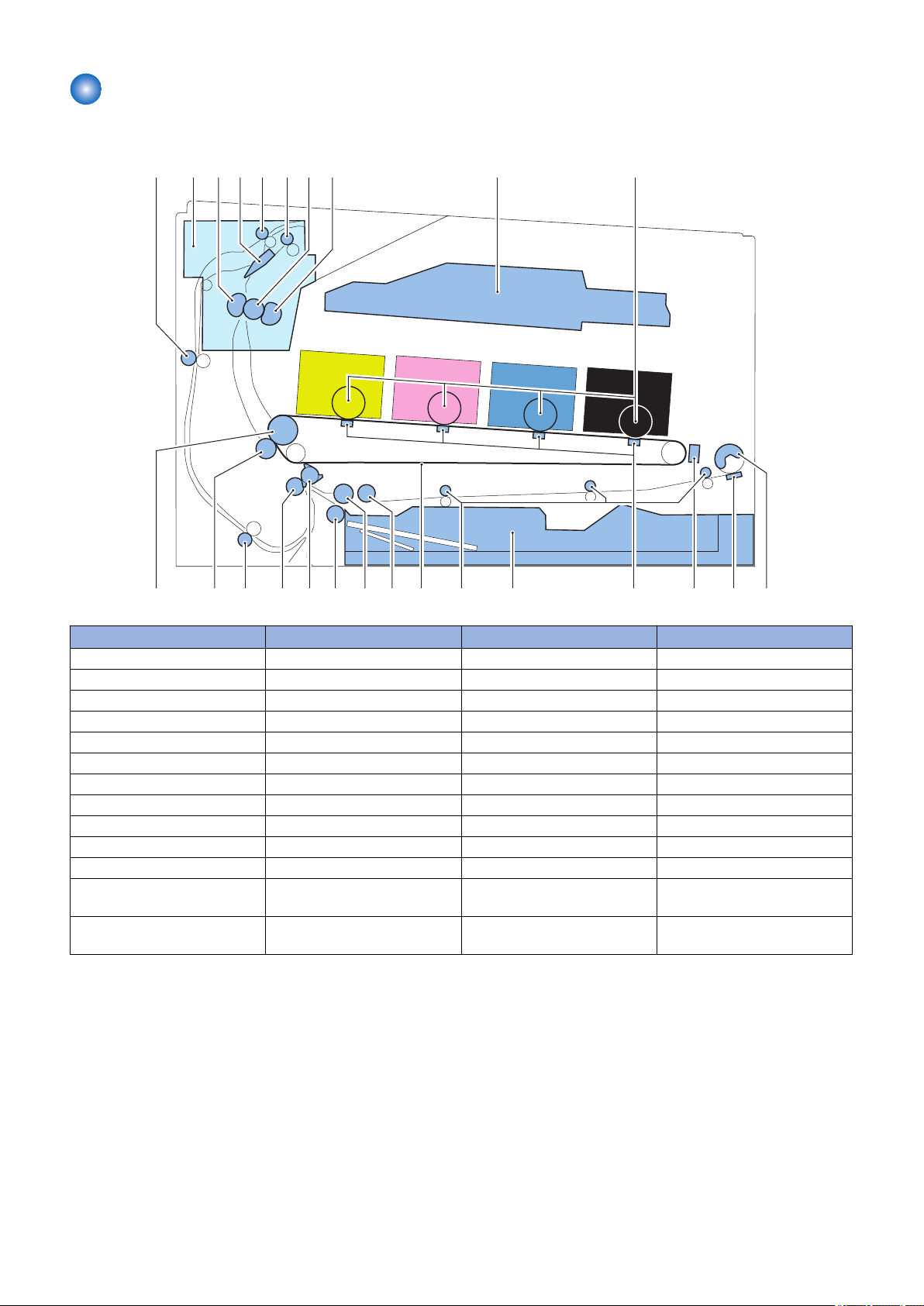

Cross Section View

[10][1] [2] [3] [4] [5] [6] [7] [8] [9]

[11][12][13]

[15]

[16][17][18][19][20][21][22][23][24][25] [14]

