Can-Am DS 450 2008, DS 450 X 2008 Shop Manual

2008

Shop Manual

DS 450™

DS 450™ X

Legal deposit:

National Library of Quebec

National Library of Canada 2007

All rights reserved. No parts of this manual may be reproduced in any form without the prior written

permission of Bombardier Recreational Products Inc. (BRP)

©

Bombardier Recreational Products Inc. (BRP) 2007

Printed in Canada

Technical Publications

Bombardier Recreational Products Inc. (BRP)

Valcourt (Quebec) Canada

®

™ Trademarks of Bombardier Recreational Products Inc. (BRP) or its affiliates.

* Trademarks of Bombardier Inc., used under license.

Can-Am™ Rotax

®

DS 450™ XP-S™

This document contains the trademarks of the following companies:

Loctite

Molykote

®

is a trademark of Loctite Corporation

®

is a trademark of Dow Corning Corporation

Snap-on®is a trademark of Snap-on Tools Corporation

TABLE OF CONTENTS

SAFETY NOTICE.................................................................................. VIII

INTRODUCTION ................................................................................... IX

GENERALINFORMATION......................................................................................... IX

VEHICLEINFORMATION .......................................................................................... IX

ENGINE EMISSIONS INFORMATION............................................................................ X

SELF-LOCKING FASTENERS PROCEDURE ..................................................................... X

LOCTITE

TIGHTENING TORQUES ......................................................................................... XIV

MANUAL INFORMATION ........................................................................................ XV

01 MAINTENANCE

01 – MAINTENANCE CHART....................................................................................... 1

02 – PRESEASON PREPARATION................................................................................. 5

03 – STORAGE PROCEDURE....................................................................................... 7

04 – SPECIAL PROCEDURES....................................................................................... 9

®

APPLICATIONPROCEDURE .......................................................................... X

FUEL SYSTEM.... .. .... ..... ..... .... .... .. .... . ... . .... .. .... . ... .. .. ... . .... .. .. ... .. ..... .... .... .. .. ... . .... .. .... 7

ENGINE................................................................................................................ 7

ELECTRICAL SYSTEM. .... .... .. .... . ... .. ..... ... . .... .. .... .... .. .. ... .. .. ... . .... .. .... .... .. .. ... .. ..... ... . .... . 7

COOLING SYSTEM .... ..... .... .... .. .... .... .. .... .... .. .... .... .. .... ..... .... . ... .. .... . ... .. .. ... .. .... . ... .. .... 7

VEHICLE ............................................................................................................... 7

TURN OVER ........................................................................................................... 9

ATVIMMERSION ..................................................................................................... 9

02 TROUBLESHOOTING

01 – TECHNICALGUIDELINES(ENGINE)...................................................................... 11

COOLING SYSTEM .... ..... .... .... .. .... .... .. .... .... .. .... .... .. .... ..... .... . ... .. .... . ... .. .. ... .. .... . ... .. ... 11

LUBRICATION SYSTEM .. .. ... . .... .. ... . .... .. ... .. .. ... .. .... . ... .. .. ... .. .... .... .. .... .... .. ... . .... .. ... . .... .. 11

CLUTCH............................................................................................................... 12

CYLINDER HEADAND CYLINDER ................................................................................. 13

CRANKSHAFT AND BALANCER SHAFT .. .. .... ..... ... . .... .. ... .. .. ... .. ... . .... .. ... .. .. ... .. ... . .... .. ... .. ... 13

GEARBOX... ..... ... .. .. ... .. ... . .... .. ... .. .... .... .. ... .. .. ... .. .... .... .. ... .. .. ... .. ... . .... .. ... .. .... .... .. ... .. 14

02 – DIAGNOSTICFLOW CHART................................................................................ 15

FUEL SYSTEM.... .. .... ..... ..... .... .... .. .... . ... . .... .. .... . ... .. .. ... . .... .. .. ... .. ..... .... .... .. .. ... . .... .. ... 15

03 ENGINE

01 – ENGINE REMOVALAND INSTALLATION................................................................ 17

GENERAL...................................................................................................... 18

PROCEDURES ................................................................................................ 18

ENGINE............................................................................................................... 18

02 – AIR INTAKE SYSTEM........................................................................................ 25

GENERAL...................................................................................................... 26

PROCEDURES ................................................................................................ 26

AIRFILTER............................................................................................................ 26

AIRFILTERHOUSING............................................................................................... 26

03 – EXHAUST SYSTEM.......................................................................................... 29

GENERAL...................................................................................................... 30

PROCEDURES ................................................................................................ 30

MUFFLER... ..... ..... .... . ... . .... .. .. .... .... .. .. .... . ... . .... .. ..... .. ... . .... .. ..... .... . .... .... .. .. .... . ... . .... 30

EXHAUST PIPE....................................................................................................... 31

SPARKARRESTER................................................................................................... 32

HEAT SHIELD......................................................................................................... 32

04 – LUBRICATION SYSTEM..................................................................................... 33

GENERAL...................................................................................................... 36

MAINTENANCE .............................................................................................. 36

ENGINEOIL .......................................................................................................... 36

I

TABLE OF CONTENTS

OIL FILTER............................................................................................................ 37

OIL TANKSTRAINER ................................................................................................ 38

INSPECTION.................................................................................................. 39

ENGINEOIL PRESSURE............................................................................................. 39

PROCEDURES ................................................................................................ 40

OIL TANK ............................................................................................................. 40

OIL HOSE CONNECTOR............................................................................................ 41

ENGINEOIL PRESSURE REGULATOR............................................................................. 42

OIL PRESSUREPUMP............................................................................................... 43

ENGINEOIL STRAINER ............................................................................................. 46

OIL SUCTION PUMP................................................................................................. 47

OIL NOZZLE ... . .... .. .. .... . .... .... .. ..... ..... .. ... . .... .. ..... ..... .... . ... . .... .. .. .... . ... . .... .. .. .... . ... . .... 48

OIL TUBE ............................................................................................................. 48

05 – COOLING SYSTEM .......................................................................................... 51

GENERAL...................................................................................................... 54

INSPECTION.................................................................................................. 54

COOLING SYSTEM LEAK TEST.. .... ..... .... . ... .. .. ... . .... .. ... . .... .. ... . .... .. ... . ..... .... . ... .. .... . ... .. ... 54

MAINTENANCE .............................................................................................. 55

COOLANT REPLACEMENT ......................................................................................... 55

PROCEDURES ................................................................................................ 57

COOLANT TANKCAP................................................................................................ 57

COOLANT TANK ..................................................................................................... 57

RADIATOR............................................................................................................ 58

COOLING FAN........................................................................................................ 59

THERMOSTAT........................................................................................................ 60

COOLANT TEMPERATURE SENSOR (CTS)........................................................................ 60

WATER PUMP HOUSING ........................................................................................... 61

WATER PUMP IMPELLER........................................................................................... 62

WATER PUMP SHAFT, BEARINGANDSEALS.................................................................... 62

06 – MAGNETO/STARTER ....................................................................................... 67

GENERAL...................................................................................................... 69

PROCEDURES ................................................................................................ 69

MAGNETO COVER................................................................................................... 69

CRANKSHAFT POSITION SENSOR (CPS)..... .. ... .. .... . ... .. .... .... .. ... . .... .. ... .. .. ... .. .. ... .. .... .... .. ... 71

STATOR............................................................................................................... 71

ROTOR................................................................................................................ 76

SPRAG CLUTCH...................................................................................................... 78

SPRAG CLUTCH GEAR.............................................................................................. 79

STARTER DRIVE GEARS ............................................................................................ 79

STARTER.............................................................................................................. 80

07 – CYLINDER HEAD/CYLINDER............................................................................... 85

GENERAL...................................................................................................... 89

MAINTENANCE .............................................................................................. 89

VALVE CLEARANCE.... ... .. .... . ... .. .... .... .. ... . .... .. ... .. .. ... .. ... . .... .. ... . .... .. .... .... . ... .. .... .... .. ... 89

INSPECTION.................................................................................................. 90

CYLINDER LEAK TEST............................................................................................... 90

PROCEDURES ................................................................................................ 91

VALVE COVER........................................................................................................ 91

TIMINGCHAIN TENSIONER........................................................................................ 94

CAMSHAFT TIMING GEAR.......................................................................................... 94

CAMSHAFT........................................................................................................... 97

VALVE LIFTERBUCKET.............................................................................................. 99

CYLINDER HEAD................................................................................................... 100

VALVE SPRINGS.................................................................................................... 102

VALVE ............................................................................................................... 103

VALVE GUIDE....................................................................................................... 106

II

TABLE OF CONTENTS

CYLINDER .......................................................................................................... 107

PISTON.............................................................................................................. 108

PISTON RINGS..................................................................................................... 111

PISTON PIN......................................................................................................... 112

08 – CRANKCASE/CRANKSHAFT.............................................................................. 115

GENERAL..................................................................................................... 117

PROCEDURES ............................................................................................... 117

MAIN SHAFTOIL SEAL ........................................................................................... 117

PRIMARY DRIVE GEAR............................................................................................ 118

TIMINGCHAIN ANDCHAINTENSIONERGUIDE............................................................... 118

TIMINGCHAIN DRIVE GEARS.................................................................................... 119

CRANKCASE... .. .... . ... .. .. ... .. .... . ... .. ..... ... . .... .. ... . .... .. .... ..... .... . ... .. .... . ... .. .. ... . .... .. ... . .. 121

BALANCER SHAFT................................................................................................. 126

CRANKSHAFT ... .... . ... .. .. ... .. .... . ... .. ..... ... .. .. ... . .... .. ... . .... .. ... . .... .. ... . ..... .... . ... .. .... . ... .. . 127

09 – CLUTCH....................................................................................................... 131

GENERAL..................................................................................................... 134

MAINTENANCE ............................................................................................. 134

CLUTCHADJUSTMENT........................................................................................... 134

PROCEDURES ............................................................................................... 136

CLUTCHRELEASECOVER........................................................................................ 136

CLUTCH CABLE.. .. .. ... .. .. ... . .... .. ... . .... .. .... .... .. .... .... .. .. ... .. .. ... .. ..... ... . .... .. ... . .... .. .... .... 139

CLUTCH LEVER .. . ..... ..... ... . .... .. .... . ... .. .. ... . .... .. .... . ... .. .. ... . .... .. .... . ... .. .. ... . .... .. .... . ... .. . 139

RETAINING PLATE AND CLUTCHSPRING...................................................................... 140

CLUTCH............................................................................................................. 141

CLUTCHCOVER ................................................................................................... 144

CLUTCHDRUM.................................................................................................... 146

10 – GEARBOX .................................................................................................... 149

GENERAL..................................................................................................... 152

PROCEDURES ............................................................................................... 152

NEUTRAL INDICATOR SWITCH .................................................................................. 152

SHIFTINGMECHANISM........................................................................................... 152

GEARBOX... ..... .... .... .. .... .... .. .... .... .. .... ..... .... . ... .. .... . ... .. .. ... .. .... . ... .. .... . ... .. .. ... .. .... . . 155

