Page 1

PROGRESSIVE DIGITAL

LABEL PRODUCTION

LabelStream 4000 series

Page 2

VALUE CHAIN DYNAMICS

Today’s marketplace is characterised by an extremely high complexity.

Spurred by intense competition and globalisation, shorter product

innovation cycles and turnaround times are critical success factors.

Digital printing oers distinct benefits that are a perfect

fit for the emerging requirements of the packaging

value chain. It can increase manufacturing flexibility

with just-in-time and on-demand production. In

addition, the inherent capability of digital printing

to change content and artwork with ease makes it a

To be successful in today’s challenging market environment

you’ll need to deliver outstanding performance along the

three major business dimensions: Time, Cost and Value.

Be responsive

Get the job done

• Short lead times

• Fast turnaround

• Time-to-market

powerful tool make communication more eective

and drive sales with shorter time-to-market. Target

group specific messaging from

alisation helps to grow revenues, extend market shares

and build brands.

versioning to person-

Zeit

Time

Reduce waste

Manage costs

Reach your audience

Impress your audience

The growing acceptance of digital printing in the

self-adhesive label market requires new production

methods to cope with rising demand. Established

technologies cannot fully meet the new market

requirements and keep up with the ever changing

market dynamics. A new level of digital productivity

• Optimised inventory

• Less overproduction

• Economic short runs

• Custom content

• Vibrant colours

• Striking embellishment

Cost

Value

is needed to cost-eciently produce short to medium

runs on an industrial-scale. Short lead and turn-around

times, customised content, high print quality and

inline finishing and embellishment will give brands

a boost while meeting the most demanding supply

chain challenges.

