Canon BJ-W3000, BJ-W3050 Service Manual

QY8-1366-000

REVISION 0

COPYRIGHT 2000 CANON INC. CANON BJ-W3000/3050 0100 GR 0.40-0 PRINTED IN JAPAN (IMPRIME AU JAPON)

JAN. 2000

0000 GR 0.40-0

Target Readers

This manual is published by Canon Inc. for qualified persons and contains the necessary technical

information for technical theory, installation, maintenance, and repair of products. This manual covers

all localities where the products are sold. For this reason, it may contain information that does not

apply to your locality.

Revisions

This manual may include technical inaccuracies or typographical errors due to improvements or

changes in the products. When amendments are made to the content of this manual, Canon will issue

technical information as the need arises. In the event of major alterations to the content of this manual

over a long or short period, Canon will publish a revised version of the manual.

The following paragraphs do not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names appearing in this manual are the registered trademarks or

trademarks of the individual companies.

Copyright

This manual is copyrighted and all rights reserved. Under the copyright laws, this manual may not be

copied, reproduced, or translated into other languages, in whole or in part, without the express written

consent of Canon Inc. except in the case of internal business use.

Copyright 2000 by Canon Inc.

CANON INC.

Quality Engineering Center

30-2 Shimomaruko 3-chome, Ohta-ku, Tokyo 146-8501, Japan

This manual was produced on an Apple®Power Macintosh®G3 personal computer and Canon LASER

SHOT LBP-730PS laser beam printer; final pages were printed on Varityper

®

4300J.

All logos graphics were produced with Adobe

®

Illustrator®5.0J / 5.5J / 8.0J and MACROMEDIA

FREEHAND 7.0J.

All documents and all page layouts were created with Adobe

®

Page Maker®6.5J and QuarkXPress 3.3J.

PREFACE

This Service Manual describes fundamental field service for the BJ-W3000/BJ-W3050 large

format printer.

This Manual is composed of the following chapters:

Chapter 1 General Description: Features, specifications and operating procedures

Chapter 2 Basic Operation: Operation of mechanical and electric functions

Chapter 3 Mechanical System: Mechanical setup and assembling/disassembling procedure

Chapter 4 Maintenance and Servicing: Periodic parts replacement, Standard service life of

consumables, Periodical services, points of maintenance and inspections

Chapter 5 Troubleshooting: Service mode, adjusting and settings, operation trouble

correction, image trouble correction

Chapter 6 Circuite diagrams

Appendix Menu guide

i

ii

PREFACE

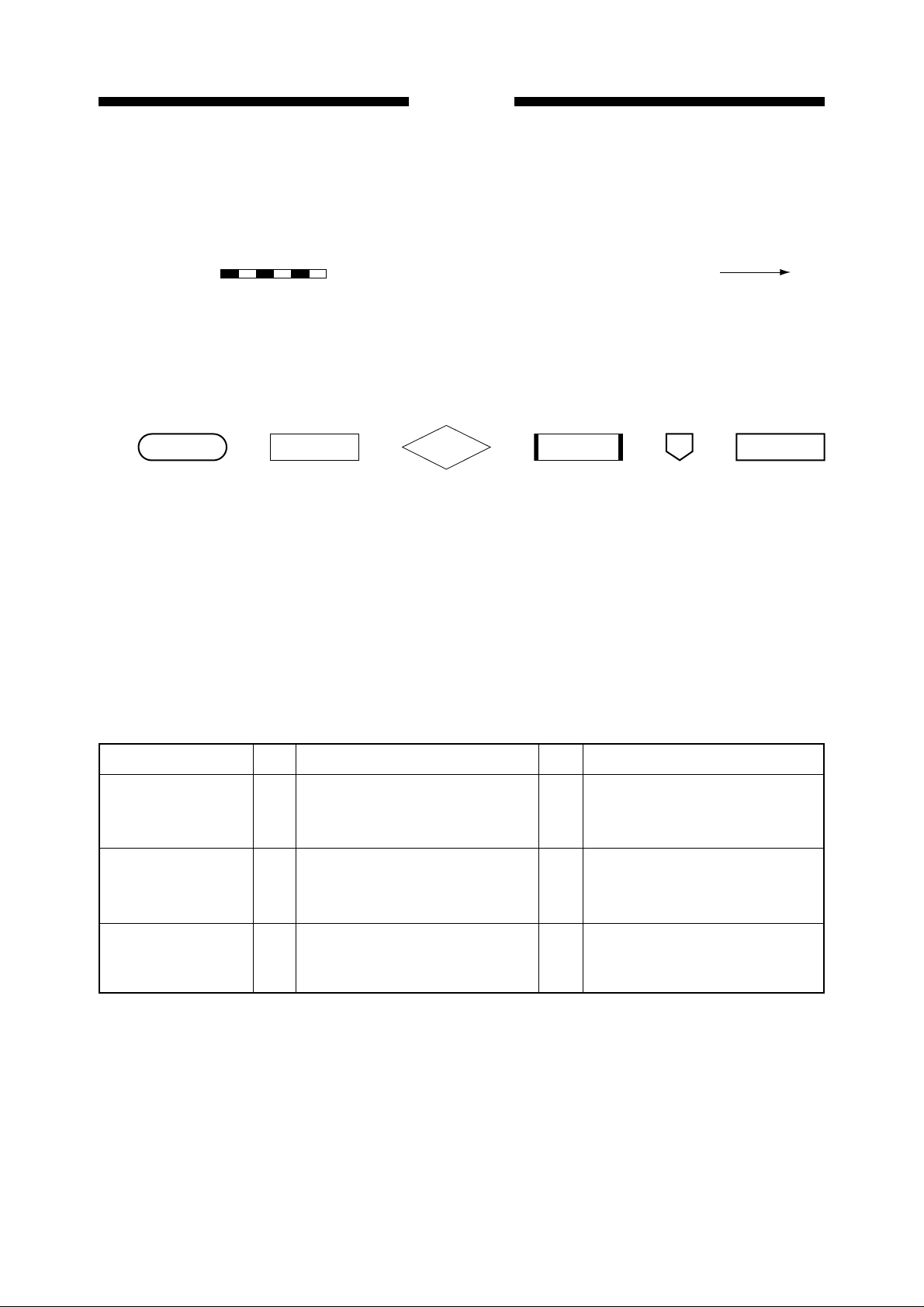

Descriptions in this manual are based on the following conventions.

1. In the Basic Operation section, the roles of each function, relationships between electrical

and mechanical systems, and the timing for each part are summarized.

The mark indicates mechanical drive transmission. The mark

accompanying a signal name indicates the flow of electrical signals.

Flow charts are also used in the summary of operation.

The symbols used in the flow charts are as follows:

Start/completion Operation Decision Remedy Jump Stop

2. In the descriptions of digital circuits, "1" or "H" indicates a high voltage level, and "0" or

"L", a low voltage level. However, the actual voltage values vary depending on the circuit.

3. It is assumed that the Printed circuit board (PCB) will not be repaired by the user. There-

fore, the descriptions of the circuits on the PCB are limited to block diagrams.

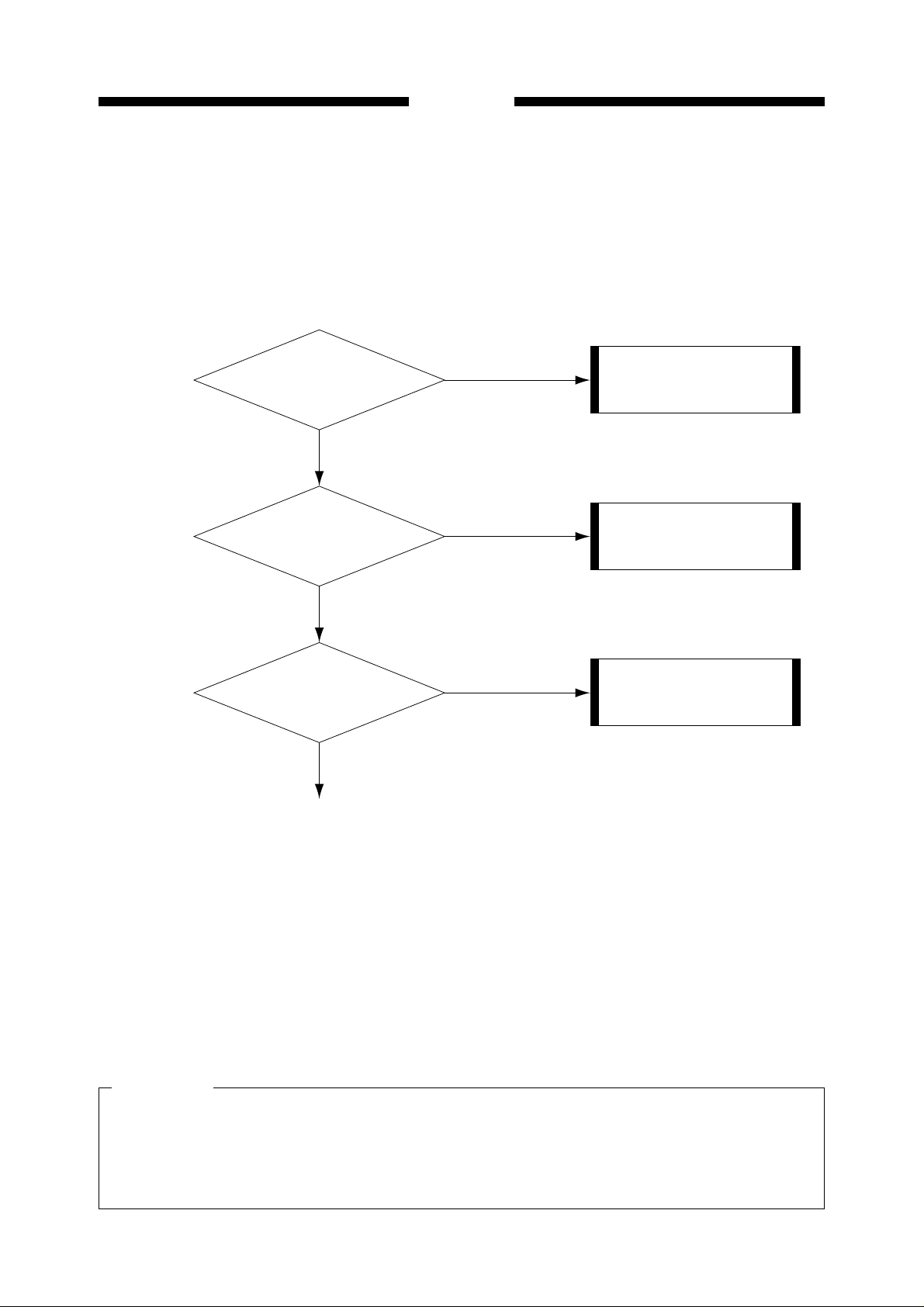

4. Troubleshooting is described using procedural tables.

The procedural table is a variation of a general flow chart.

An example is shown below.

e.g. No power is supplied.

Cause Result

Unplugged power

source

Power source failure

Blown fuse

Step RemedyCheck item

1

Is the power cord properly connected to the receptacle on the

machine and the outlet?

Is the specified voltage applied to

2

the outlet?

Is the fuse on the DC power PCB

3

(F1) blown?

NO

Connect the power code to the

machine and outlet.

Explain to the customer that the

NO

trouble is not attributable to the

machine.

