Page 1

Service Manual

Finisher, Sorter, DeliveryTray

Shift Tray-C1

June 16 2004

Page 2

Page 3

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and

repair of products. This manual covers all localities where the products are sold. For this reason, there may be

information in this man ual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products.

When changes occur in applicable products or in the contents of this manual, Canon will release technical information

as the need arises. In the event of major changes in the con tents of this manual over a long or short period, Canon will

issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied,

reproduced or translated into another language, in whole or in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Page 4

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Introduction

Memo

REF.

Indicates an item requiring di sc onnection of the power plug from the elect ric outlet.

Indicates an item intended to provide notes assisting the understanding of the topic in question.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Page 5

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sectio ns explai ning the purpose of specific fu nctions a nd the rela tionshi p between el ectrical

and mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical driv e; where a signal name accompanies the sy mbol,

the arrow indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the

delivery unit door, which results in supplying the mach ine with power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is "High", while '0' is used to

indicate "Low". (The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in

"DRMD*" indicates that the DRMD signal goes on when '0'.

In practically all cases, the inte rnal mechanisms o f a microproce ssor cannot be ch ecked in the field. Therefore , the

operations of the micropr ocessors used in the machines are not discussed: they are explaine d in terms of from

sensors to the input of the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to ch ange without notice for product improvement or oth er

purposes, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant

Service Information bulletins and be able to identify and isolate faults in the machine.

Page 6

Page 7

Contents

Contents

Chapter 1 Specifications

1.1 Product Specifications........................................................................................................... ............................1- 1

1.1.1 Specifications .................................................................................................................................. ...........1- 1

1.2 Names of Parts...................................................................................................................................................1- 3

1.2.1 Names of Parts........................................................................................................................................ .... 1- 3

Chapter 2 Functions

2.1 Basic Construction ............................................................................................................................................2- 1

2.1.1 Outline of the Electrical Circuitry................................................................................................ ..............2- 1

2.1.2 Inputs to and Outputs from the Shift Tray Driver PCB .............................................. ...............................2- 1

2.2 Basic Operation.................................................................................................................................................2- 2

2.2.1 Shift Movement..........................................................................................................................................2- 2

2.2.2 Placement of Paper.....................................................................................................................................2- 2

2.2.3 Detecting the Presence/Absence of Paper..................................................................................................2- 3

2.2.4 Delivery Movement......................................................................................................................... ...........2- 3

Chapter 3 Parts Replacement Procedure

3.1 Removing from the Host Machine.................................................................................................. ..................3- 1

3.1.1 Shift Tray............................................................................................................................... .....................3- 1

3.2 Drive System...................................................................................................................... ...............................3- 3

3.2.1 Tray Drive Unit............................................................................................................ ...............................3- 3

3.3 Electrical System...............................................................................................................................................3- 6

3.3.1 Shift Tray Driver PCB ................................................................................................................................3- 6

Chapter 4 Maintenance

4.1 Adjustment ................................................................................................................................................. .......4- 1

4.1.1 Adjustment at Time of Parts Replacement................................................................................................. 4- 1

4.2 Outline of Electrical Components.................................................................................................................... .4- 3

4.2.1 Sensors, Motors, PCBs...............................................................................................................................4- 3

Page 8

Page 9

Chapter 1 Specifications

Page 10

Page 11

Contents

Contents

1.1 Product Specifications........................................................................................................................................1-1

1.1.1 Specifications ..............................................................................................................................................1-1

1.2 Names of Parts....................................................................................................................................................1-3

1.2.1 Names of Parts............................................................................................................................................. 1-3

