Page 1

2 1 9 0 0 1 4 5 1

Read this guide thoroughly. It contains important safety information.

Minimum recommended operator

’s age: 16 years old. Experienced

operator only. Keep this Operator

’s Guide in the vehicle.

WARNING

DS 450 Series

2015

DS 450

TM

Series

Includes

Safety, Vehicle

and

Maintenance Information

(Canada/United States)

Operator’s

Guide

2015

Original Instructions

Page 2

WARNING

YOUR VEHICLE CAN BE HAZARDOUS TO OPERATE. A collision or rollover

can occur quickly, even during routine maneuvers such as turning and

driving on hills or over obstac les, if you fail to take proper precautions.

For your safety, understand and follow all the warnings contained in this

Operator's Guide and the labels on your vehicle. Failure to follow these

warnings can result in SEVERE INJURY O R DEATH!

Keep this Operator's Guide with the vehicle at all times.

WARNING

Disregarding any of the safety precautions and instructions contained in

this Operator’s Guide,

SAFETY DV D

and on-product labels could cause

injury including the possibility of death!

WARNING

This vehicle may exceed the performanc e of other vehicles you may have

ridden in the past. Take time to familiarize yourse lf with your new vehicle.

CALIFORNIA PR OPOSITION 65 WARNING

WARNING

This vehicle contains or emits chemicals known to the stat e of California to

cause cancer and birth defects or other reproductive harm.

In Canada, products are distributed by Bombardier Recreational Products Inc.

(BRP). In USA, products are distr ibuted by BRP US Inc.

The following trademarks are the property of Bombar

dier Recreational

Products Inc.:

Can-Am™

DS 4 50™ X™ xc

DS 450™ X™ mx

Rotax

®

XPS™

This document contains the trademarks of the following companies:

- Fox is a trademark of Fox Racing Shox

- Fox Float

®

X Evol™and Podium®are trad

emarks of Fox Racing Shox

vmo2015-012 en JT

®™ and the BRP logo are trademarks o f Bombardier Recreational Products Inc. or its affiliates.

©2014 Bombardi

er Recreational Products Inc. and BRP US Inc. All rights reserved.

Page 3

FOREWORD

Dieses Handbuch ist möglicherweise in Ihrer Landessprache

Deutsch

verfügbar. Bitte wenden Sie sich an Ihren Händler oder besuchen Sie:

www.operatorsguide.brp.com.

English

Español

Français

Nederlands

Norsk

Português

Suomi

Svenska

This guide may be available in your language. Check with your dealer or

go to: www.operatorsguide.brp.com.

Es posible que este manual esté disponible en su idioma. Consulte a su

distribuidor o visite: www.operatorsguide.brp.com.

Ce guide peut être disponible dans votre langue. Vérifier avec votre

concessionnaire ou aller à: www.operatorsguide.brp.com.

Deze handleiding kan beschikbaar zijn in uw taal. Vraag het aan uw dealer

of ga naar: www.operatorsguide.brp.com.

Denne boken kan finnes tilgjengelig på ditt eget språk. Kontakt d in

forhandler eller gå til: www.operatorsguide.brp.com.

Este manual pode estar disponível em seu idioma. Fale com sua

concessionária ou visite o site: www.operatorsguide.brp.com.

Käyttöohjekirja voi olla saatavissa omalla kielelläsi. Tarkista jälleenmyyjältä

tai käy osoitteessa: www.operatorsguide.brp.com

Denna bok kan finnas tillgänglig på ditt språk. Kontakta din återförsäljare

eller gå till: www.operatorsguide.brp.com.

Congratulations on your purchase of a

new Can-Am™ ATV. It is backed by the

BRP warranty and a network of authorized Can-Am dealers ready to provide

the parts, service or accessories you

may require.

Your dealer is committed to your satisfaction. He has taken training to perform the initial setup and inspection of

your vehicle as well as completed the

final adjustment before you took possession. If you need more complete

servicing information, please a

sk your

dealer.

At delivery, you were also inform

ed of

the warranty coverage and signed the

PREDELIVERY CHECK LIST

your new vehicle was prepared t

to ensure

oyour

entire satisfaction.

Know Before you Go

To learn how to reduce the risk for you

or bystanders being injured or killed,

read this Operator's Guide before you

operate the vehicle:

–

SAFETY INFORMATION

–

VEHICLE INFORMATION

Also, read all safety labels on your ATV

and watch attentively your

DVD

video.

Failure to follow the warnings contained in this Operator's Guide can

result in SER IOUS INJURY or DEATH.

Age Recommendation

This vehicle is a category S, always follow this age recommendation: A person under 16 years old should never

operate this vehicle.

.

SAFETY

This vehicle is for recreational

use by

experienced operators only.

_______________

1

Page 4

FOREWORD

WARNING

This is a high performance ATV. Inexperienced riders may overlook

risks and be surprised b y the specific behavior of this ATV in any

riding conditions.

Training Course

Never operate t his vehicle without

proper instruction. Take a training

course. All operators should receive

training from a certified instructor.

FOR MORE INFORMATION ABOUT

ATV SAFETY, contact an authorized

Can-Am dealer to find out about available training courses nearest you.

Call the Specialty Vehicle Institute of

America (SVIA) at 1 800 887-2887 or

in Canada, the Canada Safety Council

(CSC) at 1 613 739-1535.

NOTICE

which, if not followed, could severely damage vehicle components

or other property.

Indicates an instruction

About this Operator's

Guide

This Operator's Guide has been prepared to acquaint the owner/operator

of a new vehicle with the various vehicle controls, maintenance and safe

operating instructions. It is indispensable for the proper use of the product.

Keep this Operator's Guide in the vehicle as you can refer to it for things such

as maintenance, troubleshooting and

instructing others.

Note that this gu id e is ava ilab le in several languages. In the event of any discrepancy, the english version shall prevail.

Safety Messages

The types of safety messages, what

they look like and how they are used in

this guide are explained as follows:

The safety alert symbol indicates

a potential injury hazard.

WARNING

Indicates a potential hazard, if not

avoided, could result in serious injury or death.

CAUTION Indicates a hazard

situation which, if not avoided,

could result in minor or moderate

injury.

If you want to view and/or print an extra copy of your Operator's Guide, simply visit the following website www.

operatorsguide.brp.com.

The informations contained in this document are correct at the time of publication. BRP, however, maintains a policy of continuous improvement of its

products without imposing upon itself

any obligation to install them on products previously manufactured. Due

to late changes, some differences between the manu facture d product and

the descriptions and/or specifications

in this guide may occur. BRP reserves

the right at any time to discontinue or

change specifications, designs, features, models or equipment without

incurring any obligation u pon itself.

This Operator's Guide and the

DVD

when it's sold.

should remain with the ve hic le

SAFETY

While r eading th i s Operator’s G

Indicates a potential hazard that, if not avoided, could result in serious

injury or dea t h.

_______________

2

uide, remember that:

WARNING

Page 5

TABLE OF CONTENTS

FOREWORD .......................................................................... 1

Know Before you Go ............................................................. 1

Safety Messages................................................................. 2

About this Operator's Guide .................................................... 2

SAFETY INFORMATION

GENERAL PRECAUTIONS.......................................................... 8

Avoid Carbon Monoxide Poisoning ............................................. 8

Avoid Gasoline Fires and Other Hazards ....................................... 8

Avoid Burns from Hot Parts ..................................................... 8

Accessories and Modifications ................................................. 8

SPECIAL SAFETY MESSAGES .................................................... 9

OPERATION WARNINGS.......................................................... 11

RIDING THE VEHICLE .............................................................. 36

Pre-Ride Inspection ............................................................. 37

Clothing .......................................................................... 38

Carrying Passenger ............................................................. 38

Carrying Loads .................................................................. 38

Recreational Riding ............................................................. 39

Environment..................................................................... 39

Design Limitation ............................................................... 40

Off-Highway Operation......................................................... 40

General Operating and Safety Precautions ................................... 40

Riding Techniques............................................................... 42

IMPORTANT ON-PRODUCT LABELS ............................................ 49

Hang Tag ......................................................................... 49

Vehicle Safety Labels ........................................................... 50

Compliance Labels.............................................................. 52

Technical Information Label .................................................... 53

VEHICLE INFORMATION

CONTROLS/INSTRUMENT/EQUIPMENTS .................................... 56

1) Throttle Lever................................................................. 57

2) Front Brake Lever ............................................................ 57

3) Clutch Lever .................................................................. 58

4) Parking Brake ................................................................. 58

5) Multifunction Switch......................................................... 59

6) Ignition Switch................................................................ 60

7) Indicator Lamps .............................................................. 60

8) Rear Brake Pedal ............................................................. 61

9) Transmission Lever........................................................... 61

10) Tool Kit ....................................................................... 61

11) Seat .......................................................................... 62

_______________

3

Page 6

TABLE OF CONTENTS

FUEL .................................................................................. 63

Fuel Requirements.............................................................. 63

Fueling Procedure............................................................... 63

OPERATING INSTRUCTIONS..................................................... 65

Operation During Break-In Period.............................................. 65

Starting the Engine.............................................................. 65

Shifting the Transmission....................................................... 66

Stopping the Engine ............................................................ 67

SPECIAL PROCEDURES ........................................................... 69

What to Do if Vehicle Is Turned Over .......................................... 69

What to Do if Vehicle Is Immersed in Water .................................. 69

TUNE YOUR RIDE .................................................................. 70

Steering Alignment (Toe) ....................................................... 70

Rear Track Width Adjustment (X xc and X mx) ................................ 71

Caster Adjustment (X xc and X mx) ............................................ 72

Camber Adjustment (X mx) .................................................... 73

Suspension Adjustments Guideline ........................................... 75

Front Suspension (DS 450 X xc)................................................ 75

Front Suspension (DS 450 X mx)............................................... 76

Rear Suspension (DS 450 X xc) ................................................ 79

Rear Suspension (DS 450 X mx) ............................................... 80

Suspension Factory Settings................................................... 82

VEHICLE TRANSPORTATION..................................................... 84

MAINTENANCE INFORMATION

5-HOUR AND 10-HOUR INITIAL SERVICES..................................... 86

5-Hour Engine Oil and Filter Replacement .................................... 86

Initial Inspection................................................................. 86

MAINTENANCE SCHEDULE ...................................................... 87

MAINTENANCE PROCEDURES .................................................. 91

Engine Oil........................................................................ 91

Engine Coolant .................................................................. 94

Air Filter .......................................................................... 97

Air Filter Housing................................................................ 98

Muffler Spark Arrester .......................................................... 99

Radiator ........................................................................ 100

Transmission Lever ........................................................... 100

Clutch .......................................................................... 100

Throttle Cable ................................................................. 103

Throttle Lever ................................................................. 105

Spark Plugs .................................................................... 105

Battery ......................................................................... 106

Fuses........................................................................... 106

Lights........................................................................... 107

Indicator Lamps ............................................................... 109

_______________

4

Page 7

TABLE OF CONTENTS

MAINTENANCE PROCEDURES (cont’d)

Drive Chain .................................................................... 109

Drive Chain Slider ............................................................. 110

Drive Chain Sprockets ........................................................ 110

Tires/Wheels .................................................................. 111

Front Wheel Bearings......................................................... 114

Rear Axle....................................................................... 114

Suspensions................................................................... 114

Brakes.......................................................................... 116

Body............................................................................ 118

Frame .......................................................................... 118

VEHICLE CARE .................................................................... 119

Post-Operation Care .......................................................... 119

Vehicle Cleaning and Protection ............................................. 119

STORAGE AND PRESEASON PREPARATION ................................ 120

TECHNICAL INFORMATION

VEHICLE IDENTIFICATION ...................................................... 122

Vehicle Identification Number................................................ 122

Engine Identification Number ................................................ 122

NOISE EMISSION CONTROL SYSTEM REGULATION ...................... 123

Tampering with Noise Control System Is Prohibited! ...................... 123

Among those Acts Presumed to Constitute Tampering are the Acts Listed

Below:.......................................................................... 123

SPECIFICATIONS ................................................................. 124

TROUBLESHOOTING

TROUBLESHOOTING GUIDELINES ........................................... 130

.................................................................................. 133

WARRANTY

BRP LIMITED WARRANTY USA AND CANADA: 2015 CAN-AM

CUSTOMER INFORMATION

TM

ATV .. 136

PRIVACY INFORMATION........................................................ 142

CHANGE OF ADDRESS/OWNERSHIP......................................... 143

_______________

5

Page 8

TABLE OF CONTENTS

_______________

6

Page 9

SAFETY

INFORMATION

________

SAFETY INF

ORMATION

________

7

Page 10

GENERAL PRECAUTIONS

Avoid Carbon M onoxide

Poisoning

All engine exhaust contains carbon

monoxide, a deadly gas. Breathing carbon monoxide can cause headaches,

dizziness, drowsiness, nausea, confusion and eventually death.