Remove the cause of the blown

YES

fuse and replace the DC power

PCB.

• If you want to know the possible causes of any specific problem (suspected parts), refer to

the "Cause" column in the table.

In the event "No power is supplied" as shown in the above table, an unplugged power

source, power source failure, blown fuse, and other causes can be considered.

iii

ii

PREFACE

• In order to remedy a problem, check the Steps in order. Answer the first "Check item"

question. If your answer matches that given in the "Result", follow the corresponding procedure in the "Remedy" column. If your answer is not the same, go on to the next step and

repeat the same procedure.

<Remedy><Check item> <Result><Step>

Is the

power cord properly

1

connected to the receptacle

on the machine

and outlet?

YES

NO

Connect in the power code

to the machine and outlet.

Is the specified

2

3

voltage applied to the outlet?

YES

Is the fuse

on the DC power PCB (F1)

blown?

NO

NO

YES

Explain to the customer that

the trouble is not attributable

to the machine.

Remove the cause of the

blown fuse and replace the

DC power PCB.

• When checking voltages using a tester is required, it will be specified in the check item.

For instance; "measure the voltage between J102-1 (+) and JI02-2 (-) on the engine controller PCB". In this case, apply the plus and minus leads of the tester to the (+) and (-) terminals indicated after the connector numbers:

e.g. JI02-1 (+): Plus lead

JI02-2 (-): Minus lead

5. The signal address of the circuit diagram is shown by applicable pages of each controller

(indicated at the upper right of the circuit diagram) and its location.

CAUTION

When checking voltages with a tester, touching the components or connector terminals on

the PCB with the hands may cause an electric shock. It is advisable to wear rubber gloves

or the like when power is supplied to the machine to protect yourself from electric shock.

iii

iv

PREFACE

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. SPECIFICATIONS ............................................ 1-1

1. Type............................................................. 1-1

2. Exterior ........................................................ 1-1

3. Mechanism .................................................. 1-2

4. Media ........................................................... 1-4

5. Others .......................................................... 1-6

II. NAMES OF COMPONENTS............................. 1-7

A. External View............................................... 1-7

B. Carriage ....................................................... 1-8

C. Cable Connections ...................................... 1-8

D. Rear Side of Main Unit................................. 1-9

E. Printing Direction.......................................... 1-9

III. OPERATION ................................................... 1-10

A. Operation Panel......................................... 1-10

B. Printer States ............................................. 1-11

C. User Mode Menu .......................................... 13

1. Menu guide ............................................. 13

2. Menu and parameter setup.................. 1-14

3. Details of user mode menus ................ 1-14

4. Using the setup list............................... 1-25

5. Dump mode.......................................... 1-27

6. Image layout......................................... 1-27

D. Basic Operation ......................................... 1-29

E. Paper Thickness Adjustment Lever ........... 1-31

IV. CARTRIDGE REPLACEMENT ....................... 1-32

A. Replacing the BJ Print head ....................... 1-32

B. Replacing the Ink Tank ............................... 1-34

V. SIMM REPLACEMENT ................................... 1-36

A. About SIMM ............................................... 1-36

B. SIMM Installation ....................................... 1-36

C. SIMM Removal .......................................... 1-37

VI. CAUTIONS ON HANDLING ............................ 1-38

A. Cartridges .................................................. 1-38

1. Cautions on handling the BJ print

head ..................................................... 1-38

2. Cautions on handling ink tanks ............ 1-38

B. Paper Storage Environment ...................... 1-39

C. Paper ......................................................... 1-39

D. After Printing.............................................. 1-39

VII. USER MAINTENANCE................................... 1-40

A. Head Cleaning ........................................... 1-40

B. Normal Cleaning ......................................... 1-40

VIII. INSTALLATION ENVIRONMENT................. 1-41

IX. PACKAGE CONFIGURATION ....................... 1-42

X. TRANSPORTING THE PRINTER ................... 1-43

CHAPTER 2 BASIC OPERATION

I. BASIC OPERATION ......................................... 2-1

A. Functional Configuration.............................. 2-1

B. Interface Input/Output .................................. 2-2

1. Parallel interface ..................................... 2-2

2. Serial interface........................................ 2-6

C. Image Controller .......................................... 2-7

D. Engine Controller ....................................... 2-10

E. Engine controller Input/Output ................... 2-12

1. Engine controller input/output (1/3)...... 2-12

2. Engine controller input/output (2/3)...... 2-13

3. Engine controller input/output (3/3)...... 2-14

F. Summary of Operation............................... 2-15

1. When the power switch is turned ON... 2-15

2. When media is loaded.......................... 2-17

3. Printing ................................................. 2-18

II. CARRIAGE UNIT ............................................ 2-22

A. Outline ....................................................... 2-22

B. Carriage Motor Control .............................. 2-24

1. Outline.................................................. 2-24

2. Operation ............................................. 2-24

3. Detection of front cover open/closed ... 2-25

C. Linear Encoder .......................................... 2-26

1. Outline.................................................. 2-26

2. Structure............................................... 2-26

3. Output signal........................................ 2-26

4. Control.................................................. 2-27

D. Media Sensor............................................. 2-28

1. Outline.................................................. 2-28

2. Paper width detection........................... 2-28

3. Skew detection..................................... 2-29

4. Light compensation.............................. 2-31

5. Auto band adjustment .......................... 2-31

6. Automatic print position adjustment ..... 2-32

E. Detection of the Ink Tank........................... 2-34

1. Outline.................................................. 2-34

2. Method of detecting the ink tank .......... 2-34

iv

v

PREFACE

F. Remaining Ink Detection............................ 2-35

1. Outline.................................................. 2-35

2. Method of detecting remaining ink ....... 2-36

G. Cutter Unit.................................................. 2-38

1. Outline.................................................. 2-38

2. Cutting operation.................................. 2-38

III. BJ CARTRIDGE .............................................. 2-39

A. BJ Cartridge............................................... 2-39

1. Overview .............................................. 2-39

2. Structure............................................... 2-39

3. BJ print head........................................ 2-41

4. Nozzle arrangement............................. 2-42

B. BJ Print head Drive.................................... 2-43

1. Construction of electric head unit......... 2-43

2. Print signal ........................................... 2-45

IV. PURGE UNIT .................................................. 2-46

A. Outline ....................................................... 2-46

B. Capping Function....................................... 2-51

1. Outline.................................................. 2-51

2. Operation ............................................. 2-51

C. Head Cleaning........................................... 2-52

1. Outline.................................................. 2-52

2. Wiping .................................................. 2-52

3. Maintenance jet.................................... 2-53

4. Suction ................................................. 2-54

D. Waste Ink Absorber Unit............................ 2-56

1. Waste ink absorber unit ....................... 2-56

V. FEEDER UNIT ................................................ 2-57

A. Outline ....................................................... 2-57

B. Paper Feed Motor Control ......................... 2-58

1. Outline.................................................. 2-58

2. Operation ............................................. 2-58

C. Feeding Operation..................................... 2-60

1. Outline.................................................. 2-60

2. Loading paper ...................................... 2-60

3. Paper feeding during printing............... 2-61

4. Feeding operation ................................ 2-62

5. PE sensor............................................. 2-62

VI. FAN.................................................................. 2-63

VII. POWER SUPPLY ........................................... 2-65

A. Power Supply Outline ................................ 2-65

B. Power Circuit ............................................. 2-66

1. AC power supply.................................. 2-66

2. DC power supply.................................. 2-66

C. Power Circuit Protection ............................ 2-66

CHAPTER 3 MECHANICAL SYSTEM

DISASSEMBLY AND ASSEMBLY.......................... 3-1

1. List of Main Parts ......................................... 3-2

2. Outline of disassembly and assembly of

main parts .................................................... 3-3

PRECAUTIONS FOR DISASSEMBLY

AND REASSEMBLY .............................................. 3-5

I. EXTERNALS ..................................................... 3-7

A. External Cover ............................................. 3-7

1. Removing the right cover ....................... 3-7

2. Removing the upper cover and

front cover .............................................. 3-7

3. Removing the lower cover...................... 3-8

4. Removing the front cover switch............ 3-9

B. Operation Panel........................................... 3-9

1. Removing the operation panel ............... 3-9

C. Fan............................................................. 3-10

1. Removing the cooling fan..................... 3-10

2. Removing the suction fan..................... 3-12

II. CARRIAGE UNIT ............................................ 3-13

1. Removing the carriage unit .................. 3-13

2. Removing the carriage belt .................. 3-15

3. Installing the carriage belt .................... 3-16

4. Removing the linear scale.................... 3-17

5. Replacing the flexible cable ................. 3-18

III. PURGE UNIT .................................................. 3-21

1. Removing the purge unit...................... 3-21

2. Removing the waste ink absorber

unit ....................................................... 3-23

IV. FEEDER UNIT ................................................ 3-24

1. Removing the pinch roller unit.............. 3-24

2. Removing the platen ............................ 3-25

3. Installing the platen .............................. 3-26

4. Removing the paper feed roller............ 3-27

5. Removing the PE sensor ..................... 3-27

V. DRIVING UNIT ................................................ 3-28

1. Removing the carriage motor............... 3-28

2. Removing the paper feed motor .......... 3-29

3. Installing the paper feed motor ............ 3-30

4. Fastening the paper feed roller set

screws .................................................. 3-30

VI. ELECTRICAL PART........................................ 3-32

1. Removing the image controller ............ 3-32

2. Removing the engine controller ........... 3-33

3. Removing the PCB box........................ 3-34

4. Removing the power switch ................. 3-35

5. Removing the DC power supply........... 3-35

v

vi

PREFACE

CHAPTER 4 MAINTENANCE AND SERVICING

I. PERIODIC PARTS REPLACEMENT ................ 4-1

II. STANDARD SERVICE LIFE OF

CONSUMABLES............................................... 4-1

III. PERIODIC SERVICE ........................................ 4-1

CHAPTER 5 TROUBLESHOOTING

I. SERVICE MODE ............................................... 5-1

A. Outline.......................................................... 5-1

B. Service Mode Operation .............................. 5-1

1. How to enter the service mode .............. 5-1

2. Stopping the service mode .................... 5-1

C. Service Mode Map....................................... 5-2

D. Service Mode............................................... 5-3

1. Control display mode ............................. 5-3

2. Adjusting mode ...................................... 5-5

3. Operation/inspection mode .................... 5-6

4. Counter mode ........................................ 5-7

5. Initialization mode .................................. 5-8

II. ADJUSTMENTS AND SETTINGS .................... 5-9

A. About Adjustments and Settings.................. 5-9

B. Items for Adjustment and Setting................. 5-9

C. Adjustment and Setting Procedures ........... 5-10

1. Automatic printing position adjustment

and automatic band adjustment

(User-settable) ..................................... 5-11

2. Waste ink counter reset (for exclusive

use in service mode) ............................ 5-11

3. Replacing the image controller and

engine controller................................... 5-11

4. Paper feed accuracy compensation

value adjustment .................................. 5-13

5. Changing the parallel interface

communication mode ........................... 5-15

6. Image controller/engine controller

upgrade procedure............................... 5-16

III. ERROR/WARNING CODES ........................... 5-18

A. Outline ....................................................... 5-18

B. List of Error and Warning Codes ............... 5-18

1. 001xx (Media/feeding system) ............. 5-20

2. 003xx (Drive system) ........................... 5-22

3. 004xx (BJ Print head system) .............. 5-23

4. 005xx (Ink tank system) ....................... 5-24

5. 007xx (Purge system) .......................... 5-24

6. 008xx (Cutter system) .......................... 5-25

7. 011xx (Engine controller) ..................... 5-25

8. 012xx

9. 015xx (Power supply related)............... 5-26

(Internal communication system) ....

