CANON BJC55 Service Manual

QY8-1358-000

REVISION 0

COPYRIGHT 1998 CANON INC. CANON BJC-50 0498 AB 2.00-0 PRINTED IN JAPAN (IMPRIME AU JAPON)

APR. 1998

0498 AB 2.00-0

Target Readers

This manual is published by Canon Inc. for qualified persons and contains the necessary technical

information for technical theory, installation, maintenance, and repair of products. This manual covers

all localities where the products are sold. For this reason, it may contain information that does not

apply to your locality.

Revisions

This manual may include technical inaccuracies or typographical errors due to improvements or

changes in the products. When amendments are made to the content of this manual, Canon will issue

technical information as the need arises. In the event of major alterations to the content of this manual

over a long or short period, Canon will publish a revised version of the manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with the local law.

Trademarks

The product names and company names appearing in this manual are the registered trademarks or

trademarks of the individual companies.

Copyright

This manual is copyrighted and all rights reserved. Under the copyright laws, this manual may not be

copied, reproduced, or translated into other languages, in whole or in part, without the express written

consent of Canon Inc. except in the case of internal business use.

Copyright 1998 by Canon Inc.

CANON INC.

BJ Products Quality Support Dept.

16-1, Shimonoge 3-chome, Takatsu-ku, Kawasaki, Kanagawa 213, Japan

This manual was produced on an Apple Macintosh Power Mac 7300/180 personal computer and Apple

LaserWriter II NTX-J laser beam printer; final pages were printed on Agfa SelectSet Avantra 25.

A YANO 640MO drive system NJ640MO with MITSUBISHI MO disk cartridge MR230M1 were used for

storing large volumes of page layout and graphic data for this manual.

All graphics were produced with MACROMEDIA FREEHAND 7.0J.

All documents and all page layouts were created with QuarkXPress 3.3J.

I. ABOUT THIS MANUAL

Part 1: Safety and Precautions

This part contains information on how to service the unit safely. It is very important, and

must be read.

Part 2: Product Specifications

This part outlines the product and its specifications.

Part 3: Operating Instructions

This part explains how to operate the unit properly, how it is installed, and how to use

the service mode.

Part 4: Technical Reference

This part outlines the unit operation giving a technically.

Part 5: Maintenance

This part explains maintenance of the unit. It includes details of disassembly/assembly,

adjustments required when assembling, troubleshooting procedures, and wiring/circuit

diagrams, etc.

This manual does not contain complete information required for

disassembling and assembling the BJC-50 printer. Please also refer to the

separate Parts Catalog.

This manual is divided into five parts containing the information required for servicing the BJC50 printer.

I

II. TABLE OF CONTENTS

Page

1 - 1 1. PERSONAL SAFETY PRECAUTIONS

1 - 1 1.1 Moving Section of the Printer

1 - 2 1.2 Ink Stains

1 - 2 1.2.1 Ink path

1 - 3 1.2.2 Ink mist

1 - 4 1.3 BJ Cartridge Aluminum Plate

1 - 5 2. MACHINE PRECAUTIONS

1 - 5 2.1 BJ Cartridge

1 - 5 2.1.1 BJ cartridge handling

1 - 6 2.1.2 Automatically capping

1 - 6 2.1.3 When not using the printer

1 - 6 2.1.4 Ink conductivity

1 - 7 2.2 Ink Cartridge

1 - 7 2.2.1 Ink cartridge handling

1 - 8 2.3 Lithium Ion Battery Handling

1 - 8 2.3.1 Initial precautions

1 - 8 2.3.2 Storage precaution

1 - 9 2.4 Printer Handling

1 - 9 2.4.1 Precautions to prevent damage from static electricity

1 -10 2.4.2 Ink leakage precautions

1 -11 3. PRECAUTION FOR SERVICE

1 -11 3.1 Precautions Concerning the Memory Data

1 -12 3.2 Precautions to Prevent Damage from Static Electricity

1 -13 3.3 Precautions for Disassembly/Assembly

1 -14 3.4 Built-in Self-diagnostic Functions

Part 1: SAFETY AND PRECAUTIONS

Part 2:

2 - 1 1. PRODUCT OUTLINE

2 - 1 1.1 Product Outline

2 - 2 1.2 Features

2 - 2 1.2.1 Printer

2 - 3 1.3 BJ Cartridge

2 - 3 1.3.1 Color BJ cartridge [BC-11e]

2 - 4 1.3.2 Black BJ cartridge [BC-10]

2 - 5 1.4 Options

2 - 5 1.4.1 BJ cartridge container

2 - 5 1.4.2 Lithium ion battery (LB-50)

2 - 6 1.4.3 Universal adapter (AD-360U)

2 - 7 1.4.4 Color image scanner cartridge (IS-12)

2 - 7 1.4.5 Interface Cable (BIFC-50)

2 - 8 1.5 Consumables

2 - 8 1.5.1 BJ cartridge (Color and Black)

2 - 8 1.5.2 Ink cartridge

2 - 8 1.5.3 Lithium ion battery (LB-50)

