Feb 27 2007

Service Manual

i-SENSYS LBP5300 Series

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair

of products. This manual covers all localities where the products are sold. For this reason, there may be information in this

manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products. When

changes occur in applicable products or in the contents of this manual, Canon will release technical information as the need

arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition

of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or

translated into another language, in whole or in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Introduction

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Indicates an item requiring disconnection of the power plug from the electric outlet.

Indicates an item intended to provide notes assisting the understanding of the topic in question.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Memo

REF.

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol , the arrow indicates the

direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit door, which results in

supplying the machine with power.

2. In the digital circuits, '1'is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low".(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the operations of the microprocessors

used in the machines are not discussed: they are explained in terms of from sensors to the input of the DC controller PCB and from the output of the

DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service Information bulletins and be

able to identify and isolate faults in the machine."

Contents

Contents

Chapter 1 PRODUCT DESCRIPTION

1.1 Features .....................................................................................................................................................1- 1

1.1.1 Feature ....................................................................................................................................................................1- 1

1.2 System construction ................................................................................................................................... 1- 1

1.2.1 System Construction ...............................................................................................................................................1- 1

1.2.2 System Cnstruction .................................................................................................................................................1- 1

1.3 Product Specifications ................................................................................................................................1- 2

1.3.1 Product Specifications .............................................................................................................................................1- 2

1.3.2 Product Specifications .............................................................................................................................................1- 3

1.4 Name of Parts.............................................................................................................................................1- 4

1.4.1 External View...........................................................................................................................................................1- 4

1.4.2 External View...........................................................................................................................................................1- 4

1.4.3 Cross Section View .................................................................................................................................................1- 5

1.5 Using the Machine...................................................................................................................................... 1- 6

1.5.1 Control Panel...........................................................................................................................................................1- 6

1.5.2 Control Panel...........................................................................................................................................................1- 7

1.5.3 Job Menu.................................................................................................................................................................1- 8

1.5.4 Setup Menu (1)........................................................................................................................................................1- 8

1.5.5 Setup Menu (2)......................................................................................................................................................1- 10

1.5.6 Setup Menu (3)......................................................................................................................................................1- 11

1.5.7 Setup Menu (4)......................................................................................................................................................1- 13

1.5.8 Setup Menu (5)......................................................................................................................................................1- 14

1.5.9 Utility Menu............................................................................................................................................................1- 15

1.5.10 Reset Menu .........................................................................................................................................................1- 15

1.5.11 Pickup Selection Menu ........................................................................................................................................1- 15

1.6 Safety ....................................................................................................................................................... 1- 16

1.6.1 Safety of the Laser Light........................................................................................................................................ 1- 16

1.6.2 Regulations Under the Center for Devices and Radiological Health (CDRH) .......................................................1- 16

1.6.3 Safety of Toner......................................................................................................................................................1- 16

1.6.4 Handling the Laser Unit .........................................................................................................................................1- 16

Chapter 2 TECHNICAL REFERENCE

2.1 Functional Configuration............................................................................................................................. 2- 1

2.1.1 Outline .....................................................................................................................................................................2- 1

2.2 Basic Sequense..........................................................................................................................................2- 1

2.2.1 Basic Sequence of Operation..................................................................................................................................2- 1

2.2.2 Power-On Sequence ...............................................................................................................................................2- 1

2.3 LASER EXPOSURE SYSTEM ................................................................................................................... 2- 2

2.3.1 Overview/Configuration ...........................................................................................................................................2- 2

2.3.1.1 Outline...................................................................................................................................................................................... 2- 2

2.3.2 Laser Control ........................................................................................................................................................... 2- 3

2.3.2.1 Outline...................................................................................................................................................................................... 2- 3

2.3.2.2 Image masking control ............................................................................................................................................................. 2- 4

2.3.2.3 Failure detection ...................................................................................................................................................................... 2- 5

2.3.3 Laser Scanner Motor Control ..................................................................................................................................2- 5

2.3.3.1 Outline...................................................................................................................................................................................... 2- 5

2.3.3.2 Failure detection ...................................................................................................................................................................... 2- 6

2.4 IMAGE FORMATION SYSTEM.................................................................................................................. 2- 6

2.4.1 Overview/Configuration ...........................................................................................................................................2- 6

2.4.1.1 Outline...................................................................................................................................................................................... 2- 6

Contents

2.4.1.2 Print Process............................................................................................................................................................................ 2- 7

2.4.1.3 Electrostatic latent image formation block ............................................................................................................................... 2- 8

2.4.1.4 Development block .................................................................................................................................................................. 2- 9

2.4.1.5 Transfer block ........................................................................................................................................................................ 2- 10

2.4.1.6 Fixing block ............................................................................................................................................................................ 2- 11

2.4.1.7 Cleaning block ....................................................................................................................................................................... 2- 12

2.4.2 Image Stabilizaton Control.....................................................................................................................................2- 12

2.4.2.1 Image Stabilization Control .................................................................................................................................................... 2- 12

2.4.2.2 Environment related corrective control .................................................................................................................................. 2- 12

2.4.2.3 Color gradation corrective control .......................................................................................................................................... 2- 13

2.4.2.4 Color Misregistration Corrective Control ................................................................................................................................ 2- 14

2.4.3 Toner Cartridge......................................................................................................................................................2- 16

2.4.3.1 Outline.................................................................................................................................................................................... 2- 16

2.4.3.2 Memory tag ............................................................................................................................................................................ 2- 17

2.4.3.3 Cartridge presence detection ................................................................................................................................................. 2- 17

2.4.3.4 Developing roller engagement/disengagement control.......................................................................................................... 2- 17

2.4.4 Transfer Unit ..........................................................................................................................................................2- 18

2.4.4.1 ETB Unit................................................................................................................................................................................. 2- 18

2.4.4.2 Automatic bias control............................................................................................................................................................ 2- 19

2.4.4.3 ETB cleaning.......................................................................................................................................................................... 2- 20

2.4.4.4 Transfer roller engagement/disengagement control .............................................................................................................. 2- 21

2.5 Pickup/Feeding/Delivery System.............................................................................................................. 2- 24

2.5.1 Overview/Configuration..........................................................................................................................................2- 24

2.5.1.1 Outline.................................................................................................................................................................................... 2- 24

2.5.2 Other Control .........................................................................................................................................................2- 25

2.5.2.1 Cassette pick-up mechanism ................................................................................................................................................. 2- 25

2.5.2.2 Multi-purpose tray (MPT) pick-up........................................................................................................................................... 2- 26

2.5.2.3 Skew correction by the registration shutter ............................................................................................................................ 2- 27

2.5.2.4 Transport Speed Control........................................................................................................................................................ 2- 27

2.5.2.5 Warp control........................................................................................................................................................................... 2- 28

2.5.2.6 Fixing roller pressurizing/release control ............................................................................................................................... 2- 28

2.5.3 Detecting Jams ......................................................................................................................................................2- 29

2.5.3.1 Jam Detection Outline............................................................................................................................................................ 2- 29

2.5.3.2 Delay Jams ............................................................................................................................................................................ 2- 29

2.5.3.3 Stationary Jams ..................................................................................................................................................................... 2- 30

2.5.3.4 Other Jams ............................................................................................................................................................................ 2- 30

2.5.4 Duplex Feeding......................................................................................................................................................2- 30

2.5.4.1 Outline.................................................................................................................................................................................... 2- 30

2.5.4.2 Duplexing reverse/feed operation .......................................................................................................................................... 2- 31

2.5.4.3 Duplexing pick-up operation .................................................................................................................................................. 2- 33

2.6 FIXING UNIT SYSTEM ............................................................................................................................ 2- 34

2.6.1 Overview/Configuration..........................................................................................................................................2- 34

2.6.1.1 Outline.................................................................................................................................................................................... 2- 34

2.6.2 Various Control Mechanisms.................................................................................................................................2- 35

2.6.2.1 Fixing Temperature Control ................................................................................................................................................... 2- 35

2.6.3 Protective Functions ..............................................................................................................................................2- 36

2.6.3.1 outline .................................................................................................................................................................................... 2- 36

2.6.3.2 Failure detection .................................................................................................................................................................... 2- 36

2.7 EXTERNAL AND CONTROLS SYSTEM ................................................................................................. 2- 36

2.7.1 Power Supply.........................................................................................................................................................2- 36

2.7.1.1 Power Supply ......................................................................................................................................................................... 2- 36

2.7.1.2 Other Function ....................................................................................................................................................................... 2- 37

2.8 ENGINE CONTROL SYSTEM ................................................................................................................. 2- 38

2.8.1 Construction...........................................................................................................................................................2- 38

2.8.1.1 Outline.................................................................................................................................................................................... 2- 38

2.8.2 DC Controller .........................................................................................................................................................2- 38

2.8.2.1 Outline.................................................................................................................................................................................... 2- 38

2.8.2.2 Operation of each block ......................................................................................................................................................... 2- 39

2.8.2.3 Fan/Motor Control .................................................................................................................................................................. 2- 40

2.8.2.4 Drum motor failure detection.................................................................................................................................................. 2- 40

Contents

2.8.2.5 ETB motor failure detection ................................................................................................................................................... 2- 40

2.8.2.6 Fixing motor failure detection ................................................................................................................................................. 2- 40

2.8.2.7 Exhaust fan failure detection.................................................................................................................................................. 2- 40

2.8.2.8 Duplexing cooling fan failure detection .................................................................................................................................. 2- 41

2.8.3 Video Controller PCB ............................................................................................................................................2- 41

2.8.3.1 Outline.................................................................................................................................................................................... 2- 41

2.8.3.2 Overview ................................................................................................................................................................................ 2- 41

2.8.3.3 Outline of the Block ................................................................................................................................................................ 2- 42

2.8.3.4 Outline of the Block ................................................................................................................................................................ 2- 43

Chapter 3 DISASSEMBLY AND ASSEMBLY

3.1 EXTERNAL AND CONTROLS SYSTEM ...................................................................................................3- 1

3.1.1 Rear Cover ..............................................................................................................................................................3- 1

3.1.1.1 Removing the Rear Cover ....................................................................................................................................................... 3- 1

3.1.2 Right Cover..............................................................................................................................................................3- 1

3.1.2.1 Preparation for Removing the Right Cover .............................................................................................................................. 3- 1

3.1.2.2 Removing the Right Cover ....................................................................................................................................................... 3- 1

3.1.3 Left Cover ................................................................................................................................................................3- 1

3.1.3.1 Preparation for Removing the Left Cover ................................................................................................................................ 3- 1

3.1.3.2 Removing the Left Cover ......................................................................................................................................................... 3- 1

3.1.4 Upper Cover ............................................................................................................................................................3- 2

3.1.4.1 Preparation for Removing the Upper Cover............................................................................................................................. 3- 2

3.1.4.2 Removing the Upper Cover ..................................................................................................................................................... 3- 2

