Canon iR5870C, iR5870Ci, iR6870C, iR6870Ci finisher-r1 Service Manual

Service Manual

Finisher, Sorter, DeliveryTray

Finisher-R1

June 16 2004

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and

repair of products. This manual covers all localities where the products are sold. For this reason, there may be

information in this man ual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products.

When changes occur in applicable products or in the contents of this manual, Canon will release technical information

as the need arises. In the event of major changes in the con tents of this manual over a long or short period, Canon will

issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied,

reproduced or translated into another language, in whole or in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Introduction

Memo

REF.

Indicates an item requiring di sc onnection of the power plug from the elect ric outlet.

Indicates an item intended to provide notes assisting the understanding of the topic in question.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections expl aining the purpose of specific functions and the relationship between elec trical

and mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical dr ive; where a sign al name ac compa nies t he symb ol ,

the arrow indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the

delivery unit door, which results in supplying the mach ine with power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is "High", while '0' is used to

indicate "Low". (The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in

"DRMD*" indicates that the DRMD signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the

operations of the micropr ocessors used in the machines are not discussed: they are explaine d in terms of from

sensors to the input of the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to ch ange without notice for product improvement or oth er

purposes, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to hav e a good understanding o f the contents of thi s Service Manual and al l relevant

Service Information bulletins and be able to identify and isolate faults in the machine.

Contents

Contents

Chapter 1 Specifications

1.1 Product Specifications........................................................................................................... ............................1- 1

1.1.1 Finisher Unit.......................................................................................................................... .....................1- 1

1.2 Names of Parts...................................................................................................................................................1- 5

1.2.1 External View.............................................................................................................................................1- 5

1.2.2 Cross Section............................................................................................................................................. .1- 6

Chapter 2 Functions

2.1 Basic Operation.................................................................................................................................................2- 1

2.1.1 Basic Operation............................................................................................................................ ..............2- 1

2.1.2 Overview of the Electrical Circuitry..........................................................................................................2- 1

2.2 Feed Drive System ............................................................................................................................................2- 3

2.2.1 Overview....................................................................................................................................................2- 3

2.2.2 Constraction of the Control System ...........................................................................................................2- 4

2.2.3 Paper Delivery Path................................................................................................................................... .2- 7

2.3 Intermediate Process Tray Assembly..............................................................................................................2- 11

2.3.1 Stack Job Offset........................................................................................................................................2- 11

2.3.2 Processing Tray Paper Stacking Operation..............................................................................................2- 12

2.3.3 Offset Operation.......................................................................................................................................2- 12

2.3.4 Rear End Assist Operation.......................................................................................................................2- 14

2.3.5 Stack Delivery Operation.........................................................................................................................2- 14

2.4 Staple Operation..............................................................................................................................................2- 15

2.4.1 Stapler Unit...............................................................................................................................................2- 15

2.4.2 Shifting the Stapler Unit...........................................................................................................................2- 16

2.4.3 Stapling Operation....................................................................................................................................2- 19

2.5 Stack Tray Operation.......................................................................................................................................2- 24

2.5.1 Tray Operation ......................................................................................................................................... 2- 24

2.5.2 Shutter Operation .....................................................................................................................................2- 27

2.6 Detecting Jams ................................................................................................................................................2- 28

2.6.1 Detecting Jams (Finisher Unit).................................................................................................................2- 28

2.7 Power Supply ..................................................................................................................................................2- 30

2.7.1 Power Supply Route.................................................................................................................................2- 30

2.7.2 Protection Function .................................................................................................................................. 2- 30

Contents

Chapter 3 Installation

3.1 Making Pre-Checks ...........................................................................................................................................3- 1

3.1.1 Checking the Contents................................................................................................................................3- 1

3.1.2 Installing the Accessories...........................................................................................................................3- 3

3.1.3 Selecting the Site of Installation .................................................................................................................3- 4

3.2 Unpacking and Checking the Components........................................................................................................3- 5

3.2.1 Unpacking......................................................................................................................... ..........................3- 5

3.3 Installation Procedure......................................................................................................................................3- 10

3.3.1 Preparing the Finisher for Installation...................................................................................................... 3- 10

3.3.2 Preparing the Host Machine for Installation.............................................................................................3- 10

3.3.3 Connecting to the Host Machine..............................................................................................................3- 11

3.3.4 Checking the Height/Tilt..........................................................................................................................3- 13

3.4 Making Adjustments........................................................................................................................................3- 14

3.4.1 Adjusting the Height/Tilt..........................................................................................................................3- 14

3.4.2 Work After Making Checks/Adjustments................................................................................................3- 17

3.5 Attaching the Labels etc..................................................................................................................................3- 19

3.5.1 Attaching the Various Labels...................................................................................................................3- 19

Chapter 4 Parts Replacement Procedure

4.1 External Covers .................................................................................................................................................4- 1

4.1.1 Front Cover ........................................................................................................................................ .........4- 1

4.1.2 Rear Cover............................................................................................................................................. ......4- 1

4.1.3 Left Upper Cover ........................................................................................................................................4- 1

4.1.4 Upper Door........................................................................................................................ ..........................4- 3

4.1.5 Grate-shaped Upper Guide..........................................................................................................................4- 4

4.1.6 Grate-shaped Lower Guide ......................................................................................................... ................4- 6

4.2 Drive System ...................................................................................................................................................4- 10

4.2.1 Stapler........................................................................................................................................................4- 10

4.2.2 Swing Unit.................................................................................................................................................4- 11

4.3 Document Feeding System..............................................................................................................................4- 18

4.3.1 Process Tray Assembly.............................................................................................................................4- 18

4.3.2 Tray 1 ........................................................................................................................................................4- 23

4.3.3 Tray 2 ........................................................................................................................................................4- 25

4.3.4 Buffer Roller .............................................................................................................................................4- 29

4.3.5 Return Roller.............................................................................................................................................4- 31

4.3.6 Return Roller Unit .....................................................................................................................................4- 36

4.4 Electrical System.............................................................................................................................................4- 44

4.4.1 Finisher Controller PCB............................................................................................................................4- 44

4.4.2 Static Charge Eliminator 1........................................................................................................................4- 44

4.4.3 Static Charge Eliminator 2........................................................................................................................4- 51

Contents

Chapter 5 Maintenance

5.1 User Maintenance ................................................................................................................................... ...........5- 1

5.1.1 User Maintenance (Finisher Unit)......................................... ..................................................................... 5- 1

5.2 Maintenance and Inspection...................................................................................................... ........................5- 2

5.2.1 Periodically Replaced Parts ................................................................................................ ........................5- 2

