Canon BJC-6000 Service Manual

QY8-1361-000

JAN. 1999

COPYRIGHT 1999 CANON INC. CANON BJC-6000 SE 0199 0.30-0 PRINTED IN JAPAN (IMPRIME AU JAPON)

REVISION 0

0199 SE 0.30-0

Target Readers

This manual is published by Canon Inc. for qualified persons and contains the necessary technical

information for technical theory, installation, maintenance, and repair of products. This manual

covers all localities where the products are sold. For this reason, it may contain information that does

not apply to your locality.

Revisions

This manual may include technical inaccuracies or typographical errors due to improvements or

changes in the products. When amendments are made to the content of this manual, Canon will issue

technical information as the need arises. In the event of major alterations to the content of this manual

over a long or short period, Canon will publish a revised version of the manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names appearing in this manual are the registered trademarks or

trademarks of the individual companies.

Copyright

This manual is copyrighted and all rights reserved. Under the copyright laws, this manual may not

be copied, reproduced, or translated into other languages, in whole or in part, without the express

written consent of Canon Inc. except in the case of internal business use.

Copyright 1999 by Canon Inc.

CANON INC.

BJ Products Quality Support Dept.

16-1, Shimonoge 3-chome, Takatsu-ku, Kawasaki-shi, Kanagawa 213, Japan

This manual was produced on an Apple Macintosh Power Mac 9600/233 personal computer and

Apple LaserWriter II NTX-J laser beam printer; final pages were printed on Varityper 5300 with

4000-J RIP. A Canon mo-5001S Magneto-Optical Storage Subsystem with mo-502M Magneto-Optical

Storage Disk Cartridge and mo-IF2 interface kit were used for storing large volumes of page layout and

graphic data for this manual.

All graphics were produced with MACROMEDIA FREEHAND 7.0J.

All documents and all page layouts were created with QuarkXPress 3.3J.

I. ABOUT THIS MANUAL

This manual is divided into five parts containing the information required for servicing

the BJC-6000 printer.

Part 1: Safety and Precautions

This part contains information on how to service the unit safety. It is very important,

and must be read.

Part 2: Product Specifications

This part outlines the product and its specifications.

Part 3: Ope r ating Instructions

This part explains how to operate the unit properly, how it is installed, and how to

use the service mode.

P art 4: Technical Reference

This part outlines the unit operation giving a technically.

Part 5: Maintenance

This part explains maintenance of the unit. It includes details of disassembly / assembly,

adjustments required when assembling, troubleshooting procedures, and wiring /

circuit diagrams, etc.

This manual does not contain complete information required for

disassembling and assembling the BJC-6000 printer. Please also refer to

the separate Parts Catalog.

I

REF.

