Page 1

Installation Procedure

iR C6800 Series

Jan 25 2006

Page 2

Page 3

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, in-

stallation, maintenance, and repair of products. This manual covers all localities where the prod-

ucts are sold. For this reason, there may be information in this manual that does not apply to

your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or

changes in products. When changes occur in applicable products or in the contents of this manual,

Canon will release technical information as the need arises. In the event of major changes in the

contents of this manual over a long or short period, Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent

with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the

individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may

not be copied, reproduced or translated into another language, in whole or in part, without the

written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Page 4

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Introduction

Memo

REF.

Indicates an item requiring disconnection of the power plug from the electric outlet.

Indicates an item intended to provide notes assisting the understanding of the topic in question.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Page 5

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accom-

panies the symbol , the arrow indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front

door, and closing the delivery unit door, which results in supplying the machine with power.

2. In the digital circuits, '1'is used to indicate that the voltage level of a given signal

is "High", while '0' is used to indicate "Low".(The voltage value, however, differs from

circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in

the field. Therefore, the operations of the microprocessors used in the machines are not

discussed: they are explained in terms of from sensors to the input of the DC controller PCB

and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and major changes will be communicated in the form of Service

Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service

Manual and all relevant Service Information bulletins and be able to identify and isolate

faults in the machine."

Page 6

Page 7

Contents

Contents

Chapter 1 Installation Procedure

1.1 Making Pre-Checks ............................................................................................................................................ 2

1.1.1Selecting the Site of Installation ................................................................................................................. 2

1.1.2Installation Environment .............................................................................................................................. 3

1.1.3Checking the Contents................................................................................................................................. 4

1.2 Unpacking and Installation................................................................................................................................ 8

1.2.1Before Starting the Work ............................................................................................................................. 8

1.2.2Turning Off the Host Machine..................................................................................................................... 8

1.2.3Unpacking the Machine ............................................................................................................................... 8

1.2.4Attaching the Pickup Assembly ................................................................................................................ 11

1.2.5Attaching the Scanner System ................................................................................................................. 12

1.2.6Locking the Primary Transfer Roller in Place......................................................................................... 13

1.2.7Before Attaching the Developing Assembly ........................................................................................... 13

1.2.8Attaching the Color Developing Assemblies .......................................................................................... 17

1.2.9Attaching the Black Developing Assembly ............................................................................................. 20

1.2.10Attaching the Process Unit...................................................................................................................... 23

1.2.11Attaching the Fixing Assembly ............................................................................................................... 27

1.2.12Fitting the Black Toner Bottle.................................................................................................................. 28

1.2.13Checking the Environment Switch ......................................................................................................... 29

1.2.14Turning On the Main Power Switch....................................................................................................... 29

1.2.15Setting Up the Paper Cassette............................................................................................................... 30

1.2.16Changing the Deck Paper Size (right, left) ........................................................................................... 31

1.2.17Fitting the Color Toner Cartridge............................................................................................................ 32

1.2.18Supplying Black Toner ............................................................................................................................. 33

1.2.19Cleaning the Intermediate Transfer Belt ............................................................................................... 33

1.2.20Supplying Color Toner ............................................................................................................................. 34

1.2.21Setting Auto Gradation Correction......................................................................................................... 34

1.2.22Checking the Image/Operation............................................................................................................... 35

1.2.23Adjusting the Horizontal Registration .................................................................................................... 35

1.2.24Adjusting the Leading Edge Registration.............................................................................................. 37

1.2.25Securing the Machine in Place............................................................................................................... 38

1.2.26If Not Connected to a Network ............................................................................................................... 39

1.2.27Affixing the Shut-down warning label .................................................................................................... 39

1.3 Checking the Connection to the Network ..................................................................................................... 40

1.3.1Overview ...................................................................................................................................................... 40

1.3.2Using the PING Utility ................................................................................................................................ 40

1.3.3Using a Remote Host Address ................................................................................................................. 40

1.4 Troubleshooting the Network.......................................................................................................................... 41

1.4.1Overview ...................................................................................................................................................... 41

1.4.2Checking the Connection of the Network Cable.................................................................................... 41

1.4.3Using a Loopback Address ....................................................................................................................... 41

1.4.4Using a Local Host Address...................................................................................................................... 41

1.5 Installing the Card Reader............................................................................................................................... 42

Page 8

Contents

1.5.1Points to Note About Installation ............................................................................................................. 42

1.5.2Checking the Contents.............................................................................................................................. 42

1.5.3Installation ................................................................................................................................................... 42

1.5.4Using the Card Reader in Combination with NetSpot Accountant (hereafter, NSA)....................... 44

1.6 Installing the NE Controller-A1....................................................................................................................... 45

1.6.1NE Controller-A1 Installation Procedure ................................................................................................ 45

1.7 Installing the Original Tray.............................................................................................................................. 46

1.7.1Checking the Contents.............................................................................................................................. 46

1.7.2Attachment.................................................................................................................................................. 46

1.8 Installing the Key Switch Unit-A1................................................................................................................... 47

1.8.1Checking the Contents.............................................................................................................................. 47

1.8.2Attachment.................................................................................................................................................. 47

1.9 Installing the Reader Heater Kit..................................................................................................................... 49

1.9.1Checking the ComponentsÅiReader Heate-C1Åj................................................................................. 49

1.9.2Before Starting the Work........................................................................................................................... 49

1.9.3Installation Procedure................................................................................................................................ 49

1.10 Installing the Voice Guidance Kit................................................................................................................. 53

1.10.1Checking Items in the Package ............................................................................................................. 53

1.10.2Turning Off the Host Machine................................................................................................................ 54

1.10.3Installation Procedure ............................................................................................................................. 54

Page 9

Chapter 1 Installation

Procedure

Page 10

Chapter 1

1.1 Making Pre-Checks

1.1.1 Selecting the Site of Installation

0002-6395

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

Be sure that the site of installation satisfies the following requirements; if possible, visit the user's before delivery of

the machine:

(1) There must be a properly grounded power outlet that is rated as indicated (+/-10%) and that may be used ex-

clusively by the machine.

(2) The temperature of the site must be between 15 and 30 deg C and humidity, between 25% and 80%. The ma-

chine may not be installed near a water faucet, water boiler, humidifier, or refrigerator.

(3) The site must not be near a source of fire or in an area subject to dust or ammonium gas. If the area is exposed

to the direct rays of the sun, the windows must be furnished with curtains.

(4) The site must be well ventilated. However, the machine must not be installed near the air vent of the room. The

ozone generated by the machine while in operation is not of a level that can harm the health of the individuals

around the machine. Nevertheless, some may find it to be unpleasant, and the room must be ventilated often.

(5) The machine must be placed on a level floor so that all its feet remain in contact with the floor and the machine

will remain level.