■ Host machine

1. Product Overview

No. Name No. Name

[1] Duplex Feed Roller [14] Primary Transfer Brush

[2] Fixing Assembly [15] Cassette

[3] Pressure Film [16] Multi-purpose Tray Feed Roller

[4] Duplex Flapper [17] ITB

[5] Duplex Reverse Roller [18] Cassette Pickup Roller

[6] Delivery Roller [19] Cassette Feed Roller

[7] Fixing Roller [20] Cassette Separation Roller

[8] Fixing Film [21] Registration Shutter

[9] Laser Scanner Unit [22] Registration Roller

[10] Photosensitive Drum [23] Duplex Re-pickup Roller

[11] Multi-purpose Tray Pickup Roller [24] Secondary Transfer Roller

[12] Multi-purpose Tray Separation

Pad

[13] Color Displacement/Density

Sensor

[25] ITB Drive Roller

12

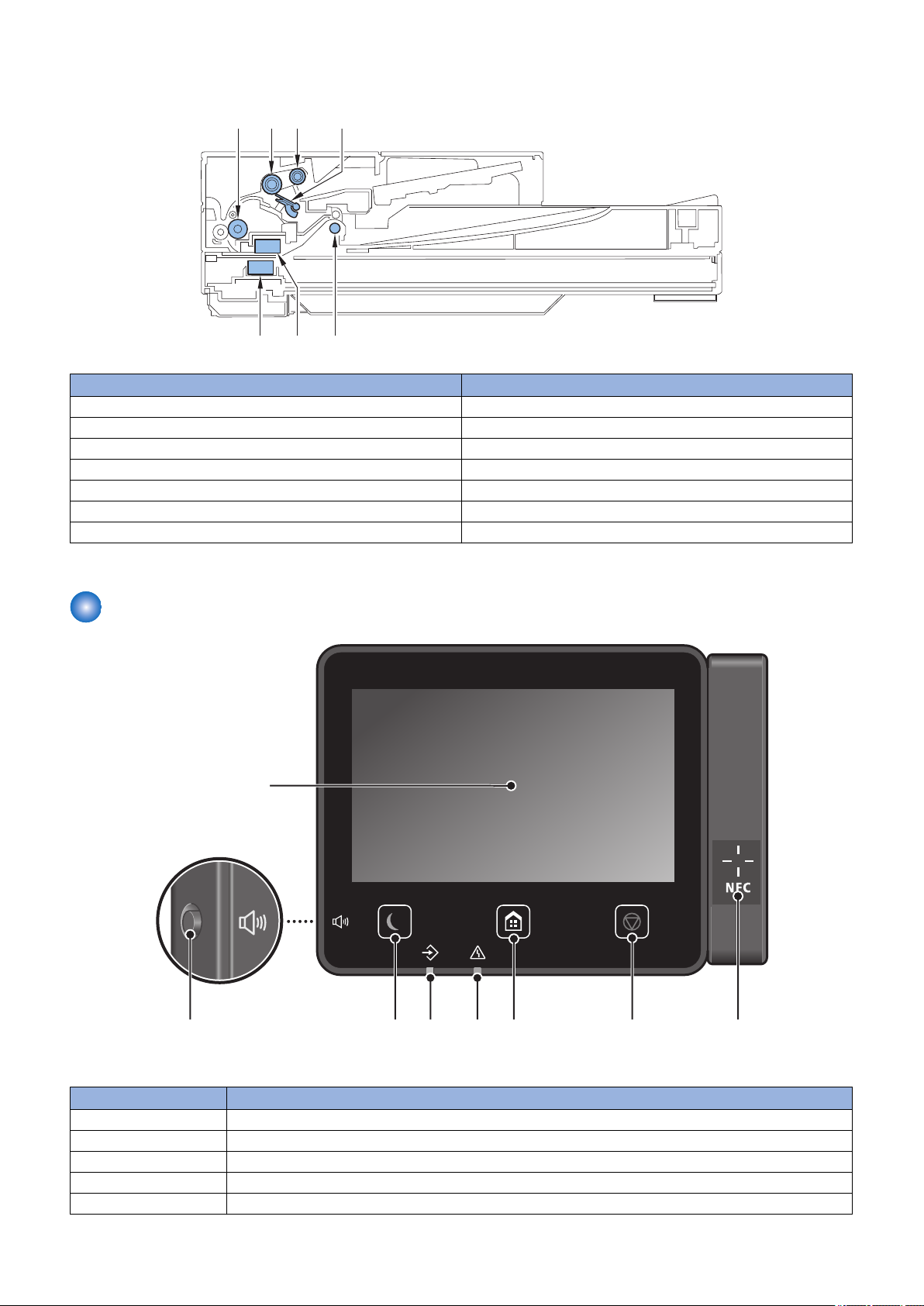

■ ADF/Reader Unit

[1]