5-26

IV. MAINTENANCE AND INSPECTION................ 4-2

A. Cleaning/Inspection Points .......................... 4-2

B. Lubrication Points ........................................ 4-3

10.021xx (User-adjusted system) ............. 5-26

11.051xx (Image controller) ...................... 5-27

12.052xx (Serial interface communication

system)................................................. 5-27

13.053xx (Parallel interface communication

system)................................................. 5-27

14.060xx (Internal data processing

system)................................................. 5-28

15.061xx (GL command system) .............. 5-29

16.062xx (GL2 command system) ............ 5-29

17.063xx (RTL command system) ............ 5-29

18.064xx (ESC command system)............ 5-30

19.065xx (PJL command system)............. 5-30

20.067xx (TIFF command system) ........... 5-30

21.097xx (Direct error code from the image

controller) ............................................. 5-31

22.098xx (Direct error code from the engine

controller) ............................................. 5-31

23.099xx (Others) ..................................... 5-31

IV. CORRECTION OF OPERATION DEFECTS .. 5-32

1. 001xx (Media/feeding system) ............. 5-32

2. 003xx (Drive system) ........................... 5-33

3. 004xx (BJ Print head system) .............. 5-34

4. 005xx (Ink tank system) ....................... 5-34

5. 007xx (Purge unit)................................ 5-35

6. 008xx (Cutter system).......................... 5-36

7. 011xx (Engine controller) ..................... 5-36

8. 012xx

9. 015xx (Power supply related)............... 5-37

10.021xx (User-adjusted system) ............. 5-37

11.051xx (Image controller) ...................... 5-37

12.052xx (Serial interface communication

13.053xx (Parallel interface communication

14.060xx (Internal data processing

15.061xx (GL command system) .............. 5-39

16.062xx (GL2 command system) ............ 5-39

17.063xx (RTL command system) ............ 5-39

18. 064xx (ESC command system) ........... 5-39

(Internal communication system) ....

system)................................................. 5-38

system)................................................. 5-38

system)................................................. 5-38

5-37

vi

vii

PREFACE

19.065xx (PJL command system)............. 5-39

20.067xx (TIFF command system) ........... 5-39

21.097xx (Direct error code from the image

controller) ............................................. 5-39

22.098xx (Direct error code from the engine

controller) ............................................. 5-39

23.099xx (Others) ..................................... 5-39

24. No power ............................................ 5-40

25.Nothing is indicated on the operation

panel .................................................... 5-41

26.Opening and closing of front cover is

not detected ......................................... 5-41

27.Wiper solenoid does not working ......... 5-41

28.Media is not fed.................................... 5-42

29.Suction fan does not rotate .................. 5-42

V. CORRECTION OF IMAGE DEFECTS............ 5-43

A. Initial Inspection ......................................... 5-43

1. Installation environment ....................... 5-43

2. Media check......................................... 5-43

B. Corrective Procedures for Image Defects.. 5-44

CHAPTER 6 CIRCUIT DIAGRAM

1. Non-ejection of ink ............................... 5-44

2. Vertical misalignment 1........................ 5-45

3. Vertical misalignment 2........................ 5-46

4. Low resolution...................................... 5-47

5. Dislocation of dots of different colors ... 5-47

6. Dot misalignment ................................. 5-48

7. Lines (Carriage direction)..................... 5-49

8. White lines (Paper feed direction)....... 5-50

9. Bleeding ............................................... 5-51

10.Dimensional accuracy problems .......... 5-51

11.Blotting boundary between filled

images.................................................. 5-52

VI. ELECTRICAL COMPONENTS ARRANGEMENT/

FUNCTIONS ................................................... 5-53

A. Sensors and Switches ............................... 5-53

B. Motors, Fans, and Solenoids ..................... 5-54

C. Logic boards .............................................. 5-55

D. Engine Controller....................................... 5-56

E. Image Controller ........................................ 5-57

A. GENERAL CIRCUIT DIAGRAM ........................ 6-1

B. IMAGE CONTROLLER....................................... 6-4

C. ENGIN CONTROLLER.................................... 6-16

APPENDIX

MENU GUIDE ......................................................... A-1

D. CARRIAGE CONTROLLER ............................ 6-33

E. PAPER SENSOR ............................................ 6-41

F. OPERATION PANEL CONTROLLER ............. 6-42

vii

viii

PREFACE

ix

CHAPTER 1

GENERAL DESCRIPTION

I. SPECIFICATIONS ............................................ 1-1

II. NAMES OF COMPONENTS............................. 1-7

A. External View............................................... 1-7

B. Carriage ....................................................... 1-8

C. Cable Connections ...................................... 1-8

D. Rear Side of Main Unit................................. 1-9

E. Printing Direction.......................................... 1-9

III. OPERATION ................................................... 1-10

A. Operation Panel......................................... 1-10

B. Printer States ............................................. 1-11

C. User Mode Menu ....................................... 1-13

D. Basic Operation ......................................... 1-29

E. Paper Thickness Adjustment Lever ........... 1-31

IV. CARTRIDGE REPLACEMENT ....................... 1-32

A. Replacing the BJ Print head ....................... 1-32

B. Replacing the Ink Tank ............................... 1-34

V. SIMM REPLACEMENT ................................... 1-36

A. About SIMM ............................................... 1-36

B. SIMM Installation ....................................... 1-36

C. SIMM Removal .......................................... 1-37

VI. CAUTIONS ON HANDLING ............................ 1-38

A. Cartridges .................................................. 1-38

B. Paper Storage Environment ...................... 1-39

C. Paper ......................................................... 1-39

D. After Printing.............................................. 1-39

VII. USER MAINTENANCE................................... 1-40

A. Head Cleaning ........................................... 1-40

B. Normal Cleaning ......................................... 1-40

VIII. INSTALLATION ENVIRONMENT................. 1-41

IX. PACKAGE CONFIGURATION ....................... 1-42

X. TRANSPORTING THE PRINTER ................... 1-43

CHAPTER 1. GENERAL DESCRIPTION

I. SPECIFICATIONS

1. Type

Type: Bubble jet printer

Purge system: Suction with tube pump

Paper feeding method: Cut sheet media; Manually set to the front.

Roll media;

Sheet feeder capacity: Cut sheet media; 1 sheet

Roll media; 1 unit (Outside dia.: 100mm or less, Media tube bore:

50.8mm (2"))

Media delivery system: Face-up delivery in front

Max. delivery sheets: 5 sheets (Plain paper)

Fixing method: Natural drying

Cutter: Automatic cutter (replaceable)

Automatic feeding (When manually set to the rear.)

2. Exterior

A0-size model:

External dimensions (main unit only); 1462 x 388 x 345 mm

External dimensions (including stand); 1462 x 700 x 1204 mm

Weight (Main unit only); Approx. 31 kg

Weight (including stand); Approx. 46 kg

A1-size model:

External dimensions (main unit only); 1182 x 388 x 345 mm

External dimensions (including stand); 1182 x 700 x 1204 mm

Weight (main unit only); Approx. 26 kg

Weight (including stand); Approx. 40 kg

1–1

CHAPTER 1. GENERAL DESCRIPTION

3. Mechanism

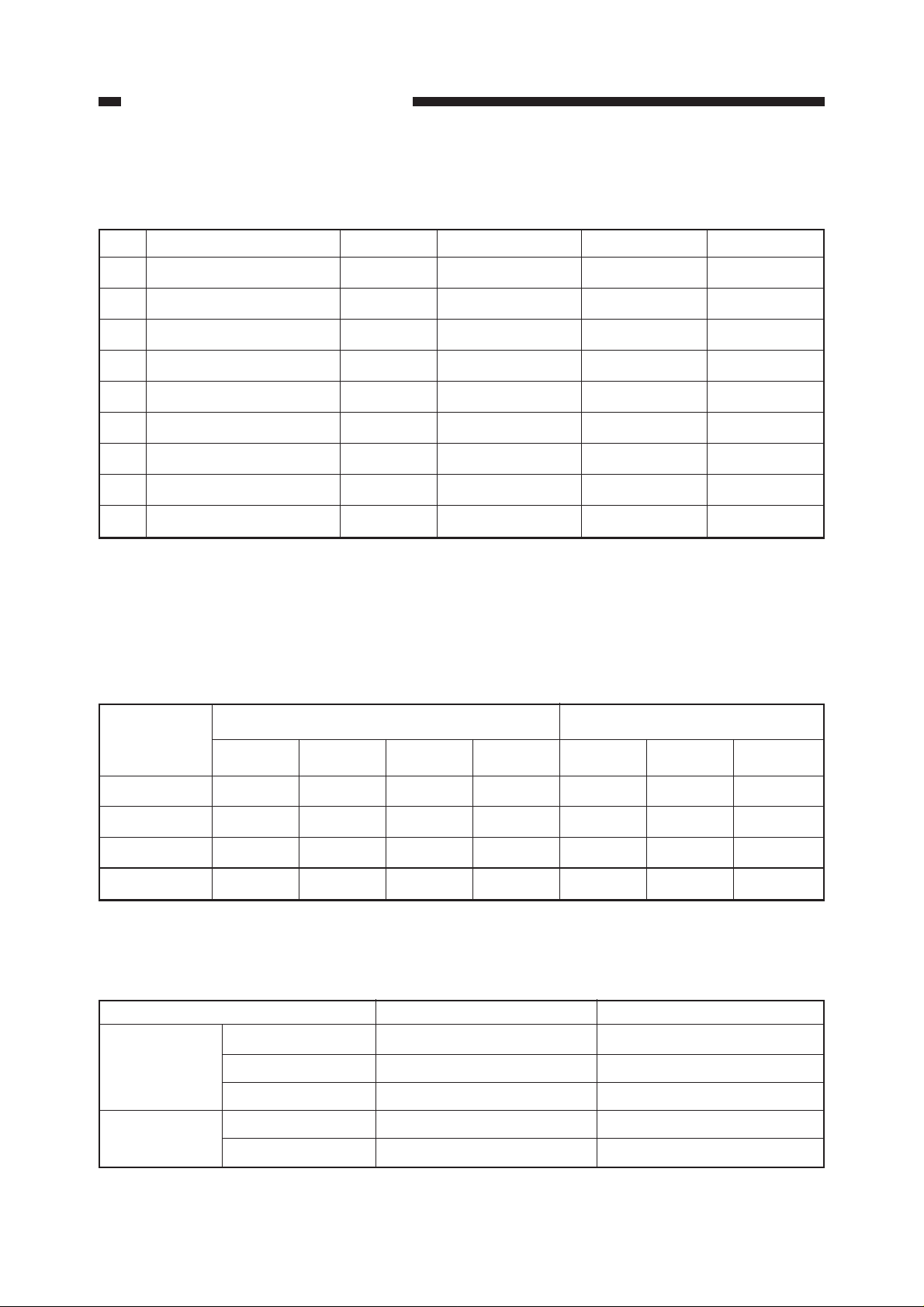

Print mode/Resolution

(No.) Mode Pass *

(1) Monochrome draft 1 pass/Bi 180dpi x 360dpi 14.4kHz M

(2) Monochrome normal 1 pass/Uni 360dpi x 360dpi 7.2kHz L

(3) Monochrome enhanced 2 pass/Uni 360dpi x 360dpi 7.2kHz L

(4)

