Page 1

Service Manual

Paper Deck

Side Paper DeckU1

Mar 22 2004

Page 2

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and

repair of products. This manual covers all localities where the products are sold. For this reason, there may be

information in this manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products.

When changes occur in applicable products or in the contents of this manual, Canon will release technical information

as the need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will

issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied,

reproduced or translated into another language, in whole or in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Page 3

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a nonspecific nature, possibly classified as Note, Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Introduction

Memo

REF.

Indicates an item requiring disconnection of the power plug from the electric outlet.

Indicates an item intended to provide notes assisting the understanding of the topic in question.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Page 4

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical

and mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol ,

the arrow indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the

delivery unit door, which results in supplying the machine with power.

2. In the digital circuits, '1'is used to indicate that the voltage level of a given signal is "High", while '0' is used to

indicate "Low".(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in

"DRMD*" indicates that the DRMD signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the

operations of the microprocessors used in the machines are not discussed: they are explained in terms of from

sensors to the input of the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other

purposes, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant

Service Information bulletins and be able to identify and isolate faults in the machine."

Page 5

Contents

Contents

Chapter 1 Specifications

1.1 Product Specifications....................................................................................................................................... 1 1

1.1.1Specifications .............................................................................................................................................. 1 1

1.2 Names of Parts................................................................................................................................................... 1 2

1.2.1Names of Parts............................................................................................................................................. 1 2

Chapter 2 Functions

2.1 Basic Construction ............................................................................................................................................2 1

2.1.1Inputs to the Side Paper Deck (1/2)............................................................................................................. 2 1

2.1.2Inputs to the Side Paper Deck (2/2)............................................................................................................. 2 2

2.1.3Outputs from the Side Paper Deck (1/1) ..................................................................................................... 2 3

2.2 Basic Operation................................................................................................................................................. 2 4

2.2.1Overview .....................................................................................................................................................2 4

2.2.2Pickup Operation......................................................................................................................................... 2 4

2.2.3Controlling the Deck Main Motor (M1D)...................................................................................................2 6

2.2.4Controlling the Deck Lifter Motor (M2D)..................................................................................................2 7

2.3 Paper Detection ................................................................................................................................................. 2 9

2.3.1Detecting the Presence/Absence of Paper...................................................................................................2 9

2.3.2Changing the Deck Paper Size..................................................................................................................2 10

2.3.3Detecting the Level of Paper..................................................................................................................... 2 10

2.4 Deck Lifter ......................................................................................................................................................2 11

2.4.1Detecting the Presence/Absence of Paper.................................................................................................2 11

2.5 Opening /Closing the Compartment................................................................................................................2 13

2.5.1Opening/Closing the Compartment...........................................................................................................2 13

2.6 Detecting Jams ................................................................................................................................................2 15

2.6.1Overview ...................................................................................................................................................2 15

2.7 Power Supply ..................................................................................................................................................2 16

2.7.1Route of power supply .............................................................................................................................. 2 16

Chapter 3 Parts Replacement Procedure

3.1 Removing from the Host Machine.................................................................................................................... 3 1

3.1.1 Compartment............................................................................................................................................... 3 1

3.1.2 Paper Deck .................................................................................................................................................. 3 2

3.2 External Covers................................................................................................................................................. 3 3

3.2.1 Front Cover ................................................................................................................................................. 3 3

3.2.2 Rear Cover .................................................................................................................................................. 3 4

3.2.3 Right Cover................................................................................................................................................. 3 4

3.2.4 Upper Cover................................................................................................................................................ 3 5

3.3 Drive System ..................................................................................................................................................... 3 6

3.3.1 Deck Pickup Clutch ....................................................................................................................................3 6

3.3.2 Deck Feed Clutch........................................................................................................................................3 7

3.3.3 Deck Main Motor........................................................................................................................................ 3 9

3.3.4 Deck Lifter Motor ..................................................................................................................................... 3 10

3.3.5 Lifter Cable (Front)................................................................................................................................... 3 13

3.3.6 Lifter Cable ...............................................................................................................................................3 15

Page 6

Contents

3.4 Document Feeding System..............................................................................................................................3 18

3.4.1 Deck Pickup Unit ......................................................................................................................................3 18

3.4.2 Deck Pickup Roller ...................................................................................................................................3 19

3.4.3 Deck Pickup/Feed Roller ..........................................................................................................................3 22

3.4.4 Deck Separation Roller .............................................................................................................................3 24

3.4.4.1 Removing the Deck Separation Roller ..............................................................................................3 24

3.5 Electrical System .............................................................................................................................................3 25

3.5.1 Deck Driver PCB ......................................................................................................................................3 25

3.5.2 Open Switch PCB......................................................................................................................................3 25

Chapter 4 Maintenance

4.1 Maintenance and Inspection ..............................................................................................................................4 1

4.1.1 Periodically Replaced Parts.........................................................................................................................4 1

4.1.2 Durables ......................................................................................................................................................4 1

4.2 Adjustment.........................................................................................................................................................4 2

4.2.1 Basic Adjustment ........................................................................................................................................4 2

4.2.2 Adjustment at Time of Parts Replacement..................................................................................................4 4

Chapter 5 Service Mode

5.1 Outline ...............................................................................................................................................................5 1

5.1.1Alarm Code..................................................................................................................................................5 1

Chapter 6 Error Code

6.1 Overview............................................................................................................................................................6 1

6.1.1Error Code ...................................................................................................................................................6 1

Page 7

Chapter 1 Specifications

Page 8

Contents

Contents

1.1 Product Specifications....................................................................................................................................... 1 1

1.1.1 Specifications ............................................................................................................................................. 1 1

1.2 Names of Parts................................................................................................................................................... 1 2

1.2.1 Names of Parts............................................................................................................................................ 1 2

Page 9

1.1 Product Specifications

Chapter 1

1.1.1 Specifications

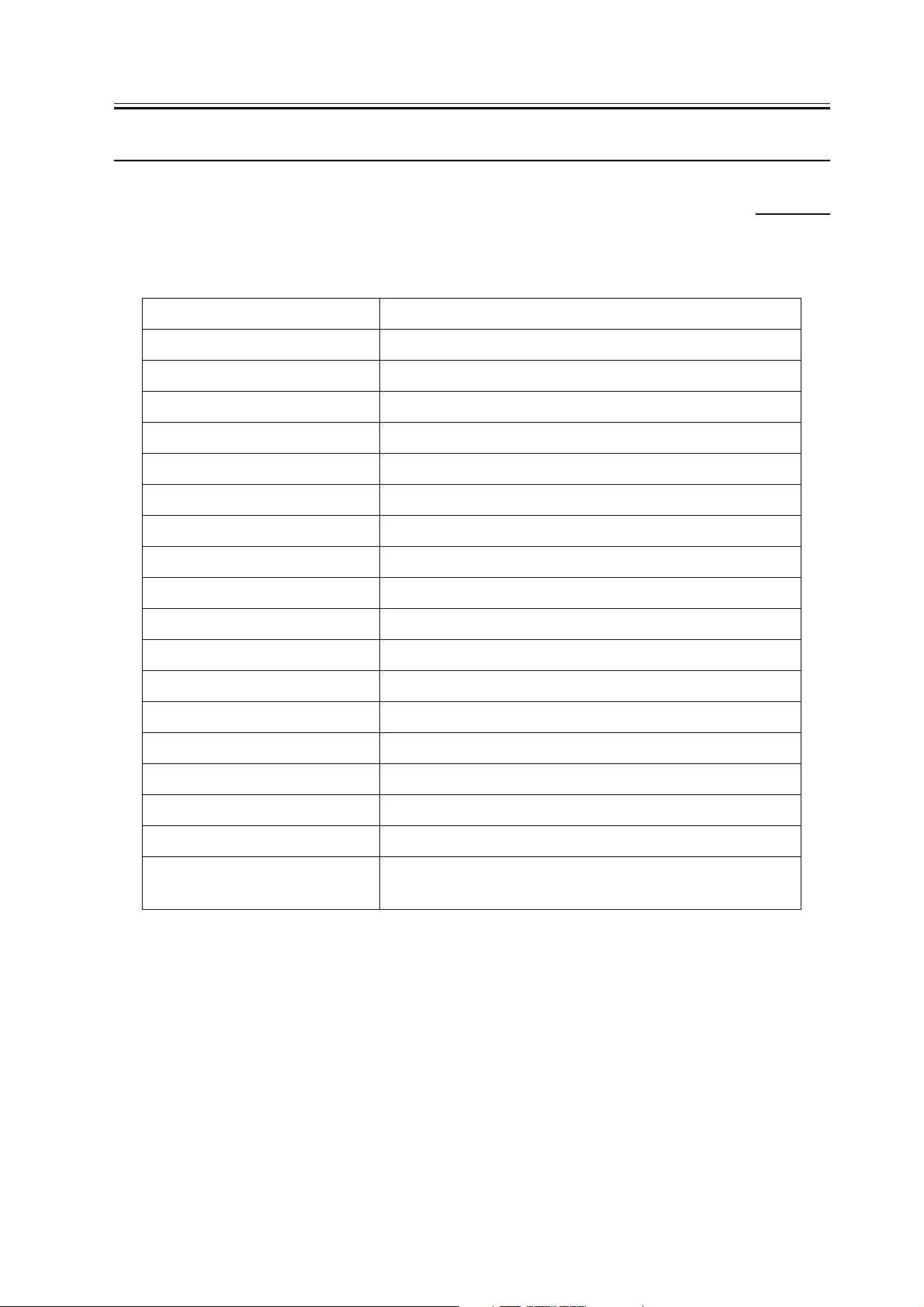

T-1-1

Item Description

Method of pickup by separation roller

Method of paper accommodation by side tray

Type of copy paper plain power (64 to 105 g/m2)

A4, B5, LTR

recycled paper (64 to 80 g/m2)

A4, B5, LTR

eco paper (80 g/m2)

A4

heavy paper (106 to 209 g/m2)

A4,B5,LTR

0003-2538

Capacity 385 mm (approximate height of stack)

(about 3,500 sheets of 80 g/m2 or about 4,000 sheets of 64 g/m2)

Switchover of paper size by size guide plate in steps and in service mode (OPTION)

Dimensions (approx.) 326.2 (W) x 583 (D) x 574.5 (H) mm

Weight 46 kg (approx.)

Source of power DC from host machine

Operating environment same as host machine

Specifications are subject to change

for product improvement.

