Canon iR5870C, iR5870Ci, iR6870C, iR6870Ci Portable Manual

Portable Manual

iR C6800 Series

Apr 25 2006

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair

of products. This manual covers all localities where the products are sold. For this reason, there may be information in this

manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products. When

changes occur in applicable products or in the contents of this manual, Canon will release technical information as the need

arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition

of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or

translated into another language, in whole or in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Indicates an item requiring disconnection of the power plug from the electric outlet.

Indicates an item intended to provide notes assisting the understanding of the topic in question.

Memo

Introduction

REF.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol , the arrow indicates the

direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit door, which results in

supplying the machine with power.

2. In the digital circuits, '1'is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low".(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the operations of the microprocessors

used in the machines are not discussed: they are explained in terms of from sensors to the input of the DC controller PCB and from the output of the

DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service Information bulletins and be

able to identify and isolate faults in the machine."

Contents

Contents

Chapter 1 Maintenance and Inspection

1.1 Periodically Replaced Parts ...............................................................................................................................1

1.1.1Overview .........................................................................................................................................................1

1.1.2Reader Unit.....................................................................................................................................................1

1.1.3Printer Unit ......................................................................................................................................................1

1.2 Durables and Consumables...............................................................................................................................1

1.2.1Overview .........................................................................................................................................................1

1.2.2Reader Unit.....................................................................................................................................................1

1.2.3Printer Unit ......................................................................................................................................................2

1.3 Scheduled Servicing Basic Procedure .............................................................................................................2

1.3.1Scheduled Servicing Basic Procedure .......................................................................................................2

1.3.2Scheduled Servicing (reader unit)...............................................................................................................3

1.3.3Scheduled Servicing (printer unit)...............................................................................................................3

1.3.4Shifting the Photosensitive Drum Phase....................................................................................................7

1.4 Cleaning ..............................................................................................................................................................13

1.4.1Cleaning the Secondary Transfer Rear Guide........................................................................................13

1.4.2Cleaning the Registration Roller, Registration Guide, and Transparency Sensor............................13

Chapter 2 Standards and Adjustments

2.1 Image Adjustment Basic Procedure ...............................................................................................................15

2.1.1Image Adjustment Basic Procedure 1 ......................................................................................................15

2.1.2Image Adjustment Basic Procedure 2 ......................................................................................................15

2.1.3Image Adjustment Basic Procedure 3 ......................................................................................................16

2.1.4Image Adjustment Basic Procedure 4 ......................................................................................................17

2.1.5Image Adjustment Basic Procedure 5 ......................................................................................................18

2.1.6Image Adjustment Basic Procedure 6 ......................................................................................................19

2.1.7Potential Control Conversion Table ..........................................................................................................20

2.2 Image Adjustments............................................................................................................................................25

2.2.1Image Position..............................................................................................................................................25

2.2.2Checking the Image Position .....................................................................................................................25

2.2.3Cassette ........................................................................................................................................................25

2.2.4Manual Feed Tray........................................................................................................................................26

2.2.5Front Deck ....................................................................................................................................................26

2.3 Scanning System ...............................................................................................................................................27

2.3.1After Replacing the CCD Unit ....................................................................................................................27

2.3.2After Replacing the Copyboard Glass......................................................................................................27

2.3.3After Replacing the Reader Controller PCB or Initializing the RAM ....................................................28

2.4 Laser Exposure System....................................................................................................................................28

2.4.1After Replacing the Laser Scanner ...........................................................................................................28

2.5 Image Formation System .................................................................................................................................28

2.5.1After Replacing the Black Developing Unit ..............................................................................................28

2.5.2Points to Note When Attaching the Polarity Positioning Plate..............................................................28

Contents

2.5.3Replacing the Color Developing Unit.......................................................................................................29

2.5.4Replacing the Starter of the Color Developing Unit...............................................................................30

2.5.5After Replacing the Primary Charging Assembly................................................................................... 32

2.5.6After Replacing the Primary Charging Wire............................................................................................ 32

2.5.7After Replacing the Pre-Transfer Charging Wire ................................................................................... 32

2.5.8After Replacing the Pre-Transfer Charging Wire ................................................................................... 32

2.5.9After Replacing the Waste Toner Box ..................................................................................................... 32

2.5.10After Replacing the ITB Cleaning Blade................................................................................................32

2.5.11After Repacking the Photosensitive Drum Cleaning Blade................................................................ 33

2.5.12Replace the Photosensitive Drum .......................................................................................................... 34

2.5.13Points to Note When Replacing the Drum Heater...............................................................................34

2.5.14Points to Note When Replacing the Drum Heater PCB......................................................................35

2.5.15After Repacking the ITB .......................................................................................................................... 36

2.5.16After Replacing the Primary Transfer Roller......................................................................................... 36

2.6 Fixing System .................................................................................................................................................... 37

2.6.1Points to Note When Attaching the Fixing Assembly............................................................................37

2.6.2After Replacing the Fixing Roller .............................................................................................................. 37

2.6.3After Replacing the Fixing Web ................................................................................................................ 37

2.6.4Position of the Fixing inlet Guide ..............................................................................................................37

2.6.5Points to Note When Attaching the Pressure Roller.............................................................................. 38

2.6.6Adjusting the Nip Pressure of the Pressure Roller ...............................................................................38

2.6.7Adjusting the Position of the Feeding Web Solenoid (SL2) ................................................................. 38

2.6.8Points to Note About the Position of the Fixing Thermal Switch ......................................................... 38

2.6.9Points to Note When Mounting the Shift Thermal Switch..................................................................... 38

2.6.10Points to Note When Mounting the Outside Heating Roller Thermal Switch ..................................39

2.6.11Points to Note When Mounting the Fixing Upper Thermistor ............................................................ 39

2.6.12Points to Note When Mounting the Fixing Lower Thermistor ............................................................ 39

2.6.13Points to Note When Mounting the External Heat Thermistor........................................................... 39

2.7 Electrical Components ..................................................................................................................................... 39

2.7.1When Replacing the Reader Controller PCB .........................................................................................39

2.7.2After Replacing the DC Controller PCB................................................................................................... 40

2.7.3Points to Note When Mounting the DC Controller PCB/ DC Controller Box .....................................40

2.7.4After Replacing the Main Controller PCB (main) ................................................................................... 41

2.7.5After Repacking the SRAM Board............................................................................................................41

2.7.6After Replacing the HDD............................................................................................................................ 41

2.7.7When Replacing the HV2 PCB.................................................................................................................41

2.7.8When Replacing the ATR Sensor/Patch Image Read Sensor ............................................................42

2.8 Pickup/Feeding System ................................................................................................................................... 42

2.8.1Adjusting the Horizontal Registration After Replacing the Pickup Cassette......................................42

2.8.2Adjusting the Manual Feed Pickup Horizontal Registration................................................................. 42

2.8.3Adjusting the Front Deck Pickup Horizontal Registration..................................................................... 42

2.8.4Registering the Paper Width Basic Value............................................................................................... 44

Chapter 3 Error Code

3.1 Error Code Details ............................................................................................................................................45

3.1.1Error Code in Detail .................................................................................................................................... 45

3.2 Error Code (SEND) ........................................................................................................................................... 61

3.2.1Self-Diagnostic Display ..............................................................................................................................61

Contents

3.2.2List of Error Codes without Messages......................................................................................................62

3.3 Jam Codes..........................................................................................................................................................65

3.3.1Jam Code (printer unit) ...............................................................................................................................65

3.3.2Jam Code (finisher-related)........................................................................................................................65

3.3.3Jam Code (ADF-related) ............................................................................................................................66

3.4 Alarm Codes.......................................................................................................................................................67

3.4.1Alarm Code...................................................................................................................................................67

Chapter 4 User Mode Items

4.1 User Mode Items................................................................................................................................................69

4.1.1Common Settings ........................................................................................................................................69

4.1.2Common Settings ........................................................................................................................................69

4.1.3Timer Settings ..............................................................................................................................................71

4.1.4Timer Settings ..............................................................................................................................................71

4.1.5Adjustment and Cleaning ..........................................................................................................................71

4.1.6Adjustment and Cleaning ..........................................................................................................................71

4.1.7Report Settings ............................................................................................................................................71

4.1.8Report Settings ............................................................................................................................................72

4.1.9System Settings ...........................................................................................................................................72

4.1.10System Settings .........................................................................................................................................73

4.1.11Copy Settings .............................................................................................................................................74

4.1.12Copy Settings .............................................................................................................................................74

4.1.13Communications Settings.........................................................................................................................75

4.1.14Communications Settings.........................................................................................................................75

4.1.15Mail Box Settings .......................................................................................................................................76

4.1.16Mail Box Settings .......................................................................................................................................76

4.1.17Printer Settings...........................................................................................................................................76

4.1.18Address Book Settings..............................................................................................................................77

4.1.19Address Book Settings..............................................................................................................................77

Chapter 5 Service Mode

5.1 Test Print.............................................................................................................................................................79

5.1.1Overview .......................................................................................................................................................79

5.1.2Test Print TYPE ...........................................................................................................................................79

5.1.3Selecting Test Print TYPE..........................................................................................................................79

5.1.416-Gradation (TYPE=4)..............................................................................................................................79

5.1.5Full Page Halftone (TYPE=5) ....................................................................................................................80

5.1.6Grid (TYPE=6)..............................................................................................................................................80

5.1.7MCYBk Horizontal Stripes (TYPE=10).....................................................................................................80

5.1.864-Gradation (TYPE=12)............................................................................................................................81

5.1.9Full Color 16-Gradation (TYPE=14) .........................................................................................................81

5.2 DISPLAY (Status Display Mode).....................................................................................................................82

5.2.1 COPIER ........................................................................................................................................................82

5.2.1.1 COPIER List .........................................................................................................................................82

5.2.1.2 COPIER List .........................................................................................................................................90

5.2.2 FEEDER .......................................................................................................................................................98

5.2.2.1 FEEDER List.........................................................................................................................................98

Contents

5.3 I/O (I/O Display Mode)...................................................................................................................................... 99

5.3.1Overview....................................................................................................................................................... 99

5.3.2DC-CON ....................................................................................................................................................... 99

5.3.3DC-CON ..................................................................................................................................................... 102

5.3.4R-CON ........................................................................................................................................................ 105

5.3.5FEEDER ..................................................................................................................................................... 107

5.3.6SORTER..................................................................................................................................................... 107

5.3.7MN-CONT .................................................................................................................................................. 111

5.4 ADJUST (Adjustment Mode)......................................................................................................................... 112

5.4.1 COPIER...................................................................................................................................................... 112

5.4.1.1 COPIER List....................................................................................................................................... 112

5.4.1.2 COPIER List....................................................................................................................................... 122

5.4.2 FEEDER..................................................................................................................................................... 134

5.4.2.1 FEEDER List......................................................................................................................................134

5.4.3 SORTER .................................................................................................................................................... 134

5.4.3.1 SORTER List .....................................................................................................................................134

5.5 FUNCTION (Operation/Inspection Mode)................................................................................................... 134

5.5.1 COPIER...................................................................................................................................................... 134

5.5.1.1 COPIER List....................................................................................................................................... 134

5.5.1.2 COPIER List....................................................................................................................................... 144

5.5.2 FEEDER..................................................................................................................................................... 154

5.5.2.1 FEEDER List......................................................................................................................................154

5.6 OPTION (Machine Settings Mode) .............................................................................................................. 155

5.6.1 COPIER...................................................................................................................................................... 155

5.6.1.1 COPIER List....................................................................................................................................... 155

5.6.1.2 COPIER List....................................................................................................................................... 179

5.6.2 FEEDER..................................................................................................................................................... 207

5.6.2.1 FEEDER List......................................................................................................................................207

5.6.3 SORTER .................................................................................................................................................... 207

5.6.3.1 SORTER List .....................................................................................................................................207

5.6.4 BOARD.......................................................................................................................................................208

5.6.4.1 BOARD List........................................................................................................................................208

5.6.4.2 BOARD List........................................................................................................................................208

5.7 TEST (Test Print Mode) ................................................................................................................................. 208

5.7.1 COPIER...................................................................................................................................................... 208

5.7.1.1 COPIER List....................................................................................................................................... 208

5.7.1.2 COPIER List....................................................................................................................................... 210

5.8 COUNTER (Counter Mode) .......................................................................................................................... 212

5.8.1 COPIER...................................................................................................................................................... 212

5.8.1.1 COPIER List....................................................................................................................................... 212

5.8.1.2 COPIER List....................................................................................................................................... 217

Chapter 6 Outline of Components

6.1 Clutch/Solenoid ...............................................................................................................................................225

6.1.1Clutches and Solenoids ...........................................................................................................................225

6.2 Motor ................................................................................................................................................................. 226

6.2.1Motors .........................................................................................................................................................226

6.3 Fan ....................................................................................................................................................................229

Contents

6.3.1Fans .............................................................................................................................................................229

6.4 Sensor ...............................................................................................................................................................231

6.4.1Sensors .......................................................................................................................................................231

6.5 Switch ................................................................................................................................................................236

6.5.1Switches ......................................................................................................................................................236

6.6 Lamps, Heaters, and Others..........................................................................................................................237

6.6.1Heaters, Lamps, and Others....................................................................................................................237

6.7 PCBs..................................................................................................................................................................239

6.7.1PCB..............................................................................................................................................................239

6.7.2PCB..............................................................................................................................................................241

Chapter 7 System Construction

7.1 Construction......................................................................................................................................................245

7.1.1Functional Construction ............................................................................................................................245

7.1.2Arrangement of the Major PCBs .............................................................................................................246

7.1.3Arrangement of the Major PCBs .............................................................................................................246

7.1.4DC Controller..............................................................................................................................................247

7.2 System Construction .......................................................................................................................................249

7.2.1System Configuration with Pickup/Delivery Accessories ....................................................................249

7.2.2System Configuration with Pickup/Delivery Accessories ....................................................................249

7.2.3System Configuration with Printing/Transmission Accessories .........................................................250

7.2.4System Configuration with Printing/Transmission Accessories .........................................................250

7.2.5Functions of Printing/Transmitting Accessories....................................................................................251

7.2.6Functions of Printing/Transmitting Accessories....................................................................................251

7.3 Product Specifications ....................................................................................................................................252

7.3.1Specifications .............................................................................................................................................252

7.3.2Specifications .............................................................................................................................................253

7.4 Function List .....................................................................................................................................................255

7.4.1Print Speed .................................................................................................................................................255

7.4.2Paper Type .................................................................................................................................................256

7.4.3Print Speed .................................................................................................................................................257

7.4.4Paper Type .................................................................................................................................................258

7.4.5Accessories ................................................................................................................................................258

Chapter 8 Upgrading

8.1 Upgrading..........................................................................................................................................................259

8.1.1Outline of the Version Upgrade ...............................................................................................................259

8.1.2Overview of Upgrading Work...................................................................................................................259

8.1.3Outline of the Functions and Operations ...............................................................................................260

8.1.4Outline of the Service Support Tool ........................................................................................................263

8.1.5Network Interface of the Machine with the SST in Use .......................................................................265

Chapter 1 Maintenance and Inspection

1.1 Periodically Replaced Parts

Chapter 1

1.1.1 Overview

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

Some parts of the machine must be replaced on a periodical basis for the machine to maintain a specific level of performance. They must be replaced regardless of

the presence/absence of external changes or damage, as the performance of the machine will be considerably affected once they fail.

