Page 1

®

SimpleVIS

Viscometer

Reference

Guide

P82.0090

Page 2

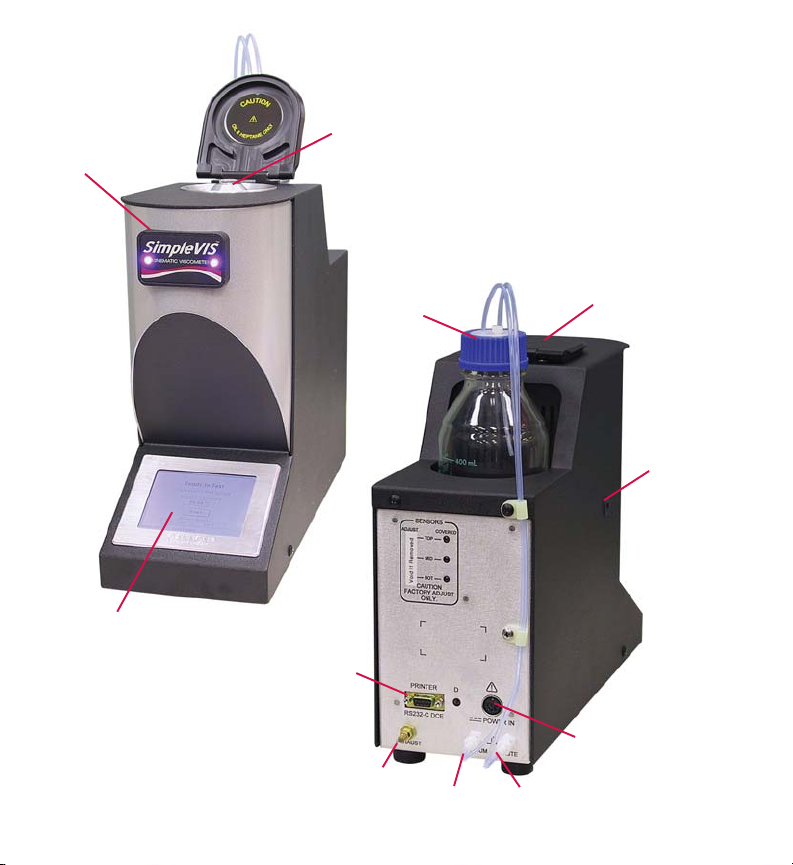

Run Status

Indicator

Lamps

Sample/Solvent Port

Touch Screen

Display

RS-232

Serial

Port

Exhaust Muffler

Waste Bottle

Vacuum Line

Dust Cover

Temperature

Calibration

Port

Power Connector

Waste Line

Page 3

SAFETY CAUTIONS Please observe the following safety procedures

and notices for proper operation of the SimpleVIS® Viscometer.

• Make sure that you read and understand all operating instructions and safety

precautions listed in this manual before installing or operating your unit. If you have

questions regarding instrument operation or documentation, contact CANNON

Instrument Company.

• Do not deviate from the installation, operation or maintenance procedures

described in this guide. Improper use of the SimpleVIS

hazardous situation and may void the manufacturer’s warranty.

• Handle and transport the unit with care. Sudden jolts or impacts may cause

damage to components.

• Do not place the SimpleVIS

SimpleVIS

®

Viscometer should be placed on a level table or bench.

®

Viscometer on an unstable cart or stand. The

• Never operate damaged or leaking equipment.

• Unless procedures specify otherwise, always turn off the unit and disconnect the

mains cable from the power source before performing service or maintenance

procedures, or before moving the unit.

• Never operate the equipment with damaged mains power cables.

• Refer all service and repairs to CANNON

®

Authorized Service Personnel.

CAUTION

In addition to the cautionary statements listed above, additional cautions may be

posted in the manual. These cautions, identified by the symbol at the left indicate

important operational procedures. Read and follow these important instructions.

Protective Conductor

The Protective Conductor Terminal symbol is used to indicate required ground

connections for your instrument electrical supply.