1-1

Page 10

Chapter 1

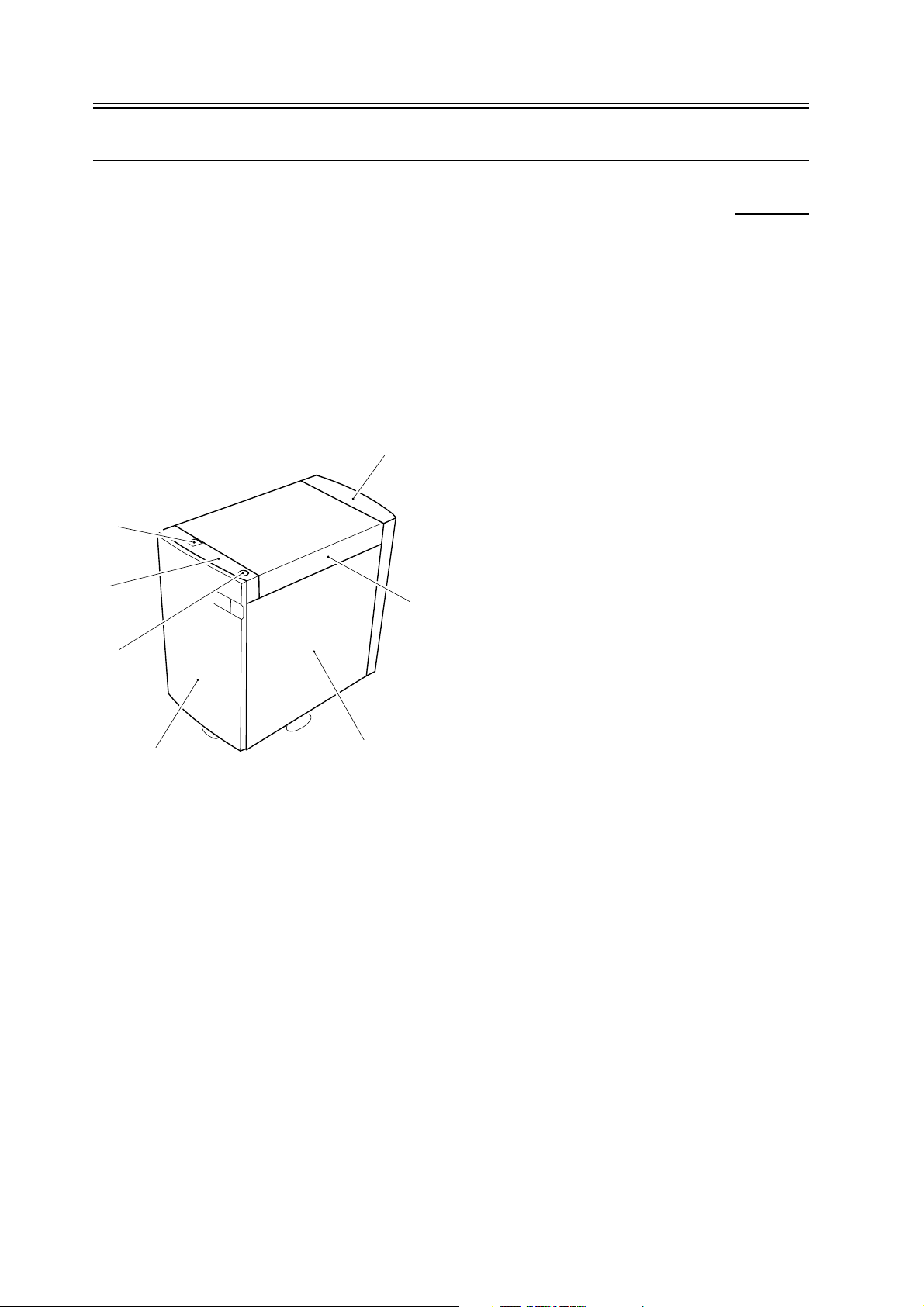

1.2 Names of Parts

1.2.1 Names of Parts

External Covers

1 Deck release grip

2 Upper front cover

3 Compartment open/close switch

4 Front cover

5 Right cover

6 Upper cover

7 Rear cover

[1]

[2]

0003-2542

[7]

[6]

[3]

F-1-1

[4]

[5]

1-2

Page 11

Chapter 2 Functions

Page 12

Contents

Contents

2.1 Basic Construction ............................................................................................................................................2 1

2.1.1 Inputs to the Side Paper Deck (1/2)............................................................................................................ 2 1

2.1.2 Inputs to the Side Paper Deck (2/2)............................................................................................................ 2 2

2.1.3 Outputs from the Side Paper Deck (1/1) ....................................................................................................2 3

2.2 Basic Operation................................................................................................................................................. 2 4

2.2.1 Overview ....................................................................................................................................................2 4

2.2.2 Pickup Operation........................................................................................................................................ 2 4

2.2.3 Controlling the Deck Main Motor (M1D)..................................................................................................2 6

2.2.4 Controlling the Deck Lifter Motor (M2D)................................................................................................. 2 7

2.3 Paper Detection ................................................................................................................................................. 2 9

2.3.1 Detecting the Presence/Absence of Paper..................................................................................................2 9

2.3.2 Changing the Deck Paper Size................................................................................................................. 2 10

2.3.3 Detecting the Level of Paper.................................................................................................................... 2 10

2.4 Deck Lifter ......................................................................................................................................................2 11

2.4.1 Detecting the Presence/Absence of Paper................................................................................................2 11

2.5 Opening /Closing the Compartment................................................................................................................2 13

2.5.1 Opening/Closing the Compartment.......................................................................................................... 2 13

2.6 Detecting Jams ................................................................................................................................................2 15

2.6.1 Overview ..................................................................................................................................................2 15

2.7 Power Supply ..................................................................................................................................................2 16

2.7.1 Route of power supply ............................................................................................................................. 2 16