Carbon monoxide is a colorless, odorless, tasteless gas that may be present

even if you do not see or smell any engine exhaust. Deadly levels of carbon

monoxide can collect rapidly, and you

can quickly be overcome and unable

to save yourself. Also, deadly levels of

carbon monoxide can linger for hours

or days in enclosed or poorly ventilated

areas. If you experience any symptoms of carbon monoxide poisoning,

leave the area immediately, get fresh

air and seek medical treatment.

To prevent serious injury or death from

carbon monoxide:

– Never run the vehicle in poorly ven-

tilated or partially enclosed areas

such as garages, carports or barn s.

Even if you try to ventilate engine

exhaust with fans or open w indows

and doors, carbon monoxide can

rapidly reach dangerous levels.

– Never run the vehicle outdoors

where engine exhaust can be drawn

into a building through openings

such as windows and doors.

Gasoline is poisonous and can cause

injury or death.

– Never siphon gasoline by mouth.

– If you swallow gasoline, get a ny in

your eye or inhale gasoline vapor,

see your doctor immediately.

If gasoline spills on you, wash with

soap and water and change your

clothes.

Avoid Burns from Hot Parts

Certain components become hot during operation. Avoid contact with

those parts during and shortly after

operation to avoid burns.

Accessories and

Modifications

Do not make unauthorized modifications, or use a ttachments or accessories that are not approved by BRP.

Since these changes have not been

tested by BRP, they may increase the

risk of crashes injuries, and they can

make th e vehicle illegal.

See your authorized Can-Am dealer for

available acces sories for your vehicle.

Avoid Gasoline Fires and

Other Hazards

Gasoline is extremely flammable and

highly explosive. Fuel vapors can

spread and be ignited by a spark or

flame m an y feet away from the engine. To reduce the risk of fire or explosion, follow these instructions:

– Never start or operate the engine

with the fuel cap removed.

– Use only an approved red gasoline

container to store fuel.

– Strictly adhere to instructions in

FUEL

________

8

subsection.

SAFETY IN

FORMATION

________

Page 11

SPECIAL SAFETY MESSAGES

THIS VEHICLE IS NOT A TOY AND CAN BE HAZARDOUS TO OPERATE.

– This vehicle handles differently from other vehicles including motorcycles and

cars.

– A collision or rollove r can occur quickly, even during routine maneuvers such as

turning and driving on hills or ove r obstacles, if you fail to take proper precautions.

SEVERE INJURY OR DEATH can result if you do not follow these instructions:

– Read this Operator's Guide and all on-product safety labels carefully and follow

the operating procedures described. Watch and pay attention to the

DVD

video before operation.

– This is a high performance ATV for off-road use only. Inexperienced riders may

overlook risks and be surprised by the specific behavior of this ATV in any terrain

condition.

– Always follow this age recommendation: A person under 16 years old should

never operate this vehicle. For experienced operators only.

– Never carry a passenger on this vehicle. Passenger(s) affect balance and steer-

ing and increase risk of losing control.

– Never operate this vehicle on any paved surfaces, including sidewalks, drive-

ways, parking lots and streets.

– Never operate this vehicle on any public street, road or highway, even a dirt or

gravel one.

– Never take place on this vehicle without wearing an approved helmet that fits

properly. You should also wear eye protection (goggles or face shield), gloves,

boots, long sleeved shirt or jacket, and long pants.

– Never use this vehicle with drugs or alcohol. They slow reaction time and impair

judgement.

– Never operate at excessive speeds. Always go at a speed that is proper for the

terrain, visibility, and operating co nditions, and your exp erie nc e.

– Never attempt w h eelies, jumps, or other stunts.

– Always inspect and confirm the safe operating condition of your vehicle prior to

ride. Always follow the inspection and maintenance procedures and schedules

described in this Operator's Guide.

– Always keep both hands on the handlebars and both feet on the footpegs of the

vehicle during operation.

– Always go slowly and be extra careful when operating on unfamiliar terrain. Al-

ways be alert to changing terrain conditions when operating this vehicle.

– Never operate on excessively rough, slippery or loose terrain until you have

learned and practiced the sk ills n ecessary to control this vehicle on such terrain.

Always be especially cautious on these kinds of terrain.

– Always follow proper procedures for turning as described further in this O pera-

tor's Guide. Practice turning at low speeds before attempting to turn at faster

speeds. Do not turn at excessive speed.

– Never operate this vehicle on hills too steep for the vehicle or fo r your abilities.

Practice on smaller hills before attem p ting larger hills.

SAFETY

________

SAFETY INF

ORMATION

________

9

Page 12

SPECIAL SAFETY MESSAGES

– Always follow proper procedures for climbing hills as desc rib ed further in

this Operator's Guide. Check t he terrain carefu lly before you start up any hill.

Never c lim b hills with exc es sively slippery or loose surface s. Shift your w e igh t

forward. Never open the throttle suddenly or make sudden gear changes.

Never go over the top of any hill at high speed.

– Always follow proper procedures for going down hills and f or braking on hills as

described further in this Operator's Guide. Check the terrain carefully before

you start down any hill. Shift your weight backward. Never go down a hill at

high speed. Avoid going down a hill at an angle that would cause the vehicle to

lean sharply to one side. Go straight down the hill where possible.

– Always follow proper procedures for crossing the side of a hill as described

further in this Operator's Guide. Avoid hills with excessively slippery or loose

surfaces. Shift your weight to the uphill side of the vehicle. Never attempt to

turn the vehicle around on any hill until you have mastered the turning technique

described in this Operator's Guide on level ground. Avoid crossing the side of a

steep hill if possible.

– Always use proper proced u re s if you stall or roll backwards when climbing a hill.

To avoid stalling, use proper gear and maintain a steady speed when

a hill. If you stall or roll backwards, follow the s pe cia l procedure for braking

described in this Operator's Guide. Dismount on the uphill side or to a side

if pointed straight uphill. Turn the vehicle around and remoun

procedure described further in this Operator's Guide.

– Always check for obstacles before operating in a new area. Never attempt to

operate over large obstacles, such as large rocks or fallen trees. Always follow

proper procedures when operating over obstacle

Operator's Guide.

– Always be careful when skidding or sliding. Learn to safely control skidding or

sliding by practicing at low speeds and on level sm ooth terrain. On extremely

slippery surfaces, such as ice, go slowly an

the chance of skidding out of control.

– Never operate this vehicle in fast flowing water or in water deeper than that

specified in this Operator's Guide. Remember that wet brakes may have

reduced stopping ability. Test yo

necessary, apply them several times to let friction dry out the pads.

– Always use the size and type of tires specified further in this Operator's Guide.

Always maintain proper tire pressure as described further in this Operator's

Guide.

– Never modify this ve hic le

Only use BRP's approved accessories.

– Never exceed the stated load limits for this vehicle including the operator and all

other added accessories.

– Never operate this vehicle without proper instruction. Take a training course.

All operators should

receive trainin g from a certified instructor.

through improper installation or use of accessories.

ur brakes after leaving water, mud or snow. If

d be very cautious in order to reduce

s as described further in this

t, following the

climbing

FOR MORE INFORMATION ABOUT ATV SAFETY, contact an authorized

Can-Am dealer to fi

USA and Canada only: call the Specialty Vehicle Institute of America (SVIA) at

1 800 887-2887 or in

10

_______

nd out about available training courses nearest you.

Canada, the Canada Safety Council (CSC) at 1 613 739-1535.

SAFETY I

NFORMATION

________

Page 13

OPERATION WARNINGS

The following warning and their format have been requested by the United States

Consumer Product Safety Commission and are required to be in the Operator's

Guide for all ATVs.

NOTE: The following illustrations are general representations only. Your model

may differ.

WARNING

POTENTIAL HAZARD

Operating this vehicle without proper instruction.

WHAT CAN HAPPEN

The risk of an accident is greatly increased if the operator does not know

how to operate this vehicle properly in different situations and on different

types of terrain.

HOW TO AVOID THE HAZARD

Beginning and inexperienced operators should c

They should then regularly practice the skills learned in the course and the

operating techniques described in this Operator's Guide.

For more information about the training course, contact an authorized

Can-Am dealer.

omplete a training course.

________

SAFETY INF

ORMATION

________

11

Page 14

OPERATION WARNINGS

V00A01Q

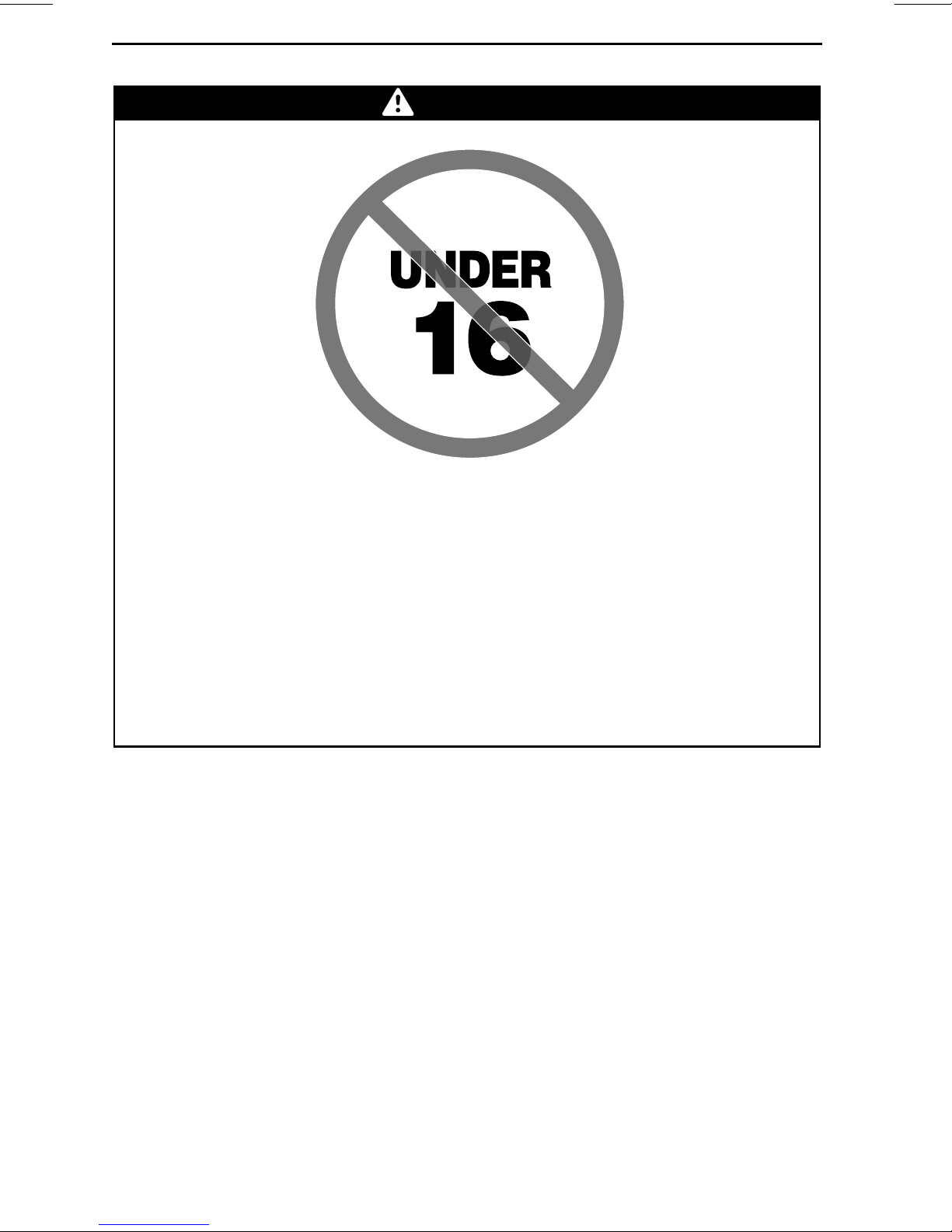

POTENTIAL HAZARD

WARNING

Failure to follow the age recommendations for this vehicle.

WHAT CAN HAPPEN

A lack of respect for this age recommendation can lead to severe injury or

death of the child.

Even though a child may be within the age group for which this vehicle is

recommended, he may not have the skills, abilities, or jud

operate this vehicle safely and may be involved in a serious accident.