[5][7]

[2] [3] [4]

[6]

[3]

[2]

[4] [5] [6] [7]

[8]

[1]

1. Product Overview

No. Name

[1] Feed Roller

[2] Separation Roller

[3] Pickup Roller

[4] Separation Pad

[5] Delivery Roller

[6] Contact Image Sensor (back side)

[7] Contact Image Sensor (front side)

Control Panel

No. Name

1 Display

2 Volume key

3 Energy Saver key

4 Data Lamp

5 Error Lamp

13

No. Name

6 Home key

7 Stop key

8 NFC (Near Field Communication) mark

1. Product Overview

14

Technical

2

Explanation

(Device)

Basic Configuration.............................16

Original Exposure/Feed System......... 17

Laser Exposure System......................22

Controller System................................24

Image Formation System....................29

Pickup Feed System........................... 35

Fixing System......................................45

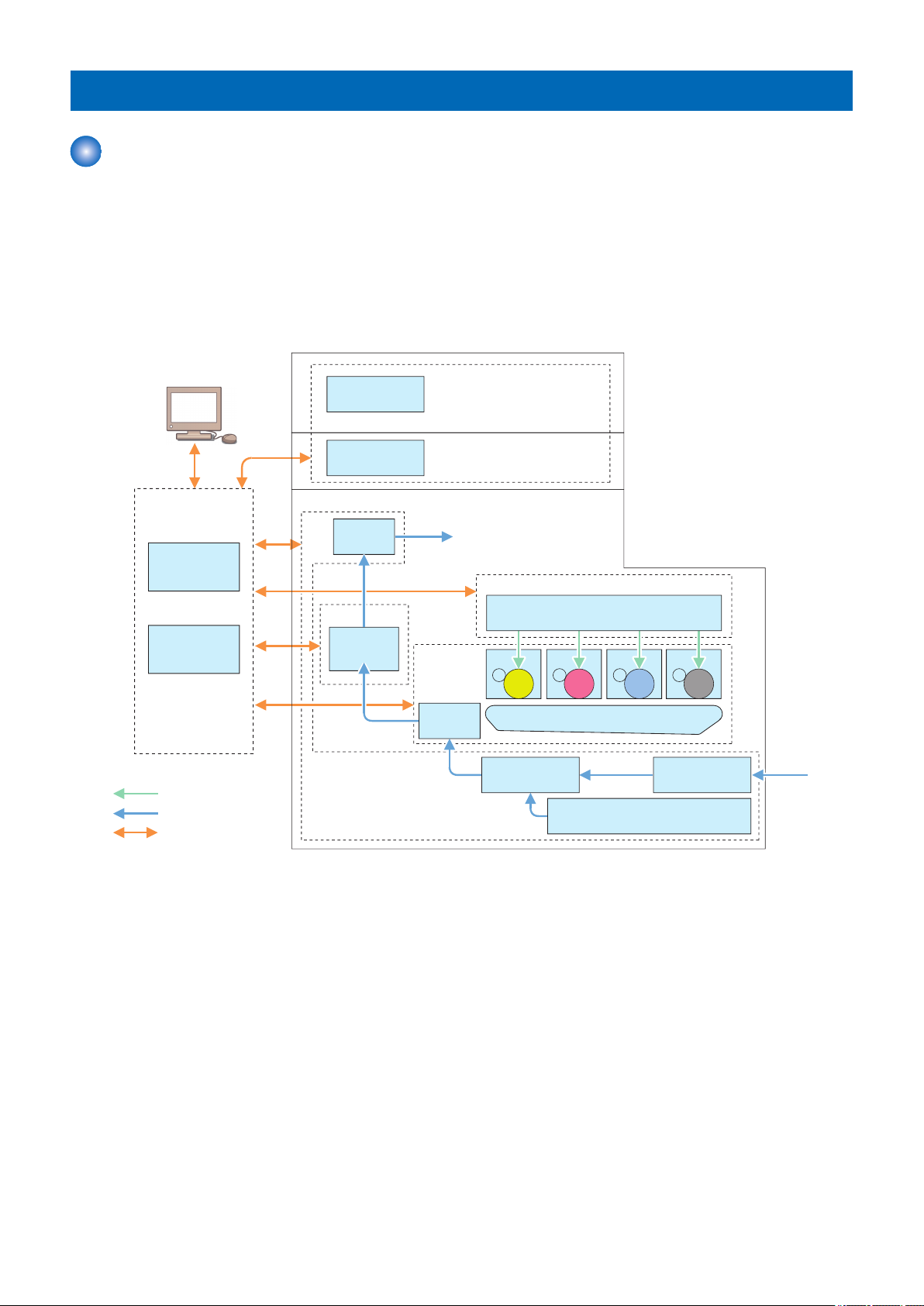

Basic Configuration

Laser beam

Paper flow

Signal flow

CIS unit

ADF

Document exposure/

feeding system

Main

controller

DC

controller

Controller system

Laser scanner

Laser exposure system

ITB unit

Secondary

Transfer

Image

formation

system

Cassette

Manual feed

pickup unit

Pickup

unit

Pickup/feed system

Fixing

assembly

Fixing system

Delivery

assembly

Drum Drum Drum Drum

Functional Configuration

Description

This machine is roughly composed of the following six blocks.

