Page 1

5'48'4%10641..'451.76+105

KOCIG

KOCIG

#55)%%QNQT0GVYQTM2TKPVGT7PKV)(%

#IWKFGHQTUGTXKEGVG

JPKEKCPU

+PUVCNNCVKQP5GTXKEG)WKFG

5'48'4%10641..'451.76+105

2#55)%%QNQT0GVYQTM2TKPVGT7PKV)(%

2CTV0WODGT

,CPWCT[

+PUVCNNCVKQP5GTXKEG)WKFG

#IWKFGHQTUGTXKEGVG

EJPKEKCPU

Page 2

Page 3

Copyright © 2005 Electronics for Imaging, Inc. and Canon, Inc. All rights reserved.

This product documentation is protected by copyright, and all rights are reserved. No part of

it may be reproduced or transmitted in any form or by any means for any purpose without

express prior written consent from Electronics for Imaging, Inc. (“EFI”), except as expressly

permitted herein. Information in this document is subject to change without notice and does

not represent a commitment on the part of EFI.

This product documentation is provided in conjunction with the EFI software (“Software”)

and any other EFI product described in this documentation. The Software is furnished under

license and may only be used or copied in accordance with the terms of the Software License

Agreement set forth below.

Patents

This product may be covered by one or more of the following U.S. Patents:

4,716,978, 4,828,056, 4,917,488, 4,941,038, 5,109,241, 5,170,182, 5,212,546, 5,260,878,

5,276,490, 5,278,599, 5,335,040, 5,343,311, 5,398,107, 5,424,754, 5,442,429, 5,459,560,

5,467,446, 5,506,946, 5,517,334, 5,537,516, 5,543,940, 5,553,200, 5,563,689, 5,565,960,

5,583,623, 5,596,416, 5,615,314, 5,619,624, 5,625,712, 5,640,228, 5,666,436, 5,745,657,

5,760,913, 5,799,232, 5,818,645, 5,835,788, 5,859,711, 5,867,179, 5,940,186, 5,959,867,

5,970,174, 5,982,937, 5,995,724, 6,002,795, 6,025,922, 6,035,103, 6,041,200, 6,065,041,

6,112,665, 6,116,707, 6,122,407, 6,134,018, 6,141,120, 6,166,821, 6,173,286, 6,185,335,

6,201,614, 6,215,562, 6,219,155, 6,219,659, 6,222,641, 6,224,048, 6,225,974, 6,226,419,

6,238,105, 6,239,895, 6,256,108, 6,269,190, 6,271,937, 6,278,901, 6,279,009, 6,289,122,

6,292,270, 6,299,063, 6,310,697, 6,321,133, 6,327,047, 6,327,050, 6,327,052, 6,330,071,

6,330,363, 6,331,899, 6,340,975, 6,341,017, 6,341,018, 6,341,307, 6,347,256, 6,348,978,

6,356,359, 6,366,918, 6,369,895, 6,381,036, 6,400,443, 6,429,949, 6,449,393, 6,476,927,

6,490,696, 6,501,565, 6,519,053, 6,539,323, 6,543,871, 6,546,364, 6,549,294, 6,549,300,

6,550,991, 6,552,815, 6,559,958, 6,572,293, 6,590,676, 6,606,165, 6,633,396, 6,636,326,

6,643,317, 6,647,149, 6,657,741, 6,662,199, 6,678,068, 6,707,563, 6,741,262, 6,748,471,

6,753,845, 6,757,436, 6,757,440, RE33,973, RE36,947, D341,131, D406,117, D416,550,

D417,864, D419,185, D426,206, D439,851, D444,793.

Trademarks

Auto-Count, ColorCal, ColorWise, Command WorkStation, DocBuilder Pro, EDOX, EFI,

Fiery, the Fiery logo, Fiery Driven, the Fiery Driven logo, Fiery Spark, MicroPress, OneFlow,

Printcafe, PrinterSite, PrintMe, Prograph, Proteus, RIP-While-Print, Splash, and Spot-On are

registered trademarks of Electronics for Imaging, Inc. in the U.S. Patent and Trademark Office

and/or certain other foreign jurisdictions. Bestcolor is a registered trademark of Best GmbH in

the U.S. Patent and Trademark Office.

ADS, AutoCal, Balance, Build, Digital StoreFront, DocStream, Fiery Link, Fiery Prints,

FreeForm, Hagen, Intelligent Device Management, Logic, PrintFlow, PrintSmith, PrintSmith

Site, PSI, PSI Flexo, RIPChips, Scan, SendMe, VisualCal, WebTools, the EFI logo, the Fiery

Prints logo, and Essential to Print are trademarks of Electronics for Imaging, Inc. Best, the Best

logo, Colorproof, PhotoXposure, Remoteproof, and Screenproof are trademarks of Best

GmbH.

All other terms and product names may be trademarks or registered trademarks of their

respective owners, and are hereby acknowledged.

Canon is a registered trademark of Canon, Inc.

Legal Notifications

APPLE COMPUTER, INC. (“APPLE”) MAKES NO WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, REGARDING

THE APPLE SOFTWARE. APPLE DOES NOT WARRANT, GUARANTEE, OR MAKE

ANY REPRESENTATIONS REGARDING THE USE OR THE RESULTS OF THE USE

OF THE APPLE SOFTWARE IN TERMS OF ITS CORRECTNESS, ACCURACY,

RELIABILITY, CURRENTNESS, OR OTHERWISE. THE ENTIRE RISK AS TO THE

RESULTS AND PERFORMANCE OF THE APPLE SOFTWARE IS ASSUMED BY YOU.

THE EXCLUSION OF IMPLIED WARRANTIES IS NOT PERMITTED BY SOME

STATES. THE ABOVE EXCLUSION MAY NOT APPLY TO YOU.

IN NO EVENT WILL APPLE, ITS DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS

BE LIABLE TO YOU FOR ANY CONSEQUENTIAL, INCIDENTAL, OR INDIRECT

DAMAGES (INCLUDING DAMAGES FOR LOSS OF BUSINESS PROFITS, BUSINESS

INTERRUPTION, LOSS OF BUSINESS INFORMATION, AND THE LIKE) ARISING

OUT OF THE USE OR INABILITY TO USE THE APPLE SOFTWARE, EVEN IF APPLE

HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. BECAUSE SOME

STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE LIMITATIONS MAY

NOT APPLY TO YOU. Apple’s liability to you for actual damages from any cause whatsoever,

and regardless of the form of the action (whether in contract, tort [including negligence], product

liability, or otherwise), will be limited to $50.

®

PANTONE

PANTONE-identified standards. Consult current PANTONE Color Publications for accurate

color. PANTONE

Colors displayed in the Software or in the documentation may not match

®

and other Pantone, Inc. trademarks are the property of Pantone, Inc. ©

Pantone, Inc., 2001. Pantone, Inc. is the copyright owner of PANTONE color data and/or

software.

This product includes software developed by the Apache Software Foundation (www.apache.org).

SOFTWARE LICENSE AGREEMENT

This is a legal agreement between you and Electronics for Imaging, Inc. (“Electronics for

Imaging”), which is the supplier of the software and updates and upgrades thereto (“Software”)

that accompanies this product (“Product”). Your installation and use of the Software indicates your

agreement to the following terms and conditions. If you do not agree to these terms, do not use

the Software and you may return the unused Software for a refund.

Electronics for Imaging grants to you a non-exclusive limited license to use the Software subject

to the following terms and conditions.

You may:

a. use the Software solely for your own customary business purposes and solely with the Product;

b. use the digitally-encoded machine-readable outline and bitmap programs (“Font Programs”)

provided with the Product in a special encrypted format (“Coded Font Programs”) to reproduce

and display designs, styles, weights, and versions of letters, numerals, characters and symbols on

monitor used with the Product (“Typefaces”) solely for your own customary business purposes;

c. use the trademarks used by Electronics for Imaging to identify the Coded Font Programs and

Typefaces reproduced therefrom (“Trademarks”); and

d. permanently transfer all of your rights under this Agreement to any recipient of the Product

only as part of a sale or transfer of the Product, provided (i) you retain no copies of the Software

(including any upgrades), (ii) you transfer to the recipient all of the Software (including any

upgrades), the media and printed materials bundled with the Product, and this Software License

Agreement, AND (iii) the recipient agrees to the terms of this Agreement.

You may not:

a. make or have made, or permit to be made, any copies of the Software, Coded Font Programs or

portions thereof, except as necessary for use with the Product purchased by you; provided,

however, that under no circumstances may you make or have made, or permit to be made, any

copies of that certain portion of the Software which has been included on any portion of the

controller board or hardware of the Product;

b. attempt to modify, create a derivative work of, disassemble, decrypt, or reverse engineer the

Software or Coded Font Programs; or

c. rent, sublicense, or lease the Software.

Proprietary Rights

You acknowledge that the Software, Coded Font Programs, Typefaces, and Trademarks are

proprietary to Electronics for Imaging and its suppliers and that title and other intellectual

property rights therein remain with Electronics for Imaging and its suppliers. This Agreement does

not grant you any right to patents, copyrights, trade secrets, trademarks (whether registered or

unregistered), or to any rights or licenses in respect of the Software, Coded Font Programs,

Typefaces, or Trademarks, except as expressly stated above. You may not adapt or use any

trademark or trade name which is likely to be similar to or confusing with that of Electronics for

Imaging or any of its suppliers or take any other action which impairs or reduces the trademark

rights of Electronics for Imaging or its suppliers. The Trademarks may be used only to identify

printed output produced by the Coded Font Programs. At the reasonable request of Electronics

for Imaging, you must supply samples of any Typeface identified with a Trademark.

Page 4

Confidentiality

You agree to hold the Software and Coded Font Programs in confidence, disclosing the

Software and Coded Font Programs only to your authorized employees having a need to use

the Software and Coded Font Programs as permitted by this Agreement and to take all

reasonable precautions to prevent disclosure to any third parties.

Remedies

Unauthorized use, copying, or disclosure of the Software, Coded Font Programs, Typefaces, or

Trademarks will result in automatic termination of this license and will make available to

Electronics for Imaging other legal remedies.

Limited Warranty And Disclaimer

Electronics for Imaging warrants that, for a period of ninety (90) days from the date of

installation by you, the Software under normal use will perform without significant errors that

make it unusable. Electronics for Imaging’s entire liability and your exclusive remedy under any

and all warranties will be, at Electronics for Imaging’s option, to use reasonable commercial

efforts to attempt to correct or work around errors, to replace the Software with functionally

equivalent software, or to refund the purchase price of the Software and terminate this

Agreement. Some states do not allow such limitations, so the above limitation may not apply

to you. EFI makes no warranty, implied or otherwise, regarding the performance or reliability

of any third party products.

EXCEPT FOR THE ABOVE EXPRESS LIMITED WARRANTY, ELECTRONICS FOR

IMAGING MAKES AND YOU RECEIVE NO WARRANTIES, REPRESENTATIONS

OR CONDITIONS ON THE PRODUCT, SOFTWARE OR CODED FONT

PROGRAMS, EXPRESS, IMPLIED, STATUTORY, OR IN ANY OTHER PROVISION

OF THIS AGREEMENT OR COMMUNICATION WITH YOU, AND ELECTRONICS

FOR IMAGING SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTY OR

CONDITION OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE

AND NONINFRINGEMENT OF THIRD PARTY RIGHTS. THE USE,

MODIFICATION, REPAIR, AND/OR INSTALLATION OF ANY THIRD PARTY

PRODUCTS, OTHER THAN AS AUTHORIZED BY ELECTRONICS FOR IMAGING

WILL VOID THE EXPRESS LIMITED WARRANTY ABOVE. SOFTWARE ERRORS

THAT ARISE FROM ACCIDENT, ABUSE, MISAPPLICATION, ABNORMAL USE,

VIRUS, WORM OR SIMILAR CIRCUMSTANCE WILL VOID THE EXPRESS

LIMITED WARRANTY ABOVE. Electronics for Imaging does not warrant that the

operation of the Software will be uninterrupted, secure or error free or that the Software will

meet your specific requirements.

