Page 1

Service Manual

Finisher, Sorter, DeliveryTray

Puncher Unit-N1

Oct 19 2006

Page 2

Page 3

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair

of products. This manual covers all localities where the products are sold. For this reason, there may be information in this

manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products. When

changes occur in applicable products or in the contents of this manual, Canon will release technical information as the need

arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition

of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or

translated into another language, in whole or in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Page 4

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Indicates an item requiring disconnection of the power plug from the electric outlet.

Indicates an item intended to provide notes assisting the understanding of the topic in question.

Memo

Introduction

REF.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Page 5

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol , the arrow indicates the

direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit door, which results in

supplying the machine with power.

2. In the digital circuits, '1'is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low".(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the operations of the microprocessors

used in the machines are not discussed: they are explained in terms of from sensors to the input of the DC controller PCB and from the output of the

DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service Information bulletins and be

able to identify and isolate faults in the machine."

Page 6

Page 7

Contents

Contents

Chapter 1 Specifications

1.1 Product Specifications ................................................................................................................................1- 1

1.1.1 Specifications ..........................................................................................................................................................1- 1

1.2 Names of Parts ...........................................................................................................................................1- 2

1.2.1 External View...........................................................................................................................................................1- 2

1.2.2 Cross Section ..........................................................................................................................................................1- 3

Chapter 2 Functions

2.1 Basic Construction......................................................................................................................................2- 1

2.1.1 Functional Construction...........................................................................................................................................2- 1

2.2 Feed Drive System .....................................................................................................................................2- 1

2.2.1 Overview..................................................................................................................................................................2- 1

2.2.2 Constraction of the Control System.........................................................................................................................2- 1

2.2.3 Punch Operation......................................................................................................................................................2- 2

2.2.4 Horizontal Registration Operation ...........................................................................................................................2- 4

2.3 Detecting Jams ...........................................................................................................................................2- 6

2.3.1 Detecting Jams........................................................................................................................................................2- 6

2.4 Power Supply ............................................................................................................................................. 2- 6

2.4.1 Power Supply Route ...............................................................................................................................................2- 6

2.4.2 Protection Function..................................................................................................................................................2- 6

Chapter 3 Parts Replacement Procedure

3.1 External Covers ..........................................................................................................................................3- 1

3.1.1 Rear Cover ..............................................................................................................................................................3- 1

3.1.1.1 Removing the Rear Cover ....................................................................................................................................................... 3- 1

3.1.2 Upper Cover ............................................................................................................................................................3- 1

3.1.2.1 Removing the Rear Cover ....................................................................................................................................................... 3- 1

3.1.2.2 Removing the Upper Cover ..................................................................................................................................................... 3- 1

3.1.3 Right Guide Unit ......................................................................................................................................................3- 1

3.1.3.1 Removing the Right Guide Unit ............................................................................................................................................... 3- 1

3.2 Drive System .............................................................................................................................................. 3- 1

3.2.1 Punch Motor ............................................................................................................................................................3- 1

3.2.1.1 Removing the Rear Cover ....................................................................................................................................................... 3- 1

3.2.1.2 Removing the Upper Cover ..................................................................................................................................................... 3- 2

3.2.1.3 Removing the Punch Motor ..................................................................................................................................................... 3- 2

3.2.2 Horizontal Registration Motor ..................................................................................................................................3- 2

3.2.2.1 Removing the Rear Cover ....................................................................................................................................................... 3- 2

3.2.2.2 Removing the Right Guide Unit ............................................................................................................................................... 3- 2

3.2.2.3 Removing the Horizontal Registration Motor ........................................................................................................................... 3- 2

3.2.3 Punch Unit ...............................................................................................................................................................3- 2

3.2.3.1 Notification when dismounting the Punch Unit......................................................................................................................... 3- 2

3.2.3.2 Removing the Rear Cover ....................................................................................................................................................... 3- 2

3.2.3.3 Removing the Right Guide Unit ............................................................................................................................................... 3- 2

3.2.3.4 Removing the Upper Cover ..................................................................................................................................................... 3- 3

3.2.3.5 Removing the Punch Unit ........................................................................................................................................................ 3- 3

3.3 Electrical System ........................................................................................................................................3- 4

3.3.1 Punch Unit Harness.................................................................................................................................................3- 4

3.3.1.1 Notification when dismounting the Punch Unit Harness ......................................................................................................... 3- 4

3.3.1.2 Removing the Rear Cover ....................................................................................................................................................... 3- 4

3.3.1.3 Removing the Right Guide Unit ............................................................................................................................................... 3- 4

Page 8

Contents

3.3.1.4 Removing the Upper Cover ..................................................................................................................................................... 3- 5

3.3.1.5 Removing the Punch Unit Harness .......................................................................................................................................... 3- 5

3.3.1.6 Installing the Punch Unit Harness ............................................................................................................................................ 3- 6

3.3.2 LED PCB..................................................................................................................................................................3- 6

3.3.2.1 Removing the Rear Cover ....................................................................................................................................................... 3- 6

3.3.2.2 Removing the Right Guide Unit ............................................................................................................................................... 3- 6

3.3.2.3 Removing the Upper Cover ..................................................................................................................................................... 3- 6

3.3.2.4 Removing the Punch Unit ........................................................................................................................................................ 3- 7

3.3.2.5 Removing the LED PCB .......................................................................................................................................................... 3- 8

3.3.3 Photosensor PCB ....................................................................................................................................................3- 8

3.3.3.1 Removing the Rear Cover ....................................................................................................................................................... 3- 8

3.3.3.2 Removing the Upper Cover ..................................................................................................................................................... 3- 8

3.3.3.3 Removing the Photosensor PCB ............................................................................................................................................. 3- 8

3.3.4 Scrap Full Detector PCB..........................................................................................................................................3- 8

3.3.4.1 Removing the Right Guide Unit ............................................................................................................................................... 3- 8

3.3.4.2 Removing the Scrap Full Detector PCB................................................................................................................................... 3- 9

3.3.5 Punch Controller PCB..............................................................................................................................................3- 9

3.3.5.1 Removing the Rear Cover ....................................................................................................................................................... 3- 9

3.3.5.2 Removing the Punch Controller PCB....................................................................................................................................... 3- 9

Chapter 4 Maintenance

4.1 User Maintenance ...................................................................................................................................... 4- 1

4.1.1 User Maintenance....................................................................................................................................................4- 1

4.2 Maintenance and Inspection ...................................................................................................................... 4- 1

4.2.1 Periodically Replaced Parts.....................................................................................................................................4- 1

4.2.1.1 Periodically Replaced Parts ..................................................................................................................................................... 4- 1

4.2.2 Durables...................................................................................................................................................................4- 1

4.2.2.1 Durables................................................................................................................................................................................... 4- 1

4.2.3 Periodical Servicing .................................................................................................................................................4- 1

4.2.3.1 Periodical Servicing ................................................................................................................................................................ 4- 1

4.3 Adjustment ................................................................................................................................................. 4- 1

4.3.1 Adjustment at Time of Parts Replacement ..............................................................................................................4- 1

4.3.1.1 Adjusting the Punch Hole Position (feed direction) .................................................................................................................. 4- 1

4.3.1.2 Sensor Output Adjustment ....................................................................................................................................................... 4- 1

4.3.1.3 Registering the Number of Punch Holes.................................................................................................................................. 4- 1

4.4 Troubleshooting.......................................................................................................................................... 4- 1

4.4.1 Error Code ...............................................................................................................................................................4- 1

4.4.1.1 E503; Puncher unit communication error................................................................................................................................. 4- 1