2 - 9 2. SPECIFICATIONS

2 - 9 2.1 General Specifications

2 -13 2.2 Paper Specifications

2 -15 2.3 Interface Specifications

2 -15 2.3.1 Parallel interface

2 -20 2.3.2 Infrared interface

2 -22 2.4 Character Code Tables

PRODUCT SPECIFICATIONS

II

Page

3 - 1 1. PRINTER SETUP

3 - 1 1.1 Unpacking

3 - 2 1.2 Installation

3 - 2 1.2.1 Installation space

3 - 3 1.2.2 Installation procedure

3 -10 1.3 Names and Functions of Parts

3 -11 2. TRANSPORTING THE PRINTER

3 -11 2.1 Carrying the Printer

3 -11 2.2 Transporting the Printer

3 -12 3. PRINTER SERVICING FUNCTIONS

3 -12 3.1 Error Indications

3 -15 3.2 Function Setting

3 -15 3.2.1 Default setting

3 -16 3.3 Control Buttons

3 -16 3.3.1 Cleaning the BJ cartridge

3 -17 3.4 Self Test Print

3 -18 3.4.1 Demonstration print

3 -19 3.4.2 Function settings list print

3 -20 3.4.3 Ripple pattern print

3 -21 3.4.4 Nozzle check pattern print

3 -21 3.4.5 All fonts pattern print

3 -22 3.5 Hexadecimal Dump Test Print

3 -23 3.6 EEPROM Data Setting

3 -23 3.6.1 EEPROM data setting mode

3 -23 3.6.2 Setting EEPROM data

3 -24 3.6.3 Displaying EEPROM data

3 -25 3.6.4 EEPROM settings list print

3 -26 3.7 Rewriting Flash ROM

3 -26 3.7.1 Flash ROM rewrite mode

Part 3: OPERATING INSTRUCTIONS

Part 4: TECHNICAL REFERENCE

4 - 1 1. OVERVIEW

4 - 1 1.1 Printer Block Diagram

4 - 2 1.2 Initial Flowchart

4 - 2 1.2.1 Print mode

4 - 3 1.2.2 Scanner mode

4 - 4 1.3 Print Signal Flow

4 - 5 1.4 Print Drive

4 - 5 1.4.1 Printing drive control

4 - 7 1.5 Scanner Drive

4 - 8 1.6 Power Off Operation Flow

4 - 9 2. FIRMWARE

4 - 9 2.1 Interface

4 - 9 2.1.1 Compatible mode

4 -10 2.1.2 Nibble mode

4 -11 2.1.3 ECP mode

4 -12 2.1.4 IrDA

4 -15 2.2 720 dpi Printing/Smoothing Feature

4 -15 2.2.1 Canon extension mode

4 -15 2.2.2 Emulation mode

4 -16 2.3 Printing Modes

4 -17 2.4 Optimum Printing Direction Control

4 -17 2.5 Automatic Emulation Switching

III

Page

4 -18 2.6 Lithium Ion Battery Recharging

4 -18 2.6.1 Switching to recharge mode

4 -18 2.6.2 Recharge protection

4 -18 2.6.3 Recharge control

4 -19 3. PRINTER MECHANISM

4 -19 3.1 Overview of the Mechanical System of the Printer

4 -20 3.1.1 Mechanical system configuration

4 -21 3.2 BJ Cartridge

4 -21 3.2.1 Color BJ cartridge structure

4 -22 3.2.2 Black BJ cartridge structure

4 -23 3.2.3 Bubble jet head-unit structure

4 -26 3.2.4 Head-maintenance function and structure

4 -28 3.3 Purge Section Structure

4 -28 3.3.1 Configuration

4 -29 3.3.2 Operation

4 -30 3.4 Paper Feed Mechanism

4 -30 3.4.1 Outline of paper feed mechanism

4 -32 3.5 Carriage Section

4 -32 3.5.1 Carriage section function

4 -33 3.5.2 Carriage section structure

4 -34 4. PRINTER ELECTRICAL SYSTEM

4 -34 4.1 Overview

4 -35 4.2 Signal Control Section

4 -35 4.2.1 Control board block diagram

4 -36 4.2.2 Control section components

4 -39 4.3 Power Supply Section

4 -39 4.3.1 Block diagram of power supply section

4 -40 4.3.2 Power supply section structure

4 -41 4.3.3 Lithium Ion Battery Recharging Circuit

4 -42 4.3.4 Lithium Ion Battery

4 -44 5. DETECTION FUNCTION

4 -44 5.1 HP Sensor

4 -44 5.2 Paper End Sensor

4 -44 5.3 Delivery Sensor

4 -44 5.4 Temperature Sensor

4 -44 5.5 Head Temperature Sensor

4 -45 5.6 Waste Ink Level Detection

4 -45 5.7 Remaining-ink Level Detection

4 -46 6. SCANNER CARTRIDGE

4 -46 6.1 Scanner Cartridge Overview

4 -46 6.1.1 Block diagram

4 -47 6.2 Scanner Cartridge Structure

4 -49 6.3 Signal Contacts

4 -50 6.4 Scan Mode

4 -50 6.5 Calibration

Part 5: MAINTENANCE

5 - 1 1. MAINTENANCE

5 - 1 1.1 Periodically-replaced Parts

5 - 1 1.2 Consumables

5 - 1 1.3 Periodic Maintenance

5 - 2 2. SERVICE TOOLS

5 - 2 2.1 List of Tools

IV

Page

5 - 3 3. APPLYING THE GREASE

5 - 4 4. ADJUSTMENT

5 - 5 5. TROUBLESHOOTING

5 - 5 5.1 Overview of Troubleshooting

5 - 5 5.1.1 Definition

5 - 5 5.1.2 Precautions for troubleshooting

5 - 7 5.2 Error Condition Diagnosis

5 - 7 5.2.1 Diagnosis flowchart

5 -11 5.2.2 Error recovery

5 -31 6. CONNECTOR POSITION & PIN ALIGNMENT

5 -31 6.1 Control Board

5 -36 6.2 Carriage Ribbon Cable

5 -37 6.3 BJ Cartridge

5 -37 6.4 Scanner Cartridge IS-12

5 -38 7. CIRCUIT DIAGRAMS

5 -38 7.1 Parts Layout

5 -38 7.1.1 Control board (Upper section)

5 -39 7.1.2 Control board (Lower section)

5 -41 7.2 Circuit Diagrams

V

III. ILLUSTRATION INDEX

Page

1 - 1 Figure 1 - 1 Moving Sections of the Printer

1 - 2 Figure 1 - 2 Ink Path

1 - 3 Figure 1 - 3 Ink Mist

1 - 4 Figure 1 - 4 BJ Cartridge Aluminum Plate

1 - 5 Figure 1 - 5 BJ Cartridge

1 - 7 Figure 1 - 6 Ink Inlet of the Ink Cartridge

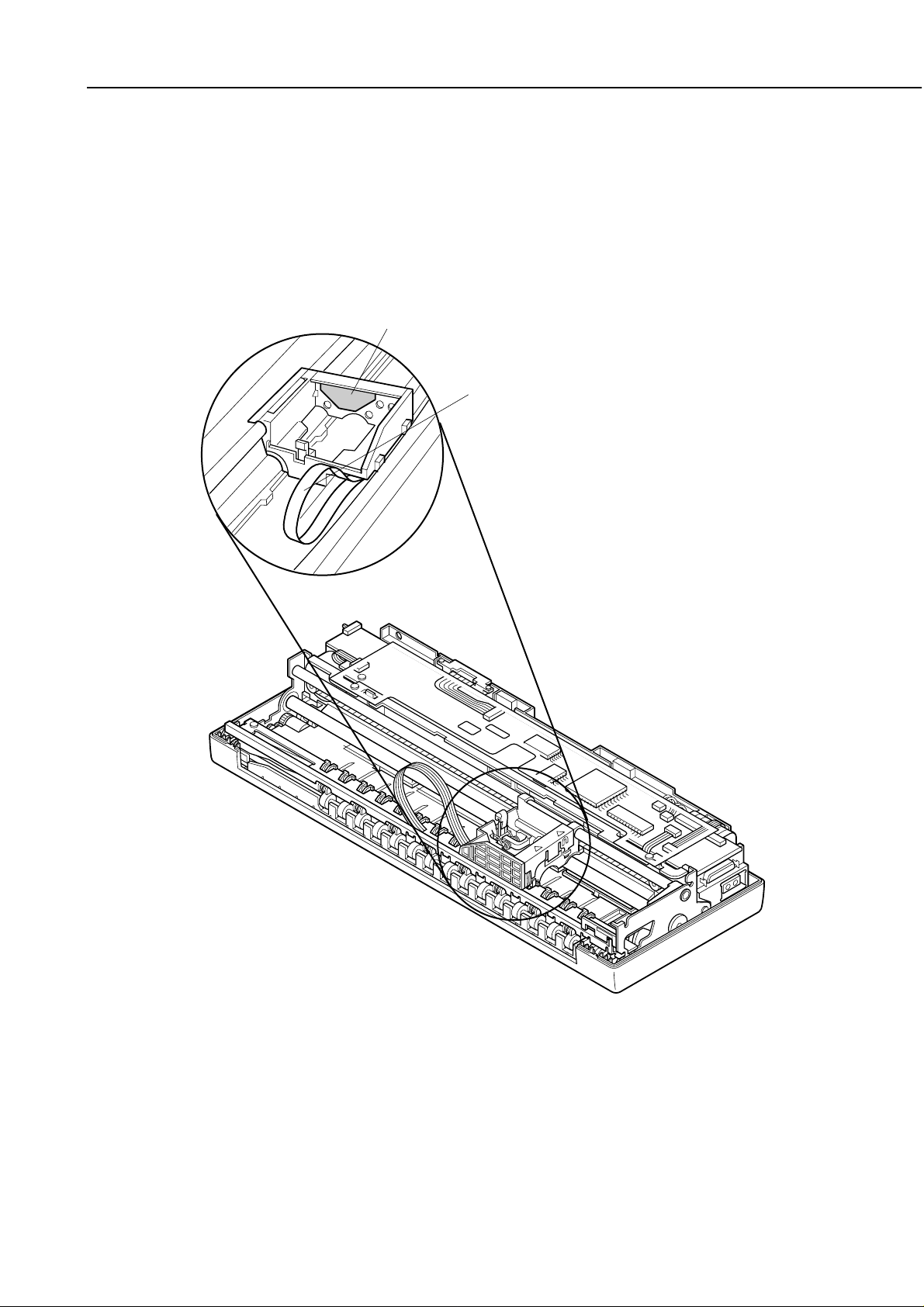

1 - 9 Figure 1 - 7 Contact Section of the Carriage Ribbon Cable

1 -10 Figure 1 - 8 Capping Position

1 -12 Figure 1 - 9 Electronic System of the Printer

1 -13 Figure 1 -10 Control Board

1 -13 Figure 1 -11 Removing Plastic Hooks

1 -14 Figure 1 -12 IrDA Unit

Part 1: SAFETY AND PRECAUTIONS

Part 2: PRODUCT SPECIFICATIONS

2 - 1 Figure 2 - 1 Printer Appearance

2 - 3 Figure 2 - 2 Color BJ Cartridge [BC-11e]

2 - 4 Figure 2 - 3 Black BJ Cartridge [BC-10]

2 - 5 Figure 2 - 4 Cartridge Container

2 - 5 Figure 2 - 5 Lithium Ion Battery

2 - 6 Figure 2 - 6 Universal Adapter

2 - 7 Figure 2 - 7 Color Image Scanner Cartridge

2 - 7 Figure 2 - 8 Interface Cable

2 - 8 Figure 2 - 9 Ink Cartridge

2 -14 Figure 2 -10 Printing Area

2 -14 Figure 2 -11 Printing Area (Envelope)

2 -19 Figure 2 -12 Timing Chart (Compatibility Mode)

2 -19 Figure 2 -13 Timing Chart (Nibble Mode)

2 -19 Figure 2 -14 Timing Chart (ECP Mode)

2 -20 Figure 2 -15 IrDA Method

2 -21 Figure 2 -16 ASK Method

Part 3: OPERATING INSTRUCTIONS

3 - 1 Figure 3 - 1 Packing Arrangement

3 - 2 Figure 3 - 2 Installation Space

3 - 3 Figure 3 - 3 Connecting the Universal Adapter

3 - 3 Figure 3 - 4 Connecting the Interface Cable

3 - 4 Figure 3 - 5 IrDA Angle of Rotation

3 - 5 Figure 3 - 6 Removing the Head Cap and the Tape

3 - 6 Figure 3 - 7 Installing the BJ Cartridge

3 - 7 Figure 3 - 8 Replacing the Ink Cartridge

3 - 8 Figure 3 - 9 Removing the Cap (Ink Cartridge)

3 - 8 Figure 3 -10 BJ Cartridge Container

3 -10 Figure 3 -11 Names and Functions of Parts

3 -12 Figure 3 -12 Control Panel

3 -18 Figure 3 -13 Demonstration Print (Sample)

3 -19 Figure 3 -14 Function Settings List Print (Sample)

3 -20 Figure 3 -15 Ripple Pattern Print (Sample)

3 -21 Figure 3 -16 Nozzle Check Pattern Print (Sample)

3 -21 Figure 3 -17 All Fonts Pattern Print (Sample)

3 -22 Figure 3 -18 Hexadecimal Dump Test Print (Sample)

VI

Page

3 -24 Figure 3 -19 Waste Ink Absorber (50% Used Sample)

3 -25 Figure 3 -20 EEPROM Settings List Print (Sample)

Part 4: TECHNICAL REFERENCE

4 - 1 Figure 4 - 1 Printer Diagram

4 - 4 Figure 4 - 2 Printing Signal Flow

4 - 5 Figure 4 - 3 Print Sequence (Black BJ Cartridge in HQ Mode)