Limitation Of Liability

IN NO EVENT WILL ELECTRONICS FOR IMAGING OR ITS SUPPLIERS BE LIABLE

FOR ANY DAMAGES, INCLUDING LOSS OF DATA, LOST PROFITS, COST OF

COVER, THIRD PARTY CLAIMS OR OTHER SPECIAL, INCIDENTAL,

CONSEQUENTIAL, RELIANCE, EXEMPLARY, PUNITIVE OR INDIRECT

DAMAGES ARISING FROM THE USE OF THE PRODUCT, SOFTWARE OR CODED

FONT PROGRAMS, HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY.

THIS LIMITATION WILL APPLY EVEN IF ELECTRONICS FOR IMAGING OR ITS

SUPPLIERS HAVE BEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGE. IN

NO EVENT SHALL THE AGGREGATE LIABILITY OF ELECTRONICS FOR

IMAGING AND ITS SUPPLIERS EXCEED THE AMOUNT PAID FOR THE

SOFTWARE. YOU ACKNOWLEDGE THAT THE PORTION OF THE PRICE WHICH

CAN BE ALLOCATED TO THE SOFTWARE REFLECTS THIS ALLOCATION OF

RISK. THESE LIMITATIONS AND EXCLUSIONS APPLY TO THE EXTENT

PERMITTED BY APPLICABLE LAW. BECAUSE SOME STATES/JURISDICTIONS DO

NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE LIMITATION MAY

NOT APPLY TO YOU.

Export Controls

The Software and Coded Font Programs are subject to the export laws and regulations of the

United States, including the United States Export Administration Regulations. You agree that you

will not export, use, disclose, or re-export the Software or Coded Font Programs in any form in

violation of any applicable export laws and regulations, or without the appropriate United States

and foreign government licenses. Your failure to comply with this provision will result in automatic

termination of this license and will make available to Electronics for Imaging other legal remedies.

Government Use

Use, duplication or disclosure of the Software by the United States Government is subject to

restrictions as set forth in FAR 12.212 or DFARS 227.7202-3 -227.7202-4 and, to the extent

required under U.S. federal law, the minimum restricted rights as set out in FAR 52.227-14,

Restricted Rights Notice (June 1987) Alternate III(g)(3)(June 1987) or FAR 52.227-19 (June

1987). To the extent any technical data is provided pursuant to the Agreement, such data is

protected per FAR 12.211 and DFARS 227.7102-2 and to the extent explicitly required by the

U.S. Government, is subject to limited rights as set out in DFARS 252.227.7015 (November

1995) and DFARS 252.227-7037 (September 1999). In the event that any of the above referenced

agency regulations are modified or superseded, the subsequent equivalent regulation shall apply.

The name of the Contractor is Electronics for Imaging, Inc.

Third Party Beneficiary

You are hereby notified that Adobe Systems Incorporated, a Delaware corporation located at 345

Park Ave., San Jose, California 95110 (“Adobe”) is a third-party beneficiary to this Agreement to

the extent that this Agreement contains provisions which relate to your use of the Font Programs,

the Coded Font Programs, the Typefaces and the Trademarks licensed hereby. Such provisions are

made expressly for the benefit of Adobe and are enforceable by Adobe in addition to Electronics

for Imaging, Inc.

Te rmination

Without prejudice to any other rights of Electronics for Imaging, your breach of this Agreement

will result in automatic termination of this license and will make available to Electronics for

Imaging other legal remedies. In such event, you must destroy all copies of the Software (including

any upgrades).

General

This Agreement shall be governed by the laws of the State of California. The United Nations

Convention on Contracts for the International Sale of Goods and any other similar convention

does not apply to this Agreement. For all disputes related to the Software, Code Font Programs,

Product and/or this Agreement, you consent to the exclusive personal jurisdiction and venue of

the state and federal courts of California.

This Agreement is the entire agreement held between you and Electronics for Imaging and

supersedes any other communications or advertising with respect to the Software and Coded Font

Programs.

If any provision of this Agreement is held invalid, such provision shall be deemed modified to the

extent necessary to be enforceable and the remainder of this Agreement shall continue in full force

and effect.

If you have any questions concerning this Agreement, please write to Electronics for Imaging, Inc.,

Attn: Licensing Dept. or see Electronics for Imaging’s web site at www.efi.com.

You hereby specifically acknowledge that this is a legal agreement between you, the end user, and

Electronics for Imaging, not Canon Inc., with respect to the Software, Font Programs, Coded Font

Programs, Typefaces and Trademarks. Electronics for Imaging has the sole and ultimate liability

for the above limited warranty, and Canon Inc., its subsidiaries or affiliates, their agents,

distributors or dealers shall have no liability with respect to the Software, Font Programs, Coded

Font Programs, Typefaces and Trademarks.

If you have any questions, see the EFI web site at www.efi.com.

Electronics for Imaging, Inc.

303 Velocity Way

Foster City, CA 94404

USA

Page 5

3

5

6

12

31

33

Contents

Overview

Scope of this guide 1

About the illustrations in this guide 2

Terminology and conventions 2

Tools you will need 2

Precautions

Exploded view

Accessing the Unit-G1/F2/C2

Checking connections

External connections 7

Internal connections 8

Power scheme 11

Replacing the Unit-G1/F2/C2 motherboard

Replacing Unit-G1/F2/C2 components

DIMM 19

BIOS chip 20

Socketed chips 21

Battery 22

CPU cooling assembly 23

Enclosed fan 24

Power supply 25

PORT 80 board 27

Hard disk drive 28

Restoring functionality after service

Printing Unit-G1/F2/C2 pages

Printing the Configuration page 32

Printing the Test Page 32

Verifying connection to the network

System software

System software installation reminders 35

Installing system software over the network port 35

Installing system software using a USB flash drive 40

Specifications

Hardware features 45

Networking and connectivity 45

Safety and emissions compliance 45

Troubleshooting

Where problems occur 46

Before you go to the customer site 48

Preliminary on-site checkout 49

Checking connections 49

Checking the network 50

Error messages and conditions 50

Printing to the Unit-G1/F2/C2 54

18

31

35

45

46

1

7

Index

Page 6

Page 7

Overview

Overview

The Canon imagePASS-G1/C2 and Canon Color Network Printer Unit-G1/F2/C2 add

computer connectivity and highly efficient PostScript and PCL printing capacity into

print engines and provide support for PCL.

N

:

OTE

The term “Unit-G1/F2/C2” is used in this manual to refer to any and all of the

following:

• imagePASS-G1/C2

•Network Printer Unit-G1/F2/C2

Generally, the Unit-G1/F2/C2 does not require regular maintenance. The Unit-G1/F2/

C2 is shipped with all necessary software already installed.

Use the procedures in this book to inspect, remove, reseat, or replace major hardware

components and to reinstall system software. Replacement parts for the Unit-G1/F2/C2

are available from your authorized service support center. You need to reinstall system

software if you replace the hard disk drive or receive a more recent version of the system

software. You may also reinstall system software as a way to troubleshoot the system.

Scope of this guide

This service guide describes how to remove or replace major Unit-G1/F2/C2 hardware

components and how to reinstall system software. It also includes product specifications

and troubleshooting information. See the Table of Contents for each topic (in bold type)

and each sub topic. Also use the Index to find the location of specific information.

This service guide does not describe in detail how to install the Unit-G1/F2/C2 into the

print engine or remove it and does not include information on the Unit-G1/F2/C2’s

dedicated power supply, power switch connector, PORT 80 board, or cables that do not

connect to the motherboard. For information on these topics, see the documentation

that accompanies the print engine.

This service guide is intended for authorized Unit-G1/F2/C2 and print engine service

technicians installing or servicing the Unit-G1/F2/C2. If you are not an authorized

service technician, do not attempt to install or service the Unit-G1/F2/C2.

Electronics for Imaging does not warrant the performance if the Unit-G1/F2/C2 is

installed or serviced by non-authorized personnel.

N

OTE

:

Unit-G1/F2/C2 customers should not use the technical service documentation.

Do not leave your copy of this service guide at the customer site after you make a

service call.

1

Page 8

Overview

About the illustrations in this guide

The illustrations in this guide reflect the current shipping version of the Unit-G1/F2/C2

at the time of publication. Components shown in these illustrations are subject to

change. To receive information about any Unit-G1/F2/C2 components that do not

match the illustrations in this guide, contact your authorized service/support center.

Terminology and conventions

The terms “replace” and “replacing” are typically used throughout this guide to mean

reinstallation of existing components. Install new components only when necessary.

The term “ network administrator” refers to the person responsible for maintaining the

network at the customer site.

The term “system software” refers to the software installed on the Unit-G1/F2/C2 hard

disk drive.

References to other Unit-G1/F2/C2 documents, such as Configuration and Setup , on the

User Documentation CD, are displayed in italics.

N

:

OTE

The note format highlights important messages and additional information.

The Caution icon indicates a need for special care and safety when handling the

equipment.

Tools you will need

To install or service the Unit-G1/F2/C2, bring the following tools and parts to the

customer site:

• ESD wrist grounding strap and antistatic mat

• #0 and #1 Phillips head screwdrivers (non-magnetic)

Also bring this guide, documentation for any optional service kits you may be installing,

and any technical notes for the Unit-G1/F2/C2.

2

Page 9

Precautions

Precautions

Always observe the following general precautions when servicing the Unit-G1/F2/C2

assembly:

1. Report any shipping damage.

If there is any evidence of shipping or handling damage to packing boxes or their

contents, save the damaged boxes and parts, call the shipper immediately to file a claim,

and notify your authorized service/support center.

2. Never alter an existing network without permission.

The Unit-G1/F2/C2 is probably connected to an existing Local Area Network (LAN)

based on Ethernet hardware. The network is the link between the customer’s computer,

existing laser printers, and other prepress equipment. Never disturb the LAN by breaking

or making a network connection, altering termination, installing or removing

networking hardware or software, or shutting down networked devices without the

knowledge and express permission of the network administrator.

3. Never assign an IP address in Network Setup.

Only the network administrator should assign an IP address to a network device.

Assigning an incorrect IP address to the Unit-G1/F2/C2 can cause unpredictable errors

on any or all devices.

4. Follow standard ESD (electrostatic discharge) precautions while working on the internal

components of the print engine.

Static is always a concern when servicing electronic devices. It is highly unlikely that the

area around the print engine is static-free. Carpeting, leather-soled shoes, synthetic

clothing fibers, silks, and plastics may generate a static charge of more than 10,000 volts.

Static discharge is capable of destroying the circuits etched in silicon microchips, or

dramatically shortening their life span. By observing standard precautions, you may avoid

extra service calls and save the cost of a new board.

When possible, work on a ground-connected antistatic mat. Wear an antistatic

wristband, grounded at the same place as the antistatic mat. If that is not possible:

•Attach a grounding strap to your wrist. Attach the other end to a good ground.

• When you remove an electronic component, place it into an antistatic bag

immediately. Do not walk across a carpet or vinyl floor while carrying an unprotected

board.

• Leave new electronic components inside their antistatic bags until you are ready to

install them.

• When you unpack the electronic components, touch a metal area of the print engine to

discharge the static on your body. Place the components on a grounded antistatic

surface, component-side up.

5. Avoid flexing a printed circuit board, and handle it by opposing edges (not corners) only.

6. Never set a cup of coffee—or any liquid—on or near any components or the print device.

3

Page 10

Precautions

Power Supply Cord Notice

CAUTION: The power supply cord is used as the main disconnect device. Ensure that the

socket-outlet is located/installed near the equipment and is easily accessible.