Page 12

Page 13

1.1 Product Specifications

Chapter 1

1.1.1 Specifications

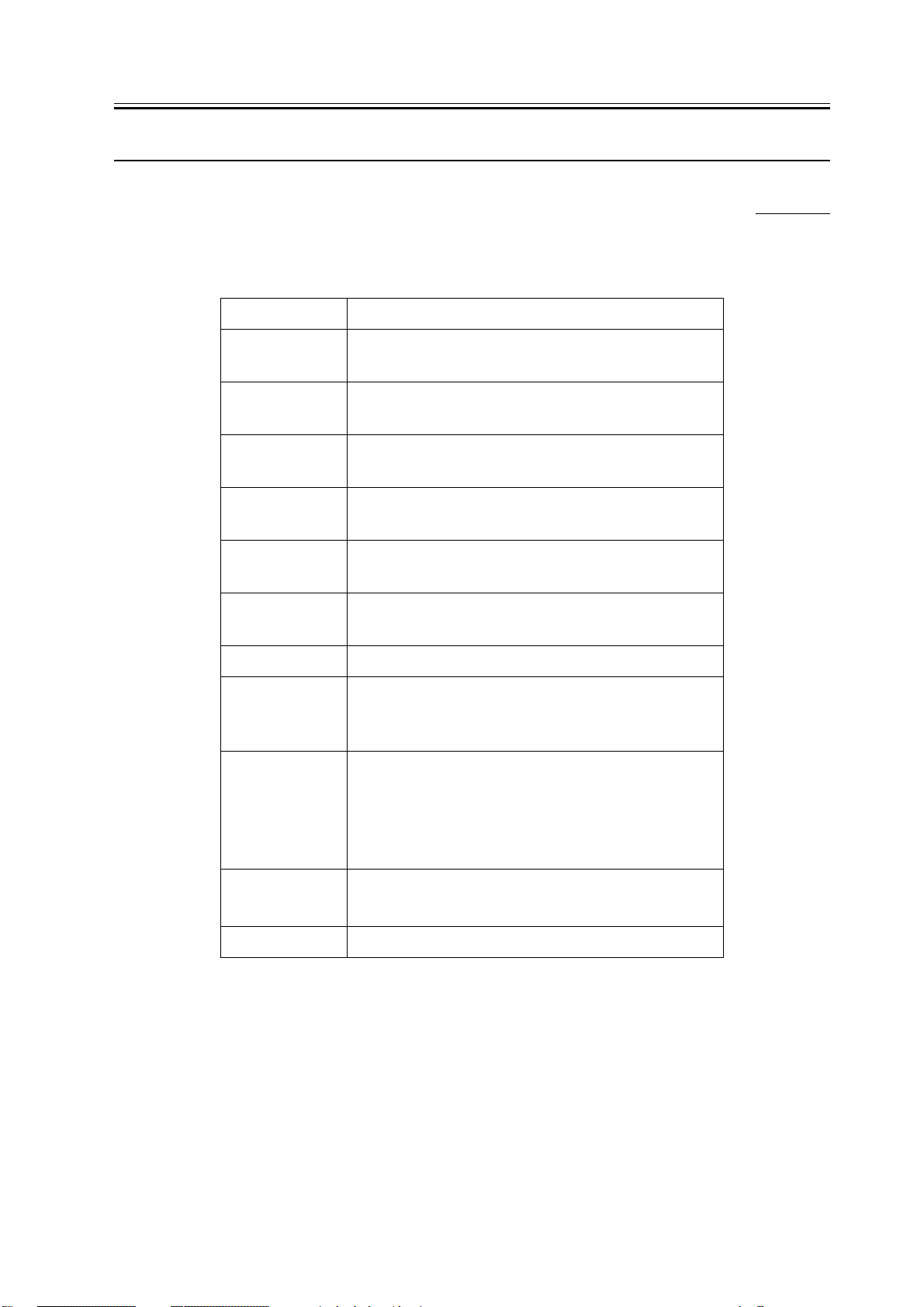

Item Description

Method of

stacking

Mode of stacking sort: offset used

Source of drive ascent/descent: by coil spring (descent by pape r we ight)

Size of paper for

stack

Weight of paper

for stack

Movement of

offset

T-1-1

ascent/descent by paper weight/coil springsort by tray shift

movement

non-sort: offset not used

shift movement: by motor

A3, A4, A4R, A5R, B4, B5, B5R, 11x17, LTR, LTR-R,

LGL, STMT-R, postcard, transparency

64 to 200 g/m

in units of sets

2

0003-8613

Distance of offset 55 mm

Maximum

number of sets in

stack

Accuracy of

alignment

Tray full

detection

Power supply 24 VDC/5 V (from host machine)

*2

sort: 500 sheets (64 g/m

non-sort: 250 sheets (64/m

sort: 50 mm or less (delivery direction)

20 mm or less (shift direction, between stacks)

between stacks: -5 mm or less (shift direction, within

stack)

non-sort: 100 mm or less

by reflection type sensor (2 pc.) monitoring height of stack

2

paper)

2

paper)

1-1

Page 14

Chapter 1

Maximum power

2 W or less

consumption

Dimensions 365.3 (W) x 547 (D) x 255.7 (H) mm

Weight 4.2 kg

Operating

same as host machine

environment

*1: the following will not be operated: A4R, A5R, B5R, 11x17, 13x19, LTR-R, STMT-R, 4-pane postcard, tab

sheet.