4.4.1.2 E505; Backup RAM error ......................................................................................................................................................... 4- 1

4.4.1.3 E590; Punch motor error.......................................................................................................................................................... 4- 1

4.4.1.4 E591; Scrap full detector sensor error ..................................................................................................................................... 4- 2

4.4.1.5 E592; Trailing edge/Horizontal registration sensor error ......................................................................................................... 4- 2

4.4.1.6 E593; Horizontal registration motor error ................................................................................................................................. 4- 2

4.5 Outline of Electrical Components ............................................................................................................... 4- 2

4.5.1 Sensors....................................................................................................................................................................4- 2

4.5.2 Microswitches ..........................................................................................................................................................4- 3

4.5.3 Motors......................................................................................................................................................................4- 4

4.5.4 PCBs........................................................................................................................................................................4- 5

4.6 Variable Resistors (VR), Light-Emitting Diodes (LED), and Check Pins by PCB ....................................... 4- 5

4.6.1 Overview..................................................................................................................................................................4- 5

4.6.2 Punch Controller PCB..............................................................................................................................................4- 6

4.7 Upgrading................................................................................................................................................... 4- 6

4.7.1 Upgrading ................................................................................................................................................................4- 6

4.8 Service Tools............................................................................................................................................ 4- 11

4.8.1 Solvents and Oils ...................................................................................................................................................4- 11

Chapter 5 Error Code

Page 9

Contents

5.1 Overview..................................................................................................................................................... 5- 1

5.1.1 Overview..................................................................................................................................................................5- 1

5.2 User Error Code .........................................................................................................................................5- 1

5.2.1 Punch scrap full .......................................................................................................................................................5- 1

5.2.2 Punch scrap overflow ..............................................................................................................................................5- 1

5.3 Service Error Code .....................................................................................................................................5- 1

5.3.1 E503 ........................................................................................................................................................................5- 1

5.3.2 E505 ........................................................................................................................................................................5- 1

5.3.3 E590 ........................................................................................................................................................................5- 1

5.3.4 E591 ........................................................................................................................................................................5- 1

5.3.5 E592 ........................................................................................................................................................................5- 2

5.3.6 E593 ........................................................................................................................................................................5- 2

Page 10

Contents

Page 11

Chapter 1 Specifications

Page 12

Page 13

Contents

Contents

1.1 Product Specifications....................................................................................................................................................1-1

1.1.1 Specifications ............................................................................................................................................................................... 1-1

1.2 Names of Parts ...............................................................................................................................................................1-2

1.2.1 External View .............................................................................................................................................................................. 1-2

1.2.2 Cross Section ............................................................................................................................................................................... 1-3

Page 14

Page 15

1.1 Product Specifications

Chapter 1

1.1.1 Specifications

Å@

Hole position

T-1-1

Item Specifications Remarks

Punching method Reciprocating punching (Sequential punching)

Paper size 2 holes (Puncher Unit-L1):

A3, A4, A4R, B4, B5, B5R

2 or 3 holes (Puncher Unit-M1):

2 holes/LGL, LTRR

3 holes/279mm x 432mm (11 x 17), LTR

4 holes (FRA)(Puncher Unit-N1):

A3, A4

4 holes (SWD)(Puncher Unit-P1):

A3, A4

Paper weight 64g/m2 to 256g/m2 TransparenCies not

Punched hole

diameter

Punched scrap

capacity

Dimensions 107 x 615 x 378mm (W x D x H)

Weight Approx. 7.2 kg

Power supply From finisher unit (24 VDC / 5 VDC)

2 holes : 6.5mm

2 or 3 holes : 8mm

4 holes : 6.5mm

2 holes: 10,000 sheets or more 80 g/m2 paper

2 or 3 holes: 3,000 sheets or more

4 holes: 5,000 sheets or more

allowed

0003-4694

1-1

Page 16

Chapter 1

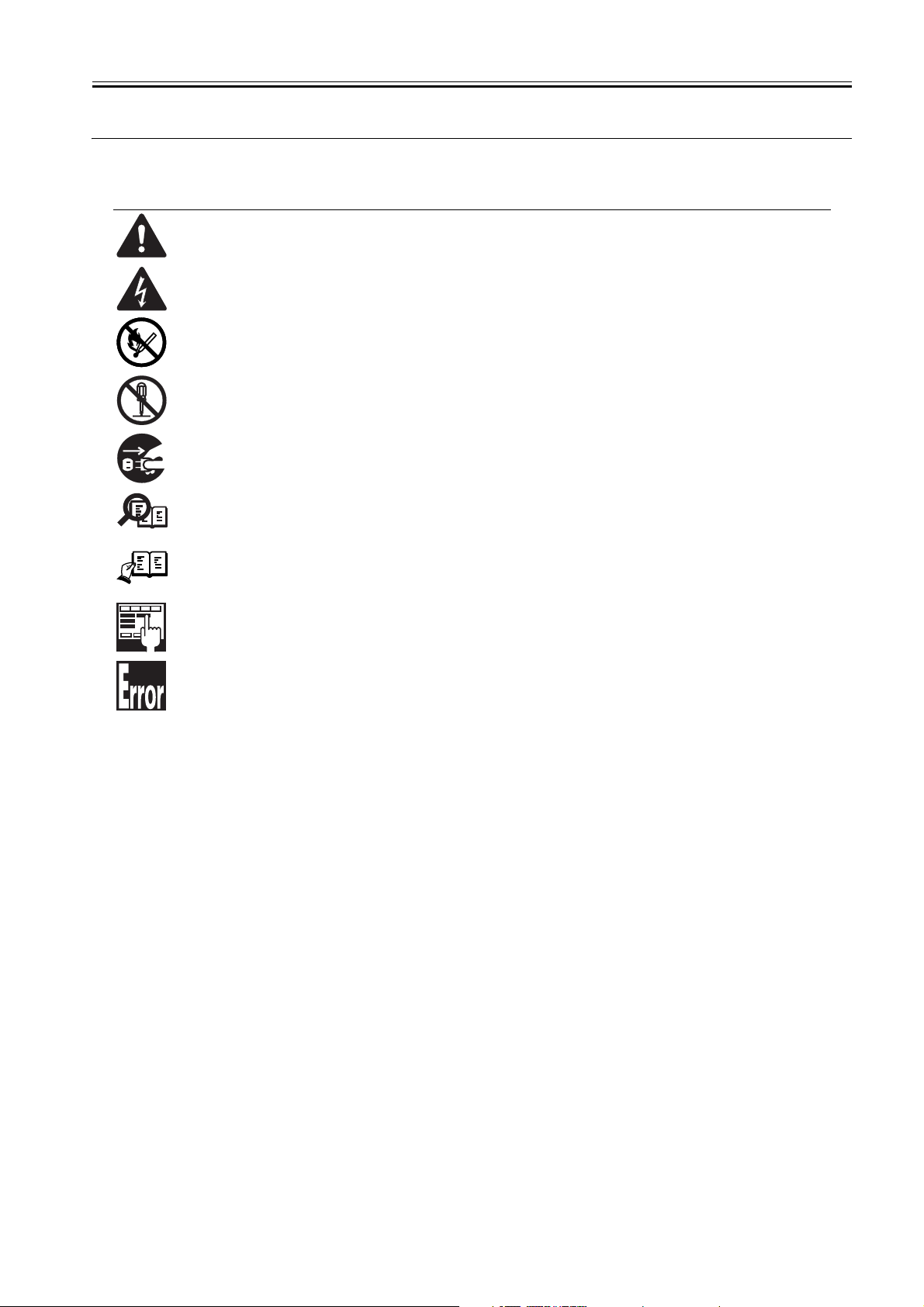

[1] Puncher unit-L1 (2-Hole)