Page 13

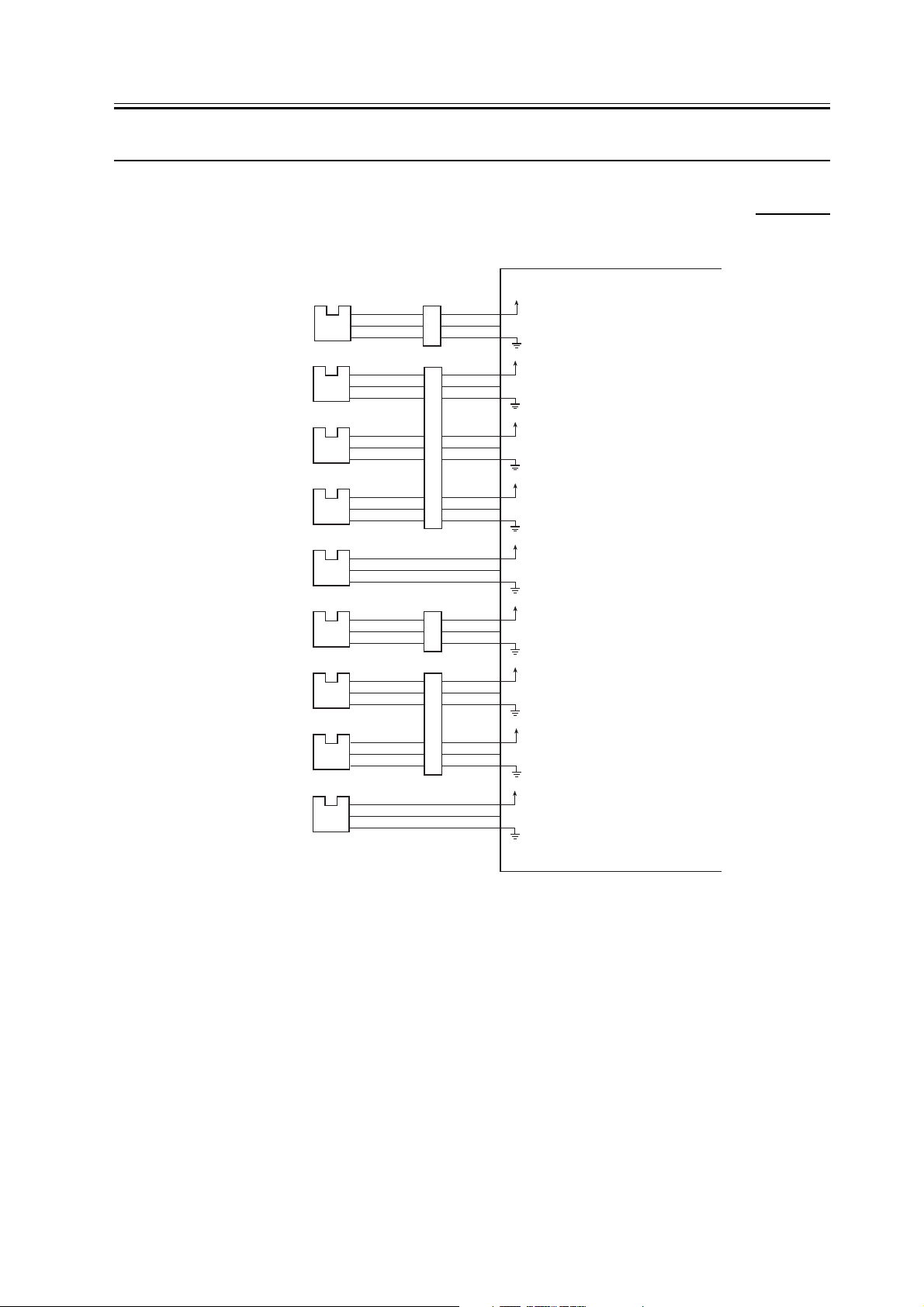

2.1 Basic Construction

Chapter 2

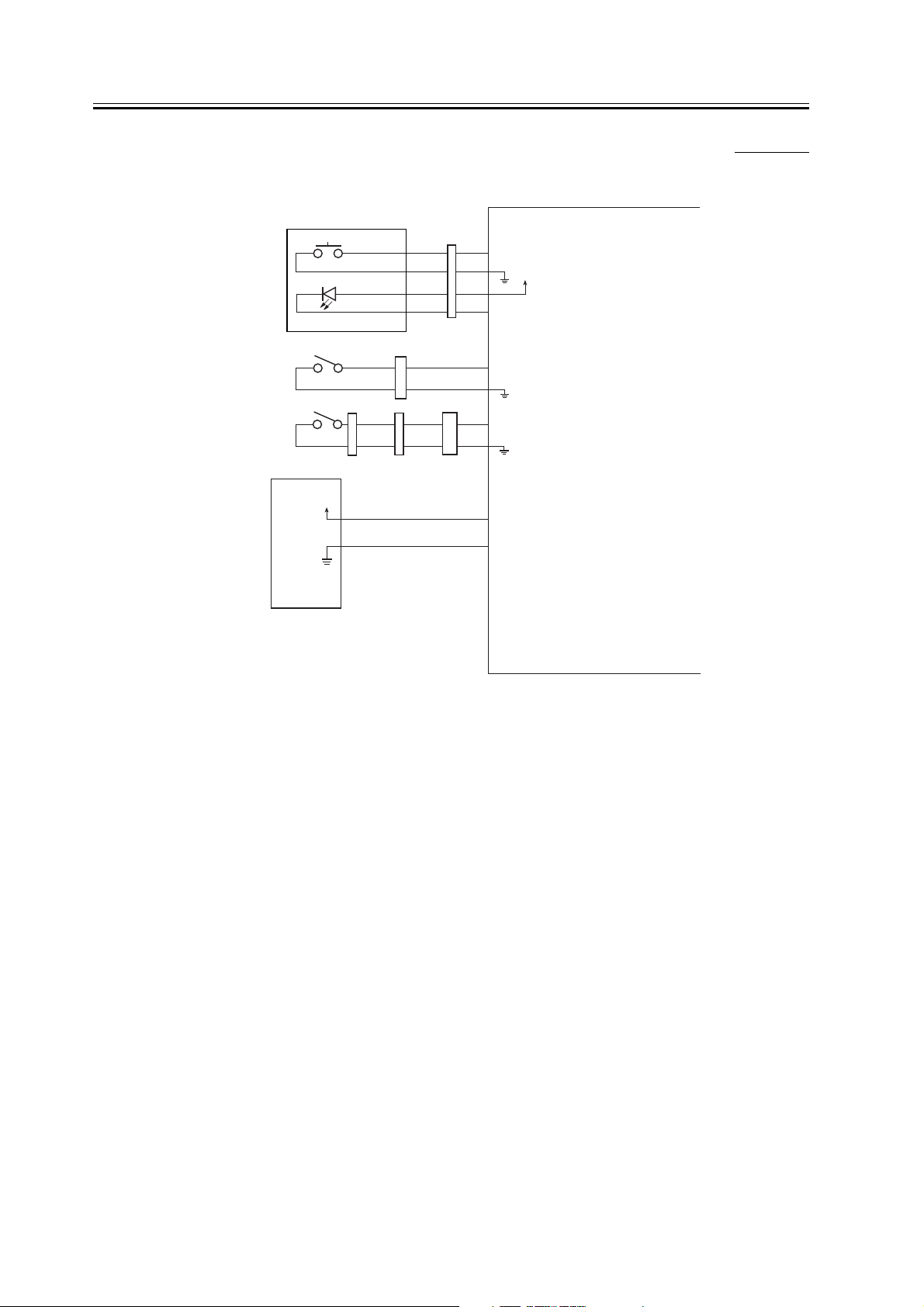

2.1.1 Inputs to the Side Paper Deck (1/2)

Deck pickup

sensor

Deck paper

absent sensor

Deck lifter upper

limit sensor

Deck lifter

position sensor

Deck set sensor

Deck feed sensor

Deck paper

supply position

Deck paper level

sensor

Deck open sensor

J10-1

PS101

PS102

PS103

PS104

J24-1

PS105

J12-1

PS106

J18-1

PS107

J19-1

PS108

J25-1

PS109

J5-1

J6-1

J7-1

J8-5

-2

-4

-3

-3

J4-4

-2

-3

-2

-3

-2

-3

-2

-3

-2

-3

-2

-3

-2

-3

-2

-3

J4-7

J4-10

J8-10

J17-3

J17-6

-3

-2

-6

-5

-9

-8

-9

-8

-2

-1

-5

-4

Side deck driver PCB

+5VR

J104-5

-4

DPPD

-3

+5VR

J103-7

-6

DPE*

-5

+5VR

J103-10

-9

DLUL

-8

+5VR

J103-13

-12

DLPD

-11

+5VR

J108-5

-4

DSET

-3

+5VR

J104-10

-9

DPFD

-8

+5VR

J107-3

-2

DPSP

-1

+5VR

J107-6

-5

DPLD

-4

+5VR

J108-8

-7

DOPND*

-6

When PS101 detects paper, '1'.

(When the light-blocking sensor is

at PS101.)

When paper is absent in the deck,

'0'.

(When the light-blocking sensor is

not at PS102.)

When the deck lifter is at the upper

limit, '1'.

(When the light-blocking sensor is

at PS103.)

When the lifter is at the pickup

position, '1'.

(When the light-blocking sensor is

at PS104.)

When the deck is set in the copier,

'1'.

(When the light-blocking sensor is

at PS105.)

When PS106 detects paper, '1'.

(When the light-blocking sensor is

at PS106.)

When the deck lifter is at the paper

supply position, '1'.

(When the light-blocking sensor is

at PS107.)

When PS108 detects the absence

of paper (level decreasing to half),

'1'.

(When the light-blocking sensor is

at PS108.)

When the compartment is set in

the deck, '1'.

(When the light-blocking sensor is

at PS109.)

0003-2548

F-2-1

2-1

Page 14

Chapter 2

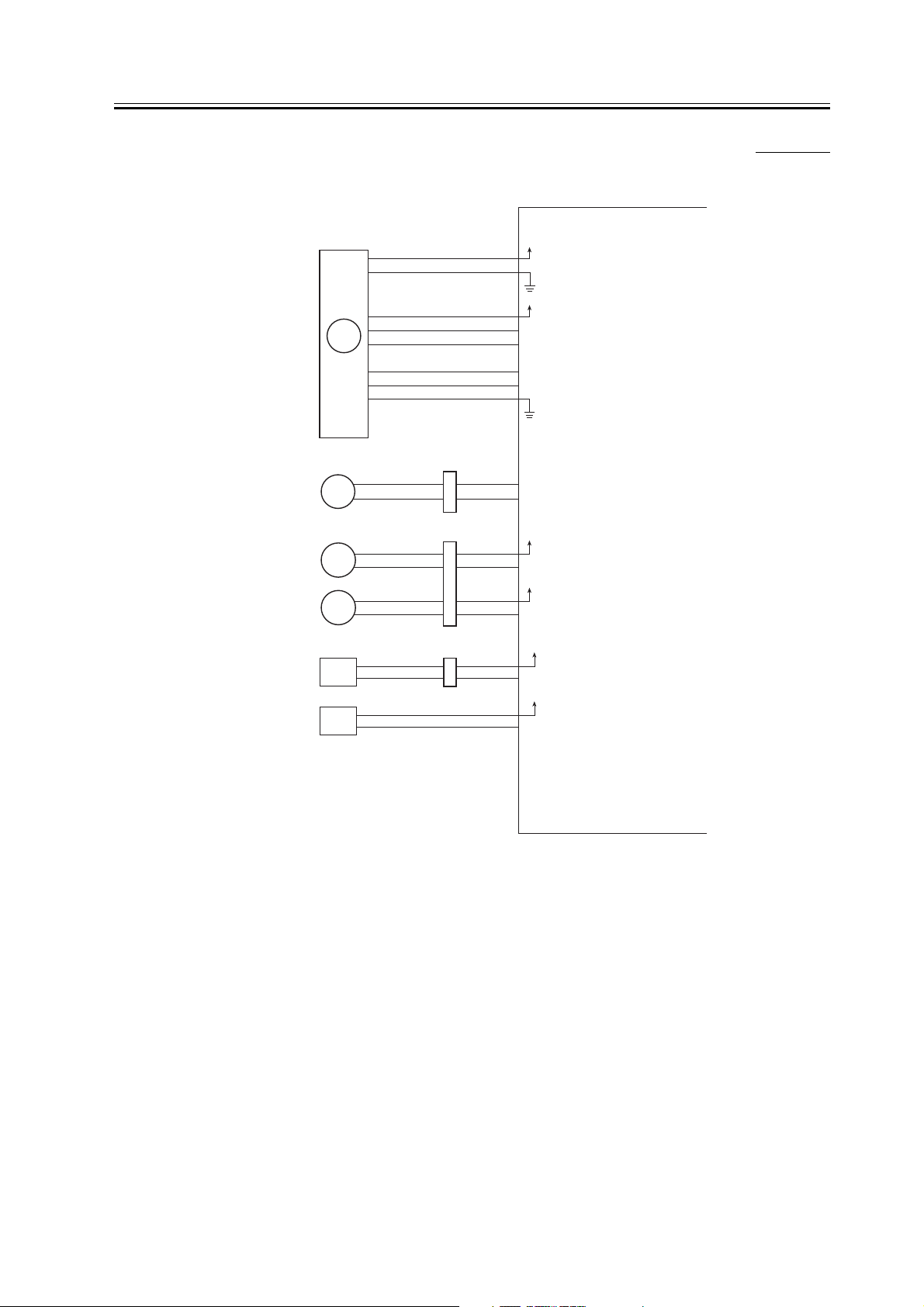

2.1.2 Inputs to the Side Paper Deck (2/2)

Deck open

switch

Deck open

indicator

Deck open

detecting switch

Deck lifter lower

limit detecting

switch

Power supply

SW100

LED100

Open switch PCB

SW101

NO

SW102

J21-1-2J20-1

NO

+24V

0VU

J2-1

J3-1

-2

-2

-3

-3

-4

-4

J26-1

-2

J17-8

-7

-3

Side deck driver PCB

J103-4

DOPN*

-3

+5VR

-2

-1

DOLON*

J109-3

DOPD*

-1

J107-8

DLLD

-7

J101-1

-2

When SW100 is pushed to open

the deck, '0'.

When the deck is open/closed,

'0'.

(The LED turns on or flashes

while the deck lifter motor is

rotating.)

When the deck is open, '0'.

(When SW101 is not pushed.)

When the deck lifter is at the

lower limit, '1'.

(When SW102 is not pushed.)

0003-2567

Copier

F-2-2

2-2

Page 15

Chapter 2

2.1.3 Outputs from the Side Paper Deck (1/1)

J106-1

J105-5

J107-9

J104-6

J104-11

Deck main

motor

Deck lifter

motor

Deck feeding

clutch

Deck pickup

clutch

M101

M102

CL101

CL102

J15-1

J22-1

J11-1

J13-2

J14-2

-2

-2

-1

-2

-6

-5

-4

-3

-1

J17-9

-10

J8-6

-7

-11

-12

Side deck driver PCB

+24VU

-2

+5VR

-1

DBIT1

-2

DBIT0

-3

DMPLK

-4

DMON

-6

-10

24VU

-7

DPFCD*

24VU

-12

DPUCD*

0003-2579

See p. 10-14.

See p. 10-16.

When '0', CL101 turns on.

When '0', CL102 turns on.

Deck pickup

roller releasing

solenoid

Deck open

solenoid

SL101

SL102

J9-2

-1

J23-2

J8-1

-2

-1

J104-1

J108-1

-2

-2

24VU

DPRSD*

24VU

DOPSD*

When '0', SL101 turns on.

When '0', SL102 turns on.