*2: the machine stops printing when the stack exceeds a specific height.

1-2

Page 15

1.2 Names of Parts

Chapter 1

1.2.1 Names of Parts

[1]

[4]

[5]

[7]

[3]

[9]

F-1-1

T-1-2

0003-8677

[10]

[8]

[2]

[6]

1 Tray 6 HP sensor (front)

2 Tray full sensor (front) 7 HP sensor (rear)

3 Tray full sensor (rear) 8 Light-blocking plate

4 Tray drive unit 9 Paper sensor

5 Shift tray drive PC 10 Delivery unit

1-3

Page 16

Page 17

Chapter 2 Functions

Page 18

Page 19

Contents

Contents

2.1 Basic Construction .............................................................................................................................................2-1

2.1.1 Outline of the Electrical Circuitry...............................................................................................................2-1

2.1.2 Inputs to and Outputs from the Shift Tray Driver PCB .............................................. ................................2-1

2.2 Basic Operation..................................................................................................................................................2-2

2.2.1 Shift Movement...........................................................................................................................................2-2

2.2.2 Placement of Paper......................................................................................................................................2-2

2.2.3 Detecting the Presence/Absence of Paper...................................................................................................2-3

2.2.4 Delivery Movement.....................................................................................................................................2-3

Page 20

Page 21

2.1 Basic Construction

Chapter 2

2.1.1 Outline of the Electrical Circuitry

0003-8683

The circuit shown below is used to drive the shift motor according to the shift control signal from the host machine

and also to send various sensor signals associated with the shift operation to the host mach ine.

Shift drive PCB

J101 J201

J102

Sensor signal

J202

Motor drive

signal

To host machine

To host machine

Shift motor

M

Sensor

A24V

A5V

Motor drive

circuit

F-2-1

2.1.2 Inputs to and Outputs from the Shift Tray Driver PCB

Shift tray driver PCB

+5V

J205

-4

-3

-2

-1

J103

-6

-5

STHPR

-4

+5V

J103

-3

-2

STHPL

-1

+5V

J104

-6

-1

-5

-2

-3

-4

J104

J106

SPEXIST*

-4

-3

-2

SPCFULL*

-1

-3

-2

SPSFULL*

-1

+5V

+5V

when tray is HP at front, '1'.

when tray is HP at rear, '1'.

when paper is present in tray, '0'.

when stack of sheets exceeds limit, '0'.

when stack of sheets exceeds limit, '0'.

HP sensor

(front)

HP sensor

(rear)

Tray paper

sensor

Tray full sensor

(read)

Tray full sensor

(front)

PS101

PS102

PS103

PS104

PS105

J203

-1

-2

-3

J204

-1

-2

-3

J206

-1

-2

-3

N.C. N.C.

J207

-1

-2

-3

J208

-1

-2

-3

0003-8686

Shift motor

M101

J105

-1

-2

SDCM1

SDCM2

F-2-2

tray moves to front when +24 V is applied to SDCM1 tray

moves to rear when +24 V is applied to SDCM2

2-1

Page 22

Chapter 2

2.2 Basic Operation

2.2.1 Shift Movement

0003-8687

The machine moves the tray to the front an d the rear (shift of 55 mm) to sort stacks (offset). The tray is driven by a

DC motor, and the rotation of the motor is converted into liner movement by means of a rack and pinion gear

mechanism. The location of the tray (front, rear) is monitored by the HP sensor mounted to the front and the rear.

Light-blocking plate

Tray drive unit

HP sensor (rear)

PS102

HP sensor (front)

PS101

F-2-3

2.2.2 Placement of Paper

0003-8689

The machine's tray is held up by the work of a coil spring . Wh en paper is placed, the tray moves down under the

weight of the paper. The height of the stack in the tray is monitored by the tray full sensor (reflection ty pe photo

sensor), and the shift tray driver PCB sends the tray full si gnal to the h ost machine when the t op of the stack re aches

a specific height.