5.2.2 Durables........................................................................................................................................... ...........5- 2

5.2.3 Periodical Servicing....................................................................................................................................5- 3

5.3 Adjustment ................................................................................................................................... .....................5- 4

5.3.1 Adjustment at Time of Parts Replacement.................................................................................................5- 4

5.4 Troubleshooting...................................................................................................................................... ...........5- 6

5.4.1 Error Code...................................................................................................................................................5- 6

5.5 Outline of Electrical Components...................................................................................................................5- 11

5.5.1 Sensors (Finisher Unit)............................................ .................................................................................5- 11

5.5.2 Microswitches (Finisher Unit)..................................................................................................................5- 14

5.5.3 Solenoids (Finisher Unit) .........................................................................................................................5- 16

5.5.4 Motors (Finisher Unit)................................... ...........................................................................................5- 17

5.5.5 Clutches (Finisher Unit)...........................................................................................................................5- 19

5.5.6 PCBs (Finisher Unit)................................................................................................................................ 5- 20

5.6 Variable Resistors (VR), Light-Emitting Diodes (LED), and Check Pins by PCB........................................5- 21

5.6.1 Overview..................................................................................................................................................5- 21

5.6.2 Finisher Controller PCB...........................................................................................................................5- 21

5.7 Upgrading........................................................................................................................................................5- 22

5.7.1 Upgrading (Finisher Unit)........................................................................................................................5- 22

5.8 Service Tools...................................................................................................................................................5- 30

5.8.1 Solvents and Oils...................................................................................................................................... 5- 30

Chapter 6 Error Code

6.1 Overview.................................................................................................................................................... .......6- 1

6.1.1 Overview....................................................................................................................................................6- 1

6.2 User Error Code................................................................................................................................................. 6- 2

6.2.1 Staple is absent............................................................................................................................. ..............6- 2

6.2.2 Stapler safety protection function activated...............................................................................................6- 2

6.2.3 Stack tray overstacking ..............................................................................................................................6- 3

6.2.4 Stapler staple jam .......................................................................................................................................6- 3

6.3 Service Error Code............................................................................................................................................6- 4

6.3.1 E500.............................................................................................................................................. ..............6- 4

6.3.2 E505.............................................................................................................................................. ..............6- 4

6.3.3 E514.............................................................................................................................................. ..............6- 4

6.3.4 E519.............................................................................................................................................. ..............6- 5

6.3.5 E530.............................................................................................................................................. ..............6- 5

6.3.6 E531.............................................................................................................................................. ..............6- 6

6.3.7 E532.............................................................................................................................................. ..............6- 6

6.3.8 E535.............................................................................................................................................. ..............6- 6

6.3.9 E537.............................................................................................................................................. ..............6- 7

6.3.10 E540..........................................................................................................................................................6- 7

6.3.11 E542..........................................................................................................................................................6- 8

6.3.12 E584..........................................................................................................................................................6- 8

6.3.13 Temporary Functional Limit......................................................................................................... ...........6- 9

Chapter 1 Specifications

Contents

Contents

1.1 Product Specifications........................................................................................................................................1-1

1.1.1 Finisher Unit................................................................................................................................................1-1

1.2 Names of Parts....................................................................................................................................................1-5

1.2.1 External View..............................................................................................................................................1-5

1.2.2 Cross Section...............................................................................................................................................1-6

1.1 Product Specifications

Chapter 1

1.1.1 Finisher Unit

Item Specifications

Stacking

method

Stacking

orientation

Stacking size

Paper weight

Bins

T-1-1

Trays 1 and 2: by lifting tray

Face up

Face down

A3, A4, A4R, A5, A5R, B4, B5, B5R,

postcard, 279 mm x 432 mm (11 x 17), LGL,

LTR, LTRR, STMT, STMTR, elongation size,

Envelope

64g/m2 to 250g/m

2

2

0004-7604

Remarks

Feed direction:

139.7 to 482.6

mm: cross

feed direction:

98.4 to 330. 2

mm; both

maximum

Modes

Stacking

capacity

Non sort: Trays 1 and 2

Sort: Trays 1 and 2

Staple: Trays 1 and 2

Tray 1: Non staple sort Equivalent of

2

80g/m

Large size: 74 mm high (500 sheets)

Small size: 147 mm high (1000 sheets)

paper.

Tray 2: Non staple sort

Large size: 74 mm high (500 sheets)

Small size: 147 mm high (1000 sheets)

Tray 1: Staple sort

Large size: 74 mm high (500 sheets)/30 sets

Small size: 147 mm high (1000 sheets)/30 sets

1-1

Chapter 1

Item Specifications

Remarks

Tray 2: Staple sort

Large size: 74 mm high (500 sheets)/30 sets

Small size: 147 mm high (1000 sheets)/30 sets

Mixed

stacking

capacity

Size mixing: 74 mm high (500 sheets)

Stapling: 74 mm high (500 sheets)/30 sets

Stapling

Stapling

capacity

By rotating cam

Small size: 50 sheets (Thickness 5.7 mm or

less)

Large size: 30 sheets

Equivalent of

2

80g/m

paper.

Notes 1 : Stacking capacity is equivalent of 80g/m2 paper.

Notes 2 : Alignment may not be correct if 750 or more small-size sheets are stacked.

Notes 3 : Stacking capability is not guaranteed for mixed size stacking.

Paper Size Definition:

Large size (feed length of 216 to 432 mm): A3, A4R, B4, B5R, 279mm x 432 mm (11 x 17), LGL, LTRR

Small size (feed length of 216 mm or less): A4, A5, A5R, B5, LTR, STMT, STMTR

ޓ

T-1-2

Item Specifications Remarks

Staple supply Special staple cartridge (5000 staples)