II. TABLE OF CONTENTS

Page

Part 1: SAFETY AND PRECAUTIONS

1 - 1 1. SAFETY PRECAUTIONS

1 - 1 1.1 Moving Parts

1 - 2 1. 2 Ink Stains

1 - 2 1.2.1 Ink paths

1 - 3 1.2.2 Ink mist

1 - 4 1 .3 Live Electrical Parts

1 - 5 2. MACHINE PRECAUTIONS

1 - 5 2.1 BJ Cartridges

1 - 5 2.1.1 BJ cartridge handling

1 - 6 2.1.2 Automatic capping

1 - 6 2.1.3 When not using the printer

1 - 6 2.1.4 Ink's electroconductivity

1 - 7 2.2 Ink Tanks

1 - 7 2.2.1 Unpacking the ink tank

1 - 7 2.2.2 Ink tank handling

1 - 8 2.3 Printer Handling

1 - 8 2.3.1 Spurs

1 - 9 2.3.2 Damage due to static electricity

1 -10 2.3.3 Ink leakage prevention

1 -11 3. NOTES ON SERVICING

1 -11 3.1 EEPROM Data

1 -12 3.2 Static Electricity

1 -13 3.3 Disassembly and Reassembly

1 -14 3 .4 Self Diagnosis

Part 2: PRODUCT SPECIFICATIONS

2 - 1 1. PRODUCT OUTLINE

2 - 1 1. 1 Outline

2 - 2 1.2 Features

2 - 3 1.3 BJ Cartridge

2 - 3 1.3.1 Black BJ cartridge

2 - 3 1.3.2 Color BJ cartridge

2 - 4 1.3.3 Photo BJ cartridge

2 - 4 1. 4 BJ Cartridge Container

2 - 5 1.5 Consumables

2 - 5 1.5.1 Black, color, and photo BJ cartridges

2 - 5 1.5.2 Ink tanks

2 - 6 2. SPECIFICATIONS

2 - 6 2 . 1 General Specifications

2 - 8 2. 2 Paper Specifications

2 -10 2.3 Interface Specifications

Part 3: OPERATING INSTRUCTIONS

3 - 1 1. PRINTER SETUP

3 - 1 1. 1 Unpacking

3 - 2 1. 2 Installation Location

3 - 3 1. 3 Installation

3 - 3 1.3.1 Connecting the interface cable

3 - 3 1.3.2 Connecting the power cord

3 - 3 1.3.3 Installing the BJ cartridges

II

Page

3 - 9 1.3.4 Aligning the print heads

3 -10 1.4 Names of Parts and Their Functions

3 -11 2. TRANSPORTING THE PRINTER

3 -11 2.1 Transporting the Printer

3 -12 3. PRINTER SERVICE FUNCTIONS

3 -12 3.1 Error Indications

3 -13 3.2 Description of Error Indications

3 -14 3.3 BJ Status Monitor

3 -14 3.3.1 Main functions of the BJ status monitor

3 -14 3.3.2 Items displayed on the BJ status monitor

3 -15 3. 4 Function Settings

3 -15 3.4.1 Function settings using the printer driver

3 -16 3. 5 Off-Line Operations

3 -16 3.5.1 Cleaning

3 -16 3.5.2 Nozzle check pattern printing

3 -17 3.5.3 Roller cleaning

3 -18 3.6 Service Mode

3 -18 3.6.1 Service mode operations

3 -19 3.6.2 Service/factory test print

3 -20 3.6.3 EEPROM information print

3 -21 3.6.4 Resetting EEPROM

3 -21 3.6.5 Model setting

3 -21 3.6.6 Automatic head position adjustment

Part 4 : TECHNICAL REFERENCE

4 - 1 1. O VERVIEW

4 - 1 1 .1 Printer Block Diagram

4 - 2 1.2 Power On Sequence Flowchart

4 - 3 1.3 Flow of Print Signals

4 - 4 1.4 Print Driving

4 - 4 1.4.1 Print drive control

4 - 6 1.4.2 Print drive method

4 - 9 1. 5 Power-Off Sequence Flowchart

4 -10 2. FIRMWARE

4 -10 2. 1 Interface

4 -10 2.1.1 Compatible mode

4 -11 2.1.2 Nibble mode

4 -12 2.1.3 ECP mode

4 -13 2.2 Print Control

4 -13 2.2.1 Print mode

4 -13 2.2.2 Multi-drop print

4 -13 2.2.3 Photo-print

4 -13 2.2.4 Automatic switching control of printing nozzles

4 -15 2.3 Automatic Printing Position Alignment Function

4 -1 6 2 . 4 Pause Between Scanning

4 -16 2. 5 Pause Between Pages

4 -16 2.6 Smear Control

4 -16 2. 7 Auto Power ON/OFF

4 -16 2.8 Head Overheat Protection

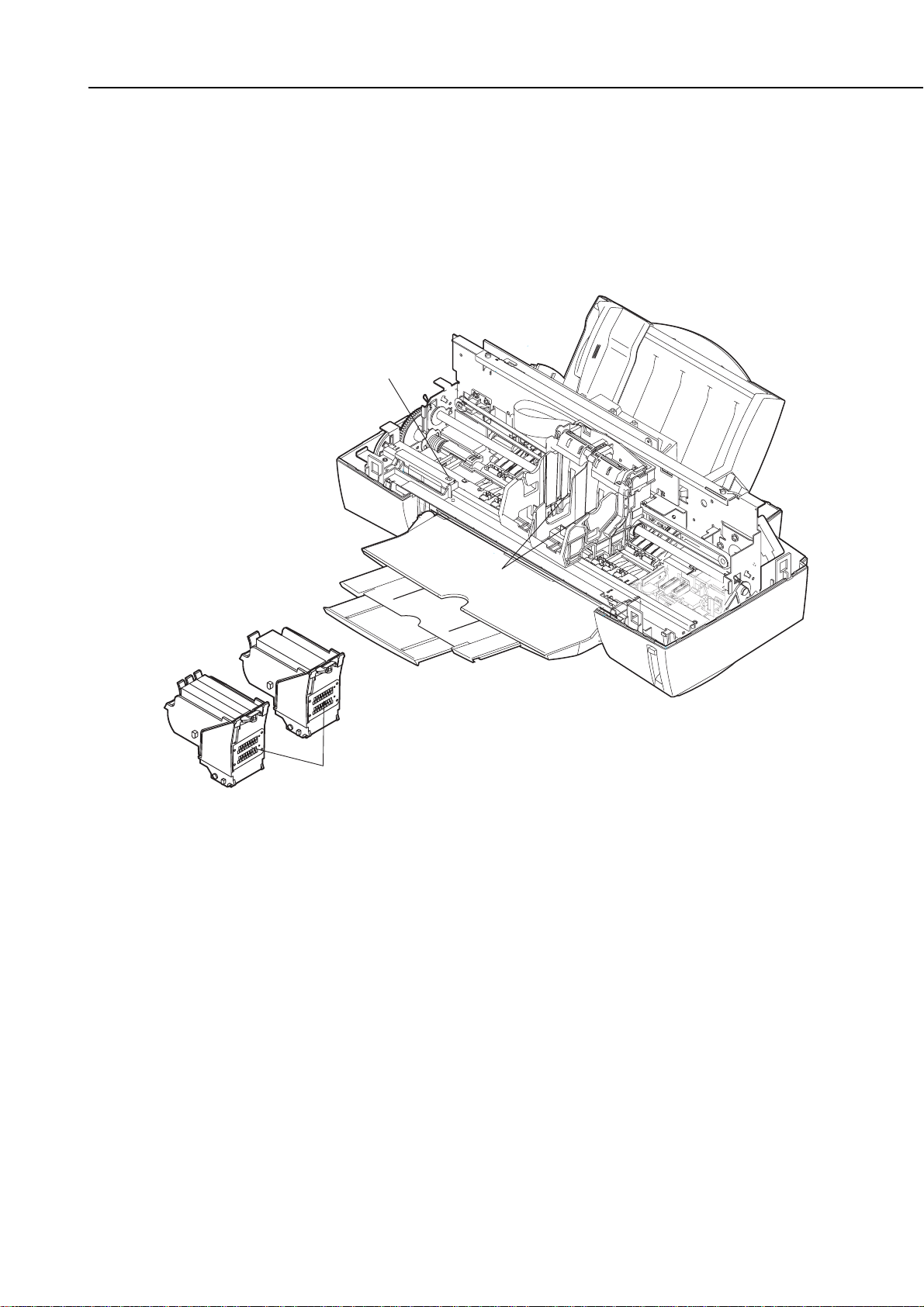

4 -17 3. PRINTER'S MECHANICAL SYSTEM

4 -17 3. 1 Overview

4 -17 3.1.1 BJ cartridge unit

4 -17 3.1.2 Carriage unit

III

Page

4 -18 3.1.3 Purge unit

4 -18 3.1.4 Paper feed unit

4 -19 3.2 BJ Cartridge

4 -19 3.2.1 Construction of the Black BJ cartridge

4 -20 3.2.2 Construction of the Color/Photo BJ cartridge

4 -21 3.2.3 Construction of the bubble jet head unit

4 -25 3.3 Purge Unit

4 -25 3.3.1 Function of the purge unit

4 -26 3.3.2 Construction of the purge unit

4 -28 3. 4 Paper Feed Unit

4 -28 3.4.1 Functions of the paper feed unit

4 -30 3.4.2 Construction of the paper feed unit

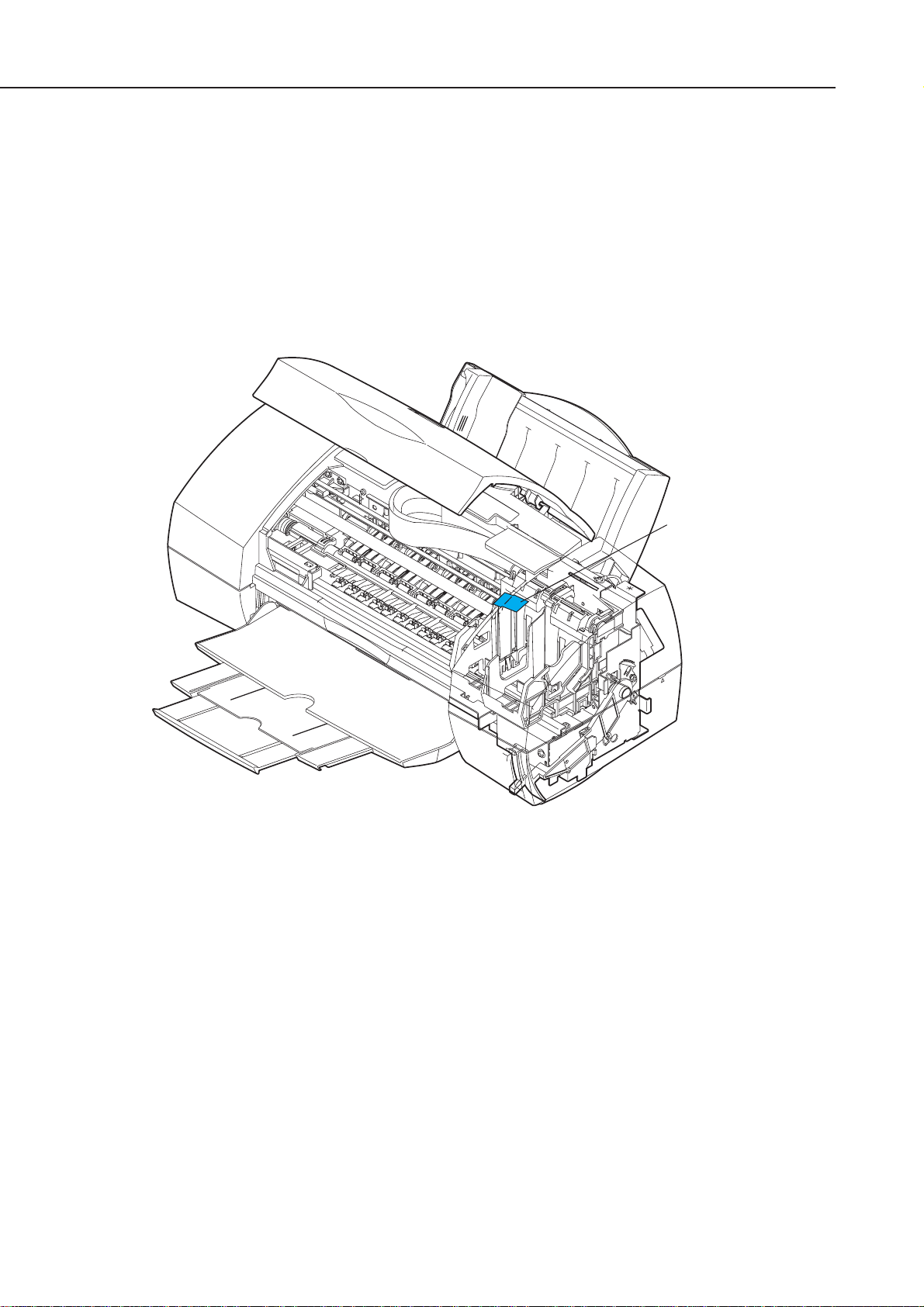

4 -32 3.5 Carriage Unit

4 -32 3.5.1 Functions of carriage unit

4 -33 3.5.2 Construction of the carriage unit

4 -36 4 PRINTER'S ELECTRICAL SYSTEM

4 -36 4. 1 Overview

4 -37 4. 2 Control Unit

4 -37 4.2.1 Control unit block diagram

4 -38 4.2.2 Logic Components

4 -41 4 .3 Power Supply Unit

4 -41 4.3.1 Power Supply Unit Block Diagram

4 -41 4.3.2 Construction o f Power Supply Unit

4 -42 5. DETECTION FUNCTIONS

4 -42 5 .1 Detection with Sensors

4 -42 5.1.1 Home position sensor

4 -42 5.1.2 Paper end sensor

4 -42 5.1.3 Print position sensor

4 -43 5.1.4 Ink sensor

4 -43 5.1.5 Cover sensor

4 -43 5.1.6 Pump sensor

4 -43 5.1.7 Printer temperature sensor (TH201)