WARNING

When supplying power to this instrument, ensure that the protective ground (earth)

terminals of the instrument are connected to the protective conductor of the

(supplied) line (MAINS) power cord. Use only the manufacturer-supplied power

cord. The main plug for the power cord should only be inserted in a socket outlet

(receptacle) provided with a protective ground (earth) contact. Do not use an

extension cord (power cable) without a protective conductor (grounding).

®

Viscometer may result in a

®

3

Page 4

~MAINS

The ~MAINS symbol indicates instructions or connections for the AC power

supply. The AC Power input must match the electrical specifications listed on the

label on the rear panel of the instrument. The supplied AC Mains power cord

must be attached to the connector labeled ~MAINS. This connection serves as a

means of disconnect and should be readily accessible.

( O )

The (O) symbol indicates the OFF position for the electrical switches for your unit

(AC Mains or accessories).

Hazardous materials

Routine SimpleVIS

handling of hazardous chemicals and solutions. CANNON

®

Viscometer operation may require the use and

®

Instrument Company

strongly urges the operators and technicians working with the SimpleVIS

Viscometer to take proper safety precautions when working with these materials.

These safety procedures can be found in the Material Safety Data Sheets which

accompany the solutions.

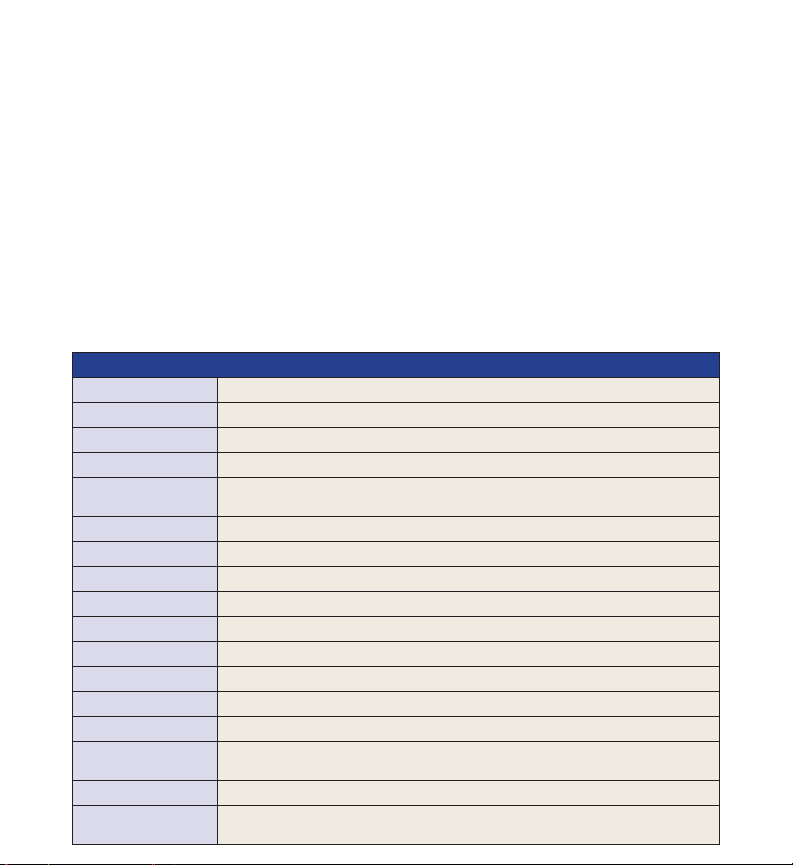

SimpleVIS® Viscometer Specifications/Compliance

Product Info. Model: SimpleVIS® Viscometer (Cat. No. 9725-S10)

Applications ISO VG Lubricants, SAE Engine and Gear Oils

Methodology Kinematic Viscosity, ASTM D7279 or ASTM D445-Modifi ed

Test Temperatures 40 or 100 °C - user selectable

Viscosity Range 40°C: 10 – 700 mm2/s (cSt)

Accuracy < 3% of measured value, calibrated

Repeatability < 2% of measured value, typical

Sample Material Type Mineral Oils, Synthetic Oils, Formulated Motor/Gear Oils

Solvent Compatibility Internal wetted components compatible with n-heptane only

Volume Requirements Sample: 450 – 500 μL Solvent: 10 – 15 mL per test

Dimensions 128 mm wide x 356 mm deep x 304 mm high (5x14x12”)