2

Page 3

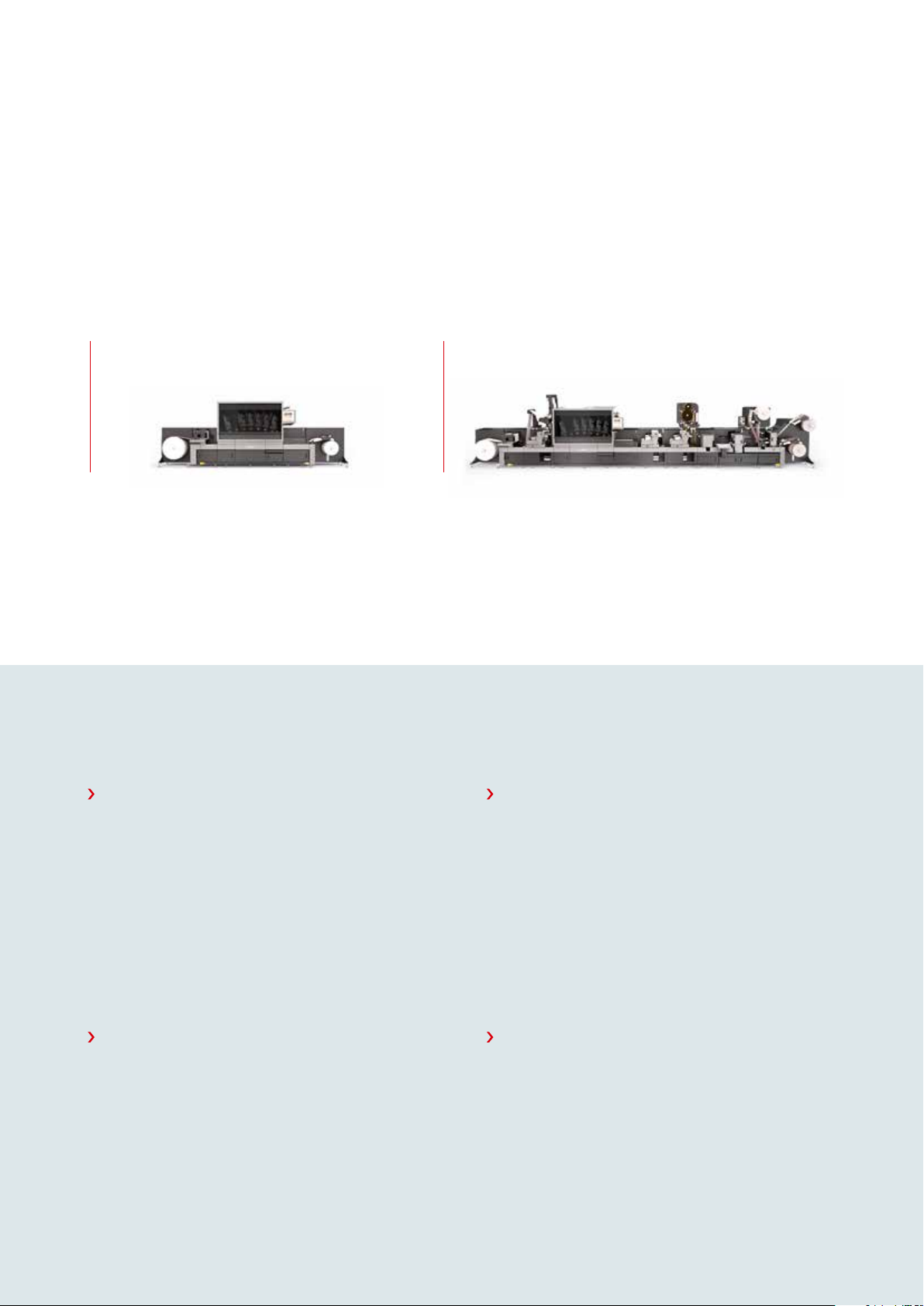

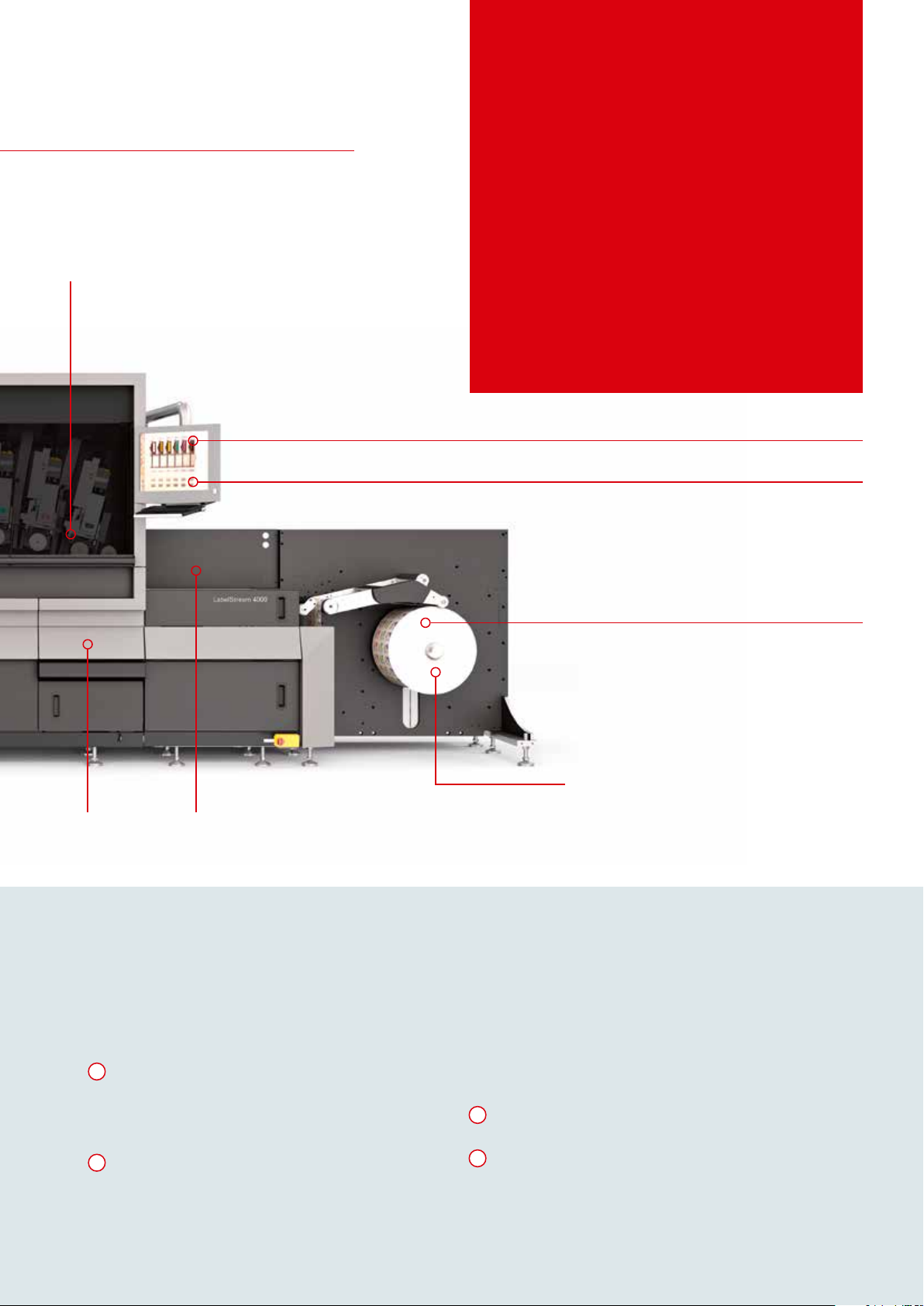

LABELSTREAM 4000 SERIES

One platform, limitless opportunities

Building on reliable UV inkjet technology and robust web transport, the six-colour press (CMYKO and

White) oers print speeds of up to 75 m/min and two print widths of 330 mm (13”) or 410 mm (16”),

resulting in an industry-leading overall output of 1,845 m²/hr. It oers minimal setup times, flexibility

to mass-customise contents and artwork, whilst enabling the shortest possible time to market. With

two distinct setups the LabelStream 4000 platform provides a choice for dierent demands:

CORE Upgrade your business HYBRID Inline file-to-finish conversion

The LabelStream 4000 CORE unit is the ideal

entry into the world of high performance

UV inkjet printing. Building on a cost-ecient,

yet powerful base unit, various options are

available to further expand the press setup to

meet additional requirements.

LabelStream provides a total package along the four dimensions Performance, Impact, Growth and

Partnership to meet highest expectations with benchmark production eciency and dependable

output, whilst providing consistent results on a wide range of media.

PERFORMANCE

Benefit from exceptional productivity!

Based on reliable UV inkjet technology, print

speeds of up to 75 m/min with two print widths

of 330 mm

industry- leading productivity of up to 1,845

m²/hr. In hybrid configurations a high level of

integration with optimised synching and setup

management further supports production

eciency.

(13”) and 410 mm (16”) ensure

The LabelStream 4000 HYBRID configuration

oers a custom

and finishing units,

single-pass label

tional and digital technologies enables a complete

inline production of high-quality self-adhesive labels.

GROWTH

Configure the system to your needs!

Choose additional components to add value or

to drive operational eciency of the Core unit.

• Enhance productivity with higher speeds and

wider print widths

• Extend the colour gamut with Orange and

add high-performance White

• Include a pre- or post-digital UV flexo unit

for spot colours or coating

mix of UV flexo, embellishment

turning it into a fully integrated

conversion line. This mix of conven-

PARTNERSHIP

Canon – your trusted partner!

Canon oers a complete package consisting

of innovative technologies integrated into

comprehensive end-to-end solutions support

ed by first-class technical service and professional services including colour and workflow

consultancy, project

development.

management and business

IMPACT

Get customer attention with quality and content!