Staple

detection

Manual

stapling

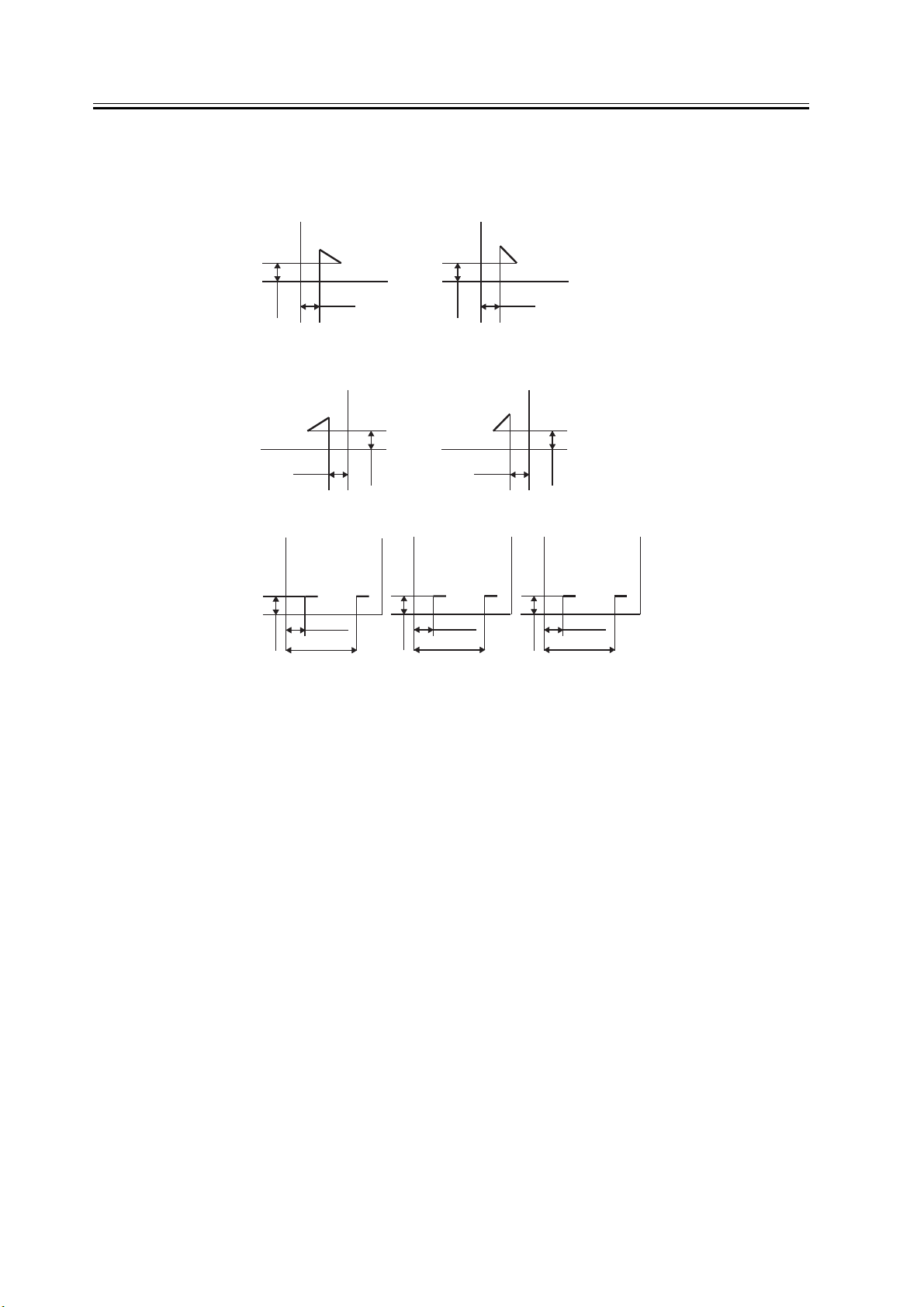

Stapling size Front 1-point stapling (30 deg.)

Provided 0 to 40

remaining

staples

Not provided

A4R, LGL, LTRR

Front 1-point stapling (45 deg.)

A3, B4, A4, B5, 279 mm x 432 mm (11 x 17),

LTR

1-2

Item Specifications Remarks

Rear 1-point stapling (30 deg.)

A4R, LGL, LTRR

Rear 1-point stapling (45 deg.)

A3, B4, A4, B5, 279 mm x 432 mm (11 x 17),

LTR

2-point stapling

A3, A4, B4, B5, 279 mm x 432 mm (11 x 17),

LTR

Chapter 1

ޓ

Paper

Provided

detection

Control panel Not provided

Display Not provided

Dimensions W:536(649) x D:657 x H:928mm If within

parentheses,

with the tray

extended.

Weight Approx. 36 kg

Power supply From host machine (24VDC/13 VDC)

Maximum

power

8 W or less during standby/70 W or less

operating

consumption

1-3

Chapter 1

F

(45d

)

F

)

<Stapling Positions>

ront 1-point stapling (30deg.

A4R, LGL and LTRR

5 -/+2 mm

5 -/+2 mm

Rear 1-point stapling (30deg.)

A4R, LGL and LTRR

5 -/+2 mm

5 -/+2 mm

2-point stapling

A3 and A4

83 -/+4 mm

203 -/+4 mm

-/+2 mm

ront 1-point stapling

A3, A4, B4, B5, 279mm x 432mm

(11x17) and LTR

5 -/+2 mm

5 -/+2 mm

Rear 1-point stapling (45deg.)

A3, A4,B4,B5, 279mm x 432mm

(11x17) and LTR

5 -/+2 mm

279mm x 432mm

(11x17) and LTR

74 -/+4 mm

194 -/+4 mm

-/+2 mm

F-1-1

-/+2 mm

eg.