Monochrome high enhanced

(5)

Monochrome high resolution

4 pass/Uni 360dpi x 360dpi 7.2kHz L

4 pass/Uni 720dpi x 720dpi*

(6) Color draft 1 pass/Bi 360dpi x 360dpi 7.2kHz Bk:M/Color:S

(7) Color normal 1 pass/Uni 360dpi x 360dpi 7.2kHz Bk:L/Color:S

(8) Color enhanced 2 pass/Uni 360dpi x 360dpi 7.2kHz Bk:L/Color:S

(9) Color high enhanced 4 pass/Unil 360dpi x 360dpi 7.2kHz Bk:L/Color:S

1

Resolution

Drive frequency

2

7.2kHz S

Dot size *

3

* 1: Bi=bi-directional, Uni=uni-directional

* 2: Equivalent

* 3: S=small dot, M=middle dot, L=large dot

Table 1-101

Print modes according to media type <Corresponds to the Nos. of table 1-101.>

Media type Monochrome Color

Draft Normal Enhanced

High resolution

Draft Normal Enhanced

Plain paper (1) (2) (3) (5) (6) (7) (8)

Coated paper (1) (2) (3) (5) (7) (8) (9)

Tracing paper (2) (3) (4) (5) (7) (8) (9)

Matte film (2) (3) (4) (5) (7) (8) (9)

Table 1-102

Maximum printing speed (Plain paper mode)

Monochrome

mode

Color mode

1–2

Print mode A0 size A1 size

Draft mode Approx. 2 minutes 15 seconds Approx. 1 minute 30 seconds

Enhanced mode Approx. 13 minutes Approx. 7 minutes

High Resolution mode

Approx. 25 minutes Approx. 13 minutes 15 seconds

Draft mode Approx. 5 minutes 15 seconds Approx. 3 minutes

Enhanced mode Approx. 15 minutes Approx. 8 minutes 30 seconds

Table 1-103

CHAPTER 1. GENERAL DESCRIPTION

Cartridge construction Head/Ink tank separation type

1 row of 160 nozzles (144 nozzles used) x 4 colors

Ink type Black: Pigment, Cyan/Magenta/Yellow: dye

Ink tank capacity Black: Approx. 23g,

Cyan/Magenta/Yellow: Approx. 20g

BJ print head service life A0 size: Approx. 400 sheets, A1 size: Approx. 500

sheets

(continuous printing on plain paper, 1-pass uni-

directional, at 20% duty (5% for each color))

Ink consumption A0 size: Bk; 25 sheets,

Cyan/Magenta/Yellow; 40 sheets

A1 size: Bk; 50 sheets,

Cyan/Magenta/Yellow; 80 sheets

(continuous printing on plain paper, 1-pass unidirectional, at 20% duty (5% for each color))

Interface Parallel interface

Complies with IEEE1284 (Compatible mode/Nibble

mode)

Connector complying with IEEE1284-B Receptacle

Serial interface

Complies with RS-232C (DCE)

D-Sub 9-pin female connector

Emulation Complies with HP-GL, HP-GL/2, and HP-RTL

Kanji font Kanji JIS first and second standard

Memory Standard: 8MB (can be increased to 72 MB: 72-pin

60ns FPM type SIMMs)

EDO memory can be used in FPM mode.

Cutter Automatic cutter (replaceable)

Waste-ink tank Provided

Maintenance jet Provided

Capping system Provided

Paper thickness adjustment Provided

Automatic printing position adjustment Provided

Self diagnostics Provided

Skewed feed detection Provided

Head detection Provided

Head insertion error detection Not provided

1–3

CHAPTER 1. GENERAL DESCRIPTION

Ink tank detection Provided

Remaining ink detection Provided

Waste-ink full detection Provided

Media out detection Provided

Remaining roll media detection Not provided

Roll media end detection Provided

Media size detection

Cut sheet media: Automatic vertical/horizontal

Roll media: Vertical; size or data designated

Carriage position detection Provided

Machine internal temperature detection Provided

detection

Horizontal; automatic detection

4. Media

Media types Plain paper, coated paper, tracing paper, and matte

film (75 ~ 100µm)

Paper thickness 75 ~ 165µm (excluding matte film) / 64 ~ 128g/m

Maximum paper width A0 model: 914mm

A1 model: 634mm

Minimum paper width/length Width; 250mm Length; 150mm

Maximum printing length Cut sheet media: 1250mm

Roll media* : Windows95/98 driver; 4.6m

WindowsNT4.0 driver; 4.6m

ADI driver; 13m

HDI driver; 18m

* : Printing length of roll media varies depending on the type of application, operating system, or driver used.

Printing margin Cut sheet media: Leading edge; 5mm/15mm

2

Trailing edge; 20mm

Right/left edge; 5mm

Roll media: Leading edge; 5mm/15mm

Trailing edge; 5mm

Right/left edge; 5mm

Maximum printing area Excludes printing margins

1–4

CHAPTER 1. GENERAL DESCRIPTION

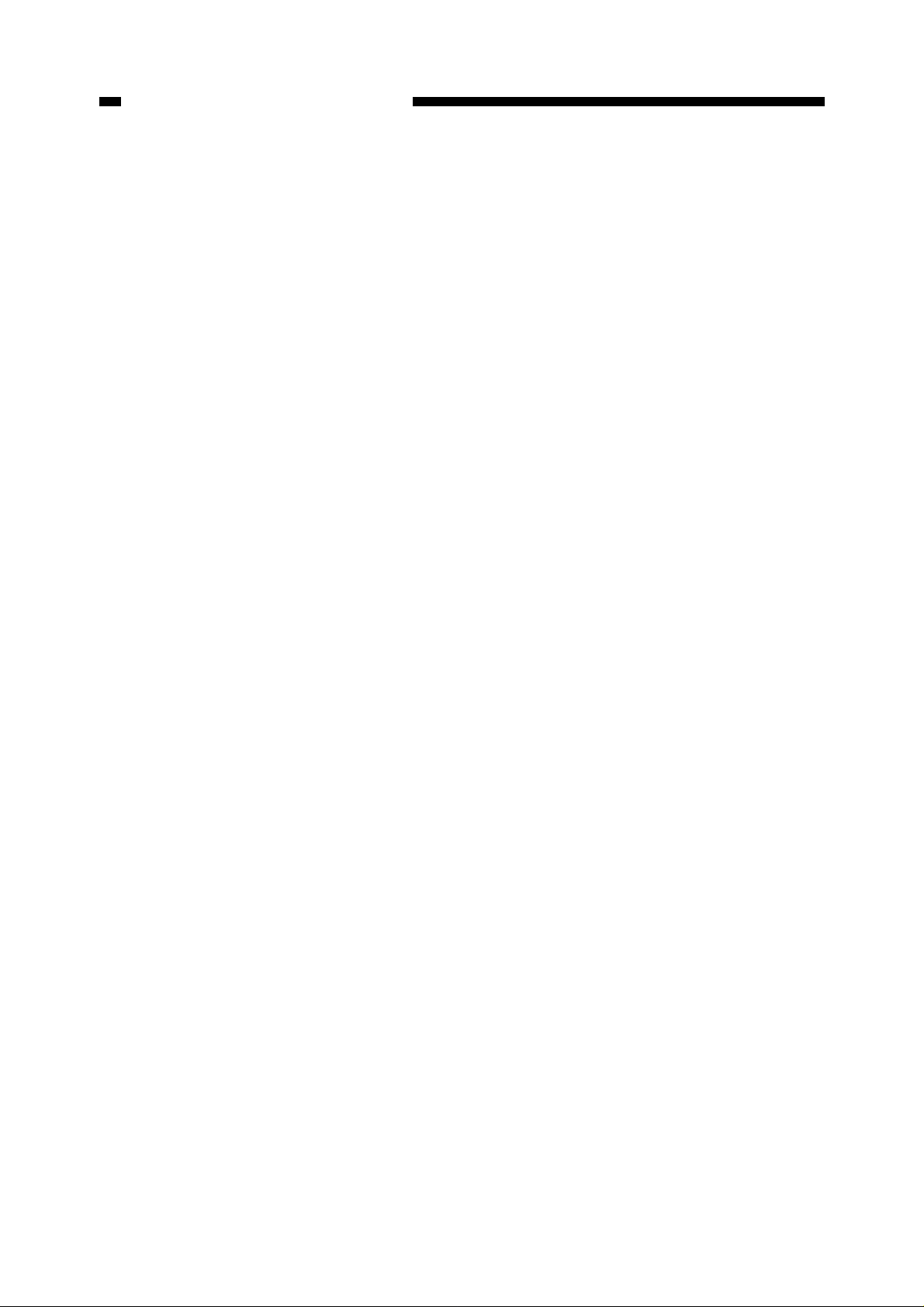

Printable papers

Paper standard mm inch A1 model A0 model

ISO A Vertical Horizontal Vertical Horizontal

A0 841.0 × 1189.0 33.1 × 46.8 NG NG OK NG

A1 594.0 × 841.0 23.4 × 33.1 OK NG OK OK

A2 420.0 × 594.0 16.5 × 23.4 OK OK OK OK

A3 297.0 × 420.0 11.7 × 16.5 OK OK OK OK

A4 210.0 × 297.0 8.3 × 11.7 NG OK NG OK

JIS B

B1 728.0 × 1030.0 28.7 × 40.6 NG NG OK NG

B2 515.0 × 728.0 20.3 × 28.7 OK NG OK OK

B3 364.0 × 515.0 14.3 × 20.3 OK OK OK OK

B4 257.0 × 364.0 10.1 × 14.3 OK OK OK OK

ISO B

B1 707.0 × 1000.0 27.8 × 39.4 NG NG OK NG

B2 500.0 × 707.0 19.7 × 27.8 OK NG OK OK

B3 353.0 × 500.0 13.9 × 19.7 OK OK OK OK

B4 250.0 × 353.0 9.8 × 13.9 OK OK OK OK

ANSI

E 863.6 × 1117.6 34.0 × 44.0 NG NG OK NG

D 558.8 × 863.6 22.0 × 34.0 OK NG OK OK

C 431.8 × 558.8 17.0 × 22.0 OK OK OK OK

B 279.4 × 431.8 11.0 × 17.0 OK OK OK OK

A 215.9 × 279.4 8.5 × 11.0 NG OK NG OK

ANSI ARCH

6 914.4 × 1219.2 36.0 × 48.0 NG NG OK NG

5 762.0 × 1066.8 30.0 × 42.0 NG NG OK NG

4 609.6 × 914.4 24.0 × 36.0 OK NG OK OK

3 457.2 × 609.6 18.0 × 24.0 OK OK OK OK

2 304.8 × 457.2 12.0 × 18.0 OK OK OK OK

1 228.6 × 304.8 9.0 × 12.0 NG OK NG OK

ISO Over

A0 910.0 × 1245.0 35.8 × 49.0 NG NG OK NG

A1 627.0 × 900.0 24.7 × 35.4 OK NG OK OK

A1L 627.0 × 1250.0 24.7 × 49.2 OK NG OK NG

A2 460.0 × 645.0 18.1 × 25.4 OK NG OK OK

A3 340.0 × 465.0 13.4 × 18.3 OK OK OK OK

EURO DIN

A0 881.0 × 1229.0 34.7 × 48.4 NG NG OK NG

A1 634.0 × 881.0 25.0 × 34.7 OK NG OK OK

A2 460.0 × 634.0 18.1 × 25.0 OK OK OK OK

A3 337.0 × 460.0 13.3 × 18.1 OK OK OK OK

A4 250.0 × 337.0 9.8 × 13.3 OK OK OK OK

KOREAN

m 540.0 × 790.0 21.3 × 31.1 OK NG OK OK

s 390.0 × 540.0 15.4 × 21.3 OK OK OK OK

1–5

CHAPTER 1. GENERAL DESCRIPTION

5. Others

Power source AC: 100 ~ 240 V (-15%, +10%)

Frequency 50/60Hz

Power consumption Max.: 120W or less

At stand-by: 22W or less

Noise Sound pressure level (Complies with ISO 9296.)