ACHTUNG: Der Netzstecker dient zur sicheren Trennung des Gerätes von der Stromversorgung. Stellen Sie sicher, dass sich die

Steckdose in unmittelbarer Nähe des Gerätes befindet und leicht zugänglich ist.

ATTENTION : Le cordon d’alimentation doit être débranché pour une mise hors tension totale du produit. La prise de courant

doit être située ou installée à proximité du matériel et être facilement accessible.

Lithium Battery Notice

CAUTION: There is danger of explosion if the battery is replaced with an incorrect type.

Replace it only with the same type recommended by the manufacturer. Dispose of used

batteries according to the manufacturer’s instructions.

ACHTUNG: Es besteht Explosionsgefahr, wenn die Batterien durch einen falschen Batterientyp ersetzt werden. Ersetzen Sie sie

deshalb nur durch denselben, vom Hersteller empfohlenen Typ. Entsorgen Sie leere Batterien entsprechend den Anweisungen

des Herstellers.

ATTENTION : Il y a danger d’explosion en cas de remplacement avec le mauvais type de batterie. Remplacer uniquement avec

une batterie du même type recommandé par le constructeur. Les batteries usagées doivent être jetées conformément aux

instructions du fabricant.

Short Circuit Protection

WARNING: This product relies on the building’s installation for short-circuit

(overcurrent) protection. Ensure that a fuse or circuit breaker no larger than 120 VAC,

15A U.S. (240 VAC, 10A international) is used on the phase conductors (all currentcarrying conductors).

WARNUNG: Dieses Produkt ist darauf angewiesen, dass im Gebäude ein Kurzschluss- bzw. Überstromschutz installiert ist.

Stellen Sie sicher, dass eine Sicherung oder ein Unterbrecher von nicht mehr als 240 V Wechselstrom, 10 A (bzw. in den USA

120 V Wechselstrom, 15 A) an den Phasenleitern (allen stromführenden Leitern) verwendet wird.

ATTENTION : La protection contre les courts-circuits (surtension) du produit est assurée par l’installation électrique du local où

il est installé. S’assurer qu’un fusible ou un disjoncteur inférieur ou égal à 120 V CA , 15 A aux Etats-Unis (240 V CA, 10 A

dans les autres pays) est utilisé pour les conducteurs de phase (conducteurs de courant).

4

Page 11

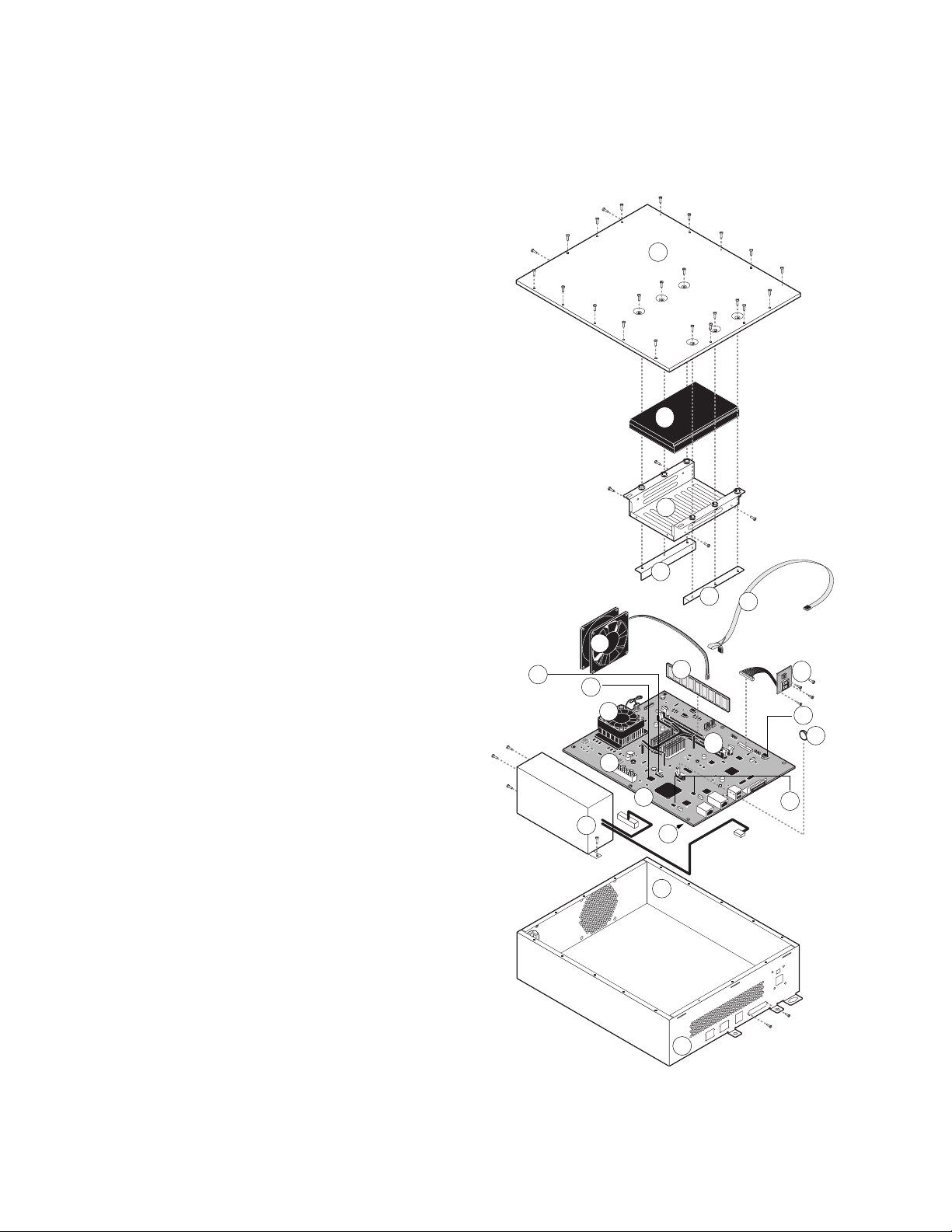

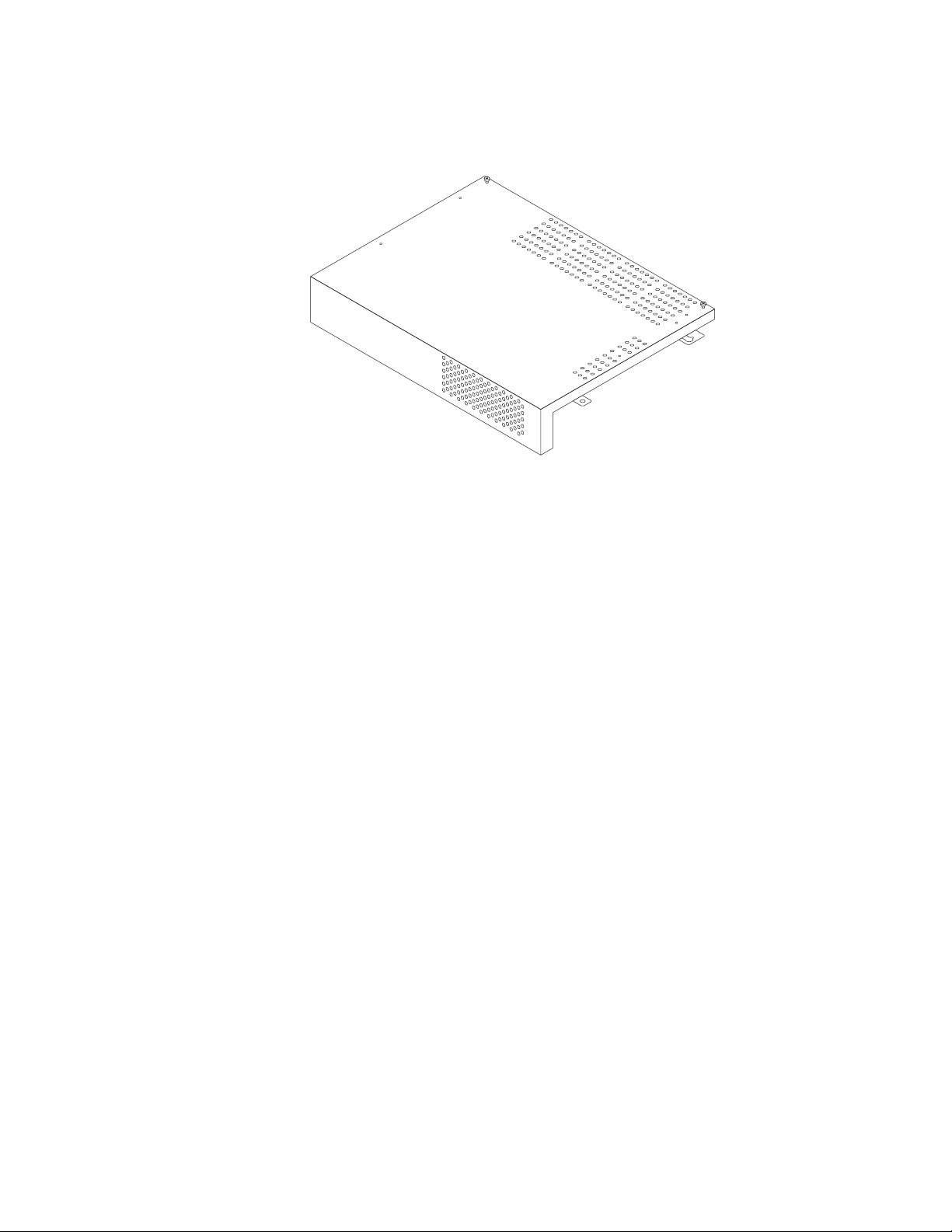

Exploded view

K

ey

Exploded view

1. Lid

2. HDD

3. Shock bracket 1

4. Shock bracket 2

5. Shock bracket 3

6. HDD cable

7. Enclosed fan

8. DIMM

9. Port 80 board with 2-digit LEDs and

Download (DL) switches (2)

10. SATA0 connector for HDD cable

11. BIOS (U530)

12. CPU cooling assembly

13. Key chip (U7201):

Marking:

Unit-G1: ER

Unit-F2: EN

Unit-C2: FB

[Kanji units:

Unit-G1: ES

Unit-F2: EP

Unit-C2: FC]

14. Battery

15. DIMM sockets (2)

16. Power connector (J8008)

17. Unit-G1/F2/C2 motherboard

18. MAC chip set

Markings:

EF (Orange) = U7701 (print engine)

EE (White) = U5060 (LAN)

19. Connectors at connector panel for:

LAN; print engine; USB device (2); print engine

20. Power supply with bracket

21. Chassis

22. Connector panel

7

10

11

12

16

NOTE: For details on power cabling, see Figure G

on page 15 and Figure H on page 16.