3.1.5 Front Cover..............................................................................................................................................................3- 2

3.1.5.1 Preparation for Removing the Front Cover .............................................................................................................................. 3- 2

3.1.5.2 Removing the Front Cover ....................................................................................................................................................... 3- 2

3.1.6 Main Drive Unit ........................................................................................................................................................3- 3

3.1.6.1 Preparation for Removing the Main Drive Unit ........................................................................................................................ 3- 3

3.1.6.2 Removing the Main Drive Unit ................................................................................................................................................. 3- 3

3.1.6.3 Points to Note When Mounting Main Drive Unit....................................................................................................................... 3- 5

3.1.7 Operation Panel Unit ...............................................................................................................................................3- 7

3.1.7.1 Preparation for Removing the Control Panel ........................................................................................................................... 3- 7

3.1.7.2 Removing the Control Panel .................................................................................................................................................... 3- 7

3.1.8 DC Controller PCB ..................................................................................................................................................3- 7

3.1.8.1 Before Removing the DC Controller PCB ................................................................................................................................ 3- 7

3.1.8.2 Preparation for Removing the DC Controller PCB ................................................................................................................... 3- 7

3.1.8.3 Removing the DC Controller PCB............................................................................................................................................ 3- 7

3.1.9 Video Controller PCB ..............................................................................................................................................3- 8

3.1.9.1 Preparation for Removing the Video Controller PCB ............................................................................................................... 3- 8

3.1.9.2 Preparation for Removing the Video Controller PCB ............................................................................................................... 3- 8

3.1.9.3 Removing the Video Controller PCB........................................................................................................................................ 3- 8

3.1.9.4 Removing the Video Controller PCB........................................................................................................................................ 3- 8

3.1.10 Memory Controller PCB.........................................................................................................................................3- 9

3.1.10.1 Before Removing the Memory Controller PCB ...................................................................................................................... 3- 9

3.1.10.2 Preparation for Removing the Memory Controller PCB ......................................................................................................... 3- 9

3.1.10.3 Removing the Memory Controller PCB .................................................................................................................................. 3- 9

3.1.11 Interface Controller PCB...................................................................................................................................... 3- 10

3.1.11.1 Removing the Network Interface Board ............................................................................................................................... 3- 10

3.1.12 Duplexing Driver PCB.......................................................................................................................................... 3- 10

3.1.12.1 Preparation for Removing the Duplexing Driver PCB .......................................................................................................... 3- 10

3.1.12.2 Removing the Duplexing Driver PCB ................................................................................................................................... 3- 10

3.1.13 Low-Voltage Power Supply Assembly .................................................................................................................3- 10

3.1.13.1 Preparation for Removing the Low-Voltage Power Supply PCB.......................................................................................... 3- 10

3.1.13.2 Removing the Low-Voltage Power Supply PCB .................................................................................................................. 3- 10

3.1.14 High-voltage PCB ................................................................................................................................................3- 11

3.1.14.1 Preparation for Removing the High-Voltage Power Supply PCB ......................................................................................... 3- 11

3.1.14.2 Removing the High-Voltage Power Supply PCB.................................................................................................................. 3- 11

3.1.15 Cooling Fan .........................................................................................................................................................3- 11

3.1.15.1 Preparation for Removing the Cooling Fan .......................................................................................................................... 3- 11

Contents

3.1.15.2 Removing the Cooling Fan................................................................................................................................................... 3- 12

3.1.16 Duplex Fan...........................................................................................................................................................3- 12

3.1.16.1 Preparation for Removing the Duplexing Fan ...................................................................................................................... 3- 12

3.1.16.2 Removing the Duplexing Fan............................................................................................................................................... 3- 12

3.2 LASER EXPOSURE SYSTEM ................................................................................................................. 3- 13

3.2.1 Laser Scanner Unit ................................................................................................................................................3- 13

3.2.1.1 Preparation for Removing the Laser / Scanner Unit .............................................................................................................. 3- 13

3.2.1.2 Preparation for Removing the Laser / Scanner Unit .............................................................................................................. 3- 13

3.2.1.3 Removing the Laser / Scanner Unit ....................................................................................................................................... 3- 13

3.3 IMAGE FORMATION SYSTEM................................................................................................................ 3- 14

3.3.1 Developing Estrangement Solenoid.......................................................................................................................3- 14

3.3.1.1 Preparation for Removing the Developing Estrangement Solenoid....................................................................................... 3- 14

3.3.1.2 Removing the Developing Estrangement Solenoid ............................................................................................................... 3- 14

3.3.1.3 Points to Note when Attaching the Developing Estrangement Solenoid ............................................................................... 3- 14

3.3.2 ETB Unit.................................................................................................................................................................3- 15

3.3.2.1 Removing the ETB Unit ......................................................................................................................................................... 3- 15

3.3.3 ETB Motor..............................................................................................................................................................3- 15

3.3.3.1 Preparation for Removing the ETB Motor .............................................................................................................................. 3- 15

3.3.3.2 Removing the ETB Motor....................................................................................................................................................... 3- 15

3.3.4 ETB Estrangement Solenoid..................................................................................................................................3- 16

3.3.4.1 Preparation for Removing the ETB Estrangement Solenoid.................................................................................................. 3- 16

3.3.4.2 Removing the ETB Estrangement Solenoid .......................................................................................................................... 3- 16

3.3.5 Toner Cartridge Motor............................................................................................................................................3- 17

3.3.5.1 Preparation for Removing the Toner Cartridge Motor............................................................................................................ 3- 17

3.3.5.2 Removing the Toner Cartridge Motor .................................................................................................................................... 3- 17

3.3.6 Color Misregistration/Image Density Sensor..........................................................................................................3- 17

3.3.6.1 Preparation for Removing the Color Displacement / Density Sensor .................................................................................... 3- 17

3.3.6.2 Removing the Color Displacement / Density Sensor ............................................................................................................. 3- 17

3.4 PICKUP/FEEDING/DELIVERY SYSTEM................................................................................................. 3- 17

3.4.1 Paper Pick-up Feeder Unit.....................................................................................................................................3- 17

3.4.1.1 Preparation for Removing the Pick-Up / Feed Assembly....................................................................................................... 3- 17

3.4.1.2 Removing the Pick-Up / Feed Assembly ............................................................................................................................... 3- 17

3.4.2 Pickup Motor..........................................................................................................................................................3- 18

3.4.2.1 Preparation for Removing the Pick-Up Motor ........................................................................................................................ 3- 18

3.4.2.2 Removing the Pick-Up Motor ................................................................................................................................................. 3- 18

3.4.3 Cassette Pickup Roller...........................................................................................................................................3- 19

3.4.3.1 Removing the Cassette Pick-Up Roller.................................................................................................................................. 3- 19

3.4.4 Cassette Pick-up Solenoid.....................................................................................................................................3- 19

3.4.4.1 Preparation for Removing the Cassette Pick-Up Solenoid .................................................................................................... 3- 19

3.4.4.2 Removing the Cassette Pick-Up Solenoid ............................................................................................................................. 3- 19

3.4.5 Cassette Separation Pad.......................................................................................................................................3- 21

3.4.5.1 Removing the Cassette Separation Pad ................................................................................................................................ 3- 21

3.4.6 Manual Pickup Roller.............................................................................................................................................3- 21

3.4.6.1 Removing the Manual Feed Pick-Up Roller ........................................................................................................................... 3- 21

3.4.7 Multi-purpose Pickup Solenoid ..............................................................................................................................3- 21

3.4.7.1 Preparation for Removing the Manual Feed Pick-Up Solenoid ............................................................................................. 3- 21

3.4.7.2 Removing the Manual Feed Pick-Up Solenoid ...................................................................................................................... 3- 21

3.4.8 Manual Separation Pad .........................................................................................................................................3- 23

3.4.8.1 Preparation for Removing the Manual Feed Separation Pad ................................................................................................ 3- 23

3.4.8.2 Removing the Manual Feed Separation Pad ......................................................................................................................... 3- 23

3.4.9 Duplexing Reverse Motor ......................................................................................................................................3- 23

3.4.9.1 Preparation for Removing the Duplexing Reversing Motor.................................................................................................... 3- 23

3.4.9.2 Removing the Duplexing Reversing Motor ............................................................................................................................ 3- 23

3.4.10 Duplexing Feed Motor..........................................................................................................................................3- 24

3.4.10.1 Preparation for Removing the Duplexing Feed Motor.......................................................................................................... 3- 24

3.4.10.2 Removing the Duplexing Feed Motor................................................................................................................................... 3- 24

3.4.11 Duplexing Flapper Solenoid .................................................................................................................................3- 25

3.4.11.1 Preparation for Removing the Duplexing Flapper Solenoid ................................................................................................. 3- 25

3.4.11.2 Removing the Duplexing Flapper Solenoid.......................................................................................................................... 3- 25

Contents

3.5 FIXING SYSTEM ...................................................................................................................................... 3- 25

3.5.1 Fixing Assembly ....................................................................................................................................................3- 25

3.5.1.1 Removing the Fixing Assembly.............................................................................................................................................. 3- 25

3.5.2 Fixing Sleeve Unit.................................................................................................................................................. 3- 26

3.5.2.1 Preparation for Removing the Fixing Sleeve Unit .................................................................................................................. 3- 26

3.5.2.2 Removing the Fixing Sleeve Unit ........................................................................................................................................... 3- 26

3.5.3 Fixing Motor...........................................................................................................................................................3- 28

3.5.3.1 Preparation for Removing the Fixing Motor ........................................................................................................................... 3- 28

3.5.3.2 Removing the Fixing Motor .................................................................................................................................................... 3- 28

Chapter 4 MAINTENANCE AND INSPECTION

4.1 Periodically Replaced Parts........................................................................................................................ 4- 1

4.1.1 Periodically Replaced Parts.....................................................................................................................................4- 1

4.2 Consumables..............................................................................................................................................4- 1

4.2.1 Durables Replaced by the User...............................................................................................................................4- 1

4.2.2 Durables Replaced by the Service Person..............................................................................................................4- 1

4.3 Periodical Service ....................................................................................................................................... 4- 1

4.3.1 Periodic Service.......................................................................................................................................................4- 1

4.4 Cleaning ..................................................................................................................................................... 4- 1

4.4.1 Pick-up roller............................................................................................................................................................4- 1

4.4.2 Separation pad ........................................................................................................................................................4- 1

4.4.3 Registration roller ....................................................................................................................................................4- 1

4.4.4 Registration shutter .................................................................................................................................................4- 1

4.4.5 Feed guide...............................................................................................................................................................4- 1

4.4.6 Delivery roller...........................................................................................................................................................4- 1

4.4.7 Fixing inlet guide......................................................................................................................................................4- 1

4.4.8 Color misregistration/Density sensor.......................................................................................................................4- 1