If possible, plan any replacement to coincide with a scheduled visit.

0002-9397

The intervals indicated may vary depending on the site environment and user habit.

1. Checking the Timing of Replacement

The timing of replacement may be checked using the following service mode items:

(1) Copier

COPIER>COUNTER>PRDC-1

(2) Accessory

COPIER>COUNTER>PRDC-2

1.1.2 Reader Unit

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0000-9633

The machine's reader unit does not have parts that must be replaced on a periodical basis.

1.1.3 Printer Unit

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

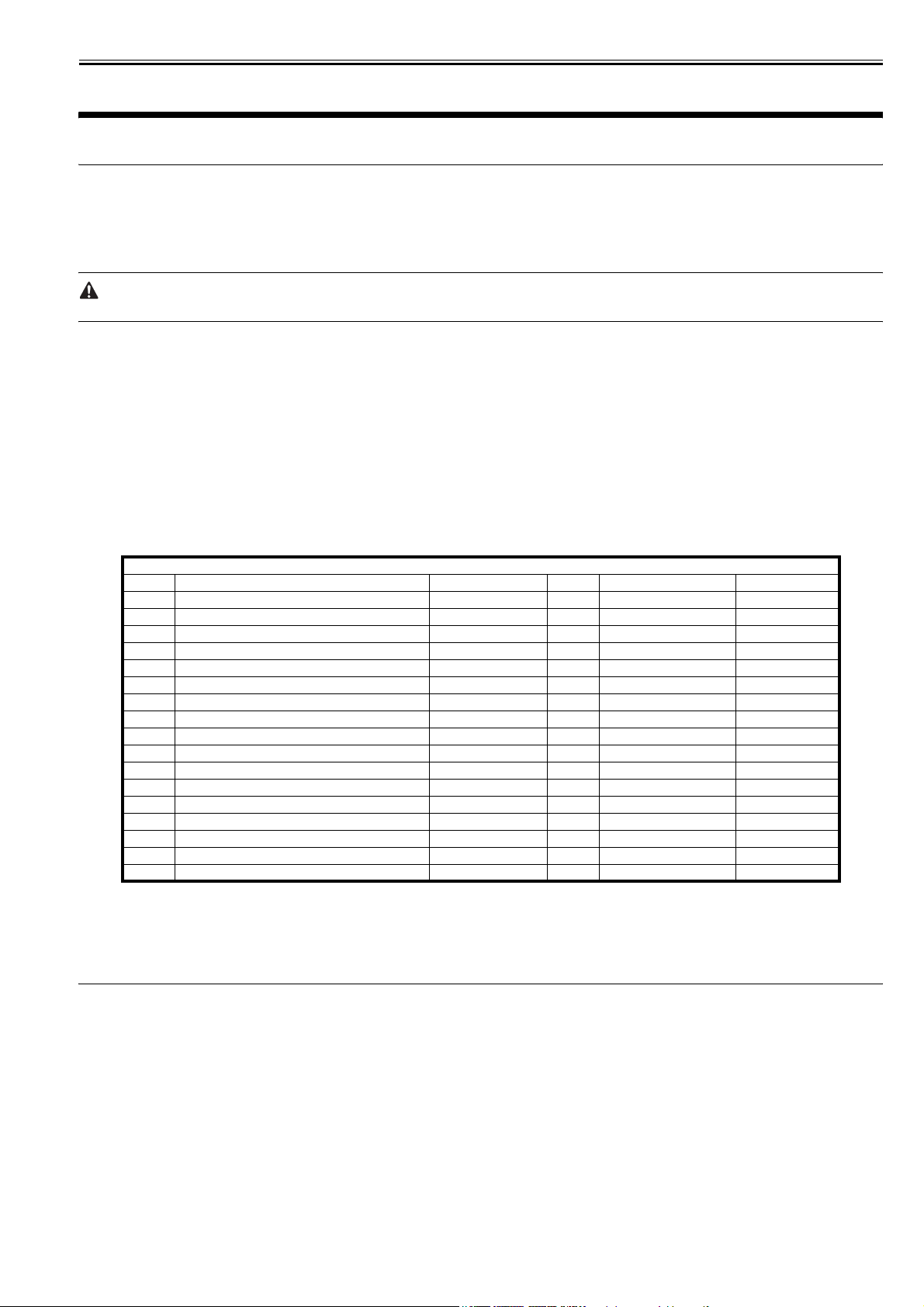

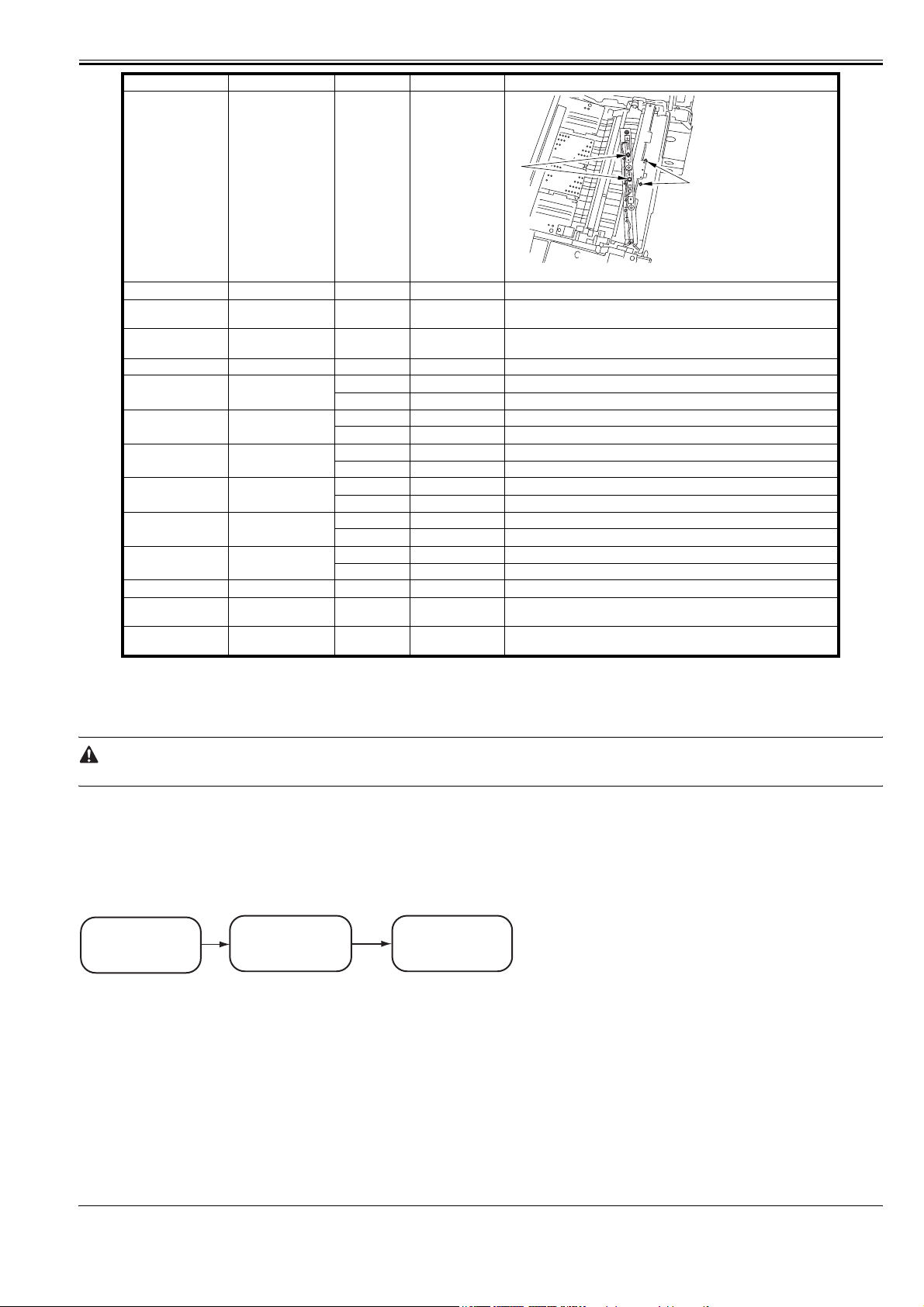

T-1-1

as of September 2005

Ref. Parts name Parts No. Q'ty Interval Remarks

1 Ozone filter FC5-2486-000 1 250,000 images*

2 Toner filter FL2-0554-000 1 250,000 images*

3 Primary charging wire FB4-3687-000 AR 500,000 images* ***

4 Charging wire cleaner 1 FL2-2427-000 1 500,000 images* **

5 Charging wire cleaner 2 FL2-2428-000 1 500,000 images* **

6 Post-charging wire FB4-3687-000 AR 500,000 images* ***

7 Post-charging assembly wire cleaner 1 FL2-2427-000 1 500,000 images*

8 Post-charging assembly wire cleaner 2 FL2-2428-000 1 500,000 images*

9 Primary grid wire FY1-0883-000 1 500,000 images*

10 Fixing thermistor FK2-0013-000 1 500,000 prints* ****

11 Pressure thermistor FK2-0013-000 1 500,000 prints* ****

12 Outside heating roller thermistor FK2-0013-000 1 500,000 prints* ****

13 Primary charging assembly FM2-0429-000 1 1,000,000 images*

14 Post-charging assembly FM2-0427-000 1 1,000,000 images*

15 Fixing thermal switch FM2-0497-000 1 1,000,000 prints

16 Pressure thermal switch FM2-0498-000 1 1,000,000 prints

17 Outside heating thermal switch FM2-0499-000 1 1,000,000 prints

0011-4548

* In the case of a black mono color print: counted as 1,in the case of a full color print: counted as 4 images.

** Under high humidity and high temperature condition, 100,000 images(iRC6800/iRC6870N/iRC6870/iRC6870N)ÅA85,000 images(iRC5800/iRC5870N/

iRC5870/iRC5870N)

*** Offered as a service part on a reel basis.

**** May be either a main thermistor or a sub thermistor, and these 2 items are offered as a service part in the form of a set.

1.2 Durables and Consumables

1.2.1 Overview

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

Some parts of the machine may have to be replaced once or more over the period of machine warranty because of wear or damage. Replace them as needed by

referring to the table of estimated lives (expressed in terms of the number of prints they make).

1. Making Checks When Replacing Durables

Use the following service mode items to find out when to replace parts:

- Machine

COPIER>COUNTER>DRBL-1

- Accessory

COPIER>COUNTER>DRBL-2

1.2.2 Reader Unit

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0005-8049

0000-9645

1

Chapter 1

The machine's reader unit does not have parts that are classified as durables.

1.2.3 Printer Unit

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

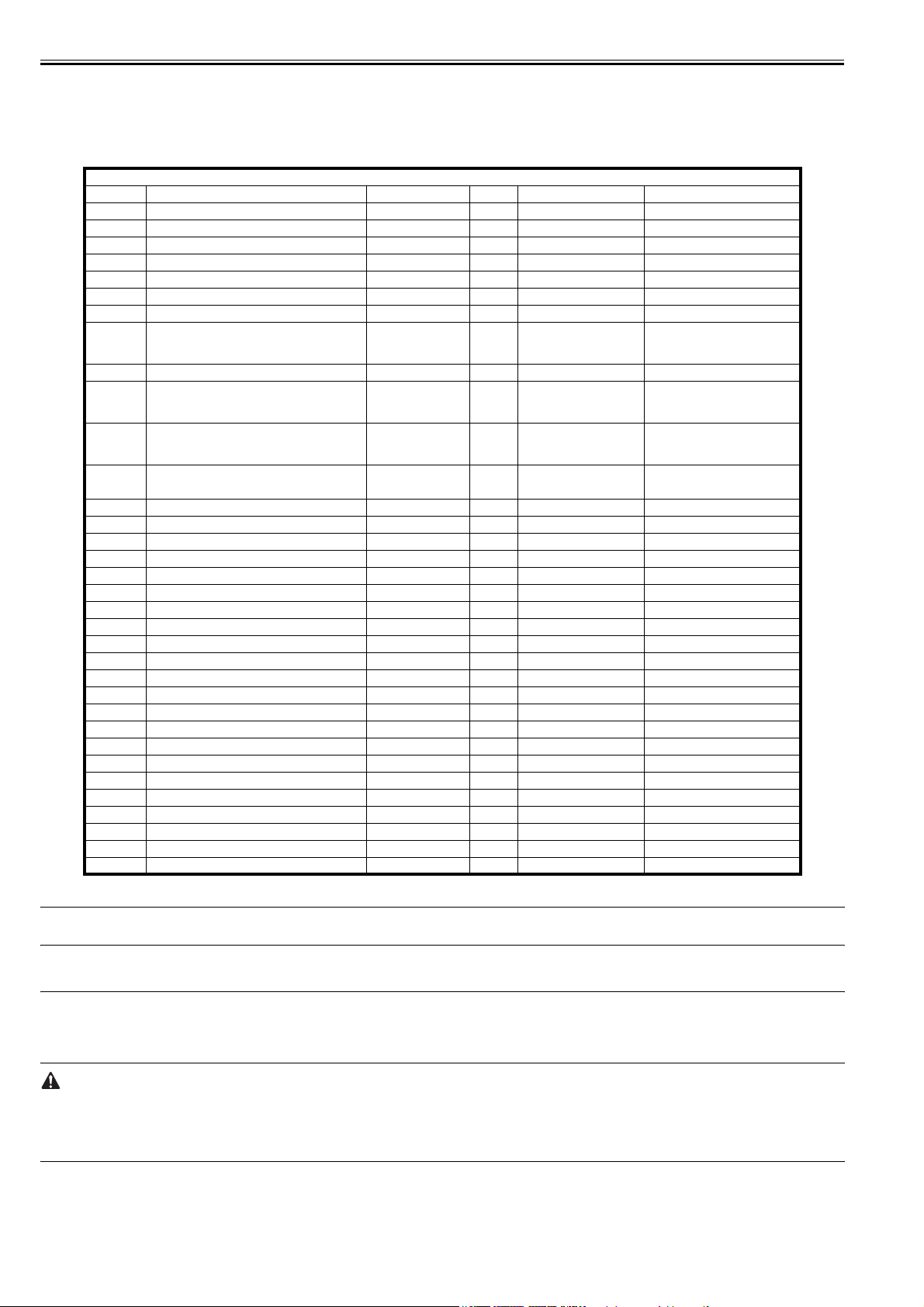

T-1-2

as of March 2004

Ref. Parts name Parts No. Q'ty Interval Remarks

[1] Feed roller (manual feed D roller) FB1-8581-000 1 120,000 prints

[2] Separation roller (manual feed C roller) FB5-0873-000 1 120,000 prints

[3] ITB cleaner scoop-up sheet FL2-0411-000 1 150,000 prints

[4] Secondary transfer static eliminator holder FL2-0598-000 1 150,000 prints

[5] Fixing roller FC5-6298-000 1 150,000 prints (*)