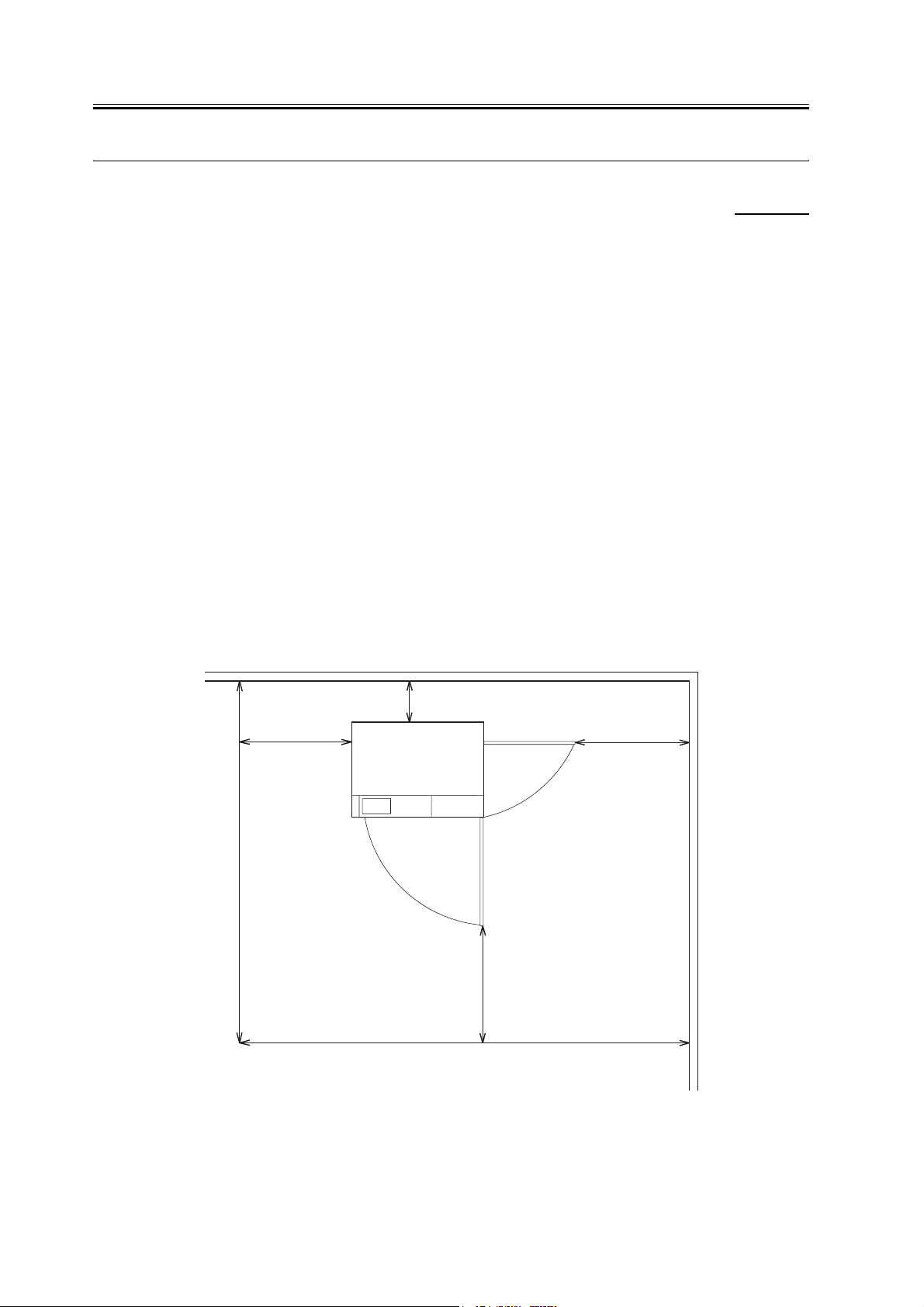

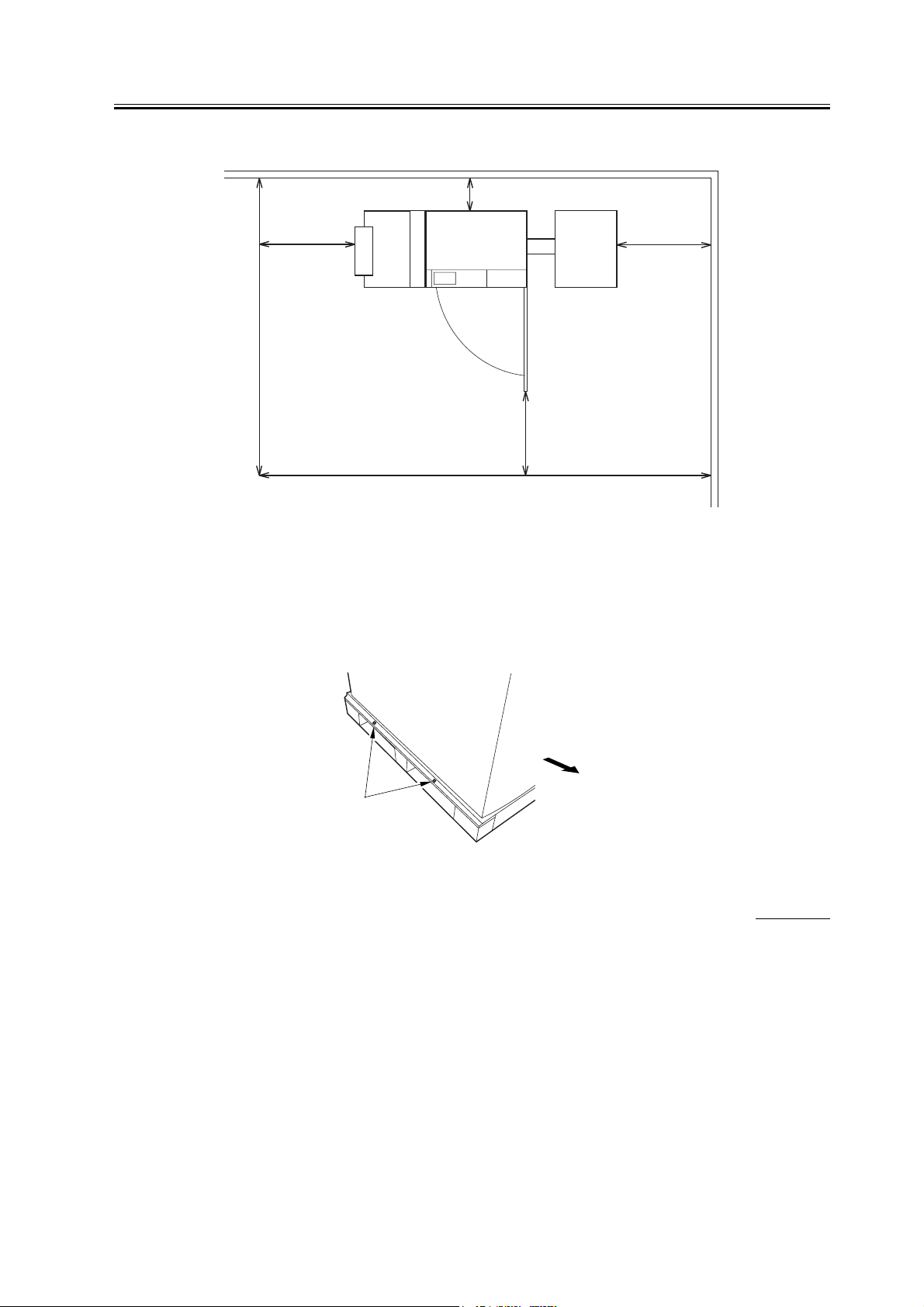

(6) There must be enough space around the machine. The following diagram shows the minimum dimensions;

whenever possible, be sure there will be more space than indicated:

(a) Copier [1]

200cm

50cm

10cm

[1]

210cm min

F-1-1

50cm

50cm

2

Page 11

(b) Copier [1] + Punch Unit [2] + Finisher [3] + Side Deck [4]

10cm

Chapter 1

[4]

50cm

200cm

50cm

[3]

[2]

[1]

50cm

310cm

F-1-2

(7) The machine will be placed on the side of the slope plate having a pin hole [1]. Be sure that the space will be

on this side (left side).

The side of the slope plate having a pin hole (left) is where the delivery side of the machine will be, with the

front of the machine facing the side indicated by the arrow.

Front

[1]

F-1-3

1.1.2 Installation Environment

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

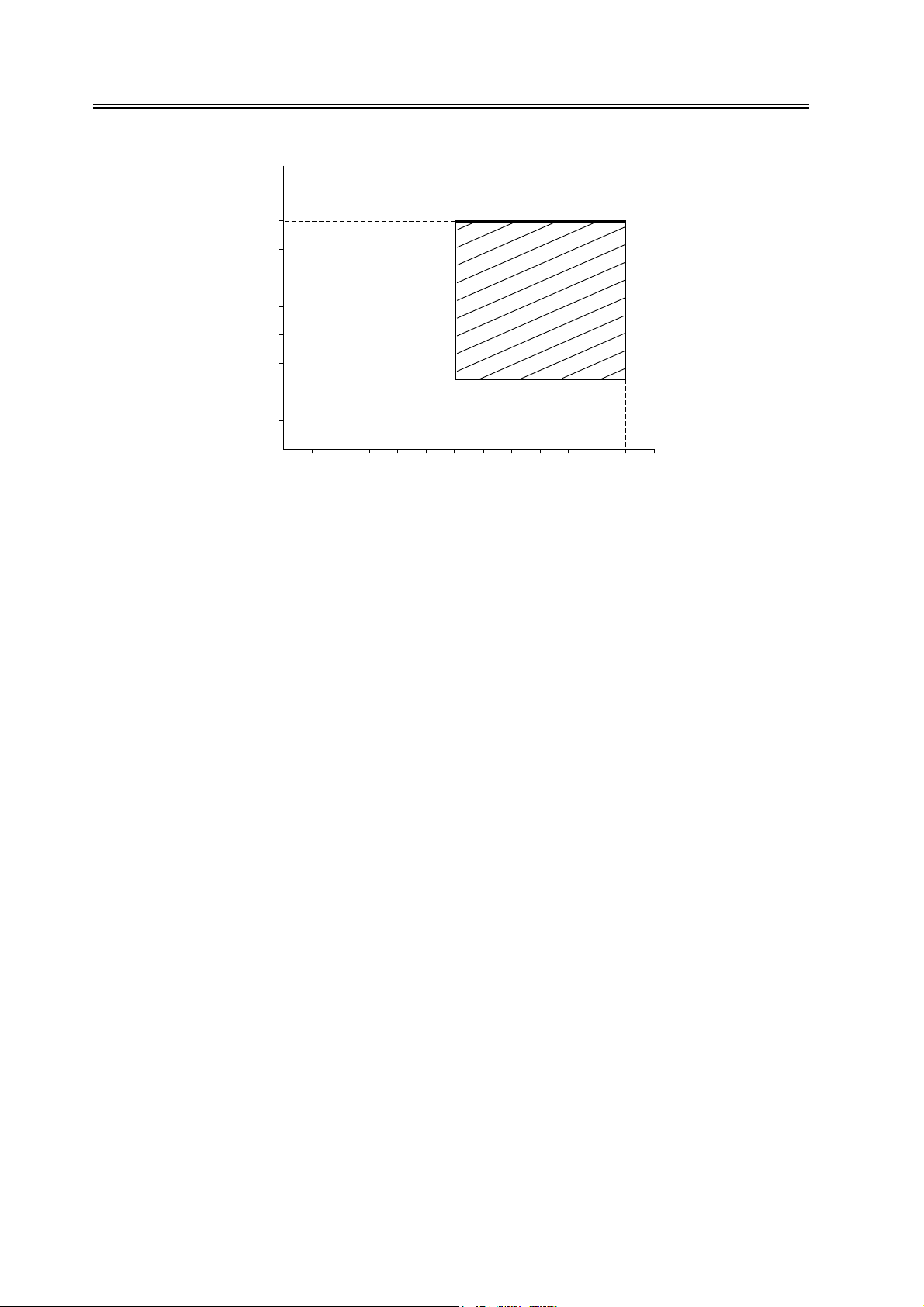

Check that the environment of the site meets the following requirements:

0002-6399

3

Page 12

Chapter 1

(%RH)

80

75

60

[1]

40

25

20

10

010152030˚C

(32) (50) (59) (68) (86) (˚F)

[2]

F-1-4

[1] Humidity

[2] Temperature

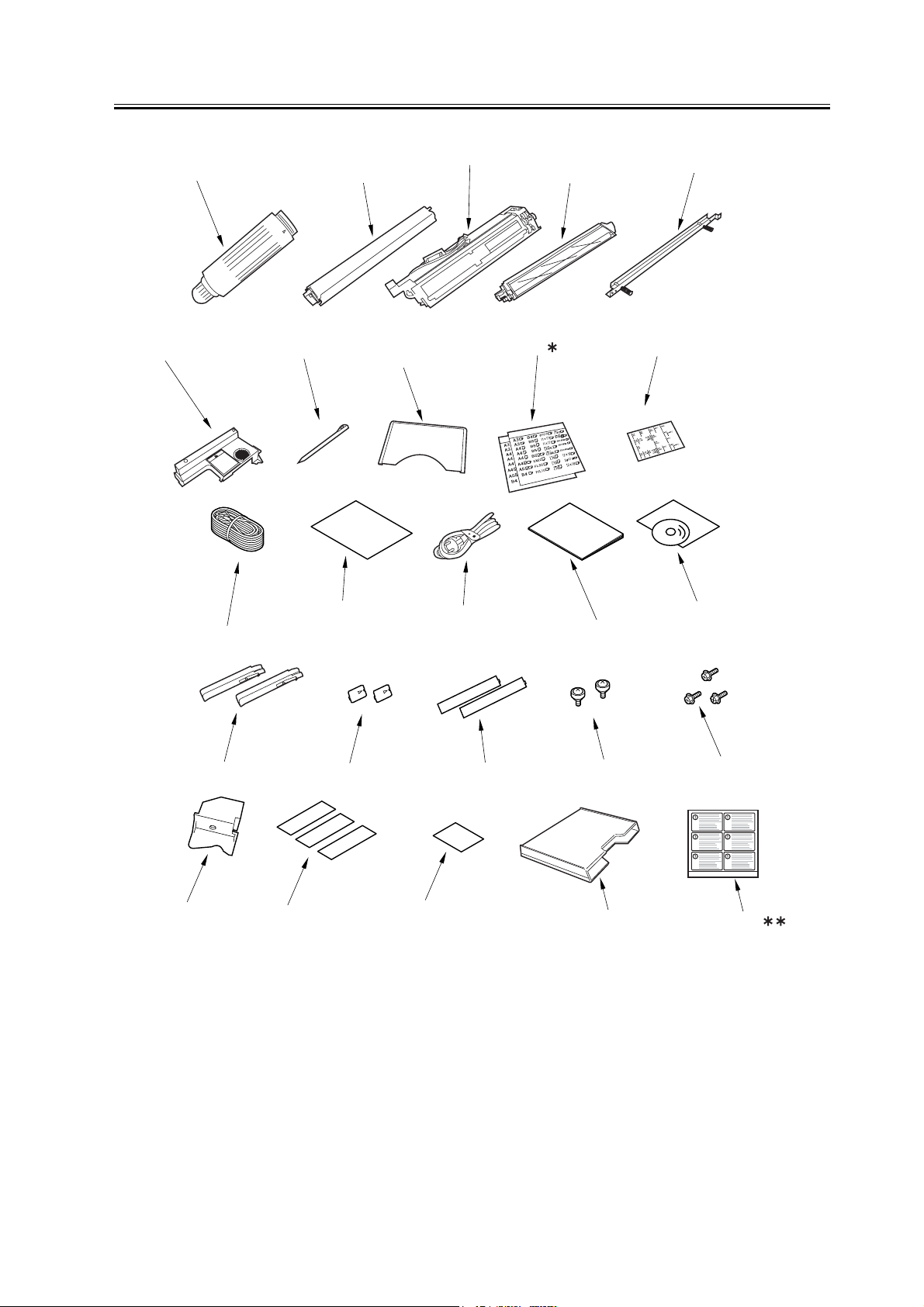

1.1.3 Checking the Contents

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN / / iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0002-6404

4

Page 13

Chapter 1

[6]

[1]

[7]

[2]

[8]

[3]

[9]

[4]

[5]

[10]

[15]

[21]

[11]

[16]

[22]

[12]

[17]

[23]

[13]

[18]

[14]

[19] [20]

[24]

F-1-5

[1] Black toner bottle (black; only for 100/230V AU model) 1 pc.

[2] Color toner cartridge(cyan, magenta, yellow;

only for 100V/230V AU model)

1 pc. each

[25]

[3] Black developing assembly (black) 1 pc.

[4] Color developing assembly (cyan, magenta, yellow) 1 pc. each

5

Page 14

Chapter 1

[5] Black developing assembly locking plate 1 pc.

[6] Process unit cover 1 pc.

[7] Touch pen 1 pc.

[8] Service book case 1 pc.

[9]* Cassette size label* 2 pc.

[10] ADF size label 1 pc.

[11] Grounding cord (100-V model only) 1 pc.

[12] QR sheet (100-V model only) 1 pc.

[13] Power cord (230-V model only) 1 pc.

[14] Service book 1 pc.

[15] User's Manual 1

[16] Grip 2 pc.

[17] Pickup assembly face place 2 pc.

[18] Delivery assembly face plate 2 pc.

[19] Binding screw (M4X8) 2 pc.

[20] RS tightening screw (M4X8) 3 pc.

[21] Left deck locking plate 1 pc.