4 -44 5.1.8 Head temperature sensor

4 -44 5.2 Other Detection Functions

4 -44 5.2.1 Waste ink amount detection

4 -44 5.2.2 BJ cartridge detection

Part 5: MAINTENANCE

5 - 1 1. MAINTENANCE

5 - 1 1.1 Parts for Periodic Replacement

5 - 1 1. 2 List of Consumables

5 - 1 1. 3 List of Periodic Maintenance

5 - 2 2. SERVICE TOOLS

5 - 2 2.1 List of Tools

5 - 3 3. APPLYING GREASE

5 - 4 4. DISASSEMBLY AND REASSEMBLY

5 - 4 4.1 Disassembly and Reassembly

5 - 4 4.2 Notes on Disassembly and Reassembly

5 - 4 4.2.1 Unlocking the carriage

5 - 5 4.2.2 Removing the printer unit

5 - 6 4.2.3 Removing the ASF unit

5 - 6 4.2.4 Removing th e a dj u st able bearings suppor ting the carriage shaft

5 - 7 4.2.5 Paper feed gears

5 - 8 5. ADJUSTMENTS AND SETTINGS

5 - 8 5.1 Adjustments and Settings

IV

5 - 8 5.1.1 EEPROM setting

5 - 8 5.1.2 Carriage belt tension adjustment

5 - 8 5.1.3 ASF gear position adjustment

5 - 8 5.1.4 Head gap adjustment

5 - 9 5. 2 Adjustment/Setting Procedures

5 - 9 5.2.1 EEPROM setting

5 - 9 5.2.2 Carriage belt tension adjustment

5 -10 5.2.3 ASF gear position adjustment

5 -11 5.2.4 Head gap adjustment

5 -13 6. TROUBLESHOOTING

5 -13 6.1 Troubleshooting Overview

5 -13 6.1.1 Overview

5 -13 6.1.2 Notes on troubleshooting

5 -15 6.2 Diagnosis

5 -15 6.2.1 Initial flowchart

5 -18 6.2.2 Action

5 -36 7. CONNECTOR POSITIONS AND PIN ASS

5 -36 7.1 Control Board

5 -40 7.2 Carriage Board

5 -43 7.3 BJ Cartridge

5 -44 7.4 AC adapter

5 -44 7.5 DC power supply cable

5 -45 7.6 Carriage Motor

5 -45 7. 7 Paper Feed Motor

5 -46 7. 8 Ink Sensor

5 -46 7. 9 Print Position Sensor

5 -46 7.10Pump Sensor

5 -47 8. CIRCUIT DIAGRAMS

5 -47 8.1 Parts Layout

5 -47 8.1.1 Control board

5 -48 8.1.2 Carriage board

5 -49 8.2 Circuit Diagrams

V

III. ILLUSTRATION INDEX

Page

Part 1: SAFETY AND PRECAUTIONS

1 - 1 Figure 1- 1 The Printer's Moving Parts

1 - 2 Figure 1- 2 Ink Paths

1 - 3 Figure 1- 3 Ink Mist

1 - 4 Figure 1- 4 Live Electrical Parts

1 - 5 Figure 1- 5 BJ Cartridges

1 - 7 Figure 1- 6 Unpacking the Ink Tank

1 - 7 Figure 1- 7 Installing the Ink Tan k

1 - 8 Figure 1- 8 Spurs

1 - 9 Figure 1- 9 Damage Due to Static Electricity

1 -10 Figure 1-10 Capping Position

1 -12 Figure 1- 11 Control Board and Other Electrical Components

1 -13 Figure 1- 12 How to Disengage a Plastic Hook

Part 2: PRODUCT SPECIFICATIONS

2 - 1 Figure 2- 1 Printer Appearance

2 - 3 Figure 2- 2 Black BJ Cartridge

2 - 3 Figure 2- 3 Color BJ Cartridge

2 - 4 Figure 2- 4 Photo BJ Cartridge

2 - 4 Figure 2- 5 BJ Cartridge Container

2 - 5 Figure 2- 6 BJ Cartridges

2 - 5 Figure 2- 7 Ink Tanks

2 - 9 Figure 2- 8 Printable Area

2 -15 Figure 2- 9 Timing Chart (Compatible mode)

2 -16 Figure 2-10 Timing Char t (Nibble mode)

2 -16 Figure 2-11 Timing Chart (ECP mode)