Weight SimpleVIS

Shipping Weight 12.3 kg (27 lbs) with all accessories

Input Power SimpleVIS

AC/DC Adapter

Power Requirements

Operating Conditions 15°-30°C, 10%-90% R.H. non-condensing, Installation Category II, Pollution degree 2

Compliance CE Mark: EMC Directive (2004/108/EC); Low Voltage Directive (2006/95/EC);

4

100°C: 5.5 – 200 mm2/s (cSt)

®

Viscometer unit: 4.6 kg (10.2 lbs)

®

Viscometer Operation Voltage: 11 – 13 VDC @ 5A peak

100~230 Volts, 50/60 Hz, 100 Watts

HI-POT (1900 VDC, 60 sec.); ROHS

®

Page 5

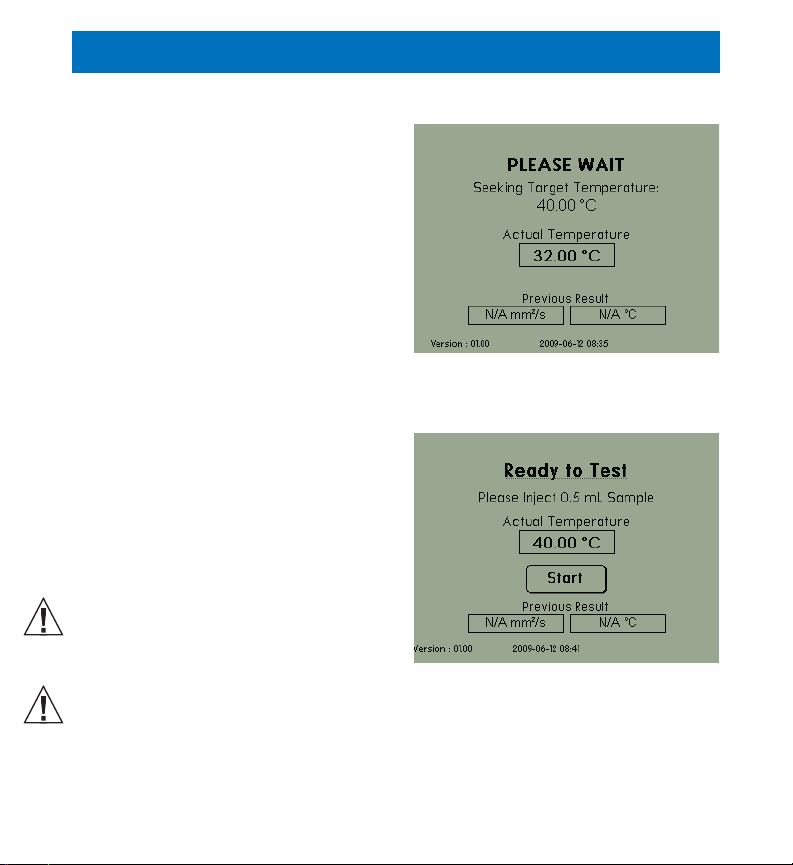

Running a Test

Running a Test

GETTING STARTED

Press the on switch on the AC/DC

adapter. The Warm up Screen will

display a “PLEASE WAIT” message.

During this time, the instrument will

seek the preset target temperature

(40 or 100°C) and when reached, the

instrument will enter an equilibration

period. The equilibration period is 180

seconds.

Note: Refer to the Basic Information

section under Select Target

Temperature for instructions on how

to select the target temperature.

Once the temperature has equilibrated

and the instrument is ready for

measurement, the run status indicator

lamps on front of instrument will

illuminate and the user will be prompted

to inject the sample on the Ready to

Test Screen.

Check the volume of the solvent

container at the beginning of every

work shift to avoid inadequate

washing during testing.

Check the volume of the Waste Bottle

frequently to avoid spillage/overfl ow. Empty the waste bottle when the

volume reaches the 400 mL line marked on the bottle. Refer to the Basic

Maintenance portion of this guide for more information.