[22] No Copy label (non-100-V model) 3 pc.

[23] Glass Cleaning instructions label (non-100-V model) 1 pc.

[24] Glass Cleaning instructions label (non-100-V model) 1 pc.

[25]** Shut-down warning label 1 pc.

* Found inside the cassette 3 (upper cassette).

** The shut-down warning label is used for iR C6870/C5870 Series only.

6

Page 15

Chapter 1

7

Page 16

Chapter 1

1.2 Unpacking and Instal-

lation

1.2.1 Before Starting the

Work

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

Keep the following in mind when installing the ma-

chine:

- When a machine is moved from a cold to warm loca-

tion, condensation can occur in its pickup/feeding

assembly, ultimately causing image faults. As nec-

essary, leave the machine alone for at least 1 hour

without unpacking, and start the work when it has

fully become used to the room temperature.

(The term "condensation" refers to a symptom in

which droplets of water occur on the surface of a

metal object brought in from a cold to warm loca-

tion as the result of rapidly cooling vapor around it.)

- The machine weighs about 230 kg. Be sure to work

in a group of 4 persons when lifting it.

- Be sure to turn the 2 adjusters (front) found on the

bottom of the machine clockwise to release them.

These adjusters can slip off the machine when the

machine is moved. Take care not to lose them.

0002-6409

[2] Turn off the main power switch.

[3] Disconnect the power cable (from the power out-

let).

iR C6870/C5870

Turning Off the Main Power

When turning off the main power, be sure to go

through the following in strict sequence to protect the

machine's hard disk:

[1] Hold down on the power switch on the control

panel for 3 sec or more.

[2] Operate on the touch panel according to the shut-

down sequence indicated so that the main power

switch may be turned off.

[3] Turn off the main power switch.

[4] Disconnect the power cable (for the power outlet).

1.2.3 Unpacking the Machine

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Open the shipping box, and remove the plastic cov-

ers.

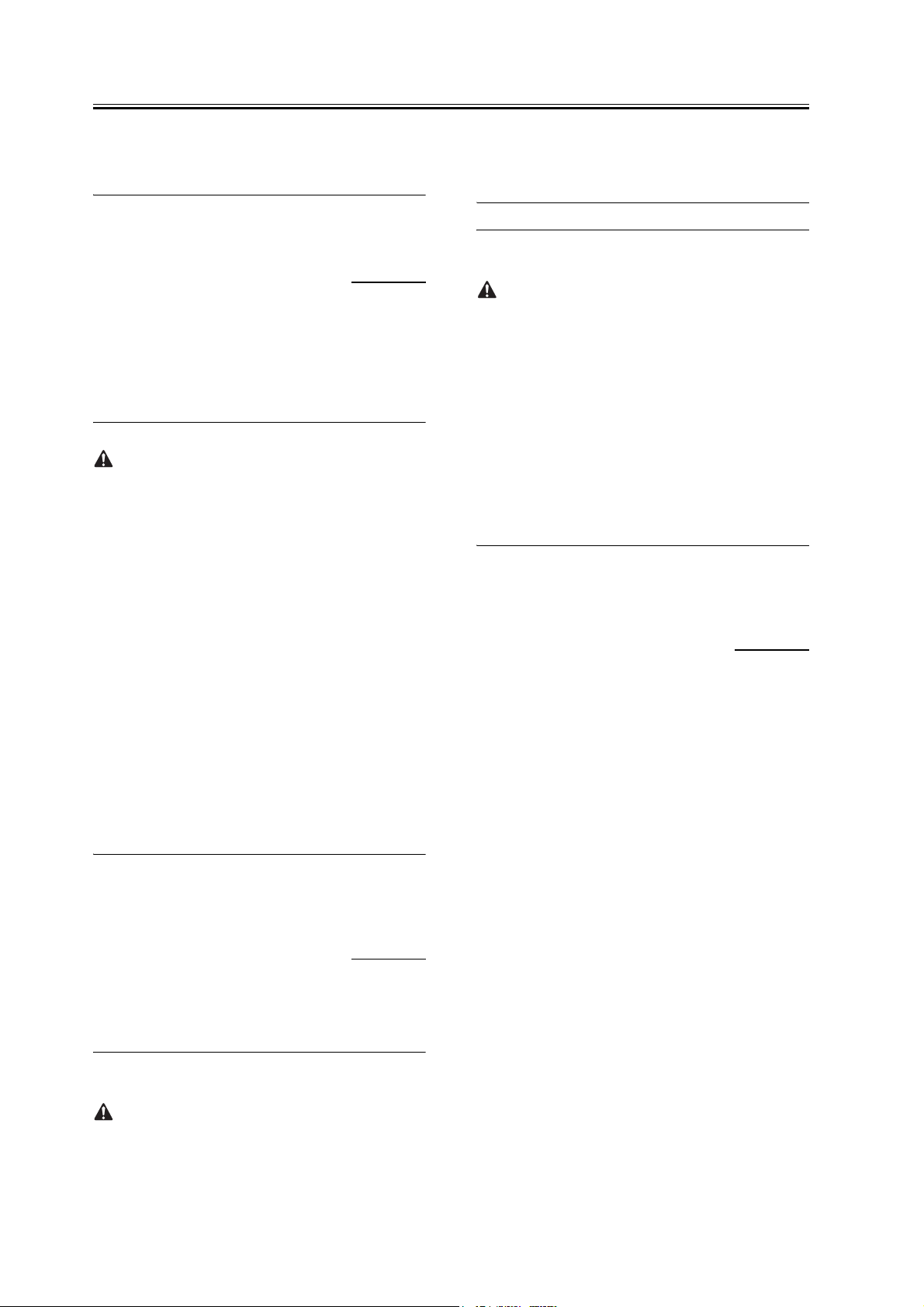

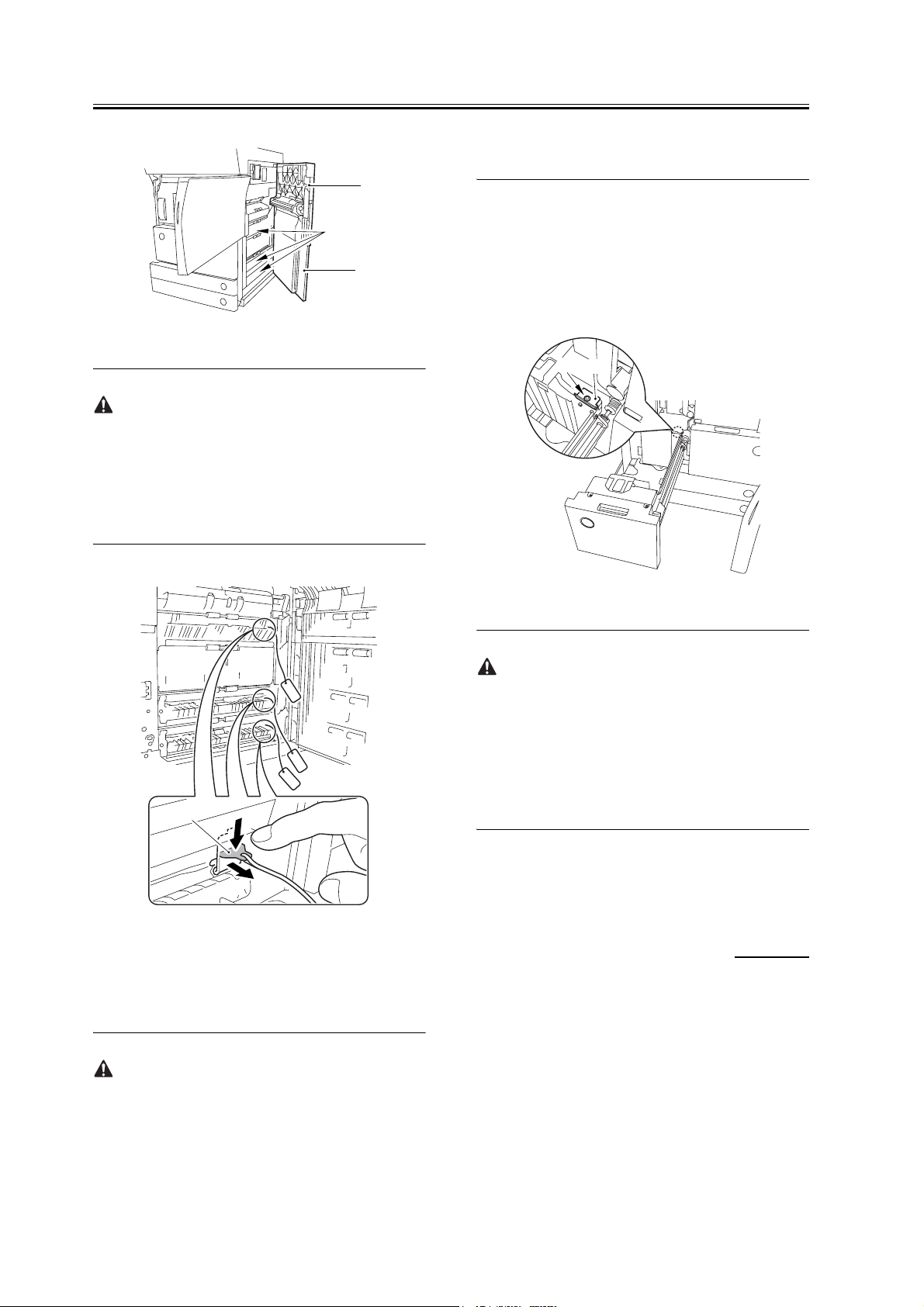

2) Insert the two grips [2] while inserting a screwdriv-

er to the grip insert hole [1] where is main body's

paper pickup side.

0002-6411

1.2.2 Turning Off the Host Machine

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

iR C6800/C5800

Turning Off the Main Power

[1] Turn off the control panel power switch.

8

0011-3879

Page 17

[2]

F-1-6

[2]

Chapter 1

[1]

[1]

F-1-8

5) Move the machine in the direction of the arrow;

then, remove the 2 slope plates [2] from the middle

of the skid [1].

3) While holding the grips on the pickup side (front,

rear), lift the machine slightly, and remove the pad

[1] in the direction of the arrow.

(weight of the machine: about 230 kg)

[1]

F-1-7

4) While holding the grips on the delivery side (front,

rear), lift the machine slightly, and remove the pad

[1] in the direction of the arrow.

At this time, do not lift the machine more than nec-

essary. Otherwise, you can lose the balance.

(weight of the machine: about 230 kg)

[2]

[1]

F-1-9

6) Detach the 2 pins taped to the back of the slope

plate.

7) Turn over the slope plate [1], and set it as shown;

then, match the skid and the slope plate by their pin

holes, and insert the pin [2] (1 pc. each).