Part 3: OPERATING INSTRUCTIONS

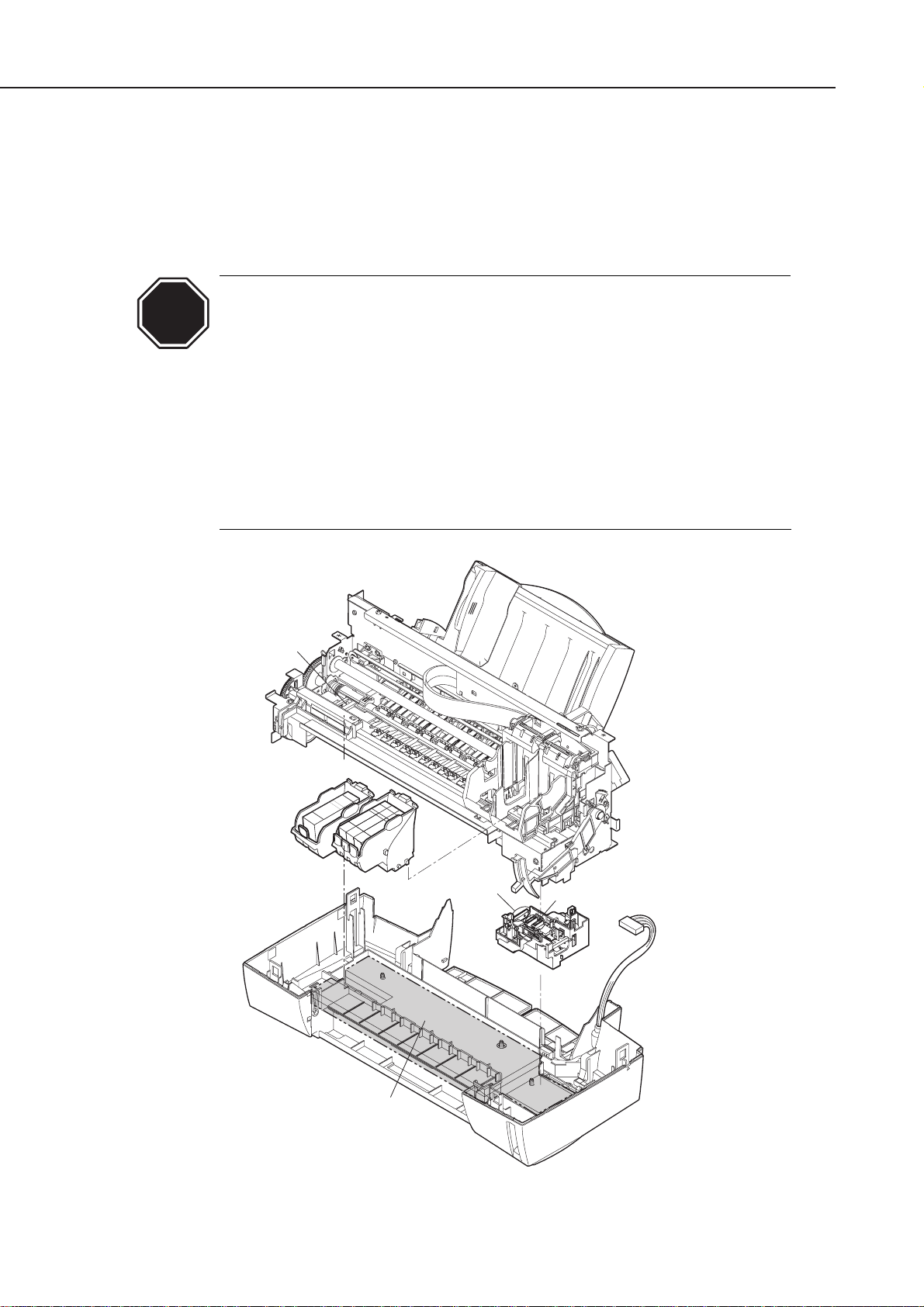

3 - 1 Figure 3- 1 Packaging

3 - 2 Figure 3- 2 Printer Dimensions

3 - 3 Figure 3- 3 Connecting the Interface Cable

3 - 3 Figure 3- 4 Connecting the Power Cord

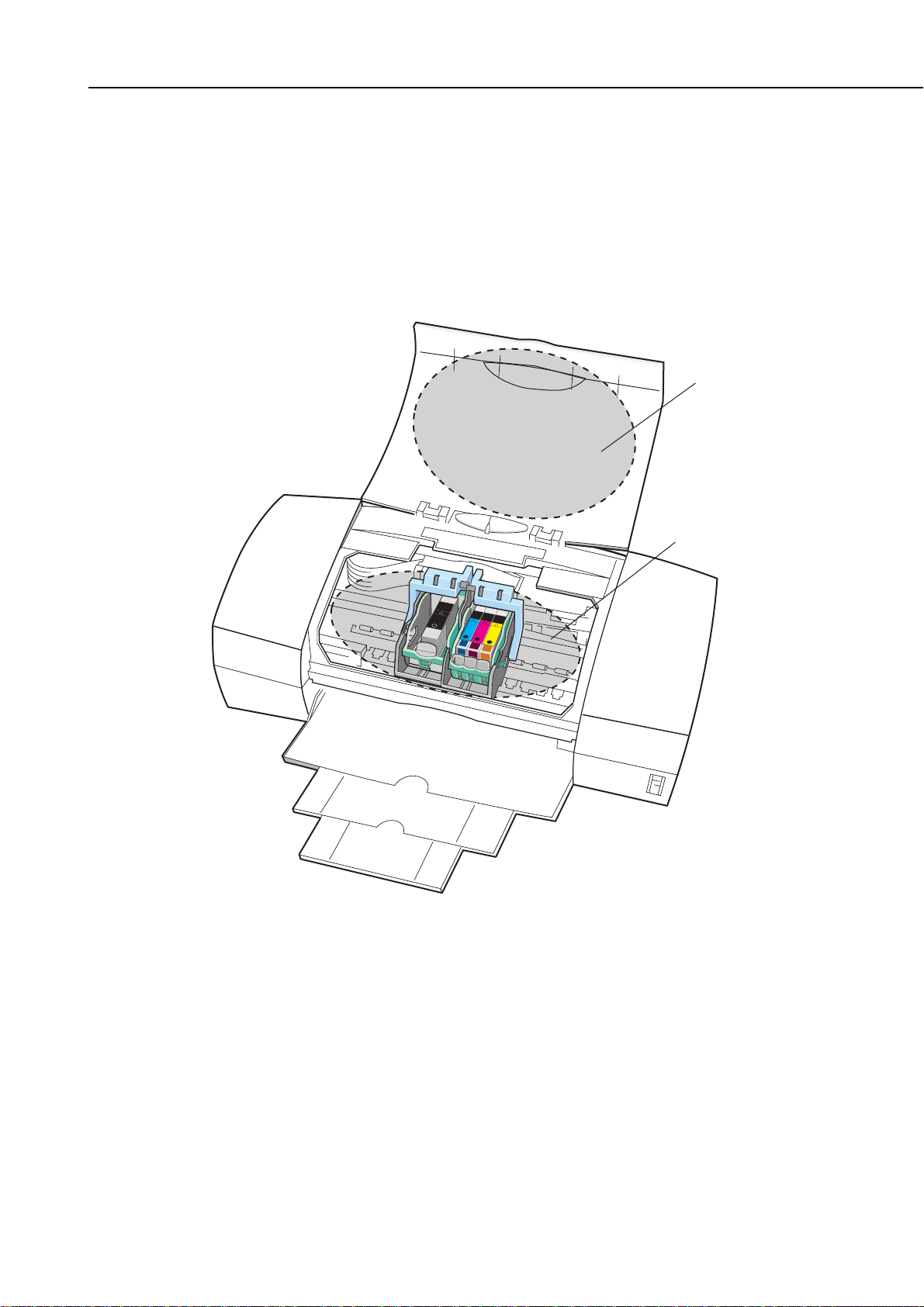

3 - 4 Figure 3- 5 Removing Head Cap and Tape from BJ Cartridge

3 - 5 Figure 3- 6 Installing BJ Cartridges

3 - 6 Figure 3- 7 Installing the Ink Tanks

3 - 7 Figure 3- 8 Replacing an Ink Tank

3 - 8 Figure 3- 9 Cartridge Container

3 - 9 Figure 3-10 Print Position Adjustment Pattern

3 -10 Figure 3- 11 Names of Parts and Their Functions

3 -12 Figure 3-12 Operator Panel

3 -14 Figure 3- 13 BJ Status Monitor (Sample)

3 -15 Figure 3- 14 Printer Driver Utility (Sample)

3 -17 Figure 3-15 Nozzle Check Pattern Print (Sample for Black/Color Cartridge)

3 -19 Figure 3-16 Service/Factory Test Print

3 -20 Figure 3-17 EEPROM Information Print (Sample)

Part 4 : TECHNICAL REFERENCE

4 - 1 Figure 4- 1 Printer Block Diagram

4 - 2 Figure 4- 2 Initial Sequence Flowchart

4 - 3 Figure 4- 3 Flow of Print Signals

4 - 4 Figure 4- 4 Printing Sequence (Black BJ cartridge, HQ mode)

4 - 6 Figure 4- 5 Print Drive Method (Multi-drop, forward direction)

VI

Page

4 - 7 Figure 4- 6 Print Drive Method (1440 x 720 dpi, forward direction)

4 - 8 Figure 4- 7 Print Drive Method (Reverse direction)

4 - 9 Figure 4- 8 Power-Off Sequence Flowchart

4 -10 Figure 4- 9 Interfacing Timing (Compatible Mode)

4 -11 Figure 4-10 Interface Timing (Nibble Mode)

4 -12 Figure 4-11 Interface Timing (ECP mode, reverse transfer)

4 -15 Figure 4-12 Automatic Printing Position Alignment

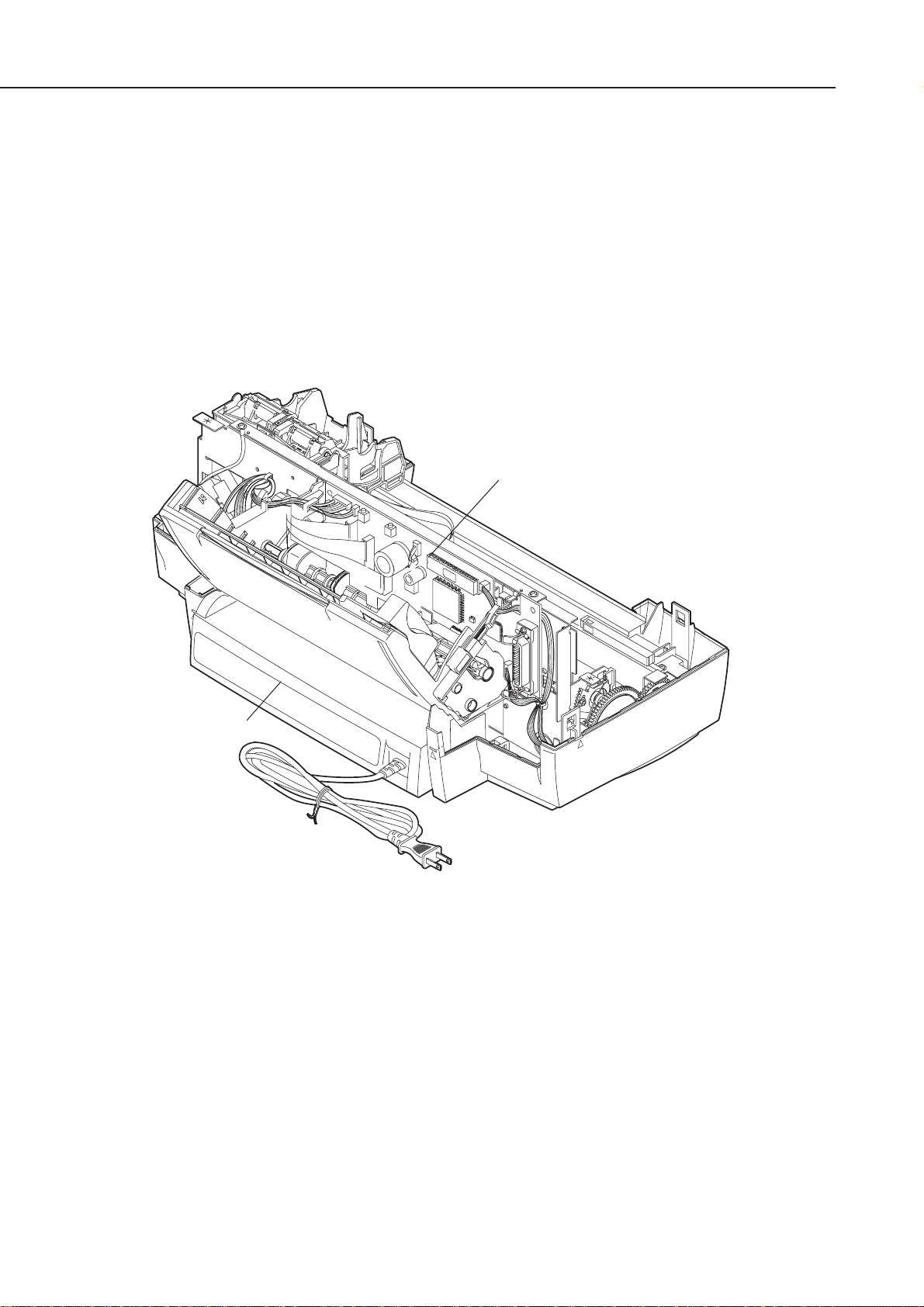

4 -17 Figure 4-13 Printer's Mechanical System

4 -19 Figure 4- 14 Black BJ Cartridge

4 -20 Figure 4- 1 5 Color/Photo BJ Cartridge

4 -21 Figure 4-16 Bubble Jet Nozzle (part)