04 ENGINE MANAGEMENT SYSTEM

01 – OVERVIEW ................................................................................................... 161

SYSTEM DESCRIPTION.................................................................................... 164

CONTROLLER AREA NETWORK(CAN).......................................................................... 164

ENGINECONTROLMODULE (ECM)............................................................................. 164

POWER DISTRIBUTION........................................................................................... 165

02 – COMMUNICATIONTOOLS/B.U.D.S.SOFTWARE..................................................... 167

MULTI-PURPOSE INTERFACE-2 (MPI-2)......................................................................... 167

B.U.D.S.SOFTWARE.............................................................................................. 168

03 – MONITORING SYSTEM/FAULT CODES. ................................................................ 171

MONITORING SYSTEM .... ..... .... . ... .. ..... ... . .... .. ... . .... .. .... ..... .... . ... .. .... . ... .. .. ... . .... .. ... . .. 171

FAULTCODES...................................................................................................... 171

FAULTCODE TABLE............................................................................................... 173

05 FUEL SYSTEM

01 – ELECTRONIC FUEL INJECTION (EFI).................................................................... 179

GENERAL..................................................................................................... 179

SYSTEM DESCRIPTION .... .... .... .. .... . ... .. .. ... . .... .. .... .... .. .. ... .. ..... ... . .... .. .... .... .. .. ... .. ..... . 179

GENERAL RECOMMENDATIONS................................................................................ 180

BASIC ADJUSTMENTS .................................................................................... 182

IDLE SPEED ..... ..... .. .... .... .. ..... ..... .... .... .. .. .... . ... . .... .. .. ... . .... .. ..... .... . ... . .... .. .. .... .... .. . 182

CLOSED THROTTLE AND IDLE ACTUATOR RESET ..... .... .... .. .. ... .. .... . ... .. ..... ... . .... .. ... . .... .. ... 182

PROCEDURES ............................................................................................... 183

III

TABLE OF CONTENTS

ENGINECONTROLMODULE (ECM)............................................................................. 183

FUEL INJECTOR ................................................................................................... 191

FUEL RAIL .......................................................................................................... 193

THROTTLE BODY .. .... ..... ..... ... . .... .. .... .... .. .... .... .. .. ... .. .. ... .. ..... ... . .... .. ... . .... .. .... .... .. .. . 195

THROTTLE POSITION SENSOR (TPS)... . ... . .... .. .. ... .. ..... .... .... .. .. ... . .... .. ..... ... . .... .. .. ... . .... .. . 198

IDLE AIRCONTROL VALVE....................................................................................... 200

CRANKSHAFT POSITION SENSOR (CPS)..... .. ... . .... .. ... . .... .. ... . .... .. ... .. .. ... .. .. ... .. .... . ... .. .... . . 201

MANIFOLD ABSOLUTE PRESSURE SENSOR (MAPS).. .... .... .. .... .... .. .... .... .. .... ..... .... .... .. .... .. 203

AMBIENT AIR PRESSURE AND TEMPERATURE SENSOR (AAPTS) .... .... . ... .. .... .... .. .... .... .. .... .... 205

COOLANT TEMPERATURE SENSOR (CTS)...................................................................... 209

02 – FUEL TANK/FUEL PUMP .................................................................................. 211

GENERAL..................................................................................................... 213

INSPECTION................................................................................................. 213

FUEL TANK LEAKTEST............................................................................................ 213

FUEL PUMP PRESSURE TEST.................................................................................... 214

PROCEDURES ............................................................................................... 216

FUEL HOSE ANDOETIKER CLAMPS............................................................................ 216

FUEL PUMP ........................................................................................................ 216

FUEL TANK ......................................................................................................... 222

06 ELECTRICAL SYSTEM

01 – IGNITION SYSTEM ......................................................................................... 225

GENERAL..................................................................................................... 225

IGNITION SYSTEM DESCRIPTION .. ..... .... .... .. .... .... .. .... ..... .... . ... .. .... . ... .. .. ... .. .... . ... .. .... . . 225

IGNITION SYSTEM OPERATION... .. ... .. .... . ... .. .. ... .. .... . ... .. .. ... .. .... . ... .. .... . ... .. .... .... .. .... .... 225

TROUBLESHOOTING....................................................................................... 225

IGNITION SYSTEM TESTING.. .. ... . .... .. .... .... .. .. ... .. .... . ... .. .. ... . .... .. ... . .... .. .... .... .. .... .... .. .. . 225

PROCEDURES ............................................................................................... 227

IGNITIONSWITCH................................................................................................. 227

ENGINESTOPSWITCH ........................................................................................... 229

IGNITIONCOIL..................................................................................................... 232

SPARKPLUG ....................................................................................................... 236

02 – CHARGING SYSTEM ....................................................................................... 239

GENERAL..................................................................................................... 239

SYSTEM DESCRIPTION .... .... .... .. .... . ... .. .. ... . .... .. .... .... .. .. ... .. ..... ... . .... .. .... .... .. .. ... .. ..... . 239

PROCEDURES ............................................................................................... 240

VOLTAGE REGULATOR/RECTIFIER .............................................................................. 240

BATTERY............................................................................................................ 243

ELECTRICAL SYSTEM MAIN GROUNDS. .... .. .... . ... .. .... . ... .. .. ... .. .... . ... .. .... .... .. .... .... .. .... .... 246

03 – STARTING SYSTEM ........................................................................................ 247

GENERAL..................................................................................................... 247

TROUBLESHOOTING....................................................................................... 247

PROCEDURES ............................................................................................... 248

STARTER SOLENOID.............................................................................................. 248

START BUTTON.................................................................................................... 253

CLUTCHSWITCH .................................................................................................. 255

04 – LIGHTS........................................................................................................ 257

GENERAL..................................................................................................... 257

LIGHTS SYSTEM DESCRIPTION.. .... .. .... ..... ..... ... . .... .. .... .... .. .. ... .. ..... ... . .... .. ... . .... .. .... .... 257

LIGHTS SYSTEM OPERATION ... .. .... .... .. .. ... .. .. ... . .... .. .... . ... .. .. ... . .... .. .... .... .. .. ... .. ..... ... . .. 257

TROUBLESHOOTING....................................................................................... 257

LIGHTS SYSTEM TESTING. ..... ..... ... . .... .. .. ... . .... .. .... . ... . .... .. .... . ... .. .. .... .... .. .. ... . .... .. .... . . 257

PROCEDURES ............................................................................................... 257

HEADLIGHTPOWER REGULATOR .............................................................................. 257

HEADLIGHTS....................................................................................................... 259

HEADLIGHTSWITCH.............................................................................................. 261

IV

TABLE OF CONTENTS

TAILLIGHT/BRAKE LIGHT ... . .... .. ... . .... .. .... ..... .... . ... .. .... . ... .. .. ... .. .... . ... .. .. ... .. .... . ... .. .... . . 262

NEUTRAL INDICATOR LIGHT(GREEN).......................................................................... 263

CHECK ENGINE INDICATOR LIGHT (YELLOW) ................................................................. 265

LOW FUEL LEVEL INDICATOR LIGHT (YELLOW) ... .... ..... .... .... .. ... . .... .. ... .. .. ... .. .. ... .. .... .... .. . 266

07 DRIVE SYSTEM

01 – DRIVECHAIN/REARAXLE ................................................................................ 271

GENERAL..................................................................................................... 273

PROCEDURES ............................................................................................... 273

DRIVECHAIN....................................................................................................... 273

FRONT SPROCKET ................................................................................................ 276

REAR SPROCKET .................................................................................................. 277

REAR AXLE......................................................................................................... 278

REAR SPROCKET HUB............................................................................................ 280

CHAIN TENSIONER................................................................................................ 281

08 CHASSIS

01 – WHEELS/TIRES.............................................................................................. 283

GENERAL..................................................................................................... 284

MAINTENANCE ............................................................................................. 284

TIRE PRESSURE .. . .... ..... .... .... .. .... . ... .. .. ... .. ..... ... . .... .. .... .... .. .. ... .. .... . ... . .... .. ... . .... .. ... 284

PROCEDURES ............................................................................................... 284

TIRE ................................................................................................................. 284

WHEEL.............................................................................................................. 285

FRONT WHEEL HUB .............................................................................................. 285

REAR WHEEL HUB ................................................................................................ 287

WHEEL BEARING.................................................................................................. 289

02 – STEERING.................................................................................................... 291

GENERAL..................................................................................................... 293

ADJUSTMENT............................................................................................... 293

STEERING ALIGNMENT........................................................................................... 293

PROCEDURES ............................................................................................... 294

HANDLEBARGRIP................................................................................................. 294

MULTIFUNCTION SWITCH........................................................................................ 294

THROTTLE LEVER .. .... .. .. ... . .... .. .... . ... . .... .. .. ... .. ..... .... . ... . .... .. .. ... .. ..... .... . ... .. .. .... .... .. . 295

THROTTLE CABLE. .... ..... ..... ... . .... .. .... .... .. .. ... .. ..... ... . .... .. .... . ... .. .. ... .. .. ... . .... .. .... .... .. . 295

HANDLEBAR....................................................................................................... 298

STEERING COLUMN .............................................................................................. 299

TIE-ROD............................................................................................................. 301

KNUCKLE........................................................................................................... 302

03 – FRONT SUSPENSION...................................................................................... 305

GENERAL..................................................................................................... 307

ADJUSTMENTS............................................................................................. 307

FACTORYSETTINGS............................................................................................... 307

ADJUSTINGSUSPENSION........................................................................................ 308

MAINTENANCE ............................................................................................. 309

LUBRICATION...................................................................................................... 309

PROCEDURES ............................................................................................... 310

SHOCK ABSORBER................................................................................................ 310

UPPER SUSPENSION ARM . .... ..... ... . .... .. ... .. .. ... .. .... . ... .. .. ... .. .... . ... .. .... . ... .. .. ... .. .... .... .. . 311

UPPER BALL JOINT ... ... . .... .. ... .. .... . ... .. .. ... .. .... .... .. ... . .... .. ... . .... .. ... .. .. ... .. .. ... .. .... .... .. . 312

LOWER SUSPENSIONARM...................................................................................... 313

LOWER BALLJOINT .............................................................................................. 314

04 – REAR SUSPENSION........................................................................................ 317

GENERAL..................................................................................................... 319

ADJUSTMENTS............................................................................................. 319

V

TABLE OF CONTENTS

FACTORYSETTINGS............................................................................................... 319

ADJUSTINGSUSPENSION........................................................................................ 319

MAINTENANCE ............................................................................................. 320

LUBRICATION...................................................................................................... 320

PROCEDURES ............................................................................................... 321

SHOCK ABSORBER................................................................................................ 321

SPRING ............................................................................................................. 322

SWING ARM........................................................................................................ 323

BELL CRANK LEVER... .... .... .. .... . ... .. ..... ... . .... .. .... .... .. .. ... .. .. ... . .... .. .... .... .. .. ... .. ..... ... . .. 325