20

17

1

2

3

4

5

6

8

15

19

9

13

14

18

F

IGURE

A

Unit-G1/F2/C2 exploded view

21

22

5

Page 12

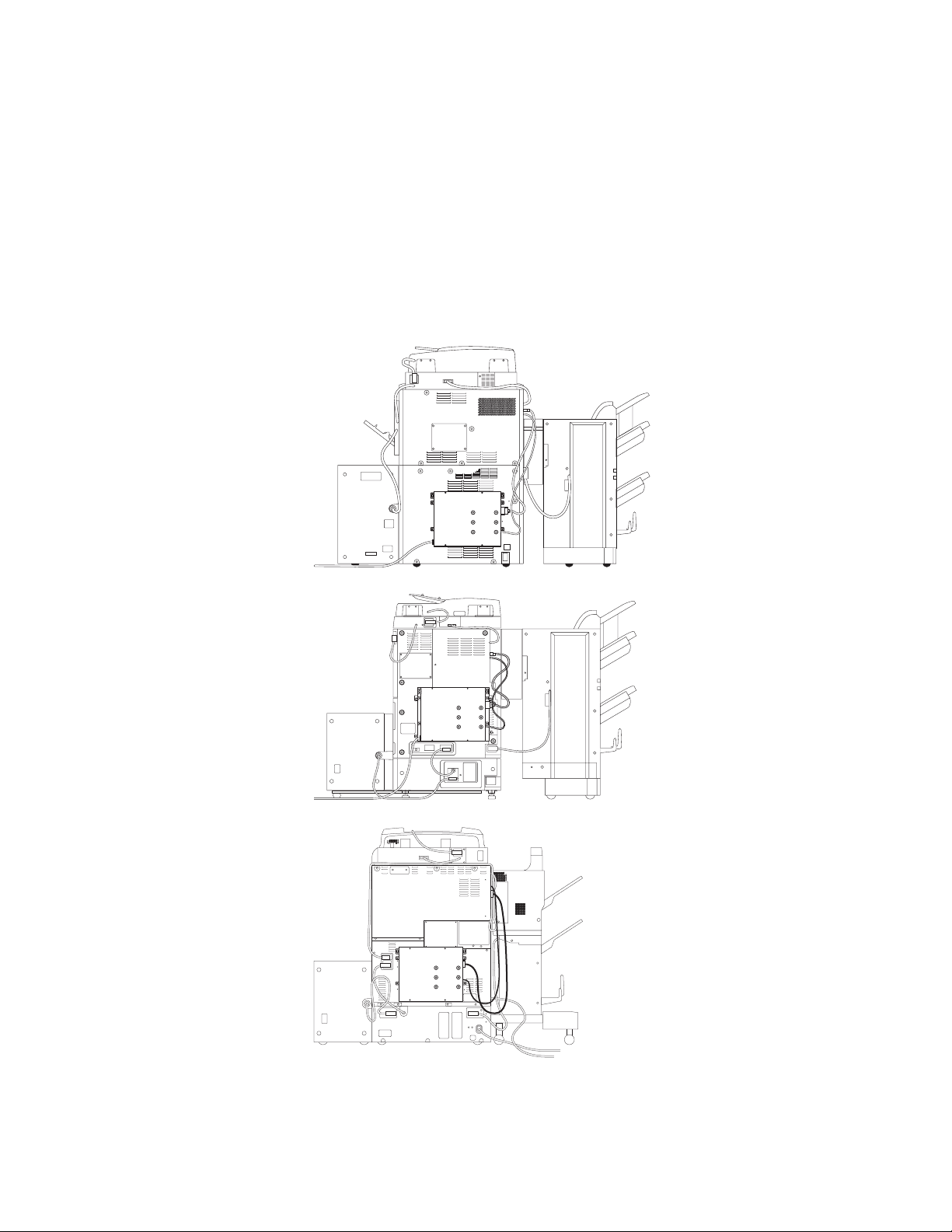

Unit-G1

Accessing the Unit-G1/F2/C2

Accessing the Unit-G1/F2/C2

To service the Unit-G1/F2/C2, you must power off and unplug the print engine and

remove the Unit-G1/F2/C2 from the print engine back panel (or mounting bracket if

there is one). Open the lid of the Unit-G1/F2/C2. If there is a mounting bracket in your

configuration, you do not need to remove the mounting bracket from the print engine

back panel.

N

OTE

:

Detailed Unit-G1/F2/C2 installation instructions are not provided in this guide.

Unit-F2

with mounting

bracket

Unit-C2

IGURE

F

6

Unit-G1/F2/C2 attached to their respective print engines

B

Page 13

Checking connections

IGURE

F

Mounting bracket for Unit-F2

C

Checking connections

The most common causes of hardware problems are faulty or loose connections. Make

sure that Unit-G1/F2/C2 cables are intact and that both ends of each cable are properly

aligned and well seated on the appropriate connectors.

External connections

Connectors for external cables are located on the connector panel, and a power cord is

located at the back of the Unit-G1/F2/C2. Check the Unit-G1/F2/C2 power cord and

then check all external cables at the Unit-G1/F2/C2 connector panel (see the following

figure). Also check the positions of the two switches on the connector panel.

7

Page 14

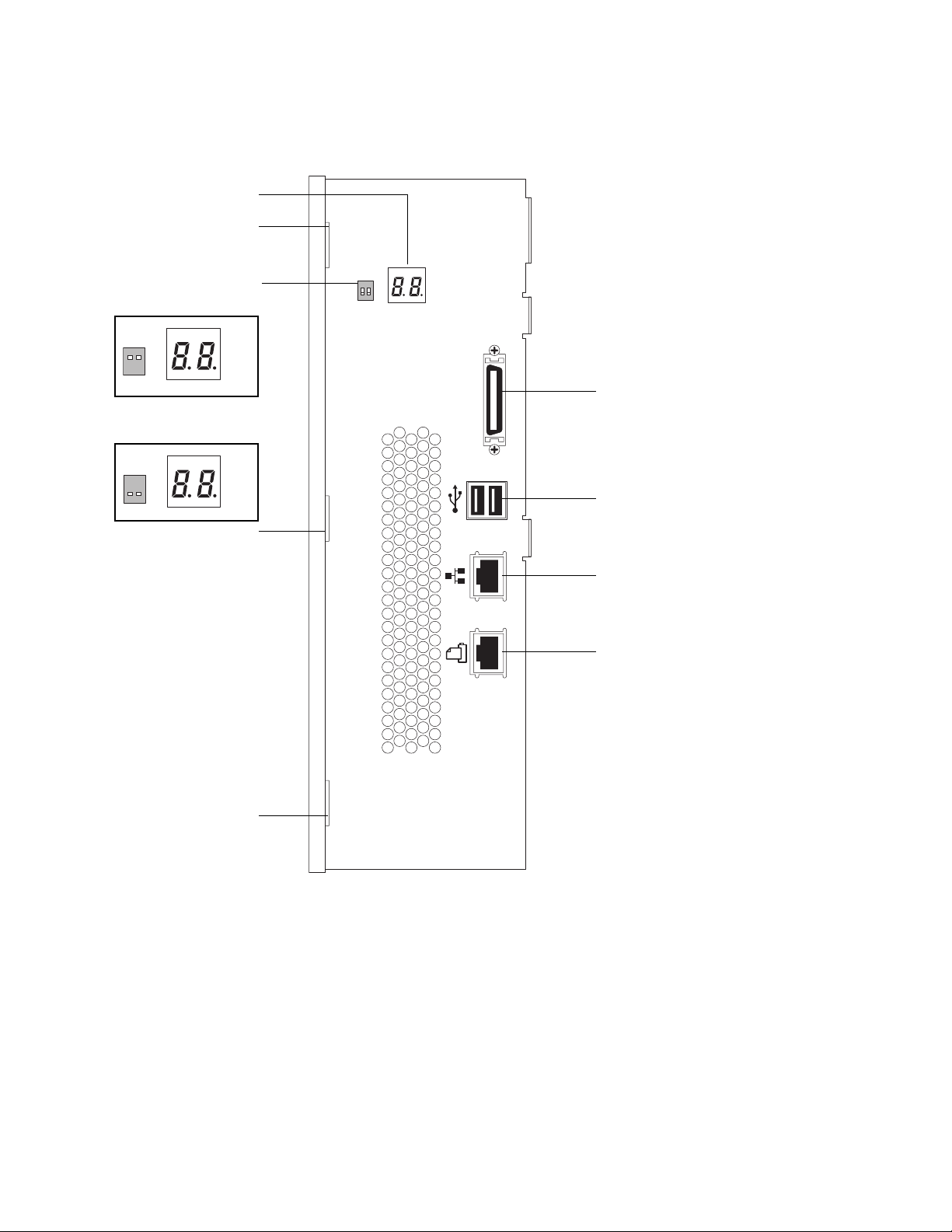

DIAG 2-digit LEDs

Tab slot

Checking connections

DL switches

Service position (up):

DL

1 2

Normal position (down):

DL

1 2

Tab slot

DIAG

DIAG

DL

DIAG

Print Engine interface connector

VIDEO

USB-A ports (2)

10BaseT/100BaseTX/1000BaseT

connector for twisted pair Ethernet

Print Engine interface connector

Tab slot

D

IGURE

F

Unit-G1/F2/C2 connector panel

After you conclude that all external connections are good, check the internal

connections.

Internal connections

Check the internal connections according to the procedure on page 10. See Figure E on

page 9 for locations of most internal connections. For the HDD, see Figure H on

page 16.

8

Page 15

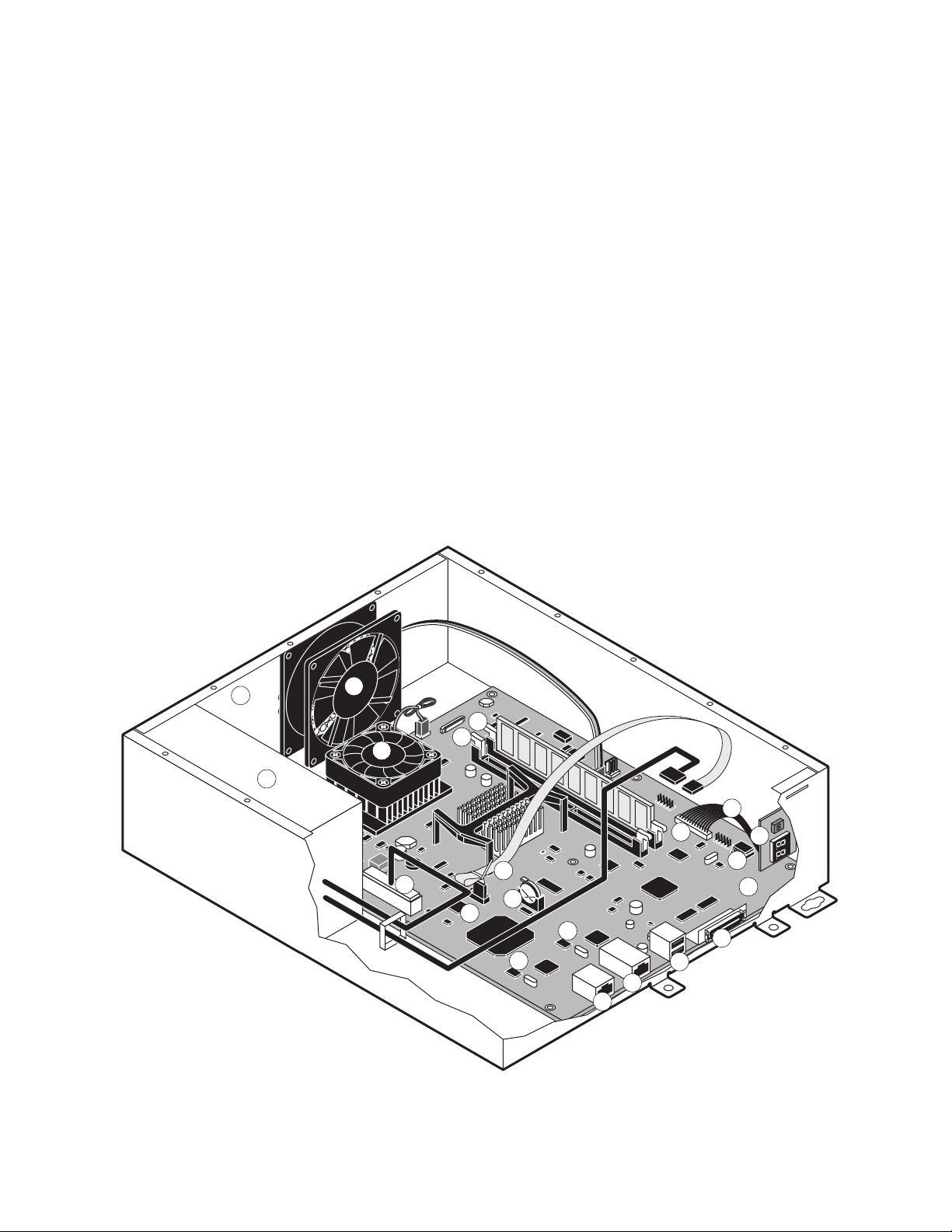

Checking connections

Key (For details on HDD cabling, see Figure G on page 15 and Figure H on page 16.)