4 -2 2 Figure 4- 17 Nozzle Arrangement

4 -22 Figure 4- 18 Signal Contacts

4 -25 Figure 4- 19 Purge Unit

4 -26 Figure 4- 20 Purge Unit

4 -27 Figure 4- 21 Pumping Operations

4 -28 Figure 4- 22 Paper Feed Pat h

4 -29 Figure 4- 2 3 Paper Thickness Adjustment Mechanism

4 -30 Figure 4- 24 Paper Feed Unit

4 -32 Figure 4-25 Carriage Unit

4 -33 Figure 4-26 Carriage Unit

4 -34 Figure 4-27 BJ Cartridge Maintenance

4 -35 Figure 4- 28 Drive Switching Unit

4 -35 Figure 4-29 Operation of the Drive Switching Unit

4 -36 Figure 4-30 Printer's Electrical System

4 -37 Figure 4-31 Control Unit Block Diagram

4 -37 Figure 4- 32 Control Unit Function Diagram

4 -38 Figure 4- 33 Control Board

4 -41 Figure 4- 3 4 Power Supply Unit Block Diagram

4 -42 Figure 4-35 Sensor Positions

4 -43 Figure 4-36 Ink Sensor

Part 5: MAINTENANCE

5 - 3 Figure 5- 1 Grease Points

5 - 4 Figure 5- 2 Unlocking the Carriage

5 - 5 Figure 5- 3 Removing the Printer Unit

5 - 6 Figure 5- 4 Removing the ASF Unit

5 - 6 Figure 5- 5 Adjustable Bearings Supporting the Carriage Shaft

5 - 7 Figure 5- 6 Feed Gear Unit Precautions

5 - 9 Figure 5- 7 Carriage Belt Tension Adjustment

5 -10 Figure 5- 8 ASF Gear Position Adjustment

5 -11 Figure 5- 9 Head Gap Adjustment (1)

5 -12 Figure 5- 10 Head Gap Adjustment (2)

5 -36 Figure 5- 11 Control Board

5 -40 Figure 5-12 Carriage Board

5 -43 Figure 5-13 BJ Cartridge

5 -44 Figure 5-14 AC adapter

5 -44 Figure 5- 15 DC Power Supply Cable

5 -45 Figure 5-16 Carriage Motor

5 -45 Figure 5- 17 Paper Feed Motor

5 -46 Figure 5-18 Ink Sensor

5 -46 Figure 5-19 Print Position Sensor

5 -46 Figure 5-20 Pump Sensor

5 -47 Figure 5- 21 Control Board

5 -48 Figure 5-22 Carriage Board

VII

VIII

IV. TABLE INDEX

Page

Part 3: OPERATING INSTRUCTIONS

3 -12 Table 3- 1 Error Indications

Part 4 : TECHNICAL REFERENCE

4 -14 Table 4- 1 Print Mode List

4 -23 Table 4- 2 Signal Contacts

Part 1

Page

1 - 1 1. SAFETY PRECAUTIONS

1 - 1 1.1 Moving Parts

1 - 2 1. 2 Ink Stains

1 - 4 1 .3 Live Electrical Parts

1 - 5 2. MACHINE PRECAUTIONS

1 - 5 2.1 BJ Cartridges

1 - 7 2.2 Ink Tanks

1 - 8 2.3 Printer Handling

1 -11 3. NOTES ON SERVICING

1 -11 3.1 EEPROM Data

1 -12 3.2 Static Electricity

1 -13 3.3 Disassembly and Reassembly

1 -14 3 .4 Self Diagnosis

SAFETY AND

PRECAUTIONS

1. SAFETY PRECAUTIONS

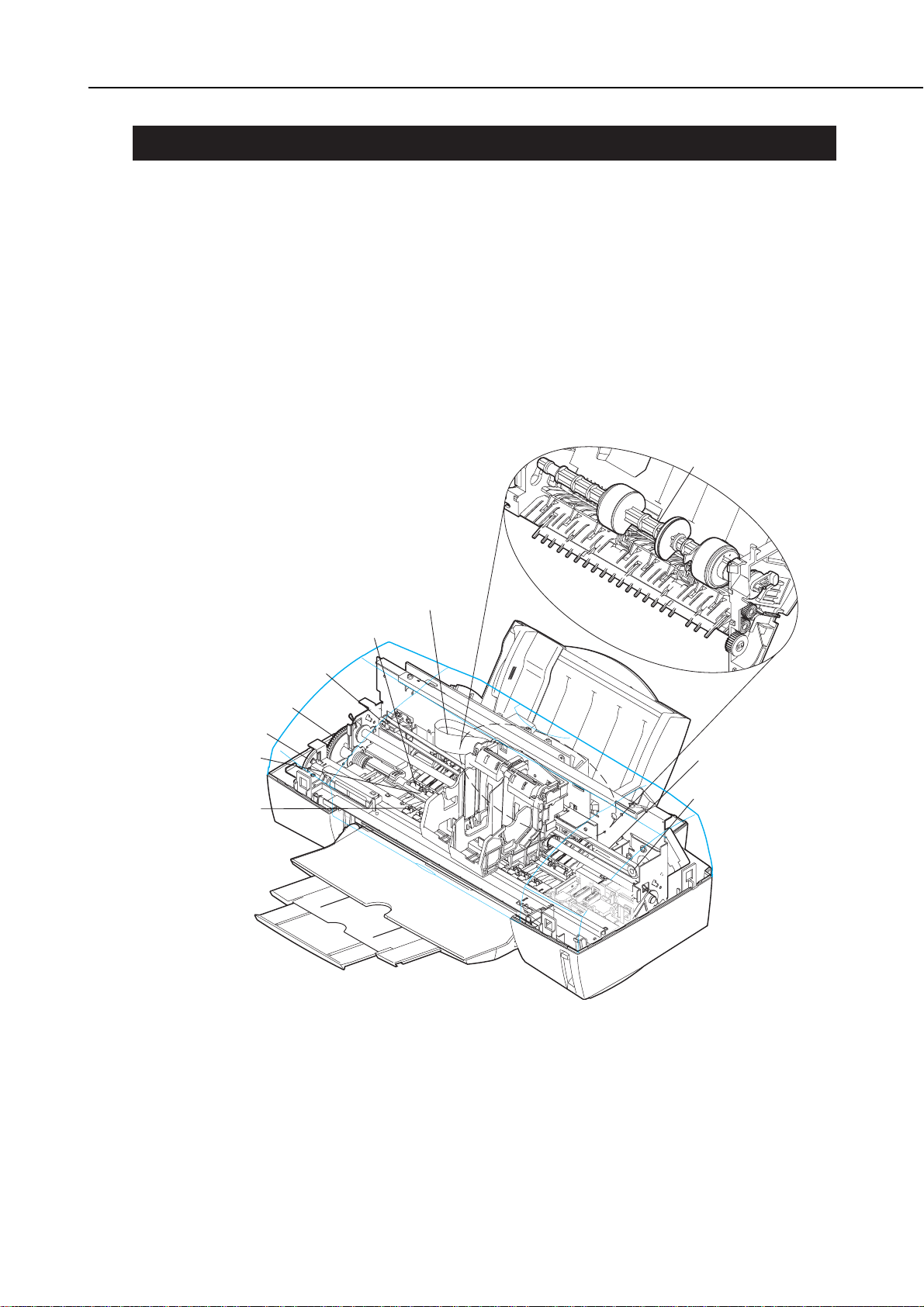

1.1 Moving Parts

Be careful not to get your fingers, hair, clothing, or accessories caught in the moving

parts of the printer.

The moving parts are driven either by the carriage motor or paper feed motor. The

carriage motor-related moving parts include the carriage, carriage belt, and carriage

ribbon-cable. The paper feed motor-related moving parts include the paper feed gears,

paper feed rollers, pinch rollers, eject roller gears, spurs, and pick-up rollers.

To prevent injuries, the printer will stop after moving the carriage to the cartridge

replacement position if the cover is opened.

1-1

BJC-6000

Part 1: Safety and Precautions

Figure 1-1 The Printer's Moving Parts

Pick-up Roller

Paper Feed Gear

Eject Roller Gear

Paper Feed Roller

Spur

Carriage Ribbon Cable

Pressure Roller

Idler Pulley

Carriage Belt

Carriage Motor

1.2 Ink Stains

1.2.1 Ink paths

Be careful not to touch the ink paths. Ink on hands could stain the printer, work

table, or clothes. The ink paths include the BJ cartridge ink tank outlet, the BJ

cartridge ink filters and nozzles, the maintenance jet receiving section, the head caps,

the wipers, and the waste ink absorber.

The ink is not harmful to the human body, but contains some organic

solvents:

The black ink contains glycerin 56-81-5 and diethylene glycol 111-46-6.