Shift

Tr ay

Shift

Tray full sensor (rear)

PS104

Tray full sensor (front)

F-2-4

PS105

Room for

more paper

Room for

more paper

No room

for paper

2-2

Page 23

Chapter 2

2.2.3 Detecting the Presence/Absence of Paper

0003-8690

The presence/absence of paper in the tray is detected by the paper sensor mounted to the tray.

Tray paper sensor

PS103

F-2-5

2.2.4 Delivery Movement

0003-8691

The paper from the host ma chine is delivered to the tray through the delivery unit, whi ch is driven by the host

machine's gear mechanism.

F-2-6

2-3

Page 24

Page 25

Chapter 3 Parts

Replacement

Procedure

Page 26

Page 27

Contents

Contents

3.1 Removing from the Host Machine.....................................................................................................................3-1

3.1.1 Shift Tray.....................................................................................................................................................3-1

3.1.1.1 Removing the Shift Tray...................................................................................................................... 3-1

3.2 Drive System......................................................................................................................................................3-3

3.2.1 Tray Drive Unit ............................ ............................................................................................................... 3-3

3.2.1.1 Removing the Shift Tray...................................................................................................................... 3-3

3.2.1.2 Removing the Shift Tray Driver PCB..................................................................................................3-4

3.2.1.3 Removing the Tray Drive Unit.............................................................................................................3-5

3.3 Electrical System................................................................................................................................................ 3-6

3.3.1 Shift Tray Driver PCB.................................................... .............................................................................3-6

3.3.1.1 Removing the Shift Tray...................................................................................................................... 3-6

3.3.1.2 Removing the Shift Tray Driver PCB..................................................................................................3-7

Page 28

Page 29

Chapter 3

3.1 Removing from the Host Machine

3.1.1 Shift Tray

3.1.1.1 Removing the Shift Tray 0004-1889

1) Remove the 3 face covers [1].

[1]

F-3-1

3) Remove the 2 screws [1], and detach the

reinforcing plate [2].

[2]

[1]

F-3-3

4) Remove the screw [1], and disconnect the

connector [2].

[2]

2) Remove the 2 screws [1], and detach th e delivery

unit [2].

[2]

[1]

F-3-2

[1]

F-3-4

5) Remove the screw [1].

[1]

F-3-5

3-1

Page 30

Chapter 3

6) Move the shift tray [1] to the right to detach the

shift tray [1] from the host machine.

F-3-6

3-2

Page 31

Chapter 3

3.2 Drive System

3.2.1 Tray Drive Unit

3.2.1.1 Removing the Shift Tray 0005-0090

1) Remove the 3 face covers [1].

[1]

F-3-7

2) Remove the 2 screws [1], and detach th e delivery

unit [2].

3) Remove the 2 screws [1], and detach the

reinforcing plate [2].

[2]

[1]

F-3-9

4) Remove the screw [1], and disconnect the

connector [2].

[2]

[1]

[2]

[1]

F-3-10

5) Remove the screw [1].

F-3-8

[1]

F-3-11

3-3

Page 32

Chapter 3

6) Move the shift tray [1] to the right to detach the

shift tray [1] from the host machine.

F-3-12

3.2.1.2 Removing the Shift Tray

Driver PCB

1) Free the 2 retaining claws [1], and d etach the cable

retaining plate [2].

[2]

0005-0091

3) Free the cable of the tray ful l sensor from the clamp

[5], and disconnect the connector [6].

[4]

[6]

[3]

[5]

[4]

F-3-14

4) From the back of the shift tray, remove the 4 screws

[7] and detach the 4 shaft retainers [8]; then, detach

the tray drive assembly [9].

[7]

[1]

F-3-13

2) Remove the 2 screws [3], and detach the 2 tray full

sensors [4] and the 2 grounding wires.

[9]

[8]

[8]

F-3-15

3-4

Page 33

Chapter 3

5) Pull off the shaft [10] from the tray drive assembly;

then, remove the 3 screws [11], and detach the shield

cover [12].

[11]

[12]

[10]

F-3-16

6) Remove the 4 screws [13], and detach the shift tray

driver PCB [14].

[13]

3.2.1.3 Removing the Tray Drive Unit

1) Remove the 2 screws [1], and disconnect th e

connector; [2]; then, detach the tray drive unit [3].

[1]

[2]

[3]

F-3-18

0003-8907

[14]

F-3-17

3-5

Page 34

Chapter 3

3.3 Electrical System

3.3.1 Shift Tray Driver PCB

3.3.1.1 Removing the Shift Tray 0004-1902

1) Remove the 3 face covers [1].