1. Chassis

2. Enclosed fan to motherboard ENC FAN1 5V

3. Power supply to motherboard J8008 and to HDD (HDD in lid not shown)

4. CPU cooling assembly to motherboard CPU FAN 5V

5. DDR DIMM2 socket (with standard DIMM)

6. DDR DIMM1 socket (for optional upgrade)

7. BIOS (U530)

8. MAC chip set (ENET EEPROM): 8a U7701; 8b U5060

9. Battery in socket (BT300)

10. Unit-G1/F2/C2 motherboard

11. Print Engine interface connectors

12. RJ-45 network connector

13. USB-A ports (2)

14. Port 80 board with DIAG 2-digit LEDs and Download (DL) switches

15. Port 80 cable

16. PORT80 connector

17. Key chip (U7201)

18. Power connector (J8008)

19. HDD SATA cable at motherboard connector SATA0

IGURE

F

2

4

18

Chassis components

E

5

6

15

16

19

9

7

8b

8a

12

11

13

14

17

10

11

1

3

9

Page 16

T

O

CHECK

Checking connections

INTERNAL

CONNECTIONS

AUTION

C

Before you touch any parts inside the print engine, make sure to wear an ESD

:

grounding wrist strap.

1. Make sure that any Unit-G1/F2/C2 cables, boards, and DIMMs are intact, properly

aligned, and well seated in their connectors (see Figure G on page 15 and Figure H on

page 16).

•Hard disk drive (HDD) and HDD SATA cable

• DIMM

•Enclosed fan and cable

• CPU cooling assembly and fan cable

• PORT 80 board and cable

•Power supply and cables

2. After verifying connections, if one or more Unit-G1/F2/C2 components are still not

getting power, check again:

• The two interface cable connections between the Unit-G1/F2/C2 and the print engine

• The print engine power supply (see the documentation that accompanies the

print engine)

10

Page 17

Checking connections

Power scheme

The Unit-G1/F2/C2 has its own power supply and AC power cable. To function, the

Unit-G1/F2/C2 must be connected to the print engine and to a proper AC power outlet.

The Unit-G1/F2/C2 will not start up until the print engine is powered on. Powering off

the print engine powers off the Unit-G1/F2/C2 also.

When you power off the print engine, the Unit-G1/F2/C2 takes awhile to shut down

and power off. Always check the DIAG LEDs on the connector panel of the Unit-G1/

F2/C2: when the LEDs go out, the Unit-G1/F2/C2 is off.

The Unit-G1/F2/C2 power supply supplies power directly to the motherboard and to

the HDD. From the motherboard, power goes to the PORT 80 board and the enclosed

fan (see Figure G on page 15 and Figure H on page 16).

The Unit-G1/F2/C2 powers off and on by means of the print engine power switch. The

Unit-G1/F2/C2 shuts down if it is disconnected from the print engine. In normal usage,

the customer can leave the Unit-G1/F2/C2 plugged in to the AC power outlet and

connected to the print engine.

Before you perform service on the Unit-G1/F2/C2 hardware:

•Power off the Unit-G1/F2/C2 using the print engine power switch

•Unplug the Unit-G1/F2/C2 from the AC power outlet

•If you plan to open the Unit-G1/F2/C2 while it is connected to the print engine ( not

recommended ), make sure also to unplug the print engine from its AC power outlet

before you open the Unit-G1/F2/C2.

11

Page 18

Replacing the Unit-G1/F2/C2 motherboard

Replacing the Unit-G1/F2/C2 motherboard

When the Unit-G1/F2/C2 motherboard needs to be replaced, use the following

procedures.

T

U

O

SHUT

DOWN

THE

G1/F2/C2

NIT-

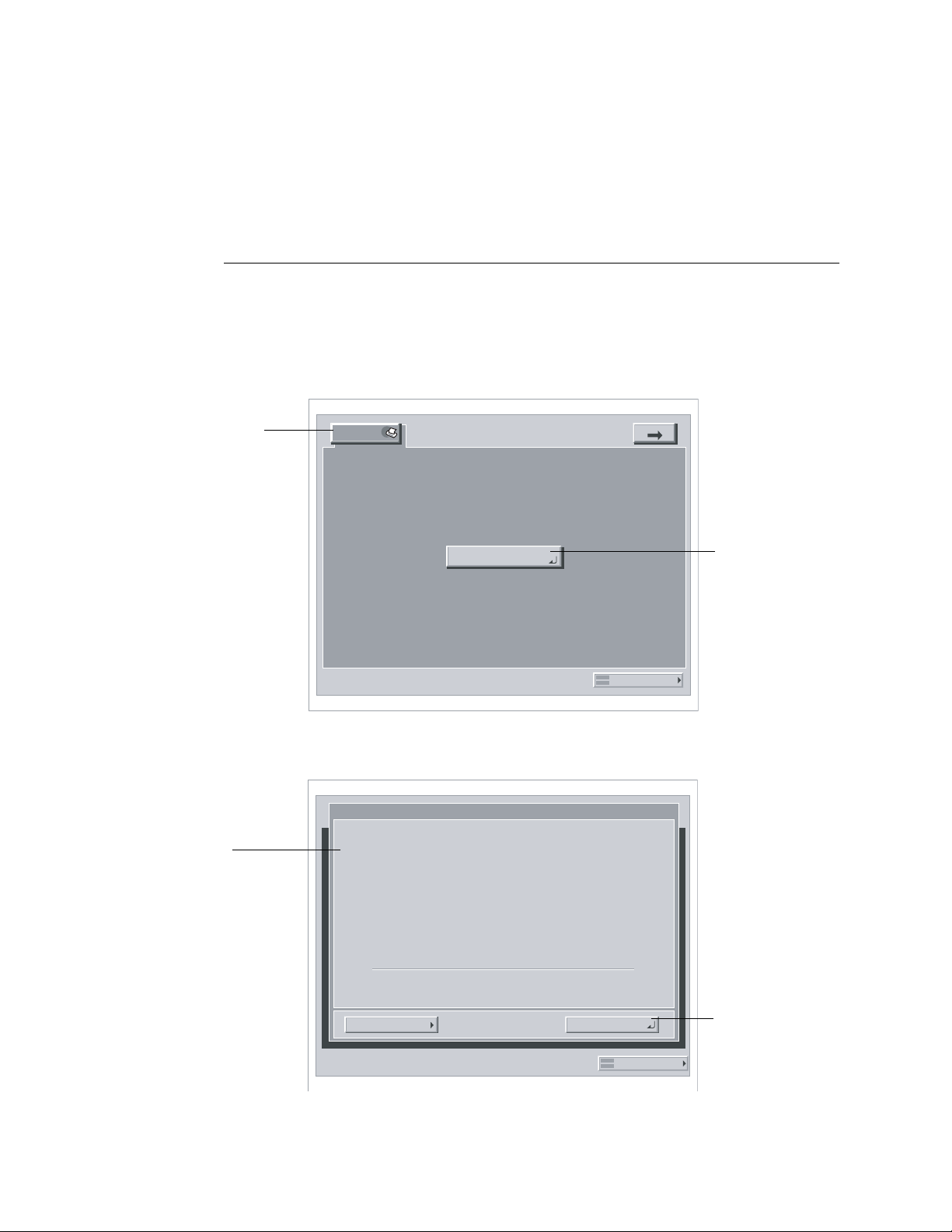

1. If the print engine is in its main mode, select the Printer tab on the print engine LCD

and then select Printer Status/Setting.

Depending on the number of feature tabs, you may need to press the arrow key to display

the screen with the Printer tab.

FROM

THE

PRINT

ENGINE

LCD

Printer tab

Idle appears on the

print engine LCD

Printer

Printer Status/

Settings

Online...Scanner

System Monitor

Printer Status/

Settings

2. Make sure that the Unit-G1/F2/C2 is idle (not processing) and select Functions from the

info screen.

Info

xxxxx

Idle

x.xx

12

xxxxMB

FunctionsDone

System Monitor

Functions

Page 19

Replacing the Unit-G1/F2/C2 motherboard

3. Select Shut Down from the Functions screen.

Functions

Print Pages

Scan Job

Suspend Printing

Resume Printing

Shut Down

1/2

DONE

System Monitor

4. Select Shut Down System from the Shut Down screen.

Shut Down

Restart System

Shut Down System

Reboot System

1/1

DONE

Shut Down

Shut Down System

System Monitor

5. After a message that it is safe to power off the system is displayed, power off the

Unit-G1/F2/C2 using the print engine power switch.

OTE

If you are recycling power, wait at least 45 seconds before powering back on.

N

:

13

Page 20

Replacing the Unit-G1/F2/C2 motherboard

TO OPEN THE UNIT- G1/F2/C2

CAUTION: Make sure you use an ESD grounding wrist strap and follow standard ESD

(electrostatic discharge) precautions while performing this procedure.

1. Shut down the Unit-G1/F2/C2 as described on page 12.

2. Unplug the print engine and remove the Unit-G1/F2/C2.

For information about removing the Unit-G1/F2/C2 from the print engine, see the

Unit-G1/F2/C2 installation instructions, not provided in this guide.

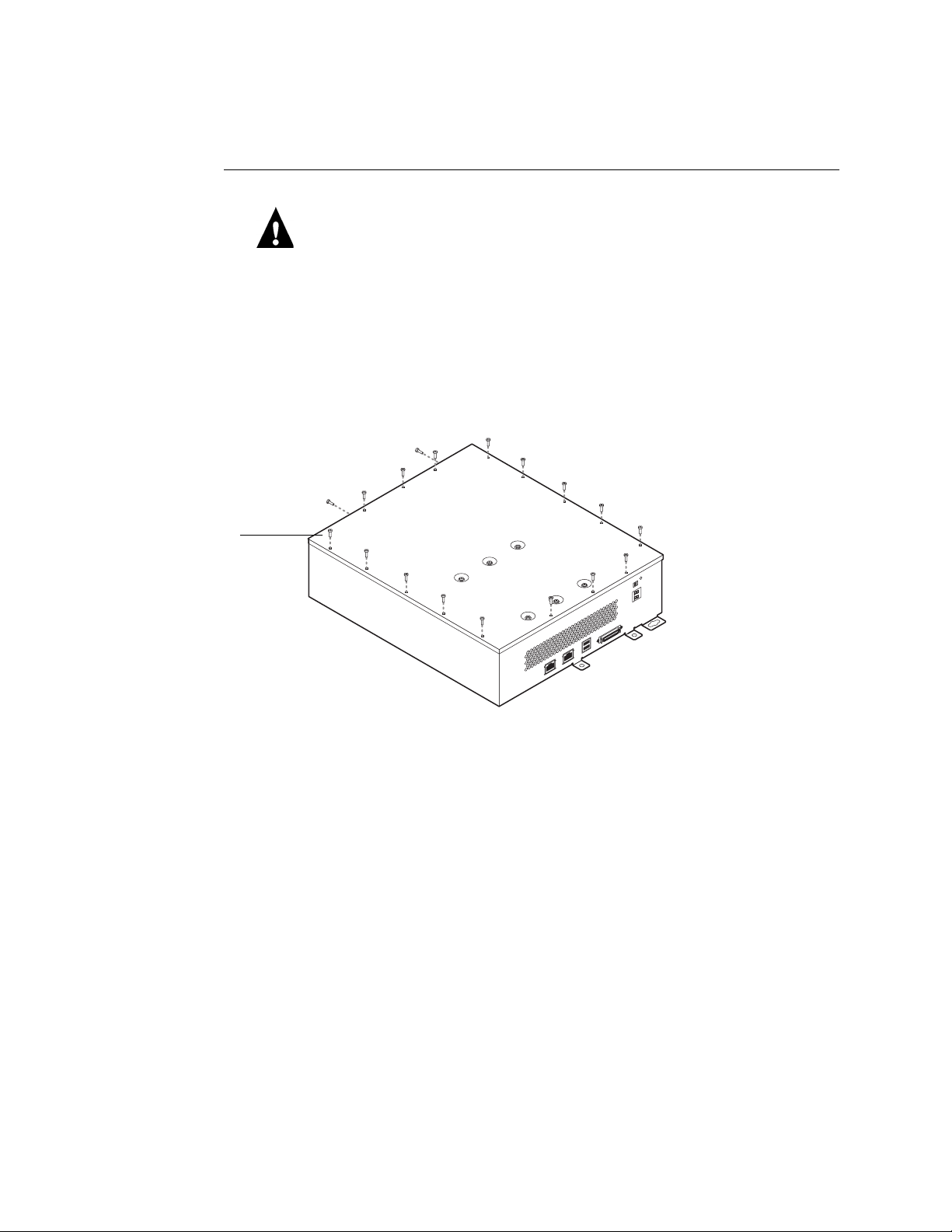

3. Position the Unit-G1/F2/C2 so that the screw holes in the lid are facing up.

4. Remove the 18 screws that secure the lid to the Unit-G1/F2/C2 and set them aside.

Lid

14

F

IGURE F Unit-G1/F2/C2 lid screws

Page 21

Lid

HDD

Replacing the Unit-G1/F2/C2 motherboard

5. Lift up the lid, hold it in a vertical position, and disconnect the cables (2) from the

HDD.