When operating: Approx. 52dB (A) or less

At stand-by: Approx. 20dB (A) or less

Operating environment Temperature: 5 ~ 35°C

(Printing quality assured: 15 ~ 30°C)

Humidity: 10 ~ 90%RH

(Printing quality assured: 20 ~ 80%RH)

Atmospheric pressure: 1013 ~ 709hPa

Storage environment* Temperature: 0 ~ 35°C

Humidity: 5 ~ 95% (RH)

* : Should be free from condensation and rapid temperature variations.

1–6

CHAPTER 1. GENERAL DESCRIPTION

II. NAMES OF COMPONENTS

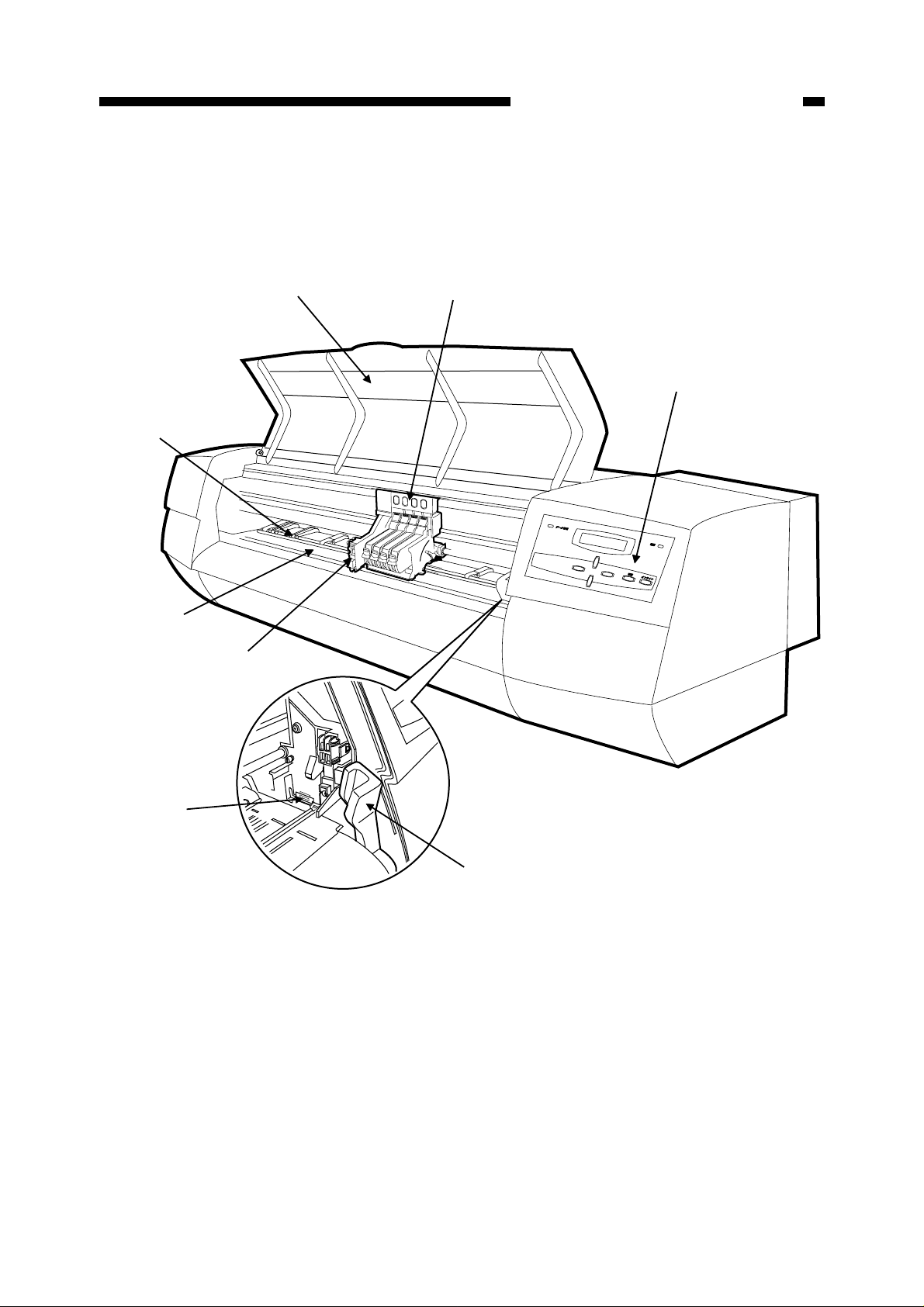

A. External View

[8]

[7]

[6]

[1]

[2]

[3]

[5]

[1] Front cover

[2] Carriage

[3] Operation panel

[4] Paper release lever

[4]

[5] Wiper (Cleaner blade)

[6] Cutter unit

[7] Platen

[8] Pinch roller

Figure 1-201

1–7

CHAPTER 1. GENERAL DESCRIPTION

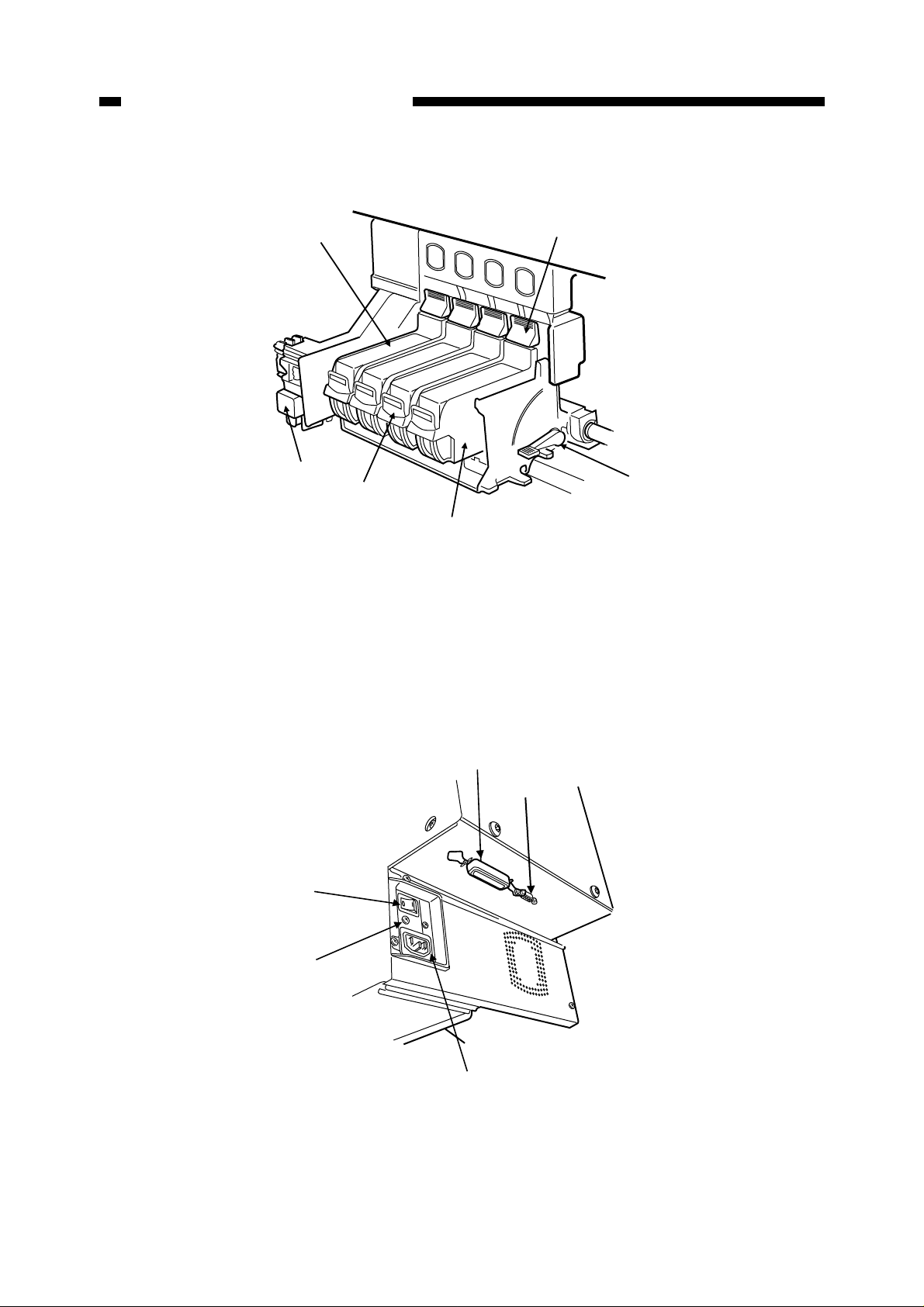

B. Carriage

[1]

[6]

[5]

[1] Ink tank

[2] BJ print head release hook

[3] Paper thickness adjustment lever

[2]

[3]

[4]

[4] BJ Cartridge

[5] Ink tank release hook

[6] Cutter unit

C. Cable Connections

[5]

[4]

[1] Parallel interface connector

Figure 1-202

[1]

[2]

[3]