5 -/+2 mm

B4 and B5

63 -/+4 mm

183 -/+4 mm

1-4

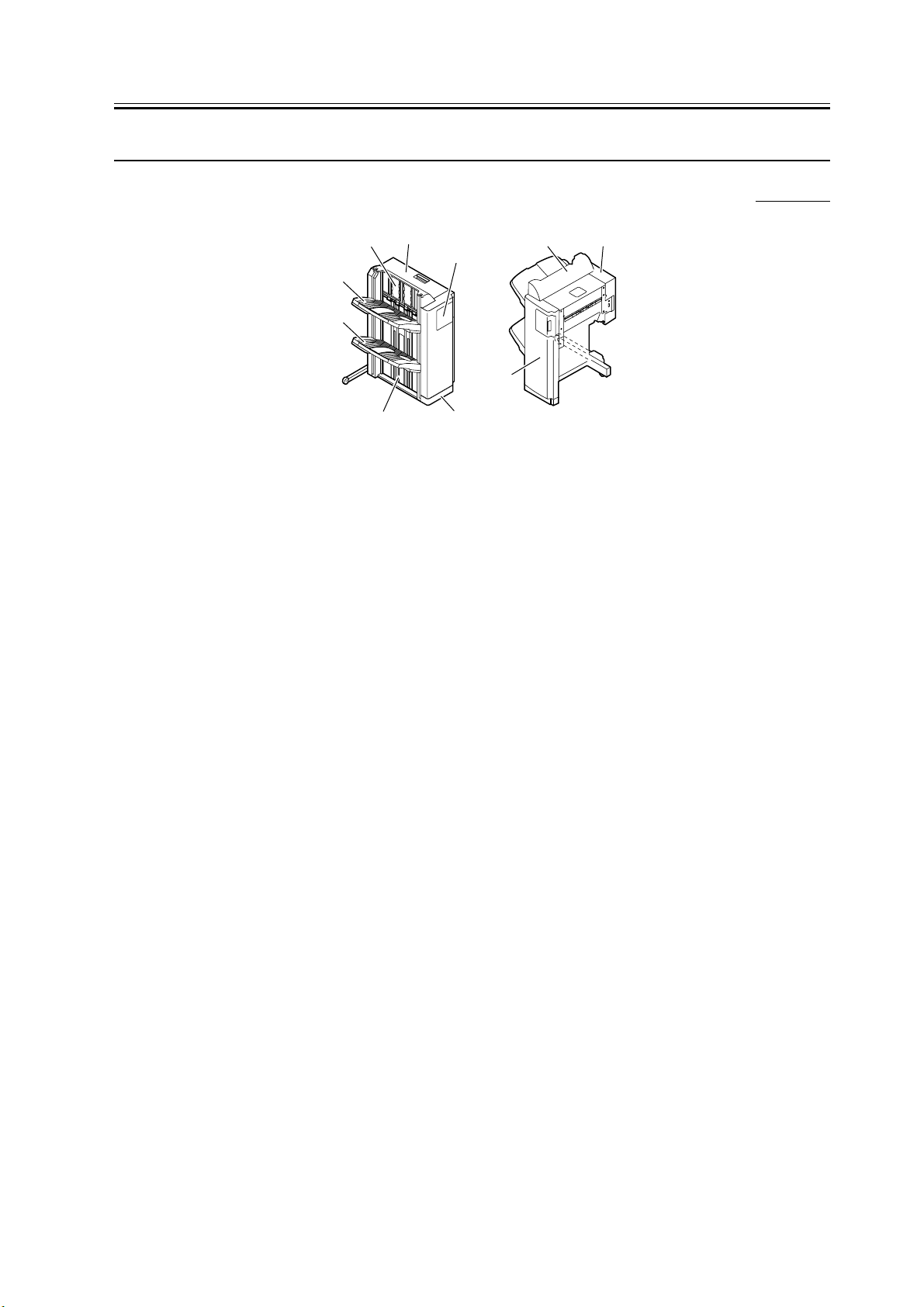

1.2 Names of Parts

Chapter 1

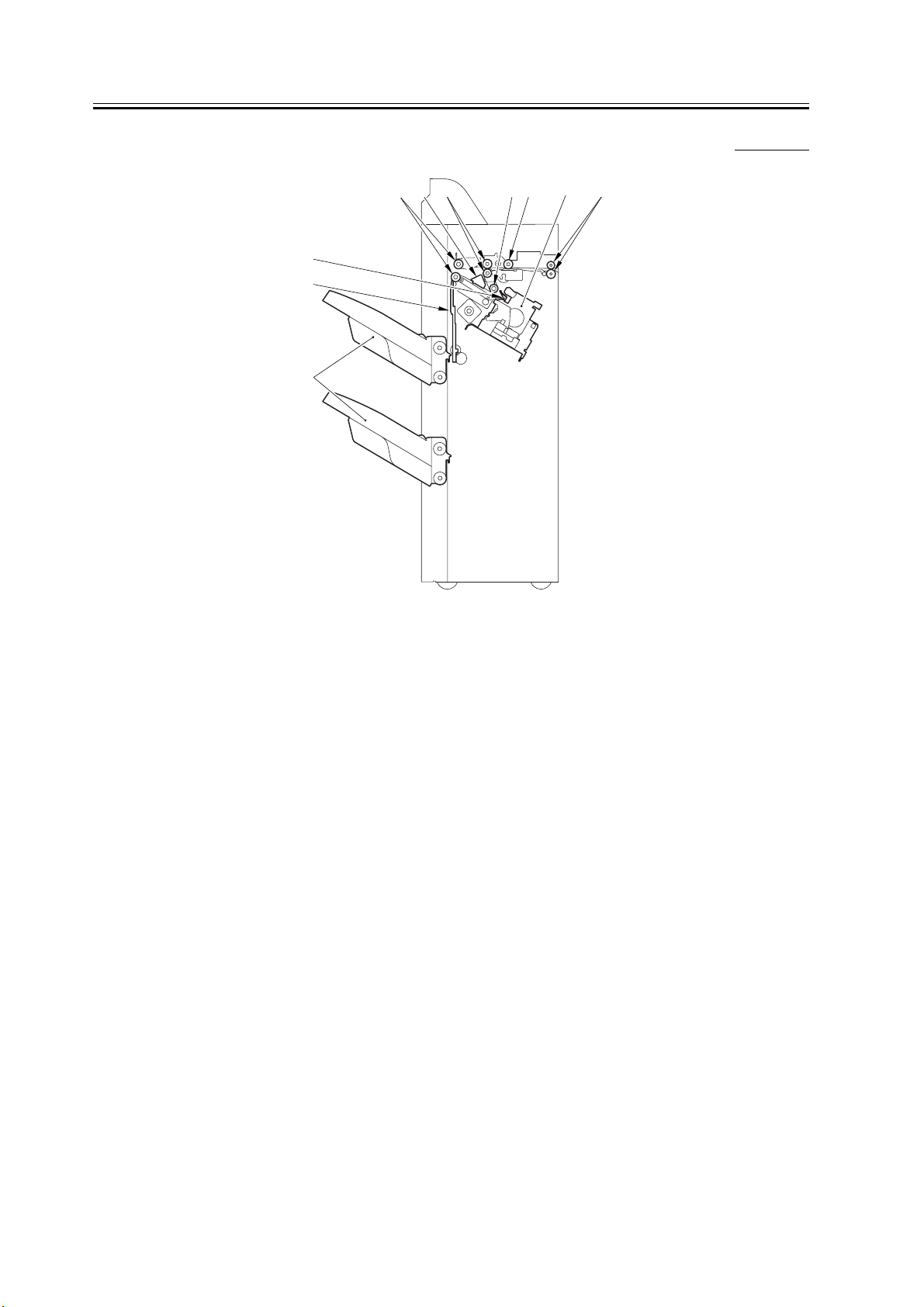

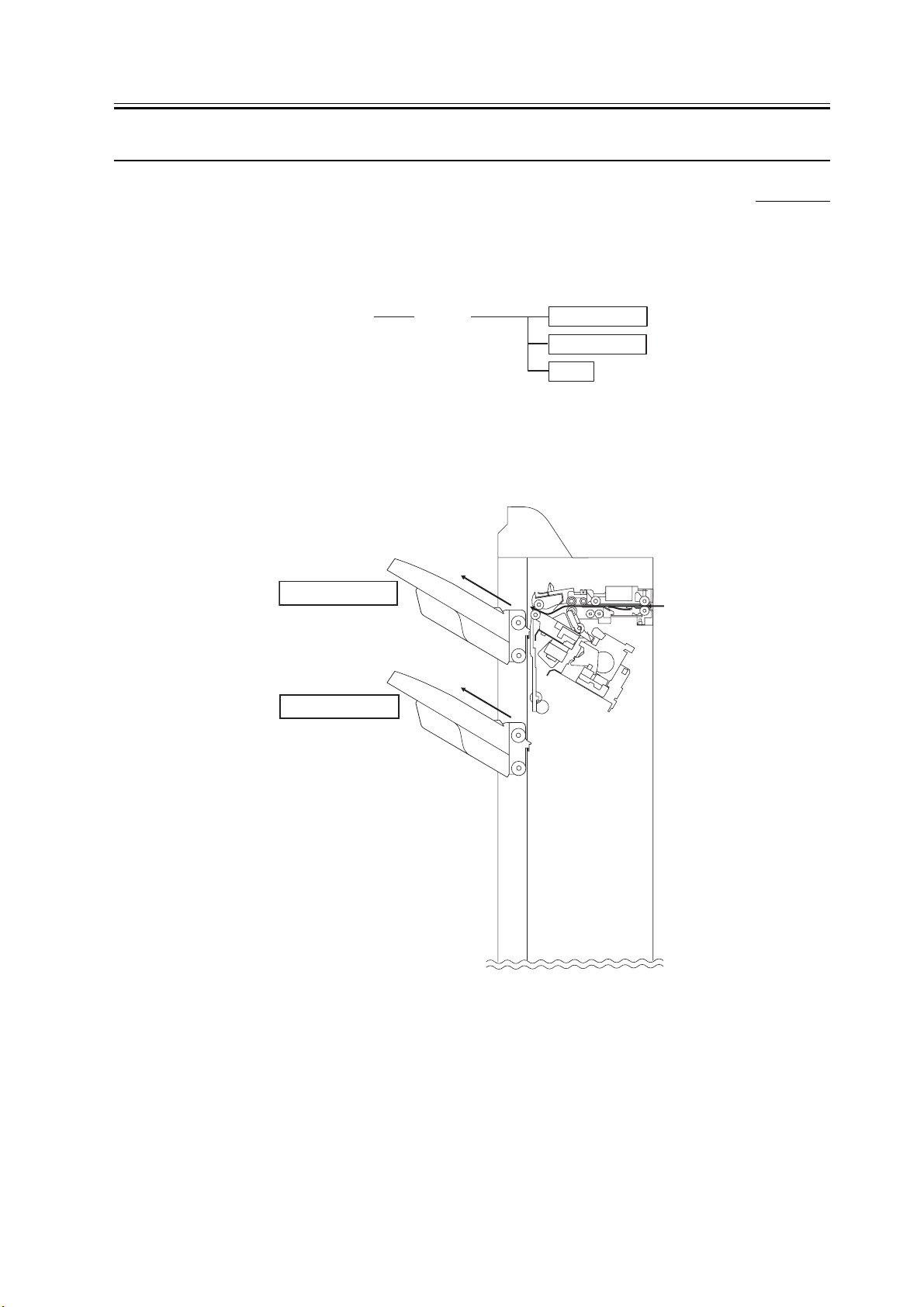

1.2.1 External View

[1] Upper cover [6] Tray 2

[2] Front door [7] Grate-shaped upper guide

[3] Foot cover [8] Front cover

[4] Grate-shaped lower guide [9] Left upper cover

[5]

[6]

[7]

[4]

[1]

[2]

[3]

F-1-2

T-1-3

[8]

[9]

0004-7606

[10]