[2]

[1]

F-1-10

9

Page 18

Chapter 1

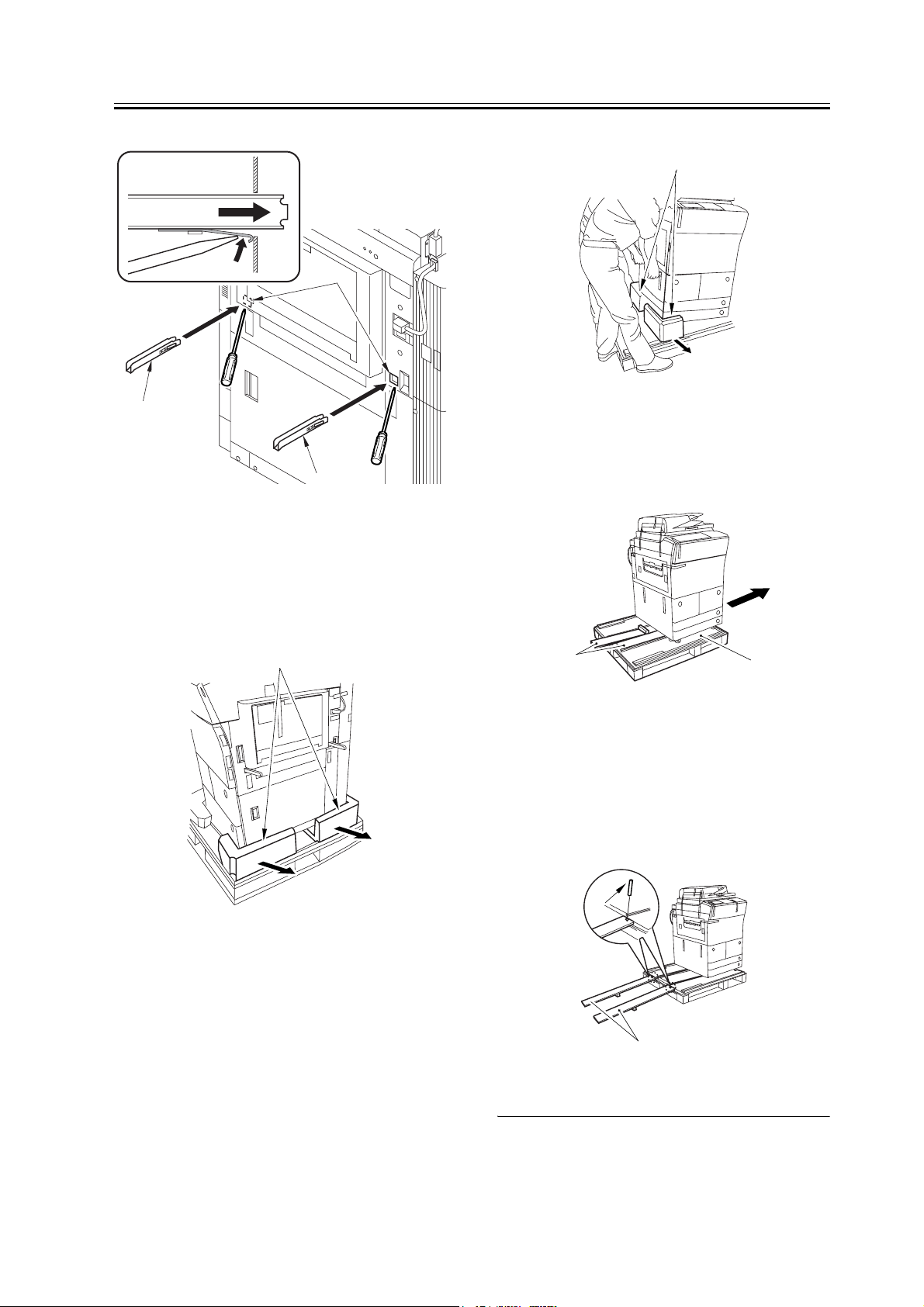

Check that the caster [1] has not rolled off the skid [2].

Also, Check that it has not ridden over the edge [3] of

the skid.

[1][2] [3]

F-1-11

8) While holding the grips on the delivery side of the

machine, move the machine along the slope plates

and off the skid.

9) Remove the packing tape from the machine.

10) Remove the two grips [2] by inserting a screw-

driver to the grip insert hole [1].

[1]

[2]

[2]

F-1-12

11) Attach the 2 included pickup assembly face plate

[2] over the holes [1] from which you have removed

the grips.

[1]

[2]

F-1-13

10

12) Remove the 2 screws [1], and rear right cover [2].

[1]

[2]

F-1-14

13) Insert the 2 grips [1] you removed in the foregoing

Page 19

Chapter 1

step in the compartment [2] found at the rear right

of the machine.

[1]

[2]

[1]

F-1-15

14) Attach the right cover (lower rear) [2] with 2

screws [1].

[1]

the grips.

[1]

[2]

F-1-18

1.2.4 Attaching the Pickup Assembly

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0002-6414

[2]

[1]

F-1-16

15) Store the 2 grips [1] on the delivery side as shown

so that they are inside the machine.

[1]

F-1-17

1) Remove the 3 shipping tags [1] from the right rear

lower cover.

[1]

F-1-19

2) Open the upper right cover [1] and the lower right

cover [2]; then, remove the 3 unlocking spacers [3]

from the pickup slot of the right deck and the cas-

settes.

16) Attach the 2 included delivery assembly face

plates over the holes [1] in which you have stored

11

Page 20

Chapter 1

[1]

[3]

[2]

F-1-20

To remove the release spacer, be sure first to push its

lever [1] in the direction of A before removing it in the

direction of B. removing the lever [1] of the release

spacer horizontally by mistake can damage the pickup

assembly. Take full care.

press on the release button. If so, remove the deck as-

sembly by hand.

5) Open the front cover.

6) Match the included left deck locking plate [1]

against the 2 holes in the left deck rear side plate;

then, secure it in place using a screw (RS tighten-

ing; M4x8) [2].

[2]

[1]

[1]

[A]

[B]

F-1-21

3) Close the upper right cover and the lower right cov-

er.

4) Press the release button, and remove the left deck.

F-1-22

- When attaching the left deck locking plate, take care

not to trap the left deck cable by the plate. (To facil-

itate the work, try lightly pressing down on the deck

cable.)

- Pull lightly on the deck cable to check that the cable

is not trapped.

7) Close the left deck.

1.2.5 Attaching the Scanner System

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0002-6566

The left deck is not supported by its locking plate, and

the deck assembly may not remove in response to a

12

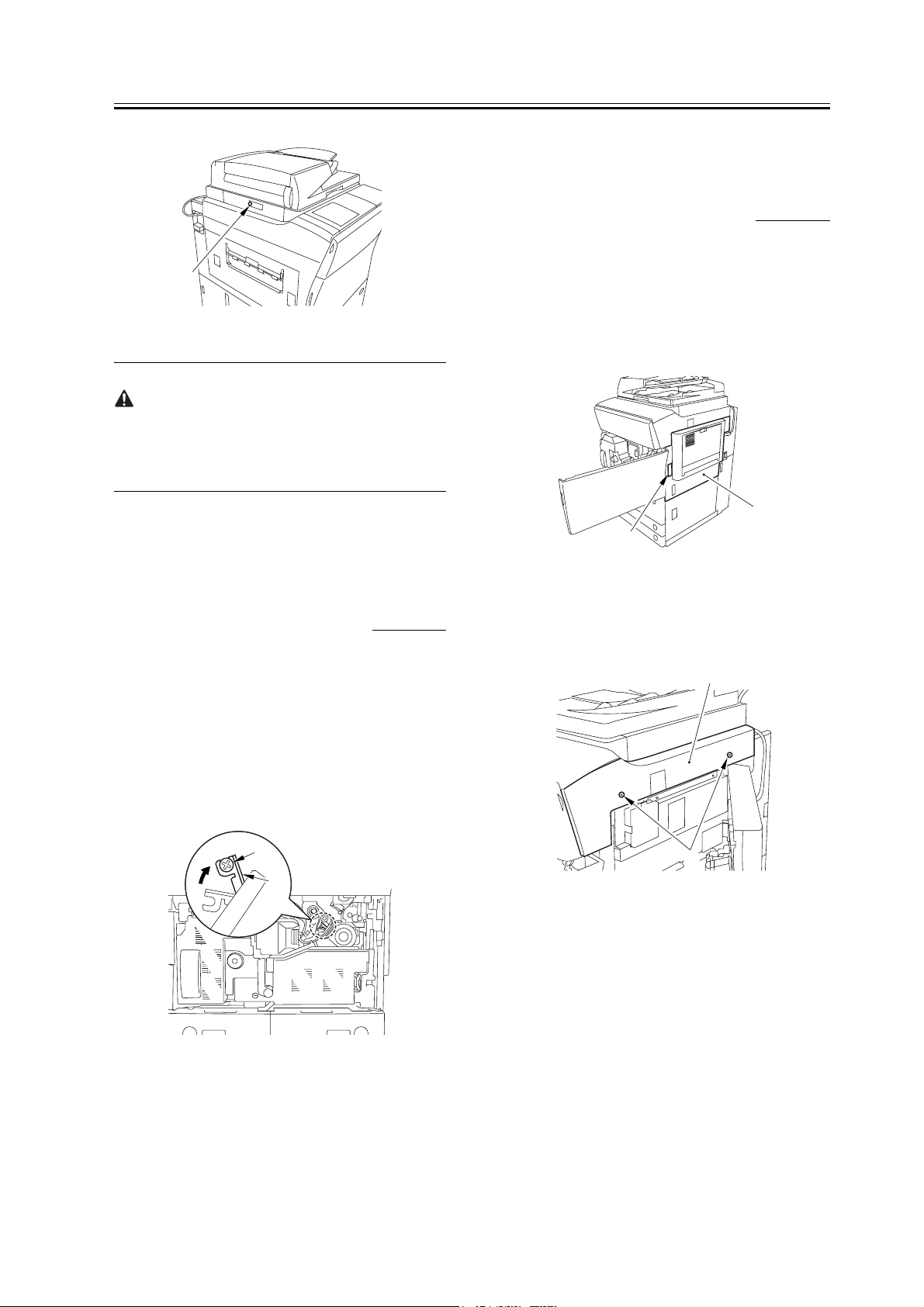

1) Open the ADF, and remove the packing material.

2) Remove the screw [1] used to attach the scanner.

Page 21

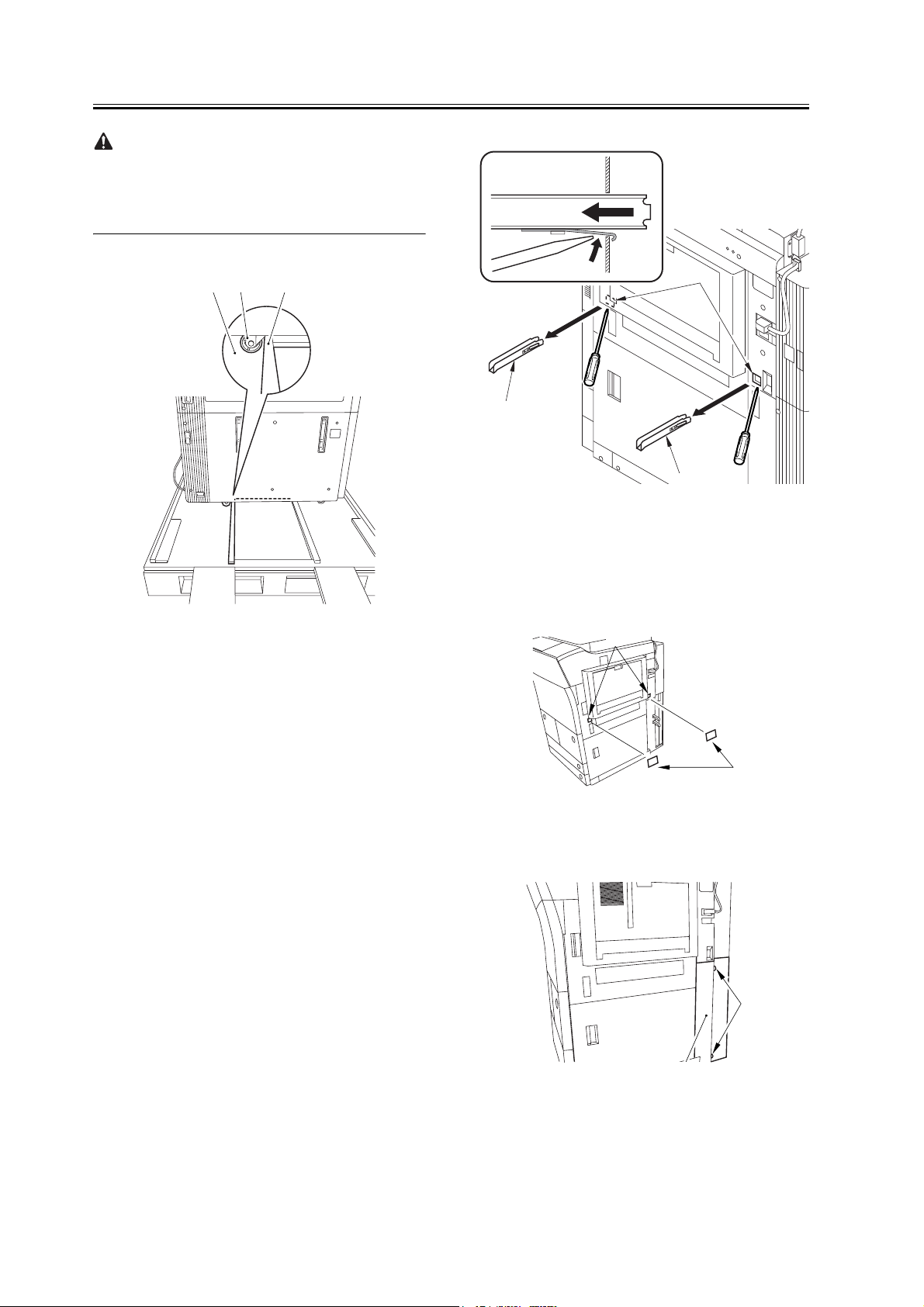

1.2.7 Before Attaching

the Developing Assem-

Chapter 1

[1]

F-1-23

Advise the user to store away the screw used to fix the

scanner system in plate. It will be used when relocat-

ing the machine in the future.