• Original Exposure/Feed System

• Laser Exposure System

• Controller System

• Image Formation System

• Pickup Feed System

• Fixing System

2. Technical Explanation (Device)

16

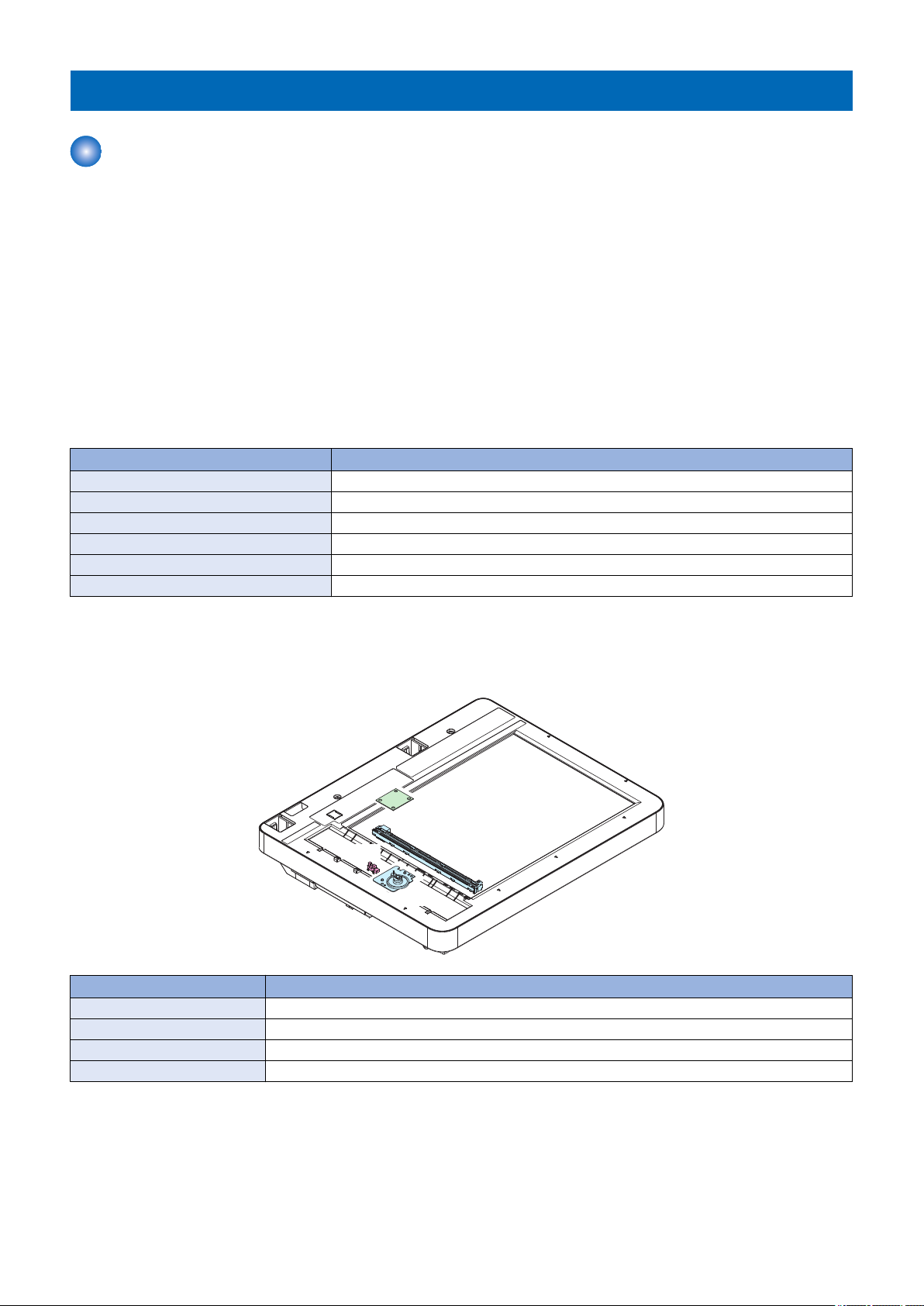

UN40

CIS

SR11

M5

2. Technical Explanation (Device)

Original Exposure/Feed System

Original Exposure System

■ Functional Configuration

Description

The original on the Copyboard Glass is read by moving the Contact Image Sensor (CIS) by rotating the Reader Motor based on

the drive signal from the Main Controller PCB.

When using the ADF, the original is read by feeding it using the ADF, without moving the Contact Image Sensor.

Simultaneous duplex scanning models have 2 Contact Image Sensors, and the front and back sides of paper are scanned at the

same time with one feed of the paper.

* This model is not included in the lineup of some of the series. (Reference: “Product Lineup” on page 5)

■ Specifications

Description

Item Specification/Function

Photo conductor LED

Reading resolution 600 dpi x 600 dpi

Number of gradations 256 gradations

Magnification ratio 25 % to 400 % (in 1% increment)

Reading Sensor 1 line

Original size detection None

■ Major Components

Description

Symbol Name

M5 Reader Motor

CIS Contact Image Sensor

SR11 CIS HP Sensor

UN40 Connecting Relay PCB

■ Dust Detection Control

Overview

Presence/absence of dust on the Stream Reading Glass is detected when an original is read. In accordance with the detection

result, the original reading position is changed or image correction is performed to prevent the dust from being printed on the

image.

17

B A C

0.5 mm

0.5 mm

2. Technical Explanation (Device)

Control of dust detection consists of the following two items:

• Dust detection correction

• Dust detection evasion

Execution Condition/Timing

Dust detection correction