[1]

F-3-19

2) Remove the 2 screws [1], and detach the deliv ery

unit [2].

3) Remove the 2 screws [1], and detach the

reinforcing plate [2].

[2]

[1]

F-3-21

4) Remove the screw [1], and disconnect the

connector [2].

[2]

[1]

[2]

[1]

F-3-22

5) Remove the screw [1].

F-3-20

[1]

F-3-23

3-6

Page 35

Chapter 3

6) Move the shift tray [1] to the right to detach the

shift tray [1] from the host machine.

F-3-24

3.3.1.2 Removing the Shift Tray

Driver PCB

1) Free the 2 retaining claws [1], and det ach the cab le

retaining plate [2].

[2]

0003-8876

3) Free the cable of the tray ful l sensor from the clamp

[5], and disconnect the connector [6].

[4]

[6]

[3]

[5]

[4]

F-3-26

4) From the back of the shift tray, remove the 4 screws

[7] and detach the 4 shaft retainers [8]; then, detach

the tray drive assembly [9].

[7]

[1]

F-3-25

2) Remove the 2 screws [3], and detach the 2 tray full

sensors [4] and the 2 grounding wires.

[9]

[8]

[8]

F-3-27

3-7

Page 36

Chapter 3

5) Pull off the shaft [10] from the tray drive assembly;

then, remove the 3 screws [11], and detach the shield

cover [12].

[11]

[12]

[10]

F-3-28

6) Remove the 4 screws [13], and detach t he shift tray

driver PCB [14].

[13]

[14]

F-3-29

3-8

Page 37

Chapter 4 Maintenance

Page 38

Page 39

Contents

Contents

4.1 Adjustment .........................................................................................................................................................4-1

4.1.1 Adjustment at Time of Parts Replacement..................................................................................................4-1

4.1.1.1 Adjusting the Tray Full Sensor Position ..............................................................................................4-1

4.2 Outline of Electrical Components......................................................................................................................4-3

4.2.1 Sensors, Motors, PCBs................................................................................................................................4-3

Page 40

Page 41

Chapter 4

4.1 Adjustment

4.1.1 Adjustment at Time of Parts

Replacement

4.1.1.1 Adjusting the Tray Full Sensor Position

Adjusting the Position of the Shift Tray Full Sensor

Be sure to go through the following whenev er yo u

have removed/replaced the tray full sensor (front,

rear):

1) Remove the 3 face covers [1].

0005-8062

3) Loosen the screw [1], and temporarily fix both of

the tray full sensors in place where they are farthest

from the paper.

[1]

[2]

[2]

[1]

F-4-3

4) Place a stack of paper about 60 mm in height over

the point of detection of either of the tray full sensors

on the shift tray.

[1]

F-4-1

2) Remove the 2 screws [1], and detach th e delivery

unit [2].

[2]

[1]

F-4-2

F-4-4

4-1

Page 42

Chapter 4

5) Select the service mode item, and press the OK key.

6) While referring to the indication, move the sensor

closer to the paper, and fix it in place where ‘ON’ is

indicated.

F-4-5

Memo: If ‘ON’ is not indicated after moving the

sensor closest to the paper, keep adding a sheet of

paper until ‘ON’ is indicated.

1. When moving the sensor (front, rear), be sure to do

so starting from where it is farthest from the paper.

This is important in respect of the characteristics of

the sensor.

2. Be sure that the grounding terminal of the sensor

(front, rear) is parallel to the sensor and, moreover, its

bend is in downward direction.

Grounding wire terminal

F-4-7

[1]

F-4-6

7) Perform step 6) for the other sensor.

8) Press the Stop key to end the adjustment.