1.2.6 Locking the Primary Transfer Roller in Place

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0002-6568

bly

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Pull the grip [1] toward the front to fully open the

upper right cover [2].

[1]

F-1-25

2) Remove the 2 screws [1], and remove the right cov-

er (upper) [2].

[2]

0002-6569

[2]

1) Lift the primary transfer roller locking lever [1] in

the direction of the arrow to lock the roller in place;

then, attach the primary transfer roller locking lever

[1] using the included binding screw (M4x8) [2].

[2]

[1]

F-1-24

[1]

F-1-26

3) Press the release button [1] of the right deck, and

slide out the right deck [2].

13

Page 22

Chapter 1

[1]

[2]

F-1-27

4) Remove the screw [1] found at the lower right;

then, remove the front cover strap [2].

[1]

F-1-30

8) Remove the 3 screws [1].

[1]

[1]

[2]

F-1-28

5) Remove the 2 screws [1] (binding) of the front cov-

er; then, fully open the front cover [2].

[1]

[1]

[2]

F-1-29

F-1-31

9) Close the black toner supply cover [1]; then, fully

open the hopper assembly [2].

[2]

[1]

F-1-32

10) Remove the 4 connectors [1] found at the upper

right.

6) Close the right deck.

7) Open the black toner supply cover [1].

14

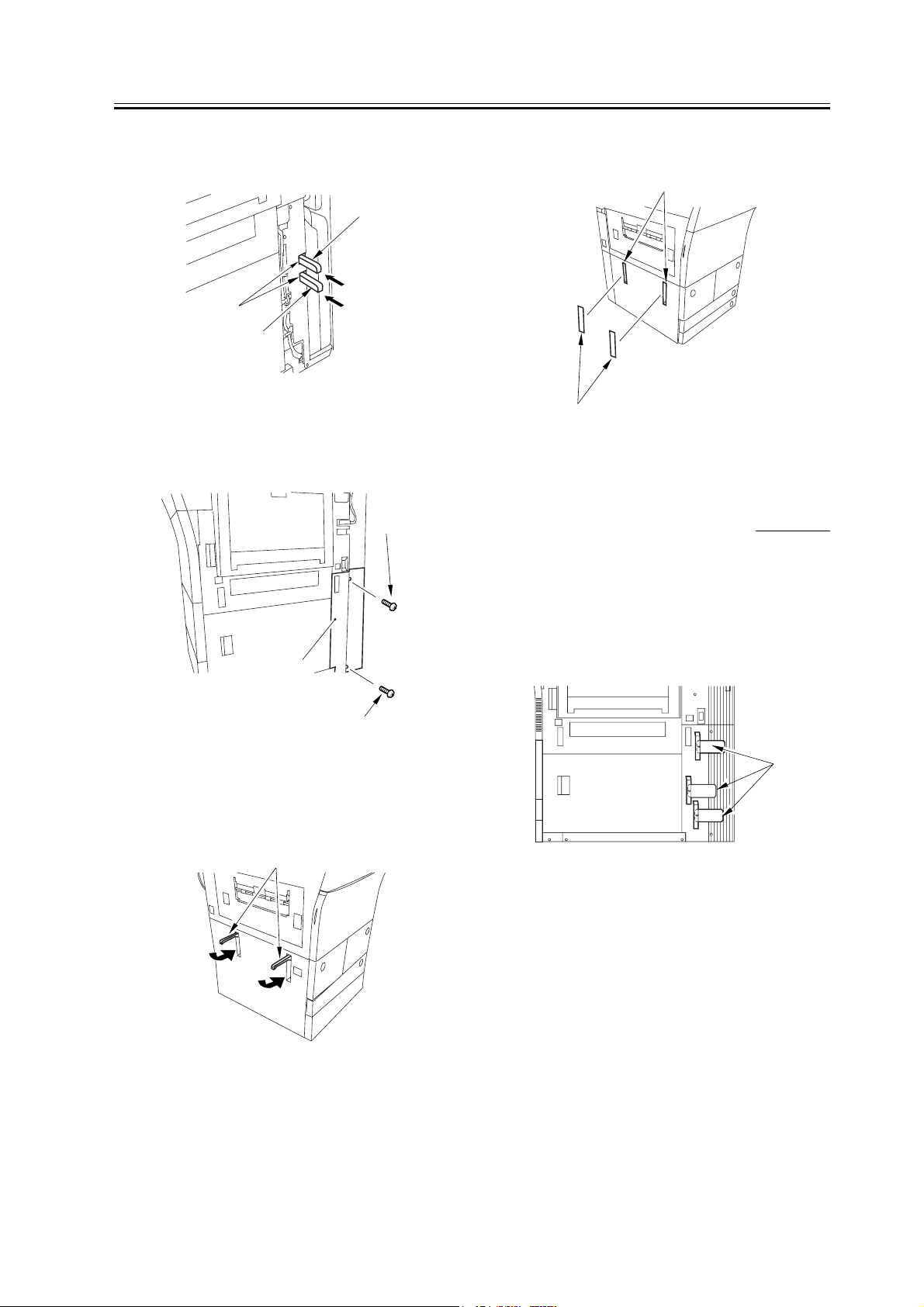

Page 23

Chapter 1

[1]

[1]

F-1-33

11) Remove the 4 connectors [1] found at the upper

left.

[1]

[1]

[2]

F-1-36

14) Hold the drum fixing member [1] in place using

the drum stop tool [2]. Then, using a screwdriver,

remove the drum fixing screw [3].

As shown in the figure, be sure to remove the screw

on the protrusion [4] of the drum stop only after

matching it against the notch [5] in the drum flange.

[1]

F-1-34

12) Remove the connector cable [1] of the high-volt-

age side from the 2 wire saddles [2] to avoid trap-

ping it. (Keep it on the cable hook [3] during the

work.)

[2]

[1]

[3]

F-1-35

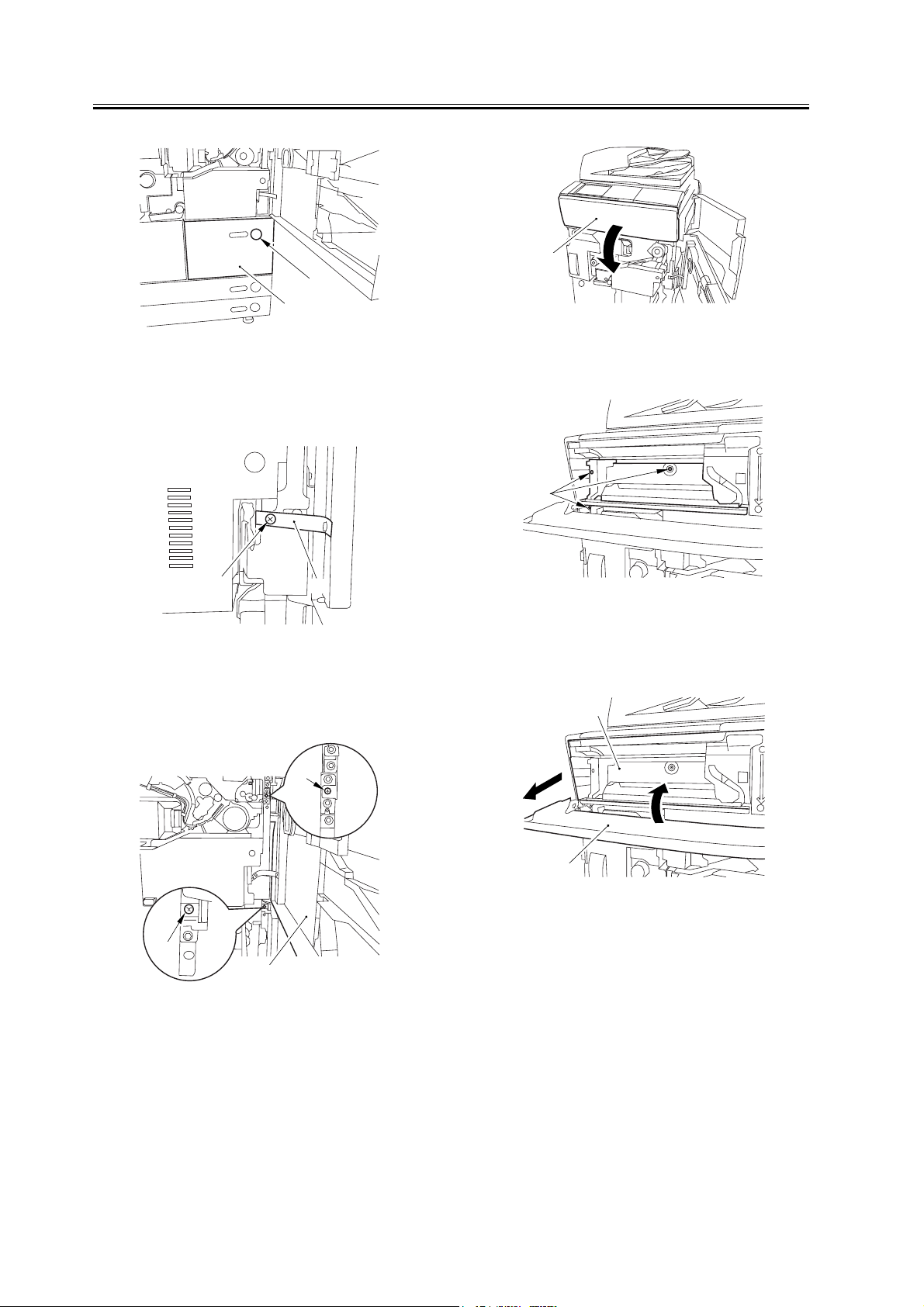

13) Remove the process unit cover [1] from the box;

then, remove the drum stop tool [2] attached to its

back.

[1]

[3]

[2]

[5]

[4]

F-1-37

15) Remove the drum fixing member [1] using preci-

sion pliers.

15

Page 24

Chapter 1

[1]

F-1-38

16) Remove the 3 binding screws (M4x8) [1].

[1]

F-1-41

19) Press the 2 slide-out hook [1] found on both sides

of the fixing/feeding assembly, and fully slide out

the fixing/feeding assembly [2].

[2]

[1]

[1]

F-1-39

17) Shift down the fixing/feeding assembly releasing

lever [1] in the direction of the arrow.

[1]

F-1-40

18) Slide out the fixing/feeding assembly [1] to the

front.

[1]

F-1-42

20) Lift both ends [1] of the process unit slightly; then,

fully slide out the process unit [2] to the front.

16

Page 25

[2]

F-1-43

[1]

Chapter 1

1) Remove the color developing assembly (yellow,

magenta, cyan) from its package box.

2) Press the lever [1] of the developing rotary solenoid

once by hand; then, turn the developing rotary [2]

counterclockwise by hand.

If you turn the developing rotary clockwise with a col-

or developing assembly inserted in place, the anti-

stray sheet attached to the sleeve of the color develop-

ing assembly can come off by friction against the pho-

tosensitive drum. Be sure to turn the developing rotary

always in counterclockwise direction.

- Be sure to take care not to deform the joint plate

found at the left end when drawing out the process

unit.

- When drawing out the process unit, be careful not to

lift the process unit more than necessary. The unit

may slip off the rails, not permitting detachment.

- When you have slid out the process unit, try placing

paper between the photosensitive drum and the de-

veloping rotary to protect the drum from scratches

and light.

1.2.8 Attaching the Color

Developing Assemblies

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0002-6670

[1]

[2]

F-1-44

3) Turn the developing rotary so that its partition side

[1] is vertical (i.e., position for attaching the devel-

oping assembly).