HOW TO AVOID THE HAZARD

No one under 16 should operate this vehicle.

gment needed to

12

_______

SAFETY I

NFORMATION

________

Page 15

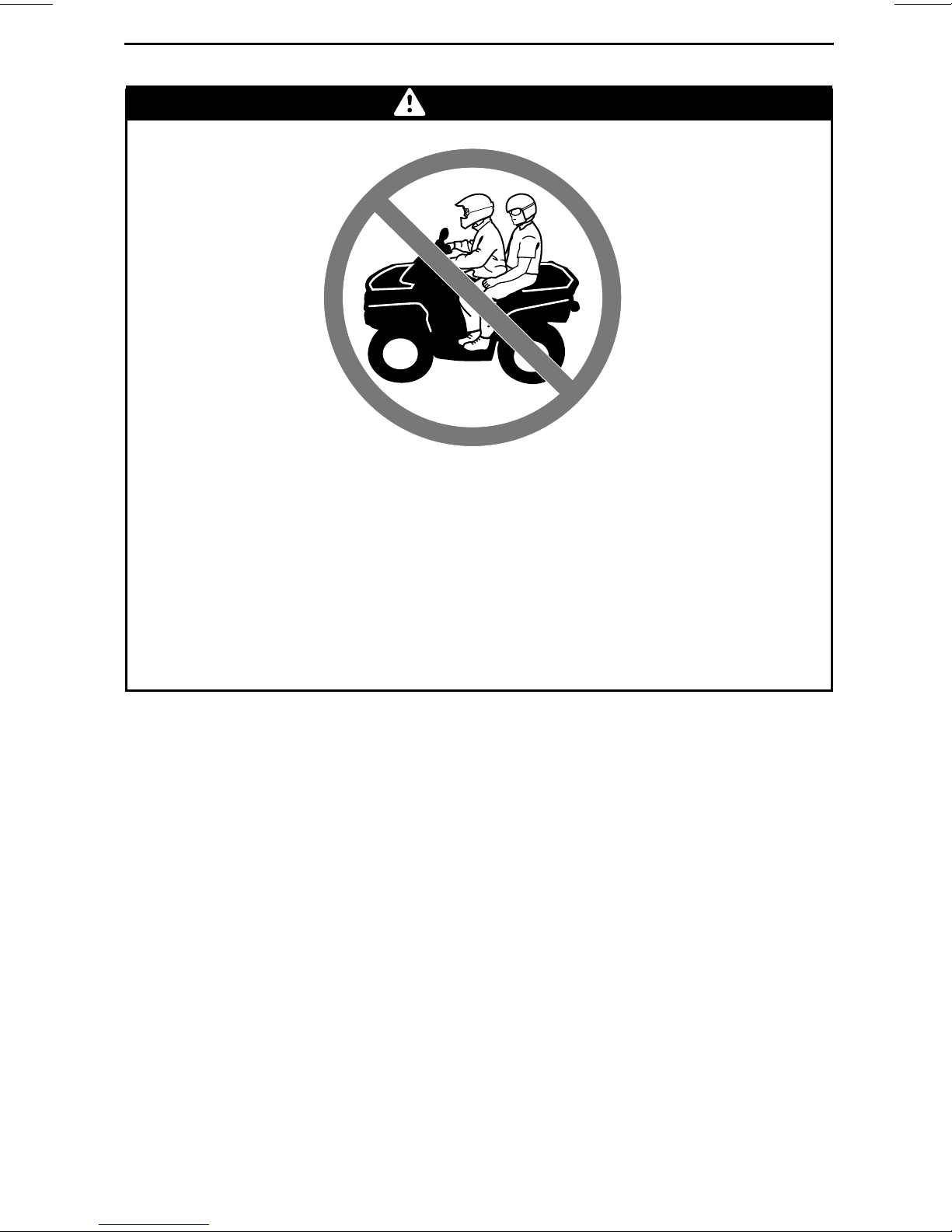

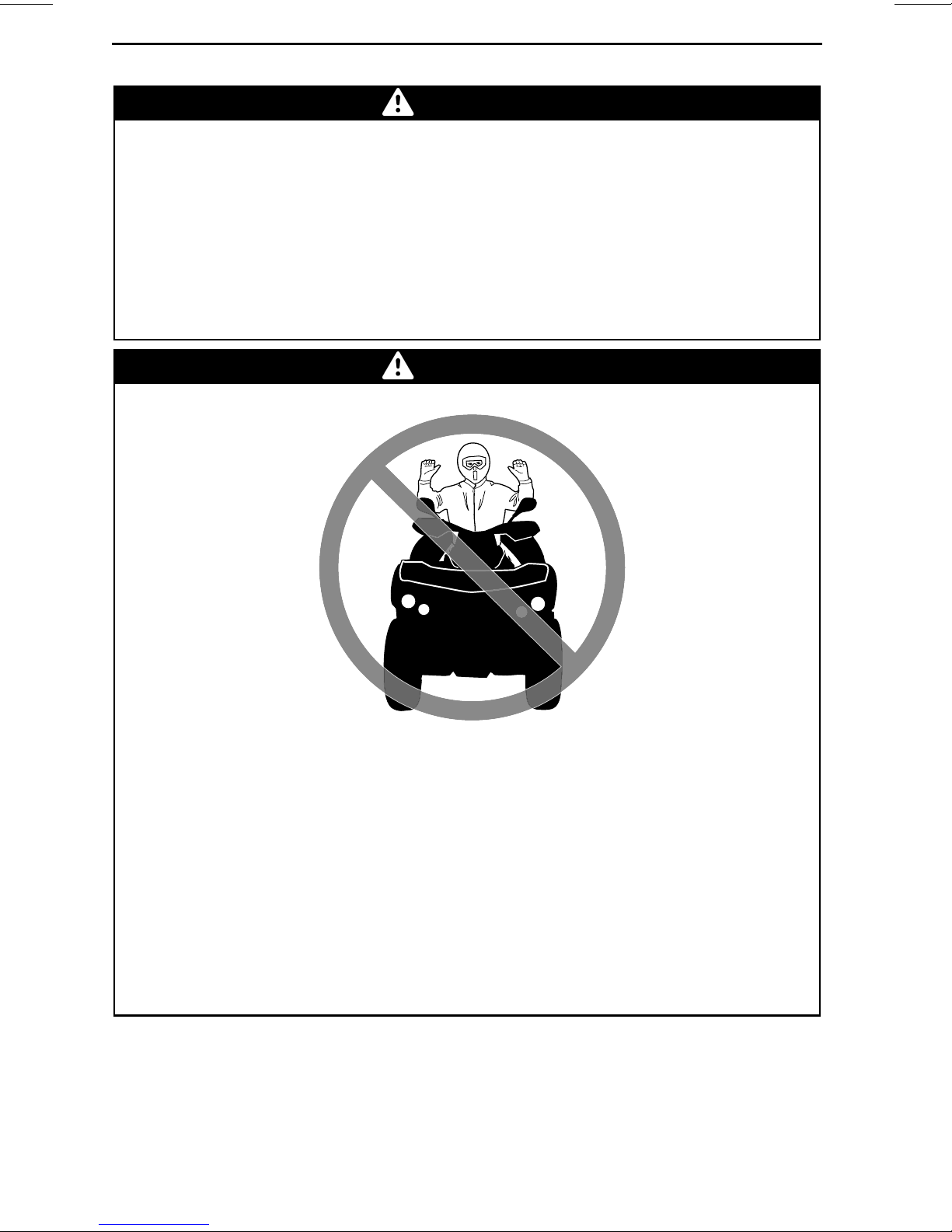

POTENTIAL HAZARD

OPERATION WARNINGS

WARNING

Carrying a passenger on this vehicle.

WHAT CAN HAPPEN

Greatly reduces your ability to balance and control this veh

Could cause an accident, resulting in harm to you and/or your passenger.

HOW TO AVOID THE HAZARD

Never carry a passenger. Even with a long seat that provides unrestricted

operator movement, it is not designed nor intended to carry passenger(s).

icle.

________

SAFETY INF

ORMATION

________

13

Page 16

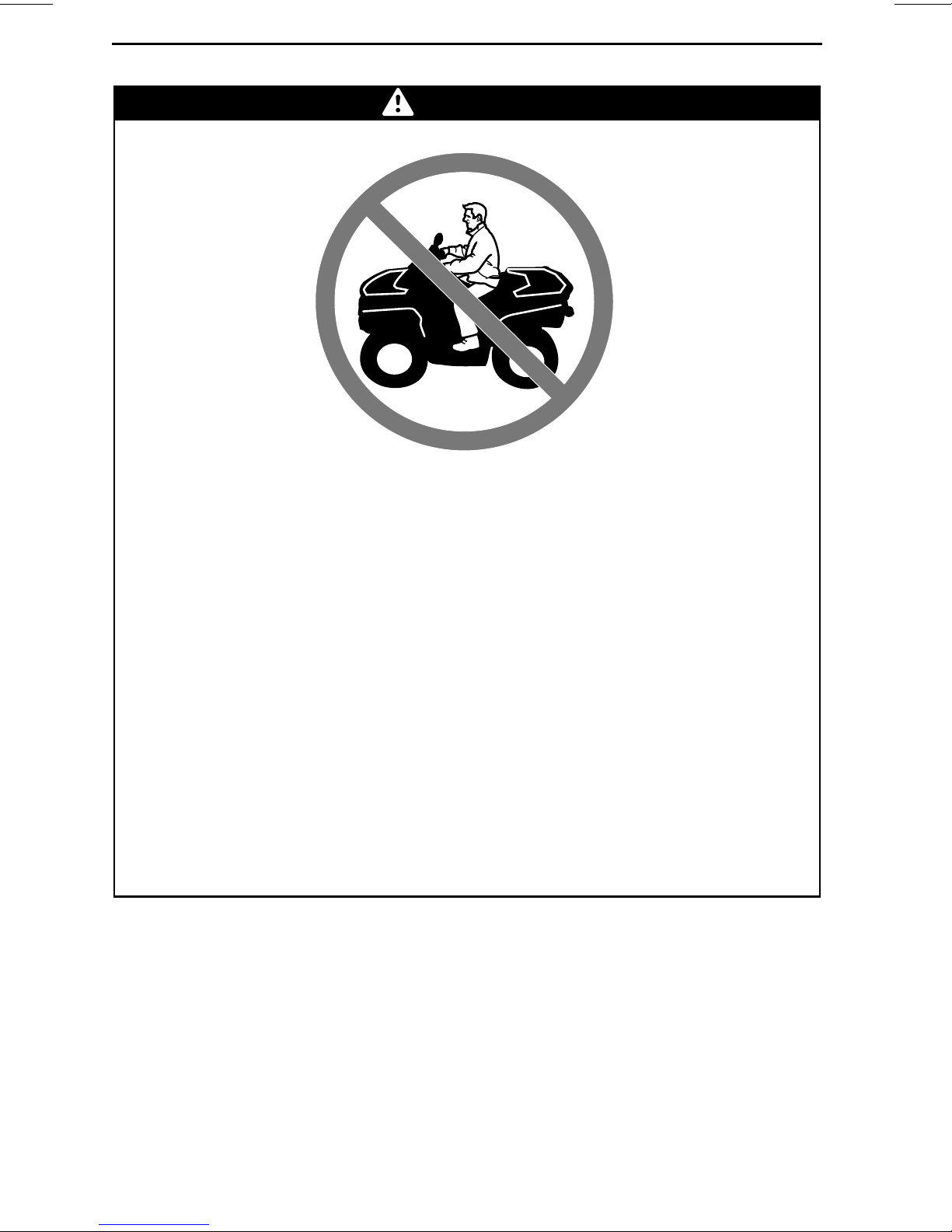

OPERATION WARNINGS

POTENTIAL HAZARD

WARNING

Operating this vehicle on paved surfaces.

WHAT CAN HAPPEN

The tires are designedfor off-roaduse only, notfor use on pa

surfaces may s eriously affect handling and control of this vehicle, and may

cause the vehicle to go out of control.

HOW TO AVOID THE HAZARD

Never operate this vehicle on any paved surfaces, including sidewalks,

driveways, parking lots and streets.

vement. Paved

14

_______

SAFETY I

NFORMATION

________

Page 17

POTENTIAL HAZARD

OPERATION WARNINGS

WARNING

Operating this vehicle on public streets, roads or highways.

WHAT CAN HAPPEN

You can collide with another vehicle.

HOW TO AVOID THE HAZARD

Never operate this vehicle on any public street, road or highway, even a dirt

or gravel one. In many states or provinces it is illegal to operate this vehicle

on public streets, roads or highways.

________

SAFETY INF

ORMATION

________

15

Page 18

OPERATION WARNINGS

POTENTIAL HAZARD

WARNING

Riding this vehicle without wearing an approved helmet, eye protectionand

protective clothing.

WHAT CAN HAPPEN

The following items concern all ATV's operator:

– Riding without an approved helmet increases the chances of a severe

head injury or death in the event of an accident.

– Riding without eye protection can result in an accident and increases the

chances of a severe injury in the event of an accident.

– Riding without protective clothing increase

in the event of an accident.