Make sure to hold the lid so that it does not fall. The HDD is mounted to the lid and is

connected to the motherboard and power supply by short cables. Do not stress the cables

and connectors by opening the lid past a vertical position.

HDD cable in

motherboard

connector SATA0

(See note on

page 31)

Motherboard

HDD SATA power cable

Power supply

FIGURE G Internal components

6. Slide the lid sideways to unhook the three tabs from the chassis (for tab slot locations

see Figure D on page 8).

15

Page 22

Power supply

Replacing the Unit-G1/F2/C2 motherboard

7. Gently set the lid upside down on a flat anti-static surface.

Enclosed fan cable

in FAN

HDD cable in SATA0

(See note on page 31)

Power supply cable

for motherboard in

J8008

Power supply cable

for HDD

HDD

F

IGURE H Accessing the Unit-G1/F2/C2

TO REMOVE THE UNIT-G1/F2/C2 MOTHERBOARD

CAUTION: Make sure you use an ESD grounding wrist strap and follow standard ESD

(electrostatic discharge) precautions while performing this procedure.

1. Shut down and open the Unit-G1/F2/C2 as described on page 12 and page 14.

2. Disconnect the following cables from the motherboard (see Figure H).

Port 80 board

cable connector

16

•Enclosed fan cable at motherboard FAN connector

• PORT 80 board cable at motherboard PORT 80 connector

• HDD cable at motherboard SATA0 connector

•Power supply cable at motherboard J8008 connector

3. Remove the 7 screws that secure the motherboard to the chassis and the 2 screws that

secure the motherboard to the connector panel.

The screw types differ. Keep like screws together.

4. Pinch the locks on any locking standoffs to release the motherboard from the chassis.

Avoid stressing or flexing the motherboard and avoid scraping any components.

5. Carefully remove the motherboard from the connector panel cutouts. Lift the

motherboard out of the chassis and set it on a flat anti-static surface.

Page 23

Replacing the Unit-G1/F2/C2 motherboard

TO REPLACE THE MOTHERBOARD IN THE CHASSIS

1. If you are replacing an old motherboard with a new motherboard, unpack the new

motherboard and install the following components from the old motherboard, because a

spare motherboard does not have these components:

• DIMM (see page 19)

•Key chip in U7201 (see page 21)

Edge connectors

DIMM

Key chip U7201

For the appropriate marking, see the information

provided in Figure A on page 5

Connector panel cutouts

[Chassis not shown]

FIGURE I Motherboard

2. Insert the edge connectors into the chassis connector panel and align the motherboard

screw holes with the standoffs in the chassis.

Avoid stressing or flexing the motherboard and avoid scraping any components.

3. Align the motherboard with any locking standoffs and snap into place.

4. Install the screws that secure the motherboard to the connector panel and to the chassis.

Tip: To prevent stress on the motherboard, tighten the two connector panel screws first;

then tighten the screws to the chassis.

5. Connect the following cables to the motherboard (see Figure H on page 16):

•Enclosed fan cable at motherboard FAN connector

• PORT 80 board cable at motherboard PORT 80 connector

• HDD cable at motherboard SATA0 connector

•Power supply cable at motherboard J8008 connector

6. Reassemble the unit and verify functionality (see page 31).

17

Page 24

Replacing Unit-G1/F2/C2 components

Replacing Unit-G1/F2/C2 components

The CPU on the custom Unit-G1/F2/C2 controls the printing image data transferred to

and from the print engine. The Unit-G1/F2/C2 provides the Ethernet networking

interface, controls hard disk drive (HDD) functions, and handles the communication

with external devices. The Unit-G1/F2/C2 has two DIMM sockets that each hold

256MB of memory (see Figure E on page 9). The HDD is attached to the inside lid and

connects to the motherboard and power supply by cables (see Figure A on page 5).

When the Unit-G1/F2/C2 is installed inside the print engine, the connectors for external

devices are easily accessible from the back of the print engine.

This section describes how to remove and install components on the Unit-G1/F2/C2:

• DIMM

• BIOS

•Socketed chips (Key chip; Mac chip set)

(If you replace the motherboard, it is not necessary to transfer the BIOS or the Mac

chip set from the old motherboard. It is necessary to transfer the Key chip.)

•Battery

• CPU cooling assembly

•Enclosed fan

•Power supply

• PORT 80 board

• HDD

CAUTION: Make sure to use an ESD grounding wrist strap and follow standard ESD

(electrostatic discharge) precautions while performing these procedures.

18

Page 25

Replacing Unit-G1/F2/C2 components

DIMM

The memory capacity for the Unit-G1/F2/C2 is 512MB. The standard configuration is

one 256MB DIMM installed in the outer socket, DDR DIMM2. To upgrade, install

another 256MB DIMM in the inner socket, DIMM1 (see page 9).

A DIMM (dual in-line memory module) is held in place by levers at each end of its

socket on the Unit-G1/F2/C2.

Approved DIMMs are available from your authorized service support center.

TO REPLACE OR UPGRADE A DIMM

1. To release a DIMM, push outward on the lever on each side of the DIMM (see Figure J).

Lever

DIMM

Socket notch

F

IGURE J Releasing a DIMM

2. Slide the DIMM straight out of the socket to avoid damaging the DIMM or the socket, and

set the DIMM aside.

3. To install a DIMM, insert it straight into the socket. Push the DIMM into the socket until

the levers snap into place.

The DIMM fits the socket only one way. The notch on the bottom of the DIMM should

line up with the notch in the socket.

Make sure that the levers close securely around the ends of the DIMM and that the

DIMM is fully seated in its socket. Avoid flexing the board while you firmly seat the

DIMM in its socket.

4. Reassemble the unit and verify functionality (see page 31).

To verify memory capacity, print a Configuration page to check the amount of memory

recorded.

19

Page 26

Replacing Unit-G1/F2/C2 components

BIOS chip

The BIOS chip is located in the PLCC32 socket on the motherboard at U530 (see

Figure E on page 9). The BIOS chip contains boot information. If you must install a

BIOS chip, use the following procedure. For installing other socketed chips, see page 21.

NOTE: It is not necessary to transfer the BIOS chip when replacing the motherboard.

TO INSTALL THE BIOS CHIP

1. Locate the motherboard PLCC32 socket (U530).

2. If a BIOS chip is already installed in the socket, remove it gently, using a PLCC extractor

(not provided).

Make sure not to put stress on surrounding components or connectors.

Socket Notch

PLCC Extractor

U

BIOS

Chip

U

FIGURE K BIOS chip in socket

3. Place the required BIOS chip on the socket so that the notch in the chip is aligned with

the notch in the socket. Press down on the chip until it snaps into place.

4. Reassemble the Unit-G1/F2/C2 and verify its functionality (see “Restoring functionality

after service” on page 31).

20

Page 27

Replacing Unit-G1/F2/C2 components

Socketed chips

Use the following procedure if you must install one or more of the following socketed

chips:

•Key chip at U7201

•MAC chip set at:

• U7701 for print engine

• U5060 for LAN

NOTE: It is not necessary to transfer the Mac chip set when replacing the motherboard.

TO INSTALL A SOCKETED CHIP

1. Locate the appropriate motherboard socket (see Figure L).

MAC chip set: U7701

MAC chip set markings:

EF (Orange) = U7701 (print engine)

EE (White) = U5060 (LAN)

2. If a chip is already installed, remove it gently using a PROM extractor (not provided).

3. Place the required chip on its socket so that the notch in the chip is aligned with the

4. Reassemble the Unit-G1/F2/C2 and verify its functionality (see page 31).

Key

chip:

U7201

U5060

FIGURE L Socketed chips

Make sure not to put stress on surrounding components or connectors.

notch in the socket. Press down on the chip until it connects firmly into place.

Make sure to align the pins on the chip with the holes in the socket. If you notice any

bent pins, straighten them gently with a pair of needlenose pliers.

N

OTE: If you must install a different MAC chip set onto the motherboard, the system

administrator may need to reconfigure the IP address in Setup. (For instructions, see

Configuration and Setup, on the User Documentation CD.)

21

Page 28

Replacing Unit-G1/F2/C2 components

Battery

The battery on the Unit-G1/F2/C2 is located at BT300. To replace it, see

“Specifications” on page 45.

CAUTION: There is danger of explosion if the battery is replaced with the incorrect type.

Replace it only with the same type recommended by the manufacturer. Dispose of used

batteries according to the manufacturer’s instructions.

ACHTUNG: Es besteht Explosionsgefahr, wenn die Batterie durch eine Batterie falschen Typs ersetzt wird. Als Ersatz dürfen

nur vom Hersteller empfohlene Batterien gleichen oder ähnlichen Typs verwendet werden. Verbrauchte Batterien müssen

entsprechend den Anweisungen des Herstellers entsorgt werden.

ATTENTION: Il y a risque d’explosion si la pile est remplacée par un modèle qui ne convient pas. Remplacez-la

uniquement par le modèle recommandé par le constructeur. Débarrassez-vous des piles usées conformément aux instructions

du constructeur.

ADVARSEL!: Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering Udskiftning må kun ske med bat-teri af samme

fabrikat og type. Levér det brugte batteri tilbage til leverandøren.

VAROITUS: Paristo voi räjähtää, los se on virheellisesti asennettu. Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä Käytetty paristo valmistajan ohjeiden mukaisesti.

ADVARSEL: Eksplosjonsfare ved feilaktig skifte av batteri. Benytt samme batteritype eller en tilsvarende type anbefalt av

apparatfabrikanten. Brukte batterier kasseres i henhold til fabrikantens instruksjoner.

VARNING: Explosionsfara vid felaktigt batteribyte. Använd samma batterityp eller en ekvivalent typ som rekommenderas

av apparat-tillverkaren. Kassera använt batteri enligt fabrikantens instruktion.

TO REPLACE THE MOTHERBOARD BATTERY

1. Pull the old battery out of its socket (see Figure M) and insert the new battery.

Battery

Socket

IGURE M Motherboard battery

F

2. Reassemble the Unit-G1/F2/C2 and verify its functionality as described on page 31.

N

OTE: When you power on the print engine, allow the Unit-G1/F2/C2 to reach Idle,

then power off and on again to reinitialize the realtime clock. Wait 45 seconds between

power off and power on.