Warm up Screen

Ready to Test Screen

5

Page 6

Running a Test

Injecting a sample

1. Using the supplied piston

operated pipettor, insert the tip

into a vial of test sample and

pull the measured amount

into the pipettor. Be sure no

bubbles exist in the oil or

results may be erratic. Refer

to pipettor instruction guide

for more information. The

pipettor volume setting should

be set to 450 ~ 500 μL

(0.45 - 0.50mL)

2. Place the pipettor at a 45°

angle into the sample/ solvent

injection port, located on

top of the instrument, and gently release the fluid in one easy operation

so that the entire sample is smoothly dispensed into the tube without

introducing bubbles.

The Ready to Test Screen contains a START button. Pressing the button is

optional as the injected sample will automatically be detected. The button is

useful for higher viscosity fluids that might take a while to trip the top sensor.

The run status indicator lamp will turn off during testing. When the viscosity

measurement is complete, the run status indicator lamp will blink and the

viscosity result will be displayed.

6

Page 7

Running a Test

Print the results (only if

optional printer is installed)

1. Press the Print button on the

display screen to printout the test

results to an attached serial printer

(optional accessory).

2. You may skip the print option and

go directly to the wash cycle. See

the next section.

Wash Cycle

1. Place the tip of the solvent bottle

along the opening of the glass

capillary in the sample/solvent port and gently squeeze until the cup is

filled with solvent to clean any oil residue that might be left over from

injecting the previous sample.

Be careful to consider bath temperature (s) and potential solvent

hazards when selecting solvents for use with the SimpleVIS

Observe appropriate safety precautions when handling solvents.

Note: Heptane (technical grade) is compatible with the

SimpleVIS

2. Press the Wash button on the display screen to start the wash cycle.

3. Wait for the solvent in the cup to be drawn down the tube.

4. Place the tip of the solvent bottle directly into the glass capillary for

approximately one second (no need to squeeze the bottle, the pump

will pull the solvent in) and then remove for several seconds to allow the

solvent to be drawn through the viscometer tube to the waste bottle. The

display screen will prompt the user when to inject and remove the solvent

bottle. Repeat this step until the display screen alerts the user to press the

Dry button to start the dry run cycle.

®

Viscometer.

Result Screen

®

Viscometer.

7

Page 8

Running a Test

Dry Cycle

Press the Dry button on the display wash screen to start the dry run cycle. The

display will show the time remaining in the dry cycle.

When the dry cycle time ends, the pump will turn off and the instrument will

return to the Warm up Screen for a period of 60 seconds. The instrument

will then be ready to run a new sample measurement at the leisure of the

operator.

Run Status Indicator

Run Status Indicator lamps on front of the instrument allow users to see

from a distance whether the instrument is ready to accept a sample. When

the instrument is ready to accept a sample, the lamps will be lit. During the

viscosity measurement, the indicator lamps will be off. The indicator lamps

will blink at the conclusion of a new test or if an instrument error occurs.

Dry ScreenWash Screen

8

Page 9

Maintenance & Calibration

The SimpleVIS® Viscometer was designed to require minimal maintenance

through simplicity of design and built-in electronic diagnostics. All new

instruments are shipped with factory calibrations. However, like most

metrological equipment, periodic maintenance and calibration is critical

to maintaining accurate long-term measurements. CANNON

Company recommends the following intervals for maintaining the proper and

accurate operation of the SimpleVIS® Viscometer.

Basic Maintenance

The main chassis of the SimpleVIS® Viscometer does not contain any

user-serviceable parts and should be returned to the manufacturer (or an

authorized dealer service center) for repair when required. Basic instrument

maintenance should be carried out weekly or each time the effluent waste

bottle is emptied.

Cleaning the Viscometer Tube

To clean the viscometer tube simply start a wash cycle by tapping the “Ready

to Test” caption field in the Ready to Test Screen three times within two

seconds. This will cause the display to switch to the Wash Screen and start a

normal wash. See discretionary washing on page 12.

Changing the Tip on the Pipettor

Refer to the pipette manual for detailed information on using the device. The

tips can be wiped off after each test and reused. Use a clean dry paper towel

to wipe the tip off.