HOW TO AVOID THE HAZARD

Always wear an approved helmet that fits properly. You should also wear:

– Eye protection (goggles or face shield)

– Gloves and boots

– Long sleeved shirt or jacket

–Longpants.

s the chances of severe injury

16

_______

SAFETY I

NFORMATION

________

Page 19

V00A07Q

POTENTIAL HAZARD

OPERATION WARNINGS

WARNING

Using this vehicle with drugs or alcohol.

WHAT CAN HAPPEN

Could seriously affect your judgment.

Could cause you to react more slowly.

Could affect your balance and perception.

Could result in an accident or death.

HOW TO AVOID THE HAZARD

Never use this vehicle with drugs or alcohol.

________

SAFETY INF

ORMATION

________

17

Page 20

OPERATION WARNINGS

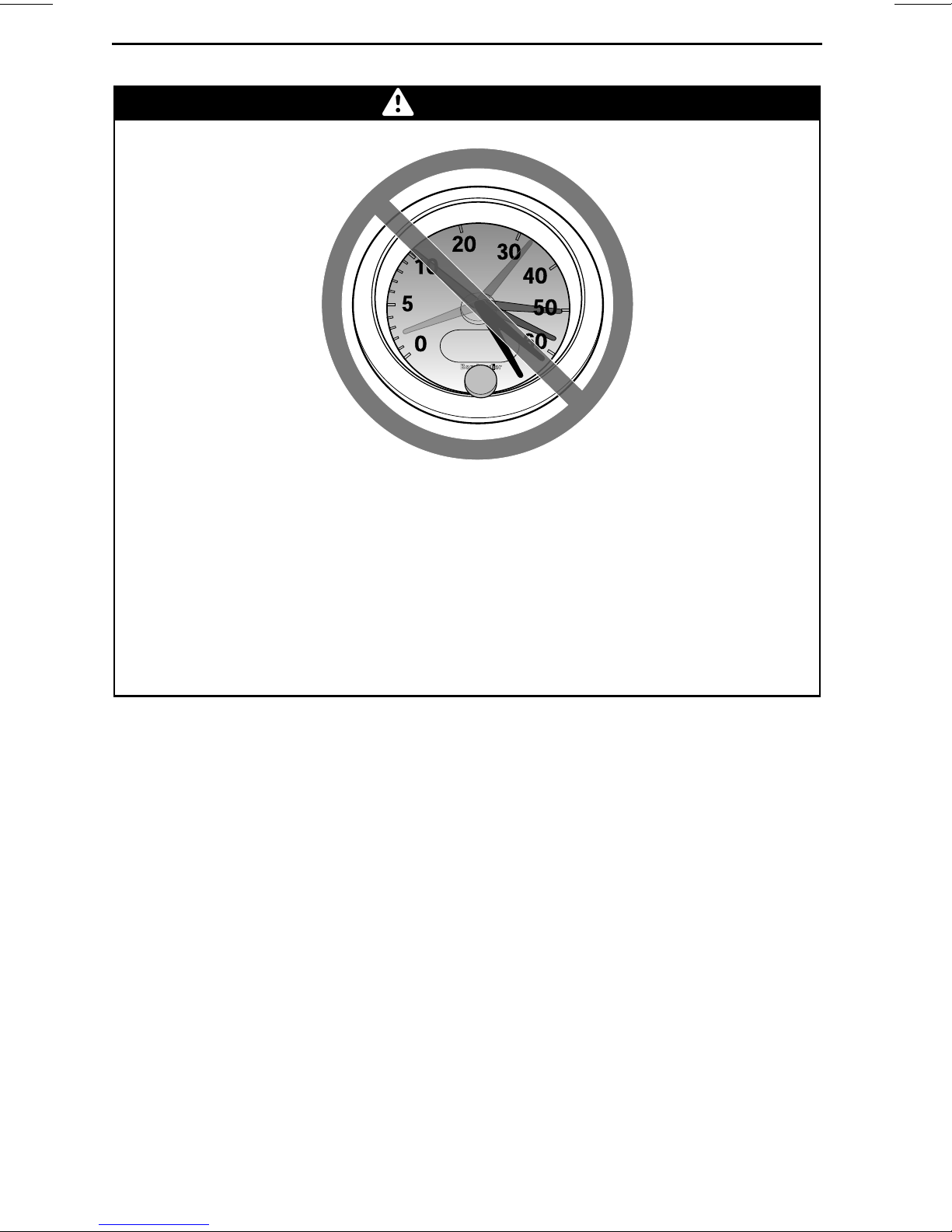

V00A08Q

POTENTIAL HAZARD

WARNING

Operating this vehicle at excessive speeds.

WHAT CAN HAPPEN

Increases your chances of losing control of the vehicle, which can result in

an accident.

HOW TO AVOID THE HAZARD

Always travel at a speed which is proper for the terrain, visi

ating conditions, and your experience.

bility and oper-

18

_______

SAFETY I

NFORMATION

________

Page 21

POTENTIAL HAZARD

OPERATION WARNINGS

WARNING

Attempting wheelies, jumps and other stunts.

WHAT CAN HAPPEN

Increases the chance of an accident, including an overturn.

HOW TO AVOID THE HAZARD

Never attempt stunts, such as wheelies or jumps. Do not try to show off.

WARNING

POTENTIAL HAZARD

Failure to inspect the vehicle before operating.

Failure to properly maintain the vehicle.

WHAT CAN HAPPEN

Increases the possibility of an accident or equipment damage.

HOW TO AVOID THE HAZARD

Always inspect your vehicle every time prior to use it to make sure the vehicle is in safe operating condition.

Always follow the inspection and maintenance procedures and schedules

described further in this Operator's G uide.

________

SAFETY INF

ORMATION

________

19

Page 22

OPERATION WARNINGS

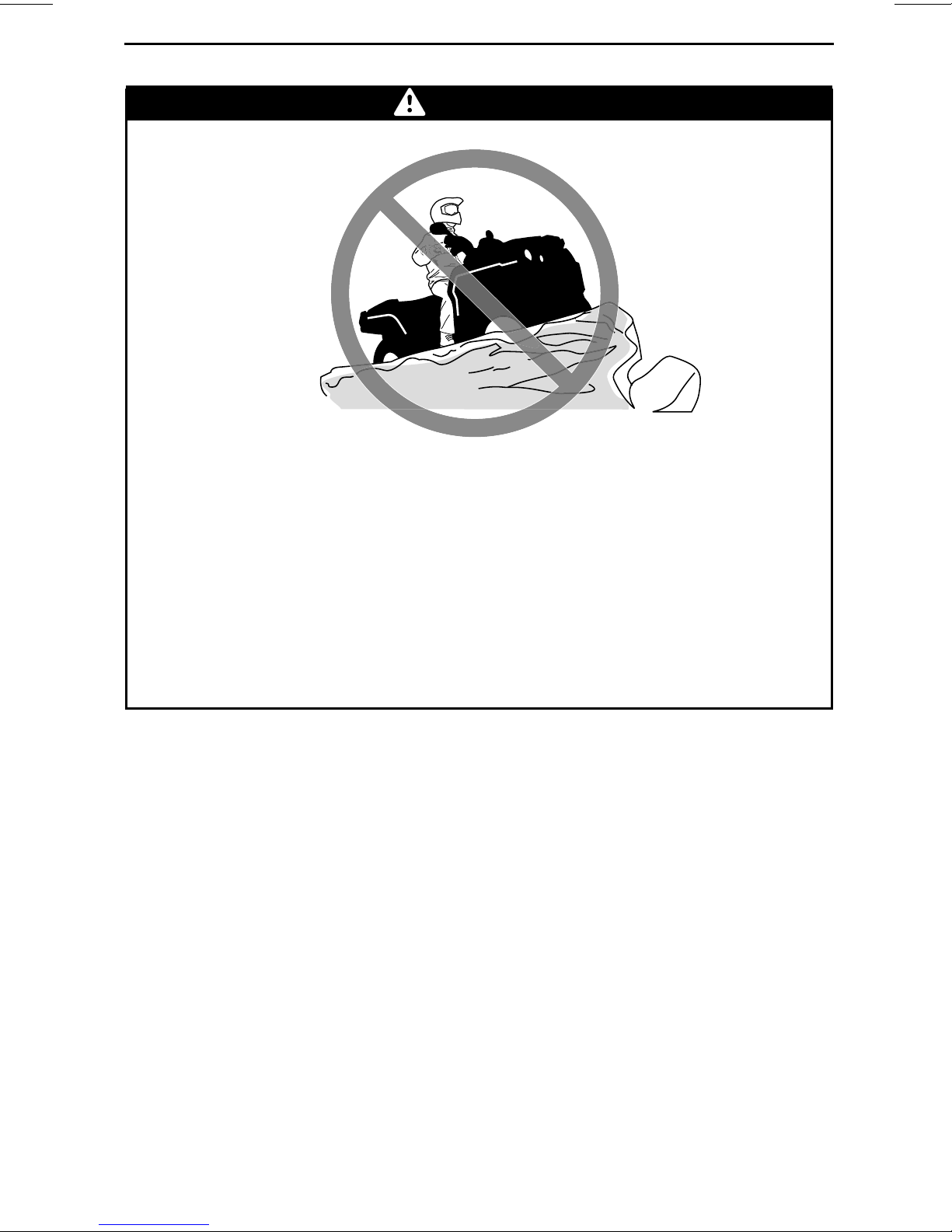

WARNING

POTENTIAL HAZARD

Riding on frozen waterways.

WHAT CAN HAPPEN

Breaking through the ice can lead to severe injury or death.

HOW TO AVOID THE HAZARD

Never ride this vehicle on a frozen surface before you are sure the ice is thick

enough and sound enough to support the vehicle and its load, as well as the

force that is created by a moving vehicle.

WARNING

POTENTIAL HAZARD

Removing hands from handlebar or feet from the fo

tion.

WHAT CAN HAPPEN

Removing even one hand or foot can reduce your ability to control the vehicle or could cause you to lose your balance a

move a foot from the footrests, your foot or leg may come into contact with

the rear wheels, which could injure you or cause an accident.

HOW TO AVOID THE HAZARD

Always keep both hands on the handlebar and both feet on the footrests

during vehicle operation.

20

_______

SAFETY I

NFORMATION

nd fall off the vehicle. If you re-

otrests during opera-

________

Page 23

OPERATION WARNINGS

WARNING

POTENTIAL HAZARD

Failure to use extra care when operating this vehicle on unfamiliar terrain.

WHAT CAN HAPPEN

You can come upon hidden rocks, bumps, or holes, without enough time to

react.

Could result in the vehicle overturning or loss of control.

HOW TO AVOID THE HAZARD

Go slowly and be extra careful when operating on unfamiliar terrain.

Always be alert to changing terrain conditions when operating the vehicle.

________

SAFETY INF

ORMATION

________

21

Page 24

OPERATION WARNINGS

POTENTIAL HAZARD

WARNING

Failure to use extra care when operating on excessively rough, slippery or

loose terrain.

WHAT CAN HAPPEN

Could cause loss of traction or vehicle c ontrol, which could result in an accident, including an overturn.

HOW TO AVOID THE HAZARD

Do not operate o n excessively rough, slippery or loose terrain until you

have learned and practiced the skills necessary to control this vehicle on

such terrain.

Always be especially cautious on these kinds of terrain.

22

_______

SAFETY I

NFORMATION

________

Page 25

POTENTIAL HAZARD

OPERATION WARNINGS

WARNING

Turning improperly.

WHAT CAN HAPPEN

Vehicle could go out of control, causing a collision or overturn.

HOW TO AVOID THE HAZARD

Always follow proper procedures for turningas described further in this Operator's Guide. Practice turning at low speeds before attempting to turn at

faster speeds.

Do not turn at excess ive spee d.