Chapter 5 TROUBLESHOOTING

5.1 MEASUREMENT AND ADJUSTMENT ......................................................................................................5- 1

5.1.1 Adjustment of Electrical Components.....................................................................................................................5- 1

5.1.1.1 After Replacing the DC controller PCB .................................................................................................................................... 5- 1

5.1.1.2 After Replacing the DC controller PCB .................................................................................................................................... 5- 1

5.1.1.3 After Replacing the Video Controller PCB ............................................................................................................................... 5- 1

5.1.1.4 After Replacing the Video Controller PCB ............................................................................................................................... 5- 1

5.1.1.5 Replacing EEPROM (When E747-000 occurs) ....................................................................................................................... 5- 1

5.1.2 Adjustment of Fixing System ..................................................................................................................................5- 1

5.1.2.1 Checking the Nip Width (fixing pressure roller)........................................................................................................................ 5- 1

5.2 SERVICE TOOLS.......................................................................................................................................5- 3

5.2.1 Standard Tools ........................................................................................................................................................5- 3

5.2.2 Solvent/Oil List.........................................................................................................................................................5- 3

5.3 ERROR CODE ........................................................................................................................................... 5- 3

5.3.1 Error Code ...............................................................................................................................................................5- 3

5.3.2 Error Code ...............................................................................................................................................................5- 5

5.3.3 A4-XX_ERROR .......................................................................................................................................................5- 9

5.3.4 A5-XX_ERROR .......................................................................................................................................................5- 9

5.3.5 A7-XX_ERROR .......................................................................................................................................................5- 9

5.3.6 D7-XX_ERROR .....................................................................................................................................................5- 10

5.3.7 D8-XX_ERROR .....................................................................................................................................................5- 10

5.4 Version Up................................................................................................................................................ 5- 10

5.4.1 Outline ................................................................................................................................................................... 5- 10

5.4.1.1 Overview of Upgrading Work ................................................................................................................................................. 5- 10

5.4.1.2 Construction of Firmware ....................................................................................................................................................... 5- 10

5.4.1.3 Outline of the Service Support Tool ....................................................................................................................................... 5- 11

5.4.2 Making Preparations..............................................................................................................................................5- 13

Contents

5.4.2.1 Registering the Firmware ....................................................................................................................................................... 5- 13

5.4.2.2 Making Connections .............................................................................................................................................................. 5- 15

5.4.3 Downloading the System Software........................................................................................................................5- 16

5.4.3.1 Downloading Procedure......................................................................................................................................................... 5- 16

5.5 Service Mode ........................................................................................................................................... 5- 19

5.5.1 Outline....................................................................................................................................................................5- 19

5.5.1.1 Outline.................................................................................................................................................................................... 5- 19

5.5.1.2 Outline.................................................................................................................................................................................... 5- 20

5.5.2 Service Mode Table...............................................................................................................................................5- 20

5.5.2.1 Service Mode Items ............................................................................................................................................................... 5- 20

5.5.2.2 Service Mode ......................................................................................................................................................................... 5- 20

Chapter 1 PRODUCT DESCRIPTION

Contents

Contents

1.1 Features ..........................................................................................................................................................................1-1

1.1.1 Feature.......................................................................................................................................................................................... 1-1

1.2 System construction .......................................................................................................................................................1-1

1.2.1 System Construction .................................................................................................................................................................... 1-1

1.2.2 System Cnstruction ...................................................................................................................................................................... 1-1

1.3 Product Specifications....................................................................................................................................................1-2

1.3.1 Product Specifications ................................................................................................................................................................. 1-2

1.3.2 Product Specifications ................................................................................................................................................................. 1-3

1.4 Name of Parts.................................................................................................................................................................1-4

1.4.1 External View .............................................................................................................................................................................. 1-4

1.4.2 External View .............................................................................................................................................................................. 1-4

1.4.3 Cross Section View...................................................................................................................................................................... 1-5

1.5 Using the Machine .........................................................................................................................................................1-6

1.5.1 Control Panel ............................................................................................................................................................................... 1-6

1.5.2 Control Panel ............................................................................................................................................................................... 1-7

1.5.3 Job Menu...................................................................................................................................................................................... 1-8

1.5.4 Setup Menu (1) ............................................................................................................................................................................ 1-8

1.5.5 Setup Menu (2) .......................................................................................................................................................................... 1-10

1.5.6 Setup Menu (3) .......................................................................................................................................................................... 1-11

1.5.7 Setup Menu (4) .......................................................................................................................................................................... 1-13

1.5.8 Setup Menu (5) .......................................................................................................................................................................... 1-14

1.5.9 Utility Menu............................................................................................................................................................................... 1-15

1.5.10 Reset Menu .............................................................................................................................................................................. 1-15

1.5.11 Pickup Selection Menu ............................................................................................................................................................ 1-15

1.6 Safety ...........................................................................................................................................................................1-16

1.6.1 Safety of the Laser Light............................................................................................................................................................ 1-16

1.6.2 Regulations Under the Center for Devices and Radiological Health (CDRH).......................................................................... 1-16

1.6.3 Safety of Toner .......................................................................................................................................................................... 1-16

1.6.4 Handling the Laser Unit............................................................................................................................................................. 1-16

Chapter 1

1-1

1.1 Features

1.1.1 Feature

0013-7282

/ i-SENSYS LBP5360 / i-SENSYS LBP5300

1. High-speed printing and high image quality

This printer realizes high-speed printing for both full-color and monochrome print. Regardless of this high-speed, the toner with fine particle enables to produce

vivid image with the resolution of 600 dpi.

Full color/Monochrome: 22 pages/min.

2. Electrostatic Transportation Belt (ETB)

This printer adopts the "Electrostatic Transportation Belt" (hereafter ETB) method for image transfer and paper feed process. In order to realize the high-speed

color printing, toner images of all four colors on the photosensitive drum are transferred onto paper directly.

3. Four consecutive drum method (Inline method)

This printer adopts the four consecutive drum method. The toner cartridges are aligned vertically and all four colors are transferred on paper in one sequential

operation. This realizes highspeed color printing, as this method needs less time to transfer compared to the rotary method where each color is transferred

separately.

4. Color on-demand fixing method

The machine uses an on-demand fixing method combined with a ceramic heater so far mostly used in a mono-color printer. The fact has led to a shorter warmup period and lower energy consumption.

5. 500-sheet paper feeder

This printer can be installed optional 500-sheet paper feeder in addition to the standard MPT (100 sheets available) and cassette (250 sheets available). This

enables high-volume printing of maximum 850 sheets.

6. Automatic duplex printing

There are simplex and duplex models for this printer. Automatic duplex printing is available with the duplex model.