F-2-3

2-3

Page 16

Chapter 2

2.2 Basic Operation

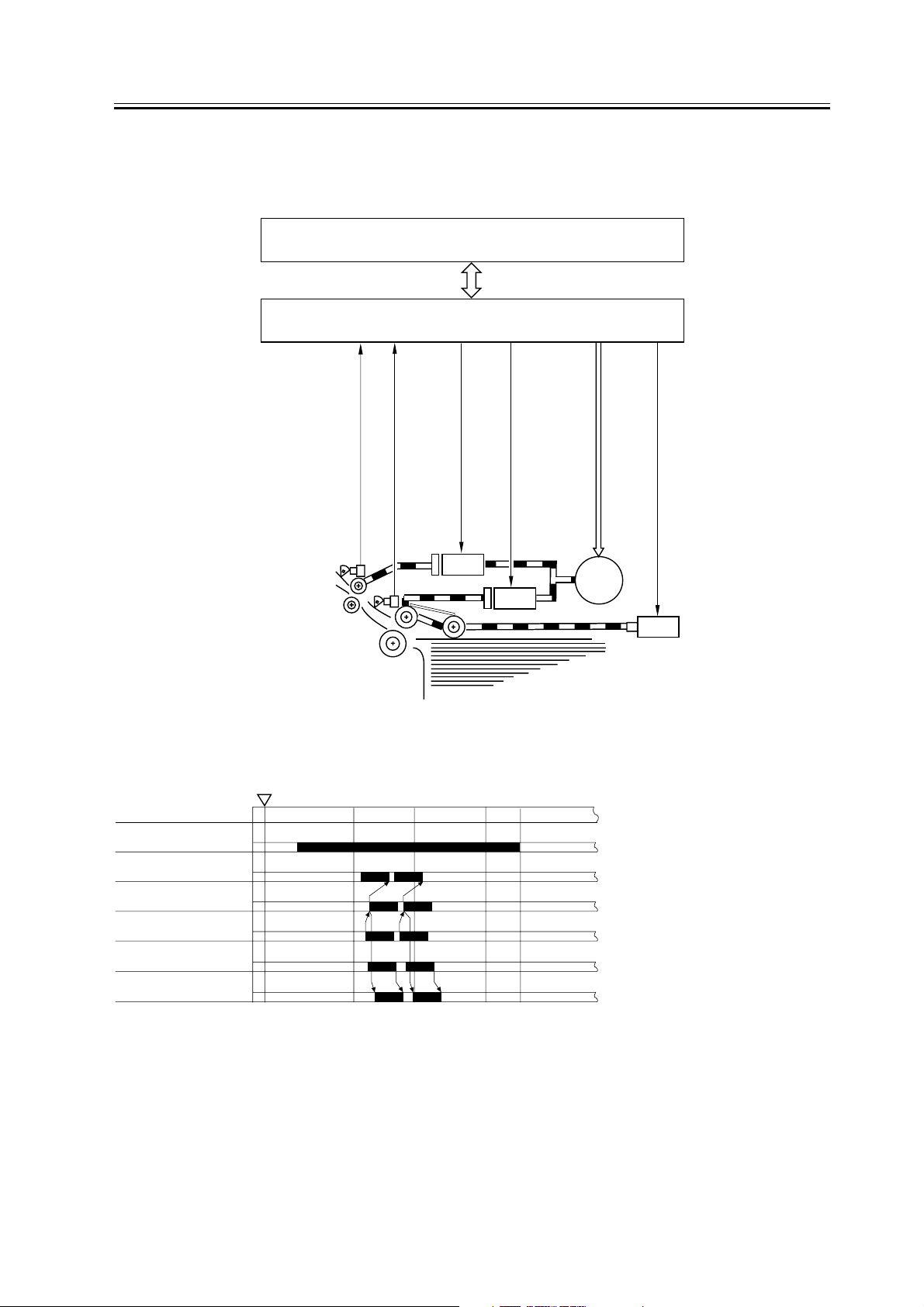

2.2.1 Overview

The side paper deck (hereafter, "deck") is capable of accommodating as many as 3500 sheets of paper at a time (A4/

LTR/B5; 80 g/m2), ready to pick up and feed paper in response to control signals from its host machine' s DC

controller.

The lifter of the deck is driven by the deck lifter motor (M102), and the pickup operation is executed using the drive

from the deck main motor (M101).

2.2.2 Pickup Operation

The paper placed in the deck is held up by the lifter at a specific point of paper pickup.

When the Start key is pressed and the deck pickup clutch (CL102) goes on, the pickup roller starts to rotate by the

drive of the deck main motor (M101), thus picking up paper. At this time, the pickup/feed roller ad the separation

roller make sure that no more that a single sheet of paper is moved ahead. Thereafter, when the deck pickup sensor

(PS101) detects the paper, the deck pickup roller release solenoid (SL101) goes on so that the pickup roller leaves

the surface of the stack of paper.

0003-2610

0003-2616

2-4

Page 17

Chapter 2

The deck feed roller starts to rotate when the deck feed clutch (CL101) goes on. The paper is then moved to the host

machine' s registration roller, where it is arched to remove any skew.

The registration roller serves to control the paper so that its leading edge will match the image on the photosensitive drum.

Deck feed paper detection

signal (DPFD)

Deck pickup detection signal

(DPPD)

PS106

PS101

DC controller PCB

Side deck driver PCB

Deck feeding clutch dive signal

(DPFCD*)

Deck pickup clutch drive signal

(DPUCD*)

CL101

CL102

(copier)

Deck pickup roller releasing

Deck main motor drive signal

M101

solenoid drive signal (DPRSD*)

SL101

Copy Start key

Deck main motor

(M101)

Deck pickup clutch

(CL102)

Deck pickup roller releasing

solenoid (SL101)

Deck pickup sensor

(PS101)

Deck feed sensor

(PS106)

Deck feeding clutch

(CL101)

F-2-5

ON

INTR

SCAN

F-2-4

PRINT

LSTR

STBY

2-5

Page 18

Chapter 2

2.2.3 Controlling the Deck Main Motor (M1D)

0003-2623

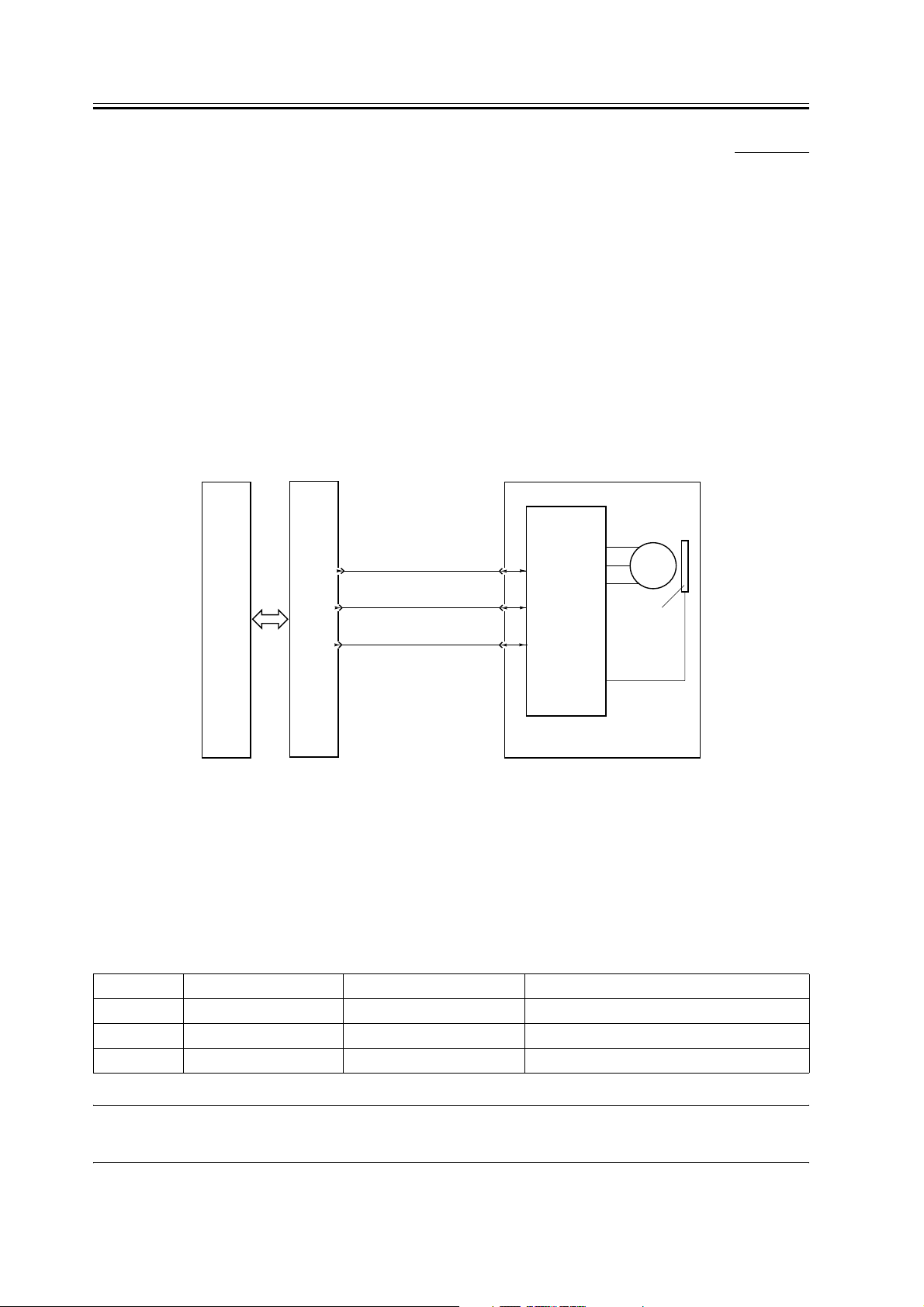

1. Controlling the Deck Main Motor (M101)

The deck main motor is controlled by the host machine' s DC controller. The following diagram shows the circuit

used to drive the deck main motor, and the circuit has the following functions:

1 turns on/off the deck main motor

2 changes the speed of rotation of the deck main motor

a. Turning On/Off the Motor

When the deck main motor drive signal (DMON) from the host machine goes '1', the motor drive circuit goes on so

that the motor starts to rotate at a specific speed. When the deck main motor drive signal (DMON) goes '0' , on the

other hand, the motor drive circuit goes off to stop the motor.

The host machine' s DC controller monitors the rotation of the deck main motor with reference to the deck main

motor PULL lock signal (DMPLK); if the PULL lock signal remains '1' for 900 msec or more white DMON is '1', it

will indicate 'E043' on the host machine' s control panel.

Deck main motor

Deck main motor drive

DC

controller

PCB

Side

deck

driver

PCB

J105

signal (DMON)

-4

Deck main motor PLL

-3

lock signal (DMPLK)

Deck main motor speed

-2

switch signal (DBIT 0)

J14

-3

-4

-5

Motor

drive circuit

M101

Encoder

(copier)

Deck main motor driver PCB

F-2-6

b. Changing the Speed of Rotation of the Motor

The deck is designed to automatically change the speed of pickup so as to support future host machines. The pickup

speed is changed in response to external clock signals (MOTOR CLK) that are sent by the host machine' s DC

controller to the side deck drive PCB in keeping with the speed of motor rotation. The relationship between the speed

of motor rotation and the frequency of the external clock signals is as follows:

T-2-1

Drive speed Rotation of motor shaft External clock setting (Hz) Drive mode

Speed 1 2885.93 1443 used when picking up plain paper

Speed 2 2308.80 1155 used when picking up H/H color (PS)

Speed 3 1847.05 924 used when picking up heavy paper (1/3 PS)

MEMO

When making color copies/prints, the drive speed is shifted to speed 2 or 3.