4 - 6 Figure 4 - 4 Print Signals

4 - 8 Figure 4 - 5 Power Off Operation Flow

4 - 9 Figure 4 - 6 Interface Timing (Compatible Mode)

4 -10 Figure 4 - 7 Interface Timing (Nibble Mode)

4 -11 Figure 4 - 8 Interface Timing (ECP Mode)

4 -12 Figure 4 - 9 IrDA

4 -13 Figure 4 -10 Base Band Transmission Format (IrDA)

4 -13 Figure 4 -11 Carrier Transmission Format (ASK)

4 -15 Figure 4 -12 720 dpi/Smoothing Function

4 -19 Figure 4 -13 Printer Mechanism

4 -21 Figure 4 -14 Color BJ Cartridge

4 -22 Figure 4 -15 Black BJ Cartridge

4 -23 Figure 4 -16 Bubble Jet Head

4 -24 Figure 4 -17 Nozzle Arrangement

4 -24 Figure 4 -18 Contact Part

4 -26 Figure 4 -19 Purge Section

4 -27 Figure 4 -20 Wiping Function

4 -28 Figure 4 -21 Purge Section Structure

4 -29 Figure 4 -22 Purge Operation

4 -30 Figure 4 -23 Paper Pass

4 -32 Figure 4 -24 Cartridge Section Function

4 -33 Figure 4 -25 Carriage Section Structure

4 -34 Figure 4 -26 Printer Block Diagram

4 -35 Figure 4 -27 Control Board Block Diagram

4 -39 Figure 4 -28 Block Diagram of Power Supply Section

4 -41 Figure 4 -29 Lithium Ion Battery Recharge Circuit

4 -43 Figure 4 -30 Battery Temperature Detection Circuit

4 -44 Figure 4 -31 Sensor Location

4 -46 Figure 4 -32 Scanner Cartridge

4 -46 Figure 4 -33 Block Diagram

4 -47 Figure 4 -34 Scanner Cartridge

4 -49 Figure 4 -35 Contact Pad Layout

Part 5: MAINTENANCE

5 - 3 Figure 5 - 1 Grease Application Sections

5 -12 Figure 5 - 2 Check Point

5 -13 Figure 5 - 3 Carriage Motor

5 -13 Figure 5 - 4 Paper Feed Motor

5 -16 Figure 5 - 5 BJ Head Temperature Sensor

5 -16 Figure 5 - 6 Carriage Ribbon Cable

5 -23 Figure 5 - 7 DC Plug

5 -24 Figure 5 - 8 Flexible Cables

5 -25 Figure 5 - 9 Head Connector

5 -31 Figure 5 -10 Control Board

5 -36 Figure 5 -11 Carriage Ribbon Cable

5 -37 Figure 5 -12 BC-11e Contact Pad

5 -37 Figure 5 -13 IS-12 Contact Pad

VII

IV. TABLE INDEX

Page

3 -12 Table 3- 1 Error Display

3 -15 Table 3- 2 Function Setting (1)

3 -15 Table 3- 3 Function Setting (2)

Page

4 -16 Table 4- 1 Printing Modes and Heating Methods

4 -25 Table 4- 2 Signal Contact Part

4 -26 Table 4- 3 Cleaning Ink Consumption

4 -43 Table 4- 4 Battery Temperature

4 -45 Table 4- 5 Detection Function

4 -49 Table 4- 6 List of Scanner Cartridge Signal Contacts

4 -50 Table 4- 7 List of Scan Mode

Part 3: OPERATING INSTRUCTIONS

Part 4: TECHNICAL REFERENCE

VIII

Part 1

SAFETY AND

PRECAUTIONS

Page

1 - 1 1. PERSONAL SAFETY PRECAUTIONS

1 - 1 1.1 Moving Sections of the Printer

1 - 2 1.2 Ink Stains

1 - 4 1.3 BJ Cartridge Aluminum Plate

1 - 5 2. MACHINE PRECAUTIONS

1 - 5 2.1 BJ Cartridge

1 - 7 2.2 Ink Cartridge

1 - 8 2.3 Lithium Ion Battery Handling

1 - 9 2.4 Printer Handling

1 -11 3. PRECAUTION FOR SERVICE

1 -11 3.1 Precautions Concerning the Memory Data

1 -12 3.2 Precautions to Prevent Damage from Static Electricity

1 -13 3.3 Precautions for Disassembly/Assembly

1 -14 3.4 Built-in Self-diagnostic Functions

1. PERSONAL SAFETY PRECAUTIONS

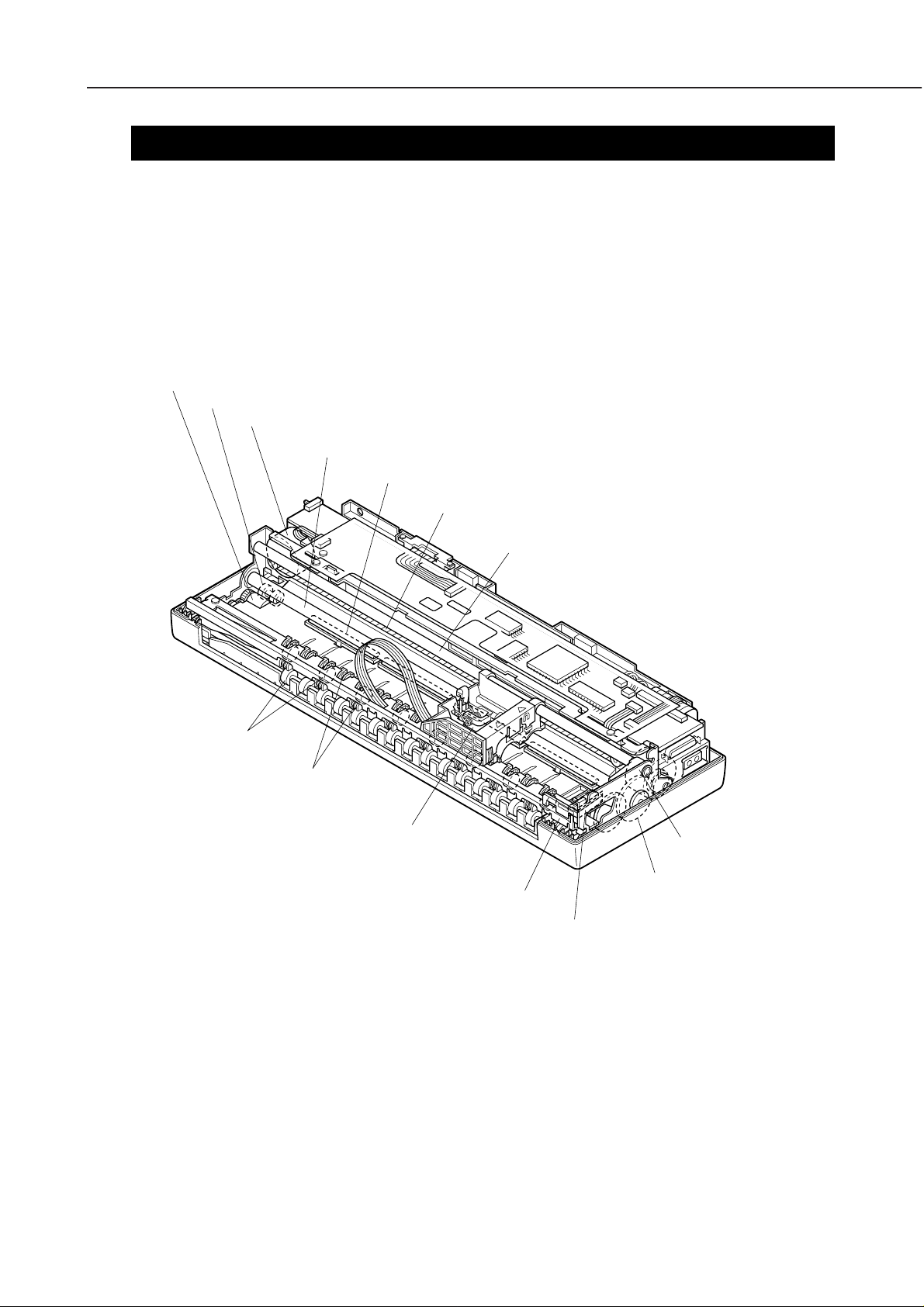

1.1 Moving Sections of the Printer

Be careful not to let your hair, clothes, accessories, etc., become caught in any of the

moving sections of the printer. The moving sections of the printer are the carriage belt,

carriage ribbon cable and carriage, which are driven by the carriage motor, and the

paper feed gear and roller, pinch roller, eject roller and spurs which are driven by the

paper feed motor.

1-1

BJC-50

Part 1: Safety and Precautions

Figure 1-1 Moving Sections of the Printer

Eject Idler Gear

Eject Idler Roller

Carriage Motor

Paper Feed Roller

Pinch Roller

Carriage Belt

Eject Roller

Carriage Shaft

Spurs

Carriage

Paper Feed Motor

Paper Feed Gear

Pump Section

Wiper Section

Part 1: Safety and Precautions

1.2 Ink Stains

1.2.1 Ink path

Be careful not to touch the ink path of the printer and get stains on the work table,

hands, clothes, etc., during repair.

The ink path is the nozzle section of the BJ cartridge, the head cap, the head wiper,

the maintenance jet receiving section and the waste ink absorber.

The ink inlets of the ink cartridge and the joint pipes of the print head body are also

part of the ink path, so take the same precautions.