During the period of time from the moment when the original of a stream reading job arrives just before the reading position

to the moment when reading of the original is completed (for each page)

Dust detection evasion

When a job starts

Description

Dust detection correction

If dust on the Stream Reading Glass is detected, the image is corrected to prevent the dust from being printed.

1. Before the original arrives, the White Plate is read through the Stream Reading Glass, and points where dust may exist

are detected.

2. The leading edge of the original is detected.

3. The detection results before and after the leading edge of the original appears on the Stream Reading Glass are

compared. If dust does not exist at the dust point detected in step 1, it is judged to be dust on the White Plate and dust

correction is not performed. If dust exists at the point detected in step 1, it is judged to be dust on the Stream Reading

Glass and dust correction is performed.

Dust detection evasion

If dust is detected when the last job paper is read, the reading position of the next stream reading job is changed in order to

avoid the dust.

The amount of adjustment for dust evasion is -0.5 mm (B), 0 mm (A), and +0.5 mm (C).

Each time dust is detected when reading the last paper of a stream reading job, the CIS moves to the three positions in the

order shown below.

A -> B -> C -> A ->

NOTE:

In the case of simultaneous duplex scanning models, this control is applied only to reading of the front side where the CIS can be

moved.

If any of the following conditions is detected 6 times in a row, it is judged that the Stream Reading Glass is soiled, and a message

prompting the user to clean the Stream Reading Glass is displayed on the Control Panel.

• Dust of 1 pixel or larger and smaller than 5 pixels is detected at 11 points or more.

• Dust of 5 pixels or larger is detected at 1 point or more.