________

SAFETY INF

ORMATION

________

23

Page 26

OPERATION WARNINGS

WARNING

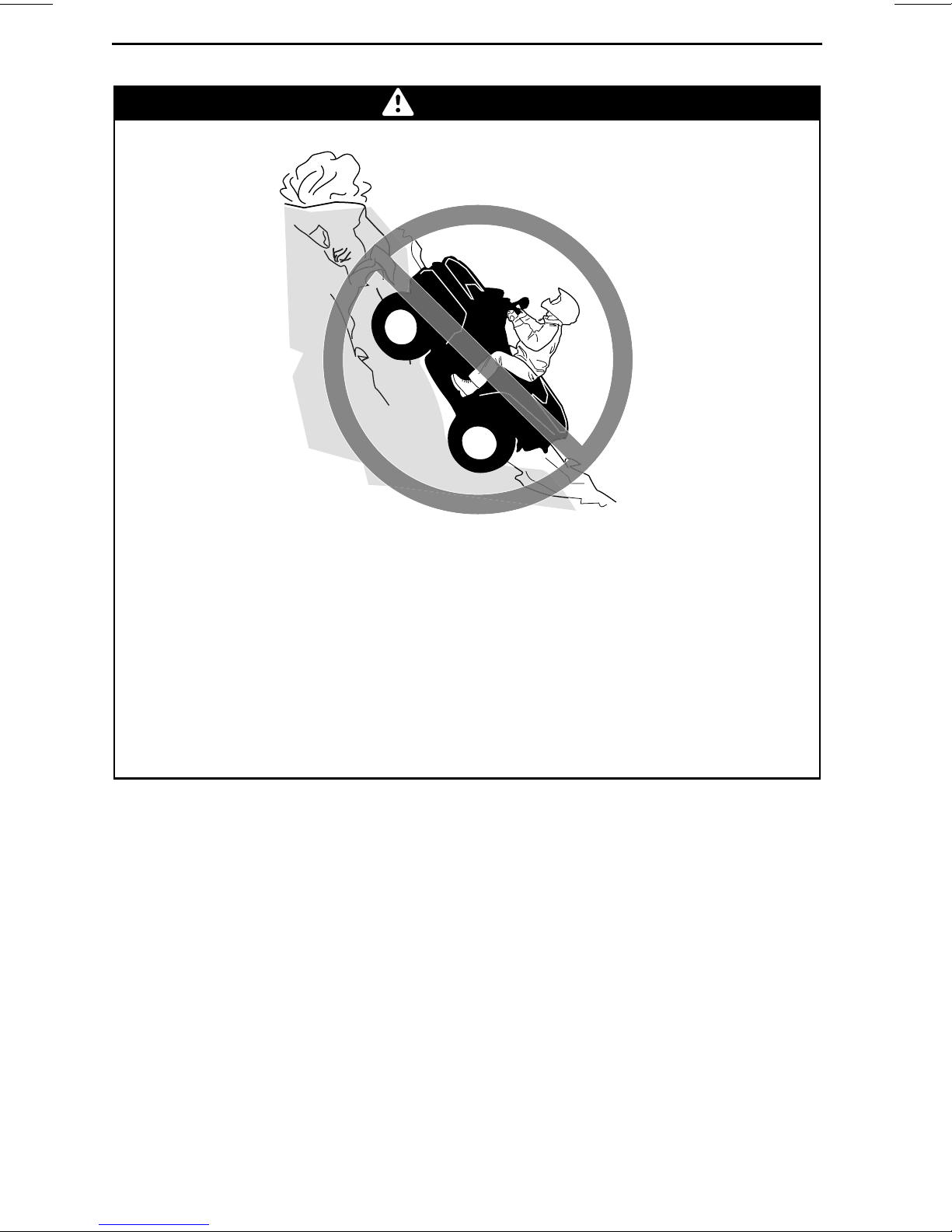

POTENTIAL HAZARD

Operating on excessively ste ep hills.

WHAT CAN HAPPEN

The vehicle can overturn more easily on extremely steep hills than on level

surfaces or small hills.

HOW TO AVOID THE HAZARD

Never operate this vehicle on hills too steep for th

ties.

Practice on smaller hills before attempting large

e vehicle or for your a bili-

r hills.

24

_______

SAFETY I

NFORMATION

________

Page 27

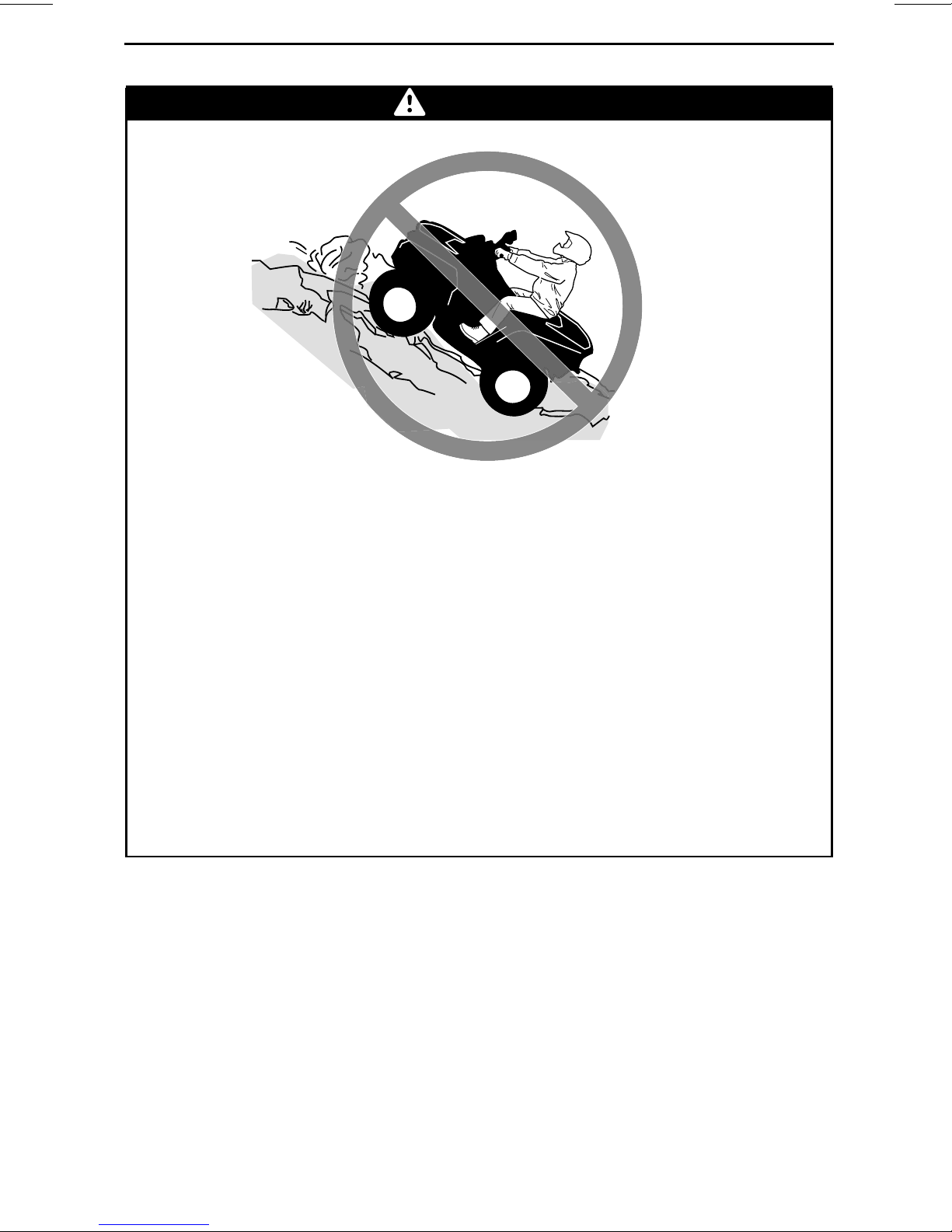

POTENTIAL HAZARD

OPERATION WARNINGS

WARNING

Climbing hills improperly.

WHAT CAN HAPPEN

Could cause loss of control or cause vehicle to overturn.

HOW TO AVOID THE HAZARD

Always follow proper procedures for climbing hills as described further in

this Operator's Guide.

Always check the terrain carefully before you start u p any hill.

Never climb hills with excessively slippery or loose surfaces.

Shift your weight forward.

Never open the throttle suddenly or make sudden gear changes. The vehi-

cle could flip over backwards.

Never go over the top of any hill at high speed. An obstacle, a sharp drop, or

another vehicle or person could be on the other side of th

e hill.

________

SAFETY INF

ORMATION

________

25

Page 28

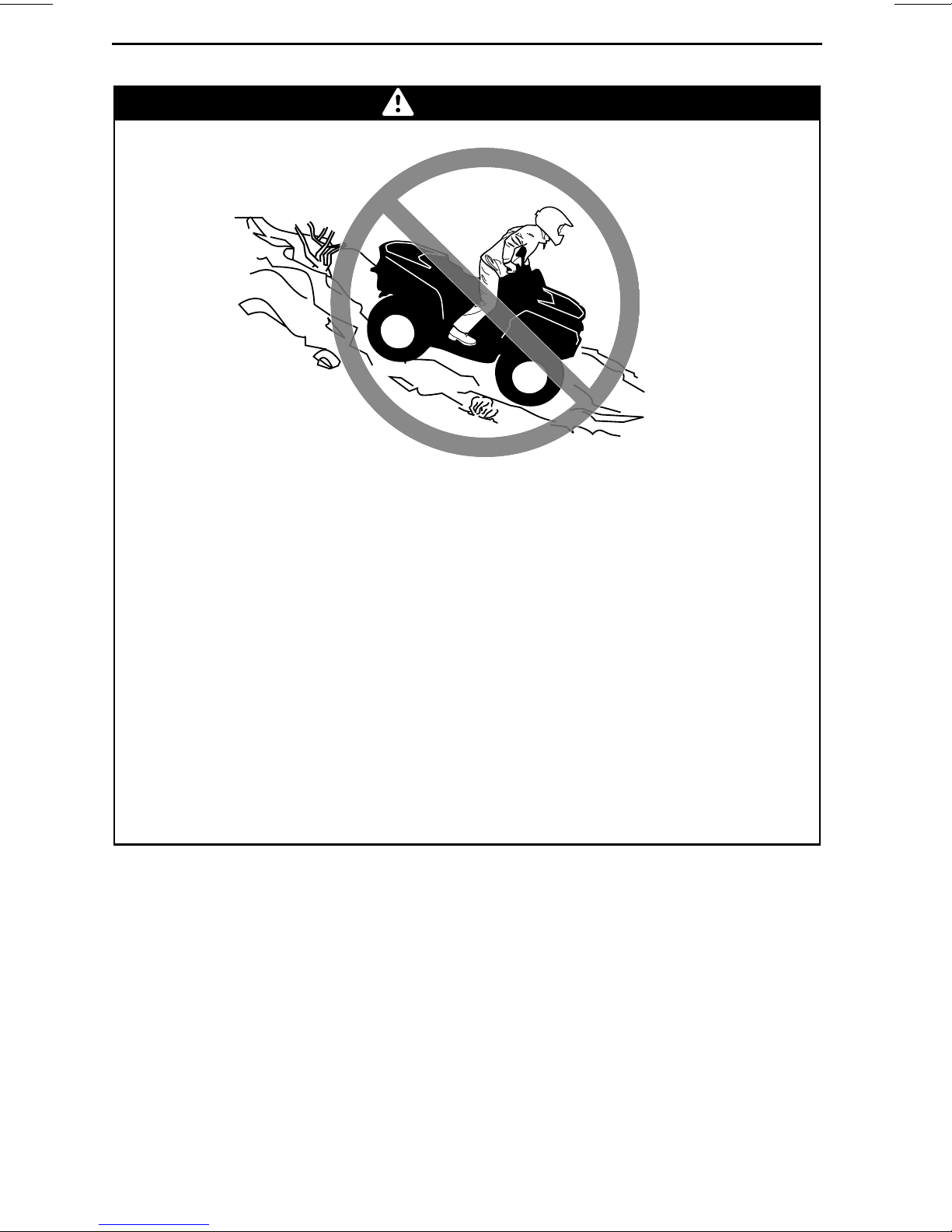

OPERATION WARNINGS

POTENTIAL HAZARD

WARNING

Going down a hill improperly.

WHAT CAN HAPPEN

Could cause loss of control or cause vehicle to overturn.

HOW TO AVOID THE HAZARD

Always follow proper procedures for going down hills as descr

in this Operator's Guide.

NOTE: A special technique is required when braking as you go

Always check the terrain carefully before you start down any hill.

Shift your weight backward.

Never go down a hill at high speed.

Avoid going down a hill at an angle which would cause the vehicle to lean

sharply to one side. Go straight down the hill where pos

sible.

ibed further

down a hill.