The ink is not a substance harmful to the human body, but it does

contain an organic solvent (Black ink: isopropyl alcohol 67-63-0, glycerin

56-81-5, ethyleneglycol 107-21-1, Color ink: isopropyl alcohol 67-63-0).

Be careful not to get any ink in your mouth or eyes. If you do get any into

your eyes, wash it out with plenty of water and consult a doctor. If you

somehow swallow a large amount of the ink, consult a doctor immediately.

At that time, please communicate the items written on the BJ cartridge

label. Since this ink contains dyes, if you get it on your clothes, etc., it

will not come out.

BJC-50

Waste InkAbsorber

Cap

Wiper

Figure 1-2 Ink Path

1-2

Pump

Ink Path

BJC-50

Part 1: Safety and Precautions

1.2.2 Ink mist

The BJ cartridge ejects the ink onto the paper. After the printer has been used for a

long time or under heavy duty use, a small amount of ink mist bouncing off the paper

during printing may soil the platen section and the purge section.

This soiling may soil the paper or the hands or clothes of service personnel, so wipe it

off with a soft cloth or the like dampened with water.

Platen Section

Purge Section

Check Point

Purge Section

Figure 1-3 Ink Mist

1-3

°c at 100% Duty printing)

1) During printing, if a temperature rise is detected to above a certain

temperature, in order to protect the printer, it will print unidirectionally

with a wait after each line until the BJ cartridge cools down. Also

ERROR

indicator will blink and printing will slow down. If this

temperature continues for more than a certain period of time, the

beeper sounds 8 times, the

ERROR

indicator and

POWER

indicator

blink to indicate a head temperature error.

Since the same type of temperature rise also occurs if printing is operated

after the ink in the cartridge has run out, these protective functions are

triggered. Therefore, the criterion for replacing the BJ cartridge or the ink

cartridge is non-fire nozzles or diminished dot size during printing or the

triggering of these protective functions.

When printing is stopped by a head temperature error, handle the printer

as explained in

Part 5: 5. TROUBLESHOOTING (page 5-5).

Part 1: Safety and Precautions

BJC-50

1-4

Danger ! High Temperature!

Figure 1-4 BJ Cartridge Aluminum Plate

1.3 BJ Cartridge Aluminum Plate

Do not touch the aluminum plate of the BJ cartridge. The aluminum plate heats up

during printing and becomes particularly hot during continuous high duty printing. It

also heats up if printing is operated after the ink in the cartridge has run out.

This printer has the following functions to protect against the above

temperature rise. The temperature is detected by the head temperature

sensor in the BJ cartridge. (ex. approx. 70

BJC-50

Part 1: Safety and Precautions

2. MACHINE PRECAUTIONS

2.1 BJ Cartridge

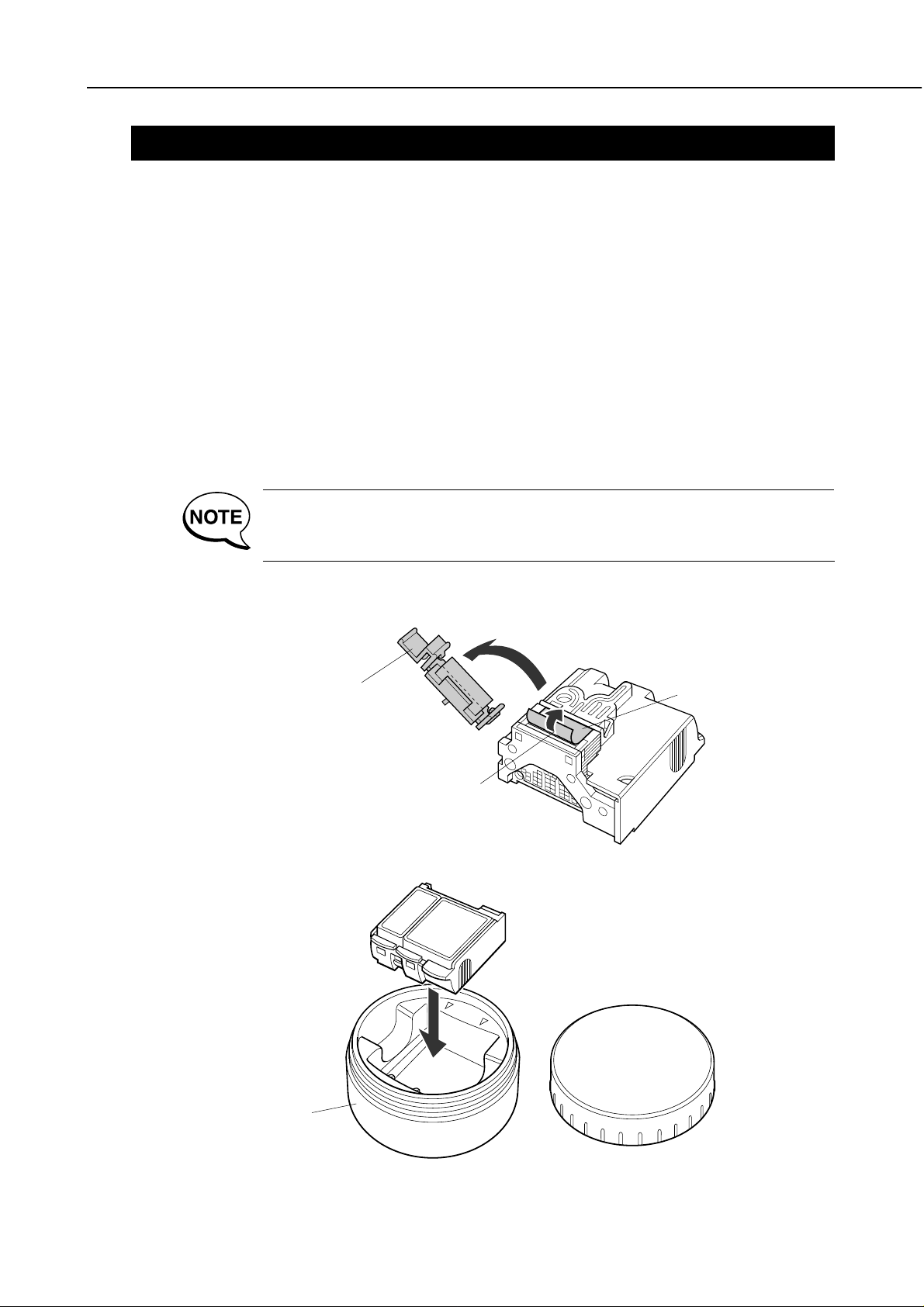

2.1.1 BJ cartridge handling

To prevent clogging at the nozzles due to foreign matters, never touch the nozzle

section of the BJ cartridge or wipe it off with tissue paper or the like. For the BJ

cartridge, take the same care with the ink filter of the print head body to prevent poor

ink suction due to foreign matters. Also, once you have removed the head cap and

peeled off the protection tape from a BJ cartridge, either install the BJ cartridge in the

printer or store it in the cartridge container to prevent clogging at the nozzles due to

ink drying or foreign objects. Do not reinstall the removed print head cap and

protection tape on the BJ cartridge. For the BJ cartridge, either install it in the

printer with the ink cartridge installed or store it in the cartridge container. If the ink

cartridge is not attached, poor ink suction due to ink drying or foreign matters can

occur. BJ cartridges cannot be disassembled, assembled, or washed.

If clogging at the nozzles or poor ink suction occurs, horizontal white lines

appear in part of the printing. If cleaning does not restore proper printing,

you must replace the BJ cartridge.

Head Cap

Cartridge Container

Protection Tape

Nozzles

Figure 1-5 BJ Cartridge

1-5

Part 1: Safety and Precautions

2.1.2 Automatically capping

When the power is switched off with the

caps the nozzle section of the BJ cartridge to protect itself and prevent ink leakage.

If you unplug the DC plug by mistake and cut off the power supply to the printer,

plug the DC plug back in, start up the printer normally, then switch off the power

with the

POWER

button.

If the nozzle section is not capped, it may clog at the nozzles due to ink

drying, or the ink may leak from the nozzles.

2.1.3 When not using the printer

Even when not using the printer, leave the BJ cartridge installed in the printer or

store it in the cartridge container.

Do the same when carrying, shipping or storing the printer.

If you remove the BJ cartridge from the printer and leave it as it is, foreign

matters may stick or dry ink may clog the nozzle, making it impossible to

use the BJ cartridge.

POWER

BJC-50

button, the printer automatically

2.1.4 Ink conductivity

The ink in the BJ cartridge is electrically conductive. If it leaks onto a mechanical

section, mop it up with a damp paper towel or the like. If it leaks onto an electrical

section, mop it up completely with tissue paper or the like. Especially, if the ink

enters as far as to the IC chip of the PCB and it is hard to wipe off completely, a new

PCB should be used.

If the Universal adapter is connected to the printer with ink leaked, this

may harm the electrical section. Never switch the power on if there has

been a leak.

1-6

BJC-50

Part 1: Safety and Precautions

2.2 Ink Cartridge

2.2.1 Ink cartridge handling

To prevent poor ink suction due to foreign matters on the ink filter of the print head

body, never touch the ink filter of the ink cartridge. When you remove the cap from

an ink cartridge, install the ink cartridge on the print head body immediately to

prevent clogging at the nozzles due to ink drying or foreign matters. Do not remove

the ink cartridge unless you are replacing it.

Do not use the protection cap removed from the ink cartridge to store the ink

cartridge. Install the ink cartridge in the print head immediately after unsealing the

pillow bag.