Service Mode

• Adjustment of the image correction level at stream reading [front]

COPIER > OPTION > BODY > DFDST-L1

• Adjustment of the image correction level at stream reading [back]

COPIER > OPTION > BODY > DF2DST-L1

Additional Functions Mode/Menu

• ON/OFF of automatic correction at the time of dust detection

Menu > Adjustment/Maintenance > Adjust Image Quality > Remove Streaks from Orig. Scanning Area

18

• ON/OFF of notification to clean the Stream Reading Glass

SR9

M11

CIS

SR10

Menu > Preferences > Display Settings > Notify to Clean Original Scanning Area

Original Feed System

■ ADF Specifications

Description

Item Specification

Original separation method Upper separation

Document scanning method Stream reading

Original basis weight

Original size A4, B5, A5, LGL, LTR, STMT

Original Tray stacking capacity

Original size detection function No

Mixed paper functions Mix of the same configuration: Yes

Finished stamp function No

Maximum document size 215.9 mm x 355.6 mm

Document processing speed Stream reading

50 to 105 g/m

Feed direction: 128 to 355.6 mm, Width direction: 105.0 to 215.9 mm

A4/LTR: 50sheets (80 g/m2)

LGL: 30sheets (80 g/m2)

Mix of different configurations: No

• Copy

• Scan

2

• 1-sided

A4/LTR: 27 ipm /28 ipm (300 dpi x 600 dpi, Black and White)

A4/LTR: 27 ipm /28 ipm (300 dpi x 300 dpi, Color)

• 2-sided

A4/LTR: 48 ipm /47 ipm (300 dpi x 600 dpi, Black and White)

A4/LTR: 28 ipm /27 ipm (300 dpi x 300 dpi, Color)

• 1-sided

A4/LTR: 27 ipm /28 ipm (300 dpi x 600 dpi, Black and White)

A4/LTR: 13.5 ipm /14 ipm (300 dpi x 300 dpi, Color)

• 2-sided

A4/LTR: 48 ipm /47 ipm (300 dpi x 600 dpi, Black and White)

A4/LTR: 28 ipm /27 ipm (300 dpi x 300 dpi, Color)