The yellow ink contains glycerin 56-81-5 and isopropyl alcohol 67-63-0.

The cyan, magenta, photo-cyan, photo-magenta and photo-black ink

contain glycerin 56-81-5, isopropyl alcohol 67-63-0, ethylene glycol 10721-1, and diethylene glycol 111-46-6.

Be careful not to get the ink into your mouth or eyes. If the ink gets into

your eyes, wash with plenty of water and consult a doctor. In case you

have swallowed a large amount of ink, consult a doctor immediately.

The ink contains dyes. If clothing is stained with the ink, the ink may not

be removed completely.

Part 1: Safety and Precautions

BJC-6000

1-2

Figure 1-2 Ink Paths

CAUTION

Maintenance

Jet Receiving

Section

BJ Cartridges

Wiper

Head Cap

Waste Ink Absorber

1.2.2 Ink mist

The BJ cartridge ejects ink onto the paper during printing. After the printer is used

for a long period or used heavily, part of the ink ejected from the nozzles, or ink mist

bouncing back from the paper could accumulate and contaminate the platen, front

cover, as well as the periphery of the purge unit. Carefully wipe off the ink mist with

a dampened soft cloth so that hands or clothing will not be stained by contaminated

parts during servicing.

1-3

BJC-6000

Part 1: Safety and Precautions

Figure 1-3 Ink Mist

Front Cover

Platen

1.3 Live Electrical Parts

When the printer is plugged into a wall outlet, the power supply unit of the printer is

live, even if the power is switched off with the

POWER

button. Be careful not to get an

electric shock or damage sensitive elements if you are checking a live printer with the

cover removed.

Part 1: Safety and Precautions

BJC-6000

1-4

Figure 1-4 Live Electrical Parts

Control Board

2. MACHINE PRECAUTIONS

2.1 BJ Cartridges

2.1.1 BJ cartridge handling

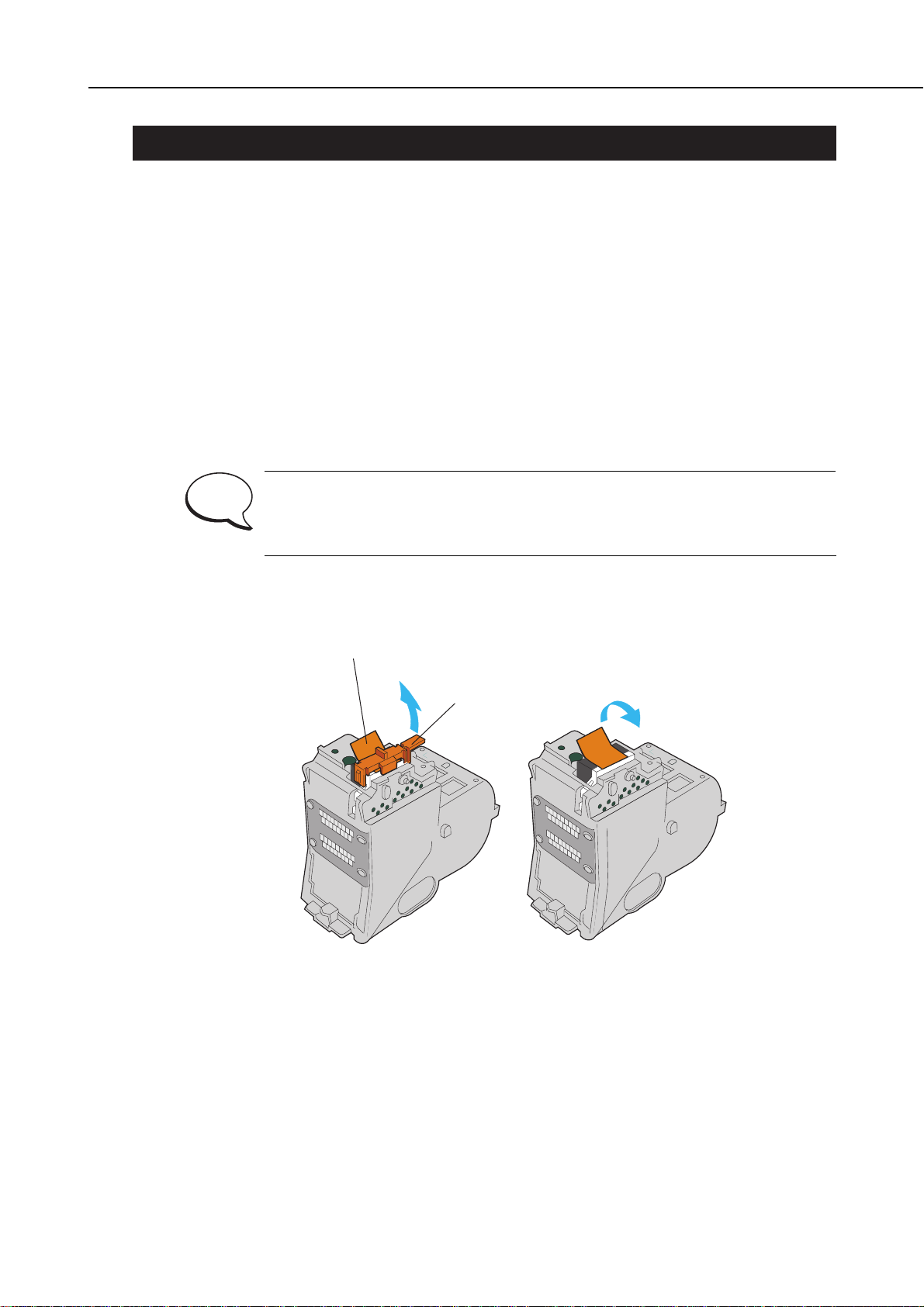

Do not unpack the BJ cartridge until you are ready to use it. Before installing the BJ

cartridge in the printer, carefully remove the head cap which protects the nozzles, the

protective tape, and the protective tank. To prevent the nozzles or other ink paths

from clogging, never touch or wipe the nozzles or other ink outlets with your bare

hands or tissue paper. After removing the head cap, the protective tape, and the

protective tank from a BJ cartridge, promptly install the cartridge in the printer or

store it in the cartridge container. Do not reuse head caps or protective tapes which

have been removed. The BJ cartridge must be installed in the printer or stored in the

cartridge container with its ink tanks installed. If the BJ cartridge is installed or

stored with its ink tanks removed, the nozzles could clog due to foreign matter or

dried ink. Do not attempt to disassemble or wash the BJ cartridge.

If a nozzle clogs, or ink fails to be fed normally, print quality degrades, and

typically a fine horizontal blank line appears in printed images. If cleaning

operations do not solve the problem, replace the BJ cartridge with a new

one.

1-5

BJC-6000

Part 1: Safety and Precautions

Figure 1-5 BJ Cartridges

NOTE

Protective Tape

Head Cap

2.1.2 Automatic capping

When the printer is turned off with the

POWER

button, it automatically caps the BJ

cartridge's nozzles to protect them as well as to prevent ink leakage. If the AC cable is

unplugged from a wall outlet before the printer is turned off with the

POWER

button,

the nozzles will not be automatically capped. In this case, plug in the AC cable again,

turn on the printer, and then turn it off with the

POWER

button. The nozzles will be

automatically capped.

If the nozzles are not capped, ink may dry out and clog the nozzles or leak

from the cartridge.

2.1.3 When not using the printer

The BJ cartridge may be either left installed in the printer or stored in the cartridge

container. This also applies when carrying, transporting, or storing the printer.

If the BJ cartridge is left in open air, out of the printer or cartridge

container, foreign matter or dried ink may clog the nozzles, resulting in

poor print quality.

2.1.4 Ink's electroconductivity

The ink in the BJ cartridge conducts electricity. If ink is spilt in the printer's

mechanical parts, use a dampened paper towel to wipe clean. If ink is spilt onto the

printer's electrical components, use tissue paper to wipe clean. If ink gets under an

IC chip on the control board and cannot be removed thoroughly, replace the control

board with a new one.

Never plug in the printer if its' electric circuitry is in contact with spilt ink.

Otherwise the electric circuitry could be damaged.