26

_______

SAFETY I

NFORMATION

________

Page 29

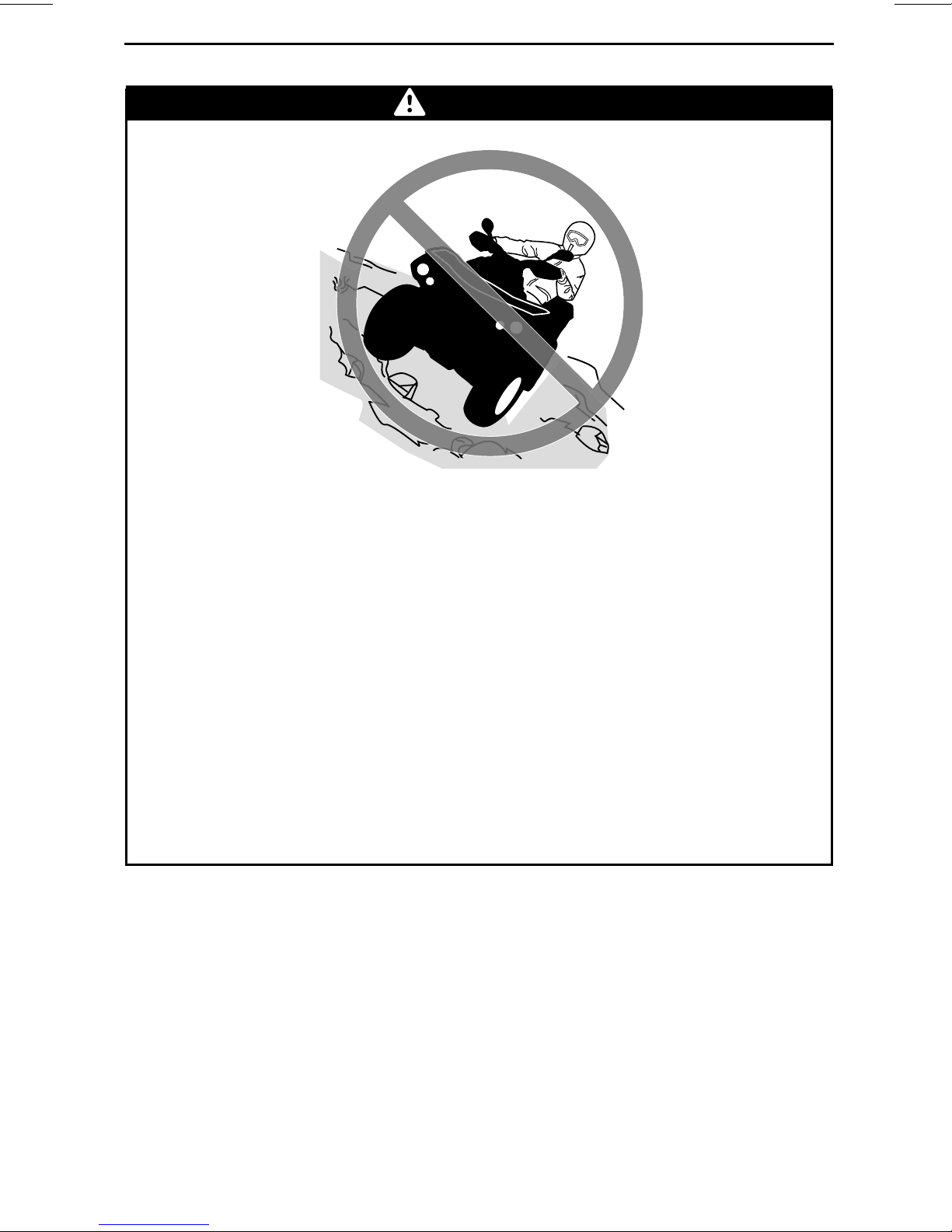

POTENTIAL HAZARD

OPERATION WARNINGS

WARNING

Improperly crossing hills or turning o n hills.

WHAT CAN HAPPEN

Could cause loss of control or cause vehicle to overturn.

HOW TO AVOID THE HAZARD

Never attempt to turn the vehicle around on any hilluntil youh

the turning technique as described further in this Operator's Guide on level

ground. Be very careful when turning on any hill.

Avoid crossing the side of a steep hill if possible.

When crossing th e side of a hill:

Always follow proper procedures as described further in this Operator's

Guide.

Avoid hills with excessively slippery or loose surfaces.

Shift your weight to the uphill side of the vehicle.

ave mastered

________

SAFETY INF

ORMATION

________

27

Page 30

OPERATION WARNINGS

WARNING

POTENTIAL HAZARD

Stalling, rolling backwards or improperly dismountingwhile climbing a hill.

WHAT CAN HAPPEN

Could result in vehicle overturning.

HOW TO AVOID THE HAZARD

Use proper gear and maintain steady speed when climbing a hill.

If you lose all f o rward s p eed:

Keep your weight uphill. Never open the throttle suddenly or make sudden

gear changes. The vehicle could flip over backwards.

Apply the brakes.

Lock parking brake after you have stopped.

Dismount on uphill side, or to a side if pointed straight uphill.

If you begin rolling backwards:

Keep your weight uphill. Never open the throttle suddenly or make sudden

gear changes. The vehicle could flip over backwards.

Never apply the rear brake while rolling backwards.

Apply the front brake gradually.

When fully stopped, apply rear brake as well and lock parking brake.

Dismount on uphill side, or to a side if pointed straight uphill.

Turn the vehicle around and remount, following the procedure described

further in this Operator's Guide.

28

_______

SAFETY I

NFORMATION

________

Page 31

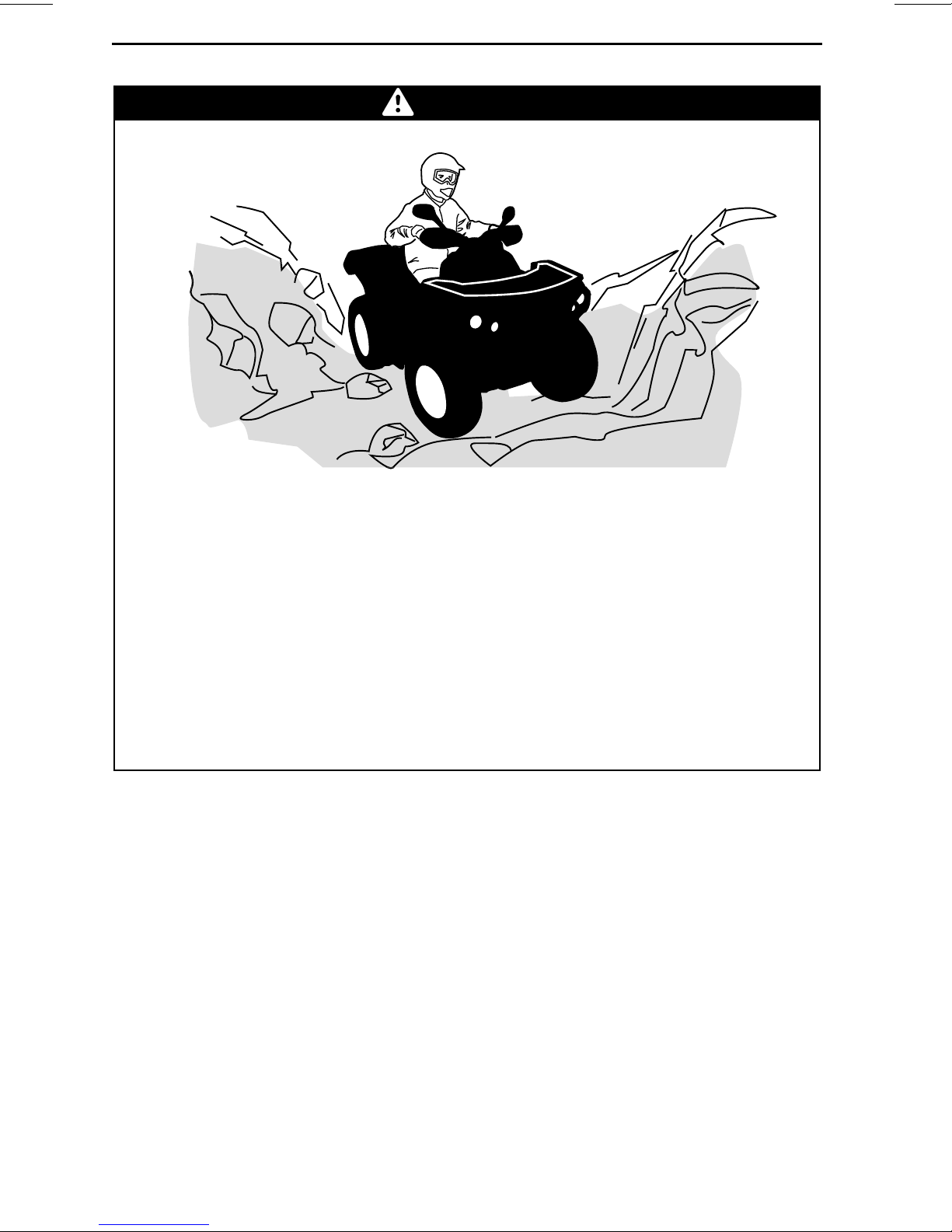

POTENTIAL HAZARD

OPERATION WARNINGS

WARNING

Improperly operating over obstacles.

WHAT CAN HAPPEN

Could cause loss of control or a collision.

Could cause the vehicle to overturn.

HOW TO AVOID THE HAZARD

Before operating in a new area, check for obstacles.

Never attempt to ride over large obstacles, such as large rocks o

trees.

When you go over obstacles, always follow proper proced

further in this Operator's Guide.

ures as described

r falle n

________

SAFETY INF

ORMATION

________

29

Page 32

OPERATION WARNINGS

POTENTIAL HAZARD

WARNING

Skidding or sliding improperly.

WHAT CAN HAPPEN

You may lose control of this vehicle.

You may also regain traction unexpectedly, which may cause the vehicle to

overturn.

HOW TO AVOID THE HAZARD

Learn to safely control skidding or sliding by practicing at low speeds and

on level smooth terrain.

On extremely slippery surfaces, such as ice, go slowly and be very cautious

in order to reduce the chance of skidding or sliding out of control.

30

_______

SAFETY I

NFORMATION

________

Page 33

POTENTIAL HAZARD

OPERATION WARNINGS

WARNING

Operating this vehicle through deep or fast flowing water.

WHAT CAN HAPPEN

Tires may float, causing lossof traction and loss of control, which could lead

to an accident.

HOW TO AVOID THE HAZARD

Never operate this vehicle in fast flowing water or in water deeper than that

specified further in this Operator 's Guide.

Check water depth and current before you attempt to cross any water. Water should not go above footrests.

Remember that wet brakes may have reduced stopping ability. Test your

brakes after leaving water. If necessary, apply them several times to let

friction dry out the pads.

________

SAFETY INF

ORMATION

________

31

Page 34

OPERATION WARNINGS

POTENTIAL HAZARD

WARNING

Operating this vehicle with improper tires, or with improper or uneven tire

pressure.

WHAT CAN HAPPEN

Use of improper tires on this vehicle, or operation of this ve

improper or uneven tire pressure, may cause loss of control, tire blow outs,

tire to move around on its rim, and increases the risk of an accident.

HOW TO AVOID THE HAZARD

Always use the size and type of tires specified further in thi

Guide for t his vehicle.

Always maintainproper tire pressure as described fu

Guide.

Always repl ac e wheels or tires that are damaged.

rther in this Operator's

hicle with

s Operator's

32

_______

SAFETY I

NFORMATION

________

Page 35

POTENTIAL HAZARD

OPERATION WARNINGS

WARNING

Operating this vehicle with improper modifications.

WHAT CAN HAPPEN

Improper installation of accessories or modification of this vehicle may

cause changes in handling which in some situations could lead to an accident.

HOW TO AVOID THE HAZARD

Never modify this vehicle through improper installation or use of accessories. All parts and accessories added to this vehicle should be approved

by BRP and should be installed and used according to

have questions, consult an authorized Can-Am dealer.

Modification of the vehicle to increase speed and p

the terms and conditionsof yourvehicle's limitedwarranty. Inaddition, certain modifications including the removal of engine or exhaust components

are illegal under most laws.

instructions. If you

erformance may violate

________

SAFETY INF

ORMATION

________

33

Page 36

OPERATION WARNINGS

POTENTIAL HAZARD

WARNING

Overloading this vehicle or carrying or towing cargo improperly.

WHAT CAN HAPPEN

Could cause changes in vehicle handling which could lead to an accident.

HOW TO AVOID THE HAZARD

Never exceed the stated load capacity for this vehicle including operator as

well as other loads and added accessories.

Cargo should be properly distributed and securely attached.

Reduce speed when carrying cargo. Allow greater distance for braking.

Always follow the instructions in this Operator's Guide for carrying cargo.

34

_______

SAFETY I

NFORMATION

________

Page 37

OPERATION WARNINGS

WARNING

V03M01Q

POTENTIAL HAZARD

Transporting flammable or dangerous material can lead to explosions.

WHAT CAN HAPPEN

This can cause serious injury or death.

HOW TO AVOID THE HAZARD

Never transport flammable or dangerous material.

________

SAFETY INF

ORMATION

________

35

Page 38

RIDING THE VEHICLE

To fully appreciate the p lea su re s and excitement of riding this vehicle, there are

some basic rules and tips that you MUST follow. Some may be new to you while

others may be common sense or obvious.

Please take the time to study this Operator's Guide and all on-product safety

labels as well as the

completely describe what you should know about this vehicle before riding it.