[5] Tray 1 [10] Rear cover

1-5

Chapter 1

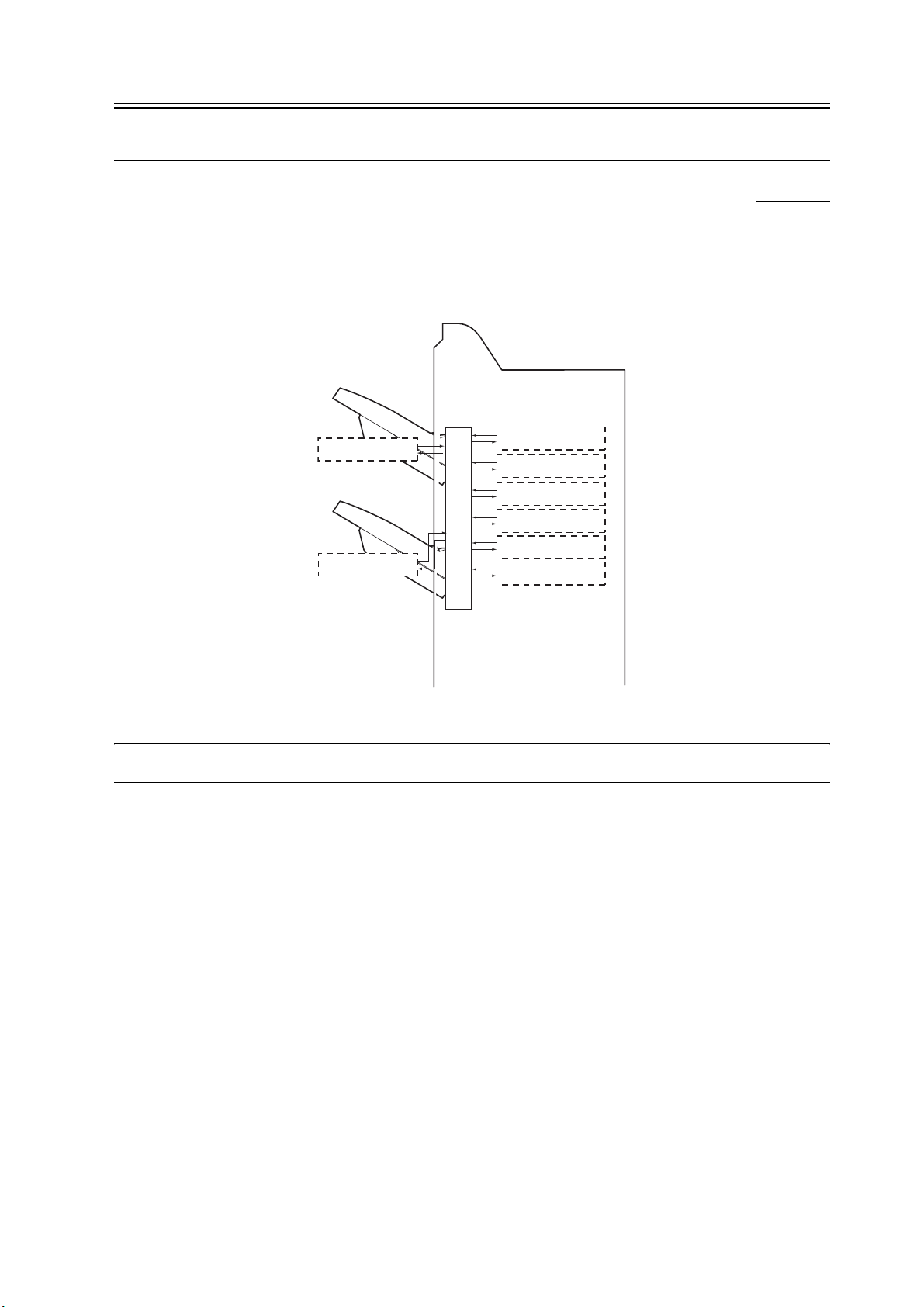

1.2.2 Cross Section

[8]

[9]

[1]

[3] [7]

[2]

0004-7607

[10][5][6][4]

F-1-3

T-1-4

[1] Delivery tray [6] Return roller

[2] Stack delivery roller [7] Inlet roller

[3] Aligning plate [8] Rear end assist guide

[4] 1st delivery roller [9] Shutter

[5] Buffer roller [10] Stapler

1-6

Chapter 2 Functions

Contents

Contents

2.1 Basic Operation..................................................................................................................................................2-1

2.1.1 Basic Operation...........................................................................................................................................2-1

2.1.2 Overview of the Electrical Circuitry...........................................................................................................2-1

2.2 Feed Drive System .............................................................................................................................................2-3

2.2.1 Overview..................................................................................................................................................... 2-3

2.2.2 Constraction of the Control System ............................................................................................................2-4

2.2.3 Paper Delivery Path.....................................................................................................................................2-7

2.3 Intermediate Process Tray Assembly...............................................................................................................2-11

2.3.1 Stack Job Offset.........................................................................................................................................2-11

2.3.2 Processing Tray Paper Stacking Operation...............................................................................................2-12

2.3.3 Offset Operation........................................................................................................................................2-12

2.3.4 Rear End Assist Operation........................................................................................................................2-14

2.3.5 Stack Delivery Operation..........................................................................................................................2-14

2.4 Staple Operation...............................................................................................................................................2-15

2.4.1 Stapler Unit................................................................................................................................................2-15

2.4.2 Shifting the Stapler Unit............................................................................................................................2-16

2.4.3 Stapling Operation.....................................................................................................................................2-19

2.5 Stack Tray Operation........................................................................................................................................2-24

2.5.1 Tray Operation .......................................................................................................................................... 2-24

2.5.2 Shutter Operation ......................................................................................................................................2-27

2.6 Detecting Jams .................................................................................................................................................2-28

2.6.1 Detecting Jams (Finisher Unit)..................................................................................................................2-28

2.7 Power Supply ...................................................................................................................................................2-30

2.7.1 Power Supply Route..................................................................................................................................2-30

2.7.2 Protection Function ................................................................................................................................... 2-30

2.1 Basic Operation

Chapter 2

2.1.1 Basic Operation

0003-9132

The finisher is designed to deliver copies arriving from its host machine, and its modes of delivery include simple

stacking, job offset, and staple.

All operations involved in these modes are controlled by the finisher controller PCB, according to the appropriate

commands from the host machine.

Tray drive system

Tray drive system

Swing guide drive system

Alignment drive system

Stapler drive system

Delivery drive system

Feeder drive system

Control system

Shutter drive system

F-2-1

Memo: The term job offset refers to shifting each sorting job, separating a single stack into several stacks.