If you keep pressing the lever of the developing rotary

solenoid, the developing rotary will not stop to permit

attaching the developing assembly. When you have

pressed the lever once, turn the developing rotary

slightly and then let go of the lever.

If you must touch a color developing assembly, be

sure that your hands are free of foreign matter (espe-

cially of metal) before doing so. (Adhesion of foreign

matter on the cylinder is likely to cause image faults.)

17

Page 26

Chapter 1

[1]

O

90

F-1-45

4) Remove the protective sheet [1] from the toner sup-

ply mouth of the developing rotary.

M

Y

C

6) Have the appropriate color developing assembly on

hand by checking the ID mark [1] attached to the

developing rotary assembly.

The following shows the ID mark attached to the

cyan color developing assembly.

M

Y

C

[1]

M

Y

C

F-1-48

[1]

F-1-46

5) Remove the 2 screws [1], and open the 2 develop-

ing assembly arms [2] in the direction of the arrow.

Be sure to attach the developing fixing arm with a

screw before turning the developing rotary.

[1]

[1]

[2]

[2]

7) Place A3 paper on a smooth table, and place the ap-

propriate color developing assembly.

8) With the developing cylinder of the color develop-

ing assembly facing upward, remove the tape [1];

then, remove the protective sheet [2] while holding

both its edges.

[2]

[1]

F-1-49

- Do not touch the developing cylinder.

- After finishing the foregoing step, be sure to change

the orientation of the color developing assembly so

that the sponge side faces upward.

18

F-1-47

9) Remove the tape [1], and remove the sponge.

Page 27

After removing sponges, toner or starting agent may

be spilled. Do not work with the supply mouth down.

F-1-50

Chapter 1

Try holding the color developing assembly by both its

ends to facilitate the work.

F-1-52

12) Close the 2 developing assembly fixing arms [1]

in the direction of the arrows; then, attach them us-

ing 2 screws [2].

10) Check for scratches on the developing cylinder

while turning the developing cylinder gear [1] 5 to

6 times in the direction of the arrow. The work also

serves to even out the starter inside the unit.

[1]

F-1-51

11) Make sure that the color developing assembly

matches the ID mark; then, attach it in the develop-

ing rotary.

To do so, start with the front of the color developing

assembly; while keeping its front fully against the

front of the developing assembly, fit its rear in

place.

[1]

[1]

[2]

[2]

F-1-53

13) Repeat steps from 2) to 12) to attach all 3 color de-

veloping assemblies in the developing rotary.

14) If the developing cylinder [1] is found as in the

figure marked NG, turn the developing rotary so

that it is positioned as shown in the figure marked

OK.

19

Page 28

Chapter 1

NG

OK

[1]

F-1-54

[1]

[1]

[2]

F-1-57

If you fail to release the torque limiter, you will not be

able to attach the locking plate of the black developing

assembly. Be sure not to leave out the work.

1.2.9 Attaching the Black

F-1-55

15) Loosen the screw [2] used to attach the torque lim-

iter [1] of the developing rotary; then, move it up-

ward to release.

[2]

[1]

F-1-56

16) Attach the torque limiter using a screw [1].

Developing Assembly

0002-6683

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

If you must touch a black developing assembly, check

that your hands are free of foreign matter (especially

of metal) before doing so. (Adhesion of foreign matter

on the cylinder is likely to cause image faults.)

1) Remove the 2 screws [1], and remove the joint plate

[2].

20

Page 29

[2]

Chapter 1

[1]

F-1-58

2) Hold the black developing assembly in lengthwise

direction, and remove it out of its package box.

- The machine's black developing assembly is

equipped with a potential sensor. Do not touch the de-

tection window [1] of the sensor.

- Do not subject the black developing assembly to im-

pact to prevent damage to the potential sensor as by

dropping it.

- Be sure to place paper before placing the black de-

veloping assembly on the floor or a table.

[1]

F-1-59

[2]

[1]

F-1-60

4) Turn the developing cylinder gear by hand to check

for scratches on the cylinder.

5) Remove the tape [2] used to keep the high-voltage

cable [1] in place.

[1]

[2]

F-1-61

6) Hold the black developing assembly [1] by both its

ends; while keeping it level, attach it in place while

pressing it downward at an angle.

At this time, be sure that the boss [2] at the rear of

the developing assembly matches the left guide [3]

of the machine.

Be sure also that the rib [4] at the front of the devel-

oping assembly matches the right guide at the front

of the machine.

3) Turn the developing cylinder gear [1] by hand to

check for scratches on the cylinder.

Do not touch the area [2] of the developing cylinder

cover indicated in the diagram; otherwise, the blade

can leave its trace on the cylinder.

21

Page 30

Chapter 1

[4]

[1]

F-1-62

[5]

[2]

[2]

[3]

[1]

F-1-64

8) Insert the high-voltage cable [1] of the black devel-

oping assembly along the side of the toner supply

mouth [2].

[2]

When attaching the black developing assembly in the

machine, try keeping the high-voltage cable [1] on top

of the assembly. Otherwise, the cable can get trapped

when the assembly is put inside the machine.

[1]

F-1-63

7) Insert the cable [1] having the tube of the black de-

veloping assembly through the hole [2] indicated in

the figure.

[1]

F-1-65

9) Connect the connector [1] found at the inside front.

[1]

F-1-66

10) Attach the joint plate [1] using 2 binding screws

[2].

22

Page 31

[1]

Chapter 1

14) Close the process unit.

[2]

F-1-67

11) Remove the paper put between the photosensitive

drum and the developing rotary.

12) Attach the protrusion [1] of the included black as-

sembly locking plate into the positioning hole [2]

found at the rear of the machine.

[2]

[1]

Take care not to trap the cable found at the right front

of the machine by the process unit. Be sure to close the

process unit while the front cover is fully open.

If you cannot fit the process unit all the way to the

rear, go through the following:

Slide out the process unit, and turn the developing ro-

tary drive gear found on the host side slightly; there-

after, be sure to close the process unit.

1.2.10 Attaching the Process Unit

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0002-6689

F-1-68

13) Attach the black developing assembly locking

plate [1] in place using the included screw (binding;

M4x8) [2].

[1]

[2]

F-1-69

1) Match the area [1] where the resistance of the high-

voltage cable is found in the upper left of the front

against the 4 pins [2] of the host machine; then, at-

tach it using the 4 clamps [3].

[2][3]

[3]

[1][2]

F-1-70

2) Insert the 2 cables [1] into the cable clamp [2].

3) Connect the 2 connectors [3], and insert the 2 cables

[4] into the 3 cable guides [5].

23

Page 32

Chapter 1

]

[1] [2

[4][5]

6) Attach the cable [1] of the black developing assem-

bly using the harness guide [2].

[3]

F-1-71

4) Connect the 3 connectors [1], and insert the cable

into the 4 cable guides [2] and the 2 cable clamps

[3].

[1] [2]

[2]

[1] [2]

F-1-74

7) Connect the connector [1] coming from the black

developing assembly.

[1]

[1] [2] [3]

F-1-72

5) Connect four connectors [1] on the upper right of

the front side and fix them with a clamp [2].

[1]

[2]

F-1-73

F-1-75

8) Attach the process unit [1] using 3 binding screws

(M4x8).

[2]

[1]

[2]

F-1-76

24

Page 33

Be sure to use the binding screws. The use of RS tight-

ening screws in the area of aluminum die-casting can

damage the threads of the screws.

9) Attach the drum fixing member [2] to the drum

flange [1]; then, hold it in place using the drum stop

tool. Thereafter, tighten the drum fixing screw [4]

using a screwdriver.

Be sure to attach the protrusion [5] of the drum stop

tool with a screw while matching it against the notch

[6] of the drum flange.

Chapter 1

is between he markings [1] "." and ".." of the drum

flange.

[1]

F-1-78

[2]

[1]

[4]

[3]

[6]

[5]

F-1-77

- If the photosensitive drum is let to turn clockwise

during the work, the scoop-up sheet can become

soiled to cause stray toner. Be sure to hold the drum

stop tool firmly in place when tightening the drum

fixing screw.

- Check that the protrusion of the drum fixing member

- Be sure to attach the drum stop tool [2] to the back

of the process unit cover [1] for possible future re-

location of the machine.

[1]

[2]

F-1-79

10) Close the fixing/feeding assembly.

11) Loose the screw [1], and move the charging as-

sembly fixing [2] in the upper right direction; then,

attach it in place using a screw.

12) Remove the connector [3], and remove the prima-

ry charging assembly [4]. Check the primary charg-

ing wire and the shielding plate for soiling. If it is

soiled with dirt or paper lint, clean it using alcohol.

25

Page 34

Chapter 1

[4] [3]

[2][1]

F-1-80

13) Remove the connector [1], and remove the screw

[2].

14) Remove the pre-transfer charging assembly [3].

Check the pre-transfer charging wire and the

shielding plate for soiling. If it is soiled with dirt or

paper lint, clean it using alcohol.

[2]

[1]

[2]

F-1-82

19) Close the black toner supply cover [1].

[2] [3]

[1]

F-1-81

15) Attach the primary charging assembly and the pre-

transfer charging assembly.

16) Close the hopper assembly.

17) Open the black toner supply cover [1].

18) Attach the hopper assembly [1] using 3 screws [2].

[1]

F-1-83

20) Slide out the right deck.

21) Attach the front cover hinge [1] using 2 binding

screws [2].

22) Attach the front cover strap [3] using a screw [3].

[2]

[4]

[2]

[1]

[3]

[1]

F-1-84

26

23) Close the right deck.

Page 35

Chapter 1

24) Slide out the fixing/feeding assembly.

25) Open the color toner supply cover [1].

[1]

F-1-85

26) Attach the process unit cover [1] using the 2 RS

tightening screws (M4x8) [2].

27) Close the color toner supply cover.

[2]

1.2.11 Attaching the Fixing Assembly

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Slide out the fixing/feeding assembly fully.

2) Open the reversal delivery cover [1].

[1]

F-1-88

3) Open the middle cover [1].

0002-6697

[1]

[3]

F-1-86

28) Attach the right cover (upper) [1] with 2 screws

[2].

[1]

[2]

F-1-87

29) Close the right upper cover.

[1]

F-1-89

4) Remove the tape [2] used to keep the tag [1] in

place.

[1]

[2]

F-1-90

27

Page 36

Chapter 1

5) Remove the 2 fixing nip releasing screws [1].

[1]

[1]

F-1-91

6) Check the fixing web for any slack; as necessary,

perform steps 7) and 8).

7) Remove the 3 screws [1] and the fixing knob [2];

then, remove the fixing front cover [3].

9) Attach back the fixing front cover and the fixing

knob by reversing the work in step 7).

10) Close the middle cover.

11) Close the reversal delivery cover.

12) Close the fixing/feeding assembly.

13) Lock the releasing lever in place; then, close the

front cover.

1.2.12 Fitting the Black Toner Bottle

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Remove the black toner bottle from its packaging

box.

2) Open the black toner supply cover [1]; then, press

down the lock lever [2].

0002-6699

[1]

[3]

[1]

[2]

[1]

F-1-92

8) Turn the gear [1] counterclockwise (viewing the

machine from the front) to remove the slack.

[2]

[1]

F-1-94

3) Hold the black toner bottle [1] as shown in the fig-

ure; then, turn the cap [2] in the direction of the ar-

row to remove from the bottle.

[2]

[1]

28

F-1-93

F-1-95

[1]

4) Hold the black toner bottle with its mouth [1] on the

Page 37

right side; then, attach it in the supply case [2] of the

machine.

[2]

[1]

F-1-96

5) Shift the attach lever [1] upward to attach the black

toner bottle [2].

[1]

Chapter 1

1) Set the environment switch to suit the site of instal-

lation.

If the site is in a high humidity environment, turn on

the environment switch [1] (so that the drum heater

will go on regardless of the state of the main power

switch [2]).

ON

ON

[1]

[2]

F-1-97

6) Close the black toner supply cover.

If you turn on the main power without first attaching

the bottle in the machine, the black toner level meter

appearing on the control panel will indicate 25% as

the remaining level of toner. Check that the black ton-

er bottle has correctly been attached in the machine

before turning on the main power.

1.2.13 Checking the Environment Switch

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0002-6701

[2]

F-1-98

At time of shipment from the factory, the environment

switch is off.