Whether you are a new user or an experienced rider, it is important for your

personal safety that you know the controls and features of this vehicle. Equally

important is knowing how to properly ride.

This is a high performance ATV for off-road use only. Inexperienced riders may

overlook risks and be surprised by the specific behavior of this ATV in any terrain

condition.

Persons with cognitive or physical impairm e nts or who are high risk takers have an

increased exposure to overturns or collisions which may result in injury including

death.

Not all vehicles are the same. Each has its own unique performance characteristics, controls and features. Each will ride and handle differently.

Become co mpletely familiar with the ope rational controls and the ge ne ral operation of the vehicle before venturing into off road conditions. Practice driving in a

suitable area free of hazards and feel the response of each control. Drive at low

speeds. Higher speeds require greater experience, knowledge and suitable riding

conditions.

SAFETY DVD

video that came with this vehicle. They more

Riding conditions vary from place to place. Each is subject to weather conditions

which may radically change from time to time and from season to season.

Riding on sand is different than riding on snow or through forests or marshes.

Each location may require a greater d eg ree of awarenes s and skills. Show good

judgement. Always proceed with caution. Please do not take any unnecessary

risks that could leave you stranded or possibly injured.

Never assume that the vehicle will go everywhere safely. Sudden changes in terrain caused by holes, depressions, banks, softer or harder “ground” or other irregularities may cause the vehicle to topple or become unstable. To avoid this, slow

down and always observe the terrain ahead. If the vehicle does begin to topple or

tip over, the best advice is to immediately get off... AWAY from the direction of the

tip over!

While reading this Operator’s Guide, remember that:

Indicates a potential hazard that, if not avoided, could result in serious

injury or dea t h.

36

_______

WARNING

SAFETY I

NFORMATION

________

Page 39

RIDING THE VEHICLE

Pre-Ride Inspection

WARNING

Perform a pre-ride inspection before each ride to detect potential problems

during operation. The pre-ride inspection can help you monitor wear and

deterioration before they become a problem. Correct any problems that

you discover to reduce the risk of a breakdown or crash. See an authorized

Can-Am dealer if necessary.

Before using this vehicle, the operator should always:

– Apply parking brake and check if it operates properly.

– Check tire pressure and condition.

– Check wheels and bearings for wear and damage.

– Check location of controls and ensure they work properly.

– Verify if steering operates freely.

– Activate throttle control lever several times to ensure it operates freely. It must

return to idle position when released.

– Activate the brake lever and brake pedal to make sure the brakes fully apply.

They must fully return when released.

– Ensure front brake lever position is adjusted to suit drivers hand.

– Check all brake line fittings for tightness and against leaks.

– With parking brake correctly applied, activate the clutch lever. It must fully re-

turn when released.

– Check drive chain for ad justment an d lubrication.

– Check sprockets for wear and damages.

– Check tightening of rear axle fasteners.

– Check swing arm, if any late ral play is detected DO NOT USE THE VEHICLE.

– Check fuel, oil and coolant levels.

– Check for oil leaks on the engine, oil tank and transmis sion.

– Check radiator cleanliness.

– Clean headlights and taillight.

– Ensure seat is properly latched.

– Look and feel for loose parts while engine is off. Check fasteners.

– Ensure the path of travel is free of persons and obstacles.

– Check operation of ignition switch, engine start button, emergency engine stop

switch, headlights, taillig ht and indicator ligh ts.

– Start engine, remove parking brake and drive forward slowly a few feet then ap-

ply all brakes individually to test them.

Correct any problem you m ay have found before riding. See an authorized

Can-Am dealer if necessary.

________

SAFETY INF

ORMATION

________

37

Page 40

RIDING THE VEHICLE

Clothing

Actual weather conditions should help you decide how to dress. However, it

is important that the operator always wears the appropriate protective clothing

and apparel, including an approved helmet, eye protection, boots, gloves, a long

sleeved shirt and pants. This type of clothing will provide you protection from

some of the minor hazards you m ay encounter en route. The operator must

never wear loose c lothing such as a scarf that may get entangled in the vehicle or

on tree branches and shrubs. Depending on conditions, antifogging goggles or

sunglasses may be required. Different colored lenses available for goggles or sun

glasses help you distinguish terrain variations. Sunglasses should only be worn

during the daytime.

Approved

helmet

Eye protection

Rigid chin

guard

V00A0RN

Chest

protector

Long

sleeves

Gloves

Long, sturdy

pants

Boots

Carrying Passenger

This vehicle is designed specifically to carry an operator only. This vehicle is not

designed nor intended t

the stability and your control of the vehicle.

Carrying Loads

Never load cargo on this v ehicle.

38

_______

o carry passenger(s). Carrying passenger(s) may affect

SAFETY I

NFORMATION

________

Page 41

RIDING THE VEHICLE

Recreational Riding

Respect the rights and limitations of others. Stay away from areas designated

for other types of off road use. This includes snowmobile trails, equestrian trails,

cross country ski trails, mountain bike trails etc. Never a ssume there are no other

usersonthetrail. Alwaysstaytothecompleterightofthetrailanddonotzigzag

toonesideofthetrailthentheother. Bepreparedtostoporpullofftothesideif

another trail user appears in front of you.

Join a local ATV club. It will provide you with a map and advice or inform you where

you can ride. If a club does not exist in your area, help to s tart one. Group riding and

club activities provide a pleasurable, social experience.

Always keep a safe distance from other riders. Your judgment of speed, terrain conditions, weather, mechanical condition of your vehicle and the “trust in

judgment” you have in others around you will help you make a better choice of

appropriate safe distance. This vehicle, like any other motorized vehicle, cannot

stop “on a dime”.

Before you ride, tell someone where you are planning to travel and your expected

time of return. Never consume alcohol or drugs before or while riding!

Depending on the length of your ride, carry additional tools or emergency equipment. Find out where you can get additional gasoline and oil. Be prepared for the

possible conditions you may encounter. An emergency first aid kit should always

be a consideration.

Environment

One of the benefits of this vehicle is that it can take you off the beaten path away

from most communities. However, you should always respect nature

rights of others to enjoy it. Do not ride in environmentally sensitive areas. Do not

drive over forest crops or shrubs... nor cut down trees or take down fencing... nor

spin your wheels and destroy the terrain. “Tread Lightly”.

This vehicle can cause OHV wildfires if debris builds up ne ar the exhaust or other

engine hot spots and ignites then falls off into dry gra

through muskeg or tall grass, where debris can build up. Should you ride in those

areas, inspect and remove all debris from your engine and hot spots.

Chasing wildlife is in many areas illegal. Wildlife can die of exhaustion after be ing

chased by a motorized vehicle. If you encounter animals on the trail, stop and observe quietly and with caution. It will be one of the b

Observe the rule... “what you t ake in, carry out”. Do not litter. Do not start campfires unless you have permission to do so... an

The hazards you may create on the trail m ay cause injury to others or yourself, even

at a later date.

Respect farm lands. Always obtain the permission of the landowner before riding

on private land. Respect crops, farm animals and property lines. If you come to a

closed a gate, close it again behind you.

Finally, do not pollute streams, lakes or rivers and do not modify the engine or muffling system, or remove any of its compo

nents.

d then only... away from dry areas.

ss. Avoid riding in wet areas,

etter memories of your life.

and the

________

SAFETY INF

ORMATION

________

39

Page 42

RIDING THE VEHICLE

Design Limitation

Although the vehicle is exceptionally rugged for its class, it is still a light vehicle by

definition and its operation must be restricted to its proper purpose.

The addition of we igh t to any part of the veh icle changes its gravitational stability

and modifies its performance.

Off-Highway Operation

The very nature of off-highway operation is dangerous. Any terrain, which has

not been specially prepared to carry vehicles, presents an inherent danger where

angularity, terrain substance and exact steepness are unpredictable. The terrain

itself presents a continual element of danger, which must be knowingly accepted

by anyone venturing over it.

An operator who takes a vehicle off-road should always exercise the utmost care in

selecting the safest path and keeping close watch on the terrain ahead of him. On

no account should the vehicle be operated by anyone who is not completely familiar with the driving instructions applicable to the vehicle, nor should it be operated

on steep or treacherous terrain.

General Operating and Safety Precautions

Care, caution, experience and driving skill are the best precautions against the hazards of vehicle operation.

Whenever there is the slightest doubt that the vehicle can safely negotiate an obstacle or a particular piece of terrain, always choose an alternate rou

In off-road operation, power and traction, not speed, are important. Never drive

faster than visibility and your ow n ability to select a safe rou te permi

Constantly watch the terrain ahead for sudden changes in slopes or obstacles,

such as rocks or stu m ps, that may cause loss of stability, resulting in t

rollover.

Never ope rate the v eh icle if the controls do not function norm

When stopped or parked, always apply the parking brake. This is especially impor-

tant when parking on a slope. On very steep inclines or if the ve

cargo, the wheels should b e blocked using rocks or bricks. Remember to turn the

fuel valve to the closed p os ition.

Uphill Driving

Due to configuration, this vehicle has excellent clim

tip over is possible before traction is lost. For example, its common to encounter

terrain situations where the top of the hill has erode d to a po int that the hill peak

rises very sharply. The vehicle can readily negotia

in doing so, when the front of the vehicle is driven to a point that the vehicle's

balance changes rearward tip over can occur.

bing ability, so much so that

te such a condition, however,

ally.

te.

t.

ip over or

hicle is carrying

The same situation may apply if an embedded object causes the front of the vehicle to climb more than desired. If such a situation occurs take an alternate route.

Be aw are of side hilling dangers when d oin g s

It is also wise to know the terrain condition on the other side of the hill or bank. All

too often there exists a sharp drop-off that

40

_______

SAFETY I

o.

is impossible to negotiate or descend.

NFORMATION

________

Page 43

RIDING THE VEHICLE

Downhill Driving

This vehicle can climb steeper slopes that it can descend safely. Therefore, it is essentialtoassurethatasaferouteexiststodescendaslopebeforeyouclimbit.

Decelerating while negotiating a slippery downhill slope could “toboggan” the vehicle. Maintain steady speed and/or accelerate slightly to regain control.

Side Hilling

Whenever possible, such operation should be avoided. If necessary, do so with

extreme caution. Sid e hilling on ste ep inclines could result in rollover. In addition,

slippery or unfirm surfaces could result in uncontrollable side sliding. Do not attempt to turn the vehicle downhill with the slide. Avoid all objects or depressions

that will intensify the raising of one side of the vehicle higher than the other, thus

causing rollover.

WARNING

Do not try to stop or save the vehicle from damage.

WARNING

Be careful when loading and transporting liquid reservoirs. They can affect

vehicle stability whenside hillingby pullingdownhill and increasing the risk

of a roll over.

Drop-Offs

This vehicle will “bottom-out” and usually stop if either the front or rear wheels are

driven over a drop-off. If the drop is sharp or deep, the vehicle will nose dive and tip

over.

WARNING

Avoid negotiating drop-offs. Reverse and select an alternate route.

Riding on Snow Covered Surfaces

When p erforming the pre-ride inspection, pay special attention to locations on the

vehicle wh ere snow and/or ice accum u lations may obstruct visibility of the tail

lamp, clog ventilation openings, block the radiator and fan, and interfere with the

movement of control levers, switches and brake pedal. Before starting with your

ATV check the steering, throttle and brake lever and pedal controls for interfere nce

free operation.

Whenever an ATV is ridden on a snow covered drive path the tire grip is generally

reduced causing the vehicle to react differently to control inputs from the operator.

On low grip surfaces, the steering responses are not as crisp and precise, stopp ing

distances are lengthened and acceleration becomes sluggish. Slow down and do

not "gun" the throttle. This will only result in spinning of the tires and possibly in an

over steering slide of the vehicle. Avoid hard braking. This will possibly re sult in a

straight line slide of the vehicle. Again, the best advice is to safely reduce speed in

anticipation of a maneuver so to give yourself time and distance to regain total vehicle control before it spins out of your control.

________

SAFETY INF

ORMATION

________

41

Page 44

RIDING THE VEHICLE

As you drive your ATV over a loose snow c overed surface, snow dust will be

picked up in the wake turbulence of the moving vehicle and transporte d to contact

and accumulate or melt on some exposed components including rotating parts

like brake discs. Water, snow or ice may affect the response time of the brake

system of your ATV. Even when not required to reduce vehicle speed apply brakes

frequently to prevent ice or snow accumulation and to dry brake pads and discs.

While doing so in low risk driving situations you will test for grip level and keep

yourself alerted to how the vehicle reacts to your control inputs. Always keep

brake pedal, footrests, floor boards, brake and throttle levers free of snow and ice.

Frequently wipe snow off seat, handgrips, head and tail lamps.