[4] Earth wire terminal

[2] Serial interface connector

[3] AC inlet

1–8

[5] Power switch

Figure 1-203

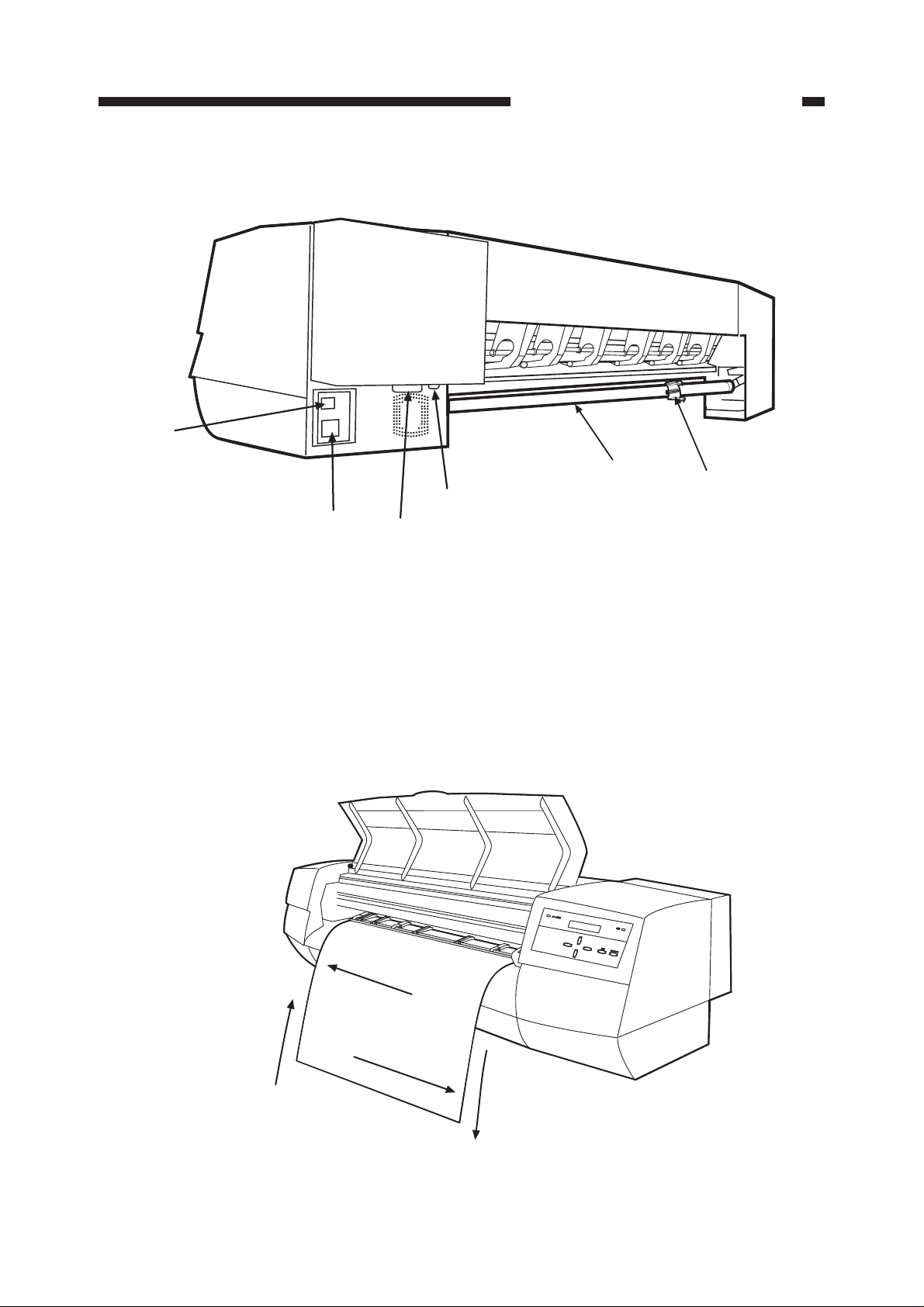

D. Rear Side of Main Unit

[6]

CHAPTER 1. GENERAL DESCRIPTION

[1] Roll media stopper

[2] Spindle

[3] Serial interface connector

E. Printing Direction

[5]

[3]

[4]

Figure 1-204

[2]

[1]

[4] Parallel interface connector

[5] AC inlet

[6] Power switch

Paper feed

backward direction

Carriage

forward direction

Carriage

backward direction

Paper feed

forward direction

Figure 1-205

1–9

CHAPTER 1. GENERAL DESCRIPTION

III. OPERATION

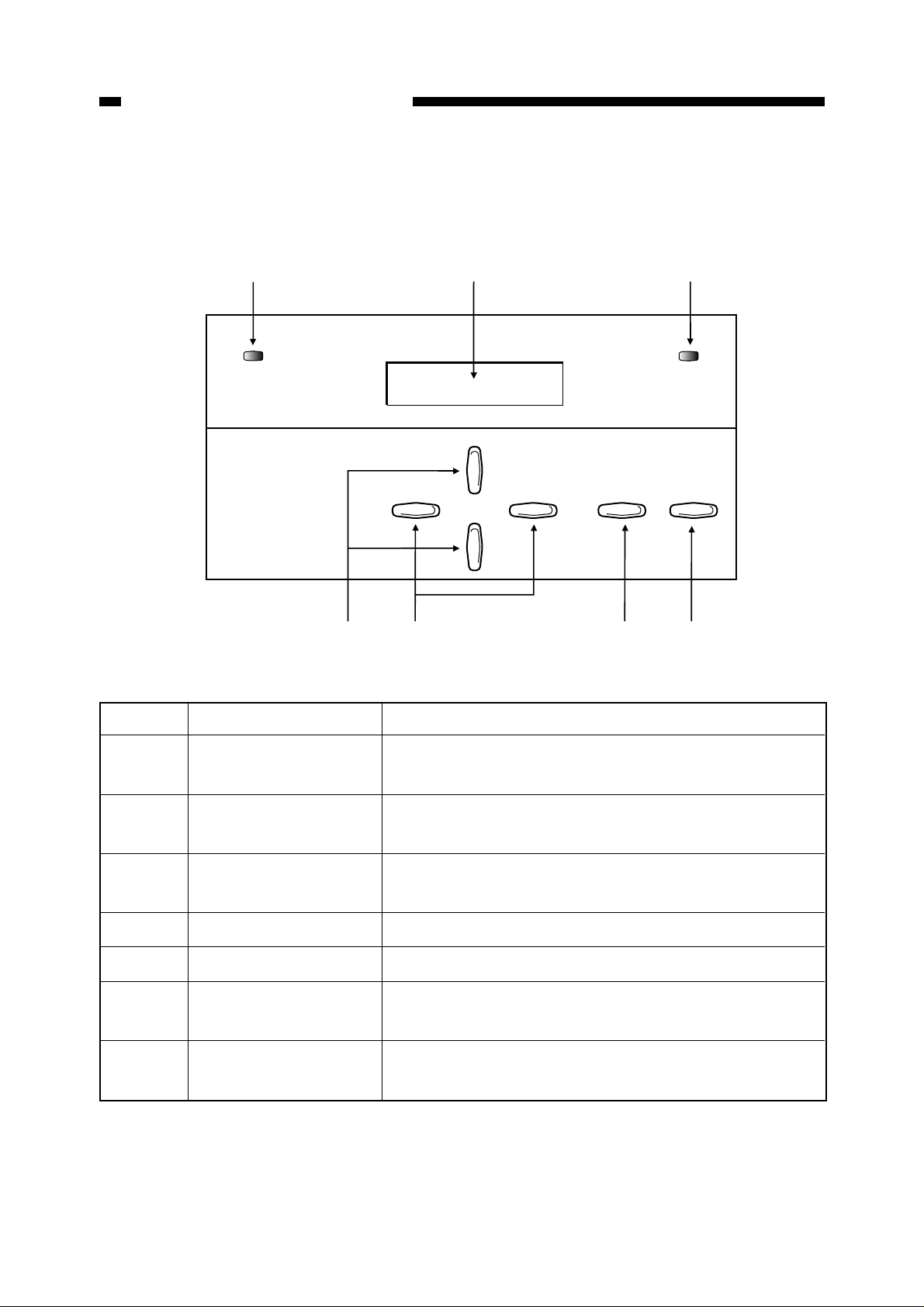

A. Operation Panel

[1]

DATA

[7]

[6]

[2] [3]

POWER

ENTER

Figure 1-301

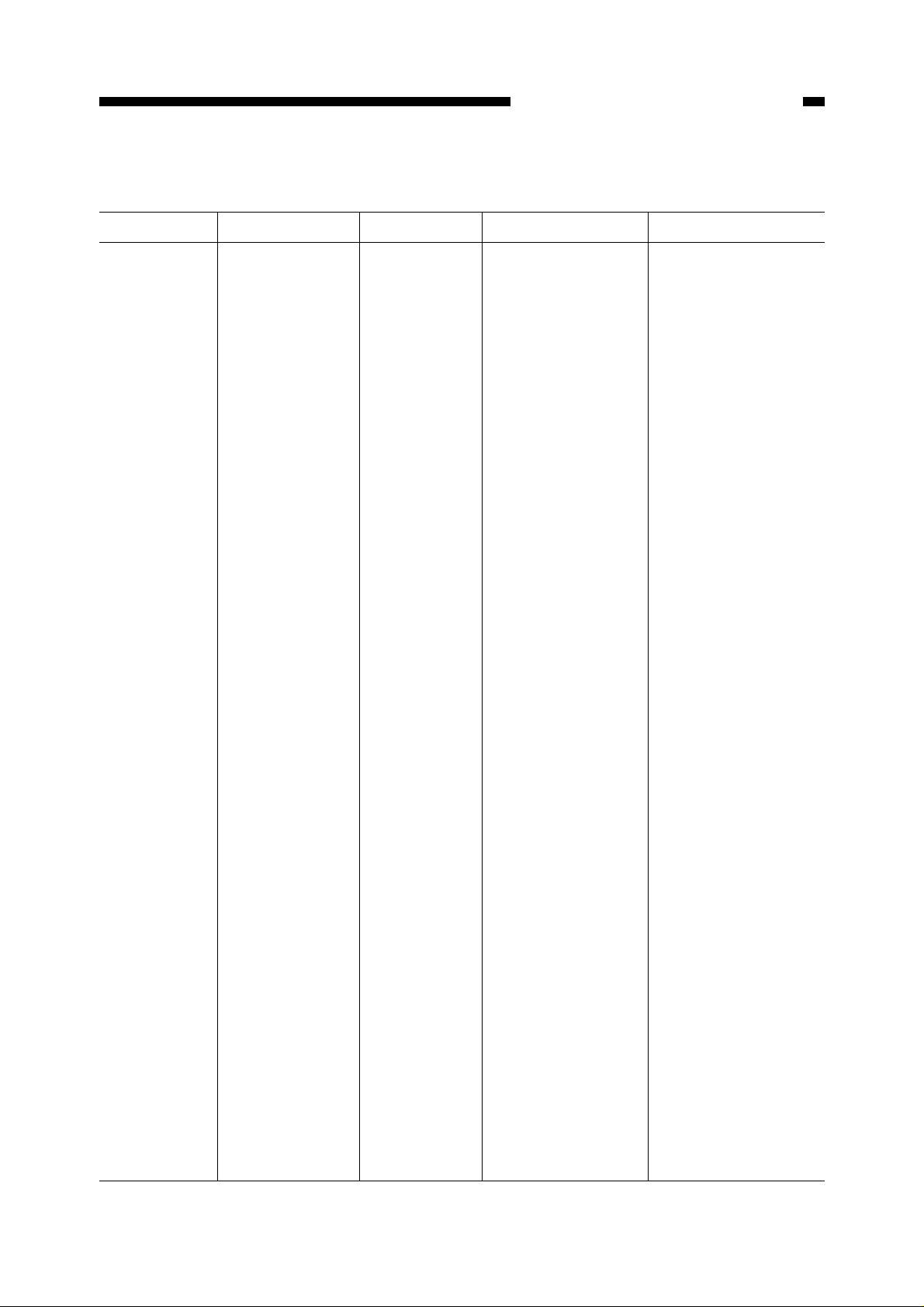

No. Name Function

ONLINE

[4][5]

[1] Data reception lamp Green when receiving data. Blinks if data is transmitted

when the printer cannot receive it.

[2] Message display Menus, parameters, error messages and other conditions

are displayed. Divided into upper and lower sections.

[3] Power lamp Green when power switch is turned on. Orange in the

sleep state. Blinks orange if an error occurs.

[4] Online key Switches between the online, offline and menu states.

[5] Enter key Enters selected menu item.

[6] Right/left arrow keys Used when selecting parameters. Also used to move the

carriage on the platen.

[7] Up/down arrow keys Used when selecting menus. Can move the paper back

and forth when offline.