1.2.14 Turning On the Main Power Switch

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0003-1015

29

Page 38

Chapter 1

- Be sure to remove all packing material from the cas-

sette before turning on the main power.

- In the case of the 230-V model, take out the power

cord from the shipping box; then, connect its one

end to the machine and the other end to the power

outlet.

- The rotary starts to rotate when the main power is

tuned on. Do not use the door switch actuator.

1) In the case of the 100V model, connect the ground-

ing wire to ground the machine.

2) Connect the machine's power plug to the power

outlet, and turn on the main power [1].

3) Execute the following in service mode to disable

initial rotation: COPIER>FUNCTION>IN-

STALL>AINR-OFF; then, set it to '1'.

[1]

F-1-99

Be sure to perform the foregoing service mode item

after turning on the power to disable initial rotation. If

the power is turned off and then on, the machine will

start initial rotation, possibly causing an error in its

image stabilization mechanism.

1.2.15 Setting Up the Paper Cassette

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Press the cassette release button, and slide out the

cassette to the front.

2) Check with the user to find out the type of paper to

use; then, check if the size configuration switch [1]

of the cassette is set to the desired paper type. If not,

set the cassette to suit the type.

3) Turn the paper size dial [2] to suit the desired paper

size.

0002-6732

30

Page 39

B5

B5

R

B4

F-1-100

[2]

Chapter 1

cassette.

9) Open the front cover; then, remove the color toner

cartridge supply tab [1] from its back.

[1]

[1]

4) Pick the lever [1] of the side guide plate, and move

the side guide plate to the desired size marking.

5) Remove the lever [2] of the rear end guide plate.

Fit the rear end guide plate to match the desired size

marking on the bottom plate of the cassette.

[2]

[1]

F-1-101

6) Attach the correct size label [1] to the front of the

cassette.

F-1-103

10) Remove the 2 color toner cartridge replacement

supply tab labels from the 2 base sheets on which

the cassette size label was found.

11) Attach the 2 color toner cartridge supply tab labels

[2] to the color toner cartridge replacement supply

tab [1].

[2]

[2]

[1]

F-1-104

[1]

F-1-102

7) Deposit paper in the cassette; then, slide the cas-

sette back into the machine.

8) As necessary, perform the same work for the other

12) Attach the color toner cartridge replacement sup-

ply tab to the back of the front cover; then, close the

front cover.

1.2.16 Changing the Deck Paper Size (right, left)

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0002-6733

31

Page 40

Chapter 1

1) Open the front cover.

2) Press the release button, and slide out the right

deck.

3) Remove the screws [4] (3 pc. in total), and remove

the rear end guide plate [1], left guide plate [2], and

right guide plate [3]. Then, attach them to suit the

needs of the user.

[2]

[1]

[4]

[3]

F-1-105

SZ-C2 (A4=0, B5=1, LTR=2).

8) Press the Reset key twice to end service mode.

1.2.17 Fitting the Color Toner Cartridge

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Remove the color toner cartridge (yellow, magenta,

cyan) from its packaging box.

2) Hold the color toner cartridge (yellow, magenta,

cyan) as shown with both hands, and turn it in the

direction of the arrows 10 times to even out the ton-

er inside it.

0002-6703

at time of shipment : A4 size (100/230V),LTR size

(120V)

4) Deposit paper in the right deck; then, attach it into

the machine.

5) Attach the size sticker [1] of the new paper size to

the frond of the deck.

[1]

F-1-106

6) As necessary, perform the same work on the left

deck.

7) After changing the size, execute the following in

service mode to register the front deck paper size:

for the right deck, COPIER>OPTION>CST>P-SZ-

C1; for the left deck, COPIER>OPTION>CST>P-

F-1-107

When turning the color toner cartridge, be sure not to

touch the shutter assembly or turn the knob; other-

wise, the toner can start to leak.

F-1-108

32

Page 41

3) Check to see that the control panel indicates the

message "Set the Toner Cartridge."

4) Open the front cover.

5) Open the color toner supply cover [1].

Chapter 1

11) Repeat steps 4) through 9) to attach the C toner

cartridge.

12) See that the control panel indicates the message

"Set the Toner Cartridge."

13) Repeat steps 4) through 9) to attach the M toner

cartridge.

1.2.18 Supplying Black

[1]

F-1-109

6) Insert the Y toner cartridge [2] through the color

toner cartridge slot [1].

[1]

[2]

F-1-110

7) Turn the lock lever [1] clockwise to attach the Y

toner cartridge [2].

[2]

Toner

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Check that the warm-up period is over (i.e., Keep

paper in the machine so that the control panel will

indicate the message "Ready to Copy").

2) Perform the following service mode item to supply

black toner: FUNCTION>INSTALL>TONER-S

(10 min avr; 13 min max.).

While this service mode item is under way, a count-

down is made on the control panel; at the end, 'OK!' is

indicated.

0002-6727

1.2.19 Cleaning the Intermediate Transfer Belt

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0002-6728

[1]

F-1-111

8) Close the color toner supply cover.

9) Close the front cover.

10) See that the control panel indicates the message

"Set the Toner Cartridge."

1) Perform the following service mode item to clean

the ITB: FUNCTION>CLEANING>TBLT-CLN

(about 20 seconds).

The notation "OK!" appears on the screen to indicate

the end of the service mode item.

33

Page 42

Chapter 1

1.2.20 Supplying Color Toner

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Perform the following service mode item to set up

color toner settings: FUNCTION>INSTALL>IN-

SET-3 (about 14 minutes).

- Do not turn off the power switch while the machine

is in operation.

- If the machine is turned off, the ITB may carry a de-

posit of toner, which can cause image faults. As nec-

essary, perform

COPIER>FUNCTION>CLEANING>TBLT-CLN

and then INISET-3 to correct the problem.

While this service mode item is under way, a count-

down is made on the control panel; at the end, "OK!"

is indicated.

This mode uses ATVC control, possibly taking a

while depending on the site environment. The count

on the screen, for this reason, may loop between 890

and 820.

2) Perform the following service mode item to supply

color toner: FUNCTION>INSTALL>SPLY-H-3

(about 45 seconds).

The notation "OK!" appears on the screen to indicate

the end of the service mode item.

0002-6729

1.2.21 Setting Auto Gradation Correction

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Clean the reading glass surface of the machine's

copyboard.

2) Press the User Mode key.

3) Make the following selections: adjust/cleaning>au-

to gradation correction>full correction>test print 1.

In a while, the machine prints out Test Print 1.

4) Place the printout (Test Print 1) on the copyboard

glass as indicated on the control panel.

5) Press [read start].

- The machine will read the printout of Test Print 1.

- When a message has appeared asking you to re-

move the printout, remove it from the copyboard

glass.

6) Press [test print 2].

In a while, the machine prints out Test Print 2.

7) Place the printout of Test Print 2 on the copyboard

glass as indicated on the control panel.

8) Press [read start].

- The machine will read Test print 2.

- When a message has appeared asking you to re-

move the printout, remove it from the copyboard

glass.

9) Press [test print 3].

In a while, the machine prints out Test Print 3.

10) Place the printout of Test Print 3 on the copyboard

as indicated on the control panel.

11) Press [read start].

- The machine will read Test Print 3.

- When a message has appeared asking you to re-

move the printout, remove it from the copyboard.

12) Press the Reset key to end User mode.

0002-6731

Do not turn off the power switch while the machine is

in operation.

34

Page 43

Chapter 1

1.2.22 Checking the Image/Operation

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Place the Test Chart on the copyboard glass, and

make copies using the cassettes and the deck as the

source of paper; then, check the output images.

- be sure there is no abnormal noise.

- be sure that images produced at different magnifi-

cations are all correct.

- be sure that as many copies as specified are made.

- be sure that the images are all correct regardless of

the source of paper used.

The output must satisfy the following standards:

- horizontal registration (margin on image left

edge): 2.5 +/-1.5 mm

- leading edge (margin on image leading edge): 4

+1.5, -1.0 mm

0002-6730

position of the adjusting plate [2].

[2]

[1]

F-1-112

- move the adjusting plate toward the rear to de-

crease the left margin.

- move the adjusting screw toward the front to in-

crease the left margin.

4) Check that the horizontal registration (left/right

margin; L1) of the copy on paper from cassette 3 is

2.5 +/-1.5 mm.

Reference:

If the output is not as indicated, see the instructions on

how to adjust the horizontal registration and leading

edge registration.

1.2.23 Adjusting the Horizontal Registration

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

Adjust the horizontal registration as follows according

to the source of paper:

1. Cassette 3

1) Press the cassette release button, and slide out the

cassette 3 to the front.

2) Open the upper right cover and the lower right cov-

er.

3) Insert a screwdriver through the hole in the front

right stay; then, loosen the screw [1] to adjust the

0002-6734

[1]

L1

[1] Paper feed direction

5) Tighten the screw.

6) Close the upper right cover and the lower right cov-

er.

7) Fit the cassette 3 back in.

2. Cassette 4

1) Perform the steps given for the cassette 3 to adjust

the horizontal registration for the cassettes 4.

3. Left Deck

1) Press the release button, and slide out the left deck.

2) Remove the left face cover [1] using a flat-blade

screwdriver.

image

F-1-113

35

Page 44

Chapter 1

[1]

F-1-114

3) Loosen the 2 screws [1], and insert a screwdriver

through the hole in the front left stay; then, turn the

adjusting screw to adjust the horizontal registration.

[1]

[2]

F-1-115

4) Make a copy using the left deck as the source of pa-

per; then, check that the horizontal registration

(left/right; L1) is 2.5 +/-1.5 mm.

[1]

image

[1]

[2]

F-1-117

Turn the screwdriver counterclockwise so as to de-

crease the horizontal registration (left/right margin)

[1].

Turn the screwdriver clockwise so as to increase the

horizontal registration (left/right margin) [2].

A full turn of the screwdriver moves the horizontal

registration (left/right margin) by 1.0 mm.

6) Tighten the 2 screws you loosened in step 3).

7) Attach the left face cover you removed in step 2)

back on the machine.

8) Close the left deck.

4. Right Deck

1) Press the release button, and slide out the right

deck.

2) Open the upper right cover and the lower right cov-

er.

3) Loosen the 2 screws [1], and insert a screwdriver

[2] through the hole in the front right stay; then, turn

the adjusting screw to adjust the horizontal registra-

tion.

L1

F-1-116

[1] Paper feed direction

5) If the output is not as indicated, make the following

adjustments:

36

[1]

[2]

F-1-118

Page 45

4) Check that the horizontal registration (left/right

marking; L1) of the copy made on paper from the

right deck is 2.5 +/-1.5 mm.

Chapter 1

[1]

L1

image

F-1-119

[1] Paper feed direction

5) If the output is not as indicated, make the following

adjustments:

[1]

[2]

F-1-120

Turn the screwdriver counterclockwise so as to de-

crease the horizontal registration (left/right margin)

[1].

Turn the screwdriver clockwise so as to increase the

horizontal registration (left/right margin) [2].

A full turn of the screwdriver will move the hori-

zontal registration (left/right margin) by 1.0 mm.

6) Tighten the 2 screws you loosened in step 3).

7) Close the right deck.

[2]

[1]

F-1-121

2) Check to see that the horizontal registration (left/

right margin; L1) of the copy made on paper from

the manual feed tray is 2.5 +/-1.5 mm.

[1]

L1

image

F-1-122

[1] Paper feed direction

3) Tighten the screws you loosened in step 1) to attach

the slide guide in place.

1.2.24 Adjusting the

Leading Edge Regis-

5. Manual Feed Tray

1) Loosen the 2 screws [1], and move the slide guide

[2] to adjust the horizontal registration.

tration

0002-6735

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

Adjust the leading edge registration as follows ac-

cording to the source of paper:

Check that the leading edge registration (leading edge

margin; L1) of the copy made on paper from the cas-

37

Page 46

Chapter 1

settes and the deck is 4.0 +1.5/-1.0 mm.

If not, go through the following:

- Select the service mode: COPIER>AD-

JUST>FEED-ADJ>REGIST.

- Then, change the setting to adjust.

(A change of '1' moves the leading edge registration

by 0.1 mm. A higher setting will move the image to-

ward the leading edge.)