Cleaning the Display Screen

Turn off the SimpleVIS

with clean or distilled water. Wring out as much water as possible to ensure

the cloth is damp but not wet. Wipe the screen in a gentle motion to remove

dust, oil, or fingerprint smudges. Finish cleaning the touch screen with a dry

lint-free cloth to wipe any excess moisture, and then turn the instrument back

on.

®

Viscometer. Wet a soft, lint-free or micro fiber cloth

®

Instrument

9

Page 10

Maintenance & Calibration

Emptying the Waste Bottle Receiver

Check the volume of the Waste Bottle frequently to avoid spillage/overflow.

Disconnect the Waste Bottle from the cap containing the drain lines.

Use appropriate precautions when handling the waste lines. Avoid

spilling or splashing waste material collected in the lines. Check for

kinks or wear in the lines. Always follow appropriate MSDS procedures

when handling samples/solvents.

Pour the collected solvent/sample mixture out of the Waste Bottle into a

proper hazardous liquid waste storage container. Securely reconnect the cap

with drain tubes to the Waste Bottle ensuring the lines are properly inserted.

(Refer to the Basic Information section of this guide for more information on

tubing connection)

Waste sample/solvents can present possible environmental and

health hazards. Dispose of all waste materials in accordance with all

applicable governmental environmental and safety regulations.

Cleaning the Tray that Houses the Waste Receiver

Use a clean dry paper towel to wipe the tray to remove any spillage of

solvent/sample. Dispose of the paper towel appropriately.

Changing Temperature

Change the temperature by tapping the temperature directly under the

“Seeking Target Temperature” caption field in the Warm Up Screen three

times within two seconds.

Calibration

The frequency of instrument calibration is dependent on the usage of the

instrument (number of samples tested monthly), the environment in which the

instrument is located, the type and cleanliness of the samples, and whether

basic maintenance has been properly carried out. CANNON

®

recommends

10

Page 11

Maintenance & Calibration

either of the two following calibration intervals.

Performance Based Method

Determine need to calibrate by performing weekly check-runs of certified

viscosity reference standards. It is recommended the results of these runs

be recorded and compared against the certified viscosity value printed on

the standard bottle. When these check-runs consistently exceed the required

precision (typically > 2 or 3%), then the instrument should be calibrated. This

method requires more user interaction, but affords the least amount of risk

that the instrument could be used when out-of-calibration.

Periodic Interval Method

On a 12-month basis, the instrument is returned to CANNON

Company for calibration and certification regardless of the prior usage and

performance. This method requires the least amount of user interaction with

the instrument, but does afford some risk as errant calibrations (if present) will

only be corrected once every 12 months.

Verifying Temperature

Periodically, the temperature should be verified with

a digital reference thermometer. The temperature

should be recalibrated if the displayed temperature

does not agree with the reference thermometer.

Note: Please contact CANNON

Company for details on suitable reference

thermometers.

The user may access Temperature

Calibration Screen from the Ready to Test

Screen by tapping the temperature field 3 times within 2 seconds. The

Temperature Calibration Screen will appear in which the user may

enter the temperature as read from the reference thermometer to the nearest

0.01°C. This may need to be repeated if the temperature still does not agree

®

Instrument

Temperature Calibration

®

Instrument

Screen

11

Page 12

Maintenance & Calibration

with the reference with the desired tolerance.

Changing the temperature calibration by more than 0.05°C will affect

the instrument viscosity calibration by 2% or more. Please consult

CANNON

It is recommended that the instrument temperature be at target for at least

30 minutes before recalibrating if the instrument has been powered down

for more than a couple of hours. This will ensure proper calibration as it

may take some time for the entire instrument to come to proper thermal

equilibration from a cold start.

Changing Date and Time

End users may need to change the date and

time displayed on the instrument. This may

be accomplished by just tapping once on the

Date/Time field at the bottom of the Warm

up Screen or the Ready to Test Screen.

These fields are soft buttons which will access

Date and Time Screen. This screen

provides list boxes to set the Year, Month, Day

of Month, Hour and Minute.