If clogging at the nozzles or poor ink suction occurs, horizontal white lines

appear in part of the printing. If cleaning does not restore proper printing,

you must replace the BJ cartridge.

Ink Inlets

Figure 1-6 Ink Inlet of the Ink Cartridge

1-7

Part 1: Safety and Precautions

2.3 Lithium Ion Battery Handling

2.3.1 Initial precautions

The enclosed lithium ion battery must be installed in the printer and charged prior to

its use. To ensure best performance, the lithium ion battery is only charged to 40% of

its full capacity at the time of shipping. The battery must be fully charged once it is

unpacked.

After connecting the AC adapter and turning on the printer, the installed

battery automatically begins charging. However, the battery will not be

charged while printing or cleaning. Charging temperature must be

between 5 and 35 degrees Celsius otherwise the battery will not be

charged.

The

CHARGE

off when charging is finished.

The lithium ion battery serves both as a battery when the Universal adapter is not

connected and a manual paper feed guide. A NO BATTERY ERROR occurs (

and

POWER

installed.

indicators light and beeper sounds 6 times) if a lithium ion battery is not

BJC-50

indicator will light while the battery is charging and it will go

ERROR

2.3.2 Storage precaution

The advantages of a lithium ion batteries compared to Nicd and NiMH batteries are

the low rate of self-discharge and the long lasting storage capacity. However, a

drawback is that lithium ion batteries are susceptible to over discharge. At high

temperatures, the rate of self-discharge is accelerated and the battery is rapidly over

discharged.

When storing the unused lithium ion battery, avoid storage in direct sunlight or near

heaters.

Also prevent storage at high temperature and make sure not to store the battery for

an extended period of time.

1-8

BJC-50

Part 1: Safety and Precautions

2.4 Printer Handling

2.4.1 Precautions to prevent damage from static electricity

The electrical charge accumulated on a person when clothes rub can damage electric

elements or change their electrical characteristics. Never touch the contact section of

the carriage ribbon cable.

Contact Section

Carriage Ribbon Cable

Figure 1-7 Contact Section of the Carriage Ribbon Cable

1-9

Part 1: Safety and Precautions

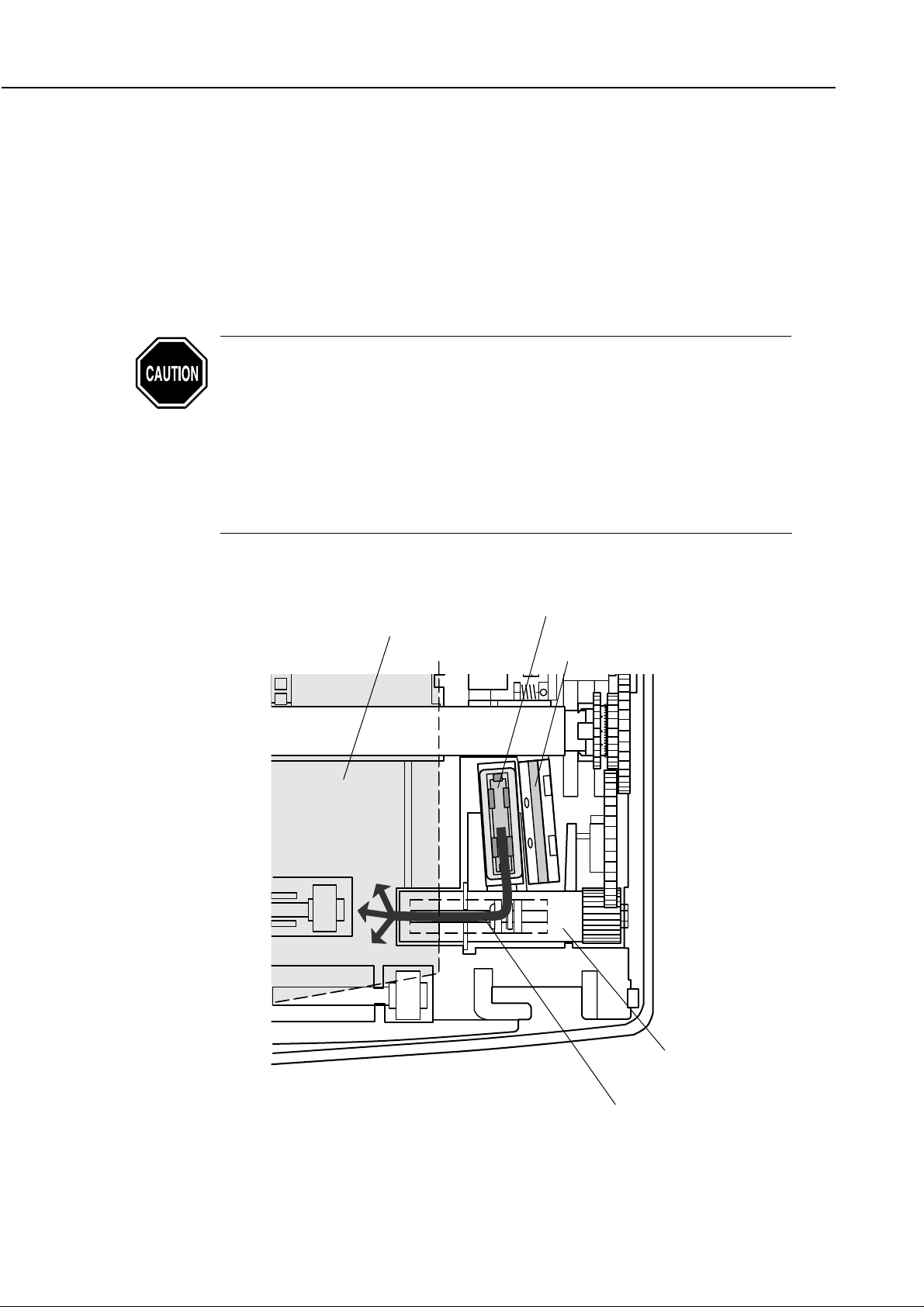

2.4.2 Ink leakage precautions

Do not carry, pack or store the printer without a BJ cartridge installed. The ink

within the cap section will flow back and soil the inside of the printer.

The nozzle section of the BJ cartridge is capped automatically when the power is

switched off with the

When the power is turned off, the carriage is locked so that it does not move from the

capping position.

POWER

BJC-50

button.

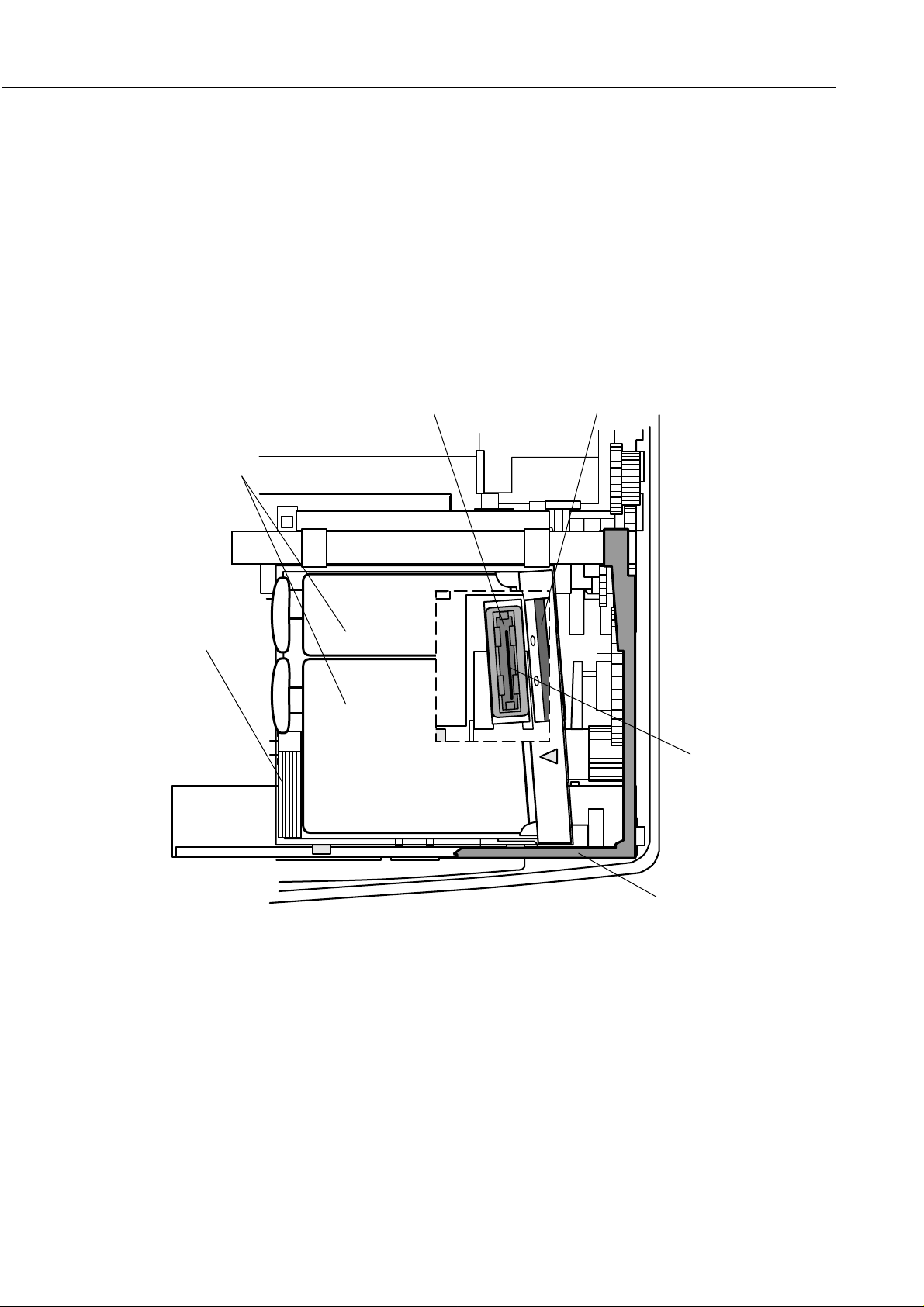

Ink Cartridges

BJ Cartridge

Cap

Wiper

Nozzles

Figure 1-8 Capping Position

1-10

Lock Arm

1) Checking EEPROM data

The number of sheets printed is counted and stored in the EEPROM to show the

printer operating status. This data can be printed by test print 3 (Ripple pattern

print).