2. Technical Explanation (Device)

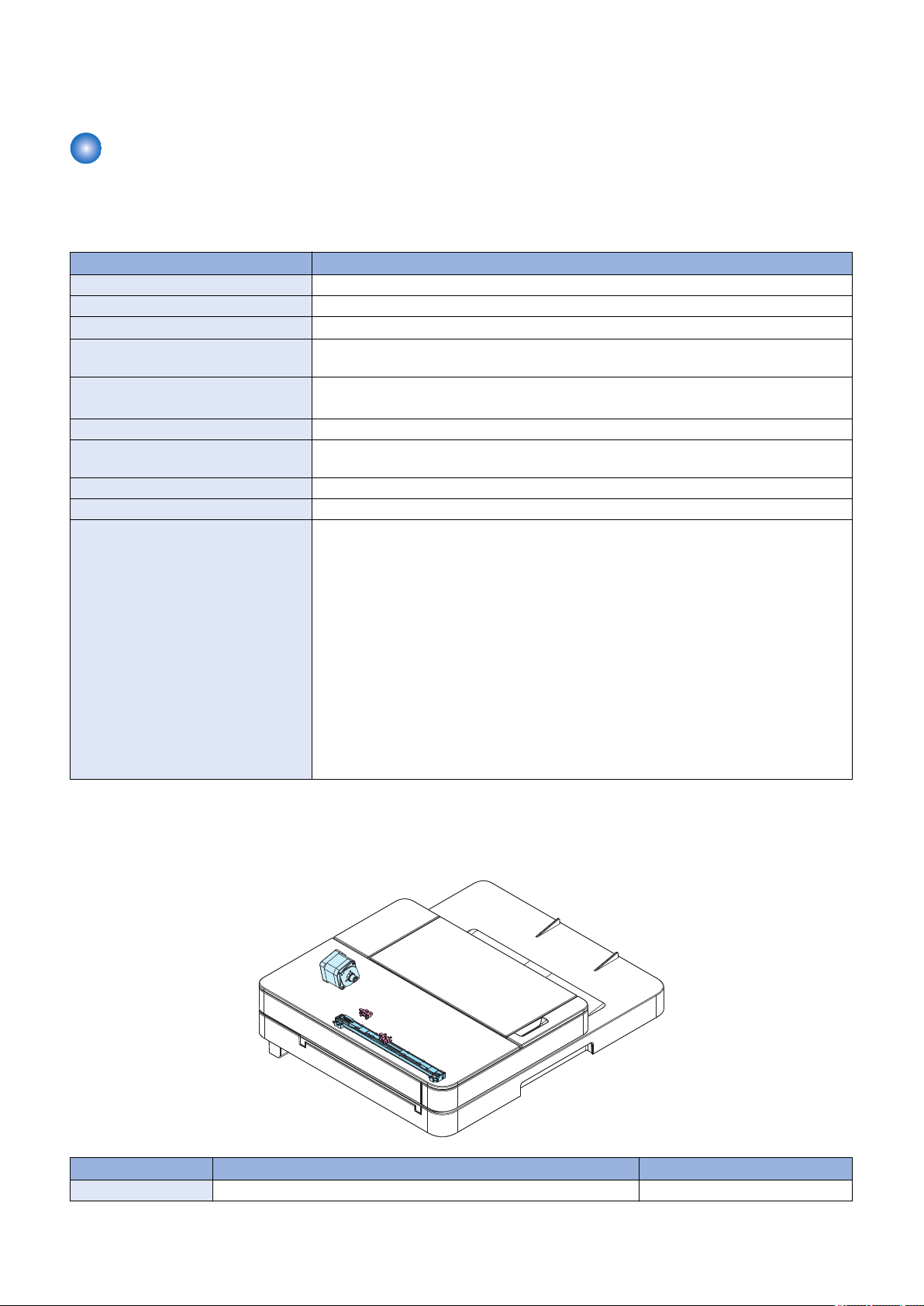

■ Major Components

Description

Symbol Name Remarks

M11 ADF Motor -

19

*

M11

MCON

2. Technical Explanation (Device)

Symbol Name Remarks

CIS Contact Image Sensor * Simultaneous duplex scanning

models only. (Reference: “Product

Lineup” on page 5)

SR9 Document Sensor -

SR10 Document End Sensor -

■ Drive Configuration

Description

When copy, fax, or scan is started, the ADF Motor (M11) is driven by a drive command from the Main Controller PCB.

The document which is placed face-up on the Original Tray is picked up and fed one sheet at a time in order from the top.

When the fed original passes over the Platen Glass, the image is read by the Contact Image Sensor (CIS), and then the original

is delivered face-down to the Document Delivery Assembly.

Symbol Name

M11 ADF Motor

MCON Main Controller PCB

* Simultaneous duplex scanning models only. (Reference: “Product Lineup” on page 5)