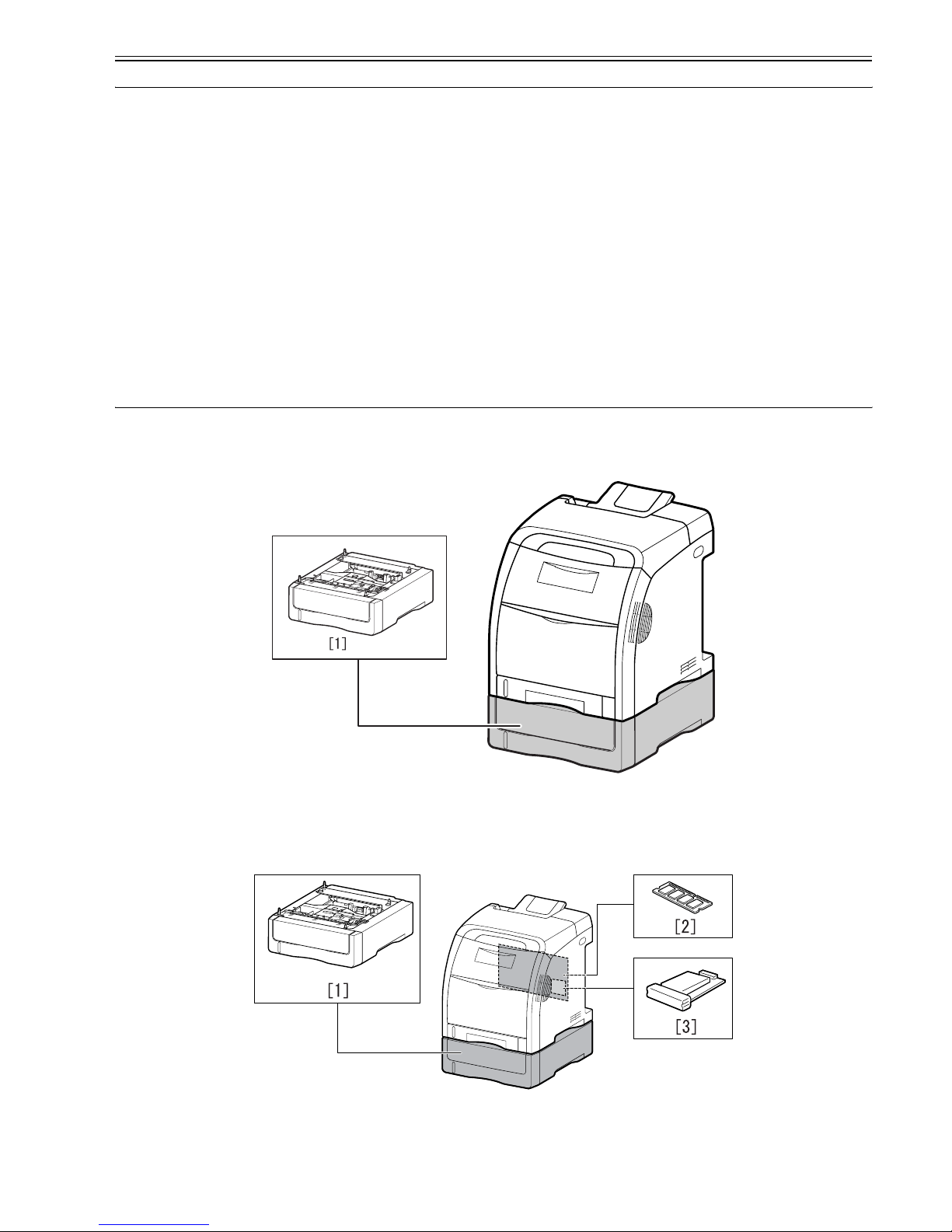

1.2 System construction

1.2.1 System Construction

0014-2771

i-SENSYS LBP5300

F-1-1

[1] Paper Feeder PF-93

1.2.2 System Cnstruction

0014-7502

i-SENSYS LBP5360

F-1-2

[1] Paper Feeder PF-93

[2] RAM

[3] Hard Disc HD-93

Chapter 1

1-2

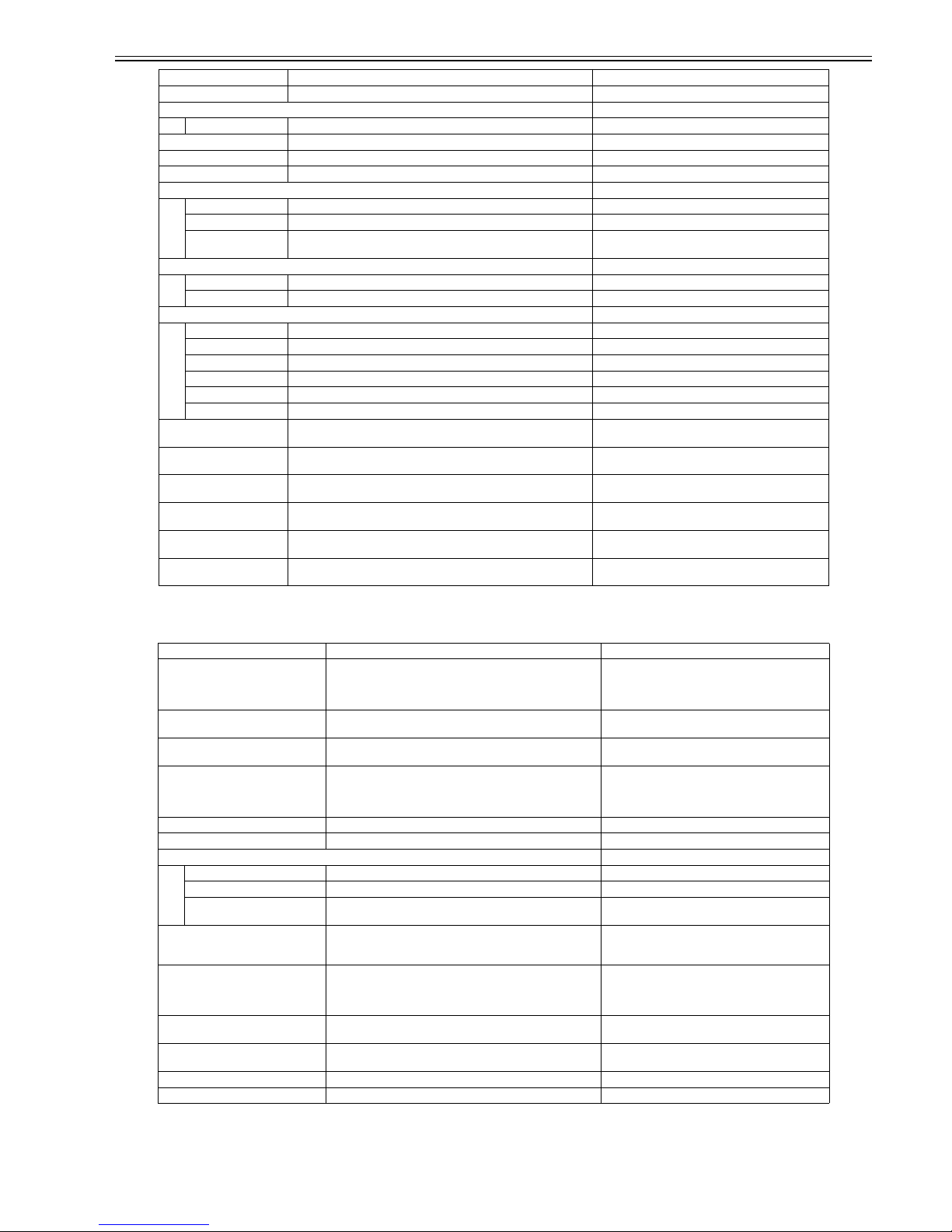

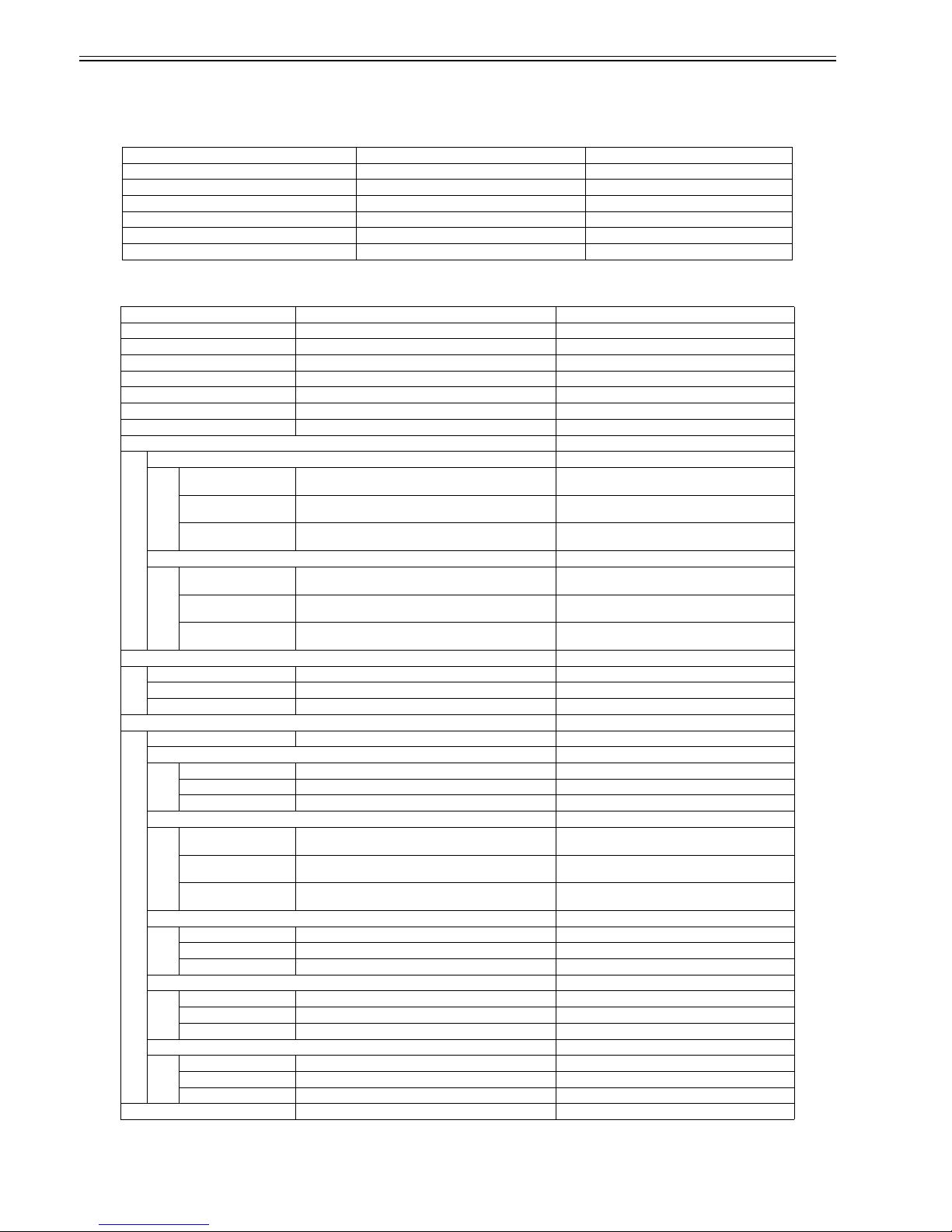

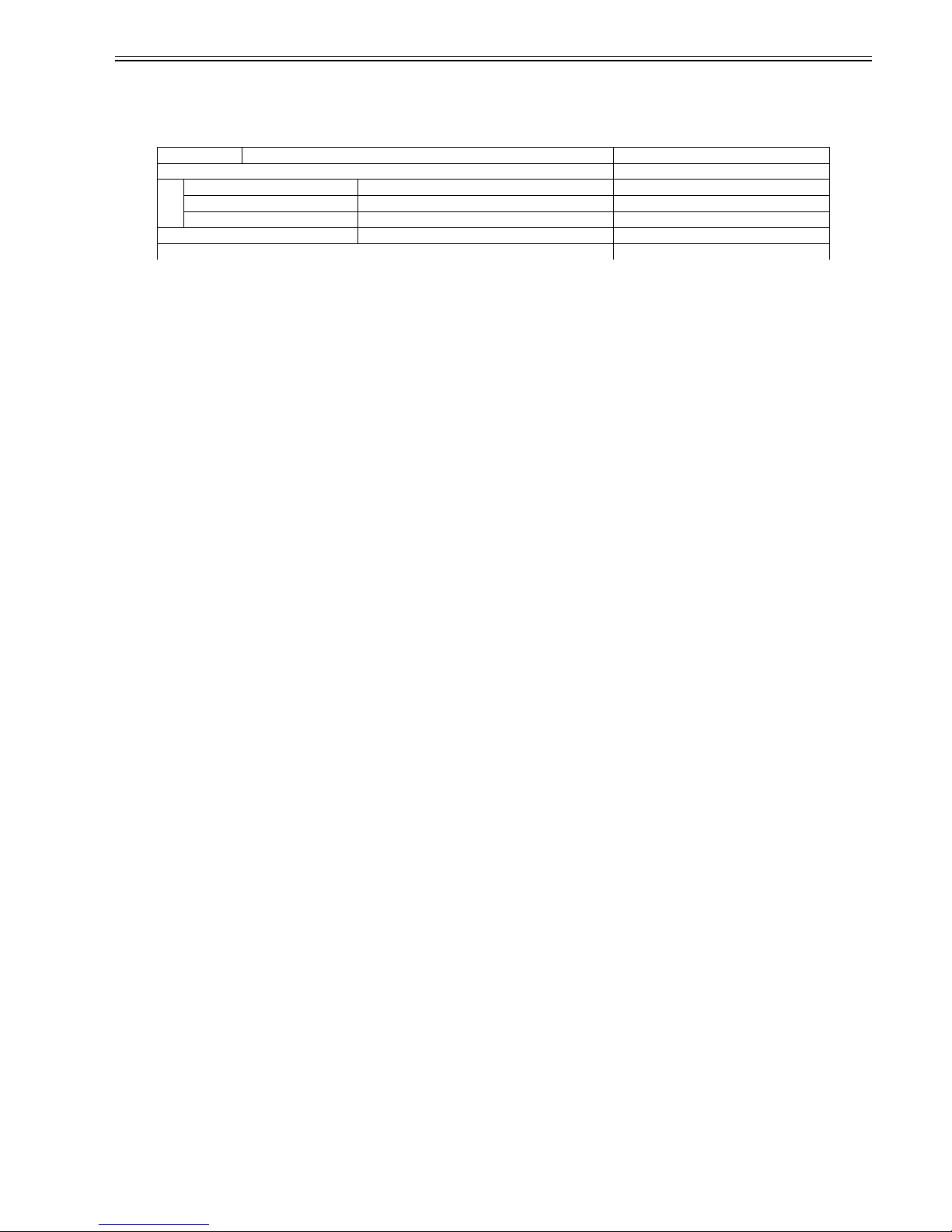

1.3 Product Specifications

1.3.1 Product Specifications

0015-7509

i-SENSYS LBP5300

Body installation method Desktop page printer

Photosensitive medium OPC drum

Charging method Roller charging

Exposure method Laser scanning

Development method Contact development

Transfer method By Electrostatic Transportation Belt

Separation method Curvature

Pickup method By cassette/manual feeder

Cassette pickup method By separation pad

Drum cleaning method By blade

Trasnsfer cleaning method Drum static collection

Fixing method On-demand

Delivery method Face-down

Contrast adjustment function Auto

Toner level detection function Available

Toner type non-magnetic, 1-component dry toner

Toner supply type By EP cartridge (Printable pages: approx. 6,000 pages (Canon Genuine