Table 1-301

1–10

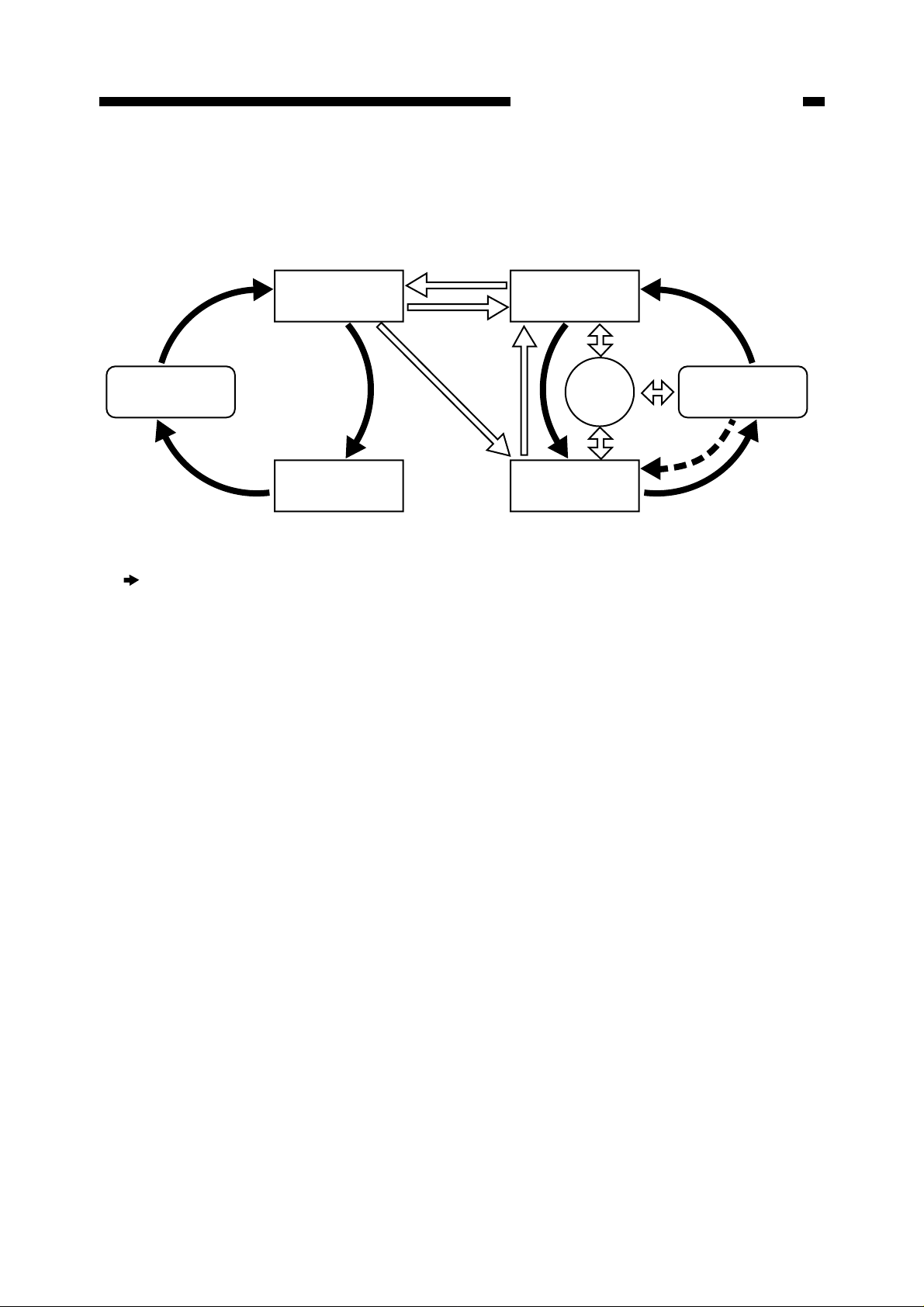

B. Printer States

Printer states and key operation are shown below.

Data received

CHAPTER 1. GENERAL DESCRIPTION

Printing

After printing on cut sheet media

*1

Menu setup screen

Pause

(Black arrows) : Change of printer states when the Online key is pressed.

*1. Some menus cannot be setup during printing.

*2. When no media is loaded, the machine cannot be returned to the “Online” state by pressing the Online key.

It returns to “Offline”.

*3. Pressing any key on the control panel, opening the front cover, or receiving data in "Sleep" state will wake the printer up.

After printing

on roll media

Online

Media setup

Offline

Sleep

*3

Menu setup screen

*2

Figure 1-302

1–11

CHAPTER 1. GENERAL DESCRIPTION

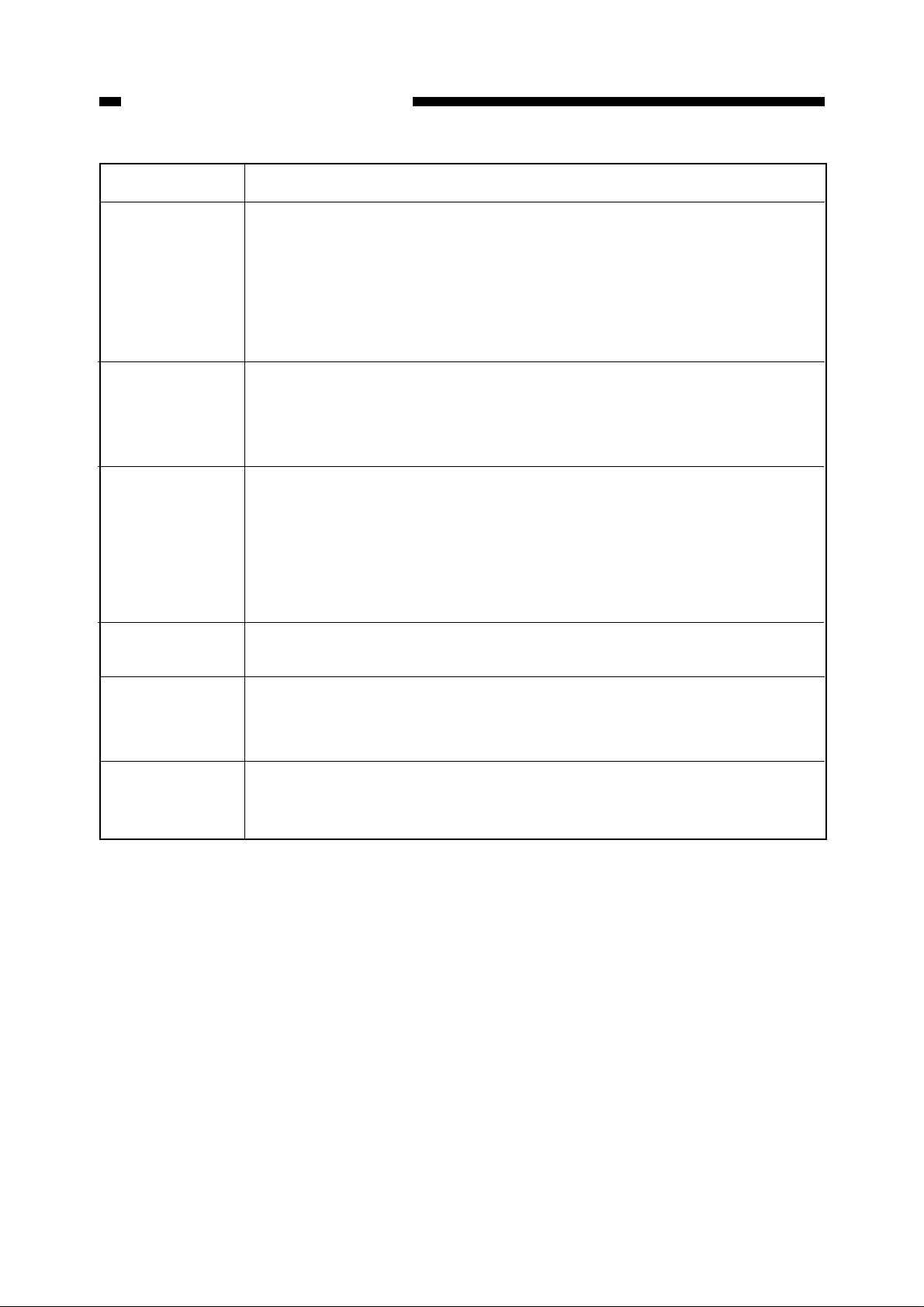

State Printer state

Online

Offline

Pause

Menu

¥ This machine can receive, analyze and print data. When printing is

started, "Printing" appears on the message display.

¥ While online, only the online key is functional. To use the other keys,

this machine should be offline or in the menu state.

¥ If no data is received for 5 minutes in this state, the printer enters the

sleep state.

¥ If data is transmitted from the host in the offline state, the printer will

ignore it.

¥ The roll media can be fed and the carriage can be moved.

¥ If no data is received for 20 minutes, the printer enters the sleep state.

¥ Printing is paused. As long as, there is sufficient space in the buffer

memory, data is received and analyzed continuously. When the reception

buffer becomes almost full in the pause state, the mode is shifted to

receive data at 1 byte/sec.

¥ By pressing the online key in the pause state, the printer will enter the

menu state.

¥ Menus and parameters can be set up. The menu items available when

paused are more limited than those available when in offline state.

Printing

Sleep

¥ The printer is printing.

¥ The operation panel keys cannot be used in the printing state. To use

the keys, the printer should be in the pause or menu state.

¥ All lamps and the display (other than the power lamp) are off.

¥ When paper is loaded and data is transmitted from the host, the printer

automatically enters the online state and starts printing.