2-6

Page 19

Chapter 2

2.2.4 Controlling the Deck Lifter Motor (M2D)

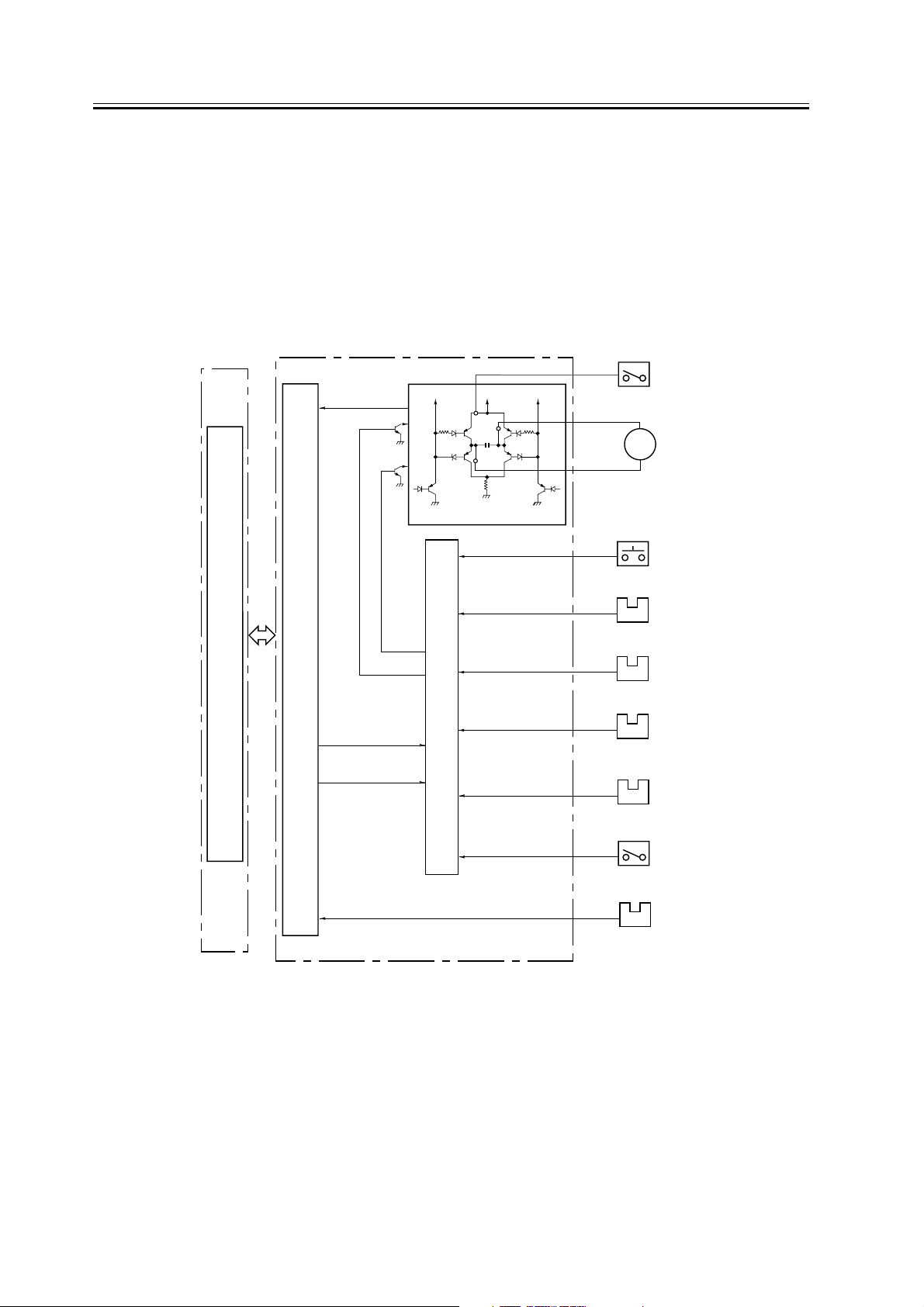

2. Controlling the Deck Lifter Motor (M102)

The deck lifter motor control circuit is found as part of the side deck driver PCB. The following is a block diagram

of the circuit:

The combination circuit shown in the diagram consists of various logic circuits, and the deck lifter motor is rotated

in normal or reverse direction using combinations of the deck lifter drive signal (DLMON*) and the deck lifer ascent

signal (DLUP*) from the host machine' s DC controller and the output signals of various sensors.

If, for some reason, the deck lifter position sensor (PS104) does not detect the lifter within 60 sec after the deck lifter

ascent signal is generated, an error code (E041) will be indicated on the host machine' s control panel.

1 Conditions Used to Move Up the Lifter

the deck is joined with its host machine, i.e., the deck set signal (DSET) is '1'.

the deck (compartment) is closed, i.e., the deck open detection signal (DOPND*) is '1'.

the deck (compartment) is closed, i.e., the deck open detecting switch is 'on'.

the deck lifter upper limit signal (DLUL) is '0' and, in addition, the deck lifter position detecting signal (DLPD) is '0'.

the deck lifer motor drive signal (DLMON*) is '0'.

the deck lifter ascent signal (DLUP* is '0'.

In the presence of these conditions, the lifter starts to move up.

0003-2639

2-7

Page 20

Chapter 2

2 Conditions Used to Move Down the Lifter

the deck (compartment) is open, i.e., the deck open detection signal (DOPND*) is '0'.

the deck lower limit detection signal (DLLD) is '0' and, in addition, the deck lifter position detection signal (DLPD)

is '0'.

the deck lifter motor drive signal (DLMON*) is '0'.

the deck lifter ascent signal (DLUP*) is '1'.

In the presence of these conditions, the lifter starts to move down.

Deck open

detection signal

(DOPD)

Deck lifter up drive signal

Deck lifter motor down signal

DC controller PCB

Deck lifter motor

drive signal

(DLMON*)

Communication conversion IC (Q17)

Deck lifter up

signal (DLUP*)

Deck paper supply position detection signal (DPSP)

Copier

Note: The communications conversion IC (Q17) in the diagram converts

serial signals to parallel signals and vice versa.

24V

24V

Motor drive circuit

Deck open signal

(DOPN*)

Deck lifter upper limit

detection signal

(DLUL)

Deck open detection

signal (DOPND*)

Deck lifter position

detection signal

(DLPD)

Combination circuit

Deck set signal

(DSET)

Deck lifter roller limit

detection signal

(DLLD)

Side deck driver PCB

24V

Deck open detecting

switch (SW101)

M102

Deck lifter

motor

Deck open

switch (SW100)

PS103

Deck lifter upper

limit sensor

PS109

Deck open

sensor

PS104

Deck lifter

position sensor

PS105

Deck set

sensor

Deck lifter lower limit

detecting switch (SW102)

PS107

Deck paper supply

position sensor

F-2-7

2-8

Page 21

2.3 Paper Detection

Chapter 2

2.3.1 Detecting the Presence/Absence of Paper

0003-2817

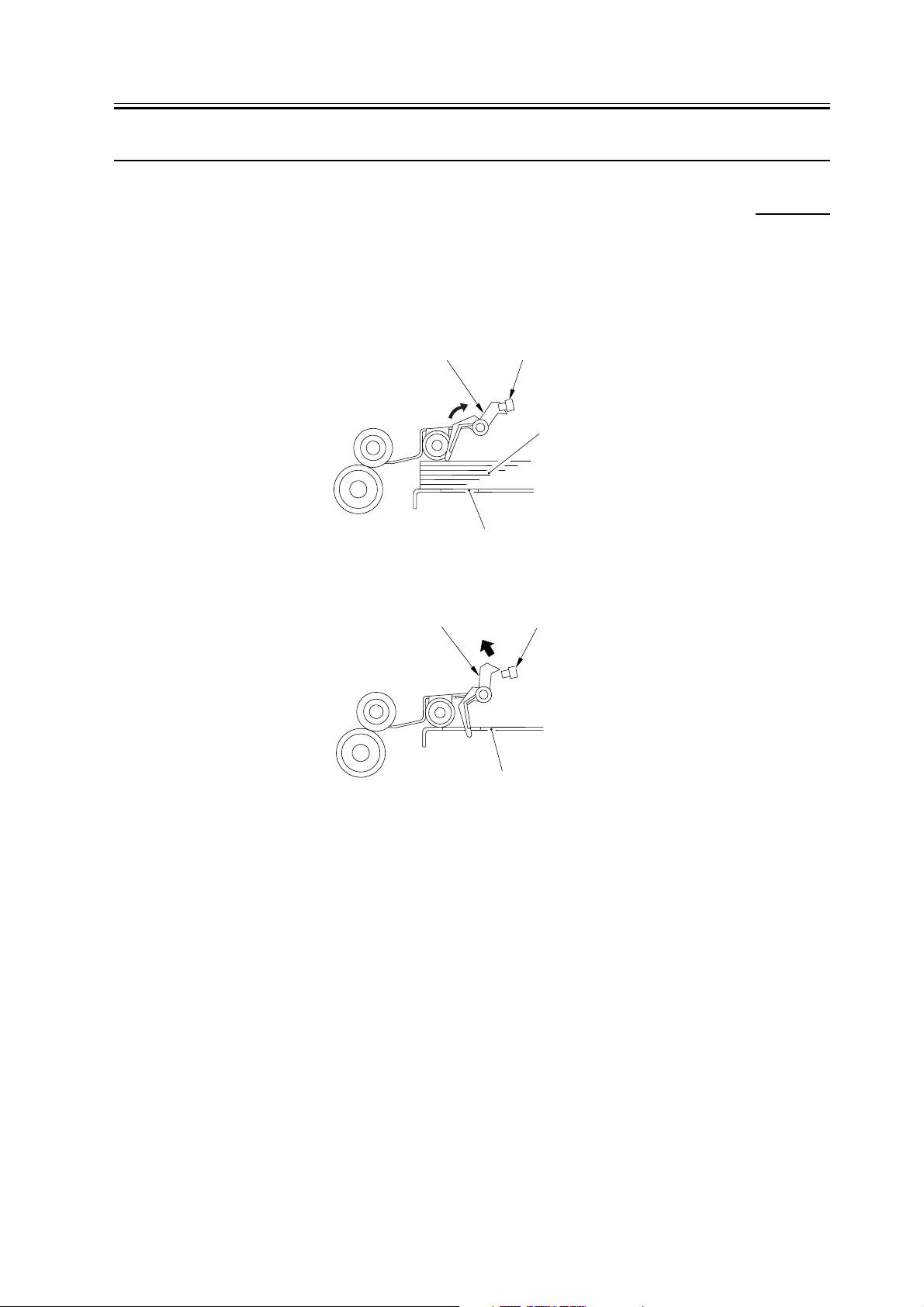

1. Detecting the Presence/Absence of Paper

The presence/absence of paper inside the deck is checked by the deck paper sensor (PS102). When paper runs out

and the paper detecting lever of the pickup roller assembly leaves the deck paper sensor, the host machine indicates

the absence of paper on its control panel.

Paper detecting lever

Deck paper absent sensor

Copy paper

Lifter

F-2-8

Paper detecting lever

Deck paper absent sensor

F-2-9

Lifter

2-9

Page 22

Chapter 2

2.3.2 Changing the Deck Paper Size

2. Changing the Deck Paper Size

To change the paper size of the deck, you must move the guide plate in the deck to suit the user' s needs and then

select the correct paper size in service mode: OPTION>ACC>DKP.

2.3.3 Detecting the Level of Paper

3. Detecting the Level of Paper in the Deck

The deck uses the deck paper supply position sensor (PS107), deck paper level sensor (PS108), and deck paper

sensor (PS102) to check the level of paper inside its compartment; the result of the check is indicated on the host

machine' s control panel. The following table shows how a check is made with reference to the states of the sensors:

T-2-2

paper level PS102 PS107 PS108

about 1750 to 3500 sheets 1 1 1

about 500 to 1750 sheets 1 1 0

0003-2666

0003-2669

1 to about 500 sheetssheets 1 0 0

no paper 0 0 0

1: the lightblocking plate is over the sensor.

0: the lightblocking plate is not over the sensor.