Cartridge, and for A4 or Letter size paper at 5 % page coverage with the

default print density setting))

Warm-up time 0 second from standby mode (20°C (68°F)

(40 seconds or less from power ON

Image margin (Leading edge) 5.0+1.5/-1.5mm

Image margin (Trailing edge) 5.0+1.5/-1.5mm

Image margin (Left/right) 5.0+1.0/-1.0mm

Number of gradations 16 gradations

Printing resolution 600dpi x 600dpi

First print time 10.1 sec or less (approx.; both mono- and full-color)

Print speed (A4) 21 impressions/min (approx.; both mono- and full color)

Cassette paper size A4, B5, A5, LGL, LTR, Exective, Foolscap, 16K

Custom sizes

When loading paper in portrait orientation:

Width 148.0 to 215.9 mm; Length 210.0 to 355.6 mm

When loading paper in landscape orientation (Only when UFR II Printer

Driver is used):

Width 210.0 to 215.9 mm; Length 210.0 to 215.9 mm

Multifeeder paper size A4, B5, A5, LGL, LTR, Exective, Stantmrnt, Foolscap, 16K, Envelope

DL, Envelope COM10, Envelope C5, Envelope Monarch, Envelope B5,

Index Card

Custom sizes

When loading paper in portrait orientation:

Width 76.2 to 215.9 mm; Length 127.0 to 355.6 mm

When loading paper in landscape orientation (Only when UFR II Printer

Driver is used):

Width 127.0 to 215.9 mm; Length 127.0 to 215.9 mm

Cassette paper type Plain paper (60 to 105 g/m2)

Multifeeder tray paper type Plain paper (60 to 105 g/m2), heavy paper (106 to 216 g/m2), Coated

paper, Envelope, Label, Transparency

Cassette capacity 250 sheets (64 g/m2)

Multifeeder tray capacity approx. 100 sheets (64 g/m2)

Delivery tray stack 200 sheets (64 g/m2)

Memory 8 MB (addition not possible)

Auto gradation correction Available

Operating environment

(Temperature range)

10 to 30 deg C

Operating environment

(Humidity range)

10 to 80%RH

Operating environment

(Atmospheric pressure)

810.6 to 1013.3 hpa (0.8 to 1.0 atm)

Noise 35 dB or less (standby); 53 dB or less (print)

Power supply rating AC220V - 240V 50/60 Hz

Power consumption (Maximum) 1213W or less

Power consumption Average during standby: approx. 45 W

Average during operation: approx. 415 W

Dimensions 412mm(W) x 453mm(D) x 437.7mm(H)

Chapter 1

1-3

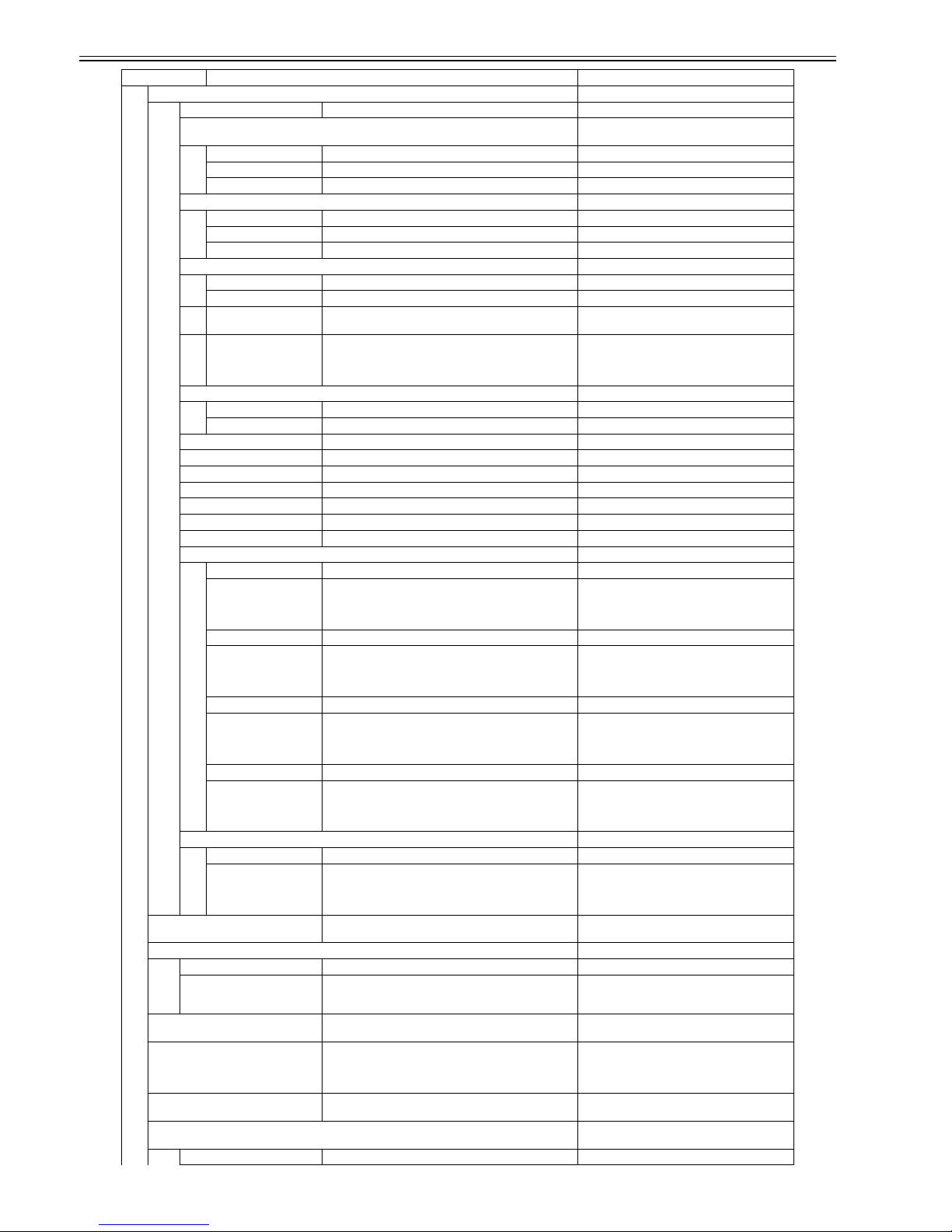

1.3.2 Product Specifications

0015-7508

i-SENSYS LBP5360

Weight 22.0 kg (approx.; excluding cartridges)

Body installation method Desktop page printer

Photosensitive medium OPC drum

Charging method Roller charging

Exposure method Laser scanning

Development method Contact development

Transfer method By Electrostatic Transportation Belt

Separation method Curvature

Pickup method By cassette/manual feeder

Cassette pickup method By separation pad

Drum cleaning method By blade

Trasnsfer cleaning method Drum static collection

Fixing method On-demand

Delivery method Face-down

Contrast adjustment function Auto

Toner level detection function Available

Toner type non-magnetic, 1-component dry toner

Toner supply type By EP cartridge (Printable pages: approx. 6,000 pages (Canon Genuine

Cartridge, and for A4 or Letter size paper at 5 % page coverage with the

default print density setting))

Warm-up time 0 second from standby mode (20°C (68°F)

(40 seconds or less from power ON

Image margin (Leading edge) 5.0+1.5/-1.5mm

Image margin (Trailing edge) 5.0+1.5/-1.5mm

Image margin (Left/right) 5.0+1.0/-1.0mm

Number of gradations 16 gradations

Printing resolution 600dpi x 600dpi

First print time 10.1 sec or less (approx.; both mono- and full-color)

Print speed (A4) 21 impressions/min (approx.; both mono- and full color)

Cassette paper size A4, B5, A5, LGL, LTR, Exective, Foolscap, 16K

Custom sizes

When loading paper in portrait orientation:

Width 148.0 to 215.9 mm; Length 210.0 to 355.6 mm

When loading paper in landscape orientation (Only when UFR II Printer

Driver is used):

Width 210.0 to 215.9 mm; Length 210.0 to 215.9 mm

Multifeeder paper size A4, B5, A5, LGL, LTR, Exective, Stantmrnt, Foolscap, 16K, Envelope

DL, Envelope COM10, Envelope C5, Envelope Monarch, Envelope B5,

Index Card

Custom sizes

When loading paper in portrait orientation:

Width 76.2 to 215.9 mm; Length 127.0 to 355.6 mm

When loading paper in landscape orientation (Only when UFR II Printer

Driver is used):

Width 127.0 to 215.9 mm; Length 127.0 to 215.9 mm

Cassette paper type Plain paper (60 to 105 g/m2)

Multifeeder tray paper type Plain paper (60 to 105 g/m2), heavy paper (106 to 216 g/m2), Coated

paper, Envelope, Label, Transparency

Cassette capacity 250 sheets (64 g/m2)

Multifeeder tray capacity approx. 100 sheets (64 g/m2)

Delivery tray stack 200 sheets (64 g/m2)

Memory 128 MB (384 MB max.)