40±3 mm

80±1 mm / 3.15±0.04 in

[2] Puncher unit-M1 (2-/3-Hole)

35±3 mm

70±1 mm / 2.76±0.04 in

108±3 mm

108±1 mm /

4.25±0.04 in

108±1 mm /

4.25±0.04 in

12±3 mm /

0.47±0.12 in

12±3 mm /

0.47±0.12 in

12±3 mm /

0.47±0.12 in

1.2 Names of Parts

1.2.1 External View

[3] Puncher unit-N1 (4-Hole (FRA))

40±3 mm

80±1 mm /

80±1 mm /

3.15±0.04 in

80±1 mm /

3.15±0.04 in

3.15±0.04 in

[4] Puncher unit-P1 (4-Hole (SWD))

35±3 mm

21±1 mm /

70±1 mm /

2.76±0.04 in

21±1 mm /

0.83±0.04 in

F-1-1

0.83±0.04 in

12±3 mm /

0.47±0.12 in

12±3 mm /

0.47±0.12 in

0003-4695

1-2

F-1-2

T-1-2

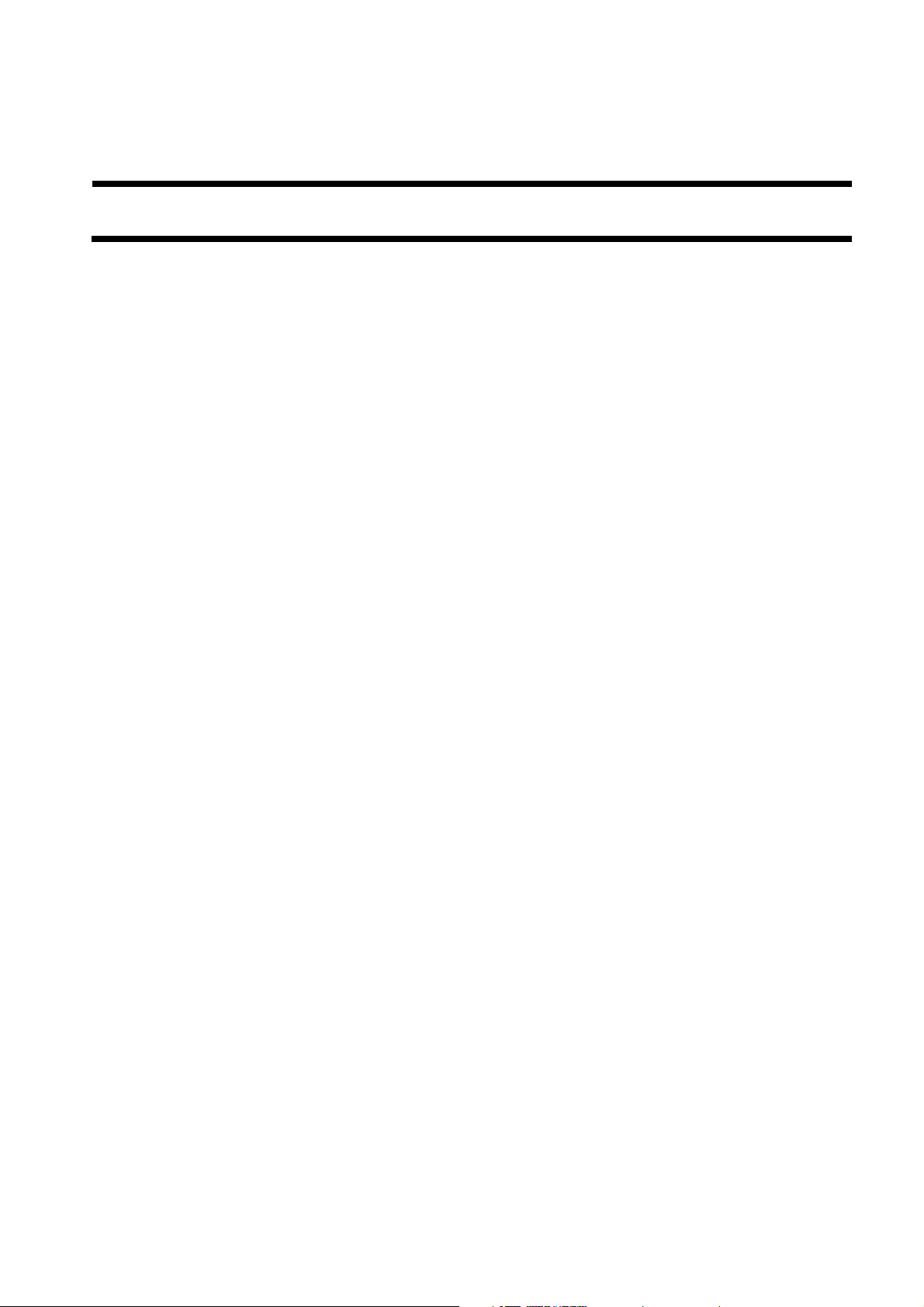

[1] Upper cover

[2] Upper cover 2

Page 17

[3] Front door

[4] Right guide assembly

[5] Rear cover

Chapter 1

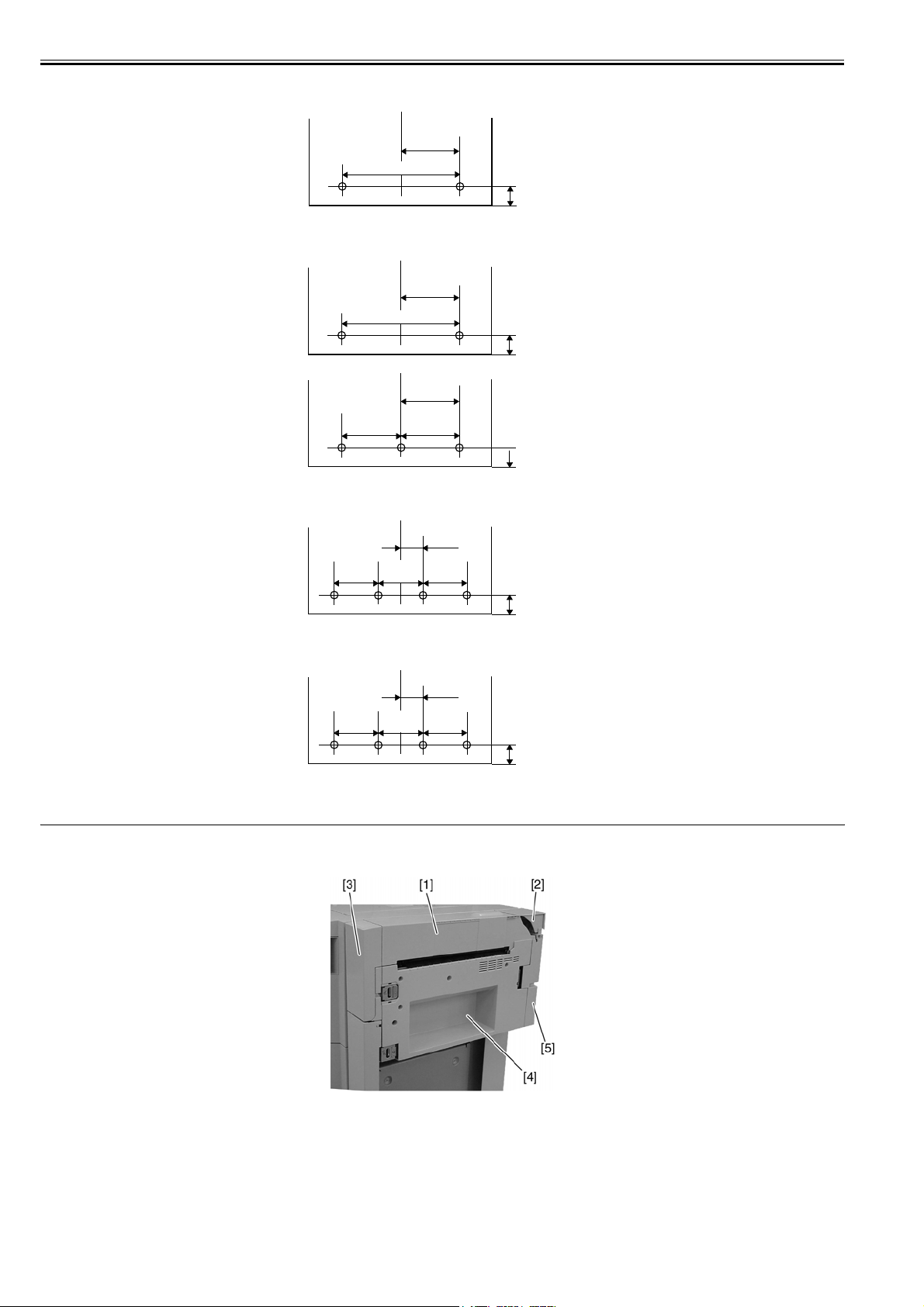

1.2.2 Cross Section

0003-4696

[1]

[2]

[3]

[4]

F-1-3

T-1-3

[1] Cam [3] Punch feed roller

[2] Hole puncher (Punch blade) [4] Punch waste case

1-3

Page 18

Page 19

Chapter 2 Functions

Page 20

Page 21

Contents

Contents

2.1 Basic Construction .........................................................................................................................................................2-1

2.1.1 Functional Construction ............................................................................................................................................................... 2-1

2.2 Feed Drive System .........................................................................................................................................................2-1

2.2.1 Overview...................................................................................................................................................................................... 2-1

2.2.2 Constraction of the Control System ............................................................................................................................................. 2-1

2.2.3 Punch Operation........................................................................................................................................................................... 2-2

2.2.4 Horizontal Registration Operation ............................................................................................................................................... 2-4

2.3 Detecting Jams ...............................................................................................................................................................2-6

2.3.1 Detecting Jams ............................................................................................................................................................................. 2-6

2.4 Power Supply .................................................................................................................................................................2-6

2.4.1 Power Supply Route ................................................................................................................................................................... 2-6

2.4.2 Protection Function ...................................................................................................................................................................... 2-6

Page 22

Page 23

2.1 Basic Construction

Chapter 2

2.1.1 Functional Construction

The puncher unit is optionally installed in the delivery path between the host machine and the finisher.

When the paper delivered from the host machine reaches the puncher unit, it is fed by the punch feed roller. Then when the trailing edge of the paper is detected,

the paper is tempo-rarily stopped and the punch axis rotates to punch holes in the trailing edge of the paper. These operations are controlled by the finisher controller

0003-8735

PCB and the punch controller PCB drives each puncher component.

Punch

drive

Feed

system

drive

system

Horizontal

registration

drive

system

Finisher unit

control system

F-2-1

Punch

controller

PCB

2.2 Feed Drive System

2.2.1 Overview

The puncher unit is located on the feed path between the host machine and the finisher, and successively punches holes when the paper stops temporarily.

The paper delivered from the host machine is fed by the punch feed roller. The punch feed roller is driven by the punch feed motor. When the trailing edge of the