[6] Pressure roller FC5-6299-000 1 150,000 prints (*)

[7] Outside heating roller FC5-2285-000 1 150,000 prints (*)

[8] ITB cleaner blade FC5-1662-000 1

[9] Secondary transfer outside roller FC5-2157-000 1 195,000 images (**)

[10] Primary transfer roller FC5-1660-000 1

[11] Cleaner blade FC5-1788-000

[12] Pickup rollerÅiDeck A rollerÅj FC5-2524-000

[13] Feed roller ÅiDeck B rollerÅj FC5-2526-000 1 each 250,000 prints Machine left/right deck

[14] Separation roller ÅiDeck C rollerÅj FC5-2528-000 1 each 250,000 prints Machine left/right deck

[15] Pickup rollerÅiCassette A rollerÅj FC5-2524-000 1 each 250,000 prints Body upper/lower cassette

[16] Feed roller ÅiCassette B rollerÅj FC5-2526-000 1 each 250,000 prints Body upper/lower cassette

[17] Separation rollerÅiCassette C rollerÅj FC5-2528-000 1 each 250,000 prints Body upper/lower cassette

[18] Primary transfer static eliminator FM2-0420-000 1 300,000 images (**)

[19] ITB FC5-1658-000 1 300,000 images (**)

[20] Secondary transfer inside roller FC5-1661-000 1 300,000 prints

[21] Cleaner scoop-up sheet FL2-0422-000 1 390,000 images (**)

[22] Edge scraper FC5-5136-000 2 500,000 images (**)

[23] Color developing assembly FM2-0446-000 3 500,000 prints

[24] web FC5-2286-000 1 500,000 prints

[25] Fixing heat insulating bush FB5-3613-000 2 500,000 prints

[26] Separation claw FM2-1672-000 4 500,000 prints

[27] Lower separation claw unit FM2-0501-000 6 500,000 prints

[28] Pressure insulating bush RB1-0325-000 2 500,000 prints

[29] Outside heat insulating bush FC5-2582-000 2 500,000 prints

[30] ITB edge scraper FC6-2843-000 2 600,000 images (**)

[31] Ozone filter (fixing) FC5-6370-000 1 1,000,000 images (**)

[32] Toner filter FL2-0554-000 1 1,000,000 images (**)

[33] Bk developing assembly Developing cylinder FM2-0434-000 1 1,000,000 prints

[34] Bk developing assembly Developing roll FC5-1863-000 2 1,000,000 prints

*: in the case of a color ratio of 10%; if 100%, 60,000 prints; if 0%, 180,000 prints.

**: in the case of a black mono color print, counted as 1 image; in the case of a full color print, counted as 4 images.

MEMO:

The estimated life is in terms of the median value found in the evaluation data. The parts number, further, is subject to change to reflect design changes.

195,000 images (**)

195,000 images

(165,000 images)

1

195,000 images

1 each

250,000 prints Machine left/right deck

Apply lubricant at time of

replacement.

(**)/The values in parentheses

represent the iRC5800/5800N/

5870/5870N.

(**)

one edge in use, Apply lubricant at

time of replacement.

0011-4549

1.3 Scheduled Servicing Basic Procedure

1.3.1 Scheduled Servicing Basic Procedure

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

- As a rule, perform scheduled servicing every 150,000 prints.

- Check with the Service Book before setting out for a scheduled service visit, and take parts for which replacement is expected.

- If the power plug is left connected for a long time in a place subject to dust, humidity, or oil smoke, a fire hazard is a possibility (i.e., the dust collecting around

the plug can absorb moisture, resulting in insulating failure). Be sure to remove the power plug on a periodical basis, and wipe off the dust and dirt collecting

around it.

1. Work Procedure

1) Report to the person in charge, and check the general condition.

2) Record the counter reading, and check the faulty prints.

3) Check following, and clean/adjust the items that are indicated:

2

0003-4125

Chapter 1

T-1-3

Items

Text copy against image density standard

for soiling of back of paper

for clarity of characters

for margin

for fixing misplaced registration, soiled back of paper

for margin standards (single-sided print) leading edge: 4.0+1.5/-1.0mm

left edge: 2.5+/- 1.5mm

(double-sided print) leading edge: 4.0+1.5/-1.0mm

left edge: 2.5+/- 2.0mm

Feeding system registration upper/lower roller

for paper lint along front edge of registration assembly

4) Check the waste toner case.

If half full or more, dispose of the waste toner in a vinyl bag or the like for collection; or, replace the waste toner case.

- If you need to dispose of the waste toner, be sure to do so in strict accordance with the regulations imposed by the local authorities.

- Do not dispose of waste toner in a fire. Doing so may cause an explosion.

5) Clean the copyboard glass and the reading glass.

6) Make test copies.

7) Make sample copies.

8) Check the operation of the leakage breaker.

With the power switch at ON, push the test switch of the leakage breaker to check that it operates normally (i.e., the breaker switch shifts to the OFF side to cut

off the power).

If the leakage beaker fails to operate normally, replace it, and run a check once again.

2. Resetting the Breaker

When you have made the check, turn off the main power switch, and turn on the breaker switch, and then turn the main power switch back on.

9) Put the sample copies in order, and clean up the area around the machine.

10) Record the final counter reading; at this time, be sure to fill out the blanks for 'FX-UP-RL' and 'DV-UNT-K' (service counters).

11) Fill out the Service Book, and report to the person in change. Be sure to update the history of checks on the leakage breaker in the Service Book.

1.3.2 Scheduled Servicing (reader unit)

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0011-4553

Do not use solvents or oils other than those indicated herein.

T-1-4

Unit Location Work Intervals Remarks

Original exposure system Face/back of the copyboard glass

Original exposure system Face/back of the copyboard glass

Original exposure system Scanner rail clean/

Original exposure system Scanner mirror (No. 1 through No. 3

Original exposure system Reflecting plate clean 195,000 images

(large)

(small)

mirrors)

clean 195,000 images clean the white plate on the back.

clean 195,000 images

lubricate

clean 195,000 images

as needed

The foreign values are estimates only, and are subject to change based on future data.

1.3.3 Scheduled Servicing (printer unit)

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

Do not use solvents or oils other than those permitted.

0011-4556

3

Chapter 1

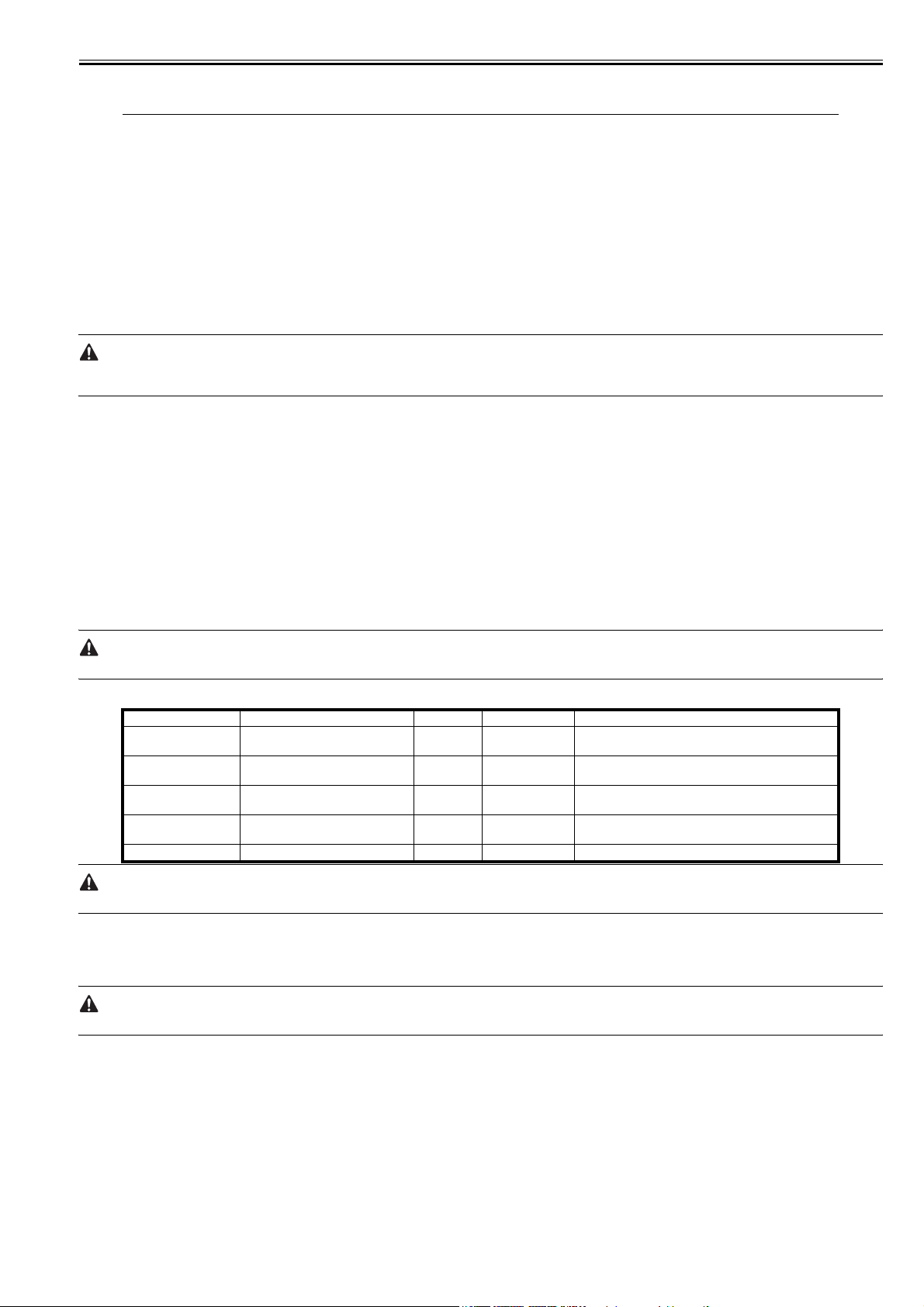

Unit Location Item Interval Remarks

Externals and controls Ozone filter replace 250,000 images

Externals and controls Toner filter replace 250,000 images

T-1-5

[1]

Externals and controls Dust-collecting filter

å€äwån Dust-colleting glass clean 250,000 prints

Charging assembly Primary charging

Charging assembly Primary charging wire clean upon installation

Charging assembly Primary grid wire clean upon installation,

Charging assembly Charging wire cleaner

Charging assembly Post-charging

Charging assembly Post-charging wire clean upon installation

Charging assembly Post-Charging wire

Charging assembly Charging assembly

(primary)

assembly

1/2

assembly

cleaner 1/2

shielding plate

clean 250,000 prints

replace 1,000,000 images

replace 500,000 images

250,000 images

replace 500,000 images

replace 500,000 images

replace 1,000,000 images

replace 500,000 images

replace 500,000 images

clean upon installation,

250,000 images

[2]

[1]