Auto gradation correction Available

Operating environment

(Temperature range)

10 to 30 deg C

Operating environment

(Humidity range)

10 to 80%RH

Operating environment

(Atmospheric pressure)

810.6 to 1013.3 hpa (0.8 to 1.0 atm)

Noise 35 dB or less (standby); 53 dB or less (print)

Power supply rating AC220V - 240V 50/60 Hz

Power consumption (Maximum) 1257W or less

Power consumption Average during standby: approx. 45W

Average during operation: approx. 416W

Dimensions 412mm(W) x 453mm(D) x 437.7mm(H)

Weight 22.0 kg (approx.; excluding cartridges)

Chapter 1

1-4

1.4 Name of Parts

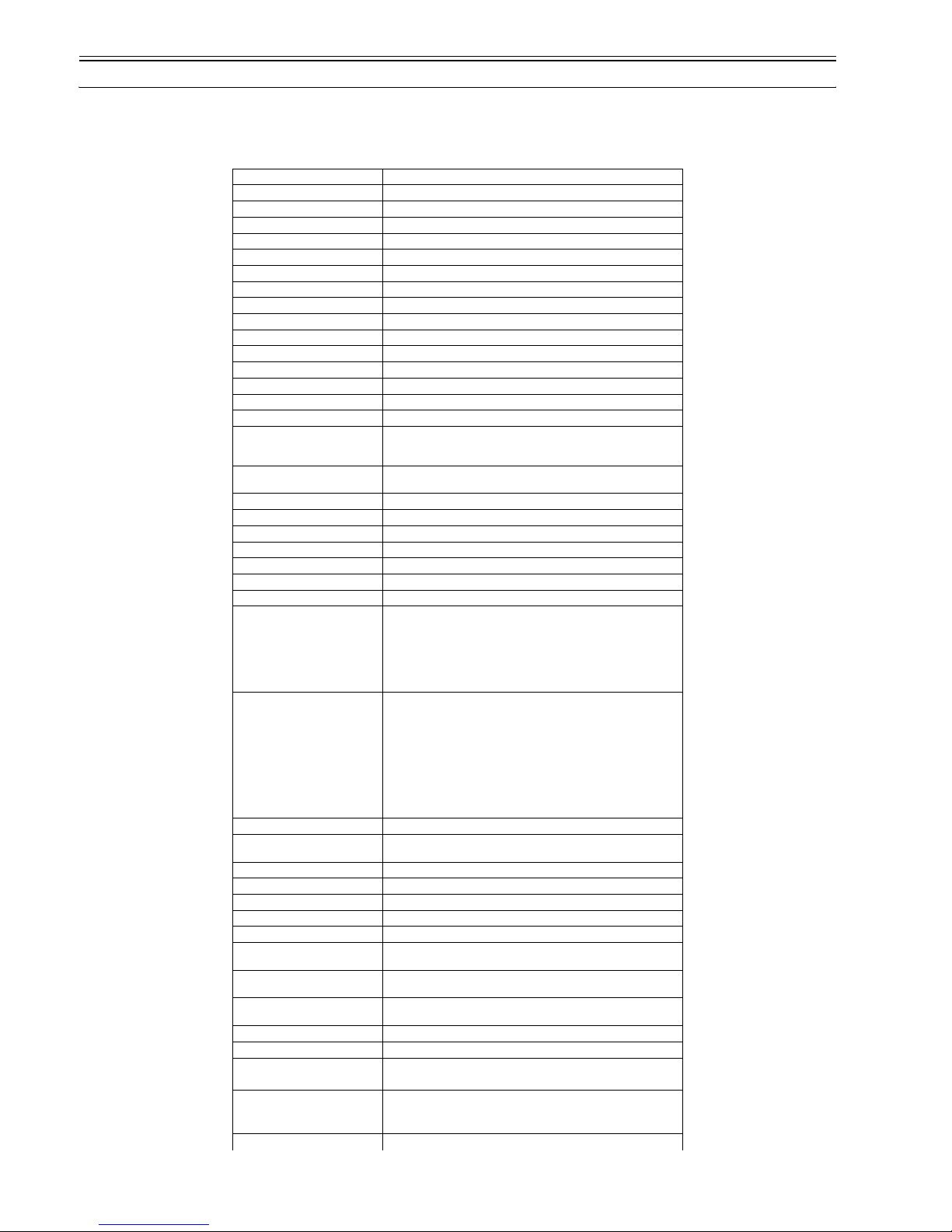

1.4.1 External View

0014-2125

i-SENSYS LBP5300

F-1-3

F-1-4

1.4.2 External View

0014-9930

/ i-SENSYS LBP5360

[1] Auxiliary Tray [2] Output Tray

[3] Top Cover [4] Power Switch

[5] Control Panel [6] Front Cover

[7] Paper Cassette [8] Tray Extension

[9] Auxiliary Tray [10] Multi-purpose Tray

[11] Paper Guides

[1] Cassette Protective Cover [2] Rear Cover

[3] LAN Connector [4] 100 Indicator (Green)

[5] LNK Indicator (Green) [6] ERR Indicator (Orange)

[7] USB Connector [8] Power Socket

[11]

[10]

[9]

[8]

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[7]

[8]

[6]

[5]

[4]

[3]

[9]

[1][2]

Chapter 1

1-5

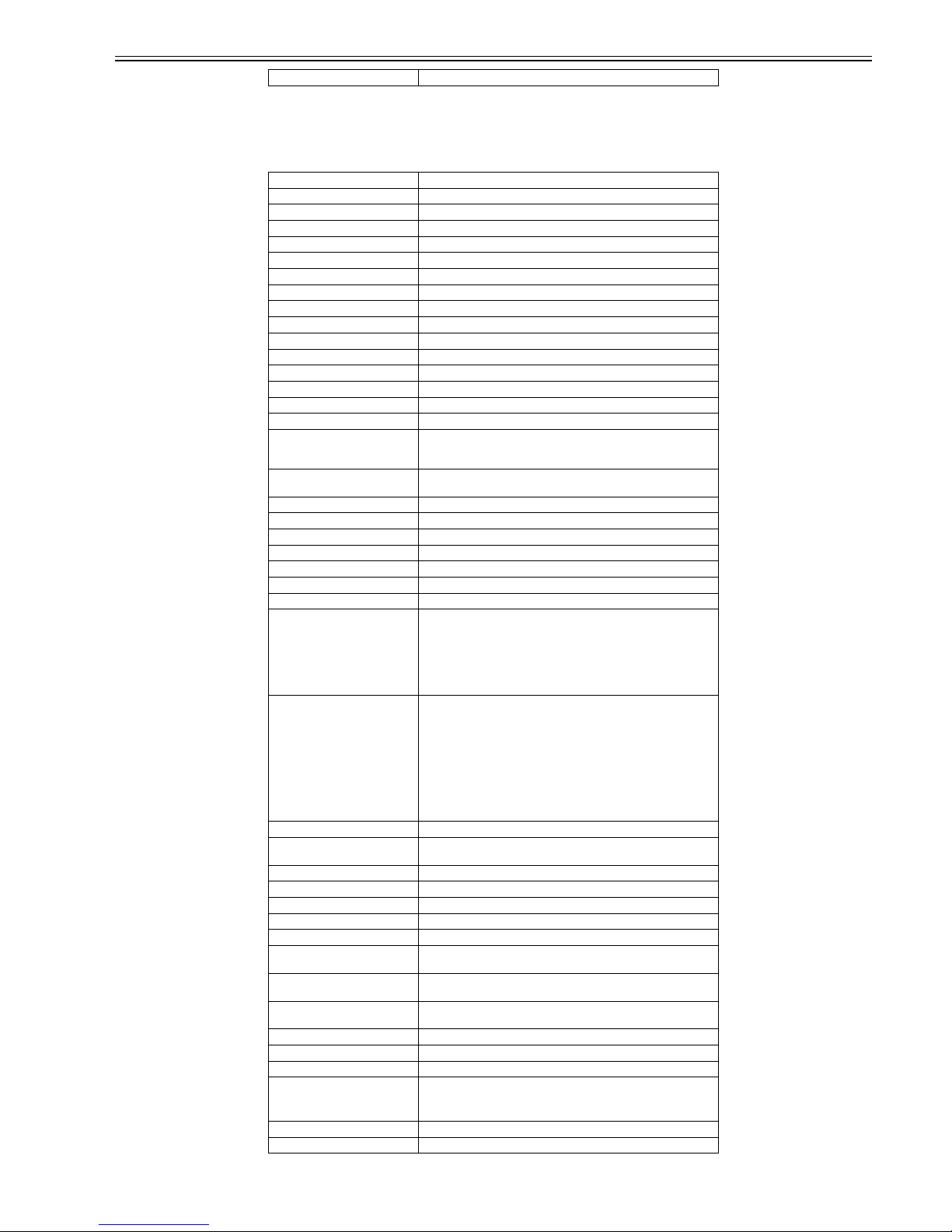

F-1-5

F-1-6

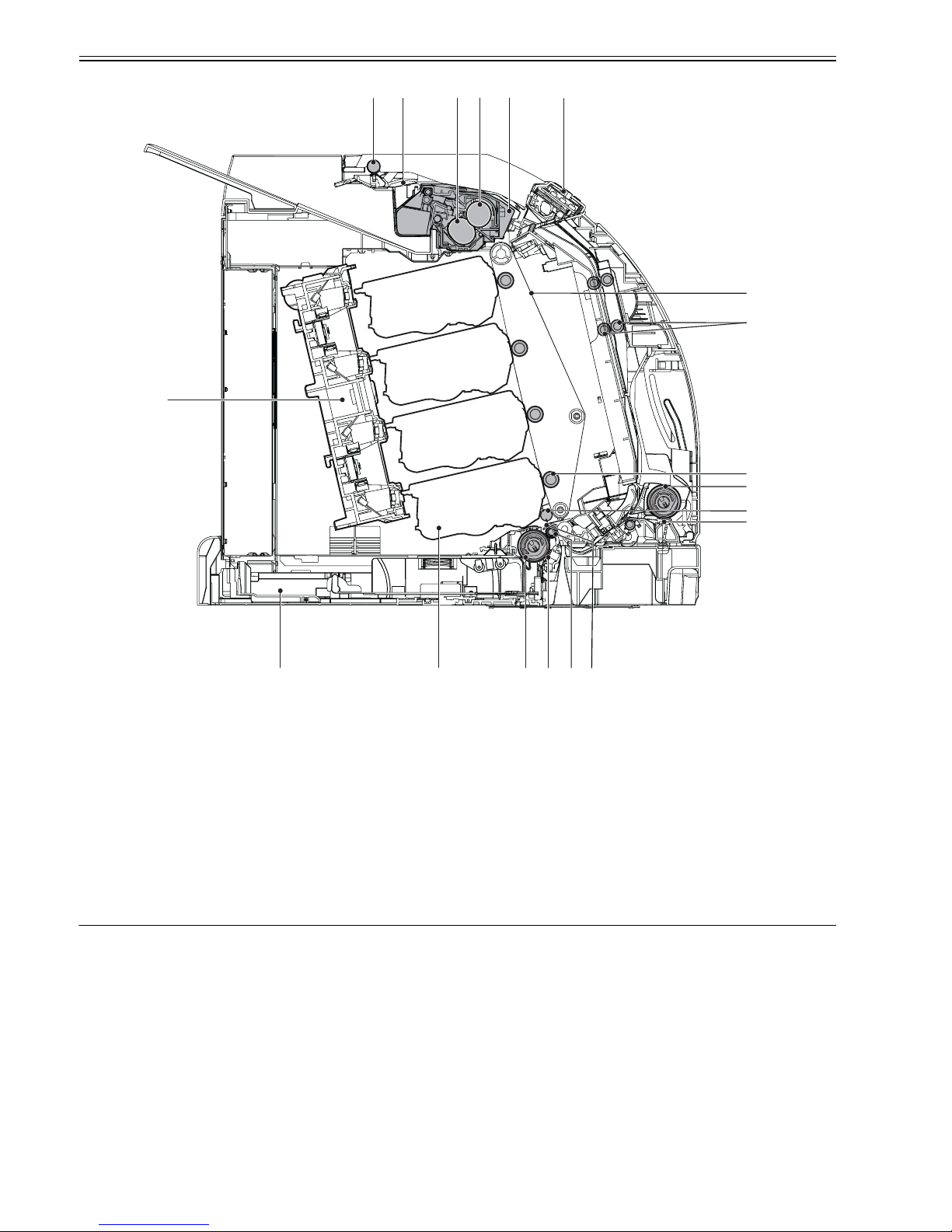

1.4.3 Cross Section View

0014-2126

/ i-SENSYS LBP5360 / i-SENSYS LBP5300

[1] Auxiliary Tray [2] Output Tray

[3] Top Cover [4] Power Switch

[5] Control Panel [6] Front Cover

[7] Paper Cassette [8] Tray Extension

[9] Auxiliary Tray [10] Multi-purpose Tray

[11] Paper Guides

[1] Cassette Protective Cover [2] Rear Cover

[3] Expansion Slot [4] USB Connector

[5] 100 Indicator (Green) [6] LNK Indicator (Green)