2.1.2 Overview of the Electrical Circuitry

0003-9133

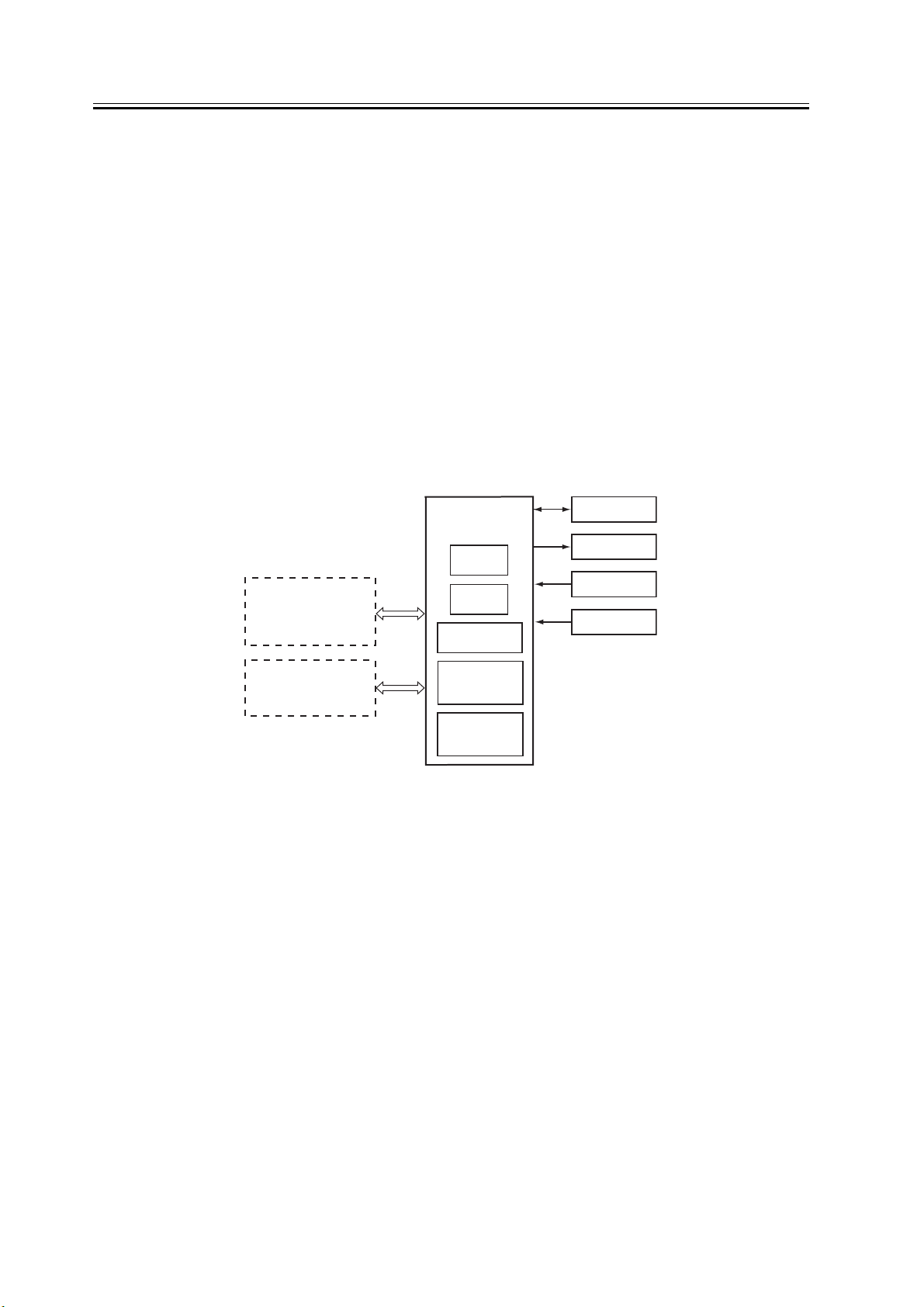

The finisher's sequence of operation is controlled by the finisher controller PCB. The finisher controller PCB is a

16-bit microprocessor (CPU), and is used for communication with the host machine (serial) in addition to

controlling the finisher's sequence of operations.

The finisher controller PCB responds to the various commands comin g fro m the host mac hin e through a serial

communications line to drive solenoids, motors, and other loads. In addition, it communica te s the finisher's va rious

states (information on sensors and switches) to the host machine through a serial communications circuit.

2-1

Chapter 2

The ICs used on the finisher controller PCB are designed for the following:

<IC101 (CPU)>

Controls sequence of operations.

Contains sequence programs.

<IC106 (EEP-ROM)>

Backs up adjustment values.

Backs up initial setting data.

<IC102 (communications IC)>

Communicates with the host machine.

<IC107 (regulator IC)>

Generates 5V.

<IC108 (regulator IC)>

Generates 3.3V.

The following figure shows the flow of signals between the finisher and the options controller.

Punch controller PCB

(Puncher unit

(option))

Host machine (DC

controller PCB CPU)

Finisher

controller PCB

IC101

CPU

IC106 EEP-

ROM

IC102

Communications IC

IC107

Regulator IC

IC108

Regulator IC

F-2-2

Motor

Solenoid

Switch

Sensor

2-2

2.2 Feed Drive System

Chapter 2

2.2.1 Overview

0004-4413

The finisher is designed to operate according to the commands from its host machine to deliver arriving copies to

trays in the appropriate mode: simple stacking, job offset, stapling.

There are three delivery methods.

Method of delivery

Normal

delivery

Simple stacking

Stack job offset

Staple

Front 1-point stapling

Rear 1-point stapling

2-point stapling

F-2-3

Normal delivery tray

Normal delivery tray

F-2-4

2-3

Chapter 2

2.2.2 Constraction of the Control System

The copy sent from the host machine is delivered to the ejection tray or processing tray according to the ejection type.

Job offset or stapling is performed, according to the instruction from the host machine, for copy delivered to the

staple tray.

When ejecting from the processing tray, rear end assist guide is used in addition to the stack ejection roller to eject

the stack.

The inlet motor (M31), stack ejection motor (M32), and rear end assist motor (M39) are step motors. These motors

are rotated forward or backward by the microcomputer (CPU) in the finisher controller PCB.

The following two sensors are provided in the copy delivery path to detect the a rriva l or passing of copies.

Inlet sensor (PI33)

Delivery path sensor (PI34)

Also, each ejection tray has sensors to detect the presence of copy on the tray.

First tray paper sensor (PI42)

Second tray paper sensor (PI43)

If the copy does not reaches or passes eac h sensor within prescribed time, the finisher controller PCB determines that

the jam has occurred and stops the operation. Then it notifies the host machine th at a j am has o ccurred. When a ll of

the doors are closed after fixing the jam, the fin isher checks whether copy is detected by any of the above two sensors

(inlet sensor, delivery path sensor). If any of the sensors detects a copy, the finisher determines that the jam is not

fixed and sends jam processing signal to the host machine once more.