PIVOTARM......................................................................................................... 326

05 – BRAKES....................................................................................................... 329

GENERAL..................................................................................................... 332

SYSTEM DESCRIPTION .... .... .... .. .... . ... .. .. ... . .... .. .... .... .. .. ... .. ..... ... . .... .. .... .... .. .. ... .. ..... . 332

MAINTENANCE ............................................................................................. 332

BRAKE FLUID .. . ... . .... .. .... .... .. .. ... .. .... . ... . .... .. .... .... .. .. ... .. .. ... . .... .. .... .... .. .. ... .. .... . ... . .. 332

PROCEDURES ............................................................................................... 334

CALIPER ............................................................................................................ 334

BRAKE PADS .. ... . ..... .... .... .. .... .... .. .... .... .. .. ... .. .... . ... .. .. ... .. .... . ... .. .... . ... .. .. ... .. .... . ... .. . 336

BRAKE DISC... .. ... .. .. ... . .... .. .... .... .. .... . ... .. .. ... . .... .. .... .... .. .. ... .. ..... ... . .... .. .... .... .. .. ... .. . 338

BRAKE LEVER... ..... .... .... .. .. ... . .... .. .... .... .. .. ... . .... .. .... .... .. .. ... . .... .. .... .... .. .. ... . .... .. .... .. 339

FRONT MASTER CYLINDER...................................................................................... 340

REAR MASTERCYLINDER........................................................................................ 340

BRAKE PEDAL.... .... .. ..... ... . .... .. ... . .... .. .... . ... .. .. ... .. ..... ... . .... .. .... .... .. .. ... .. .. ... .. ..... ... . .. 342

BRAKE DISC HUB.. .... ..... .... .... .. ... . .... .. ... . .... .. ... . .... .. .... ..... ... . .... .. ... .. .... . ... .. .. ... .. .... . . 344

REAR CALIPER BRACKET.. . .... ..... ... . .... .. ... . .... .. .... .... .. .... ..... ..... ... . .... .. ... . .... .. ... . .... .. ... 344

FRONT BRAKE LIGHT SWITCH.. .. ... .. .... ..... .... .... .. ... . .... .. ... .. .. ... .. .... . ... .. .... .... .. ... . .... .. ... 345

REAR BRAKE LIGHT SWITCH .. . .... .... . ... .. .. ... .. .... .... .. ... . .... .. ... . .... .. ... .. .. ... .. .. ... .. .... .... .. . 346

FLEXIBLE BRAKE HOSE.. .. ... . .... .. .... . ... . .... .. .. ... .. ..... .... .... .. .. ... . .... .. .... . ... . .... .. .... . ... .. .. . 347

06 – BODY.......................................................................................................... 351

GENERAL..................................................................................................... 354

PROCEDURES ............................................................................................... 354

DECALS............................................................................................................. 354

SEAT................................................................................................................. 354

ACCESSCOVER.................................................................................................... 356

CONSOLE........................................................................................................... 356

FRONT BUMPER................................................................................................... 356

FRONT BODY ASSEMBLY .. . .... .. ... .. .. ... .. .. ... .. .... .... .. ... . .... .. ... .. .. ... .. .... .... .. ... . .... .. ... .. .. . 356

FRONT FENDER.................................................................................................... 358

FRONT GRILLE..................................................................................................... 358

SIDE PANELS....................................................................................................... 358

FRONT FASCIA..................................................................................................... 359

FOOTREST.......................................................................................................... 359

FOOTREST SUPPORT............................................................................................. 359

REAR FENDER..................................................................................................... 359

REAR BUMPER .................................................................................................... 360

ENGINESKIDPLATE............................................................................................... 360

NERF BAR .......................................................................................................... 361

07 – FRAME........................................................................................................ 363

GENERAL..................................................................................................... 364

PROCEDURES ............................................................................................... 364

FRAME.............................................................................................................. 364

REAR FRAME EXTENSION........................................................................................ 364

REAR ENGINESUPPORTS........................................................................................ 365

FOOTPEG........................................................................................................... 365

SIDE MEMBER..................................................................................................... 366

LOWER SUSPENSIONARMATTACHMENTS................................................................... 367

VI

TABLE OF CONTENTS

09 TECHNICAL SPECIFICATIONS

01 – DS450/DS450 X............................................................................................ 369

10 WIRING DIAGRAM

01 – DS450/DS450 X............................................................................................ 377

WIRINGDIAGRAM................................................................................................. 377

VII

SAFETY NOTICE

SAFETY NOTICE

This manual has been prepared as a guide to correctly service and repair 2008 Can-Am ATVs as describe

in the model list in the

This edition was primarily published to be used by mechanical technicians who are already familiar with

all service procedures relating to BRP products. Mechanical technicians should attend training courses

given by B.R.P.T.I.

Please note that the instructions will apply only if proper hand tools and special service tools are used.

It is understood that this manual may be translated into another language. In the event of any discrepan-

cy, the English version shall prevail.

The content depicts parts and/or procedures applicable to the particular product at time of writing. Ser-

vice and Warranty Bulletins may be published to update the content of this manual. Make sure to read

and understand these. It does not include dealer modifications, whether authorized or not by BRP, after

manufacturing the product.

In addition, the sole purpose of the illustrations throughout the manual, is to assist identification of the

general configuration of the parts. They are not to be interpreted as technical drawings or exact replicas

of the parts.

The use of BRP parts is most strongly recommended when considering replacement of any component.

Dealer and/or distributor assistance should be sought in case of doubt.

The engines and the corresponding components identified in this document should not be utilized on

product(s) other than those for which it was designed.

INTRODUCTION

.

WARNING

Unless otherwise specified, engine should be turned OFF and cold for all maintenance and repair

procedures.

This manual emphasizes particular information denoted by the wording and symbols:

WARNING

Identifies an instruction which, if not followed, could cause serious personal injury including possibility of death.

CAUTION: Denotes an instruction which, if not followed, could severely damage vehicle components.

NOTE: Indicates supplementary information needed to fully complete an instruction.

Although the mere reading of such information does not eliminate the hazard, your understanding of the

information will promote its correct use. Always use common shop safety practice.

BRP disclaims liability for all damages and/or injuries resulting from the improper use of the contents.

We strongly recommend that any services be carried out and/or verified by a highly skilled professional

mechanic. It is understood that certain modifications may render use of the vehicle illegal under existing

federal, provincial and state regulations.

VIII vmr2008-002

INTRODUCTION

GENERAL INFORMATION

This shop manual covers the following BRP made 2008 Can-Am ATVs.

MODEL COLOR ENGINE MODEL NUMBER

INTRODUCTION

DS 450 EFI

DS 450 EFI X

Yellow/Black 449

Black 449

The information and component/system descriptions contained in this manual are correct at time

of writing. BRP however, maintains a policy of

continuous improvement of its products without

imposing upon itself any obligation to install them

on products previously manufactured.

Due to late changes, there may be some differences between the manufactured product and the

description and/or specifications in this document.

BRP reserves the right at any time to discontinue

or change specifications, designs, features, models or equipment without incurring obligation.

VEHICLE INFORMATION

Model Number

MANUFACTURED BY:

FABRIQUÉ PAR:

MFD. DATE FAB:

2BPS1234X2V000123

VIN / NIV:

12/2003

1234

MODEL:

2

1

3F8A, 3F8B, 3F8C

3G8A, 3G8B, 3G8C

Vehicle Identification Number (V.I.N.)

vmo2008-011-026_a

TYPICAL

1. Vehicle Identification Number (V.I.N.)

Engine Identification Number (E.I.N.)

MADE IN/FABRIQUÉ AU:

XXXXX

vmo2008-011-094_a

TYPICAL — VEHICLE IDENTIFICATION NUMBER LABEL

1. Serial number

2. Model number

vmr2008-002 IX

TYPE: ATV / VTT

vmo2008-011-026_b

1. Engine Identification Number (E.I.N.)

INTRODUCTION

ENGINE EMISSIONS

INFORMATION

Manufacturer's Responsibility

Manufacturers of ATVs engines must determine

the exhaust emission levelsfor each engine horsepower family and certify these engines with the

United States of America Environmental Protection Agency (EPA). An emissions control information label, showing emission levels and engine

specifications, must be placed on each vehicle at

the time of manufacture.

Dealer Responsibility

When performing service on ATVs that carry an

emissions control information label, adjustments

must be kept within published factory specifications.

Replacement or repair of any emission related

component must be executed in a manner that

maintains emission levels within the prescribed

certification standards.

Dealers are not to modify the engine in any manner that would alter the horsepoweror allow emission levels to exceed their predetermined factory

specifications.

Exceptions include manufacturer's prescribed

changes, such as altitude adjustments for example.

Owner Responsibility

The owner/operator is required to have engine

maintenance performed to maintain emission

levels within prescribed certification standards.

The owner/operator is not to, and should not allow anyone to modify the engine in any manner

that would alter the horsepower or allow emissions levels to exceed their predetermined factory

specifications.

The responsibilities listed above are general and

in no way a complete listing of the rules and regulations pertaining to the EPA requirements on exhaust emissions for ATVs products. For more detailed information on this subject, you may contact

the following locations:

FORALLCOURIERSERVICES:

U.S. Environmental Protection Agency

Office of Transportation and Air Quality

1310 L Street NW

Washington D.C. 20005

REGULAR US POSTAL MAIL:

1200 Pennsylvania Ave. NW

Mail Code 6403J

Washington D.C. 20460

INTERNET: http://www.epa.gov/otaq/

E-MAIL: otaqpublicweb@epa.gov

SELF-LOCKING FASTENERS

PROCEDURE

The following describes the most common application procedures when working with self-locking

fasteners.

Use a metal brush or a screw tap to clean the

hole properly then use a solvent, let act during 30

minutes and wipe off. The solvent utilization is to

ensure the adhesive works properly.

LOCTITE®APPLICATION

PROCEDURE

The following describes the most common application procedures when working with Loctite

products.

NOTE: Always use proper strength Loctite product as recommended in this manual.

EPA Emission Regulations

Some ATVs manufactured by BRP are certified

to the EPA as conforming to the requirements

of the regulations for the control of air pollution

from new ATV engines. This certification is contingent on certain adjustments being set to factory

standards. For this reason, the factory procedure

for servicing the product must be strictly followed

and, whenever practicable, returned to the original intent of the design.

X vmr2008-002

INTRODUCTION

Threadlocker

Uncovered Holes (bolts and nuts)

1

2

A00A3LA

1. Apply here

2. Do not apply

Clean threads (bolt and nut) with solvent.

Apply Loctite Primer N (P/N 293 800 041) on

threads and allow to dry.

Choose proper strength Loctite threadlocker.

Fit bolt in the hole.

Apply a few drops of threadlocker at proposed

tightened nut engagement area.

Position nut and tighten as required.