2-10

Page 23

2.4 Deck Lifter

Chapter 2

2.4.1 Detecting the Presence/Absence of Paper

The lifter of the deck is joined to a reel by means of a cable, and is driven by the deck lifter motor (M102); i.e., the

lifter moves up or down depending on the direction of rotation of the motor.

When the deck (compartment) is pushed inside the host machine, the deck open detecting switch (SW101) is pushed.

The lifter starts to move up as soon as the deck open sensor (PS109) detects the lightblocking plate; the lifter stops

to move up when the deck position sensor (PS104) detects the top of the stack of paper placed on the lifter

In the rare event that the lifter should fail to stop moving up after the sensor lever blocks the deck lifter position sensor

for some reason, the deck lifter upper limit sensor (PS103) will go on to stop the lifter, thereby preventing damage

to the deck.

The lifter, on the other hand, starts to move down when the deck open switch (SCREW100) is pushed, and will keep

moving down until the lifter moves past the sensor lever of the deck paper supply position sensor (PS107), i.e., falling

edge of the sensor output.

The addition of paper in this condition will push the lever of the deck paper supply position sensor, causing the lifter

to move farther down until the stack of paper moves past the sensor lever.

The lifter repeats its descent operation each time paper is added until the deck lifter lower limit detecting switch

(SW102) is pushed (maximum paper supply position).

0003-2819

2-11

Page 24

Chapter 2

The host machine' s DC CPU monitors the timing at which sensors associated with deck lifter operation go on; and,

if the deck paper supply position sensor (PS107) is '0' when the deck lifter position sensor (PS104) and the deck level

sensor (PS108) are '1' (not a normal combination), it will indicate an error code (E041) on the host machine' s control

panel.

Deck lifter

position sensor

(PS104)

Deck lifter upper

limit sensor

(PS103)

Deck pickup / feeding roller

Deck open

switch

(SW100)

Deck main

motor

Deck paper

level sensor

(PS108)

Deck open

detection switch

(SW101)

M101

Deck paper

supply position sensor

(PS107)

Deck pickup roller

M102

Deck lifter

motor

Deck lifter lower

limit detecting switch

(SW102)

Deck separation roller

Deck lifter

cable

Lifter

Copy paper

F-2-10

2-12

Page 25

2.5 Opening /Closing the Compartment

Chapter 2

2.5.1 Opening/Closing the Compartment

0003-2823

1. Opening/Closing the Deck

When the deck open switch (SW100) is pushed, the deck open solenoid (SL102) goes on to free the lock on the deck

(compartment); as a result, the deck is pushed several centimeters to the front by the work of a spring. At the same

time, the deck lifter motor (M102) starts to rotate to move down the lifter inside the deck.

When the deck (compartment) is pushed into the host machine, the deck open sensor (PS109) detects the light

blocking plate, permitting the lifter to move up as far as the pickup position.

When the deck lifter motor rotates to open/close the deck, the deck open indicator (LED100) on the open switch PCB

goes on or flashes.

J100

-1

SW100

-4

LED100

Open switch PCB

(compartment)

Deck lifter

Deck open signal (DOPN*)

Deck open indicator LED activation signal (DOLON*)

Deck lifter upper limit detection signal

PS103

(DLUL)

PS109

Deck open detecting signal (DOPND*)

SW101

Deck open detection signal (DOPD*)

J103

- 4

J103

- 1

J103

- 9

J108

- 7

J109

- 3

Side

deck

driver

PCB

DC

controller

PCB

Open

SW102

M102

Deck open solenoid drive signal

(DOPSD*)

SL102

Deck lifter lower limit detection signal

(DLLD)

Deck lifter motor drive signal

F-2-11

J108

-11

J107

- 8

J107

(copier)

2-13

Page 26

Chapter 2

2. Sequence of Operation Used to Open/Close the Deck.

Deck open

switch ON

Compartment set

Deck open indicator

(LED100)

Deck lifter motor

(M102)

Deck paper supply position

sensor (PS107)

Deck lifter lower limit

detecting switch (SW102)

Deck open solenoid

(SL102)

Deck open detecting switch

(SW101)

Deck open sensor

(PS109)

Deck lifter position sensor

(PS104)

Flashing On

Flashing

**

Compartment open

Deck lifter down Deck lifter up

* : Varies according to the level of the stack.

F-2-12

Off

2-14

Page 27

2.6 Detecting Jams

Chapter 2

2.6.1 Overview

0003-2825

The side paper deck is equipped with the following 2 sensors used to find out whether or not paper is moving

smoothly. The machine checks for the presence of a jam at such times as initiated its DC controller PCB and with

reference to the signals from these sensors. When the machine's DC controller PCB identifies a jam, it discharges

sheets ahead of the jam and stops the ongoing operation, after which it will indicate jam removal instructions on its

control panel.

T-2-3

Sensor No. Name Principal function

PS106 deck feed sensor detecting delay jams

PS101 deck pickup sensor detecting delay jams

1. when the machine's power switch is turned on or at the end of the waitup period or during standby, the presence

of paper is detected over the deck feed sensor (PS106).

2. deck pickup/vertical path delay jam

Copy Start key

Deck pickup clutch

(CL102)

Jam check

Deck pickup sensor

(PS101)

Deck feed sensor

(PS106)

Deck main motor

(M101)

ON

INTR

Jam indicator

SCAN

Normal Error

PRINT

F-2-13

2-15

Page 28

Chapter 2

2.7 Power Supply

2.7.1 Route of power supply

[1]

0003-2834

[2]

F-2-14

[1] Side deck I/F cable

[2] Side deck heater cable

2-16

Page 29

Chapter 3 Parts

Replacement

Procedure

Page 30

Contents

Contents

3.1 Removing from the Host Machine.................................................................................................................... 3 1

3.1.1 Compartment..............................................................................................................................................3 1

3.1.1.1 Removing the Compartment................................................................................................................ 3 1

3.1.2 Paper Deck .................................................................................................................................................3 2

3.1.2.1 Detaching from the Host Machin........................................................................................................3 2

3.1.2.2 Opening the Compartment ..................................................................................................................3 2

3.1.2.3 Removing the Right Cover.................................................................................................................. 3 2

3.1.2.4 Detaching the Deck from the Host Machine....................................................................................... 3 3

3.2 External Covers................................................................................................................................................. 3 3

3.2.1 Front Cover................................................................................................................................................. 3 3

3.2.1.1 Opening the Compartment ..................................................................................................................3 3

3.2.1.2 Removing the Front Cover.................................................................................................................. 3 3

3.2.2 Rear Cover.................................................................................................................................................. 3 4

3.2.2.1 Removing the Rear Cover................................................................................................................... 3 4

3.2.3 Right Cover ................................................................................................................................................ 3 4

3.2.3.1 Opening the Compartment ..................................................................................................................3 4

3.2.3.2 Removing the Right Cover.................................................................................................................. 3 4

3.2.4 Upper Cover ............................................................................................................................................... 3 5

3.2.4.1 Removing the Rear Cover................................................................................................................... 3 5

3.2.4.2 Opening the Compartment ..................................................................................................................3 5

3.2.4.3 Removing the Upper Front Cover....................................................................................................... 3 5

3.2.4.4 Removing the Upper Cover................................................................................................................. 3 5

3.3 Drive System ..................................................................................................................................................... 3 6

3.3.1 Deck Pickup Clutch.................................................................................................................................... 3 6

3.3.1.1 Removing the Rear Cover................................................................................................................... 3 6

3.3.1.2 Opening the Compartment ..................................................................................................................3 6

3.3.1.3 Removing the Upper Front Cover....................................................................................................... 3 6

3.3.1.4 Removing the Upper Cover................................................................................................................. 3 6

3.3.1.5 Removing the Pickup Unit .................................................................................................................. 3 7

3.3.1.6 Removing the Pickup Clutch............................................................................................................... 3 7

3.3.2 Deck Feed Clutch....................................................................................................................................... 3 7

3.3.2.1 Removing the Rear Cover................................................................................................................... 3 7

3.3.2.2 Opening the Compartment ..................................................................................................................3 8

3.3.2.3 Removing the Upper Front Cover....................................................................................................... 3 8

3.3.2.4 Removing the Upper Cover................................................................................................................. 3 8

3.3.2.5 Removing the Pickup Unit .................................................................................................................. 3 8

3.3.2.6 Removing the Feed Clutch.................................................................................................................. 3 9

3.3.3 Deck Main Motor .......................................................................................................................................3 9

3.3.3.1 Removing the Rear Cover................................................................................................................... 3 9

3.3.3.2 Removing the Deck Main Motor (M101) ........................................................................................... 3 9

3.3.4 Deck Lifter Motor .................................................................................................................................... 3 10

3.3.4.1 Opening the Compartment ................................................................................................................ 3 10

3.3.4.2 Positioning the Deck Lifter ...............................................................................................................3 10

3.3.4.3 Removing the Compartment.............................................................................................................. 3 11

3.3.4.4 Removing the Deck Lifter Motor (M2D)..........................................................................................3 12

3.3.5 Lifter Cable (Front) .................................................................................................................................. 3 13

3.3.5.1 Opening the Compartment ................................................................................................................ 3 13

3.3.5.2 Removing the Lifter Cable (deck front)............................................................................................3 13

3.3.5.3 Stringing the Lifter Cable.................................................................................................................. 3 14

Page 31

3.3.6 Lifter Cable...............................................................................................................................................3 15

3.3.6.1 Opening the Compartment.................................................................................................................3 15

3.3.6.2 Removing the Compartment..............................................................................................................3 15

3.3.6.3 Removing the Lifter Cable (deck rear)..............................................................................................3 16

3.3.6.4 Stringing the Lifter Cable..................................................................................................................3 17

3.4 Document Feeding System..............................................................................................................................3 18

3.4.1 Deck Pickup Unit......................................................................................................................................3 18

3.4.1.1 Removing the Rear Cover..................................................................................................................3 18

3.4.1.2 Opening the Compartment.................................................................................................................3 18

3.4.1.3 Removing the Upper Front Cover .....................................................................................................3 18

3.4.1.4 Removing the Upper Cover...............................................................................................................3 18

3.4.1.5 Removing the Deck Pickup Unit.......................................................................................................3 19

3.4.2 Deck Pickup Roller...................................................................................................................................3 19

3.4.2.1 Removing the Rear Cover..................................................................................................................3 19

3.4.2.2 Opening the Compartment.................................................................................................................3 19

3.4.2.3 Removing the Upper Front Cover .....................................................................................................3 20

3.4.2.4 Removing the Upper Cover...............................................................................................................3 20

3.4.2.5 Removing the Deck Pickup Unit.......................................................................................................3 20

3.4.2.6 Removing the Deck Pickup Roller ....................................................................................................3 21

3.4.2.7 Points to Note When Mounting the Deck Pickup Roller...................................................................3 21

3.4.3 Deck Pickup/Feed Roller..........................................................................................................................3 22

3.4.3.1 Removing the Rear Cover..................................................................................................................3 22

3.4.3.2 Opening the Compartment.................................................................................................................3 22

3.4.3.3 Removing the Upper Front Cover .....................................................................................................3 22

3.4.3.4 Removing the Upper Cover...............................................................................................................3 22

3.4.3.5 Removing the Deck Pickup Unit.......................................................................................................3 23

3.4.3.6 Removing the Deck Pickup/Feed Roller ...........................................................................................3 23

3.4.3.7 Points to Note When Mounting the Deck Pickup/Feed Roller..........................................................3 23

3.4.4 Deck Separation Roller.............................................................................................................................3 24

3.4.4.1 Removing the Deck Separation Roller ..............................................................................................3 24

3.5 Electrical System .............................................................................................................................................3 25

3.5.1 Deck Driver PCB......................................................................................................................................3 25

3.5.1.1 Removing the Rear Cover..................................................................................................................3 25

3.5.1.2 Removing the Deck Driver PCB .......................................................................................................3 25

3.5.2 Open Switch PCB.....................................................................................................................................3 25

3.5.2.1 Opening the Compartment.................................................................................................................3 25

3.5.2.2 Removing the Upper Front Cover .....................................................................................................3 26

3.5.2.3 Removing the Open Switch PCB.......................................................................................................3 26

Page 32

Chapter 3

3.1 Removing from the Host

Machine

3.1.1 Compartment

3.1.1.1 Removing the

Compartment

1) Place a stack of paper [3] (about 8 cm in height) on

the floor on which to place the deck [2], thus

preventing damage to the roll support plate [1].