Motherboard

22

3. Configure the time and date in Setup.

Page 29

TO REPLACE THE CPU COOLING ASSEMBLY

To CPU FAN 5V connector

Cooling assembly

Tension screw

(1 of 4)

Replacing Unit-G1/F2/C2 components

CPU cooling assembly

The CPU cooling assembly consists of a heatsink and fan for dissipating heat generated

by the CPU. If it stops functioning, the Unit-G1/F2/C2 will shut down automatically.

1. Shut down and open the Unit-G1/F2/C2 as described on pages 12 and 14.

2. Remove the motherboard from the chassis as described on page 18.

3. Disconnect the fan cable from the motherboard CPU FAN 5V connector.

F

IGURE N CPU cooling assembly and fan connection

4. Pinch each of the four tension screws on the underside of the motherboard to detach the

CPU cooling assembly from the motherboard.

When replacing the fan, make sure to install it in its original orientation.

5. Align the new CPU cooling assembly over the CPU and then push the four tension screws

through the motherboard screw holes until they snap into place.

6. Connect the fan cable to the motherboard CPU FAN 5V connector.

The motherboard connector is keyed so that the cable fits only one way.

7. Install the motherboard into the chassis as described on page 17.

8. Reassemble the unit and verify functionality as described on page 31.

23

Page 30

Replacing Unit-G1/F2/C2 components

Enclosed fan

One enclosed fan cools the system by blowing air out the back of the chassis (see Figure E

on page 9). If it stops functioning, the Unit-G1/F2/C2 will shut down automatically.

TO REPLACE AN ENCLOSED FAN

1. Shut down and open the Unit-G1/F2/C2 as described on pages 12 and 14.

Enclosed fan

Front view

24

Rivet (1 of 4)

Back view

2. Disconnect the fan cable from the motherboard ENC FAN1 5V connector.

3. Remove the 4 rivets that secure the fan to the chassis and remove the fan.

Tip: Press the rivet from inside the chassis in order to dislodge the rivet easily.

4. Secure the new fan inside the chassis using the rivets you removed. Make sure the new

fan is in the same orientation as the old fan.

When replacing the fan, make sure to install it such that the air will blow out the back of

the chassis.

5. Connect the fan cable to a motherboard ENC FAN1 5V connector.

6. Reassemble the unit and verify functionality as described on page 31.

Page 31

Replacing Unit-G1/F2/C2 components

Power supply

The Unit-G1/F2/C2 has its own dedicated power supply. To remove and/or replace it,

use the following procedures and refer to the following figure.

Power supply

To motherboard connector J8008

Routing clamp

OTE: The power supply includes two identical HDD

ATA power cables. If one breaks, use the other one.

FIGURE O Power supply cables

TO REMOVE THE POWER SUPPLY

CAUTION: Make sure you wear an ESD grounding wrist strap and follow standard ESD

(electrostatic discharge) precautions while handling Unit-G1/F2/C2 components.

To HDD SATA power

connector (HDD in lid

is not shown)

1. Shut down and open the Unit-G1/F2/C2 as described on pages 12 and 14.

2. Remove the power supply cable from motherboard connector at J8008.

(You already removed the HDD SATA power cable from the HDD.)

3. Take the power supply cables out of any routing clamps that are attached to the chassis.

Note the routing so that you can route the cables correctly later.

4. Remove the screws that secure the power supply to the chassis: 3 to the back; 1 to the

bottom (through the power supply bracket). See Figure A on page 5 for locations.

Set the screws aside so you can replace them later.

5. Remove the power supply from the chassis.

NOTE: If you will be installing a new power supply you may need to transfer the power

supply bracket from the old power supply to the new power supply (2 screws).

25

Page 32

Replacing Unit-G1/F2/C2 components

TO REPLACE THE POWER SUPPLY

CAUTION: Make sure you attach an ESD grounding wrist strap and follow standard ESD

(electrostatic discharge) precautions before handling Unit-G1/F2/C2 components.

1. Position the power supply in the chassis (see Figure O on page 25).

2. Secure the power supply to the chassis with the 4 screws you removed earlier: 3 to the

back; 1 to the bottom (through the power supply bracket). See Figure A on page 5.

3. Insert the power supply cables into the one or more routing clamps.

Routing clamps keep the cables away from system components as much as possible.

4. Connect the power supply cable to the motherboard at power connector J8008.

Lid

4-pin power connector

NOTE: Keep the tie-wrap in place.

[not used]

HDD cable at

motherboard

connector SATA0

(See note below)

Tie-wrap

Motherboard

The tie-wrap is required to keep a bend in the

HDD cable in order to avoid stressing the SATA0

connector when the lid is closed.

F

IGURE P Replacing the power supply

5. Reassemble the unit and verify functionality (see page 31).

N

OTE: When you attach the HDD SATA power cable to the HDD, make sure to keep

the tie-wrap in place on the HDD SATA power cable. The tie-wrap is required to protect

the motherboard connector SATA0 when the lid is closed.

HDD

HDD SATA power cable

Routing clamp

Power supply

Screw to back (1 of 3)

For location of 1 screw to

bottom, see page 5.

26

Page 33

Replacing Unit-G1/F2/C2 components

PORT 80 board

The Unit-G1/F2/C2 uses a PORT 80 board to offer service mode switches for installing

system software over the network and DIAG LEDs arrayed as a 2-digit display. To

remove and/or replace it, use the following procedures and refer to the following figure.

Port 80 cable

to PORT80

connector

Port 80 board

Snap rivet

(1 of 4)

FIGURE Q Cable to PORT 80 board

TO REMOVE THE PORT 80 BOARD

CAUTION: Make sure you wear an ESD grounding wrist strap and follow standard ESD

(electrostatic discharge) precautions while handling Unit-G1/F2/C2 components.

1. Shut down and open the Unit-G1/F2/C2 as described on pages 12 and 14.

2. Remove the Port 80 board cable from the motherboard PORT 80 connector.

Do not pull the wires of the cable. Pull the cable out by its connector.

3. Remove the snap rivets that secure the Port 80 board to the connector panel of the

chassis and remove the Port 80 board.

You may need pliers to squeeze the end of the rivet while you push the rivet through the

board and chassis. Set the rivets aside so you can replace them later.

TO REPLACE THE PORT 80 BOARD

CAUTION: Make sure you attach an ESD grounding wrist strap and follow standard ESD

(electrostatic discharge) precautions before handling Unit-G1/F2/C2 components.

1. Position the PORT 80 board in the chassis (see Figure Q on page 27) and secure the PORT

80 board to the chassis with the snap rivets you removed earlier.

2. Connect the Port 80 board cable to the PORT 80 board and to the motherboard PORT 80

connector.

3. Reassemble the unit and verify functionality (see page 31).

27

Page 34

Replacing Unit-G1/F2/C2 components

Hard disk drive

The factory-installed hard disk drive (HDD) is formatted and loaded with all Unit-G1/

F2/C2 software, including operating software, system software, network drivers, and

printer fonts. Because the HDD is used to store spooled print jobs, available disk space is

displayed on the print engine LCD.

If the HDD needs to be replaced, you will need to install the system software on the new

one. (Replacement drives are shipped without Unit-G1/F2/C2 system software

installed.) For more information, see “System software” on page 35.

Proper handling

Handle the HDD with care:

•Use proper ESD practices when grounding yourself and the Unit-G1/F2/C2.

•Keep magnets and magnetic-sensitive objects away from the HDD.

•Do not remove the screws on top of the HDD. Loosening these screws voids the

warranty.

•Never drop, jar, or bump the HDD.

•Handle the HDD by its sides and avoid touching the printed circuit board.

• Allow the HDD to reach room temperature before installation.

HDD problems may be a result of the following:

• Loose or faulty connection

•Faulty HDD

Before you decide that the HDD needs to be replaced, make sure that the cables to the

HDD are intact and connected properly. See Figure R on page 29.

To remove and/or replace the HDD, use the following procedures and refer to the

following figures.

28

Page 35

TO REMOVE THE HDD

Lid

4-pin power connector [not used]

To motherboard SATA0 connector

Replacing Unit-G1/F2/C2 components

CAUTION: Make sure you wear an ESD grounding wrist strap and follow standard ESD

(electrostatic discharge) precautions while handling Unit-G1/F2/C2 components.

1. Shut down and open the Unit-G1/F2/C2 as described on pages 12 and 14.

Chassis

NOTE: Disconnect the HDD cables from the HDD

before you remove the lid from the chassis (see

page 16).

F

IGURE R HDD cables and connectors

2. After removing the lid from the chassis, remove the HDD from the shock bracket (4

screws). Set the screws aside (see Figure S on page 30).

It is not necessary to remove or disassemble the shock bracket.

From power supply

29

Page 36

Replacing Unit-G1/F2/C2 components

Shock bracket

NOTE: It is not necessary to disassemble and

remove the shock bracket from the lid.

IGURE S HDD and shock bracket

F

3. Place the HDD in an antistatic bag.

Do not touch the HDD with magnetic objects, such as magnetic screwdrivers. Do not

place items near the HDD that are sensitive to magnets, such as credit cards and

employee ID cards. See “Proper handling” on page 28.

HDD

Screw (1 of 4)

Screw hole

(1 of 4)

TO REPLACE THE HDD

CAUTION: Make sure you attach an ESD grounding wrist strap and follow standard ESD

(electrostatic discharge) precautions before handling Unit-G1/F2/C2 components.

1. Handle the HDD with care.

Do not touch it with magnetic objects or place any objects near it that are sensitive to

magnets. See “Proper handling” on page 28.

2. Secure the HDD to the shock bracket using the 4 screws you removed earlier (see

Figure S).

3. Reassemble the unit and verify functionality (see page 31).

After you reattach the chassis lid, hold the lid in a vertical position while you reconnect

the HDD cables from motherboard SATA0 connector and from the power supply.

The connectors are keyed for proper orientation of the cables. Note that the 4-pin power

connector is not used. See Figure R on page 29.

Tip: The power supply includes two identical HDD SATA power cables but you only

need one. If one breaks, use the other one.

30

Page 37

Restoring functionality after service

Restoring functionality after service

To complete service procedures performed on the Unit-G1/F2/C2, install the Unit-G1/

F2/C2 inside the print engine as described in the Unit-G1/F2/C2 installation

instructions (not provided in this guide) and verify that it is working properly. To verify

the installation, check the connections of the Unit-G1/F2/C2 first to the print engine

and then to the network.

TO REASSEMBLE AND VERIFY THE UNIT- G1/F2/C2

1. Reseat any boards, cables, connectors, and other parts of the Unit-G1/F2/C2 that you

loosened or removed during inspection or service. (Exception: Do not connect cables to

the HDD until step 2).

2. Install the lid and connect the HDD cables—Insert the three tabs into the tab slots on

the connector panel (see Figure D on page 8); hold the lid vertically while connecting

the cables to the HDD (see Figure R on page 29); close the lid over the chassis and

secure the lid to the chassis with the 18 screws you removed earlier (see Figure F on

page 14).

3. Install the Unit-G1/F2/C2 in the print engine and reassemble the print engine as

described in the Unit-G1/F2/C2 installation instructions (not provided in this guide).

4. If you installed a new HDD, install system software (see “System software” on page 35.)

A spare HDD is shipped without system software.

5. Before you leave the customer site, verify Unit-G1/F2/C2 operation as described in the

following flow diagram.

Power up and print Unit-G1/F2/C2

Test Page (see page 32).

Connect the Unit-G1/F2/C2 to the

network and verify (see page 33).

Check the Setup options (see

Configuration and Setup).

F

IGURE T Steps to verify Unit-G1/F2/C2 connection

Printing Unit-G1/F2/C2 pages

The print engine LCD allows you to print special pages from the Unit-G1/F2/C2. These

pages include the Configuration page and the Test Page.