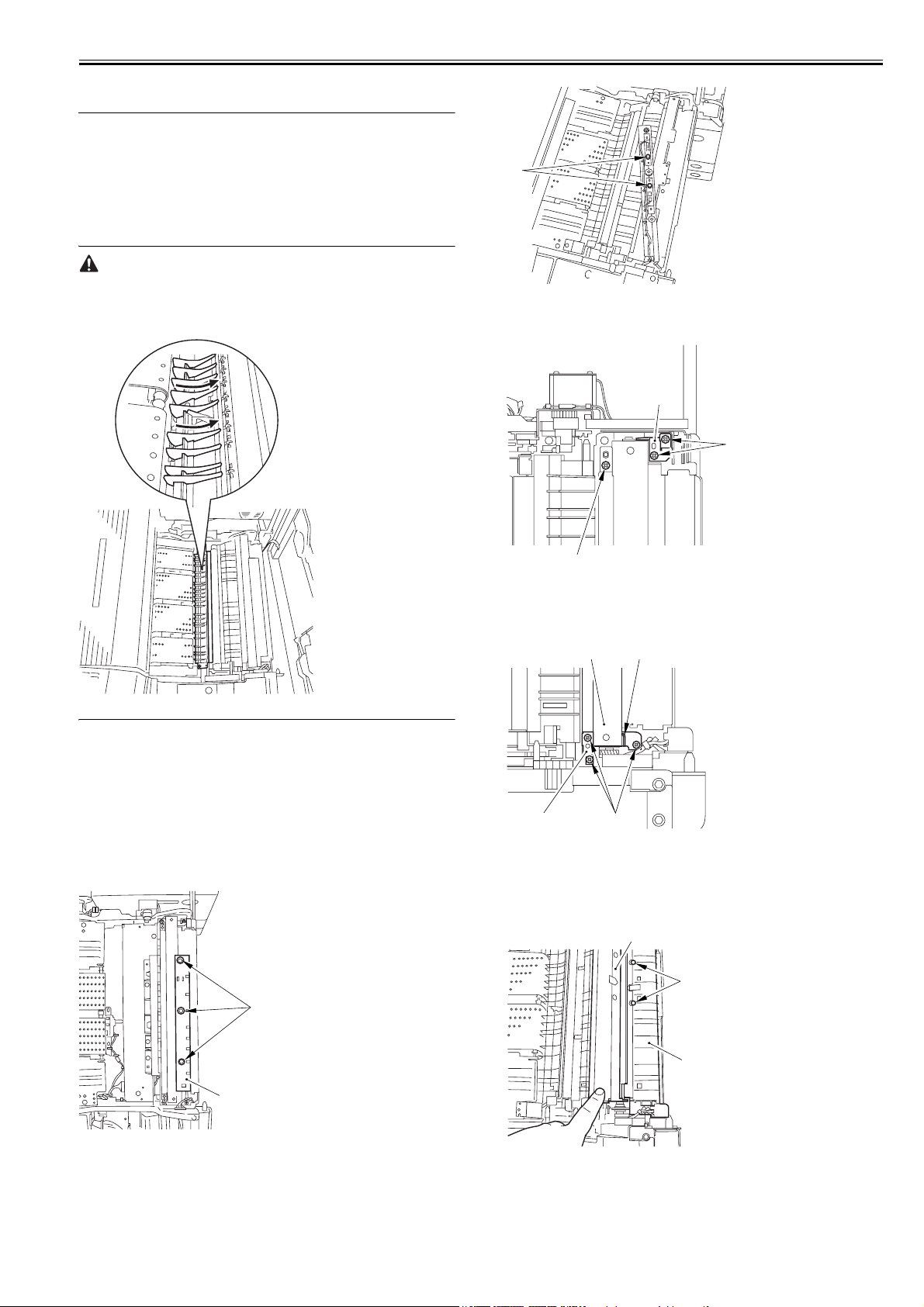

[1]Toner filter

[2]Ozone filter

inside of the right upper cover

4

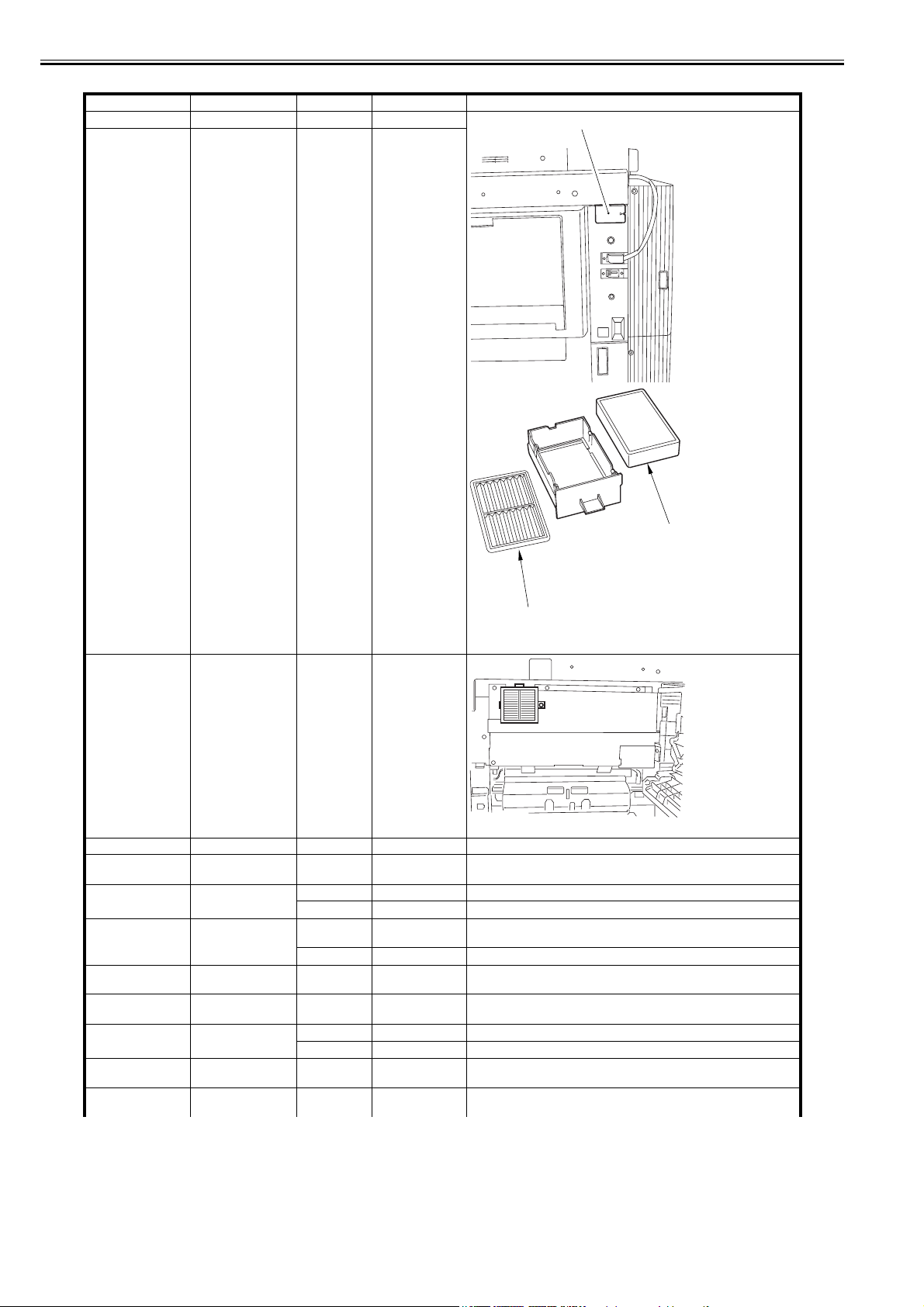

Unit Location Item Interval Remarks

Photosensitive drum Drum heater sliding

area

clean/lubricate 1,000,000 images

[1] [1]

Clean the terminal [1] of the slip ring using alcohol; then, apply a small

amount of lubricant (FY9-6008).

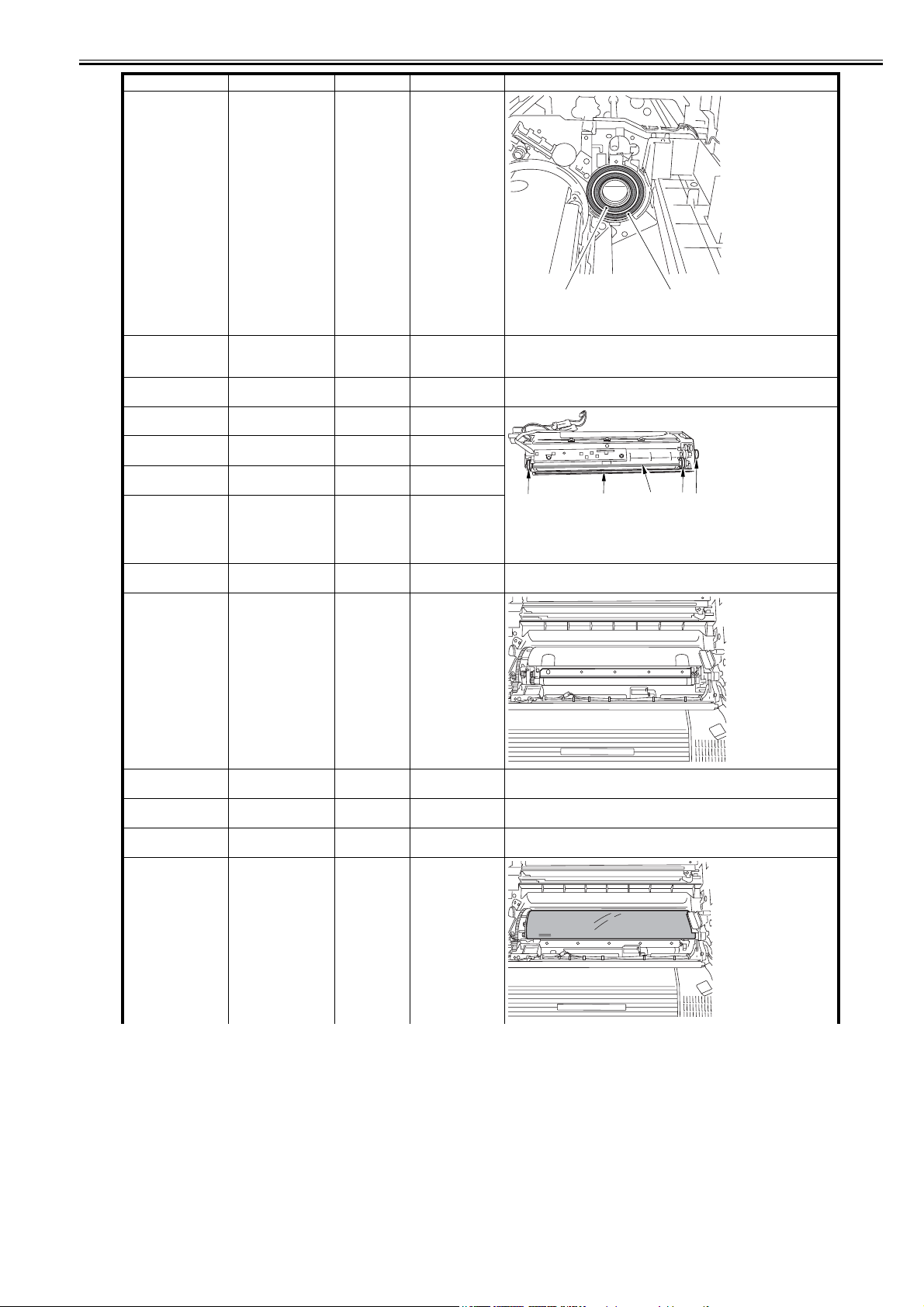

Photosensitive drum Shifting the

Black developing

assembly

Black developing

assembly

Black developing

assembly

Black developing

assembly

Black developing

assembly

Color developing

assembly

Color developing

assembly

photosensitive drum

phase

Developing cylinder check upon installation

Developing stray

toner-blocking sheet

Developing cylinder

drive gear

Developing roll clean 250,000 prints

Bias roller toner

collection case

Developing cylinder check upon installation

Developing stray

toner-blocking sheet

adjustment 250,000 imags

clean 250,000 prints

clean 250,000 prints

clean 250,000 images

clean 250,000 prints

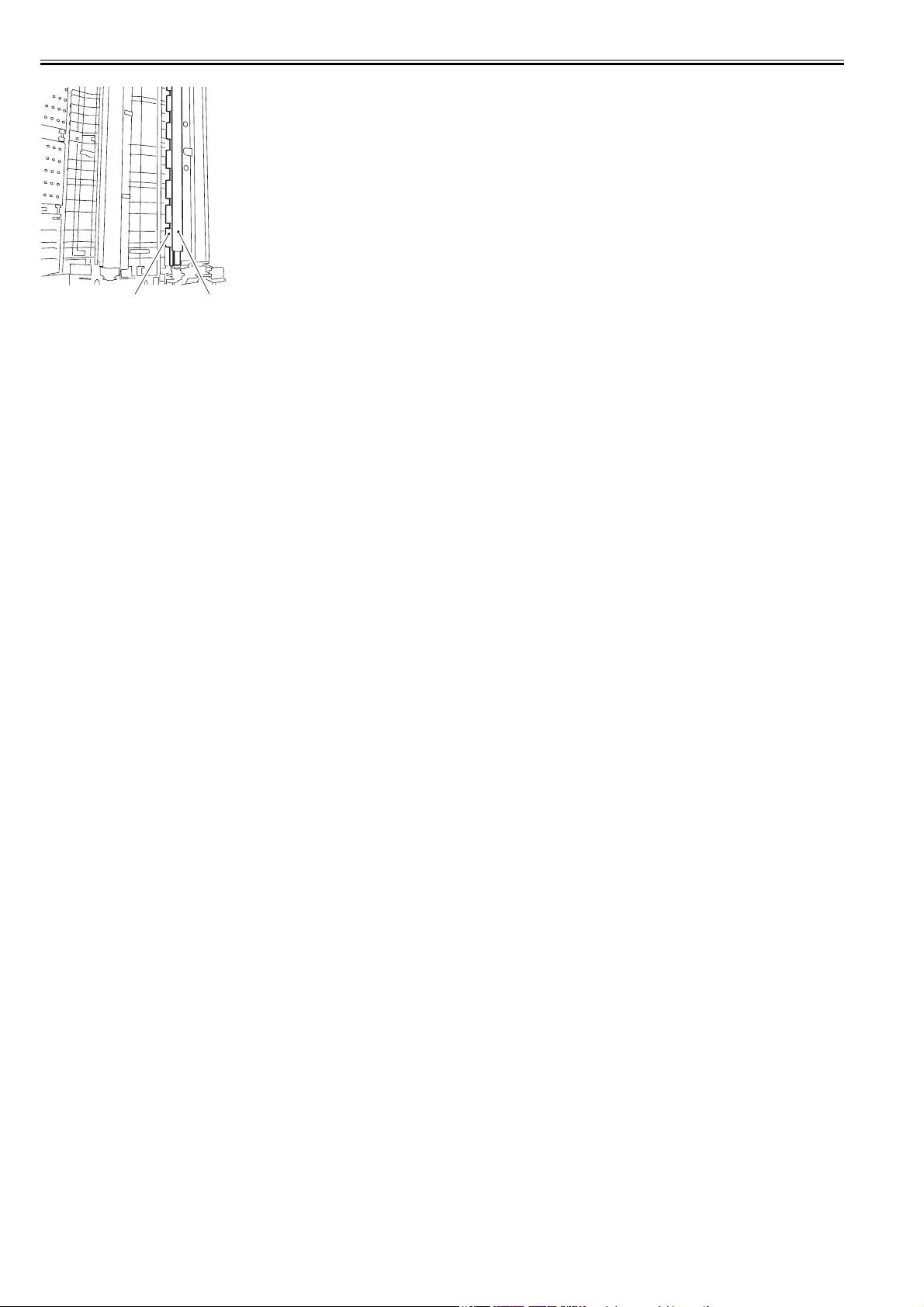

[3] [1][4]