[2]

[3]

[1]

F-3-1

2) Push the deck release grip [1] to detach the deck

from its host machine; then, push down the latch

plate [2] found at the rear left to open the

compartment.

[3]

0003-8452

A

3) Remove the 3 screws [1], and detach the right cover

[2].

[2]

[1]

F-3-3

4) Remove the screw [1] of the harness guide,

disconnect the connector [2], and remove the 3 screws

each on the right and left of the compartment rail [3];

then, lift the compartment [5] slightly to detach it

toward the front.

[1]

[4]

(rear)

F-3-2

[1]

[2]

[2]

[4]

[3]

[5]

F-3-4

5) Place the compartment [5] on the base you prepared

in step 1).

3-1

Page 33

Chapter 3

3.1.2 Paper Deck

3.1.2.1 Detaching from the

Host Machin

1) Place a stack of sheets [3] (A: about 8 cm in height)

on the floor on which to place the deck [2], thus

preventing the deformation of the roll support plate

[1].

[2]

[3]

[1]

F-3-5

[3]

0003-2842

A

3.1.2.2 Opening the

Compartment

1) Push the deck release grip [1] to detach the deck

from its host machine. Then, push down the latch

plate [2] found at the rear left to open the

compartment.

[1]

(rear)

[2]

F-3-6

0003-2941

3.1.2.3 Removing the Right

Cover

0003-2906

1) Detach the deck from its host machine; then,

remove the 3 screws [1], and detach the right cover

[2].

[2]

[1]

F-3-7

3-2

Page 34

Chapter 3

3.1.2.4 Detaching the Deck

from the Host Machine

1) Remove the 4 screws [1], and detach the deck [2]

from the deck base [3].

[2]

(left)

F-3-8

[3]

[1]

0003-2907

3.2 External Covers

3.2.1 Front Cover

3.2.1.1 Opening the

Compartment

1) Push the deck release grip [1] to detach the deck

from its host machine. Then, push down the latch

plate [2] found at the rear left to open the

compartment.

[1]

0003-2937

(right)

[1]

F-3-9

2) Hold the deck by the locations indicated in the

figure; then, lift the deck [4], and place it on the base

you prepared in "Detaching from the Host Machine".

(rear)

[2]

F-3-11

3.2.1.2 Removing the Front

Cover

1) Loosen the 4 screws [1], and detach the front cover

[2] of the deck toward the front.

[1]

0003-2848

F-3-10

[4]

[2]

F-3-12

3-3

Page 35

Chapter 3

Be sure to mount the front cover so that the gap

between the front over and the upper front cover is 3

+/1 mm.

Upper front cover

3.2.3 Right Cover

3.2.3.1 Opening the

Compartment

1) Push the deck release grip [1] to detach the deck

from its host machine. Then, push down the latch

plate [2] found at the rear left to open the

compartment.

0003-9073

Front cover

m

m

1

±

3

F-3-13

3.2.2 Rear Cover

3.2.2.1 Removing the Rear

Cover

1) Detach the deck from its host machine; then,

remove the 6 screws [1], and detach the rear cover [2].

[1]

0003-2852

[1]

(rear)

[2]

F-3-15

3.2.3.2 Removing the Right

Cover

1) Detach the deck from its host machine; then,

remove the 3 screws [1], and detach the right cover

[2].

[2]

0003-2866

[2]

F-3-14

3-4

[1]

[1]

[1]

F-3-16

Page 36

Chapter 3

3.2.4 Upper Cover

3.2.4.1 Removing the Rear

Cover

1) Detach the deck from its host machine; then,

remove the 6 screws [1], and detach the rear cover [2].

[1]

[1]

[2]

0003-2910

3.2.4.3 Removing the Upper

Front Cover

1) Remove the 3 screws [1], and disconnect the

connector [2]; then, detach the upper front cover [3].

[1]

F-3-19

[2]

0003-2926

[3]

3.2.4.4 Removing the Upper

Cover

0003-2868

[1]

F-3-17

3.2.4.2 Opening the

Compartment

1) Push the deck release grip [1] to detach the deck

from its host machine. Then, push down the latch

plate [2] found at the rear left to open the

compartment.

[1]

(rear)

0003-2939

1) Remove the 2 screws [1], and detach the upper

cover [2].

[1]

[2]

F-3-20

F-3-18

[2]

3-5

Page 37

Chapter 3

3.3 Drive System

3.3.1 Deck Pickup Clutch

3.3.1.1 Removing the Rear

Cover

1) Detach the deck from its host machine; then,

remove the 6 screws [1], and detach the rear cover [2].

[1]

[1]

[2]

0003-2929

3.3.1.3 Removing the Upper

Front Cover

1) Remove the 3 screws [1], and disconnect the

connector [2]; then, detach the upper front cover [3].

[1]

F-3-23

[2]

0003-2931

[3]

3.3.1.4 Removing the Upper

Cover

0003-2932

[1]

F-3-21

3.3.1.2 Opening the

Compartment

1) Push the deck release grip [1] to detach the deck

from its host machine. Then, push down the latch

plate [2] found at the rear left to open the

compartment.

[1]

0003-2940

1) Remove the 2 screws [1], and detach the upper

cover [2].

[1]

[2]

F-3-24

(rear)

F-3-22

3-6

[2]

Page 38

Chapter 3

3.3.1.5 Removing the Pickup

Unit

1) Disconnect the 2 connectors [1], and remove the 5

screws [2]; then, detach the deck pickup unit [3].

[1]

[2]

[2]

F-3-25

When mounting the deck pickup unit [3], be sure

to tighten the 3 screws shown in the figure first.

[3]

0003-8509

[2]

3.3.1.6 Removing the Pickup

Clutch

1) Disconnect the connector [1], and remove the E

ring [2]; then, detach the deck pickup clutch [3].

[1]

[3]

[4]

F-3-27

When mounting the pickup clutch, be sure that the

clutch is fitted in the stop [4].

Moreover, be sure that the harness is hooked on the U

groove [5] of the guide.

[2]

[5]

0003-2934

F-3-26

Screws

[3]

3.3.2 Deck Feed Clutch

3.3.2.1 Removing the Rear

Cover

1) Detach the deck from its host machine; then,

remove the 6 screws [1], and detach the rear cover [2].

[1]

[1]

[2]

0003-2936

F-3-28

[1]

3-7

Page 39

Chapter 3

3.3.2.2 Opening the

Compartment

1) Push the deck release grip [1] to detach the deck

from its host machine. Then, push down the latch

plate [2] found at the rear left to open the

compartment.

[1]

(rear)

[2]

F-3-29

0003-2943

3.3.2.3 Removing the Upper

3.3.2.4 Removing the Upper

Cover

1) Remove the 2 screws [1], and detach the upper

cover [2].

[1]

F-3-31

0003-2945

[2]

3.3.2.5 Removing the Pickup

Unit

1) Disconnect the 2 connectors [1], and remove the 5

screws [2]; then, detach the deck pickup unit [3].

0003-8508

Front Cover

0003-2944

1) Remove the 3 screws [1], and disconnect the

connector [2]; then, detach the upper front cover [3].

[1]

[2]

[3]

F-3-30

[2]

[1]

[2]

F-3-32

[3]

[2]

3-8

Page 40

When mounting the deck pickup unit [3], be sure

to tighten the 3 screws shown in the figure first.

Chapter 3

3.3.3 Deck Main Motor

3.3.3.1 Removing the Rear

[3]

Screws

F-3-33

3.3.2.6 Removing the Feed

Clutch

1) Remove the harness retainer [1], disconnect the

connector [2], and remove the Ering [3]; then, detach

the deck feed clutch [4].

0003-2948

Cover

0003-8453

1) Detach the deck from its host machine; then,

remove the 6 screws [1], and detach the rear cover [2].

[1]

[1]

[2]

[1]

F-3-35

[1]

[3]

[4]

[2]

[5]

F-3-34

When mounting the feed clutch, be sure that the

clutch is fitted in the stop [5].

3.3.3.2 Removing the Deck

Main Motor (M101)

1) Disconnect the 2 connectors [1], and remove the 4

screws [2]; then, detach the deck main motor [3]. At

this time, be sure to take care not to damage the gear

found at the tip of the motor spindle.

[2]

[1]

[3]

F-3-36

0003-8454

3-9

Page 41

Chapter 3

3.3.4 Deck Lifter Motor

3.3.4.1 Opening the

Compartment

1) Push the deck release grip [1] to detach the deck

from its host machine. Then, push down the latch

plate [2] found at the rear left to open the

compartment.

[1]

(rear)

[2]

F-3-37

0003-8466

3.3.4.2 Positioning the Deck

Lifter

1) If there is any paper, remove all.

2) Turn on the host machine's power switch.

3) If the deck lifter is in its up position, move it so that

the distance A from the bottom plate of the

compartment of the deck lifter is about 7 cm. Push

the sensor flag [2] of the paper supply position

sensor found inside the compartment [1] so that the

deck lifter moves down. (The deck lifter will stop as

soon as you release the flag.)

Insert a hex wrench [3] into the hole of the lifter drive

shaft [4] to fix it in place (against turning).

[1]

0003-8468

[2]

F-3-38

[3]

[4]

7 cm (approx.)

F-3-39

4) Connect the power plug, and turn on the host

machine's power switch.

3-10

Page 42

Chapter 3

3.3.4.3 Removing the

Compartment

1) Place a stack of paper [3] (about 8 cm in height) on

the floor on which to place the deck [2], thus

preventing damage to the roll support plate [1].

0003-9101

[2]

8 cm (approx.)

3) Remove the screw [1] and the stopper plate [2];

then, slide father out the compartment [3].

[2]

(rear left of the

compartment)

[1]

[3]

F-3-42

4) Remove the 3 screws [1], and detach the right cover

[2].

[3]

[1]

[3]

F-3-40

2) Push the deck release grip [1] to detach the deck

from its host machine; then, push down the latch

plate [2] found at the rear left to open the

compartment.

