Canon 10BAR 450D User Manual

Camera Housing – Model 450D (Canon)

User Manual

Contents:

1. Introduction

2. Specifications

3. Function Controls

4. Set up Instructions

5. Use & Care of Housing

6. Service

7. Warranty

1. Introduction

10BAR Underwater Housings are small, light and rugged enough to be used on every dive. Use of a

clear polycarbonate allows for visual inspection of camera condition and the O-ring seal. 10BAR

Housings are designed for the ever -increasing variety of models of digital still and video cameras.

Advanced computer aided design and CNC manufacturing technologies ensure precise dimensions. Each

housing body is first injection molded, and then machined to configure to individual camera model. A

range of lens ports and controls are fitted, to tailor the housing to your camera model.

2. Specifications 450D

Test Pressure

Closure Design

Body Material

Overall Size

Total Weight

Buoyancy (with camera)

Features

Accessories

Optional accessories

Housings are individually tested to 10 Bar (90 m / 300 ft.) Recommended

working pressure 60 m.

O-ring, Air Lock

Polycarbonate

200 x 300 x 230 mm (LxWxH)

Approximately 2.6 Kg (Housing only)

Approximately neutral in salt water

Visible main O-ring for final pre-dive check

Double O-ring design on all controls

Bulkhead and hot shoe plug for External 580-EX e-TTL strobe

Standard Zoom Port18~55mm Lens

450D Opening key / Lever

Silicone O-ring grease

Spare main O-ring

Carrying bag

Cleaning Kit

Semi-Dome Port for 10~22mm Lens

580-EX e-TTL Flashlight Housing

Flex Arm

Ball-Joint Arm

Synchronous Cord

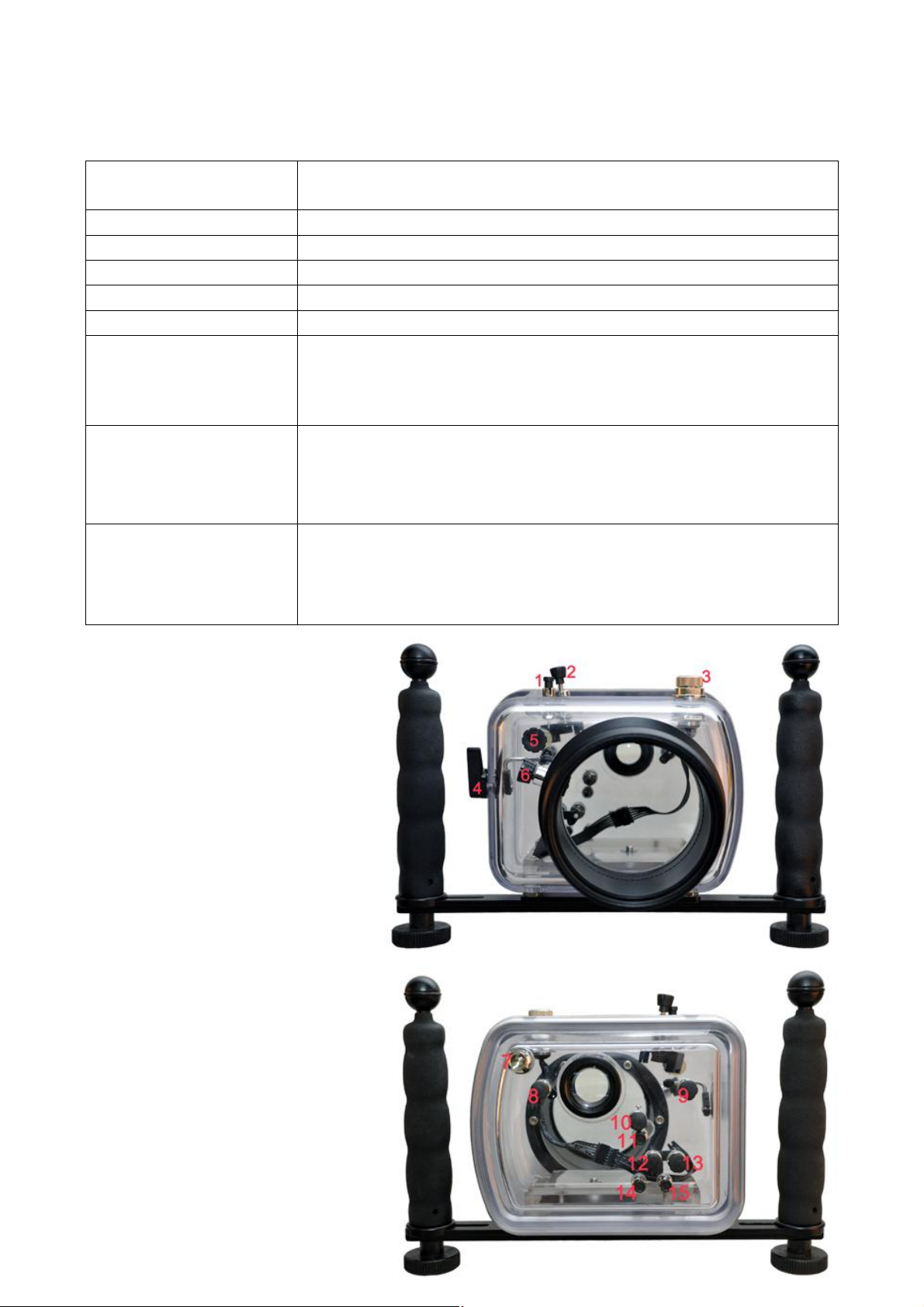

3. Function Controls 450D

1. ISO speedset

2. Mode Dial / Power switch

3. Flashlight syn bulkhead

4. Shutter

5. Main Dial

6. Zoom

7. Pressure release plug

8. Menu / DISP.

9. (AE/FE Lock/Index/Reduce) /

(AF point selection / Magnify)

10. Aperture / Exposure compensation

11. Print / Share / White balance selsction

12. Cross keys- (Metering mode) /

(Picture Style selection) /

(Drive Mode selection) /

(AF mode selection)

13. Setting

14. Playback

15. Erase

2

4. Set up Instructions

4.1 Air Lock:

The body and lid are designed with the Air Lock system “no clip” closure arrangement. Testing has shown that this

arrangement allow the water to exert an even pressure on the O-ring, increasing the reliability of the watertight seal.