[7] LAN Connector [8] Parallel Connector

[9] Power Socket

[11]

[10]

[9]

[8]

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[9]

[7]

[8]

[6]

[5]

[4]

[3]

[1][2]

Chapter 1

1-6

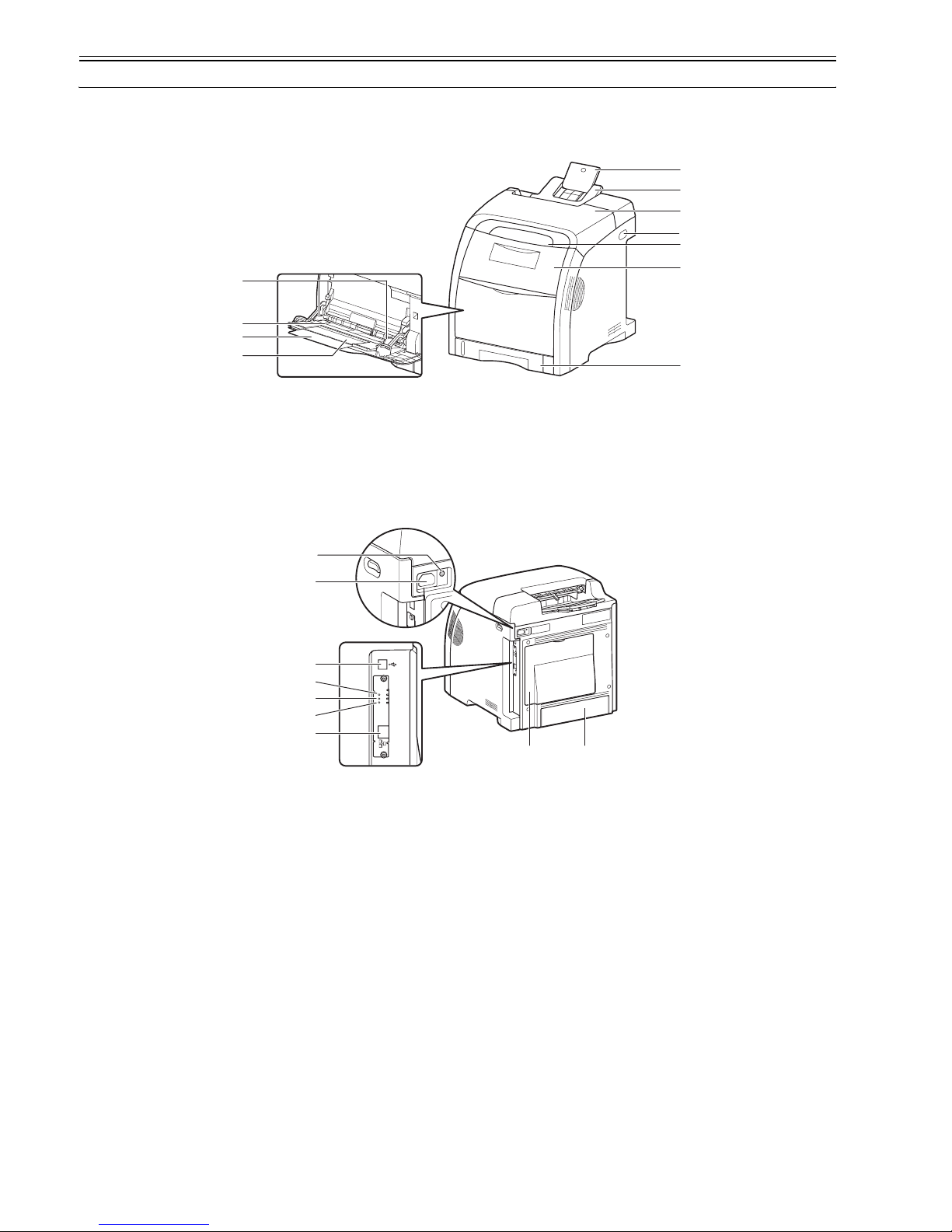

F-1-7

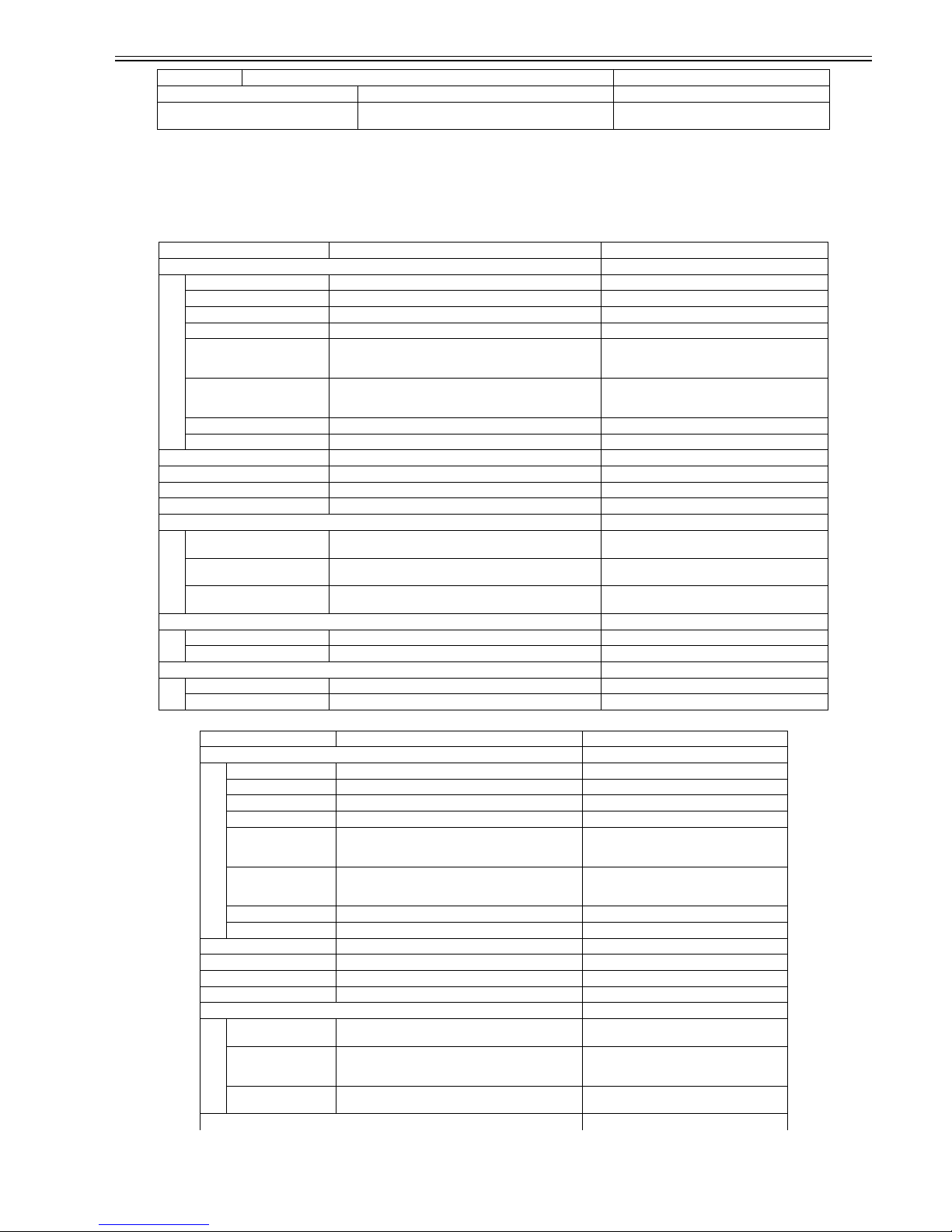

1.5 Using the Machine

1.5.1 Control Panel

0014-2127

i-SENSYS LBP5300

[1] Duplexing reverse roller [2] Duplexing flapper

[3] Fixing sleeve [4] Fixing pressure roller

[5] Fixing unit [6] Control panel

[7] ETB [8] Duplexing feed roller

[9] Transfer roller [10] Multi-purpose tray pick-up roller

[11] Attraction roller [12] Multi-purpose tray paper separation pad

[13] Registration shutter [14] Registration roller

[15] Cassette paper separation pad [16] Cassette pick-up roller

[17] EP cartridge [18] Cassette

[19] Laser/Scanner unit

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[16] [14][13][15]

[17]

[18]

[19]