[1]

(rear)

[2]

F-3-41

[2]

[1]

F-3-43

3-11

Page 43

Chapter 3

5) Remove the screw [1] of the harness guide,

disconnect the connector [2], and remove the 3 screws

each on the right and left of the compartment rail [3];

then, lift the compartment [5] slightly to detach it

toward the front.

[1]

[2]

[4]

[4]

[3]

[5]

F-3-44

6) Place the compartment [5] on the base you prepared

in step 1).

3.3.4.4 Removing the Deck

Lifter Motor (M2D)

1) Disconnect the connector [1], and remove the 5

screws [2]; then, detach the deck lifter motor unit

[3].

[1]

[2]

[3]

F-3-45

0003-8470

[2]

3-12

Page 44

Chapter 3

3.3.5 Lifter Cable (Front)

3.3.5.1 Opening the

Compartment

1) Push the deck release grip [1] to detach the deck

from its host machine. Then, push down the latch

plate [2] found at the rear left to open the

compartment.

[1]

(rear)

[2]

F-3-46

0003-8472

Push the flag [2] of the paper position sensor found

inside the compartment [3] until the deck lifter

comes into contact with the screwdrivers.

(The deck lifter will stop when you let go of the flag.)

[1]

[3]

[2]

F-3-47

3.3.5.2 Removing the Lifter

Cable (deck front)

1) If there is any paper, remove all.

2) Insert 2 long screwdrivers [1] to keep the lifter in

position.

3) So that the left and right holes of the compartment

side plate and the left and right holes of the lifter

will match, move down the lifter by pushing the

flag [1] of the paper supply position sensor.

Connect the power plug, and turn on the host

machine's power switch.

0003-8473

4) Loosen the 4 screws [1], and detach the front cover

[2].

Do not remove the screws.

[1]

[2]

F-3-48

3-13

Page 45

Chapter 3

Use the 4 screws used to keep the front cover in

place when adjusting the position of the front cover

so that the gap A between the front cover and the

upper front cover is 3 +/1 mm.

Upper front cover

Front cover

m

m

1

±

3

F-3-49

5) Remove the 4 screws [1], and detach the roll

support plate [2].

[1]

8) Remove the 2 screws [7], and detach the right cable

fixing plate [8]; then, detach the inside lifter cable

[9].

9) Remove the 2 set screws [12] and detach the

outside pulley [11] to detach the inside lifter cable

[9] from the inside pulley [10].

[12] [6] [9]

[4] [5] [10][11] [8] [7]

[2]

F-3-50

6) Remove the coupling shaft [1] and the Ering [2];

then, detach the pulley cover [3].

7) Remove the 2 screws [4], and detach the left cable

fixing plate [5]; then, detach the outside lifter cable

[6].

[3]

[2]

[1]

F-3-51

3.3.5.3 Stringing the Lifter

Cable

1) Check to make sure that the lifter drive shaft [1] and

the lifter [2] are fixed in place using a hex wrench

[3] and 2 long screwdrivers [4], respectively.

2) Fix the 4 cable fixing plates [5] in place to the lifter

using 2 screws each.

3) Hook the lifer cable [6] on the 4 pulleys [7] above.

4) Hook the ball of the lifter cable on the 2 front/rear

pulleys [8] of the lifter drive shaft; then, wind it

about 1.5 times along the groove of the pulley.

At this time, be sure to keep the lifter cable taut so that

the long drivers used to keep the lifter are slightly

lifted by the cable.

0003-8479

3-14

Page 46

Chapter 3

5) Fix the 2 pulleys [5] in place to the lifter drive shaft

with a set screw [9] (1 pc. each).

6) Fit all removed pulleys to the lifter shaft; then,

measure the height A from the base plate of the

compartment to the top face of the lifter, thus

making sure that the lifter is level.

[7]

[5]

[1]

[7]

[8]

[6]

[A]

[5]

[9]

[8]

[3]

[5]

[A]

[A]

[9]

[5]

[A]

[2]

[4]

F-3-52

3.3.6 Lifter Cable

3.3.6.2 Removing the

Compartment

1) Place a stack of paper [3] (about 8 cm in height) on

the floor on which to place the deck [2], thus

preventing damage to the roll support plate [1].

0003-9131

[2]

8 cm (approx.)

[3]

F-3-54

[1]

[3]

3.3.6.1 Opening the

Compartment

1) Push the deck release grip [1] to detach the deck

from its host machine. Then, push down the latch

plate [2] found at the rear left to open the

compartment.

[1]

(rear)

[2]

F-3-53

0003-8480

2) Push the deck release grip [1] to detach the deck

from its host machine; then, push down the latch

plate [2] found at the rear left to open the

compartment.

[1]

(rear)

[2]

F-3-55

3-15

Page 47

Chapter 3

3) Remove the screw [1] and the stopper plate [2];

then, slide father out the compartment [3].

[2]

(rear left of the

compartment)

[1]

[3]

F-3-56

4) Remove the 3 screws [1], and detach the right cover

[2].

5) Remove the screw [1] of the harness guide,

disconnect the connector [2], and remove the 3 screws

each on the right and left of the compartment rail [3];

then, lift the compartment [5] slightly to detach it

toward the front.

[1]

[2]

[4]

[4]

[3]

[5]

F-3-58

6) Place the compartment [5] on the base you prepared

in step 1).

F-3-57

[1]

[2]

3.3.6.3 Removing the Lifter

Cable (deck rear)

1) Remove the screw [1] (1 pc. each), and remove the

upper sensor cover [2] and the lower sensor cover

[3].

2) Disconnect the 4 connectors [4].

[2]

[4]

[4]

[4]

[3]

F-3-59

0003-8482

[1]

3-16

There are 2 claws on the upper sensor cover. Be

sure to take care not to break the claws when

detaching it.

Page 48

Chapter 3

3) Remove the 5 screws [3], and detach the plate [4].

[4]

[3]

[1]

[3]

[2]

[3]

F-3-60

4) Insert a hex wrench [2] into the hole of the lifter

drive shaft [1] to keep it from turning.

If you fail to keep it in place, the lifter cable will

become slack when the lifter motor unit is removed.

3.3.6.4 Stringing the Lifter

Cable

1) Check to make sure that the lifter drive shaft [1] and

the lifter [2] are fixed in place by means of a hex

wrench [3] and 2 long screwdrivers [4].

2) Fix the 4 cable fixing plates [5] in place to the lifter

by 2 screws each.

3) Hook the lifter cable [7] on the 4 pulleys [8] above.

4) Hook the ball of the lifter cable on the 2 pulleys [8]

at the front/rear of the lifter drive shaft; then, wind

it about 1.5 times along the groove of the pulley.

At this time, see to it that the long screwdrivers used

to keep the lifter in place are slightly lifted and the

lifter cable becomes taut.

5) Fix the 2 pulleys [5] in place using the set screws (1

pc. each) to the lifter drive shaft.

6) Fix all removed pulleys in place to the lifter drive

shaft; then, measure the height A from the base

plate of the compartment to the top face of the lifer,

thus making sure that the lifer is level.

0003-8483

[2]

[1]

F-3-61

5) Remove the 5 screws [1], and detach the lifter

motor unit [2].

[1]

[1]

[6]

[A]

[5]

[9]

[8]

[7]

[3]

[1]

[A]

[5]

F-3-63

[5]

[A]

[7]

[8]

[9]

[5]

[A]

[2]

[4]

[2]

F-3-62

3-17

Page 49

Chapter 3

3.4 Document Feeding

System

3.4.1 Deck Pickup Unit

3.4.1.1 Removing the Rear

Cover

1) Detach the deck from its host machine; then,

remove the 6 screws [1], and detach the rear cover [2].

[1]

[1]

[2]

0003-8502

3.4.1.3 Removing the Upper

Front Cover

1) Remove the 3 screws [1], and disconnect the

connector [2]; then, detach the upper front cover [3].

[1]

F-3-66

[2]

0003-8504

[3]

3.4.1.4 Removing the Upper

Cover

1) Remove the 2 screws [1], and detach the upper

cover [2].

0003-8505

[1]

F-3-64

3.4.1.2 Opening the

Compartment

1) Push the deck release grip [1] to detach the deck

from its host machine. Then, push down the latch

plate [2] found at the rear left to open the

compartment.

[1]

(rear)

0003-8503

[1]

F-3-67

[2]

F-3-65

3-18

[2]

Page 50

Chapter 3

3.4.1.5 Removing the Deck

Pickup Unit

1) Disconnect the 2 connectors [1], and remove the 5

screws [2]; then, detach the deck pickup unit [3].

[1]

[2]

[2]

F-3-68

When mounting the deck pickup unit [3], be sure

to tighten the 3 screws shown in the figure first.

[3]

0003-8507

[2]

3.4.2 Deck Pickup Roller

3.4.2.1 Removing the Rear

Cover

1) Detach the deck from its host machine; then,

remove the 6 screws [1], and detach the rear cover [2].

[1]

[1]

[2]

0003-8510

F-3-69

Screws

[3]

[1]

F-3-70

3.4.2.2 Opening the

Compartment

1) Push the deck release grip [1] to detach the deck

from its host machine. Then, push down the latch

plate [2] found at the rear left to open the

compartment.

[1]

(rear)

[2]

F-3-71

0003-8511

3-19

Page 51

Chapter 3

3.4.2.3 Removing the Upper

Front Cover

1) Remove the 3 screws [1], and disconnect the

connector [2]; then, detach the upper front cover [3].

[1]

F-3-72

[2]

0003-8513

[3]

3.4.2.4 Removing the Upper

Cover

1) Remove the 2 screws [1], and detach the upper

cover [2].

0003-8514

3.4.2.5 Removing the Deck

Pickup Unit

1) Disconnect the 2 connectors [1], and remove the 5

screws [2]; then, detach the deck pickup unit [3].

[1]

[2]

[2]

F-3-74

When mounting the deck pickup unit [3], be sure

to tighten the 3 screws shown in the figure first.

[3]

0003-8516

[2]

[1]

F-3-73

[2]

[3]

Screws

F-3-75

3-20

Page 52

Chapter 3

3.4.2.6 Removing the Deck

Pickup Roller

1) Turn over the deck pickup unit; then, remove the

resin ring [1] (1 pc. each) and the 2 deck pickup

rollers [2].

The deck pickup roller has its own direction of

rotation, requiring care when mounting it.

[1]

0003-8518

3.4.2.7 Points to Note When Mounting

the Deck Pickup Roller

Front of the Machine (collar [3]; silvercolored)

It has its own direction of rotation [1]; when mounting

the deck pickup roller [2] to the front of the machine,

be sure that the marking [4] found on the collar [3] is

to the front of the machine and the marking [5] found

on the side of the roller is to the rear of the machine.

Rear of the Machine (collar [8]; goldcover)

It has its own direction of rotation [6]; when mounting

the deck pickup roller [7] to the rear of the machine,

be sure that the marking [9] found on the collar [8] and

the marking [10] found on the side of the roller are to

the rear of the machine.

[6]

[9]

[10]

0003-8519

[2]

F-3-76

[8]

[7]

[5]

[4]

[1]

[2]

[3]

F-3-77

3-21

Page 53

Chapter 3

3.4.3 Deck Pickup/Feed Roller

3.4.3.1 Removing the Rear

Cover

1) Detach the deck from its host machine; then,

remove the 6 screws [1], and detach the rear cover [2].

[1]