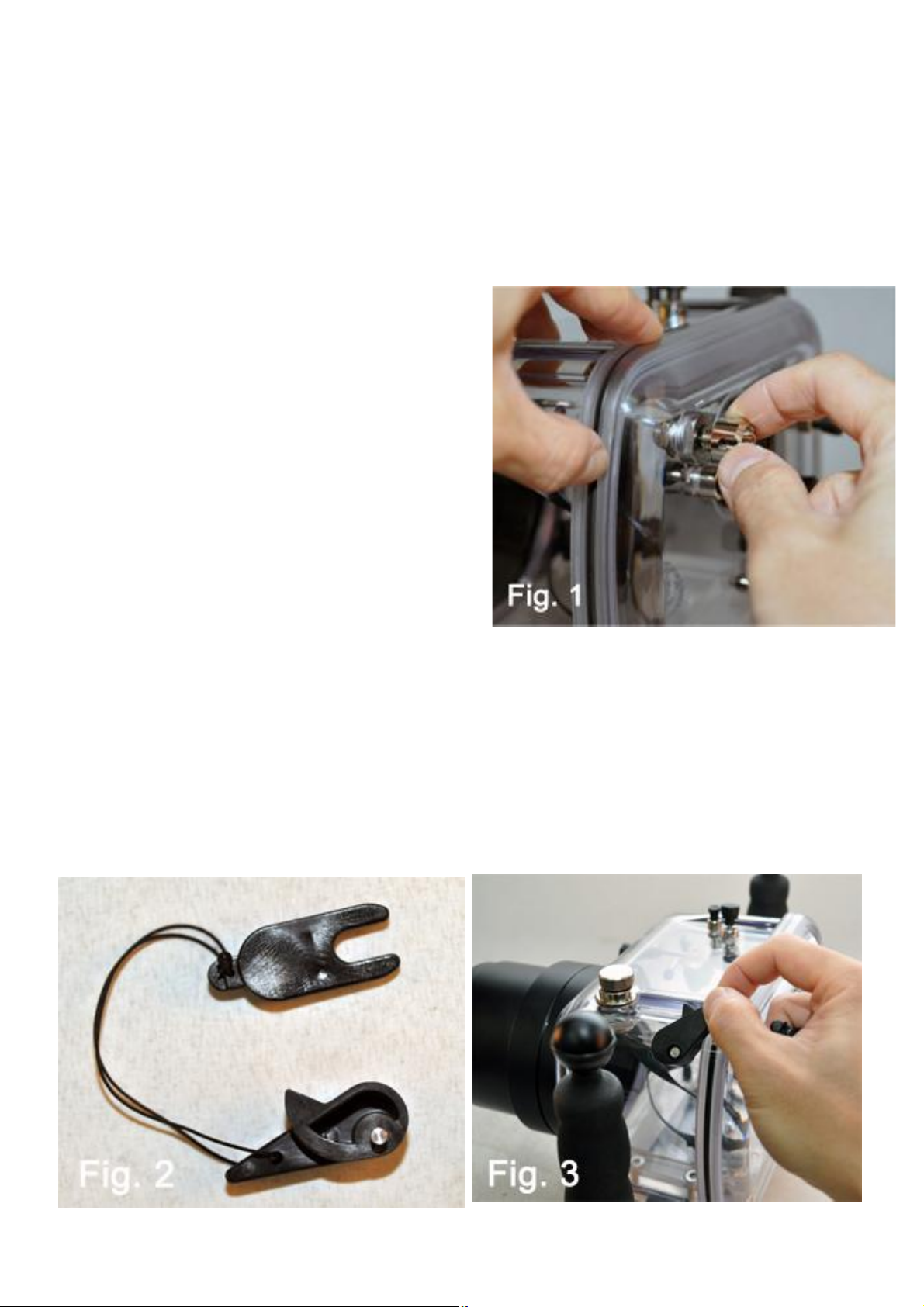

4.2 Pressure release plug

To open the housing, the pressure release plug must be first

unscrewed and then pulled out all the way (Counter-clockwise)

(Fig 1). This provides a passage for the air to pass though

and eliminate the pressure different between the inside of the

housing and the ambient. The plug onsists of an internal

double O-ring seal on the stainless steel slide shaft.

These internal O-rings form the watertight seal. There is also a

large outer O-ring under the knob. This O-ring serves to

prevent contamination of the slide shaft, with dirt, salt etc., and

is not required for watertight integrity. If this O-ring should

become detached, it can simply be pushed back in place.

4.3 Opening levers

After unscrewing and pulling out the pressure release plug, the lid can be opened. To overcome the friction of opening,

use lever (Fig. 2) to push against the lid with a cam action. Be sure they are inserted all the way flat to the housing before

turning to avoid damaging the protrusions on the lid. The body has four holes on each corner edges for opening. Gently

lever off the lid with the supplied opening lever (Fig. 3) taking care not to twist the lid excessively. The lid should be

opened keeping it approximately paralleled to the body at all times, turn first one corner a little, then the other a little,

and repeat again until the lid is opened. Remember to unscrew and pull out the pressure release plug all the way first,

otherwise the air pressure will resist attempts at opening. Lay the lid on a flat stable surface after opening.

3

Loading...

Loading...