0004-4426

2-4

Chapter 2

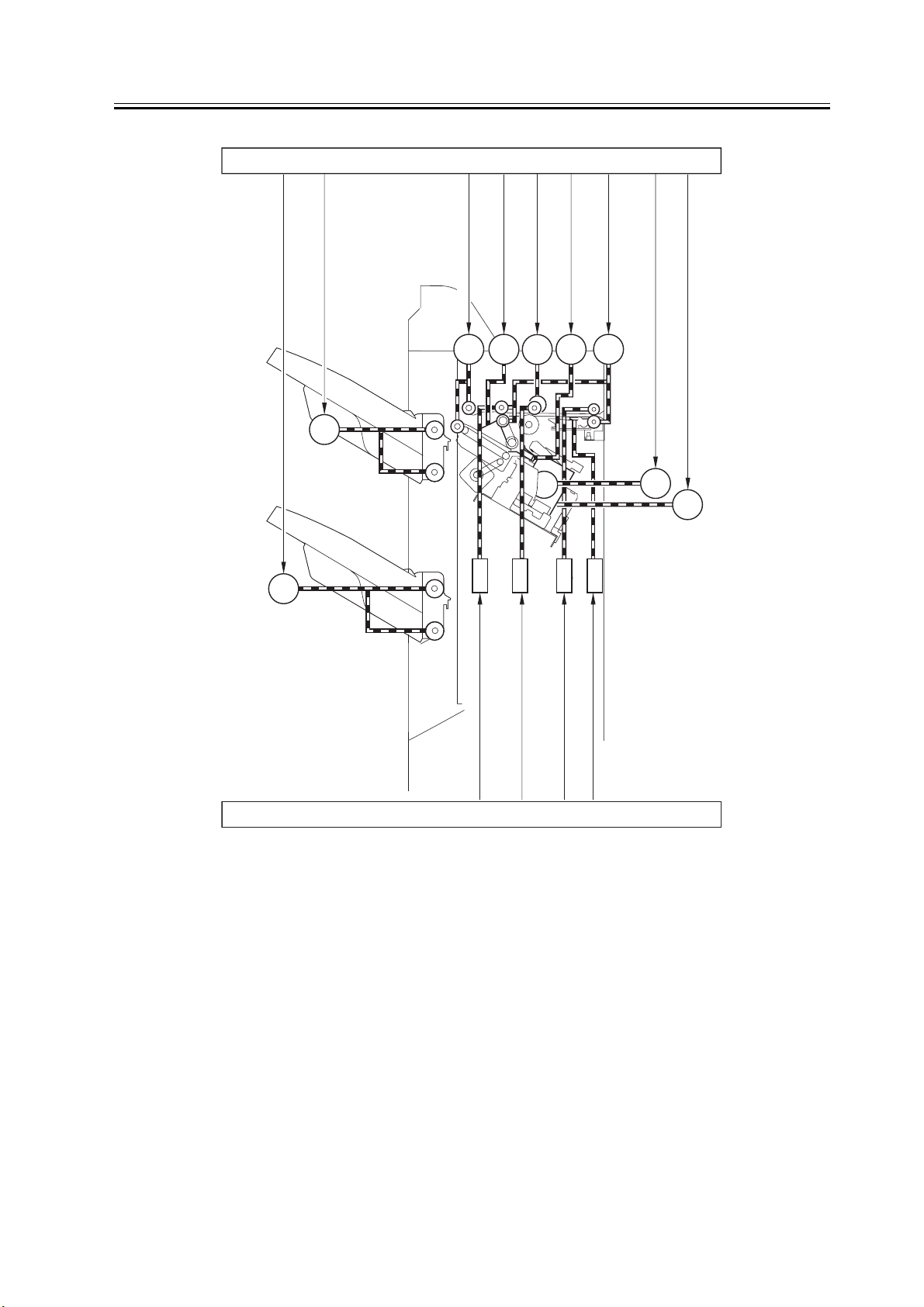

Finisher controller PCB (1/2)

motor drive signal

Rear end assist motor drive signal

M39

Inlet motor drive signal

Stapler motor drive signal

Stapler drive motor drive signal

Aligning plate front/rear

M33

M34

Gear change motor drive signal

M40

First tray shift motor drive signal

Second tray shift motor drive signal

Stack ejection motor drive signal

M32 M31

M37

M35

M41

M38

SL32

SL33

Buffer roller separation solenoid drive signal

1st eject roller separation solenoid drive signal

DELIV-ROL-SL

Finisher controller PCB (2/2)

F-2-5

BUFF-ROL-SL

Inlet roller separation solenoid drive signal

SL31

INLET-ROL-SL

Buffer rear end holding solenoid drive signal

SL34

BUFF-P-SL

2-5

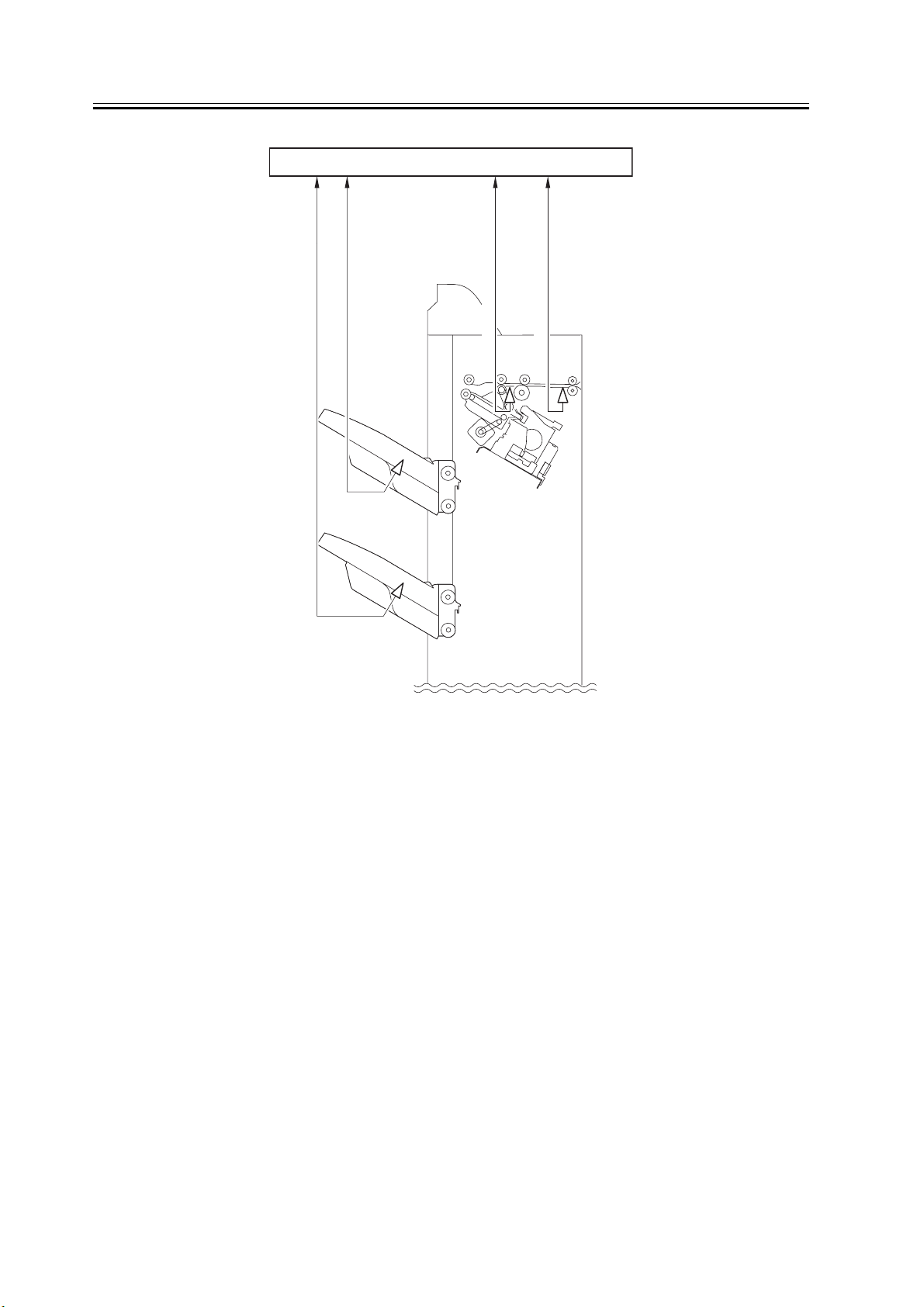

Chapter 2

Finisher controller PCB

Inlet paper detection sensor INLET

First tray paper detection sensor TRY1-P

Second tray paper detection sensor TRY2-P

Delivery path paper detection sensor TIMING

F-2-6

2-6

Loading...

Loading...