The depth of the snow cover may hide rocks, tree stumps or other objects and if it

is wet may totally impede the drivability as the vehicle beco mes bogged down or

completely looses traction in slushy snow. Look far ahead and always be watchful

of any visible clues that might indicate the presence of such obstacles. In doubt

steer clear. Avoid driving on any frozen body of water before checking that the

ice will safely support the ATV, its riders and its load of cargo. Remember that a

given thickness of ice may be sufficient to support a snowmobile but not

of an identical weight because of the smaller load bearing surface of the four tire

contact patches as compared to that of a snowmobile track and skis.

Always remember that the vehicle handling an d stability is affected when riding

with a passenger. So never attempt maneuvers with a passenger that may cause

the vehicle to enter into a slide that if halted abruptly will result

the passen ge r and/or a vehicle roll or tipover.

in the ejection of

an ATV

To maximize comfort and avoid frostbite, always wear clot

equipment appropriate for the weather conditions you will be exposed to during

your ride.

At the end of each ride it is a g ood practice to clean the vehicle body and all moving

components (brakes, steering components, drivelines, controls, radiator fan etc.)

from any snow or ice accumulations. Wet snow will turn t

down period and become more difficult to remove at the next pre-ride inspection.

hing and ATV protective

o ice during the shut

Riding Techniques

Riding your vehicle too fast for the conditions may result in injury. Apply only

enough throttle to proceed safely. Statistics show that high speed turns usually

result in mishaps and injury. Always remember

weight alone may entrap you should it fall and pin you down.

This vehicle is not designed for jumping

impacts such as jumping. Performing “wheelies” can cause the vehicle to flip over

onto you. Both practices have a high risk for you a nd should be avoided at all times.

To maintain proper control it is strongly advised that you keep your hands on the

handlebar and within easy reach of all controls. The same holds true for your feet.

To minimize the possibility of any leg

at all times. Do not direct your toes outwards nor place your foot out to assist

turning as they can be hit or snagged by passing obstacles or may contact the

wheels.

nor can it, or you, absorb the energy of high

or foot injury, keep your feet on the footrests

that this vehicle is heavy! Its pure

Always use proper riding techniques to avoid vehicle overturns on hills and rough

terrain and in turns.

42

_______

SAFETY I

NFORMATION

________

Page 45

RIDING THE VEHICLE

vmo2012-012-520

Even though there is an adequate suspensions system on this vehicle there are

“washboard” or rough terrain conditions that will make you feel uncomfortable

and even cause back injury. “Posting” or riding in a crouched position will often

be required. Slow down and allow you r flexed le g s to absorb impact.

This vehicle is not designed for riding on roads or highways. In most places it is an

illegal practice. Ridin g your vehicle on roads or highways could cause a collision to

occur with another vehicle.

The tires of this vehicle are not suited for paved road use. Also this vehicle is

not equipped with a rear differential (rear wheels are always turning at the same

speed). For these reasons, pavement may seriously affect the handling and

control of the vehicle.

Riding on roads or soft shoulders may confuse other road users, especially if your

lights are on.

If you have to cross a road, the lead driver should get off his vehicle, then observe

and give directions to the other riders. The last person after crossing then a ssists

the lead driver to cross. Do not travel on sidewa lks. They are designated for

pedestrian use.

Water can be a unique hazard. If it is too deep the vehicle may “float” and topple.

Check the water depth and current before you attempt to cross any water. Water

should not go above the footrest. Be wary of slippery surfaces such as rocks,

grass, logs, etc., both in the water and on its banks. A loss of traction may occur.

Do not attempt to enter the water at high speed. The water will act as a brake and

could throw you off the vehicle.

________

SAFETY INF

ORMATION

________

43

Page 46

RIDING THE VEHICLE

vmo2012-012-524

Wet brakes w ill affect the braking ability of your vehicle. Mak e sure you dry the

brakes by applying them several times after the vehicle leaves the water, mud or

snow.

Mud or marsh lands may be encountered near water. Be prepared for sudden

“holes” or changes in depth. Similarly so, be watchful of hazards such as rocks,

logs, etc., partially covered by vegetation.

If your trip crosses frozen waterways, make sure that the ice is thick enough and

sound enough to support the total weight of yourself, the vehicle and its load. Be

ever watchful of open water... it is a sure indication that the ice thickness will vary.

If in doubt, do not attempt to cross.

Ice will also affect the control of the vehicle. Slow down and do not “gun” the

throttle. This will only result in spinning of the tires and possible tip over of the

vehicle. Avoid rapid braking. This again will possibly result in an uncontrolled slide

and tip over of the vehicle. Slush should be avoided at all times since it could block

the operation or controls of the vehicle.

Riding in snow ma y affect the brakes stopping ability. Safely reduce speed an d

allow greater distance for braking. Snow projection may cause ice build up or

snow accumulation on brake components and controls. A pply brakes frequently

to prevent ice or snow accumulation. Carefully inspect the brake system before

each ride and always k eep brake pedal, footrests, floor boards and brake levers

free of snow and ice.

Sand and riding on sand dunes or on snow is another unique experience but

there are some basic precautions that should be observed. Wet, deep or fine

sand/snow may create a loss of traction and cause the vehicle to slide, drop off

or become “bogged” down. If this occurs look for a firmer base. Again, the best

advice is to slow down and be watchful of the conditions.

When riding in sand dunes it is advisable to equip the vehicle with an antenna type

safety flag. This will help make your location more visible to others over the next

sand dune. Proceed carefully should you see another safety flag ahead. Since the

antenna type safety flag can snag and rebound on your body if caught, do not use it

in areas where there are low hanging branches or obstacles.

44

_______

SAFETY I

NFORMATION

________

Page 47

RIDING THE VEHICLE

Riding on loose stones or g r avel is very sim ila r to riding on ice. They will affect

the steering of vehicle... possibly causing it to slide and tip over especially at

high speeds. In addition, braking distance may be a affected. Remember that

“gunning” the throttle or sliding may cause loose stones to be ejected rearwards

into the path of another rider's way. Never do it deliberately.

vmo2012-012-525

If you do get into a slide or skid, it may help to turn the handlebar into the direction

of the skid until you regain control. Never jam the brakes and lock the wheels.

Respect and follow all posted trail signs. They are there to help you and others.

Obstacles in the “trail” should be traversed with caution. This includes loose

rocks, fallen trees, slippery surfaces, fences, posts, and embankments and

depressions. You should avoid them whenever possible. Remember that some

obstacles are too large or dangerous to cross and should be avoided. Small rocks

or fallen trees may be safely crossed... approach at a 90° angle. Stand on the

footrests while keeping your knees flexed. Adjust speed without losing momentum and do not “gun” the throttle. Hold handlebar firmly. Place your body weight

rearwards and proceed. Do not try to lift the vehicle front wheels off the ground.

Be aware that the object may be slippery or may move while crossing.

When driving on hills or slopes two things are highly important... be prepared

for slippery surfaces or terrain variations and obstacles and... use proper body

positioning.

When stopped or parked always apply the parking device. This is especially important when parking on a slope. On very steep inclines or if the ATV is carring a cargo,

the wheels should be blocked using rocks or bricks.

________

SAFETY INF

ORMATION

________

45

Page 48

RIDING THE VEHICLE

Uphill

Before trying to climb a hill, keep these things in mind. Hill Climbing should only

be attempted by experienced operators. Start on shallow slopes. Always drive

straight uphill and keep your body weight forward t ow ards the top of th e hill.

Keep your feet on the footrests, shift your ATV into a lower gear and accelerate

before you start to climb. Try to keep a steady speed and go easy on the throttle

to avoid acceleration. Abrupt slope or terrain variatio n or rolling one wheel over

an obstacle could have a big impact on the stability as it will lift the front of the

vehicle increasing the risk of tipping over. Som e hills are too steep to safely stop or

recover from after an unsuccessful climbing attempt. Try to avoid steep inclines.

If you're not careful, you could tip over when going up hills. I f the hill is too steep

and you cannot proceed or the vehicle begins to roll backwards, apply the brake,

being careful not to slide. Dismount then use the “K” turn (while walking back,

next to the vehicle on the up hill side and with a hand on the brake lever, s lowly

back the rea r of the vehicle toward t he top of the hill then drive downhill). Always

walk or dismount on the upside of the slope while keeping clear of the vehicle and

its rotating wheels. Do not try to hold on to the vehicle if it begins to to

clear. Do not ride over the crest of the hill at high speed. Obstacles, including

sharp drop-offs, may exist.

pple. Stay

vmo2012-012-526

46

_______

SAFETY I

NFORMATION

________

Page 49

RIDING THE VEHICLE

Downhill

Keep your body weight rearwards. Stay seated. Apply the brake gradually to prevent skidding. Do not “coast” down the slope using solely engine compression or

in neutral gear.

Decelerating while negotiating a slippery downhill slope could “toboggan” the

vehicle. Maintain steady speed and/or accelerate slightly to regain control. Try

to avoid steep inclines. If you're not careful, you could tip over when going down

hills.

vmo2012-012-523

________

SAFETY INF

ORMATION

________

47

Page 50

RIDING THE VEHICLE

Side Hilling

This is one of the most risky types of riding sin ce it may drastic ally change the balance of the vehicle. It should be avoided wherever possible. If it is necessary to do

so however, it is important that you ALWAYS keep your body weight on the upside

of the slope... and be prepared to dismount on that side should the vehicle begin

to topple.

WARNING

Do not try to stop or save the vehicle from damage.

WARNING

Be careful when loading and transporting liquid reservoirs. They can affect

vehicle stability whenside hillingby pullingdownhill and increasing the risk

of a roll over.

vmo2012-012-527

While reading this Operator’s Guide, remember that:

Indicates a potential hazard that, if not avoided, could result in serious

injury or dea t h.

48

_______

WARNING

SAFETY I

NFORMATION

________

Page 51

IMPORTANT ON-PRODUCT LABELS

Hang Tag

This vehicle comes with a hang tag and labels containing important safety information.

Any person who rides this vehicle should read and understand this information before riding.

vmo2009-005-003_en

704901107

vmo2006-005-009_en

________

SAFETY INF

ORMATION

________

49

Page 52

IMPORTANT ON-PRODUCT LABELS

Vehicle Safety Labels

Read and understand all the safety labels on your vehicle.

These labels are affixed to the vehicle

for the safety of the operator or bystanders.

The following labels are on your vehicle

and they should be considered permanent parts of the vehicle. If missing or

damaged, they can be replaced free

of charge. See an authorized Can-Am

dealer.

NOTE: In the event of any d iscrepancy between this guide and the vehicle, the safety labels on the vehicle

have precedence over the labels in this

guide.

vmo2008-011-098_b

vmo2008-011-021_a

vmo2014-012-001_a

vmo2008-011-023_a

vmo2014-018-002_b

UNDERNEATH ACCESS COVER

50

_______

SAFETY I

NFORMATION

________

Page 53

vmo2009-003-004_en

LABEL 1

NEVER USE UNDER

THE INFLUENCE OF

DRUGS OR ALCOHOL.

IMPORTANT ON-PRODUCT LABELS

704902777A

LABEL 4

V01M02Z

LABEL 2

V02M05Y

LABEL 3

V01M07Z

LABEL 5

Improper tire pressure or

overloading can cause

loss of control, resulting

in SEVERE INJURY or

DEATH.

ALWAYS maintain proper tire pressure as shown.

NEVER set tire pressure below minimum. It could cause the tire to

disloge from the rim.

NEVER exceed the vehicle load capacity of 100 kg (220 lb)

Including weight of operator and accessories.

704901365

LOAD

UP TO

100 kg

(220 lb)

COLD TIRE PRESSURE

FRONT

MAX: 48.3 kPa (7 PSI)

MIN: 34.5 kPa (5 PSI)

REAR

MAX: 48.3 kPa (9 PSI)

MIN: 34.5 kPa (7 PSI)

LABEL 6 - DS 450™ X™ XC

________

SAFETY INF

ORMATION

________

51

Page 54

IMPORTANT ON-PRODUCT LABELS

Improper tire pressure or

overloading can cause

loss of control, resulting

in SEVERE INJURY or

DEATH.

ALWAYS maintain proper tire pressure as shown.

NEVER set tire pressure below minimum. It could cause the tire to

disloge from the rim.

NEVER exceed the vehicle load capacity of 100 kg (220 lb)

Including weight of operator and accessories.

704902001

LOAD

UP TO

100 kg

(220 lb)

COLD TIRE PRESSURE

FRONT

MAX: 68.9 kPa (10 PSI)

MIN: 55.2 kPa (8 PSI)

REAR

MAX: 62.1 kPa (9 PSI)

MIN: 48.3 kPa (7 PSI)

LABEL6-DS450™X™MX

vmo2010-010-100_a

LABEL 7

Compliance Labels

704903327