The waste ink quantity data is also stored in the EEPROM. This data is used to

indicate a waste ink full error to prevent ink leakage if the amount of waste ink

absorbed becomes full.

2) When replacing the control board

If the control board on which the EEPROM is mounted is replaced, the quantity of

waste ink absorbed must be set in the EEPROM by visually checking the amount of

waste ink absorbed into the absorber from behind the printer base unit.

If it is not set, the waste ink full error is not displayed, and ink may leak.

3) When replacing the printer base unit

If a waste ink full error is displayed and the printer base unit is replaced, the waste

ink amount data in the EEPROM must be set to zero. If it is not set to zero, a waste

ink full error is displayed and the printer stops operating before the waste ink

absorber is filled with waste ink.

After the EEPROM is rest, the data it contained cannot be printed out with

a test printout.

If you want to check the stored data, be sure to execute test printout

before resetting the EEPROM.

When the stored data is reset, both the total count of printed sheets and

the total waste ink amount will be reset together. These settings cannot

be reset individually.

4) Rewriting the flash ROM

The flash ROM on the control board serves as the control section of the printer. In

earlier models a socket type masked ROM had to be upgraded by physically inserting

a new upgraded masked ROM. The flash ROM can be rewritten and hence upgrading

has been facilitated.

When flash ROM needs to be upgraded, a FD containing the upgrading program will

be distributed. Using this FD in a computer, the flash ROM of the printer can be

upgraded. In order to rewrite the flash ROM, both the printer and computer need to

be set in the rewrite modes.

For details on checking the memory data with test print and for clearing

them, see

Part 3: 3.6 EEPROM Data Setting (page 3-23).

When operation is stopped for the waste ink full error, handle the printer

as explained in

Part 5: 5. TROUBLESHOOTING (page 5-5 )

.

When rewriting the flash ROM, refer to the settings in

Part 3: 3.7 Rewriting

the Flash ROM (page 3-26)

.

1-11

BJC-50

Part 1: Safety and Precautions

3. PRECAUTION FOR SERVICE

3.1 Precautions Concerning the Memory Data

This printer counts the total waste ink amount for the black BJ cartridge and the color

BJ cartridge and stores these data in the EEPROM on the control board. Observe the

following precautions during servicing.

Part 1: Safety and Precautions

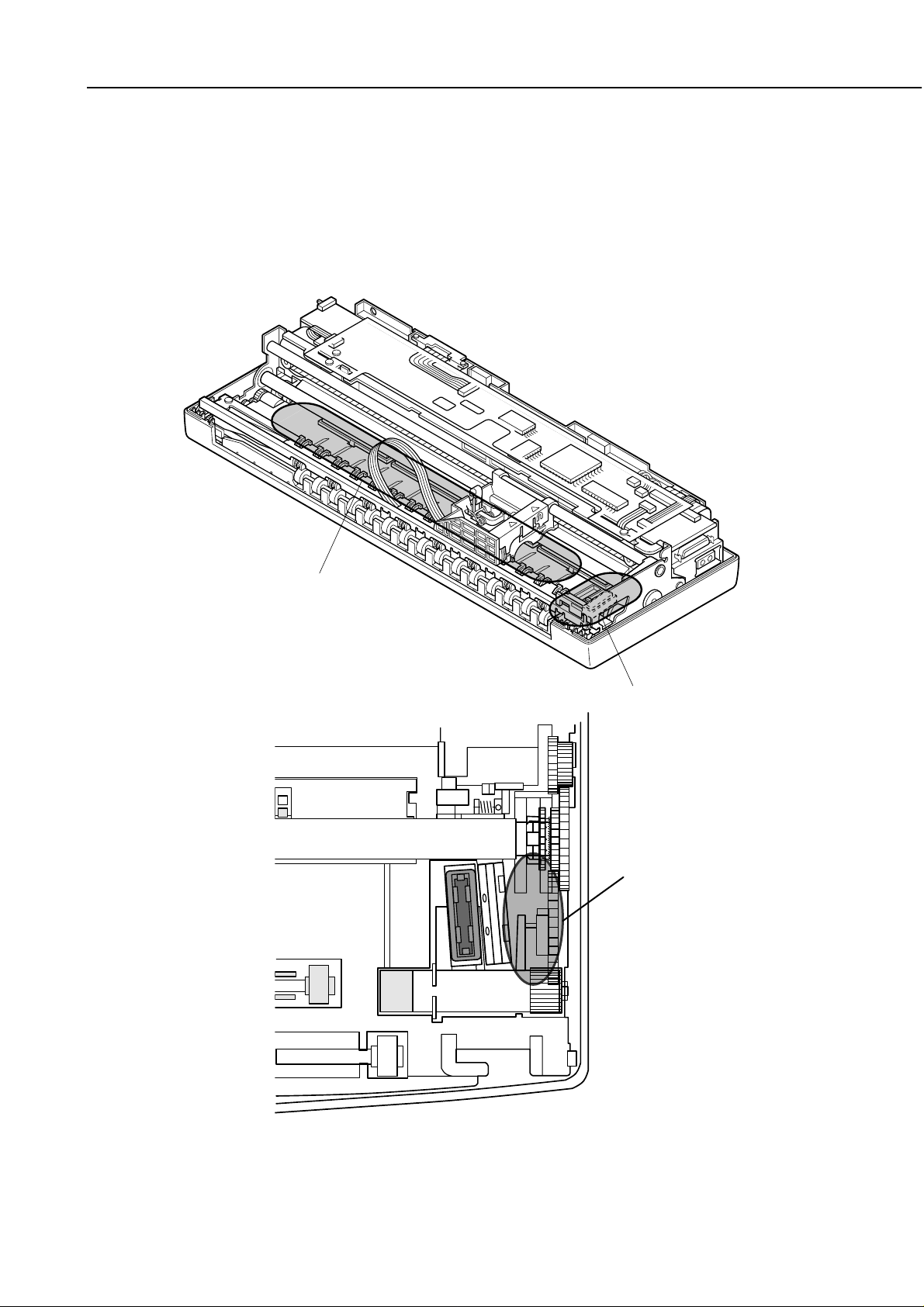

3.2 Precautions to Prevent Damage from Static Electricity

The electrical charge accumulated on a person when clothes rub can damage electric

elements or change their electrical characteristics. In order to prevent static electricity,

make sure to touch some metallic part that is grounded to release the static electricity

accumulated on your body before disassembling the printer for service.