Chapter 1

1-7

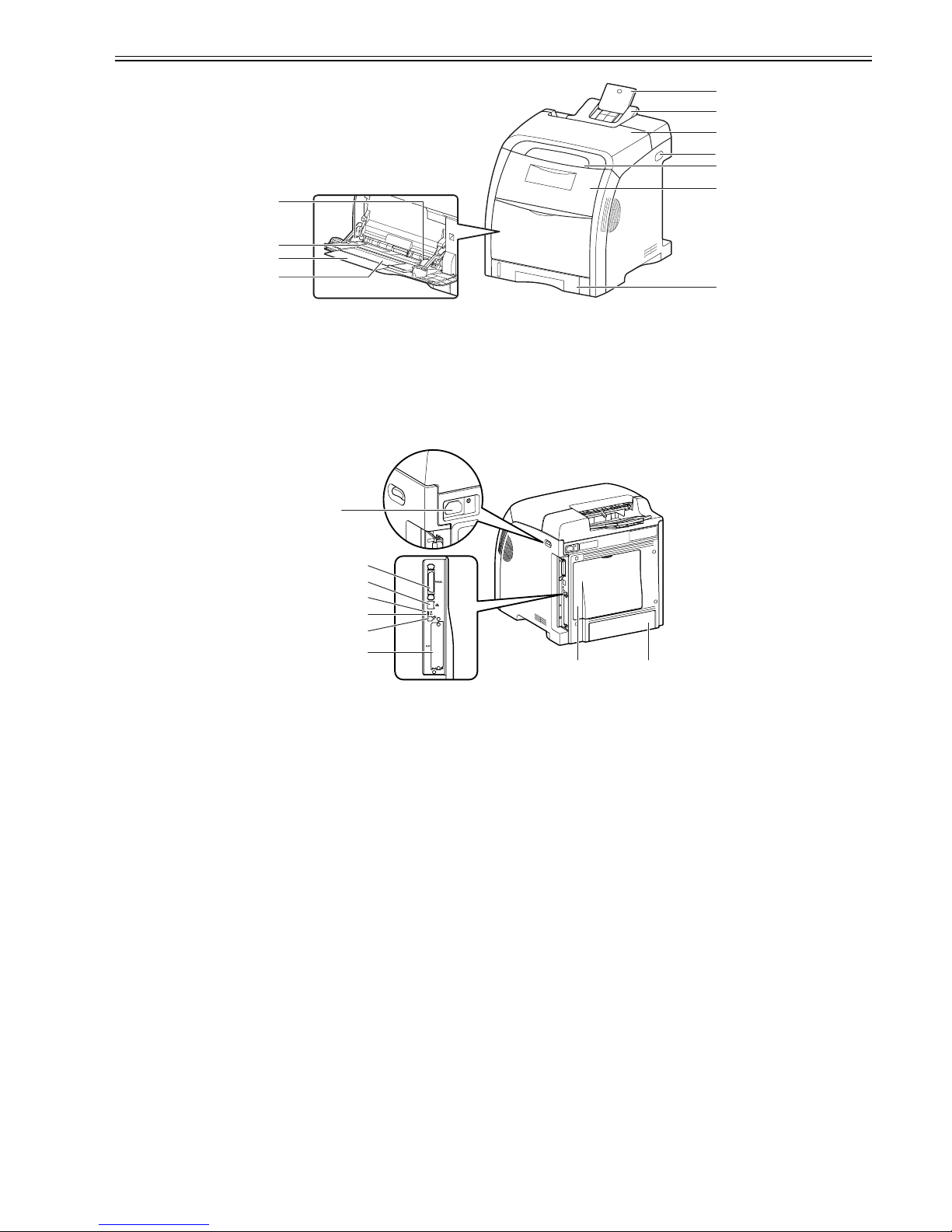

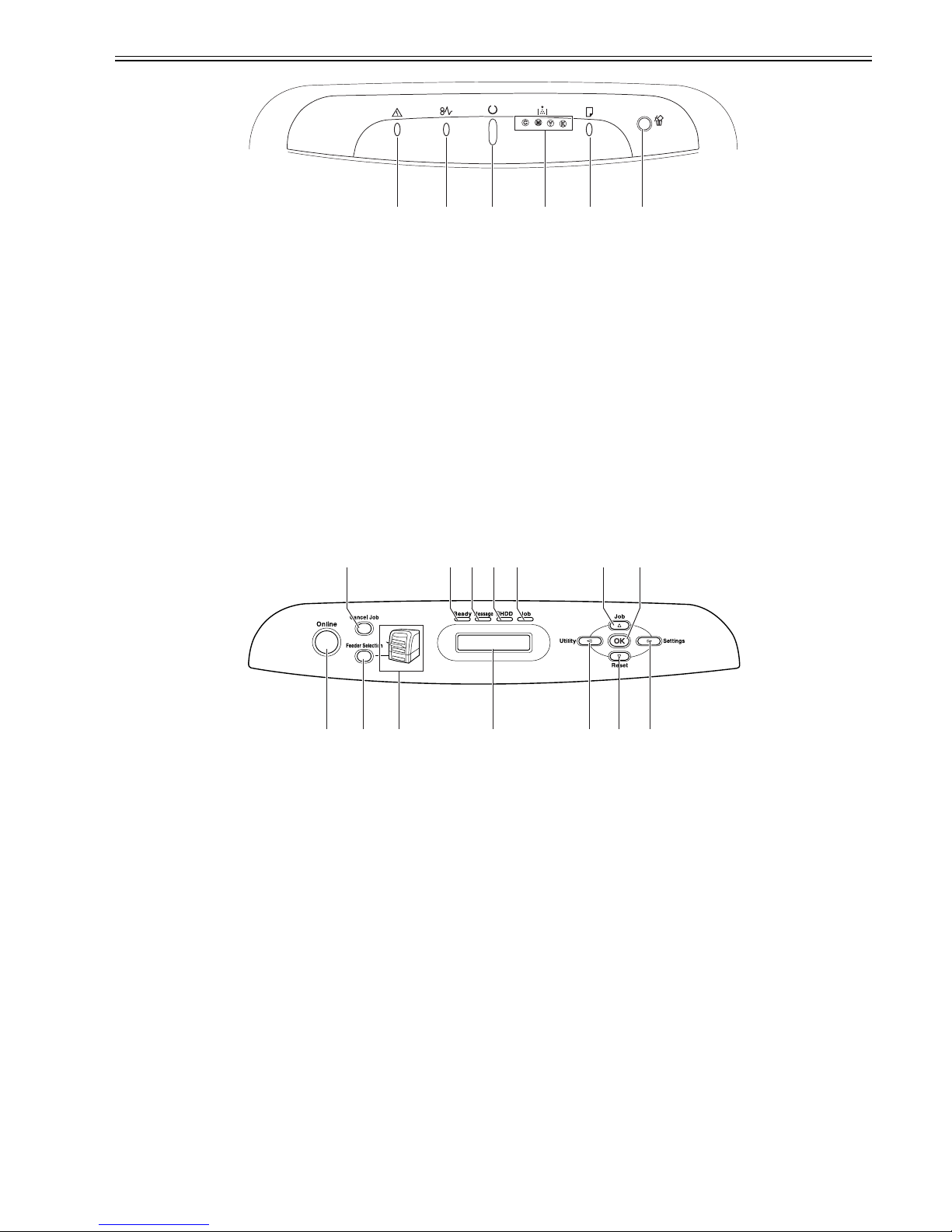

F-1-8

[1] Alarm Indicator (Orange)

On: Service call is occurring.

Blinking: An error is occurring, disabling printing.

[2] Paper Jam Indicator (Orange)

Blinking: A paper jam is occurring, disabling printing.

[3] Ready Indicator (Green)

On: The printer is in the sleep mode and ready to print.

Blinking: The printer is busy performing some kind of processing or operation, such as printing, warming up, calibrating, or pausing a job.

[4] Toner Indicator (Orange)

On: Toner cartridge replacement is required.

Blinking: Cannot print because toner cartridge replacement is required or any toner cartridge is not installed properly.

Indicator of the color that requires toner cartridge replacement comes on or blinks. "K", "Y", "C", and "M" indicate black, yellow, cyan, and magenta

respectively.

[5] Load Paper Indicator (Orange)

On: There is no paper in any paper source.

Blinking: No paper or paper of an inappropriate size is loaded.

[6] Cancel Job Key/ Cancel Job Indicator (Orange)

Pressing this key cancels the job in which an error is occurring and that in a printing process. The indicator comes on while pressing the key. The indicator blinks

while a job is in the cancellation process.

1.5.2 Control Panel

0015-1827

i-SENSYS LBP5360

The control panel consists of a status indication segment, control keys, and LEDs. The following shows the individual LEDs and the functions of the keys:

F-1-9

[1] [Cancel Job] Key

On offline:

Cancels the job when the Job indicator is on or blinking. Does not function when the Job indicator is off.

On online:

Cancels the job when the Job indicator is on or blinking. Does not function when the Job indicator is off.

[2] Ready Indicator (Green)

On:

The printer is ready to print. (If the printer has entered Power Save Mode when it is online, only the Ready indicator (green) is on, and all the other indicators

are off.)

Blinking:

The printer is performing a self-diagnostic test. The printer is in a warm-up state.

Off:

The printer cannot print.

[3] Message Indicator (Orange)

On:

The printer cannot print because a problem has occurred in the printer. (If the printer has entered Power Save Mode when it is offline, only the Message indicator

(orange) is on, and all the other indicators are off.)

Off:

The printer is in a normal state.

[4] HDD Indicator (Green)

On:

Data is being read from the hard disk or being written to the hard disk.

Off:

Data is not being read from the hard disk or being written to the hard disk.

[5] Job Indicator (Green)

On:

The printer is receiving print data, or any print data remains in the printer memory.

Blinking:

The printer is processing print data.

Off:

There is no print data in the printer memory.

[6] [Job] Key

[1] [2] [3] [4] [5] [6]

[14] [11] [8][9][10][13] [12]

[1] [7][2] [3] [4] [5] [6]

Chapter 1

1-8

On offline:

Does not function when the printer is offline.

On online:

Displays the JOB menu.

On menu operation:

Goes back to the previous menu (Goes back up the hierarchy).

[7] [OK] Key

On offline:

Does not function when the printer is offline.

On online:

Does not function when the printer is online.

On menu operation:

Goes to the next menu (Goes down the hierarchy). In a lowest menu level (When a setting value is displayed), determines the setting.

[8] [Settings] Key

On offline:

Displays the SETUP menu.

On online:

Displays the SETUP menu. However, the [User Maintenance Menu] options cannot be specified when the printer is online.

On menu operation:

Displays the next right item in the menu. Increases the setting value.

[9] [Reset] Key

On offline:

Displays the RESET menu.

On online:

Displays the RESET menu.

On menu operation:

Goes to the next menu (Goes down the hierarchy). In a lowest menu level (When a setting value is displayed), determines the setting.

[10] [Utility] Key

On offline:

Does not function when the printer is offline.

On online:

Displays the UTILITY menu.

On menu operation:

Displays the next left item in the menu. Decreases the setting value.

[11] Display

Displays the printer status, messages, the settings and setting values of the menu functions.

[12] Paper Source Indicators (Green)

On:

The indicator for the currently selected paper source comes on.

Blinking:

There is no paper in the currently selected paper source, or the paper cassette is not set. For the multi-purpose tray, the indicator comes on even when no paper

is loaded.

Off:

No paper source is selected. No paper cassette including the optional one or paper feeder is set.

13] [Feeder Selection] Key

On offline:

Displays the SELECT FEEDER menu.

On online:

Displays the SELECT FEEDER menu.

On menu operation:

Does not function.

[14] [Online] Key/Online Indicator (Green)

Turns on (online)/off (offline) the connection to the computer. This key also has the function that, when an error has occurred, releases the printer from the error

temporarily and continues the paused job. However, depending on the error, you may not be able to cancel it out.

The Online indicator under the Online key indicates the following printer status with its status.

On:

Online (The printer can receive print data from the computer.)

Off:

Offline (The printer cannot receive print data from the computer.)

However, if the printer has entered Power Save Mode, the Online indicator is off even when the printer is online.

1.5.3 Job Menu