paper reaches the puncher unit, the inlet roller of the finisher unit temporarily stops the paper and holes are punched on the trailing edge of the paper.

The following shows the names and functions of the motors and sensors used in punching operation:

Motor Function

Punch motor (M61) Drives the punch unit.

Horizontal registration motor (M62) Drives the punch slide unit.

Punch feed motor(M63) Drives the punch feed roller.

Sensor Function

Horizontal registration home position sensor

(PI61)

Punch motor clock sensor (PI62) Detects the punch motor clock.

Punch home position sensor (PI63) Detects the punch shaft home position.

Horizontal registration sensor (LED1 to

LED4,PTR1 to PTR4)

Trailing edge sensor (LED5,PTR5) Detects the trailing edge of paper.

Scrap full detector sensor (LED6,PTR6) Detects the state of the punch waste case (full).

T-2-1

T-2-2

Detects the punch slide unit home position.

Detects the position of the rear edge of paper.

2.2.2 Constraction of the Control System

The puncher unit consists of a die and hole puncher (punch blade).

The hole puncher is driven by the punch motor (M61). The hole puncher is attached to the

eccentric cam of the punch shaft, and rotary action of the punch shaft is converted to reciprocal motion to perform punching.

Punch motor (M61) is a DC motor. The home position of the punch shaft is detected by punch home position sensor (PI63). To stop the DC punch motor accurately

at its home po-sition, the punch motor clock sensor (PI62) counts a predetermined number of clock pulses to stop the punch motor. A single punch operation is

performed by rotating the punch shaft 180° from its home position.

Five light sensors (photosensor PCB) are located at the upper side of the inlet paper feed path of the puncher unit and a set of five LEDs (LED PCB) are located at

the lower side. These sensors and LEDs function as five sensors. The frontmost sensor (LED5, PTR5) are the trailing edge sensor and are used for detecting the

trailing edge of the paper. The remaining sensors (LED1 to LED4, PTR1 to PTR4) are horizontal registration sensors, and are used for detecting the inner position

of the paper for determining the hole punching position.

The punch motor, puncher unit and above sensors comprise the punch slide unit. This unit moves backwards and forwards according to the size of the paper. Backward and forward movement is driven by the horizontal registration motor (M62). The home position of the punch slide unit is detected by the horizontal registration

home position sensor (PI61). The horizontal registration motor (M62) is a 2-phase stepping motor.

The punch motor and horizontal registration motor is driven by the punch controller PCB

according to control signals from the finisher controller PCB.

Punch scraps caused by punching are stored in the punched scrap container. Scrap full detection is performed by a reflective sensor (LED6 and PTR6 on the scrap

full detector PCB unit).

0003-9479

0003-4698

2-1

Page 24

Chapter 2

Punch controller PCB (1/2)

PAEND

Trailing edge detection signal

Horizontal registration detection signal

(LED1 to 4, PTR1 to 4) SREG1 to 4

5

5

Punch motor clock (PI62)

Punch motor (M61) drive signal

detection signal PUNCHCLK

PTR1

2

3

4

LED1

2

3

4

PUNCHHP

Punch home position (PI63)

detection signal

SREGHP

(LED6,PTR6) DFULL

Scrap full detection signal

Horizontal registration home position (PI61) detection signal

Punch feed motor (M63) drive signal

Horizontal registration motor (M62) drive signal

Punch controller PCB (2/2)

F-2-2

2.2.3 Punch Operation

The hole puncher is driven by the punch motor (M61), and its position is monitored by the punch home position sensor (PI63).

The hole puncher makes a single round-trip movement (punching) as the punch shaft rotates 180°Å@from home position.

In the case of a 2-or-3 hole type, the half sector of the punch shaft is used when punching 2 holes while the half sector on the opposite side is used when punching

0003-4699

3 holes as instructed by the host machine.

<2-/4-hole Type>

At the home position, the punch home position sensor is ON. Punching of the first sheet ends when the punch shaft has rotated in the forward direction 180°, and

the state of the punch home position sensor has changed from OFF to ON. Punching of the second sheet ends when the punch shaft has rotated in the reverse direction

180° , and the state of the punch home position sensor has changed from OFF to ON.