BJC-50

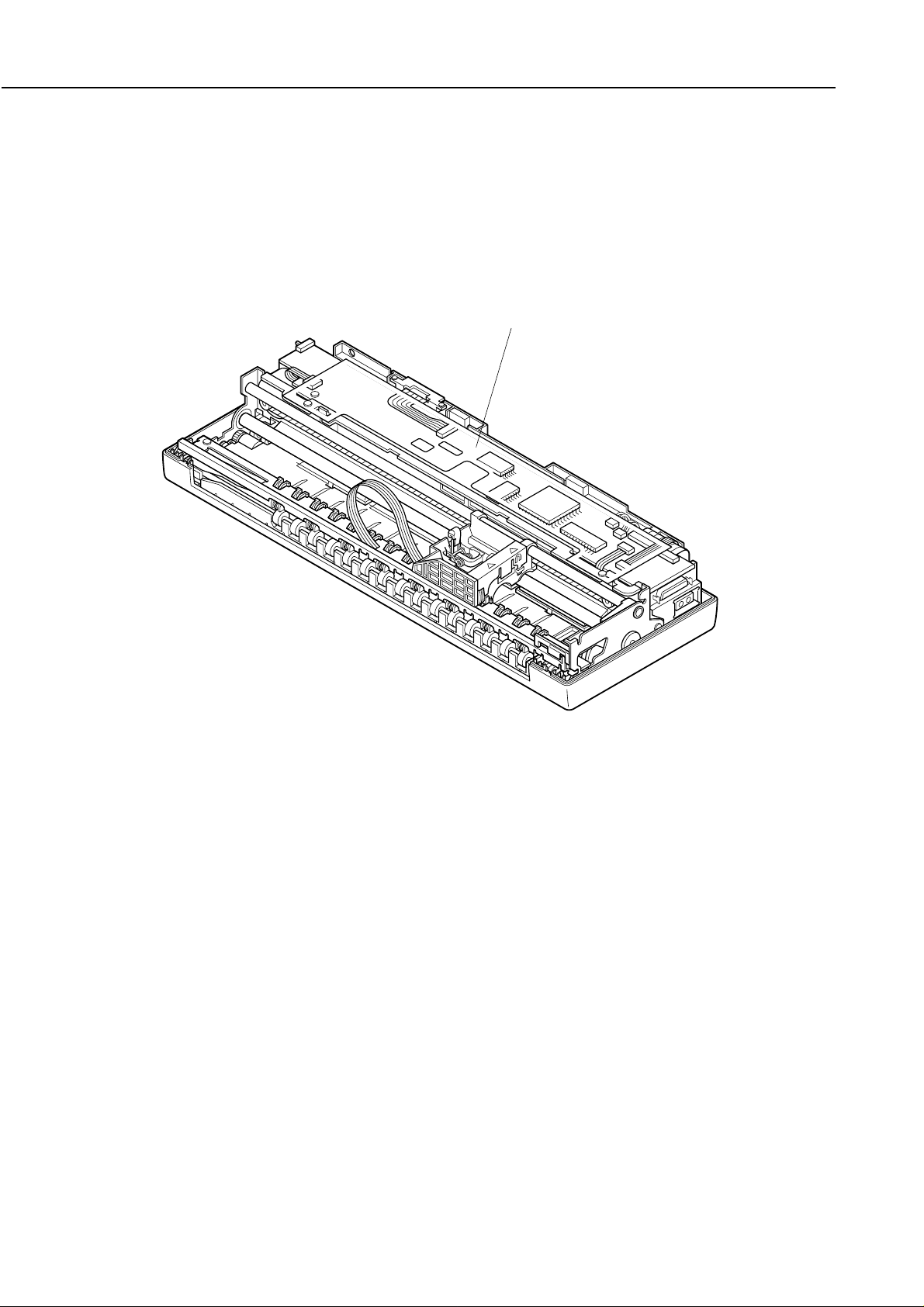

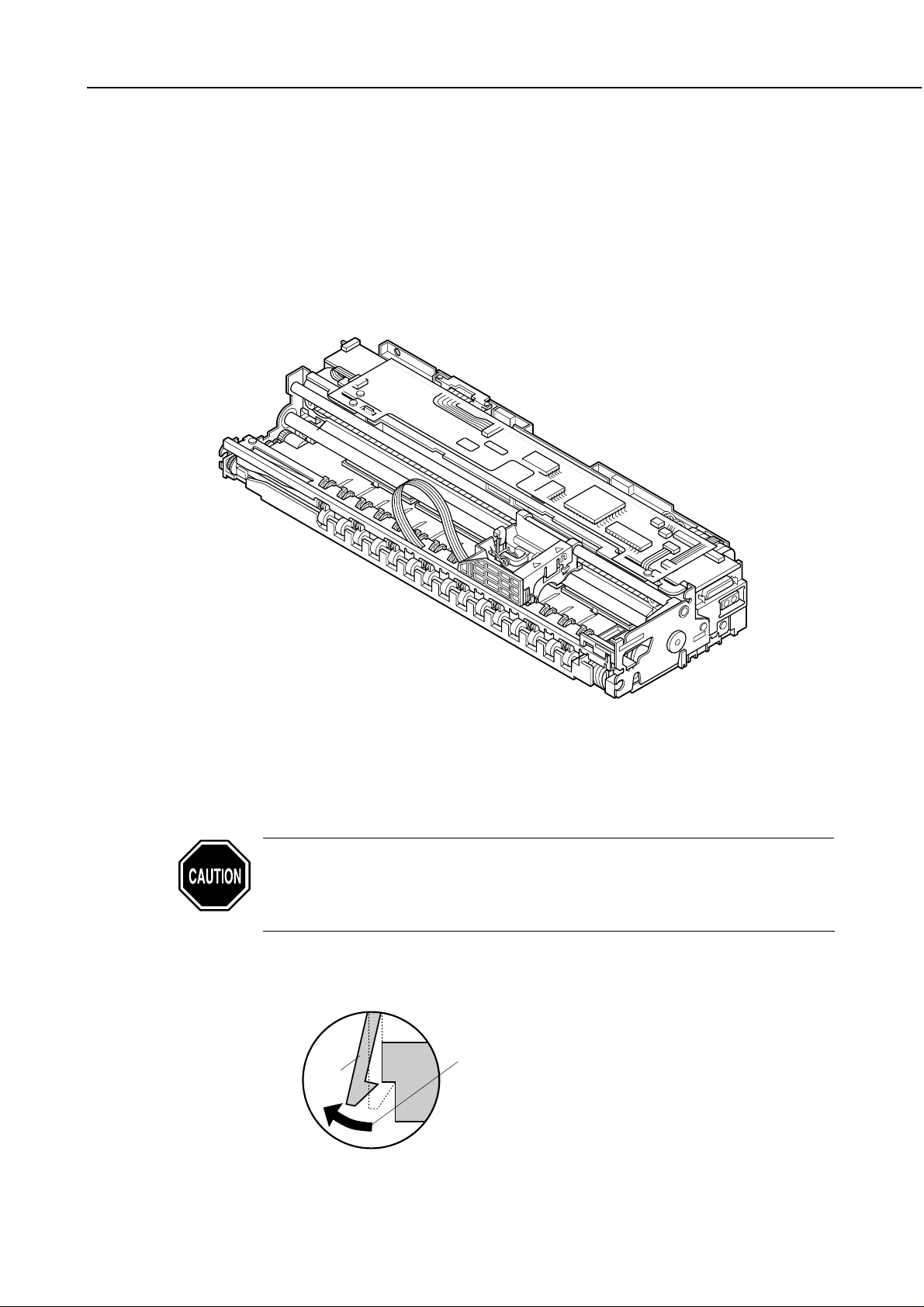

Control PCB Ass’y

Figure 1-9 Electronic System of the Printer

1-12

BJC-50

Part 1: Safety and Precautions

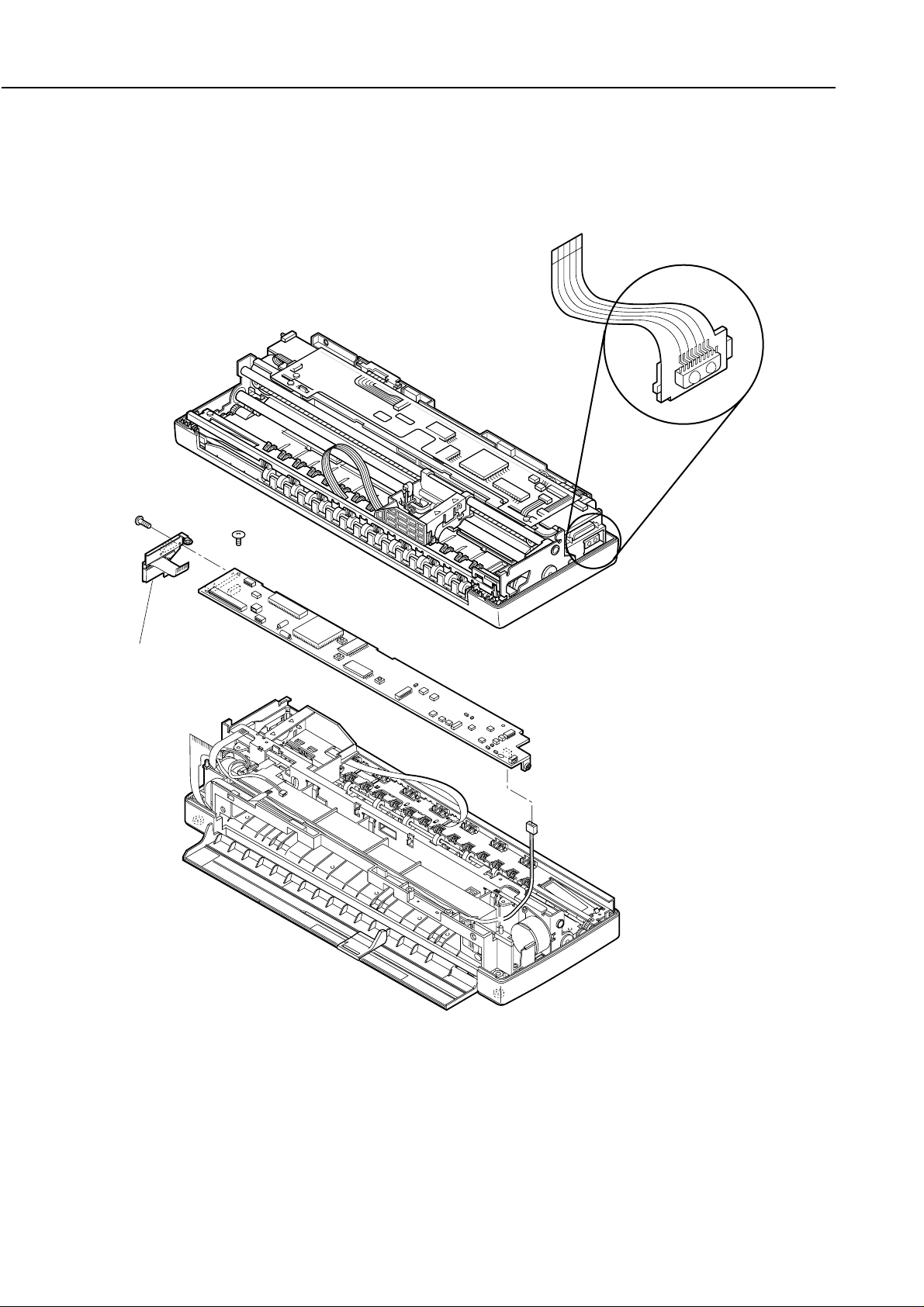

3.3 Precautions for Disassembly/Assembly

The printer is made by combining many plastic parts. When disassembling the printer,

be careful not to brake or bend plastic hooks.