Blind Holes

1

2

Apply several drops on screw threads.

Tighten as required.

Stud in Blind Holes

1

3

2

lmr2007-040-005_a

1. On stud threads

2. On hole threads

3. Onto nut threads

Clean threads (stud and hole) with solvent.

Apply Loctite Primer N (P/N 293 800 041) on

threads and allow to dry.

Put 2 or 3 drops of proper strength Loctite thread-

locker along the threaded hole.

NOTE: To avoid a hydro lock situation, do not apply

too much Loctite.

Apply several drops of proper strength Loctite on

stud threads.

Install stud.

Install cover, etc.

Apply drops of proper strength Loctite on uncov-

ered threads.

Tighten nuts as required.

Preassembled Parts

1

lmr2007-040-004_a

1. On screw threads

2. On hole threads

Clean threads (screw and hole) with solvent.

Apply Loctite Primer N (P/N 293 800 041) on

threads (screw and nut) and allow to dry for 30

seconds.

Choose proper strength Loctite threadlocker.

Apply 2 or 3 drops along the threaded hole.

NOTE: Toavoid a hydro lock situation, do not apply

too much Loctite.

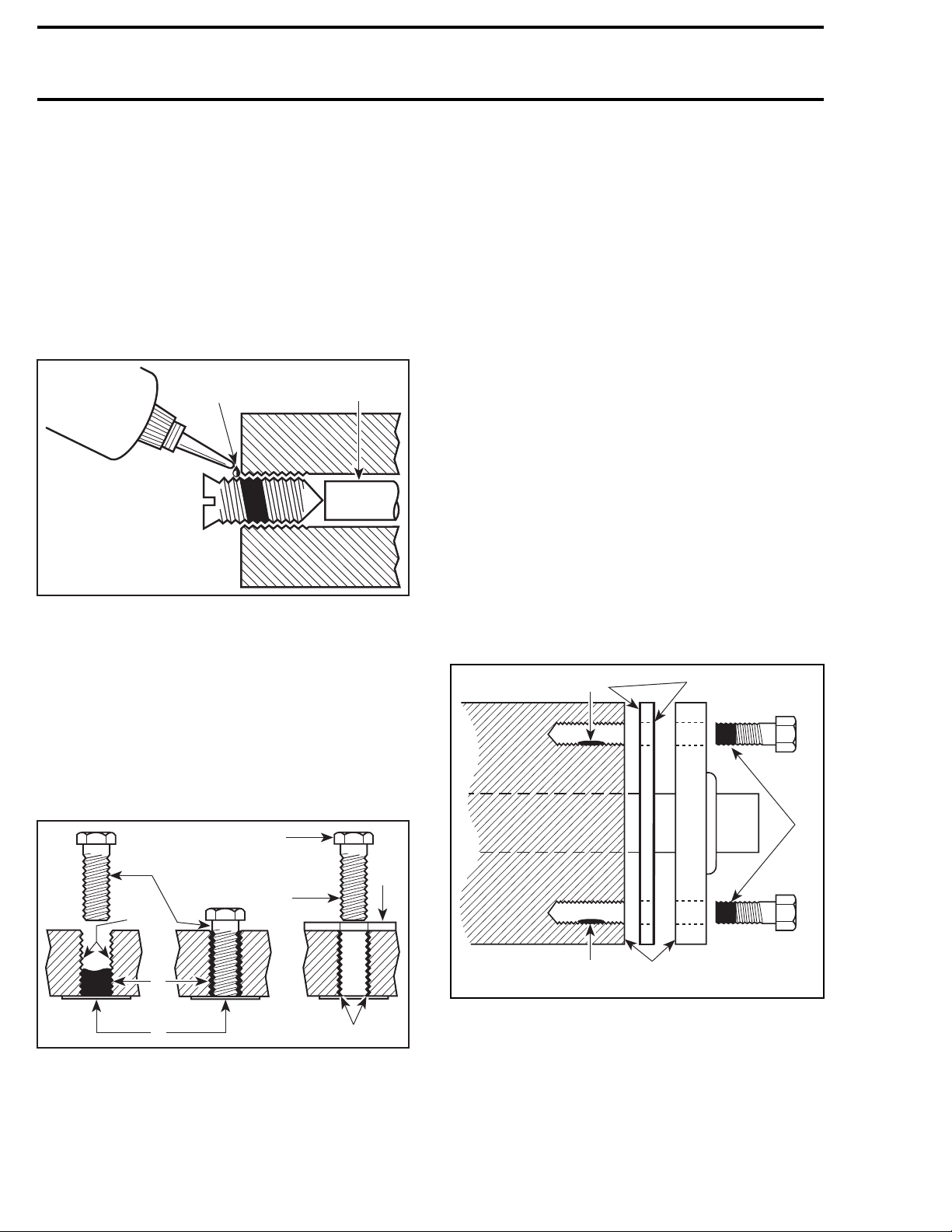

vmr2008-002 XI

2

A00A3OA

1. Apply here

2. Do not apply

Clean bolts and nuts with solvent.

INTRODUCTION

Assemble components.

Tighten nuts.

Apply drops of proper strength Loctite on bolt/nut

contact surfaces.

Avoid touching metal with tip of flask.

NOTE: For preventive maintenance on exist-

ing equipment, retighten nuts and apply proper

strength Loctite on bolt/nut contact surfaces.

Adjusting Screw

2

A00A3PA

1. Apply here

2. Plunger

1

Adjust screw to proper setting.

Apply drops of proper strength Loctite threadlock-

er on screw/body contact surfaces.

Avoid touching metal with tip of flask.

NOTE: if it is difficult to readjust, heat screw with

a soldering iron (232°C (450°F)).

Standard Thread Repair

Follow instructions on Loctite FORM-A-THREAD

81668 package.

If a plate is used to align bolt:

– Apply release agent on mating surfaces.

– Put waxed paper or similar film on the surfaces.

Twist bolt when inserting it to improve thread conformation.

NOTE: NOT intended for engine stud repairs.

Repair of Small Holes/Fine Threads

Option 1: Enlarge damaged hole, then follow

STANDARD THREAD REPAIR

procedure.

Option 2: Apply FORM-A-THREAD on the screw

and insert in damaged hole.

Permanent Stud Installation (light duty)

Use a stud or thread on desired length.

DO NOT apply release agent on stud.

STANDARD THREAD REPAIR

Do a

.

Allow to cure for 30 minutes.

Assemble.

Gasket Compound

21

Stripped Thread Repair

5

2

A00A3QA

1. Release agent

2. Stripped threads

3. Form-A-Thread

4. Tape

5. Cleaned bolt

6. Plate

7. New threads

8. Threadlocker

1

8

3

4

6

lmr2007-040-006_a

1

1. Proper strength Loctite

7

2. Loctite Primer N (P/N 293 800 041) and Loctite 518

(P/N 293 800 038) on both sides of gasket

3. Loctite Primer N only

3

Remove old gasket and other contaminants with

Loctite Chisel remover (P/N 413 708 500). Use a

mechanical mean if necessary.

NOTE: Avoid grinding.

Cleanbothmatingsurfaceswithsolvent.

XII vmr2008-002

1

INTRODUCTION

Spray Loctite Primer N on both mating surfaces

and on both sides of gasket. Allow to dry 1 or 2

minutes.

Apply Loctite 518 (P/N 293 800 038) on both sides

of gasket, using a clean applicator.

Place gasket on matingsurfaces and assemble immediately.

NOTE: If the cover is bolted to blind holes (above),

apply proper strength Loctite on the threads of

hole. Tighten.

If holes are sunken, apply proper strength Loctite

on bolt threads.

Tighten as usual.

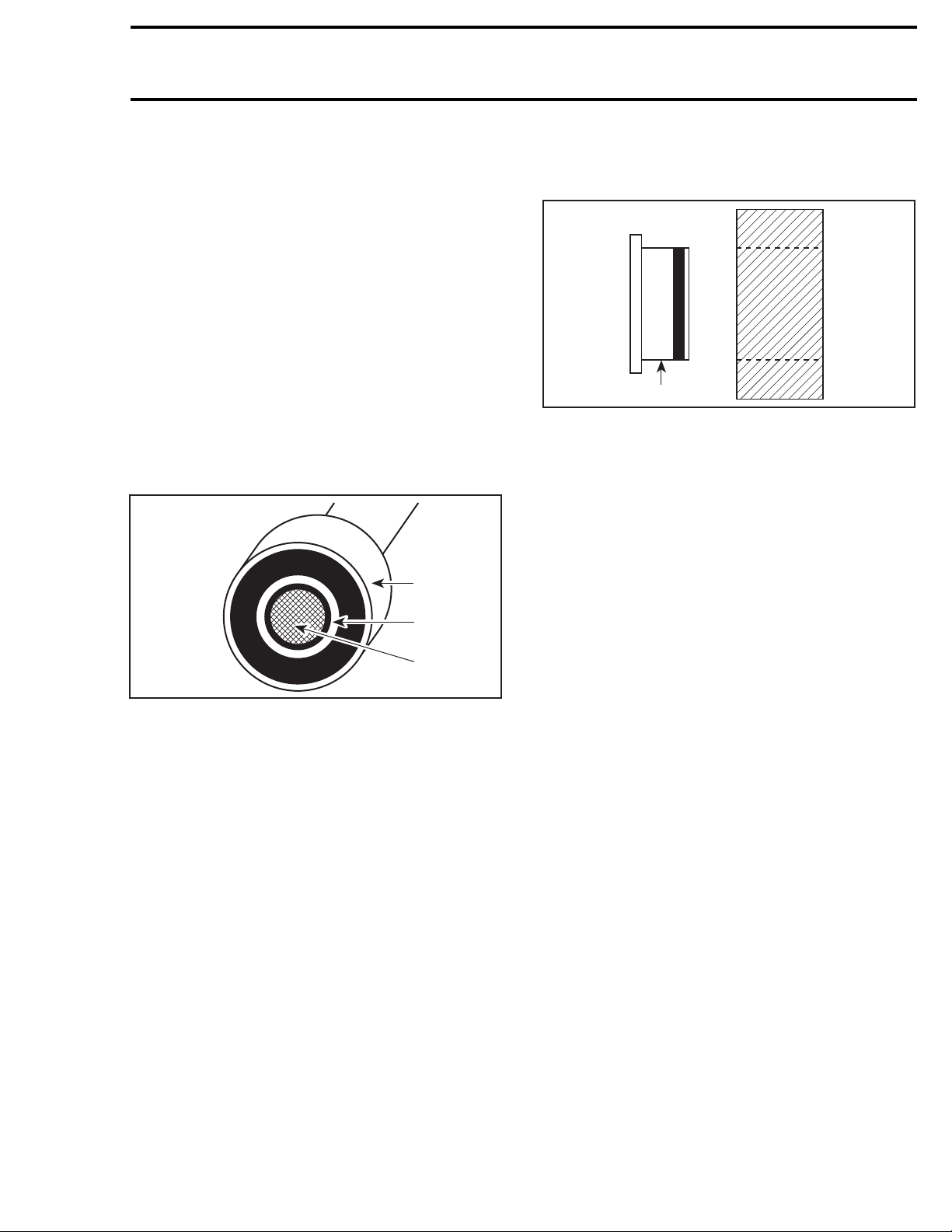

Mounting on Shaft

Mounting with a Press

1

2

3

A00A3UA

1. Bearing

2. Proper strength Loctite

3. Shaft

Cleanshaft externalpart and element internal part.