Part 1: Safety and Precautions

BJC-6000

1-6

CAUTION

CAUTION

CAUTION

2.2 Ink Tanks

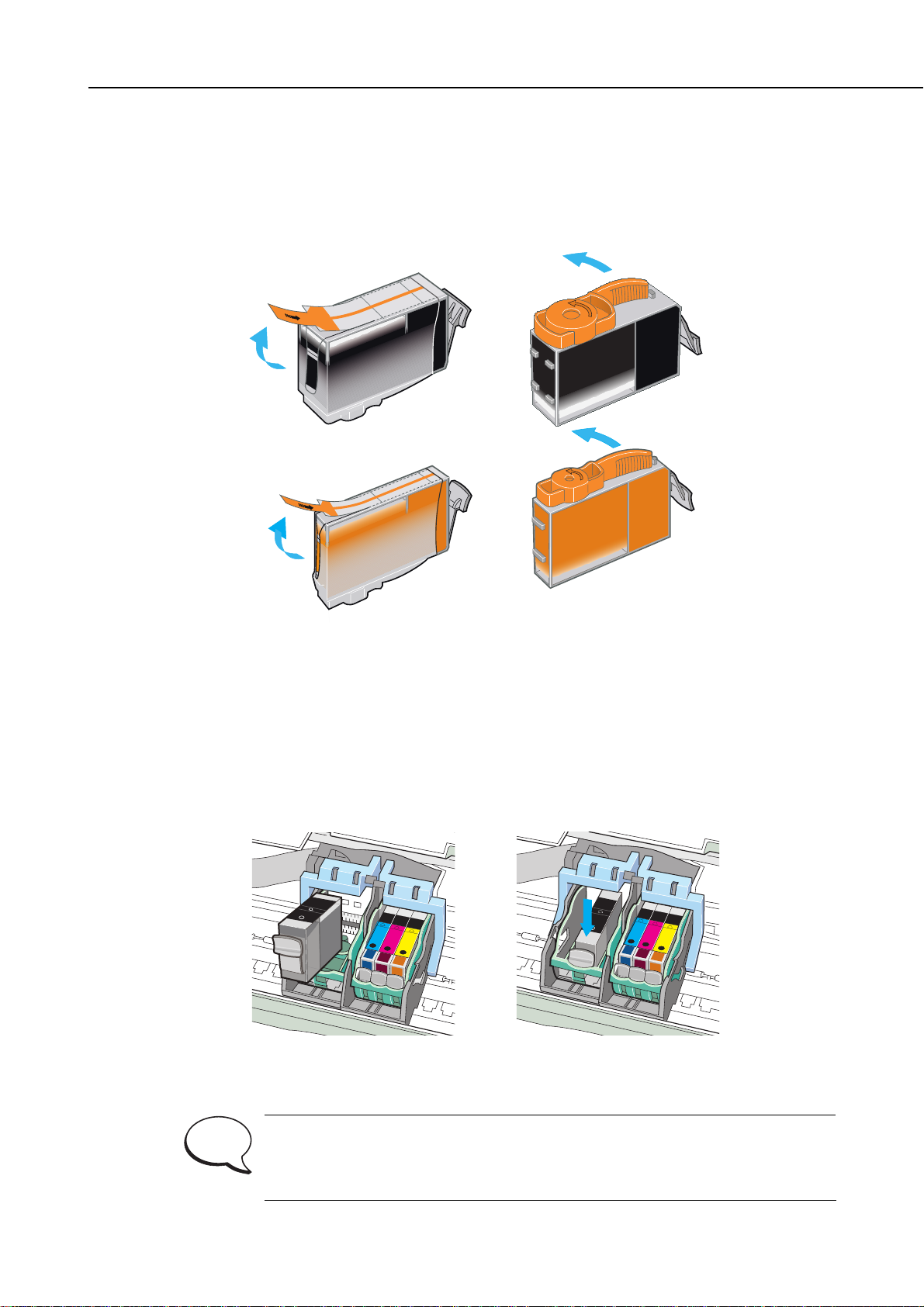

2.2.1 Unpacking the ink tank

Do not unpack the ink tank until you are ready to use it. When installing it in the BJ

cartridge, unpack the ink tank, peel off the vinyl lamination, and remove the cap from

the ink outlets.

2.2.2 Ink tank handling

If the joint of the BJ cartridge connecting to the ink tank supply piece is contaminated,

suction of ink into the BJ cartridge could fail. Therefore, never touch the ink tank's

ink supply piece. After removing the cap from the ink tank supply piece, promptly

install the ink tank in the BJ cartridge to prevent the nozzles from clogging due to dried-ink.

Do not remove the ink tank from the BJ cartridge unless you are replacing it.

If a nozzle clogs, or otherwise ink fails to be fed normally, print quality

degrades, and typically a fine horizontal blank line appears in printed

images. If cleaning operations do not solve the problem, replace the BJ

cartridge with a new one.

1-7

BJC-6000

Part 1: Safety and Precautions

Figure 1-6 Unpacking the Ink Tank

Figure 1-7 Installing the Ink Tank

NOTE

2.3 Printer Handling

2.3.1 Spurs

Take care not to bend the tips of the spurs. The tips of the spurs make contact with

printed paper and are contaminated with ink, but due to their small surface contact

area, the tips, cleaned by the spur cleaners, will not stain the printed paper.

However, if the tips are bent and their surface contact area increases, they collect

more ink and are not easily cleaned by the spur cleaners, and thereby stain the

printed paper by making dotted lines on it.

Part 1: Safety and Precautions

BJC-6000

1-8

Figure 1-8 Spurs

Spurs

2.3.2 Damage due to static electricity

Static electricity may be generated by your clothes rubbing against each other and

may accumulate in your body. If you touch electrical elements, the discharge of static

electricity could damage them or change their electrical characteristics. For this

reason, never touch the sensor contacts or the printer's BJ cartridge contacts.

1-9

BJC-6000

Part 1: Safety and Precautions

Figure 1-9 Damage Due to Static Electricity

Ink Sensor

Contact

Points

Contact Points

2.3.3 Ink leakage prevention

When you turn off the printer using the

POWER

button, the printer moves the carriage

to the capping position, caps the nozzles, and locks the carriage in position with the

lock arm. If electric power is not available to the printer, during transportation for

example, this automatic capping and locking is not available. In this case, manually

move the carriage to the capping position and secure it with tape to ready the printer

for transportation.

Part 1: Safety and Precautions

BJC-6000

1-10

Figure 1-10 Capping Position

Tape

3. NOTES ON SERVICING

3.1 EEPROM Data

The printer keeps track of the total sheets printed by each BJ cartridge configuration

(Black/Color and Photo/Color) and the total waste ink amount and stores that

information in the EEPROM (IC 602) on the logic board. Observe the following

precautions during servicing:

1) Before servicing

You can check the EEPROM data with a test print. The total sheets printed by each

configuration can provide important information on how much the printer has been

used.

2) If the control board (EEPROM) is replaced (or if stored data is cleared by

mistake)

Check the waste ink absorber, and replace it with a new one if necessary. If you fail

to replace the waste ink absorber in time, the waste ink full alarm might not be

issued in time and waste ink could leak (depending on the current ink absorbing

capacity of the waste ink absorber). When replacing the logic board (EEPROM) with

a new one, be sure to clear the data on the new EEPROM, because the data is not

defined.

3) After the waste ink absorber is replaced

After replacing the waste ink absorber, as prompted by the waste ink full alarm,

clear the data on the EEPROM.

Once cleared, the EEPROM data cannot be restored (cannot be checked

with a test print). Always check the EEPROM data with a test print before

clearing it. The data includes information on the user settings, the total

sheets of printed paper and the total amount of waste ink absorbed. Note

that you cannot edit the data from the operator panel.

The printer calculates the total amount of waste ink absorbed based on

the estimated usage of the printer. To prevent the capacity of the waste

ink absorber from being exceeded, the waste ink full alarm is issued when

the waste ink absorber gets full, suspending the operation of the printer.

Refer to

Part 3: 3.6.4 Resetting EEPROM

(Page 3-21) for the procedures for

checking the EEPROM data with a test print or for clearing the data.

Refer to

Part 5: 6. TROUBLESHOOTING

(Page 5-13) for the troubleshooting

procedures to be followed when the waste ink full alarm is issued.

1-11

BJC-6000

Part 1: Safety and Precautions

CAUTION

REF.

3.2 Static Electricity

Static electricity may be generated by your clothes rubbing against each other and may

accumulate in your body. If you touch electrical elements, the discharge of the static

electricity could damage them or change their electrical characteristics. To prevent

damage due to such electrostatic discharge, ground yourself by touching a metal fitting

which is grounded before disassembling or otherwise servicing the printer.