Take special care not to rip or bend the flexible cables when removing and reinserting

them on the control board as they are very thin and frail. Also to prevent

misconnection, make sure the cable is fully inserted in the connector.

Details of disassembly and reassembly procedures are given in the Parts Catalog.

Figure 1-10 Control Board

Some of the plastic parts contain glass fibers for extra rigidity and

precision. Due to their inflexible nature these plastic hooks break easily.

Use a precision screwdriver or the like for disassembly, and do not apply

excessive force to release a hook.

Never apply excessive force

Hook

when releasing a hook.

Figure 1-11 Removing Plastic Hooks

1-13

Part 1: Safety and Precautions

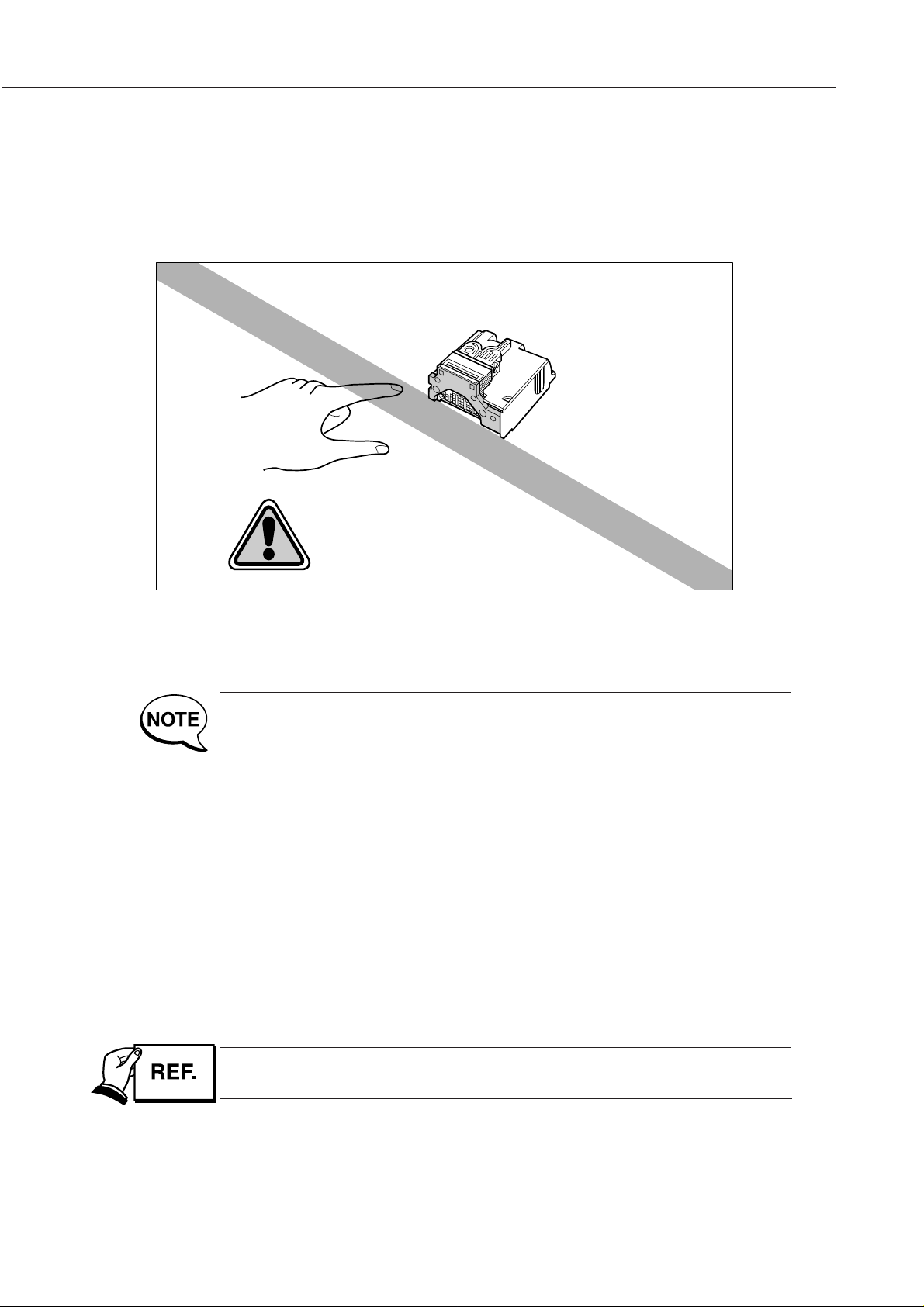

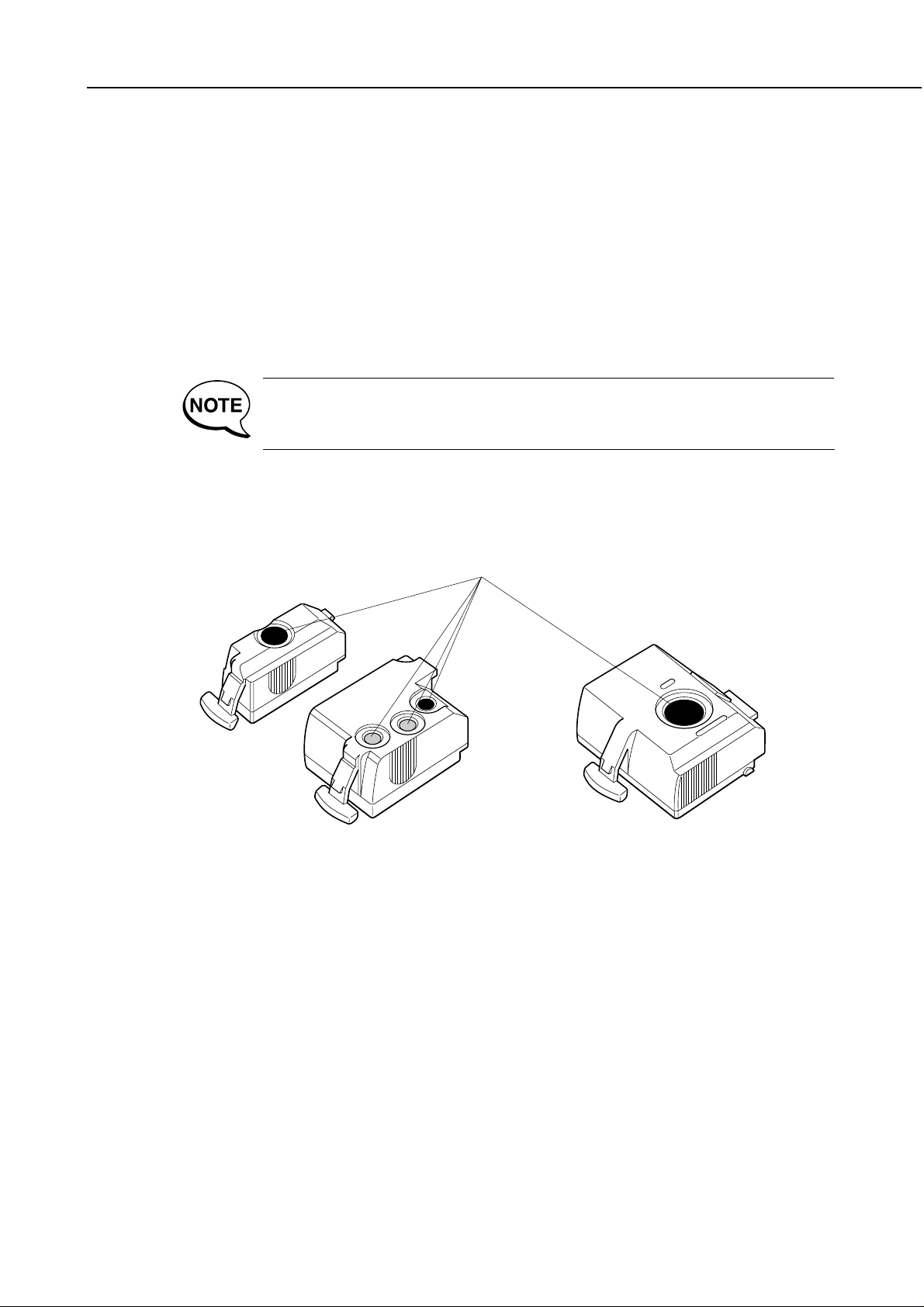

When replacing the IrDA unit, be careful not to touch the light emitting and receiving

parts. (Touching these parts may offset the optical axis or soil the lens and possibly

inhibit infrared communication.)

BJC-50

IrDA unit

Figure 1-12 IrDA Unit

3.4 Built-in Self-diagnostic Functions

The printer has built-in self-diagnostic functions to judge hardware defects. The

results of self-diagnosis are indicated by the indicators and the beeper. For details, see

Part 3: 3.1 Error Indications (page 3-12).

1-14

Part 2

PRODUCT

SPECIFICATIONS

Page

2 - 1 1. PRODUCT OUTLINE

2 - 1 1.1 Product Outline

2 - 2 1.2 Features

2 - 3 1.3 BJ Cartridge

2 - 5 1.4 Options

2 - 8 1.5 Consumable

2 - 9 2. SPECIFICATIONS

2 - 9 2.1 General Specifications

2 -13 2.2 Paper Specifications

2 -15 2.3 Interface Specifications

2 -22 2.4 Character Code Table

Loading...

Loading...