[1]Developing stray toner-blocking sheet

[2]Developing cylinder drive gear

[3]Developing roll

[4]Bias roller toner collection case

Chapter 1

[2][3]

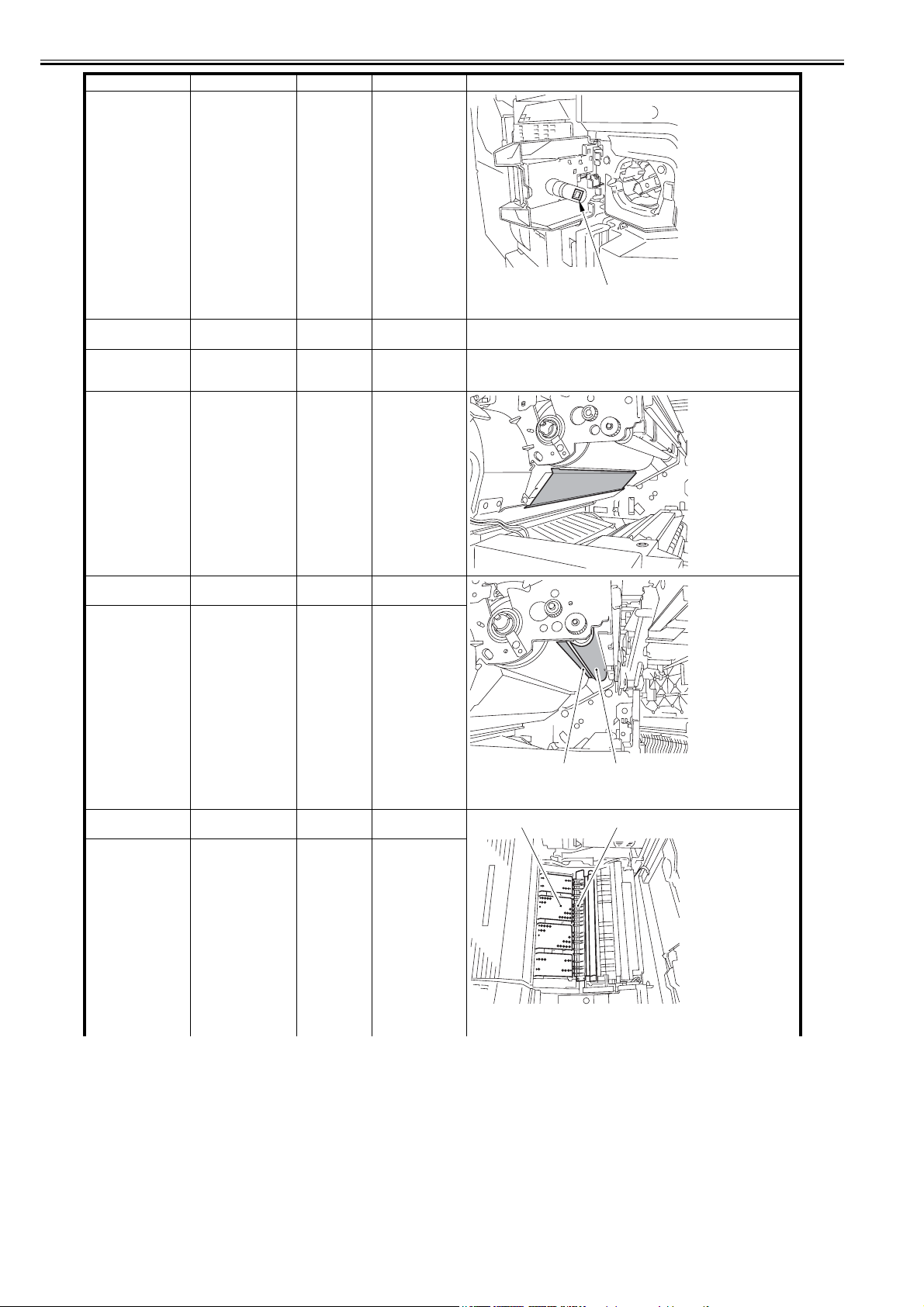

Color developing

assembly

Color developing

assembly

Color developing

assembly

Color developing

assembly

å€ ATR sensor clean 250,000 images

Color toner écåü

sensor window

Sleeve ends bushing clean 250,000 images

Bottle cover clean 250,000 images

clean 250,000 images

5

Chapter 1

Unit Location Item Interval Remarks

Color developing

assembly

ITB Patch åüÅ@sensor

ITB ITB inside scraper/

ITB area Pre-transfer corona

Color toner cartridge

placementÅ@åü

sensor window

window

roller(when replacing

primary transfer roller)

assembly rail,

thereunder

clean 250,000 images

[1]

[1]Color toner cartridge placement åü sensor window

clean 250,000 images

clean 195,000 images

clean 150,000 prints

ITB area Scoop-up sheet base,

ITB area Cleaner container,

Secondary transfer

assembly

Feeding assembly Pre-Fixing Feeding

thereunder

hereunder

Secondary transfer

rear guide

belt

clean 150,000 prints

clean 150,000 prints

clean 150,000 prints

clean 150,000 prints

[1] [2]

[1]Scoop-up sheet base, thereunder

[2]Cleaner container, hereunder

[2] [1]

[1] Secondary transfer rear guide

[2] Pre-Fixing Feeding belt

6

Unit Location Item Interval Remarks

Feeding assembly OHP sensor clean 250,000 prints

[1]

[1]clean upper/lower OHP sensor using blow brush

Feeding assembly Registration roller clean 250,000 prints

Feeding assembly Registration roller

Hopper assembly Toner receptacle/

Fixing assembly Fixing web check upon installation

Fixing assembly Fixing thermistor clean 150,000 prints

Fixing assembly Pressure thermistor clean 150,000 prints

Fixing assembly Outside heating roller

Fixing assembly Fixing thermal switch clean 300,000 prints

Fixing assembly Pressure thermal

Fixing assembly Outside heating

Fixing assembly Inlet guide clean 150,000 prints use lint-free with specified solvent.

Delivery assembly Upper/lower

Waste toner collection

assembly

guide

supply mouth

thermistor

switch

thermal switch

separation claw

Waste toner box inspect 250,000 images*

clean 250,000 prints

clean 250,000 prints

replace 500,000 prints

replace 500,000 prints

clean 150,000 prints

replace 500,000 prints

replace 1,000,000 prints

clean 150,000 prints

replace 1,000,000 prints

clean 150,000 prints

replace 1,000,000 prints

clean 150,000 prints use lint-free paper with specified solvent.

Chapter 1

[1]

*:

The black developing cylinder need not be cleaned on a periodical basis. If you must clean the surface of the cylinder, be sure to dry wipe it with lint-free paper,

NEVER using water or solvent.

**:

The intervals are based on a color ratio of 10% and image ratio of 5%, and thus are subject to variation depending on the actual ratios.

The foregoing values are estimates only, and are subject to change based on future data.

1.3.4 Shifting the Photosensitive Drum Phase

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

The photosensitive drum can develop drum memory unless the image write start position is moved at specific intervals. Be sure to move the drum phase every so

many copies/prints have been made as shown below.

0006-0350

1. Overview of the Work

1. Preparatory work 2. Mechanical work

- making test copies

(service mode)

- disabling initial rotation

(service mode)

F-1-1

shifting the photosensitive

drum phase

3. Updating the density

initial data

- rewriting the density initial

data (service mode)

- executing auto gradation

correction

2. When to Perform the Work

- every some copies or prints made continuously

- when removing and attaching the drum (i.e., when the initial drum phase is lost) Here,3.

"Mechanical Work" in the detailed instructions is not needed. To avoid the possible discrepancy in phase, however, be sure to perform 1. "Preparatory Work"

and 3. "Updating the Density Initial Data."

3. Detailed Instructions

1) Preparatory Work

1-1) Turn off the main power switch, and wait until the machine has entered a ready state.

1-2) To stabilize the machine operation, generate 5 test pattern printouts (A3, double-sided) by executing the following in service mode:

COPIER>TEST>PG>TYPE=16.

7

Chapter 1

Be sure not to forget to select a cassette loaded with A3 paper and double-sided printing in service mode.

- to select a particular cassette in service mode, perform COPIER>TEST>PG>PG-PICK=3 or =4.

- to select double-sided printing in service mode, perform COPIER>TEST>PG>2-SIDE=1.

1-3) Set "1" to the following service mode to disable initial multiple rotation: COPIER>FUNCTION>INSTALL>AINR-OFF.

1-4) Turn off the main power switch.

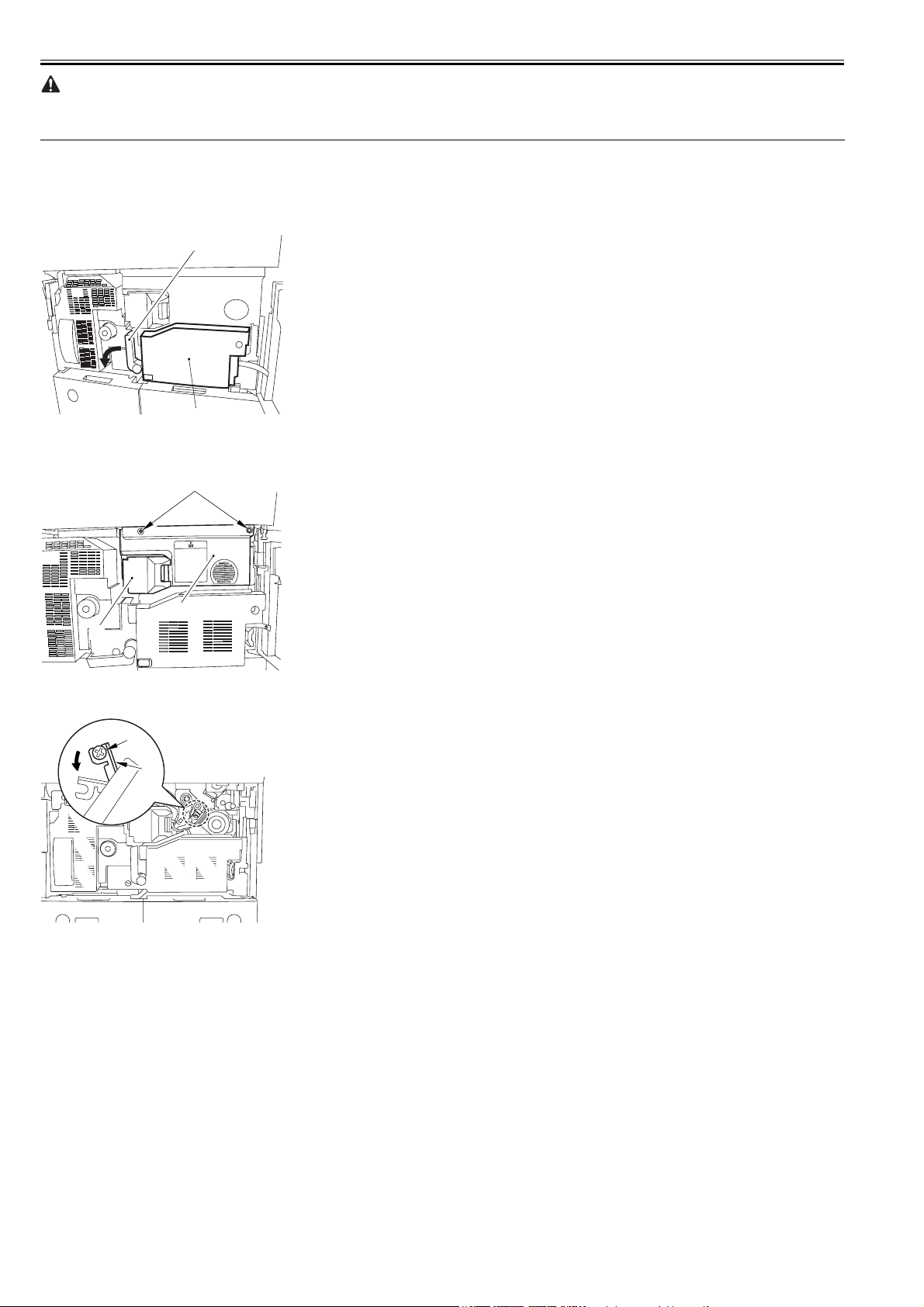

2) Mechanical Work

2-1) Open the front cover.

2-2) Shift down the fixing/feeding release lever [1], and slide out the fixing/feeding assembly [2] to the front.

[1]

[2]

F-1-2

2-3) Open the color toner supply cover [1]. Remove the 2 screws [2], and remove the process cover [3].

[2]

[3]

[1]

F-1-3

2-4) Remove the screw [1], and shift down the primary transfer roller locking lever [2] (so that the primary transfer roller is freed).