Apply a strip of proper strength Loctite on shaft

circumference at insert or engagement point.

NOTE: Retaining compound is always forced out

whenappliedonshaft.

DO NOT use antiseize Loctite or any similar prod-

uct.

No curing period is required.

Case-In Components

Metallic Gaskets

A00A3VA

1. Proper strength Loctite

Clean inner housing diameter and outer gasket diameter.

Spray housing and gasket with Loctite Primer N

(P/N 293 800 041).

Apply a strip of proper strength Loctite on leading

edge of outer metallic gasket diameter.

NOTE: Any Loctite product can be used here. A

low strength liquid is recommended as normal

strength and gap are required.

Install according to standard procedure.

Wipe off surplus.

Allow it to cure for 30 minutes.

NOTE: Normally used on worn-out housings to

prevent leaking or sliding.

It is generally not necessary to remove gasket

compound applied on outer gasket diameter.

1

Mounting in Tandem

Apply retaining compound on internal element

bore.

Continue to assemble as shown above.

vmr2008-002 XIII

INTRODUCTION

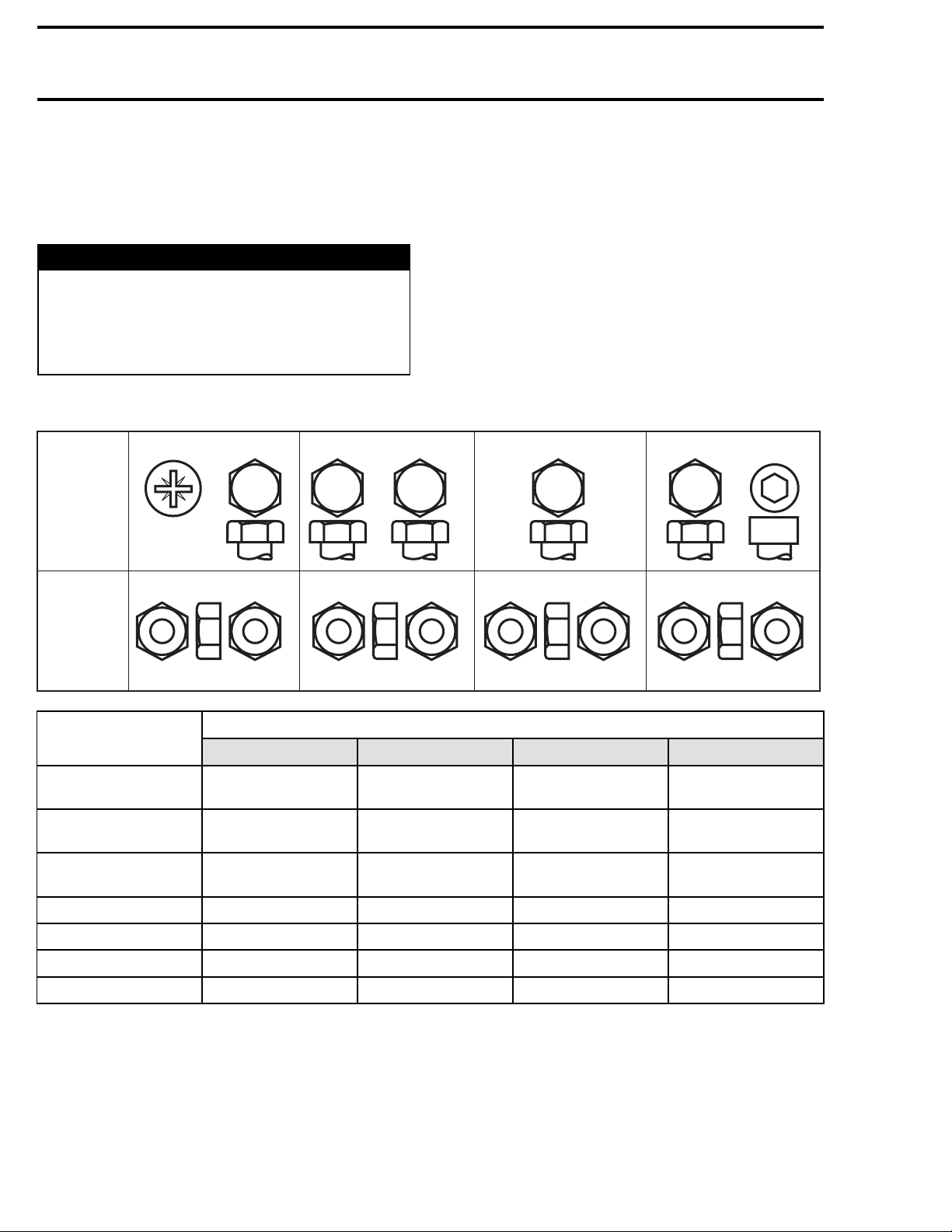

TIGHTENING TORQUES

Tighten fasteners to torque mentioned in exploded views and/or text. When they are not specified, refer to following table.

WARNING

Torque wrench tightening specifications

must strictly be adhered to.

Locking devices (e.g.: locking tabs, elastic

stop nuts, cotter pins, etc.) must be replaced

with new ones.

Property

markings

Property

markings

A00A8BS

class

and

head

class

and

nut

4.8

4.8

4.8

5

5

8.8

8.8

8.8

8

8

In order to avoid a poor assembling, tighten

screws, bolts or nuts in accordance with the

following procedure:

Manually screw all screws, bolts and/or nuts.

Apply the half of the recommended torque value.

CAUTION: Be sure to use the proper tightening

torque for the proper strength grade.

NOTE: When possible, always apply torque onthe

nut.

Torque to the recommended torque value.

NOTE: Always torque screws, bolts and/or nuts in

a criss-cross sequence.

9.8

9.8

9.8

10.9

10.9

10.9

10

12.9

12.9

12.9

12

10

12.9

12

FASTENER SIZE

M4

M5

M6

M8 15 N•m (133 lbf•in) 25 N•m (18 lbf•ft) 32 N•m (23 lbf•ft) 40 N•m (30 lbf•ft)

M10 29 N•m (21 lbf•ft) 48 N•m (35 lbf•ft) 61 N•m (45 lbf•ft) 73 N•m (53 lbf•ft)

M12 52 N•m (38 lbf•ft) 85 N•m (63 lbf•ft) 105 N•m (77 lbf•ft) 128 N•m (94 lbf•ft)

M14 85 N•m (63 lbf•ft) 135 N•m (100 lbf•ft) 170 N•m (125 lbf•ft) 200 N•m (148 lbf•ft)

5.8

Grade

1.5–2N•m

(13 – 18 lbf•in)

3–3.5N•m

(27 – 31 lbf•in)

6.5 – 8.5 N•m

(58 – 75 lbf•in)

FASTENER GRADE/TORQUE

8.8

Grade

2.5–3N•mN•m

(22 – 27 lbf•in)

4.5 – 5.5 N•m

(40 – 47 lbf•in)

8–12N•m

(71 – 106 lbf•in)

10.9

3.5–4N•m

(31 – 35 lbf•in)

7–8.5N•m

(62 – 75 lbf•in)

10.5 – 15 N•m

(93 – 133 lbf•in)

Grade

12.9

Grade

4–5N•m

(35 – 44 lbf•in)

8–10N•m

(71 – 89 lbf•in)

16 N•m (142 lbf•in)

XIV vmr2008-002

MANUAL INFORMATION

The manual is divided into many major sections as

you can see in the main table of contents at the

beginning of the manual.

Each section is divided in various subsections, and

again, each subsection has one or more division.

The illustrations show the typical construction of

the different assemblies and, in all cases, may not

reproduce the full detail or exact shape of the parts

shown, however, they represent parts which have

the same or a similar function.

CAUTION: Most components in the vehicles

are built with parts dimensioned in the metric

system. Most fasteners are metric and must

not be replaced by customary fasteners or

vice-versa. Mismatched or incorrect fasteners

could cause damage to the vehicle or possible

personal injury.

As many of the procedures in thismanual are interrelated, we suggest that before undertaking any

task, you read and thoroughly understand the entire section or subsection in which the procedure

is contained.

A number of procedures throughout the book require the use of special tools. Before starting any

procedure, be sure that you have on hand all required tools, or approved equivalents.

The use of RIGHT and LEFT indications in the text,

always refers to the driving position (sitting on the

vehicle).

INTRODUCTION

vmr2008-002-001_a

TYPICAL

1. Left

2. Right

This manual uses technical terms which may be

different from the ones of the

PARTS CATALOGS

.

When ordering parts always refer to the specific

model

vmr2008-002 XV

PARTS CATALOGS

.