The following illustrates punching when two sheets are punched.

1) A hole is punched in the trailing edge of the first sheet.

2-2

Page 25

Punch home

position sensor

(PI63)

Chapter 2

Sensor flag

Punch shaft

Eccentric

cam

Die

Die

[punch shaft stopped/

home position]

Hole

puncher

Sheet

Punched scrap

[punch shaft rotated 90˚

in the forward direction /

hole punched]

F-2-3

[punch shaft rotated 180˚

in the forward direction /

punch operation completed]

2) A hole is punched in the trailing edge of the second sheet.

[punch shaft stopped/

home position]

<2-/3-hole Dual Use Type>

At the home position, the punch home position sensor is ON. To punch two holes, punching of the first sheet ends when the punch shaft half peripheral area has

rotated in the forward direction 180°, and the state of the punch home position sensor has changed from OFF to ON. At this time, the 3-hole puncher is moved

reciprocally in the escape direction (hole puncher rise direction) on the remaining half peripheral area on the punch shaft. Punching of the second sheet ends when

the punch shaft half peripheral area has rotated in the reverse direction 180°, and the state of the punch home position sensor has changed from OFF to ON. Also

at this time, the 3-hole puncher is moved reciprocally in the escape direction (hole puncher rise direction) on the remaining half peripheral area on the punch shaft.

To punch three holes, the 2-hole puncher is moved reciprocally in the escape direction (hole puncher rise direction).

The following illustrates punching when two sheets are punched with two holes.

[punch shaft rotated 90˚

in the reverse direction/

hole punched]

F-2-4

[punch shaft rotated 180˚

in the reverse direction/

punch operation completed]

1) A hole is punched in the trailing edge of the first sheet.

Punch home

position

sensor (PI63)

Eccentric

cam

Sensor flag

Punch shaft

Hole

puncher

Die

Die

[punch shaft stopped/

home position]

Sheet

[punch shaft is rotated 90˚

in the forward direction/

hole punched]

Punched scrap

[punch shaft is rotated 180˚

in the forward direction/

punch operation completed]

F-2-5

When two holes are punched, the 3-hole puncher is fed reciprocally in the escape direction (hole puncher rise direction) as shown below.

2-3

Page 26

Chapter 2

[punch shaft stopped/

home position]

[punch shaft is rotated 90˚

in the forward direction/

hole puncher rises to

topmost position]

F-2-6

[punch shaft is rotated 180˚

in the forward direction/

hole puncher returns to

original position]

2) A hole is punched in the trailing edge of the second sheet.

[punch shaft stopped/

home position]

[punch shaft is rotated 90˚

in the reverse direction/

hole punched]

F-2-7

[punch shaft is rotated 180˚

in the reverse direction/

punch operation completed]

When two holes are punched, the 3-hole puncher is fed reciprocally in the escape direction (hole puncher rise direction) as shown below.

[punch shaft stopped/

home position]

2.2.4 Horizontal Registration Operation

Horizontal registration drive of the punch slide unit is performed by the horizontal registration motor (M62). The home position of the punch slide unit is detected

by the horizontal registration home position sensor (PI61). The punch slide unit detects the trailing edge of the paper by the trailing edge sensor (LED5, PTR5) and

horizontal registration sensors (LED1 to 4, SREG1 to 4) and is moved to the trailing edge position matched to the paper size.

[punch shaft is rotated 90˚

in the reverse direction/

hole puncher rises to

topmost position]

F-2-8

[punch shaft is rotated 180˚

in the reverse direction/

hole puncher returns to

original position]

0003-4700

The following shows horizontal registration operation.

1) When the leading edge of the paper from the host machine is detected by the trailing edge sensor (LED5, PTR5) on the puncher unit, the horizontal registration

motor (M62) starts to move the punch slide unit towards the front.

2-4

Page 27

Chapter 2

Punch slide unit

Horizontal registration motor (M62)

Trailing edge detection sensor

(LED5,PTR5)

Sheet delivery direction

Sheet

F-2-9

2) After the horizontal registration sensors (LED1 to 4, PTR1 to 4) detect the edge of the paper at its inner side in keeping with the paper size signals arriving from

the host ma-chine, the horizontal registration motor (M62) drives the punch slide unit to a predetermined position further towards the front, and stops the unit at

this position.

Horizontal registration sensor 1(LED1,PTR1)

: detects the edge of A3, A4, LTR, and 279 mm x 432 mm (11'' x 17'') papers

Horizontal registration sensor 2 (LED2,PTR2)

: detects the edge of B4, B5, LTR-R, and LGL papers

Horizontal registration sensor 3 (LED3,PTR3)

: detects the edge of A4R paper

Horizontal registration sensor 4 (LED4,PTR4)

: detects the edge of B5R paper

F-2-10

3) When the trailing edge sensor (LED5, PTR5) detects the trailing edge of the paper, drive of the punch feed motor (M63) is stopped to stop paper feed. Next, the

punch motor (M161) is driven to punch holes in the paper.

Punch

F-2-11

4) When punching ends, drive of the punch feed motor (M63) is started, the horizontal registration motor (M62) is operated in the reverse direction, and the punch

slide unit is returned to its home position where it comes to a stop.

5) Even if paper to be punched continues to arrive, the punch slide unit returns to its home position for each arriving sheet, and steps 1 to 4 are repeated.

2-5

Page 28

Chapter 2

2.3 Detecting Jams

Trailing edge detection

sensor (LED5, PTR5)

Horizontal registration sensor

(LED1 to 4, PTR1 to 4)

Punch home position

sensor (PI63)

Horizontal registration home

position sensor (PI61)

Horizontal registration

motor (M62)

Punch motor (M61)

First feed motor (M63)

: Motor CW : Motor CCW

F-2-12

2.3.1 Detecting Jams

The finisher unit identifies any of the following conditions as a jam, and sends the jam signal to the host machine. In response, the host machine may stop copying

0003-4704

operation and indicate the presence of a jam on its control panel.

T-2-3

Jam type Sensor Jam Condition Code

Feeding

delay

Feeding

stationary

Punch PI63 When the punch home position sensor (PI63 ) does not turn

LED5,PTR5When the rear end sensor (LED, PTR5) does not detect

LED5,PTR5When paper does not exit the rear end sensor (LED,

paper after a prescribed time (distance) has elapsed since

receiving a delivery signal from the host machine.

PTR5) after feeding for a prescribed time (distance) after

the rear end sensor (LED, PTR5) has detected paper.

on after a prescribe time has elapsed since it is turned off.

Power-on LED5,PTR5When paper is detected by the rear end sensor (LED,

iR C3100/

3170/2570

1002 1012

1102 1122

1644 1644

1645 1645

iR4570/

3570, 2570/

2270

PTR5) during power on.

2.4 Power Supply

2.4.1 Power Supply Route

24V power and 5V power are supplied from the finisher controller PCB when the power switch on the host machine is turned ON.

24V power is used for driving motors, while 5V power is used for driving sensors and the ICs on the punch controller PCB.

24V power to the motors is not supplied when either of the two door switches on the puncher unit is open.

Upper door

switch

(MSW61)

Front door

switch

(MSW62)

0003-4702

24V

Punch controller PCB

Finisher

controller

PCB

5V

F-2-13

2.4.2 Protection Function

The 24V power supplies are equipped with a fuse designed to blow when an overcurrent flows.