[1]

[2]

F-1-4

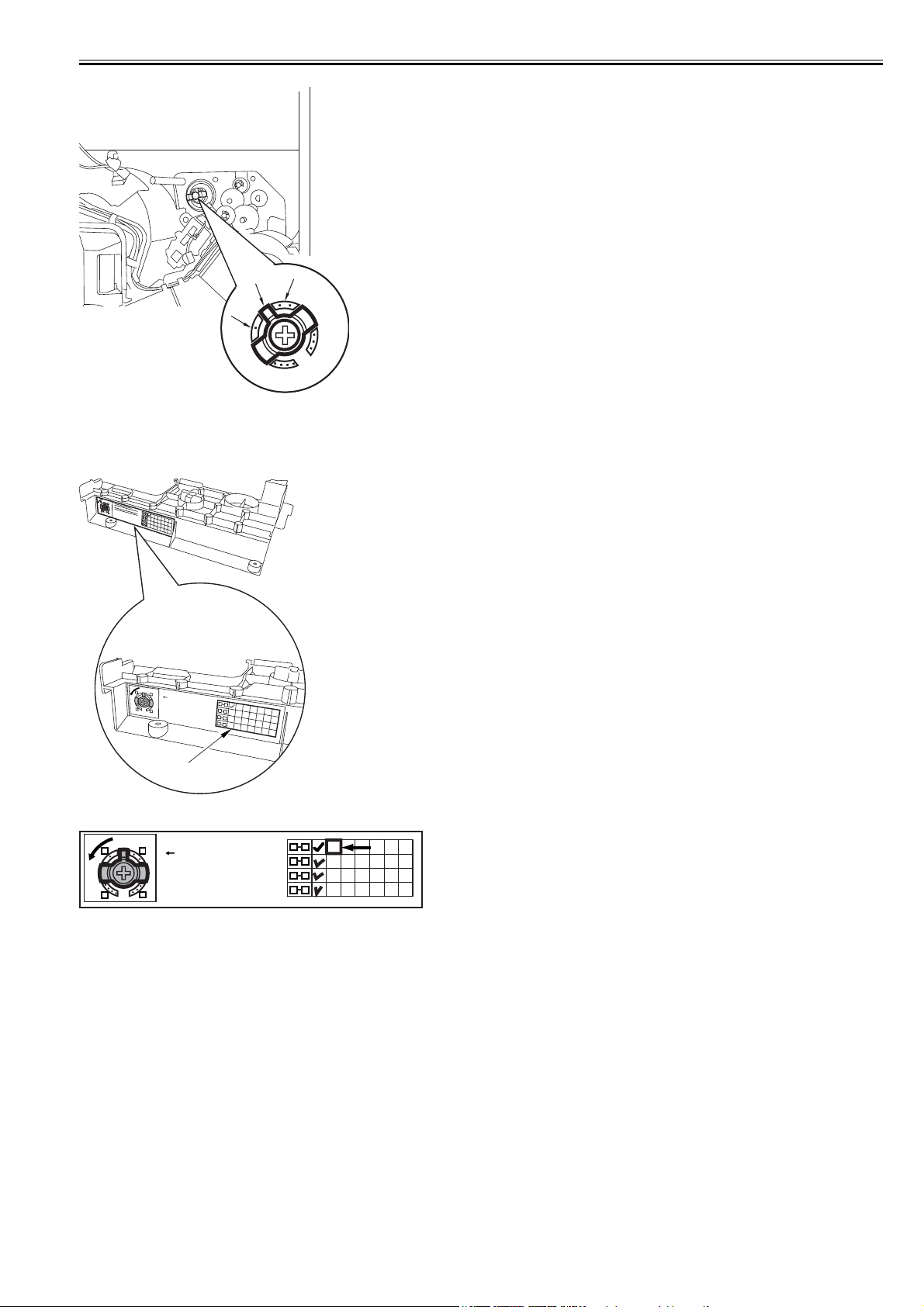

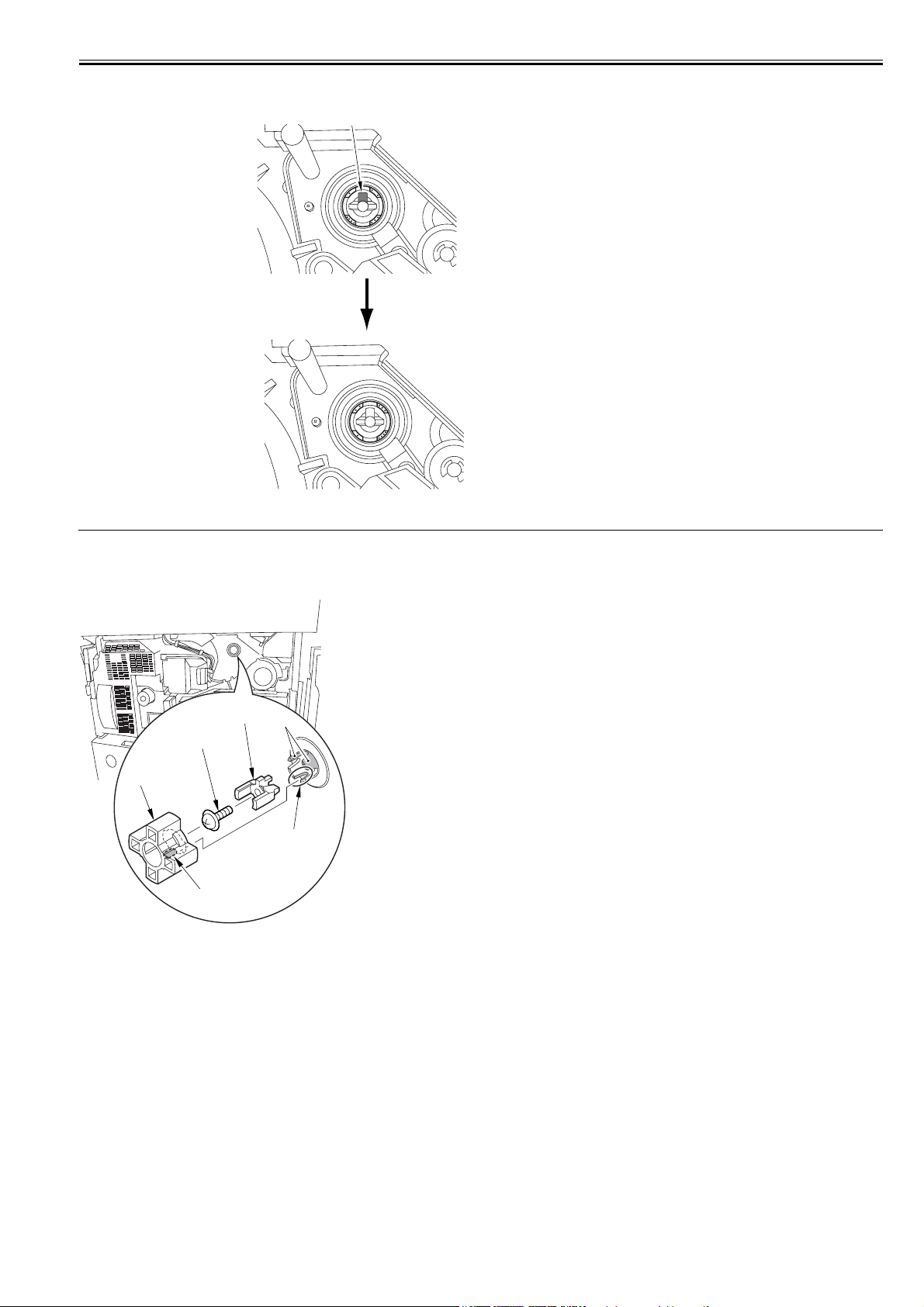

2-5) Check the position of the marking [2] on the drum flange in relation to the protrusion [1] of the drum fixing member. (checking the drum phase)

In the figure, the marking [2] on the drum flange is at "." on the left and ".." on the right in relation to the protrusion [1] of the drum fixing member.

8

Chapter 1

[2]

[1]

[2]

F-1-5

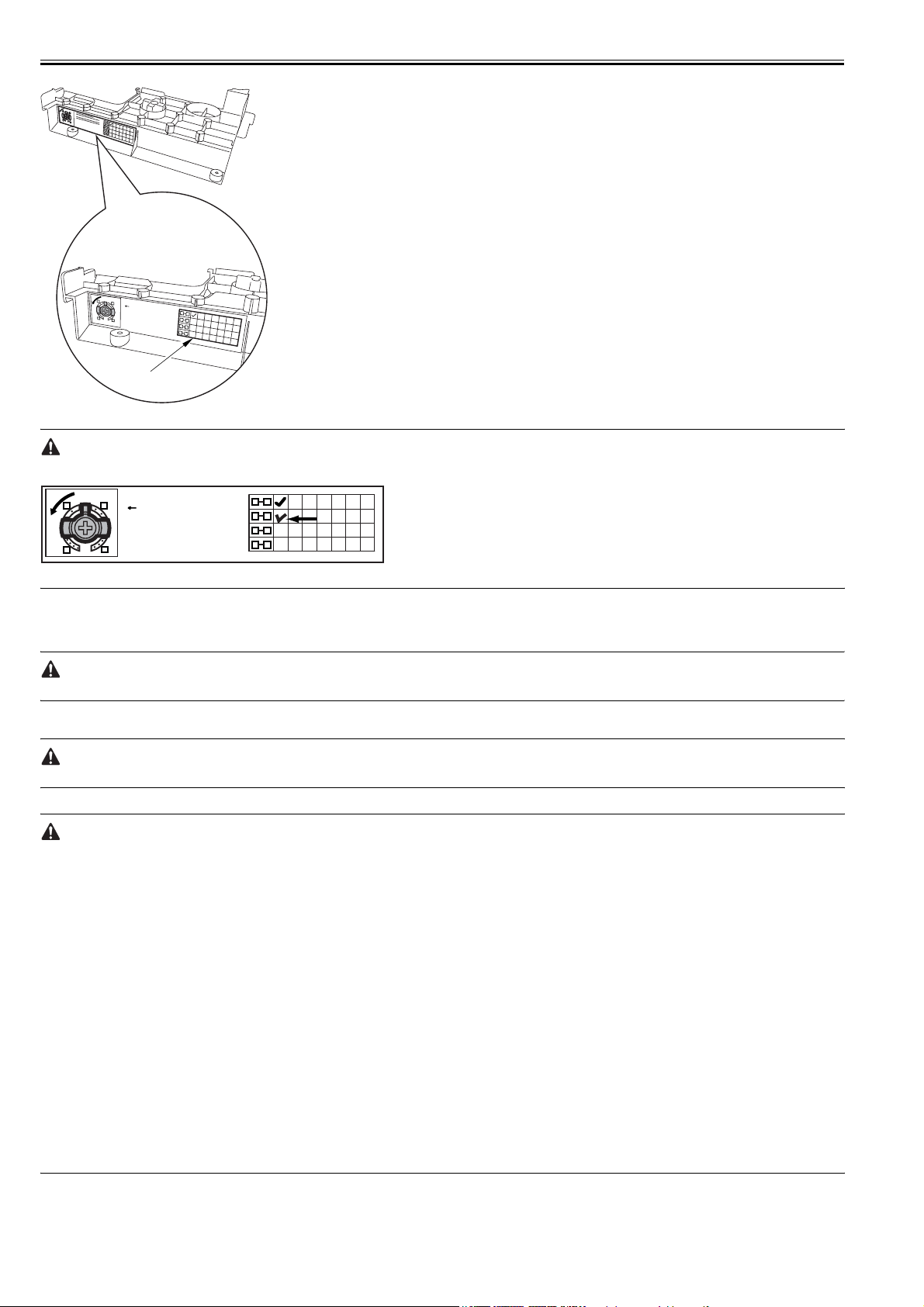

At this time, check the drum phase label [1] attached behind the process unit cover. If there is no check mark on the label indicating the present phase position, be

sure to put a check mark.

1

1. C

O

P

IE

R

>

2

T

2

. C

E

S

O

T

>

P

IE

P

R

G

>

>

F

T

3.

U

Y

N

P

C

E

=

T

IO

1

N

6

>

4

IN

. C

S

O

T

A

P

L

IE

L

>

R

>

A

F

5

IN

. C

U

R

N

O

-O

C

P

T

F

IE

IO

F

=

R

>

N

>

1

F

6

M

. P

U

IS

N

A

C

C

S

T

-P

C

>

IO

A

L

N

D

>

R

M

-P

1

IS

-A

C

D

-P

J

=

>

2

O

P

K

-P

R

IN

T

=

O

4

3

K

2

3

3

4

4

1

[1]

F-1-6

1. COPIER > TEST > PG > TYPE = 16

1

4

2. COPIER > FUNCTION > INSTALL > AINR-OFF = 1

2

3.

4. COPIER > FUNCTION > MISC-P > DR-P-ADJ = OK

5. COPIER > FUNCTION > MISC-P > P-PRINT = OK

6. PASCAL

3

1 2

2 3

3 4

4 1

[2]

F-1-7

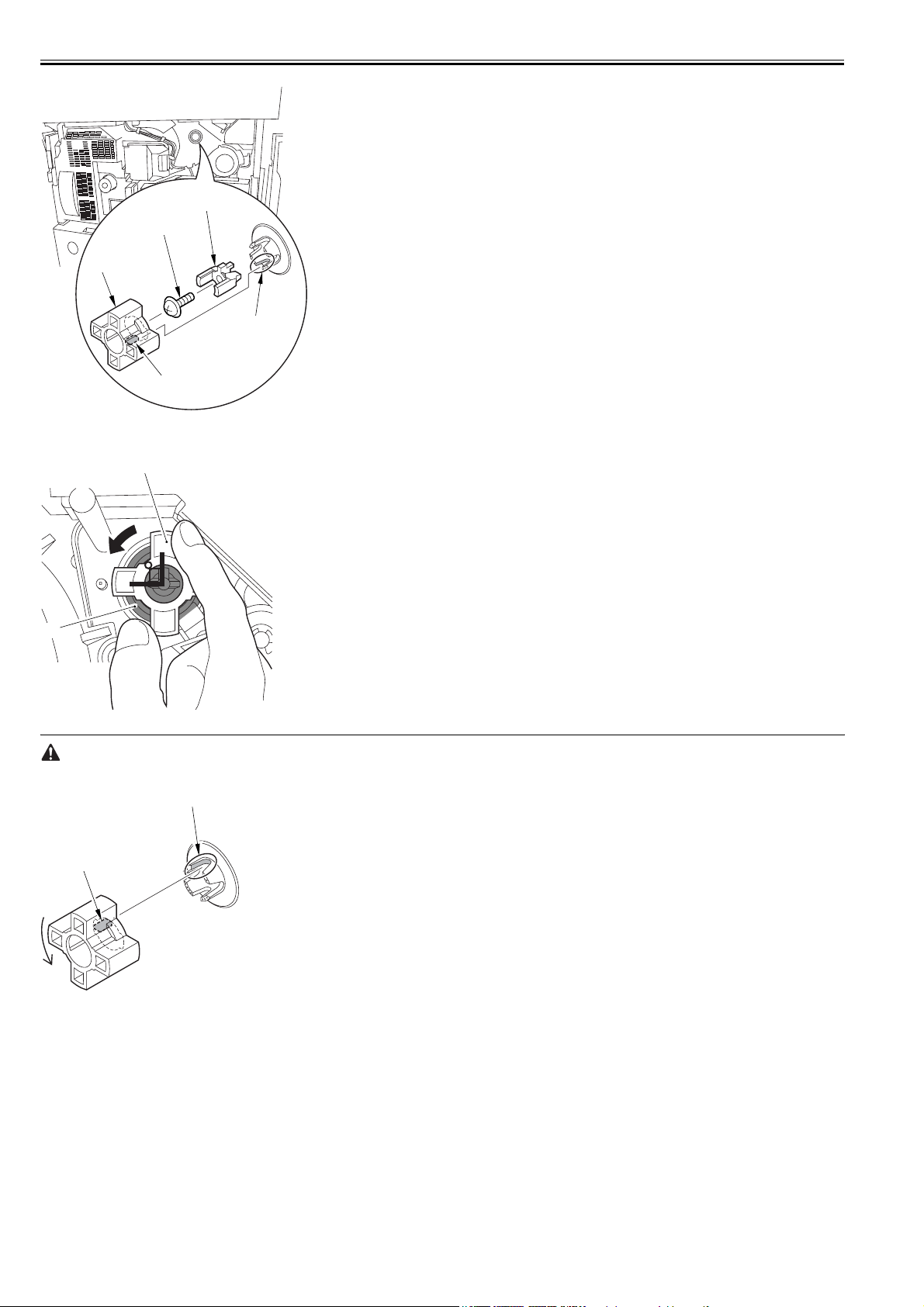

2-6) Hold down the drum fixing member [1] using the drum stop tool [2]: then, using a screwdriver, remove the drum fixing screw [3].