• Large colour gamut & vibrant colours

• Screen-like white opacity of up to 80 %

-

• Customised content and targeted messaging

• Flexibility for trigger-based campaigns

• Inline embellishment in hybrid configuration

3

Page 4

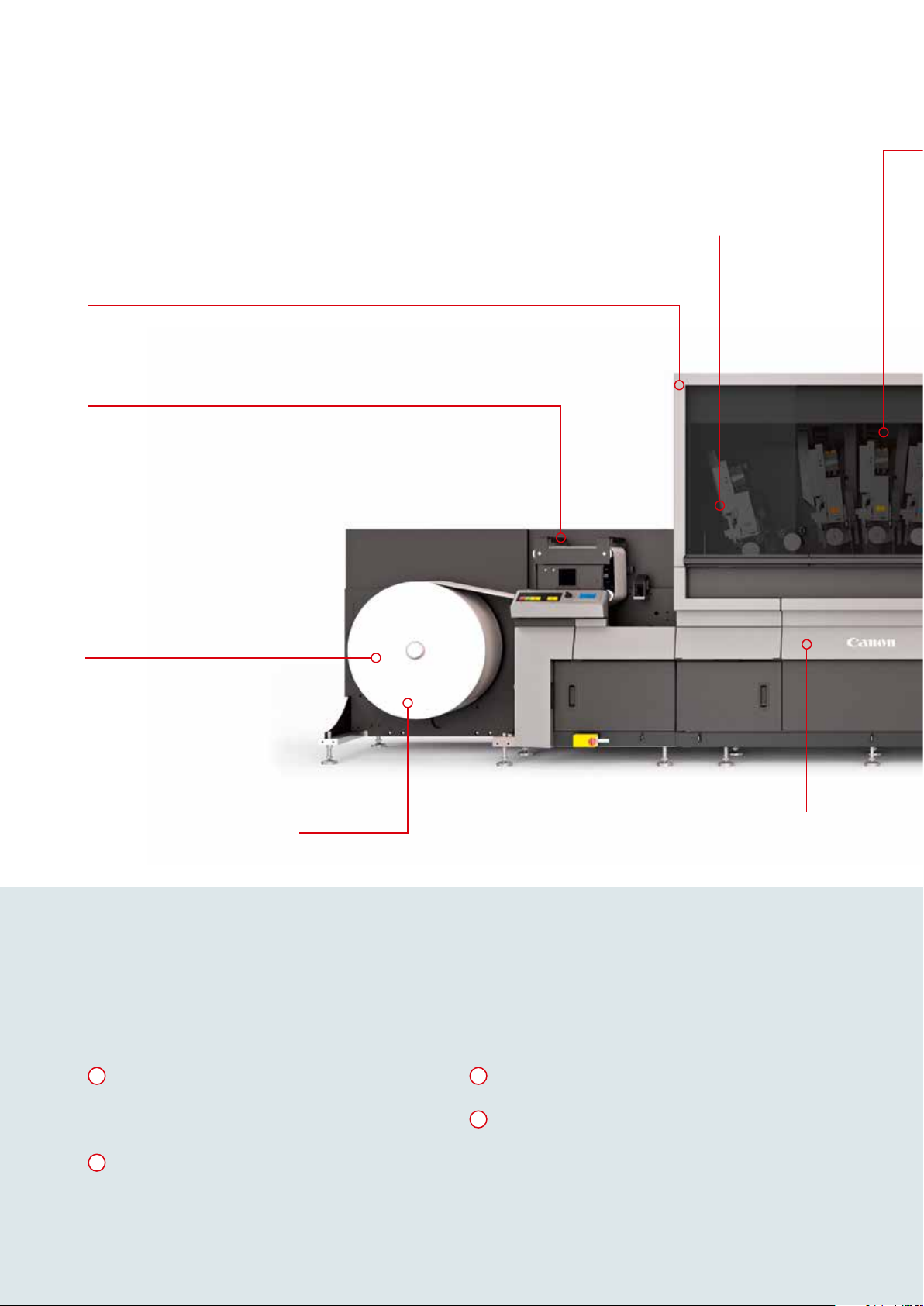

CORE: A POWERFUL

DIGITAL BASE UNIT

Full production speed of 50 m/min

Edge guide and web tension

Xaar 2001 UV Inkjet printheads with resolutions of

up to 720 x 1080 dpi

From 200 mm to

330 mm print width

1000 mm diameter unwind

and rewind with integrated

roll lift

GROWTH PATH: FOR MORE TO COME

Colour channels

The Core unit can be extended with additional

digital colour channels:

White – to attain flexo-like opacity levels in a

single-pass (> 70 %) at production speed or

up to 80% at slightly reduced speed (Alpine

White).

Orange – to enhance the coverage of Pantone

colour gamut up to 96 % and to match important brand colours without compromise on

speed.

High performance inks providing excellent

light fastness, chemical and scratch resistance

Web treatment

Optional web treatment components to

safeguard a reliable high quality production:

Corona treater – prepare the substrate for

excellent adhesion

Web cleaner – choose between single or

dual-sided contact or non-contact to remove

dust and debris

4

Page 5

Super-sized CMYK colour gamut

(610 cubic ∆E) and excellent colour

consistency, up to 6 colours (WCMYKO)

LED Intercolour pinning after

each colour to manage dot gain

New feature highlights

LabelStream has received major updates regarding

colour, productivity and Total Cost of Ownership

(TCO). The following features are now available

for both the CORE and HYBRID configuration:

• Alpine White: screen-like digital White with

up to 80 % opacity

• Orange gamut extension: optional 5th colour to

further enlarge the already super-sized CMYK

colour gamut

• Enhanced job management features

• Improved synching of digital and analogue modules

• New entry-level configuration

• Diversified service and pricing models

Single-point of operation

Open workflow architecture for easy

integration in existing workflows;

Integrated VDP support

Visual inspection table

Web transport built on a proven label printing press