Table 1-302

1–12

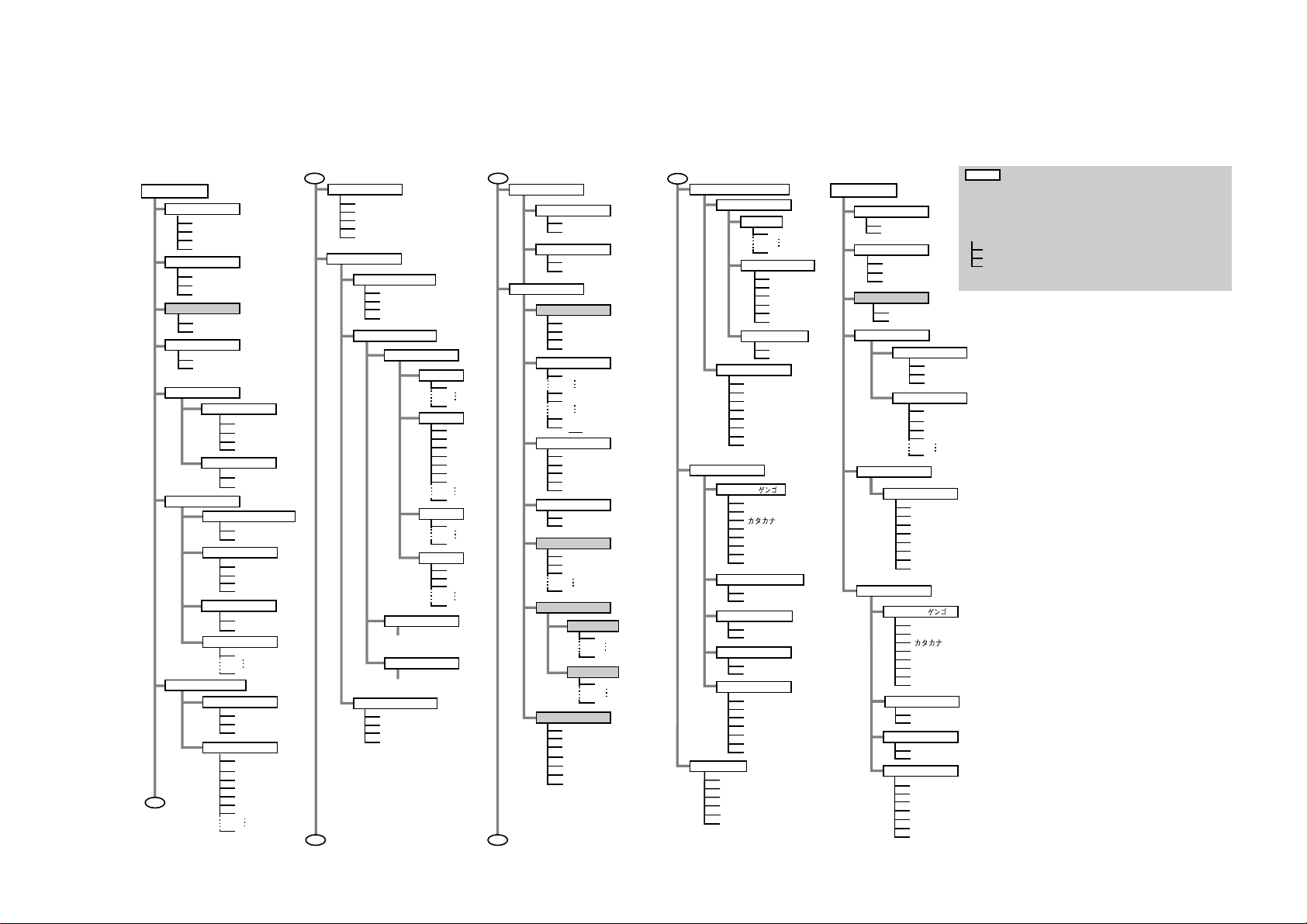

C. User Mode Menu

1. Menu guide

The following diagram shows the menu hierarchy of this printer.

Normal menu

Main menu

Print Operation

Abort Print

Buffer Clear

Replot

Force Print

Head Cleaning

All

Black

New T ank

Force Cutting

Yes

No

Adjustment

Auto Adjust

Auto Band-Adj.

Print Mode

Print Quality

Color/Mono

Media setup

Roll/Cut Sheet

Media Type

Margin

Copy

Auto Cut

Cut Type

Drying Time

A

Normal

Enhanced

Hi-Resolution

Draft

Color

Mono

Roll Media

Cut Sheet

Plain Paper

Coated Paper

Tracing Paper

Film

Normal

Large

1

99

Cut

Cut Line

No Cut

Off

Auto

30 seconds

1 minute

2 minutes

5 minutes

10 minutes

60 minutes

A

Emulation

Auto Sense

HP-GL

HP-GL/2+RTL

HP RTL

TIFF

Pen Setup

Select Tab le

Software

Pen T ab le 1

Pen T ab le 2

Pen T ab le 3

Modify Tab le

Pen T ab le 1

Pen

*1

*1

*1

*1

*1

Reset Tab le

*1

Width

Color

Join

Pen T ab le 2

(*Same as Pen Table 1)

Pen T ab le 3

(*Same as Pen Table 1)

Pen T ab le 1

Pen T ab le 2

Pen T ab le 3

All Pen Table

31

255

B

Line Type

Line Intersect

Overlay

Merge

Line Shading

On

Off

Print Layout

Auto Layout

Off

Nesting

Media Save

Best

Scale

0

15

1

2

3

4

5

7

9

0

1

2

3

9

100%

999%

99%

Auto

Rotation

180°

270°

Auto

Y-Mirror

Off

On

Layout Size

ISO-A

ISO-B

JIS-B

User

User Size

Nesting Timer

30 seconds

1 minute

2 minutes

5 minutes

10 minutes

30 minutes

60 minutes

1%

0°

90°

Length

Width

*2

*2

80mm

18000mm

80mm

627mm (914mm)

C

Internal Print

Interface Setup

RS-232C

EOP Timer

System Setup

Language ( )

Auto Adjust Mode

Feed Priority

Reset Defaults

Information

Demonstration

Menu Map

Color Palette

Setup List

Nozzle Check

Dump Mode

Baud Rate

2400bps

38400bps

Data Bit-Parity

7none

7even

7odd

8none

8even

8odd

Handshake

Hardware

Xon/Xoff

10 seconds

30 seconds

1 minute

2 minutes

5 minutes

10 minutes

30 minutes

60 minutes

English(mm)

English(inch)

Francais

Deutsch

Italiano

Espanol

Svenska

On

Off

Print Length

Band Joint

Yes

No

I/C: Ver.

I/Boot: Ver .

E/C: Ver .

E/Boot: Ver .

E/Slv: Ver .

Memory

Error

CB

Printing Menu

Main Menu

Print Operation

Abort Print

Buffer Clear

Head Cleaning

All

Black

New T ank

Force Cutting

Yes

No

Auto Cut

Cut Type

Drying Time

Interface Setup

EOP Timer

System Setup

Language ( )

Auto Adjust Mode

Feed Priority

Information

Cut

Cut Line

No Cut

Off

Auto

30 seconds

1 minute

60 minutes

10 seconds

30 seconds

1 minute

2 minutes

5 minutes

10 minutes

30 minutes

60 minutes

English(mm)

English(inch)

Francais

Deutsch

Italiano

Espanol

Svenska

On

Off

Print Length

Band Joint

I/C: Ver.

I/Boot: Ver .

E/C: Ver .

E/Boot: Ver .

E/Slv: Ver .

Memory

Error

: Indicates the menu

(Select the item using the up and down arrow keys.)

(The shaded items are indicated only in the roll media mode.)

*1: Can be set as a printer driver property, This fares priority

over the operation panel setting when printing using the driver.

*2: Can be set as a printer driver property, but both this setting

and that of the operation panel will affect the printing.

xxx

: Indicates set value.

xxx

Press the right or left arrow key to accept the set value.

xxx

Press the ENTER key to accept or execute the selection.

(Underlined items are indicated only in the cut sheet media

mode.)

1-13

CHAPTER 1. GENERAL DESCRIPTION

2. Menu and parameter setup

Menus and parameters are selected as described below.

1) By pressing the online key in the offline or pause state, the printer enters the menu state.

2) Select a menu item by pressing the right and left arrow keys.

3) After selecting a menu, move to the parameter menu by pressing the down arrow key.

CAUTION

Menu display varies depending on the state. (offline or pause)

4) Select parameters by pressing the right and left arrow keys.

5) Accept the selected parameter by pressing the Enter key.

CAUTION

When "Head Cleaning", "Force Cutting" or other item for immediate execution is selected,

the operation is started by pressing the Enter key. If the up arrow key is pressed instead, the

operation will not start and the selected parameter is cancelled.

3. Details of user mode menus

The user mode menus are shown below.

[1] Print Operation

Used to change the current print operation.

• Abort Print

Printing is stopped in the pause state.

• Buffer Clear

All current operations are stopped from

• Replot

The data printed last is printed again.

• Force Print

The EOP timer is started and the printer

is forced to print from the printing

stand-by state.

in the offline or pause state, and all

printing data in the memory are cleared.

1–14

CHAPTER 1. GENERAL DESCRIPTION

[2] Head Cleaning

Used to clean the cartridge heads.

• All

All heads are cleaned.

• Black

Only the black head is cleaned.

• New Tank

If the ink tank has been removed, use this

menu to prevent non-discharge of ink.

[3] Force Cutting

Used to cut the set paper.

Paper is cut.

• Yes

Paper is cut.

•No

Paper is not cut.

[5] Print Mode

a. Print Quality

[Default: Normal]

The print quality can be selected for the

type of data or paper.

• Draft

For higher-speed, lower-quality output.

• Normal

For printing line drawings, etc.

• Enhanced

For printing files including graphics or

solid printing.

• High-Resolution (monochrome only)

For printing monochrome line drawings at an equivalent resolution to 720

dpi.

[4] Adjustment

• Auto Adjust

Printing position is automatically

adjusted.

• Auto Band-Adj.

Paper feed rate is automatically

adjusted.

b. Color/Mono

[Default: Color]

Monochrome or color mode can be se-

lected.

• Color

Color data will be printed in color.

• Mono

Color data will be printed in gray scale.

1–15

CHAPTER 1. GENERAL DESCRIPTION

[6] Media Setup

Used to change paper settings.

a. Roll/Cut Sheet

[Default: Previous setting preserved]

Select roll media or cut sheet.

• Roll Media

Select this to use roll media. If a cut

sheet is loaded, it will be ejected.

• Cut Sheet

Selected when cut paper is used. If roll

media is loaded, it is reverse fed and

withdrawn.

b. Media Type [Default: Plain paper]

[7] Auto Cut

a. Cut Type

[Default: Cut]

Select the type of cut for roll media after

completion of printing.

•Cut

Cuts the roll media automatically after

completion of printing.

• Cut Line

After completion of printing, a cutting

line is printed.

• No Cut

After completion of printing, the roll

media is not cut.

The following media types can be se-

lected:

• Plain Paper

• Coated Paper

• Tracing Paper

• Film

c. Margin [Default: Normal]

Margin size at the media leading edge can

be selected.

• Normal

Leaves a margin of 5mm.

• Large

Leaves a margin of 15mm.

d. Copies [Default: 1]

Specify the number of copies to be

b. Drying Time (only for roll media)

[Default: Off]

Sets the time for drying the ink after

completion of printing.

•Off

Paper is ejected as usual.

• Auto

Optimum drying time is automatically

selected according to the media type and

printing mode.

In the case of draft mode, the drying

time is the same as for [Off].

• 30 sec., 1 min., 2 min., 5 min.,

10 min., 20 min., 30 min., 40 min.,

50 min., 60 min.

printed.

1 - 99

1–16

CHAPTER 1. GENERAL DESCRIPTION

CAUTION

In the draft mode, the ink may not

dry, depending on the environment.

Set the drying time as required.

REFERENCE

Drying time for each media type is as

follows:

• Plain paper: 30 sec.

• Coated paper: none

• Tracing paper: 2 min.

• Film: 7 sec.

[8] Emulation

• HP RTL

Should only be used when printing

raster data. After the raster data is

received and 1 band is analyzed, printing is started.

• HP-GL (759x)

Conforms to the HP-759X series

format.

[9] Pen Setup

Composed of the pen setup selection

menu, pen table changing menu, and pen

table initialization menu.

a. Select Table

[Default: Auto Sense]

Emulation can be set to match the file type

output from the computer.

• Auto Sense

HP-GL/2+RTL, HP RTL, HP-GL, and

TIFF data is automatically detected and

printed.

• HP-GL/2+RTL

Emulates HP-GL/2 and HP-RTL. Data

is accumulated in the memory buffer

and printing is started with the EOP

command, or when the EOP timer times

out.

[Default: Software]

Specifies whether to use the setting desig-

nated by the software or the pen table setting.

• Software

Pen setup from the application is

used. (See Table 1-305.)

• Pen Table (1 to 3)

Pen setup (pen table) stored in the

printer can be used. (See Table 1-304.)

1–17

Loading...

Loading...