As shown, be sure to remove the screw only after matching the protrusion [4] of the drum stop tool against the cut-off [5] of the drum flange.

9

Chapter 1

[1]

[3]

[2]

[5]

[4]

F-1-8

2-7) Attach the drum stop tool [1] in the drum flange [2]; then, turn the drum counterclockwise by 90 deg.

[1]

90

[2]

F-1-9

(1) When attaching the tool to the flange, be sure to turn the drum only after matching the protrusion [2] of the tool against the cut-off [1] of the drum flange.

[1]

[2]

F-1-10

(2) The drum phase position is identified by means of a marking of 1 to 4 dots on the flange. At time of shipment from the factory, dent A in the drum shaft is

between "." and "..".

The following figures show the position of the drum flange before an after a shift is introduced:

10

Position of the Flange Before the

Phase Is Shifted (at time of shipment)

Position of the Flange After the

Phase Is Shifted (after the shift

work for the first time)

Chapter 1

[A]

F-1-11

(3) Do not shift the drum phase as part of normal work involving drawing out of the process unit.

2-8) After attaching the drum fixing member [2] to the drum flange [1], hold it down from above using the drum stop tool [3]. Thereafter, tighten the drum fixing

screw [4] with a screwdriver.

Be sure to fix the protrusion [5] of the drum stop tool in place with a screw after matching it

against the cut-off [6] of the drum flange.

[2]

[1]

[4]

[3]

[6]

[5]

F-1-12

2-9) After checking the drum phase position, put a check mark on the drum phase label [1] attached behind the process cover.

11

Chapter 1

1

1

. C

O

P

IE

R

>

2

T

2

.

E

C

S

O

T

>

P

IE

P

R

G

>

>

F

T

3.

U

Y

N

P

C

E

=

T

IO

1

N

6

>

4

IN

.

C

S

O

T

A

P

L

IE

L

>

R

>

A

F

5

I

N

.

U

R

C

N

-O

O

C

P

T

F

I

IO

F

ER

=

>

N

>

1

F

6.

M

U

P

I

N

S

A

C

C

S

T

-P

C

>

IO

A

L

N

>

D

R

M

-P

1

I

-A

S

C

D

-P

J

=

>

2

O

P

K

-P

R

IN

T

=

O

4

3

K

2

3

3

4

4

1

[1]

F-1-13

The following figure shows a label with a check mark indicating that the work has been performed.

1. COPIER > TEST > PG > TYPE = 16

1

4

2. COPIER > FUNCTION > INSTALL > AINR-OFF = 1

2

3.

4. COPIER > FUNCTION > MISC-P > DR-P-ADJ = OK

5. COPIER > FUNCTION > MISC-P > P-PRINT = OK

6. PASCAL

3

1 2

2 3

3 4

4 1

[1]

F-1-14

2-10) Attach the cover by performing step 2-1 through 2-4 in reverse.

3) Updating the Density Initial Data.

3-1) Turn on the main power switch, and wait until the machine has entered a ready state.

3-2) Perform the following in service mode: COPIER>FUNCTION>MISC-P>DR-P-ADJ

When the machine ends the service mode item normally, the setting (AINR-OFF) will automatically return to "0".

3-3) Perform the following in service mode: COPIER>FUNCTION>MISC-P>P-PRINT. Then, record the values of the following on the service label attached

behind the front cover: COPIER>ADJT>DENS>P-SGNL-Y/M/C.

Store the output of P-PRINT in the service book case. If there is previous output in the case, replace it with the new output.

3-4) Perform auto gradation correction in user mode (adjust/cleaning>auto gradation correction>full correction).

Be sure to perform the foregoing steps to position the drum in phase whenever you are not sure whether the drum is in correct phase.

1. Related Service Mode Item

a. counter mode for phase shift work: COPIER>COUNTER>MISC>DRM-PHAS

Particulars

Use it to indicate the counter reading for determining the intervals of the work. (The denominator indicates the counter reading of the work intervals, while the

numerator indicates the counter reading on an actual machine).

- Settings:

00000000 to 99999999

- At Time of Shipment

denominator of counter reading:

200,000 images (Japan); 100,000 images (outside Japan)

(numerator of counter reading):

0

b. message switchover mode associated with the foregoing counter: COPIER>OPTION>BODY>DRM-DISP

Particulars

Use it to enable/disable the indication of the foregoing count reading:

Settings:0 to 2

0: disable indication

1: indicate in service mode only (factory default)

2: indicate both on User screen and in service mode

c. confirmation mode for phase shift work: COPIER>DISPLAY>ALARM-2

A record of the work will be indicated in terms of the number of times the work has been performed.

12

1.4 Cleaning

Chapter 1

1.4.1 Cleaning the Secondary Transfer Rear Guide

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C

0004-6732

/ iR 6870Ci / iR 6870C

1) Open the front cover.

2) Slide out the fixing/feeding assembly.

3) Remove the ribs one by one by moving lint-free paper moistened with

alcohol in the direction of the arrow in the figure.

- Do not dry wipe, as the ribs are likely to become charged.

- The ribs of the secondary transfer rear guide are located near the static

eliminating brush [3]; do not move the lint-free paper in the wrong

direction to avoid trapping and bending the static eliminator.

[1]

F-1-17

5) Remove the 2 screws [1], and remove the grounding spring [2].

6) Remove the screw [3].

[2]

[1]

[3]

F-1-18

7) Remove the 3 screws [1], and remove the registration roller upper stay [3]

together with the grounding spring [4] while removing the spring [2] off

its hook.

F-1-15

1.4.2 Cleaning the Registration Roller, Registration Guide, and Transparency Sensor

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C

/ iR 6870Ci / iR 6870C

1) Slide out the fixing/feeding assembly.

2) Press the leaf springs on both sides, and slide the fixing/feeding assembly

farther out.

3) Remove the 3 screws [1], and turn overt the transparency upper sensor unit

[2].

0005-6999

[1]

[2]

[3] [2]

[4] [1]

F-1-19

8) Open the registration upper guide [1], and clean the back [1] of the upper

guide and the lower guide [2] using lint-free paper moistened with

alcohol.

9) Remove the paper lint building up on the transparency sensor [3] using a

blower brush.

[1]

[3]

[2]

F-1-16

4) Remove the paper lint building up over the transparency sensor [1] using

a blower brush.

F-1-20

10) Turn the upper registration roller [1] and the lower registration roller [2]

to clean them with lint-free paper moistened with alcohol.

13

Chapter 1

F-1-21

[2] [1]

14

Chapter 2 Standards and Adjustments

2.1 Image Adjustment Basic Procedure

Chapter 2

2.1.1 Image Adjustment Basic Procedure 1

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

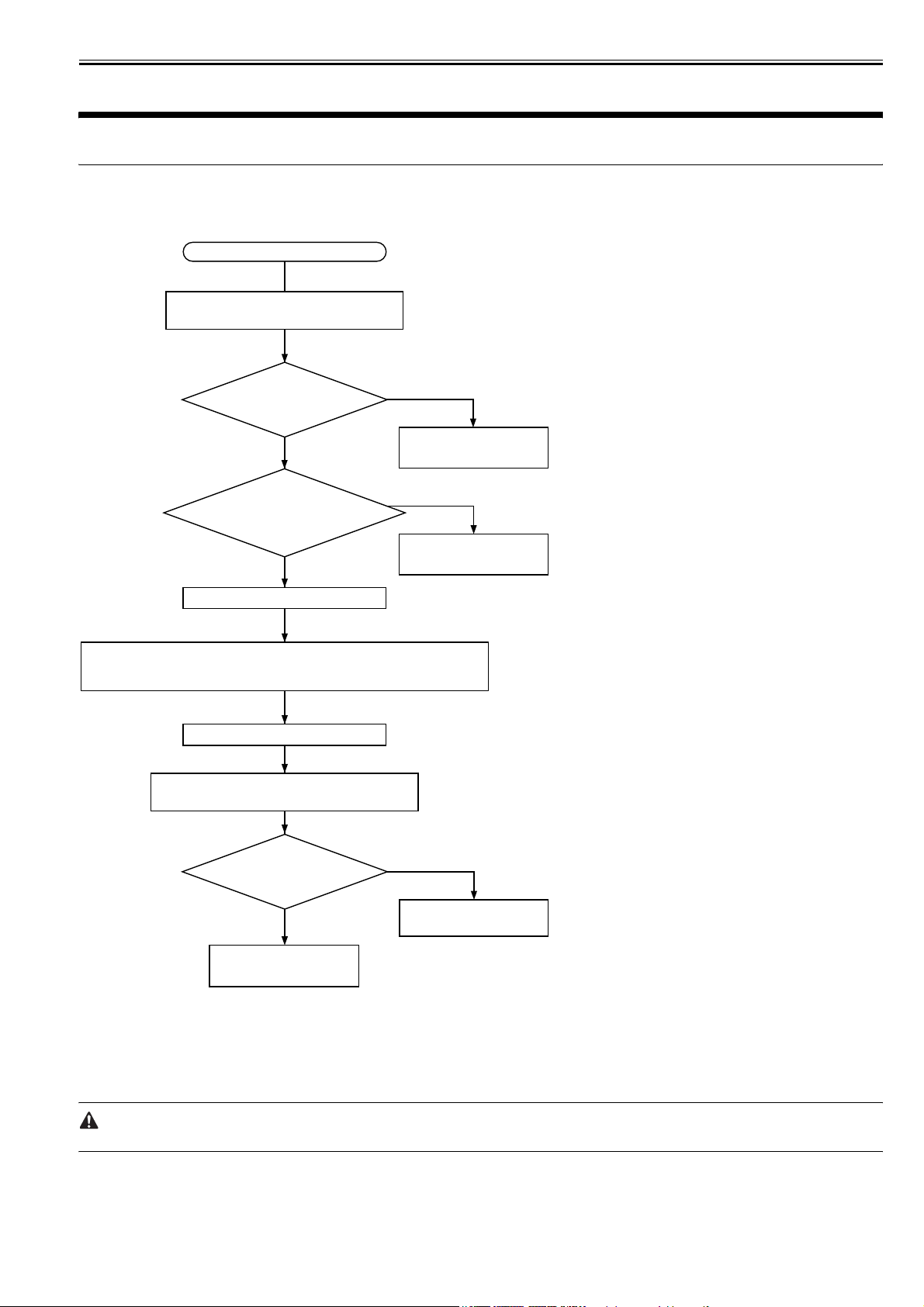

START

Turn off the potential control mechanism:

COPIER>OPTION>BODY>P0-CNT '0'

Is the image better?

See*1

YES

Execute the following:

COPIER>FUNCTION>

DPC>OFFSET.

OK

Turn off the main power switch.

NO

To image adjustment

basic procedure 2

NG

Check the potential

sensor harness.

0005-4335

1. Short circuit CP82 found on the DC controller PCB and GND (frame).

2. Disconnect the connector J426 for the DC controller PCB found on

the potential control PCB.

Turn on the main power switch.

Make the following selections in service mode:

COPIER>DISPLAY>DPOT>DPOT-K.

Is the setting between

0 and 30?

YES

Replace the potential

sensor unit.

F-2-1

*1: Make a Bk mono copy. If the said fault is absent, make a full color copy. (Be sure not to make more than 5 full color copies.)

1. At the End of the Work

When done, go through he following so that the machine is ready to generate images of optimum quality.

1) Enable the potential control mechanism in service mode (set '1' to the following, and execute the item: COPIER>option>PO-CNT).

2) Perform image stabilization control in service mode (i.e., execute COPIER>FUNCTION>MISC-P>INTR-EX).

3) If the sure to perform full correction in user mode (under auto gradation correction) to ensure optimum density.

NO

Replace the DC

controller PCB.

When done, be sure to set '1' to the service mode item (potential control function); otherwise, image faults can occur.