31

Page 38

Printing Unit-G1/F2/C2 pages

Printing the Configuration page

The Configuration page lists all the settings in effect from the current Setup. After you

have finished running Setup, print a Configuration page to confirm your settings. If the

Unit-G1/F2/C2 is rebooting, allow the Unit-G1/F2/C2 to reboot and return to Idle

before printing a Configuration page.

Before you perform any service procedure, print the Unit-G1/F2/C2 Configuration page

(if possible) so that you are prepared to return the settings to their former configurations,

if necessary.

After the connection to the network is made, the network administrator can customize

Setup options according to the network and user environment. Using the Configuration

page as a guide helps speed up this process. For more information, see

Configuration and Setup, on the User Documentation CD.

Printing the Test Page

Before connecting the Unit-G1/F2/C2 to the network, print the Test Page. The Test Page

is a file that resides in the Unit-G1/F2/C2. Output verifies that the Unit-G1/F2/C2 is

functional and connected properly to the print engine.

TO PRINT UNIT-G1/F2/C2 PAGES FROM THE PRINT ENGINE LCD

1. Select the Printer tab on the print engine LCD, and then select Printer Status/Setting.

2. Select Functions from the print engine LCD.

3. Select Print Pages from the print engine LCD.

4. Select the Test Page, Configuration page, or other page from the Print Pages menu.

5. Examine the Test Page.

If the Test Page prints, you know that the Unit-G1/F2/C2 is functional and that the

connection between the Unit-G1/F2/C2 and the print engine is good. When you

examine the Test Page, keep in mind that:

• All patches should be visible, even though they may be very faint (in the 5% and 2%

range).

• Each patch set should show uniform gradation from patch to patch as the tone lightens

from 100% to 0%.

Poor image quality may indicate a need to calibrate the system or service the

print engine.

6. Post the current Configuration page near the Unit-G1/F2/C2 for quick reference.

Users may need the information on this page which describes the current Setup

configuration.

32

Page 39

Verifying connection to the network

Verifying connection to the network

The Unit-G1/F2/C2 provides twisted pair connectivity to an Ethernet network.

Category 3, category 4, or category 5 unshielded twisted pair (UTP) network cable can

be used for 10BaseT. Category 5 UTP cable must be used for 100BaseTX. See the

following figure and procedure for where to connect and how to verify the network

connection.

Unit-G1/F2/C2 connector

panel

DL

DIAG

VIDEO

Network connector

FIGURE U Unit-G1/F2/C2 network connector

33

Page 40

Verifying connection to the network

TO CONNECT A TWISTED PAIR CABLE TO THE UNIT- G1/F2/C2

1. Shut down and power off the Unit-G1/F2/C2 before connecting the Unit-G1/F2/C2 to any

network device (see “To shut down the Unit-G1/F2/C2 from the print engine LCD” on

page 12).

2. Connect the network cable to the appropriate RJ-45 network connector on the Unit-G1/

F2/C2 connector panel (see Figure U on page 33).

3. Configure Setup options.

It is the network administrator’s responsibility to configure Setup according to the

network and user environment. Default settings in Setup may be adequate although they

may not be optimal for the user’s environment. For setup information, refer the network

administrator to Configuration and Setup, on the User Documentation CD.

4. After configuring Setup options, verify the network connection.

Once the network connection has been made and the Unit-G1/F2/C2 has the correct

Setup configuration and is Idle, the Unit-G1/F2/C2 should be available on the network.

The network administrator should perform any additional network Setup, verify the

network connection, verify that the Unit-G1/F2/C2 appears in the list of printers, and

print a few test documents from a networked computer that will use the Unit-G1/F2/C2.

(For more information, see Configuration and Setup, on the User Documentation CD.)

34

Page 41

System software

System software

The Unit-G1/F2/C2 system software is installed on the HDD at the factory. You must

install system software if a more recent version is required, if you replace the HDD, or if

you discover problems with the current system. To upgrade to a newer version of system

software, you can install all system software over the LAN port or use a USB flash drive.

System software installation reminders

Keep in mind the following when installing system software:

• Fonts—Installing system software deletes all fonts that the customer has installed on

the Unit-G1/F2/C2. Only resident fonts will be restored during system software

installation. Fiery Downloader can be used to reinstall additional fonts.

To determine which additional fonts were downloaded to the Unit-G1/F2/C2, print

the Fonts List before you format the HDD and again after you complete the system

software installation. Any fonts not listed after installation must be reinstalled. For

more information, see Utilities, on the User Documentation CD.

•

Language—Screens for installing system software are always displayed in English,

even if the print engine is configured for another language.

• Compatibility—The latest user software must be installed onto all computers that print

to the Unit-G1/F2/C2. Using incompatible versions of the system and user software

may result in system problems.

Installing system software over the network port

The System Software CD contains the system software and Fiery System Software

Installer. To install system software using the LAN port on the Unit-G1/F2/C2, you

need:

•For 100BaseTX—One Category 5 or higher Ethernet cross-over cable

(4-pair/8-wire, short-length)

For 1000BaseT—One Category 5e or higher Ethernet cross-over cable

(4-pair/8-wire, short-length)

•A Windows XP/2000 computer with:

–A CD-ROM drive, built in or attached

–Support for 100BaseTX or 1000BaseT

35

Page 42

System software

TO INSTALL SYSTEM SOFTWARE USING ETHERNET

1. Shut down the Unit-G1/F2/C2 and power off the print engine (see page 12).

2. Disconnect the customer’s LAN from the LAN port. Disconnect anything connected to the

USB-A ports.

Do not disconnect the two interface cables between the print engine and the Unit-G1/

F2/C2.

DL

DIAG

print engine interface port

VIDEO

USB-A ports

LAN port

LAN port

print engine interface port

FIGURE V Disconnecting from the customer’s LAN

3. Connect an Ethernet cross-over cable to the LAN port and to a Windows XP/2000 PC.

DL

DIAG

VIDEO

To print engine

Ethernet cross-over cable

X

To print engine

Windows 2000/XP PC

36

FIGURE W Creating an isolated Ethernet network using a cross-over cable

Tip: To identify a cross-over cable, compare the connectors on the cable. The ribbon

sequence will be identical. A normal cable will not have identical wiring on both ends.

Page 43

Service position (up):

System software

4. Power on the PC and insert the System Software CD into the PC CD-ROM drive.

5. Navigate to the CD-ROM drive and click the icon for the Installer.exe file if it does not

start automatically.

6. If you are prompted to find the install.ini file, navigate to the top level of the CD-ROM

drive. Select the install.ini file and click Open.

7. Click next at the Welcome screen. Read the Software License Agreement and click the “I

Agree” checkbox if you wish to continue the installation process, then click Next.

8. At the Connection Type screen, make sure Ethernet is selected. Click Next to advance to

the Confirmation screen.

9. Flip the Unit-G1/F2/C2 service switches up to the service mode position (see Figure X).

DL

1 2

Normal position (down):

DL

1 2

DIAG

DL switches

DL

DIAG

DIAG

F

IGURE X Switches on the connector panel

After you have finished installing system software, make sure to flip the service switches

down to the normal position.

10. Power on the Unit-G1/F2/C2 using the print engine AC power switch and wait 10

seconds.

To avoid confusion, ignore the text and graphics on this Confirmation screen. The

procedure on this screen may not depict Unit-G1/F2/C2 hardware.

11. Click Next on the PC screen.

37

Page 44

System software

12. At the Installation screen, click Next to commence installation. Wait while the files are

copied and installed.

The progress is slow at first. For most computers, expect to wait approximately 25

minutes to complete—do not cancel.

If you do click Cancel click Finish, and then power off the print engine, wait 10 seconds,

and then repeat this procedure from the beginning. If the installation terminates

abnormally, you may need to reboot the PC also. To avoid confusion, ignore the text and

graphics on the cancel screen.

13. Click Exit when the message is displayed that the installation is successful. Remove the

System Software CD from the PC.

14. Power off the print engine.

15. Flip the service switches down to the normal position (see Figure X).

16. Disconnect the cross-over cable from the LAN port and the Windows XP/2000 PC.

DL

DIAG

LAN port

VIDEO

F

IGURE Y Dismantling the isolated Ethernet network

To print engine

Ethernet cross-over cable

Windows 2000/XP PC

X

To print engine

17. Reconnect the LAN cable that you removed earlier to the Unit-G1/F2/C2 connector

panel.

18. Power on the print engine and wait a few minutes.

19. At the Languages Setup screen, select the name of the language you want to use, and

then select OK. Wait a few minutes.

38

Page 45

System software

20. If the Select Market Region screen is displayed, select the name of the region for the

Unit-G1/F2/C2 and then select OK. Wait a few minutes.

The Select Market Region screen is displayed only if English was selected from the

language selection screen.

NOTE: If you select English as the language, you must then select “UK” or “Other”. If you

select UK, the default paper size is A4 and the time stamp is DD/MM/YY. If you select

“Other” the default paper size is LT and the time stamp is MM/DD/YY.

21. A screen may appear briefly regarding print engine functions. See other documentation

for details.

22. At the Setup screen, select Run Setup and select OK. Reenter the customer’s settings

from the Configuration page that you printed earlier.

Enter settings for Server, Network, and Printer Setup, in that order. Ignore the settings

not included on the Configuration page if it is more appropriate for the site

administrator to set them. For more information, see Configuration and Setup, on the

User Documentation CD.

23. After all setup options are configured, select Exit Setup from the Setup screen, and then

press OK.

The Unit-G1/F2/C2 will reboot with the updated system software and setup options.

24. Allow the Unit-G1/F2/C2 to reach Idle.

39

Page 46

System software

Installing system software using a USB flash drive

To install system software using a USB flash drive attached to the Unit-G1/F2/C2, you

need the following items:

• USB 2.0 flash drive [not provided] with 1 Gigabyte capacity and a data transfer LED

Not all USB 2.0 flash drives have been validated for use with the Unit-G1/F2/C2. If

the one you are using does not work, try another brand.

• Any PC [not provided] with:

–Intel x86-compatible microprocessor

– CD-ROM drive, built in or attached

–Support for USB 2.0

(USB 1.1 may work but may be very slow)

– 256MB, minimum, memory capacity

•System Software CD (if the number of CDs increases to 2 in a subsequent upgrade,

you may need to increase the Gigabyte capacity of the USB 2.0 flash drive to 2GB)

• USB Flash Tool CD

To install system software using a USB 2.0 flash drive, you must use a flash drive that has

been prepared already. The procedures in this section are:

•“To prepare a USB flash drive”

•“To install system software using a prepared USB flash drive”

40

Page 47

System software

TO PREPARE A USB FLASH DRIVE

NOTE: Make sure the boot priority on your PC is set to boot first from the CD-ROM

drive.

To find out how to access/change the PC’s BIOS configuration, see the documentation

that accompanies your PC. Typically, pressing a key during power up (such as F2 or DEL

or F8) will access the BIOS configuration screen.

1. Power on the PC and as soon as the CD-ROM drive LED goes out, load the USB Flash Tool

CD into the PC’s CD-ROM drive.

If you load the CD too late, the PC boots as usual. In that case, restart the PC so that the

PC boots from the CD.

2. Allow the PC to boot from the CD (several minutes, depending on your PC).

Tr oubleshooting tips: If the PC fails to display the Flash Drive Setup screen within 30

minutes, make sure that the PC boot priority is set to boot first from the CD-ROM drive

and make sure that no devices are connected to the USB-A ports. If the PC still fails to

display the Flash Drive Setup screen, try another PC. It could be that your PC is not

compatible with the boot program on the USB Flash Tool CD.

3. Follow the on-screen USB Flash Tool screen prompts. Other status screens may appear

briefly but are not necessarily described here:

N

OTE: To respond to a prompt use only the keyboard, not the mouse.

Screen prompt What you need to do:

1. Please plug in a USB flash drive and

insert a valid product CD, and press OK.

2. Total Number of CD: x

Continue with flash drive setup?

Yes No

3. Flash programming in progress. Please

wait.