L2

[1]

Image

F-1-123

[1] Paper feed direction

1.2.25 Securing the

[1]

[2]

[3]

F-1-124

Areas to Avoid

- inside the machine (behind the front cover)

- louver

- grip slot

Machine in Place

0002-6736

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) If the machine is already at its site of installation,

attach it using the 2 adjusters.

2) Remove the double-sided tape from the back of the

service book case [1]; then, attach the case by

matching its right edge against the line marking [3]

found on the right side of the bottom plate [2] of the

machine.

Be sure to match the front edge of the service book

case against the front edge of the base plate of the ma-

chine.

3) As appropriate, attach the 3 included labels ([1],

[2], [3]) to the locations indicated in the figure:

[1] Do Not Copy label (non-Japanese model)

[2] Cleaning Instructions label (non-Japans model)

[3] ADF size label

[2]

[1]

F-1-125

Attaching the ADF Size Label

Spread the ADF size guide plate [1] fully; then, match

segment A of the plate and the A4/A3 marking of the

label [2].

38

Page 47

Chapter 1

PRINT (printout) to the Service Label attached behind

the front cover.

A4

A3

A

1.2.26 If Not Connected

[2]

to a Network

0005-3940

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

[1]

F-1-126

4) Attach the touch pen [1] on the control panel.

[1]

F-1-127

5) Clean up the area around the machine, and fill out

the service book.

6) Make necessary settings in user mode (date, time)

and service mode (COPIER>OPTION>USER).

MEMO:

If the machine is not connected to a network, its con-

trol panel will display the message "Check Connec-

tion to the Network." To disable the message, set

the following service mode item to "0":

COPIER> OPTION> BODY> NWERR-SW (level 2)

1.2.27 Affixing the Shutdown warning label

iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

For iR C6870/C5870 Series

1) Affix the Shut-down warning label (in an appropri-

ate language) [1] to the right cover (rear upper) of

the machine [2].

0011-7812

When shipped from the factory, the 230-V model is

set to English for its language of display. If needed,

change the setting.

7) Perform the following service mode item, and store

the output away in the service book case: COPI-

ER>FUNCTION>MISC-P>P-PRINT.

In the course of installing the machine, be sure to

record the various adjustment values indicated by P-

[1]

[2]

F-1-128

39

Page 48

Chapter 1

1.3 Checking the Connection to the Network

1.3.1 Overview

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

Go through the steps herein only if the machine is con-

nected to a network.

If the user's network is based on TCP/IP, use the PING

utility to check that the Ethernet PCB has properly

been installed and the network settings have correctly

been made. If the user's network is based on IPX/SPX

or AppleTalk, you need not make this check.

If the machine is equipped with a network board and

yet not connected to a network, it will indicate an net-

work-related error message. To disable the indication

of such a message, use the following service mode

item (set it to "0"): COPIER>OP-

TION>BODY>NWERR-SCREW.

1.3.2 Using the PING Utility

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Select the followings in service mode: COPI-

ER>TEST>NETWORK>PING.

2) Enter the IP address of the machine using the key-

pad on the control panel; then, press [OK].

3) Press the Start key.

The machine will indicate 'OK' if the result of the

check is good and 'NG' if not good.

0002-6738

0002-6739

<NETWORK>

PING

[1]

[1] Result (OK/NG)

[2] IP address field

< 1/1 >

0. 0. 0. 0

F-1-129

<READY >

[2]

+/-

OK

1.3.3 Using a Remote Host Address

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

You can also use a remote host address and perform

the PING utility to check if the connection to the net-

work is correct or not.

The term 'remote host address' refers to the IP address

of a PC terminal connected to and operating on the

TCP/IP network to which the machine is connected.

1) Inform the system administrator that you will be

checking the network connection using the PING

utility.

2) Check the system administrator for the remote

home address you can use.

3) Enter the remote home address to the appropriate

PING field.

- See if 'OK' has appeared to indicate that the con-

nection to the network is correct.

- If the machine indicates 'NG, ' the connection is

not correct; go through the following:

0002-6747

40

Page 49

Chapter 1

1.4 Troubleshooting the Network

1.4.1 Overview

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

Go through the steps herein only if the machine is con-

nected to a network.

If the machine's connection to the network fails, sus-

pect the following causes:

- The connection between the network and the

Ethernet PCB is faulty.

- The machine's TCP/IP settings are incorrect.

- The Ethernet PCB is faulty, or is not attached cor-

rectly.

- The network is faulty.

To identify the cause, go through the following:

1.4.2 Checking the Connection of the Network

Cable

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Check if the network cable is correctly connected to

the Ethernet PCB.

- If yes, go to the next check.

- If no, correct it, and run a check using the remote

host address once again.

0002-6749

0002-6750

chine's TCP/IP settings are correct by performing

PING using a loopback address.

1) Enter a loopback address (127.0.0.1) in the appro-

priate PING field.

- If the result of the check is not good, check the ma-

chine's TCP/IP settings once gain, and perform

PING once again.

- If the result of the check is good, go to the follow-

ing check.

1.4.4 Using a Local Host Address

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

A local host address is the machine's IP address, and it

comes back after reaching the network PCB when you

perform PING, enabling you to check whether the net-

work PCB is normal.

1) Enter the machine's IP address in the appropriate

PING field.

If 'NG' is indicated, go through the following

check/remedy, and perform PING once gain:

- The machine's IP address is not correct: check

with the system administrator to find out if the ma-

chine's IP address is correct and valid.

- The connection of the network PCB is faulty:

check the connectors used to connect the network

PCB.

- The network PCB is faulty: replace the network

PCB.

If 'OK' is indicated, suspect a fault in the user's net-

work environment; contact the system administrator

for appropriate correction.

0002-6752

1.4.3 Using a Loopback Address

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

A loopback address comes back before it reaches the

network PCB; as such, you can check whether the ma-

0002-6751

41

Page 50

Chapter 1

1.5 Installing the Card Reader

1.5.1 Points to Note About Installation

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

You need a Card Reader Attaching Kit-C1 for the in-

stallation.

1.5.2 Checking the Contents

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0002-6804

0003-0860

2. Card Reader Attaching Kit-C1

[1]

[1] Card reader mount 1 pc.

[2]* Joint plate 1 pc.

[3]* Screw (Bind; M4X6) 1 pc.

[4] Screw (RS tight; M4X10) 2 pc.

*Not use in this machine

1.5.3 Installation

[2] [3] [4]

F-1-131

0002-6753

1. Card Reader-C1

[1] [2] [3]

C

F-1-130

[1] Card Reader-C1 1 pc.

[2] RS tightening screw (M4x10) 1 pc.

[3] Toothed washer 1 pc.

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Make the following selections in the host machine's

service mode: COPIER>FUNCTION>IN-

STALL>CARD; then, enter a number (1 to 2001).

- Use the lowest number of the cards that will be

used by the usered.

- As many as 1000 cards, starting with the number

you enter, will be registered.

2) Turn off the host machine's main power switch.

3) Remove the 2 screws [1], and remove the right cov-

er (upper) [2].

42

Page 51

[1][2]

F-1-132

4) Attach the card reader base [1] using the 2 included

screws [2].

Chapter 1

[2] [3]

[1]

F-1-135

7) Route the card reader harness through the wire sad-

dle, and connect the connector [1].

[1]

[2][1]

F-1-133

5) Insert the harness [1] of the card reader through the

hole [2] in the card reader base.

[1] [2]

F-1-134

6) Attach the card reader [2] to the card reader base [3]

using the included screw and toothed washer [1].

F-1-136

8) Cut the section [1] of the right cover (upper) indi-

cated in the figure using nippers.

[1]

F-1-137

9) Attach the right cover (upper) you removed in step

3).

10) Turn on the main power switch, and check that a

message has appeared asking for a control card.

11) Insert a control card, and check that the machine

is ready to make copies.

43

Page 52

Chapter 1

1.5.4 Using the Card

Reader in Combination

with NetSpot Accountant (hereafter, NSA)

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Make the following selections in Additional Func-

tion: system control settings>group ID con-

trol>count control; then, check to see IDs 00000001

thorough 00001000 have been created (i.e., if you

entered '1' as the first number in service mode):

COPIER>FUNCTION>INSTALL>CARD).

2) Make the following selections in Additional Func-

tion: system control settings>network set-

tings>TCP/IP settings>IP address; then set up the

following: IP address, gateway address, subnet

mask.

Take care. If you fail to register [system control

group] and [system control ID No.], you will not be

able to perform 'register card to device' as part of

NSA setup work.

0002-6799

3) Under [system administrator info] of Additional

Function, enter any number for [system control

group] and [system control ID No.].

4) Turn off the control panel switch.

5) Turn off and then on the main power switch.

44

Page 53

Chapter 1

1.6 Installing the NE Controller-A1

1.6.1 NE Controller-A1 Installation Procedure

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

Installation procedure on the iR C6800 series is only

described here. Regarding setting methods, operation

check and notes, refer to the installation manual sup-

plied with this machine.

1) Detach the upper cover of controller (Refer to the

installation manual).

2) Connect the plug of AC adapter to the controller

(Refer to the installation manual).

3) Unscrew 4 screws [1] and detach the blanking plate

[2] of the rear cover (upper).

0003-6957

[2]

F-1-139

5) Mount the controller [1] on the rear cover (upper)

using 4 screws supplied with the controller.

F-1-140

[1]

[2]

[1]

[2]

[2]

[1]

F-1-138

4) Connect the cable [1] of controller to the connector

[2] of the copier.

6) Take the slack out of the cables between the iR host

machine and the controller, make bundles of them

at the side of host machine, and fix them with the

cable clamp [1].

[1]

F-1-141

7) Make necessary settings and check operations by

following the installation manual for NE controller-

A1.

45

Page 54

Chapter 1

1.7 Installing the Original Tray

1.7.1 Checking the Contents

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

[1] Original holder 1 pc.

[2] Stepped screw (M4) 2 pc.

0002-6801

[1]

[2]

F-1-143

2) Hook the original holder [1] on the stepped screws

you attached in step 1).

[1]

[1] [2]

F-1-142

1.7.2 Attachment

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Attach the 2 stepped screws [2] in the right cover

(upper) [1].

0002-6754

F-1-144

46

Page 55

Chapter 1

1.8 Installing the Key Switch Unit-A1

1.8.1 Checking the Contents

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

[1] Key switch unit 1 pc.

[2] Control key 1 pc.

[3] Binding screw (M4x6) 1 pc.

[1]

[2]

0003-1366

[3]

[2]

[3]

[1]

F-1-146

6) Cut off the section [1] of the right cover (upper rear)

indicated in the figure.

F-1-145

1.8.2 Attachment

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

1) Turn off the control panel power switch.

2) Turn off the main power switch.

3) Remove the power plug.

4) Remove the reader communications cable [1].

5) Remove the 2 screws [2], and detach the right cover

(upper rear) [3].

0002-6756

[1]

F-1-147

7) Remove the 2 screws [1], and remove the plate [2].

[2][1]

[1]

F-1-148

8) Insert the protrusion [1] of the key switch into the

plate [2]; then, attach it using the included screw

[3].

47

Page 56

Chapter 1

[1] [2] [3]

F-1-149

9) Insert the harness [1] of the key switch through the

wire saddle [2].

[2]

[1]

F-1-150

10) Connect the connector [1] of the key switch.

[1][2]

[2]

F-1-152

12) Attach the right cover (upper rear) you removed in

step 5).

13) Insert the power plug, and turn on the main power

switch.

14) Start service mode, and make the following selec-

tions: COPIER>FUNCTION>INSTALL>KEY:

then, enter '1'.

15) Turn off and then on the main power switch.

16) Check that a message has appeared asking for the

control key.

17) Insert the control key, and check that the machine

is ready to make copies.

[1]

F-1-151

11) Attach the plate (key switch) [1] using the 2

screws [2] you removed in step 7).

48

Page 57

Chapter 1

1.9 Installing the Reader Heater Kit

1.9.1 Checking the ComponentsÅiReader

Heate-C1Åj

iR C6800C / iR C6800CN / iR 5800C / iR 5800CN /

/ iR 5870Ci / iR 5870C / iR 6870Ci / iR 6870C

0011-7561

[3] Disconnect the power cable (from the power out-

let).