Part 1: Safety and Precautions

BJC-6000

1-12

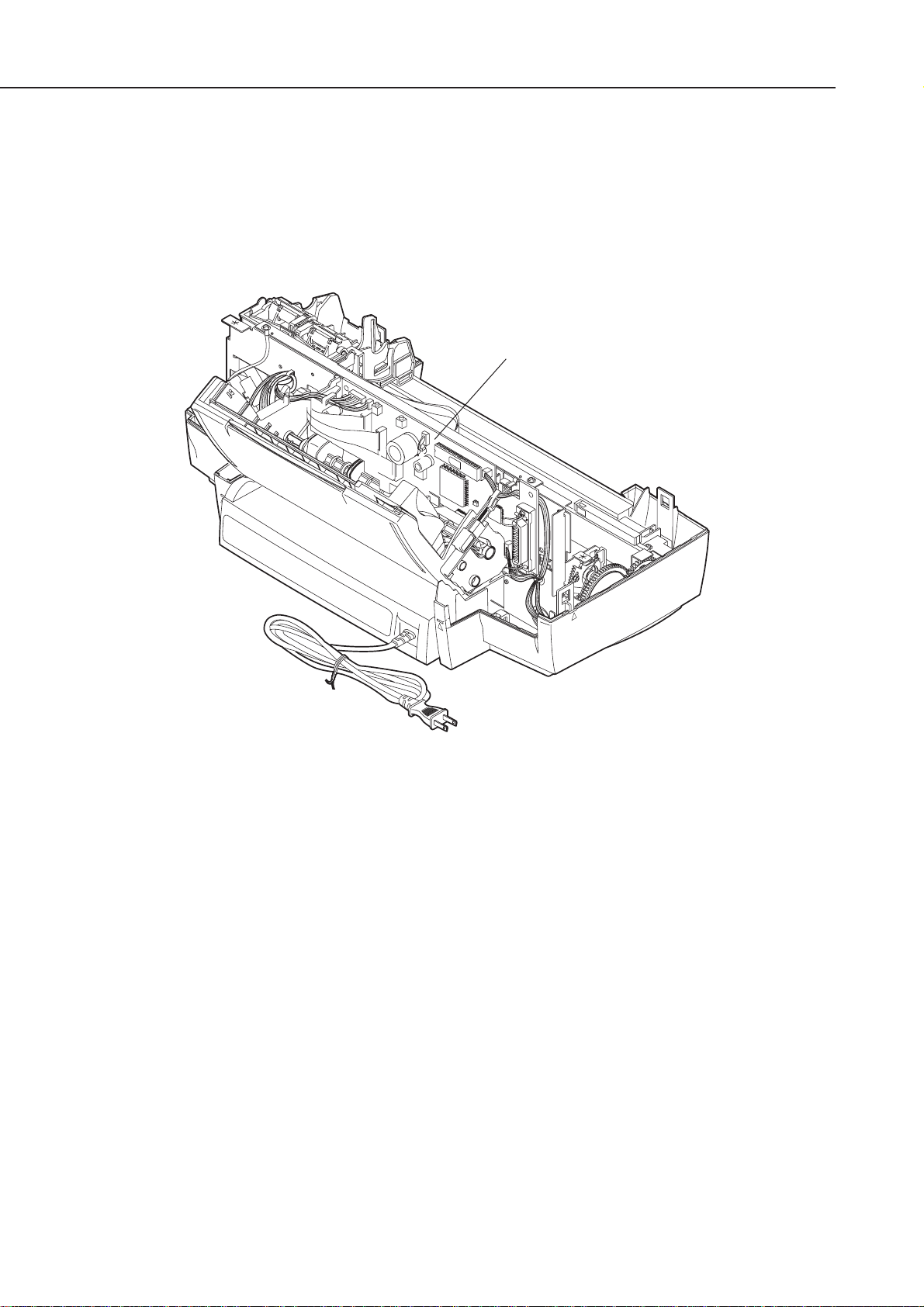

Figure 1-11 Control Board and Other Electrical Components

Control Board

AC Adapter

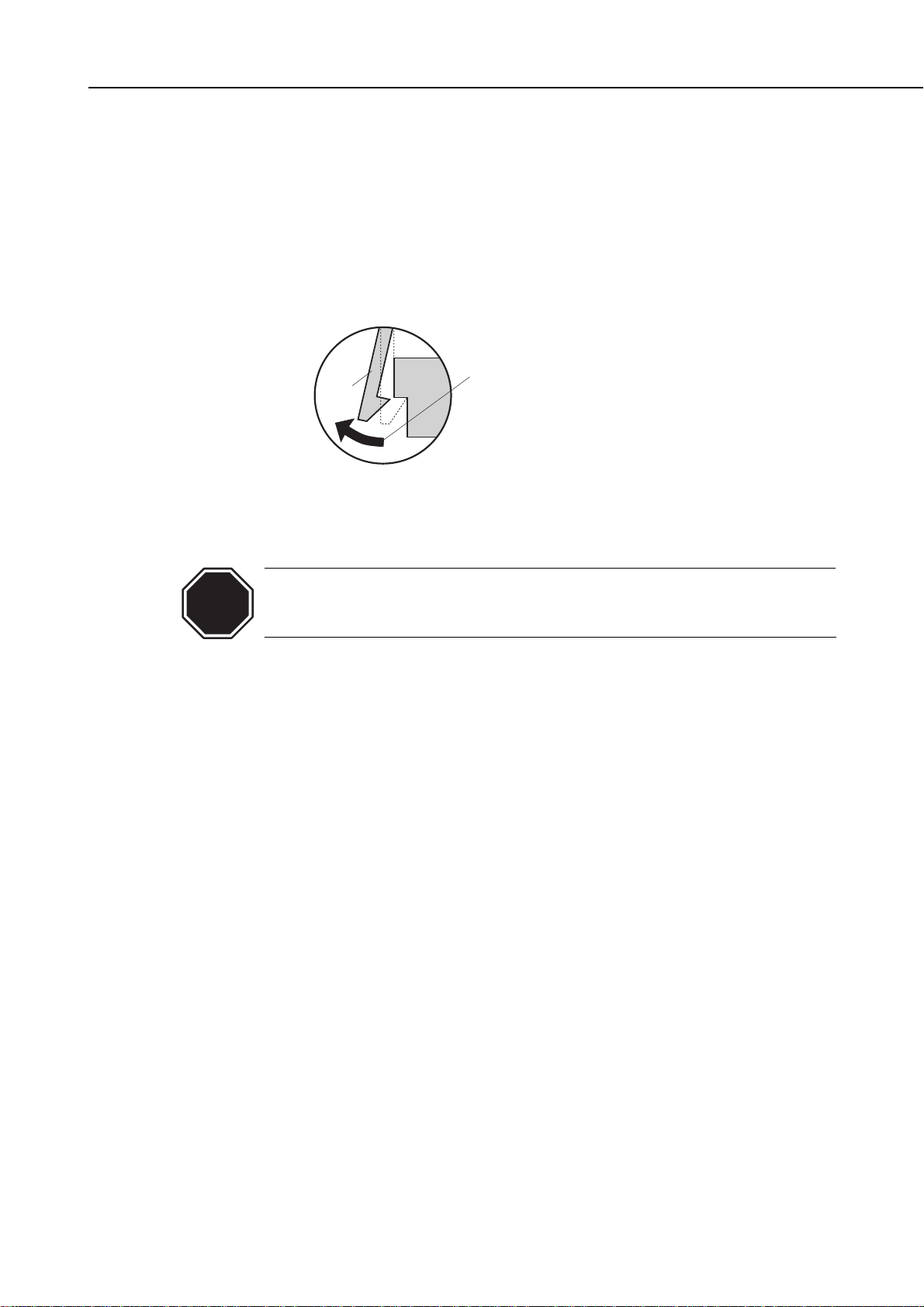

3.3 Disassembly and Reassembly

Disassembly and reassembly must be done according to the relevant parts catalog,

which illustrates the step-by-step procedures to be followed. Additional notes are

provided in

Part5: 4. DISASSEMBLY AND REASSEMBLY

(Page 5-4).

The printer uses many plastic parts. Do not apply excessive force to them. In

particular, take care not to break or deform plastic hooks during disassembly.

Some plastic parts contain glass fibers to conform to tight dimensional

tolerances. Plastic hooks are among such parts, lacking flexibility, and

are easily broken. Do not forcibly disengage them using a screwdriver.

1-13

BJC-6000

Part 1: Safety and Precautions

Figure 1-12 How to Disengage a Plastic Hook

Never apply excessive force

Hook

when releasing a hook.

CAUTION

3.4 Self Diagnosis

The printer has self-diagnosis features to detect hardware defects. The results of the

diagnosis are indicated by the

indicator

and

power lamp (flashing)

on the operator panel as

well as by the buzzer. For details, refer to

Part 3: 3.1 Error Indications

(Page 3-12).

Part 1: Safety and Precautions

BJC-6000

1-14

Part 2

Page

2 - 1 1. PRODUCT OUTLINE

2 - 1 1. 1 Outline

2 - 2 1.2 Features

2 - 3 1.3 BJ Cartridge

2 - 4 1. 4 BJ Cartridge Container

2 - 5 1.5 Consumables

2 - 6 2. SPECIFICATIONS

2 - 6 2.1 General Specifications

2 - 8 2. 2 Paper Specifications

2 -10 2.3 Interface Specifications

PRODUCT

SPECIFICATIONS

Loading...

Loading...