INTRODUCTION

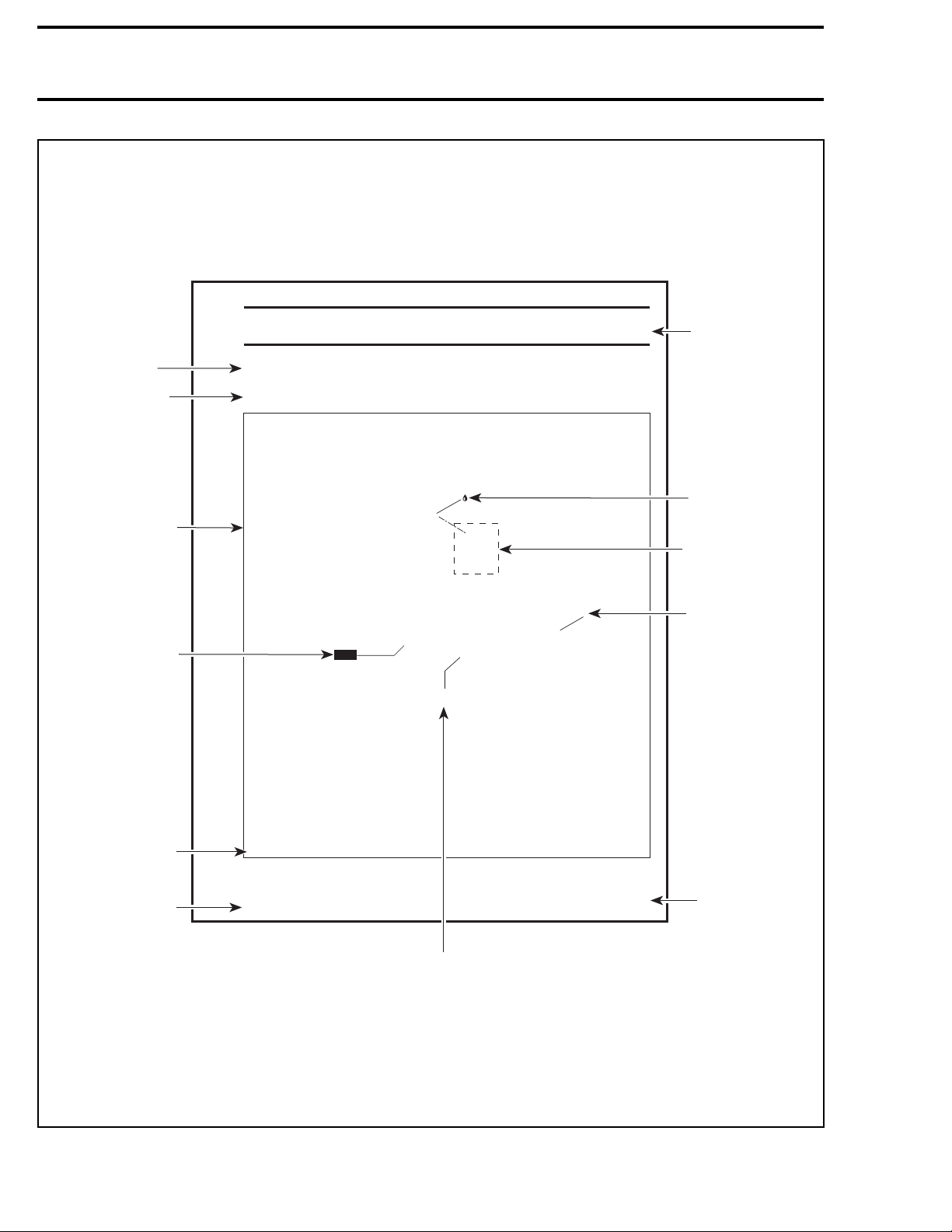

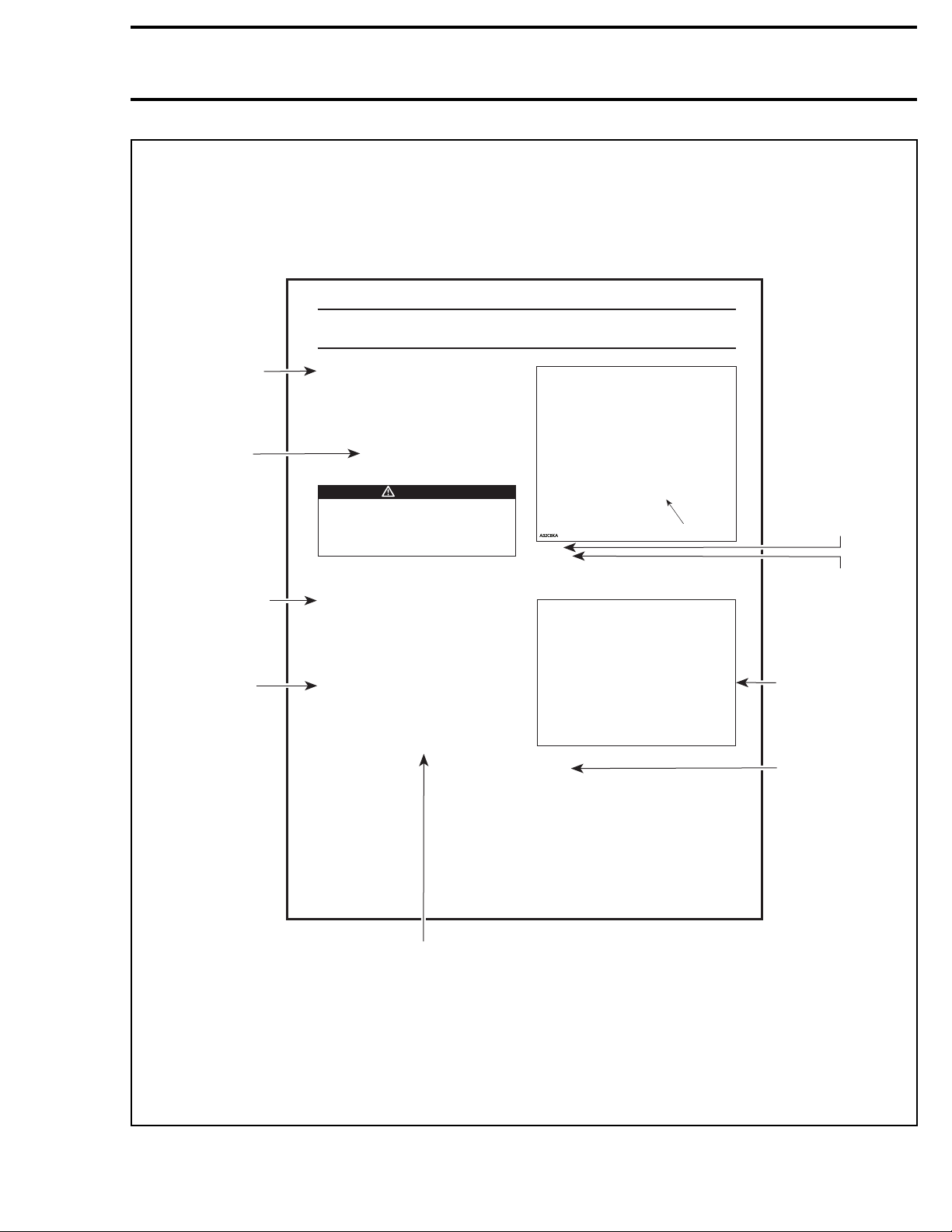

TYPICAL PAGE

Subsection title

Indicates applicable

models.

Exploded view assists

you in identifying parts

and their related

positions.

NEW indicates that the

part must be replaced

with a new one.

MAGNETO

Models

NEW

Loctite 243

5 Nm

(44 lbfin)

Section 06 ENGINE

Subsection 01 (MAGNETO)

Model

Page heading

indicates section

and subsection.

Drop represents a

service product

to be applied.

Dotted box contains

parts applicable to a

specific model.

Bold face number

1

is used to identify

a part referred to

the text.

Illustration number

for publishing process.

Document number for

publishing process.

XXX0000

mmr2008-001

55

Page number

Specific torque applicable to this installation.

cations.

Typical_iso_2008_en

CAUTION: Pay attention to torque specifi

Some of these are in

Use appro

lbfin instead of lbfft.

priate torque wrench.

XVI vmr2008-002

Tittle in bold

indicates category

of information to be

carried out.

Reference to a

specific section

or subsection.

Indicates component

procedures apply to.

Indicates specific

procedure to be

carried out.

TYPICAL PAGE

GENERAL

GENERAL

NOTE:

NOTE:

The following procedures can be done

The following procedures can be done

without removing the engine.

without removing the engine.

During assembly/installation, use the torque val-

During assembly/installation, use the torque values and service products as in the exploded

ues and service products as in the exploded

views.

views.

Clean threads before applying a threadlocker. Re-

Clean threads before applying a threadlocker. Refer to the

fer to the

SELF-LOCKING FASTENERS

SELF-LOCKING FASTENERS

TITE APPLICATION

TITE APPLICATION

this manual for complete procedure.

this manual for complete procedure.

Torque wrench tightening specifications

Torque wrench tightening specifications

must be strictly adhered to.

must be strictly adhered to.

Locking devices (e.g.: locking tabs, elastic

Locking devices (e.g.: locking tabs, elastic

stop nuts, self-locking fasteners, etc.) must

stop nuts, self-locking fasteners, etc.) must

be replaced with new ones.

be replaced with new ones.

PROCEDURES

PROCEDURES

MAGNETO FLYWHEEL

MAGNETO FLYWHEEL

Magneto Flywheel Cleaning

Magneto Flywheel Cleaning

Clean all metal components in a non-ferrous metal

Clean all metal components in a non-ferrous metal

cleaner.

cleaner.

CAUTION:

CAUTION:

a clean cloth.

a clean cloth.

Magneto Flywheel Removal

Magneto Flywheel Removal

Remove muffler, refer to the

Remove muffler, refer to the

section.

section.

Remove acoustic panel.

Remove acoustic panel.

Remove rewind starter.

Remove rewind starter.

Remove starting pulley

Remove starting pulley

sections at the beginning of

sections at the beginning of

WARNING

WARNING

Clean magneto flywheel using only

Clean magneto flywheel using only

EXHAUST SYSTEM

EXHAUST SYSTEM

no. 2

no. 2

.

.

and

and

LOC-

LOC-

Section 03 ENGINE

Subsection 09 (MAGNETO SYSTEM)

Subsection 09 (MAGNETO SYSTEM)

TYPICAL

TYPICAL

1. Starting pulley

1. Starting pulley

NOTE:

NOTE:

To remove starting pulley bolts, hold mag-

To remove starting pulley bolts, hold mag-

neto flywheel with a socket as shown.

neto flywheel with a socket as shown.

mmr2007-016-002

TYPICAL

TYPICAL

Models

Models

Remove the connecting flange retaining the

Remove the connecting flange retaining the

rewind starter to the engine housing.

rewind starter to the engine housing.

Section 03 ENGINE

1

1

INTRODUCTION

TYPICAL

indicates a general

view which may

not represent exact

details.

Call-outs pertaining

to above illustration.

Illustration always

follows text to which

it applies.