2-6

24V

24V

5V

5V

5V

Motor system

Motor system

LED PCB

Sensors

Logic

0003-4703

Page 29

Chapter 3 Parts Replacement Procedure

Page 30

Page 31

Contents

Contents

3.1 External Covers..............................................................................................................................................................3-1

3.1.1 Rear Cover ................................................................................................................................................................................... 3-1

3.1.1.1 Removing the Rear Cover ...............................................................................................................................................................................3-1

3.1.2 Upper Cover................................................................................................................................................................................. 3-1

3.1.2.1 Removing the Rear Cover ...............................................................................................................................................................................3-1

3.1.2.2 Removing the Upper Cover ............................................................................................................................................................................3-1

3.1.3 Right Guide Unit.......................................................................................................................................................................... 3-1

3.1.3.1 Removing the Right Guide Unit .....................................................................................................................................................................3-1

3.2 Drive System..................................................................................................................................................................3-1

3.2.1 Punch Motor................................................................................................................................................................................. 3-1

3.2.1.1 Removing the Rear Cover ...............................................................................................................................................................................3-1

3.2.1.2 Removing the Upper Cover ............................................................................................................................................................................3-2

3.2.1.3 Removing the Punch Motor ............................................................................................................................................................................3-2

3.2.2 Horizontal Registration Motor ..................................................................................................................................................... 3-2

3.2.2.1 Removing the Rear Cover ...............................................................................................................................................................................3-2

3.2.2.2 Removing the Right Guide Unit .....................................................................................................................................................................3-2

3.2.2.3 Removing the Horizontal Registration Motor.................................................................................................................................................3-2

3.2.3 Punch Unit ................................................................................................................................................................................... 3-2

3.2.3.1 Notification when dismounting the Punch Unit ..............................................................................................................................................3-2

3.2.3.2 Removing the Rear Cover ...............................................................................................................................................................................3-2

3.2.3.3 Removing the Right Guide Unit .....................................................................................................................................................................3-2

3.2.3.4 Removing the Upper Cover ............................................................................................................................................................................3-3

3.2.3.5 Removing the Punch Unit ...............................................................................................................................................................................3-3

3.3 Electrical System............................................................................................................................................................3-4

3.3.1 Punch Unit Harness...................................................................................................................................................................... 3-4

3.3.1.1 Notification when dismounting the Punch Unit Harness ...............................................................................................................................3-4

3.3.1.2 Removing the Rear Cover ...............................................................................................................................................................................3-4

3.3.1.3 Removing the Right Guide Unit .....................................................................................................................................................................3-4

3.3.1.4 Removing the Upper Cover ............................................................................................................................................................................3-5

3.3.1.5 Removing the Punch Unit Harness .................................................................................................................................................................3-5

3.3.1.6 Installing the Punch Unit Harness...................................................................................................................................................................3-6

3.3.2 LED PCB ..................................................................................................................................................................................... 3-6

3.3.2.1 Removing the Rear Cover ...............................................................................................................................................................................3-6

3.3.2.2 Removing the Right Guide Unit .....................................................................................................................................................................3-6

3.3.2.3 Removing the Upper Cover ............................................................................................................................................................................3-6

3.3.2.4 Removing the Punch Unit ...............................................................................................................................................................................3-7

3.3.2.5 Removing the LED PCB .................................................................................................................................................................................3-8

3.3.3 Photosensor PCB ......................................................................................................................................................................... 3-8

3.3.3.1 Removing the Rear Cover ...............................................................................................................................................................................3-8

3.3.3.2 Removing the Upper Cover ............................................................................................................................................................................3-8

3.3.3.3 Removing the Photosensor PCB .....................................................................................................................................................................3-8

3.3.4 Scrap Full Detector PCB.............................................................................................................................................................. 3-8

3.3.4.1 Removing the Right Guide Unit .....................................................................................................................................................................3-8

3.3.4.2 Removing the Scrap Full Detector PCB .........................................................................................................................................................3-9

3.3.5 Punch Controller PCB.................................................................................................................................................................. 3-9

3.3.5.1 Removing the Rear Cover ...............................................................................................................................................................................3-9

3.3.5.2 Removing the Punch Controller PCB .............................................................................................................................................................3-9

Page 32

Page 33

3.1 External Covers

3.1.1 Rear Cover

Chapter 3

3.1.1.1 Removing the Rear Cover

1) Remove three screws [1] and remove the rear cover [2].

F-3-1

3.1.2 Upper Cover

3.1.2.1 Removing the Rear Cover

1) Remove three screws [1] and remove the rear cover [2].

0003-6789

0003-6790

F-3-3

3.1.3 Right Guide Unit

3.1.3.1 Removing the Right Guide Unit

1) Remove four screws [1], and remove the right guide assembly [2].

0003-6792

F-3-2

3.1.2.2 Removing the Upper Cover

1) Open the front door [1], remove three screws [2], and remove the upper

cover [3].

0003-6791

F-3-4

3.2 Drive System

3.2.1 Punch Motor

3.2.1.1 Removing the Rear Cover

1) Remove three screws [1] and remove the rear cover [2].

F-3-5

0003-6793

3-1

Page 34

Chapter 3

3.2.1.2 Removing the Upper Cover

1) Open the front door [1], remove three screws [2], and remove the upper

0003-6794

cover [3].

F-3-6

3.2.1.3 Removing the Punch Motor

1) Disconnect the connector [1].

2) Remove two screws [2] and remove the punch motor [3].

0003-6795

F-3-9

3.2.2.3 Removing the Horizontal Registration Motor

1) Disconnect the connector [1].

2) Remove two screws [2] and slide the horizontal registration motor [3] in

the direction of the arrow to remove.

0003-6798

F-3-7

3.2.2 Horizontal Registration Motor

3.2.2.1 Removing the Rear Cover

1) Remove three screws [1] and remove the rear cover [2].

0003-6796

F-3-10

3.2.3 Punch Unit

3.2.3.1 Notification when dismounting the Punch Unit

When removing the punch unit, the punch unit section sometimes opens.

If necessary, perform work with the punch unit section in an open state.

3.2.3.2 Removing the Rear Cover

1) Remove three screws [1] and remove the rear cover [2].

0003-8233

0003-6800

F-3-8

3.2.2.2 Removing the Right Guide Unit

1) Remove four screws [1], and remove the right guide assembly [2].

3-2

0003-6797

F-3-11

3.2.3.3 Removing the Right Guide Unit

1) Remove four screws [1], and remove the right guide assembly [2].

0003-6799

Page 35

F-3-12

Chapter 3

section [2] to the front side.

3.2.3.4 Removing the Upper Cover

1) Open the front door [1], remove three screws [2], and remove the upper

0003-6801

cover [3].

F-3-13

3.2.3.5 Removing the Punch Unit

1) Remove E-ring [1], washer [2], and puncher spring [3].

0003-6802

F-3-15

3) Remove the three screws [1], and remove the sensor mount (upper) [2].

Then, remove the connector [3] on the photosensor PCB.

F-3-16

4) Disconnect the connector [1] and remove the screw [2], and remove the

horizontal registration home position sensor [3].

[3]

F-3-14

2) Turn the gear [1] in the direction of the arrow, and move the punch unit

[1]

[2]

F-3-17

5) Turn the gear [1] in the direction of the arrow, and move the punch unit

section [2] to the far side.

3-3

Page 36

Chapter 3

F-3-18

6) Remove the tie wrap with lock [1] while holding its claw between your

fingers. (The tie wrap must be removed without being cut.)

7) Disconnect the three connectors [2] and remove the screw [3], and remove

the harness guide [4].