Discretionary Washing

Tube washing is normally performed after a

test is completed, but there may be other times

when the tube needs washing. For example, if

the user injects oil into the tube and the sensors

do not detect it for some reason. In cases

such as this, the wash cycle may be started

by tapping the “Please Wait” caption field in

the Warm up Screen or the “Ready to Test”

caption field in Ready to Test Screen or

the “Timing Started” caption field in Timing

Screen three times within 2 seconds. This will

cause the display to switch to Wash Screen

and start a normal wash cycle.

12

®

before proceeding.

Date and Time Screen

Timing Screen

Page 13

Basic Information

Unpack your SimpleVIS® Viscometer

Remove all packing materials from the components. The SimpleVIS®

Viscometer should be placed on a stable laboratory table or bench.

1. Verify that you have received all components for the SimpleVIS

Viscometer. Report missing items to CANNON

®

Instrument Company

immediately.

2. Inspect each component for signs of damage. Report damages to the

shipper and CANNON

®

Instrument Company immediately.

3. Retain all packing materials until the instrument is connected and

functioning properly. If any component(s) must be returned to CANNON®

Instrument Company, the damaged item(s) should be packaged in the

included shipping case.

Setting up your SimpleVIS® Viscometer

Complete the following rear panel electrical connections:

1. Plug the AC/DC power adapter into the power connector on the rear

panel of the instrument. The connector will only go in one way correctly.

Make sure the power switch on the AC/DC adapter is off.

2. Plug the power cord into the AC/DC adapter. Plug the other end of the

power cord into an appropriate AC Mains outlet matching the voltage

requirements indicated on the AC/DC adapter.

3. Do not turn on the AC/DC adapter switch at this time.

(Optional printer: Plug the 9 pin serial printer cable into the RS232-C port on

the rear panel of the instrument. Then plug the other end into the printer.)

Complete the following tubing connections:

1. Locate the glass waste bottle and securely (but not overly) tighten the

bottle cap to ensure an air-tight seal. Place the bottle in the holder on the

top rear of the SimpleVIS

2. Connect both pieces of the1/8” transparent tubing into the bottle cap.

3. Make sure that the waste line extends into the cap further than the

®

Viscometer.

®

13

Page 14

Basic Information

vacuum line by approximately 2 inches.

4. Connect the other ends of both pieces of

tubing as indicated in the photo image.

Select Target Temperature

1. Press the on switch on the AC/DC

adapter. The Warm up Screen will

display a “PLEASE WAIT” message

2. Select the temperature by tapping the

temperature directly under the “Seeking

Target Temperature” caption field in the

Warm Up Screen three times within

two seconds. This will cause the display to

switch to the Set Temperature Screen.

3. Select the desired temperature then press

the save button.

Returning your instrument to Cannon® Instrument Co.

1. Please contact CANNON® Instrument Company to receive a Return

Authorization (RA) number from our Technical Service Department.

2. Download our Instrument Repair/Calibration Return Form and fill in all

required information on the form

3. Carefully package and ship your instrument with all required information

in the case supplied with the instrument. The RA number needs to be

clearly marked on the package label. Ship to the following address:

Cannon Instrument Company

ATTN: Return Authorization Number: ________

2139 High Tech Road

State College, PA 16803 USA

When returning your instrument please include the following information:

The name and telephone number of the person in your company to contact

regarding the instrument.

14

Page 15

Components for

the SimpleVIS

®

Viscometer

9725-S10

Waste Bottle

Media Cap

P82.0075

Plug

P65.3203

1/8” Transparent

Tubing

P81.2185

Waste Bottle

P82.0075

Pipette Seals,

pkg. of 8

(optional)

P82.0056

Printer Cable

(optional)

P82.0065

Printer Power

Supply

(optional)

Printer with

Power Supply

(optional)

P82.0076

Pipettor

P82.0055

Solvent

Container

P82.0053

AC/DC

Adapter

P82.0028

Pipette Tips

(optional) P82.0054

Power

Supply Cord

P74.2110

(120V)

15

Page 16

2139 High Tech Road • State College • PA • 16803

814-353-8000 • 800-676-6232 • Fax 814-353-8007

cannon@cannoninstrument.com • www.cannoninstrument.com

simplevismanual.indd 07.09.12

Loading...

Loading...