Italic bold face type-

setting indicates a

procedure applicable

to a specific

model(s).

mmr2008-001

57

Bold face number following part

name refers to exploded view

at beginning of subsection.

typical_txt_2008_en

vmr2008-002 XVII

Section01MAINTENANCE

Subsection 01 (MAINTENANCE CHART)

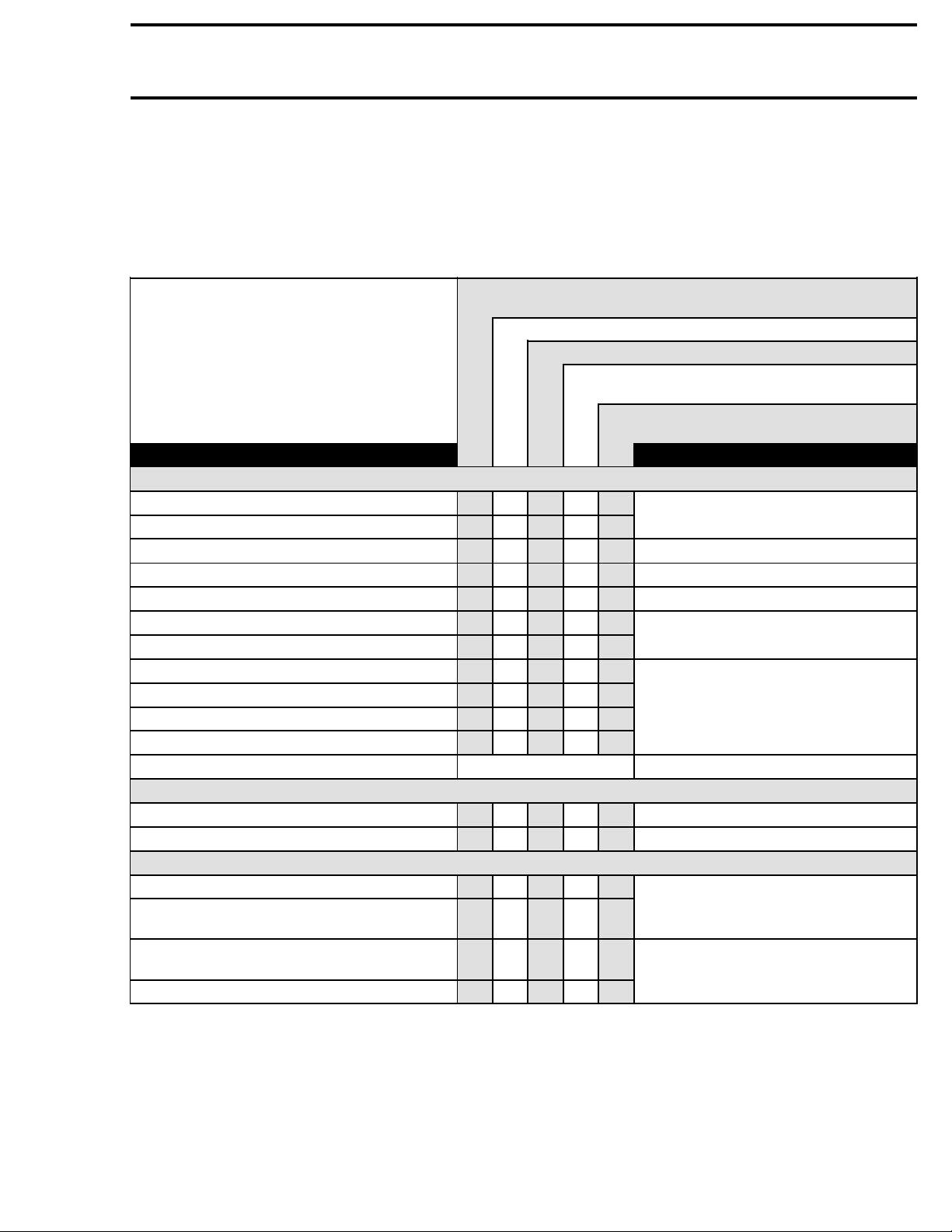

MAINTENANCE CHART

The schedule should be adjusted according to operating conditions and use.

NOTE: The chart gives an equivalence between number of hours and months/year. Perform the mainte-

nance operation to whatever time comes first.

IMPORTANT: Intensive use of the ATV, will require greater frequency of inspection and maintenance.

10HOURSOR30DAYSOR400KM(250mi)

(The initial maintenance is very important and must not be neglected.)

A:

ADJUST

C:

CLEAN

I:

INSPECT

L:

LUBRICATE

R:

REPLACE

PART/TASK REFER TO

ENGINE

Engine oil

(1)

and filter R R

Oil reservoir strainer C

Engine valves I, A I, A

Engine mounting fasteners I I

Air filter

(2)

Exhaust system I I

Spark arrester C

Coolant

II

Cooling system pressure test I I

Radiator cap pressure test I I

Radiator

(3)

I, C I, C

Clutch

ENGINE MANAGEMENT (EMS)

EMS sensors I I

EMS fault codes

II

FUEL SYSTEM

Throttle body I I, L

Throttle cable I, A

Fuel lines, fuel rail, connections, check valves

and fuel tank pressure test

II

Fuel pump pressure I

EVERY 25 HOURS OR 1250 KM (800 mi)

EVERY 50 HOURS OR 2500 KM (1600 mi)

EVERY 100 HOURS OR 5000 KM (3100 mi) OR

1YEAR

EVERY 200 HOURS OR 10000 KM (6200

mi) OR 2 YEAR

LUBRICATION SYSTEM

CYLINDER HEAD/CYLINDER

ENGINE REMOVAL/NSTALLATION

(3)

R

AIR INTAKE SYSTEM

EXHAUST SYSTEM

(4)

R

COOLING SYSTEM

(5)

CLUTCH

ELECTRONIC FUEL INJECTION

ENGINE MANAGEMENT

I, A,

ELECTRONIC FUEL INJECTION

L

FUEL TANK/FUEL PUMP

vmr2008-003 1

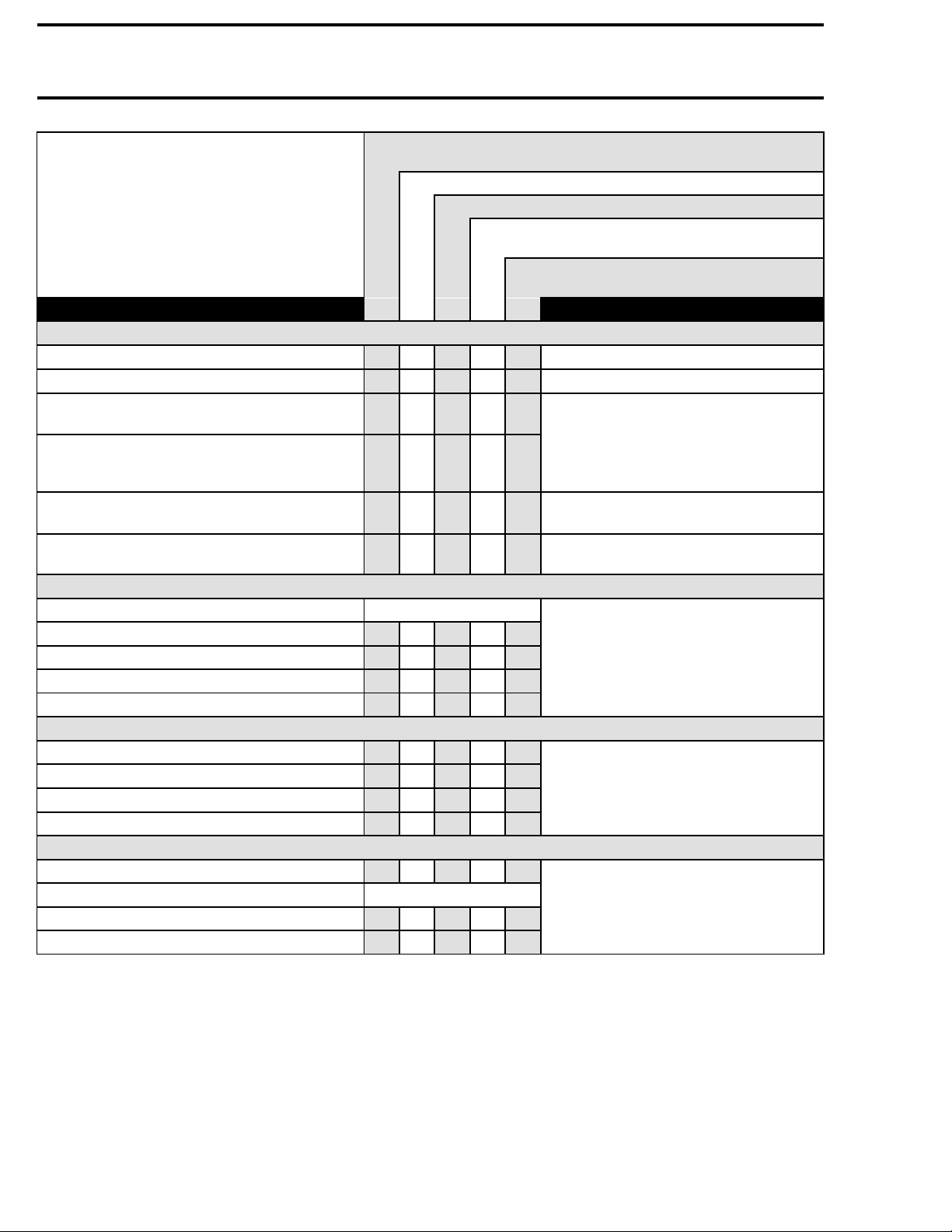

Section 01 MAINTENANCE

Subsection 01 (MAINTENANCE CHART)

10HOURSOR30DAYSOR400KM(250mi)

(The initial maintenance is very important and must not be neglected.)

ADJUST

A:

CLEAN

C:

INSPECT

I:

LUBRICATE

L:

REPLACE

R:

PART/TASK REFER TO

ELECTRICAL SYSTEM

Spark plugs

(6)

II R

Battery connections I I

ECM connectors

(visual inspection without disconnecting)

Electrical connections and fastening

(ignition system, starting system, fuel

II

injectors etc.)

Ignition switch, start button and engine

run/stop switch

Lighting system (HI/LO intensity, brake light,

beam aiming, etc.)

II

II

DRIVE SYSTEM

Drive chain and slider

Drive chain sprockets

Drive chain tensioner

(3)

(8)

IIR

II

Rear axle bearings I I

Rear axle and rear axle nut

(8)

II

STEERING

Handlebar fasteners I I

Steering column and bearing

(3)

II

Tie rod ends I I

Front wheel alignment I, A I, A

WHEELS/TIRES

Wheel nuts/studs I I

Tires

Front wheel bearings I I

Rear wheel hub L

EVERY 25 HOURS OR 1250 KM (800 mi)

EVERY 50 HOURS OR 2500 KM (1600 mi)

I

(7)

(9)