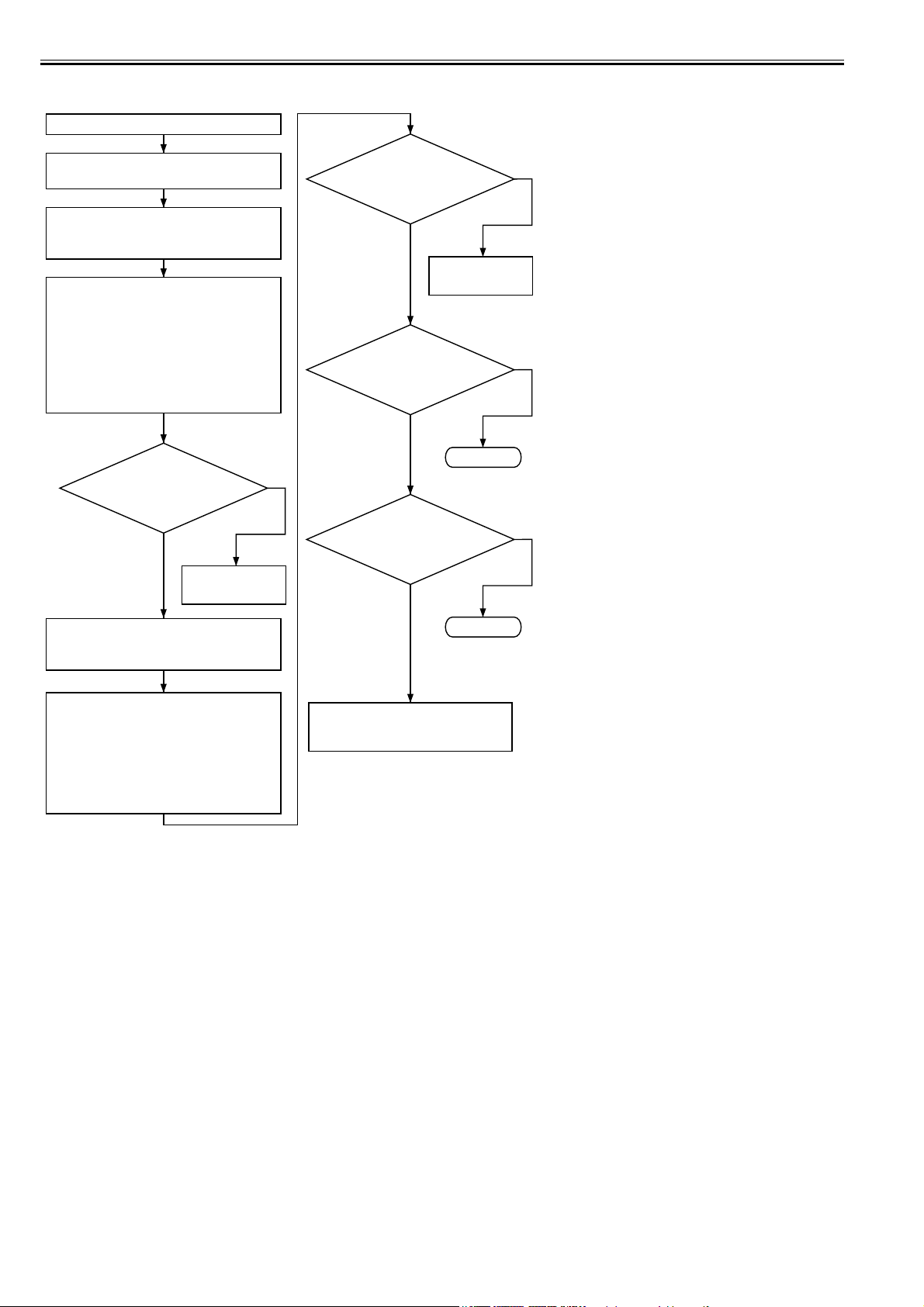

2.1.2 Image Adjustment Basic Procedure 2

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0005-4336

15

Chapter 2

<Check the Primary / Grid output>

Image adjustment basic procedure 2

Turn off the potential control mechanism:

COPIER>OPTION>BODY>P0-CNT '0'

Measure the voltage PR-CNT at

J1111B-9 found on the DC controller

PCB during copying operation.

Make the following selections in service

mode (primary current level of the

primary charging assembly):

COPIER>DISPLAY>HV-STS>PRIMARY.

Using the "Potential Control Conversion

Table," convert the reading (in uA)

indicated during printing operation into a

control voltage. Refer to the result as

conversion value A.

Is the difference between

the actual measurement of

PR-CNT and the foregoing

value A within +/-10%?

NO

YES

Replace the DC

controller PCB.

Is the difference between

the actual measurement of

GRID-CNT and the foregoing

value B within +/-10%?

YES

Replace the DC

controller PCB.

Try replacing HVT1.

Is the fault corrected?

NO

Try replacing the

photosensitive drum.

Is the fault corrected?

NO

NO

YES

END

YES

Measure the voltage GRID-CNT at

END

J111B-8 found on the DC controller PCB

during copying operation.

Make the following selections in service

mode (grid voltage level of the primary

charging assembly): COPIER>DISPLAY>

HV-STS>GRID. Using the "Potential

To image adjustment basic

procedure 3

Control Conversion Table," convert the

reading (unit V) indicated during printing

operation into a control voltage. Refer to

the result as conversion value B.

F-2-2

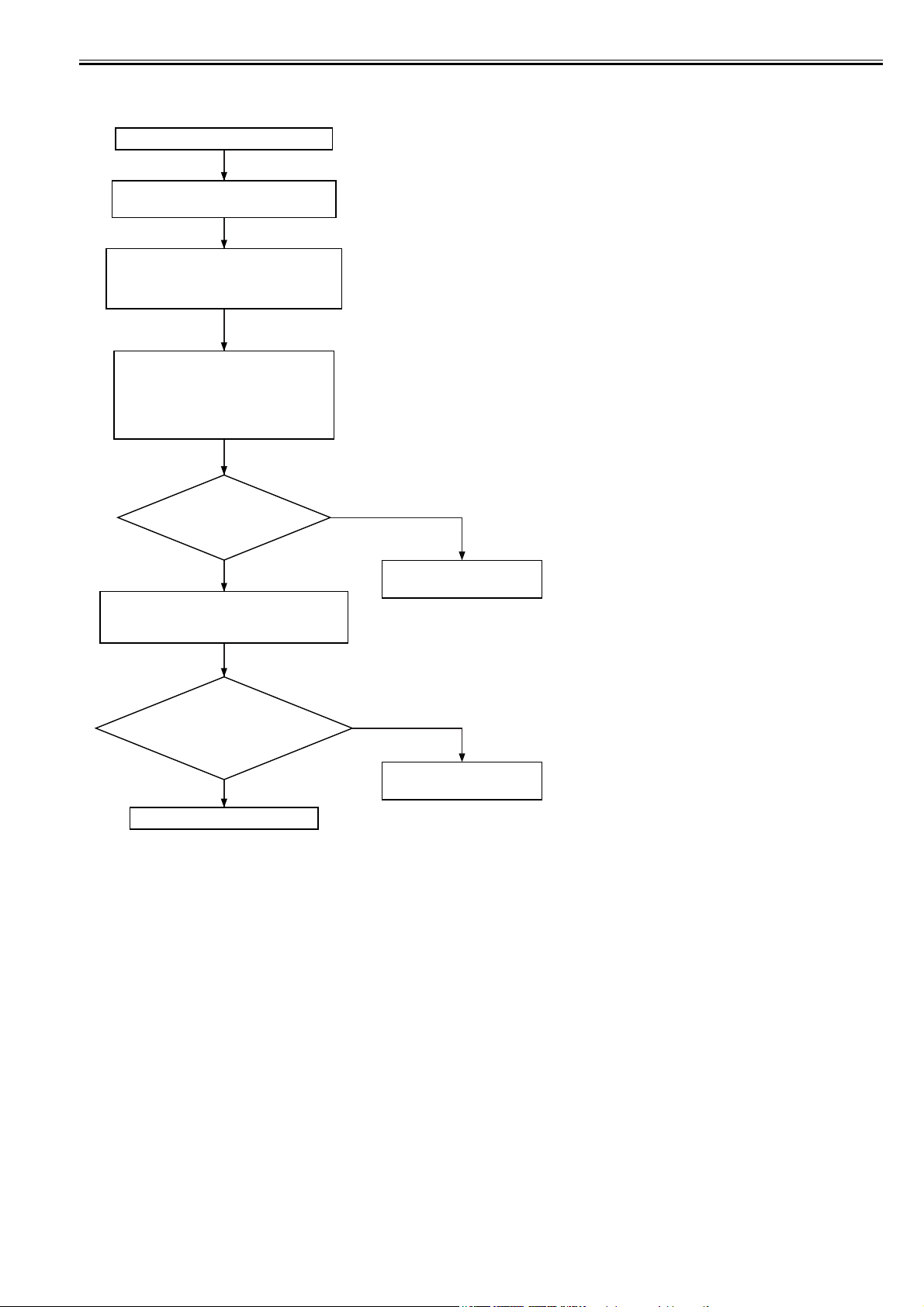

2.1.3 Image Adjustment Basic Procedure 3

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0005-4337

16

<Check the Laser output>

Image adjustment basic procedure 3

Turn on the potential control mechanism:

COPIER>OPTION>BODY>P0-CNT '1'

Make the following selections in service mode,

and set '1' :

COPIER>FUNCTION>DPC>DPC. Thereafter,

turn off and then on the main power switch.

Check the following service mode settings:

COPIER>DISPLAY>DPOT>LPWR-Y

COPIER>DISPLAY>DPOT>LPWR-M

COPIER>DISPLAY>DPOT>LPWR-C

COPIER>DISPLAY>DPOT>LPWR-K

Chapter 2

Unconditional execution

of potential control mechanism

Is the reading

YES

between 00 and FF?

NO

To image adjustment basic

procedure 4

Check the voltage level of CP11 found on

the DC controller PCB during black printing

operation.

Is the voltage level

NO

(laser output)

of CP11 within the

limit (2.0 V)?

YES

To image adjustment basic

procedure 4

Replace the laser scanner unit.

F-2-3

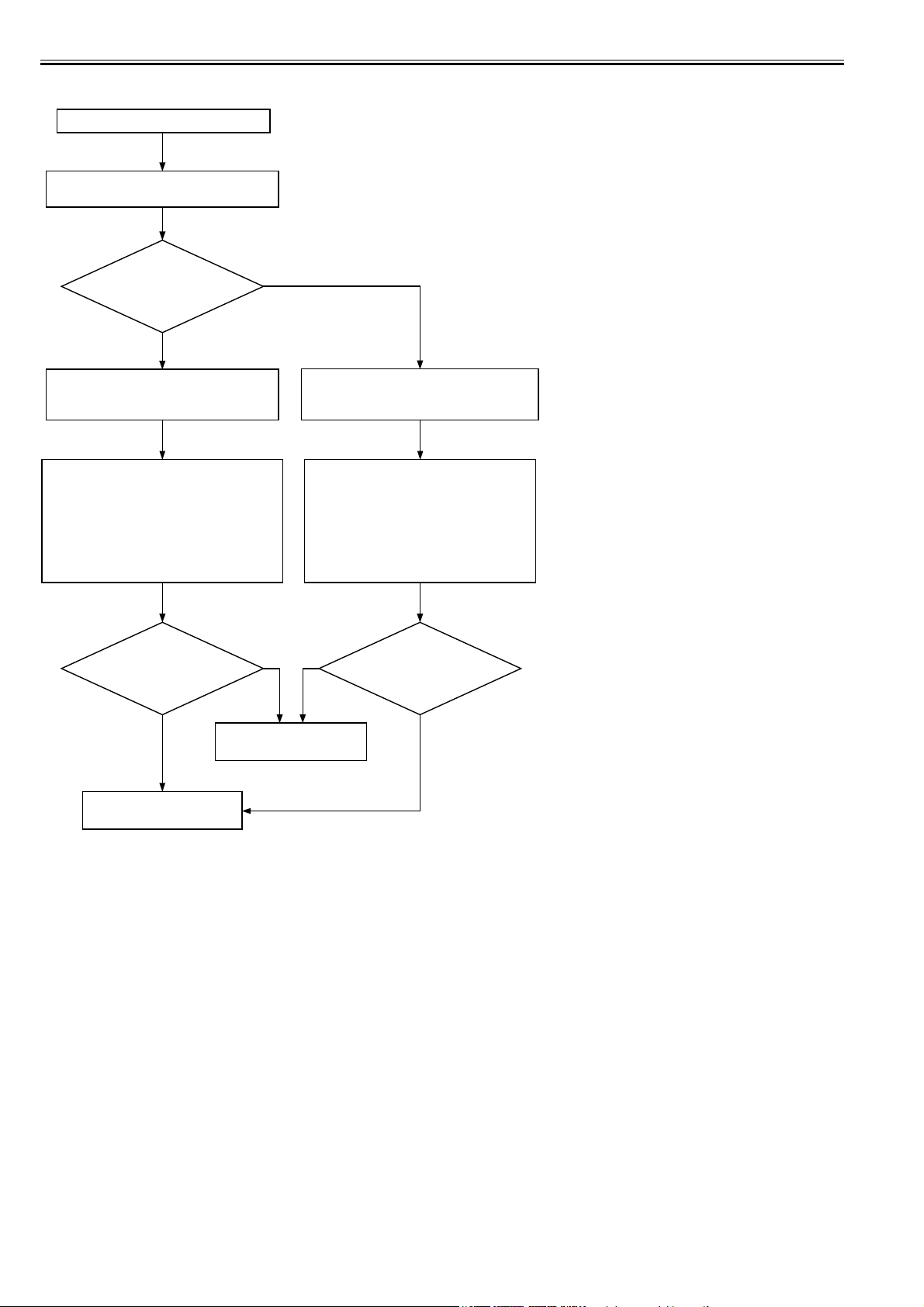

2.1.4 Image Adjustment Basic Procedure 4

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0005-4338

17

Chapter 2

<Check the Developing output>

Image adjustment basic procedure 4

Turn on the potential control mechanism:

COPIER>OPTION>BODY>P0-CNT '1'

Is the fault in

a color or in the black?

Bk

Color

Measure the voltage DEV_DC_CONT at

J1132A-11 found on the DC controller

PCB during black printing operation.

Make the following selections in service

mode (DC level of black developing bias):

COPIER>DISPLAY>HV-STS>BIAS. Using

the "Potential control Conversion Table,"

convert the reading (in V) indicated during

black printing operation into a control

voltage. Refer to the result as conversion

value D.

Is the difference

between the actual measurement

of DEV-DC-CNT and the

foregoing value D

within +/-10%?

YES YES

NO NO

Replace the DC controller

PCB.

To image adjustment basic

procedure 5

F-2-4

Measure the voltage DEV_CL_DC_CONT

at J1132A-9 found on the DC controller

during full color printing operation.

Make the following selections in service

mode (DC level of color developing bias)

: COPIER>DISPLAY>HV-STS>BIAS.

Using the "Potential control Conversion

Table," convert the reading (in V)

indicated during full color printing

operation into a control voltage. Refer to

the result as conversion value C.

Is the difference between

the actual measurement of

DEV-DC-CNT and the foregoing

value C within +/-10%?

2.1.5 Image Adjustment Basic Procedure 5

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

18

0005-4339

Loading...

Loading...