Productivity

Increased production eciency for higher volume

demands or peak production capacity.

Print speed: optional print speeds of up to

75 m/min for highest performance requirements, resulting in an overall output of

1,845 m²/hr (at 410 mm print width).

Print width: optional 16” (410 mm) extended

print width for a 25% productivity boost and

web width flexibility.

Wide range of standard label stocks

including PP, PE, PPET, paper and

cartonboard from 40 to 600 microns

Up to 430 mm media width

Flexo lite

Extend your digital production unit with spot

colours, varnishing and coating capabilities to

meet the most common protection and embellishment needs in a simple and cost-ecient manner.

Pre flexo unit – for additional spot colours

or flexo white

Post flexo unit – for additional spot colours

or coating and varnishing

5

Page 6

HYBRID

Inline file-to-finish label conversion

Hybrid printing combines the benefits of digital with conventional converting techniques to balance

application costs and quality for the most cost-ecient production. The system can be expanded to

a full hybrid configuration with a custom mix of additional flexo, embellishment and finishing units

turning it into a fully integrated single-pass label conversion line to meet various demands and budgets.

This mix of conventional and digital technologies enables fast and aordable production of high- quality

self-adhesive labels.

Delam / relam Digital print unit Lamination unit Waste matrix

Hybrid press options

UV-Flexo units

Turnbar

Delam / relam

Semi rotary die cutting

Full rotary die cutting

Cold foiling

Lamination

Varnish

Waste matrix

Dual rewinder

Slitting

Turnbar

Dual rewinder

UV-Flexo unit Semi rotary die cutter Slitter

LabelStream provides accurate registration and

fast sync between flexo and digital. It requires

minimal operator intervention, in order to drive

uptime and high quality output, whilst reducing

waste. The seamless interplay of the two technologies, driven by LabelStream’s central control

panel, allows for easy recalling of job settings

and automated job setup. Job changes can take

eect, on-the-fly, without halting the press to

adjust digital and analogue components.