4-2

Page 43

4.2 Outline of Electrical Components

Chapter 4

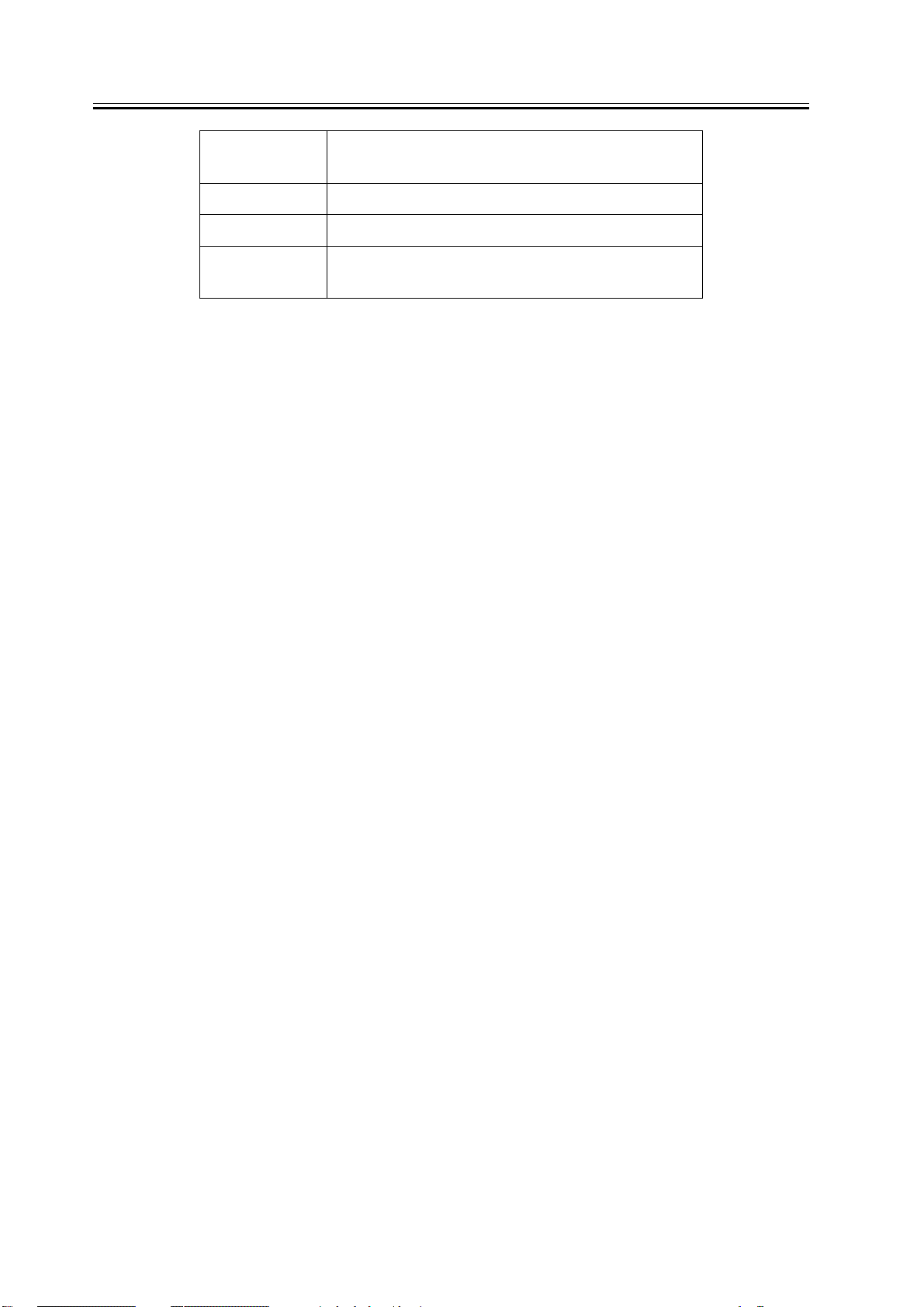

4.2.1 Sensors, Motors, PCBs

Name

Notation

Description

Shift Motor

M101

shifts the tray

HP sensor (front)

PS101

detects tray stop position (front)

HP sensor (rear)

PS102

detects tray stop position (rear)

Tray paper sensor

PS103

detects the sheet on the tray

Limit sensor (rear)

PS104

detects sheet full on the tray

T-4-1

Parts No. I/O

FH6-1829 J105 MTR>37

O008-2

FH7-7462

FH7-7462

FH7-7462

WG8-5485 J104

1 :HP

detection

O008-1

1 :HP

detection

O008-3

1 :paper

detection

Connector

No.

J103

J103

J104

0006-4194

PART-

CHK

PS105

[1]

Limit sensor (front)

detects sheet full on the tray

Shift tray driver PCB

controls tray shifting

WG8-5485

FG6-6841

O008-4

1 :full

J106

4-3

Page 44

Chapter 4

[1] PS102

M101

PS104

PS103

F-4-8

PS105

PS101

4-4

Page 45

March 18 2004

Page 46

Loading...

Loading...