[2]

The slide shaft support [1] is not attached to punch unit section that are

currently set as service parts. When replacing the punch unit section, be

sure to attach the slide shaft support that was in use beforehand. If you

forget to attach the slide shaft support, the machine may malfunction.

[1]

[3]

[2]

F-3-22

3.3 Electrical System

3.3.1 Punch Unit Harness

3.3.1.1 Notification when dismounting the Punch Unit Harness

When removing the punch unit, the punch unit section sometimes opens.

If necessary, perform work with the punch unit section in an open state.

0003-8728

[2]

[3]

[1]

[4]

F-3-19

8) Lift up the front side of the punch unit section [1] first, then move in the

direction of the arrow to remove the punch unit section [1].

F-3-20

9) Disconnect the connector [1] on LED PCB.

3.3.1.2 Removing the Rear Cover

1) Remove three screws [1] and remove the rear cover [2].

F-3-23

3.3.1.3 Removing the Right Guide Unit

1) Remove four screws [1], and remove the right guide assembly [2].

0003-6804

0003-6805

[1]

F-3-21

10) Remove the slide shaft support [1], the sensor mount (lower) [2] and the

puncher knob [3] from the punch unit section.

3-4

F-3-24

Page 37

Chapter 3

3.3.1.4 Removing the Upper Cover

1) Open the front door [1], remove three screws [2], and remove the upper

0003-6803

cover [3].

F-3-25

3.3.1.5 Removing the Punch Unit Harness

1) Disconnect the two connectors [2] on the punch controller PCB [1] and

remove the harness from the edge saddle [3].

0003-6807

F-3-28

6) Remove the three screws [1] and sensor mount (upper) [2].

7) Disconnect the connector [3] on the photosensor PCB and the connector

[4] on the LED PCB and remove the harness from the edge saddle [5].

F-3-26

2) Remove the two tie wraps with lock [1] while holding its claw between

your fingers. (The tie wraps must be removed without being cut.)

3) Disconnect the three connectors [2].

4) Free the harness [4] from the three harness stops [3].

[2]

[2]

[3]

[1]

[3]

[1]

[4]

[3]

F-3-27

5) Turn the gear [1] in the direction of the arrow, and move the punch unit

section [2] to the front side.

F-3-29

8) Free the harness [2] from the four harness stops [1].

F-3-30

3-5

Page 38

Chapter 3

9) Disconnect the connector [1] of the horizontal registration motor and the

connector [2] of the horizontal registration home position sensor, and remove the punch unit harness.

F-3-31

3.3.1.6 Installing the Punch Unit Harness

0003-6806

Offset punch unit harnesses can cause malfunction. The punch unit

harnesses must be firmly installed at the positions described below.

1) Fasten the punch unit harnesses so that the two tie wraps [1] of the punch

unit harnesses are on the outside of the two respective clamps [2].

3.3.2 LED PCB

3.3.2.1 Removing the Rear Cover

1) Remove three screws [1] and remove the rear cover [2].

F-3-34

3.3.2.2 Removing the Right Guide Unit

1) Remove four screws [1], and remove the right guide assembly [2].

0003-6809

0004-0830

PI62

PI63

M61

LED PCB

Potosensor

PCB

PI61

M62

F-3-32

F-3-33

[1]

[1]

Punch Controller

PCB

F-3-35

3.3.2.3 Removing the Upper Cover

1) Open the front door [1], remove three screws [2], and remove the upper

cover [3].

F-3-36

0003-6810

3-6

Page 39

Chapter 3

3.3.2.4 Removing the Punch Unit

1) Remove E-ring [1], washer [2], and puncher spring [3].

F-3-37

2) Turn the gear [1] in the direction of the arrow, and move the punch unit

section [2] to the front side.

0004-0831

horizontal registration home position sensor [3].

[3]

[1]

[2]

F-3-40

5) Turn the gear [1] in the direction of the arrow, and move the punch unit

section [2] to the far side.

F-3-38

3) Remove the three screws [1], and remove the sensor mount (upper) [2].

Then, remove the connector [3] on the photosensor PCB.

F-3-41

6) Remove the tie wrap with lock [1] while holding its claw between your

fingers. (The tie wrap must be removed without being cut.)

7) Disconnect the three connectors [2] and remove the screw [3], and remove

the harness guide [4].

[2]

[2]

[3]

[1]

[4]

F-3-42

8) Lift up the front side of the punch unit section [1] first, then move in the

direction of the arrow to remove the punch unit section [1].

F-3-39

4) Disconnect the connector [1] and remove the screw [2], and remove the

3-7

Page 40

Chapter 3

F-3-43

9) Disconnect the connector [1] on LED PCB.

F-3-47

[1]

F-3-44

10) Remove the slide shaft support [1], the sensor mount (lower) [2] and the

puncher knob [3] from the punch unit section.

The slide shaft support [1] is not attached to punch unit section that are

currently set as service parts. When replacing the punch unit section, be

sure to attach the slide shaft support that was in use beforehand. If you

forget to attach the slide shaft support, the machine may malfunction.

[1]

[3]

[2]

F-3-45

3.3.2.5 Removing the LED PCB

1) Remove the screw [1], and remove the LED PCB [2].

0004-0827

3.3.3.2 Removing the Upper Cover

1) Open the front door [1], remove three screws [2], and remove the upper

0003-6812

cover [3].

F-3-48

3.3.3.3 Removing the Photosensor PCB

1) Remove the screw [1].

0004-0829

2) Disconnect the connector [2] and the remove the Photosensor PCB [3].

F-3-46

3.3.3 Photosensor PCB

3.3.3.1 Removing the Rear Cover

1) Remove three screws [1] and remove the rear cover [2].

3-8

0003-6813

F-3-49

3.3.4 Scrap Full Detector PCB

3.3.4.1 Removing the Right Guide Unit

1) Remove four screws [1], and remove the right guide assembly [2].

0003-6817

Page 41

F-3-50

Chapter 3

3.3.4.2 Removing the Scrap Full Detector PCB

1) Remove the screw [1], disconnect the connector [2], and remove the scrap

0003-6818

full detector PCB unit [3].

F-3-51

3.3.5 Punch Controller PCB

3.3.5.1 Removing the Rear Cover

1) Remove three screws [1] and remove the rear cover [2].

0003-6819

F-3-53

F-3-52

3.3.5.2 Removing the Punch Controller PCB

1) Remove the two screws [1], disconnect seven connectors [2], and remove

the punch controller PCB [3].

0003-6820

3-9

Page 42

Page 43

Chapter 4 Maintenance

Page 44

Page 45

Contents

Contents

4.1 User Maintenance ..........................................................................................................................................................4-1

4.1.1 User Maintenance ........................................................................................................................................................................ 4-1

4.2 Maintenance and Inspection...........................................................................................................................................4-1

4.2.1 Periodically Replaced Parts ......................................................................................................................................................... 4-1

4.2.1.1 Periodically Replaced Parts.............................................................................................................................................................................4-1

4.2.2 Durables ....................................................................................................................................................................................... 4-1

4.2.2.1 Durables ..........................................................................................................................................................................................................4-1

4.2.3 Periodical Servicing ..................................................................................................................................................................... 4-1

4.2.3.1 Periodical Servicing .......................................................................................................................................................................................4-1

4.3 Adjustment.....................................................................................................................................................................4-1

4.3.1 Adjustment at Time of Parts Replacement .................................................................................................................................. 4-1

4.3.1.1 Adjusting the Punch Hole Position (feed direction) .......................................................................................................................................4-1

4.3.1.2 Sensor Output Adjustment ..............................................................................................................................................................................4-1

4.3.1.3 Registering the Number of Punch Holes.........................................................................................................................................................4-1