6

Page 7

The Canon inkjet DNA as basis for your success

As worldwide No. 1 in inkjet webfed printing and technology leader in UV inkjet based large format

printing Canon identified the key factors of our customers for a successful digital printing business.

This experience and insights became part of our DNA over time, influencing our strategies, products

and services to help our customers build a profitable business. However, there is no shortcut to true

inkjet DNA. It has grown and evolved with each installation of more than 1,600 high-volume inkjet

presses and 8,500 UV-based Large Format Printing systems.

Business Model

Service

Solution

Technology

Bespoke business development

Maximum uptime and availability

End-to-end solutions from file-to-finish

Best of class technology components

Worry-free operation

Matched to your business situation and production environment, we develop solutions, establish the

corresponding work processes, and instruct your sta for the operation, and daily maintenance of your

printing presses. Your uptime is our highest priority! We provide maintenance contracts according to

your needs – with service levels supporting extended working hours and reaction times as fast as two

hours (depending on local service capabilities). Our service models are fully proven and tested in many

multi-shift operations printing high volume applications, enabling our customers to meet tight deadlines.

Dense service network

~ 250 service technicians in Central Europe

dedicated to inkjet production printing

to keep your production up and running.

Sophisticated logistics network

The spare parts you need are nearby thanks

to our global logistics network.

Tailored service models

Choose between various service models

depending on your needs.

Professional Services & Training

Operator training and consultancy for colour,

workflow and applications completes the package.

Comprehensive service model

Local presence in each country (Central Europe)

Travel and labour cost

Spare parts

Replacement parts (inc. printheads)

Preventive maintenance

Remote diagnostics

Service for digital and analogue components

2 hour qualified call back in local language*

4 hour on site*

Extended hours (standby)

2 hours on-site (depending on local availability)

included optional *during oce hours

7

Page 8

TECHNICAL DATA

LabelStream 4000 series at a glance

Print Modes

Performance 720 x 720 dpi at 75 m/min (> 65 % white opacity)

Quality 720 x 1,080 dpi at 50 m/min (> 70 % white opacity)

Alpine White 720 x 1,080 dpi at 36 m/min (80 % white opacity)

Graphics 720 x 360 dpi at 50 m/min

Media & Print Width

Digital print width 330 mm | 410 mm

Flexo print width 420 mm

Web width 430 mm

Technology

Printing technology Single pass UV inkjet

Xaar 2001+ UV hybrid side shooter® with variable dot size and

greyscale technology

Productivity 792 – 1,845 m²/hr

Ink / colours UV CMYK

Optional colours UV White and Orange

Media

Thickness 40 – 450 μm (hybrid)

40 – 600 μm (digital)

Type

Trademark notice

Canon is a registered trademark of Canon Inc. LabelStream is a trademark or registered trademark of Canon Production Printing Netherlands B.V. All other trademarks are the property of

their respective owners and hereby acknowledged.

No part of this publication may be copied,modified, reproduced or transmitted in any form or by any means, electronic, manual, or otherwise, without the prior written permission of Canon

Production Printing. Illustrations and printer output images are simulated and do not necessarily apply to products and services oered in each local market. The content of this publication

should neither be construed as any guarantee or warranty with regard to specific properties or specifications nor of technical performance or suitability for particular applications. The content

of this publication may be subject to changes from time to time without notice. Canon Production Printing shall not be liable for any direct, indirect or consequential damages of any nature,

or losses or expenses resulting from the use of the contents of this publication.

Backed liners: e.g. PE, PP, PVC, PET, paper (uncoated, coated)

Linerless / unsupported: e.g. Kraft, carton, BO-PET, BO-PP, metallised film

© 2020 Canon Production Printing

Loading...

Loading...