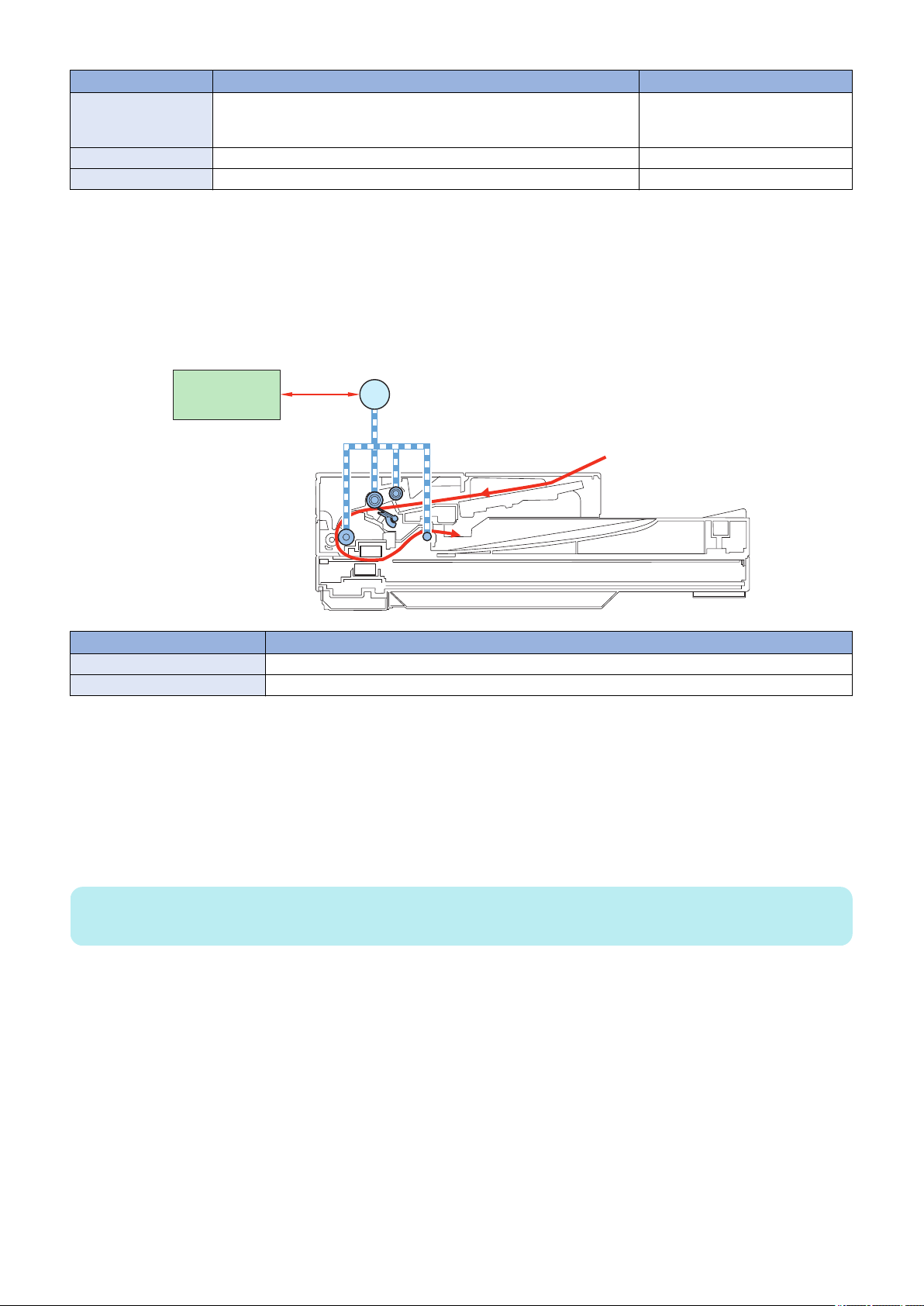

■ Original Detection

Overview

This machine has the following two types of original detection functions.

• Original Detection

• Original Edge Detection

NOTE:

This machine does not have a document size (original width) detection function.

Description

Original Detection

As the actuator is pushed up by placing an original on the Original Tray, the Document Sensor (SR9) is turned ON (light is

transmitted -> light is blocked) so that the presence of an original is detected.

Original Edge Detection

As the actuator is pushed up by the leading edge of the fed original, the Document End Sensor (SR10) is turned ON (light

is blocked -> light is transmitted) so that the leading edge of the original is detected.

In addition, when the trailing edge of the original passes the position of the actuator, the actuator returns to the original

position, which causes the Document End Sensor (SR10) to turn OFF (light is transmitted -> light is blocked) to detect the

trailing edge of the original.

Note that the original length that can be read by this machine is 400 mm and less; if an original longer than that is fed, it is

stopped due to jam. The original length is determined by the time required from when the Document End Sensor (SR10)

detects the original's leading edge to when it detects its trailing edge.

20

SR10

SR9

MCON

*

Symbol Name

SR9 Document Sensor

SR10 Document End Sensor

* Simultaneous duplex scanning models only. (Reference: “Product Lineup” on page 5)

■ Jam Detection

2. Technical Explanation (Device)

Execution Condition/Timing

When the power is turned ON or when the original is being read

Description

In the following cases, it is judged that an ADF jam has occurred.

• When the original is late in arriving the Document End Sensor or remains in the ADF while the original is being read

• When the Document End Sensor detects presence of paper when the power is turned ON (residual paper jam)

• When a document of 400 mm or more is detected

When a jam is detected, the reading operation stops and "Paper is jammed." is displayed on the screen of the Control Panel.

In the case of models equipped with the fax function (built-in speaker), a warning tone (beep sound) sounds when a jam is

detected.

The jam can be cleared by removing the jammed paper, opening and then closing the ADF Upper Cover, and placing the original

again.

21

Loading...

Loading...