EVERY 100 HOURS OR 5000 KM (3100 mi) OR

1YEAR

EVERY 200 HOURS OR 10000 KM (6200

mi) OR 2 YEAR

IGNITION SYSTEM

CHARGING SYSTEM

ELECTRICAL CONNECTORS

IGNITION SYSTEM

and

STARTING SYSTEM

FUSES/LIGHTS

DRIVE CHAIN/REAR AXLE

STEERING SYSTEM

WHEELS/TIRES

2 vmr2008-003

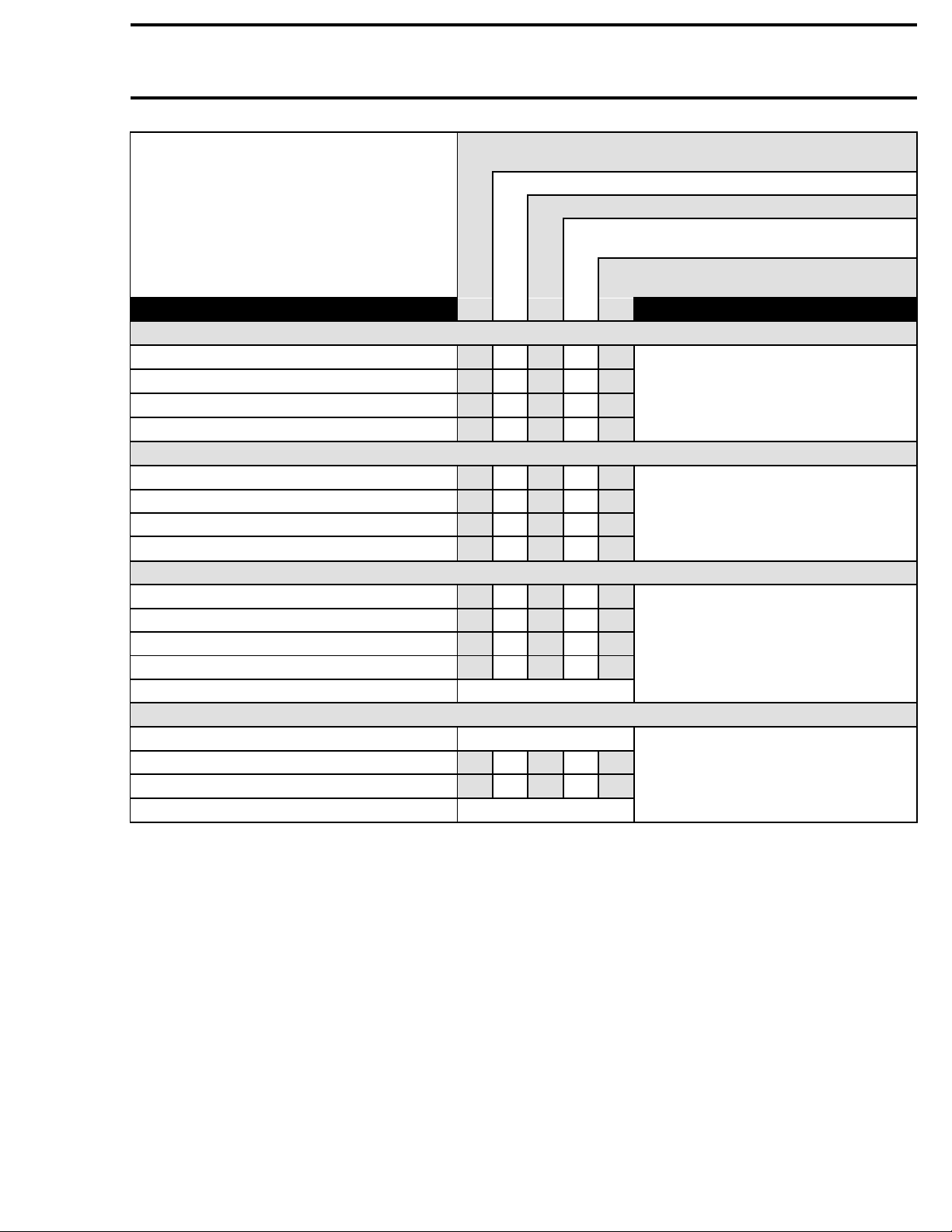

Subsection 01 (MAINTENANCE CHART)

10HOURSOR30DAYSOR400KM(250mi)

(The initial maintenance is very important and must not be neglected.)

ADJUST

A:

CLEAN

C:

INSPECT

I:

LUBRICATE

L:

REPLACE

R:

PART/TASK REFER TO

REAR SUSPENSION

Swing arm I I L

Suspension linkage

I, L I, L

Shock absorber

Shock absorber lower pivot L

FRONT SUSPENSION

Suspension arms

II,L

Ball joints boots I I

Ball joints

(3)

II

Shock absorbers

BRAKES

Brake fluid I I R

Brake pads

(3)

Brake discs I

Brake hoses I

Brake line fittings

BODY/FRAME

Skidplate(DS450X)

Frame fastener I I

Frame I

Operator's seat and its fasteners

EVERY 25 HOURS OR 1250 KM (800 mi)

EVERY 50 HOURS OR 2500 KM (1600 mi)

EVERY 100 HOURS OR 5000 KM (3100 mi) OR

1YEAR

I

I

I

(10)

(10)

(10)

Section01MAINTENANCE

EVERY 200 HOURS OR 10000 KM (6200

mi) OR 2 YEAR

REAR SUSPENSION

FRONT SUSPENSION

BRAKES

BODY AND FRAME

Inspect oil level at every ride.

(1)

Clean at every ride.

(2)

More often under severe use such as dusty area, sand, snow, wet or muddy conditions.

(3)

Every 50 hours, check coolant strength.

(4)

Inspectadjustmentateveryride.

(5)

Make sure that the spark plug gap is correct.

(6)

Inspect, adjust and lubricate at every ride.

(7)

Check tightness.

(8)

Check tire pressure and wear at every ride.

(9)

Inspect at every ride.

(10)

vmr2008-003 3

Section01MAINTENANCE

Subsection 02 (PRESEASON PREPARATION)

PRESEASON PREPARATION

Prior to use vehicle, proper vehicle preparation is

required after a storage period.

Any worn, broken or damaged parts found during

the storage procedure should have been replaced.

If not, proceed with the replacement.

Using the maintenance chart, performed items in

the column indicated: EVERY 100 HOURS OR

5000 KM (3100 mi) OR 1 YEAR.

vmr2008-004-001_a

1. Use this column

Furthermore, proceed with the following:

Vehicles Prepared as per Storage Procedure

Remove rag from muffler.

Test drive vehicle to confirm proper operation.

Vehicles Not Prepared as per Storage Procedure

Replaceengineoilandfilter.

Drain fuel tank and fill with fresh fuel.

Test drive vehicle to confirm proper operation.

vmr2008-004 5

Section01MAINTENANCE

Subsection 03 (STORAGE PROCEDURE)

STORAGE PROCEDURE

SERVICE PRODUCTS

Description Part Number Page

BRP fuel stabilizer................................................................. 413 408 600 .............................................7

storage oil............................................................................. 413 711 600 .............................................7

storage oil (US)..................................................................... 413 711 900 .............................................7

IftheATVisnotusedoristobestoredforan

extended period of time, more than 4 months, be

sure to perform the storage procedures described

below.

FUEL SYSTEM

Fuel System Protection

With the additives used in today's fuel, it is critical

to use the BRP fuel stabilizer (P/N 413 408 600)

or an equivalent to prevent fuel deterioration and

fuel system gumming. Follow the manufacturer's

instructions for proper use.

CAUTION: Fuel stabilizer should be added

prior to engine lubrication to ensure fuel system components protection against varnish

deposits.

Pour fuel stabilizer in fuel tank. Fill up fuel tank.

Do not drain fuel system.

ENGINE

Engine Oil and Filter Replacement

Change engine oil and filter. Refer to

TION SYSTEM

.

Engine Internal Lubrication

Engine internal parts must be lubricated to protect

them from rust formation during the storage period.

WARNING

This procedure must only be performed in a

well-ventilated area. Do not run engine during storage period.

Proceed as follows:

Start the engine and allow it to run at idle speed

until the engine reaches its operating temperature.

Stop the engine.

LUBRICA-

Remove spark plugs andspray storage oil (P/N 413

711 600) into cylinder.

NOTE: For US citizens, use storage oil (US)

(P/N 413 711 900) only.

CAUTION: Do not inject storage oil into throttle

body bore to avoid blocking idle bypass valve.

Press start button, 1 or 2 seconds maximum, to

lubricate cylinder.

Reinstall the spark plugs.

ELECTRICAL SYSTEM

Battery Removal

Remove the battery. Store it in dry and cool place.

Refer to

BATTERYinCHARGING SYSTEM

.

COOLING SYSTEM

Coolant Inspection

Test coolant density using an antifreeze hydrometer.

NOTE: Follow manufacturer's instructions for

proper use.

Change coolant if necessary. Refer to

SYSTEM

.

COOLING

VEHICLE

Vehicle Cleaning

Clean vehicle. Refer to

ucts to be used.

CAUTION: Never use a high pressure washer

to clean the vehicle. USE LOW PRESSURE ONLY (like a garden hose). The high pressure can

cause electrical or mechanical damages.

Vehicle Protection

Using clean rag, block the muffler. The rag will

prevent the intrusion of small animals, leaves or

other debris.

BODY

for cleaning prod-

vmr2008-005 7

Section 01 MAINTENANCE

Subsection 03 (STORAGE PROCEDURE)

Protect the vehicle with a cover to prevent dust

accumulation during storage.

CAUTION: The vehicle has to be stored in a

cool and dry place. If vehicle is stored outside,

it must be covered with an opaque tarpaulin.

This will prevent sun rays and grime from affecting plastic components and vehicle finish.

8 vmr2008-005

Section01MAINTENANCE

Subsection 04 (SPECIAL PROCEDURES)

SPECIAL PROCEDURES

SERVICE PRODUCTS

Description Part Number Page

XP-S Lube............................................................................. 293 600 016 .............................................9

TURN OVER

When vehicle is turned over or stays tilted on the

side, put the vehicle back on its wheels, then wait

3 to 5 minutes before starting the engine.

Inspect air filter housing drain tube for oil accumulation, if any oil is found, clean air filter and air filter

housing. Refer to

Check oil level in oil tank and refill if necessary.

Start engine and let it run, around 1 minute, then

stop engine. Check oil level immediately, refer to

LUBRICATION SYSTEM

dure.

AIR INTAKE SYSTEM

section for proper proce-

section.

ATV IMMERSION

ATV Submerged for a Long Time

(More than One Hour)

Engine

Disassemble engine to clean the internal parts and

check if there is no rust or corrosion onany internal

parts. Refer to

Drainairfilterhousingthencleananddryairfilter.

Remove muffler and empty it. Let muffler dry

then reinstall it on the vehicle.

Fuel System

Flush fuel tank and refill with new gas.

Lubricate the throttle body. Refer to

ENGINE

IC FUEL INJECTION

Chassis

Look for water in:

– Brake system (replace brake fluid)

– Chain tensioner.

Lubricate all cables. Check if the cables operate

properly.

Lubricate suspension arms and swing arm.

Lubricate drive chain.

Spray all metal parts with XP-S Lube (P/N 293 600

016).

sections.

ELECTRON-

.

ATV Submerged for a Short Time

(Less than Oone Hour)

Fuel System

Drain air filter housing then clean and dry air filter.

Lookforwaterinfueltank, in doubt, flush fuel tank

and refill with new gas.

Engine

Check if engine oil is contaminated (oil will be

milky). If so, perform the following instructions:

Drainengineoil.

Refill engine at the proper level with the recom-

mended oil. Crank engine several times.

Remove spark plugs.

Add a small quantity of engine oil in cylinder

(approximately 2 teaspoonfuls). Do not reinstall

spark plugs at this moment.

Check condition of spark plugs. If spark plugs appear good reinstall them, if not install new ones.

Start the engine and allow it to run at idle speed

until the engine reaches its operating temperature.

Stop the engine.

Change engine oil and filter.

NOTE: Change oil as many times as necessary,

until there is no white appearance in engine oil.

Chassis

Lubricate all cables. Check if the cables operate

properly.

Lubricate suspension arms and swing arm.

Lubricate drive chain.

Spray all metal parts with XP-S Lube (P/N 293 600

016).

vmr2008-006 9

Loading...

Loading...