4.4 Troubleshooting .............................................................................................................................................................4-1

4.4.1 Error Code.................................................................................................................................................................................... 4-1

4.4.1.1 E503; Puncher unit communication error ....................................................................................................................................................... 4-1

4.4.1.2 E505; Backup RAM error ............................................................................................................................................................................... 4-1

4.4.1.3 E590; Punch motor error.................................................................................................................................................................................4-1

4.4.1.4 E591; Scrap full detector sensor error.............................................................................................................................................................4-2

4.4.1.5 E592; Trailing edge/Horizontal registration sensor error ...............................................................................................................................4-2

4.4.1.6 E593; Horizontal registration motor error....................................................................................................................................................... 4-2

4.5 Outline of Electrical Components..................................................................................................................................4-2

4.5.1 Sensors ......................................................................................................................................................................................... 4-2

4.5.2 Microswitches .............................................................................................................................................................................. 4-3

4.5.3 Motors .......................................................................................................................................................................................... 4-4

4.5.4 PCBs ............................................................................................................................................................................................ 4-5

4.6 Variable Resistors (VR), Light-Emitting Diodes (LED), and Check Pins by PCB.......................................................4-5

4.6.1 Overview...................................................................................................................................................................................... 4-5

4.6.2 Punch Controller PCB.................................................................................................................................................................. 4-6

4.7 Upgrading.......................................................................................................................................................................4-6

4.7.1 Upgrading .................................................................................................................................................................................... 4-6

4.8 Service Tools................................................................................................................................................................4-11

4.8.1 Solvents and Oils ....................................................................................................................................................................... 4-11

Page 46

Page 47

4.1 User Maintenance

Chapter 4

4.1.1 User Maintenance

T-4-1

No. Item Timing

1 Punch waste removal When prompted (indicator on host machine control

0003-4705

4.2 Maintenance and Inspection

4.2.1 Periodically Replaced Parts

4.2.1.1 Periodically Replaced Parts

The Puncher unit does not have parts that must be replaced on a periodical

basis.

Item Interval Description Remark

Transmittance sensor 25 million sheets Cleaning Wipe with dry cloth

0003-4706

4.3 Adjustment

4.3.1 Adjustment at Time of Parts Replacement

4.3.1.1 Adjusting the Punch Hole Position (feed direction)

This adjustment is possible only with the host machine service mode.

4.3.1.2 Sensor Output Adjustment

Perform this adjustment when replacing the punch controller PCB, transmittance sensor (photosensor PCB/LED PCB), or deflection sensor (scrap full

detector PCB unit).

1) Check that the power of the host machine is off and then remove the rear

cover of the puncher.

2) Set SW601 on the punch controller PCB as shown below.

ON

1234

F-4-1

3) Turn on the power of the host machine.

4) Press SW602 on the punch controller PCB. Sensor output is adjusted au-

tomatically when the switch is pressed.

Adjustment is complete if LED601 and 602 on the punch controller PCB

flashes alternately.

5) Press SW602 or 603 on the punch controller PCB to end the adjustment

mode and set all bits of SW601 to OFF.

6) Turn off the power of the host machine.

4.3.1.3 Registering the Number of Punch Holes

This operation registers which puncher unit is attached to the IC on the punch

driver PCB so that the puncher unit can be identified by the finisher. For this

reason, this operation must be performed when the punch driver PCB has

been replaced.

1) Check that the power of the host machine is off and then remove the rear

cover of the puncher.

2) Set SW601 on the punch controller PCB as shown below.

ON

1234

F-4-2

3) Turn on the power of the host machine.

4) Press SW602 on the punch controller PCB to select the number of punch

holes.

The items in the following table are displayed repeatedly from top to bottom

each time SW602 is pressed.

Number of

punch holes

2 hole(Puncher

Unit-L1)

T-4-3

LED601/602

Flash 1 times per cycle

0003-4709

0003-4710

0003-4711

panel)

4.2.2 Durables

4.2.2.1 Durables

There are no durables that require durables.

4.2.3 Periodical Servicing

4.2.3.1 Periodical Servicing

T-4-2

Number of

punch holes

2/3

hole(Puncher

Unit-M1)

4 hole(Puncher

Unit-N1(FRA))

4 hole(Puncher

Unit-P1(SWD))

LED601/602

Flash 2 times per cycle

Flash 3 times per cycle

Flash 4 times per cycle

5) Press SW603 on the punch controller PCB. The number of punch holes is

registered to the punch controller PCB each time the switch is pressed.

Registration is complete if LED601 and 602 on the punch controller PCB

flashes alternately.

6) Press SW602 or 603 on the punch controller PCB to end the adjustment

mode and set all bits of SW601 to OFF.

7) Turn off the power of the host machine.

4.4 Troubleshooting

4.4.1 Error Code

4.4.1.1 E503; Puncher unit communication error

<Finisher controller PCB/Punch controller PCB>

1) Does it improve when the host machine power switch is turned OFF/ON?

YES : End

<Wiring>

2) Is the wiring between the finisher controller PCB and punch controller

PCB normal?

NO : Repair the wiring.

<Finisher controller PCB/Punch controller PCB>

3) Does it improve when the finisher controller PCB and punch controller

PCB are replaced?

YES : End

4.4.1.2 E505; Backup RAM error

<Punch controller PCB>

1) Does it improve when the host machine power switch is turned OFF/ON?

YES : End

No : Replace the punch controller PCB.

4.4.1.3 E590; Punch motor error

<Punch home position sensor (PI63)>

1) Check the punch home position sensor. Does the sensor operate normally?

NO : Replace the sensor.

<Punch motor clock sensor (PI62)>

2) Check the punch motor clock sensor. Does the sensor operate normally?

NO : Replace the sensor.

<Wiring>

3) Is the wiring between the punch controller PCB and sensors normal?

NO : Repair the wiring.

<Punch mechanism/Punch motor (M61)>

4) Is there any abnormality in the punch mechanism?

YES : Repair the punch mechanism.

NO : Replace the punch motor.

<Punch controller PCB/Finisher controller PCB>

5) Does it improve when the punch controller PCB is replaced?

0003-4707

0003-4708

0003-4712

0003-4713

0003-4714

4-1

Page 48

Chapter 4

YES : End

NO : Replace the finisher controller PCB.

4.4.1.4 E591; Scrap full detector sensor error

<Wiring>

1) Is the wiring between the scrap full detector PCB and the punch controller

PCB normal?

NO : Repair the wiring.

<Scrap full detector PCB>

2) Does it improve when the scrap full detector PCB is replaced?

YES : End

NO : Replace the punch controller PCB.

<Punch controller PCB/Finisher controller PCB>

3) Does it improve when the punch controller PCB is replaced?

YES : End

NO : Replace the finisher controller PCB.

0003-8758

4.4.1.5 E592; Trailing edge/Horizontal registration sensor error

<Wiring>

1) Is the wiring between the LED PCB/photosensor PCB and the punch con-

troller PCB normal?

NO : Repair the wiring.

<LED PCB/Photosensor PCB>

2) Does it improve when the LED PCB/photosensor PCB is replaced?

YES : End

NO : Replace the punch controller PCB.

<Punch controller PCB/Finisher controller PCB>

3) Does it improve when the punch controller PCB is replaced?

YES : End

NO : Replace the finisher controller PCB.

4.4.1.6 E593; Horizontal registration motor error

<Horizontal registration home position sensor (PI61)>

1) Check the horizontal registration home position sensor. Does the sensor

operate normally?

NO : Replace the sensor.

<Wiring>

2) Is the wiring between the punch controller PCB and the sensor normal?